Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Near net shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

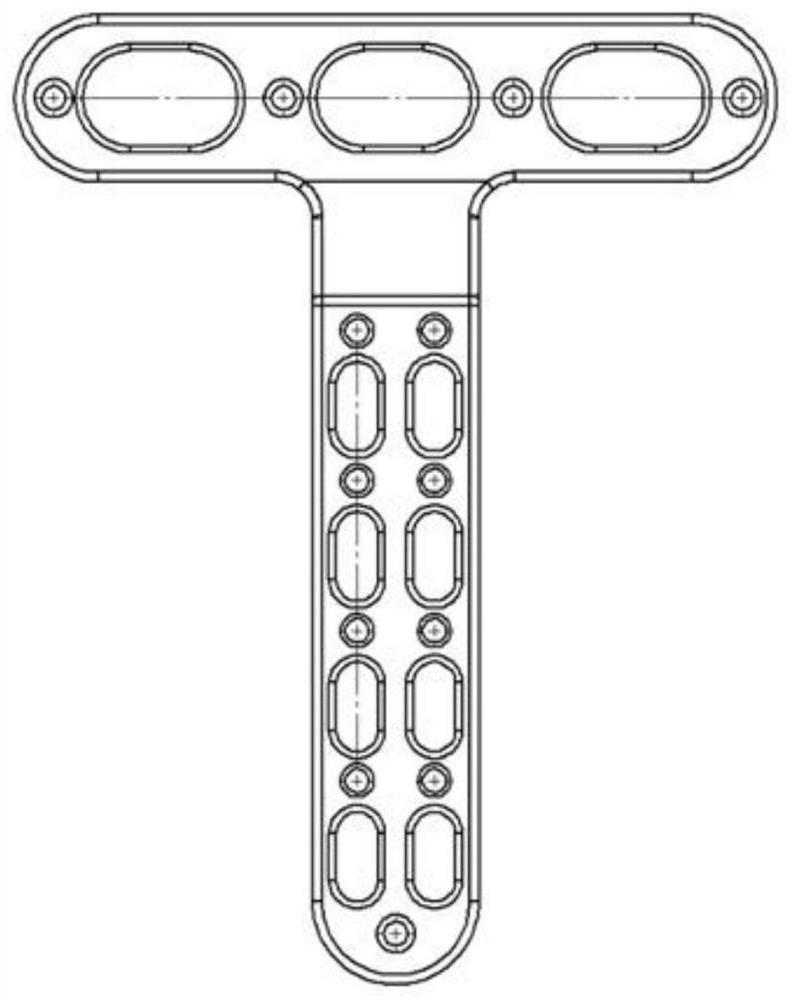

Medical biology degradable magnesium alloy composite material

InactiveCN102652840AControl degradation timeEnhance memoryCoatingsProsthesisSurface layerUltimate tensile strength

The invention relates to a novel degradable medical magnesium alloy composite material. The medical magnesium alloy composite material provided by the invention has the characteristics of high strength, good temperature memory and controllable degradation velocity and can be used in the field of orthopedic implantation. The composite material is characterized in that the composite material contains Mg-Al-Zn magnesium alloys, wherein the content of Al is 0.5-3.5wt% and the content of Zn is 0.5-1.8wt%; besides, the magnesium alloy material can contain a few impurities including Fe, Mn, Cu and Ni, wherein the total of the impurities is not greater than 0.3wt%; and a medical biology degradable material exists on the surface layer of the composite material and can be a pure carbon dioxide copolymer, pure polyhydroxyalkanoate or a blend of the carbon dioxide copolymer and polyhydroxyalkanoate, which has to be medically purified before use.

Owner:吉林金源北方科技发展有限公司

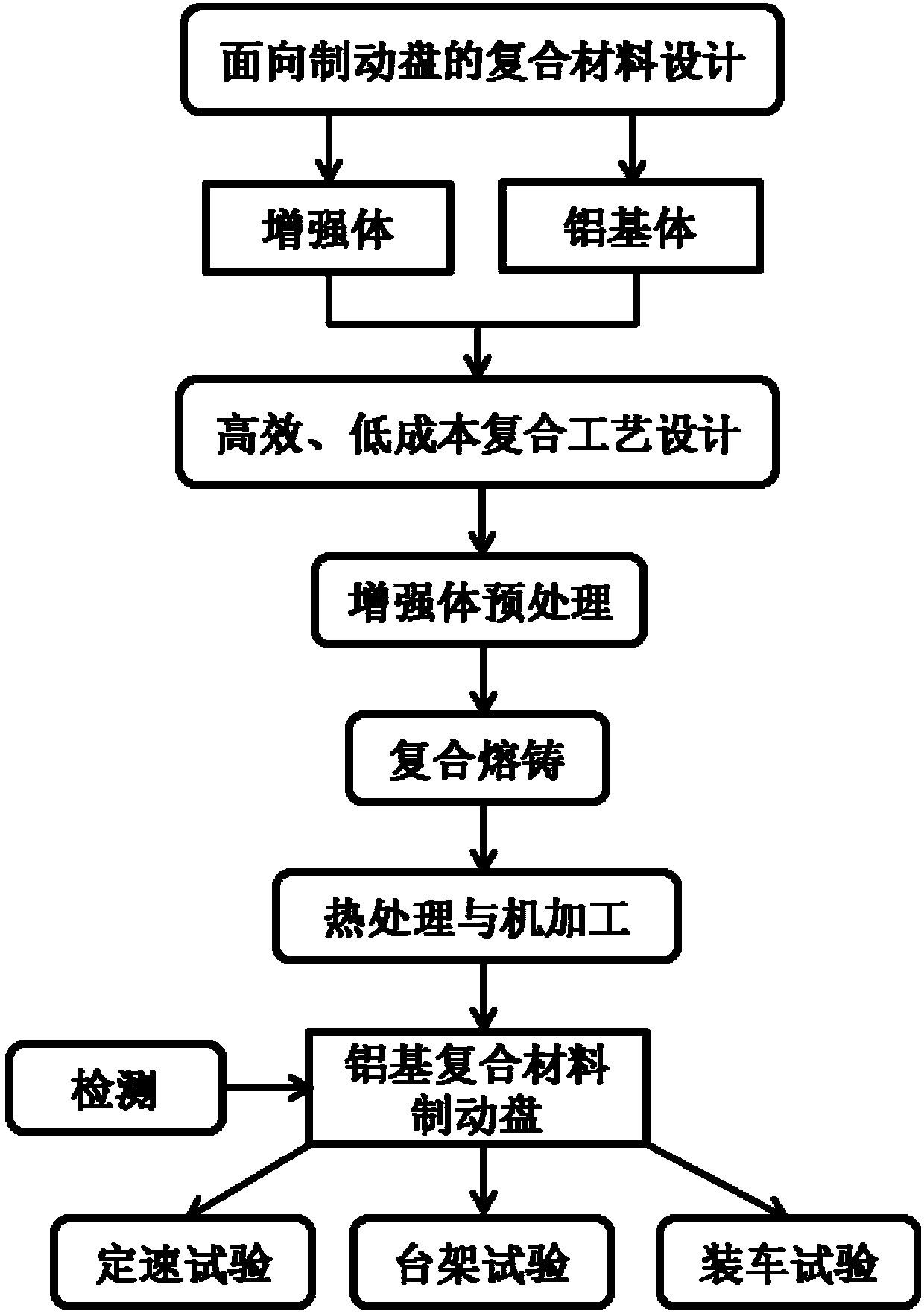

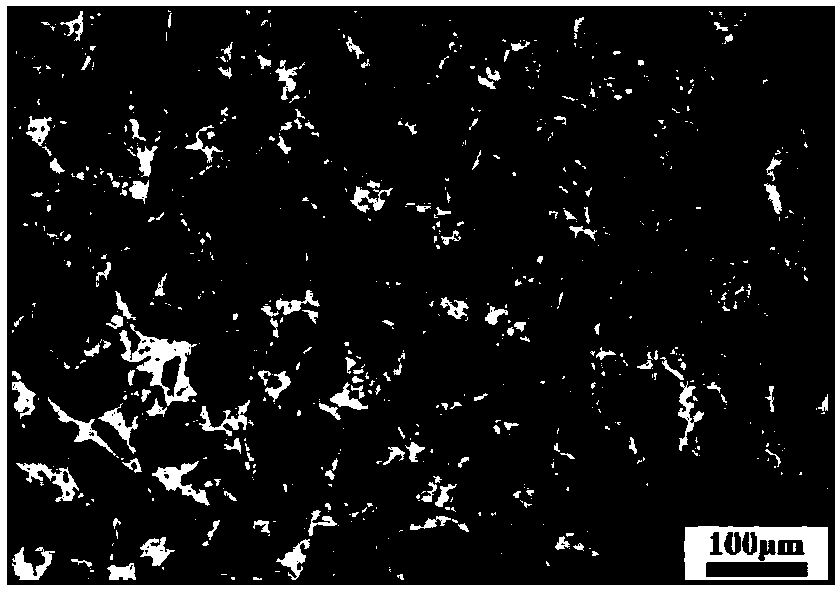

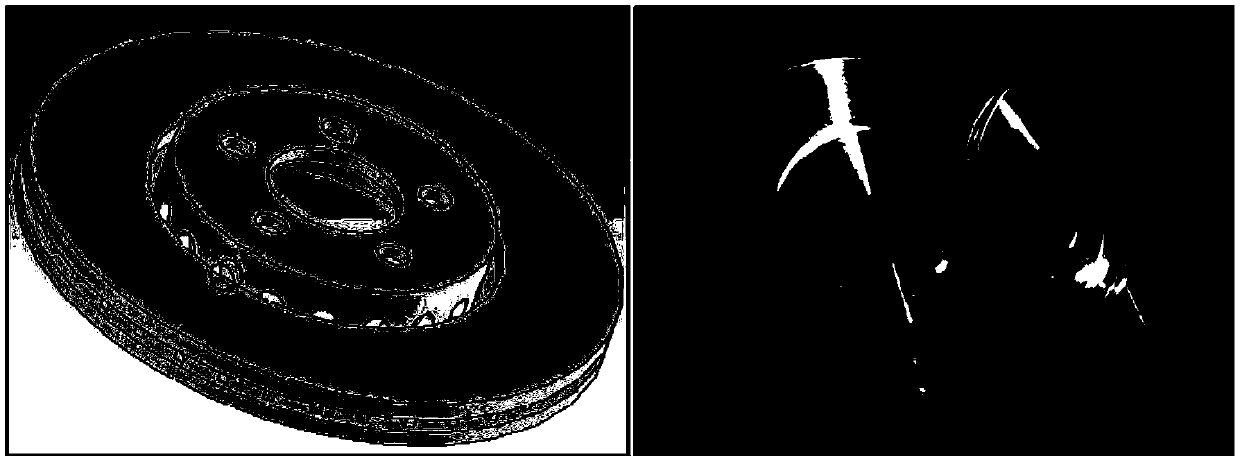

Aluminum-based composite material vehicle brake disc preparation method

The invention provides an aluminum-based composite material vehicle brake disc preparation method, which comprises: 1) pretreatment of reinforcement particles; 2) composite fusion casting; and 3) machining and heat treatment. According to the present invention, the volume content of the ceramic reinforcement body in the aluminum-based composite material is high (20-45%), and the near-final moldingof the aluminum-based composite material vehicle brake disc can be achieved through the composite fusion casting method; the method has advantages of simple and efficient process, low preparation cost and mass production; the weight of the prepared aluminum-based composite material vehicle brake disc is reduced by 50-60% compared to the weight of the cast iron brake disc, the thermal conductivityof the prepared aluminum-based composite material vehicle brake disc is improved by more than 2 times, and the prepared aluminum-based composite material vehicle brake disc has good high-temperaturewear resistance; and the wear of the prepared aluminum-based composite material vehicle brake disc is only 0.33-0.36 mm after the vehicle provided with the prepared aluminum-based composite material vehicle brake disc drives 20000 km, such that the aluminum-based composite material vehicle brake disc is expected to replace the cast iron vehicle brake disc, and can provide assistance for the lightweight of the vehicle.

