Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1241 results about "Heat press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A heat press is a machine engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset period of time. While heat presses are often used to apply designs to fabrics, specially designed presses can also be used to imprint designs on mugs, plates, jigsaw puzzles, caps, and other products.

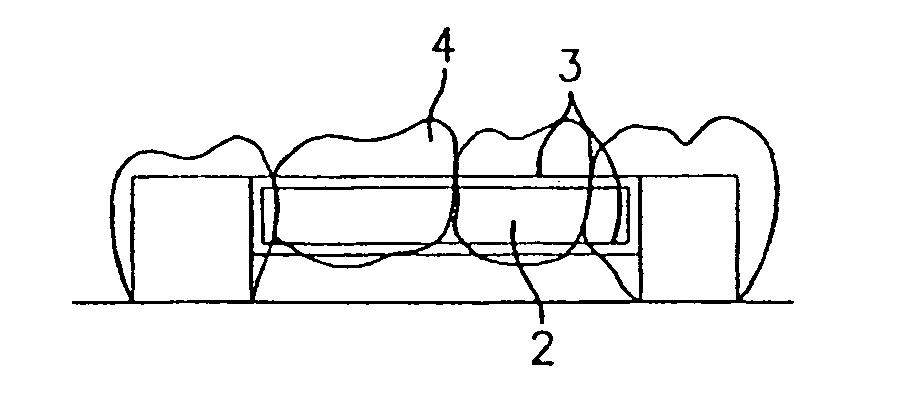

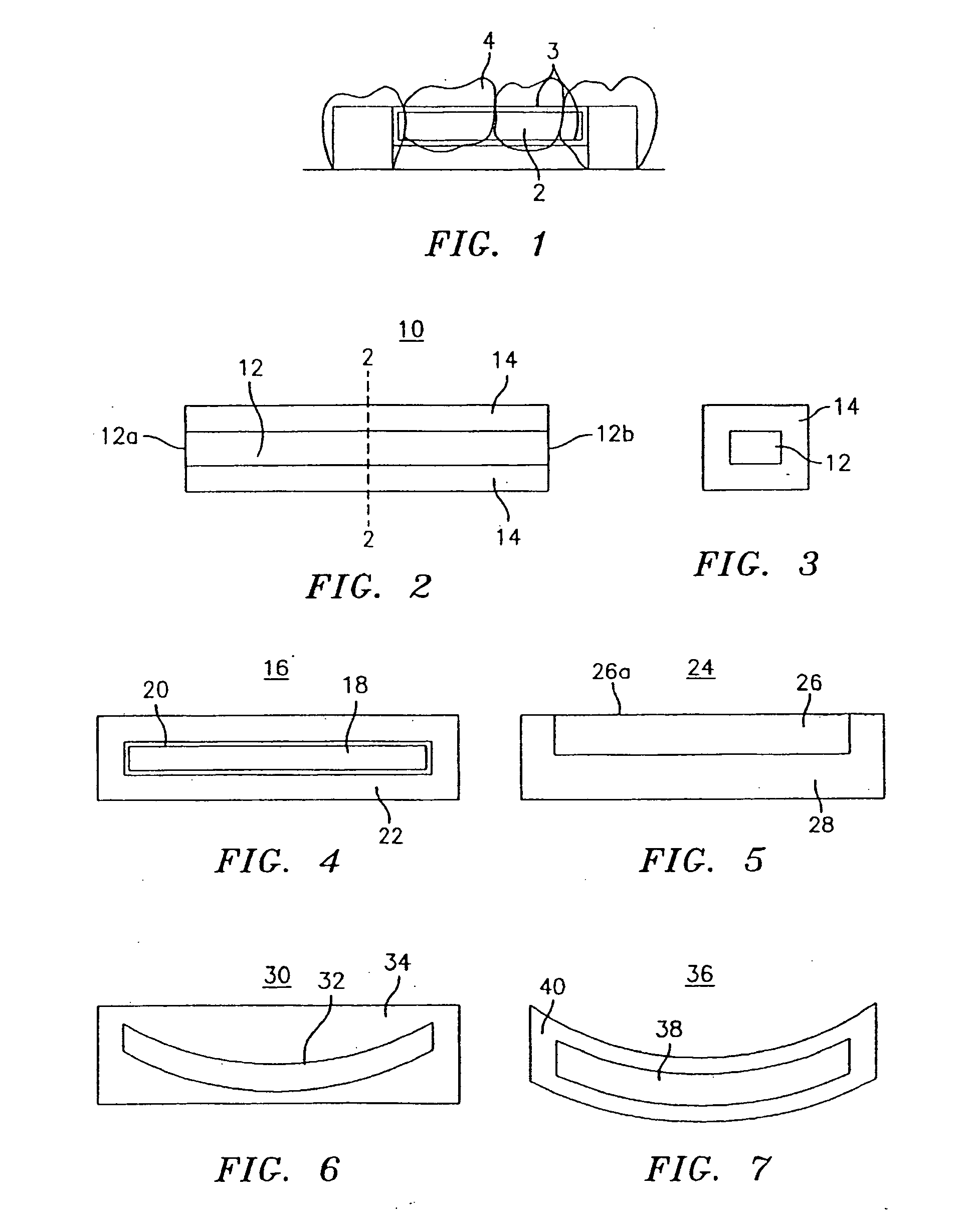

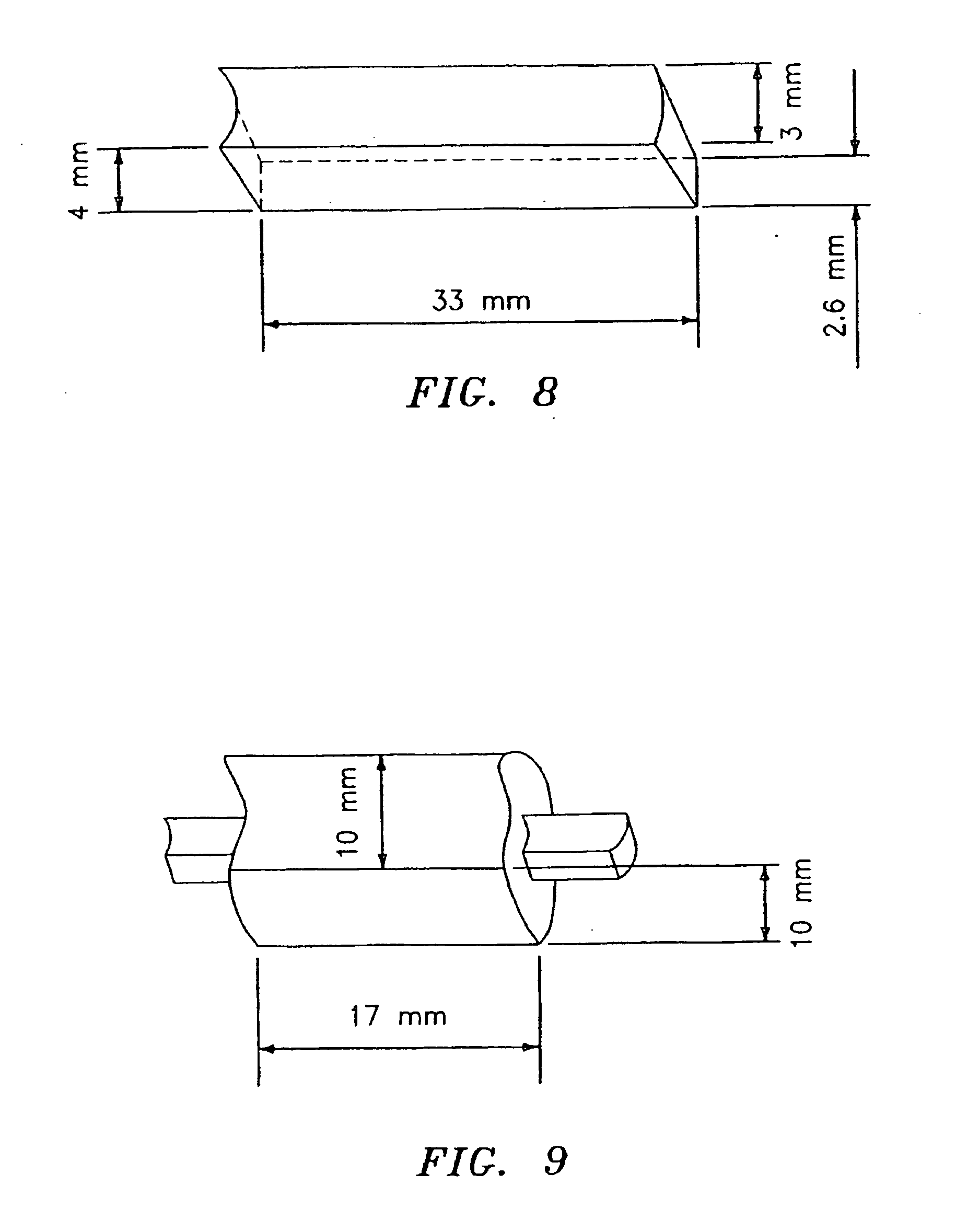

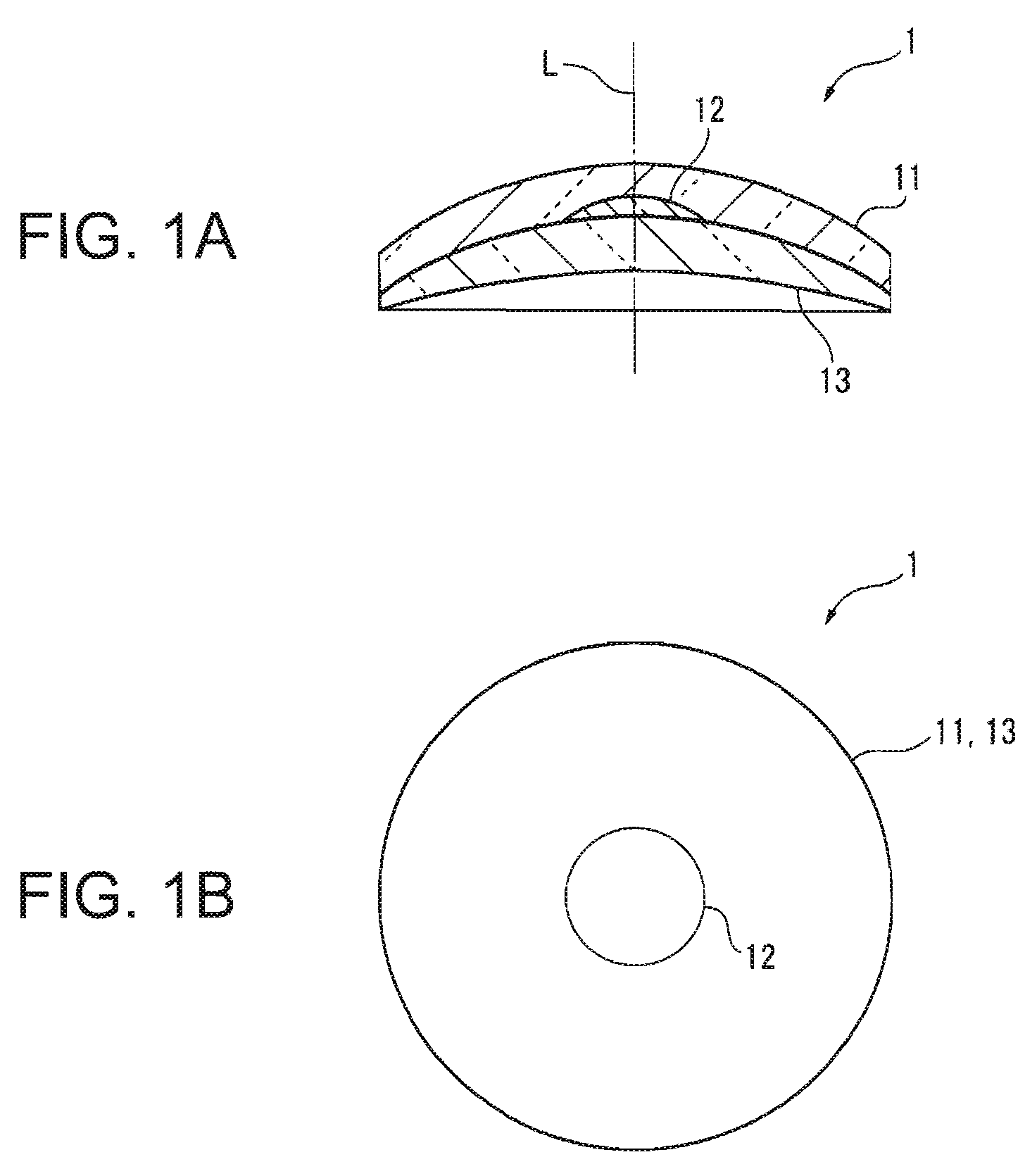

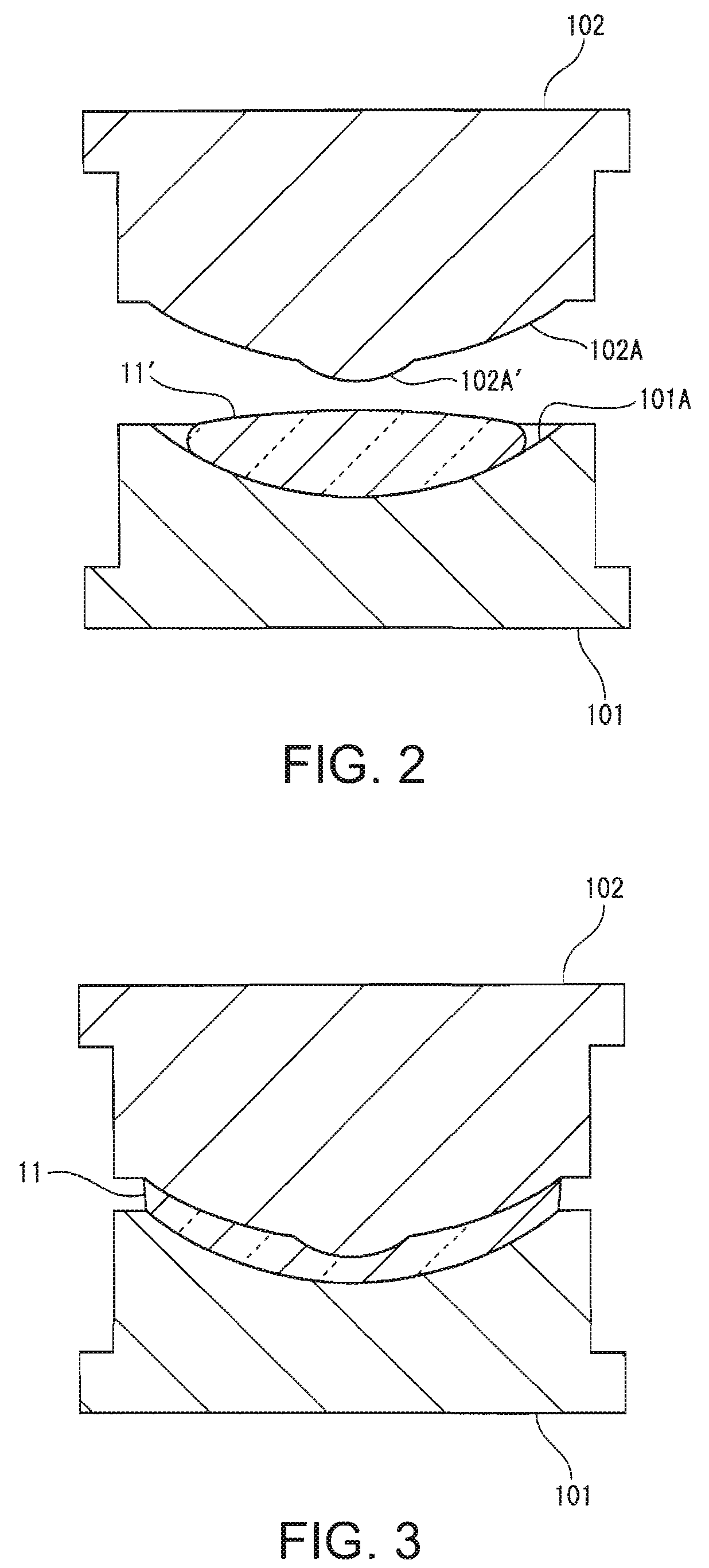

High-strength dental restorations

InactiveUS20050127544A1Improve adhesionHigh strengthHair accessoriesImpression capsDental ProductHigh intensity

Lithium disilicate based glass-ceramics contain high strength ceramic components for use in the manufacture of dental products. The glass-ceramics have good pressability, i.e., the ability to be formed into dental products by heat-pressing using commercially available equipment. The strength of the dental articles is increased with the inclusion of the high strength ceramic components.

Owner:ARDENT

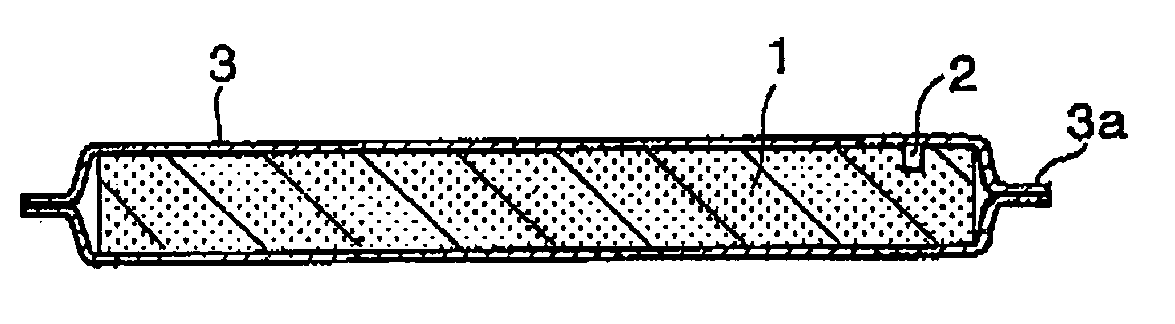

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

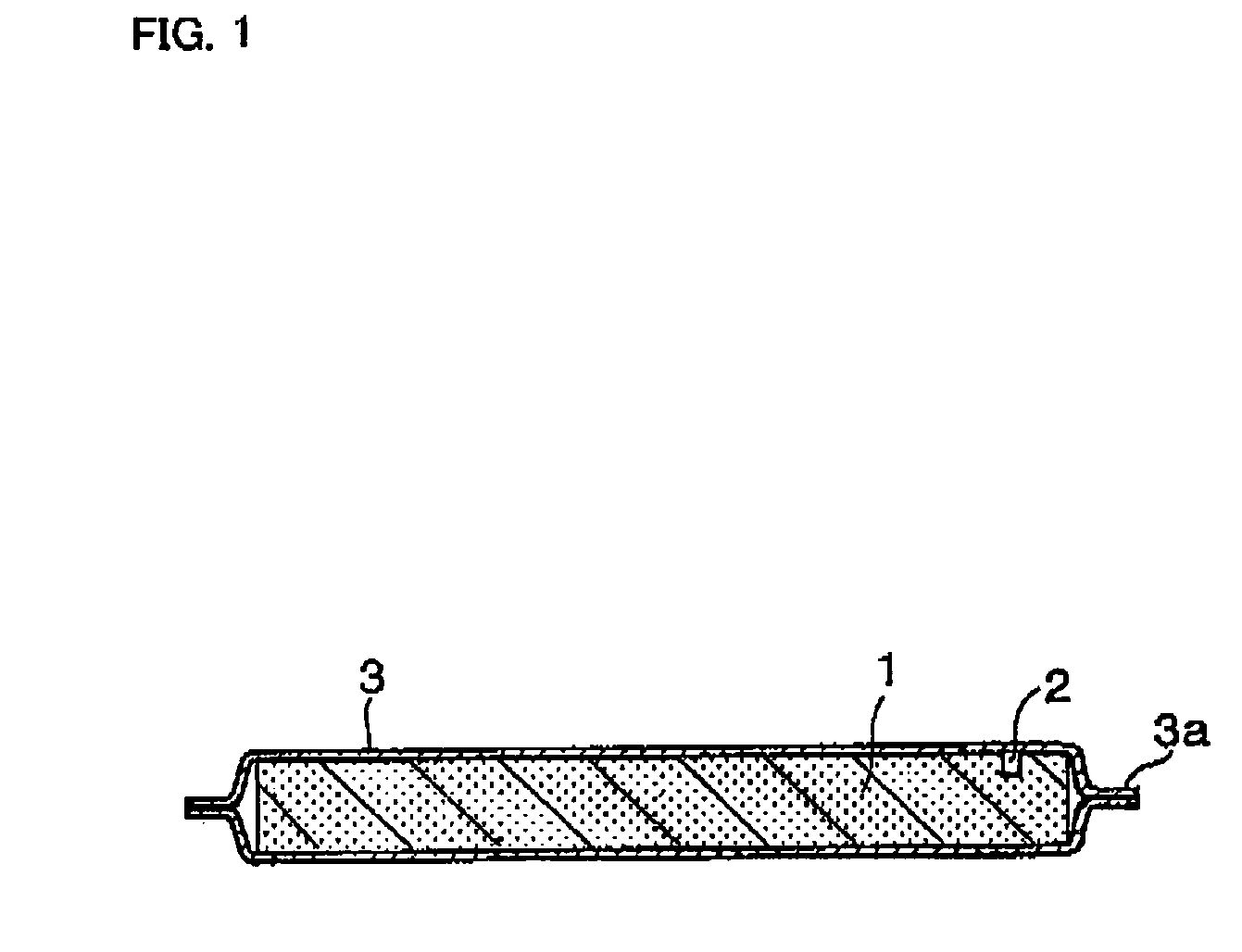

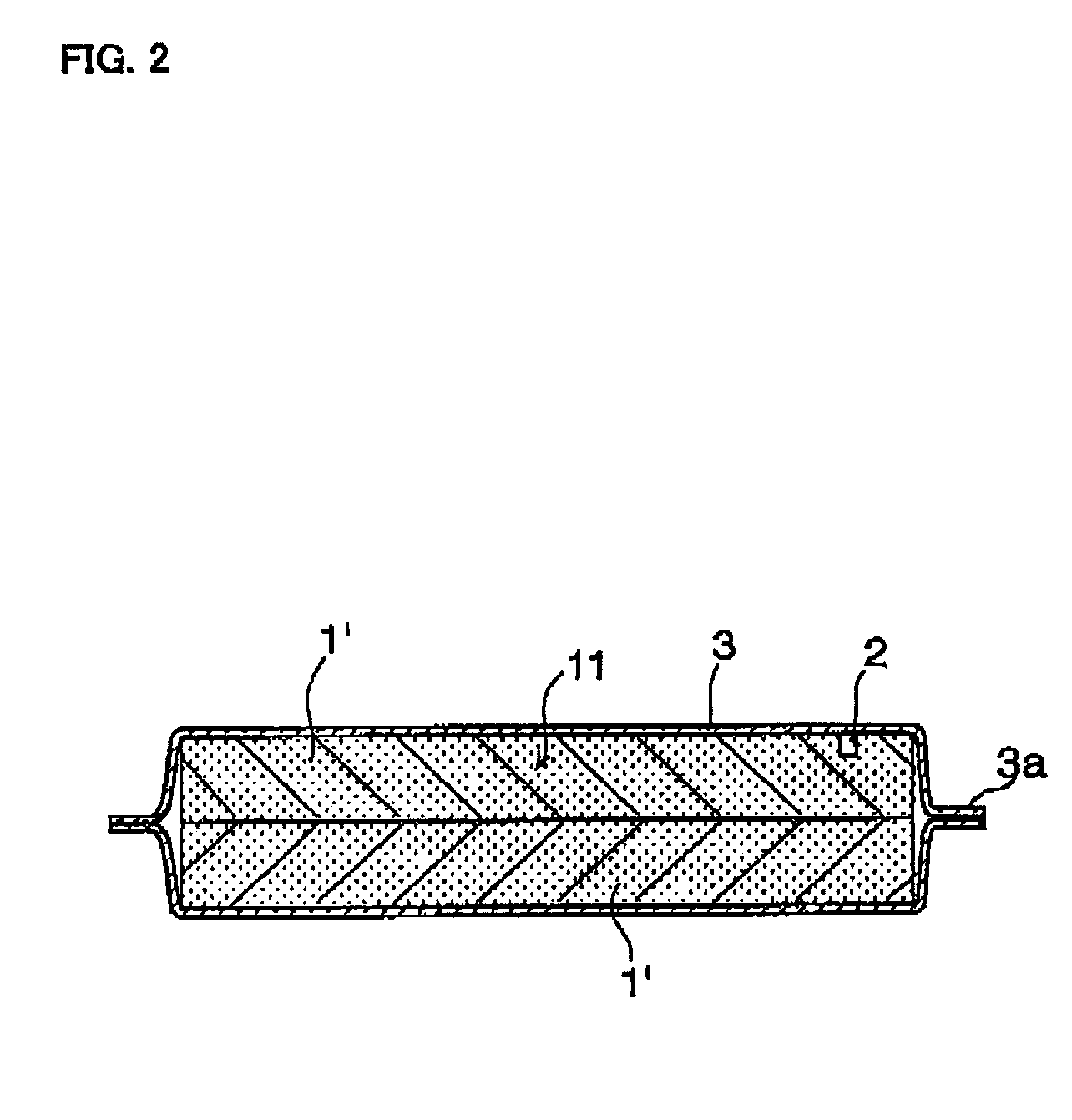

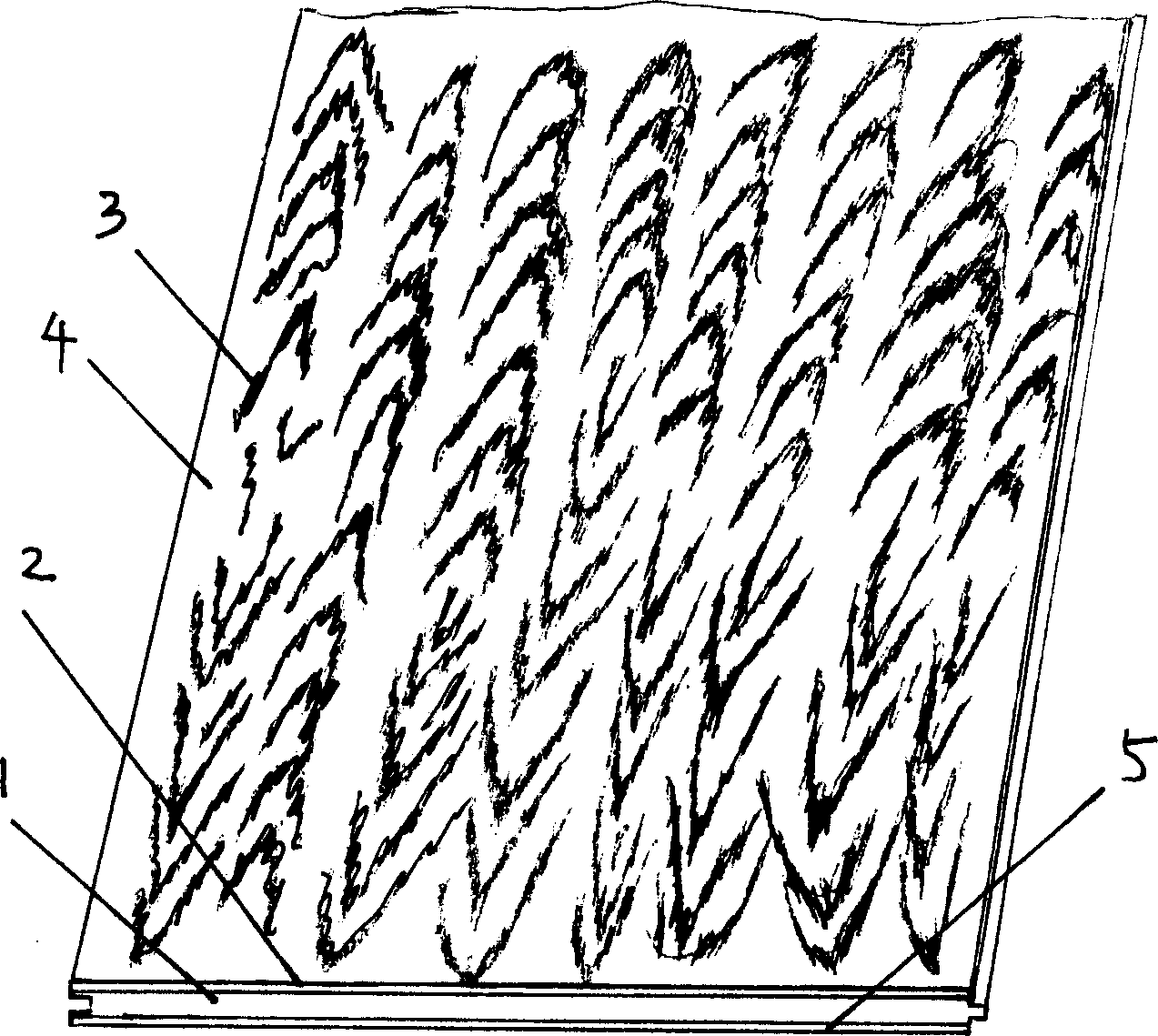

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

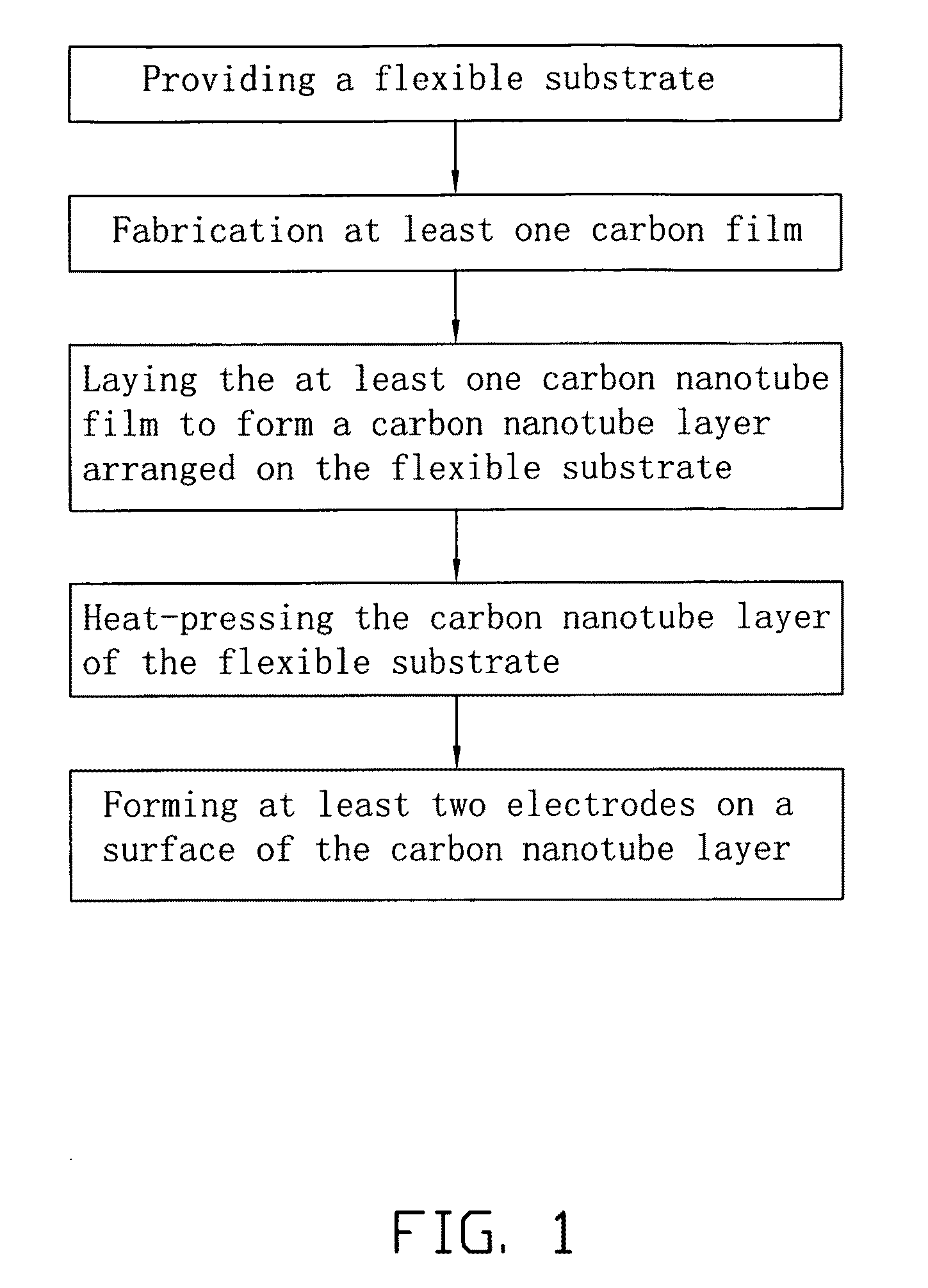

Method for making touch panel

ActiveUS20090160799A1Adhesive processesVessels or leading-in conductors manufactureCarbon nanotubeTouch panel

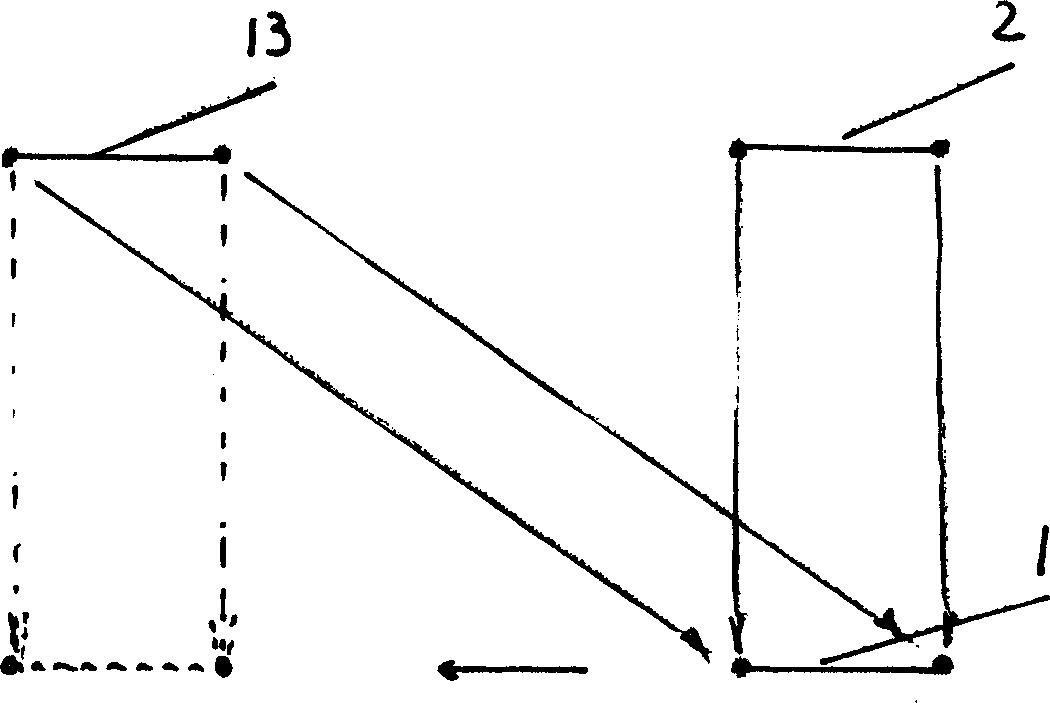

An exemplary method for making a touch panel includes the steps of: providing a flexible substrate; fabricating a carbon nanotube film; laying the carbon nanotube film to form a carbon nanotube layer stacked on the flexible substrate; heat-pressing the carbon nanotube layer of the flexible substrate; and separately forming at least two electrodes on a surface of the carbon nanotube layer, thereby forming the touch panel.

