Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1015 results about "Ceramic sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintering of ceramics. Sintering (Firing) of ceramic materials is the method involving consolidation of ceramic powder particles by heating the “green” compact part to a high temperature below the melting point, when the material of the separate particles difuse to the neghbouring powder particles.

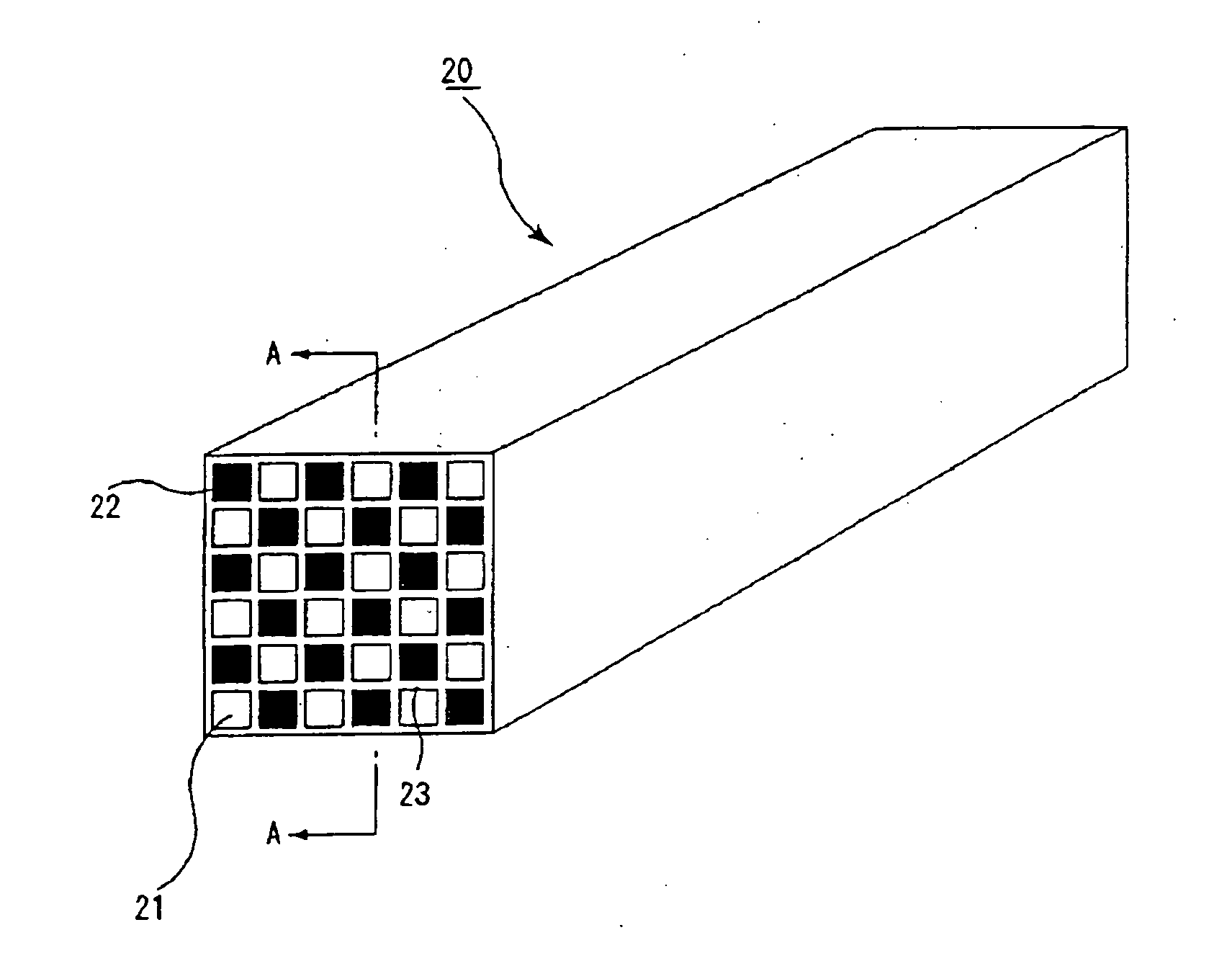

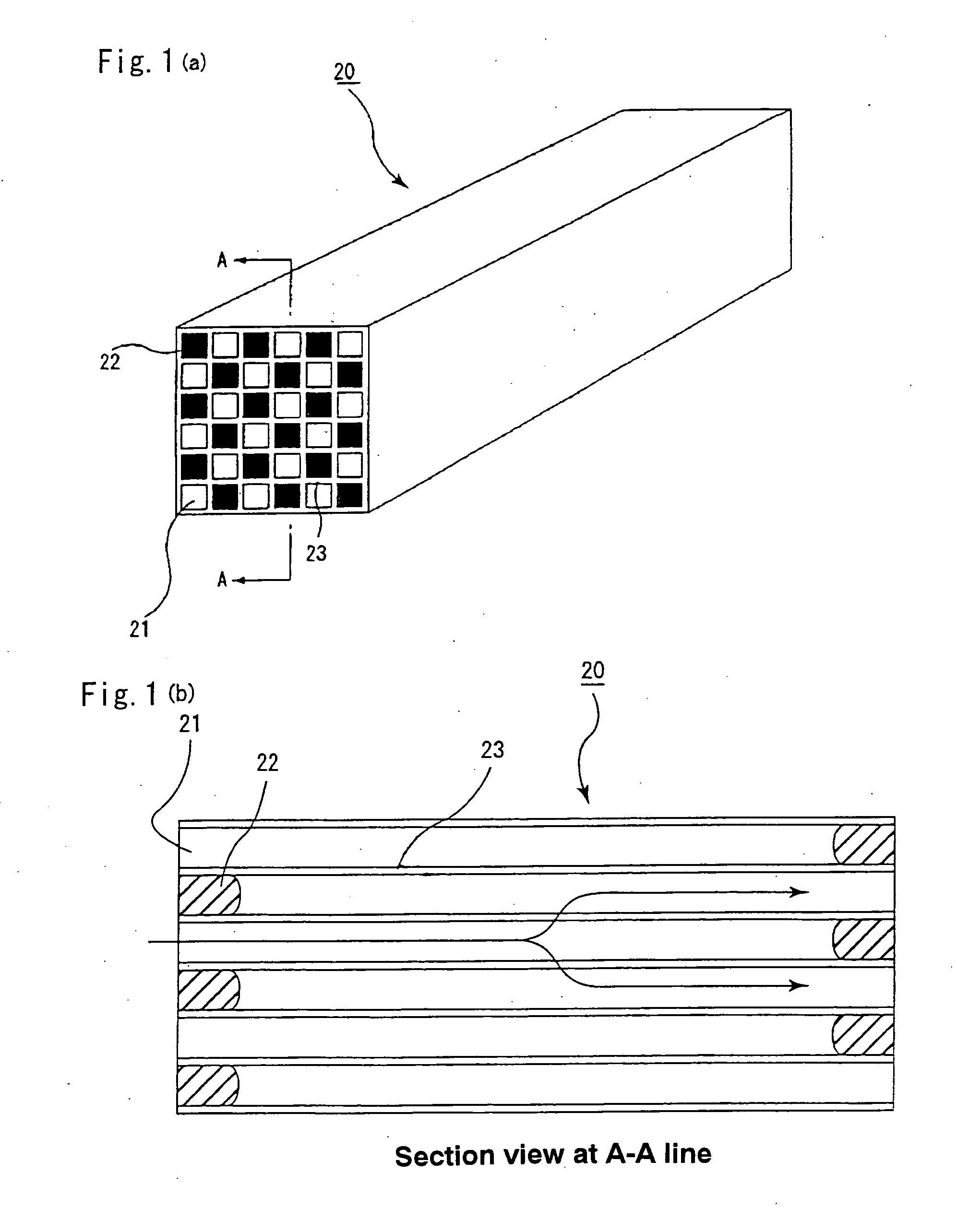

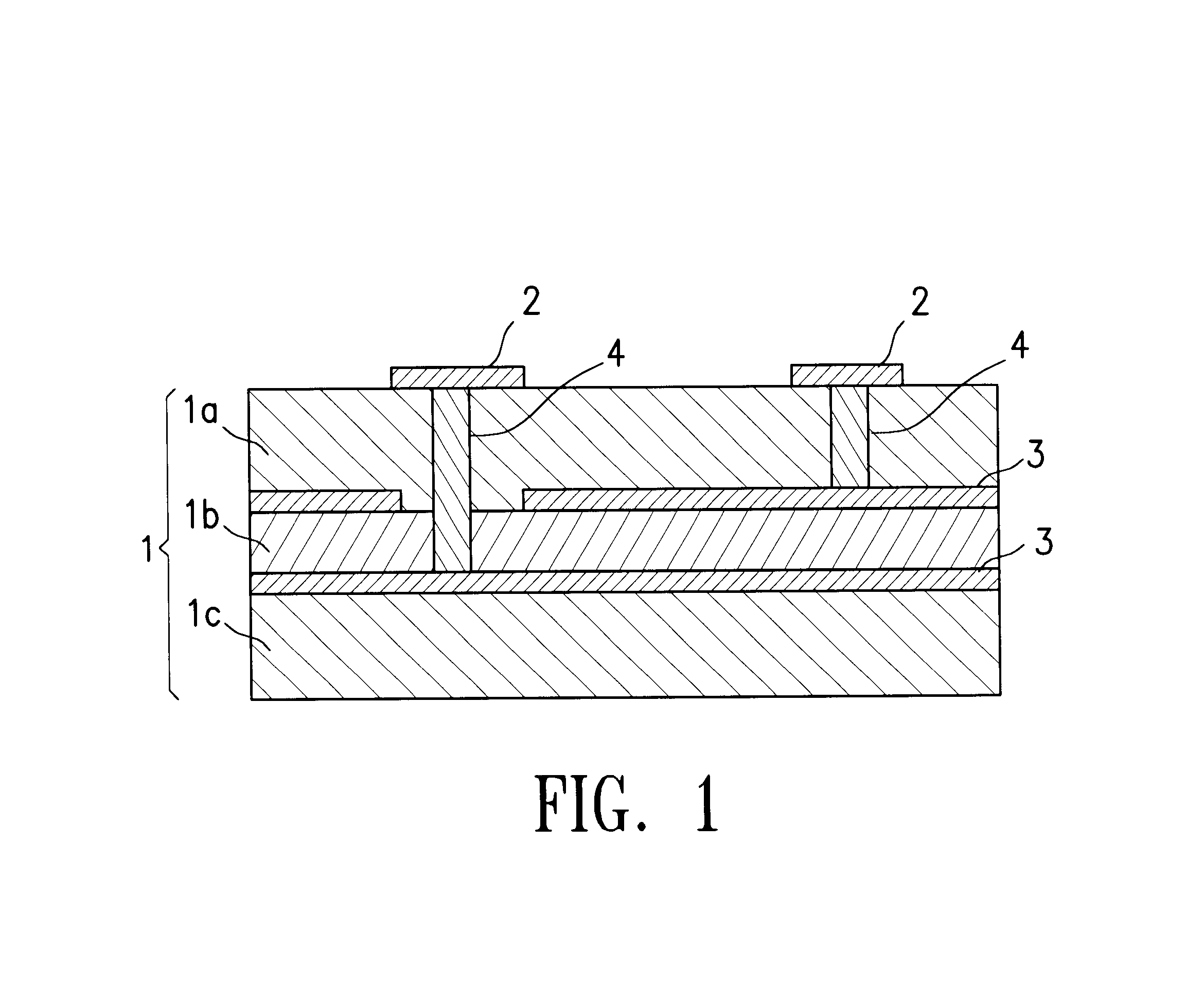

Sintered ceramic compact and ceramic filter

InactiveUS20060051556A1Shock mitigationAvoid micro cracksDispersed particle filtrationExhaust apparatusCeramic sinteringMetallurgy

The present invention provides for a ceramic sintered body and a ceramic filter having a long-term stability which can prevent cracks from occurring due to the breakage of ceramic particles when thermal stress is applied in regeneration process and the like, and can prevent catalyst carried from deteriorating when regeneration treatment is conducted repeatedly. The invention is a ceramic sintered body comprising ceramic coarse particles and porous bonding layers existing between the ceramic coarse particles to connect the particles and comprising ceramic fine particles having an average particle size smaller than that of the ceramic coarse particles and / or the aggregates thereof, and a ceramic filter prepared by using the ceramic sintered body.

