Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

864 results about "Nanoceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanoceramic is a type of nanoparticle that is composed of ceramics, which are generally classified as inorganic, heat-resistant, nonmetallic solids made of both metallic and nonmetallic compounds. The material offers unique properties. Macroscale ceramics are brittle and rigid and break upon impact. However, nanoceramics take on a larger variety of functions, including dielectric, ferroelectric, piezoelectric, pyroelectric, ferromagnetic, magnetoresistive, superconductive and electro-optical.

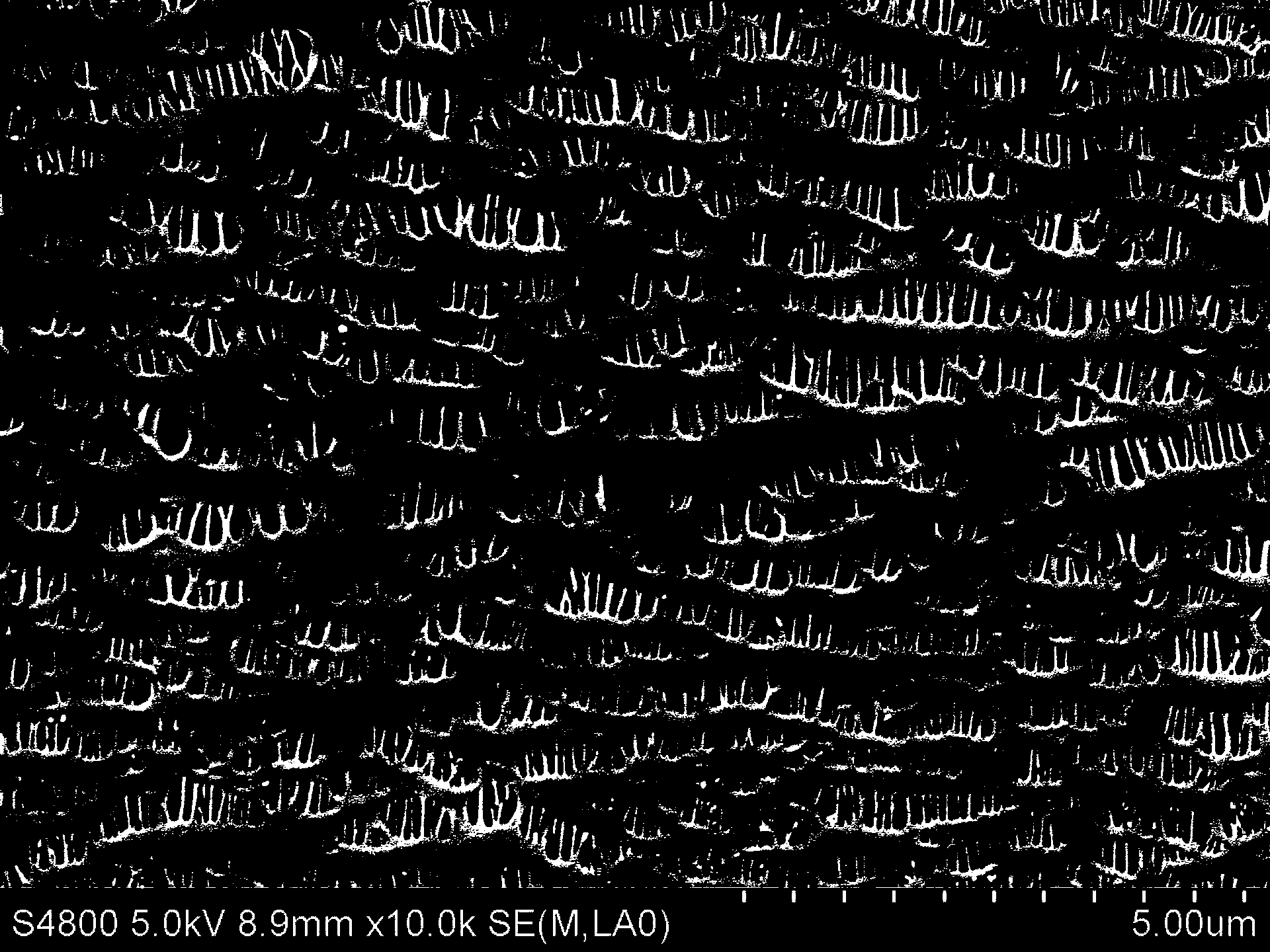

Method for preparing nano ceramic fibers

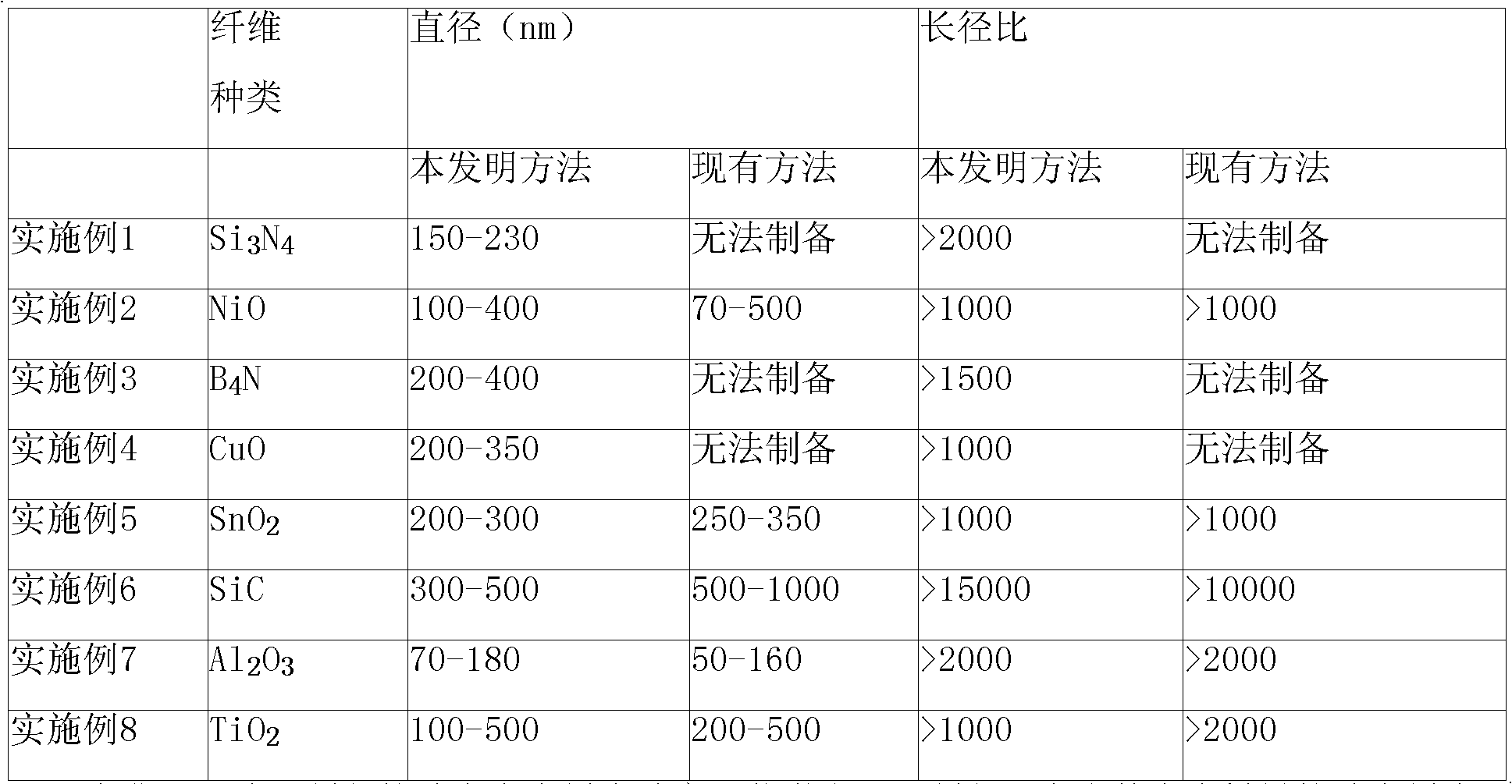

InactiveCN101880917AAverage diameter distributionHigh aspect ratioInorganic material artificial filamentsFilament/thread formingFiberWater baths

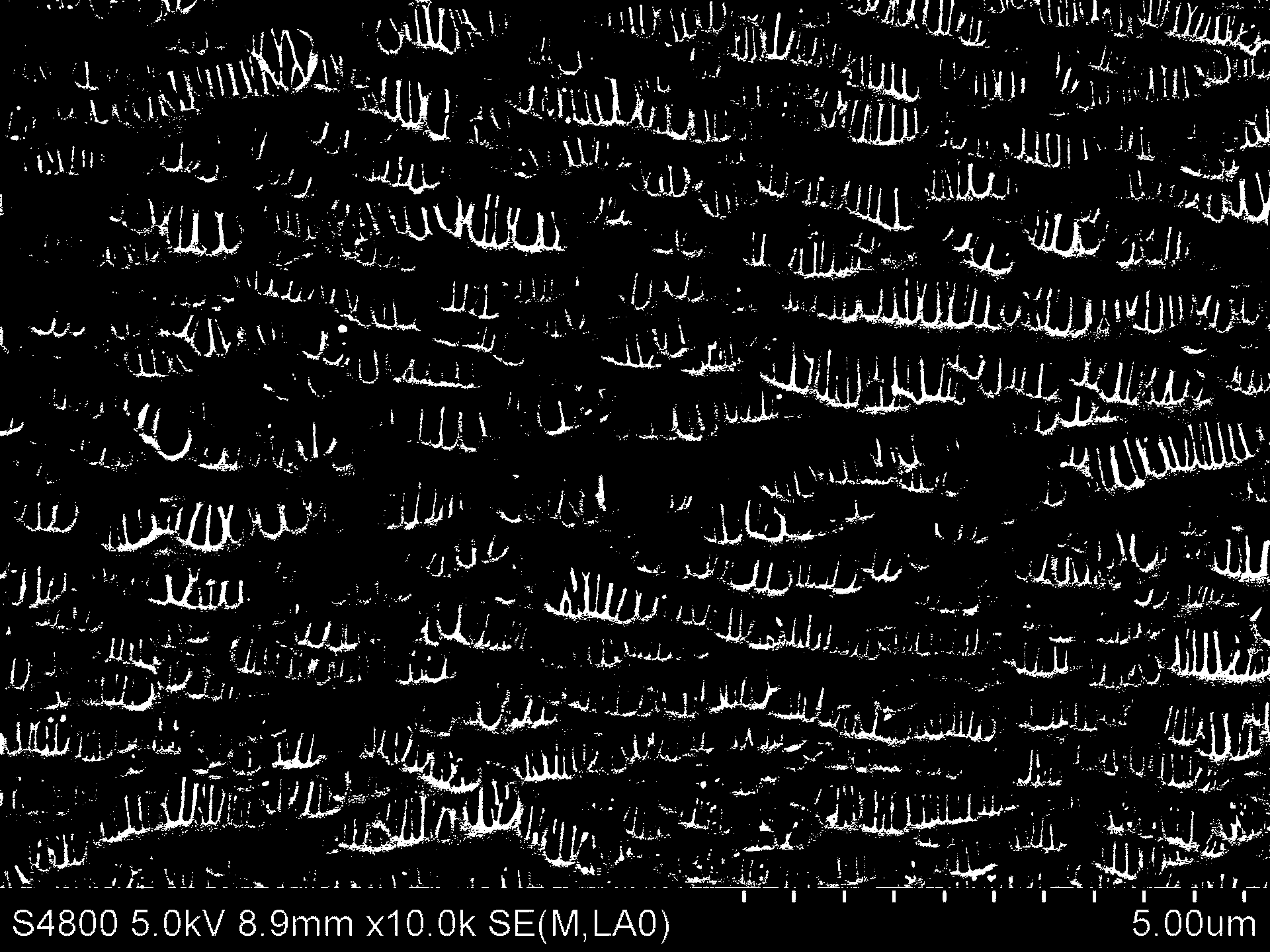

The invention discloses a method for preparing nano ceramic fibers, which is implemented by the following steps: 1, preparing 3 to 15 volume percent of 10 to 30 nanometer ceramic nanoparticles, 5 to 30 volume percent of spinnable high polymer, 0.5 to 5 volume percent of dispersant and the balance of solvent, wherein the total volume of the raw materials is 100 volume percent; 2, adding the spinnable high polymer into the solvent, heating the mixture in a water bath with magnetic stirring to obtain solution of spinnable high polymer; 3, adding the ceramic nanoparticles and the dispersant into the solution of spinnable high polymer obtained by the step 2, keeping the temperature of the mixture constant in a water bath, performing dispersion and ultrasonic dispersion, and performing swelling at a constant temperature to obtain ceramic nanoparticle / spinnable high polymer / solvent spinning solution; 4, controlling the electrostatic spinning process parameters of the spinning solution obtained by the step 3 to obtain nano fibers; and 5, sintering the nano fibers at 400 to 1,200 DEG C to obtain nano ceramic fibers.

