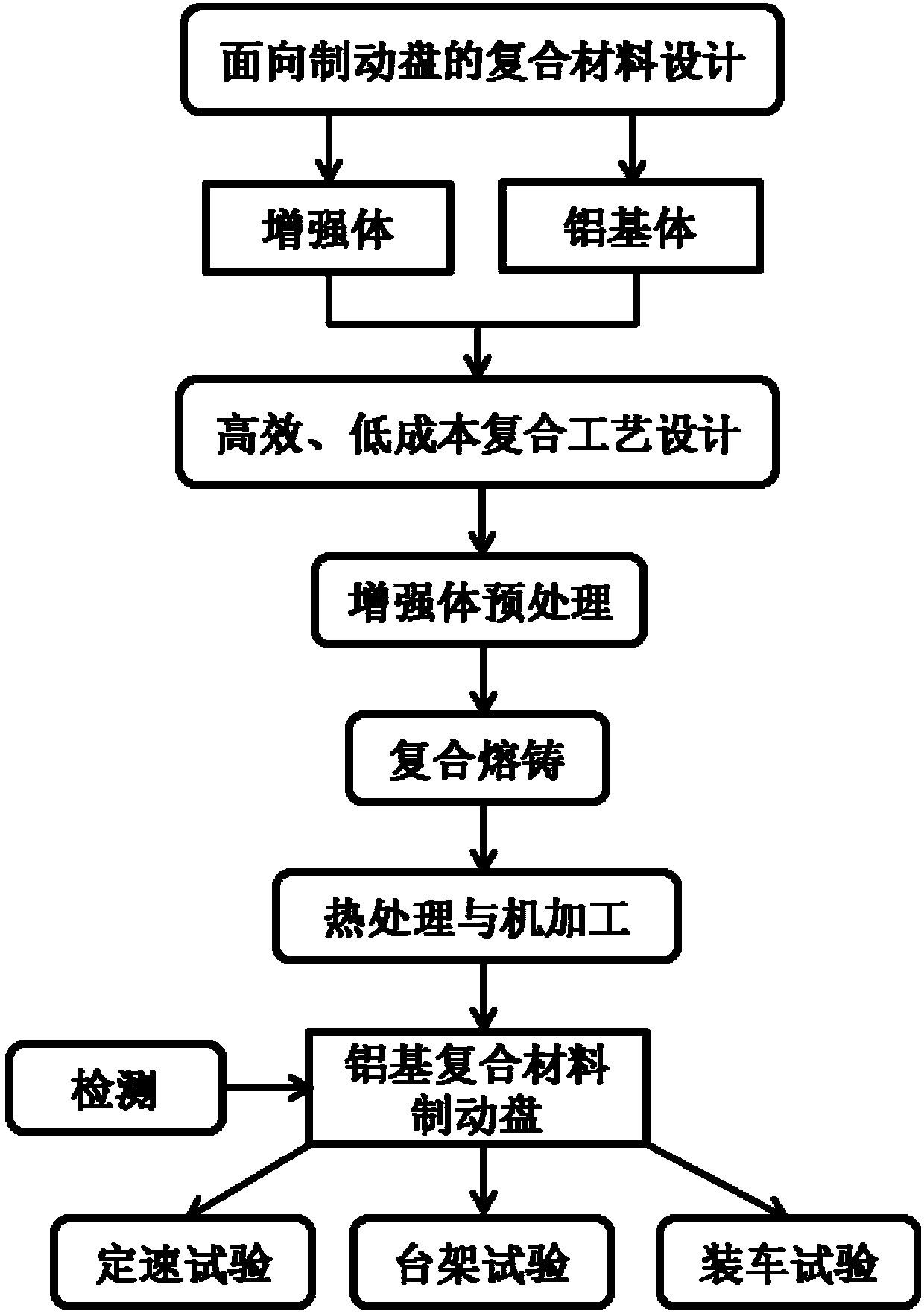

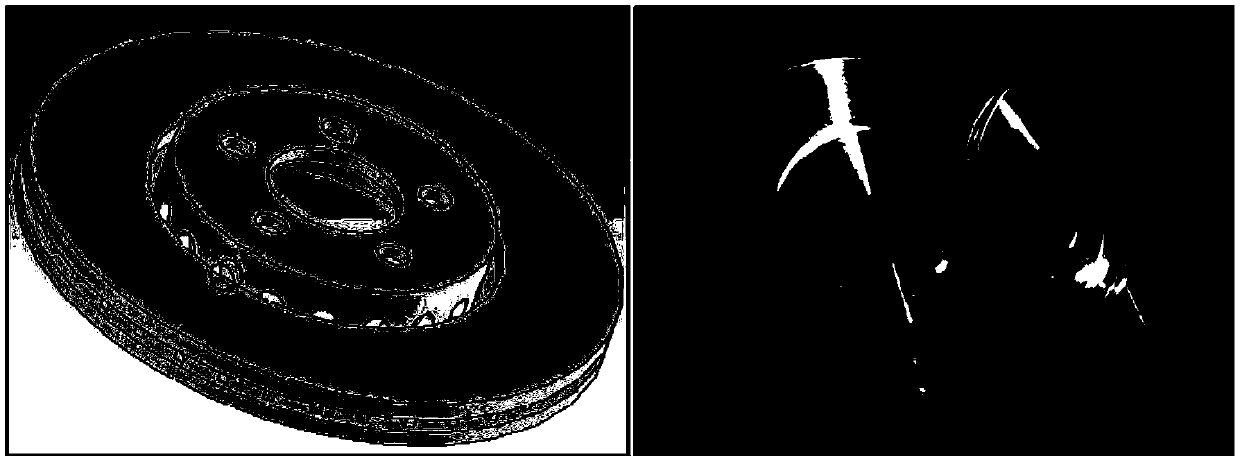

Aluminum-based composite material vehicle brake disc preparation method

An aluminum-based composite material and automobile braking technology, which is applied in the field of automobile brake discs, can solve problems such as liquid fluidity and difficulty in preparing brake disc components, and achieve low production costs, good high temperature stability, and easy batch production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a preparation method of an aluminum-based composite material automobile brake disc, comprising the following steps:

[0039] The silicon carbide was added to the hydrofluoric acid aqueous solution, then washed with deionized water and suction filtered; then added to the sodium hydroxide solution for alkali washing, washed with deionized water, suction filtered, and finally placed in a drying oven at 100°C The silicon carbide particles were placed in a box-type resistance furnace, heated to 800° C., kept for 1 hour, and cooled to room temperature with the furnace.

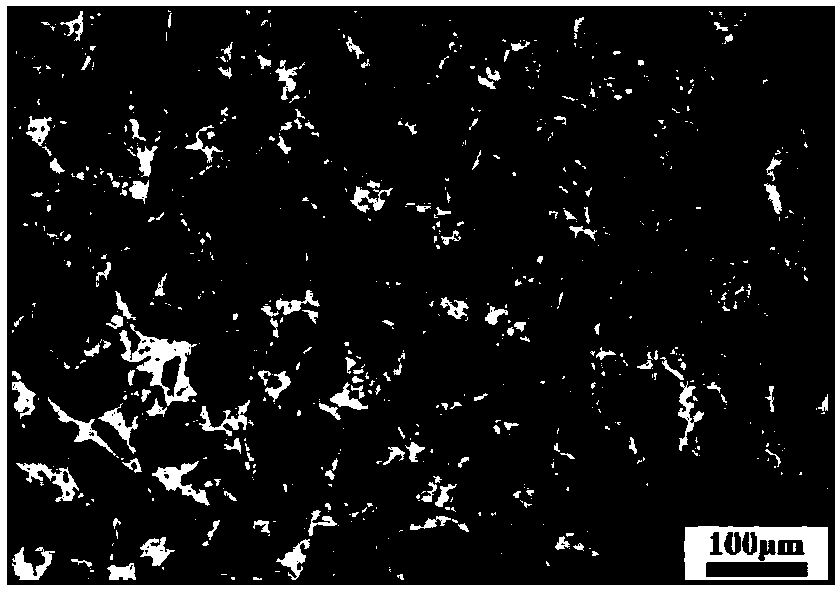

[0040] Add 5Kg of A356 aluminum alloy into the crucible, raise the temperature to 620°C, and when all the aluminum is melted, add 1.5Kg of silicon carbide particles with an average particle size of 10 μm, and start stirring. The stirring temperature is 600°C, the stirring speed is 500rmp, and the stirring time is It lasted for 1 hour; after the stirring, the temperature was inc...

Embodiment 2

[0048] The present embodiment provides a preparation method of an aluminum-based composite material automobile brake disc, comprising the following steps:

