Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

652 results about "Solid state reaction method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-YAG:Ce phosphor compositions and their methods of preparation

ActiveUS20080138268A1High crystallinityHigh emission intensityRare earth metal compoundsLuminescent compositionsPhosphorSolid state reaction method

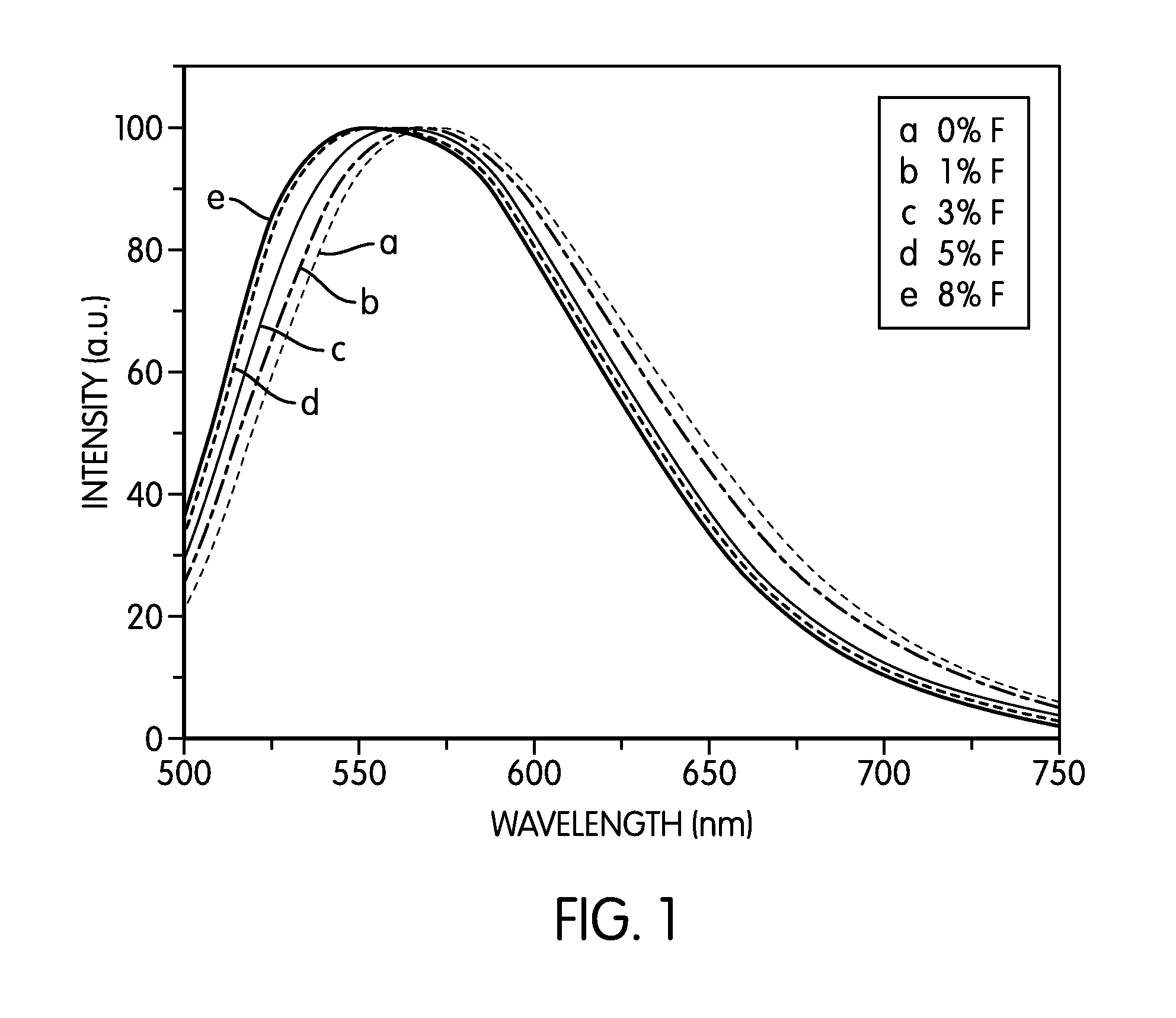

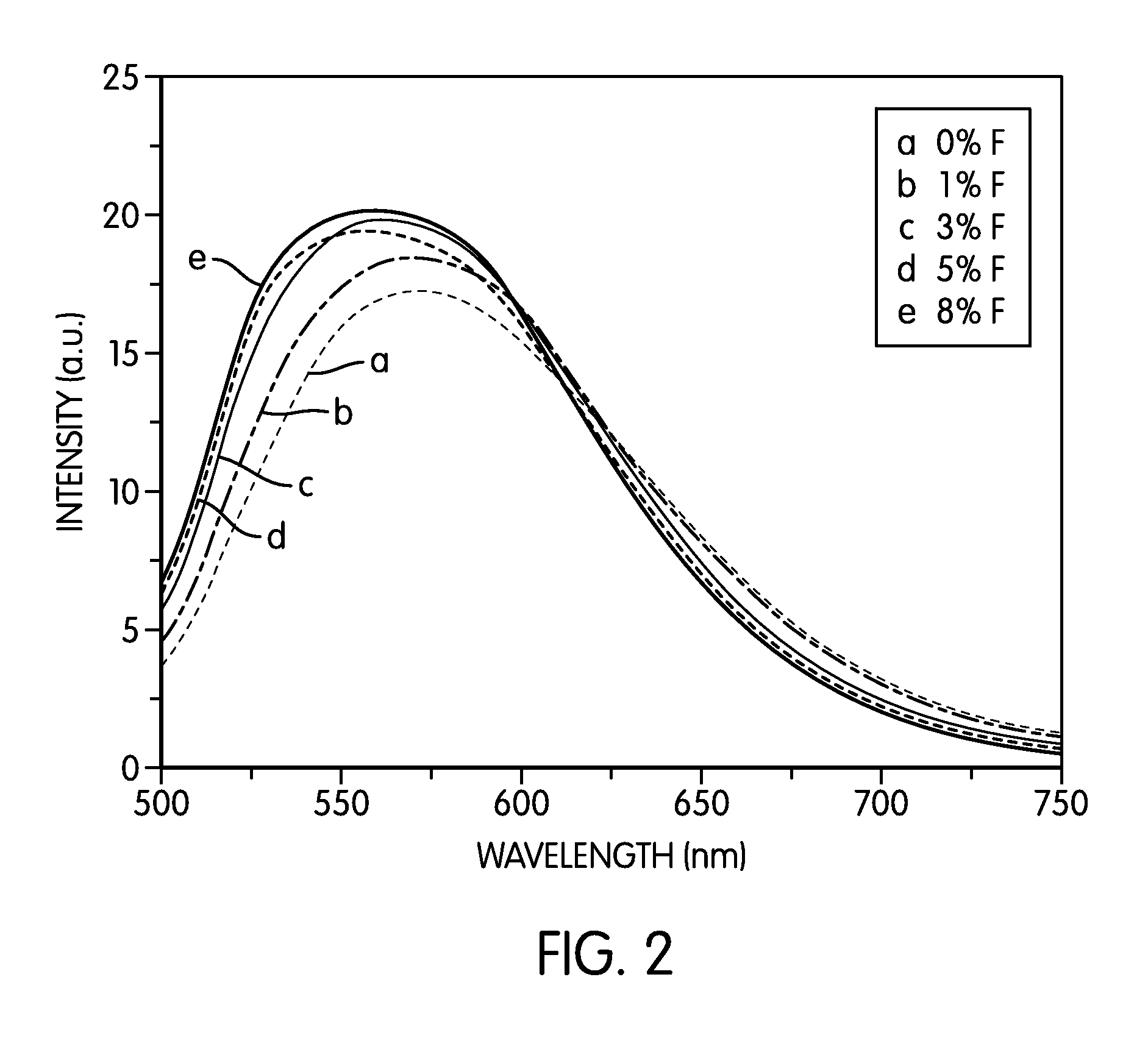

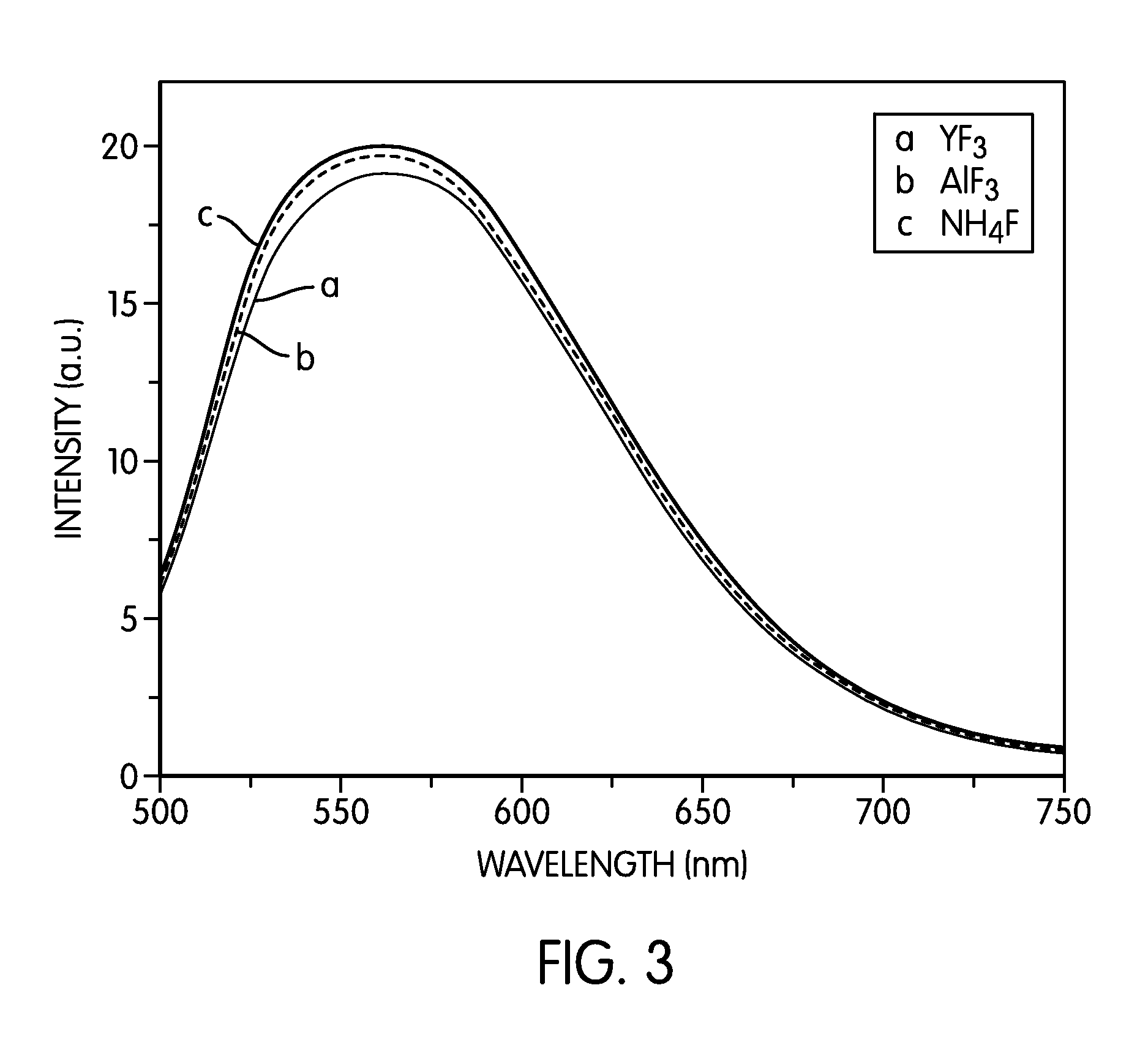

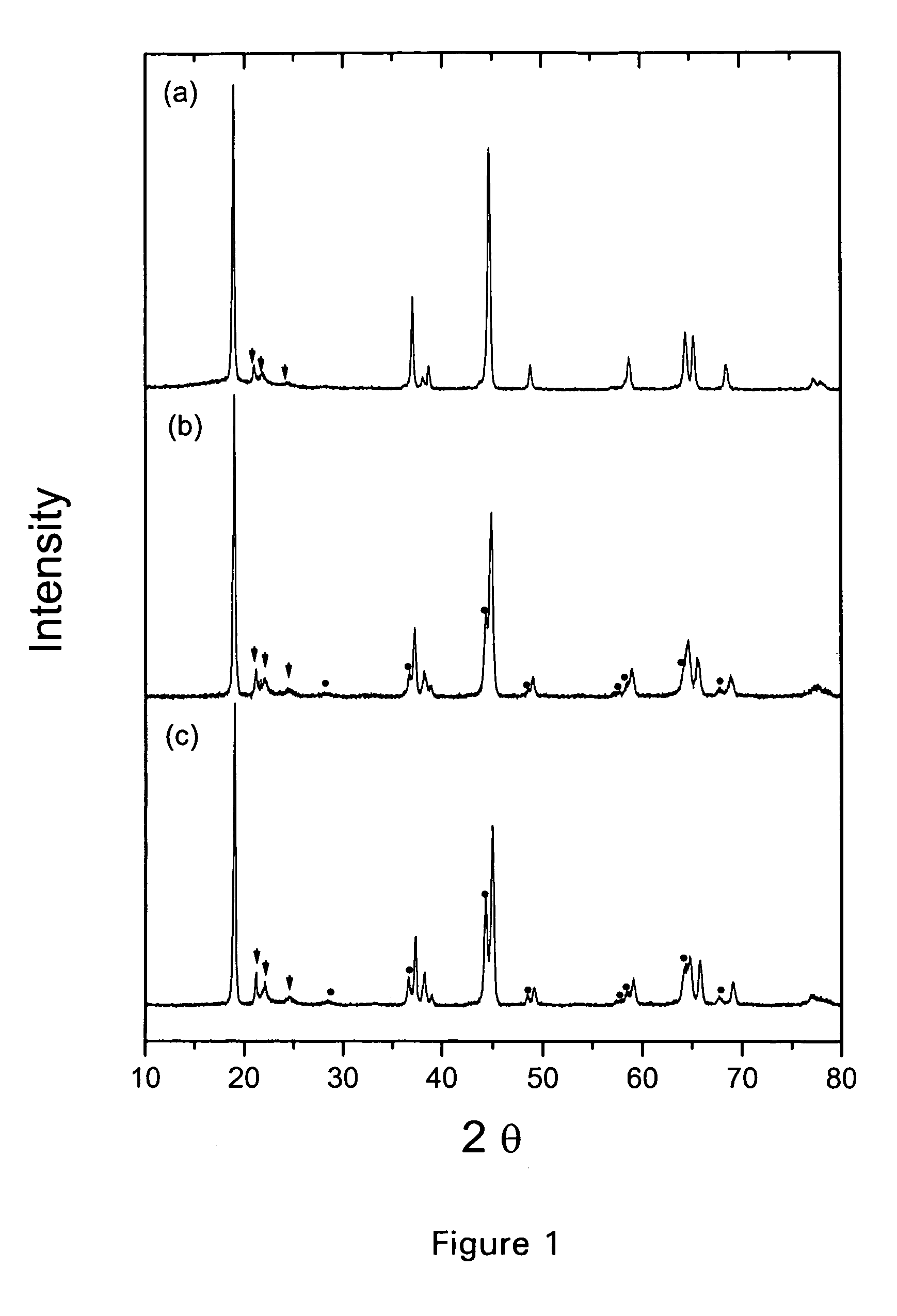