Owner:XIAN UNIV OF TECH

Angioplasty super balloon fabrication with composite materials

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

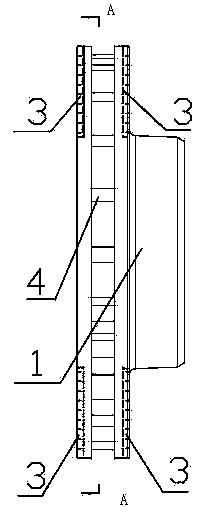

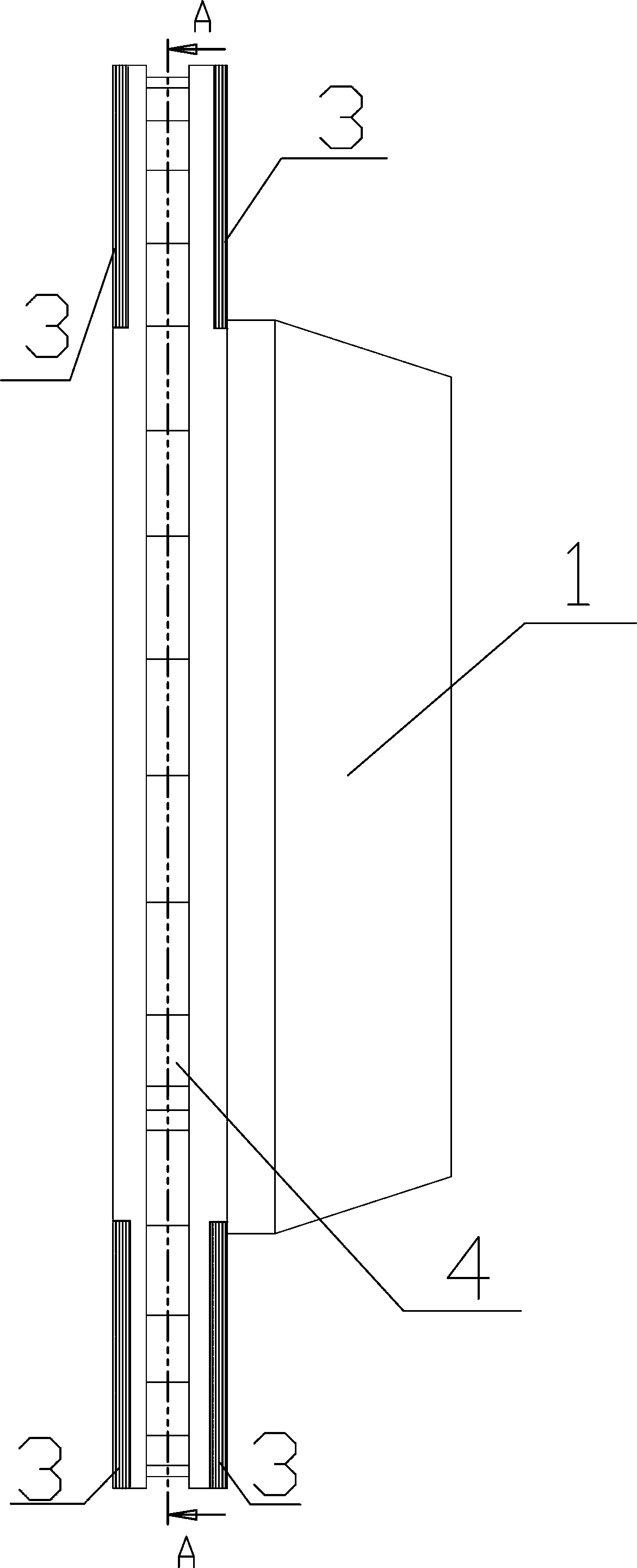

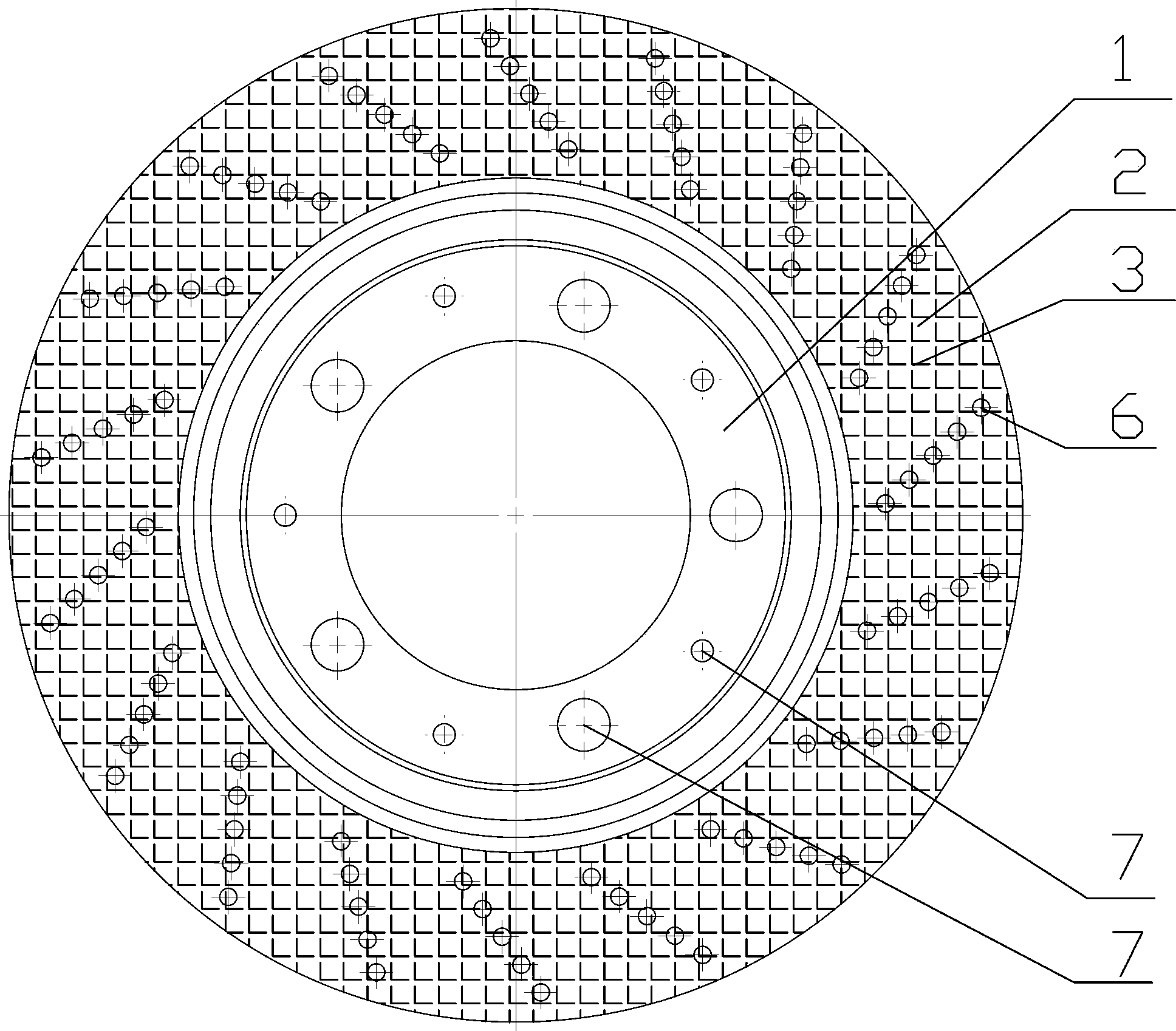

Road vehicle brake disc made of carborundum foamed ceramics/aluminum alloy composite materials and production method of road vehicle brake disc

ActiveCN104235237AReduce weightImprove feeding capacityBraking membersSlack adjustersNanoceramicAlloy composite

The invention discloses a road vehicle brake disc made of carborundum foamed ceramics / aluminum alloy composite materials and a production method of the road vehicle brake disc. The body of the reinforced-aluminum-alloy brake disc with a carborundum foamed ceramics framework is made of reinforced aluminum alloy materials such as aluminum alloy or nano ceramics particles or carbon nano-tubes. The carborundum foamed ceramics framework is integrally casted on two symmetrical friction surfaces of the brake disc, and heat dissipation grooves or air holes can be casted or do not need to be casted on the friction surfaces. A plurality of heat dissipation ribs are casted in the peripheral direction of non-friction surfaces. Mounting holes are formed in the disc body. The production method includes the steps of production of the carborundum foamed ceramics framework, preprocessing of the framework, design and production of a casting mold of the brake disc, lower-pressure casting of the brake disc, heat treatment of the brake disc, precision processing of the brake disc and storage of a finished product. The brake disc is simple in production technology, light in weight, high and stable in friction factor, high in heat conductivity, long in service life and applicable to existing road vehicles.

Owner:SHIJIAZHUANG DONGDA HUITONG NEW MATERIAL CO LTD

Nanometer ceramic material used for 3D printing and 3D printing molding method thereof

The invention discloses a nanometer ceramic material used for 3D printing and a 3D printing molding method thereof. By utilizing the high plasticity and the caking property of inorganic clay, inorganic clay is taken as a binder, and a nanometer ceramic particle and inorganic clay are combined, so that the nanometer ceramic material used for 3D printing is obtained. Then 3D printing molding is performed and also laser sintering is employed, a nano-scale ceramic crystal grain is formed by sintering inorganic clay, and a nanometer ceramic product is prepared from the nano-scale ceramic crystal grain and the nanometer ceramic particle. The molding method is simple in technology, is easy for industrialized production, promotes popularization and application of the 3D printing molding technology in life, and possesses wide market prospect.

Owner:HARBIN UNIV OF SCI & TECH +1

Nano ceramic water-proof climate resisting high mechanical strength protection layer paint

InactiveCN100999645AImprove waterproof performanceGood weather resistanceAntifouling/underwater paintsGeneral water supply conservationWeather resistanceUltimate tensile strength

The present invention discloses one kind of nanometer antiweathering and waterproof ceramic paint with high mechanical strength and its preparation process and application. The paint consists of filming material, stuffing, assistant and modifying nanometer powder preferably in the weight ratio of 20-60 to 30-65 to 1-5 to 1-10. The paint of the present invention has excellent waterproof performance, high weather resistance, high mechanical strength and easy use, and may be used as the protecting layer of high temperature pipeline.

Owner:孙启明

Composite membrane for lithium ion batteries and preparation method thereof

ActiveCN103956450AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-to process under the action of a dehydrating agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:DONGFANG ELECTRIC CORP LTD

Nanometer ceramic spring producing method

InactiveCN1472448ASolve the problems of industrial productionSimple processLow internal friction springsHigh volume manufacturingSlurry

A process for preapring nano ceramic spring includes such steps as mixing ZrO2 nanoparticles with premixed liquid, ball grinding, vacuum deaerating, adding trigger moulding, solidifying demoulding, drying, heating to 700-1200 deg.C for 0.5-2 hr, degumming, immersing in slurry for 10-30 min, putting in supporter in powder, and sintering at 1400-1700 deg.C for 0.5-3 hr.

Owner:NANJING TECH UNIV

Filter plate of porous ceramic covered by Nano ceramic membrane filter, and fabricating method

InactiveCN101092307AAvoid easy cloggingExtended service lifeCeramicwareCzochralski methodNanoceramic

This invention discloses a porous ceramic filtration plate coated with nanoscale ceramic filtration film for liquid-solid separation. The nanoscale ceramic filtration film is prepared by: hydrolyzing aluminum isopropoxide, preparing a sol with HNO3, refluxing, aging to form aluminum sol, adding Al2O3 nanopowder, mixing, dispersing to form uniform nanoscale film gel, uniformly coating onto the surface of a substrate by Czochralski method, drying and sintering. The obtained porous ceramic filtration plate can effectively block the majority of fine particles in ore slurry, and has such advantages as no blockage, long service life and wide applications.

Owner:江苏省陶瓷研究所有限公司

Nano ceramic high-temperature-resistant thermal-insulation coating, and its preparing method and use

InactiveCN1935912AAchieve insulation effectImprove insulation effectFireproof paintsMicrosphereThermal insulation

The invention discloses new nanometer ceramic high temperature resistant heat preservation paint and the preparing method and use. Its components part by weight are as follows: film forming matter 10-35, filling 50-75, ceramic micro-balloon 8-50, and modified nanometer material 3-12. The produced nanometer ceramic high temperature resistant heat preservation paint can prevent solid heat transfer and radiant heat transfer, thus it can greatly improve heat preservation effect. And its high temperature resistant can reach 1000 degree centigrade.

Owner:王继征

Nano ceramic coating with high emissivity

The invention discloses a nano ceramic coating with high emissivity, which is prepared from a high temperature resistant basic material, an additive with high emissivity, a binder, a stabilizing agent and a solvent. The high temperature resistant basic material and the additive with high emissivity are one or several of alumina, silicon oxide, boron nitride, silicon carbide, ferric oxide and cerium oxide. The binder is one or several of silica gel, potassium silicate solution, aluminium phosphate solution, silicon oxide hydrate, ethanol and water. By weight percentage, the high temperature resistant basic material and the additive with high emissivity account for 5-78%, the binder accounts for 5-30%, the stabilizing agent accounts for 0.5-3% and the balance of solvent is water. The coating which can be used above 1300 DEG C has the advantages of being wide in work temperature range with the maximum service temperature close to 2000 DEG C, applicable to various base materials, strong in adhesive force to the base materials, applicable to reaction atmosphere, good in long-time durability and strong in heat shock endurance, improving thermal efficiency, lowering temperature of the base materials, and being excellent in abrasion and corrosion resistance, less in impact on environment, convenient to use and the like.