Owner:TSINGHUA UNIV +1

Method of manufacturing multifocal lens and multifocal lens

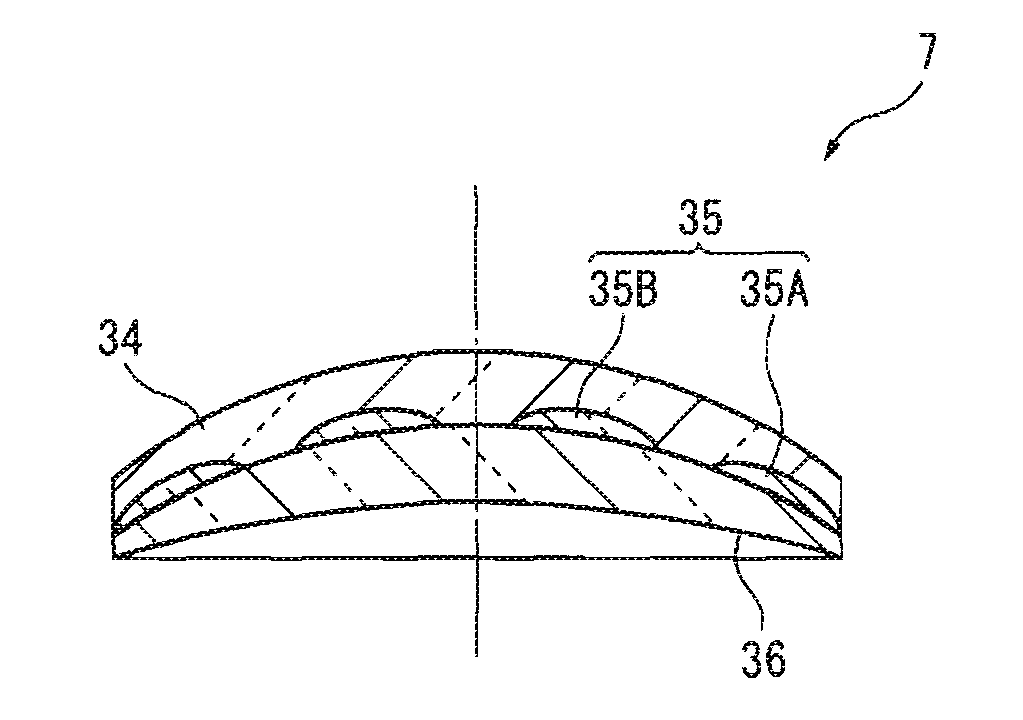

InactiveUS20070195263A1Excellent optical propertiesReduce harmOptical articlesOptical partsConvex sideLens plate

A multifocal lens includes a group including M layered lenses. M-kinds (M is an integer of two or more) of lens materials having glass deformation point temperatures of At1, At2, . . . , AtM, are used and diluted by a heat press method. A contact surface of an N−1th lens (N is an arbitrary integer of two or more and M or less) contacted with an Nth lens is a concave face, a contact surface of the Nth lens contacted with the N−1th lens is a convex face. The glass deformation point temperatures have a relation of AtN-1>AtN.

Owner:SEIKO EPSON CORP

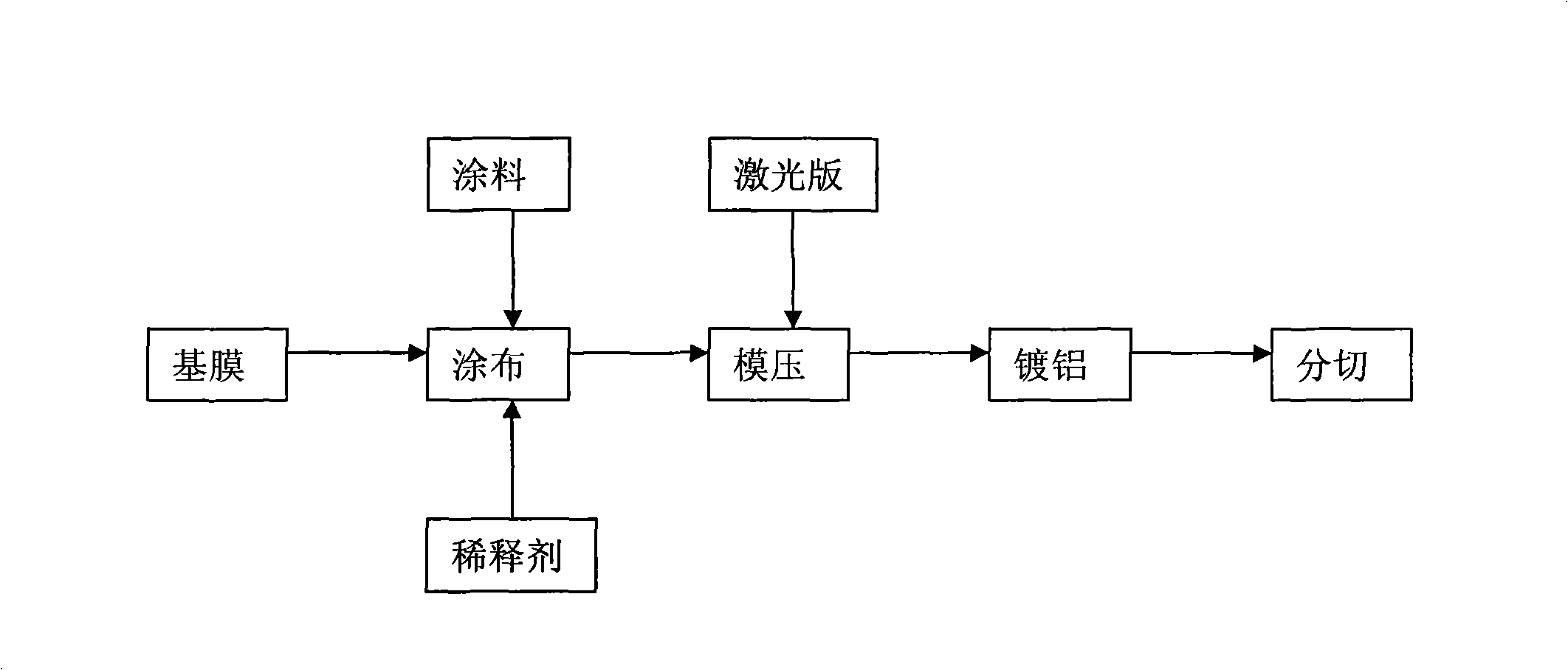

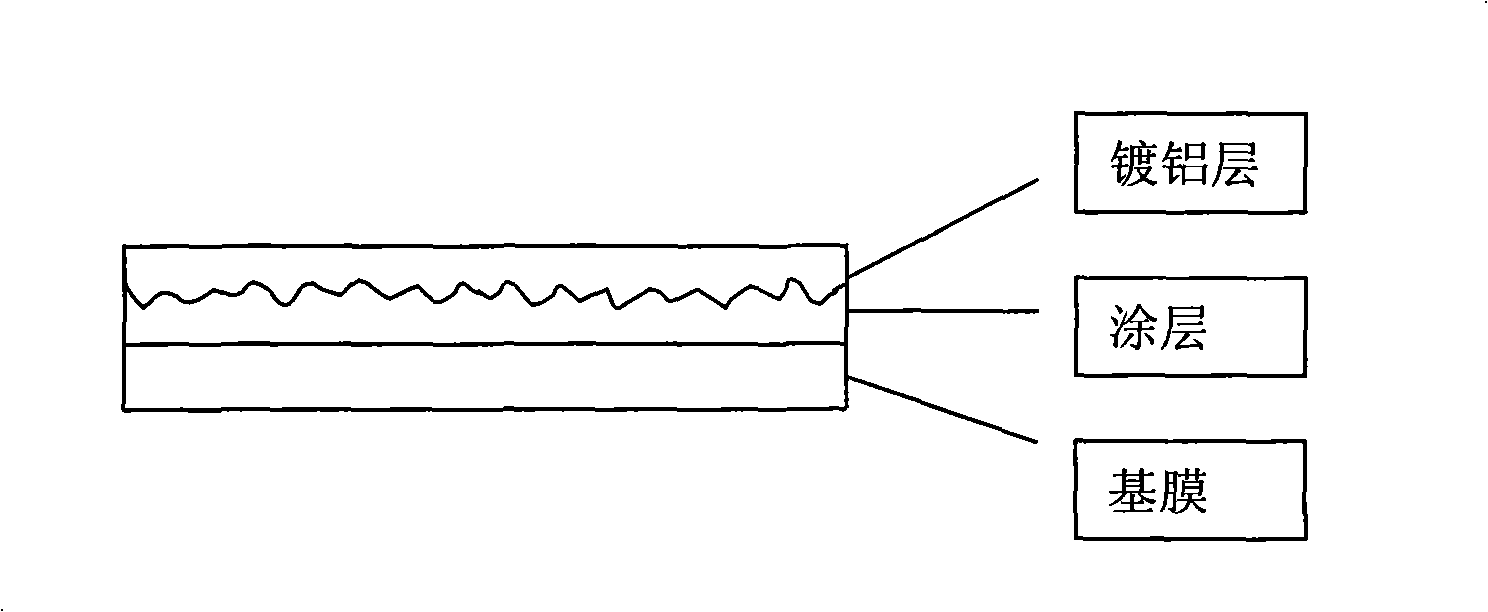

Process for producing PET laser transfer membrane

InactiveCN101537745ASimple processNovel processDecorative surface effectsPretreated surfacesBasementCoated membrane

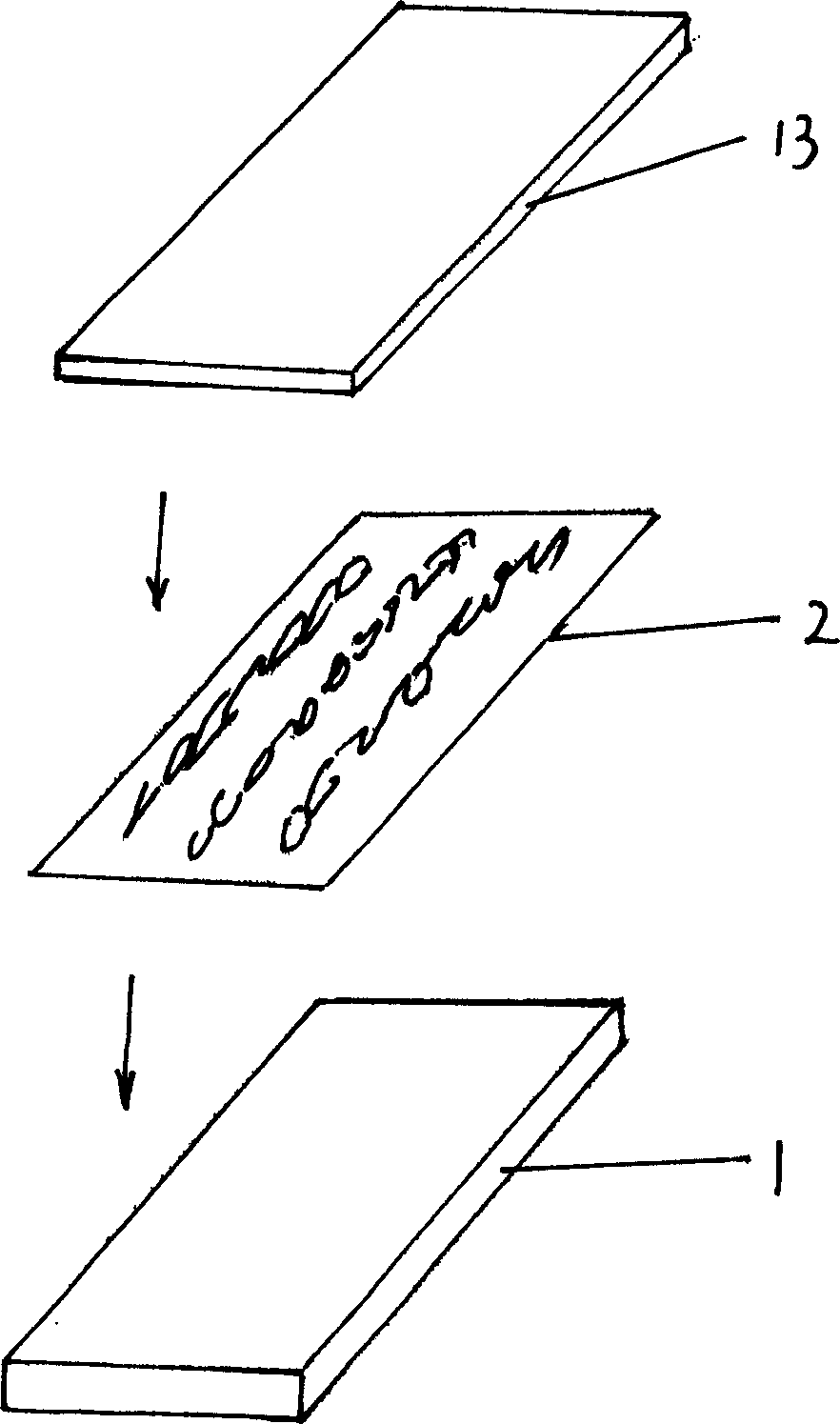

The invention relates to a process for producing a PET laser transfer membrane. A PET membrane is used as a basement transfer membrane, and laser transfer pigment is coated and spread on the PET membrane. The method includes the following steps: a laser transfer pigment is coated and spread on the PET basement transfer membrane by an anilox roll at one step to form a coating layer, and a precoating membrane can be formed after the operation of drying is carried out; the precoating membrane is processed by the operation of laser mould pressing, and interference figures on a laser slab are printed on the coating layer of the precoating membrane by heat pressing so as to form a mould pressing membrane; and aluminum is coated on the mould pressing membrane, an aluminum layer is formed on an information layer, and the PET laser transfer membrane can be prepared, wherein the pigment includes thermoplastic acroid resin and cellulose acetate. The process has the advantages that the special singly coated laser transfer pigment and the unique manufacture process control are selected, and the entire process is simple, novel, stable and reliable. As the laser mould pressing transfer coating layer has the properties of easy mould pressing, favorable stripping, and the like, the operation of coating just needs to be carried out for one time, and therefore the production efficiency can be greatly improved. After being transferred and stripped, the aluminum coated membrane can be recycled to be repeatedly used for many times, and therefore cost can be greatly reduced; and the PET laser transfer membrane is the environmentally friendly anti-counterfeit laser material for packaging and printing.

Owner:上海宝绿包装材料科技有限公司

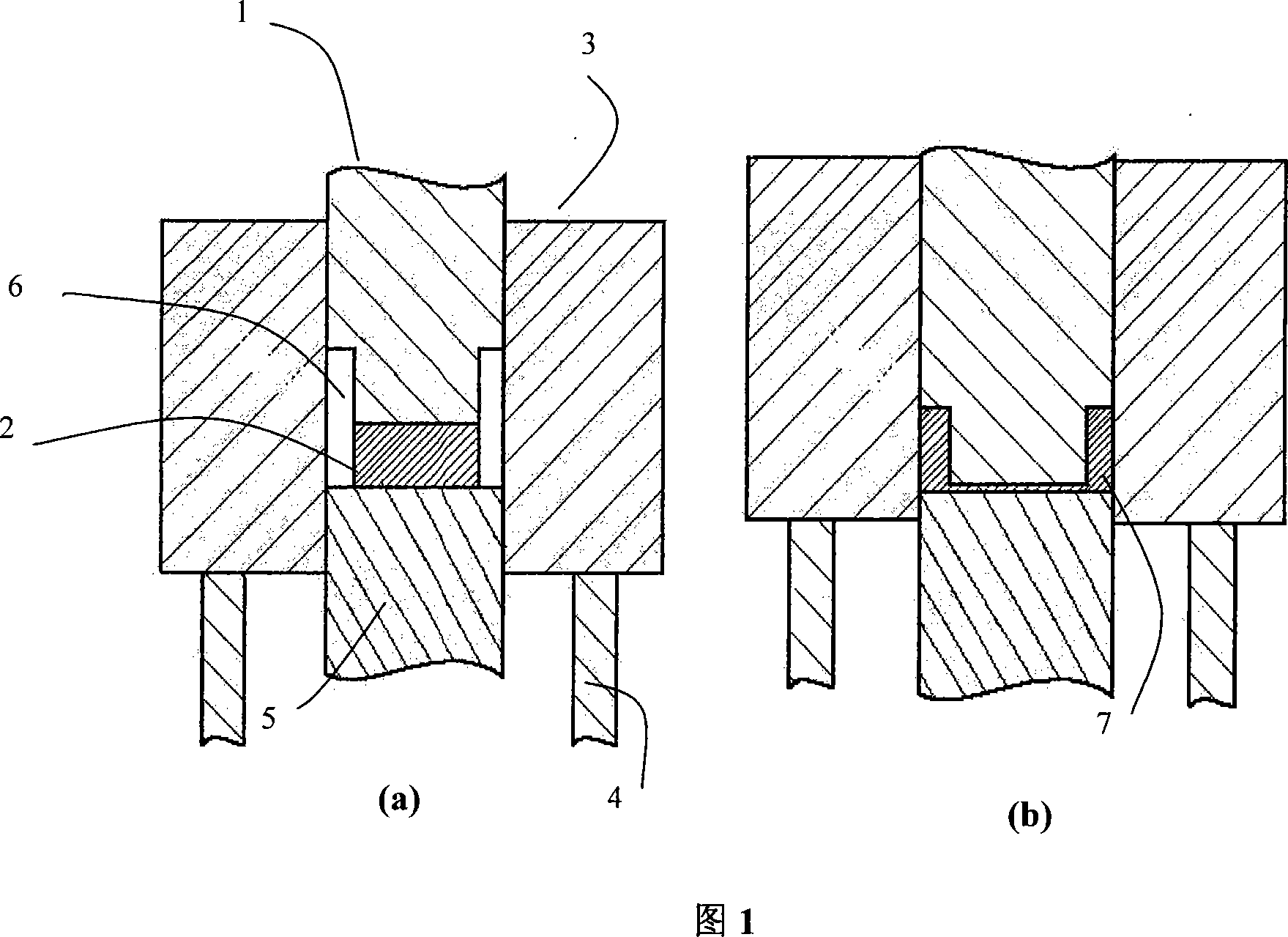

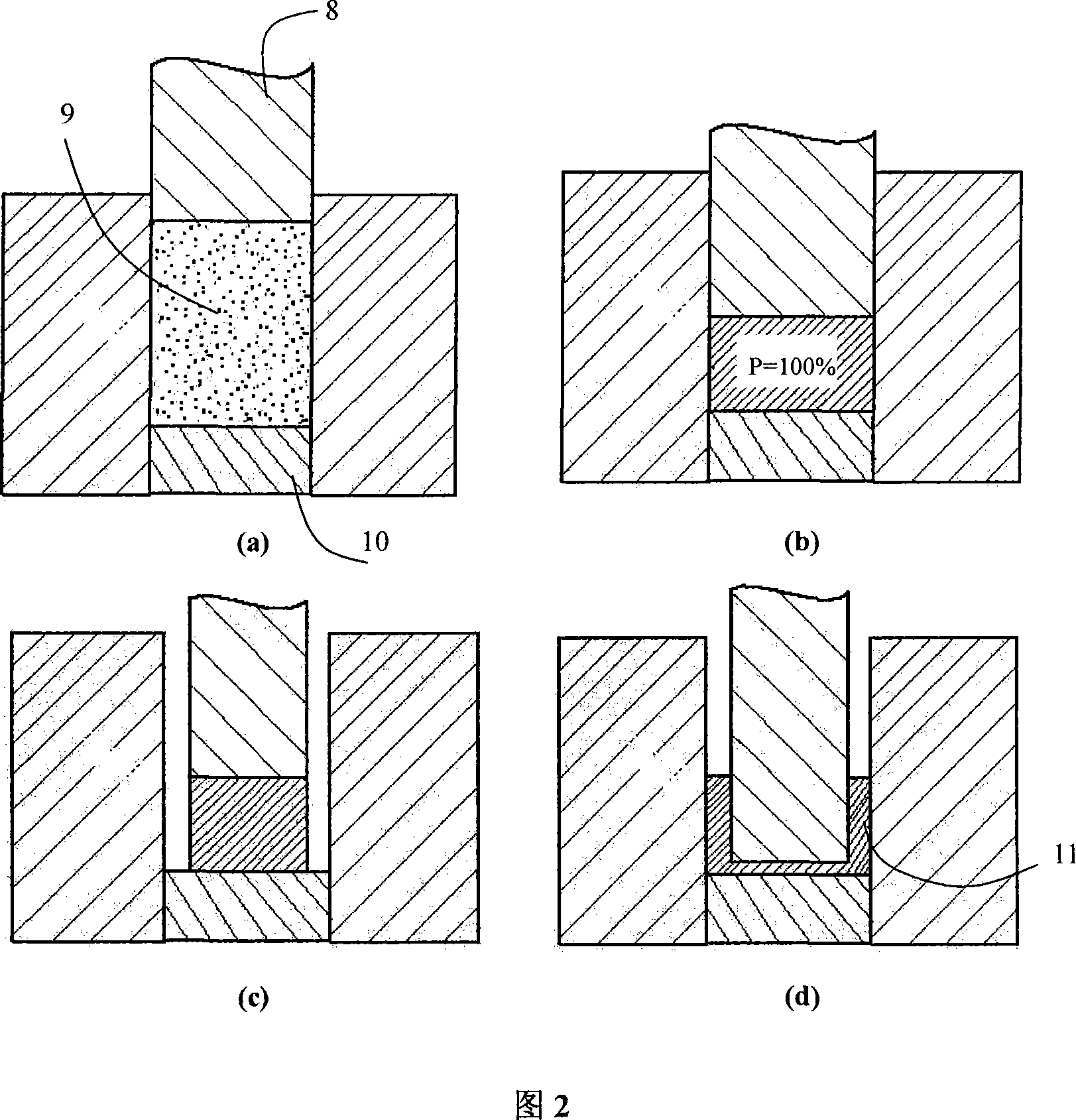

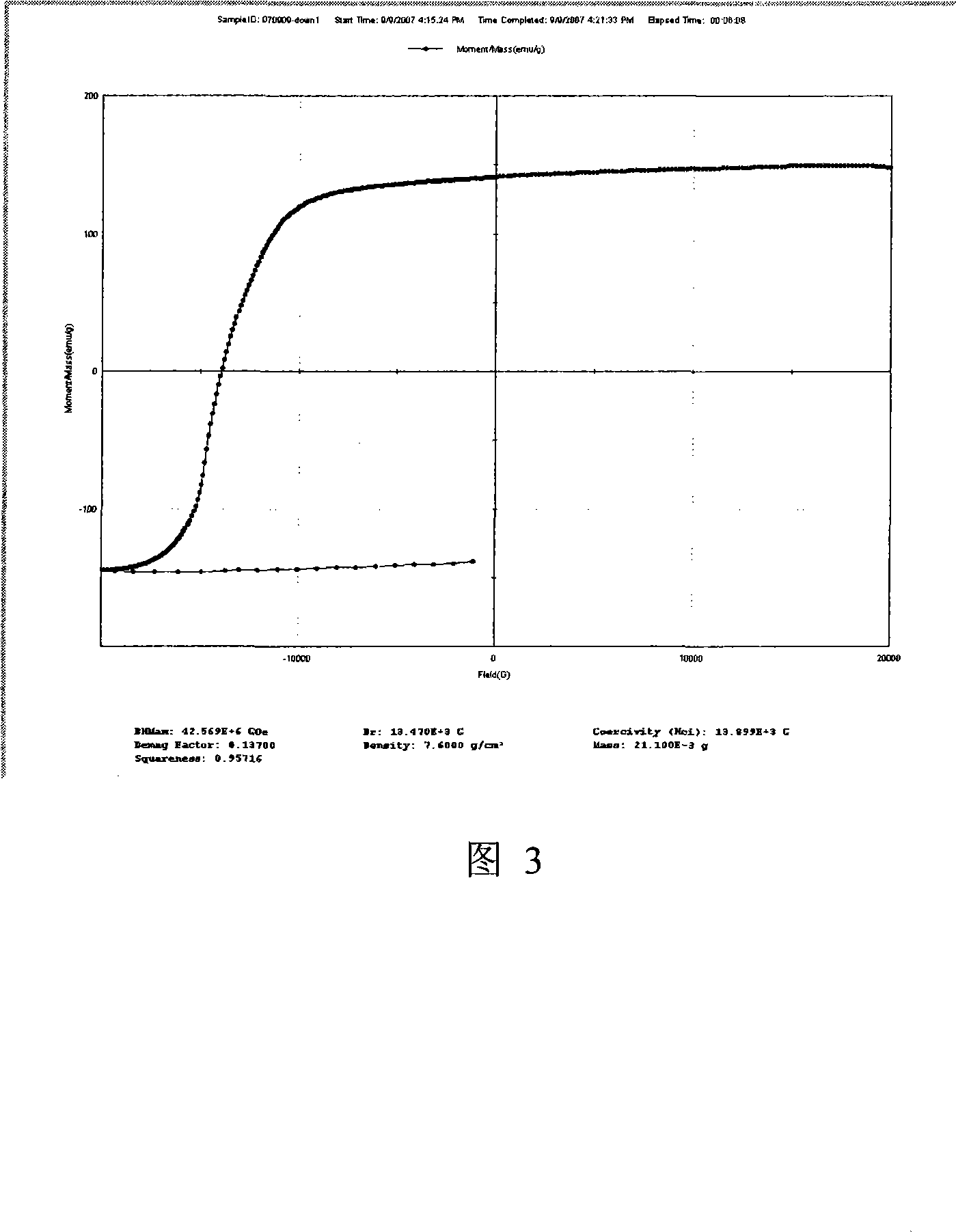

High performance radial hot pressing magnet ring and preparation method thereof

ActiveCN101202143AWide range of sizesNear-net shapePermanent magnetsInorganic material magnetismQuenchingLow oxygen

The invention relates to a radial heat-pressing magnetic ring with high performance and the manufacturing method thereof. After a thin belt manufactured by quick quenching is broken, the thin belt is pressed under a high temperature between 600 DEG C and 800 DEG C into an overall density isotropy magnet, and the magnet is extruded into a ring shape by a floating double-direction pressing process at the temperature of 700 DEG C to 900 DEG C. The direction selection of the heat pressing ring is a radial direction selection, and a crystal granule size can be 500nm to a max extent; wherein, the two-step heat pressing processes are all carried out in a high vacuum condition or a condition that argon gas is filled for protection after the high vacuum is realized. The magnetic ring obtained through the invention has low oxygen content, thus the magnetic ring has relatively high magnetic property. And the floating double-direction pressing can reduce plastic rheological resistance so as to lead the magnetic ring to be provided with a higher magnetism and consistency and a crack of the magnetic ring can be effectively restrained.