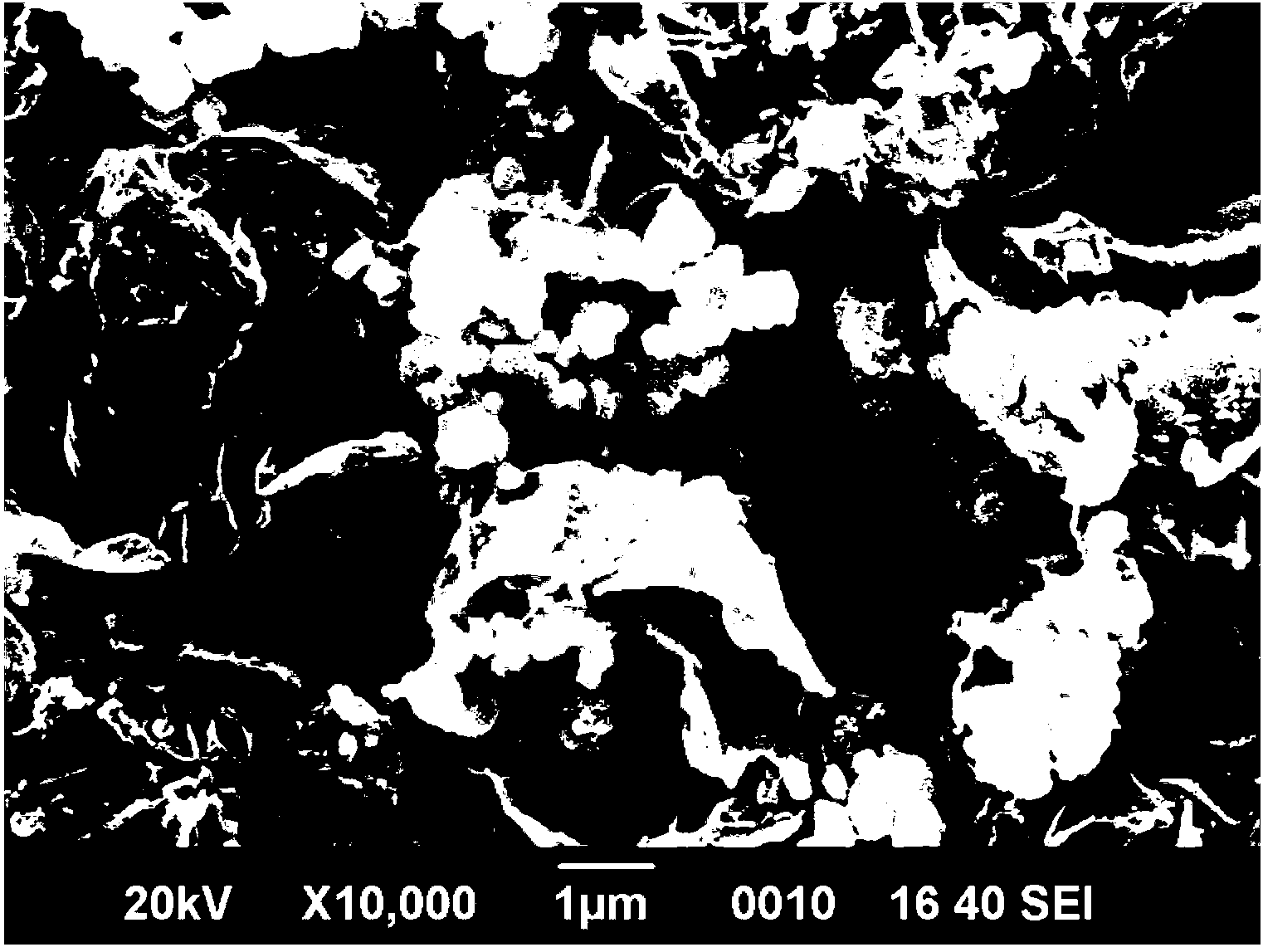

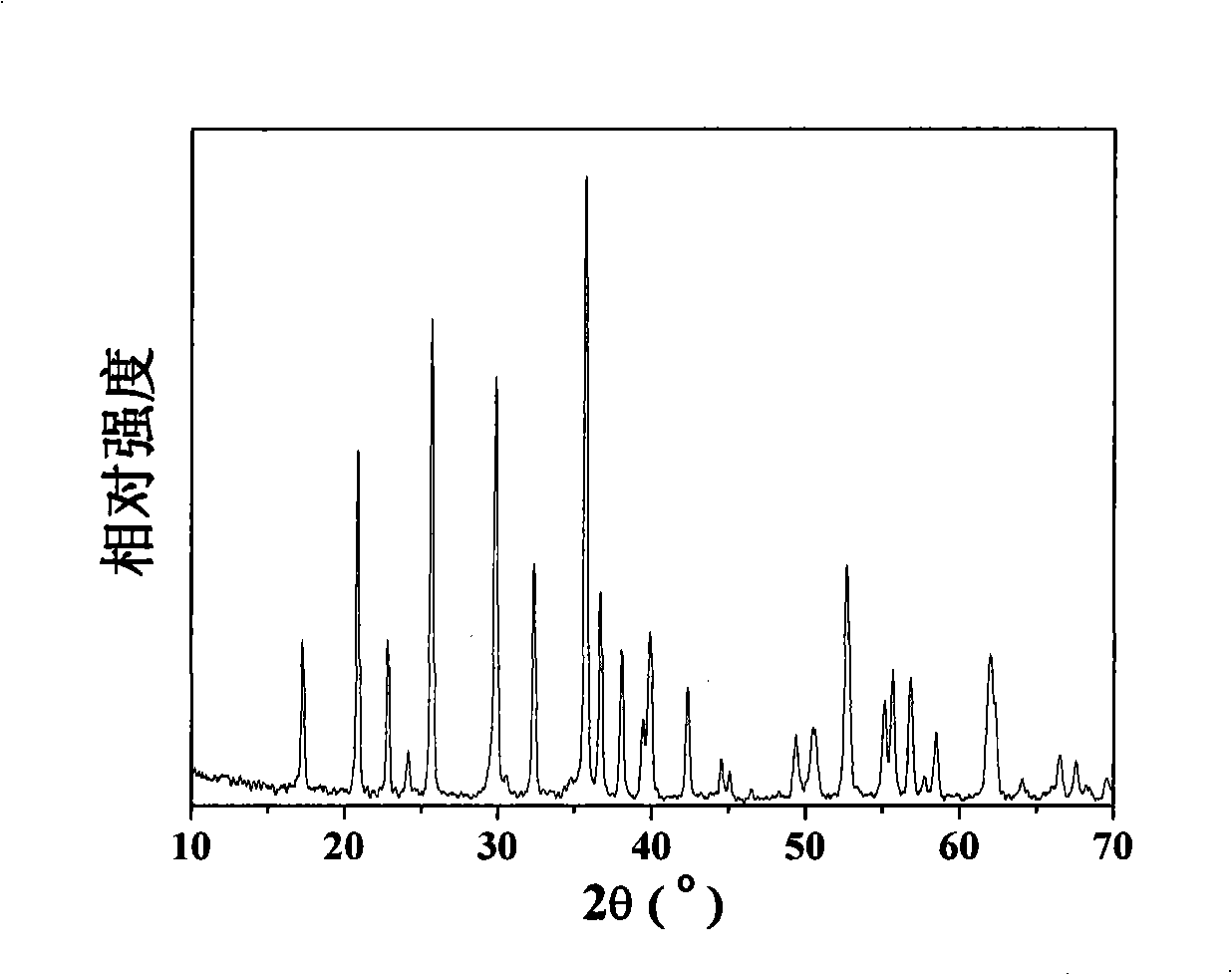

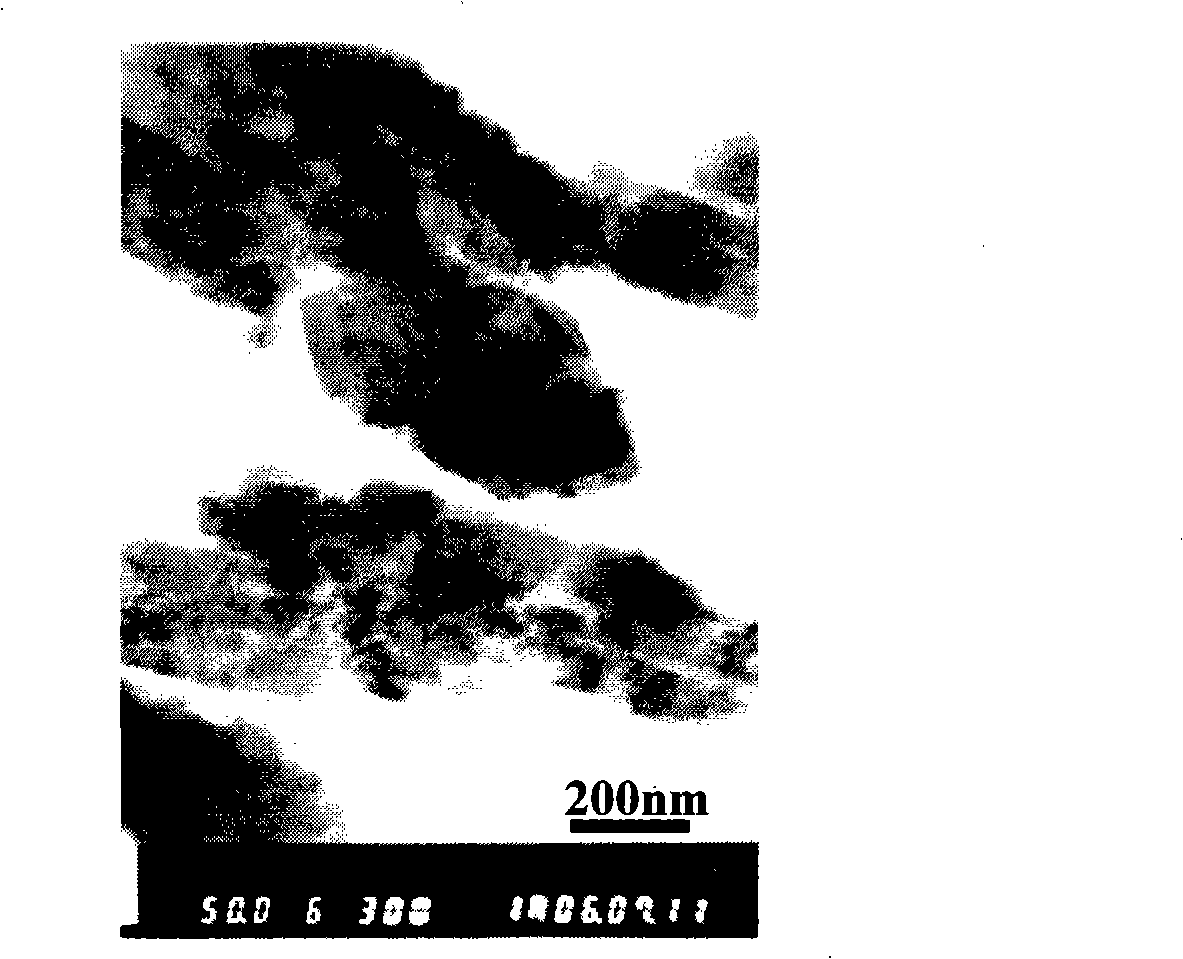

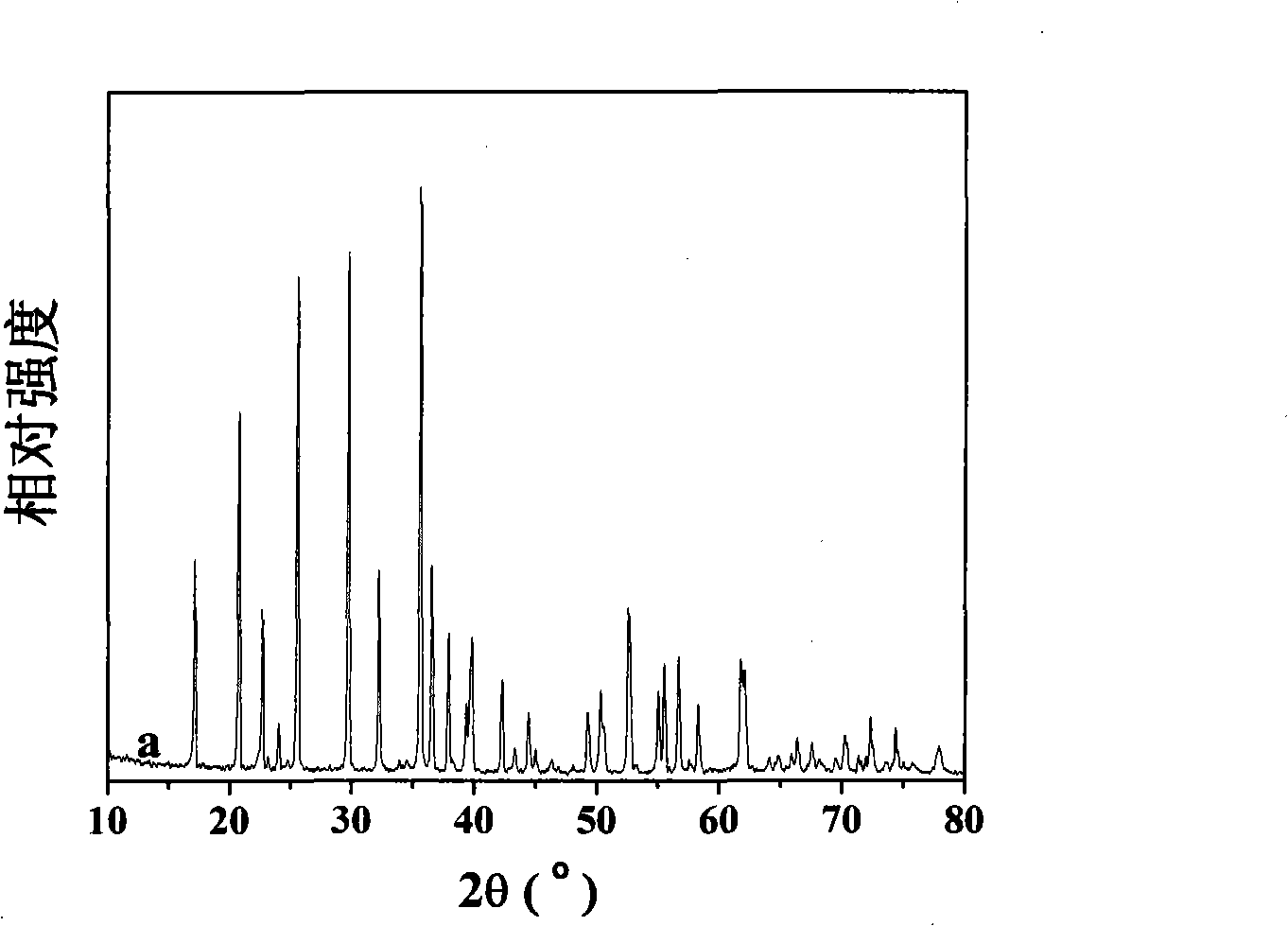

Disclosed herein are cerium doped, garnet phosphors emitting in the yellow region of the spectrum, and having the general formula (Y,A)3(Al,B)5(O,C)12:Ce3+, where A is Tb, Gd, Sm, La, Sr, Ba, Ca, and / or Mg, and substitutes for Y, B is Si, Ge, B, P, and / or Ga, and substitutes for Al, and C is F, Cl, N, and / or S, where C substitutes for O. Relative to a solid-state-reaction method, the instant co-precipitation methods provide a more homogeneous mixing environment to enhance the distribution of the Ce3+ activator in the YAG matrix. Such a uniform distribution has the benefit of an increased emission intensity. The primary particle size of the as-prepared phosphor is about 200 nm, with a narrow distribution.

Owner:INTEMATIX

Layer cathode methods of manufacturing and materials for Li-ion rechargeable batteries

ActiveUS7314684B2Lower performance requirementsRapid coolingSecondary cellsAlkali metal oxidesLithiumSolid state reaction method