Owner:赵凯

Nano ceramic composite thin polypropylene multifunction fiber and preparing method

ActiveCN101070635AFunctionalImprove economyMonocomponent polyolefin artificial filamentProtective garmentCeramic compositeThermal insulation

The invention discloses nano-ceramic composite fine polypropylene fiber and the processing method. The fiber contains nano-ceramic powder with 12-45 of 300, polypropylene with 250-270 of 300, polyethylene wax with 2-18 of 300 by weight. The denier of the fiber monofilament is 0.5-1.5D, the breaking strength is more than 2.5cN / dtex. We can get the fiber by the step of nano-ceramic powder aqueous dispersion, pre-dispersed precursor, composite masterbatch, composite sections, and high-speed spinning. The nano-ceramic powder is made up of ZrO2, or ZrO2 and ZrC, or TiO2 and Ag+. This type of fiber can be made of various type of textiles, such as sports apparel, underwear, bedding, shirt, socks and so on. The textiles with the function of launch biological waves of energy, anti-UV, anti-bacterial, absorption and barrier the near-infrared. So that to make the textiles have the function of anti-bacterial, energy health, insulation sunscreen, regenerative thermal insulation, dry and comfortable and so on.

Owner:吴进前

Nano ceramic water-base gel casting method

The invention relates to a nano-ceramic water-based gelcasting method. It first models the nano-ceramic powder in the method of gelcasting, and then presses the drying biscuit in the mould to form the model. This invention greatly improves the density of nanometer ceramic biscuit and its microstructure.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for crack resistant treatment of laser cladded nano-ceramic coating

InactiveCN1542166AImprove toughnessGood mechanical propertiesMetallic material coating processesCeramic coatingNanoceramic

The treating process of laser smelting and coating nano anti-cracking ceramic coating onto the surface of metal substrate includes the following steps: bottoming the metal surface to be treated; spraying nano ceramic grain material; painting nano laser absorbing paint; and smelting and coating with high power CO2 laser under protecting Ar atmosphere. The nano anti-cracking ceramic coating formed on the surface of metal substrate has excellent physical and chemical performance.