Owner:CENT IRON & STEEL RES INST +1

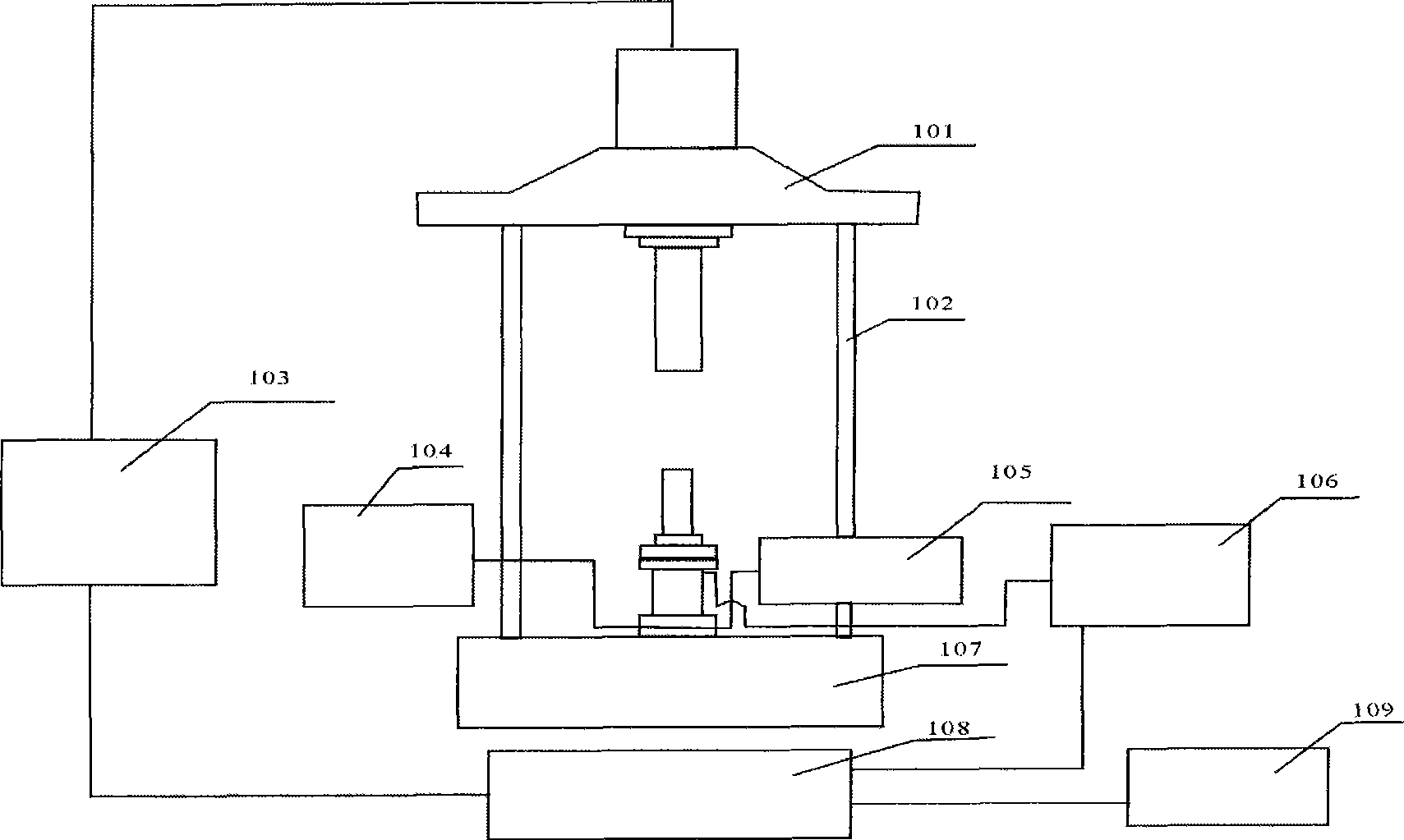

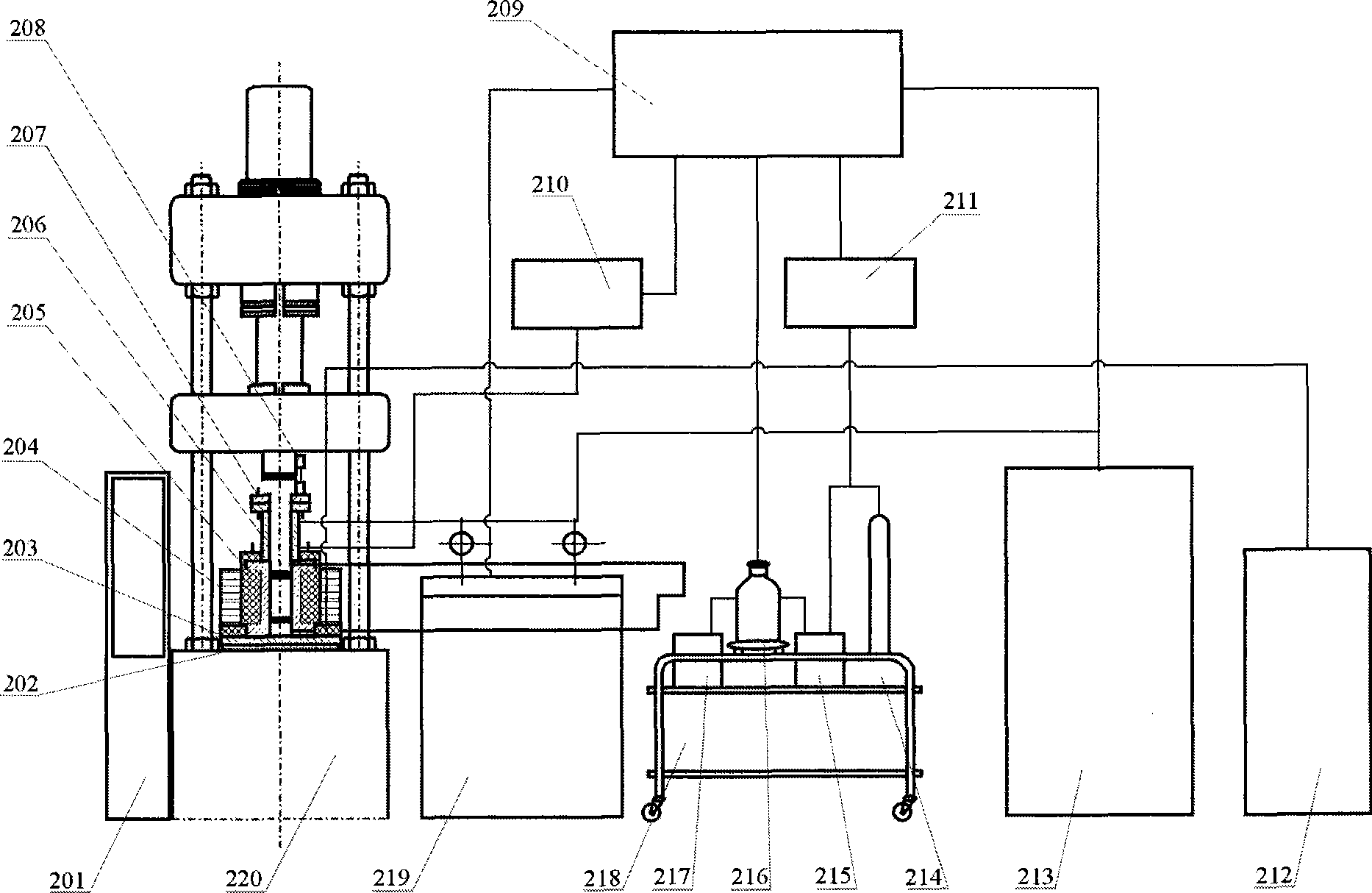

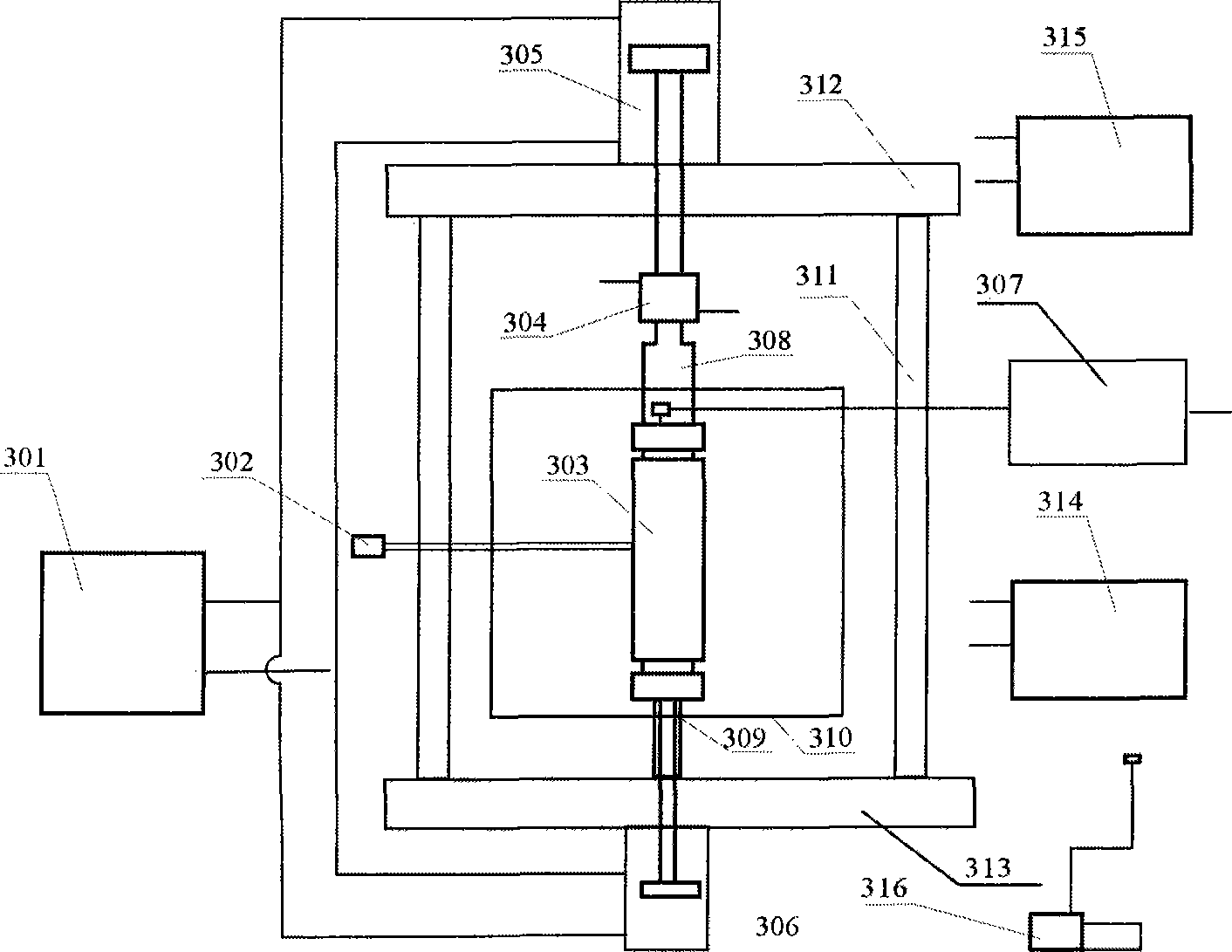

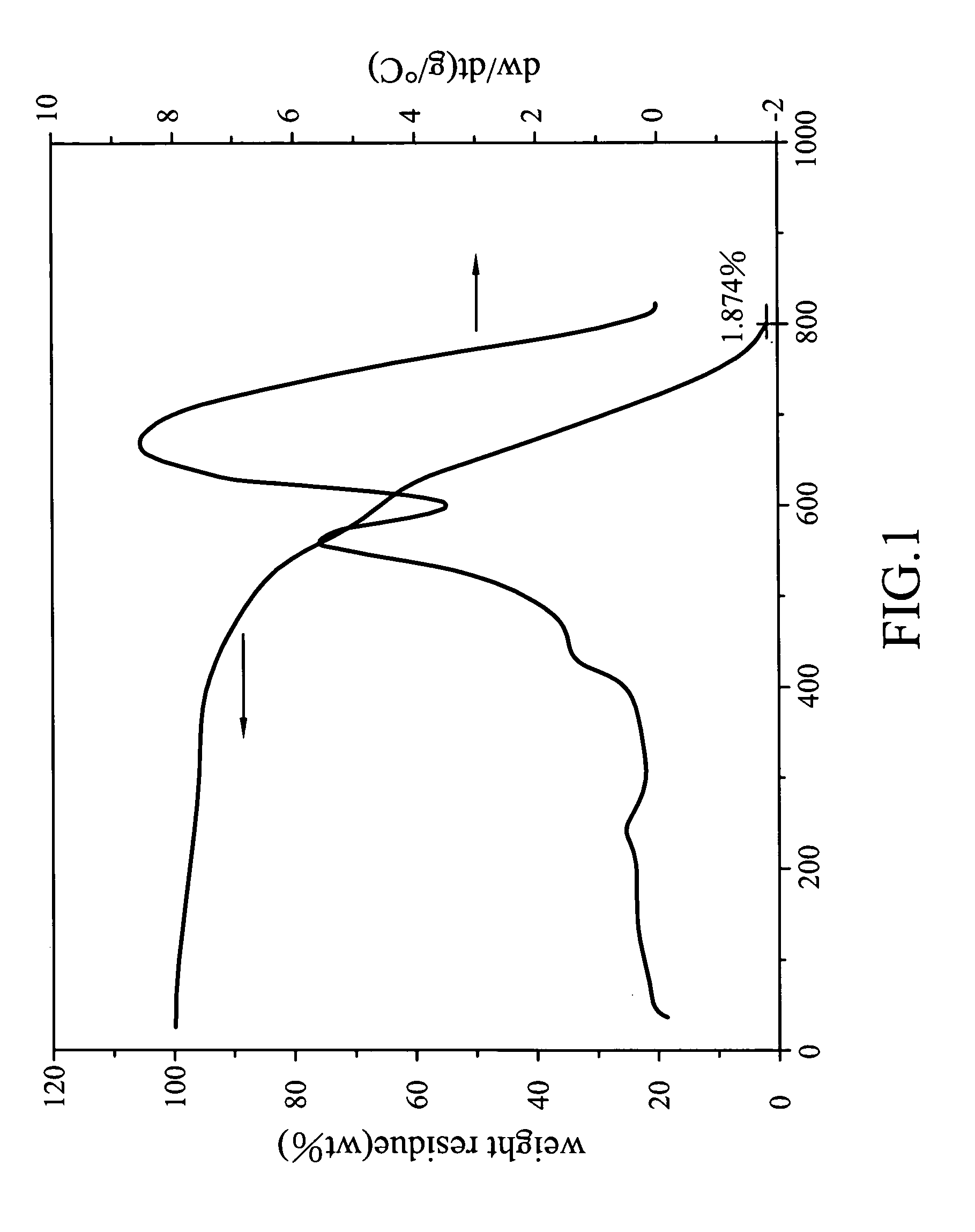

Hydrocarbon source rock formation pore heat-pressing hydrocarbon-generation simulator and use method thereof

ActiveCN101520962ARealize automatic controlRealize monitoringEducational modelsFormation fluidPetroleum

The invention discloses a hydrocarbon source rock formation pore heat-pressing hydrocarbon-generation simulator and a use method thereof, pertaining to an experimental apparatus for simulating the process of heat-pressing hydrocarbon-generation for hydrocarbon source rocks in the field of geological research on petroleum and natural gas. The simulator is composed of such five parts as a high temperature high pressure reaction unit, a two-way hydraulic automation control unit 301, an automatic hydrocarbon expulsion product collecting and fluid supplementing unit, a data acquisition and automatic control unit, peripheral auxiliary equipment and apparatus casing. The invention can carry out heating and pressurizing closed and open or controllable hydrocarbon generation and expulsion simulated experiments with the reservation of original pores of a hydrocarbon source rock sample 518, within the limited pore spaces and in simultaneous consideration of lithostatic pressure, formation fluid pressure and confining pressure similar to the geological conditions, thereby improving a hydrocarbon source rock hydrocarbon generation and expulsion simulated experimental apparatus so as to provide an effective means for researches on the development of a hydrocarbon generation mechanism, oil-gas migration, oil and gas production quantity in basins as well as oil and gas resource prediction, and thus having wide application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

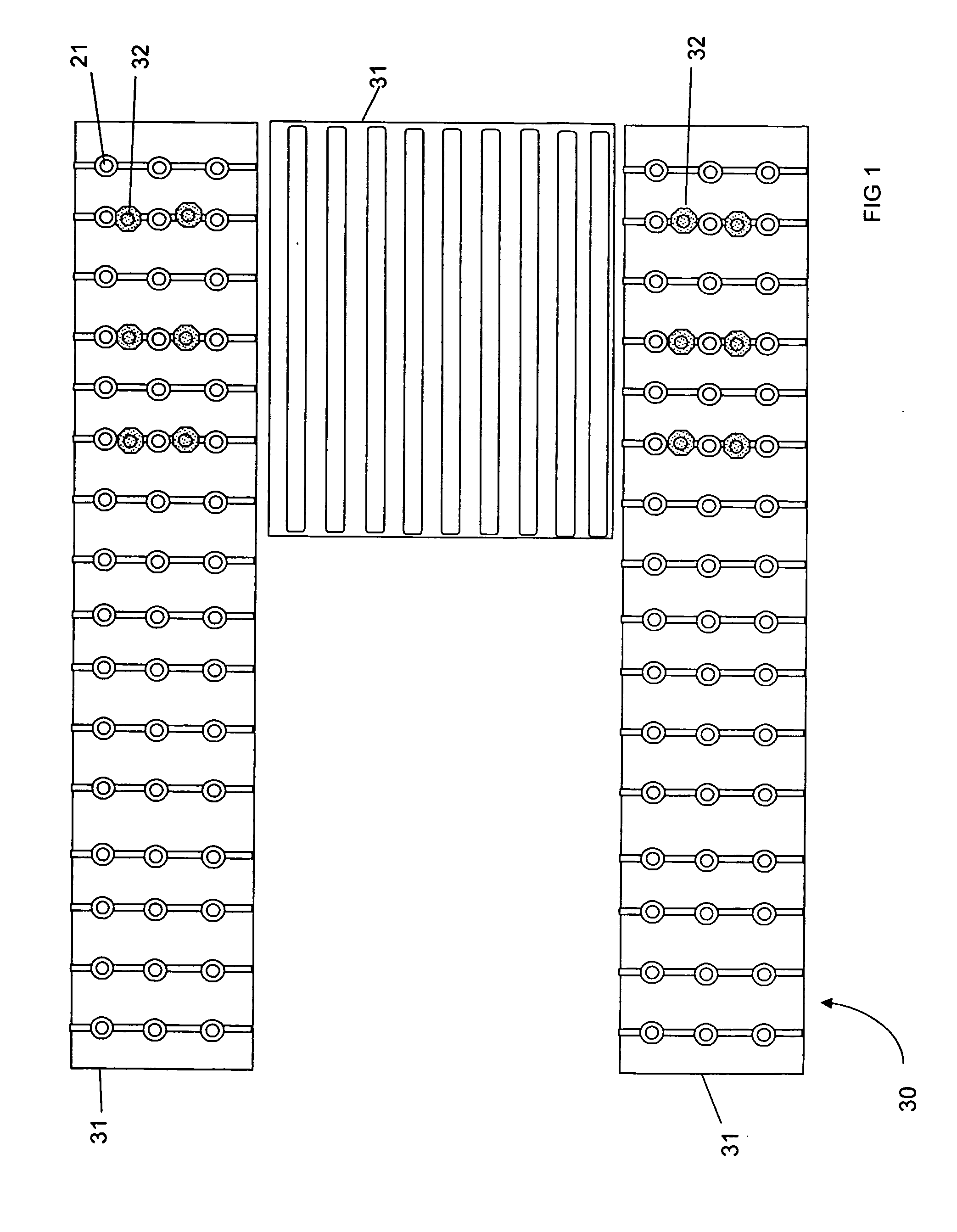

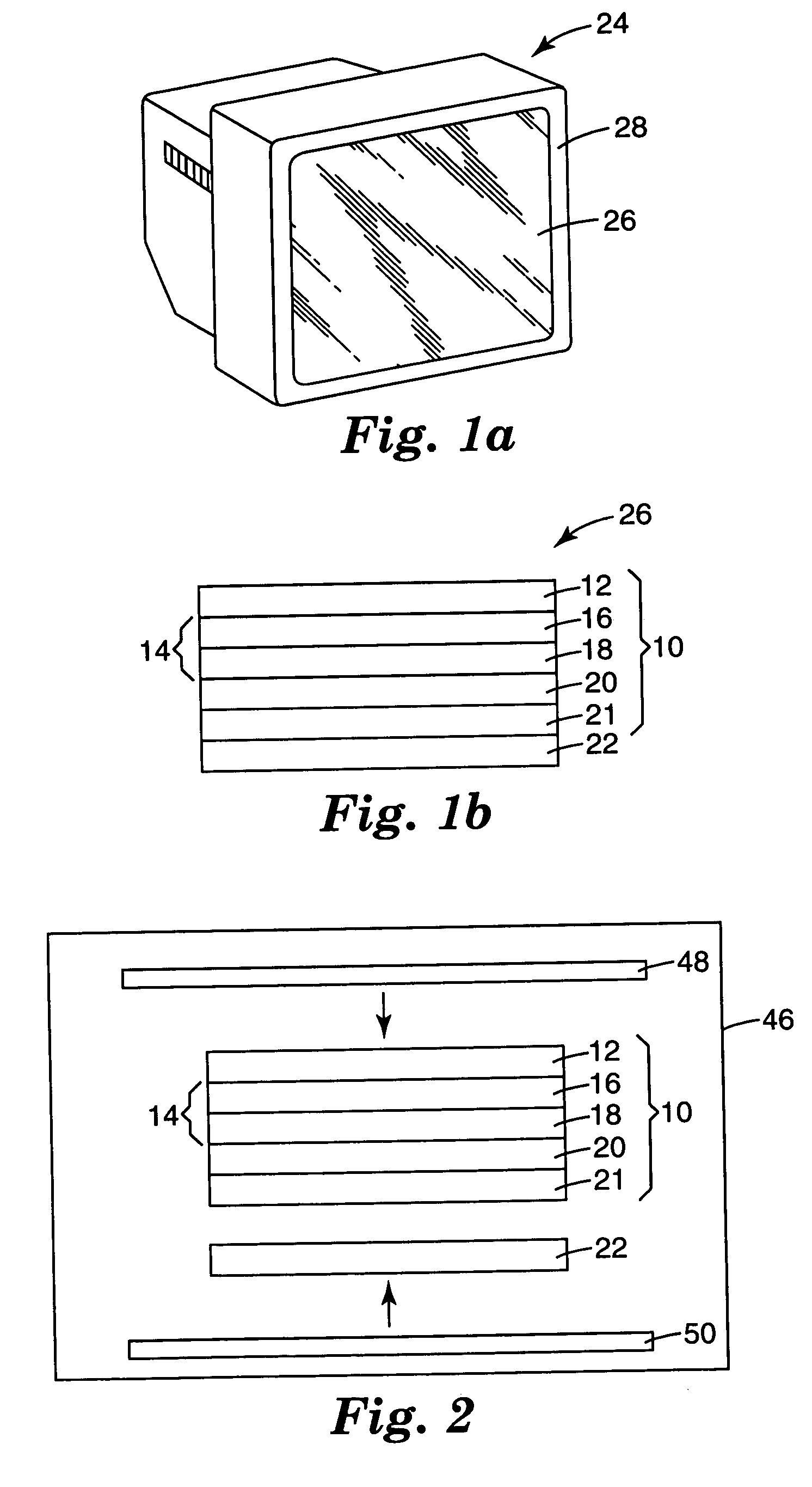

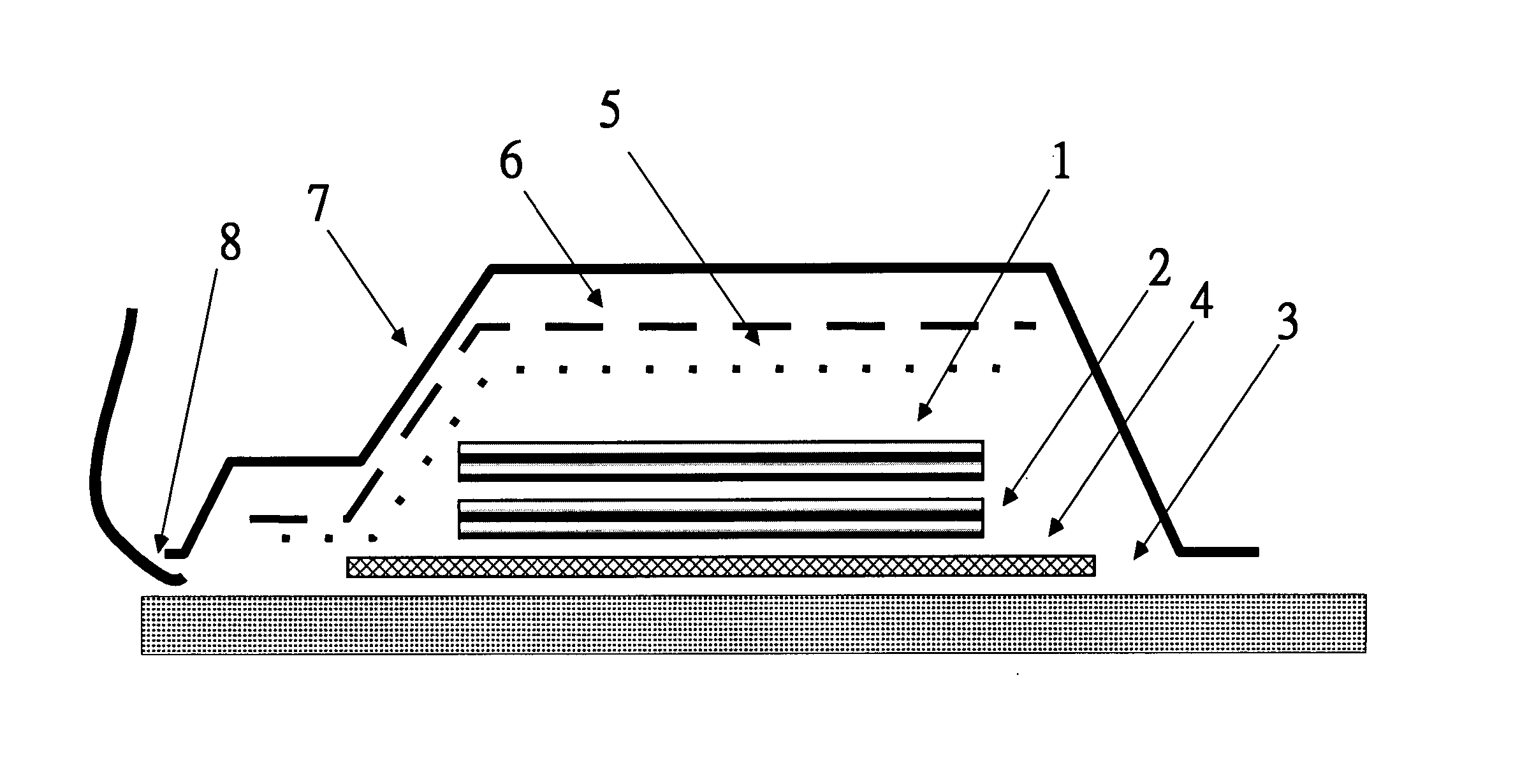

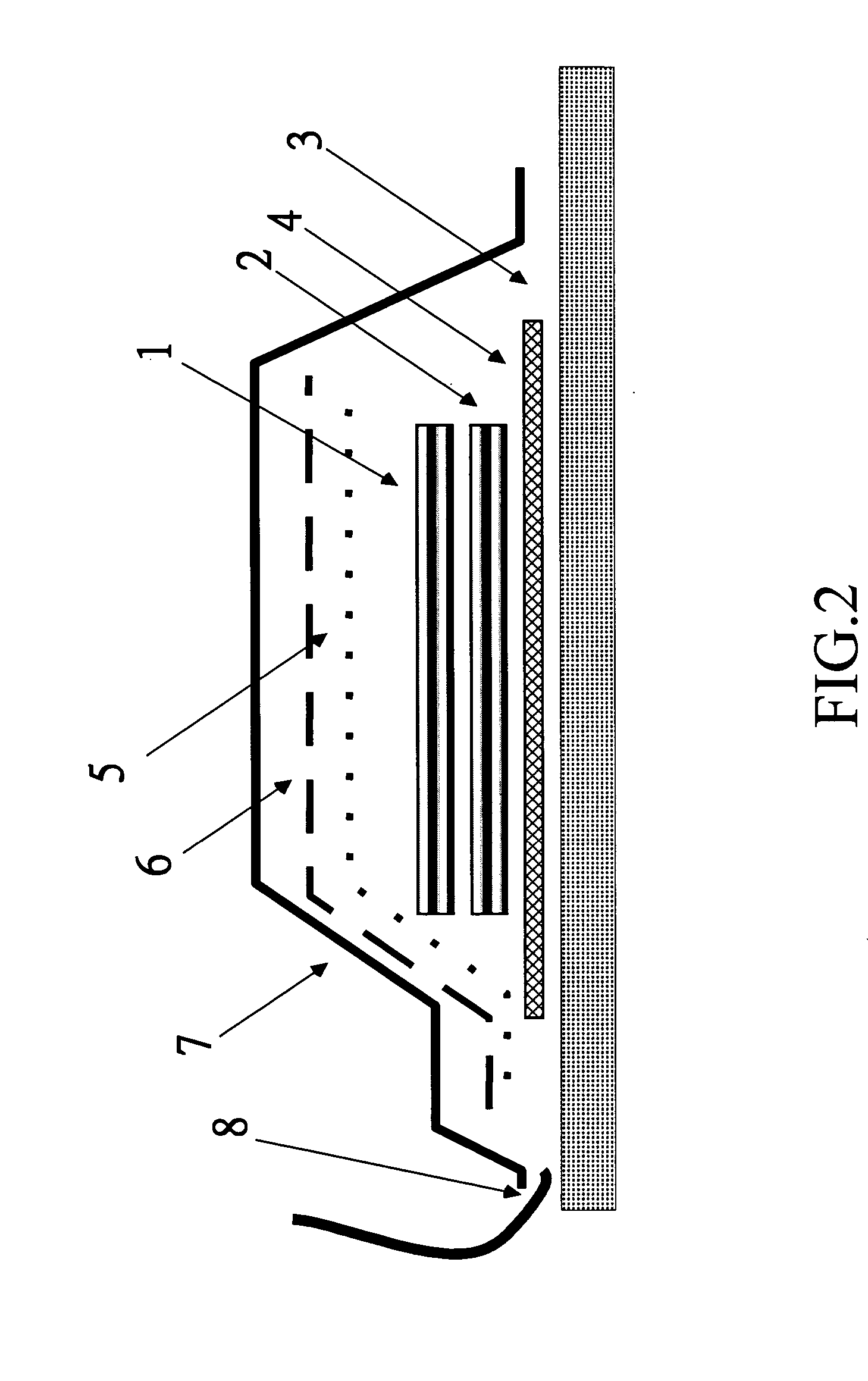

High volume inkjet garment printer with heat presses

InactiveUS20070068403A1Easy to transportIncrease volumeScreen printersTypewritersEngineeringHeat press

A method and apparatus for printing images on a high volume of printable substrates such as garments is disclosed. The apparatus comprises an inkjet printer, a conveyor system, heat presses and beds. The beds are trays with garment attachments such as platens for holding multiple garments in place during printing. In the preferred embodiment, the method first involves loading garments onto the beds and platens. The beds then travel along the conveyor system which includes one or more conveyor tables and optional heat presses. The beds are preferable placed under a heat press for pre-pressing the garments. Then the conveyor system facilitates the transfer of the beds to a high volume inkjet printer, where both an underbase and an image can be printed on each garment. After printing images on the garments, the beds are transferred again to the conveyor system and optionally delivered to another heat press to cure the image. Finally, the garments are unloaded from the beds and new un-printed garments are loaded.