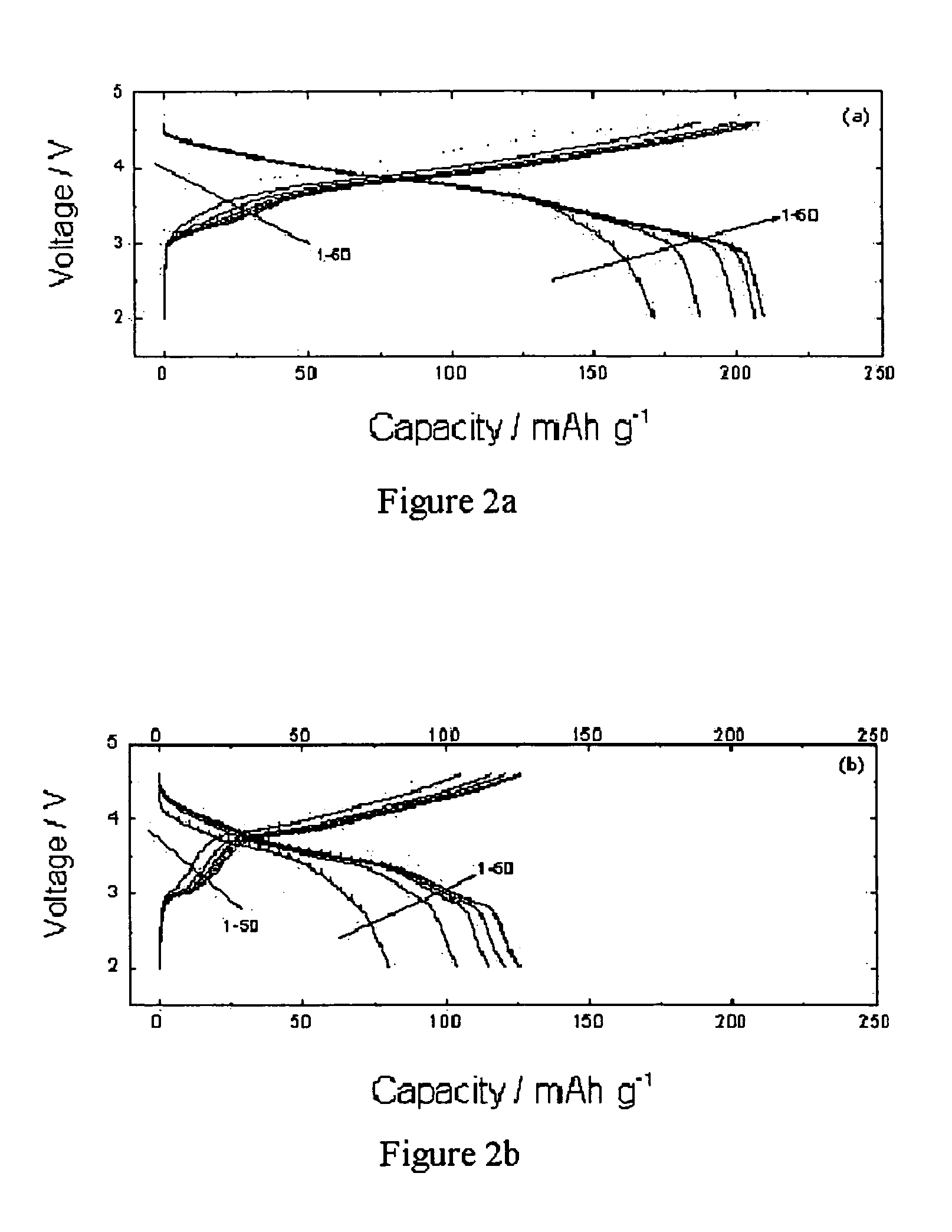

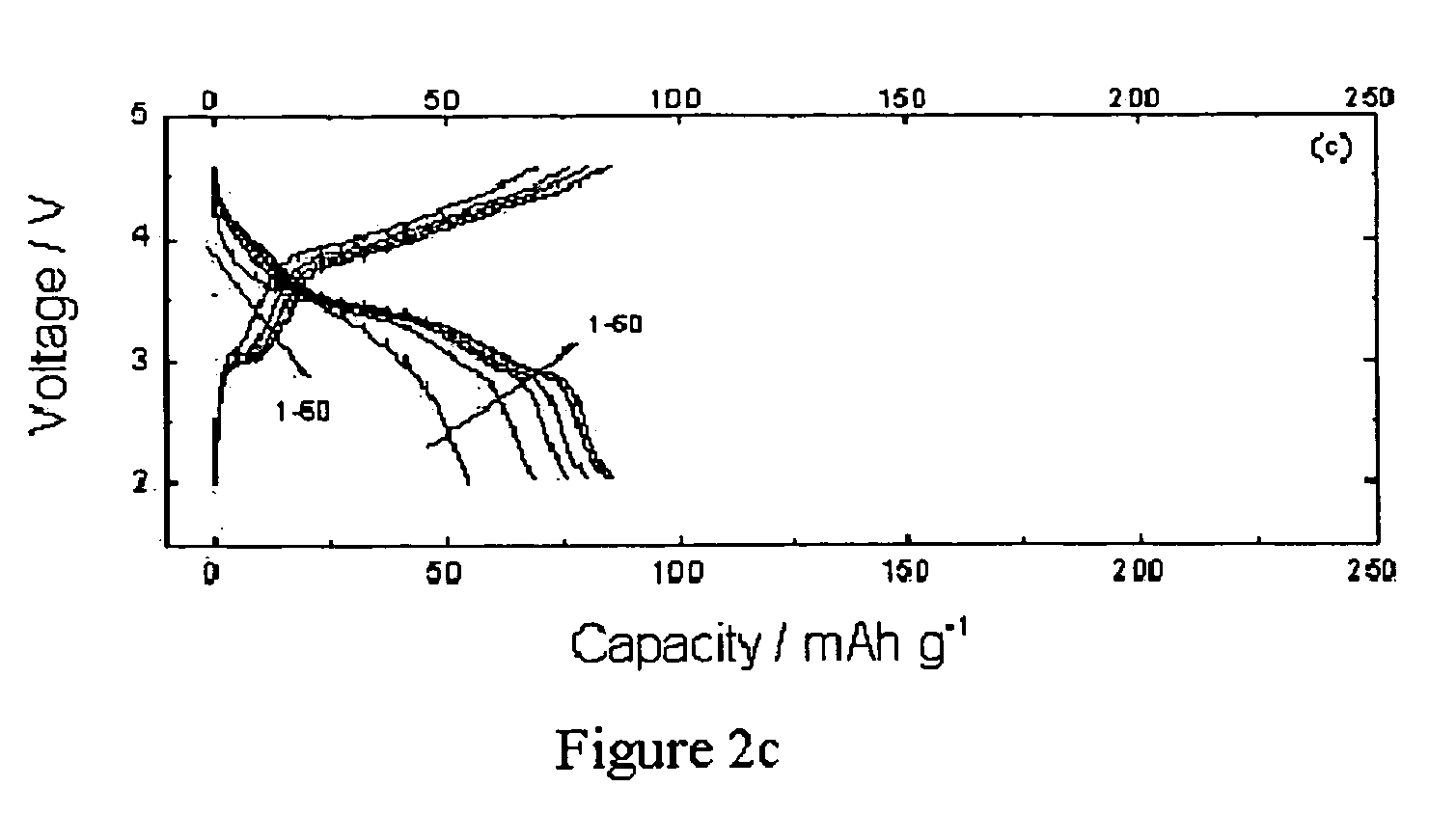

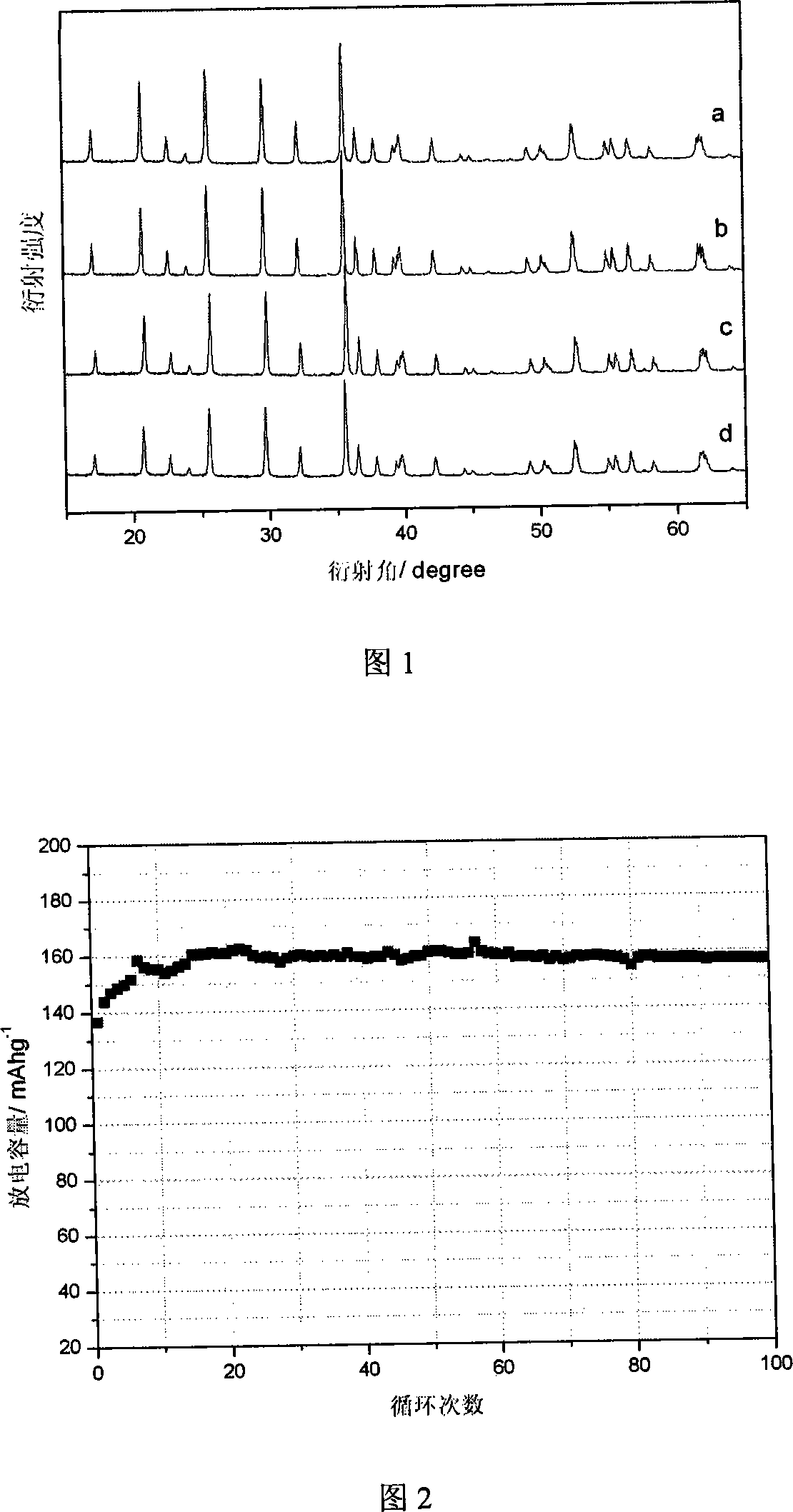

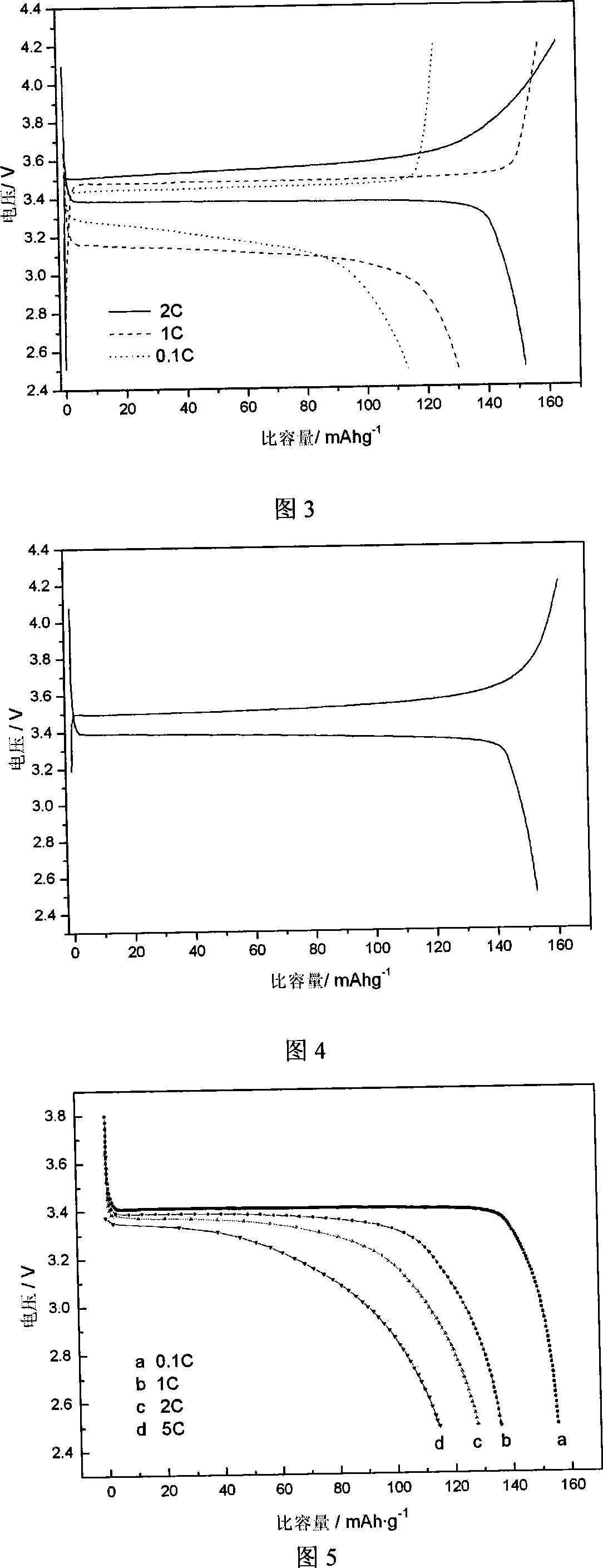

A positive electrode active material for lithium-ion rechargeable batteries of general formula Li1+xNiαMnβAγO2 and further wherein A is Mg, Zn, Al, Co, Ga, B, Zr, or Ti and 0<x<0.2, 0.1≦α≦0.5, 0.4≦β≦0.6, 0≦γ≦0.1 and a method of manufacturing the same. Such an active material is manufactured by employing either a solid state reaction method or an aqueous solution method or a sol-gel method which is followed by a rapid quenching from high temperatures into liquid nitrogen or liquid helium.

Owner:CHICAGO UNIV OF THE +1

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039AControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingGas phasePhosphate

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

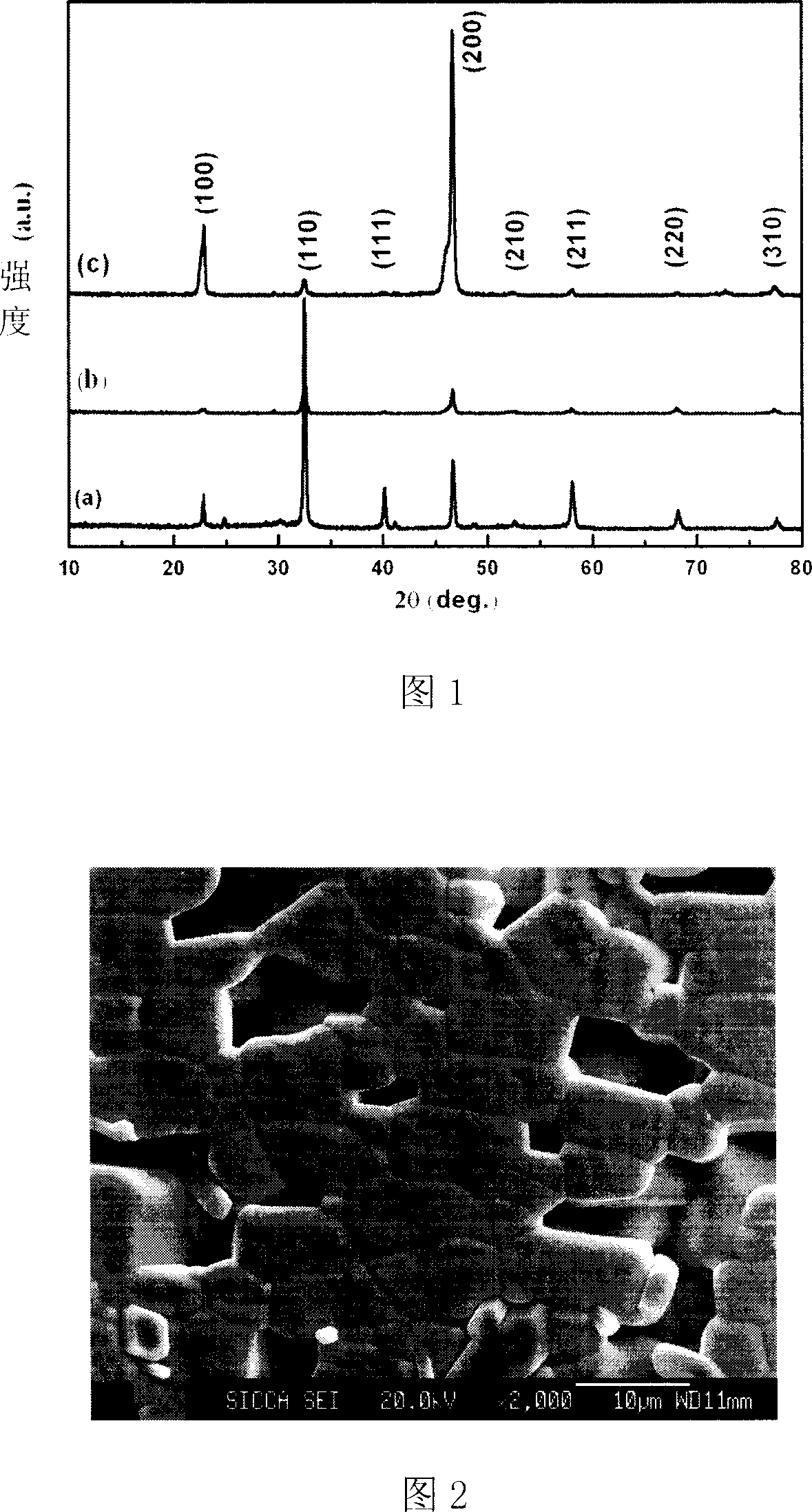

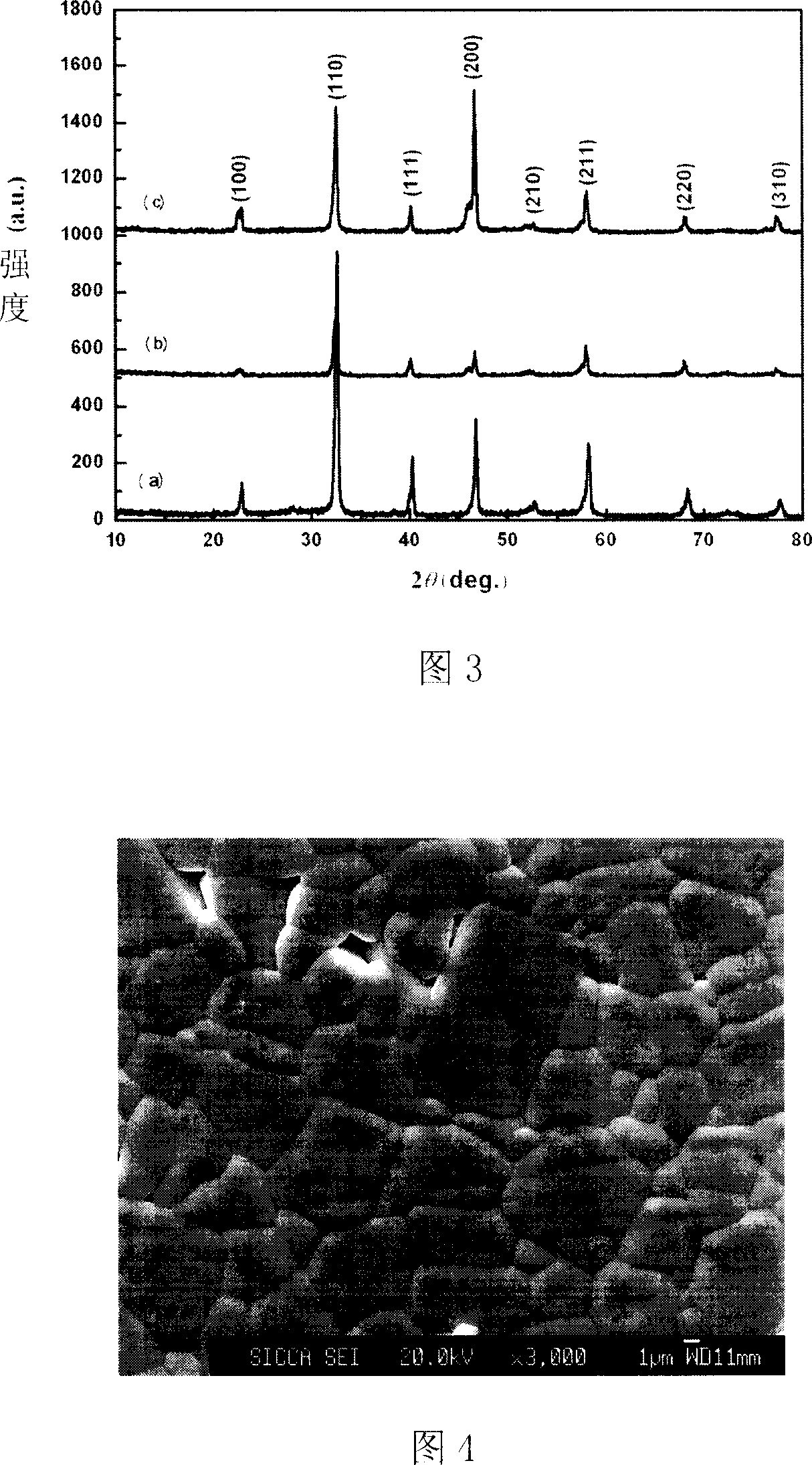

Method for preparing lanthanum zirconate powder

InactiveCN101407336ALow thermal conductivityGood heat insulationZirconium compoundsRare earth metal compoundsSolid reactionPyrochlore

The invention relates to a method for preparing a lanthanum zirconic acid powder, which belongs to the preparation field of ceramic powder used for high temperature heat barrier. The method uses lanthanum oxide or lanthanum soluble salt and zircon salt for respectively preparing the solutions containing La<3+> and Zr<4+>; the two solutions are mixed and dropped into a precipitator (or the precipitator is dropped into the mixing solutions) under continual stirring to obtain precipitate; and the precipitate are washed with a plurality of times, then dried, ground and finally calcined at certain temperature to obtain La2Zr2O7 of defect fluorite structure or pyrochlore constitution. Compared with the existing universal solid reaction process, the method lowers the synthesis temperature by 500-700 DEG C. The heat-insulating property (heat diffusivity) of the obtained power is reduced by about 50 percent compared with YSZ, and reduced by about 40 percent compared with the lanthanum zirconic acid powder obtained by the solid reaction process. The method solves the problems of overhigh heat diffusivity, severe sinter and phase change inefficiency in the existing ceramic materials used for the coating of high temperature heat barrier.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Barium titanate/polyvinylidene fluoride composite dielectric film and preparation method thereof