Owner:SHANGHAI UNIV OF ENG SCI

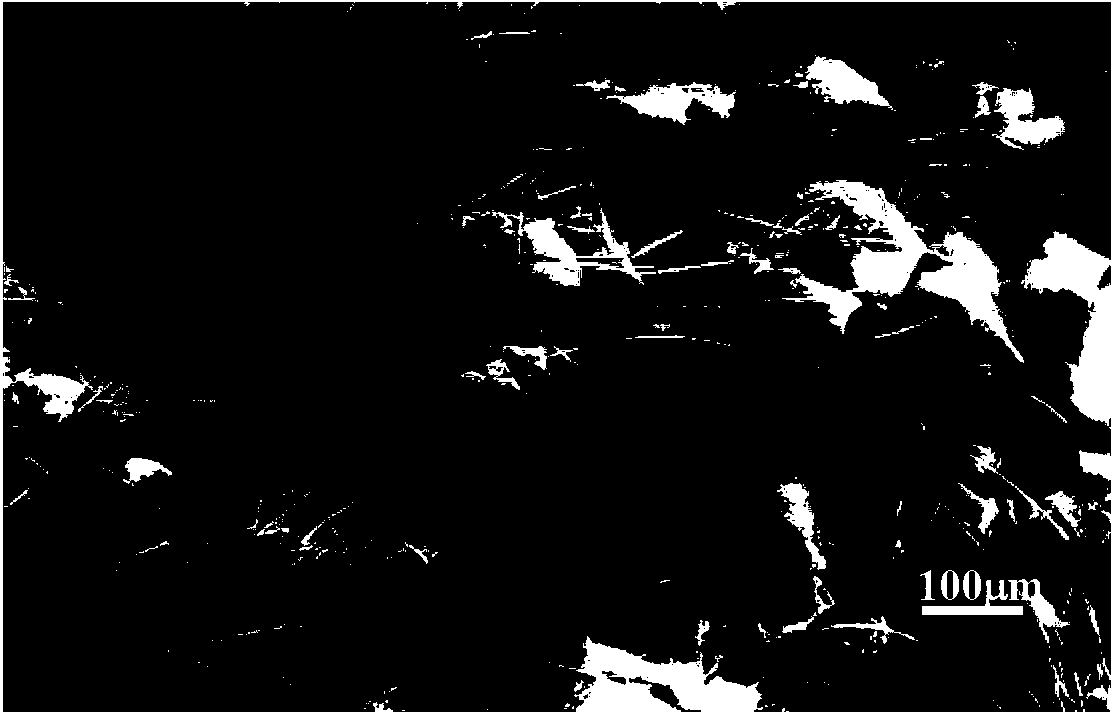

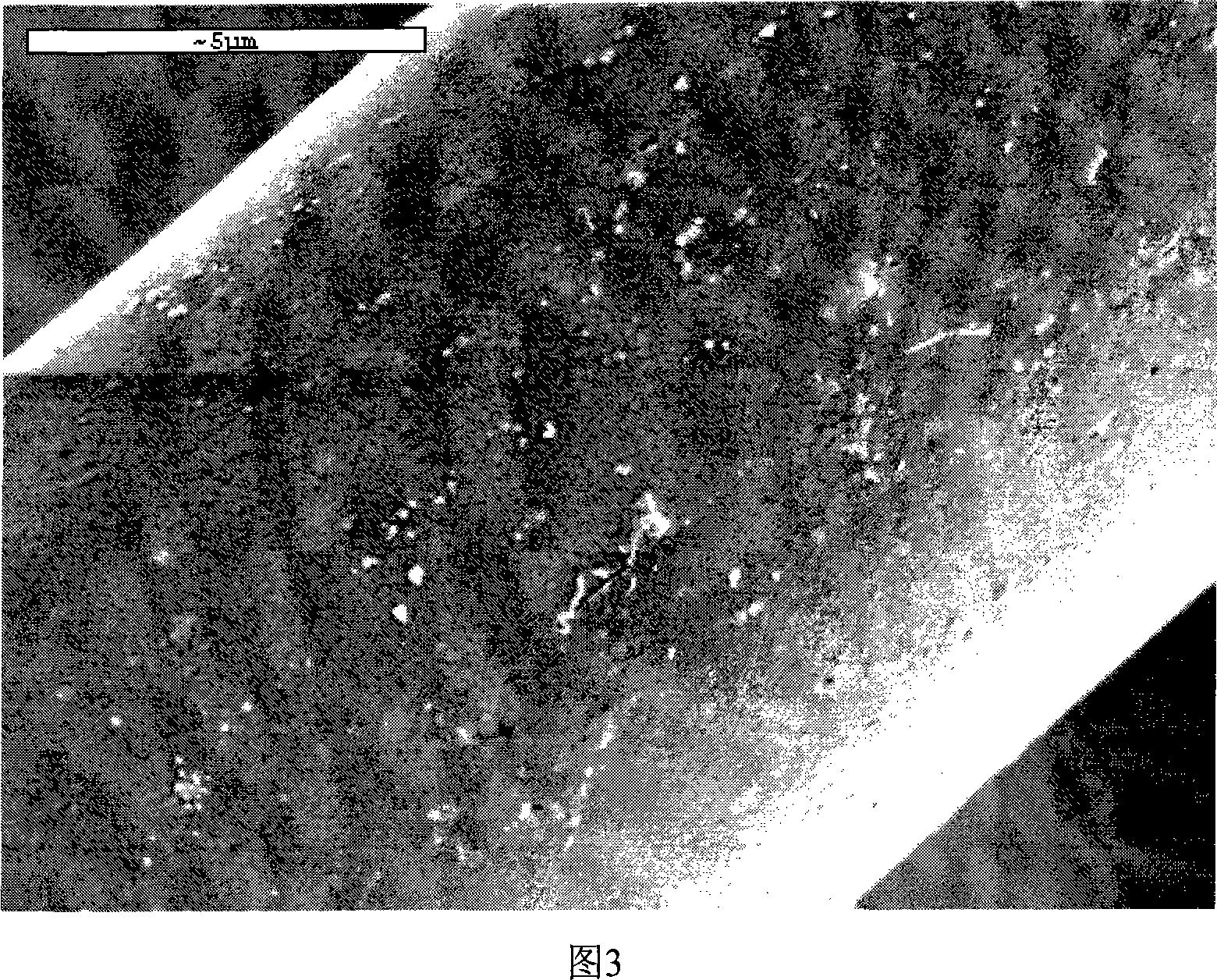

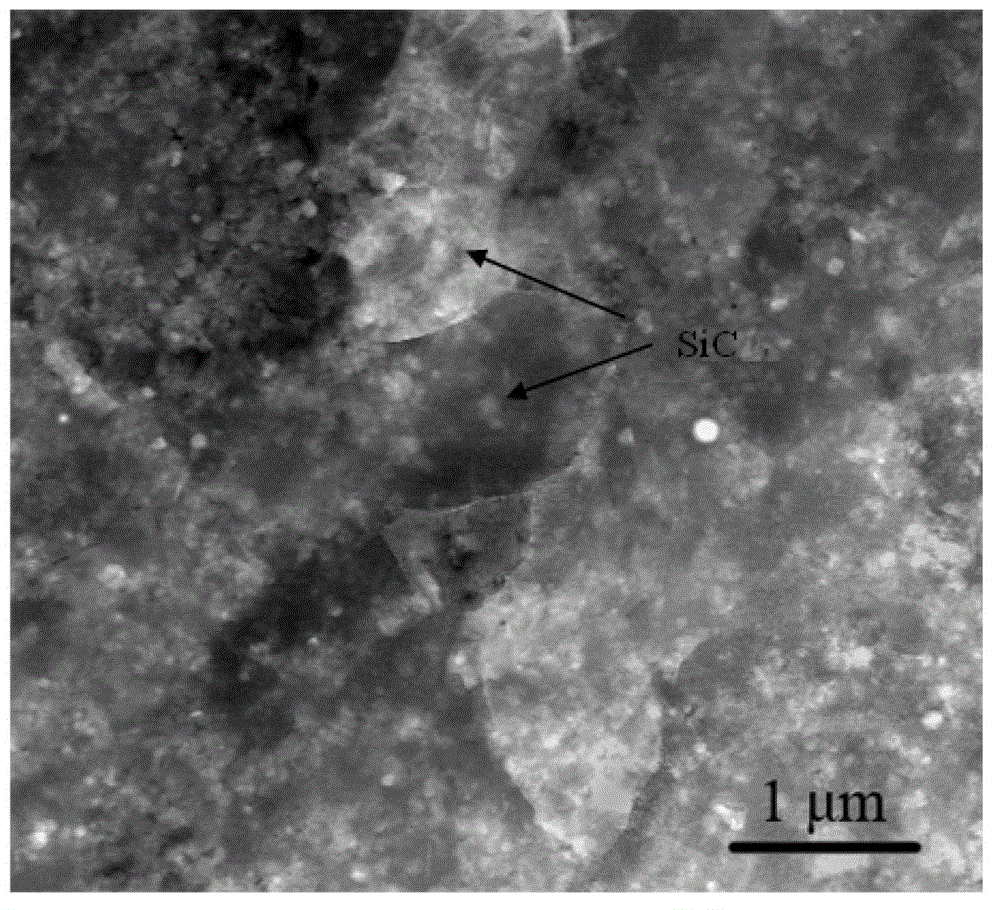

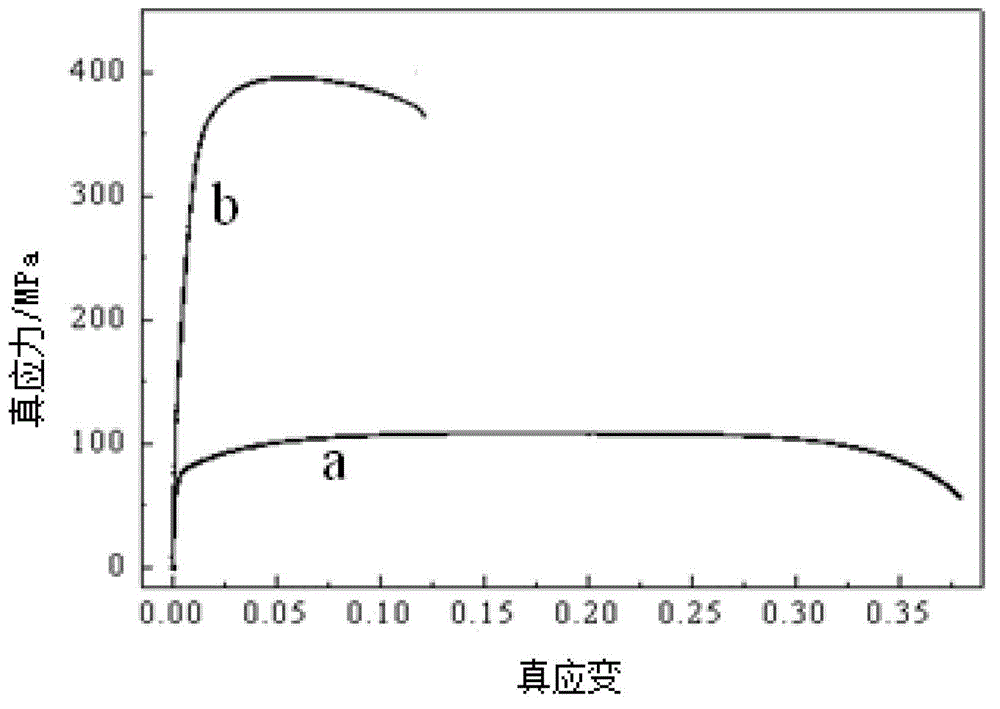

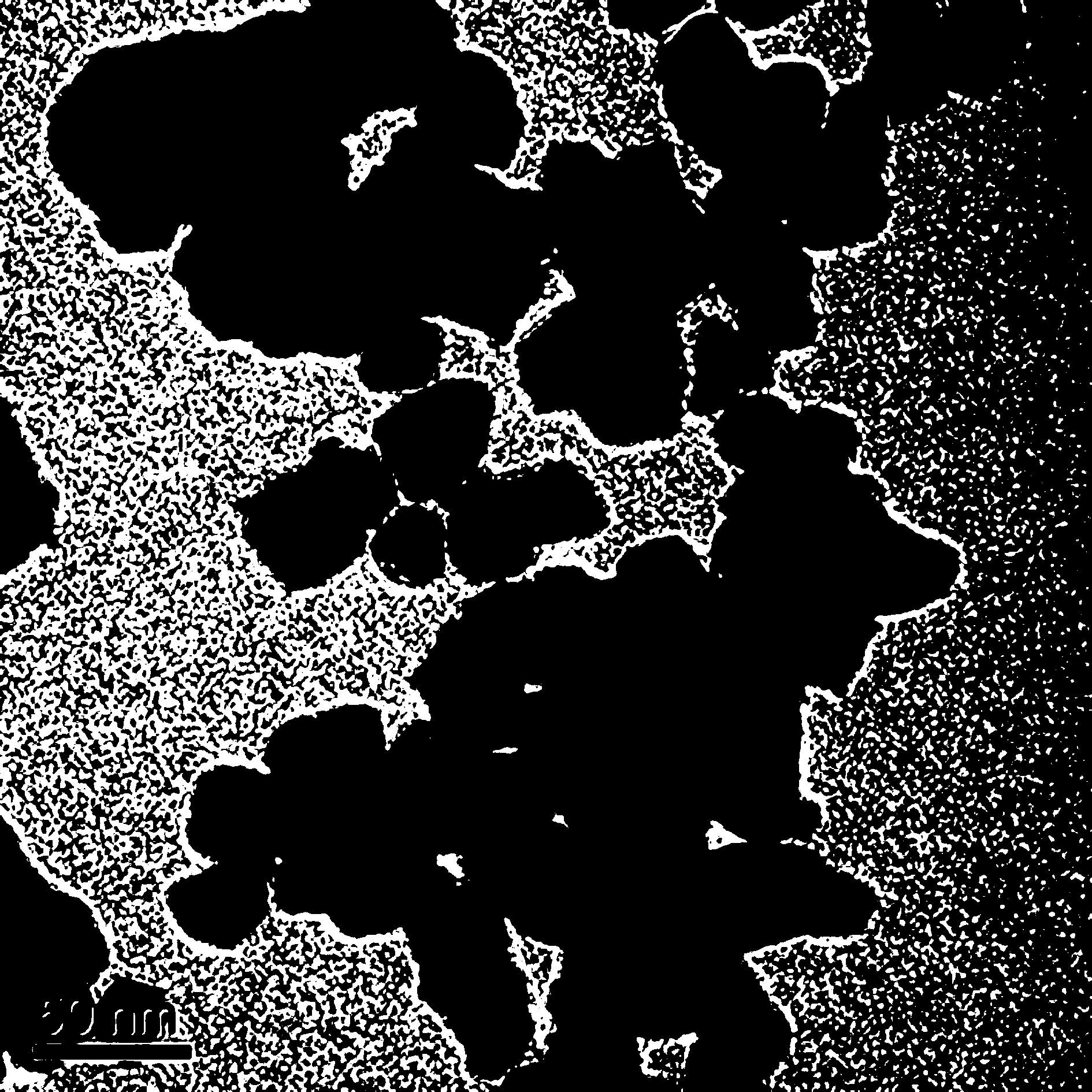

Reinforced intragranular aluminum matrix composites with nano ceramic particles added externally and preparation process thereof

InactiveCN102747254AAvoid the tendency to easily distribute on grain boundariesEvenly distributedNanoparticleNanoceramic

The invention relates to reinforced intragranular aluminum matrix composites with nano ceramic particles added externally and a preparation process thereof. According to composites and the preparation process, the problems that particle sizes of nano particle reinforced aluminum matrix composites prepared by an existing in-situ method is hard to be controlled within the nanoscale range and nano particle reinforced aluminum matrix composites prepared by an existing external addition method are grain-boundary type nano particle reinforced aluminum matrix composites and low in strength and plasticity are solved. The preparation process comprises 1, weighing out constituents, and adding stearic acid which accounts for 0.6-8% of the gross mass to conduct ball milling; 2, conducting vacuum hot pressed sintering to form blocks after ball milling; and 3, conducting hot extrusion deformation on blocks to obtain nano ceramic particle reinforced aluminum matrix composites. Composites prepared bythe process are high in strength and good in plasticity. Composites and the preparation process are applicable to the field of preparation of aluminum matrix composites.

Owner:HARBIN INST OF TECH

Nano ceramic cutter and preparation method thereof

ActiveCN103708832AImprove anti-aging propertiesPrimary particle size ultra-fineNanoceramicYttria-stabilized zirconia

The invention relates to a nano ceramic cutter and a preparation method thereof. The composition of the nano ceramic cutter can be yttrium oxide stabilized zirconium oxide including synergic doping of one or more third components among aluminum oxide, magnesium oxide, calcium oxide and titanium oxide; and the nano ceramic cutter specifically comprises the following components: 80-95wt% of zirconium oxide, 2-8wt% of yttrium oxide, 0-20wt% of aluminum oxide, 0-5wt% of magnesium oxide, 0-4wt% of calcium oxide, 0-0.5wt% of titanium oxide and 0-2wt% of other rare-earth oxides. After the green body of the nano ceramic cutter prepared through the method is calcined at 1300-1350 DEG C, the theoretical density is up to 99.7%; the nano ceramic cutter is high in bending strength and favorable in fracture toughness; and the process is simple and easy to realize large-scale production.

Owner:YAAN YUANCHUANG CERAMIC

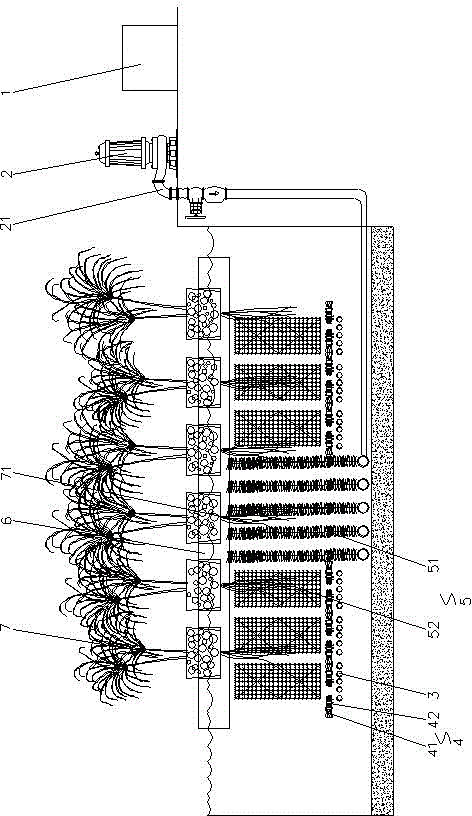

Water environment ecological management and rehabilitation system and application thereof

ActiveCN104418427AIncrease dissolved oxygenImprove liquidityTreatment using aerobic processesTreatment with aerobic and anaerobic processesMicroorganismSolar water

The invention discloses a water environment ecological management and rehabilitation system. The water environment ecological management and rehabilitation system comprises a solar water-quality detection controller, an air pump, nano-microporous ceramic aerators, hydraulic impellers and biological grilles, wherein the solar water-quality detection controller is respectively connected with the air pump, the nano-ceramic aerators and the biological grilles, the air pump is connected with the nano-ceramic aerators, the hydraulic impellers are arranged above the nano-ceramic aerators, the biological grilles are arranged above the hydraulic impellers, floating-type ecological floating beds floating on the water surface are arranged above the biological grilles and the nano-ceramic aerators are respectively connected with the hydraulic impellers, the biological grilles and the floating-type ecological floating beds. By the water environment ecological management and rehabilitation system disclosed by the invention, the intelligent braking control is achieved and the system is very convenient to mount, use and manage, low in cost, free of noise and efficient to manage. Since the biological grilles and the ecological floating beds adopted in the system are attached with efficient and side-effect-free probiotics microbial flora and coenzyme, eutrophic organic and inorganic pollution sources in the water body can be decomposed.

Owner:FUJIAN FUYONGDE ENVIRONMENTAL TECH CO LTD

Composite ceramic membrane for lithium ion batteries and preparation method thereof

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

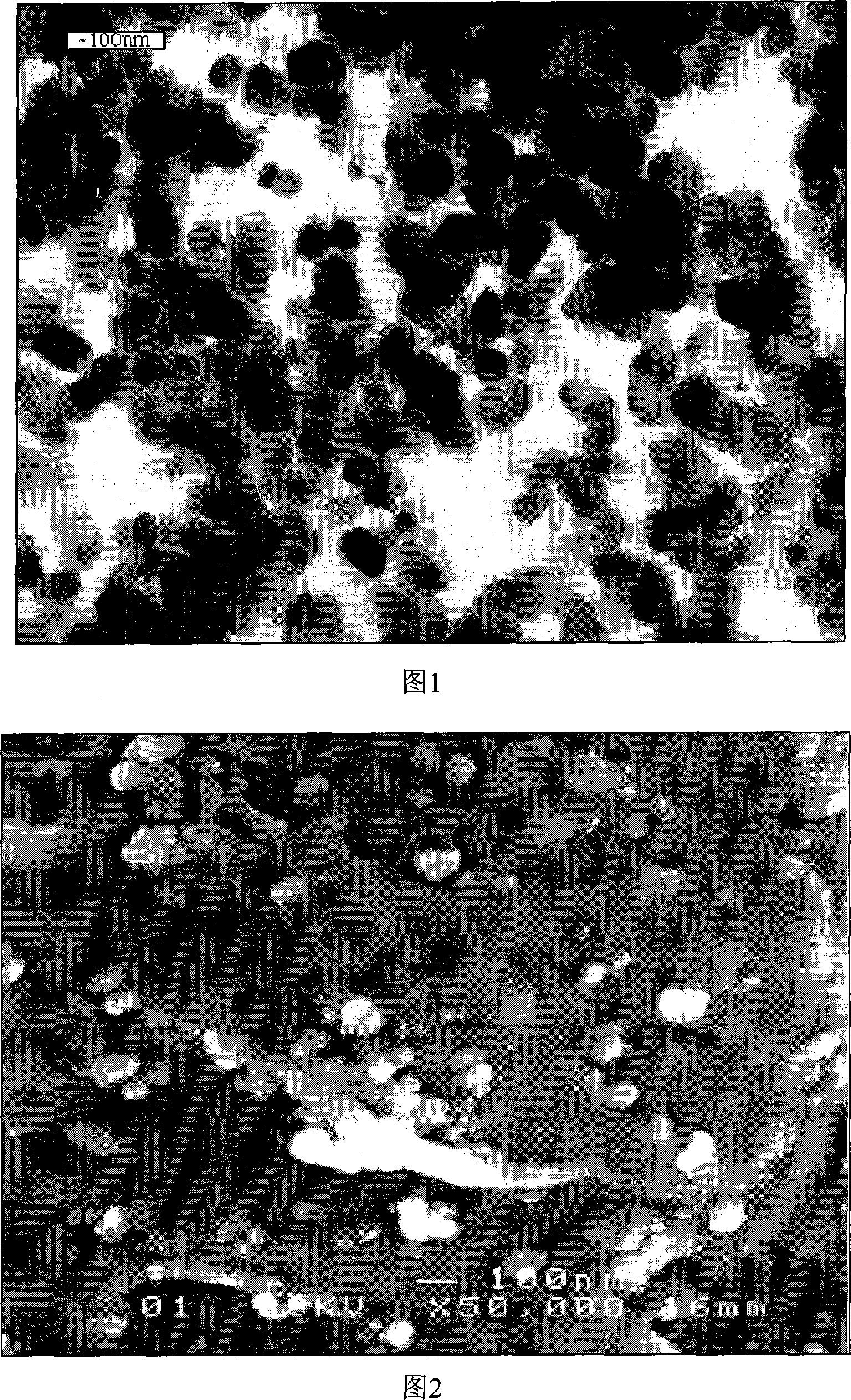

Mechanical process of preparing composite nanometer ceramic and micron metal powder

