Bismuth scandate-lead titanate high-temperature piezoelectric ceramic material and preparation method thereof

A high-temperature piezoelectric and ceramic material technology, applied in the field of high-temperature piezoelectric ceramic materials, can solve problems such as the decrease of piezoelectric dielectric properties, the deviation of chemical dosage ratio, and the increase of sintering temperature, so as to reduce the sintering temperature, reduce the process cost, and improve performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

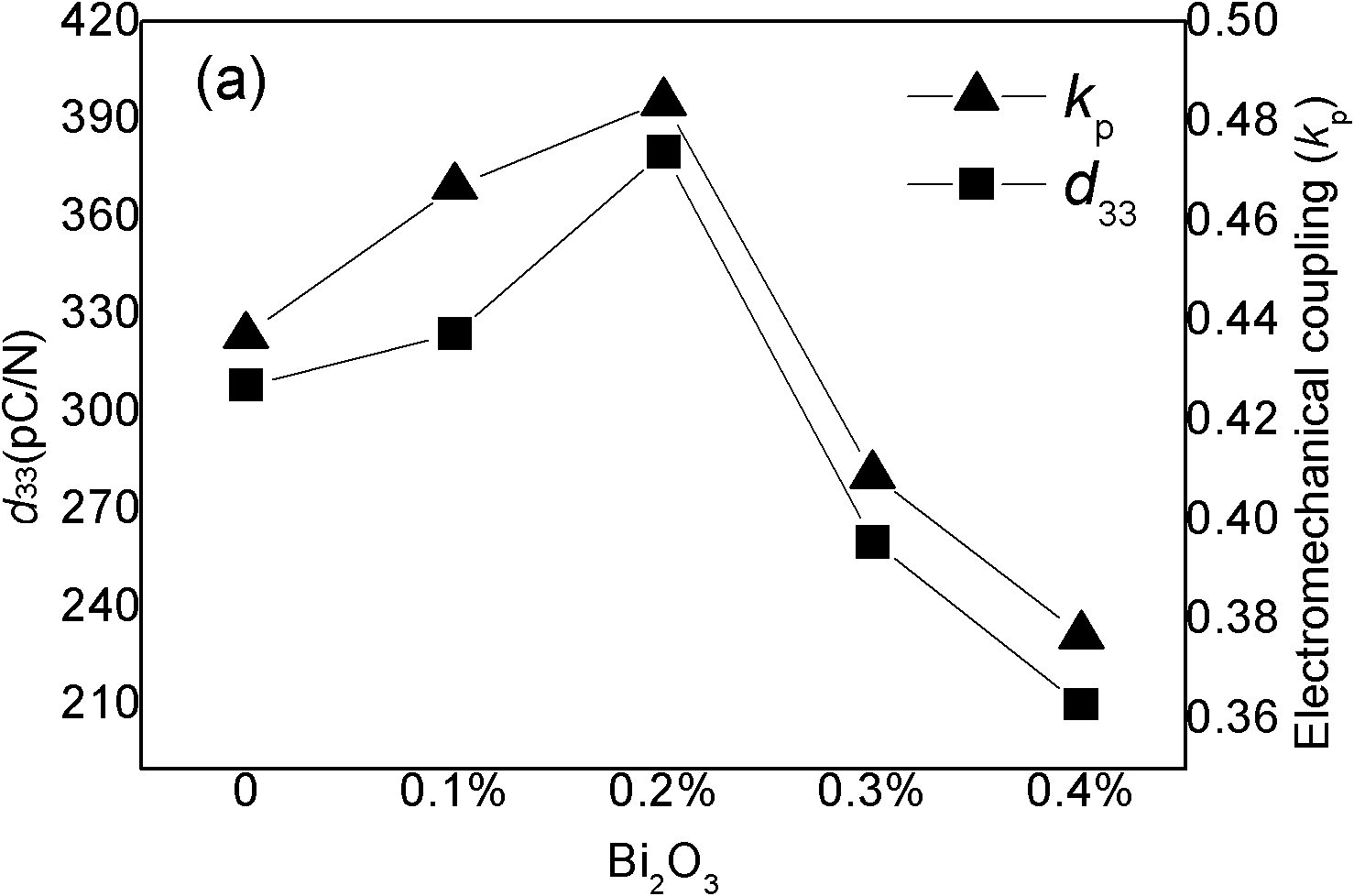

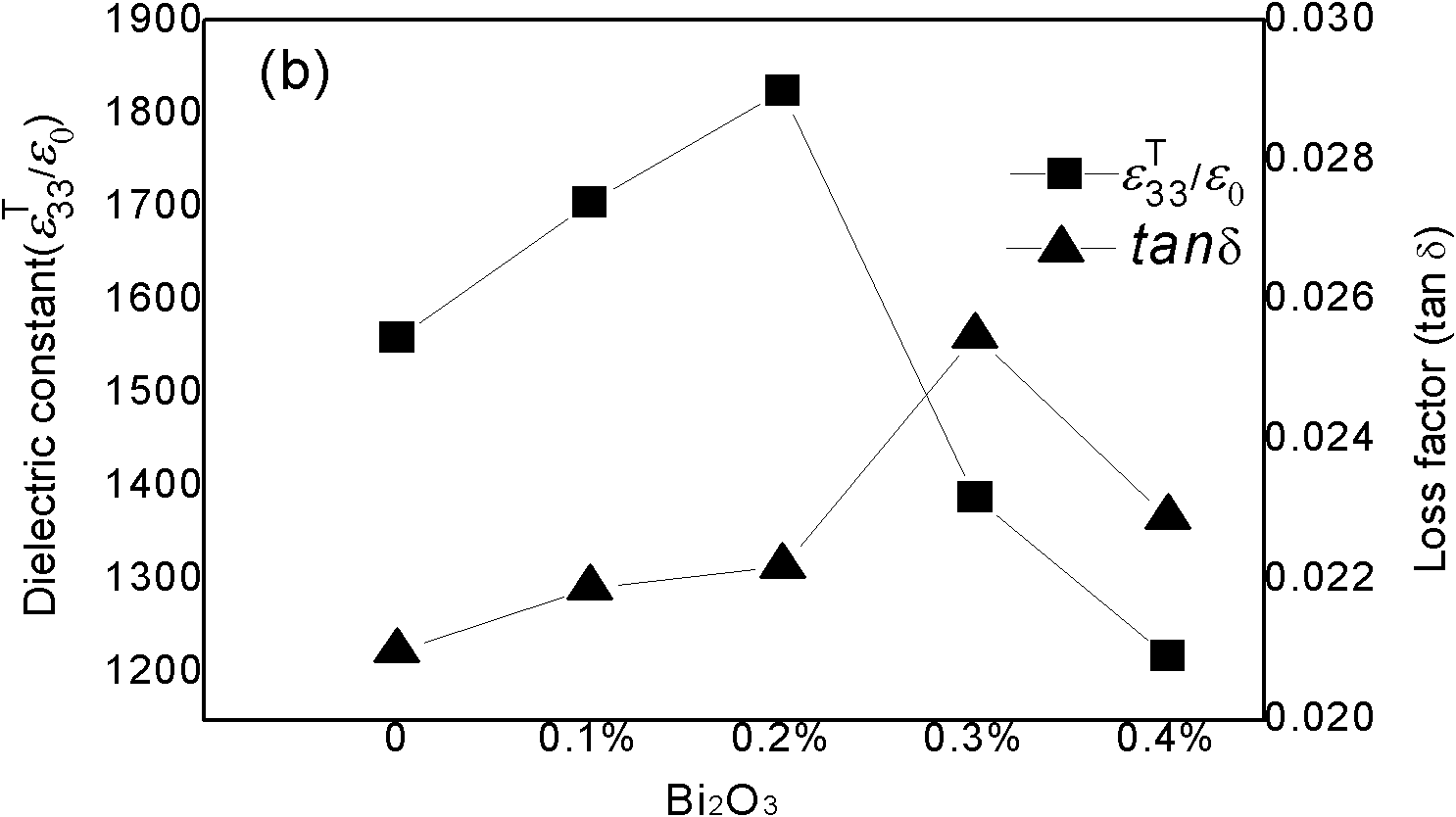

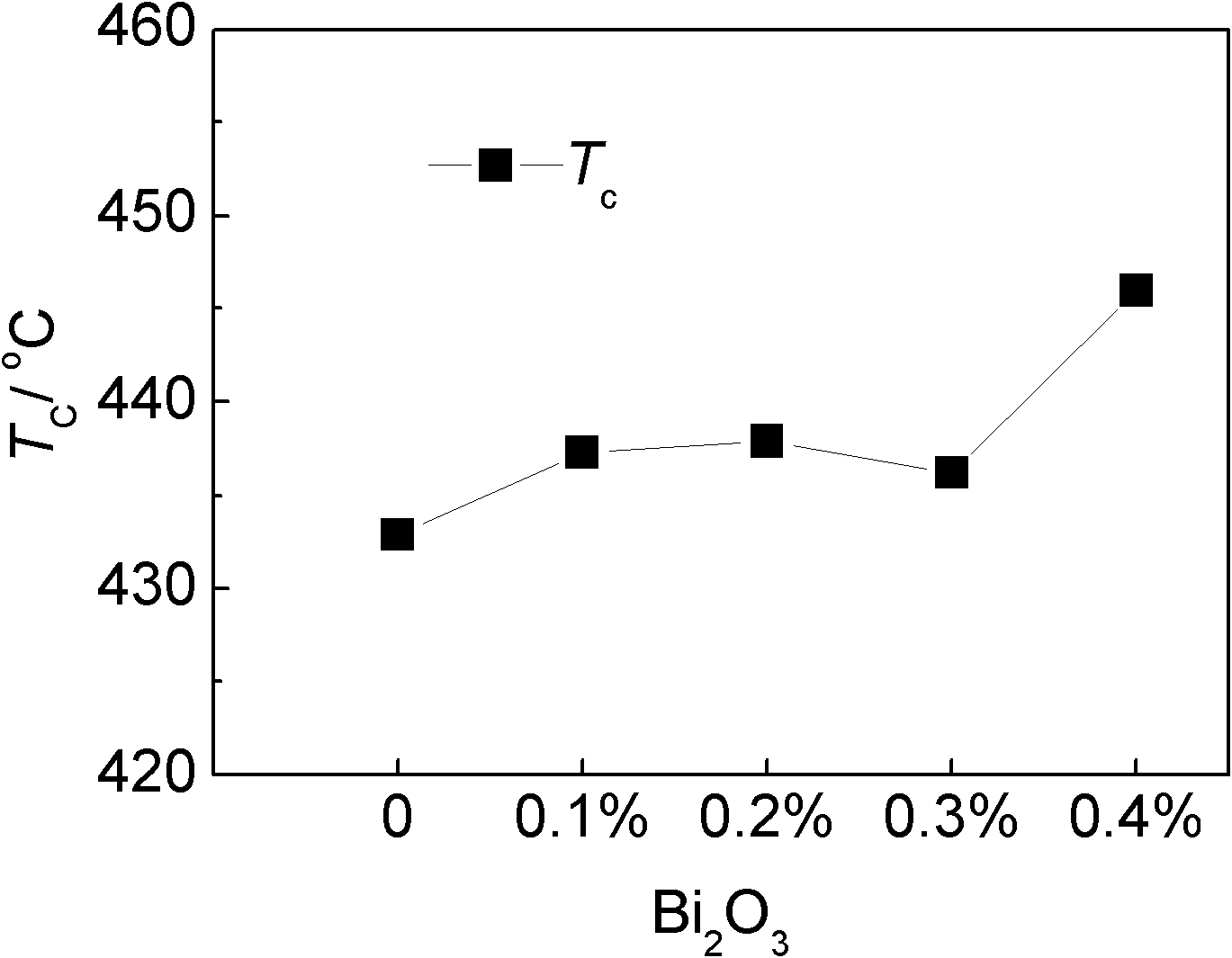

[0036] Purchasing industrially pure Sc from the market 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 As raw material, according to 0.363 BiScO 3 -0.637 PbTiO 3 The stoichiometric ratio, weighed Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 , and then weighed accounted for Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 and TiO 2 0.1% Bi by weight 2 o 3 , put it into a ball mill tank, add distilled water accounting for 50% of the total weight of the above raw materials, mix and grind for 2 hours on a planetary ball mill at a speed of 200 rpm; dry the ball milled mixture