Silicon carbide ceramic preform, aluminum-based silicon carbide ceramic material, and preparation method of silicon carbide ceramic preform

A silicon carbide ceramic and aluminum-based silicon carbide technology, which is applied in the field of silicon carbide ceramic preform and its preparation, aluminum-based silicon carbide ceramic material and its preparation field, can solve the problem of large shrinkage, low strength and poor structural uniformity of ceramic green body. problems, to achieve the effects of reducing environmental hazards, improving yield, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

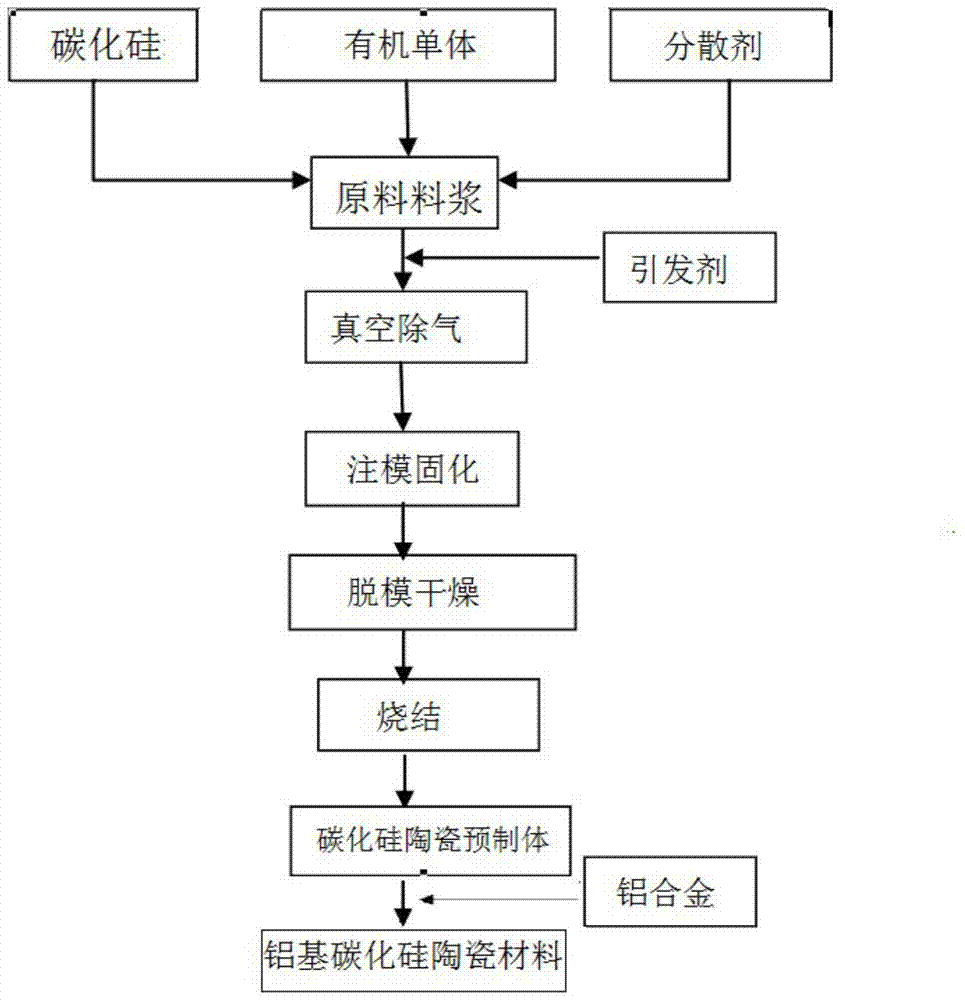

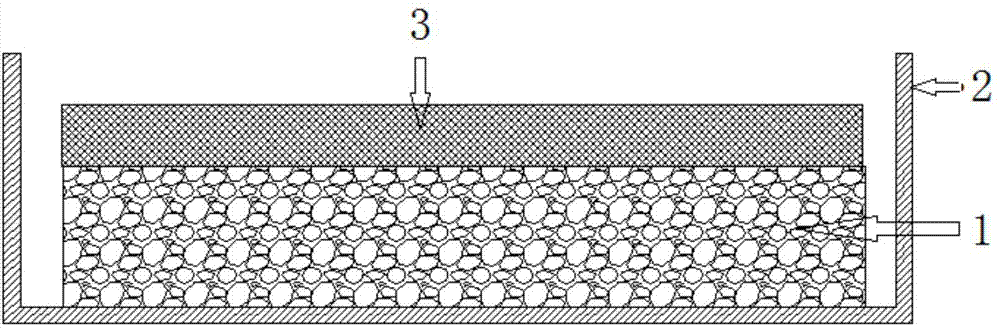

[0048] Specifically, an embodiment of the present invention provides a method for preparing a silicon carbide ceramic preform, the method mainly adopts a gel injection molding process, such as figure 1 As shown, it mainly includes the preparation of raw material slurry, adding initiator to the raw material slurry, vacuum degassing, injection molding and curing so that the monomer is polymerized into a macromolecular gel, demolding and drying, and sintering treatment steps, specifically including the following :

[0049] 1) Mixing the raw materials for preparing the silicon carbide ceramic preform evenly to prepare a raw material slurry. Wherein, the raw materials for preparing the silicon carbide ceramic preform include silicon carbide, dispersant, organic monomer and water.