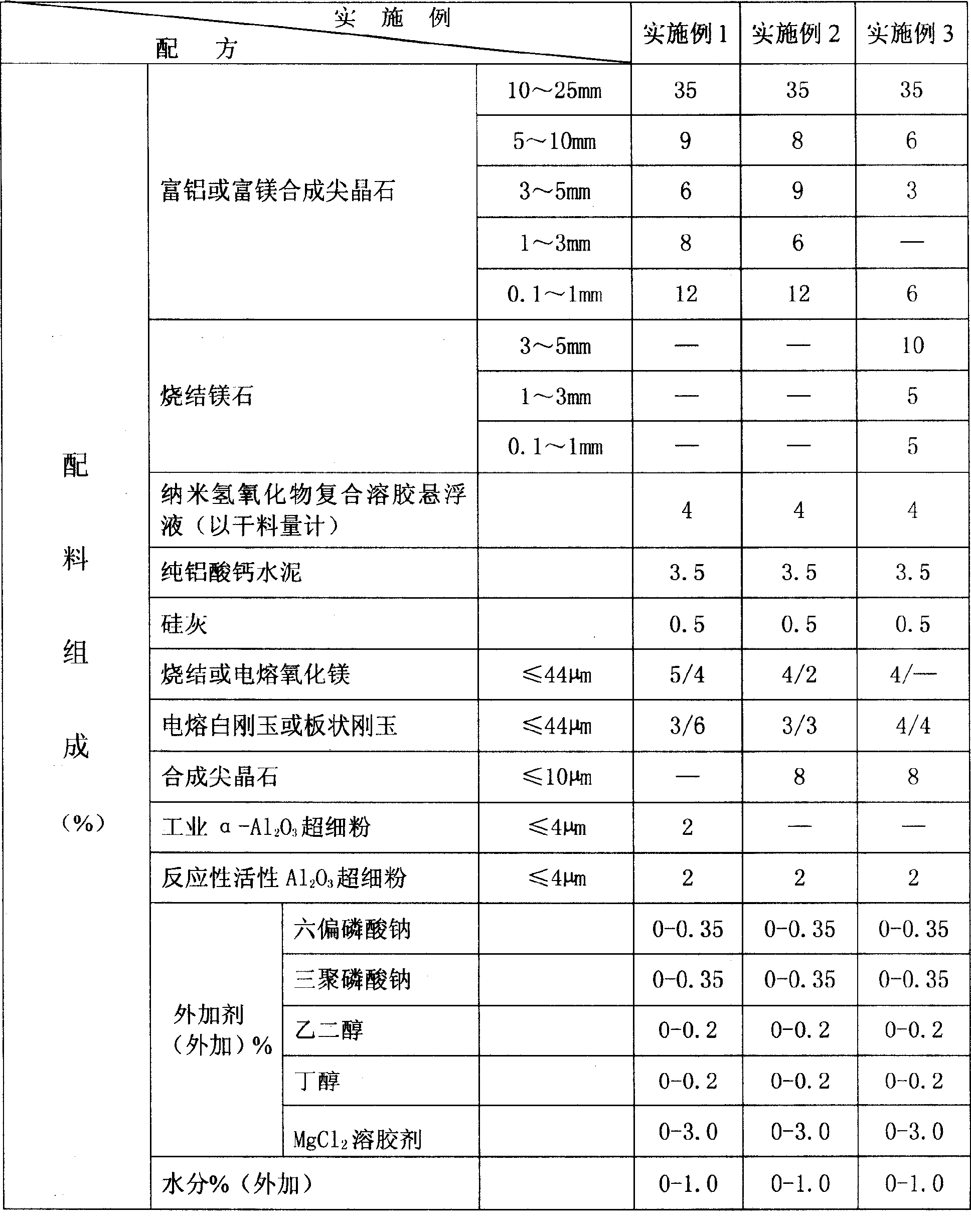

The present invention discloses mechanical process of preparing composite nanometer ceramic / micron metal powder. The composite nanometer ceramic / micron metal powder is prepared with marketable micron and nanometer powder as material, and through establishing the theoretical model of the weight ratio between the micron powder and the nanometer powder, preparing stable suspension of nanometer ceramic powder, mixing the nanometer suspension and the micron powder, and mechanical compounding. The process has simplicity, short treating time, easy control, continuous production and other features, and is suitable for engineering application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nano Al2O3 and MgO composite ceramic bonded spinel-magnesia fireproof casting material and preparation method thereof

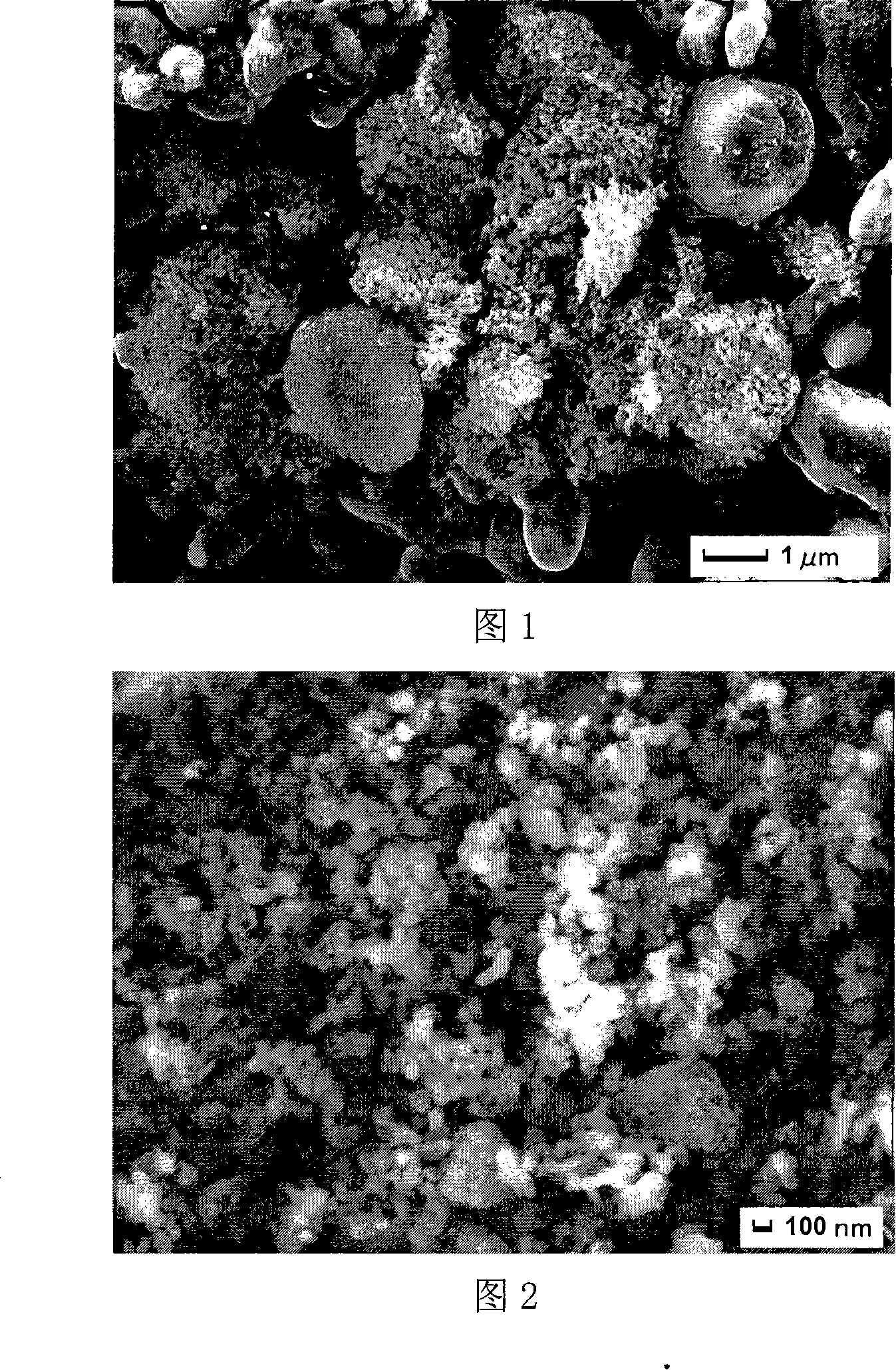

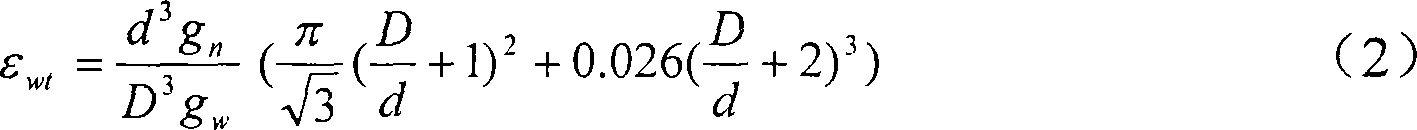

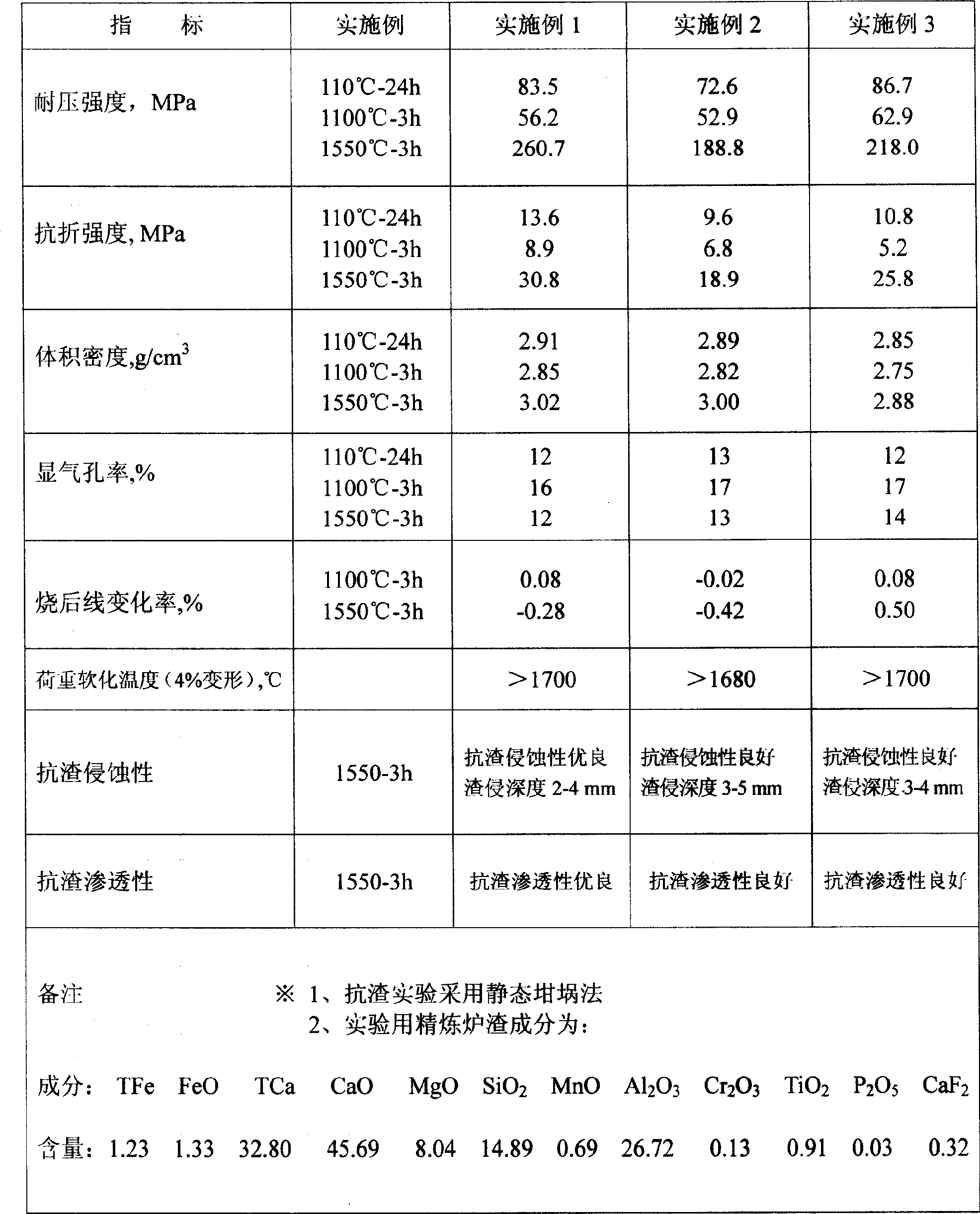

The invention relates to a nano Al2O3 and MgO composite oxide ceramic bonded spinel-magnesia fireproof casting material and a preparation method thereof. Al(OH)3 and Mg(OH)2 composite sol suspension is used as a nano ceramic bond, directly added into a mixture and subjected to in-situ synthesis reaction to form a nano structural matrix using spinel and magnesia as main components so as to form the nano spinel-magnesia fireproof casting material. The mixing materials of the casting material are characterized in that the spinel is used as aggregate or proper amount of sintered magnesia of less than or equal to 5 millimeters is added into the spinel aggregate to improve the total MgO content of the casting material; and the matrix material consists of a nano ceramic bond system, magnesia, little AlO3 with different properties and admixture, wherein after the synthesis reaction of the secondary spinel, the matrix material swells and is densified under constraint so as to cause the improvement of macrostructure and microstructure, improvement of performance and enhancement of durability and form the spinel-magnesia casting material with more excellent corrosion resistance and soakage resistance. The casting material is used in slag lines in integral secondary refining ladles, and obtains good using effect.