Owner:GRAPHIC ARTS ACQUISITION

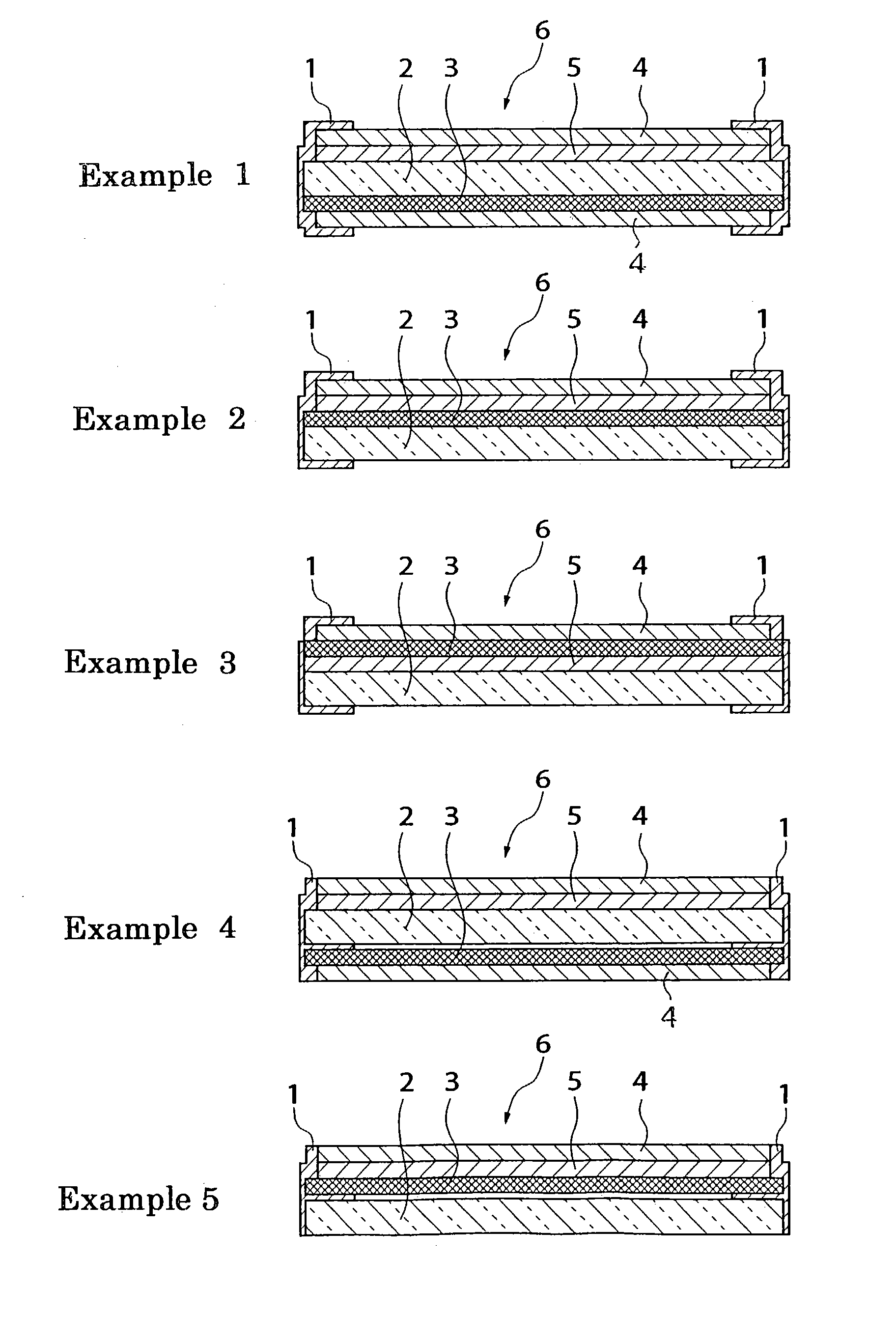

Transparent electromagnetic wave-shielding laminate for display, process for producing same and display unit

InactiveUS20040018375A1Improve production efficiencyMagnetic/electric field screeningScreening apparatusElastomerThermoplastic elastomer

There are disclosed a transparent electromagnetic wave-shielding laminate for display, the laminate comprising an electromagnetic wave-shielding layer wherein at least periphery of a terminal cross section of the layer and / or periphery of an edge thereof is covered with an electroconductive elastomer composition containing an electroconductive filler and a thermoplastic elastomer; a process for producing an electromagnetic wave-shielding laminate comprising bringing an electroconductive elastomer composition into contact with at least periphery of a terminal cross section of an electromagnetic wave-shielding layer and / or periphery of an edge of the layer, and in this state, heat press bonding the composition from a lamination direction and / or cross sectional direction to form an exposed portion on at least peripheral end of the laminate, the portion comprising the composition which is grounded to the layer; other processes for producing the same; and a display unit comprising the transparent electromagnetic wave-shielding laminate. The above laminate, which is producible in high production efficiency, is capable of following the unevenness on the electromagnetic wave-shielding laminate and on the display side grounding portion, thereby surely enabling grounding connection and electromagnetic wave-shielding.

Owner:NISSHINBO IND INC

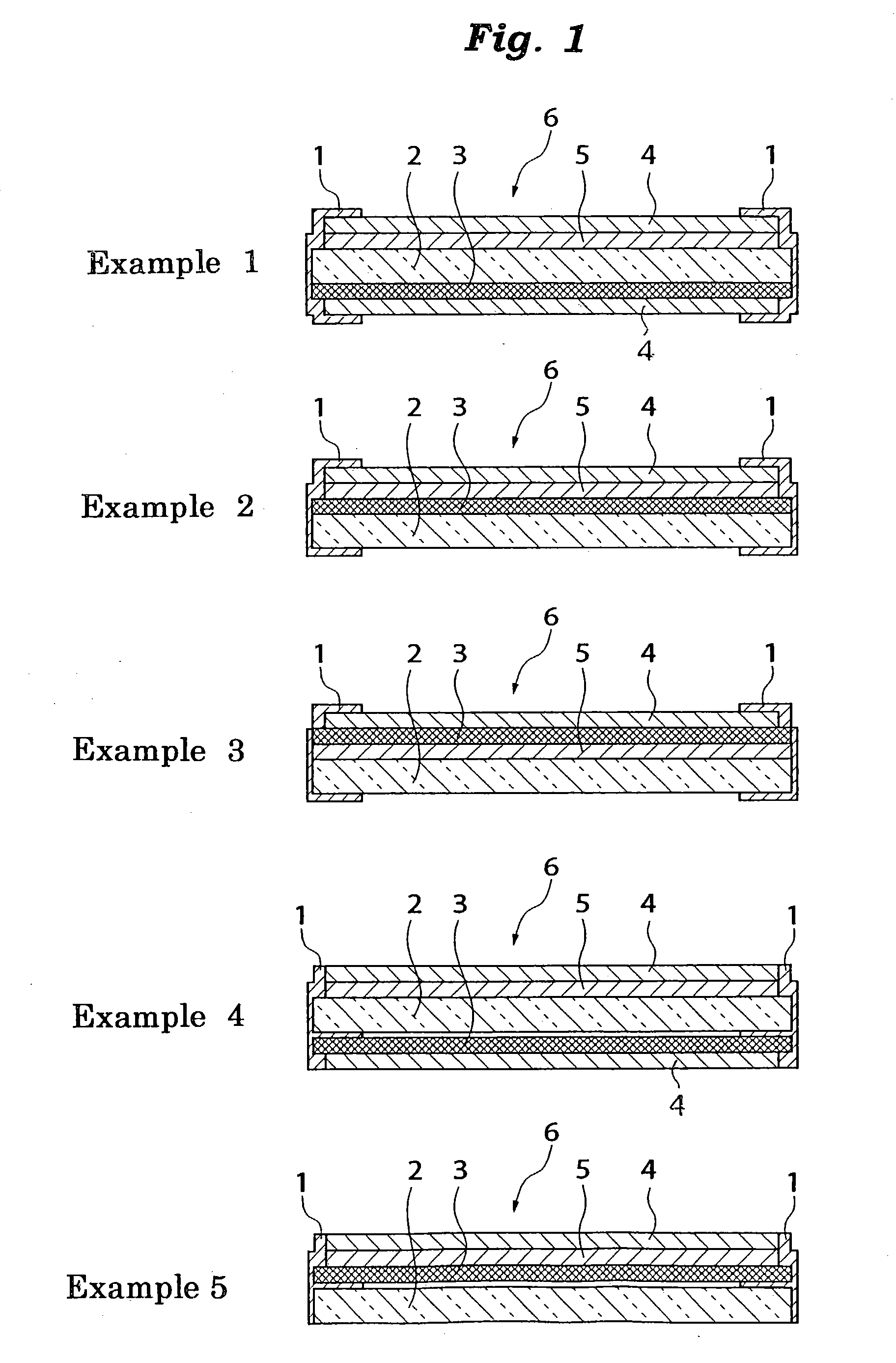

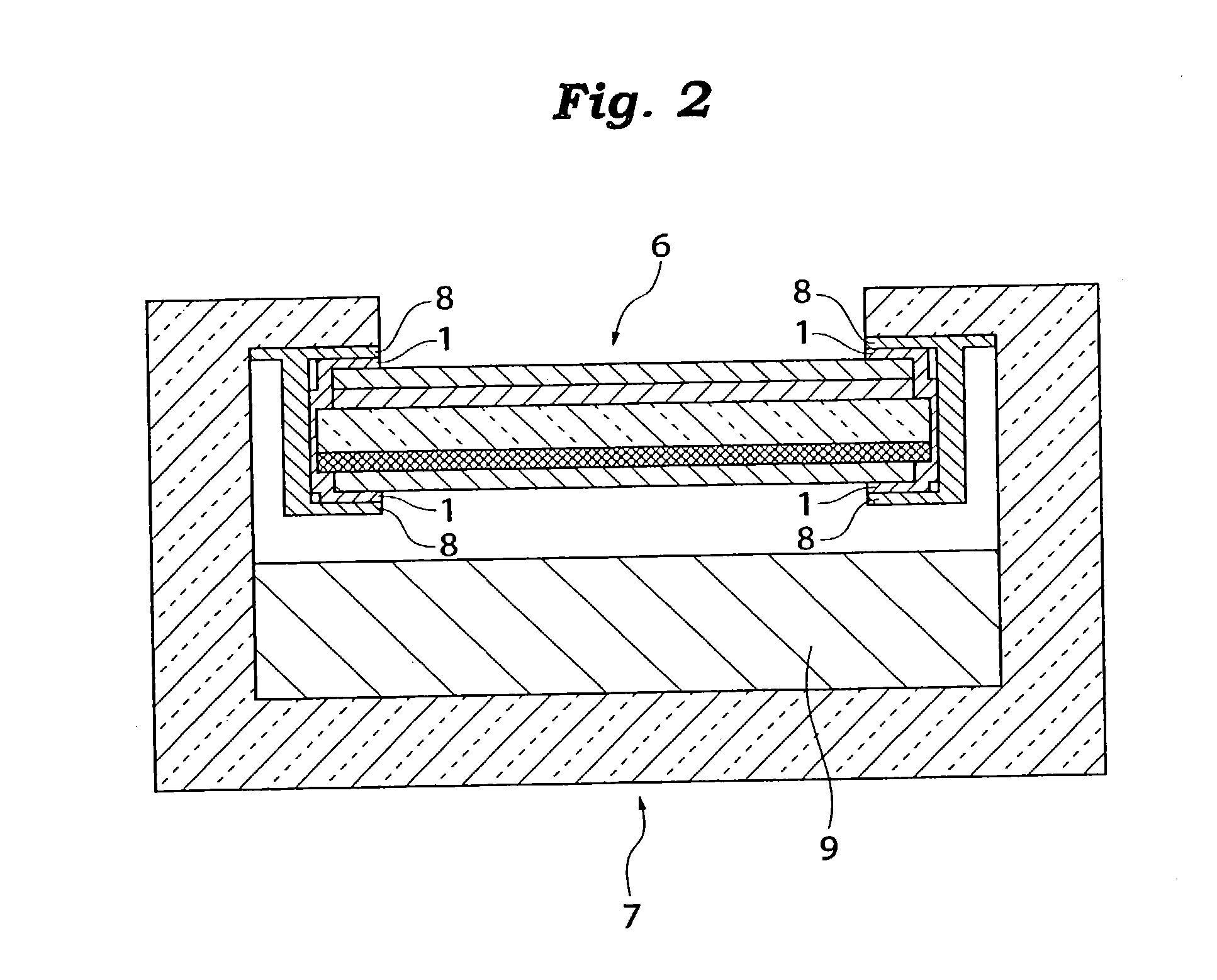

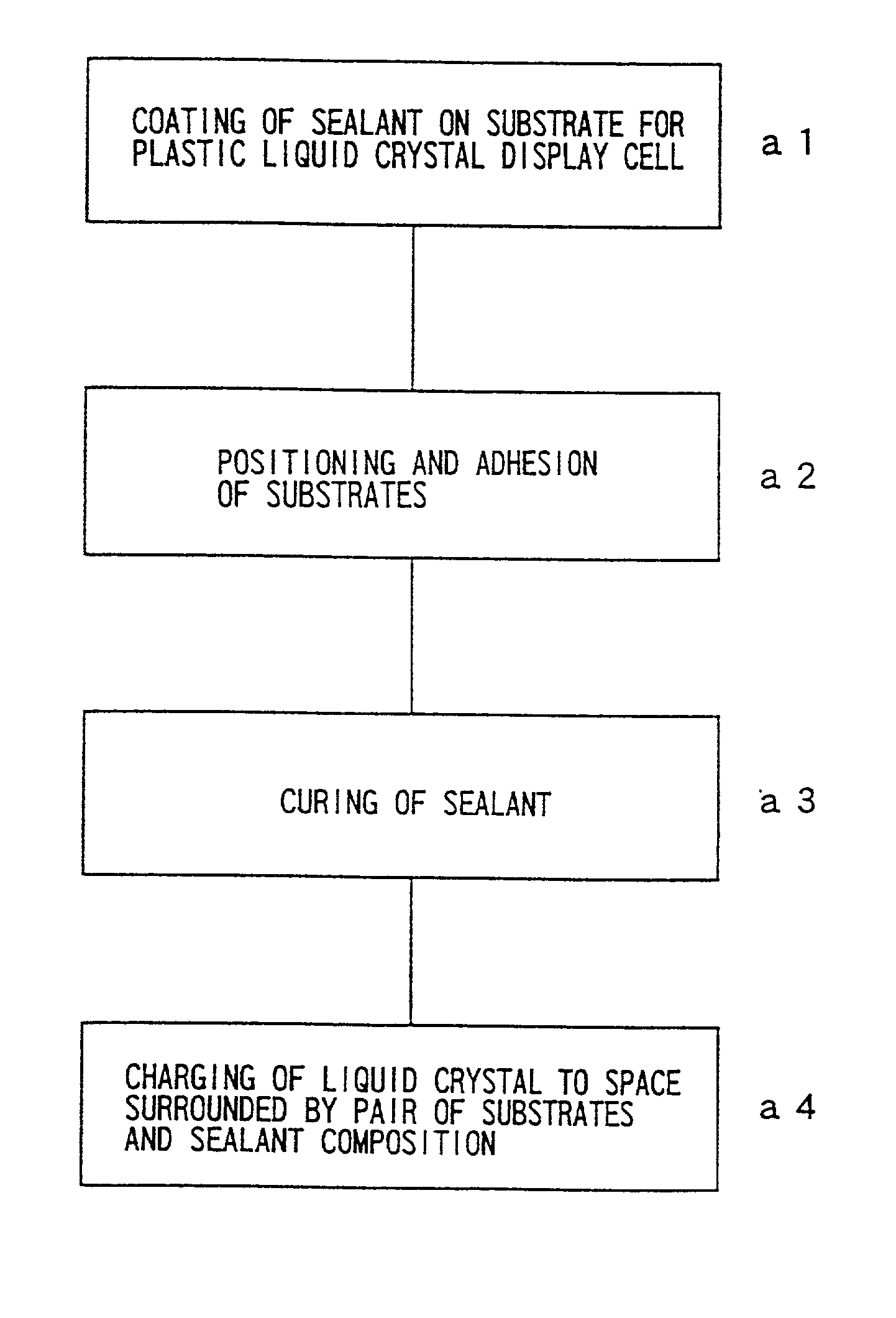

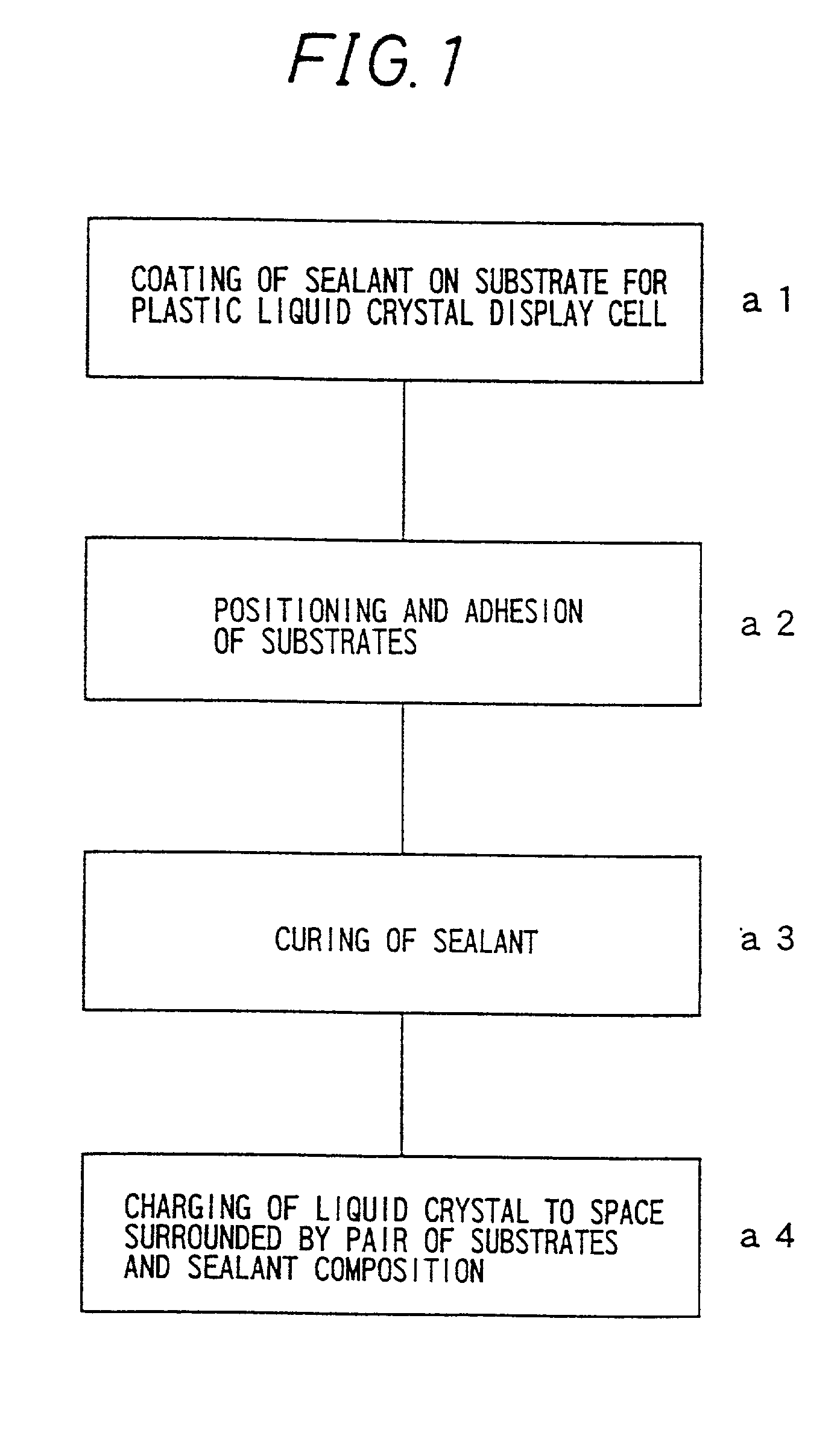

Sealing material for plastic liquid crystal display cells

InactiveUS20020176046A1Improves sealing reliabilityLiquid crystal compositionsEpoxy resin adhesivesEpoxySealant

An object of the invention is to provide a sealant composition for a plastic liquid crystal display cell that is capable of being applied to a sheet heat press adhesion method and of producing a plastic liquid crystal display cell having high reliability under a high temperature and high humidity environment. A two-component sealant composition for a plastic liquid crystal display cell of the invention contains the following components (1) to (6): (1) from 15 to 84% by weight of a liquid epoxy resin having from 1.7 to 6 in weight average of epoxy groups in one molecule and an ionic conductivity of an aqueous solution obtained by extraction separation by contact mixing with 10 times by weight of pure water at from 40 to 80° C. of 2 mS / m or less, (2A) from 10 to 50% by weight of a curing agent containing one or a mixture of two or more selected from (2A-1) a tetrafunctional mercapto compound or (2A-2) a modified polymercapto derivative, having an ionic conductivity of an aqueous solution obtained by extraction separation by contact mixing with 10 times by weight of pure water at from 40 to 80° C. of 0.6 mS / m or less, (3) from 0.01 to 15% by weight of a curing accelerator, (4) from 5 to 50% by weight of an inorganic filler, (5) from 0.1 to 5% by weight of a silane coupling agent, and (6) from 1 to 25% by weight of rubbery polymer fine particles having a softening temperature of 0° C. or less and an average particle diameter of primary particles of from 0.01 to 5 mum.

Owner:MITSUI CHEM INC

Transferable antireflection material for use on optical display

InactiveUS20060147614A1Increased durabilityLow refractive indexSpecial surfacesCoatingsDisplay deviceRefractive index

An optical display, and method for forming an optical display, having improved antireflection properties and durability is formed by applying a transferable antireflection material to an optical substrate through the use of an in-mold or heat press technique or alternatively by an ultraviolet exposure technique. The transferable antireflection material is formed prior to application to the substrate and has at least a low refractive index layer and a high refractive index layer coupled to a release film. The low index reflection layer is preferably a silicone-modified fluoropolymer material having good durability, low refractivity, and appropriate adhesion to the release layer and subsequently applied high index refraction layer. The optical display is then coupled to a housing of an article for use.

Owner:3M INNOVATIVE PROPERTIES CO

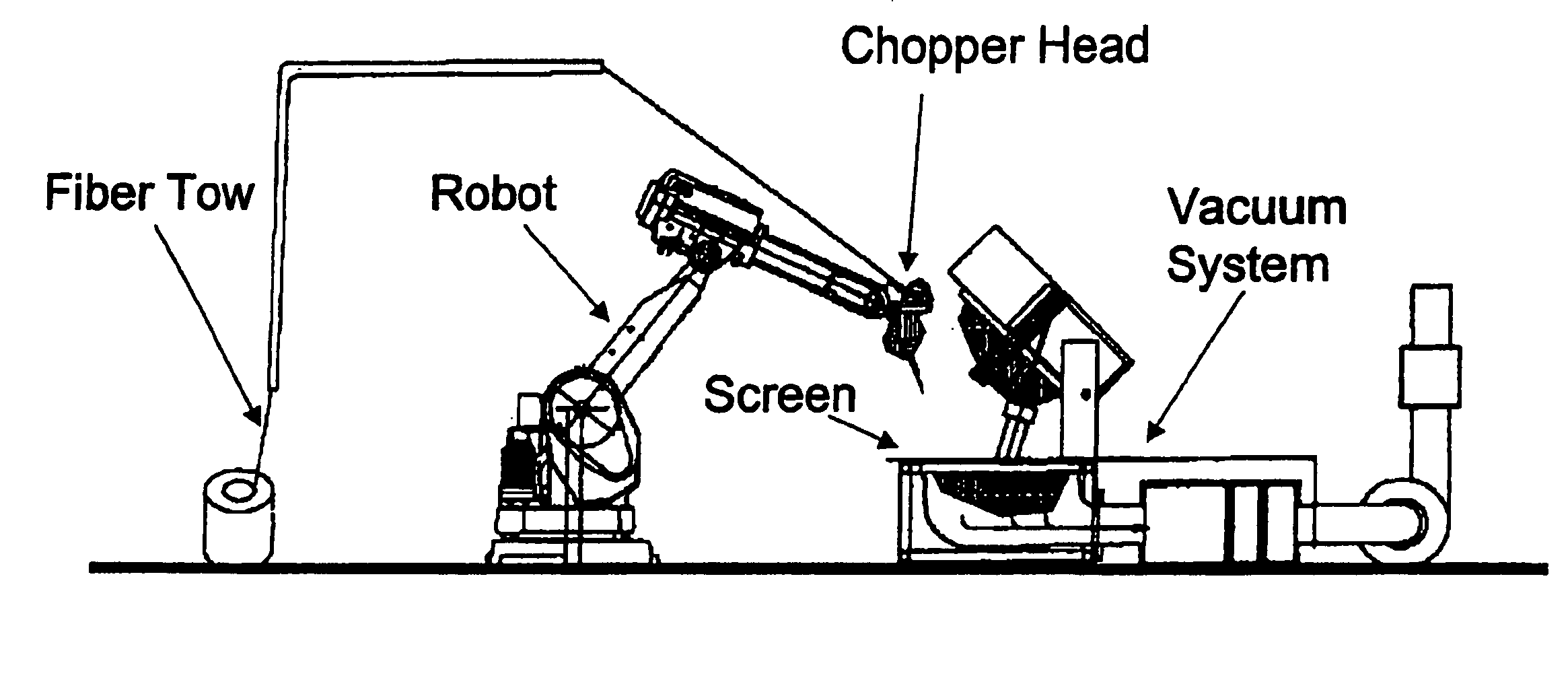

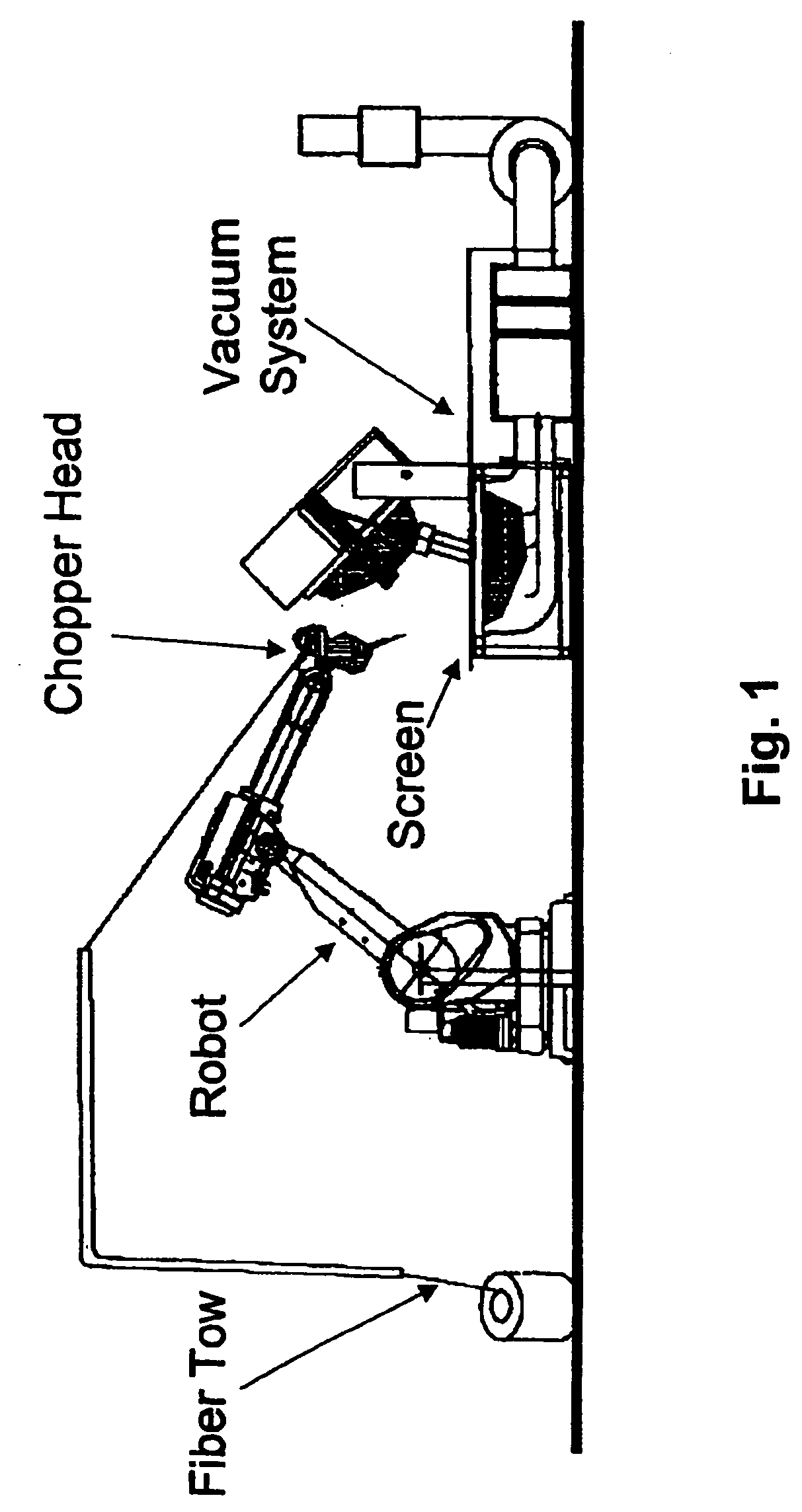

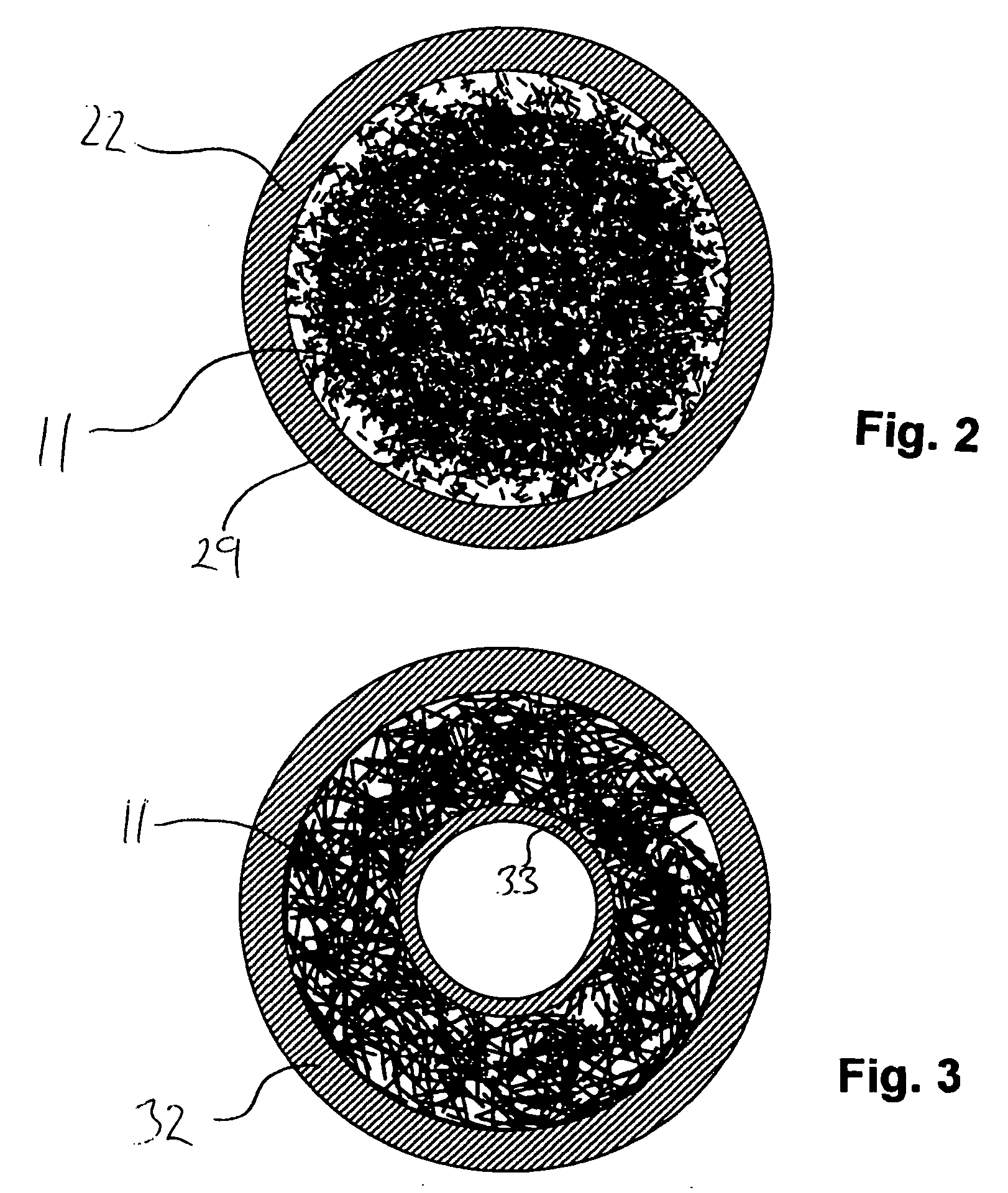

Manufacture of thick preform composites via multiple pre-shaped fabric mat layers