at 100°C Put it in a crucible, pre-fire at 740°C, and hold for 2 hours; add distilled water accounting for 50% of the total weight of the powder after pre-fired synthesis, and grind at 200 rpm for 4 hours; after grinding, add A suitable amount of binder material is placed in a mold and pressed into the required ceramic green sheet, wherein the binder is an aqueous solution of 5% by weight of PVA, and its consumption is 6% of...

Embodiment 2

[0039] The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material provided in this example is prepared according to the following method:

[0040] (1) Purchasing industrially pure Sc from the market 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 As raw material, according to 0.363 BiScO 3 -0.637PbTiO 3 The stoichiometric ratio, weighed Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 , and then weighed accounted for Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 and TiO 2 0.2% Bi by weight 2 o 3 , put in the ball mill tank, add distilled water, mix and ball mill; the amount of distilled water is Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 60% of the total weight of raw materials, the rotating speed during ball milling is 100 rpm, and the ball milling time is 2h;

[0041] (2) After drying the mixed material after ball milling, wherein, the drying temperature of the mixed material is 100°C, and after pre-burning at 740°C for 2 hours, distilled water is added again, and ...

Embodiment 3

[0048] The bismuth scandate-lead titanate high-temperature piezoelectric ceramic material provided in this example is prepared according to the following method:

[0049] (1) Purchasing industrially pure Sc from the market 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 As raw material, according to 0.363 BiScO 3 -0.637PbTiO 3 The stoichiometric ratio, weighed Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 , and then weighed accounted for Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 and TiO 2 0.3% Bi by weight 2 o 3 , put in the ball mill jar, add distilled water, mix and ball mill, wherein the amount of distilled water is Sc 2 o 3 、 Bi 2 o 3 , Pb 3 o 4 、TiO 2 60% of the total weight of raw materials, the rotating speed during ball milling is 200 rpm, and the ball milling time is 2h;

[0050] (2) After the ball-milled mixture is dried, the drying temperature is 100°C. After pre-burning at 740°C for 2 hours, distilled water is added again, mixed and ball-milled. The amount of distill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com