Owner:深圳优越科技新材料有限公司

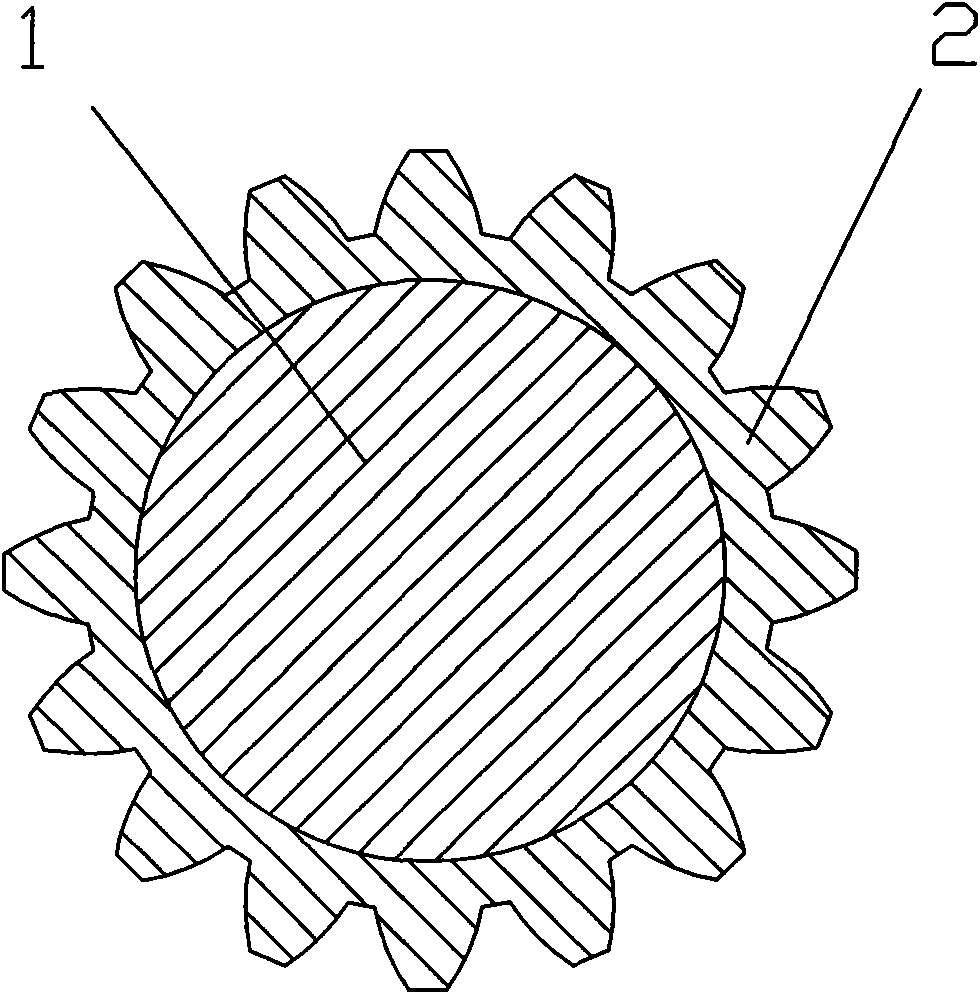

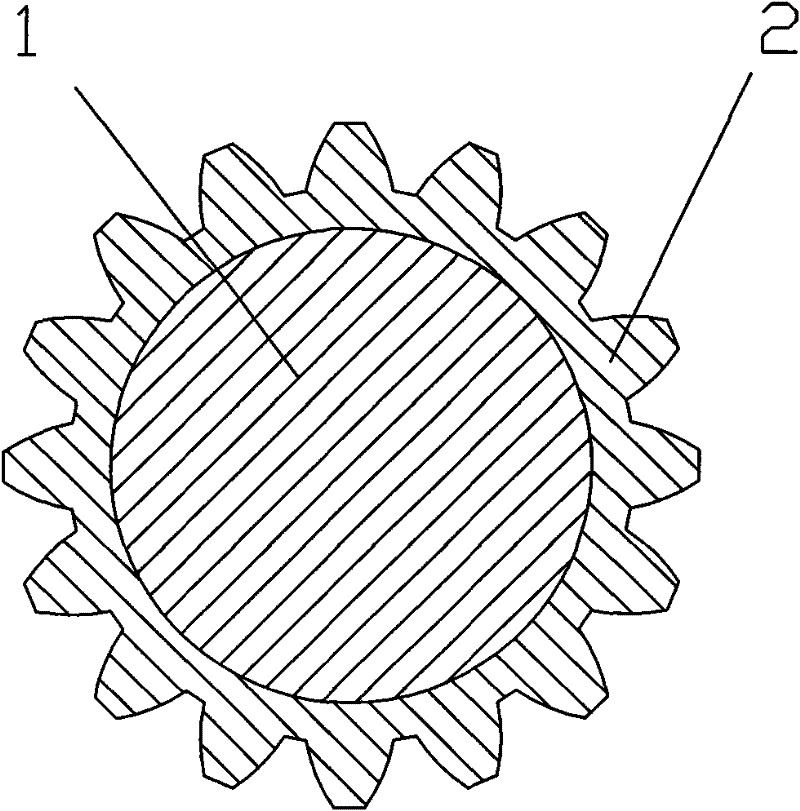

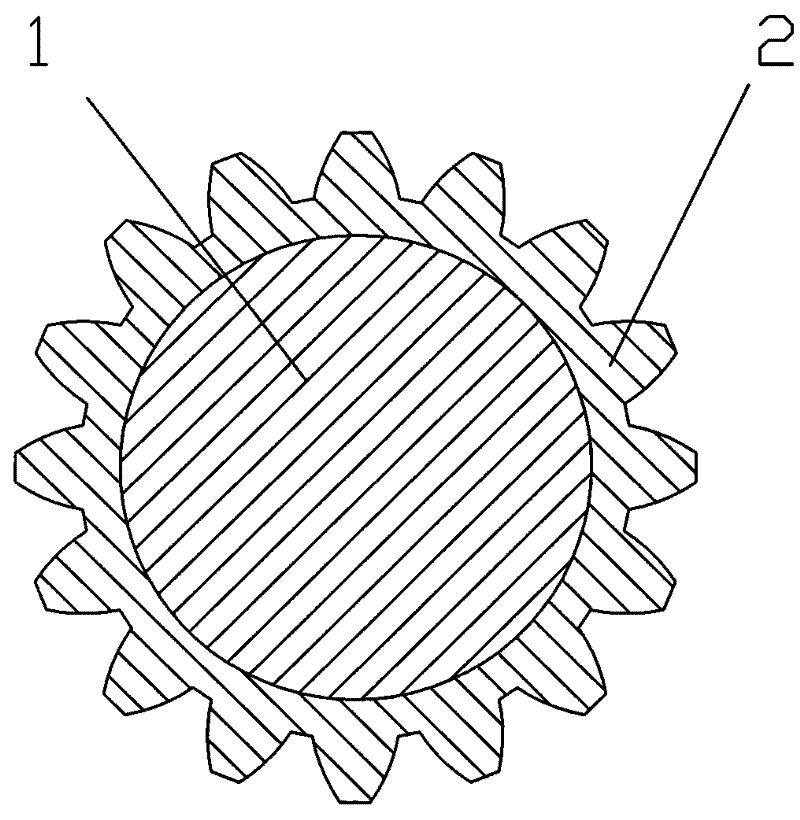

Iron-based gradient structure gear and manufacturing method thereof

ActiveCN101555937AHigh bonding strengthSpread evenlyPortable liftingGearing elementsSurface layerHigh surface

The invention discloses an iron-based gradient structure gear and a manufacturing method thereof; to realized high surface layer hardness and high core / shell layer bonding strength, Fe2Ni is adopted as a core layer and the Fe2Ni added with an alloying element Cr is adopted as a shell layer; through strengthening effect of Cr, sintering / heat treatment is adopted to facilitate surface layer hardness to exceed 40 HRC and realize the metallurgical bonding of the core layer and the shell layer; sintering time is adjusted to realized homogeneous diffusion of Cr outside the interface and core / shell layer bonding strength is higher than 280 MPa.