Owner:高树森

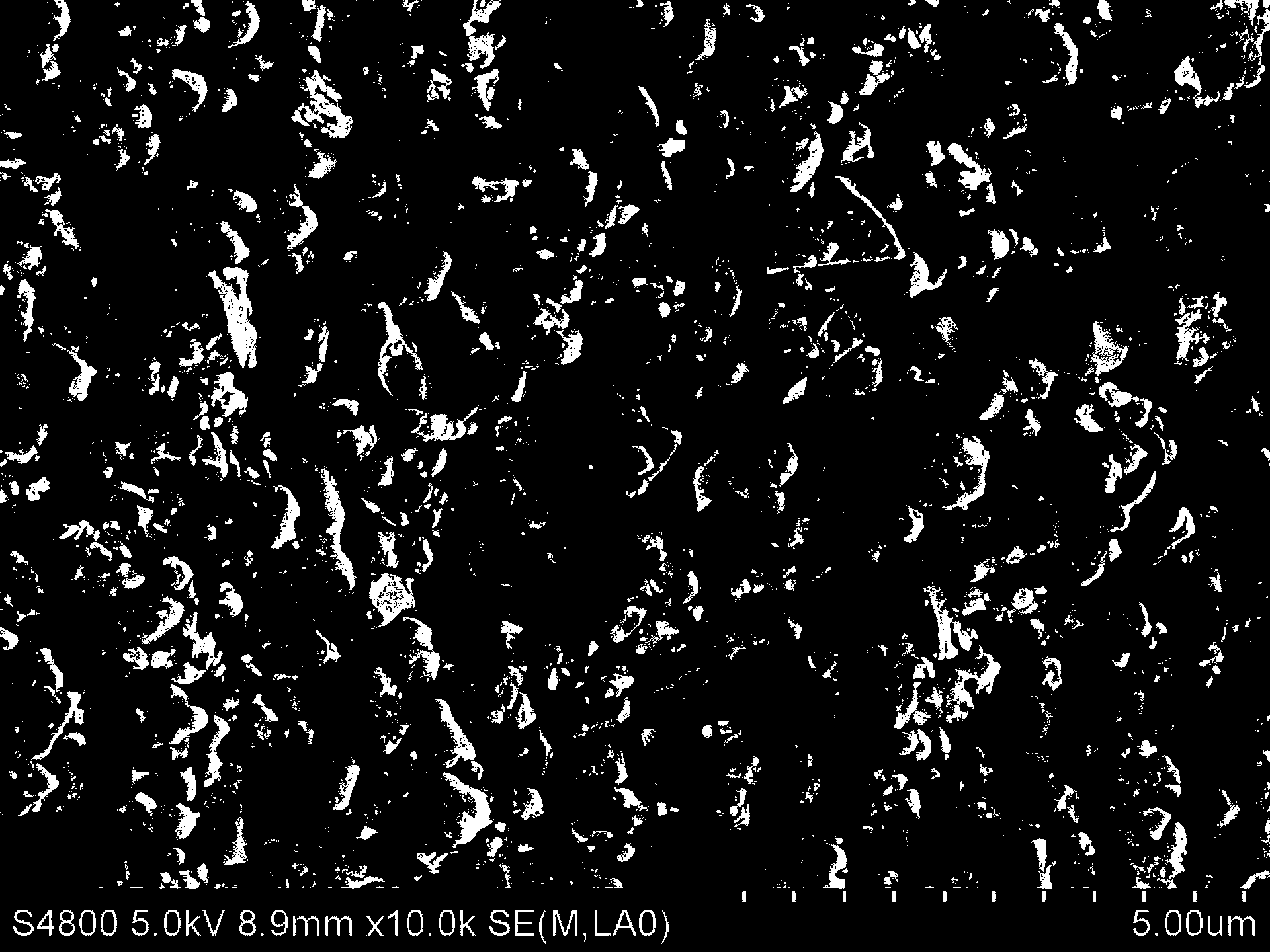

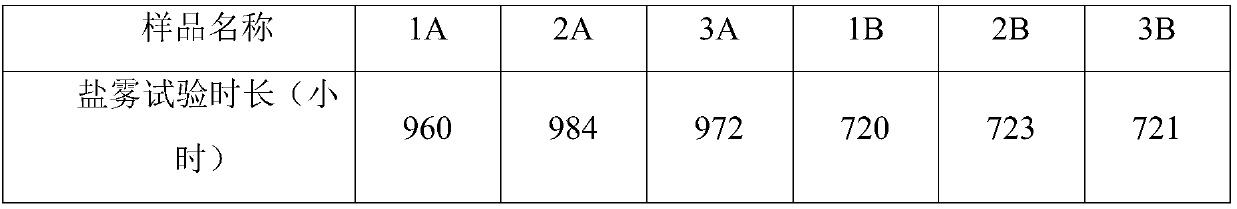

Preparation method of sintered nd-fe-b magnet surface wearproof anticorrosive coating

The invention relates to a preparation method of a sintered nd-fe-b magnet surface wearproof anticorrosive coating. The preparation method comprises the following steps: preparing the wearproof anticorrosive coating material; preheating a sintered nd-fe-b magnet; and then, adopting the electrostatic spraying technology to coat the surface of the sintered nd-fe-b magnet with the prepared wearproofanticorrosive coating material and finally carrying out curing treatment. According to the preparation method, the wearproof anticorrosive coating is prepared on the surface of the sintered nd-fe-b magnet; the wearproof anticorrosive coating prepared by combining the respective advantage of organic polymer materials and nano-ceramics has higher mechanical property and corrosion resisting property,can provide longer corrosion prevention function to the sintered nd-fe-b magnet and can meet the using requirements of the working environment with strength and hardness requirements.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

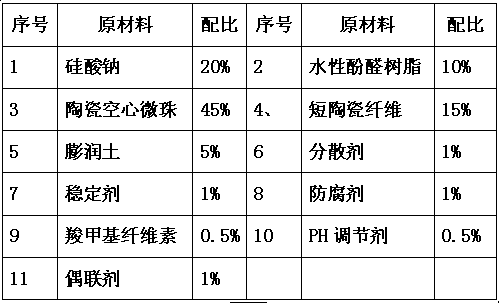

High-temperature-resistant heat insulation coating

The invention discloses a high-temperature-resistant heat insulation coating which has the temperature-resistant range of -80 DEG C to 1800 DEG C and the heat conduction coefficient of 0.03W / m.K only at 70 DEG C and has the characteristics of acid and alkali resistance, wear resistance, pressure resistance, watertightness, insulativity, fire prevention, mildew prevention, corrosion prevention, convenience in construction, long life and the like. The high-temperature-resistant heat insulation coating is a grey white slurry body and selects and uses silicate and water-based phenolic resin as film forming materials and nano ceramic hollow particles, silicon-aluminum fibers and various reflection materials as main powder materials. The high-temperature-resistant heat insulation coating can be used for effectively inhibiting and shielding infrared radiation heat and heat conduction, has the heat insulation efficiency of about 90%, and also can be used for inhibiting heat radiation and heat loss of high-temperature objects, keeping 70% of indoor heat, effectively insulating cold energy of low-temperature objects, inhibiting cold loss caused by environmental radiation heat and preventing condensed water from being generated.

Owner:赵志海

Polycrystalline optical window materials from nanoceramics

InactiveUS20060011839A1Exceptional propertyImprove transmittanceMaterial nanotechnologyRadiation pyrometryNanoceramicSingle crystal

Optical windows for protecting infrared sensing instruments are manufactured from nano-sized crystallites by compressing the crystallites into a continuous mass under high pressure in the presence of a pulsed electric current, preferably one produced by spark plasma sintering. The resulting materials have excellent optical and mechanical properties that make them favorable as replacements for the conventional single-crystal sapphire.

Owner:RGT UNIV OF CALIFORNIA

Polycrystalline optical window materials from nanoceramics

InactiveUS7148480B2Exceptional propertyImprove transmittanceMaterial nanotechnologyRadiation pyrometryNanoceramicSingle crystal

Optical windows for protecting infrared sensing instruments are manufactured from nano-sized crystallites by compressing the crystallites into a continuous mass under high pressure in the presence of a pulsed electric current, preferably one produced by spark plasma sintering. The resulting materials have excellent optical and mechanical properties that make them favorable as replacements for the conventional single-crystal sapphire.