Owner:IBIDEN CO LTD

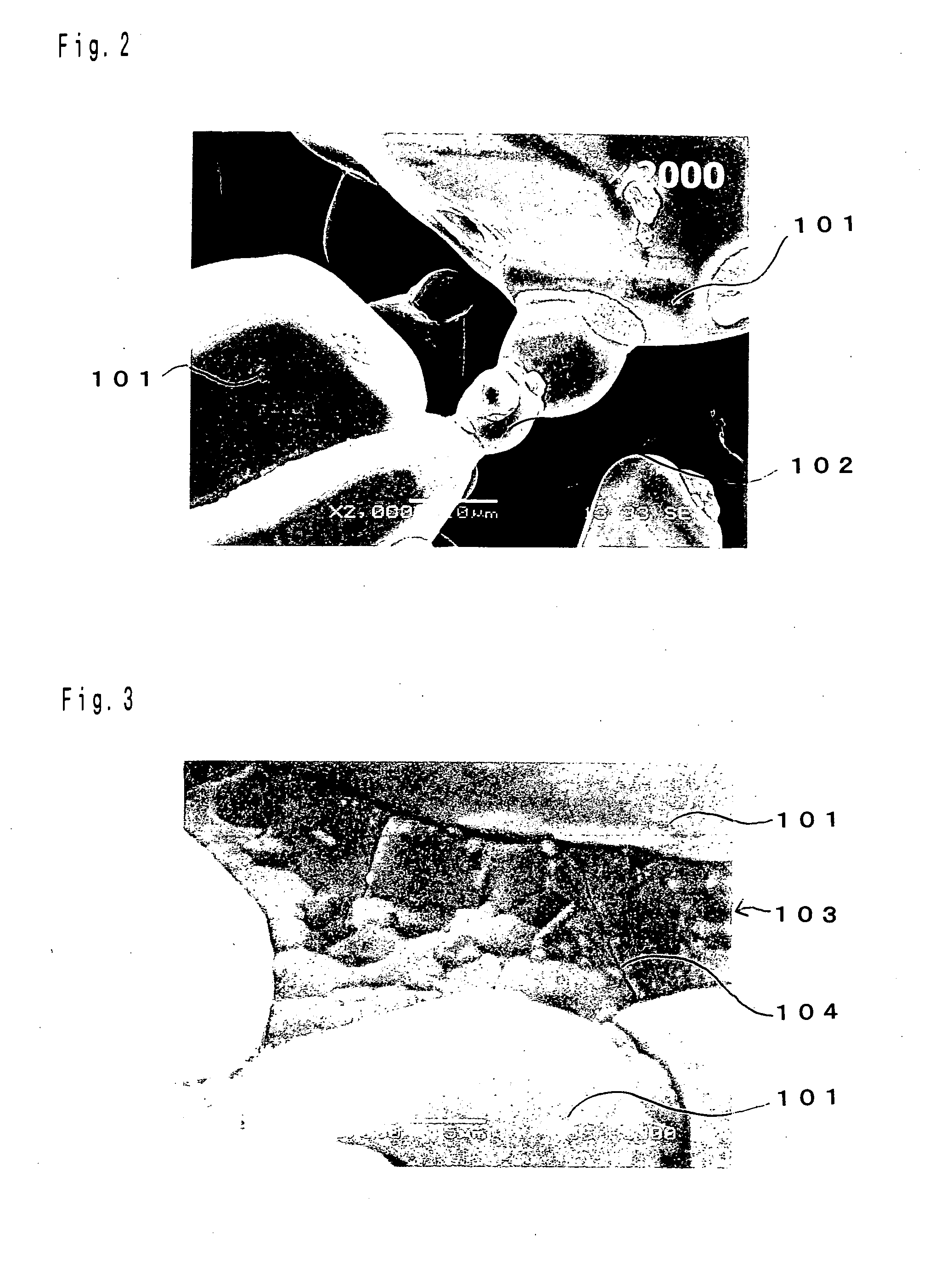

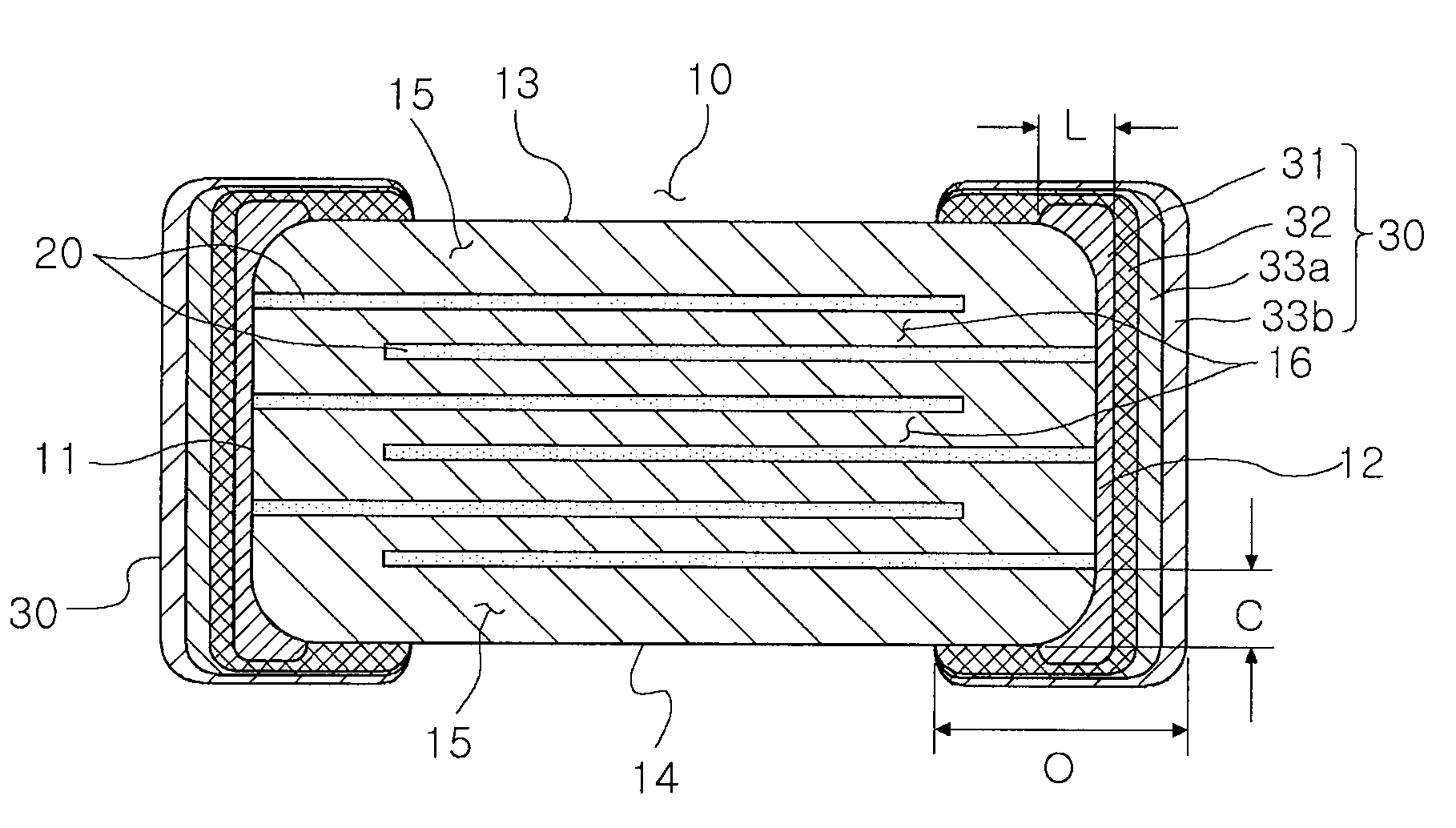

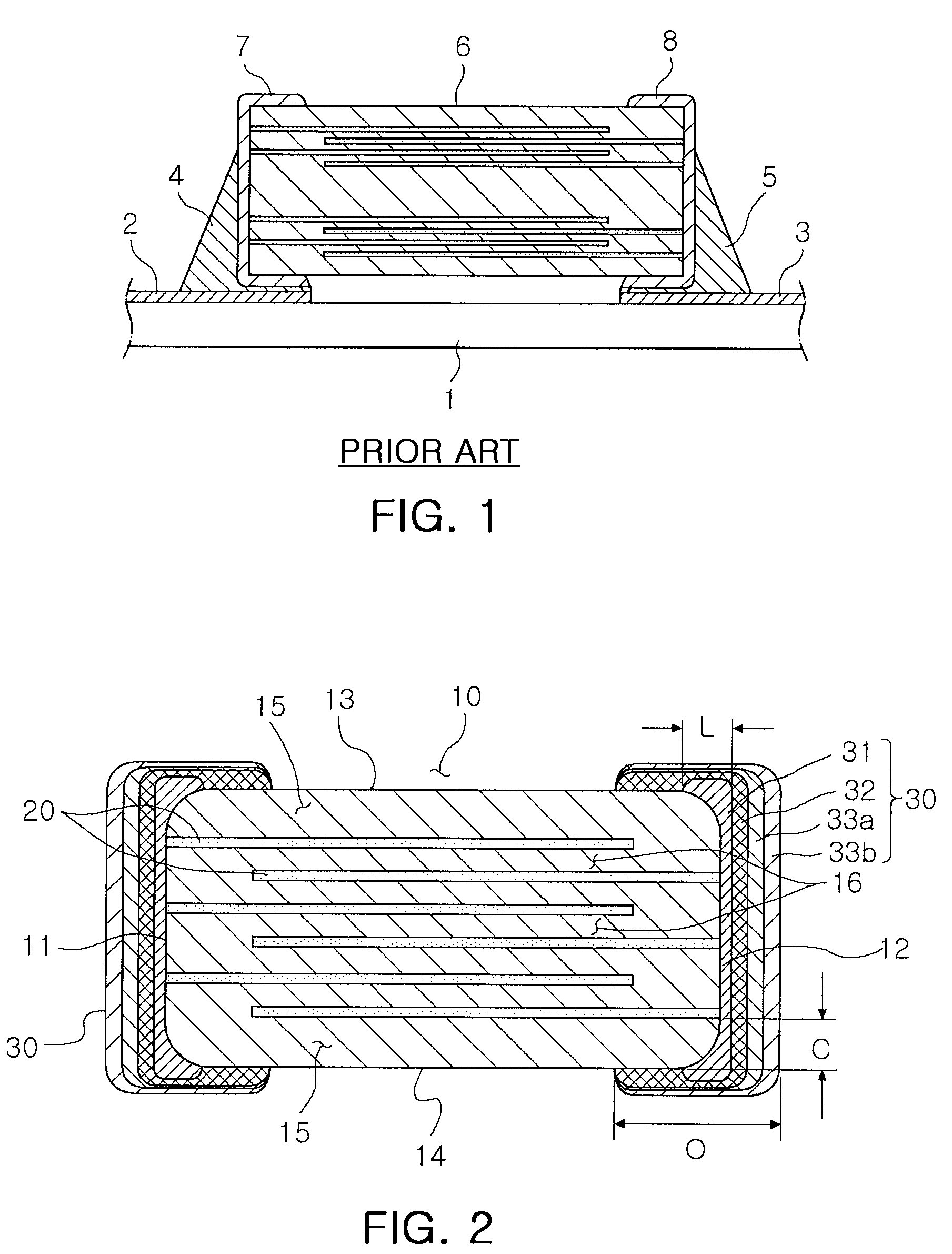

Ceramic electronic component

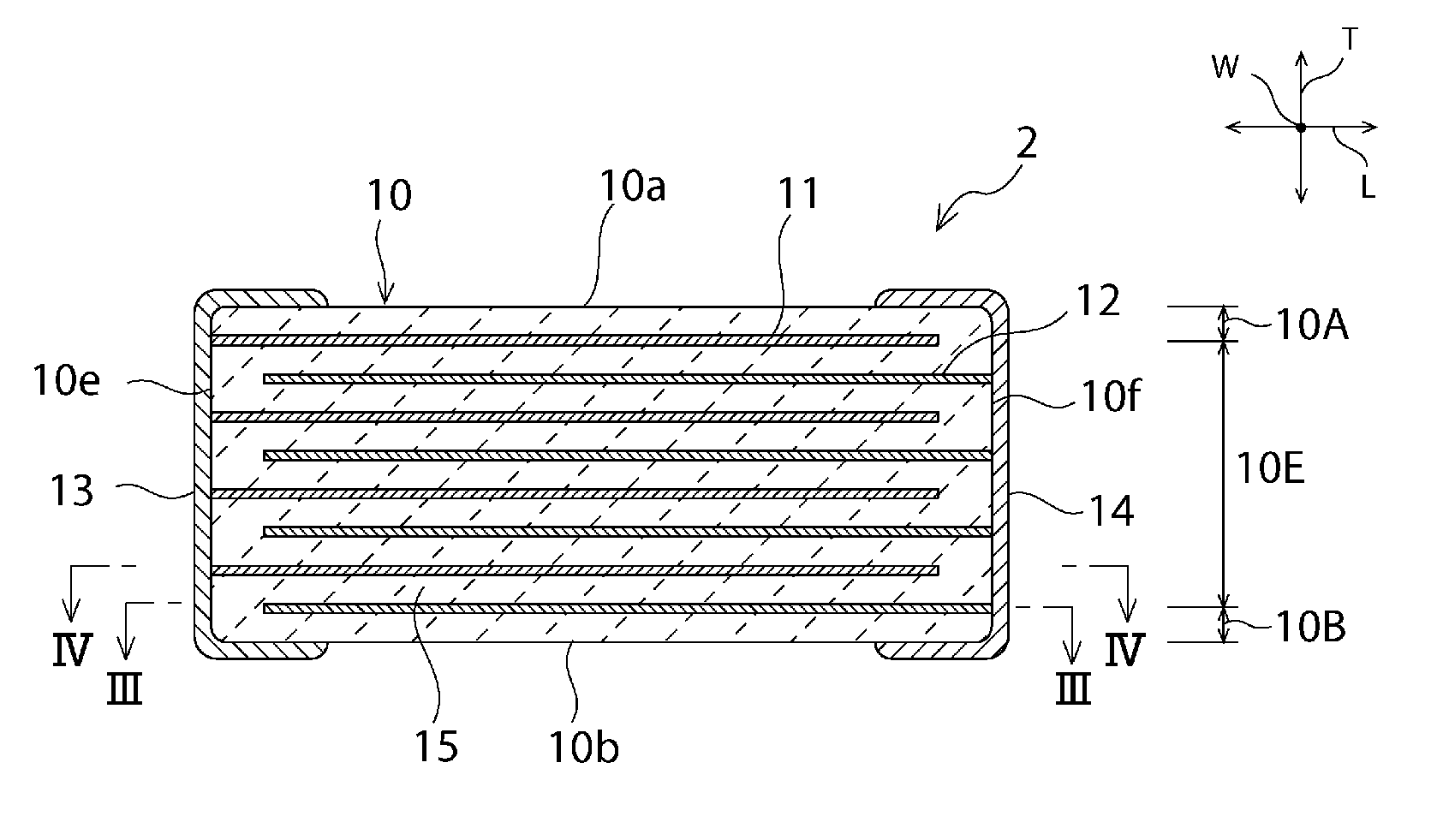

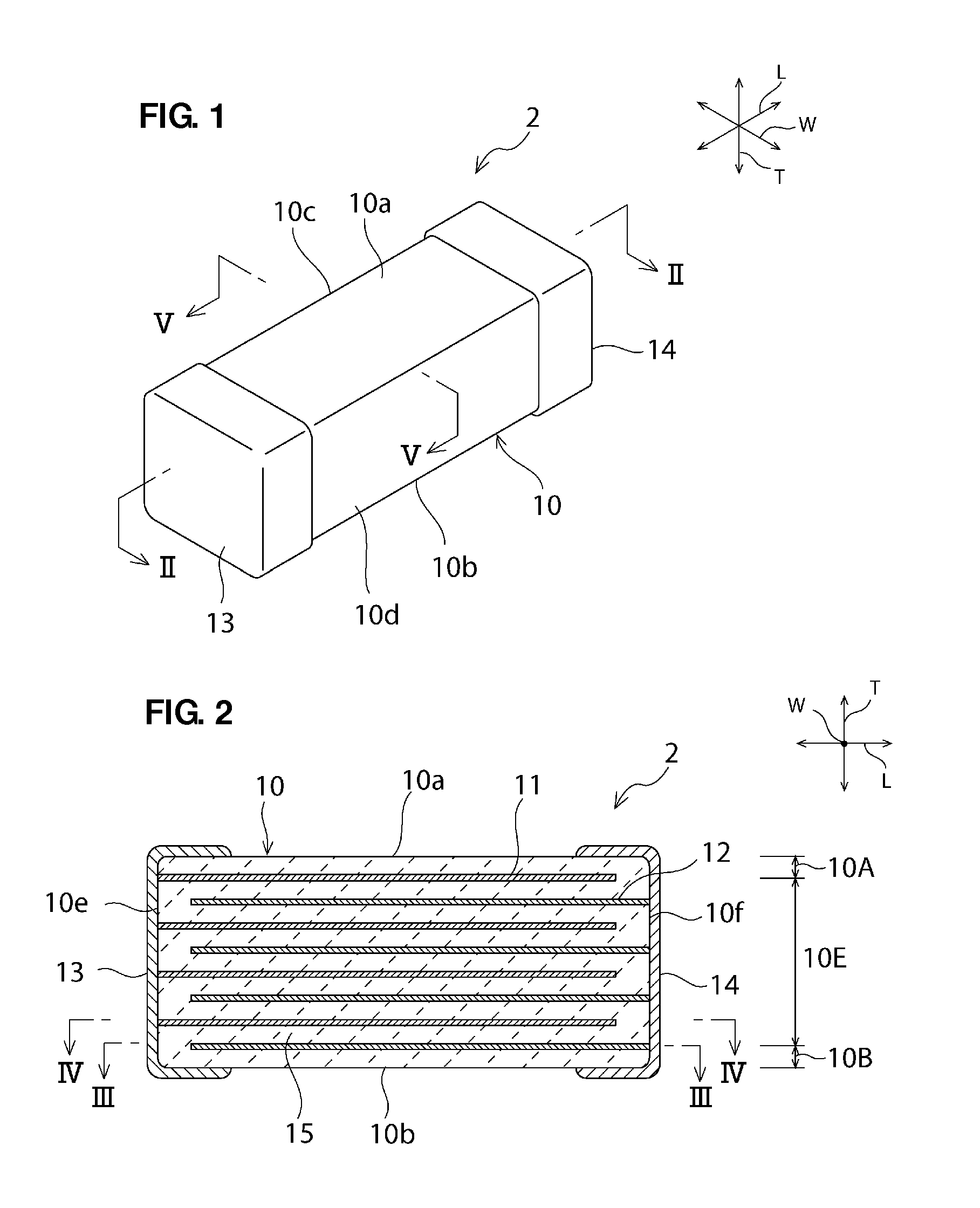

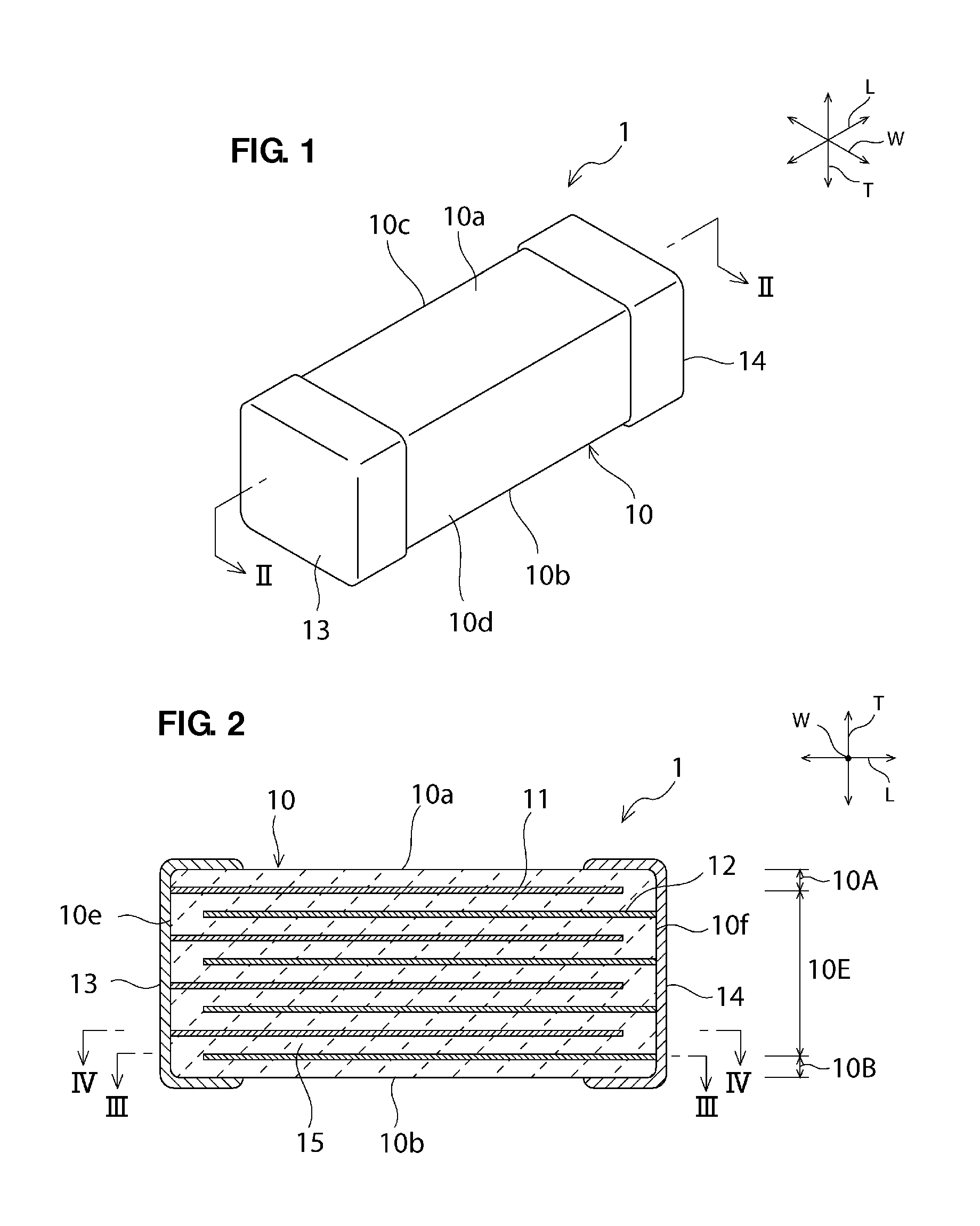

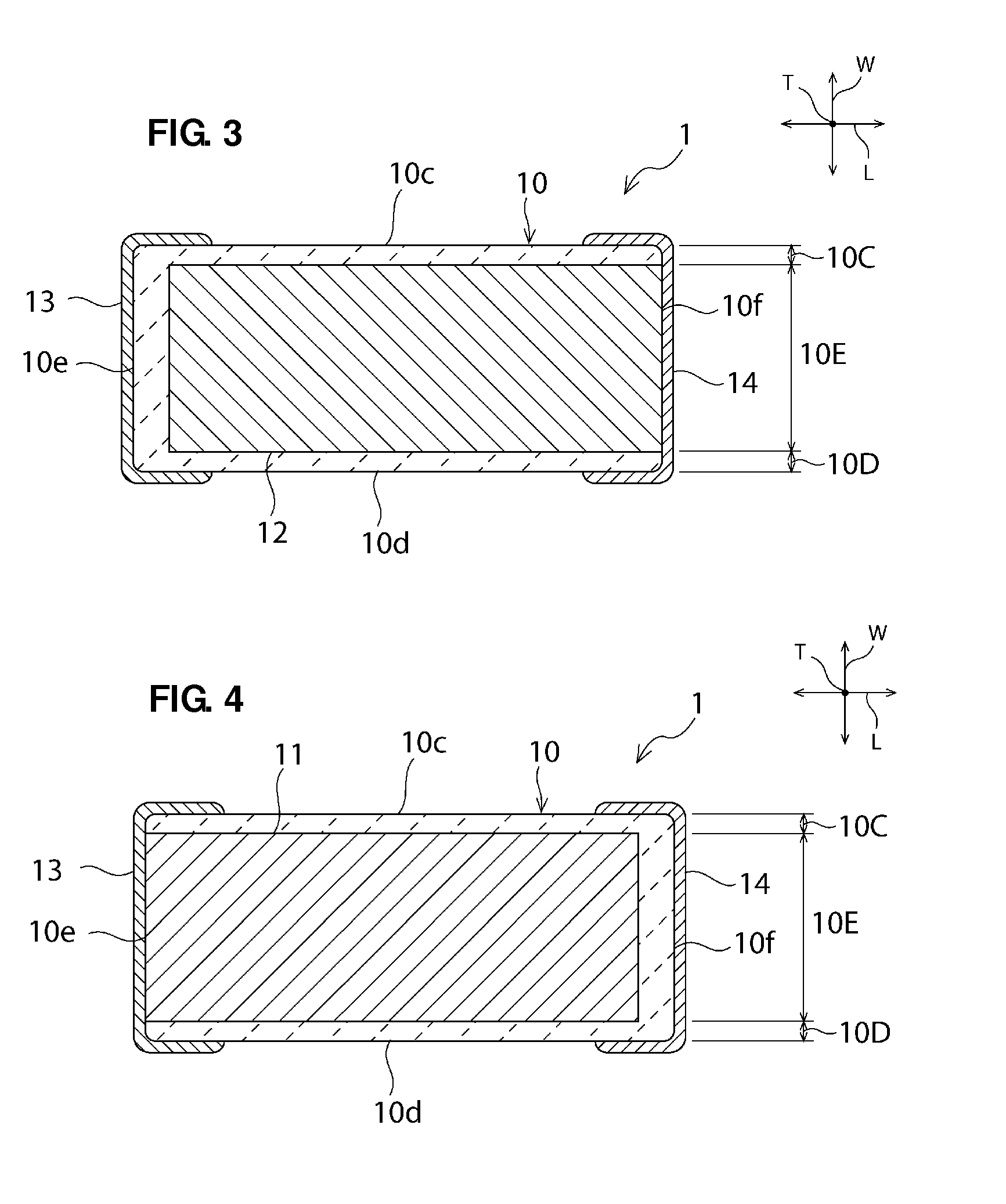

ActiveUS20110007449A1Improve the level ofFixed capacitor electrodesFixed capacitor dielectricCeramic sinteringMetallurgy

There is provided a ceramic electronic component including a ceramic sintered body, internal conductive layers, and external electrodes. Each of the external electrodes includes a first electrode layer, a conductive resin layer covering the first electrode layer, and a second electrode layer covering the conductive resin layer and having an extension length greater than the length of the first electrode layer extending from one of the side surfaces of the ceramic sintered body to the portions of the top and bottom surfaces thereof. The distance from the top or bottom surface of the ceramic sintered body to the closest layer of the internal conductive layers is greater than or equal to the length of the first electrode layer extending from one of the side surfaces of the ceramic sintered body to the portions of the top and bottom surfaces thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

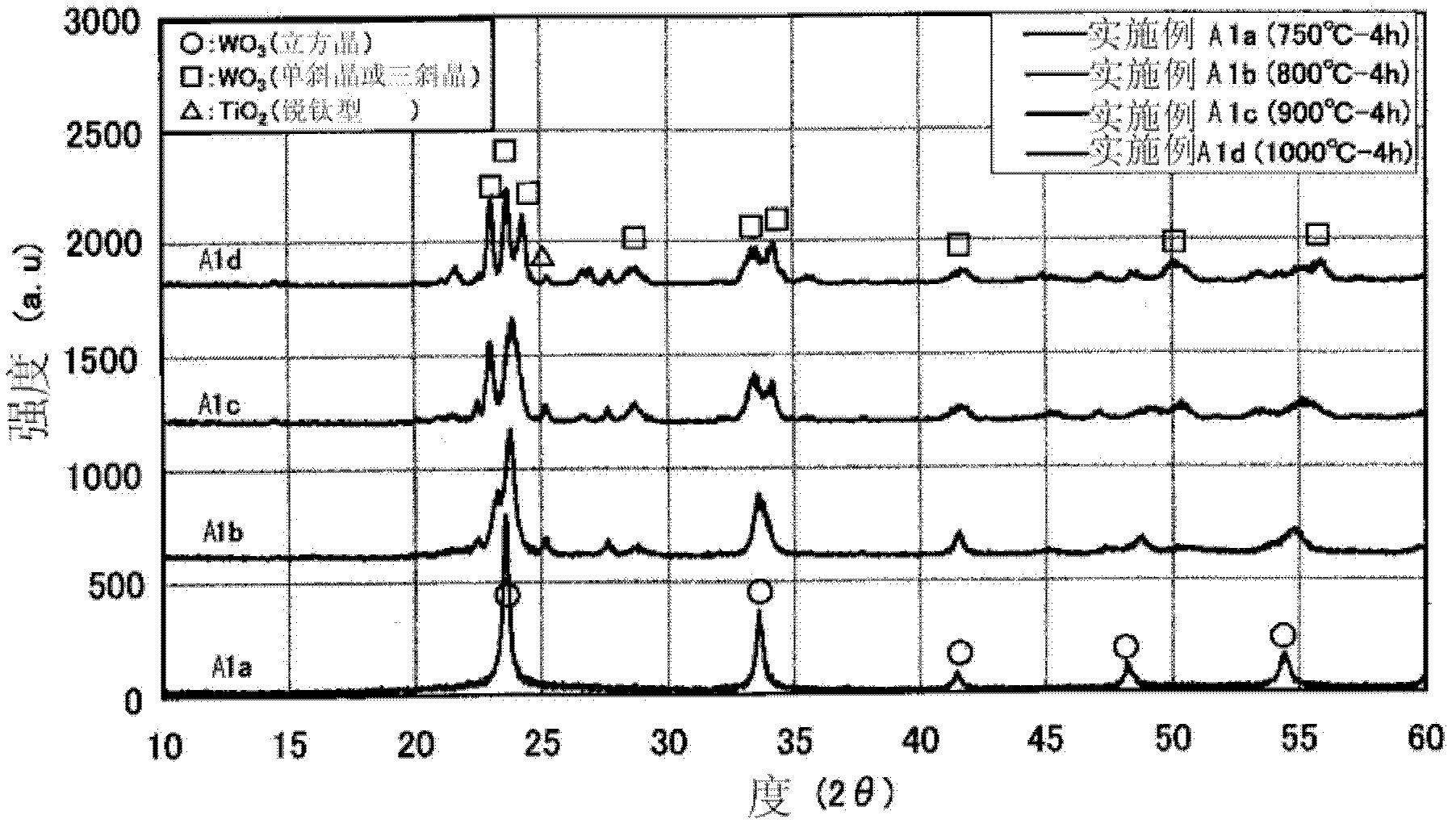

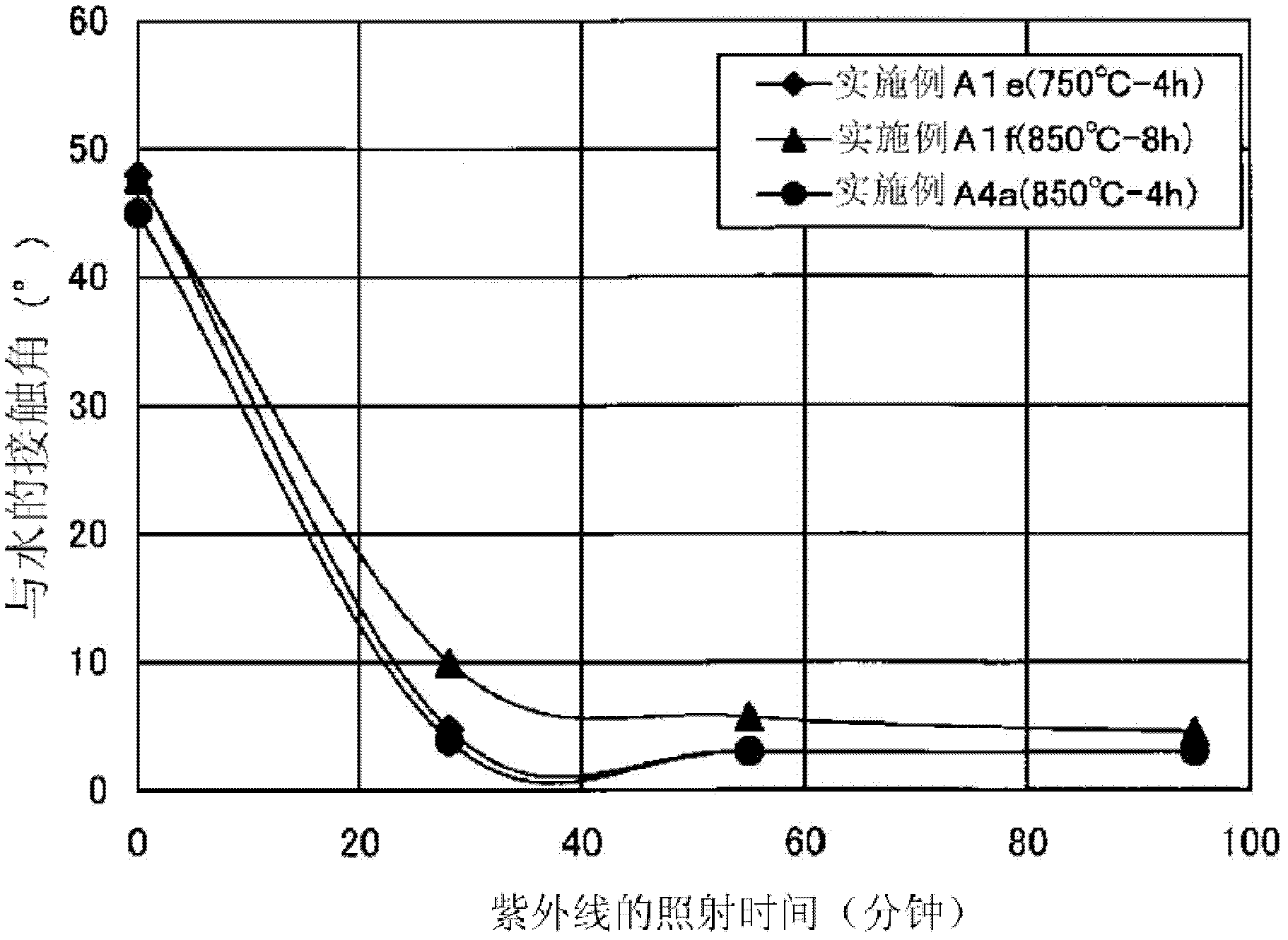

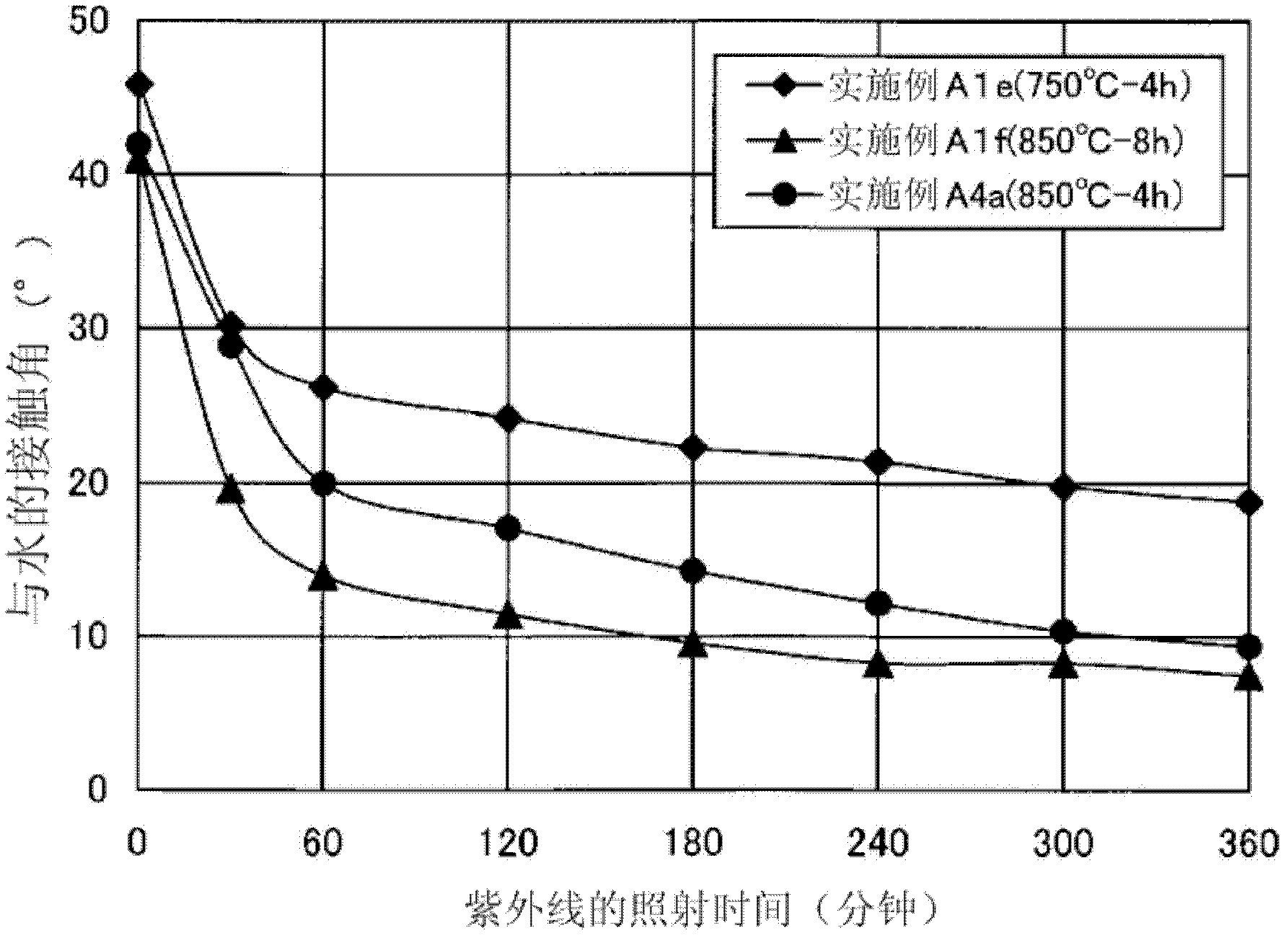

Glass ceramic, sintered glass ceramic material, glass ceramic complex, glass micropowder, slurry-like mixture, and photocatalyst

Disclosed are a glass ceramic, a sintered glass ceramic material, a glass ceramic complex, a glass ceramic micropowder, a slurry-like mixture, and a photocatalyst, each of which comprises a crystalline phase comprising tungsten oxide and / or a solid solution thereof and has a photocatalytic activity. The glass ceramic may contain 10 to 95 mol% of a WO3 component and may additionally contain 0 to 60 mol% of a P2O5 component, 0 to 60 mol% of a B2O3 component, 0 to 60 mol% of an SiO2 component, and / or 0 to 60 mol% of a GeO2 component relative to the total amount of all components in terms of oxide contents.