Owner:CENT SOUTH UNIV

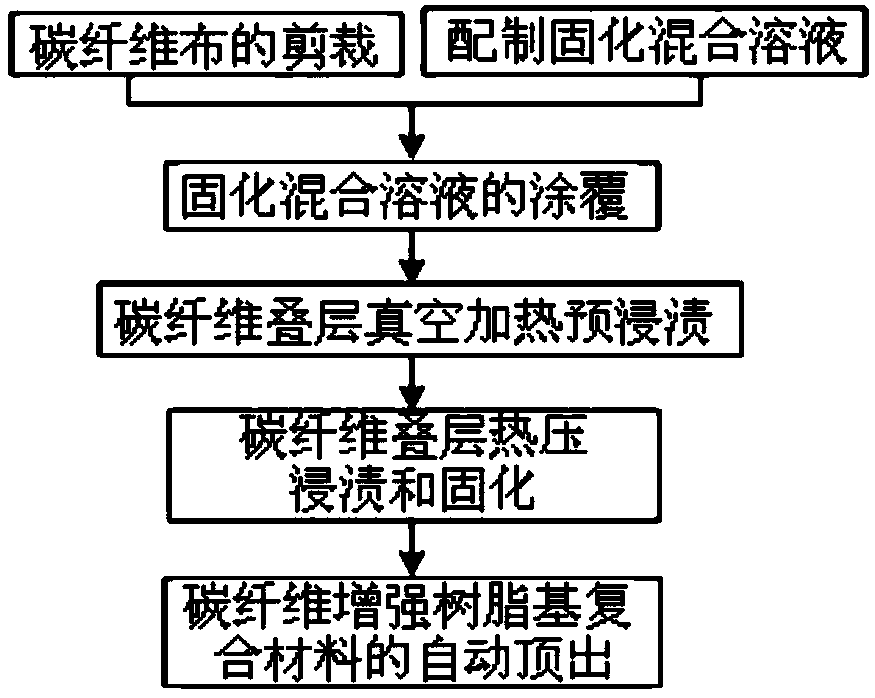

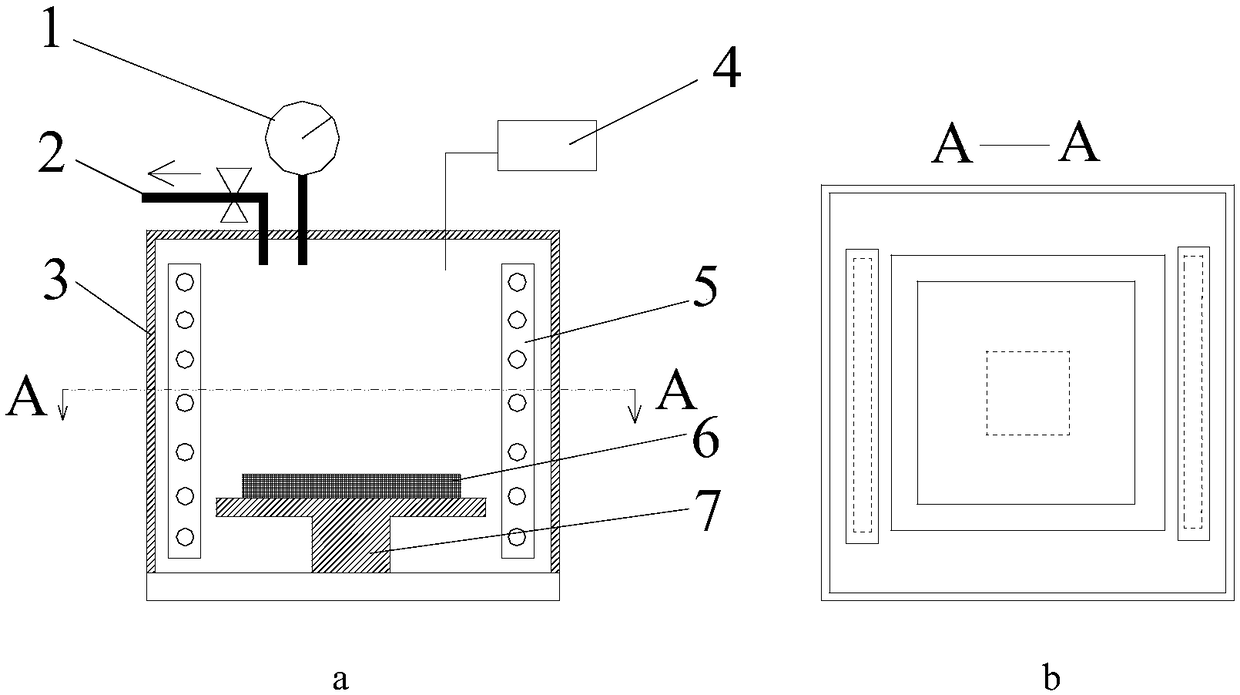

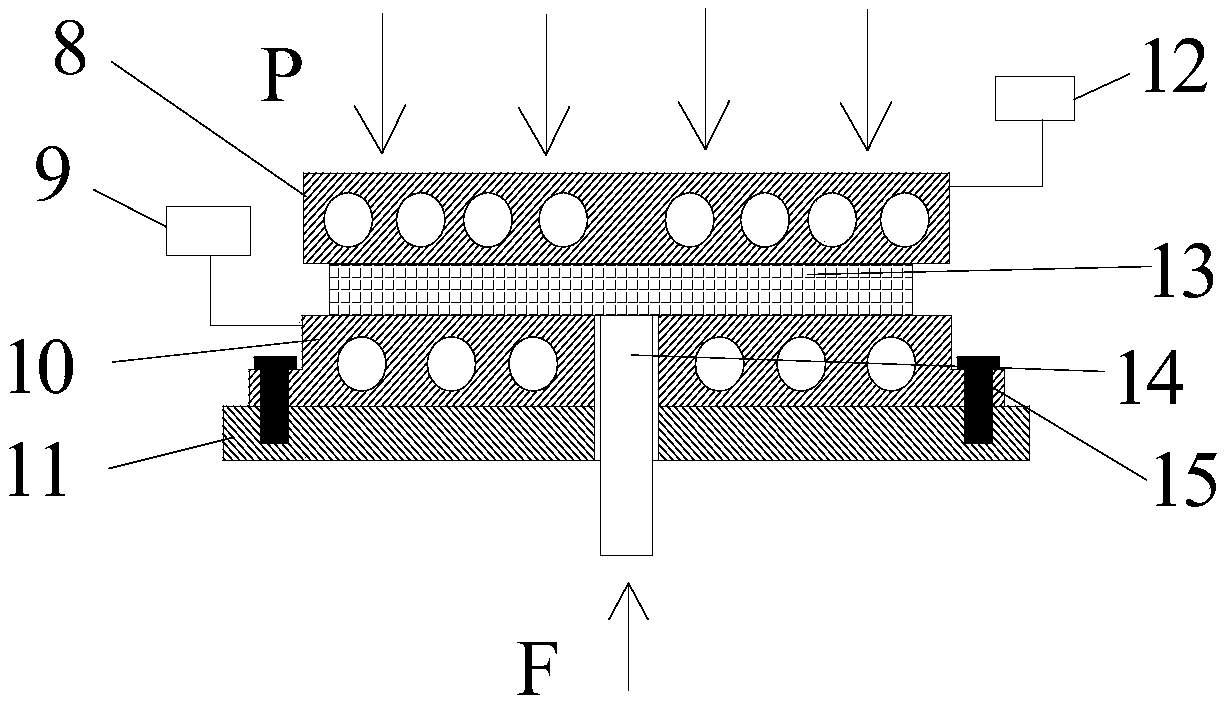

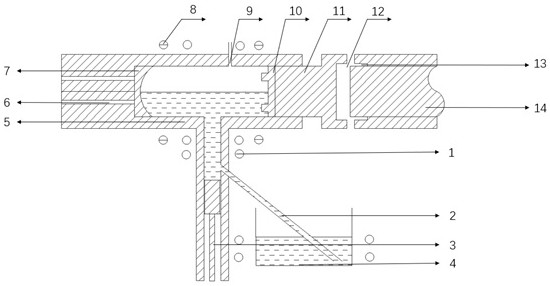

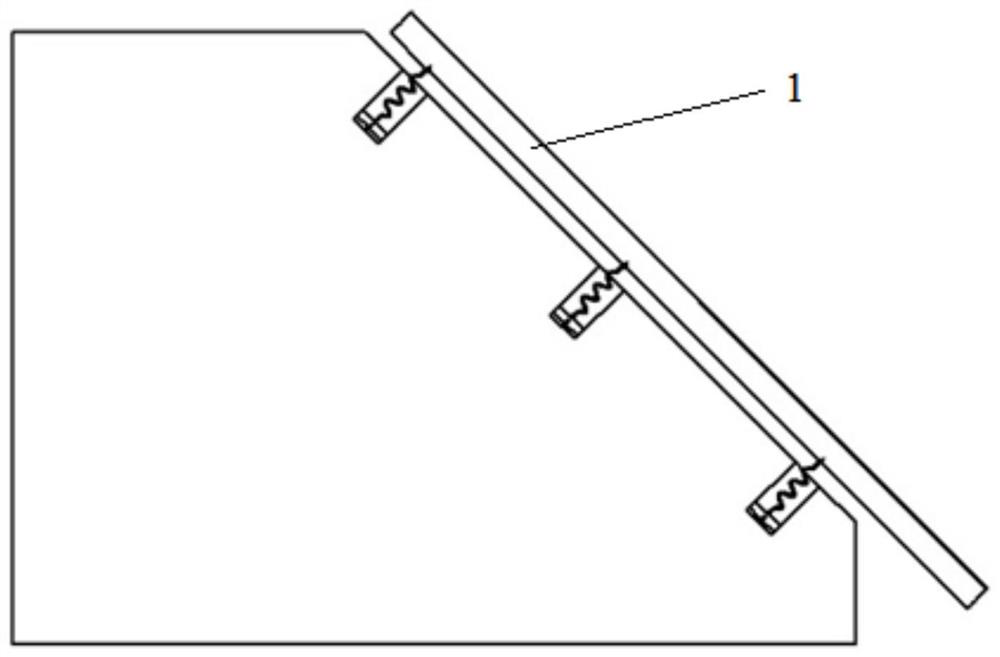

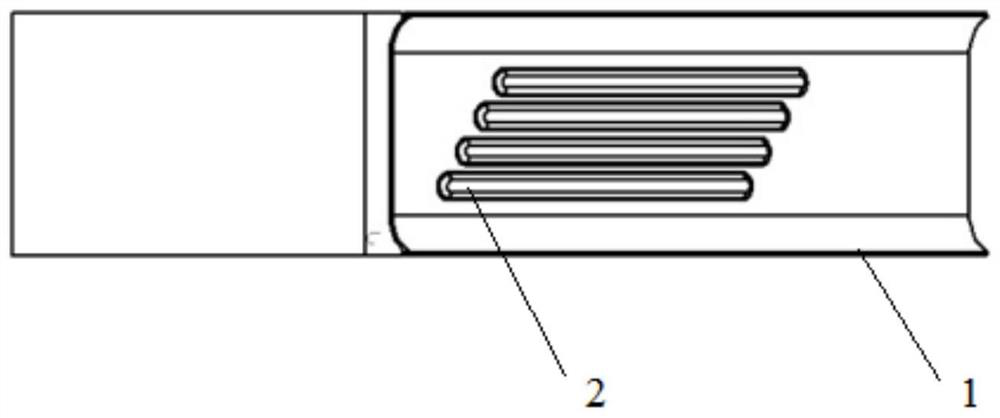

Vacuum impregnation and hot-press curing molding method for carbon fiber composite material

The invention relates to a vacuum impregnation and hot-press curing molding method for a carbon fiber composite material. The vacuum impregnation and hot-press curing molding method comprises vacuum heating and pre-dipping and hot-pressing dipping and curing forming, heating and dipping and extrusion forming of the composite material are achieved through a vacuum heating dipping device and a pressing and dipping and curing device, so that the gas impurities in the carbon fiber cloth laminated layer can be discharged in time, the defect of vacuum impregnation can be made up, so that the curingsolution can be better filled into the gap of the carbon fiber cloth, the defects of pores, shrinkage cavities and shrinkage porosity of the extruded composite material can be obviously reduced, the density is obviously improved, and then the performance of the composite material is improved. According to the vacuum impregnation and hot-press curing molding method, the composite materials with different shapes and sizes can be formed in a near-net mode according to the shape matched with the upper die and the lower die.

Owner:XIDIAN UNIV

Liquid die forging/rolling composite forming method for magnesium alloy irregular-section large-size ring piece

The invention relates to a liquid die forging / rolling composite forming method for a magnesium alloy irregular-section large-size ring piece, which comprises the following steps: smelting, liquid die forging, homogenizing, excess heat isothermal rolling, heat treatment and finishing, wherein in the liquid die forging process, after a liquid die forging die is fixed onto an indirect extrusion casting machine, the smelted magnesium alloy solution is quantitatively cast into the liquid die forging die, and kept under the specific pressure of 140-200 MPa for 35-150 seconds to obtain the similar end-section ring blank, wherein the casting temperature is 680-740 DEG C, the pressurization speed is 50-100 mm / s, and the cavity filling time is 1-6 seconds; and in the excess heat isothermal rolling process, when the homogenized similar end-section ring blank is cooled to 300-400 DEG C, isothermal rolling is carried out on a radial / axial composite ring rolling machine. The method provided by the invention can simplify the blank making process of the alloy ring piece, lower the cost, enhance the production efficiency, effectively improve the microstructure state of the liquid die forging die magnesium alloy ring piece, and enhance the comprehensive mechanical properties.