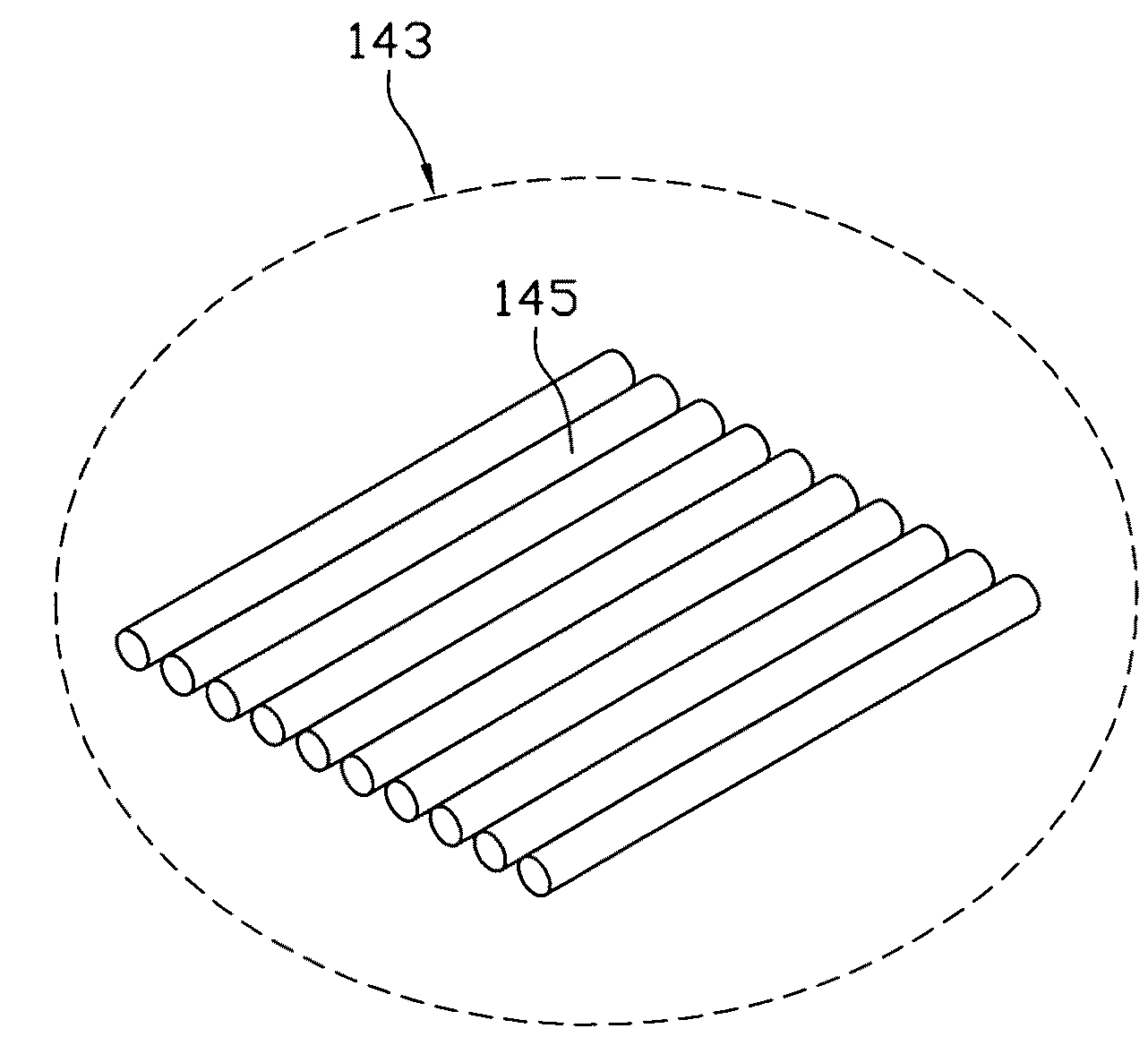

Preform for carbon-carbon composite part (55) comprising multiple layers of fibrous mats (51, 52, 53) wherein each mat (51, 52, 53) comprises random carbon-containing fibrous matrix (11) having polymeric binder distributed therein and wherein adjacent mats (51, 52, 53) are bound together by additional polymer binder, stitching, and interlocking tabs. Also, method of manufacturing thick multi-layer composite preform, by: providing optionally reconfigurable tool including perforated screen through which vacuum can be drawn; delivering chopped fibers (b) to the tool while drawing vacuum therethrough to form fibrous object; delivering binder (c) to the fibrous object; melting or curing the binder (d) to make a fibrous mat (51, 52, 53); assembling plurality of the fibrous mats (51, 52, 53) and additional binder into the shape of a preform (e); and heat-pressing the resulting mat assembly (f) into finished thick preform (55).

Owner:HONEYWELL INT INC +2

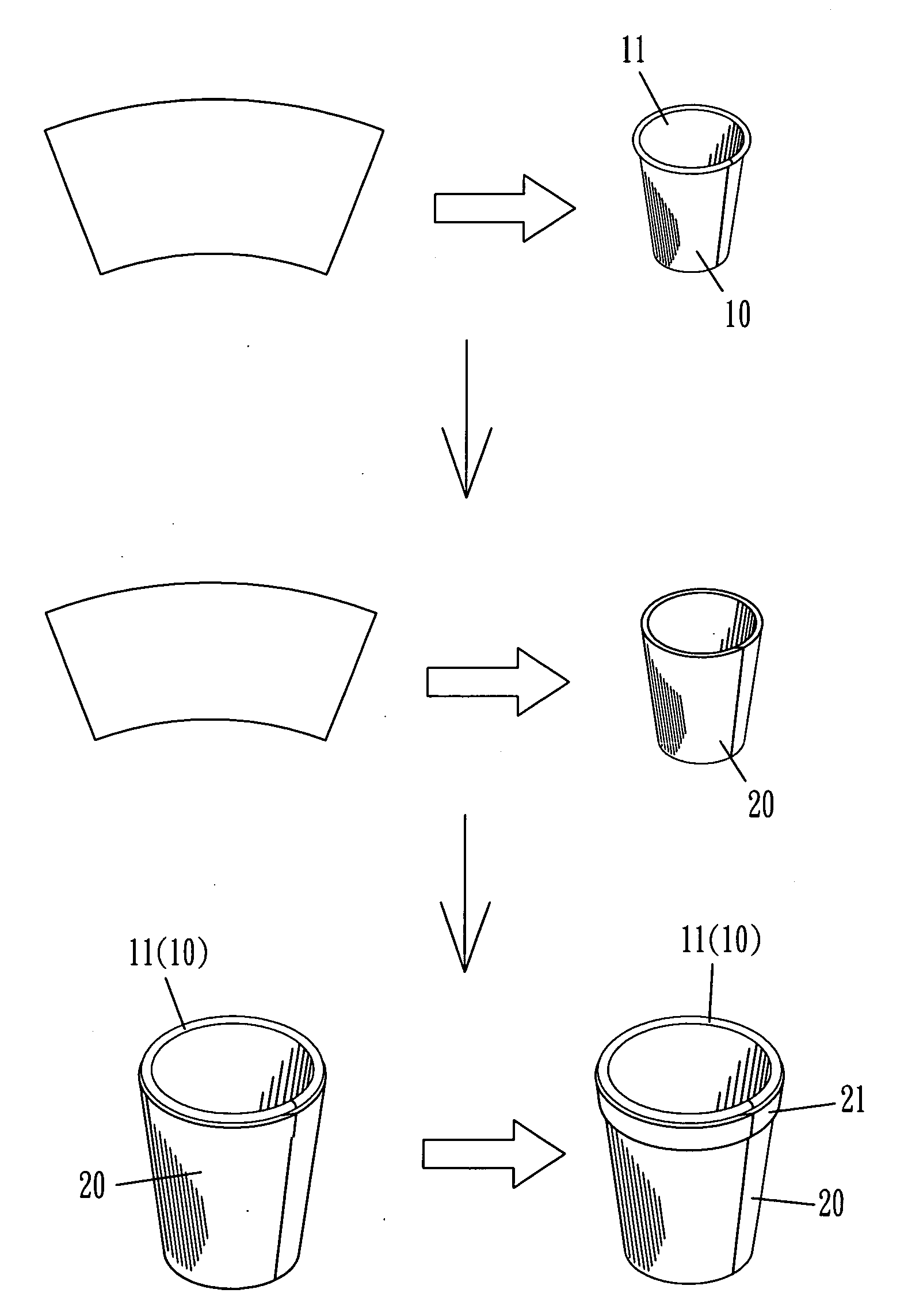

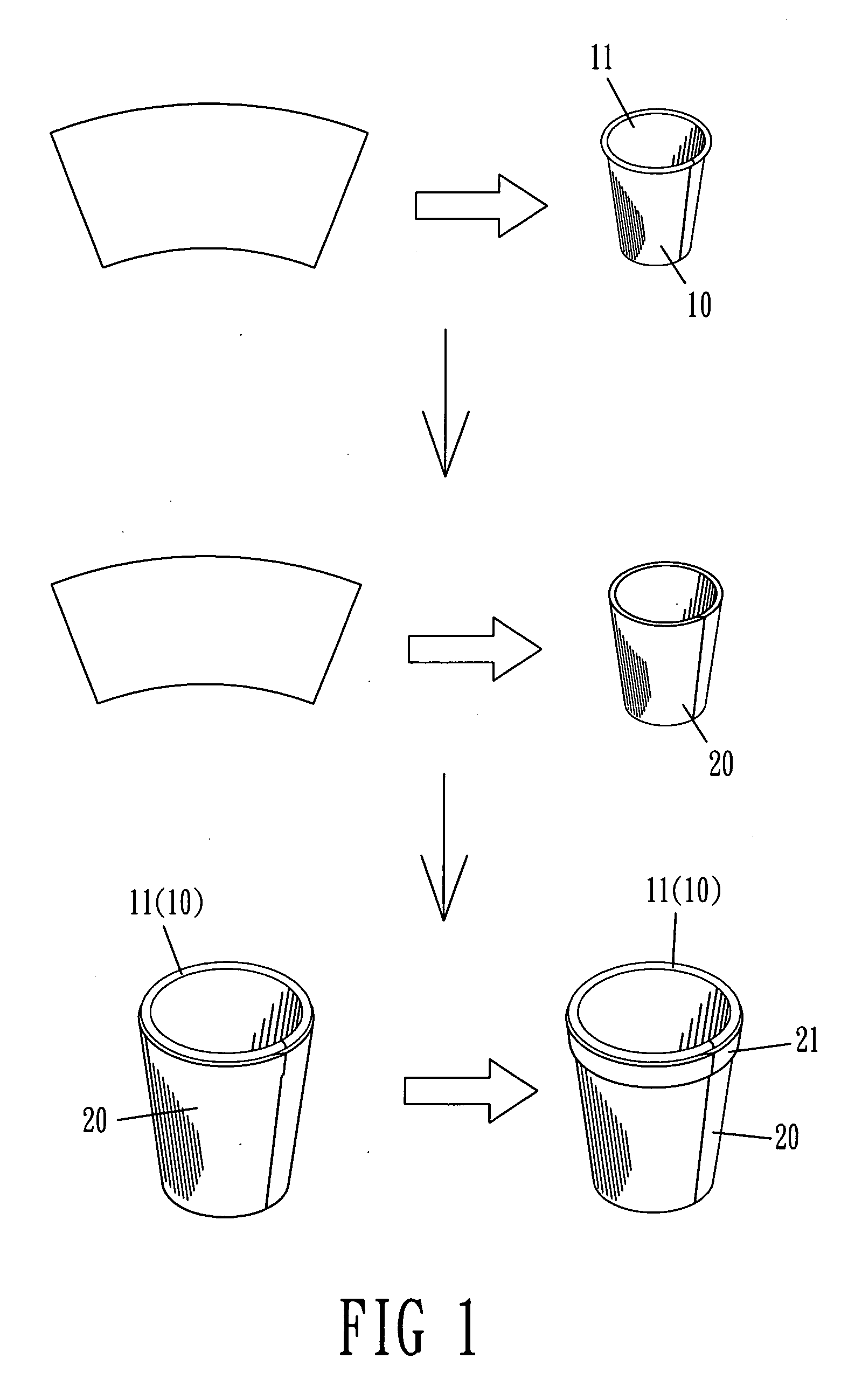

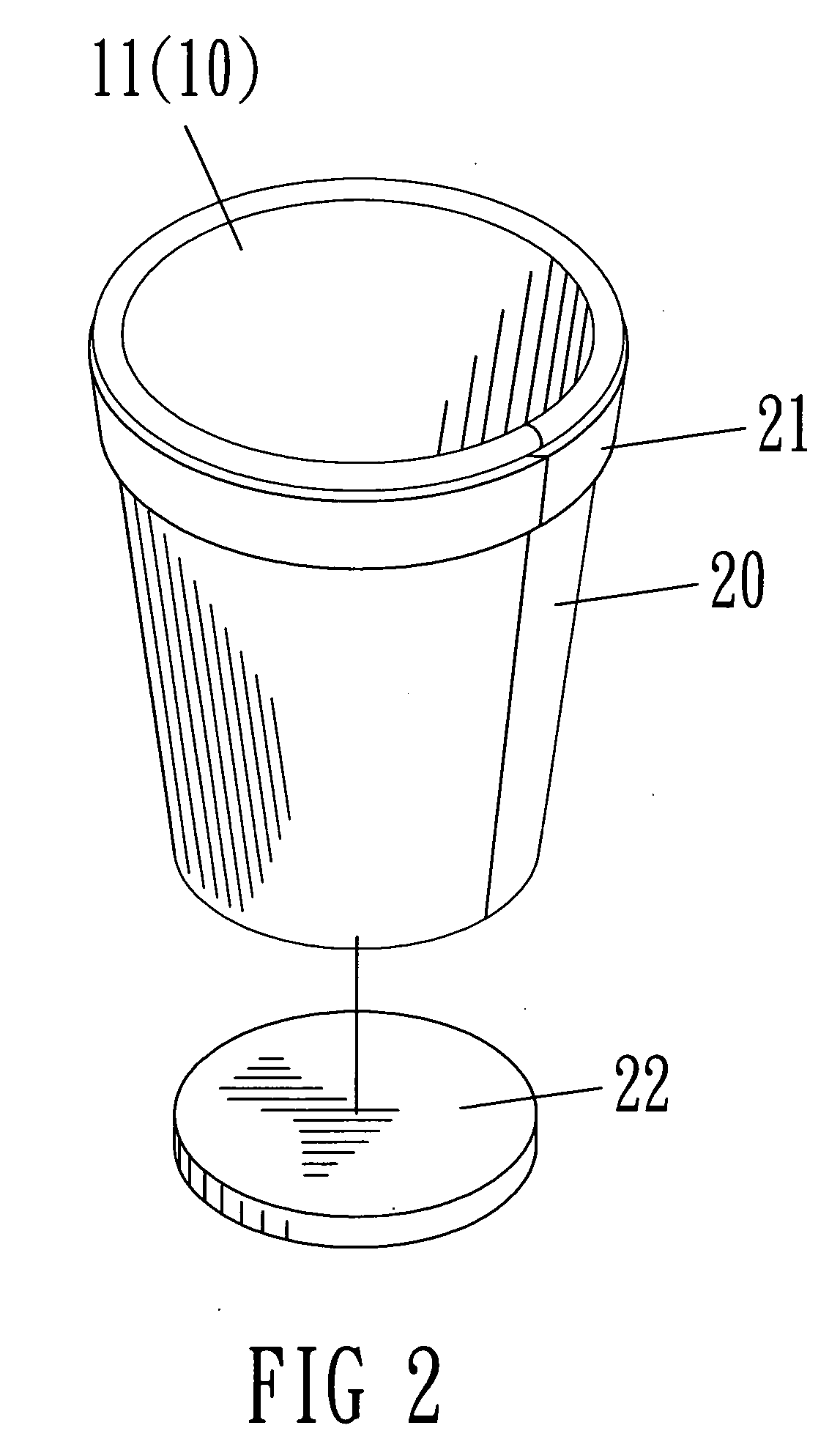

Bio-degradable cup and method for making the same

A bio-degradable cup includes an IXPE foam cup and a paper cup which is securely received in the foam cup. The paper cup includes a bio-degradable film coated to an inside thereof. The paper cup is made from a paperboard with a bio-degradable film coated and the paperboard is cut, folded and heat-pressed to be the paper cup. The foam cup is made from a foam board made by IXPE and the foam board is cut, shaped and folded into pieces and each piece is made to be the foam cup by way of heat pressing. A heat treatment is applied to an inside of the foam cup to obtain a sticky inner surface of the foam cup and the paper cup is securely connected to the sticky inner surface of the foam cup. A lip is made around an outer top edge of the foam cup.

Owner:CHANG HSI CHING

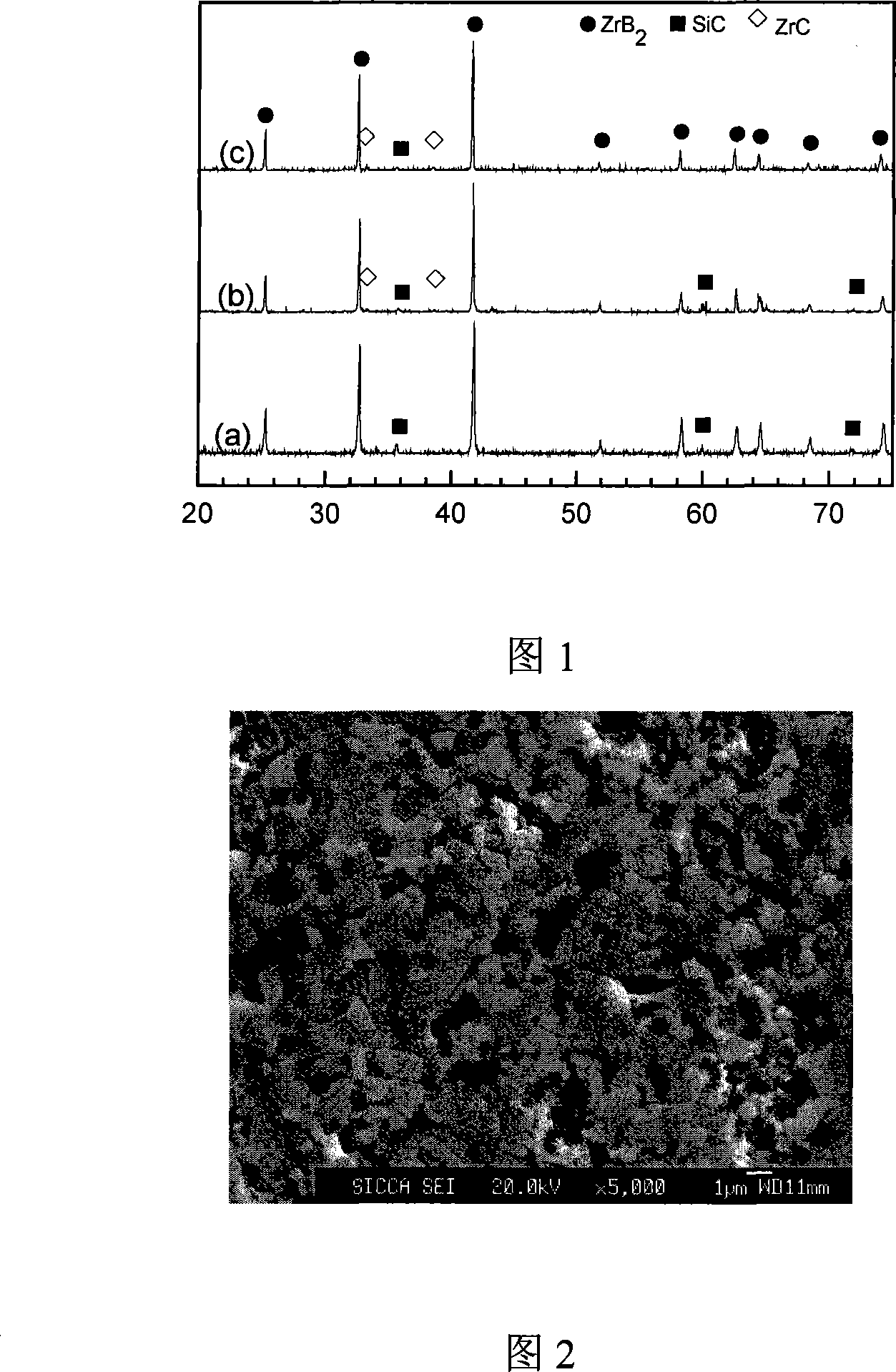

Method for preparing ZrB2-SiC-ZrC diphase ceramic material

The invention relates to a process for preparing ZrB2-SiC-ZrC complex phase ceramic materials, which is characterized in that purity of zirconium powder is not less than 98%, silicon powder and boron carbide powder are used as raw materials, batching according to reaction equation (2+x)Zr+(1-x)Si+B4C=2ZrB2+(1-x)SiC+ZrC, 0<=x<=0.5 of generating ZrB2-SiC-ZrC, then, materials containing different components are obtained. The raw materials after being ball ground and dried are sintered with heat pressing between 1500-1700DEG C by adjusting sintering technique parameter and employing self-propagating reaction of the raw materials generated in the process of heating up, thereby obtaining the ZrB2-SiC-ZrC complex phase ceramic materials of different components. Relative density of the materials prepared by the invention is larger than 97%, bending strength is 600-900MPa, fracture toughness property is 4.5-6MPa,m1 / 2, and hardness is 16-19GPa.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

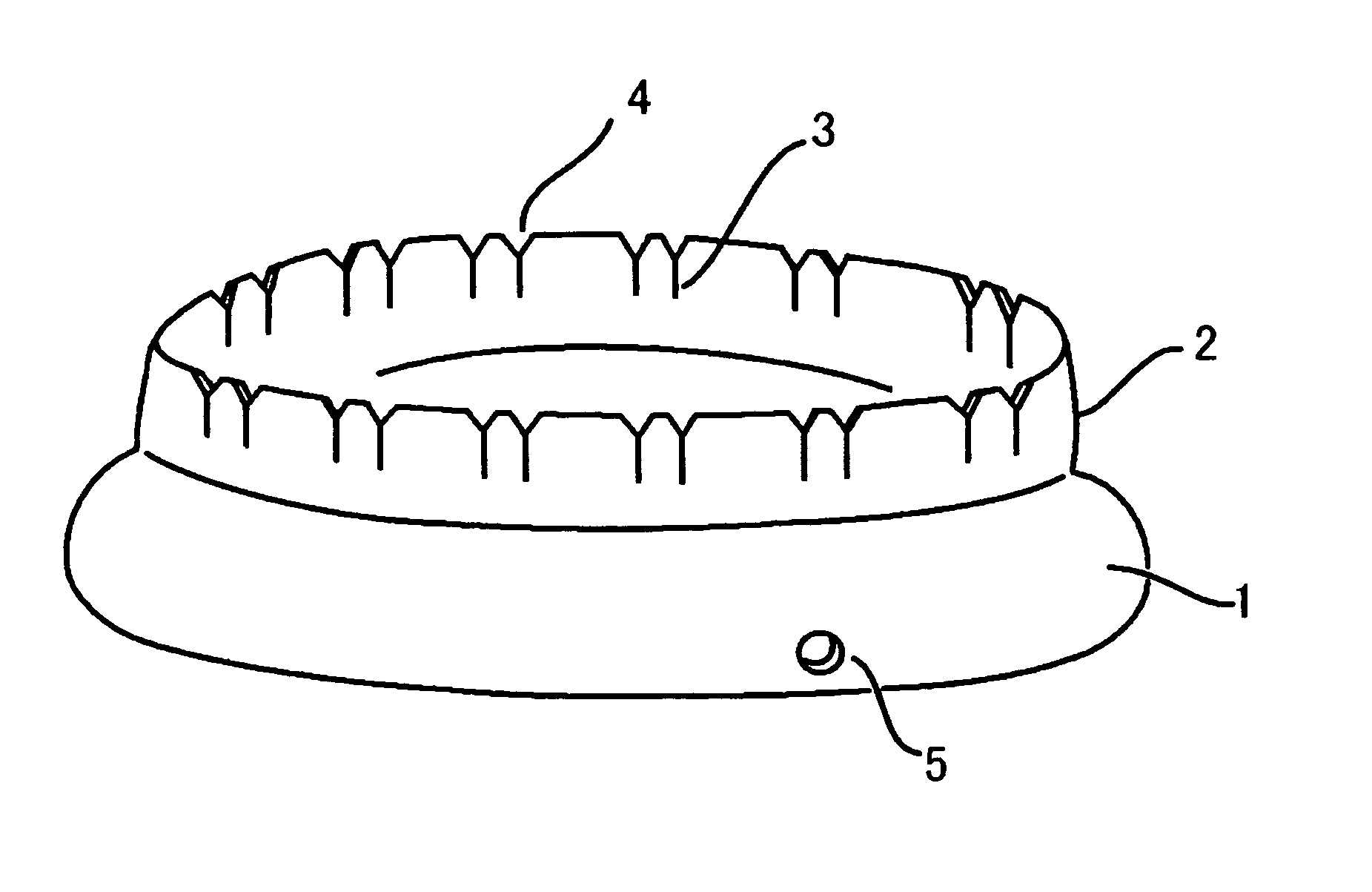

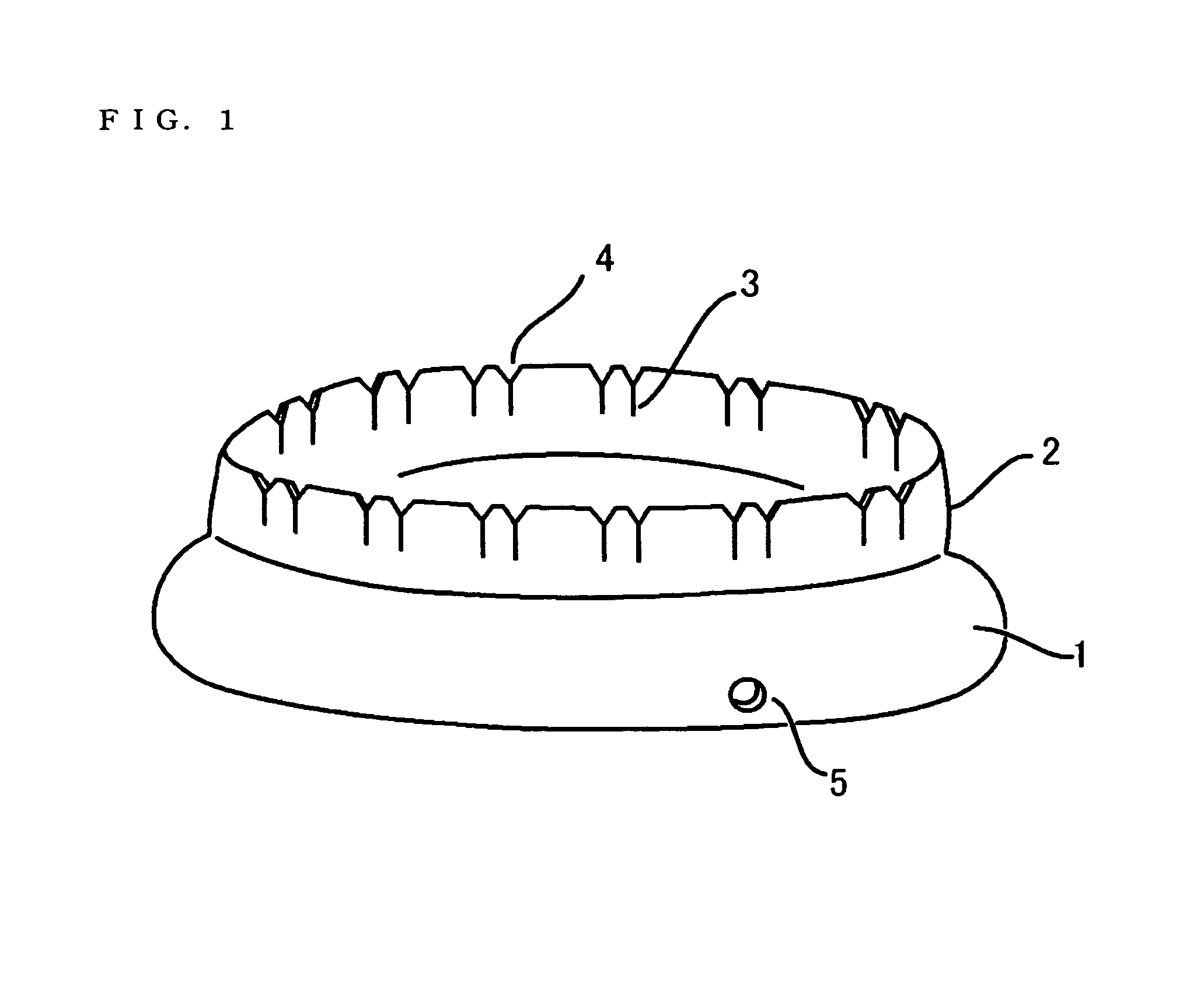

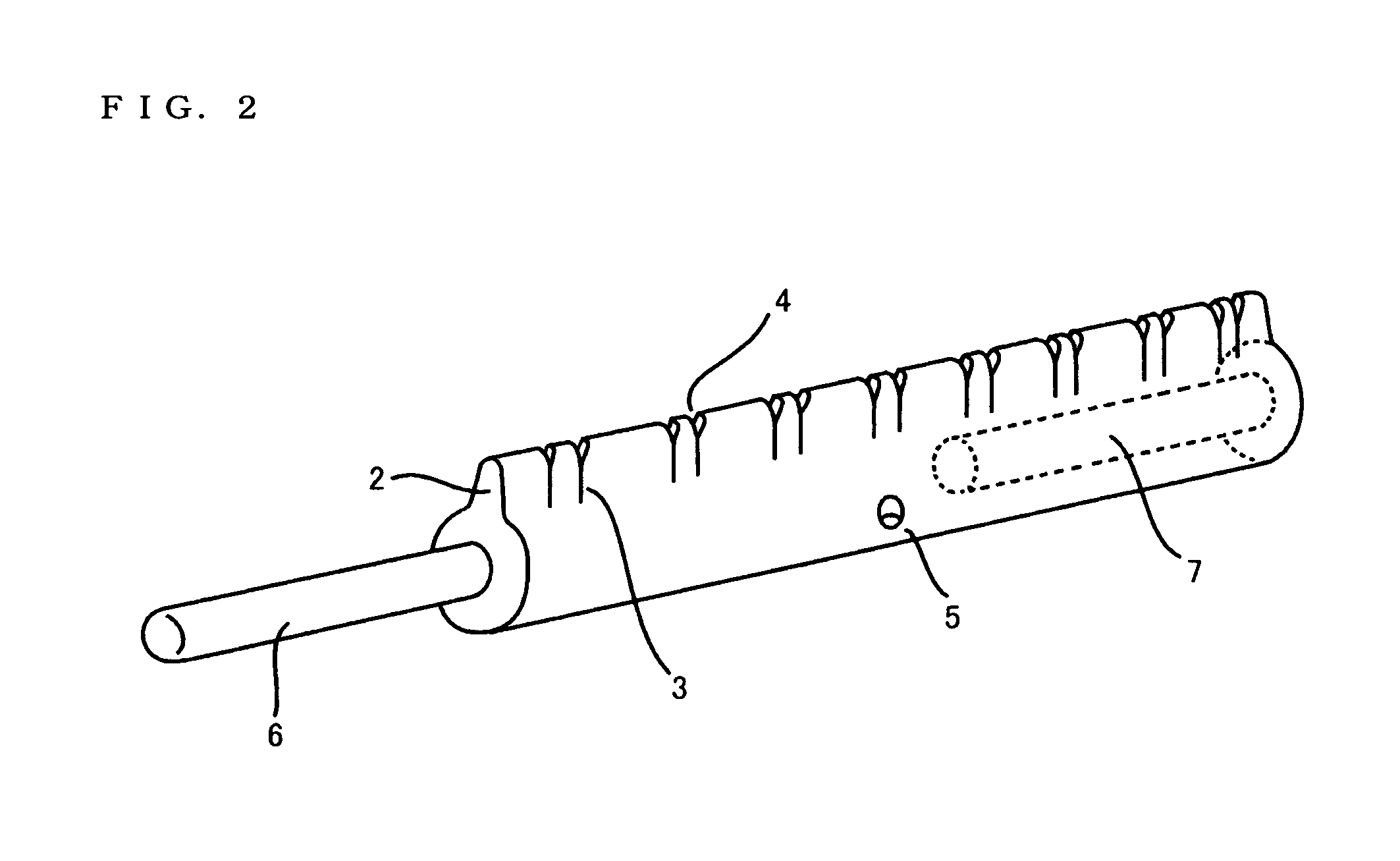

Apparatus for holding and arranging threads in surgical operations

InactiveUS7244260B2Lower manufacturing requirementsReduce distribution costsSuture equipmentsDiagnosticsSurgical operationEngineering