Owner:OHARA

Monolithic ceramic electronic component

ActiveUS20120250221A1Small sizeImprove performanceFixed capacitor electrodesFixed capacitor dielectricCeramic sinteringElectronic component

An electronic component includes a ceramic sintered body, and a plurality of first and second inner electrodes alternately arranged inside the ceramic sintered body to be opposed to each other in a third direction with a ceramic layer interposed between the adjacent first and second inner electrodes. The first and second inner electrodes are each arranged to be exposed to a third or fourth surface without being exposed to fifth and sixth surfaces. Heterogeneous regions, which include solid solutions of metals included in the first and second inner electrodes and the ceramic sintered body, are arranged continuously in opposite end portions of the ceramic sintered body in a first direction to extend from one side end to an opposite side end of a region where the first and second inner electrodes are disposed in a third direction.

Owner:MURATA MFG CO LTD

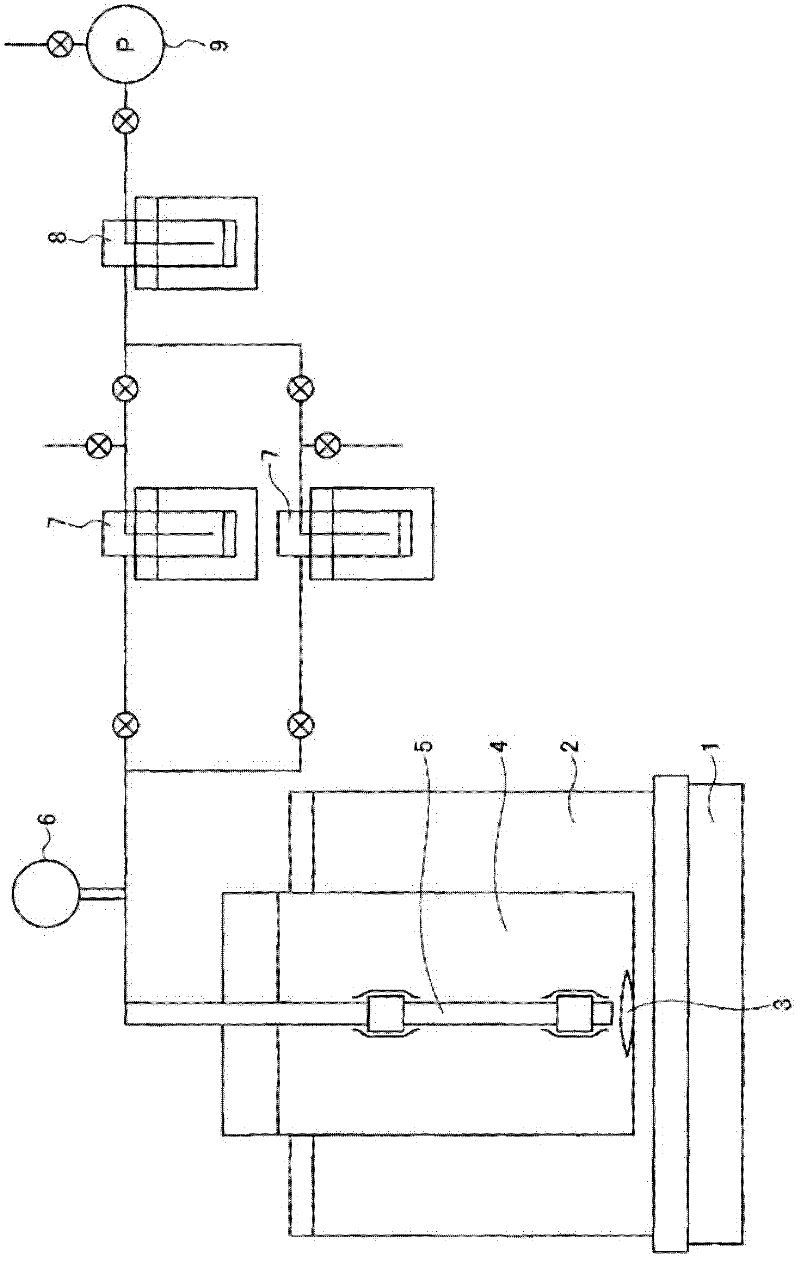

Method for manufacturing high-density rigid carbon-fiber heat-insulation material

The invention relates to a method for manufacturing a high-density rigid carbon-fiber heat-insulation material. The method comprises the following steps: fully and evenly mixing ground or cut carbon fibers with a bonding agent and a dispersing agent, wherein the ground or cut carbon fiber accounts for 20 to 80 portions by weight, the bonding agent accounts for 80 to 20 portions by weight, and theweight ratio of the bonding agent to the dispersing agent is 1:0.4-1:1; carrying out pouring and compression molding on the mixture to obtain a prefab product made of rigid heat-insulation material of specified shape; and carrying out infusible treatment and carbonization treatment to manufacture rigid carbon-fiber heat-insulation material. The method has the advantages of simple process, high stability and convenient operation. Due to the characteristics of excellent heat insulation performance, low thermal capacity, low density, high strength, and the like, the high-density rigid carbon-fiber heat-insulation material is particularly suitable to be used as a heat-insulation material for high-temperature furnaces such as vacuum heat treatment furnaces, single crystal pulling furnace, ceramic sintering furnace and the like.

Owner:辽宁奥亿达新材料股份有限公司

Ceramics of containing powder body of cubic silicon nitride, and preparation method

This invention discloses a ceramic containing cubic nitride powder. The ceramic is composed of: gamma-Si3N4 5-100 wt.%, at least one of Al2O3, ZrO2, alpha- or beta-Si3N4, SiC, BN and AlN 0-95 wt.%, and at least one of Y2O3, Al2O3 and La2O (sintering aid) 0-10 wt.%. The ceramic is prepared by: preparing the raw materials, dry-cooling, grinding by isostatic cool pressing, dry-pressing, assembling the sintering chamber, and sintering under an ultrahigh pressure. The method has such advantages as simple process, easy operation, low sintering temperature, and short sintering time. The ceramic has such advantages as high compactness, uniform microstructure, and good mechanical properties, and can be used in the fields of mechanics, chemical engineering, aviation and photoelectronics.

Owner:SOUTHWEAT UNIV OF SCI & TECH

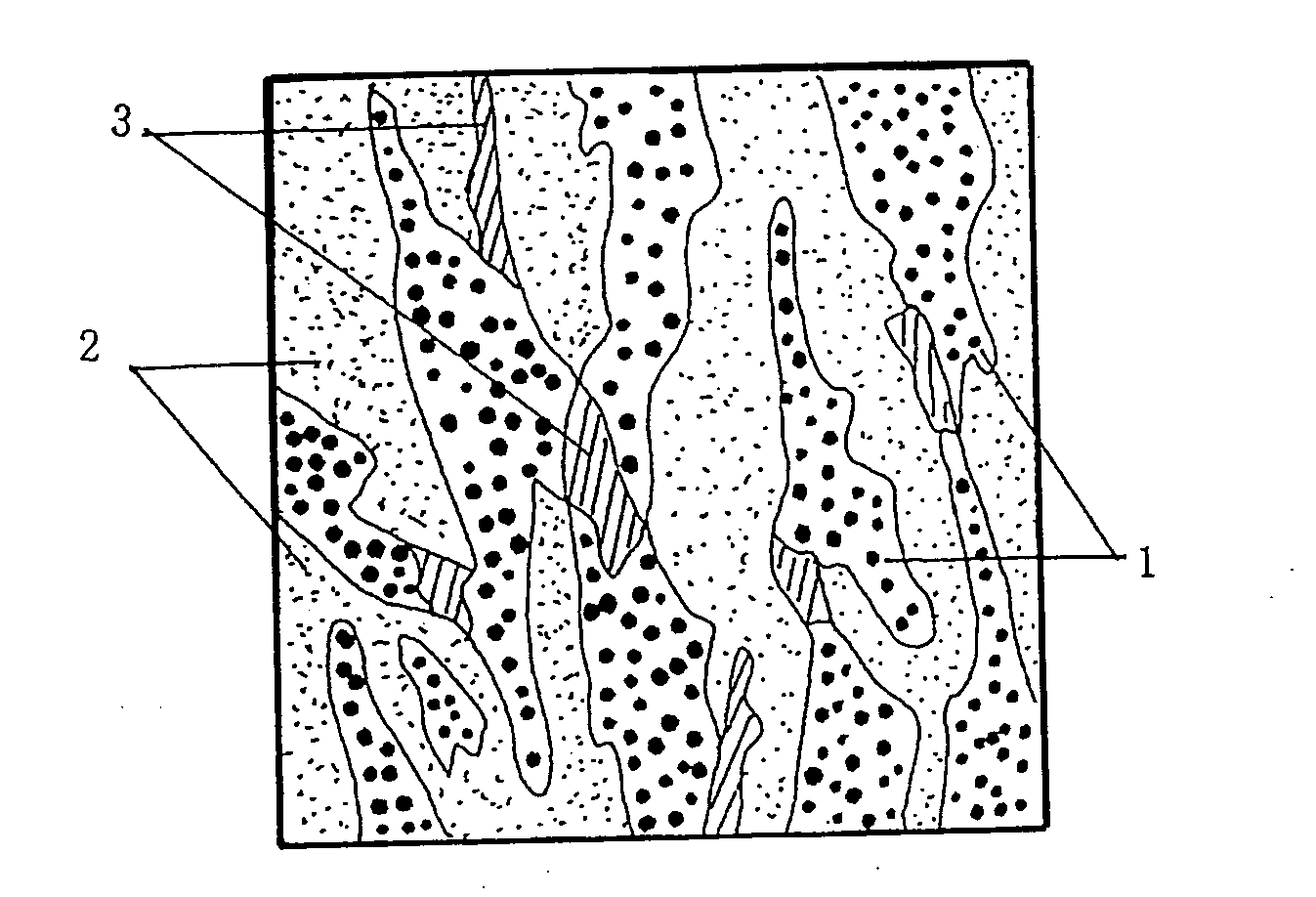

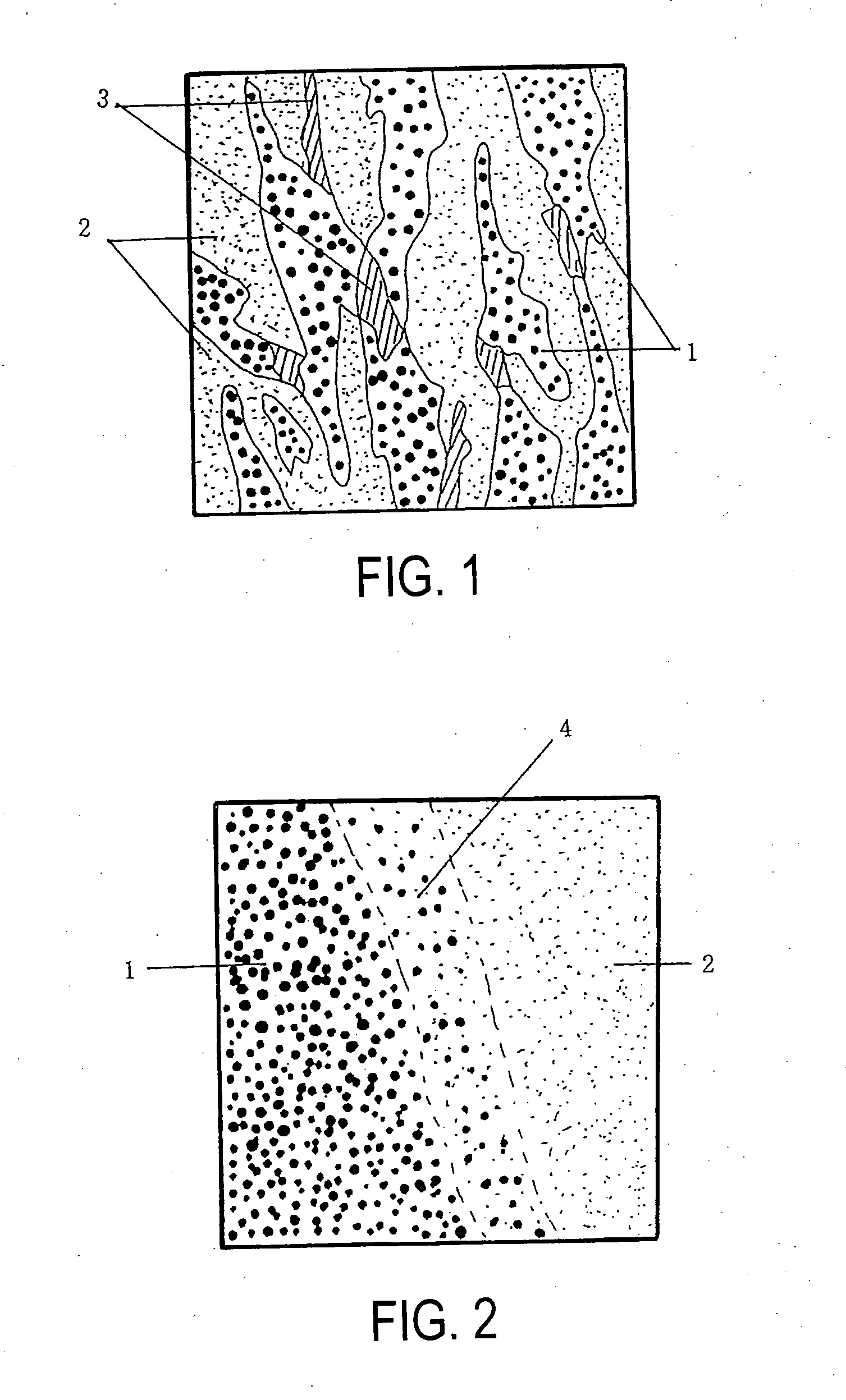

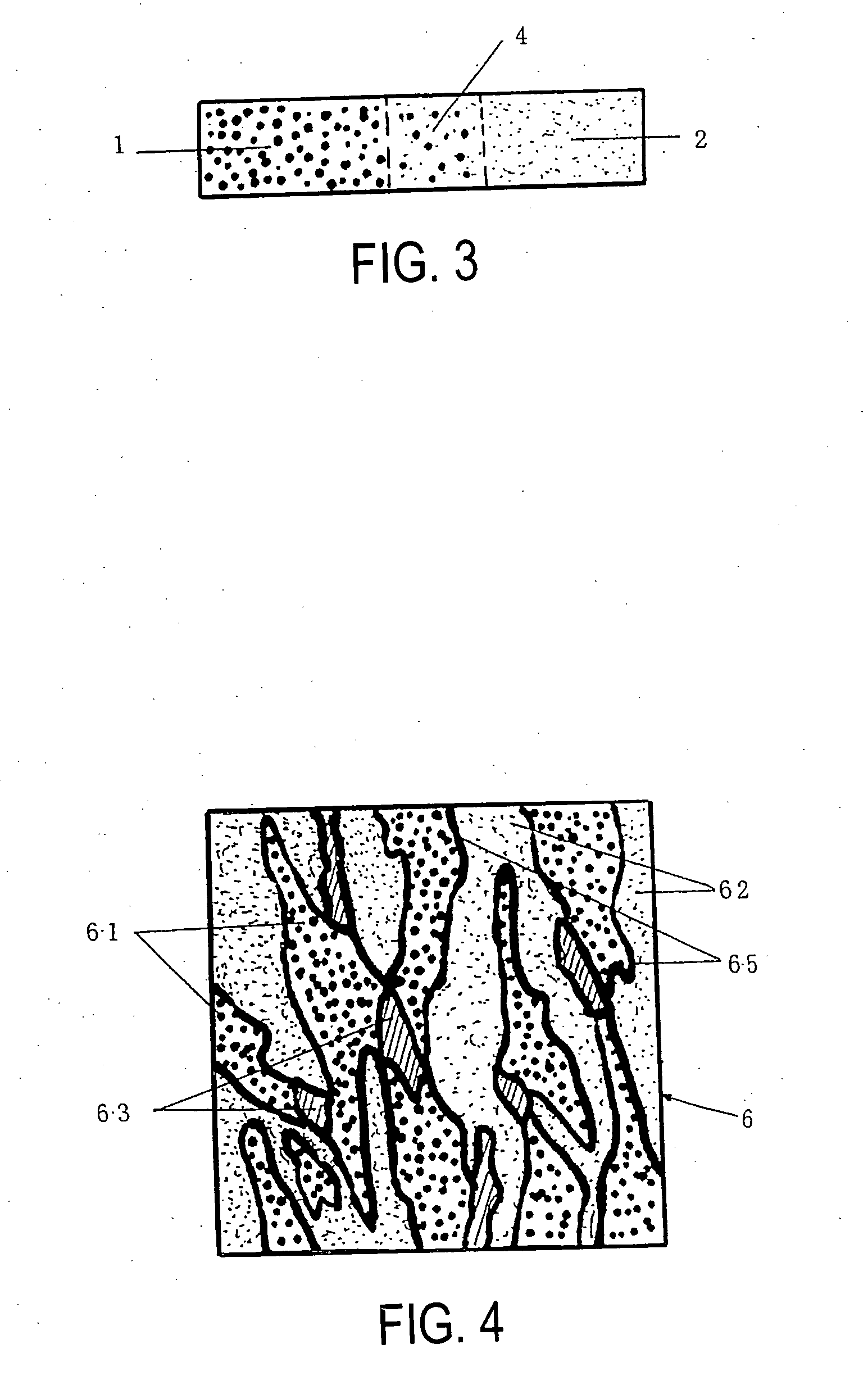

Three-dimensional colour pattern slabs which formed by sintering ceramic powder

InactiveUS20050013991A1Overcome defectsLess color differenceDead plant preservationArtificial flowers and garlandsCeramic sinteringMetallurgy

This invention relates to a the 3D color pattern slab formed by sintering ceramic powder, which is formed by pressing and sintering ceramic powders with minimum diameter of 0.1 mm-0.8 mm to provide a 3D color pattern slab formed by sintering ceramic powder, which is characterized in that, the ceramic product includes clear cut ceramic sintered pattern regions having 2-10 various kinds of colors or different shades of a single or mixed colors; at least 2 types of pattern regions each occupies 10%-90% of the total area of the ceramic product, in which at least each pattern region having at least one type of colored ceramic powder uniformly distributed in 80%-100% of the pattern area and 70%-100% from surface to the inside 70%-100% of the thickness of the ceramic product; also, in a 1 mm-20 mm intersecting region between said two types of colored pattern regions, the mixture ratio of the different colored powder material between two different color pattern regions can reach from 1:50 to 50:50. In this way imitation stone slab imitating natural stone in 3D space, with virtues of lower water absorption, less color difference, and higher degree of smoothness, and free of radioactive contamination etc.

Owner:YANG DENING

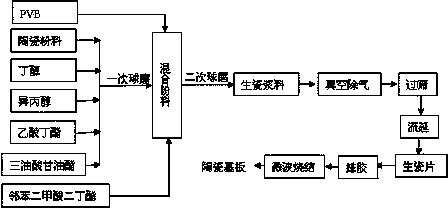

Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

The invention discloses an aluminum oxide ceramic substrate with high heat conductivity. The aluminum oxide ceramic substrate is prepared by steps of stirring a ceramic powder material, a binder, a plasticizer, a dispersant and a solvent uniformly, preparing a ceramic raw-ceramic substrate through a tape casting method, glue discharging and sintering. The aluminum oxide ceramic substrate is characterized in that the solvent is a mixture of butanol, isopropanol and butyl acetate, and the ceramic powder material comprises aluminium oxide powder and auxiliary agents. The invention also discloses a preparation method for the aluminum oxide ceramic substrate with the high heat conductivity. According to the aluminum oxide ceramic substrate and the preparation method, the solvent system which comprises the butanol, the isopropanol and the butyl acetate are used as the main solvent in place of traditional toluene, thus enhancing dissolution of PVB by the solvent, thereby guaranteeing uniformity of raw ceramic slurry, making physical properties of sintered ceramic stable, reducing environmental influences of the exhausted gas during production processes compared to traditional modes of production, contributing to energy conservation and emission reduction, and reducing the cost.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

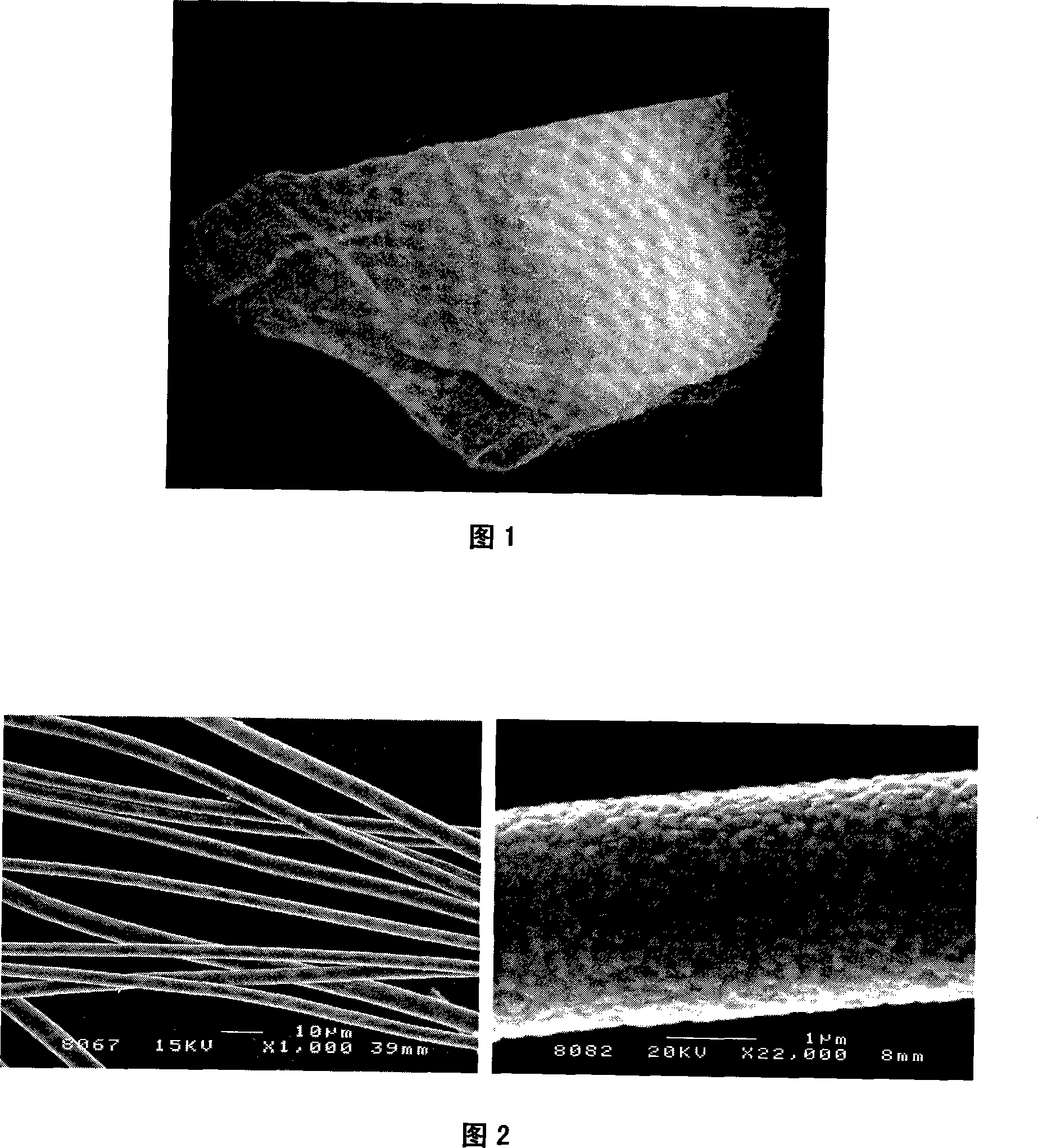

Method for preparing zirconium oxide refractory fibre

The present invention provides a method for preparing a zirconium oxide refractory fiber. The method adopts zirconium oxychloride, aqueous hydrogen peroxide solution, yttrium chloride or yttrium nitrate as raw material, the inorganic zirconium spinnable glue solution is made by reaction and compression, the gelatinous fiber can be obtained by centrifugal fiber forming, and after heat treating sintering the zirconium oxide refractory fiber which has the following advantages can be obtained: crystal phase composition with square phase and / or cubic phase zirconium oxide, purity up to 99.5% above, diameter around 5 mu m, length approximate continuous, soft and flexible property and without slag including sphere. The using temperature of the fiber is above 1600 DEG C, the material can be used as extreme temperature refractory, heat insulation material, protecting material, ablative material, satellite battery separator material and the like, used for the fields of aerospace, war industry and national defense, atomic energy and the like; the fiber can also be used as the flame-proof heat-insulating material of the extraordinary high-temperature electric furnace with temperature 1600 DEG C to 2200 DEG C, the oil or gas burning furnace and other extraordinary high-temperature heating mechanism, and is used for the fields of ceramic sintering, crystal growth, metal smelting, petroleum cracking, scientific researching and the like. The invention totally adopts the inorganic raw material, has the advantages of low cost, no pollution, simple technique and excellent effect.