Owner:SOUTHWEST UNIVERSITY

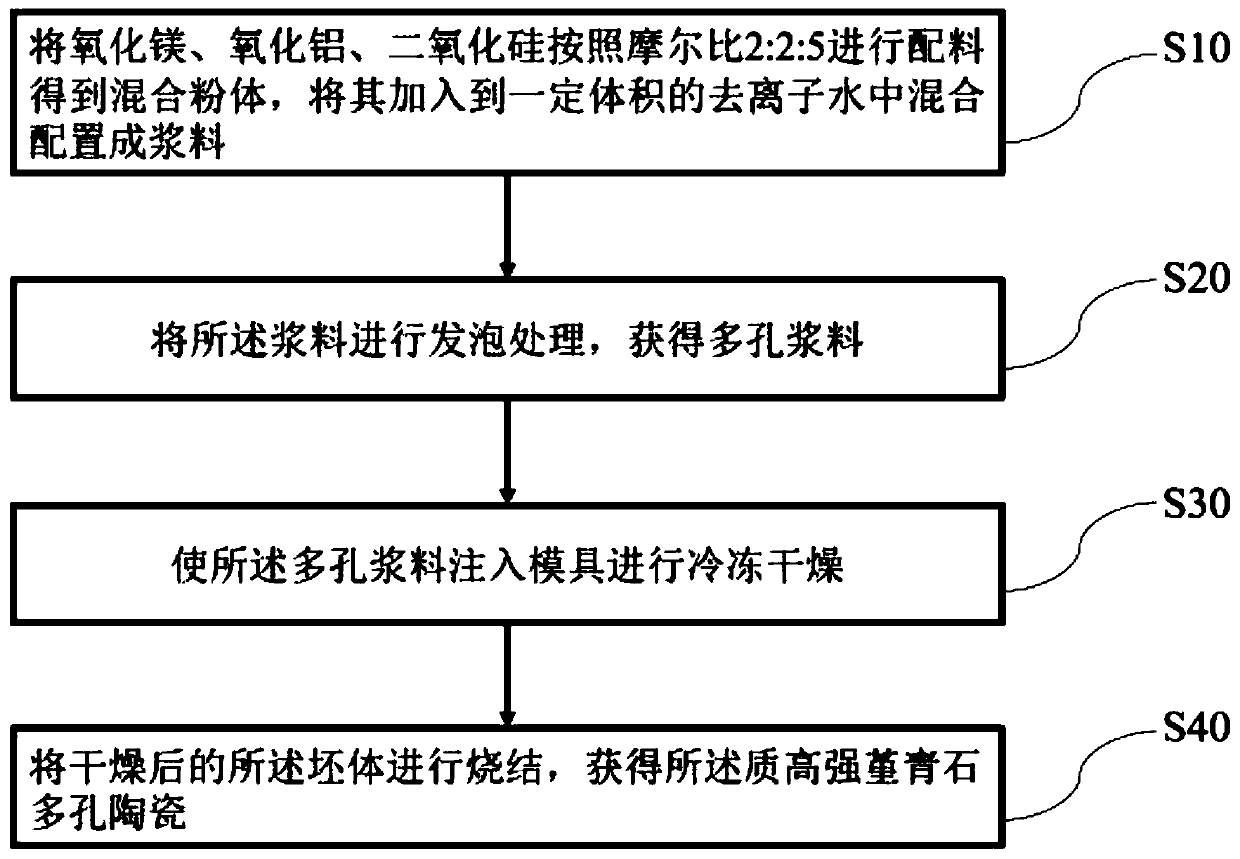

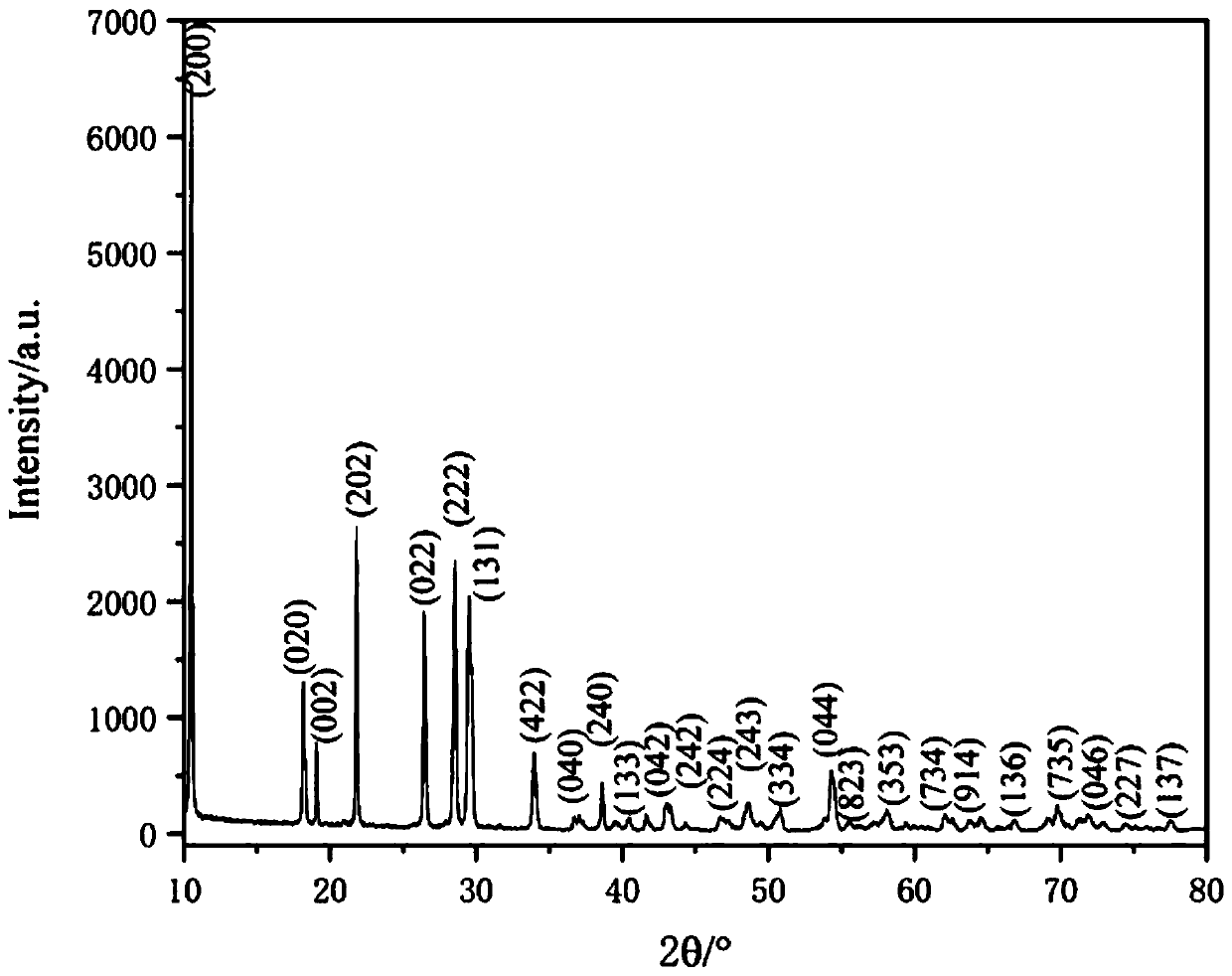

Green preparation method of light high-strength cordierite porous ceramic and filter

InactiveCN110668802AImprove permeabilityHigh strengthCeramic shaping apparatusFiltration separationFreeze-dryingCordierite

The invention provides a green preparation method and a filter for a lightweight high-strength cordierite porous ceramic. The preparation method comprises the following steps: step S10, mixing magnesium oxide, aluminum oxide and silicon dioxide according to a cordierite stoichiometric ratio to obtain mixed powder, adding the mixed powder into deionized water with a certain volume, ball milling andmixing to prepare slurry; step S20, foaming the slurry to obtain foam slurry; step S30, injecting the foam slurry into a mold for freeze drying; step S40, sintering the dried green body to obtain thelightweight high-strength cordierite porous ceramic. According to the invention, the green preparation method is small in additive dosage used and environment-friendly, the size change from injectionmolding to sintering is less than 2% (the bus shrinkage range is-1.87% to 0.45%), and the method accords with the technical characteristic of green preparation.

Owner:BEIJING JIAOTONG UNIV

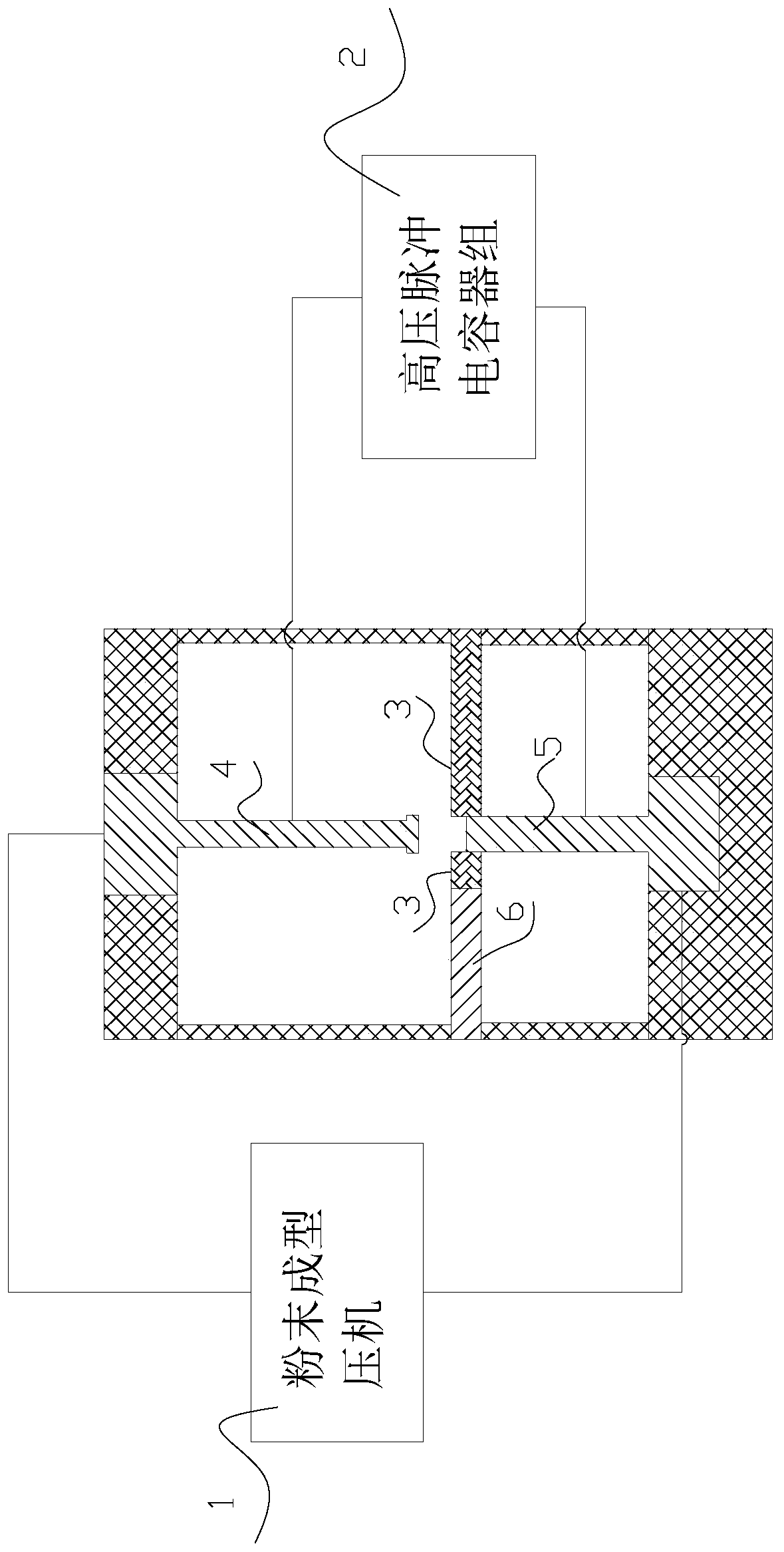

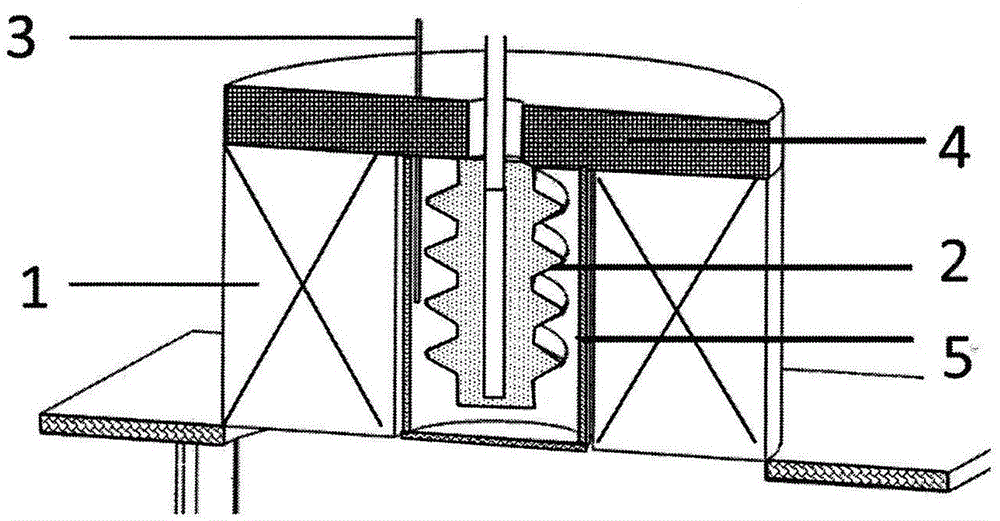

Pulse discharge flash sintering metal-based part near-net forming technology method

InactiveCN109894615ASimple processHigh energy consumptionAdditive manufacturing apparatusPorosityMetal powder

The invention discloses a pulse discharge flash sintering metal-based part near-net forming technology method, and belongs to the technical field of powder metallurgy. The problems that a traditionalpowder metallurgy part production process is high in power consumption, tedious and complex in process flow and low in production efficiency are solved. The method mainly comprises the steps of pushing metal powder into a mold, and forming the metal powder through stamping; enabling the inner wall, making contact with the metal powder, of the mold to have the insulation property; and enabling stamping to serve as an electrode of a pulse discharge body, and enabling stamping to synchronously carry out pulse discharge in the metal powder forming process. According to the method, the process flowis greatly simplified, large-scale industrialized application is easily achieved, the near-net forming advantage is achieved, the product quality is high, porosity adjusting control is convenient, practicality is high, and the method has the important significance in the powder metallurgy industry manufacturing field.

