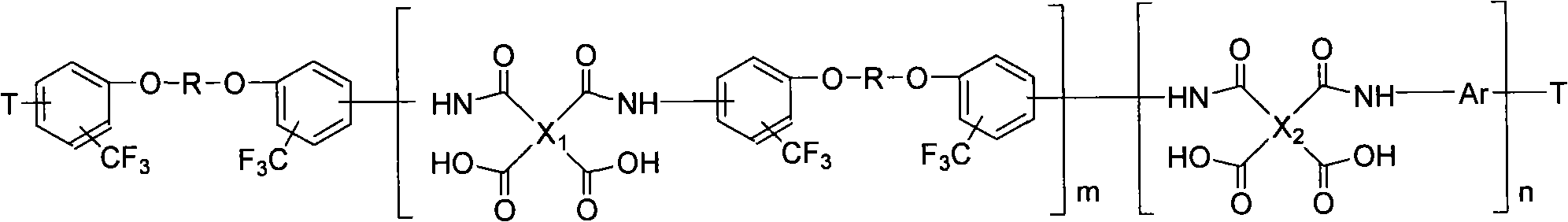

Polyimide resin, its midbody, preparation method and application thereof

A technology of polyimide resin and polyamic acid, which is applied in the field of polyimide resin, can solve the problems of low glass transition temperature, unsuitable processing and application requirements, and high Tg of polyimide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