[0049] The silicon carbide was added to the hydrofluoric acid aqueous solution, then washed with deionized water and suction filtered; then added to sodium hydroxide solution for alkali washing, washed with deionized water, suction filtered, and finally placed in a drying oven at 200 ° C The silicon carbide particles are placed in a box-type resistance furnace, heated to 1200 ° C, kept for 2 hours, and cooled to room temperature with the furnace.

[0050] Add 5Kg A356 aluminum alloy into the crucible, raise the temperature to 710°C, and when all the aluminum is melted, add 4.8Kg silicon carbide particles with an average particle size of 30 μm, and start stirring. The stirring temperature is 750°C, the stirring speed is 2000rmp, and the stirring time is It lasted for 2 hours; after the stirring, the temperature was increase...

Embodiment 3

[0058] The present embodiment provides a preparation method of an aluminum-based composite material automobile brake disc, comprising the following steps:

[0059] The silicon carbide was added to the hydrofluoric acid aqueous solution, then washed with deionized water and suction filtered; then added to sodium hydroxide solution for alkali washing, washed with deionized water, suction filtered, and finally placed in a drying oven at 200 ° C The silicon carbide particles are placed in a box-type resistance furnace, heated to 1200° C., maintained for 1 hour, and cooled to room temperature with the furnace.

[0060] Add 5Kg A356 aluminum alloy into the crucible, raise the temperature to 700°C, and when all the aluminum is melted, add 3.2Kg silicon carbide particles with an average particle size of 30μm, and start stirring. The stirring temperature is 680°C, the stirring speed is 2000rmp, and the stirring time is It lasted for 2 hours; after the stirring, the temperature was incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com