Owner:YANGZHOUSSHINE POWDER METALLURGY

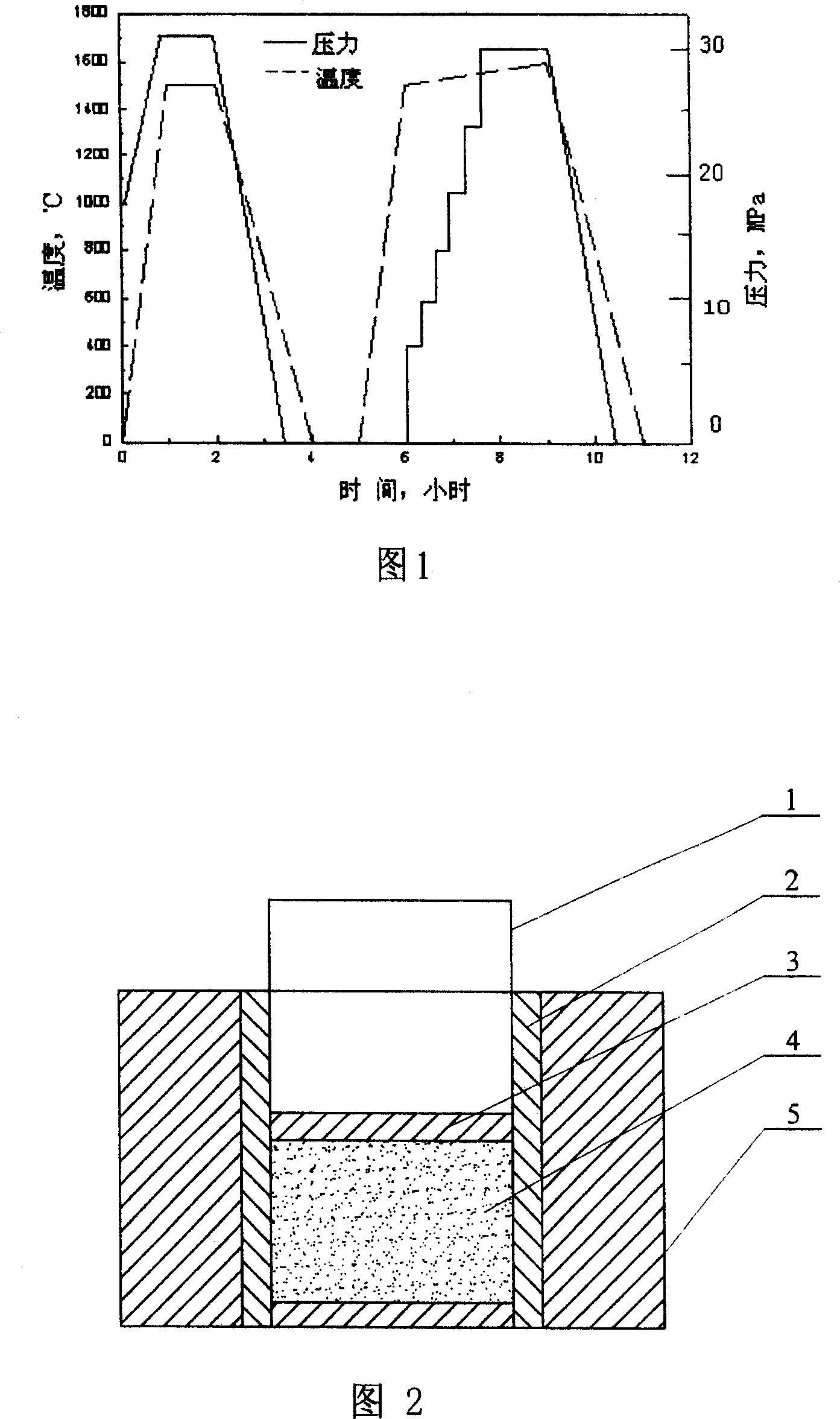

Preparation process of low-thermal-expansion wear resistant shaft sleeve

The invention discloses a preparation process of a low-thermal-expansion wear resistant shaft sleeve. The preparation process comprises the following steps: 1) the surface treatment is performed for SiC powder and carbon fiber short filaments; 2) the SiC powder and the carbon fiber short filaments are mixed with Al powder; 3) the vacuum hot isostatic pressing sintering is performed; and 4) the thermal spinning is performed for a sintered blank. A bearing sleeve, prepared by the preparation process, has such advantages as low thermal expansion coefficient, high wear resistance and excellent lubricity to play an important role on guarantee of the size precision and the surface quality of a rolled piece.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

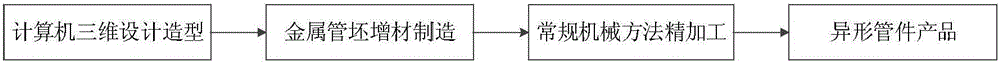

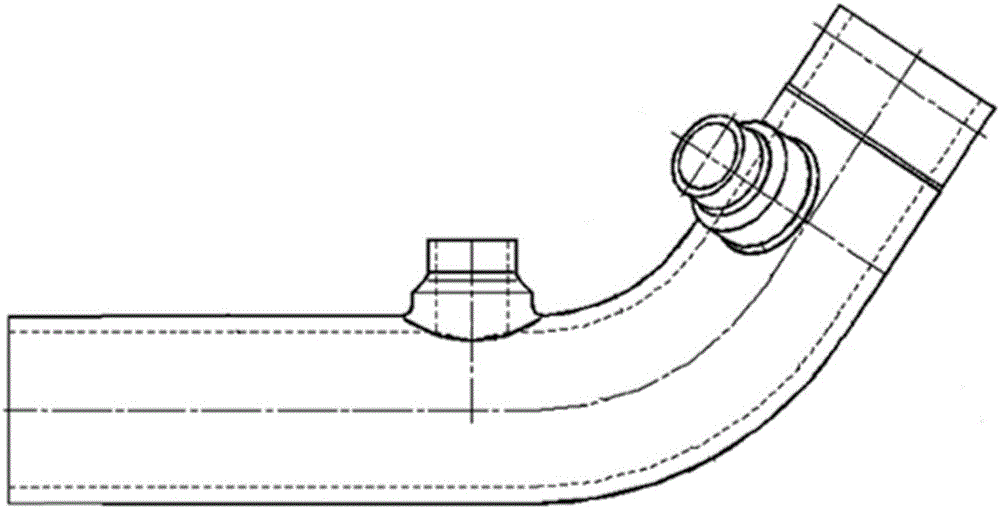

Manufacturing method of large-diameter special section pipe

The invention belongs to the technical field of metal pipe manufacturing, and specifically, relates to a manufacturing method of a large-diameter complex-shaped metal special section pipe through an additive manufacturing method. The method comprises the following steps: performing solid modeling of a pipe through a computer three-dimensional modeling software, and considering enough allowance for subsequent processing during design; making a pipe blank according to the obtained three-dimensional computer model through adoption of an additive manufacturing method (also called 3D printing), such as laser melting deposition (LMD) or laser engineered net shaping (LENS), suitable for metal materials; and carrying out proper precision machining of the pipe blank through conventional methods such as machining or grinding. Compared with a traditional technical method, such as casting, forging, and machining, the method has the advantages that a metal structure and mechanical properties of a pipe become more uniform and stable, the machining difficulty is greatly reduced, the manufacturing process is quickened, and massive raw materials are saved.

Owner:CHINA IRON & STEEL RES INST GRP +1

Liquid die forging and rolling compound formation method for 7050 aluminum alloy irregular-section large ring piece

The invention relates to a liquid die forging and rolling compound formation method for a 7050 aluminum alloy irregular-section large ring piece. The method comprises the following steps of: 1) smelting; 2) performing liquid die forging, namely fixing a liquid die forging mold on an indirect extrusion casting machine, pouring an alloy solution into the die forging mold at the pouring temperature of between 700 and 730 DEG C, pressurizing at the speed of 35 to 40 mm / s, filling for 1 to 6 seconds at the specific pressure of 160 to 200 MPa, keeping the pressure for 35 to 45 seconds, and thus obtaining a similarly final section ring blank; 3) homogenizing, namely cooling the similarly final section ring blank to the temperature of 430 DEG C, keeping the temperature for 18 hours, heating to the temperature of 467 DEG C, and keeping the temperature for 12 hours; 4) performing afterheat isothermal rolling, namely cooling the homogenized similarly final section ring blank to the temperature of between 430 and 440 DEG C, and performing afterheat isothermal rolling on a radial shaft compound ring rolling machine; 5) performing thermal treatment, namely performing keeping the ring blank obtained through afterheat isothermal rolling at the temperature of 470 DEG C for 40 min, then heating to the temperature of 485 DEG C and keeping the temperature for 40 min, quenching in cold water and keeping the temperature of 135 DEG C for 12 hours, heating to the temperature of 170 DEG C and keeping the temperature for 2 hours, and cooling to the temperature of 135 DEG C and keeping the temperature for 12 hours; and 6) finishing.

Owner:SOUTHWEST UNIV

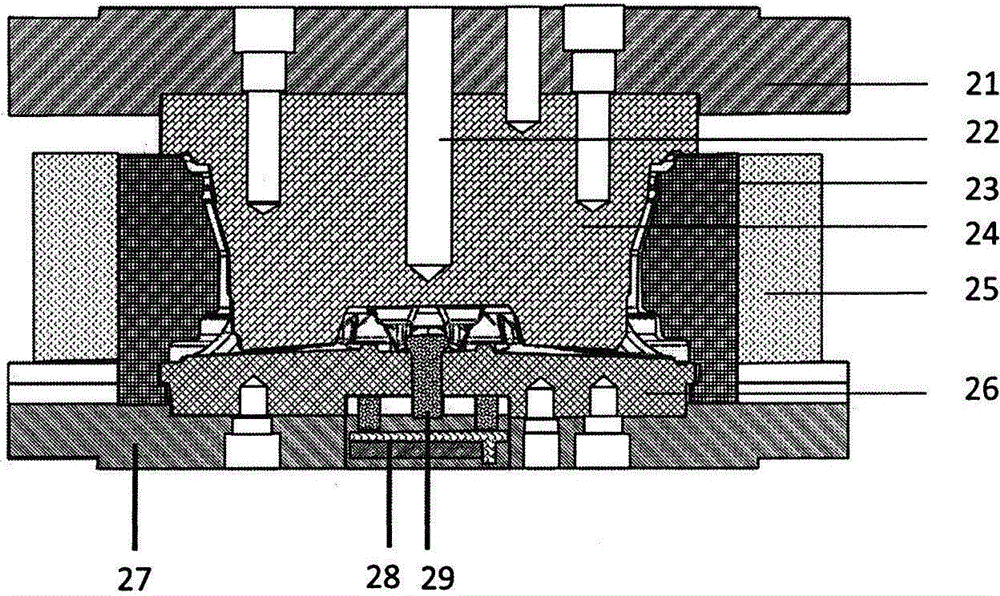

Forming device and method for preparing high-structural strength aluminum alloy hub

ActiveCN105798261ASmall and uniform tissueImprove structural strengthTemperature controlUltimate tensile strength

The invention discloses a forming device and a method for preparing a high-structural strength aluminum alloy hub. The forming device consists of an alloy smelting device, a quantitative pouring cup, a graphite crucible, an electromagnetic stirring melt treatment device, a rheologic extrusion casting forming mold and an extrusion casting machine, wherein the quantitative pouring cup, the graphite crucible, the alloy smelting device, the electromagnetic stirring melt treatment device and the extrusion casting machine are known equipment; the rheologic extrusion casting forming mold includes an upper template and a lower template for connecting with the extrusion casting machine to form an upper mold core, a lower mold core and a side mold of a casting cavity of a hub to be cast; a temperature control device is arranged in the center position of the upper mold core; a side mold locking device is arranged on the outer side of the side mold; and an ejector rod and an ejector rod support plate are arranged on the lower mold core. The aluminum alloy hub prepared by the device and the method is uniform and fine in structure and high in structural strength; the structural strength is near the strength of forged hub; and meanwhile, the nearly final formation of the aluminum alloy hub can be realized, and the utilization rate and the complex shape of low-pressure casting materials are realized.

Owner:有研金属复材技术有限公司

Degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588AEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisOsteoblastDie casting

The invention provides a degradable antibacterial magnesium alloy and a preparation method of the degradable antibacterial magnesium alloy, and relates to the field of metal biomedical materials. Thedegradable antibacterial magnesium alloy comprises main active elements of Ag, Cu, Zn and Sr, and by means of composition optimization design of the magnesium alloy, the components comprise, by mass,1.35-1.65% of Ag, 0.9-1.1% of Cu, 3.6-4.4% of Zn, 0.9-1.1% of Sr, 0.36-0.44% of Ca and the balance Mg and other inevitable impurities. After the magnesium alloy material implant finishes the action, the magnesium alloy material implant can be completely degraded to avoid secondary operation removal, the medical cost and the pain of patients are reduced, the antibacterial property of the implant isimproved, and the magnesium alloy material implant has the functions of promoting osteoblast formation and inhibiting osteoclast bone absorption; the degradable antibacterial magnesium alloy adopts asemi-solid rheological die casting process, the microstructure of the product is uniformly distributed, the internal structure is compact, the defects of pores, segregation and the like are few, andthe requirements for high quality and high precision of implant products can be met.

Owner:NORTHEASTERN UNIV

Liquid die forging and rolling compound formation method for aluminum alloy irregular-section large ring piece

InactiveCN102689155AIncrease productivityHigh material utilizationMetal rollingEngineeringThermal treatment

The invention discloses a liquid die forging and rolling compound formation method for an aluminum alloy irregular-section large ring piece. The method comprises the following steps of: smelting, performing liquid die forging, homogenizing, performing afterheat isothermal rolling, performing thermal treatment and finishing, wherein the step of performing liquid die forging comprises the following substeps of: fixing a liquid die forging mold on an indirect extrusion casting machine, pouring a quantitative amount of aluminum alloy solution obtained through smelting into the liquid die forging mold at the pouring temperature of between 650 and 730 DEG C, pressurizing at the speed of 35 to 40 mm / s, filling for 1 to 6 seconds at the specific pressure of 100 to 200 MPa, keeping the pressure for 35 to 60 seconds, and thus obtaining a similarly final section ring blank; and the step of performing afterheat isothermal rolling comprises the following substeps of: cooling the homogenized similarly final section ring blank to the temperature of between 430 and 480 DEG C, and performing afterheat isothermal rolling on a radial shaft compound ring rolling machine. According to the liquid die forging and rolling compound formation method for the stainless steel irregular-section large ring piece, the flow of a blank preparation process for an aluminum alloy ring piece can be simplified, the cost can be reduced, and the production efficiency can be improved; and furthermore, the microstructure state of the aluminum alloy ring piece can be effectively improved, and the comprehensive mechanical performance is improved.