Owner:RGT UNIV OF CALIFORNIA

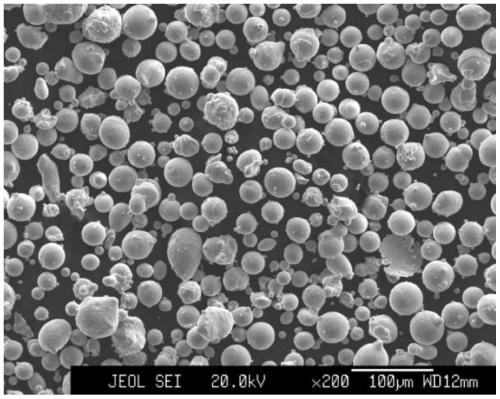

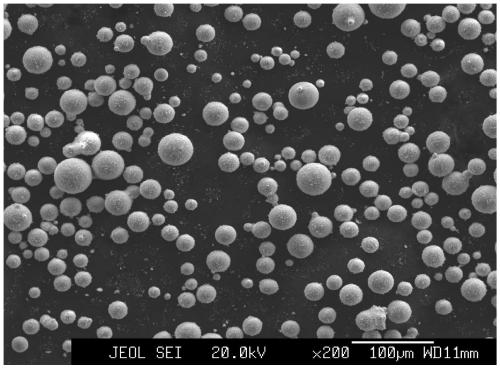

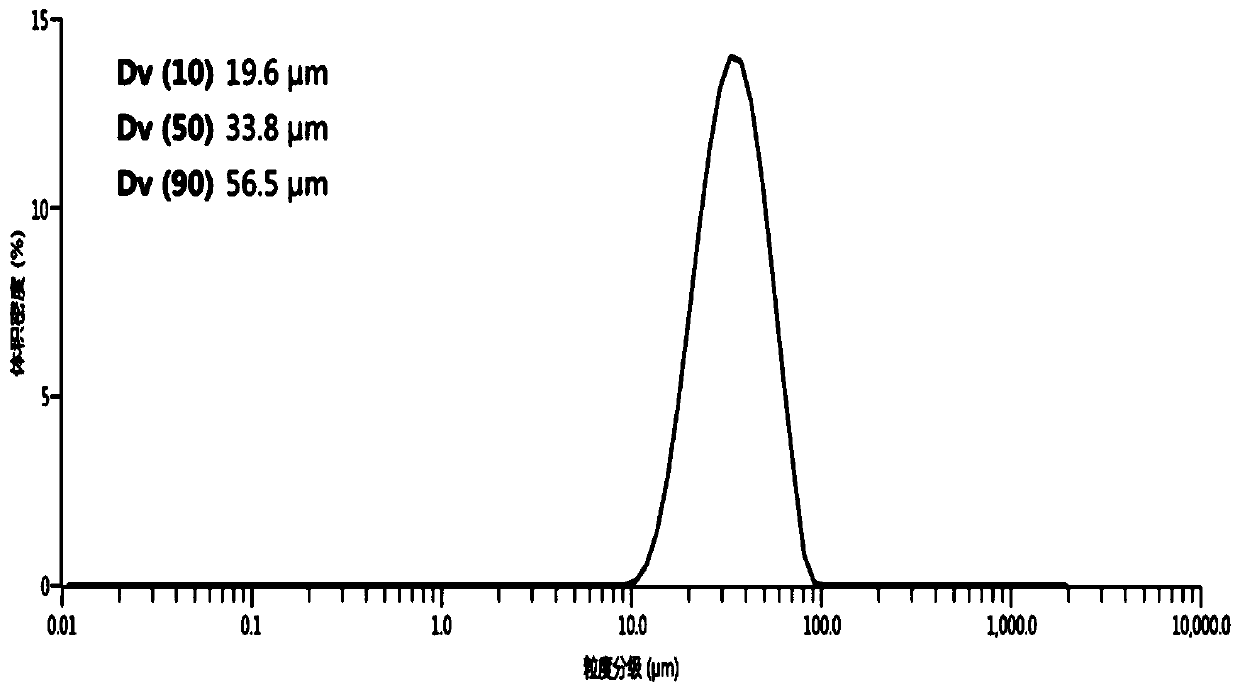

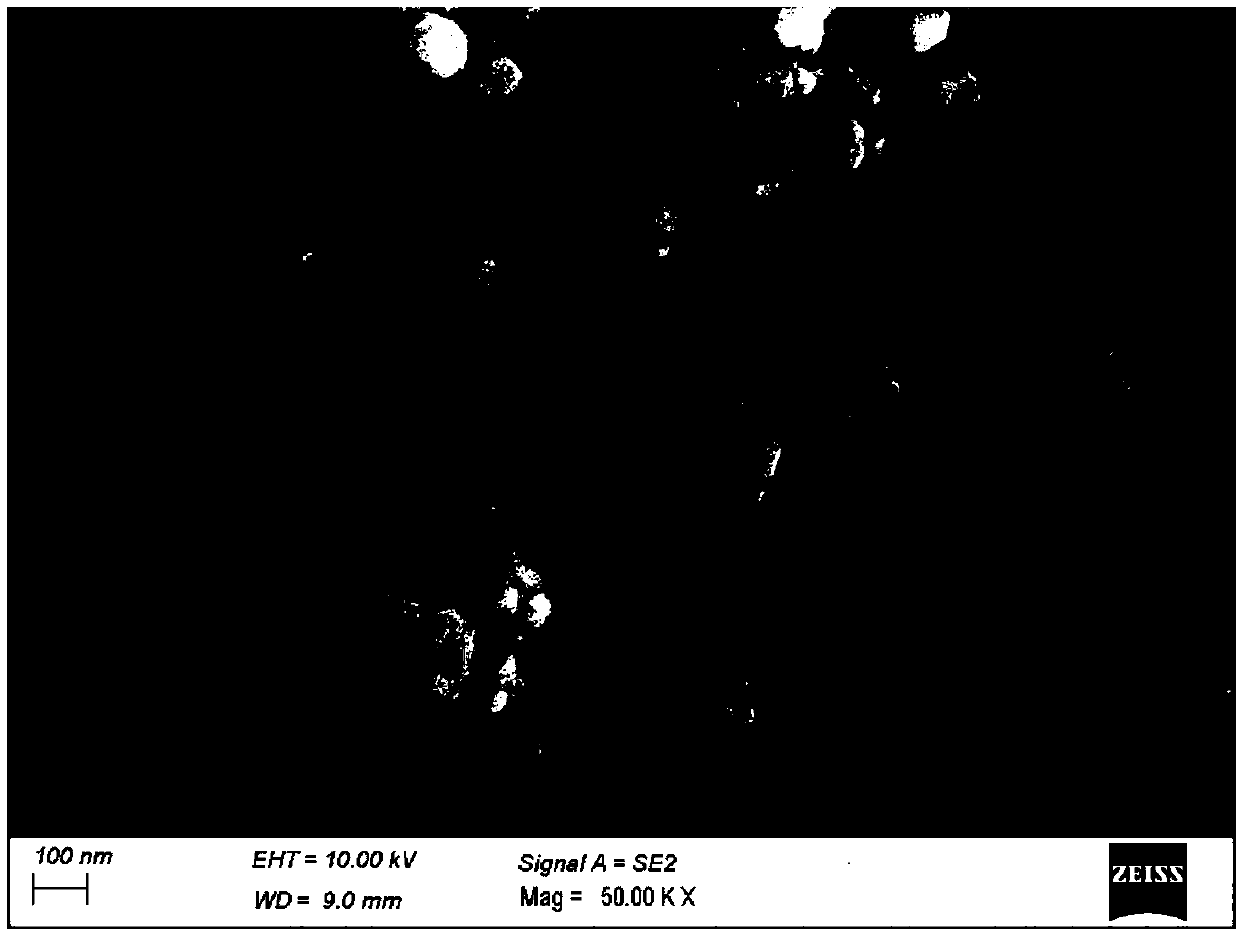

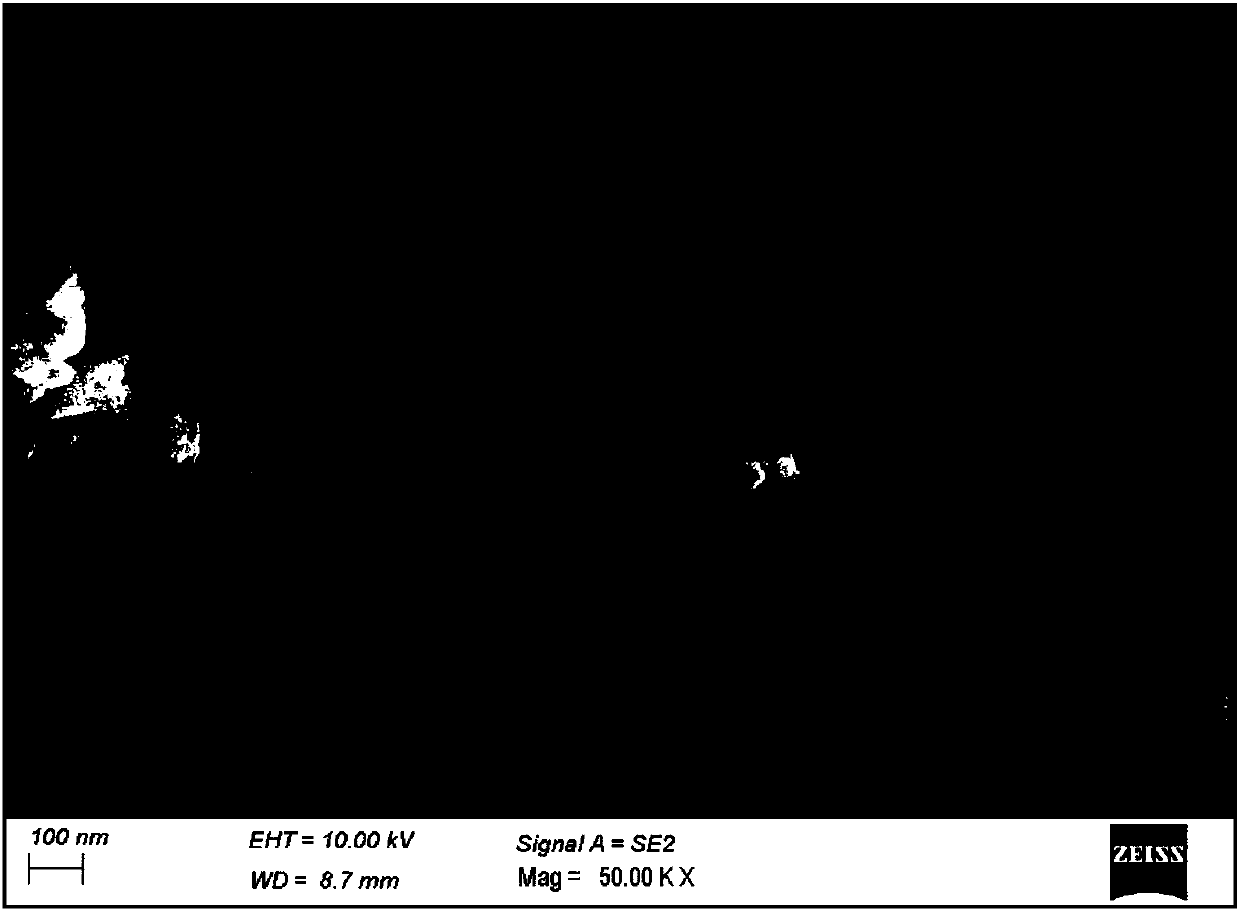

Nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing as well as preparation method and application thereof

ActiveCN111168057AImprove liquidityReduce oxygen contentAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysNanoceramic

The invention discloses nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing and a preparation method and application thereof, and belongs to the technical field of metal additive manufacturing. The preparation method of the nano ceramic reinforced high-entropy alloy composite powder for additive manufacturing comprises the following steps of powder mixing, powderplasma spheroidizing, redundant nano ceramic particle removing, powder particle size grading and mixing. According to the preparation method, high-entropy alloy serves as matrix powder, nano ceramicparticles serve as reinforcing phase particles, high-entropy alloy powder with the nano ceramic particles evenly attached to the surface is obtained in an ultrasonic dispersion and mechanical stirringmode, and then the spherical nano ceramic particle reinforced high-entropy alloy composite powder is prepared through the radio frequency plasma spheroidizing technology; and the process for preparing the nano ceramic reinforced high-entropy alloy composite powder is simple, and the prepared powder is excellent in performance and suitable for mass production.

Owner:SOUTH CHINA UNIV OF TECH

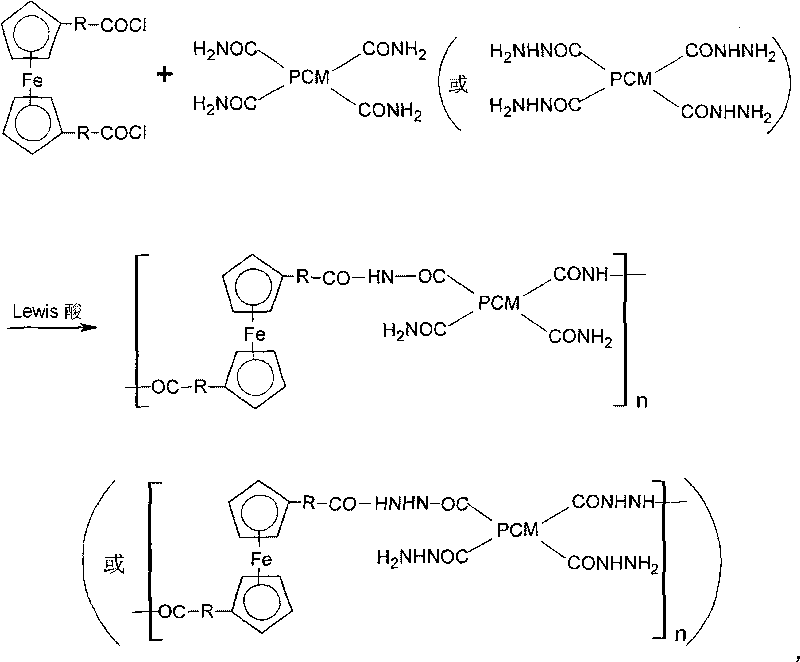

Composite electromagnetic medium material containing dicyclopentadienyl iron phthalocyanine metal organic magnetic body and preparation method thereof

InactiveCN101692366AOrganic/organic-metallic materials magnetismMetallocenesDielectric lossIron phthalocyanine

The invention discloses a composite electromagnetic medium material containing a dicyclopentadienyl iron phthalocyanine metal organic magnetic body and a corresponding preparation method. The material consists of the dicyclopentadienyl iron phthalocyanine metal organic magnetic body (A) containing Cu, Co or Ni, a nano ceramic powder material (B), a thermoplastic resin material (C) and a modifier (D). The material has the remarkable characteristics that the material has higher electromagnetic parameter product (mu'epsilon'=30-100) and lower dielectric loss (tg delta is less than 2*10 -3 ) at the extensive frequency band of 0.1 to 45GHz; when the material is used for manufacturing a micro-strip antenna or an electronic device, the bandwidth of the material can reach over 15 to 40 percent so as to greatly reduce the geometric dimension of the electronic device or the antenna and keep good gain; and the material has simple process and low price and is easy to realize industrialization.

Owner:深圳市康源新通信技术有限公司 +1

Preparation method of single phase nano-CaTiO3 powder using collosol-gel low temperature synthesis

The present invention discloses a preparation method of low-temperature synthetic single-phase nano CaTiO3 ceramic powder body by using sol-gel process. Said method includes the following steps: dissolving inorganic salt of calcium in anhydrous ethyl alcohol; dissolving butyl titanate in the mixed solution of anhydrous ethyl alcohol and acetic acid; drop-adding nitric acid and acrylic acid to regulate pH value; according to mole ratio of 1:1 of calcium: titanium mixing the above-mentioned two solutions, adding proper quantity of dispersing agent; uniformly stirring the obtained solution, sealing and standing still to obtain gel, drying and grinding said gel, calcining so as to obtain the invented nano ceramic powder body.

Owner:ZHEJIANG UNIV

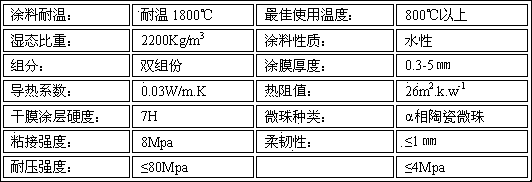

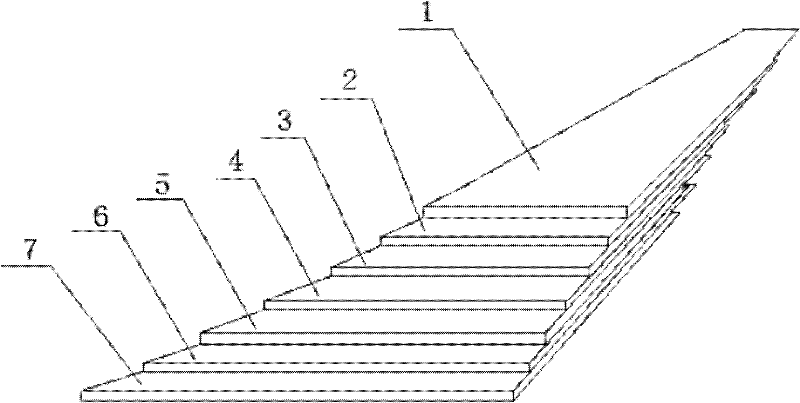

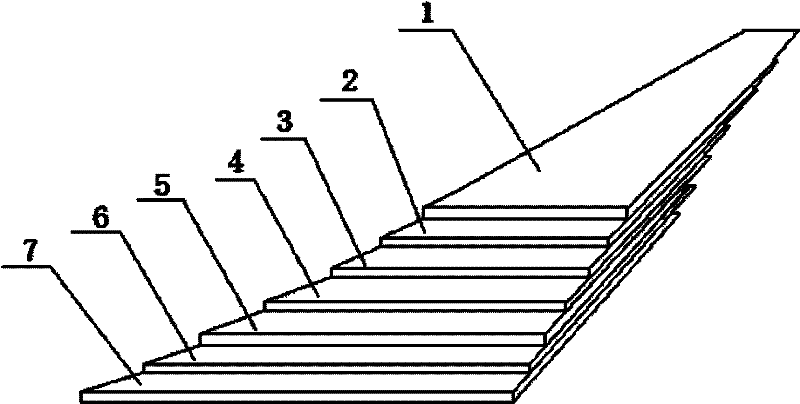

Nano-ceramic thermal insulation film and preparation method thereof

ActiveCN102259448AInhibitory activitySuppresses heat radiationSynthetic resin layered productsLaminationComposite filmInsulation layer

The invention relates to a nanophase ceramics heat insulation film, comprising a heat insulation film main body, wherein the heat insulation film main body comprises at least two layers of composite films, one layer is a heat insulation layer which is a nanophase ceramics heat insulation layer made of nanophase ceramics materials, the outer side of the nanophase ceramics heat insulation layer is provided with a scratching resistance layer, and the scratching resistance layer is the outmost layer of the heat insulation film. The preparation method of the nanophase ceramics heat insulation film comprises the following steps: selecting base materials; evenly coating the heat insulation layer containing the nanophase ceramics particles on the base material; drying; coating one projection layer on one side of the heat insulation film main body, and arranging one layer of heating resistance layer on the other side; drying; coating the scratching resistance layer on the projection layer; coating a safe base layer on the heating resistance layer; drying; coating a gluing layer on the safe base layer in a pressure sensing mode; coating a releasing layer on the gluing layer; and drying. According to the nanophase ceramics heat insulation film, the strength and the service life of a carrier can be improved and prolonged.