Owner:山东红阳高温节能材料股份有限公司

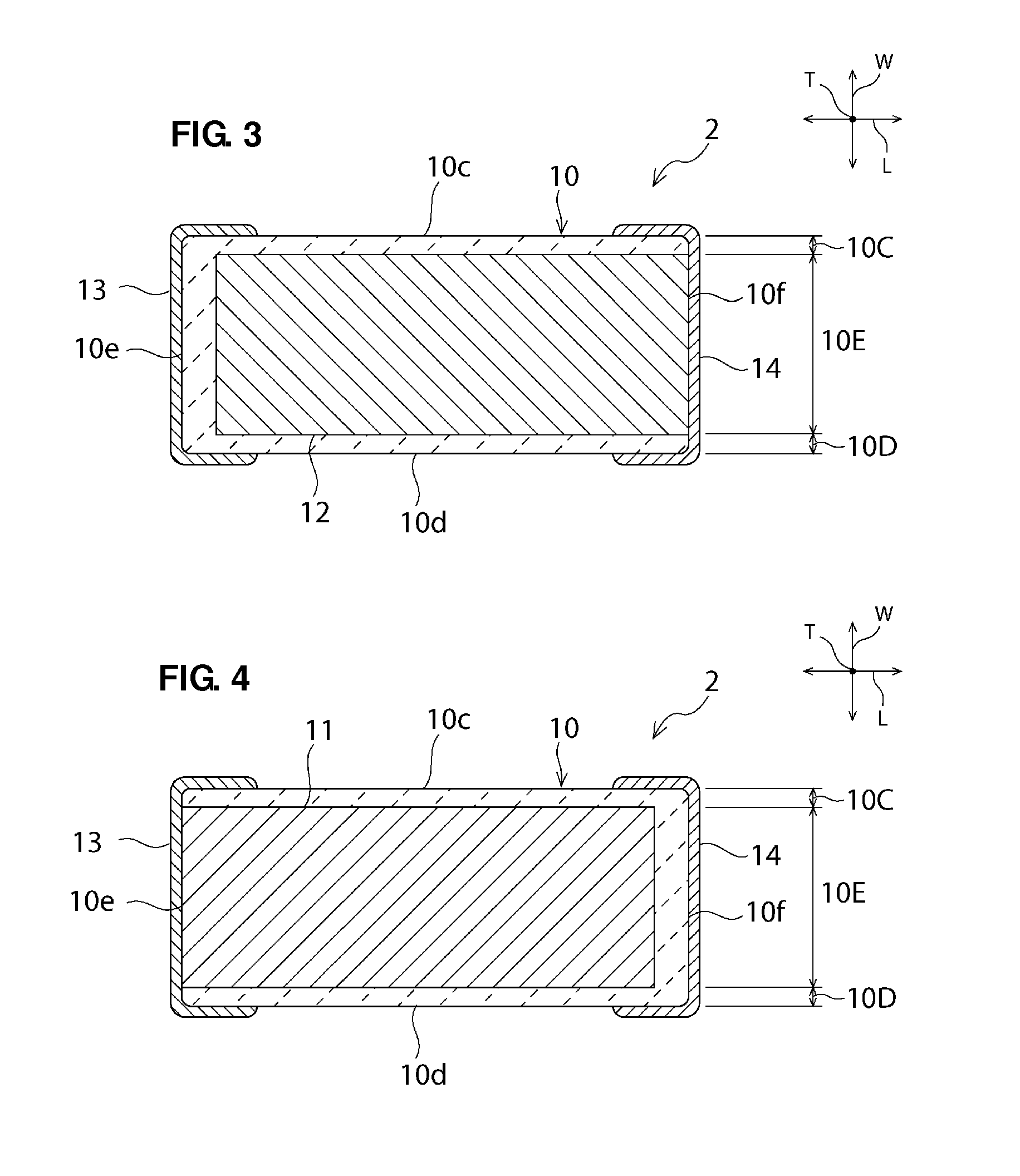

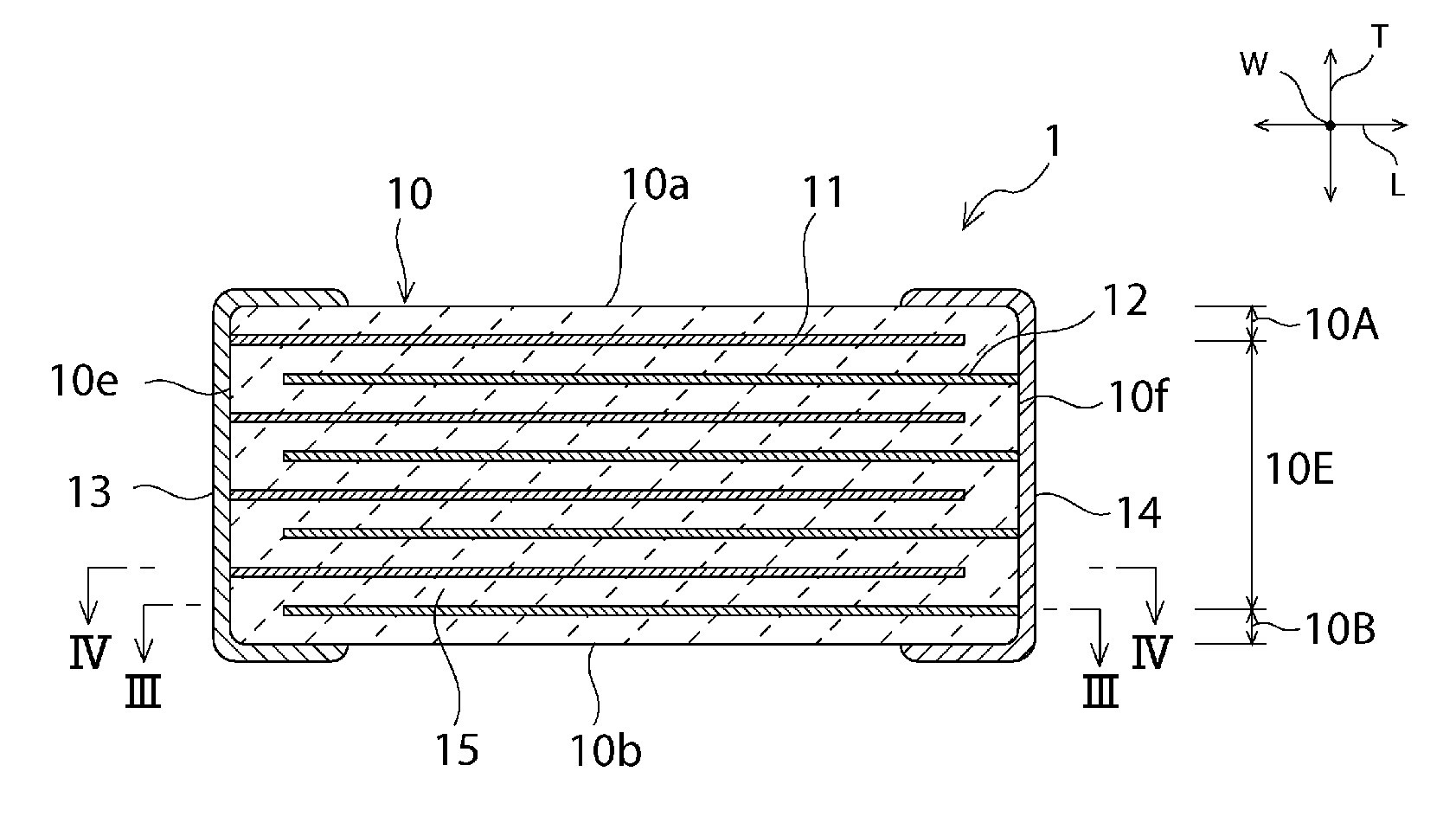

Monolithic ceramic capacitor

ActiveUS20120250217A1Improve performanceSmall sizeFixed capacitor electrodesFixed capacitor dielectricCeramic sinteringMetallurgy

A monolithic ceramic capacitor includes a ceramic sintered body including a plurality of stacked ceramic layers, and first and second inner electrodes alternately arranged inside the ceramic sintered body to oppose each other in a stacking direction of the ceramic layers with the ceramic layers interposed between the adjacent first and second inner electrodes. Among the ceramic layers, a number N of the ceramic layers disposed between the first inner electrodes and the second inner electrodes is at least 232. A proportion of volume occupied by the first and second inner electrodes in the ceramic sintered body is at least about 0.37. A size of each of side gap portions is about 40 μm or less.

Owner:MURATA MFG CO LTD

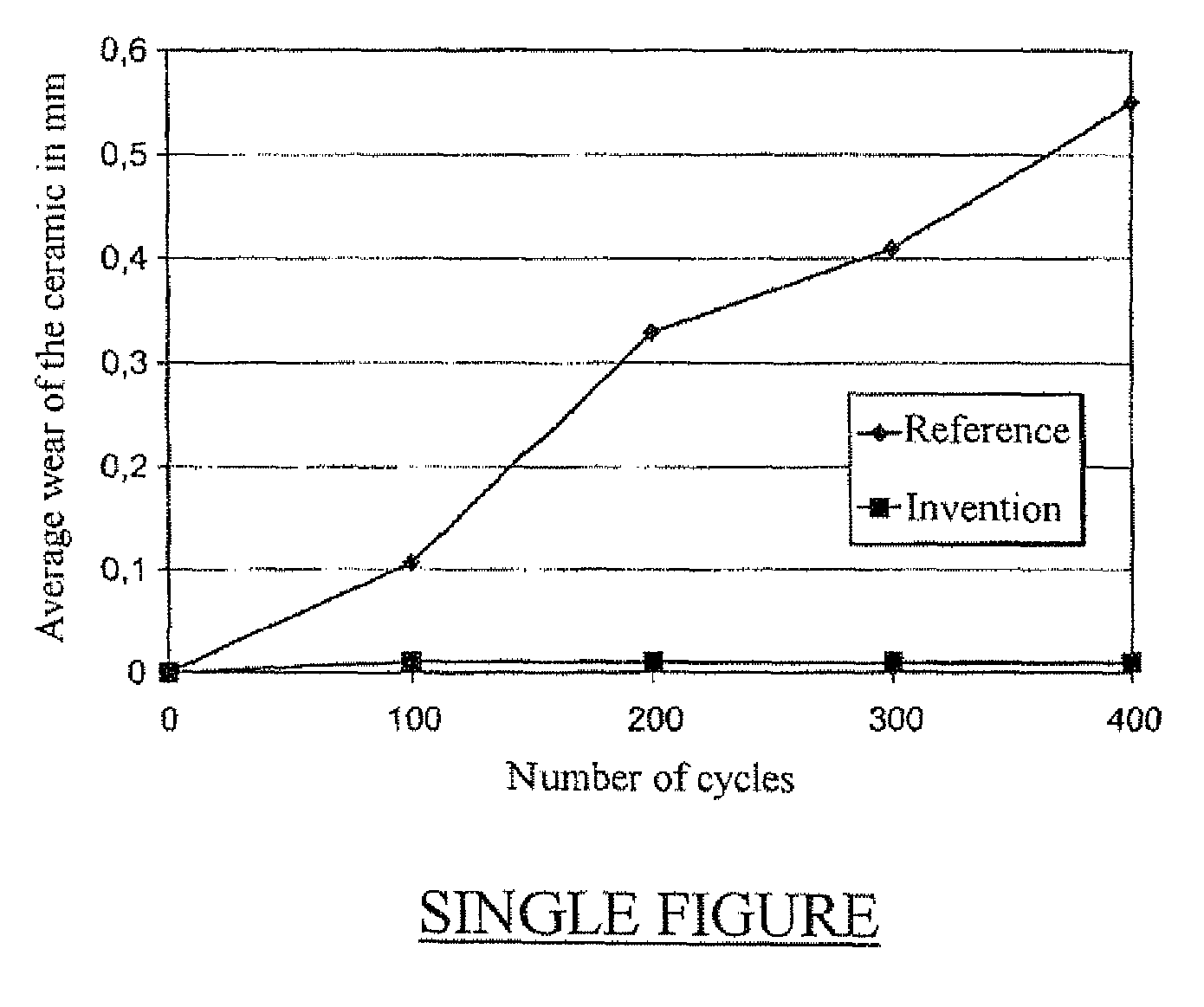

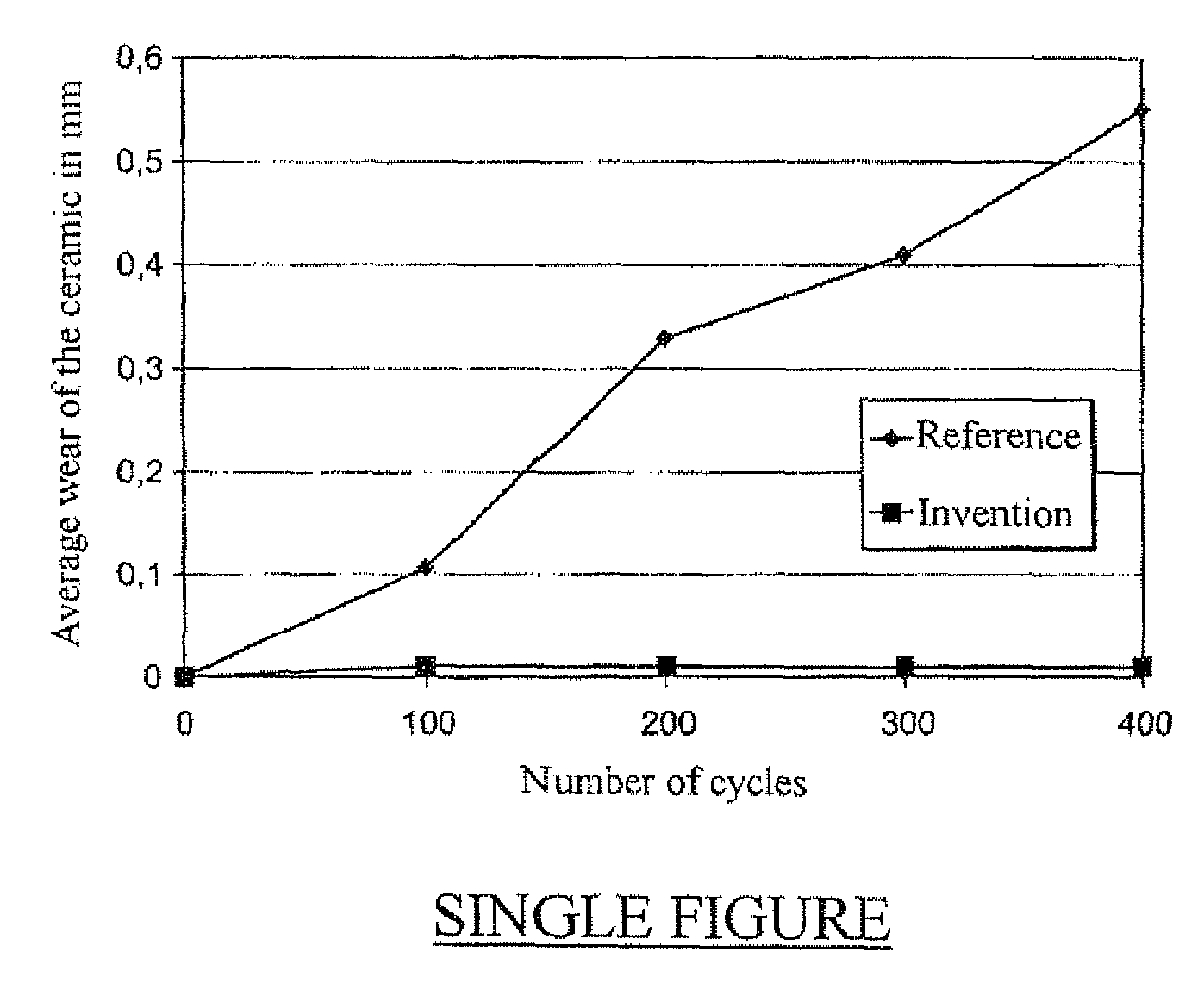

Process for the preparation of a sintered ceramic spark plug

Process for the preparation of a ceramic wherein: 50% to 75% by weight of a compound intended to form a conductive phase, and 25% to 50% by weight of one or more materials allowing the formation of insulating phases composed of silicon nitride and modified silicon oxynitride are mixed in a receptacle containing a liquid after a thermal treatment leading to sintering of the ceramic; this mixture is subjected to grinding, drying and sieving operations; this mixture is pressed; and this mixture is sintered so as to obtain a ceramic with a porosity of between 0 and 30%. The sintering is carried out under a pressure of at least 50 bar of a gas which is inert towards the constituents of the mixture. Ceramic thus obtained and spark plug comprising it.

Owner:AEVA

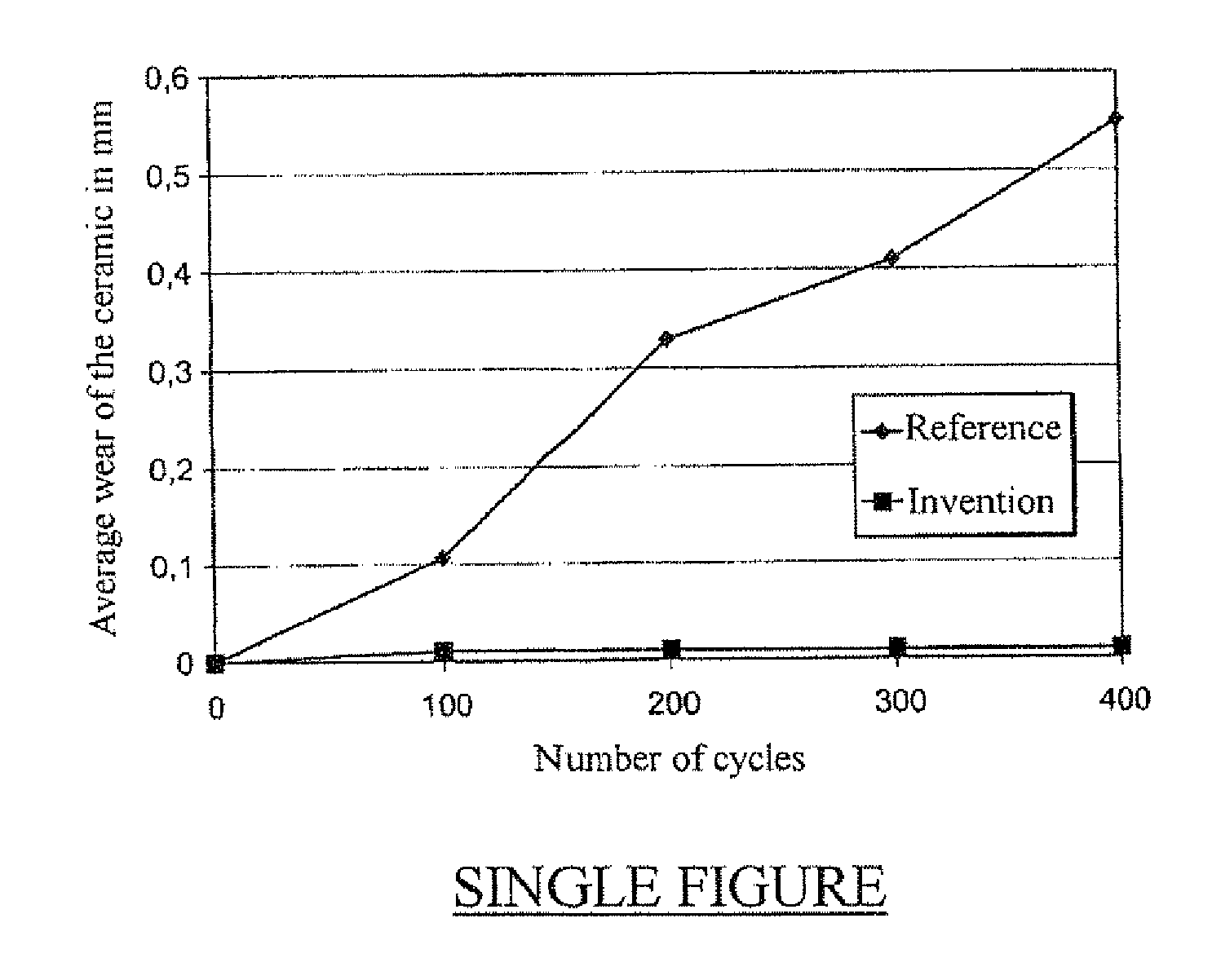

Process for the preparation of a sintered ceramic, ceramic thus obtained and spark plug comprising it

Process for the preparation of a ceramic wherein:50% to 75% by weight of a compound intended to form a conductive phase, and 25 % to 50% by weight of one or more materials allowing the formation of insulating phases composed of silicon nitride and modified silicon oxynitride are mixed in a receptacle containing a liquid after a thermal treatment leading to sintering of the ceramic;this mixture is subjected to grinding, drying and sieving operations;this mixture is pressed;and this mixture is sintered so as to obtain a ceramic with a porosity of between 0 and 30%.The sintering is carried out under a pressure of at least 50 bar of a gas which is inert towards the constituents of the mixture.Ceramic thus obtained and spark plug comprising it.

Owner:AEVA

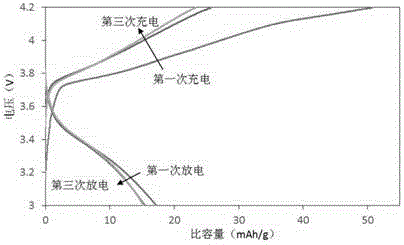

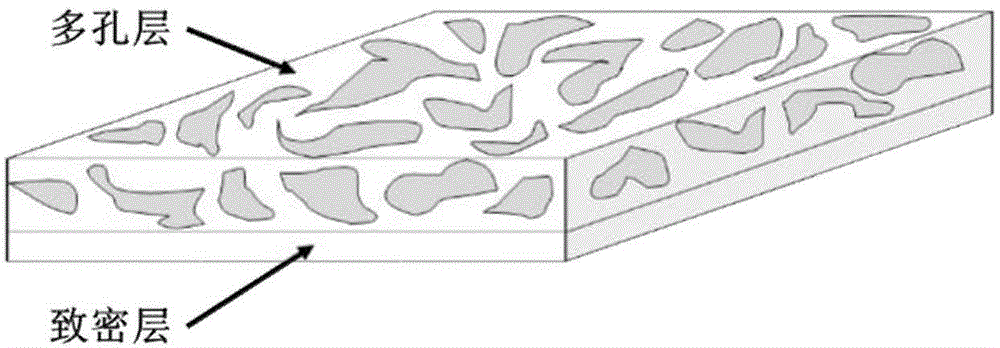

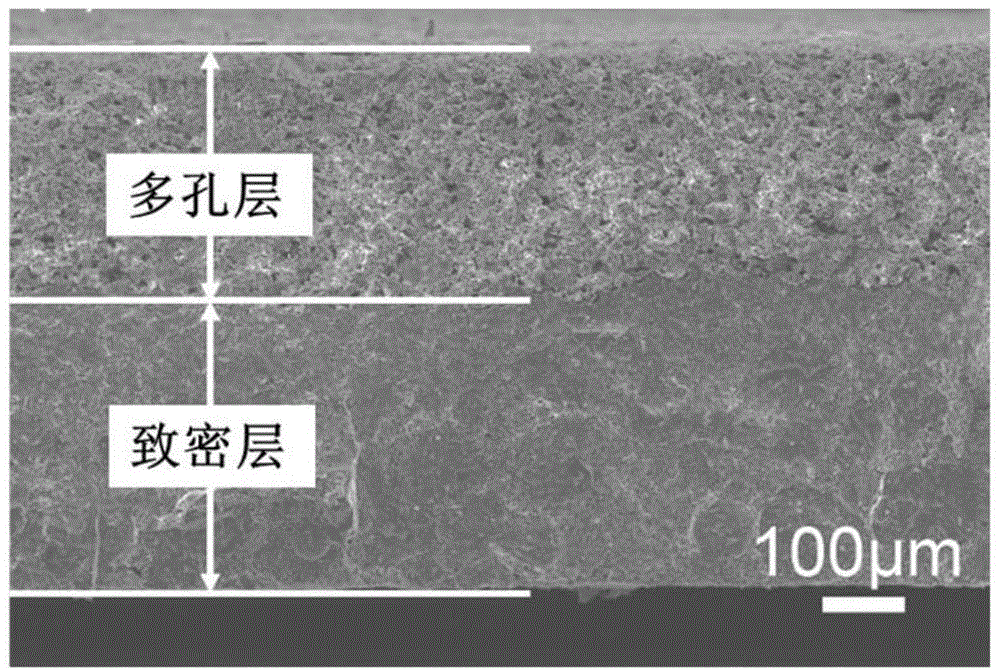

Porous-compact double-layer electrolyte ceramic sintered body, lithium ion battery and lithium-air battery

ActiveCN104916869ASolve the leakFix security issuesFuel and secondary cellsFinal product manufactureCeramic sinteringAll solid state

The invention discloses a porous-compact double-layer electrolyte ceramic sintered body based on inorganic solid state lithium ion electrolyte materials, an all-solid-state secondary lithium ion battery, an all-solid-state secondary lithium-air battery, and preparation methods. The preparation method for the sintered body comprises the following steps: first, powder of inorganic solid state lithium ion electrolyte materials is provided; second, part of the powder and pore forming agents are mixed, and mixed powder is obtained; third, the other part of the powder and the mixed powder form a green body, the green body comprises a first green body layer and a second green body layer which are stacked mutually, the other part of the powder forms the first green body layer and the mixed powder forms the second green body layer; fourth, the green body is subjected to sintering, the pore forming agents are burnt off, the porous-compact double-layer electrolyte ceramic sintered body is obtained, the first green body layer forms a compact layer and the second green body forms a porous layer.