Owner:SOUTHWEST UNIVERSITY

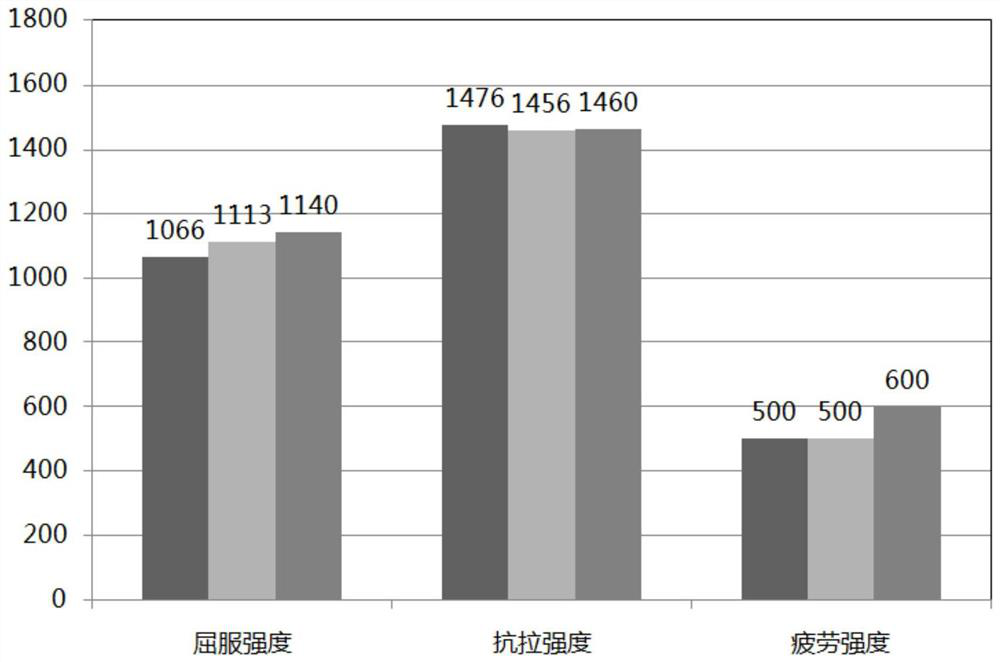

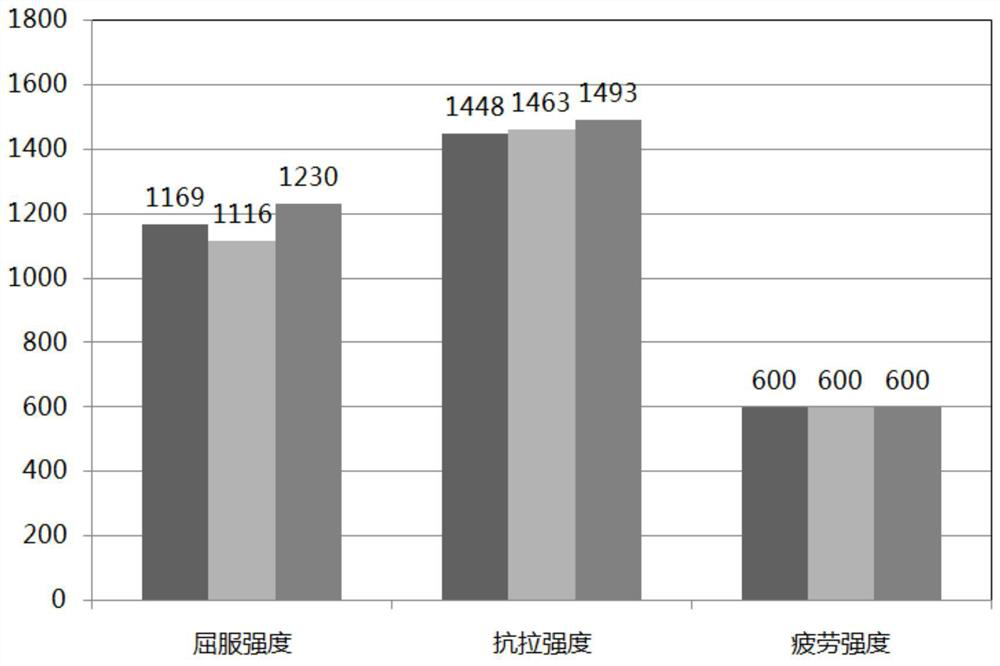

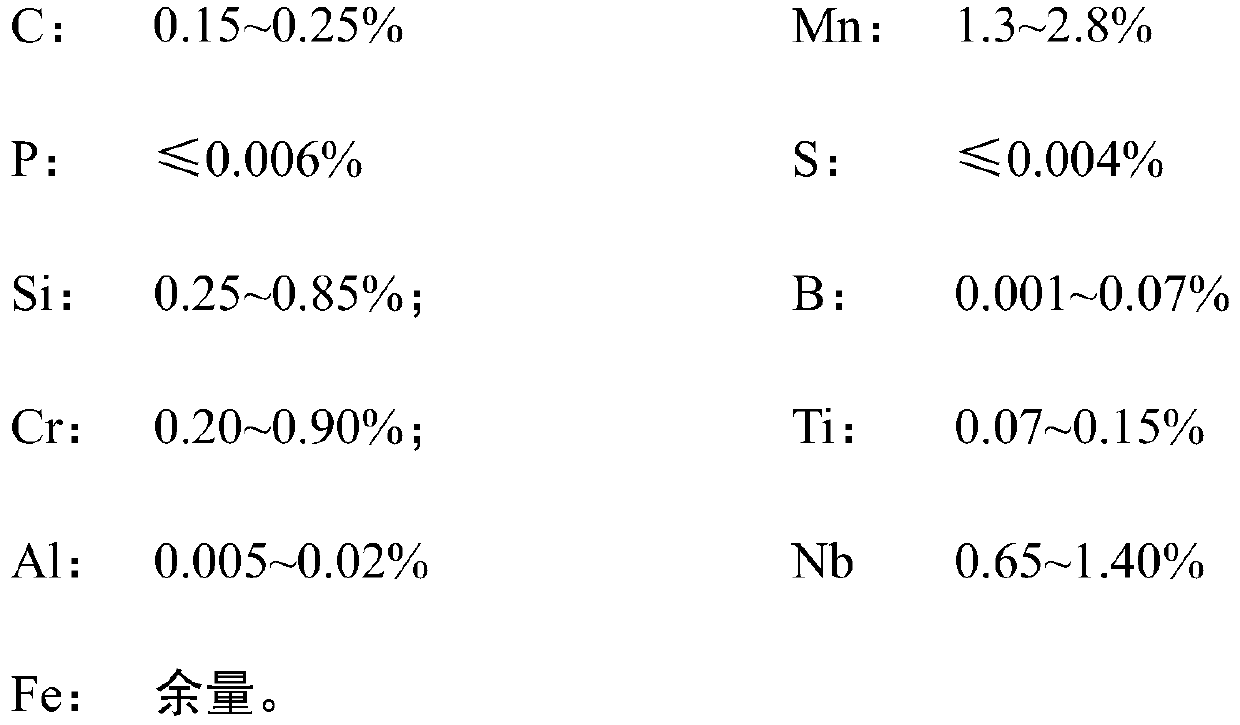

Ultrahigh-strength steel with near net shaping function and preparation method thereof

ActiveCN108950411AGood elasticity and plasticityEasy to processMaterials preparationRoom temperature

The invention discloses ultrahigh-strength steel with a near net shaping function and a preparation method thereof, and belongs to the technical field of manufacturing of ultrahigh-strength steel. Thepreparation method comprises the steps of S1, material preparation; S2, alloy smelting; S3, performance heat treatment, specifically, an alloy ingot obtained in step S2 is placed in a heat treatmentfurnace so as to be subject to performance heat treatment, and according to the specific process of performance heat treatment, heat preservation is conducted for 12-24 h at the temperature of 900-1150 DEGC, then the alloy ingot is cooled to the temperature of 500-750 DEGC with the furnace and then is maintained at the temperature of 5-10 h, and finally, the alloy ingot is air-cooled to the room temperature; and S4, pressure processing of alloy. Compared with similar materials, the ultrahigh-strength steel having the near net shaping function and prepared through the process has the advantagesof excellent mechanical property and near net shaping function.

Owner:NANJING INST OF TECH

Negative pressure drainage type casting and forging forming device and method for metal material

The invention provides a negative pressure drainage type casting and forging forming device for a metal material. The negative pressure drainage type casting and forging forming device comprises an electromagnetic heater, a liquid lifting device, a high-pressure casting piston, a melting furnace, a mold cavity, an ejection mechanism, a left mold, a negative pressure pumping device, a right mold, a mold control mechanism, an air guide hole, a cavity and a forging and pressing device. Wherein the mold cavity is connected with a negative pressure pumping device; the outer surface of the mold cavity is coated with an electromagnetic heater; one end of the liquid lifting device is connected with the feeding end of the mold cavity, and the other end of the liquid lifting device is inserted into the melting furnace. A high-pressure casting piston is arranged at a feeding port of the mold cavity; a left mold and a right mold are respectively arranged at the left end and the right end in the mold cavity; one end of the right mold is connected with a shape control mechanism; and a forging and pressing device is arranged beside the shape control mechanism. According to the device, a metal product is formed through the melt negative pressure pumping drainage-high-pressure extrusion casting-continuous forging technology, the structure of a casting can be remarkably improved, and the comprehensive performance of the product is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Liquid die forging rolling compound forming method for 2A70 aluminium alloy large ring member with different cross sections

InactiveCN102689160AIncrease productivityIncrease profitMetal rollingThermal treatmentMaterials science

The invention discloses a liquid die forging rolling compound forming method for a 2A70 aluminium alloy large ring member with different cross sections. The liquid die forging rolling compound forming method comprises the following steps of: 1), smelting; 2), liquid die forging: fixing a forged die on an indirect extrusion casting machine; pouring alloy solution in the forged die for mold-filling for 1-5s at the pouring temperature between 700 and 720 DEG C and specific pressure between 180 and 200 MPa in the pressurizing speed of 35-40mm / s; and keeping the pressure for 40-60s under the pressure to obtain a ring blank with a nearly end cross section; 3) homogenization: cooling the ring blank with the nearly end cross section to 495 DEG C for keep the temperature for 16h; 4) afterheat isothermy rolling: reducing the temperature of the homogenized ring blank with the nearly end cross section to 430-450 DEG C, and performing isothermy rolling on a radial-shaft compound ring rolling machine; 5) thermal treatment: raising the temperature of the ring blank to 535 DEG C, keeping the temperature for 3 hours and performing water quenching; and then, raising the temperature to 190 DEG C and keeping the temperature for 12h; and 6) finishing.

