Carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire

A toughening, self-protecting technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of reduced service life, high brittleness, low impact toughness, etc., to achieve excellent wear resistance, The effect of good economy and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

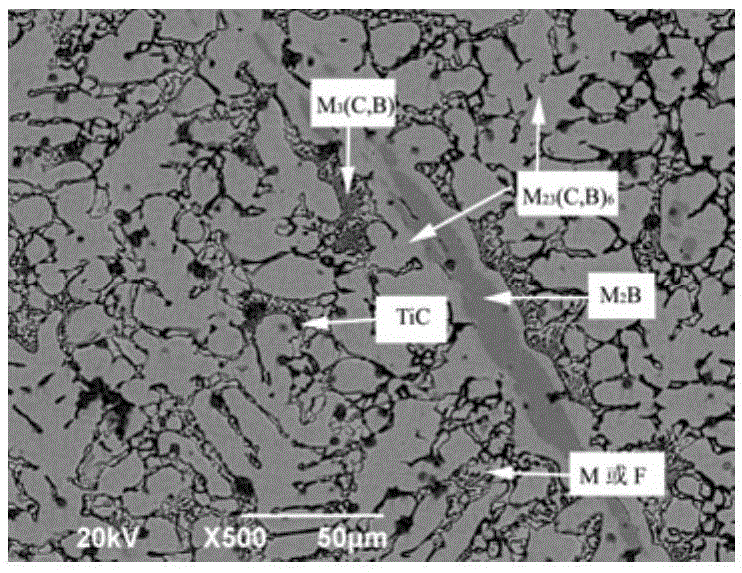

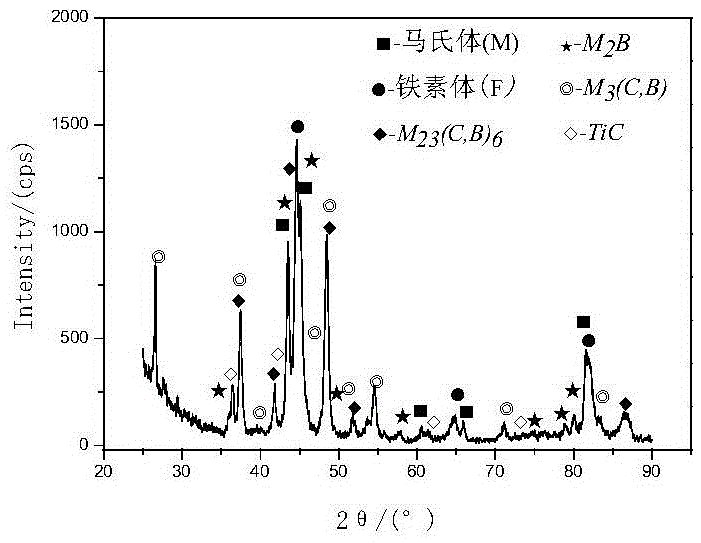

Embodiment 1

[0053] During production, ferroboron, high-carbon ferrochrome, graphite and other alloy powders are weighed according to the composition ratio of the powder core, and all powders are passed through a 60-mesh sieve. The wear-resistant surfacing flux-cored wire was prepared and formed on the YHZ-1 flux-cored wire forming machine manufactured by Tianjin Sanying Welding Co., Ltd. The outer sheath of the wear-resistant surfacing flux-cored wire is H08A cold-rolled steel strip (width 16mm×thickness 0.36mm, the same below), and the sheath is equipped with graphite, metal and alloy powder to form a powder core. The composition of the powder core (weight percentage ) is: 40% of ferroboron, 40% of high carbon ferrochrome, 6% of ferrotitanium, 2.0% of flake graphite, 1.0% of superfine graphite, 3% of medium carbon ferromanganese, 4% of ferrosilicon, 4% of reduced iron powder, The powder core filling rate is 50%. The components of the powder core are stirred evenly and then rolled into Φ...

Embodiment 2

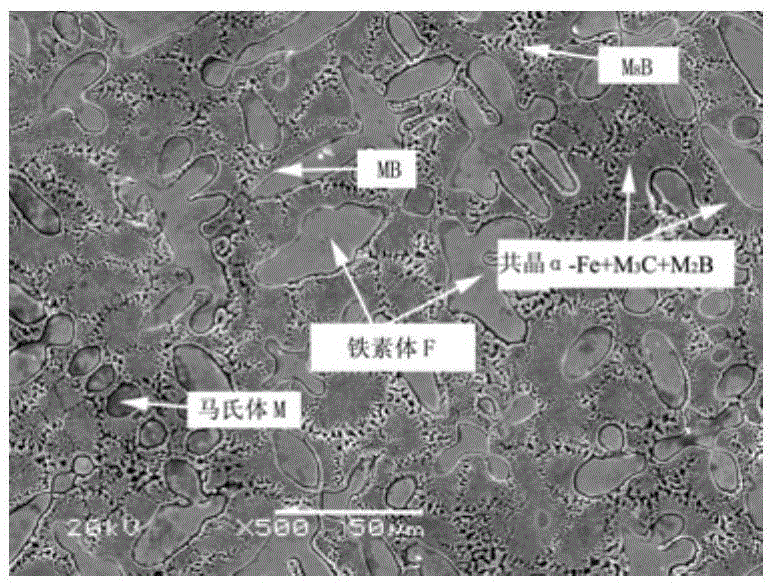

[0059] During production, ferroboron, graphite, high-carbon ferrochrome and alloy powders are weighed according to the composition ratio of the powder core, and all powders are passed through a 60-mesh sieve. The wear-resistant surfacing flux-cored wire was prepared and formed on the YHZ-1 flux-cored wire forming machine manufactured by Tianjin Sanying Welding Co., Ltd. The outer sheath of the wear-resistant surfacing flux-cored wire is H08A cold-rolled steel strip (16mm×0.36mm), and the sheath is equipped with graphite, metal and alloy powder to form a powder core. The composition (weight percentage) of the powder core is: boron iron 50%, high-carbon ferrochrome 30%, ferro-titanium 7.5%, flake graphite 3%, superfine graphite 0.5%, medium-carbon ferromanganese 5%, ferrosilicon 3%, reduced iron powder 1%, and the powder core is filled with The rate is 49%. The components of the powder core are stirred evenly and then rolled into Φ4.4 flux-cored welding wire, and the diameter i...

Embodiment 3

[0062] During production, weigh and weigh ferroboron, graphite, high-carbon ferrochrome and alloy powder according to the composition and ratio requirements of the powder core, and all the powders are passed through a 60-mesh sieve. The flux-cored wire was prepared and formed on the YHZ-1 flux-cored wire forming machine manufactured by Tianjin Sanying Welding Co., Ltd. The outer sheath of the flux-cored wire is H08A cold-rolled steel strip (16mm×0.36mm), and the sheath is equipped with graphite, metal and alloy powder to form a powder core. The composition (weight percentage) of the powder core is: boron iron 45%, high Carbon ferrochrome 35%, titanium iron 9%, flake graphite 2.5%, superfine graphite 0.5%, medium carbon ferromanganese 4%, ferrosilicon 3%, reduced iron powder 1%, the filling rate of the powder core is 51% . The components of the powder core are stirred evenly and then rolled into Φ4.4 flux-cored welding wire, and the diameter is reduced by 0.2mm each time, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com