Owner:TSINGHUA UNIV

Ceramic reinforced metal matrix abrasion-resisting compound material and preparation method

The invention discloses a ceramic reinforced metal matrix abrasion-resisting compound material and a preparation method. The compound material comprises a metal matrix abrasion-resisting component body, wherein a plurality of blind holes are formed on the surface of the metal matrix abrasion-resisting component body, and self-fluxing alloy powder metallurgically bonded with the metal matrix abrasion-resisting component body and ceramic sintering bodies are arranged in the blinding holes. At a sintering temperature of a vacuum furnace, the self-fluxing alloy powder is fused and is metallurgically bonded with the abrasion-resisting component body while the abrasion-resisting component body and the ceramic are not deformed. The process is simple and the prepared material with a required hardness can be acquired without being subjected to the heat treatment. By using the preparation method, the problem that the ceramic is difficult to be bonded with a metal substrate is solved and the defect caused by a pouring process is avoided. The ceramic, alloy and metal on the surface of the abrasion-resisting component are regularly distributed, the abrasion resistance of the abrasion-resisting component is ensured and the shock resistance is also ensured.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

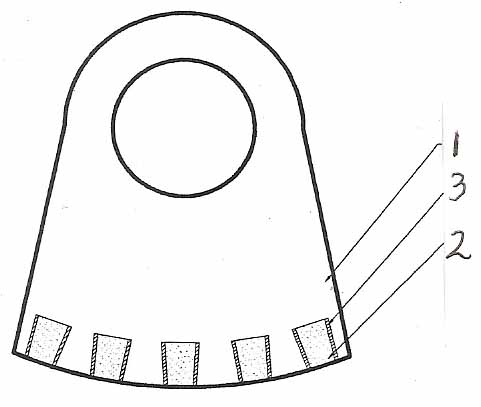

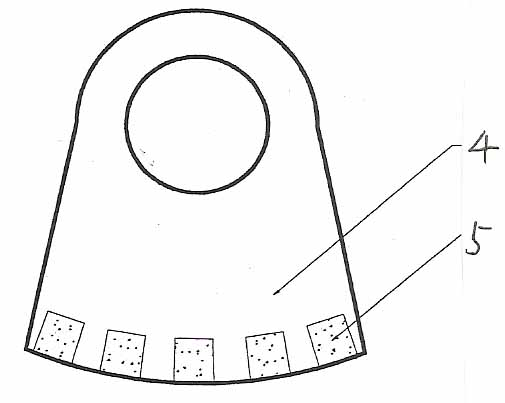

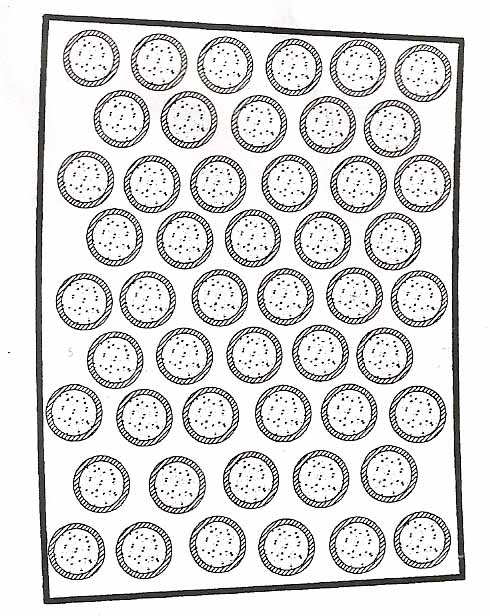

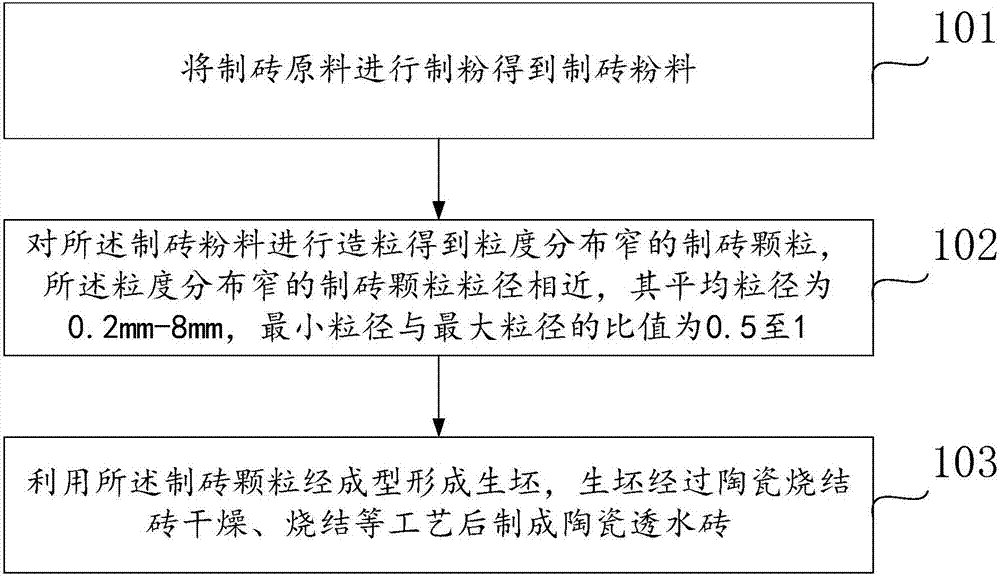

Method for preparing ceramic water permeable brick by virtue of granulation process

InactiveCN107141009ASimple manufacturing processThe quality of the preparation process is controllableCeramic shaping apparatusCeramic materials productionMetallurgyCeramic sintering

The invention provides a method for preparing a ceramic water permeable brick by virtue of a granulation process. The method comprises the following steps: pulverizing brick-making raw materials into brick-making powder; granulating the brick-making powder so as to obtain brick-making particles with similar particle sizes, wherein the ratio of the minimum particle size to the maximum particle size of the brick-making particles is 0.5 to 1; and forming a green body by virtue of the brick-making particles, and carrying out processes of ceramic sintering brick drying, sintering and the like on the green body, so as to obtain the ceramic water permeable brick. According to the method, a preparation process of the ceramic water permeable brick can be greatly simplified, the quality in the preparation process is relatively controllable, and the range of the raw materials of the water permeable brick is greatly extended to various waste, inferior raw mineral materials and the like; and the method has remarkable economic, environment-friendly and social benefits and wide application prospects.

Owner:UNIV OF SCI & TECH BEIJING

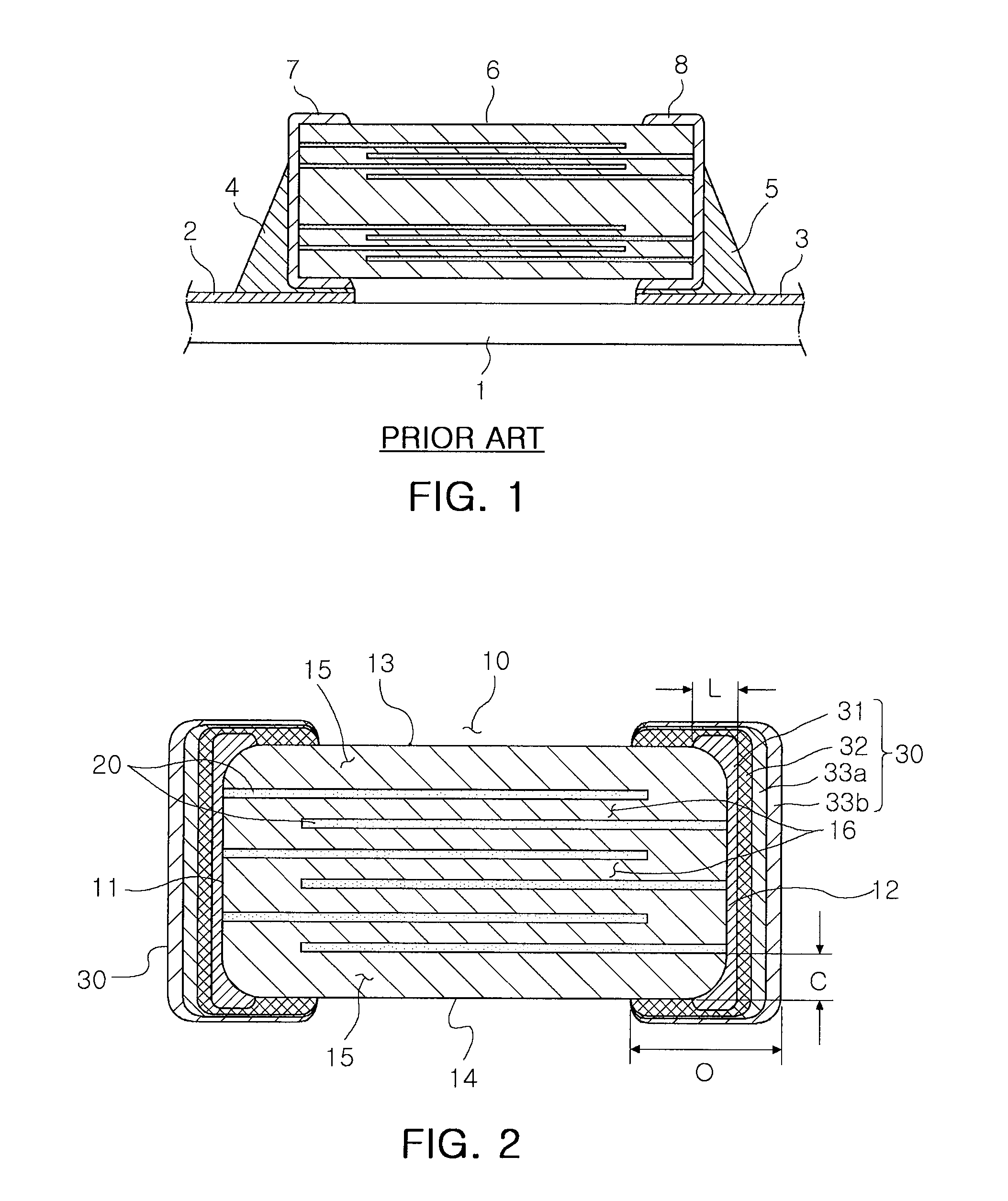

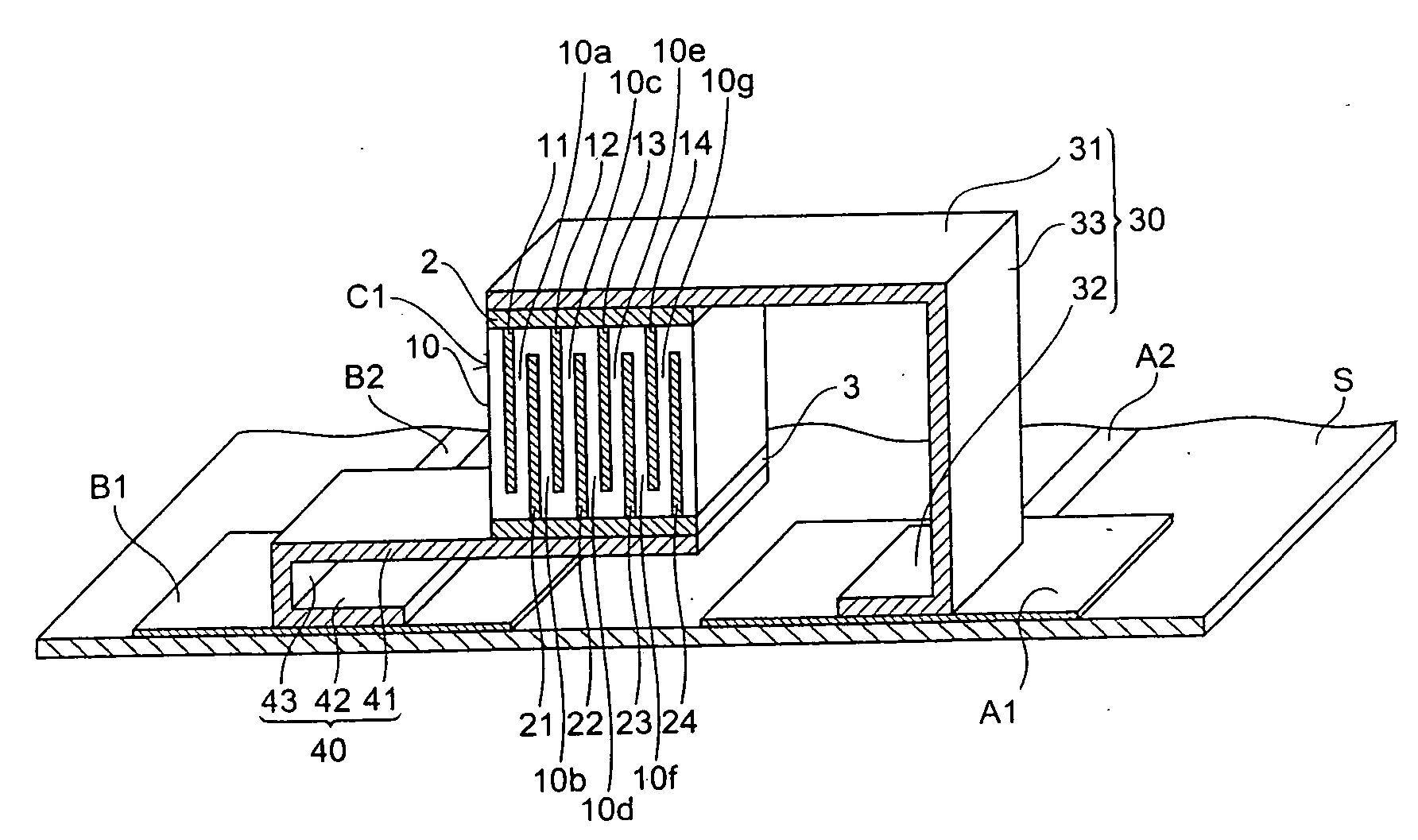

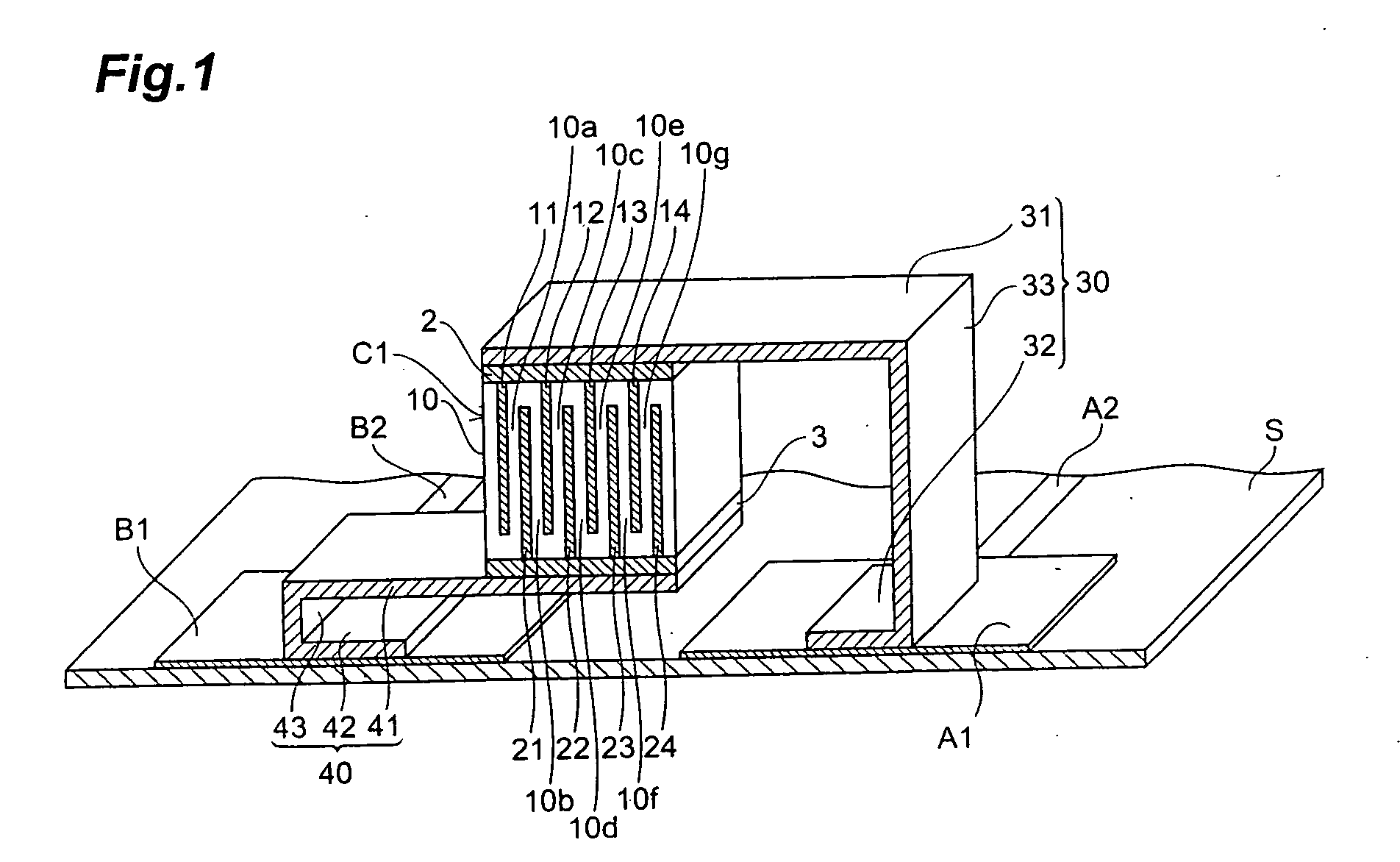

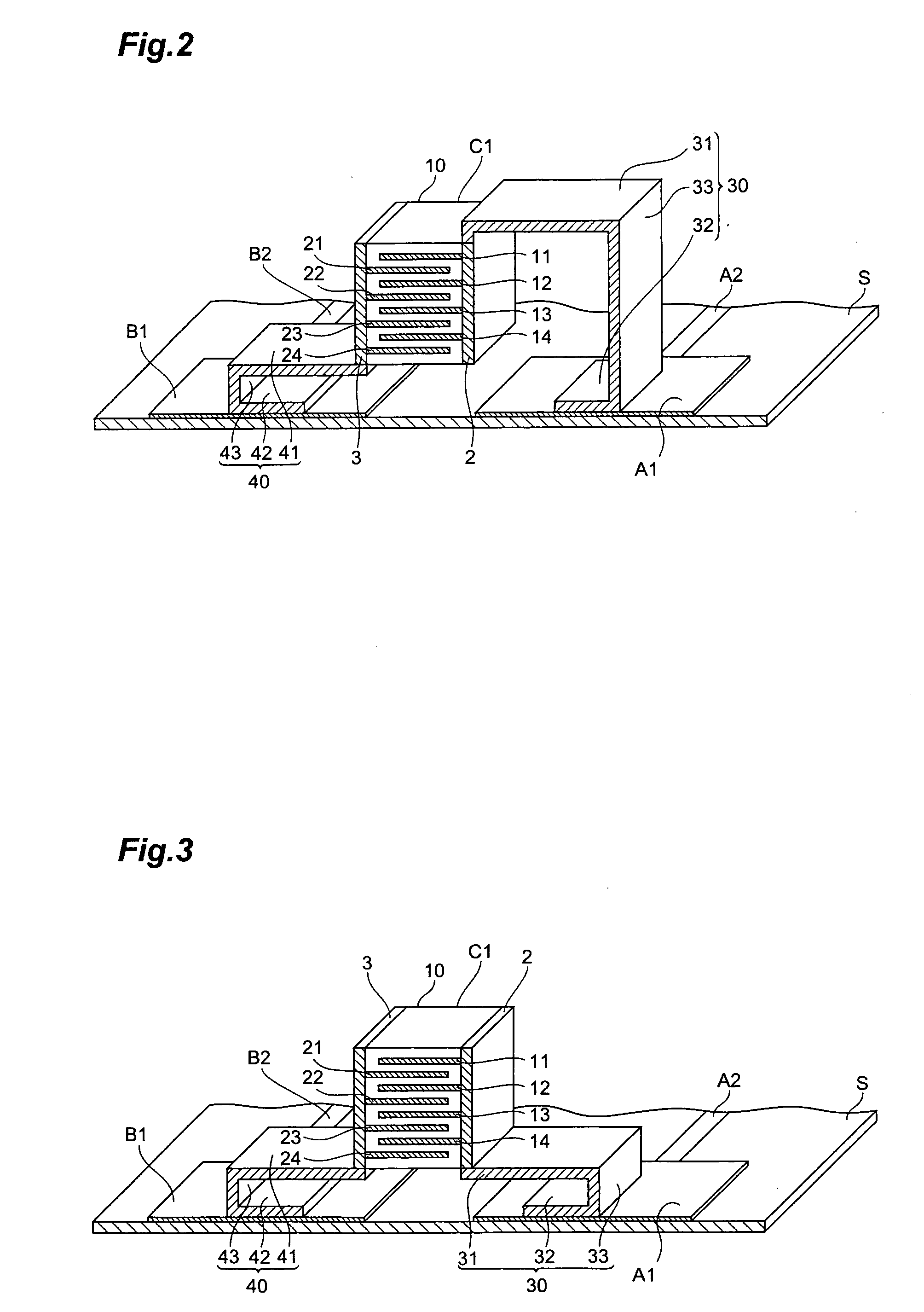

Ceramic capacitor mounting structure and ceramic capacitor

ActiveUS20070188975A1Reduce the soundAbsorb vibrationFurnace safety devicesFinal product manufactureCeramic sinteringCeramic capacitor

A ceramic capacitor comprises a ceramic sintered body, and first and second terminal electrodes formed on outer surfaces of the ceramic sintered body. The first terminal electrode is electrically connected to a land formed on a substrate through a first metal terminal. The first metal terminal has a first capacitor connecting portion mechanically connected to the first terminal electrode, a first terminal portion mechanically connected to the land, and a first intermediate portion electrically connecting the first capacitor connecting portion and the first terminal portion to each other. The first capacitor connecting portion of the first metal terminal is parallel to the substrate.