Owner:SOUTHWEST UNIVERSITY

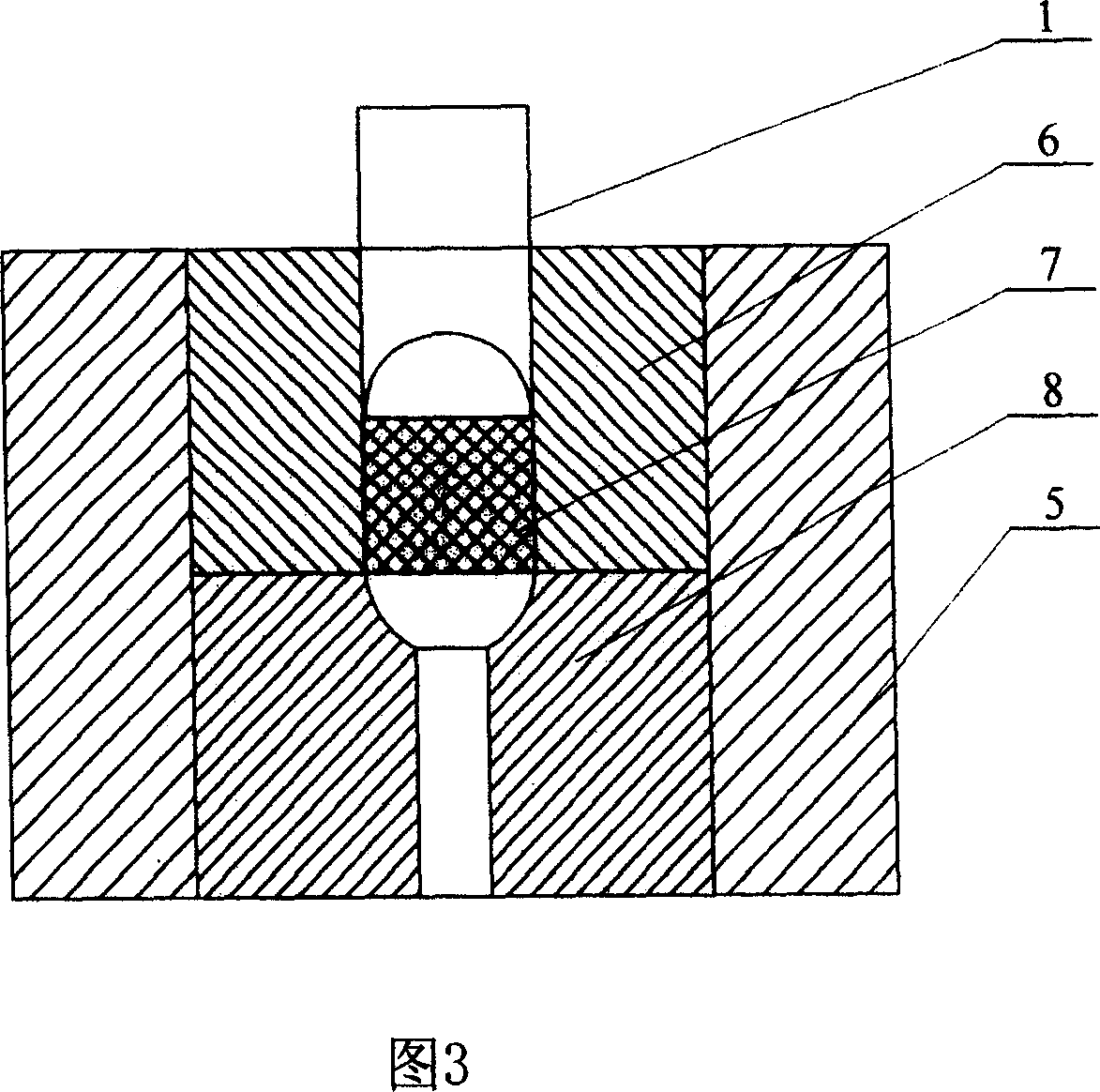

Shaping method of nanometer bioceramic artificial joint

The process of forming artificial joint of nanometer bioceramic relates to nanometer ceramic material forming technology, and aims at solving the problem of forming complicated shape ceramic product. The process includes the following steps: 1. hot pressing and sintering composite Al2O3 / ZrO2 powder or ZrO2 / HAP powder to prepare nanometer ceramic block; and 2. closed die forging to form ceramic product at high temperature. By means of the twice forming process, the present invention can form ceramic part of complicated shape. The present invention has the advantages of simple forming process, easy manufacture of mold, low cost, etc.

Owner:HARBIN MEDICAL UNIVERSITY

Liquid die-forging and rolling composite forming method for die steel special-section large ring piece

The invention discloses a liquid die-forging and rolling composite forming method for a die steel special-section large ring piece. The method comprises the following steps of: smelting, performing liquid die-forging, homogenizing, performing afterheat isothermal rolling, performing thermal treatment and performing fine adjustment, wherein the step of performing liquid die-forging comprises the following substeps of: fixing a liquid die-forging die on an indirect extrusion casting machine, and quantitatively pouring a die steel solution obtained through smelting into the liquid die-forging die at the pouring temperature of between 1,600 and 1,650 DEG C under the pressurization speed of between 30 and 60 mm / s, wherein the filling time is 1 to 6 seconds, and the specific pressure is 150 to 200 MPa; and keeping the pressure of between 150 and 200 MPa for 35 to 100 seconds, and thus obtaining a similar final section ring blank; and the step of performing afterheat isothermal rolling comprises the following substeps of: cooling the homogenized similar final section ring blank to the temperature of between 1,000 and 1,180 DEG C, and performing afterheat isothermal rolling on a radial shaft composite ring rolling machine. By the liquid die-forging and rolling composite forming method for the die steel special-section large ring piece, the process flow of manufacturing a blank of an alloy ring piece can be simplified, the cost can be reduced, and the production efficiency can be improved; and furthermore, the microstructure state of the die steel ring piece can be effectively improved, and the comprehensive mechanical property can be improved.

Owner:SOUTHWEST UNIV

A kind of degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588BEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisMg alloysMetallurgy

The invention provides a degradable antibacterial magnesium alloy and a preparation method thereof, and relates to the field of metal biomedical materials. The main active elements of the degradable antibacterial magnesium alloy material are Ag, Cu, Zn and Sr. Through the optimized design of magnesium alloy components, The corresponding mass fractions of each component are: Ag: 1.35~1.65%, Cu: 0.9~1.1%, Zn: 3.6~4.4%, Sr: 0.9~1.1%, Ca: 0.36~0.44%, the balance is Mg and others unavoidable impurities. After the magnesium alloy material implant is completed, it can be completely degraded to avoid secondary surgical removal, reducing medical costs and patient pain. At the same time, it improves the antibacterial property of the implant, promotes the formation of osteoblasts and inhibits osteoclasts. The function of cellular bone absorption; the degradable antibacterial magnesium alloy adopts a semi-solid rheological die-casting process. The microstructure of the product is evenly distributed, the internal tissue is dense, and there are few defects such as pores and segregation, which can meet the high quality and high performance of implant products. Accuracy requirements.

Owner:NORTHEASTERN UNIV LIAONING

Liquid die forging rolling composite forming method for H13 hot work die steel unusual section large forging

InactiveCN102672439BIncrease productivityIncrease profitRoll mill control devicesMetal rolling arrangementsHot workHeat treating

Owner:SOUTHWEST UNIV

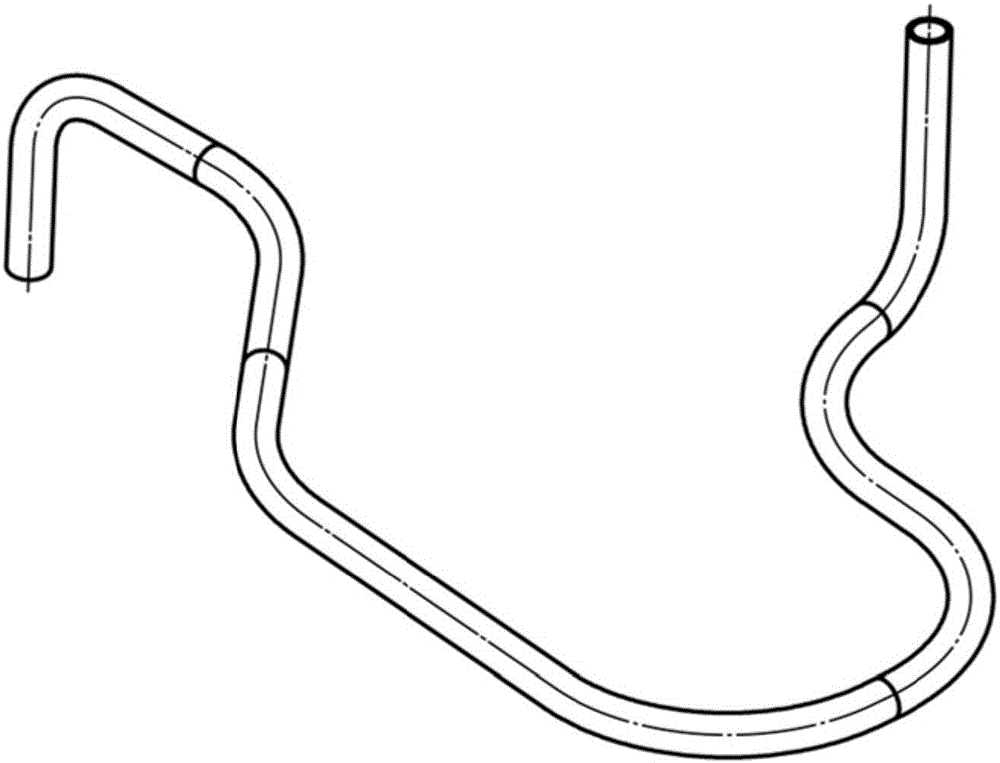

A Method for Inhibiting Buckling in Creep-Aging Forming of Aluminum Alloy Components with Complex Curvature

ActiveCN111575615BIncrease stiffnessInhibition of bucklingFurnace typesHeat treatment furnacesAge formingAluminium alloy

The invention discloses a method for suppressing buckling in the creep aging forming of aluminum alloy components with complex curvature, which comprises first pasting and fixing a restraint plate on the peripheral position of the upper surface of the base metal aluminum alloy plate, and then attaching the restraint plate and the base metal aluminum alloy plate together Wrap it in air felt, and lay a vacuum bag to form a closed space. After vacuum treatment, put the above-mentioned treated whole and mold together into an autoclave for creep aging forming to obtain an aluminum alloy component with complex curvature. The invention considers that the stiffness of the member is insufficient during the loading process, and the buckling is suppressed by arranging a restraint plate on the load-bearing side of the member to suppress buckling, and does not need an additional device for applying blank holder force, and can be applied to hot pressing commonly used in creep aging forming In the tank device, the occurrence of buckling is effectively suppressed, and the forming quality is improved; the risk of vacuum film damage is reduced, the forming accuracy is improved, and the probability of component success is increased; at the same time, the blank holder area does not need to be reserved before sheet forming, Conducive to the near-net shape of the component.

Owner:CENT SOUTH UNIV

Iron-based gradient structure gear and manufacturing method thereof

ActiveCN101555937BNo subsequent surface treatment requiredLow costPortable liftingGearing elementsHigh surfaceHardness

Owner:CENT SOUTH UNIV

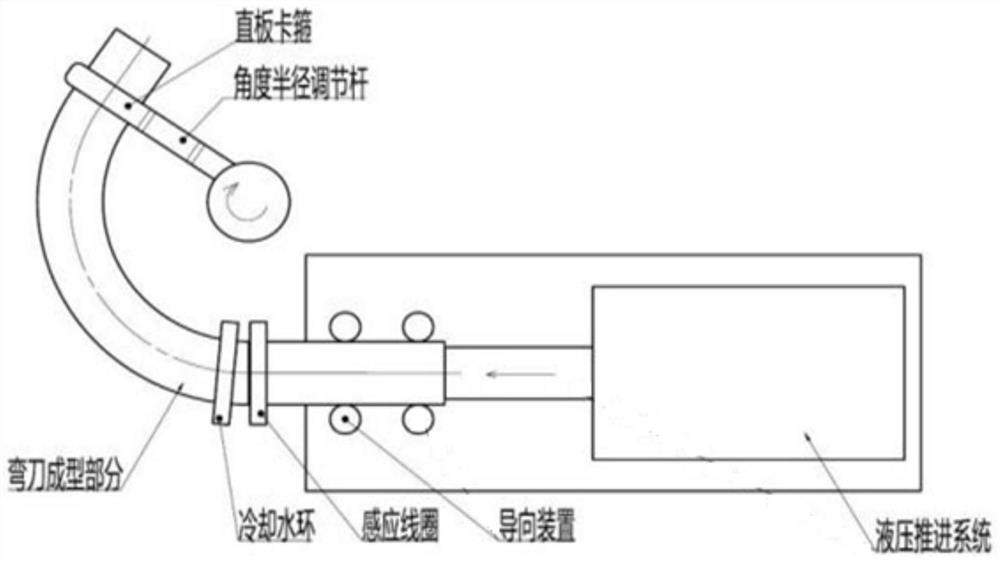

A hot push-bending forming method of a wind tunnel scimitar

ActiveCN111515276BPrecise Width ControlImprove low temperature toughnessShaping toolsAerodynamic testingThermodynamicsStructural engineering

The invention discloses a hot push bending forming method of a wind tunnel scimitar. The forming method includes a. selecting a long steel plate with a rectangular cross-section and a width-to-thickness ratio of 7 to 10; b. installing a cooling water ring and an induction coil matching the cross-sectional size of the steel plate on the pushing machine; c. passing the steel plate through One end of the supercooled water ring and the induction coil is fixed on the push table of the hydraulic propulsion system of the pushing machine, and the other end is fixed on the straight plate clamp of the pushing machine, and the straight plate clamp is connected to the angle radius adjustment rod; d. Induction coil heating Part of the steel plate, when the local temperature of the steel plate reaches the bendable temperature, the hydraulic propulsion system of the pushing machine slowly pushes the steel plate forward, the straight plate clamp rotates around the angle radius adjustment rod, the steel plate is continuously bent at the position of the induction coil, and a flat semicircle is obtained after forming Ring machete. The scimitar forming method of the forming method has the advantages of stable forming, high speed, high precision, good mechanical properties, small blank tonnage required, obvious technical and economic advantages, and has the value of popularization and application.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT +2

Liquid die forging and rolling compound formation method for stainless steel irregular-section large ring piece

Owner:SOUTHWEST UNIV

Liquid die forging/rolling composite forming method for magnesium alloy irregular-section large-size ring piece

The invention relates to a liquid die forging / rolling composite forming method for a magnesium alloy irregular-section large-size ring piece, which comprises the following steps: smelting, liquid die forging, homogenizing, excess heat isothermal rolling, heat treatment and finishing, wherein in the liquid die forging process, after a liquid die forging die is fixed onto an indirect extrusion casting machine, the smelted magnesium alloy solution is quantitatively cast into the liquid die forging die, and kept under the specific pressure of 140-200 MPa for 35-150 seconds to obtain the similar end-section ring blank, wherein the casting temperature is 680-740 DEG C, the pressurization speed is 50-100 mm / s, and the cavity filling time is 1-6 seconds; and in the excess heat isothermal rolling process, when the homogenized similar end-section ring blank is cooled to 300-400 DEG C, isothermal rolling is carried out on a radial / axial composite ring rolling machine. The method provided by the invention can simplify the blank making process of the alloy ring piece, lower the cost, enhance the production efficiency, effectively improve the microstructure state of the liquid die forging die magnesium alloy ring piece, and enhance the comprehensive mechanical properties.

