Mechanical process of preparing composite nanometer ceramic and micron metal powder

A nano-ceramic powder and nano-ceramic technology, applied in the field of preparation of new materials, can solve the problems of difficult preparation and large limitations, and achieve the effect of simple and clear meaning, easy acquisition and reduced error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

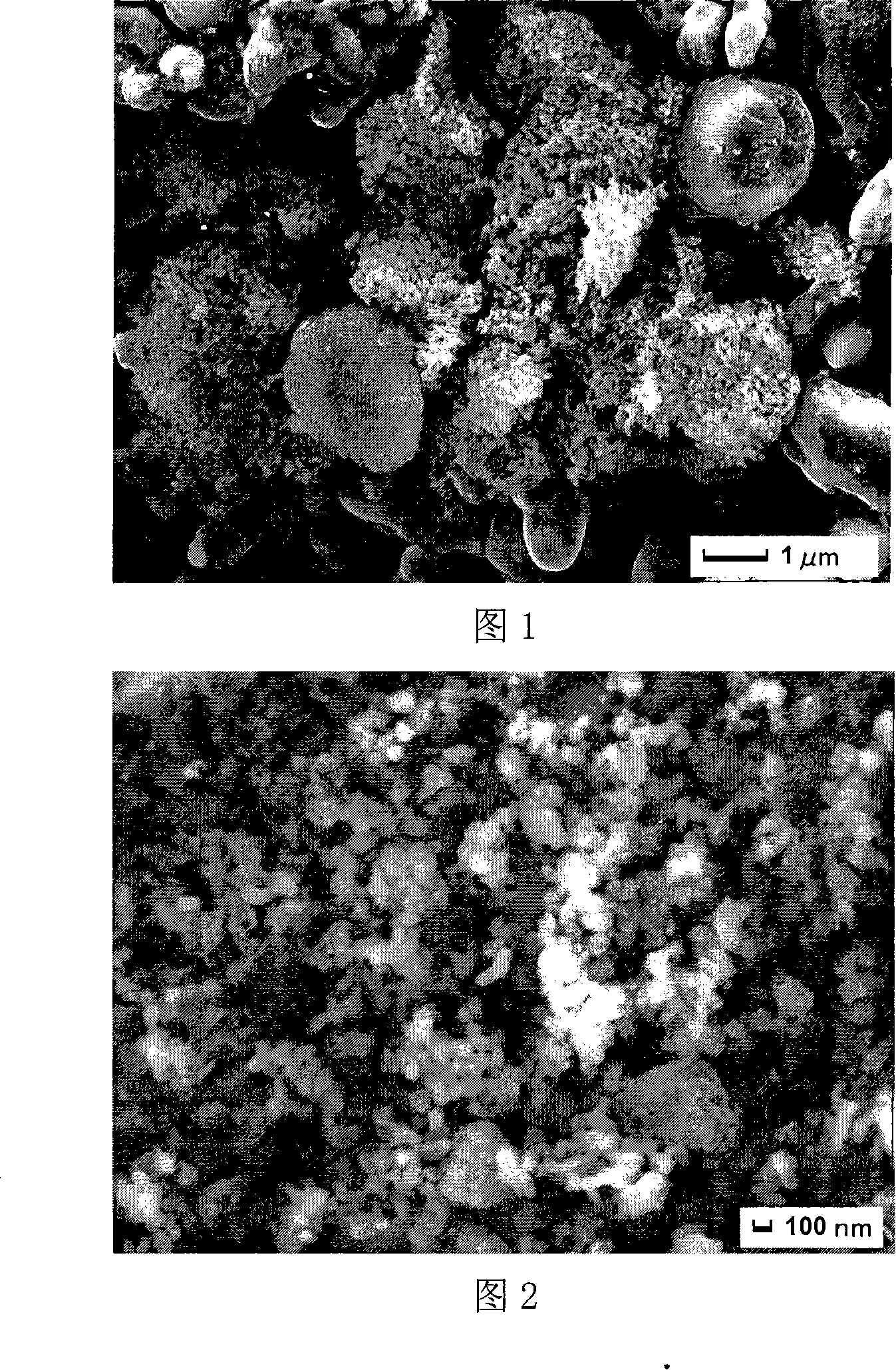

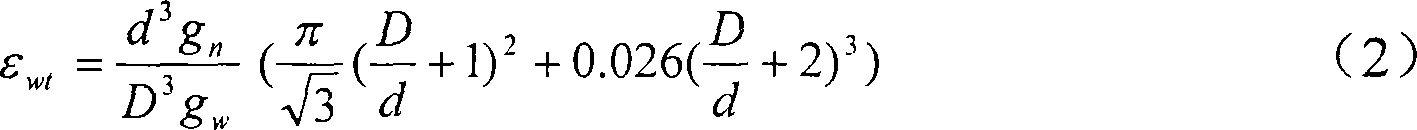

[0046] Example 1: Select commercially available pure aluminum powder with an average particle size of 6 μm and SiC powder with an average particle size of 25 nm, and the density of the micron powder material is 2.7 g / cm 3 , the density of the nanopowder material is 3.2g / cm 3 . In this example, the particle diameters of the nanometer powder and the micrometer powder differ by 2 orders of magnitude, so formula 2 is used to calculate their mass ratio to be 4:100. Put the nano-SiC powder into absolute ethanol and disperse it with an emulsifying shearing machine, and let it stand for 60 minutes to make a uniform and stable nano-suspension, then weigh the nano-SiC suspension and micron pure aluminum according to the calculated ratio. The powder is mixed, and then the powder is mechanically compounded by wet ball milling. The ball milling speed is 150r / min, the ball milling time is 60 minutes, and the ball-to-material ratio is 3:1. Nano-ceramic / micro-metal composite powder with unif...

example 2

[0047] Example 2: select commercially available NiCrAlY powder with an average particle size of 75 μm and Al with an average particle size of 20 nm 2 o 3 Powder, the density of micron powder material is 8.5g / cm 3 , the density of the nanopowder material is 3.97g / cm 3 . Since the particle diameters of the nano-powder and the micro-powder in this example differ by 3 orders of magnitude, formula 1 is used to calculate the mass ratio, and the mass ratio of the nano-ceramic powder and the micro-metal powder is 1.2:100. Nano Al 2 o 3 Put the powder into anhydrous ethanol and disperse it by ultrasonic wave for 30 minutes, and let it stand for 60 minutes to make a uniform and stable nano-suspension, and then weigh the nano-Al 2 o 3 The suspension is mixed with micron NiCrAlY powder, and then the powder is mechanically compounded by wet ball milling. The ball milling speed is 260r / min, the ball milling time is 30 minutes, and the ball-to-material ratio is 3:1. Nano-ceramics with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com