Owner:TDK CORPARATION

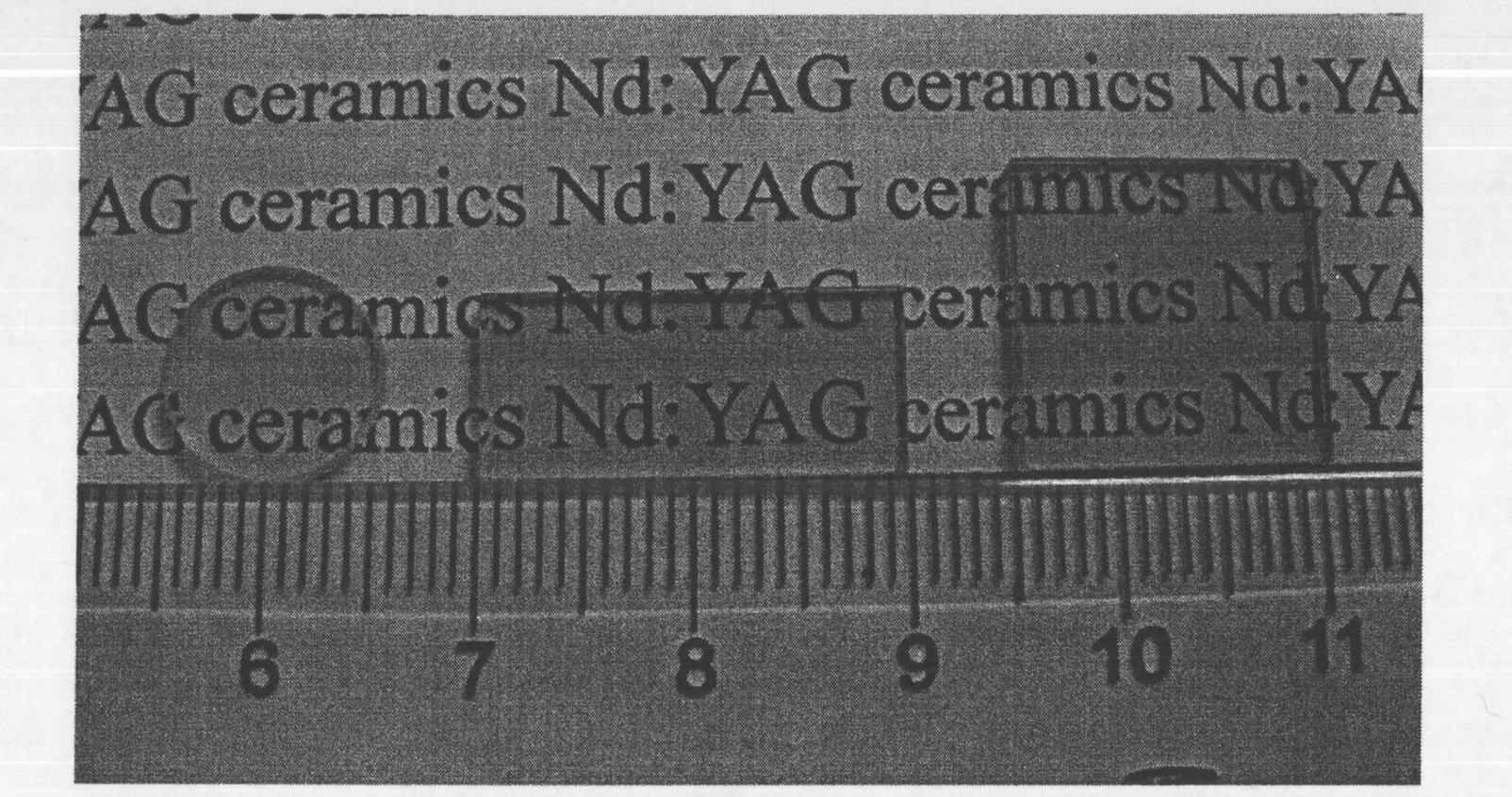

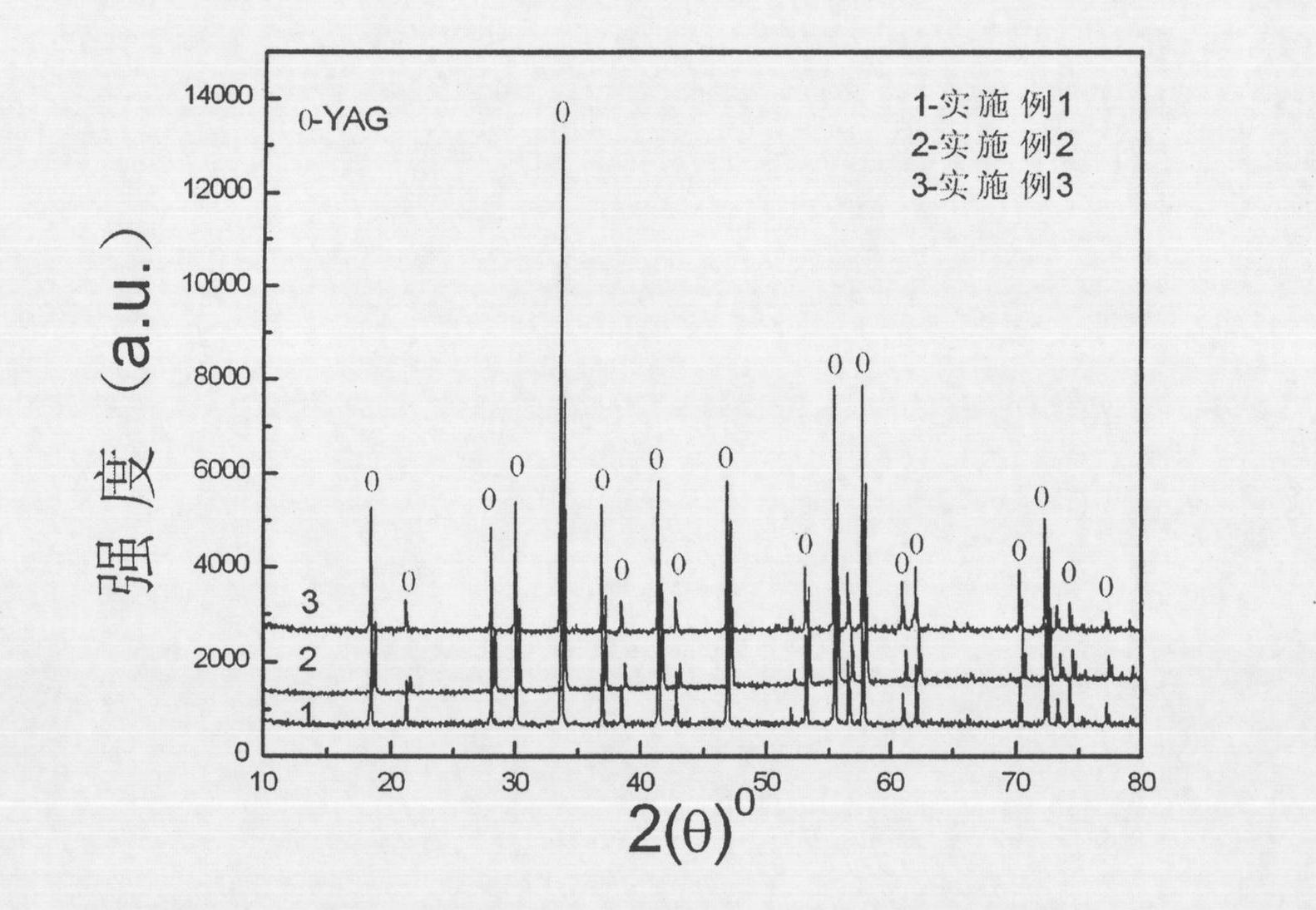

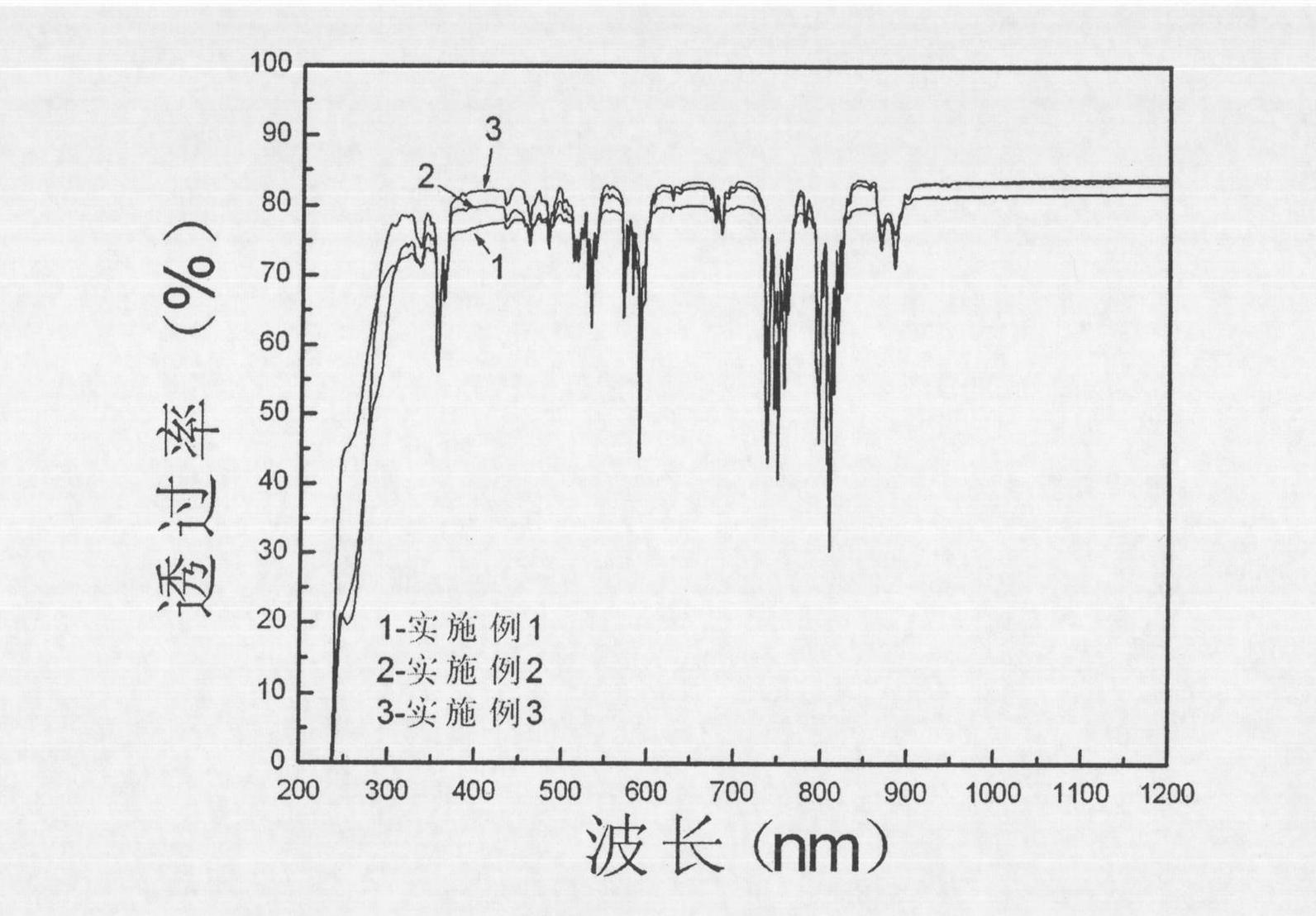

Method for preparing Re:YAG polycrystalline transparent ceramic by using different molding modes

The invention relates to a method for preparing Re:YAG polycrystalline transparent ceramic by using different molding modes, which adopts commercial high-purity Y2O3, Al2O3 and Re2O3 as raw materials, adopts MgO, CaO or TEOS (tetraethyl orthosilicate) as sintering additive, and prepares a raw blank by a cold isostatic pressing, slip casting or tape casting process to react and sinter the transparent polycrystalline Re:YAG ceramic. The method comprises the following steps: mixing and adding the oxides into a liquid medium; adding a certain amount of dispersant, adhesive, plasticizer, pressing agent and defoaming agent, carrying out ball milling, and mixing; treating the slurry under different conditions in different molding modes to obtain the raw blank; and sintering the degreased raw blank in a vacuum furnace. For the Re:YAG ceramic sintering body with thickness of 1.5mm, the transmission rate of straight light in the wavelength of 1064nm is not lower than 80% after the Re:YAG ceramic sintering body is subjected to double-sided polishing. For the raw blank which is prepared by different molding modes and is sintered for 10 hours at 1750 DEG C, sizes of ceramic grains are different, wherein regarding the raw blank prepared by cold isostatic pressing, the average grain of the ceramic is 13.5mu m; regarding the raw blank prepared by slip casting, the average grain of the ceramic is 3.5mu m; and regarding the raw blank prepared by tape casting, the average grain of the ceramic is 1.5mu m.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

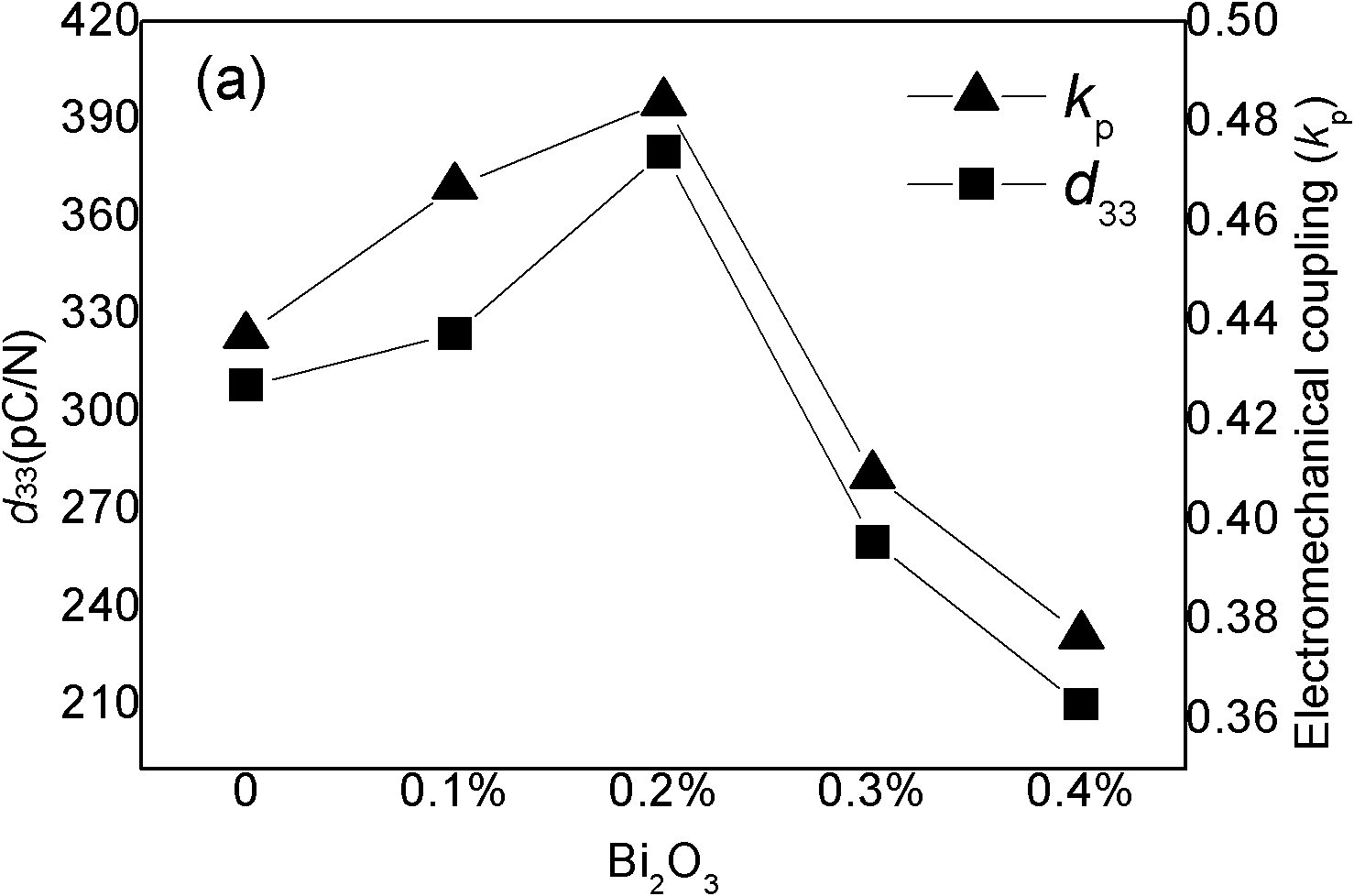

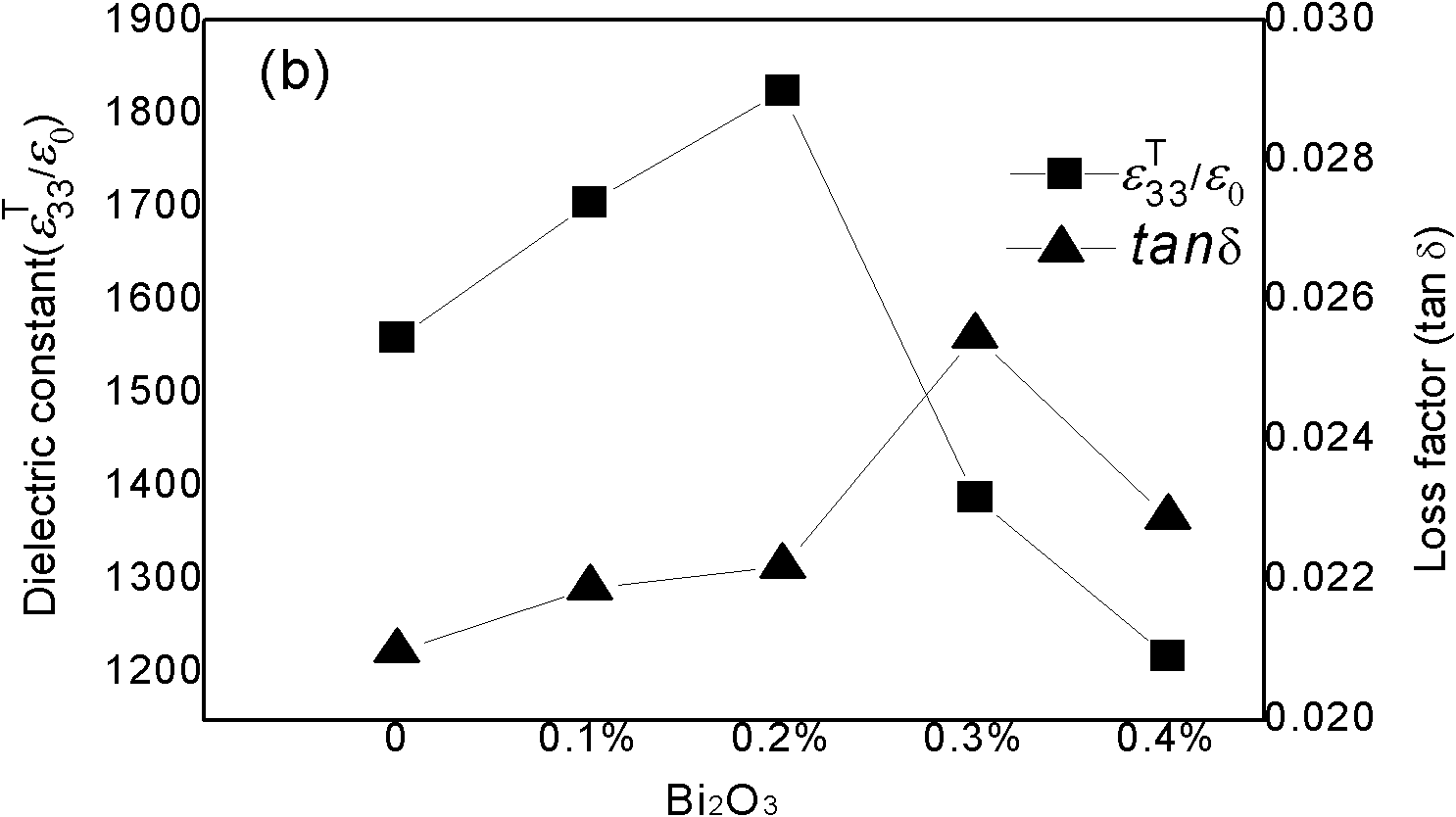

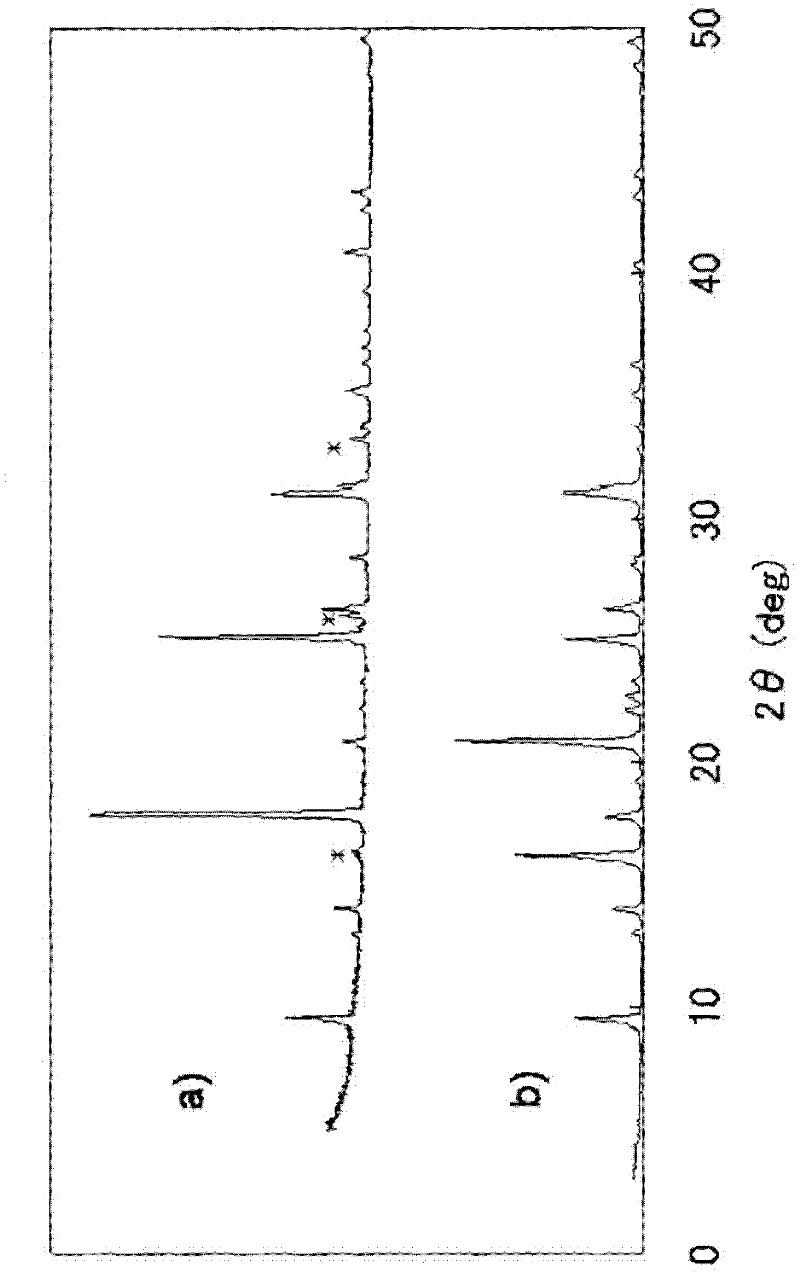

Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

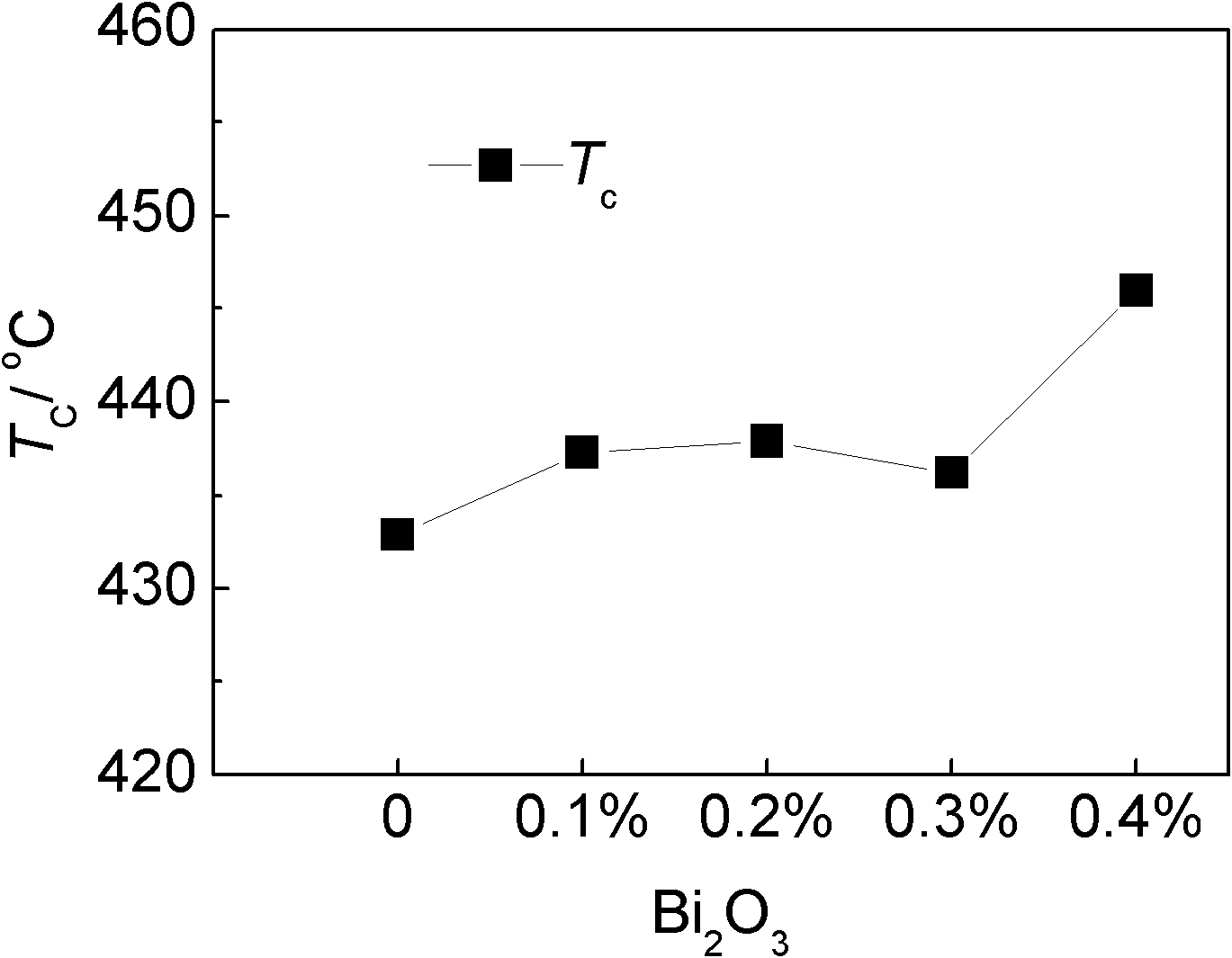

InactiveCN102180665AStoichiometric ratio is accurateLower sintering temperatureCeramic sinteringCurie temperature

The invention discloses a bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material comprises a matrix with the chemical formula of xBiScO3-(1-x)PbTiO3 and bismuth trioxide (Bi2O3) in an amount which is less than 0.4 percent of the total weight of the matrix. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material is prepared by adding excess Bi2O3 into raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3, wherein x is 0.35 to 0.38; and the using amount of the excess Bi2O3 is 0.1 to 0.4 percent of the total weight of the raw materials of Sc2O3, Bi2O3, Pb3O4 and TiO2 in the metering ratio according to the chemical formula of xBiScO3-(1-x)PbTiO3. The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material solves the problems that ceramic sintering temperature is increased and piezoelectric and dielectric properties are reduced due to deviation of a stoichiometric ratio caused by bismuth volatilization in the sintering process of BSPT ceramic, and has high Curie temperature, excellent piezoelectric property and an actual application value in high-temperature electronic equipment. The invention also discloses a preparation method for the bismuth scandate-lead titanate high-temperature piezoelectric ceramic material. In the preparation method, the piezoelectric ceramic material is prepared by synthesizing and sintering at lower temperature, so production cost is reduced, process steps are simplified, and the material has actual application value.