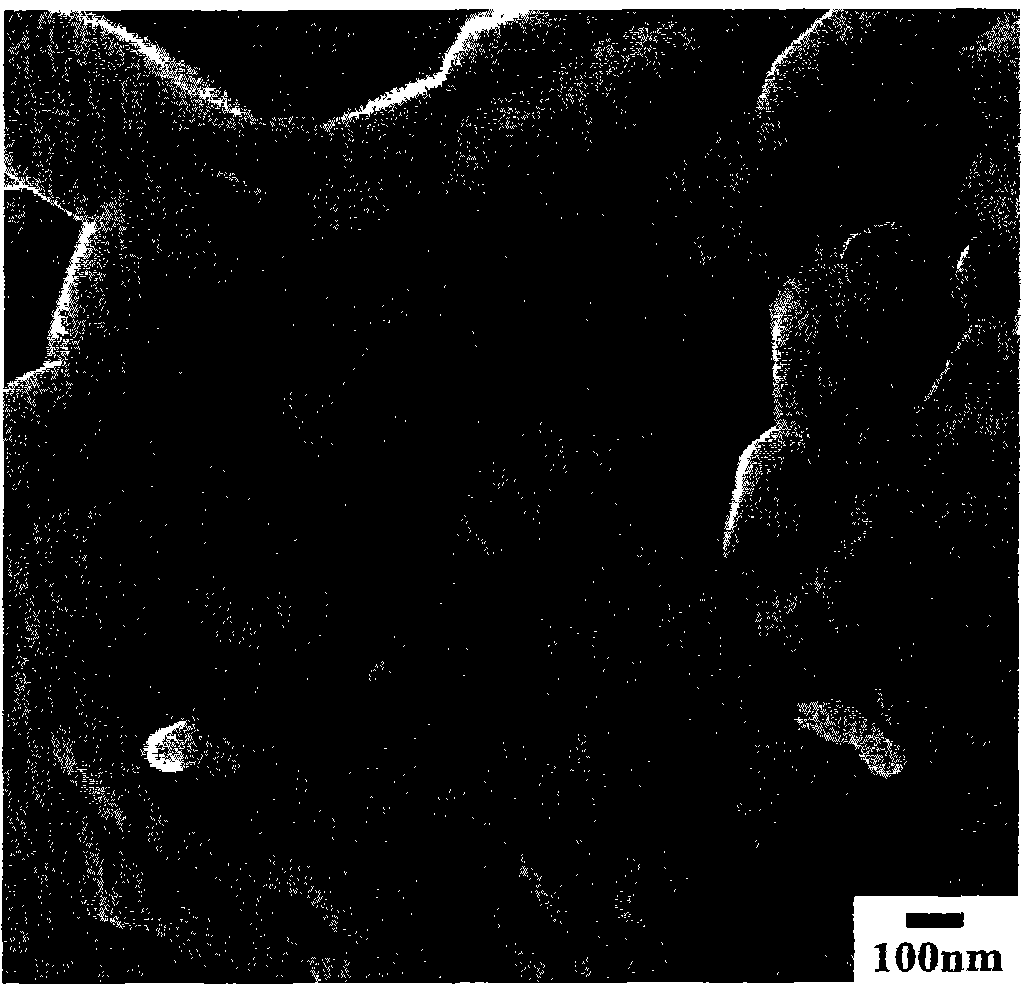

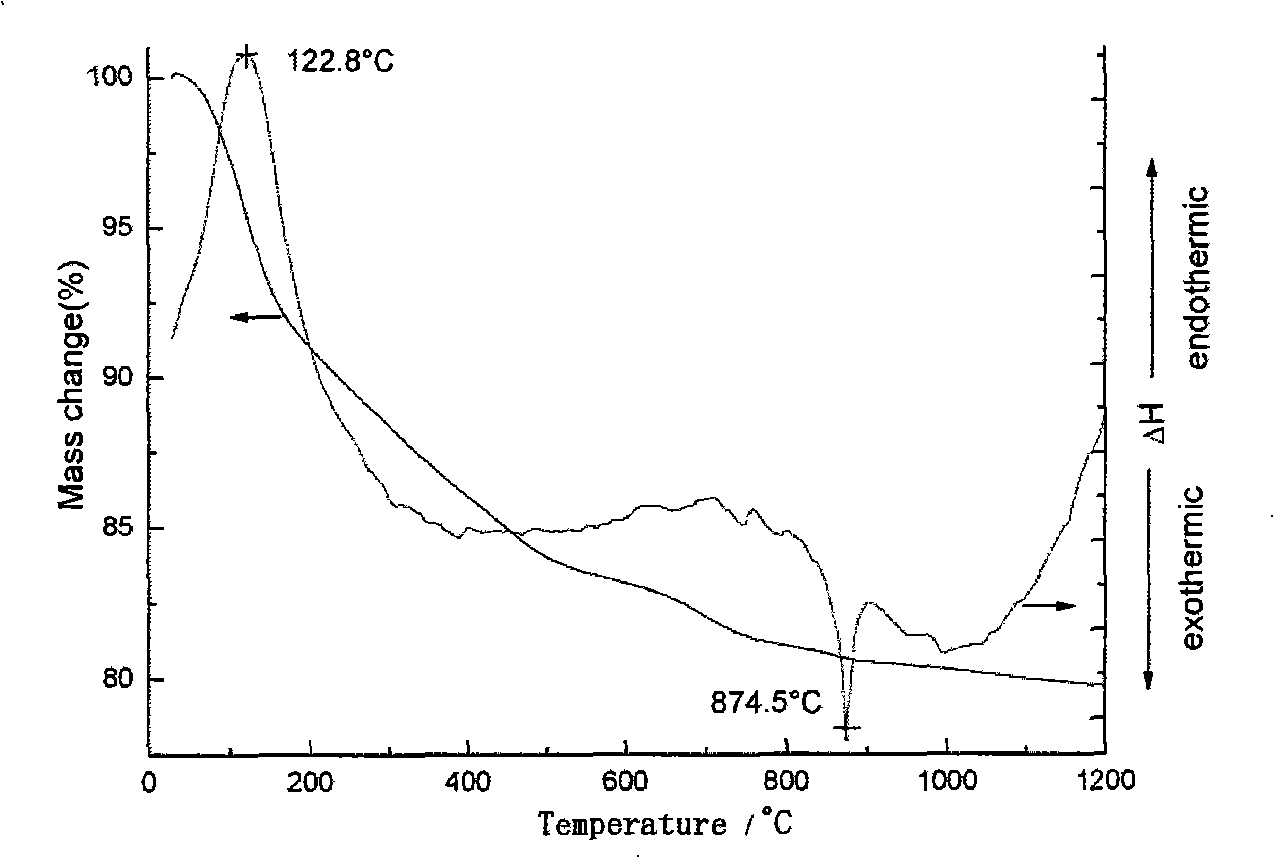

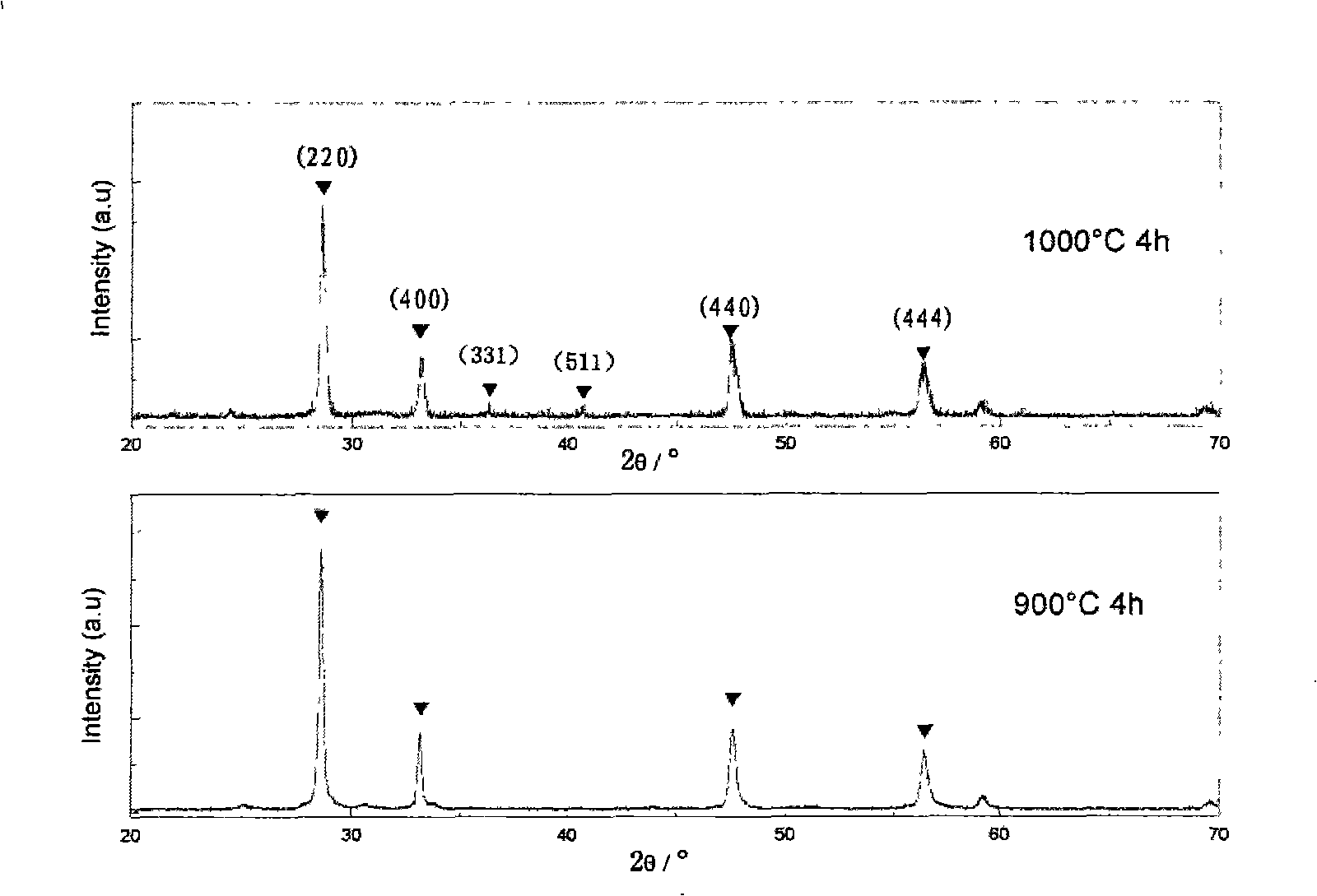

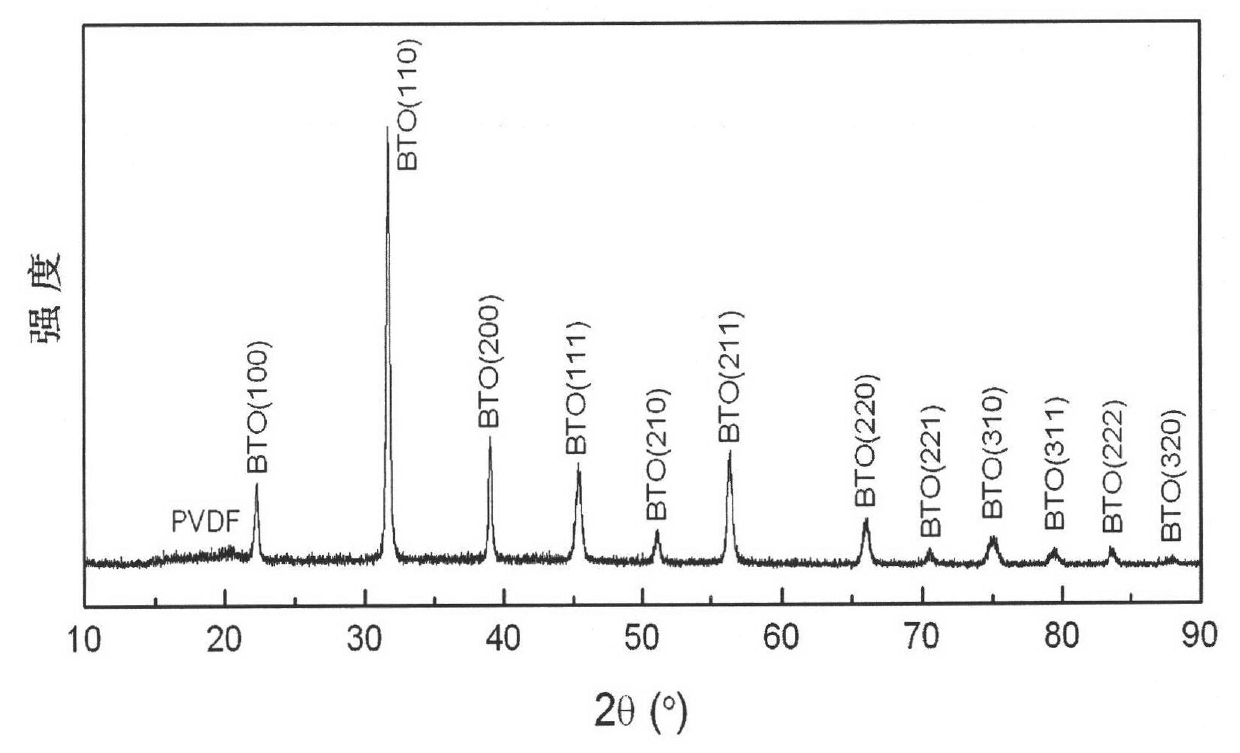

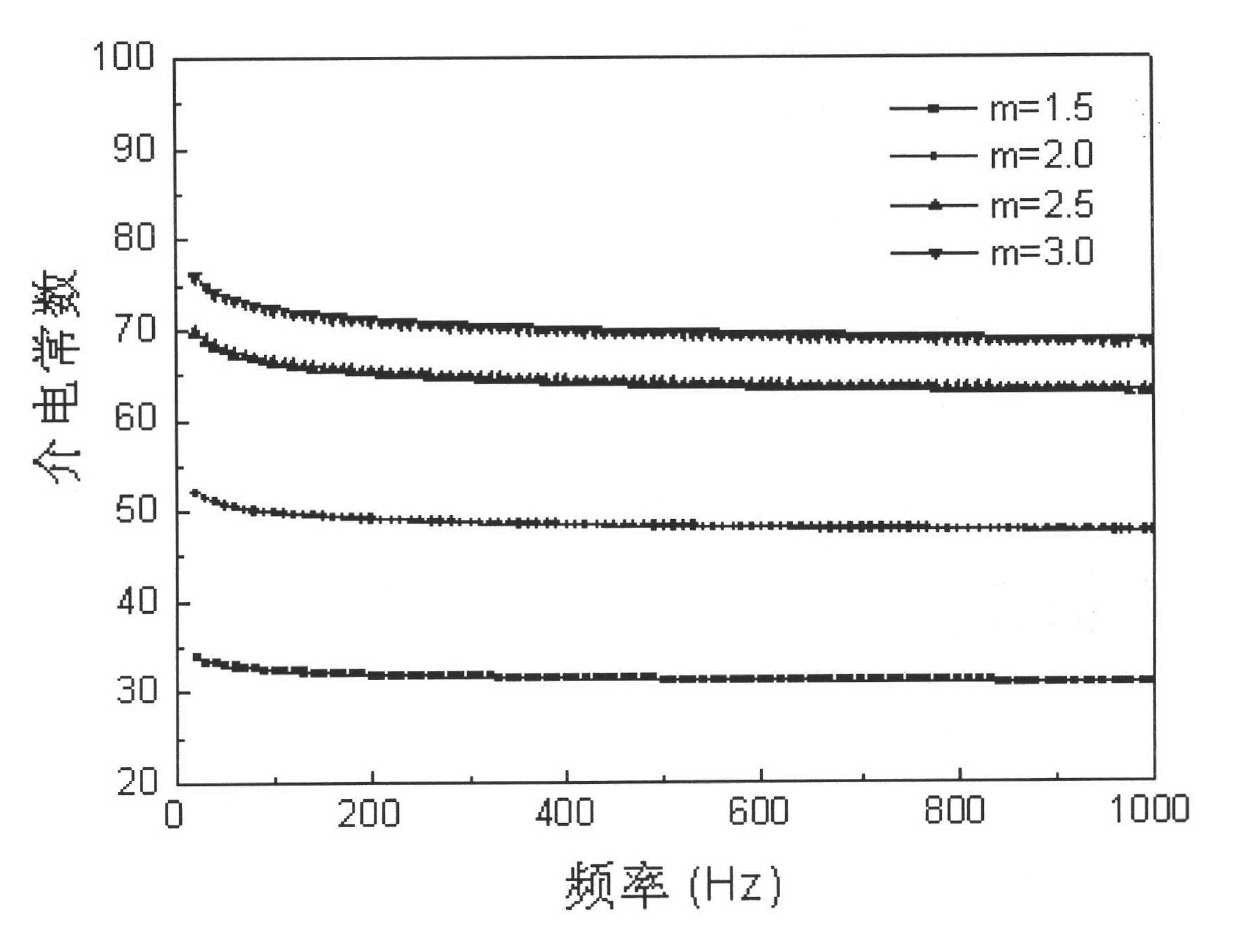

ActiveCN102558718AImproved rheological propertiesIncrease BTO contentBarium titanateSolid state reaction method

The invention provides a barium titanate / polyvinylidene fluoride composite dielectric film and a preparation method thereof. The film comprises barium titanate and polyvinylidene fluoride with the weight ratio of 1.5-5.0:1, and the thickness of the film is less than 50 mu m. In the frequency range of 100 Hz-1 MHz, the relative dielectric constant of the film can reach more than 70, and the dielectric loss is lower than 5*10<-2>. By compounding BaTiO3 ceramic and PVDF polymer, the dielectric film material with high dielectric constant and low dielectric loss is prepared. According to the invention, the barium titanate / polyvinylidene fluoride composite dielectric film with uniform distribution of ceramic particles, controllable thickness, high dielectric constant and low dielectric loss is prepared by preparing barium titanate ceramic powder through solid phase reaction or chemical coprecipitation and then using high temperature drying gel method or solvent induced phase separation gel method. The dielectric film is especially suitable for capacitor, ferroelectric memory, and other electronic devices.

Owner:GRIMAT ENG INST CO LTD

Lead-less piezoelectric sodium bismuth titanate-bariumtitanate ceramic and its prepn process

InactiveCN101020608AEasy to prepareEasy to printPiezoelectric/electrostrictive/magnetostrictive devicesScreen printingBarium titanate

The present invention is one kind of lead-less piezoelectric sodium bismuth titanate-barium titanate ceramic, and belongs to the field of lead-less piezoelectric ceramic. The lead-less piezoelectric sodium bismuth titanate-barium titanate ceramic has the chemical formula of (Na1 / 2Bi1 / 2)1-xBaxTiO3, where, x is 0.05-0.1, and has ceramic crystal grains parallel to the grain boundary. Its preparation process includes the following steps: molten salt procedure to synthesize Bi4Ti3O12 template or solid phase reaction procedure to synthesize Na0.5Bi4.5Ti4O15 precursor material powder; preparing slurring with Na2CO3, BaCO3, Bi2O3 and nanometer TiO2; silk screen printing to obtain thick ceramic film; cutting, superposing and sintering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparing method for nitrogen extended titania light catalyst

InactiveCN1583250AEfficient purificationImprove environmental qualityPhysical/chemical process catalystsHydrogenSolid state reaction method