Owner:上海浩驰科技股份有限公司

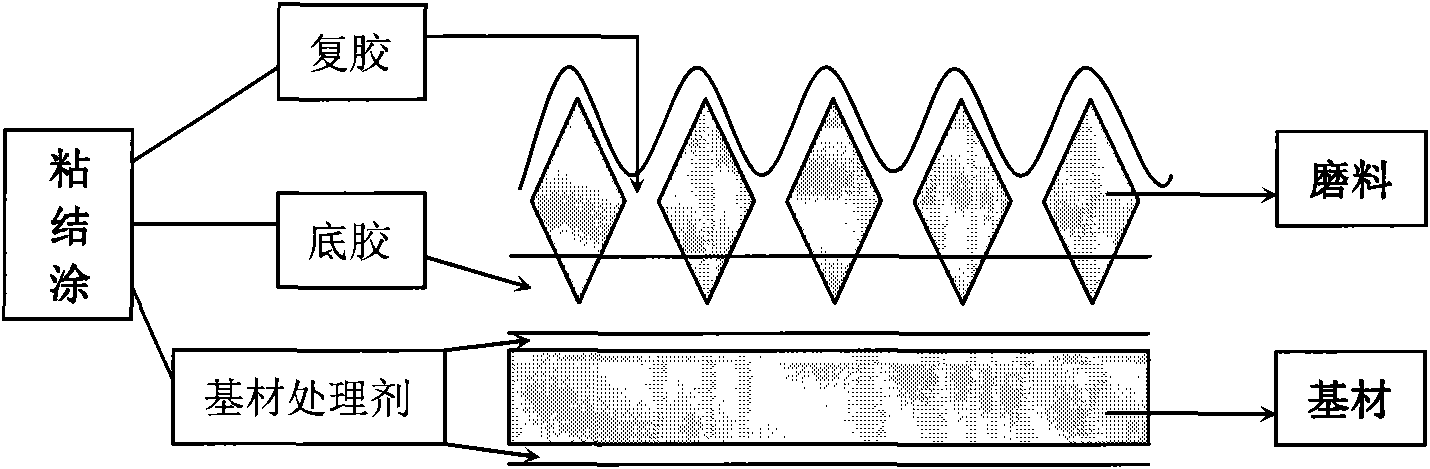

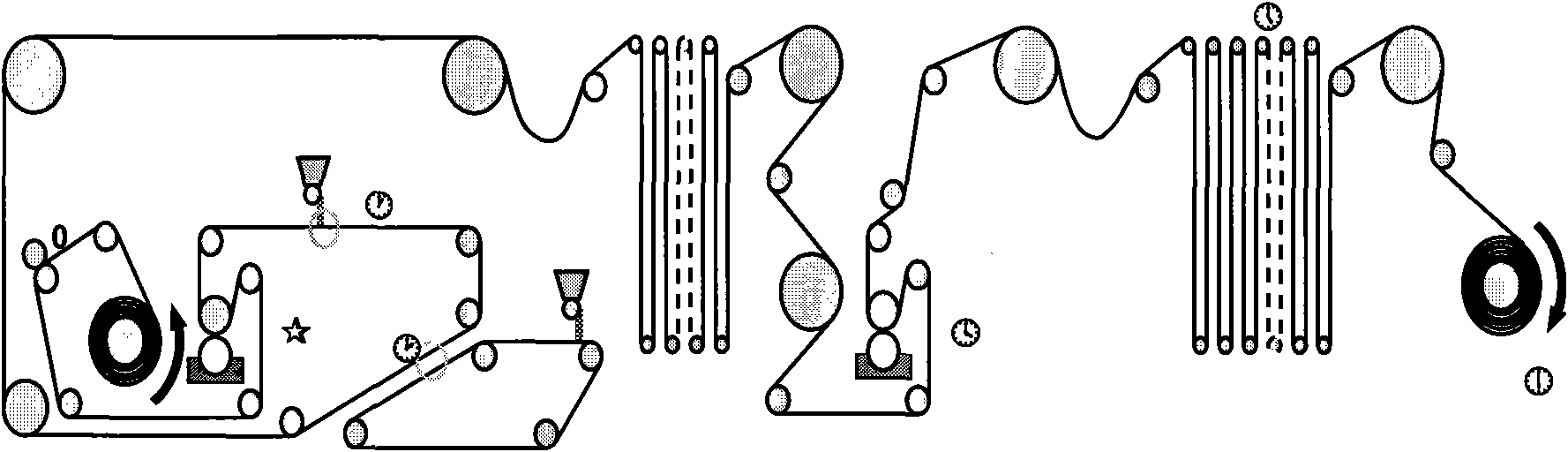

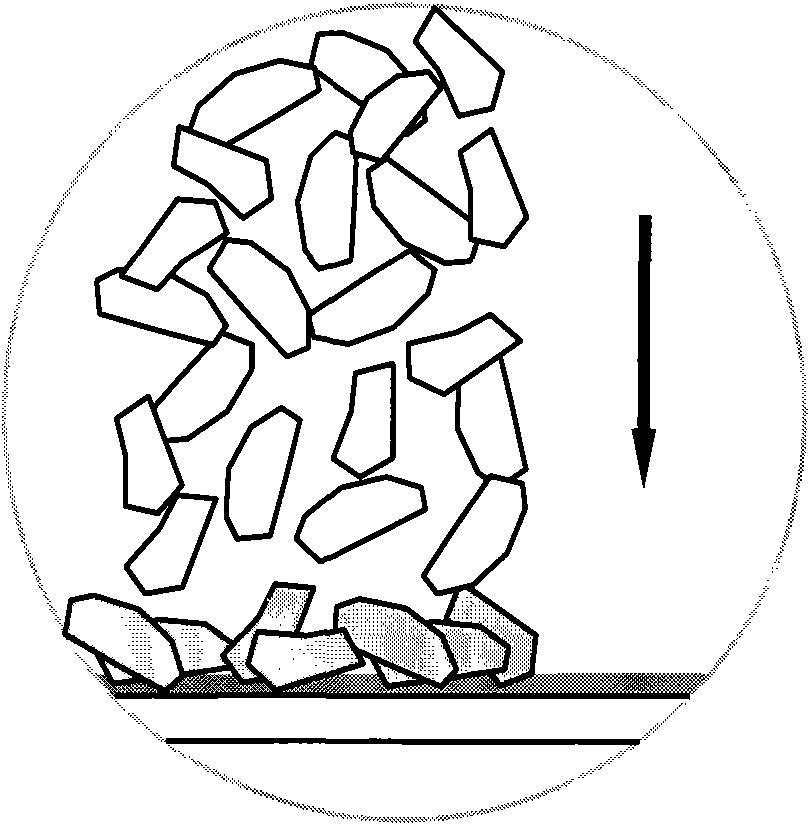

Nanometer ceramic alumina coated abrasive tool and manufacture method thereof

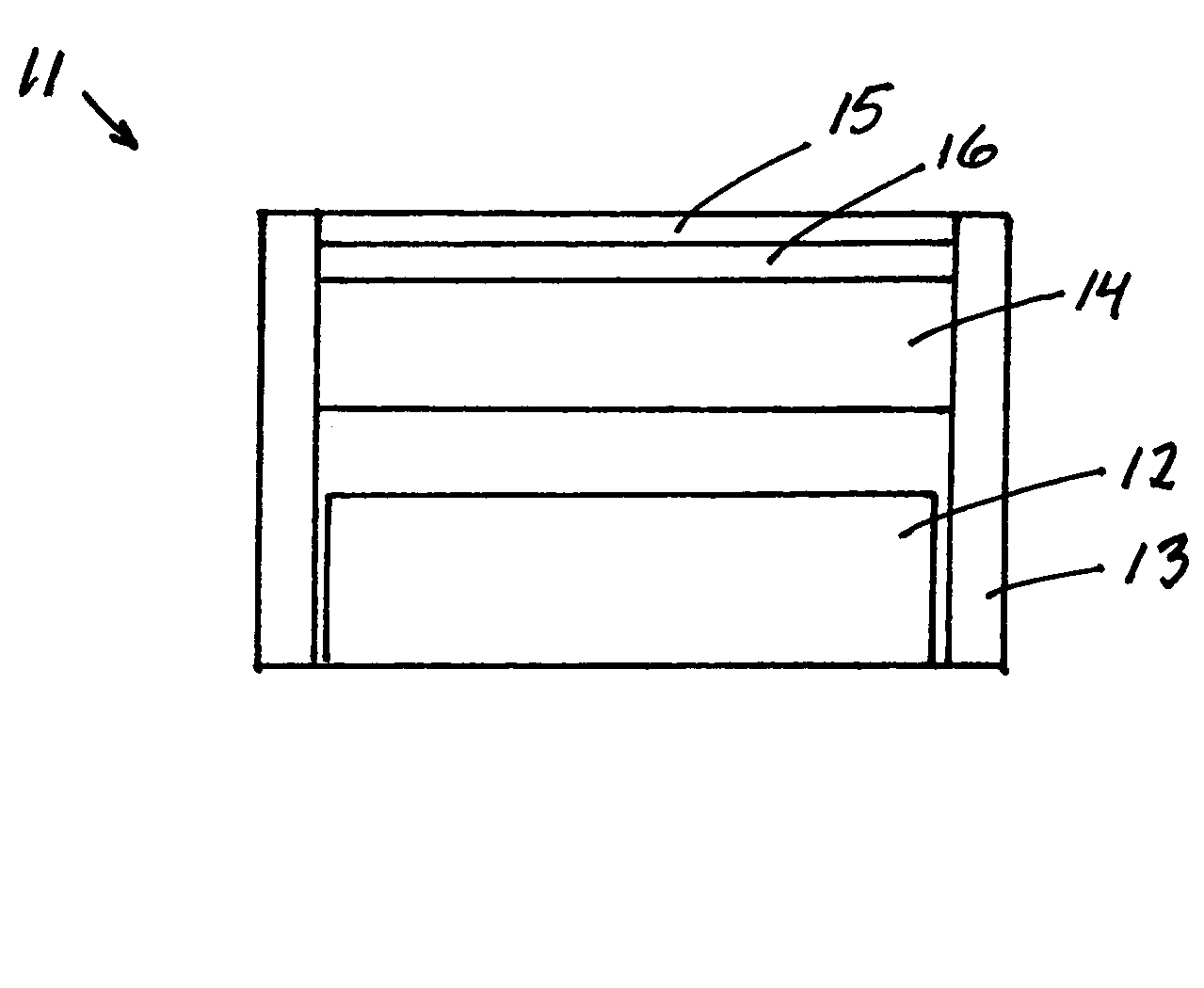

ActiveCN101653925AHigh hardnessImprove toughnessOther chemical processesAbrasion apparatusNanoceramicHardness

The invention relates to a nanometer ceramic alumina coated abrasive tool and a manufacture method thereof. The abrasive tool comprises a substrate, a bottom glue layer, abrasives and a composite gluelayer, wherein the substrate comprise a first surface and a second surface which are opposite; the bottom glue layer is arranged on at least one part of the first surface; the abrasives forming a grinding surface are arranged on at least one part of the bottom glue layer; and the composite glue layer is formed on at least one part of the abrasive surface. The manufacture method comprises the following steps: unreeling the substrate; coating the abrasives on the surface at one side of the substrate to form the bottom glue layer; then, planting sand on the bottom glue layer; drying the bottom glue layer after sand planting to stimulate the drying of the bottom glue layer and basically volatilize volatile components; coating the abrasives on the bottom glue layer after the sand planting to form the composite glue layer; drying the composite glue layer in the same drying mode; and finally, curing the composite glue layer. The nanocrystalline ceramic alumina abrasives are introduced for coating and manufacturing the abrasive tool, and the characteristics of the ceramic alumina abrasives made of nanometer polycrystalline, i.e. high hardness, good toughness, fine crystallization, good self-sharpening, and the like, are utilized to reduce the grinding heat and the grinding stress of working pieces.

Owner:SUZHOU FAR EAST ABRASIVES

Yttria-stabilized zirconia ceramic and preparation method thereof

The invention provides an yttria-stabilized zirconia ceramic and a preparation method thereof. The preparation method disclosed by the invention comprises the following steps: providing nano-ceramic powder containing zirconia, yttria and alumina; pressing the nano-ceramic powder to obtain a ceramic body; and calcining the obtained ceramic body, thereby obtaining the yttria-stabilized zirconia ceramic, wherein the calcination temperature is 1350-1520 DEG C. According to the yttria-stabilized zirconia ceramic and the preparation method thereof disclosed by the invention, the alumina is added inthe preparation process of the yttria-stabilized zirconia ceramic, and because one of the alumina is segregated to a crystal boundary of the ceramic structure, growth of ceramic grains can be hindered, the ceramic sintering temperature is effectively reduced, the effect of refining the ceramic grains is achieved, and the light transmittance and mechanical property of the ceramic are further improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com