Owner:MORNSUN GUANGZHOU SCI & TECH +1

High-temp. honeycomb ceramic heat storage body and its preparation method

The present invention relates to a high-temp. cellular ceramic heat-storing body and its preparation technology. Said heat-storing body is made up by using Al2O3, MgO, ZrO2, carboxymethyl cellulose, polyvinyl alcohol, glycerine and tung oil as raw material through the processes of mixing, grinding, drying and sintering. Its fire-resisting temp. is greater than 1790 deg.C, axial compression strength is greater than or equal to 15 MPa, radial compression strength is greater than or equal to 5 MPa, pore wall density is greater than or equal to 2.65g / cu.cm, volume weight is grether than or equal to 0.66g / cu.cm, heat conducting coefficient; room temp. 10.1W / (m.k) and 1300 deg.C is 5.8W / (m.k); specific heal; room temp. is 0.884J / (g.k) and 1300 deg.C is 1.96J / (g.k) and its thermal expansion coefficient is less than 62.5X10 to the minus seventh deg.C(-1).

Owner:WUHAN UNIV OF TECH

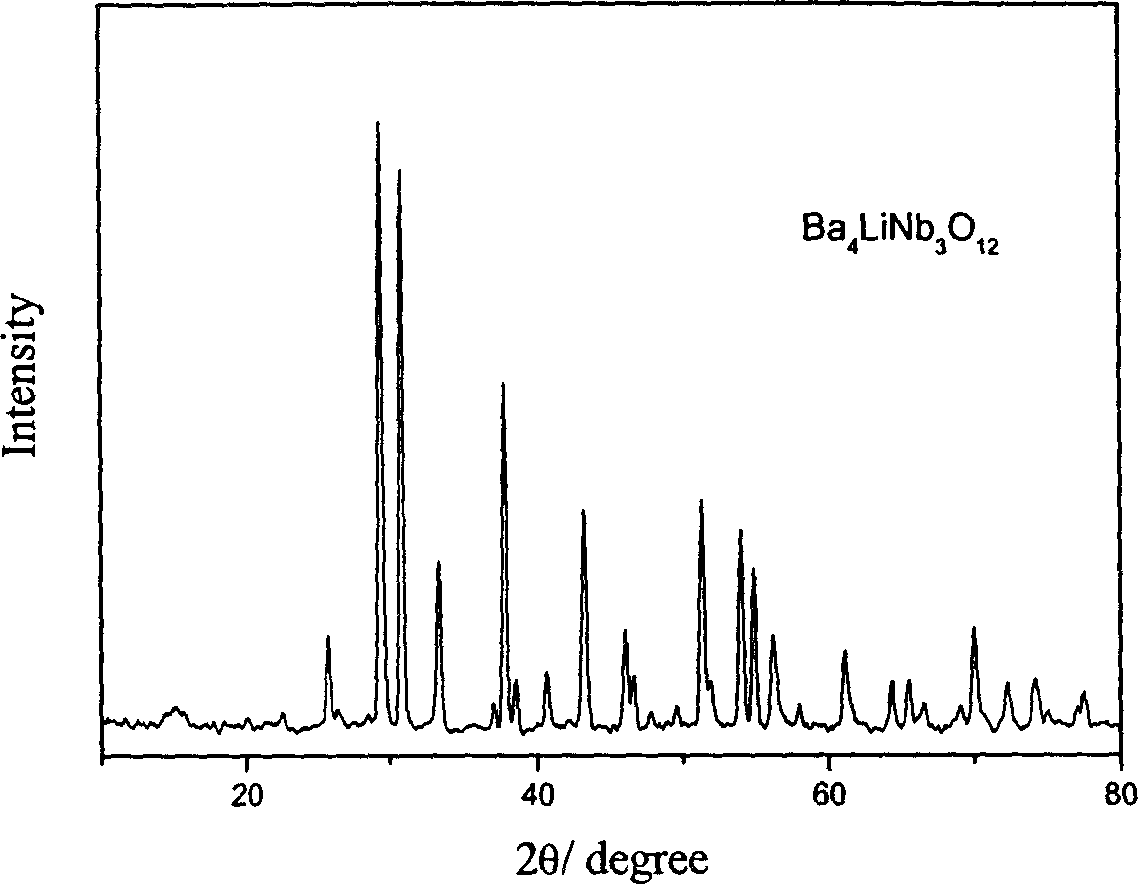

Low temp. sintering niobate microwave dielectric ceramic and preparation process thereof

The invention discloses a low temperature sintering niobate high frequency dielectric ceramic used in microwave component and ceramic capacitor or temperature compensating capacitor. The main phase of the ceramic is (Ba1-xSr x)4LiNb3-yTayO12, of which 0.00<=x<=1, 0.00<=y<=2. It is well sintering, low consumption, and high frequency dielectric constant could reach to 40-90.

Owner:WUHAN UNIV OF TECH

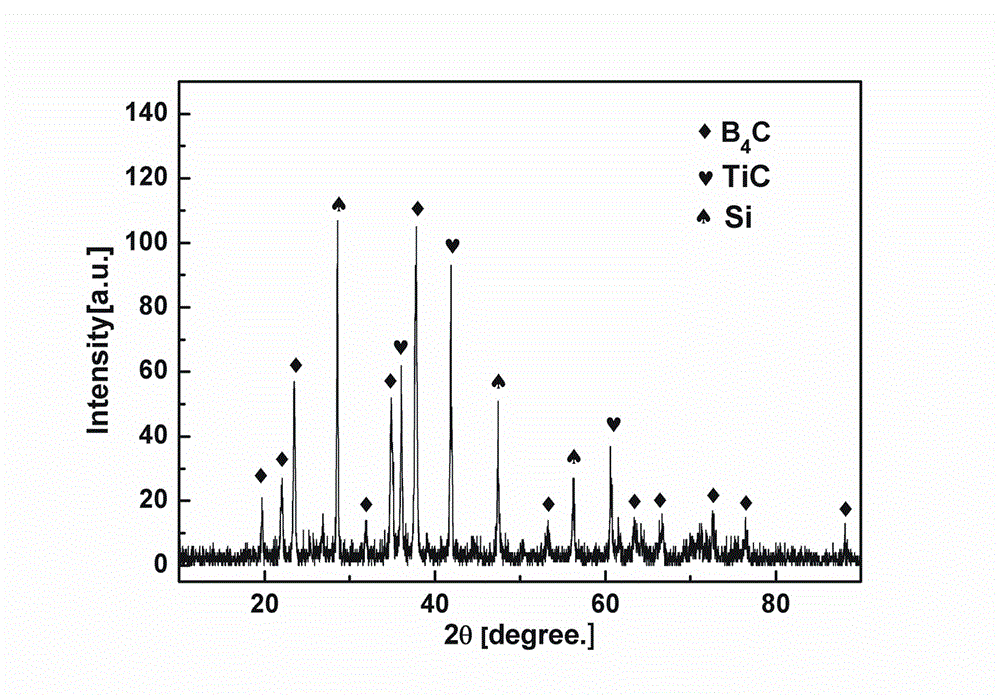

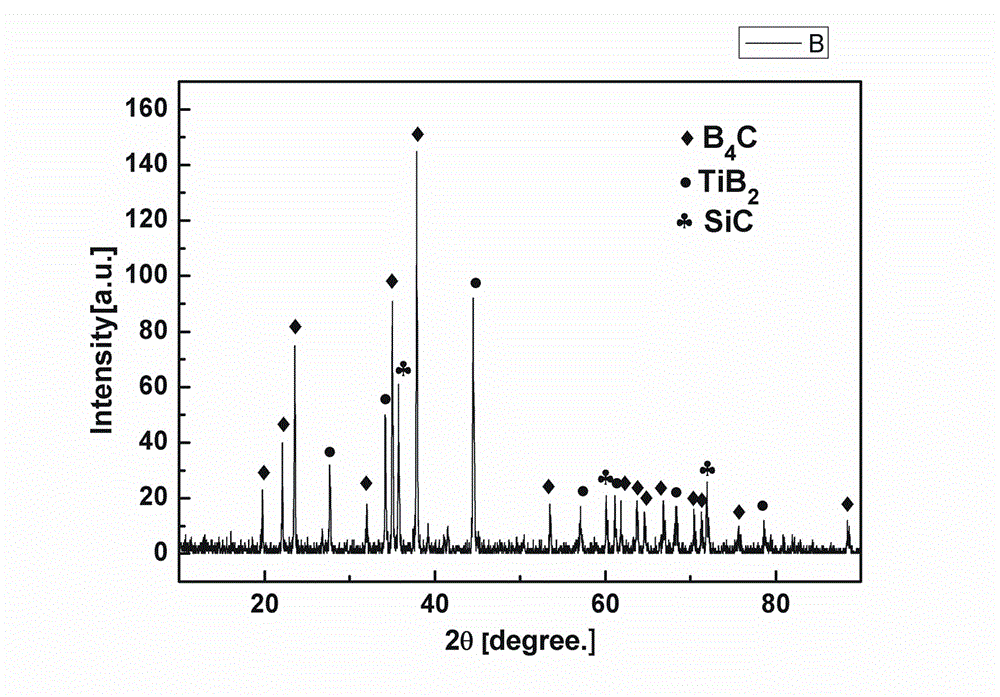

High-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and preparation method thereof

The invention relates to a high-hardness ceramic composite material of boron carbide-titanium boride-silicon carbide and a preparation method thereof, and belongs to the technical field of a ceramic material. The composite ceramic is prepared from boron carbide, silicon carbide and silicon powder in a hot-pressing sintering manner via reaction. The composite ceramic contains 50-90wt% of boron carbide, 27-5.4wt% of titanium boride and 23-4.6wt% of silicon carbide. The defects of overhigh sintering temperature, and difficulty of improvement of the toughness and the hardness at the same time of the existing boron carbide ceramic are solved; carbon generated by reaction of the boron carbide and the titanium boride is removed by monatomic silicon; and the carbon for reducing the hardness of the base material is converted into hard material silicon carbide which is evenly dispersed, so as to play roles in enhancing the toughness and improving the material hardness. The high-toughness boron carbide composite ceramic can be prepared at low temperature on the premise of not reducing the hardness of a base body.

Owner:WUHAN UNIV OF TECH

Powder comprising ceramic granules

ActiveUS20120282469A1Raise the level of performanceReduce contentSynthetic resin layered productsCellulosic plastic layered productsCeramic sinteringVitrification

The invention relates to a granulated powder intended, in particular, for the production of ceramic sintered parts, said powder having the following chemical weight composition, based on dry matter, namely: at least 1% of a first binder having a glass transition temperature less than or equal to 25° C.; 0-4% of an additional binder having a glass transition temperature greater than 25° C.; 0-4% of a temporary additive different from the first binder and the additional binder, the total content of the first binder, the additional binder and the temporary additive being less than 9%; 0-15% of an additive for sintering the ceramic material; at least 2% impurities; and the remainder comprising a ceramic material, and optionally an agent for stabilising said ceramic material, to make up 100%. According to the invention, the median diameter D50 of the powder is between 80 and 130 μm, the percentile D99.5 is less than 500 gm and the relative density of the granules is between 30% and 60%.

Owner:FIVEN NORGE AS

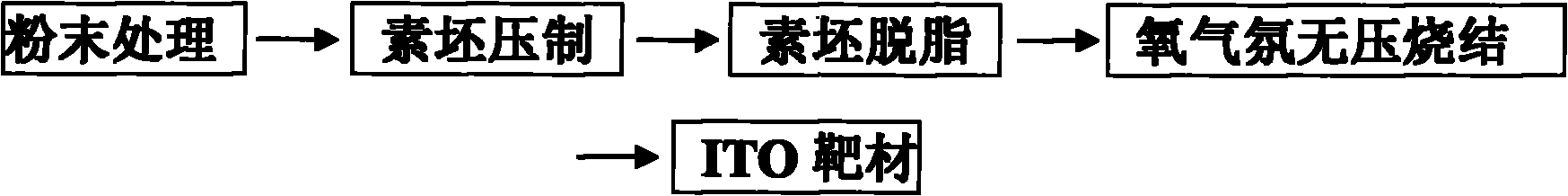

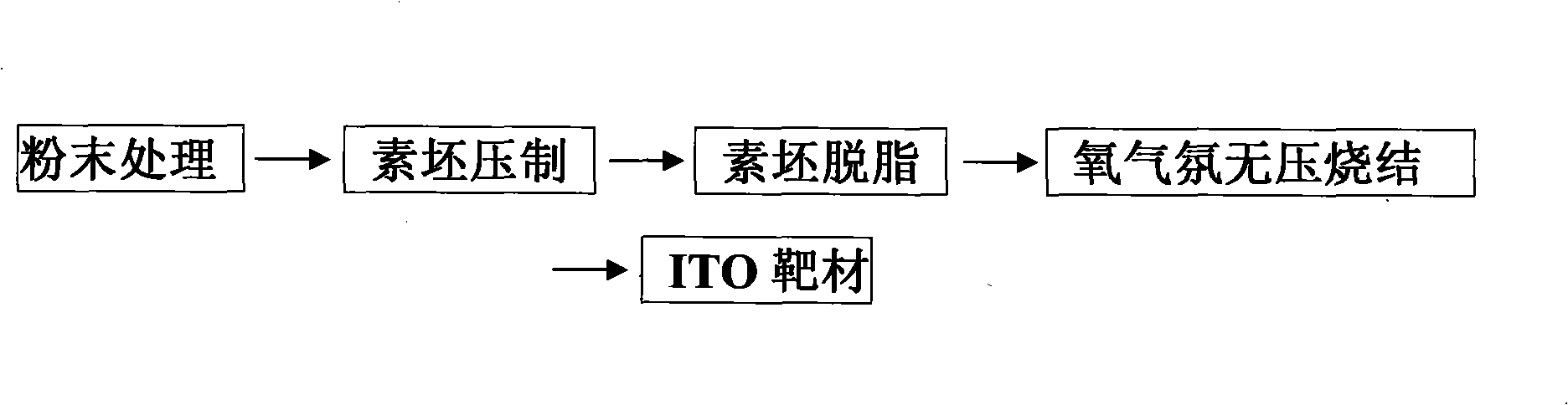

Method of preparing ITO target material by oxygen atmosphere pressureless sintering process

The invention discloses an innovative method of sintering ITO target material, and aims to realize pressureless oxygen atmosphere sintering by optimizing sintering process, and finally to obtain target material having high density and high performance. With sintering method as the basis and according to sintering characteristics of the ITO target material, the method adopts segmented sintering process, and controls oxygen partial pressure of the sintering atmosphere by controlling oxygen flow entering into a hearth to inhibit decomposition of the target material, and to finally obtain the high conductive performance target material, the density of which is more than 99.3%. The oxygen atmosphere pressureless sintering method is a novel ceramic sintering method, and is mainly applied to thesintering of oxide ceramics easy to decompose. Equipment for the method is simple, and products to be sintered are not restricted by size, so large-size ceramics can be produced. It is the first timeto produce the ITO target material by the method, and the ITO target material produced by the method is better than that produced by the commonly used sintering process with hot pressing, sintering process with hot isostatic pressing or common normal pressure sintering process.

Owner:KUNMING UNIV OF SCI & TECH

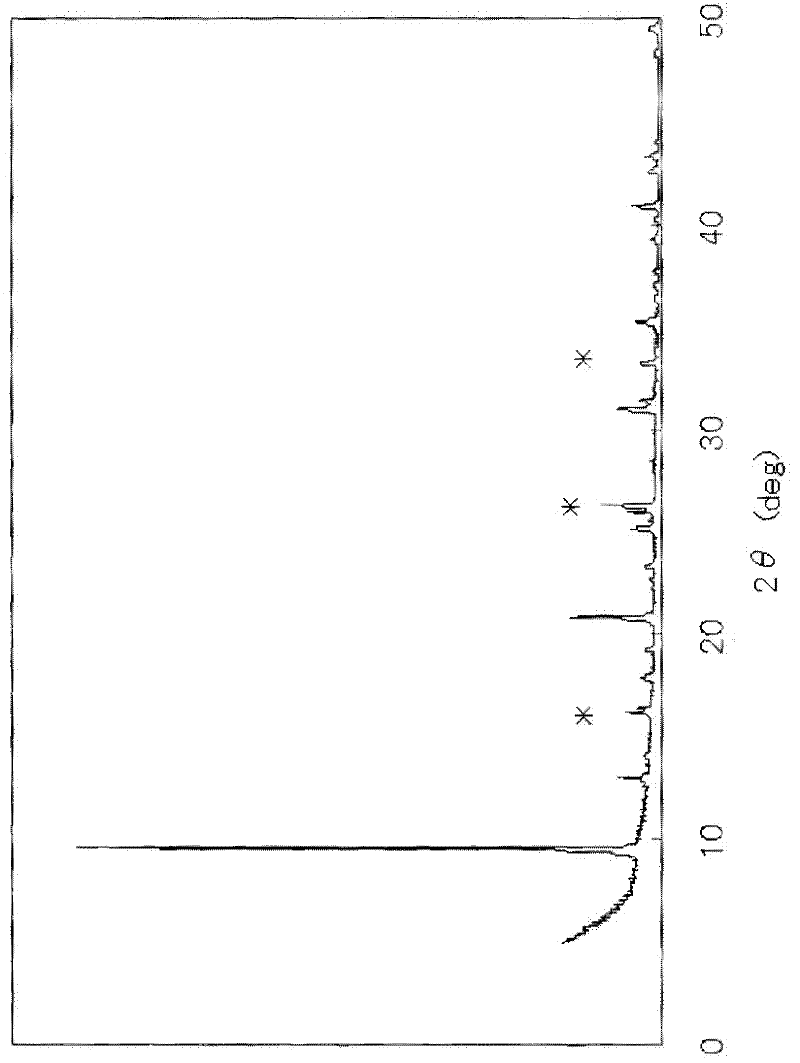

Inorganic porous support-zeolite membrane complex, method for producing same and separation method using same

InactiveCN102333584ALarge amount of processingThe separation effect is sufficientMembranesDispersed particle separationCeramic sinteringOrganic acid

Disclosed are a zeolite membrane complex capable of establishing both of practically sufficient treatment rate and separation performance, which is usable, in particular, in the presence of an organic acid, can be used for separating / concentrating a gas or liquid mixture containing an organic matter, is economically advantageous without requiring a high energy cost, and is not restricted in application range; a method for producing the same; and a separation / concentration method using the membrane complex. A complex composed of an inorganic porous support and a zeolite membrane, characterized in that the inorganic porous support contains a sintered ceramic, and a CHA type zeolite crystal layer is provided, as the zeolite membrane, on the surface of the inorganic porous support.

Owner:MITSUBISHI CHEM CORP

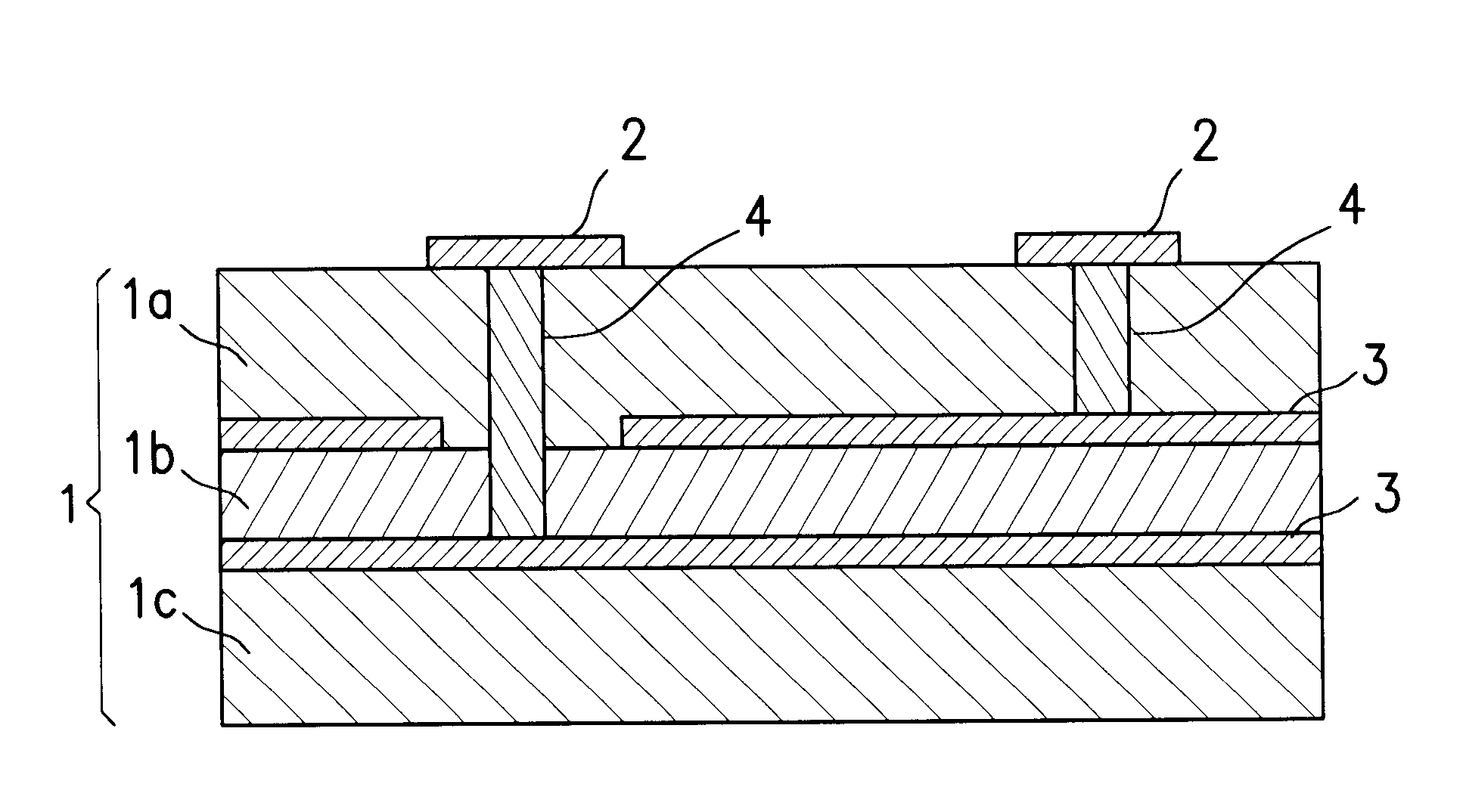

Ceramic wiring board

InactiveUS6447888B2Easy laminationReduce the differenceSemiconductor/solid-state device detailsPrinted circuit aspectsCeramic sinteringThermal expansion

A ceramic wiring board provided with an insulating layer of a high dielectric constant formed of a ceramic sintered product having a high dielectric constants wherein the ceramic sintered product contains a crystal phase of lanthanum titanate and a glass phase present on the grain boundaries of the crystal phase, and has a coefficient of thermal expansion at 40 to 400.degree. C. of not smaller than 8.times.10.sup.-6 / .degree. C. and a specific inductive capacity at 1 MHz of not smaller than 10. The wiring board contains a capacitor and is very useful in realizing various electric circuit devices in small sizes, and can be further reliably mounted on a printed board that uses an organic resin as an insulating material.