An apparatus for holding and arranging threads in surgical operations with a flexible structure being in a ring form, connecting straight linear forms or divided linear forms, with flexible metal inserted within foaming material. V shape ditches are cut on the upper portion, and the base has adhesiveness. Affordable and simple manufacturing method is established with extrusion molding process or heat press molding process, after which extrusion cut process is conducted with the mold. Labor within hospitals can be reduced, by providing an affordable apparatus which prevents the threads from being damaged, also solving the concern of tissue damage due to thread tension, as the threads are accurately held and arranged without any mixing up with neighboring threads, and the apparatus size, the fixing position of the apparatus, and the operating tissue area can be adjusted at the surgeon's will.

Owner:SHIRAI MOMOKO

High-density polyethylene glued board producing method

InactiveCN101284384AReduce CooldownSave energyWood veneer joiningLow-density polyethyleneWeather resistance

A method for manufacturing a HDPE wood plywood mainly includes: rolling dense pin holes on the cementing surface of a veneer; replacing urea formaldehyde, phenolic aldehyde and other adhesives with HDPE plastic film; laying up in the common conventional plywood lay-up method and only laying the HDPE film instead of the adhesives; heating and pressuring the lay-up on a hot press machine and then pressuring and cooling on a cold press machine. The problems that the HDPE is immiscible with the wood, and can not be taken for the adhesive of the wood are solved by applying the principle of mechanical locking; The heat loss and the time consumption of the hot press machine can be avoided when the lay-up is cooled, for pressing is carried out on the hot press machine and the cold press machine respectively. The plywood product has formaldehyde-pollution-free production, high strength, durability, weather resistance, acid and alkali resistance, high water resistance, good appearance and low price. The manufacturing process has no pollution, and is environment-friendly, energy-saving, efficient and simple.

Owner:林群祥

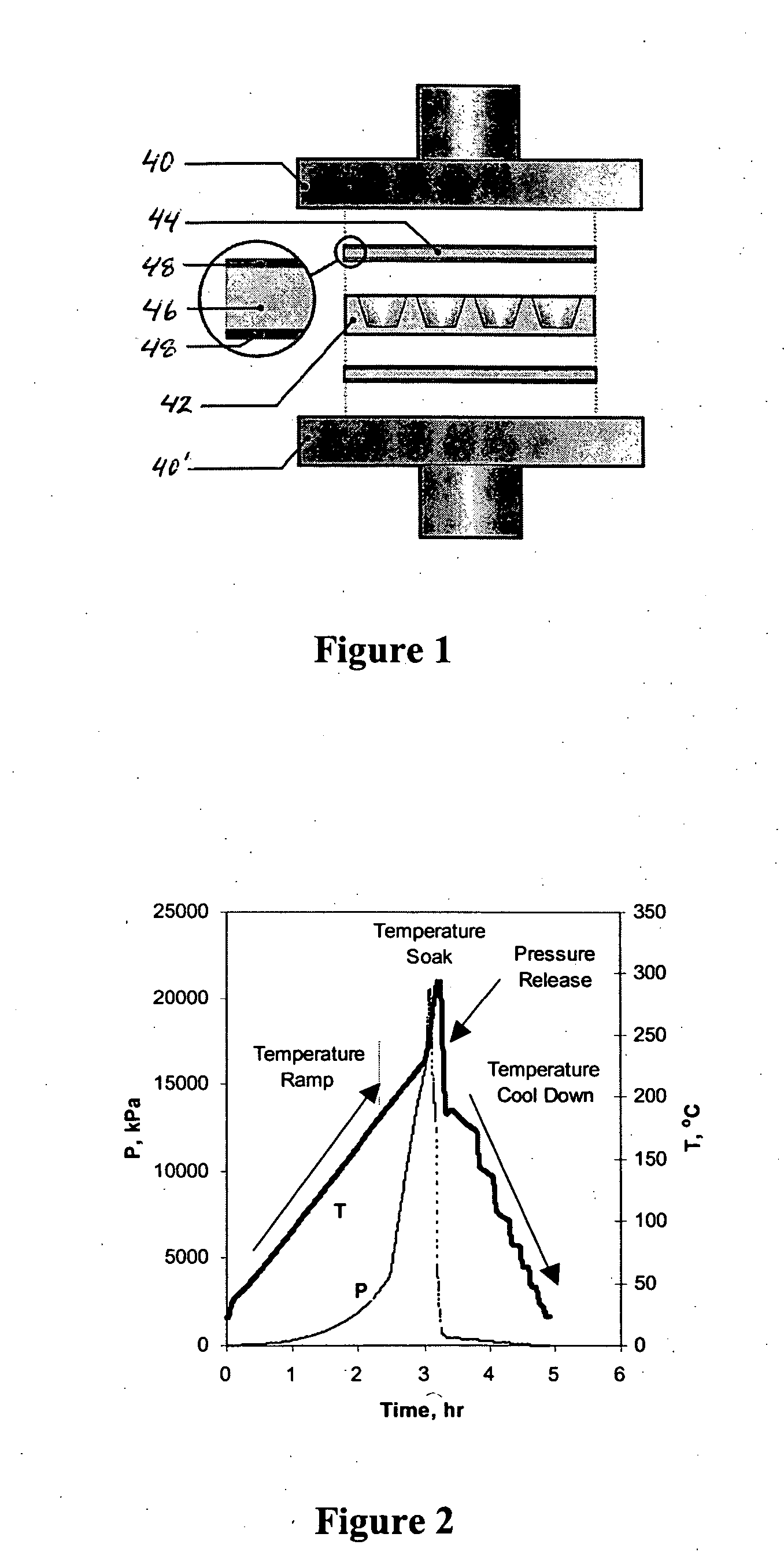

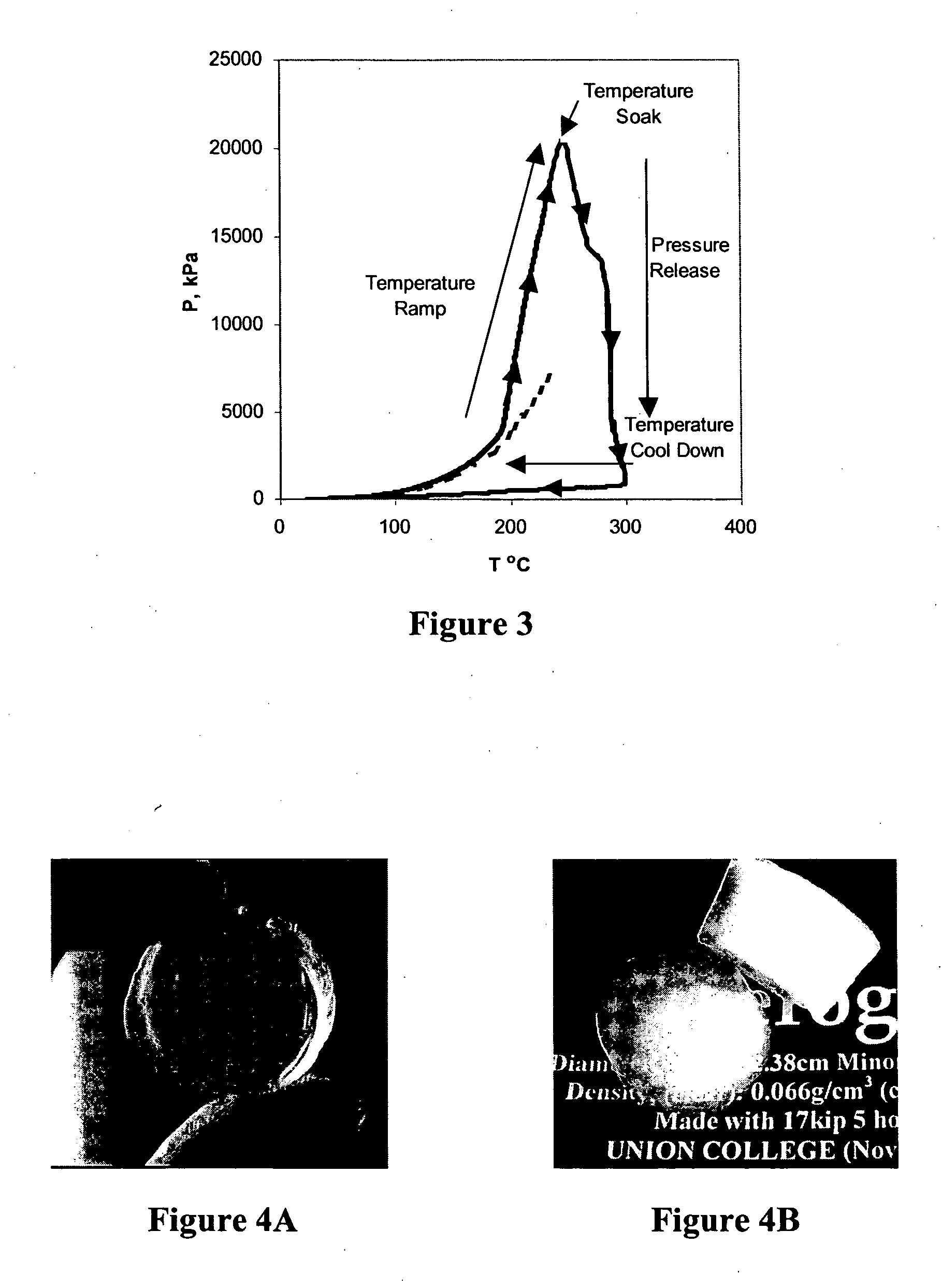

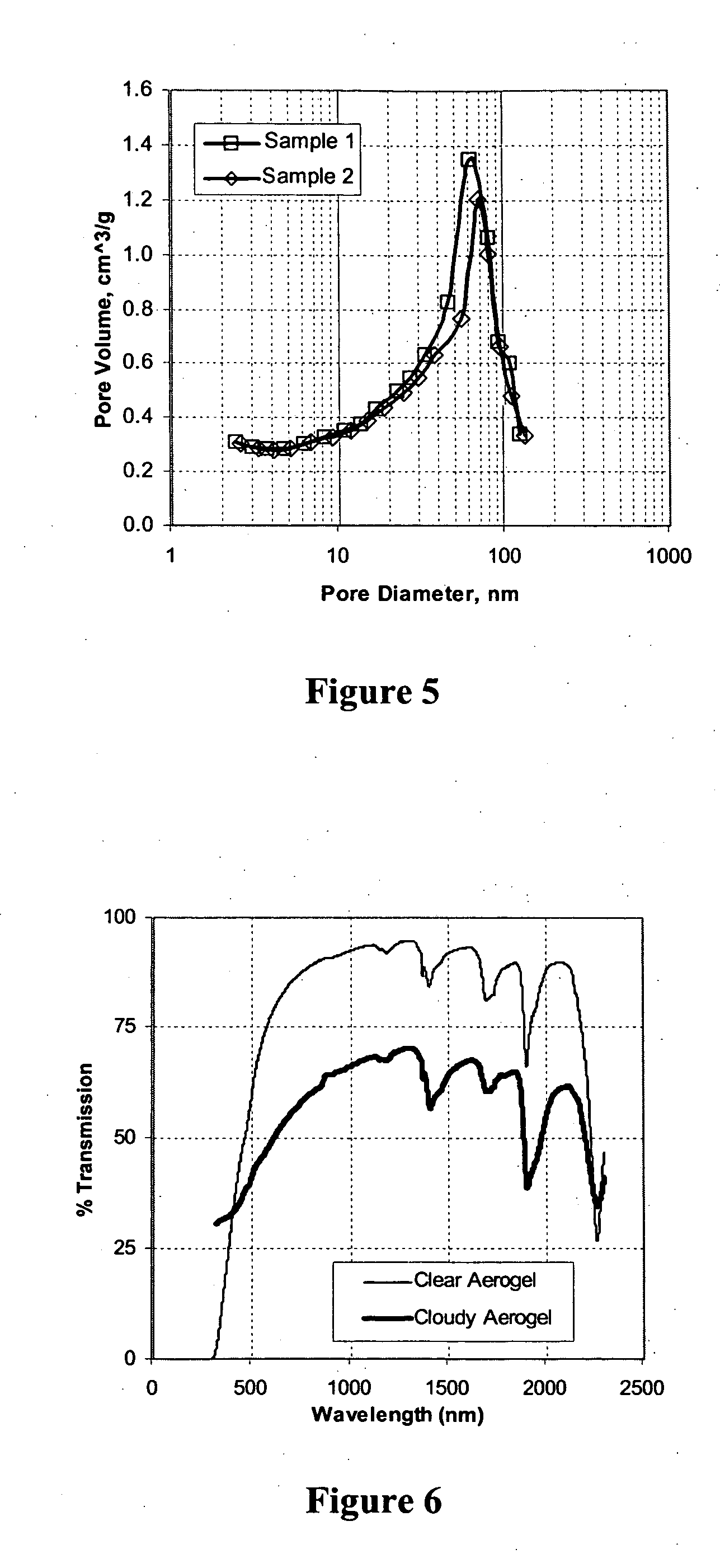

Method and device for fabricating aerogels and aerogel monoliths obtained thereby

ActiveUS20050159497A1Improve automationThe process is simple and fastCeramic shaping apparatusAerogel preparationBiomedical engineeringChemical sensor

Method and devices for rapidly fabricating monolithic aerogels, including aerogels containing chemical sensing agents, are disclosed. The method involves providing a gel precursor solution or a preformed gel in a sealed vessel with the gel or gel precursor at least partially filling the internal volume of the vessel and the sealed vessel being positioned between opposed plates of a hot press; heating and applying a restraining force to the sealed vessel via the hot press plates (where the restraining force is sufficient to minimize substantial venting of the vessel); and then controllably releasing the applied restraining force under conditions effective to form the aerogel. A preferred device for practicing the method is in the form of a hot press having upper and lower press plates, and a mold positioned between the upper and lower plates. Doped aerogel monoliths and their use as chemical sensors are also described.

Owner:UNION COLLEGE

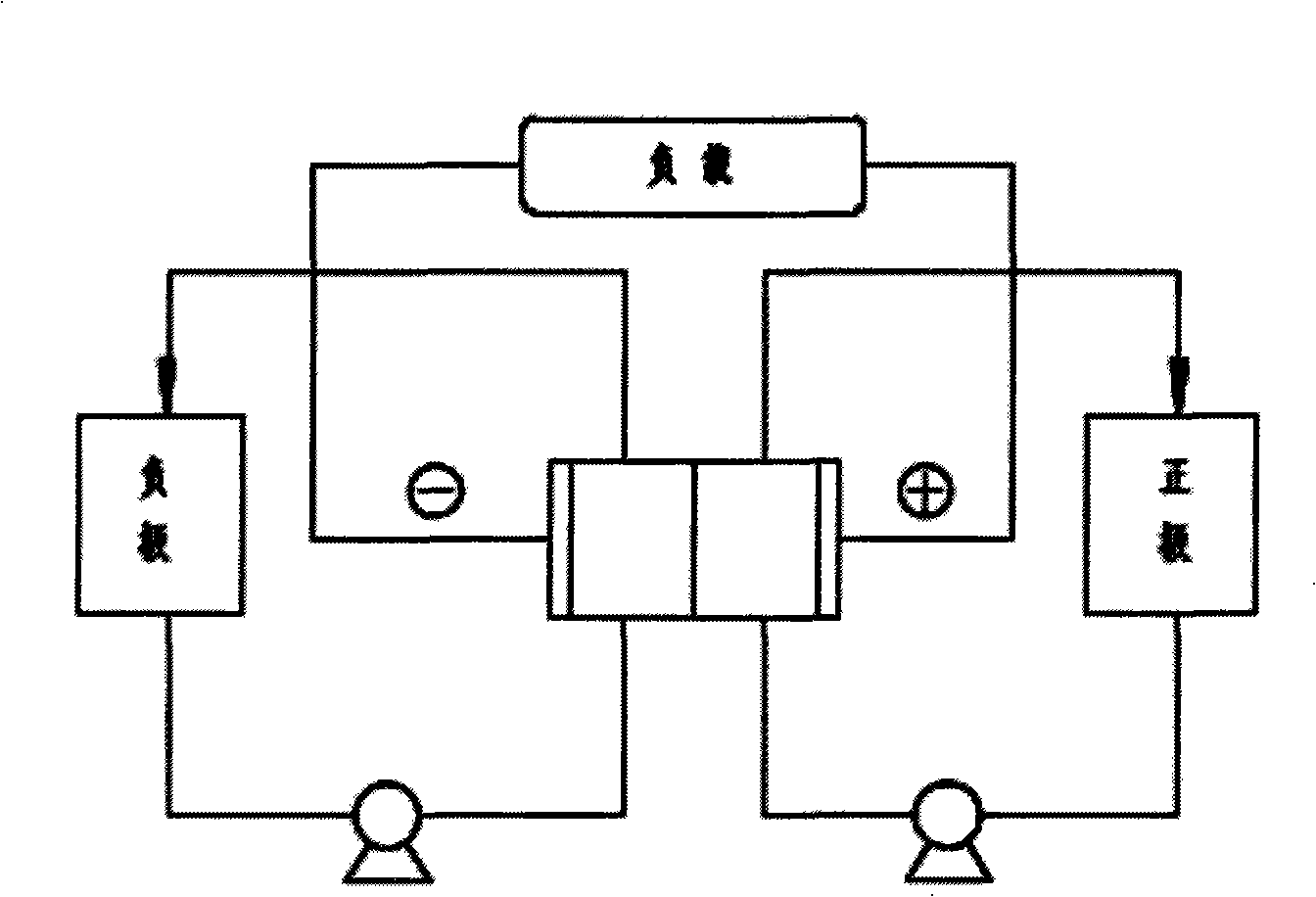

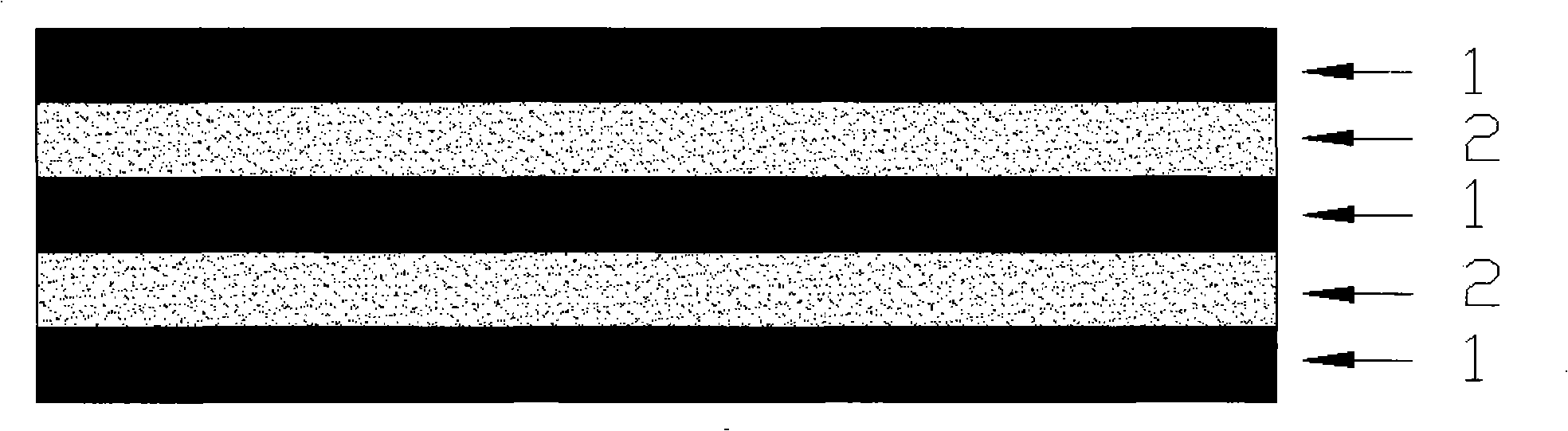

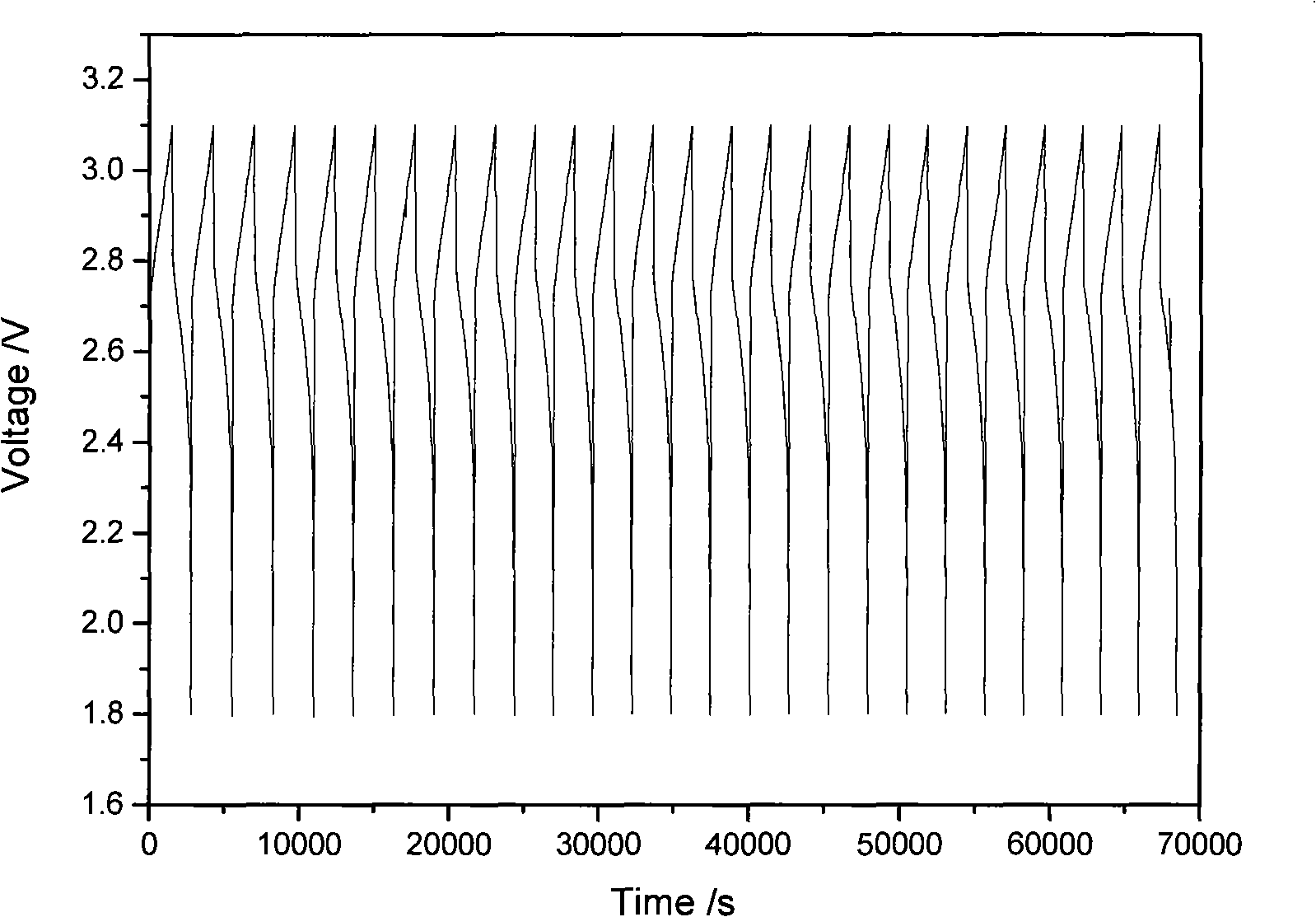

Flexibility enhanced bipolar plate for liquid energy-storing battery and manufacture thereof

ActiveCN101308924AGood liquid resistanceImprove Coulombic efficiencyElectrode manufacturing processesActive material electrodesChemical storageRedox

The invention relates to a redox flow storage battery in chemical storage technology, and in particular relates to a reinforcing soft graphite bipolar plate used in a redox flow storage battery and the fabrication method thereof. The bipolar plate is composed of soft graphite layers and a carbon conductive composite material layer, which are staggered and are spliced together. The external two layers are soft graphite layers. The invention adopts carbon conductive composite material to reinforce the soft graphite plate and introduces heat pressing technique to fabricate a reinforcing soft graphite bipolar plate which is of good conductivity and good liquidity resistance and mechanical property. The reinforcing soft graphite bipolar plate is simple in fabrication technique and the reinforcing soft graphite bipolar plate made through the technique is low in cost and is easy to realize in batch production.