[0050] In this step, the volume ratio of silicon carbide to raw material slurry is (40-70):100. The mass ratio of dispersant to silicon carbide is (0.5-2):100. The mass ratio of organic monomer to wat...

Embodiment 1

[0077] Prepare a silicon carbide preform of 65% volume fraction (herein, 65% volume fraction refers to the volume fraction of silicon carbide in the silicon carbide preform, the following is the same); the specific steps are as follows:

[0078] 1. Add 208.6 grams of silicon carbide particles with a particle size of 3-20 microns, 4 grams of acrylamide monomer, 1 gram of methylenebisacrylamide, 30 grams of water, and 2 grams of ammonia water into a stirring tank, and stir for 24 hours to obtain Raw material slurry.

[0079] 2. Add 1.2 g of azobisisoheptylcyanide to the raw material slurry, and stir for 30 minutes to obtain a ceramic slurry.

[0080] 3. Place the ceramic slurry in a vacuum degassing tank, and perform vacuum degassing on the ceramic slurry; among them, keep the vacuum degree in the vacuum degassing tank at 5×10 -2 Pa, the time of vacuum degassing is 5 minutes.

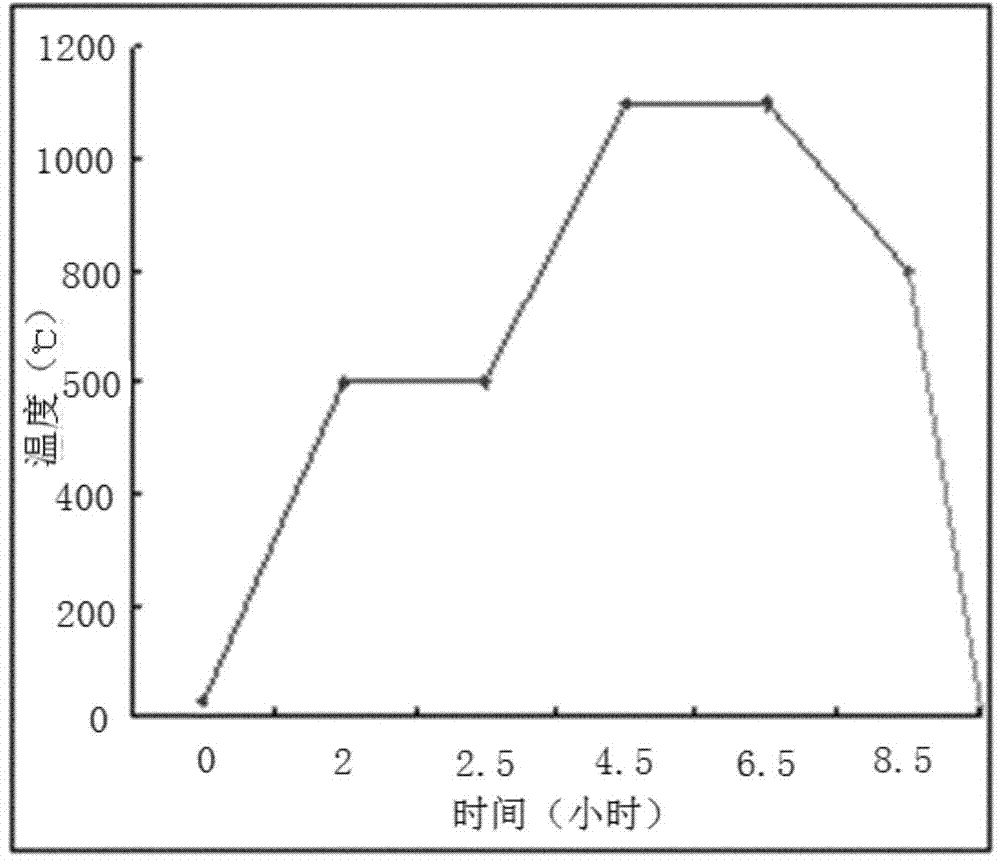

[0081] 4. Inject the vacuum-degassed ceramic slurry into a non-porous mold, and place it in an oven ...

Embodiment 2

[0084] Prepare a silicon carbide preform with a volume fraction of 60%; the specific steps are as follows:

[0085] 1. Add 1926 grams of silicon carbide particles with a particle size of 10 microns, 66 grams of carbon powder, 40 grams of acrylamide monomer, 10 grams of methylenebisacrylamide, 320 grams of water, and 19 grams of ammonia water into the mixing tank, and stir A raw material slurry was obtained after 24 hours.

[0086] 2. Add 11 grams of azobisisoheptylcyanide to the raw material slurry, and stir for 30 minutes to obtain a ceramic slurry.

[0087] 3. Place the ceramic slurry in a vacuum degassing tank, and perform vacuum degassing on the ceramic slurry; among them, keep the vacuum degree in the vacuum degassing tank at 5×10 -6 Pa, the time of vacuum degassing is 5 minutes.

[0088] 4. Inject the vacuum-degassed ceramic slurry into a non-porous mold, and place it in an oven at 70°C for 3 hours to keep the ceramic slurry solidified, and then place it in a dry phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com