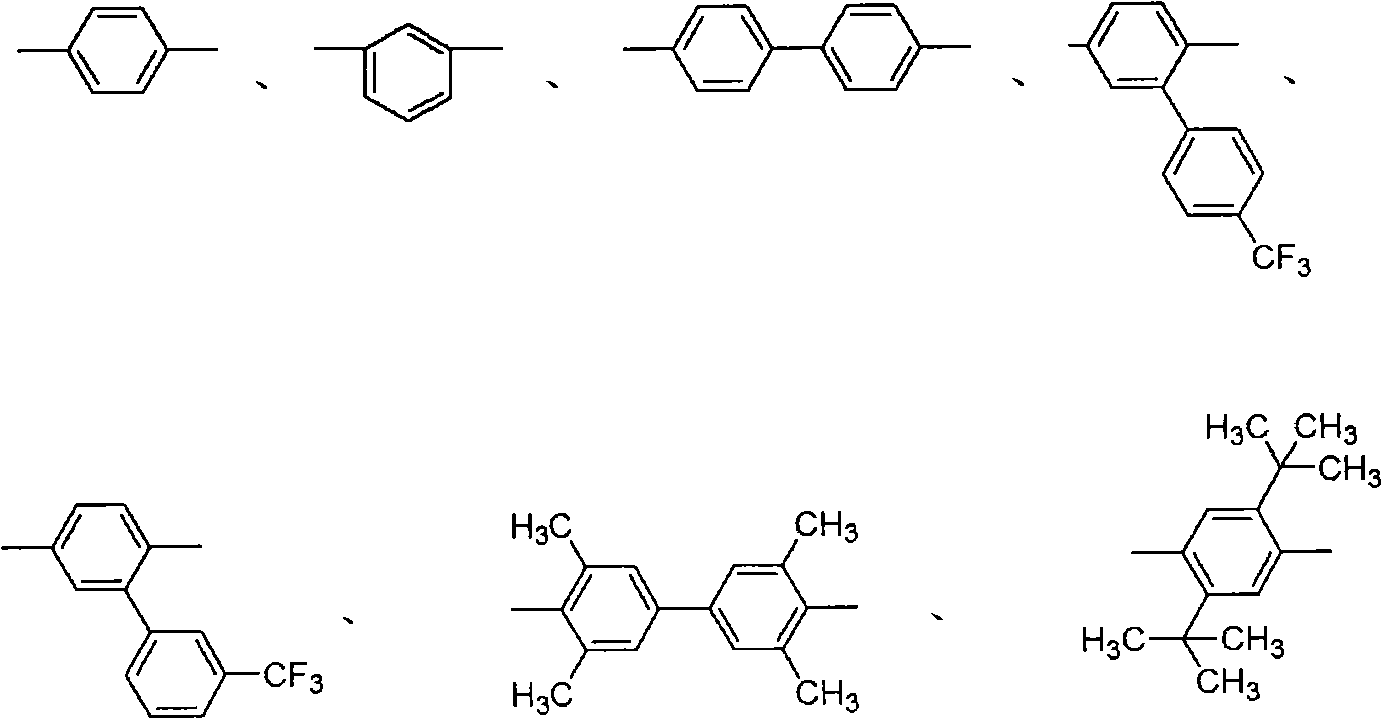

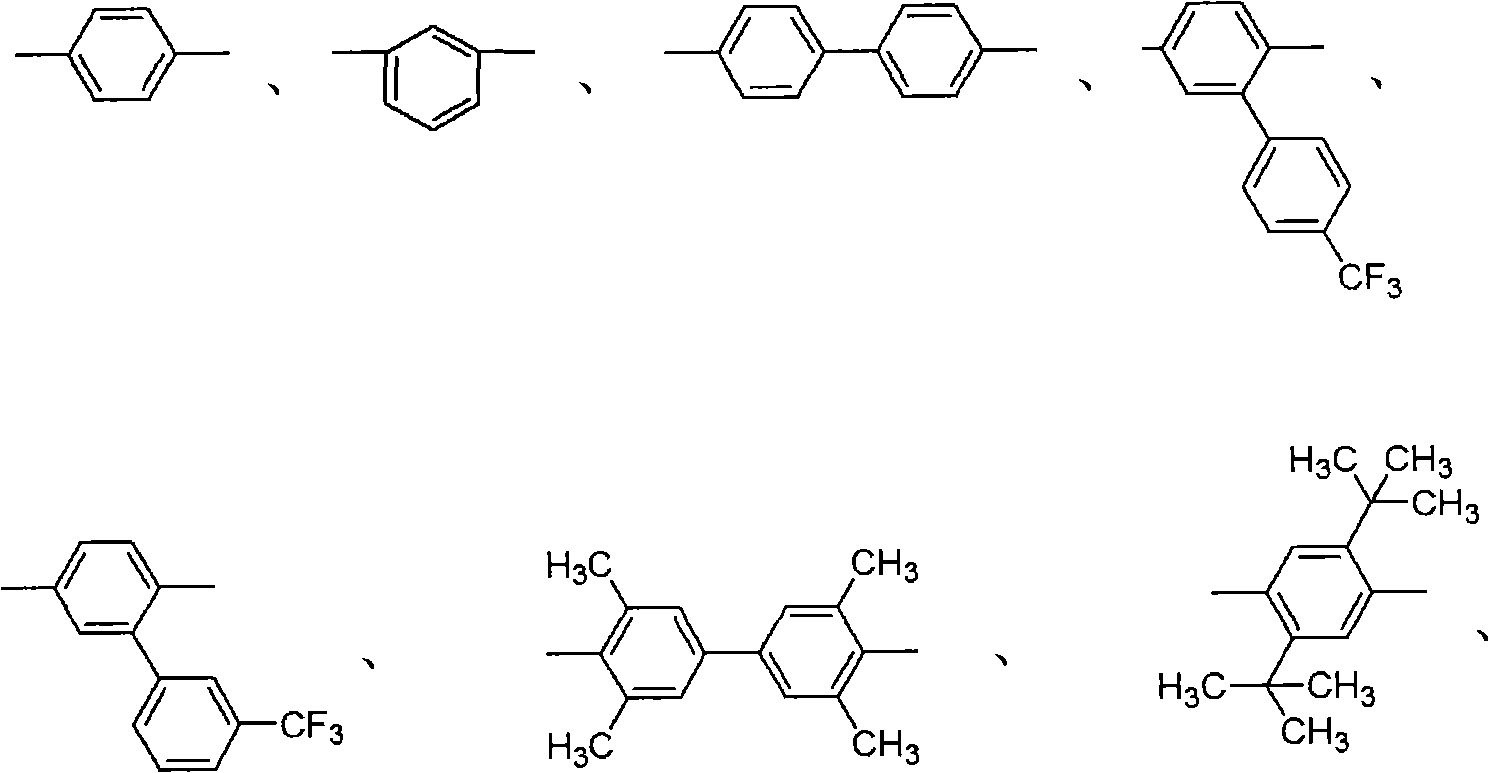

Method used

Image

Examples

preparation example Construction

[0059] Preparation of the first part polyimide resin

[0060] The polyimide resin provided by the invention is obtained by chemical imidization or thermal imidization of polyamic acid (PAA). Specifically, under the protection of an inert gas, in a three-necked flask equipped with a thermometer and a condenser tube, dissolve the diamine monomer in an organic solvent, stir at 20-50°C, and add tetracarboxylic dianhydride mono If necessary, add an end-capping agent, and finally add the required organic solvent. The amount of organic solvent should be controlled so that the solid content of the resin is between 10-30%. Stir for 0.5-24 hours to obtain PAA . Polyimide can be obtained from PAA through the following three methods:

[0061] 1) Add dehydrating agent and catalyst to the PAA reaction system, at 5-70°C, the preferred reaction temperature is 10-60°C; the reaction time is 1-25 hours, the preferred reaction time is 2-20 hours. Pour this solution into a large amount of poor ...

Embodiment 1

[0065] Embodiment 1, prepare polyimide resin

[0066] Under the protection of nitrogen, add 214.17g (0.5mol) p-6FAPB, 2.5L NMP into a 5L three-neck flask equipped with mechanical stirring, thermometer and condenser, and stir at 25°C. After 6FAPB is completely dissolved, slowly Add 212.50g (0.47mol) 3FDA, react at 20 ℃, add 8.89g (0.06mol) phthalic anhydride (PA) after forming homogeneous solution, continue to stir for 2 hours, obtain homogeneous polyimide precursor solution polyamic acid (PAA ). Add 100mL of acetic anhydride and 50mL of triethylamine into the reaction system, raise the temperature to 60°C, continue stirring for 10 hours, pour the obtained polyimide solution into a large amount of methanol, wash thoroughly, and dry the obtained precipitate at 150°C To constant weight, the chemically imidized polyimide is obtained. The measured intrinsic viscosity is 0.60dL / g, and the glass transition temperature Tg is 258°C.

[0067] The diamine p-6FAPB used in this example ...

Embodiment 2

[0068] Embodiment 2, prepare polyimide resin

[0069] Under nitrogen protection, add 214.17g (0.5mol) m-6FAPB and 2.5L m-cresol into a 5L three-necked flask equipped with mechanical stirring, a thermometer and a condenser, and stir at 25°C. After 6FAPB is completely dissolved, divide Slowly add 164.81g (0.46mol) DSDA in batches, react at 20°C to form a uniform solution, add 11.85g (0.08mol) phthalic anhydride (PA), and continue stirring for 2 hours to obtain a uniform polyimide precursor solution polyamic acid (PAA). Add 100mL of acetic anhydride and 50mL of triethylamine into the reaction system, raise the temperature to 50°C, continue stirring for 12 hours, pour the obtained polyimide solution into a large amount of methanol, wash thoroughly, and dry the obtained precipitate at 150°C To constant weight, the chemically imidized polyimide is obtained. The measured intrinsic viscosity is 0.54dL / g, and the glass transition temperature Tg is 246°C.

[0070] The diamine m-6FAPB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com