Owner:DALIAN RONGKE POWER

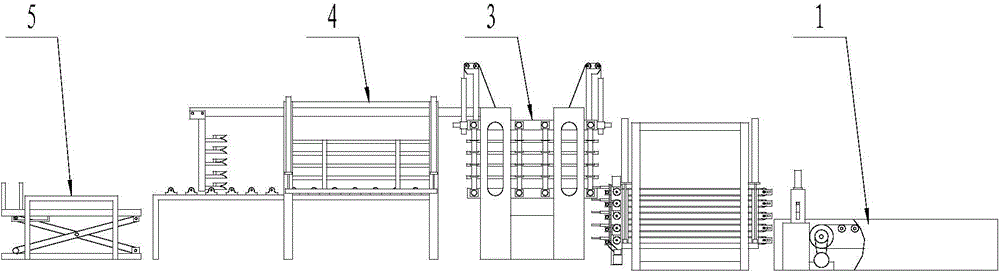

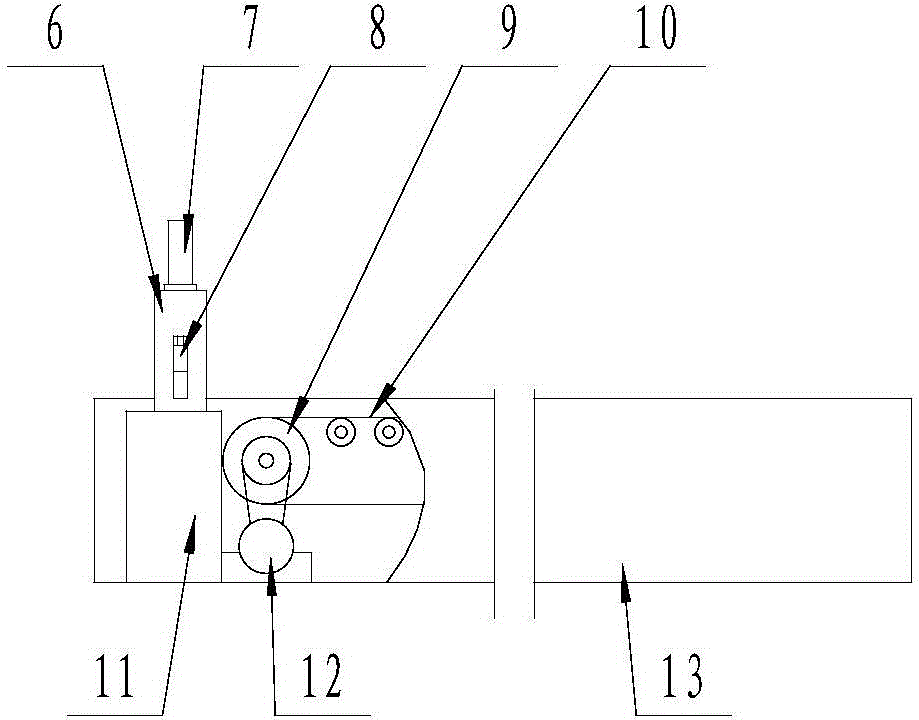

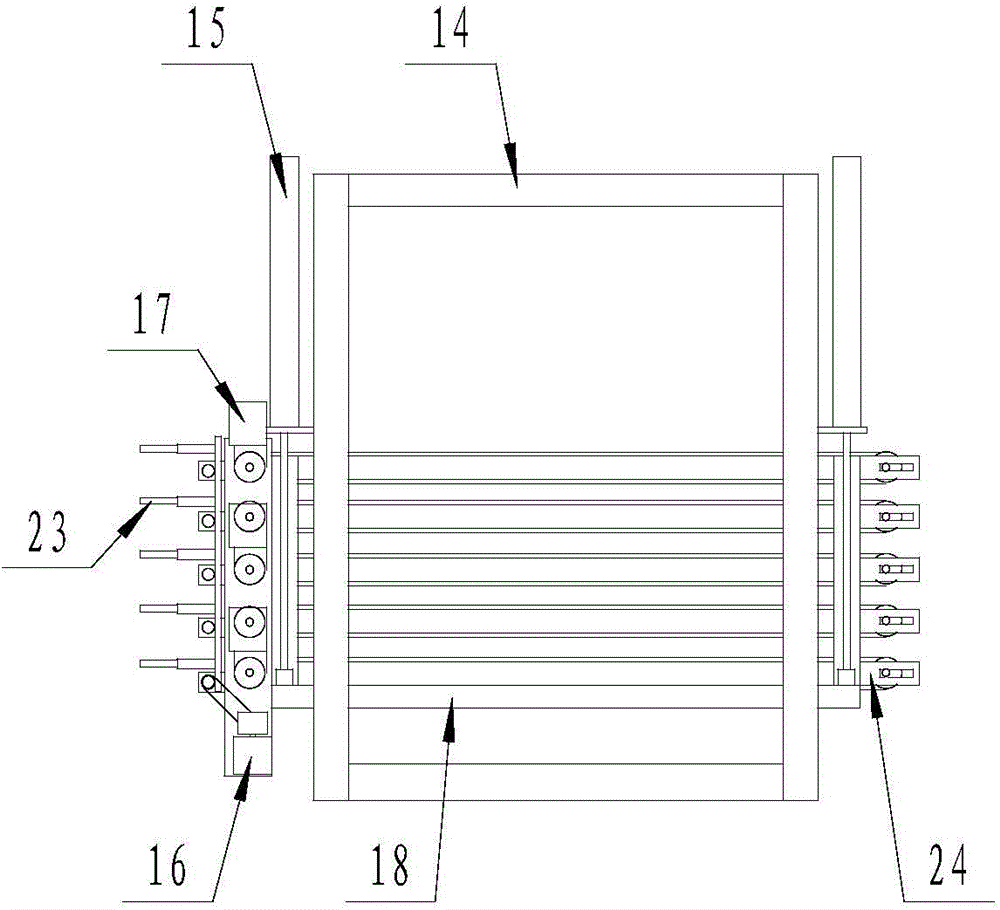

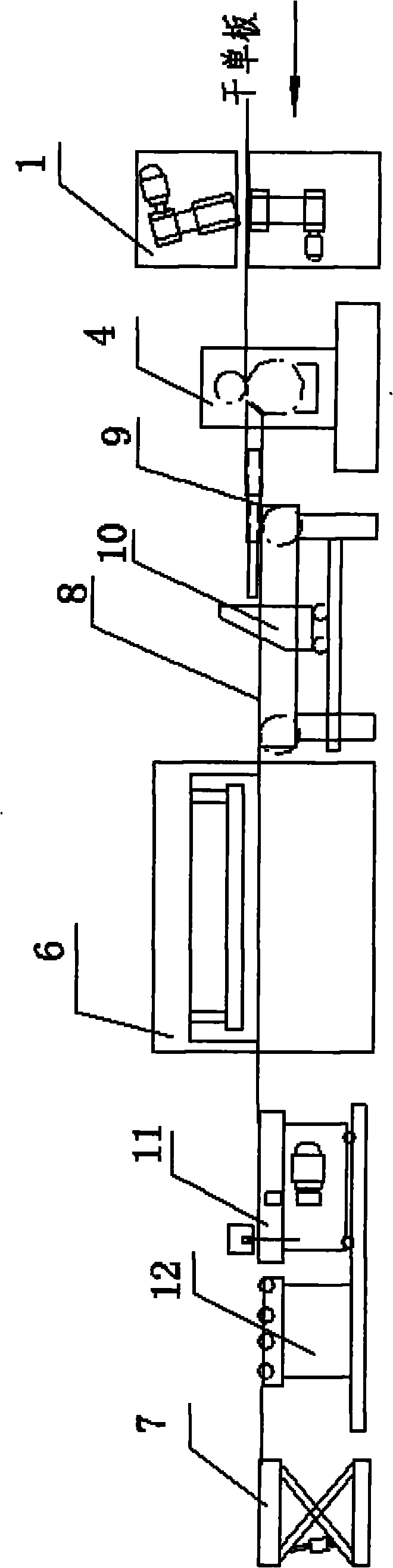

Woodworking plate paving-hot-pressing all-in-one machine

InactiveCN104526796AImprove processing qualityRise steadilyOther plywood/veneer working apparatusPlywood pressesControl systemSlide plate

The invention discloses a woodworking plate paving-hot-pressing all-in-one machine and belongs to the field of plate machining machinery. The woodworking plate paving-hot-pressing all-in-one machine comprises a jointed plate conveying platform, an automatic feeder, a multilayer thermal press, an automatic plate taking device, a plate stacker and a programming control system. The automatic feeder comprises a feeder frame, a lifting table, a lifting oil cylinder I connected with the lifting table and at least two plate storing platform layers arranged on the lifting table. Transmission devices and conveying sliding plates connected with the transmission devices are arranged on the plate storing platforms. The machine is used for woodworking plate production and machining, automatic conveying, automatic sawing, automatic multilayer thermal press placing in, automatic plate taking and automatic stacking can be achieved, following plate joining operation is not affected, the automatic degree and the production efficiency are high, and plate machining quality is high.

Owner:姜皓月

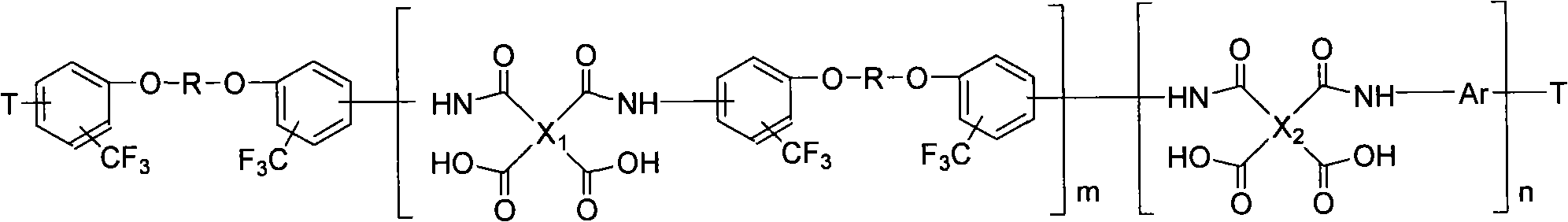

Polyimide resin, its midbody, preparation method and application thereof

ActiveCN101343362AImprove heat resistanceImprove mechanical propertiesLamination ancillary operationsSynthetic resin layered productsChemical structureMetal foil

The invention discloses polyamide resin and intermediate compound thereof as well as the preparation method and the application. The polyamide resin is provided with the chemical structure shown in formula II, wherein, X1 and X2 can be identical or different, representing quadrivalent aryl; Ar represents bivalent aryl, and T represents end capping reagent. The polyamide resin is obtained by polyamic acid shown in formula I structure general formula through chemical imidization or thermal imidization. The polyamide resin is dipped through prosomatic polyamic acid solution or polyamic acid solution being obtained after being dissolved with solvent with a low-boiling point, the basal body is strengthened, and the prepreg is obtained. After the heat-press forming operation is performed, a metal foil layer is covered, and a metal foil layer pressing plate is obtained. The polyamide resin provided by the invention has the advantages of excellent heat resisting property, high mechanical property, low dielectric constant and dissipation, high electrical insulation property and low water absorbing capacity, thereby being especially suitable for manufacturing core plates of packaging subsctrates for packaging super large-scale integrated circuits.

Owner:INST OF CHEM CHINESE ACAD OF SCI

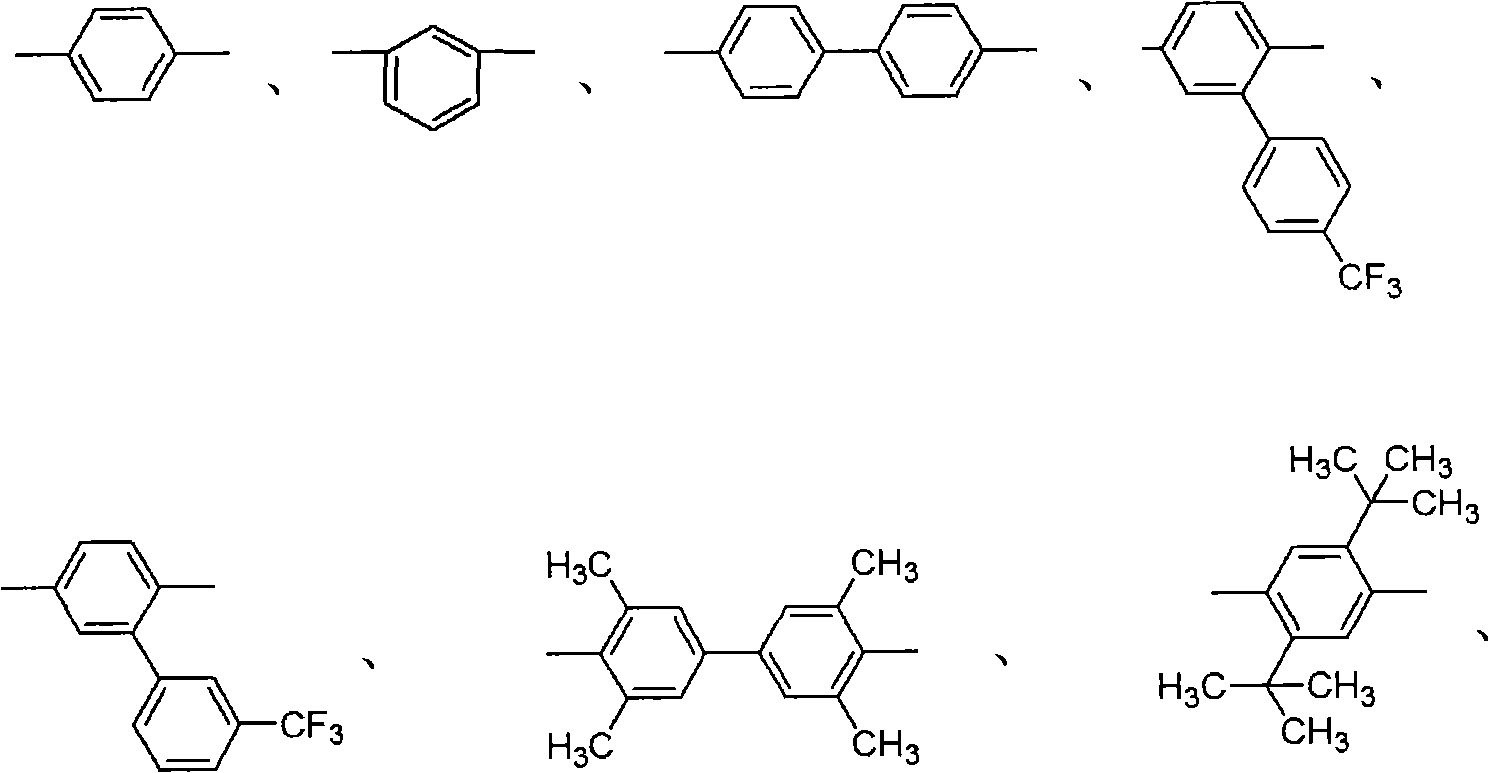

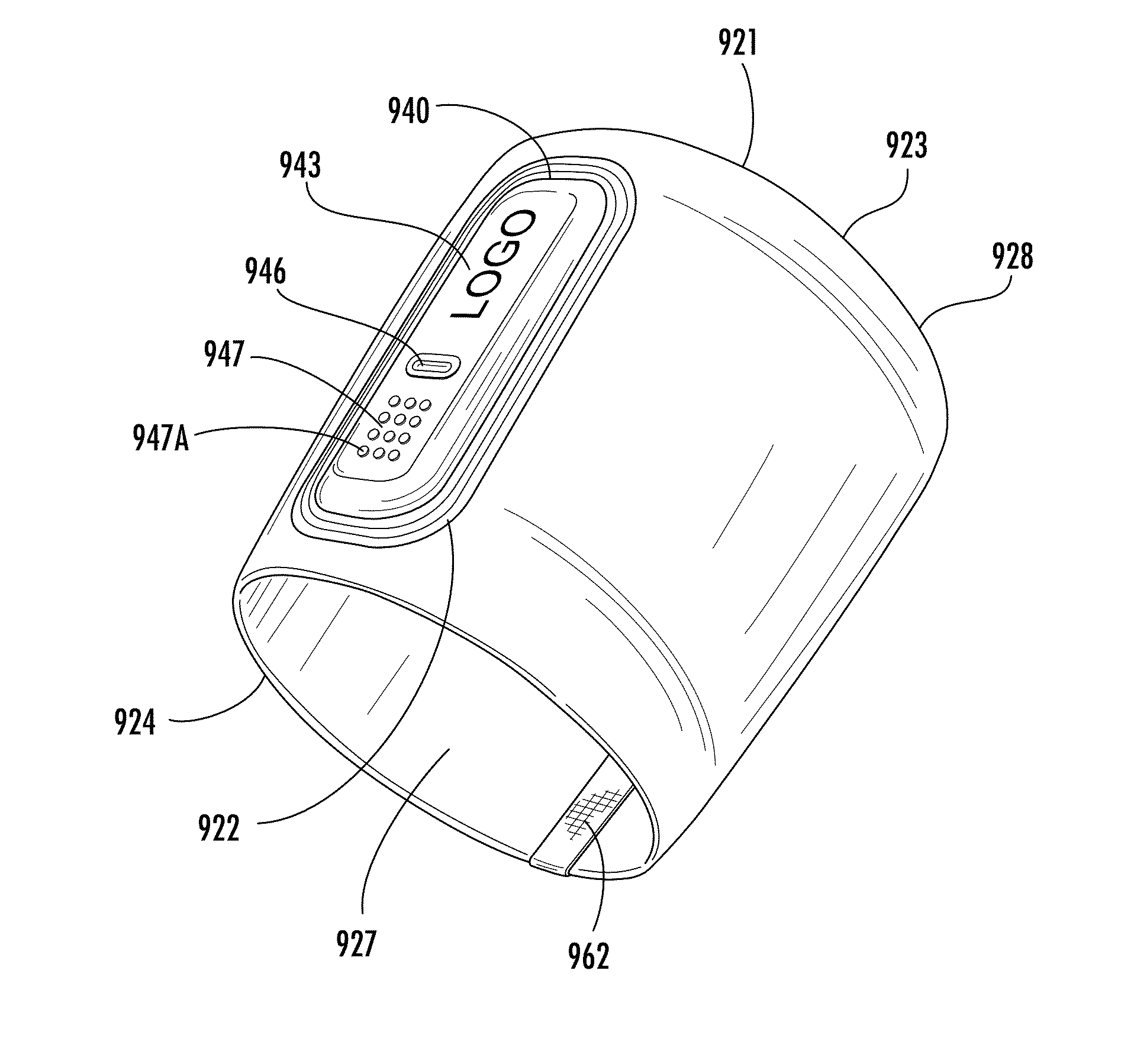

Athletic Band with Removable Module

ActiveUS20160136882A1Physical therapies and activitiesMechanical/radiation/invasive therapiesEngineeringHeat press

Owner:NIKE INC

Artificial wood grain floor and its press-paste technique and equipment

InactiveCN1737295ASimple structureStable structureDecorative surface effectsOrnamental structuresHydraulic cylinderSheet steel

This invention relates to a simulate wood card, in addition to a plaster technique and device, characterized in that it based on a hot press, and the lower of the bay has a working bench, and the upper of the bay is connected with a press hydraulic cylinder and a connecting board which can be moved up and down; the work bench can be a transforming bench which can be shifted outside; on the connecting board upon the bay it sets at least one wood sheet steel form with inner heating system and wood grain in the lower surface; the bay also has at least two infrared generators; the method of using the device comprises the following steps: fixing the wood sheet steel form on the top of the hot press, aligning the impregnated wood paper according to the interior wiring of the flooring base material, laying it on the transforming working bench and aligning with the upper wood sheet steel form, plastering with the hot press to get the base material, which has a wood paper with at least one wood pattern, and on the surface of the wood paper it has warp wood grain.

Owner:SENJIA WOOD IND MFG PLANT HANGZHOU +1

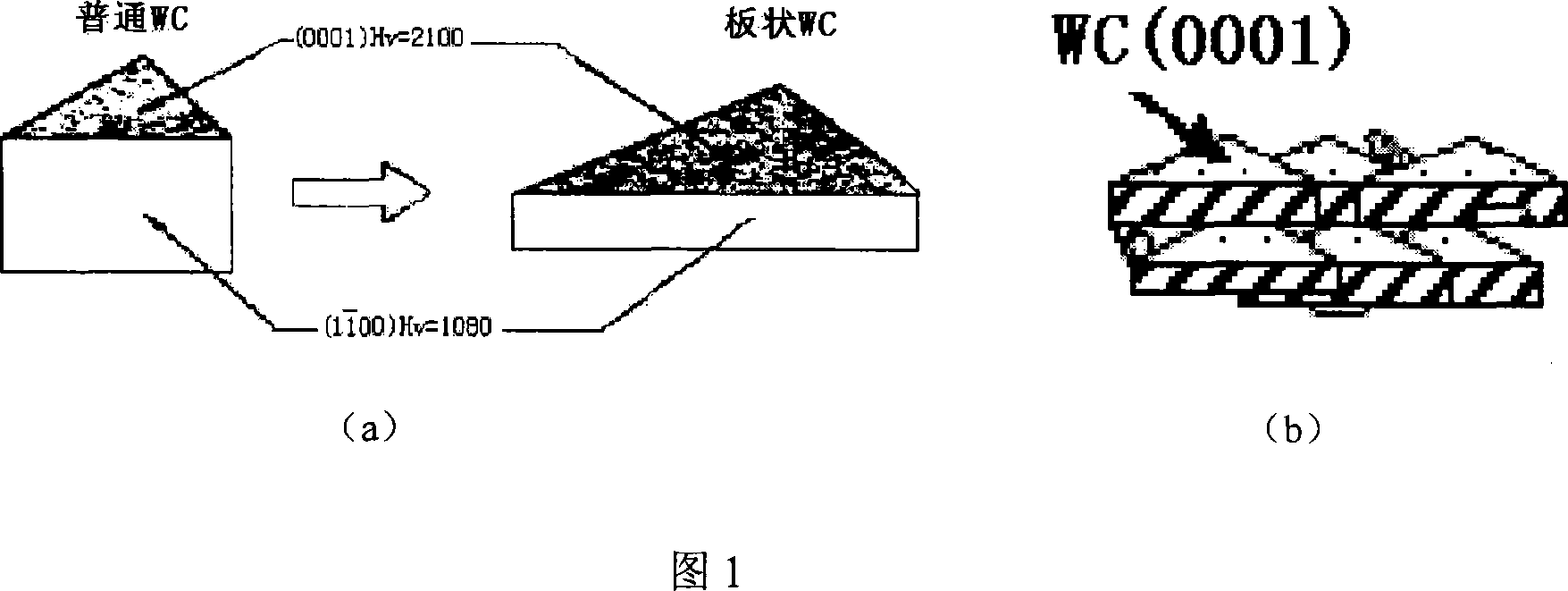

Method for preparing hard alloy containing slab-shaped tungsten carbide crystal grain

The present invention relates to a process of a hard alloy containing tabular tungsten carbide (WC) crystal grains, belonging to the technology field of WC hard alloy preparing, and is characterized in that the tabular WC single crystal grains are used as seed crystals and mixed with commercial WC powder and Co powder. The mixture ratio of the raw materials is WC powder 80-90 percent, Co powder 5-15 percent and WC crystal grain of the seed crystal 3-8 percent. After high-energy ball milling and in particular adopting a special heat pressing technology, the mixed materials can be made into a hard alloy containing directionally arrayed tabular WC crystal grains. Advantages of the present invention are that the quantity, size and ratio of the length and the thickness of the tabular WC crystal grains can be controlled by adjusting the size and the quantity of the added tabular WC seed crystals, thereby optimizing the performance of the hard alloy. The invention is simple in technology, low in cost and good in reproducibility.

Owner:SHANGHAI UNIV

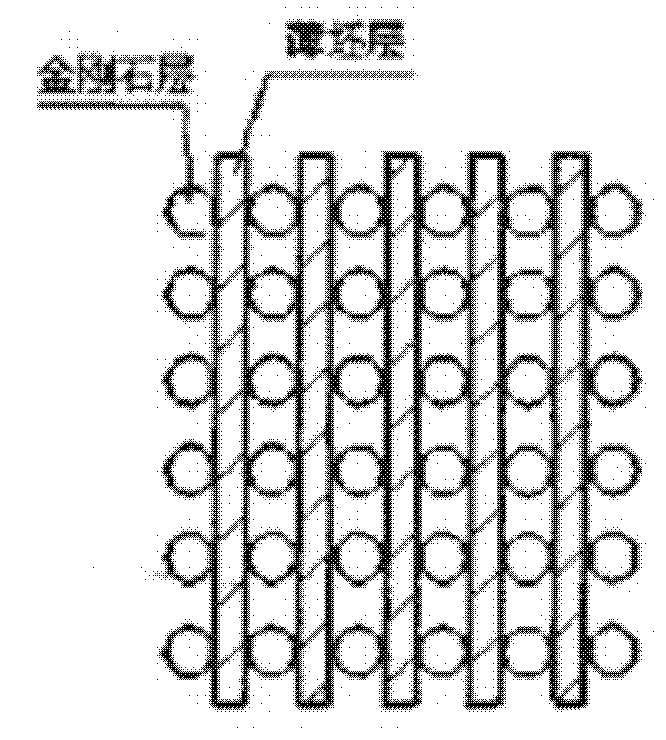

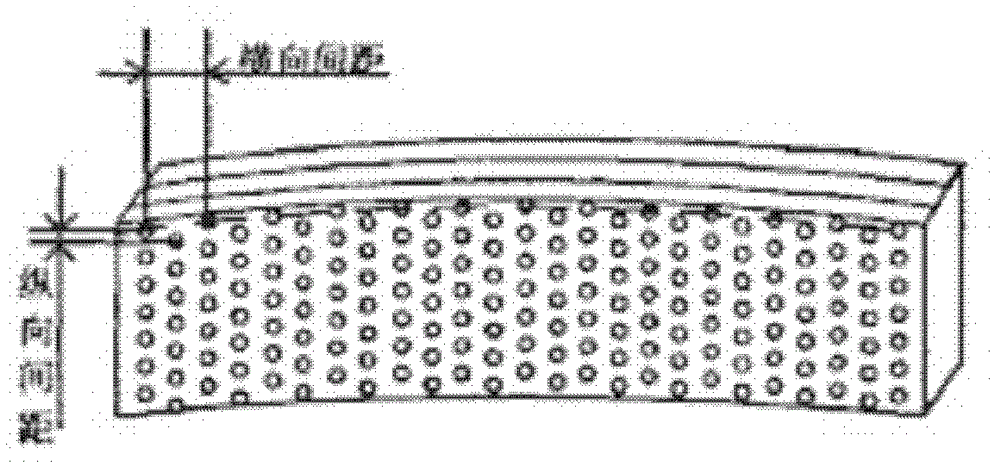

Manufacture method evenly distributing and orderly arranging diamond saw blades

InactiveCN103056450AImprove sharpnessExtended service lifeMetal sawing tool makingThree-dimensional spaceGraphite

The invention relates to a manufacture method evenly distributing and orderly arranging diamond saw blades. The manufacture method mainly resolves the problems that diamond saw blade segments are low in sharpness and short in service life caused by the fact that diamond particles are arranged and distributed unevenly and disorderly in existing diamond saw blade segments. The manufacture method includes the steps: enabling casing powder to be mixed evenly, manufacturing casing-sheet-shaped thin stocks through a cold-pressing forming technology; designing the methods of even distribution and order arrangement, adopting laser boring to manufacture red copper frameworks, spraying one layer of thin and special pressure-sensitive glue on the surfaces of the casing-sheet-shaped thin stocks, enabling the red copper frameworks to be placed on the surfaces of the casing-sheet-shaped thin stocks, and then enabling diamonds to be released on the red copper frameworks and using a steel flat plate to slightly sweep the diamonds, guaranteeing that a diamond can fall into each hole in each red copper framework, cleaning extra diamonds on the red copper frameworks, uncovering the red copper frameworks, due to the fact that pressure-sensitive agents on the casing-sheet-shaped thin stocks play a cementing action to the diamonds, and the diamonds can be fixed on the surface of the casing-sheet-shaped thin stocks and form even distribution and orderly arrangement; enabling the casing thin stocks with a multiple layers with the diamond particles to be overlapped together to combine metal segments to be installed inside a graphite mould, and forcing power-on sintering on a hot pressing machine. Therefore, the obtained diamond segments not only have the structure of even distribution and orderly arrangement of three-dimensional space, but also improve sharpness of the diamond blades and prolong service life of the diamond blades.

Owner:HUNAN FEIYUE NEW MATERIAL TECH

Formaldehyde-free decorative board and preparation method thereof

The invention discloses a formaldehyde-free decorative board and a preparation method thereof. The decorative board is formed by overlaying multiple layers of wood veneers with adhesive, wherein the adhesive is plastic film. The preparation method is as follows: the plastic film is evenly laid between every two adjacent wood veneers, and the use level of the plastic membranes is over 100g / m ; a veneer press is used for pressing, with the pressure over 100 tons, the veneer press performs heat pressing firstly and cold pressing later, the temperature of heat pressing is over 100 DEG C and the temperature of the cold pressing is 20 DEG C to 100 DEG C The decorative board contains no formaldehyde, causes no poison or pollution on human body and surrounding environment and truly realizes the environment protection. In addition, the invention adopts the cheap plastic film as the adhesive, the production cost is low, the technology is simple, and qualitative indexes of the product completely satisfy the national standards.