Owner:SOUTHWEST UNIV

A kind of ultra-high strength steel with near-net shape and its preparation method

The invention discloses ultrahigh-strength steel with a near net shaping function and a preparation method thereof, and belongs to the technical field of manufacturing of ultrahigh-strength steel. Thepreparation method comprises the steps of S1, material preparation; S2, alloy smelting; S3, performance heat treatment, specifically, an alloy ingot obtained in step S2 is placed in a heat treatmentfurnace so as to be subject to performance heat treatment, and according to the specific process of performance heat treatment, heat preservation is conducted for 12-24 h at the temperature of 900-1150 DEGC, then the alloy ingot is cooled to the temperature of 500-750 DEGC with the furnace and then is maintained at the temperature of 5-10 h, and finally, the alloy ingot is air-cooled to the room temperature; and S4, pressure processing of alloy. Compared with similar materials, the ultrahigh-strength steel having the near net shaping function and prepared through the process has the advantagesof excellent mechanical property and near net shaping function.

Owner:NANJING INST OF TECH

Liquid forging and rolling composite molding method of nickel-base superalloy hetero-cross-section large ring piece

The invention provides a liquid forging and rolling composite molding method of a nickel-base superalloy hetero-cross-section large ring piece. The liquid forging and rolling composite molding method comprises the following steps of: smelting, liquid forging, homogenization, waste heat isothermal rolling, heat processing and finishing. The step of liquid forging comprises: fixing a liquid forging mold on an indirect extrusion casting machine, subsequently casting a certain quantity of obtained nickel-base superalloy solution to the liquid forging mold, wherein the casting temperature is 1350-1450 DEG C, the pressuring speed is 35-50mm / s, the mold filling time is 1-6s, the specific pressure is 300-400MPa; and keeping the pressure for 35-90 seconds under the pressure so as to obtain a final cross section nearest ring blank. The step of waste heat isothermal rolling comprises: carrying out waste heat isothermal rolling on a radial axis composite ring rolling machine after the final cross section nearest ring blank subjected to homogenization is cooled to 1020-1140 DEG C. By utilizing the liquid forging and rolling composite molding method of the nickel-base superalloy hetero-cross-section large ring piece, not only can the blank manufacturing process of the alloy ring piece be simplified, the cost is reduced and the production efficiency is improved, but also the micro-texture state of the nickel-base superalloy ring piece is improved, and the comprehensive mechanical property is improved.

Owner:SOUTHWEST UNIV

Liquid die forging rolling compound forming method for 2A70 aluminium alloy large ring member with different cross sections

Owner:SOUTHWEST UNIV

Liquid die forging and rolling composite forming method for 6082 aluminum alloy large rings with different cross-sections

InactiveCN102699636BIncrease productivityIncrease profitMetal rollingThermal treatmentMaterials science

The invention discloses a liquid die-forging and rolling composite forming method for a 6082 aluminum alloy special-section large ring piece. The method comprises the following steps of: 1) smelting; 2) performing liquid die-forging, namely fixing a die-forging die on an indirect extrusion casting machine, and pouring an alloy solution into the die-forging die at the pouring temperature of between 650 and 680 DEG C under the pressurization speed of between 35 and 40 mm / s, wherein the filling time is 1 to 6 seconds, and the specific pressure is 100 to 150 MPa; and keeping the pressure of between 100 and 150 MPa for 35 to 60 seconds, and thus obtaining a similar final section ring blank; 3) homogenizing, cooling the similar final section ring blank to the temperature of 550 DEG C, and keeping the temperature for 6 hours; 4) performing afterheat isothermal rolling, namely cooling the homogenized similar final section ring blank to the temperature of between 450 and 480 DEG C, and performing isothermal rolling on a radial shaft composite ring rolling machine; 5) performing thermal treatment, namely keeping the temperature of the ring blank at 525 DEG C for 1 hour, quenching in the water, rising the temperature to 165 DEG, and keeping the temperature for 12 hours; and 6) performing fine adjustment.

Owner:SOUTHWEST UNIV

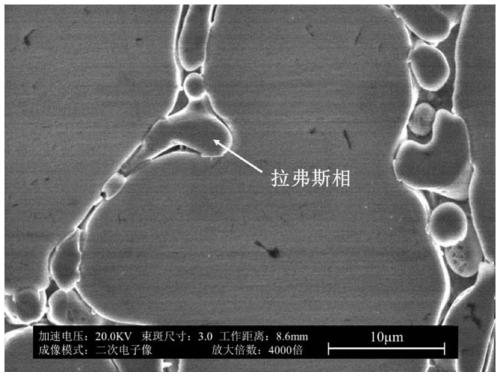

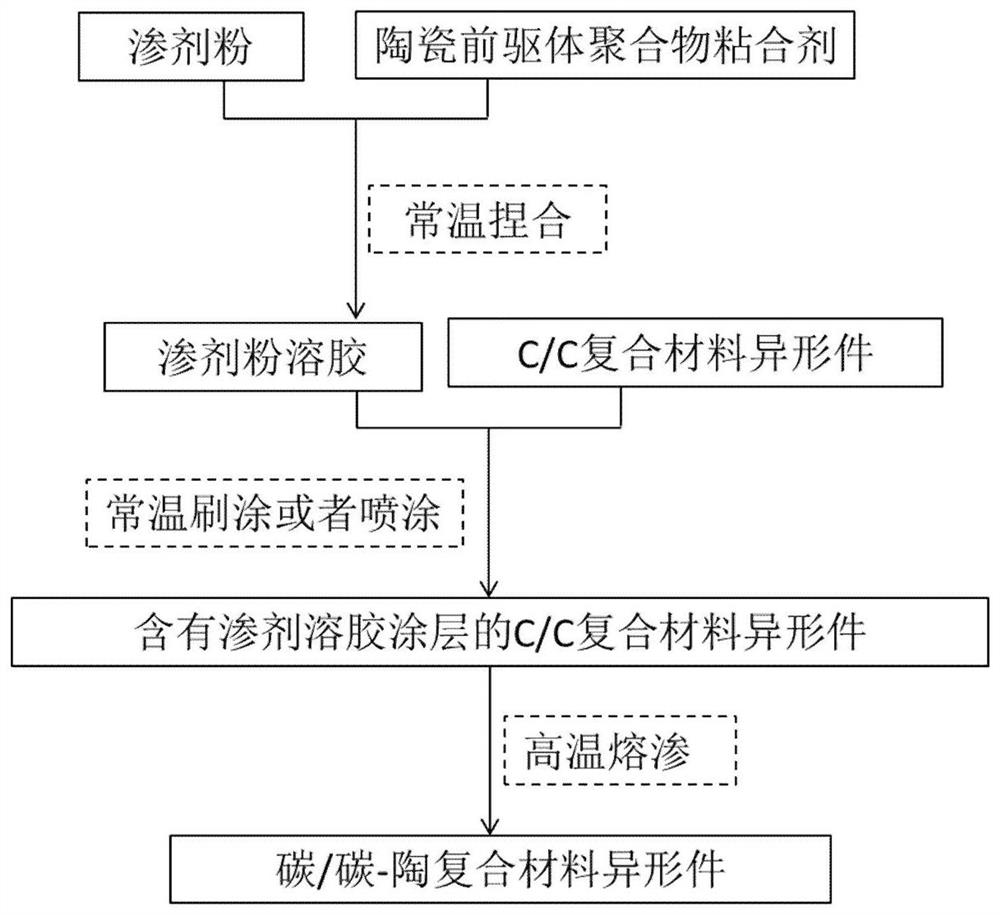

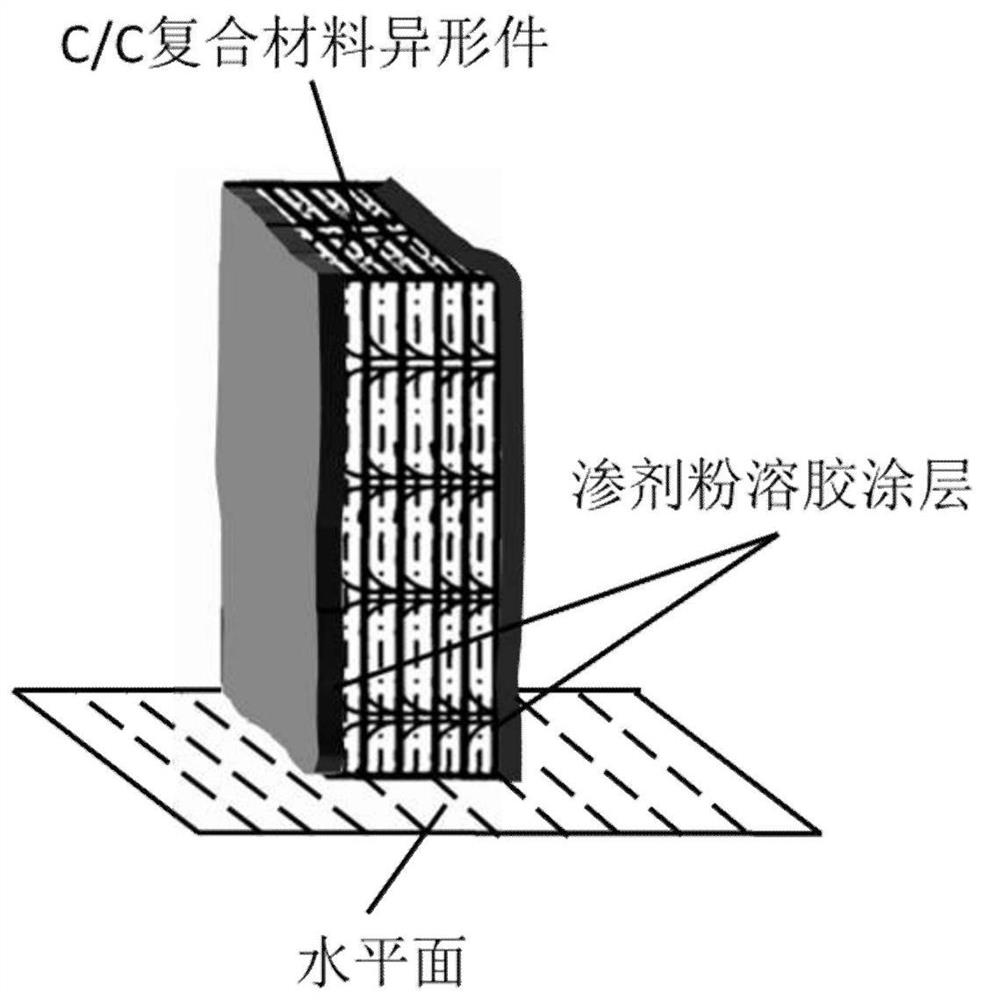

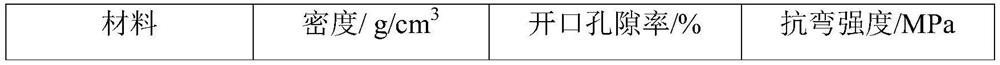

A gel infiltration ceramic modification method for special-shaped parts of c/c composite materials

The invention discloses a gel infiltration ceramic modification method for C / C composite special-shaped parts, which includes the following steps: (1) Mix and knead ceramic precursor polymer binder and infiltration agent powder to obtain The sol in which the penetrant powder is evenly dispersed; (2) Coat the sol prepared in step (1) on the surface of the C / C composite special-shaped parts; (3) Apply the C containing sol coating prepared in step (2) / C composite special-shaped parts are heated under vacuum or in an inert atmosphere to solidify the sol and pyrolyze it to form a ceramic aerogel. After the temperature reaches 40 to 100°C above the melting point of the penetrant powder, the heat is maintained to make the gel in The infiltration agent powder is melted and fully infiltrated into C / C composite special-shaped parts to obtain carbon / carbon-ceramic composite special-shaped parts. The method of the present invention has good infiltration effect, the coating is not easy to fall off, the process is simple, and the utilization rate of infiltration materials is high. The mechanical properties of C / C composite special-shaped parts are greatly improved after being modified by this method.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com