Owner:KYOCERA CORP

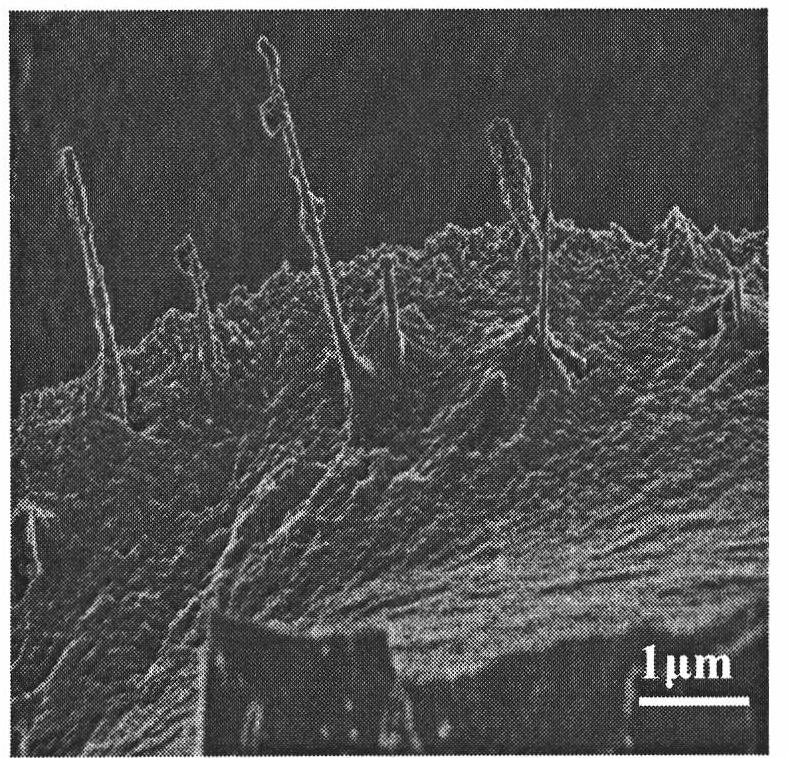

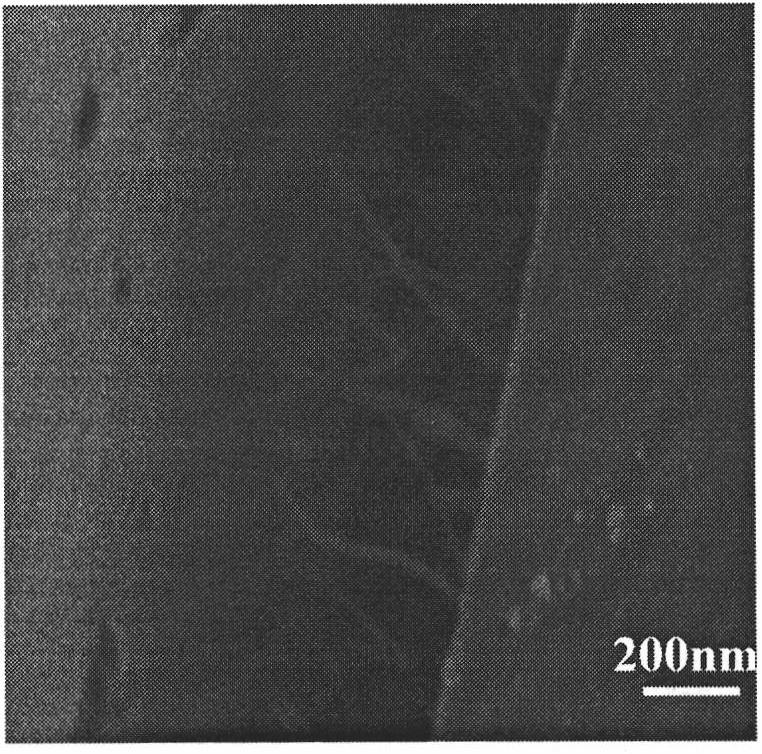

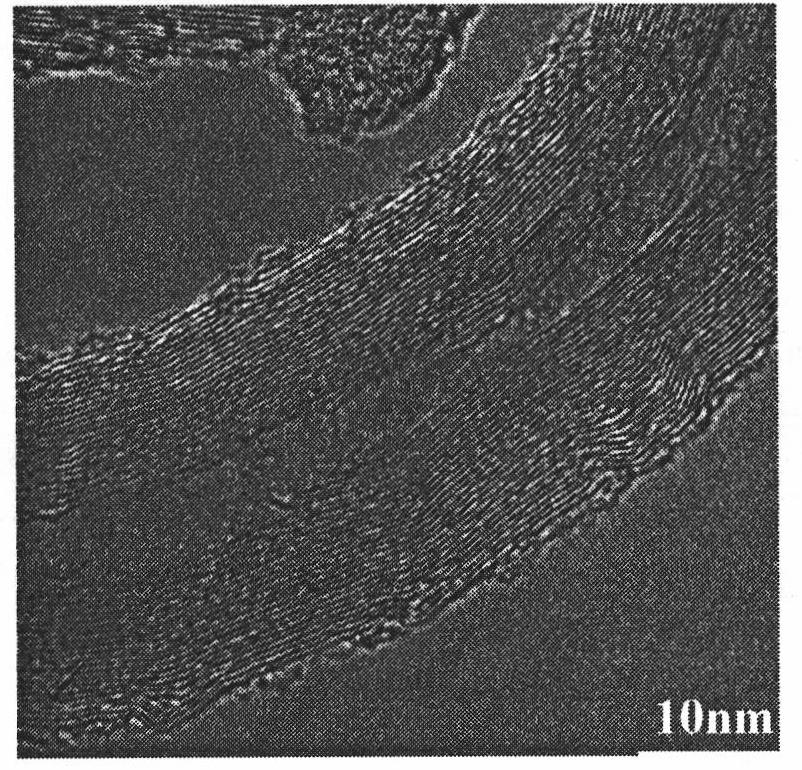

Ceramic and carbon nano-fiber composite material and preparation method thereof

ActiveCN101774814AImprove performanceEvenly dispersedNanostructure manufactureCeramicwareCeramic sinteringCeramic composite

The invention relates to a ceramic and carbon nano-fiber composite material and a preparation method thereof. The preparation method has a principle of directly growing carbon nano-fiber in a ceramic hole which is formed in a ceramic body in the ceramic forming process to prepare the ceramic and composite material. The specific process comprises the following steps: mixing a metallic catalyst and ceramics; inputting carbonous gas to a system in an intermediate stage of preparing the ceramics by sintering or pyrogenation; directly growing the carbon nano-fiber in the hole by utilizing the metallic catalyst formed in the ceramic hole; and further rising the temperature and sintering or pyrolyzing the ceramics which grows the carbon nano-fiber to prepare the carbon nano-fiber and ceramic composite material. Through the in-situ preparation method, the ceramic composite material with the uniformly-distributed carbon nano-fiber can be prepared. As the growing of the carbon nano-fiber is completed by one step in the process of sintering or pyrolyzing the ceramics, the flow process is simple and controllable, and has the characteristics of low preparation temperature; the composite materials with different shapes and sizes can be prepared; and the flow process can be applied to the preparation of the high-performance fiber reinforced ceramic composite material and in an application field thereof.

Owner:TIANJIN UNIV

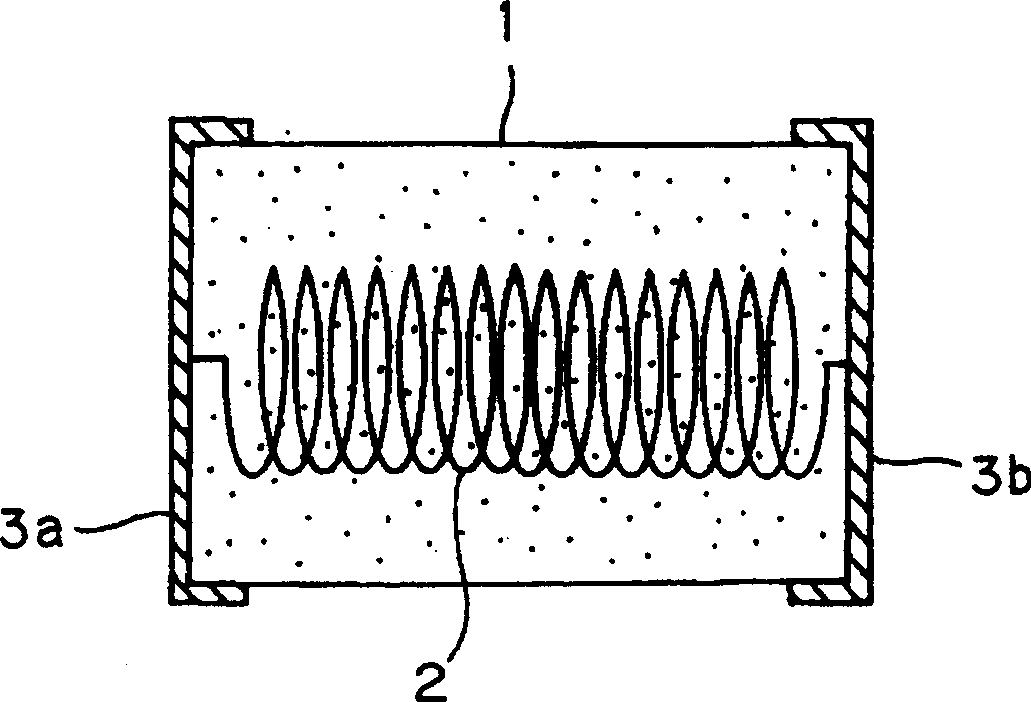

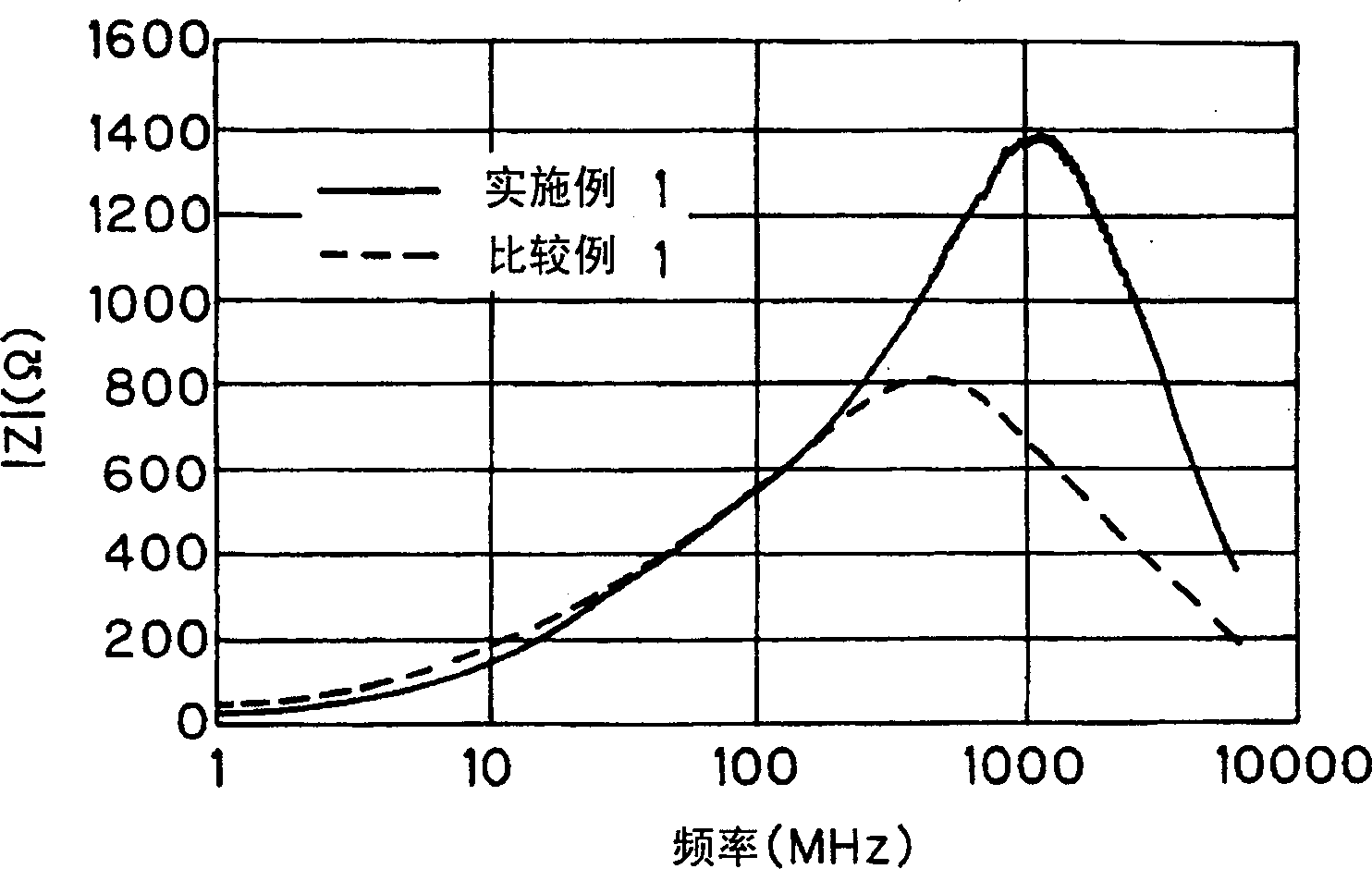

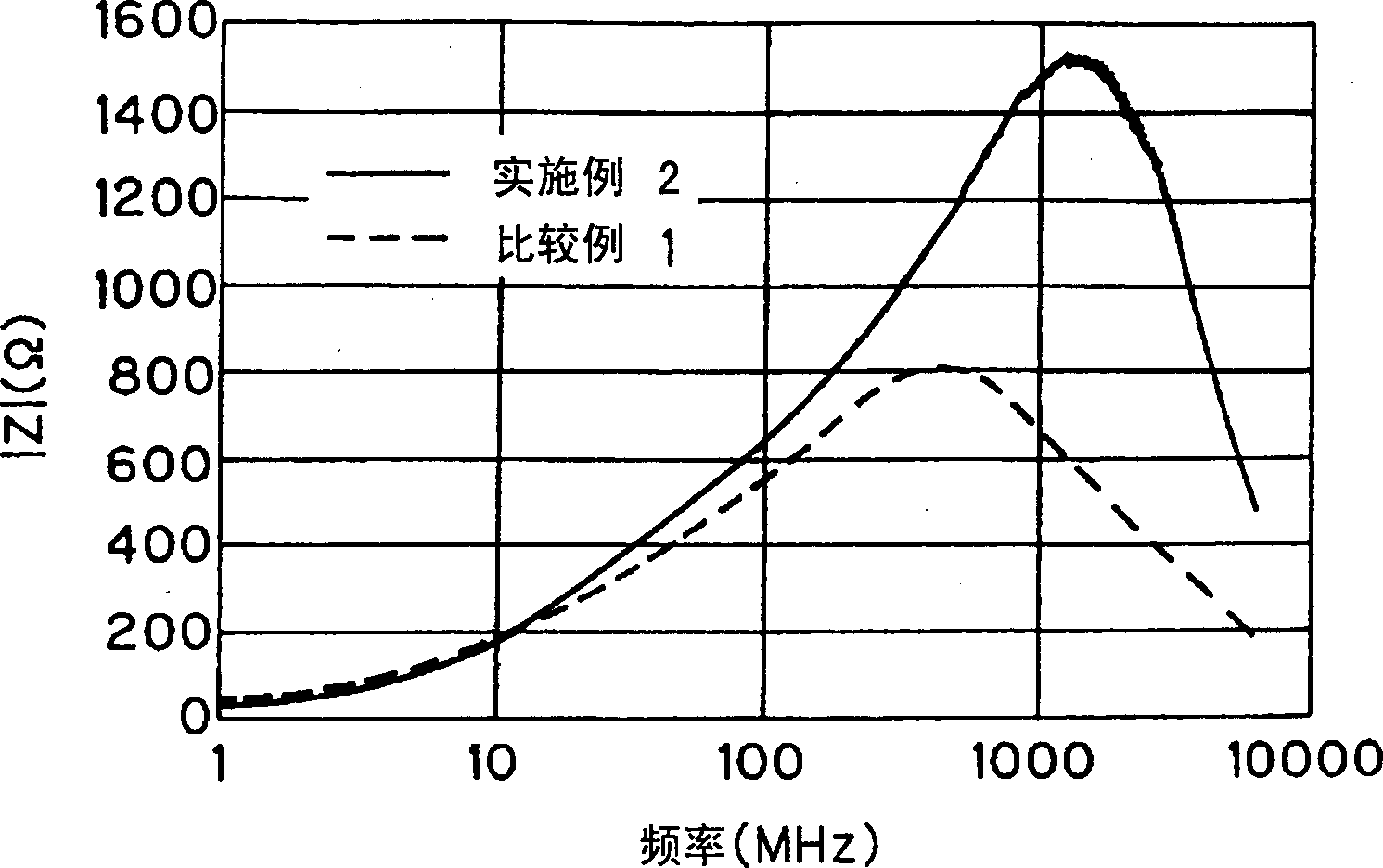

Ceramic electronic component and manufacturing method thereof

InactiveCN1448968ALow dielectric constantImprove reliabilityMultiple-port networksFixed capacitor dielectricCeramic sinteringMetallurgy

The invention provides a ceramic electronic component having the low dielectric constant of a ceramic sintered body and excellent impedance properties in a GHz zone and capable of obtaining high impedance properties in a wide frequency range, and its manufacturing method. This ceramic electronic component is formed by forming a green compact which includes an electrode therein with a ceramic compound comprising a ceramic raw material, a binder and a spherical or granular combustible material having adhesiveness to the binder. The green compact is fired to form the ceramic sintered compact including the electrode and containing about 35 to 80 volume percent pores. The pores of the ceramic sintered compact are filled with resin or glass.

Owner:MURATA MFG CO LTD

Ceramic electronic component

ActiveUS8174816B2Improve the level ofFixed capacitor electrodesFixed capacitor dielectricCeramic sinteringMetallurgy

There is provided a ceramic electronic component including a ceramic sintered body, internal conductive layers, and external electrodes. Each of the external electrodes includes a first electrode layer, a conductive resin layer covering the first electrode layer, and a second electrode layer covering the conductive resin layer and having an extension length greater than the length of the first electrode layer extending from one of the side surfaces of the ceramic sintered body to the portions of the top and bottom surfaces thereof. The distance from the top or bottom surface of the ceramic sintered body to the closest layer of the internal conductive layers is greater than or equal to the length of the first electrode layer extending from one of the side surfaces of the ceramic sintered body to the portions of the top and bottom surfaces thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

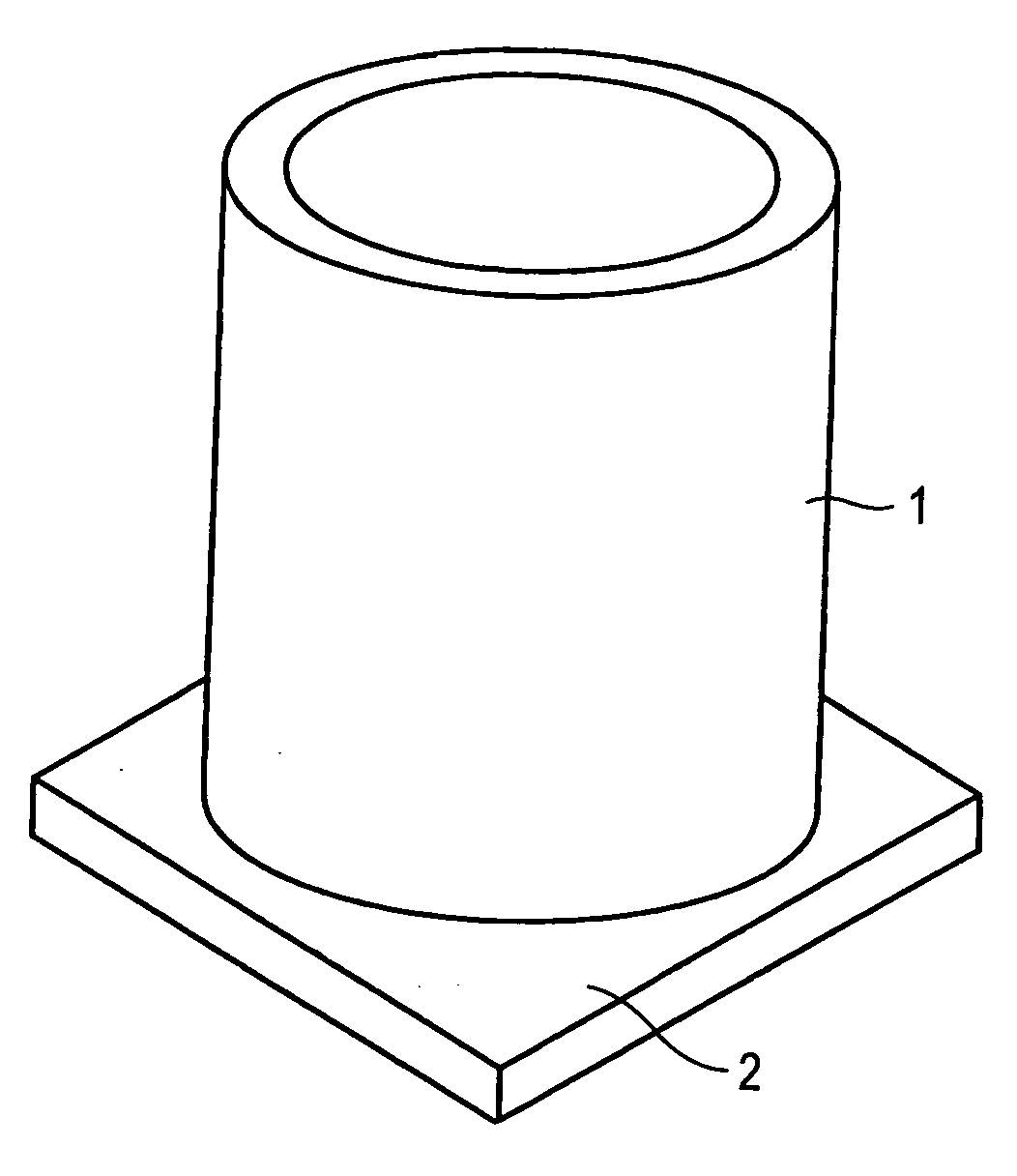

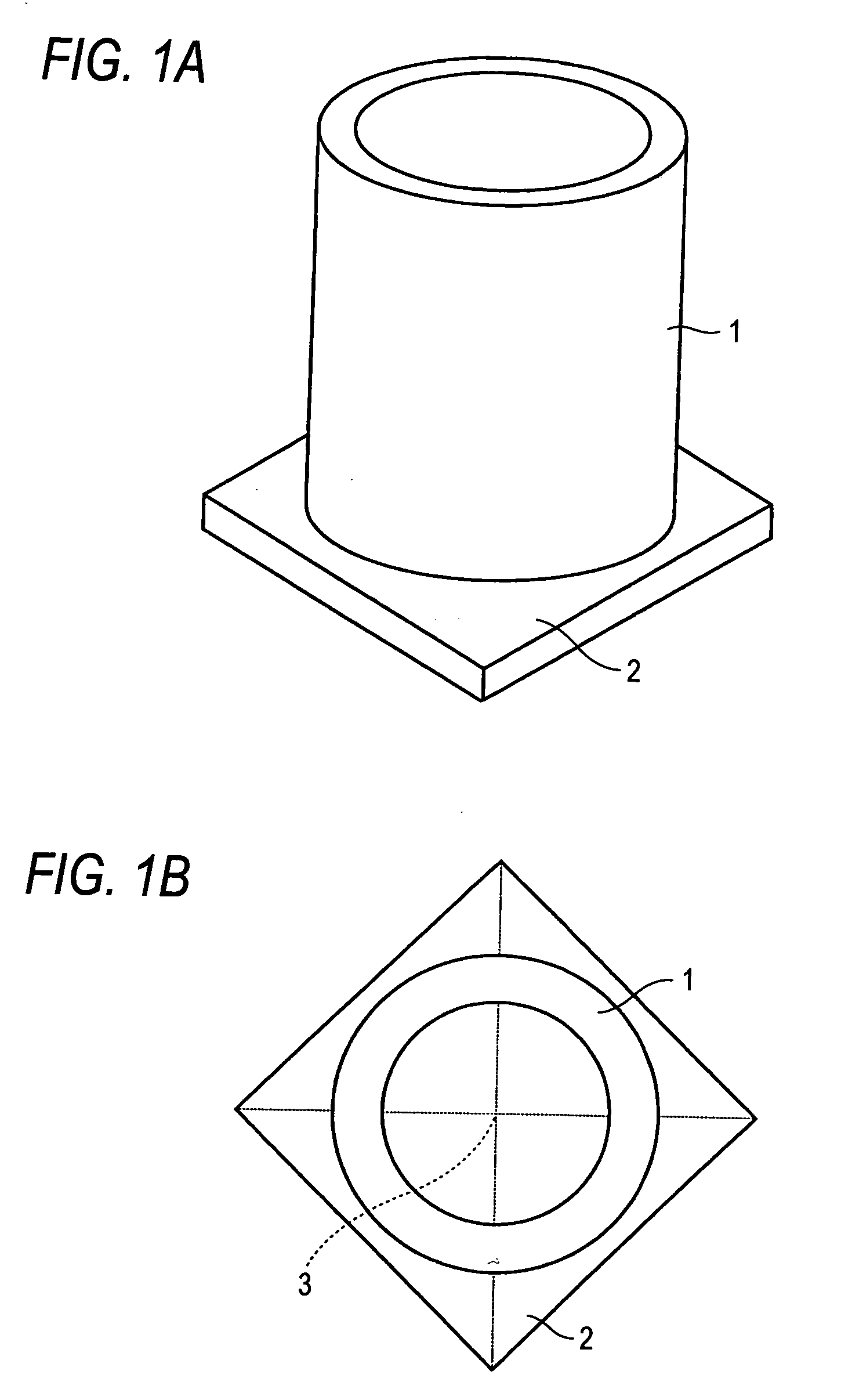

Cylindrical sputtering target, ceramic sintered body, and process for producing sintered body

ActiveUS20060151321A1High densityQuality improvementCellsVacuum evaporation coatingCeramic sinteringHigh density

A hollow cylindrical ceramic sintered body having high density, a process for producing the sintered boy, and a cylindrical ceramic sputtering target having high quality without cracks or breakage, are disclosed. The hollow cylindrical ceramic sintered body is obtained by placing a cylindrical ceramic molding to be sintered on a plate-like ceramic molding having a coefficient of sintering shrinkage similar to that of the cylindrical ceramic molding, and then sintering the resulting assembly, thereby obtaining a hollow cylindrical ceramic sintered body having a relative density of 95% or higher. The cylindrical ceramic sputtering target is prepared using the hollow cylindrical ceramic sintered body.

Owner:TOSOH CORP

Large grain spherical sub-micron/nano composite fiber-ceramic powder

The present invention relates to ceramic material technology. The composite fiber-ceramic powder consists of two or three of the following materials: submicron powder of below 1 micron size in 60-97wt% of one or two selected from alumina, zirconia, cobalt clad carbide, Ni-Cr carbide, SiC and SiN; nano-grade powder of below 100 nm size in 2-40 wt% of one or two selected from alumina, titania, zirconia, silica, SiC and SiN; and short fiber ceramic of 1 micron below diameter and 5 micron below length in 3-10 wt% of one selected from alumina, SiC and SiN. Inside the large particle powder, the components have close combination, good flowability and excellent transportation characteristic, so that the composite powder may be used in hot spraying, laser melting and covering and other surface process and ceramic sintering to prepare excellent composite ceramic coating and block.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com