Owner:深圳伟伦嘉禾环保装饰材料有限公司

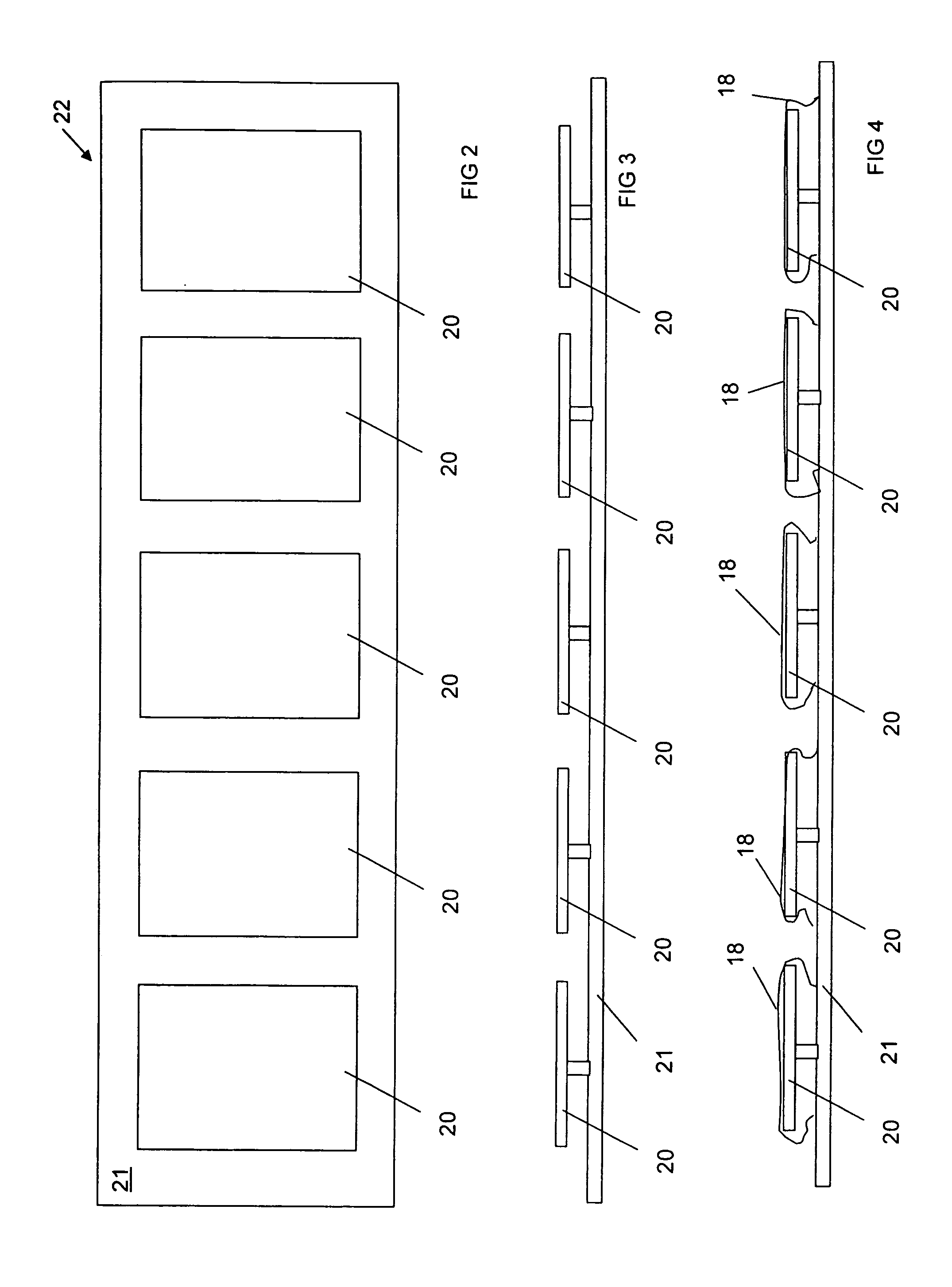

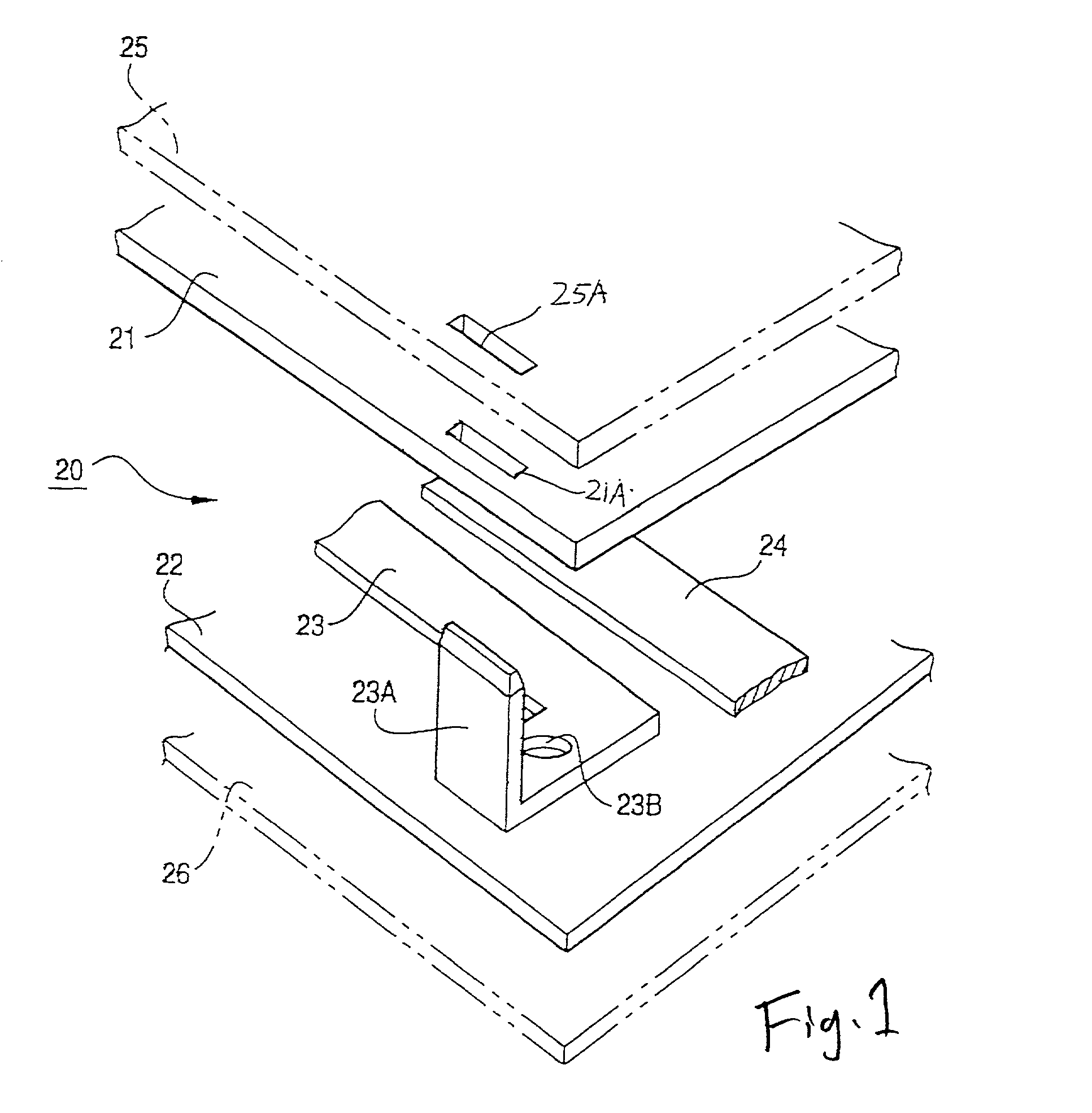

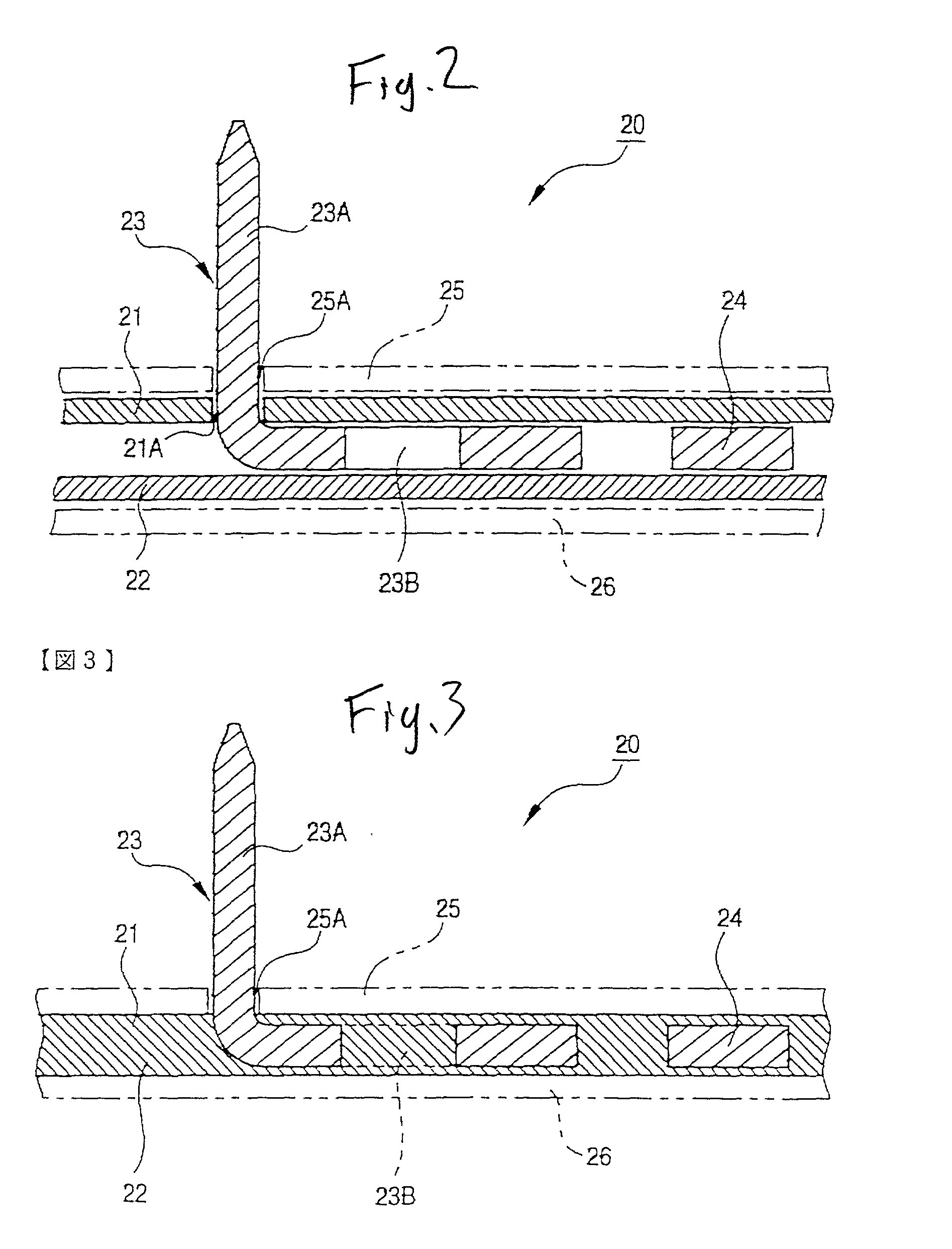

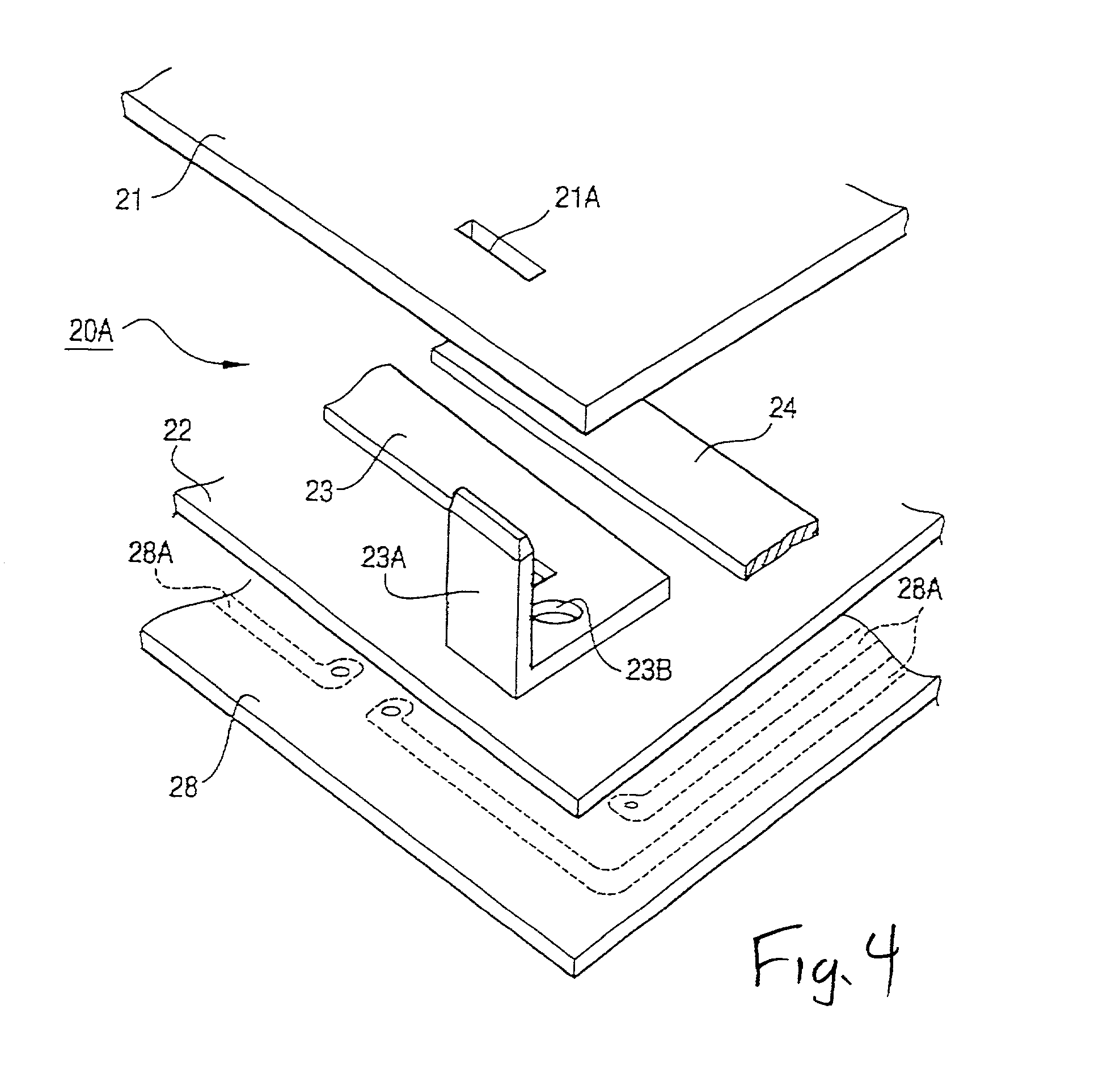

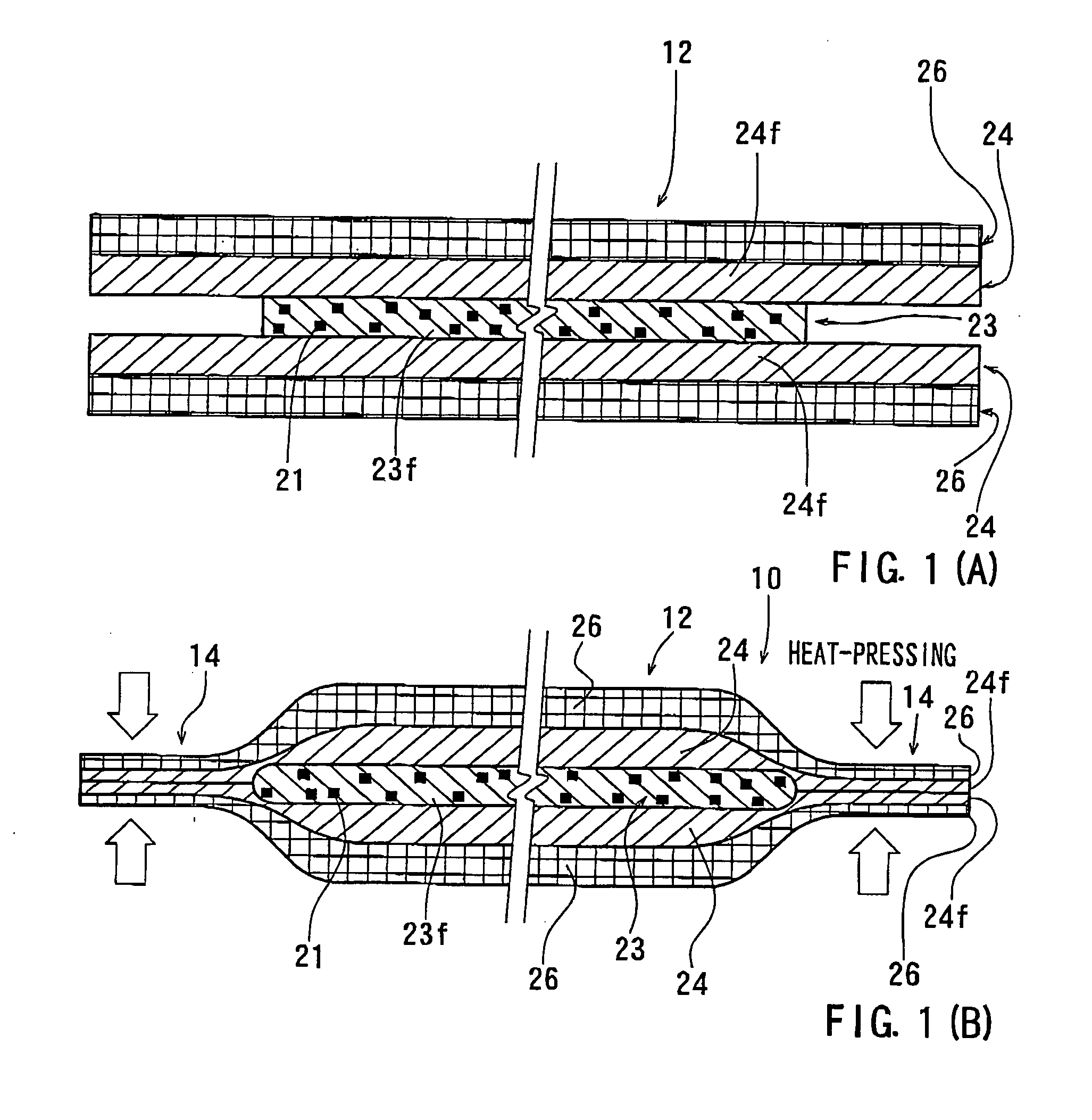

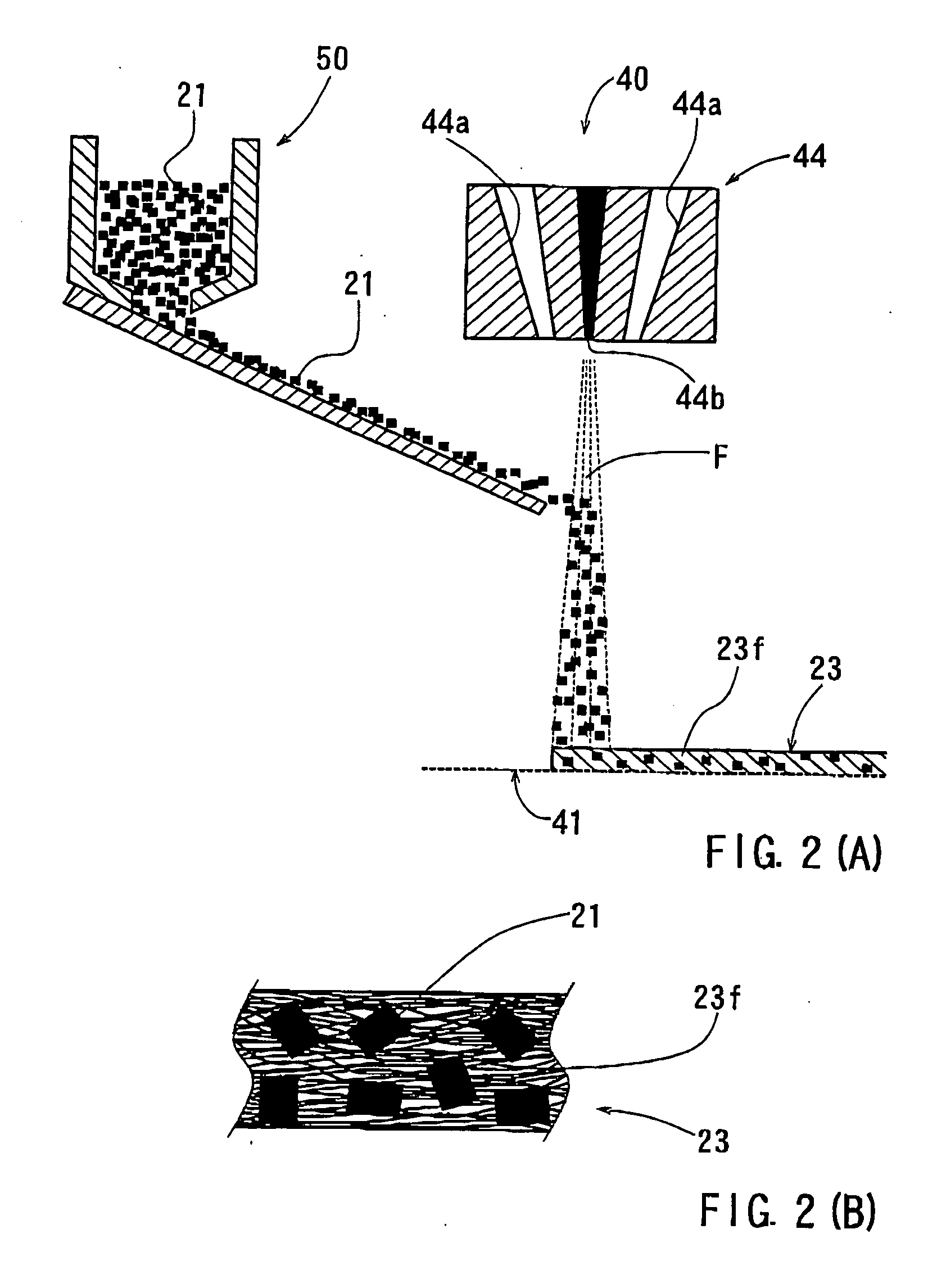

Bus bar wiring plate body for electric coupling box

The bus bar wiring plate body (20) for an electric coupling box according to the present invention is arranged in a manner that bus bar members (23, 24) are wired between pre-hardening epoxy resin plates (21, 22) and these pre-hardening epoxy resin plates are subjected to the heat pressing process to thereby integrate the pre-hardening epoxy resin plates (21, 22) and the bus bar members (23, 24) in a laminated state. When hardened epoxy resin plates (25, 26) are disposed at the outsides of the pre-hardening epoxy resin plates (21, 22) as shown by phantom lines, respectively, the strength of the bus bar wiring plate body (20) can be improved. Thus, since the bus bar members (23, 24) are sealed in an insulated state, leak current can be reduced surely. Further, the thickness of the bus bar wiring plate body (20) can be reduced to a large extent, so that the electric coupling box can be miniaturized and lightweighted.

Owner:YAZAKI CORP

Preparation process for manufacturing insulated paper by para position fiber and meta position fiber

InactiveCN1884692AImprove evennessGood flexibilityPlastic/resin/waxes insulatorsSynthetic cellulose fibresManufacturing technologyPulp and paper industry

The invention discloses a manufacturing technology of copy-allocating insulated paper of para and meta aramid fiber, which comprises the following steps: adopting para-aramid chopped fiber and meta aramid pulp fiber to dispense insulated paper according to certain proportion; dispersing the fiber through PEC or congenic adjuvant; improving paper evenness and flexibility; proceeding heat pressing for para aramid fiber to modify physical strength and insulating property.

Owner:SHAANXI UNIV OF SCI & TECH

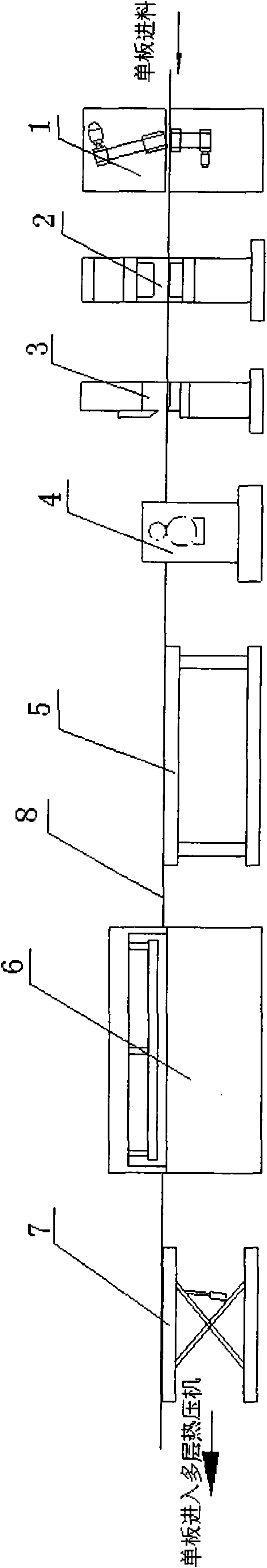

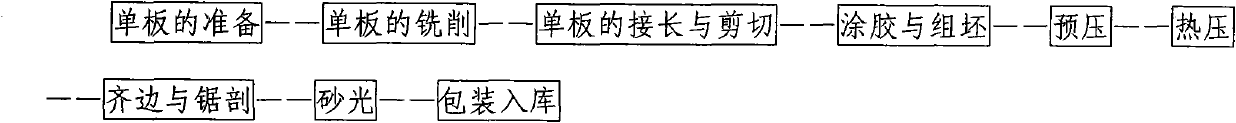

Complete production equipment for laminated veneer lumbers

InactiveCN101947801AReduce investmentPrecise positioningPlywood pressesVeneer pressesNumerical controlProduction line

The invention discloses complete production equipment for laminated veneer lumbers, which comprise an abrasive belt slant milling machine, a glue spreading machine, a veneer performing press, a material storing table and a multilayer thermal press. The complete production equipment is characterized by arranging a telescopic feeder and a numerical control locating assembly machine in sequence between the glue spreading machine and the veneer performing press, and a movable cutting saw and a conveying roller are arranged in sequence between the veneer performing press and the material storing table, wherein the abrasive belt slant milling machine, the glue spreading machine, the telescopic feeder, the numerical control locating assembly machine, the veneer performing press, the movable cutting saw, the conveying roller, the material storing table and the multilayer thermal press are connected in sequence to form a production line through an operating platform. Compared with the traditional complete production equipment for laminated veneer lumbers, the invention saves equipment investment, the location of the lumbers is very accurate due to the adoption of the numerical control locating assembly machine, production efficiency and product quality are obviously improved, assembled veneers can be infinitely prolonged, the production field of the laminated veneer lumbers is widened, and meanwhile, the degree of automation is also obviously increased.

Owner:NANJING FORESTRY UNIV

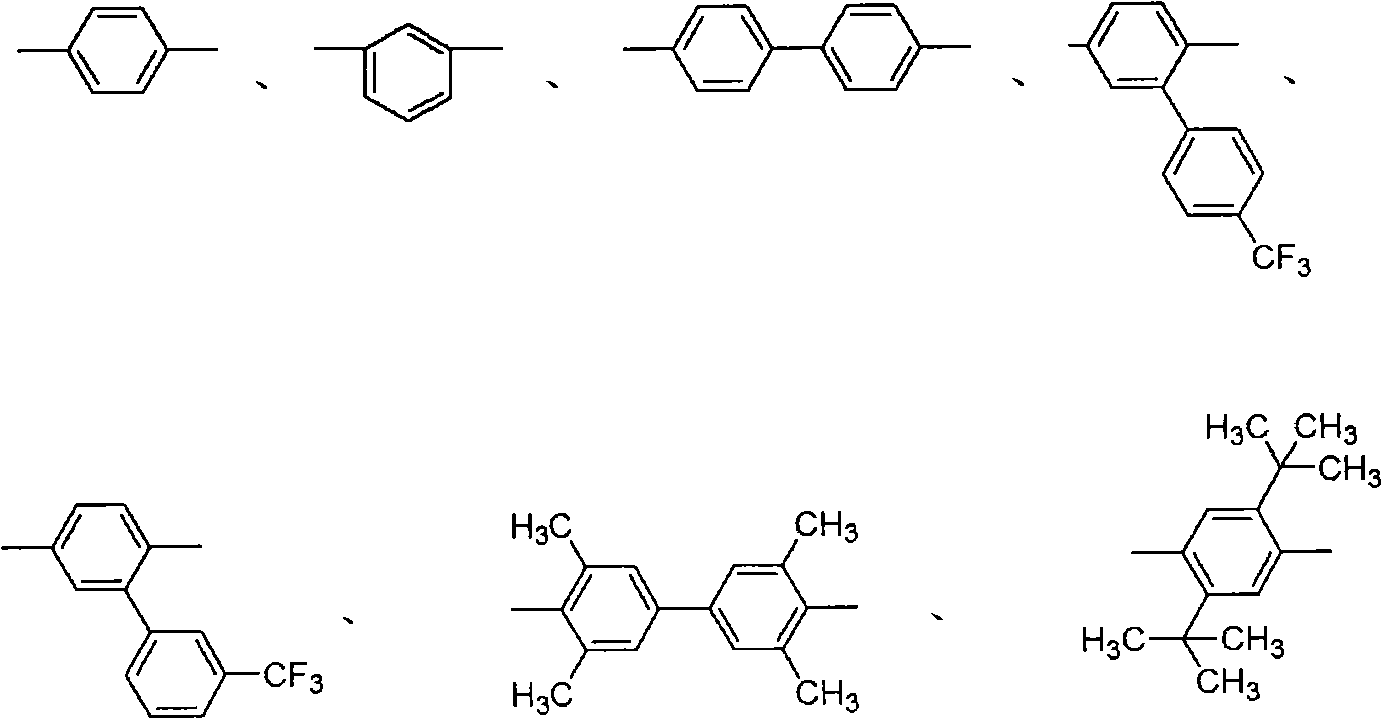

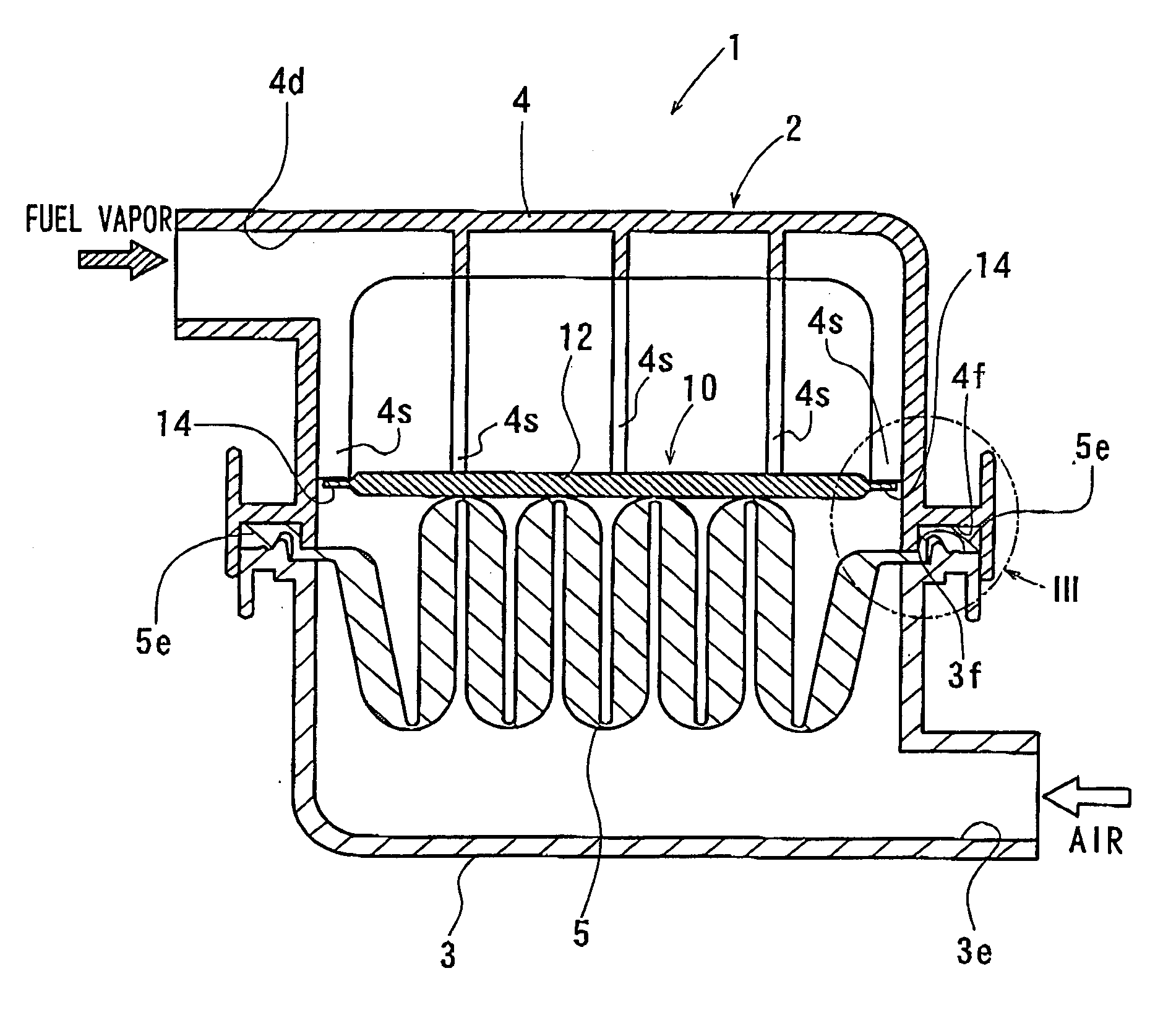

Fuel vapor adsorption filters

ActiveUS20050279210A1Improve adsorption capacityLow costGas treatmentNon-fuel substance addition to fuelSorbentThermal compression

A fuel vapor adsorption filter includes a fuel vapor adsorption agent; a filter body containing the fuel vapor adsorption agent therein, and a frame formed to surround the filter body. The frame is adapted to be mounted within an intake air channel connected to an engine, so that the filter body is operable to adsorb a fuel vapor within the intake air channel when the engine has been stopped. Non-woven fabrics form the filter body. The non-woven fabrics have peripheral edge portions. Heat-pressing the peripheral edge portions of the non-woven fabrics forms the frame.

Owner:TOYOTA BOSHOKU KK

Process of maniudacturing dual-layered thermal insulation composite panel

InactiveUS20060118992A1High temperature resistanceImprove insulation performanceLaminationLamination apparatusCarbon fibersThermal insulation

A dual-layered thermal insulation composite panel includes an out layer of high-temperature resistant carbon fiber reinforced phenolic resin composite and an inner layer of low thermal conductivity and high-purity silica fiber reinforced phenolic resin composite. A hot press or autoclave may be used to pressurize said materials into shaping. The dual-layered thermal insulation composite panel achieves excellent performance in thermal resistance, thermal insulation and mechanical strength.

Owner:NAT CHUNG SHAN INST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com