Owner:SHANGHAI JIAO TONG UNIV

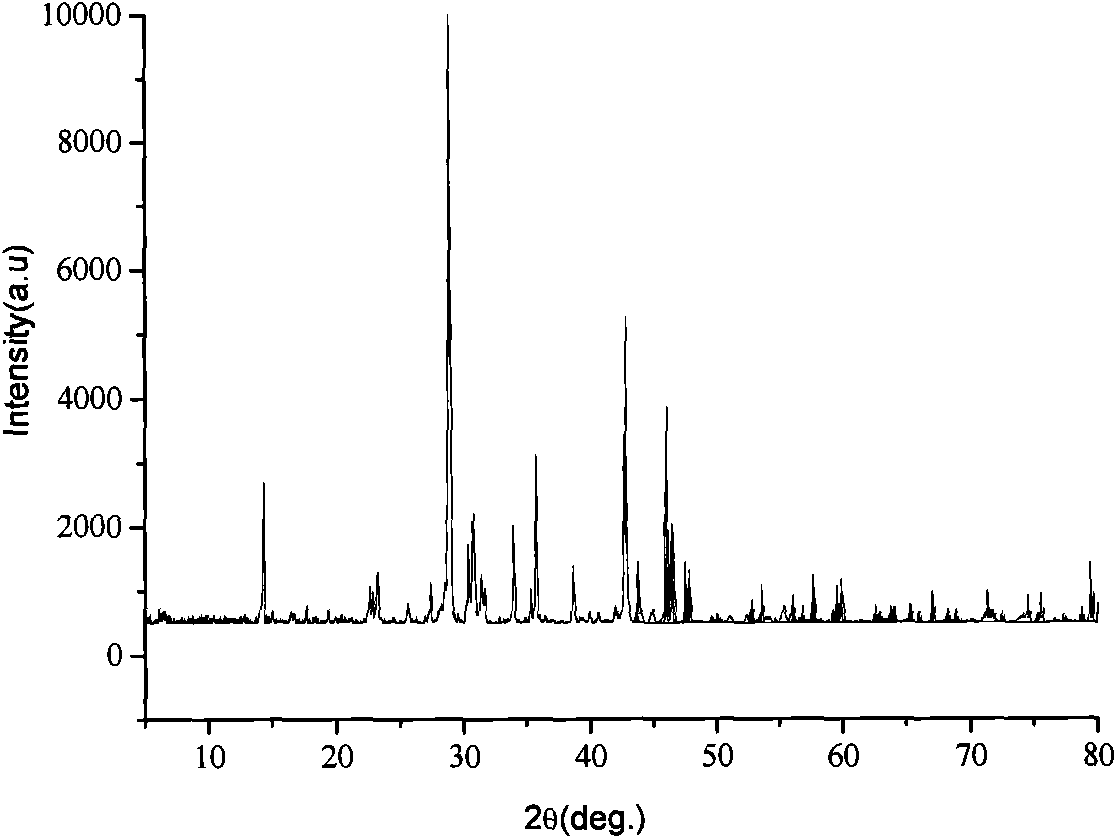

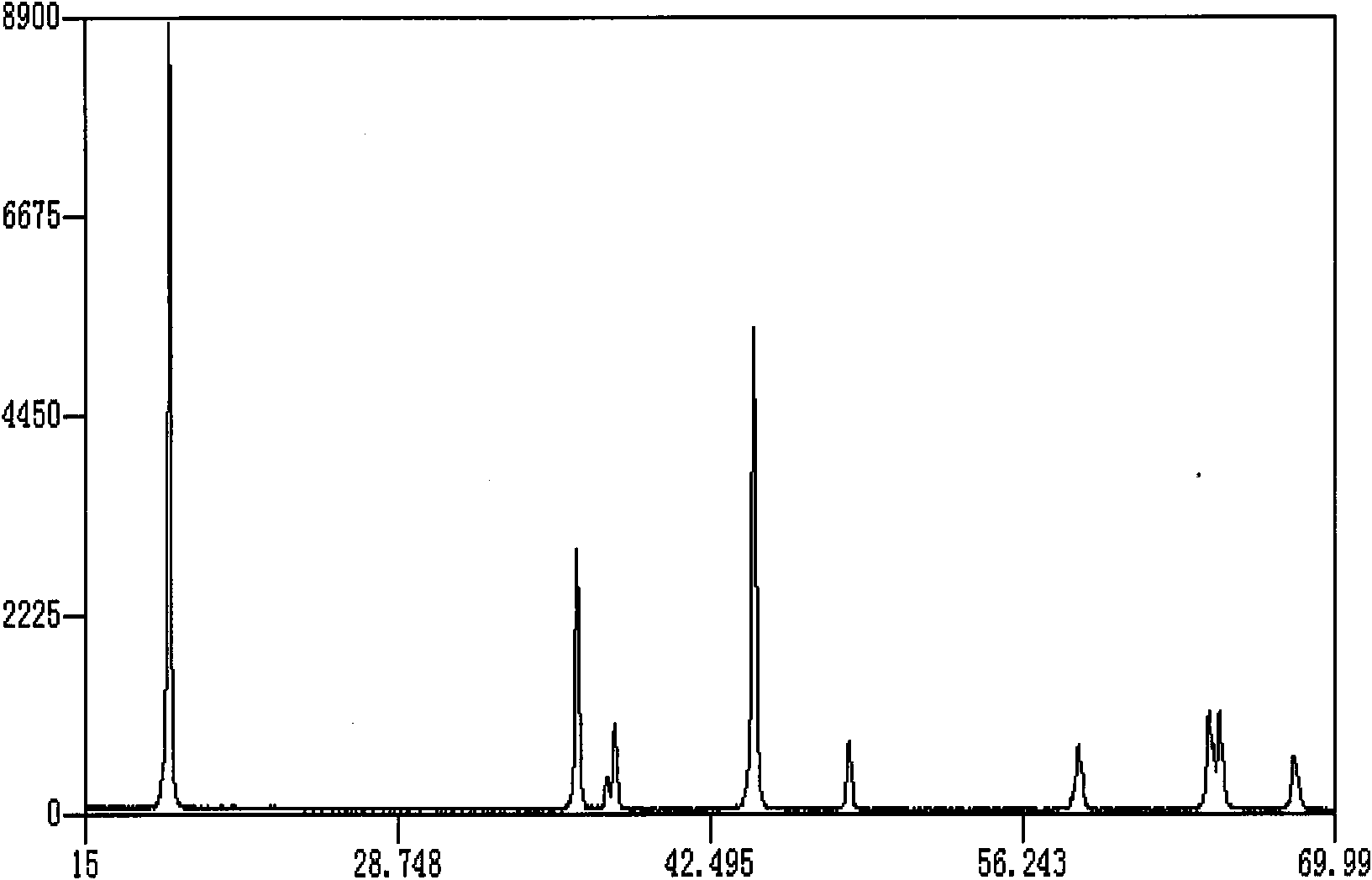

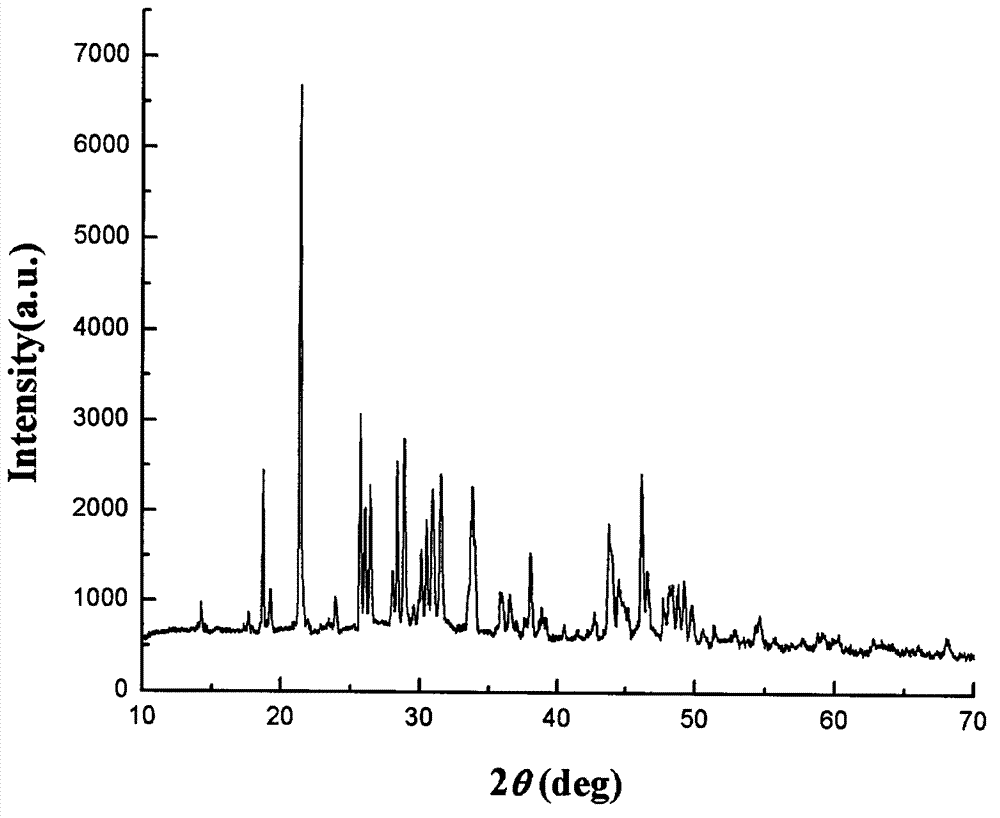

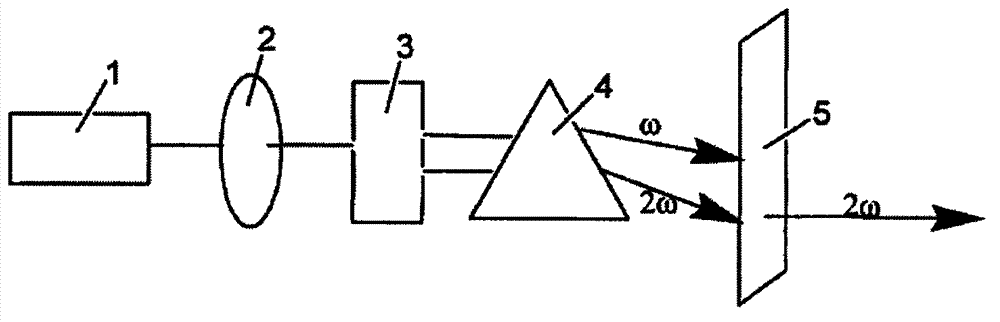

Nonlinear optical crystal of potassium borate chloride compound and preparation method as well as application thereof

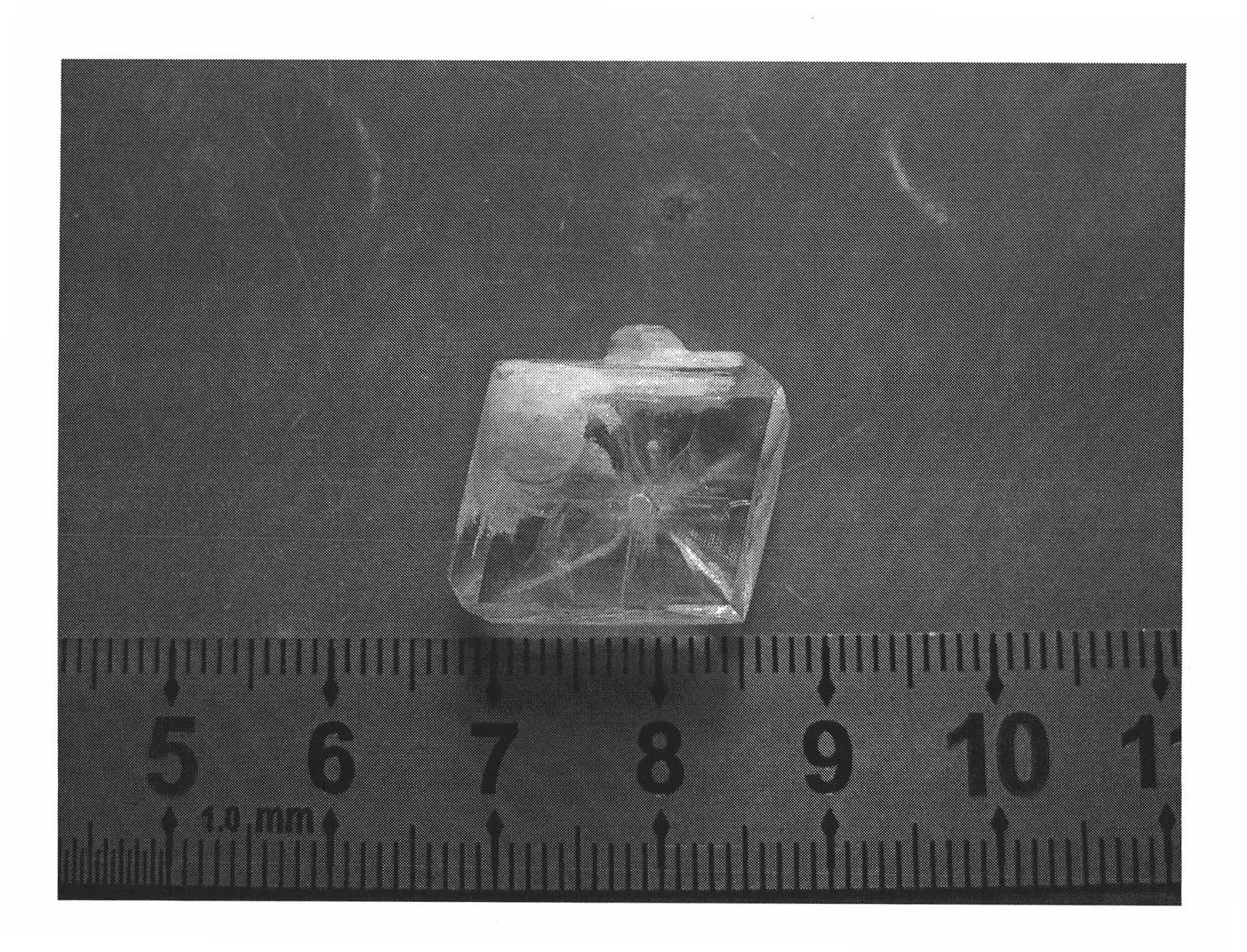

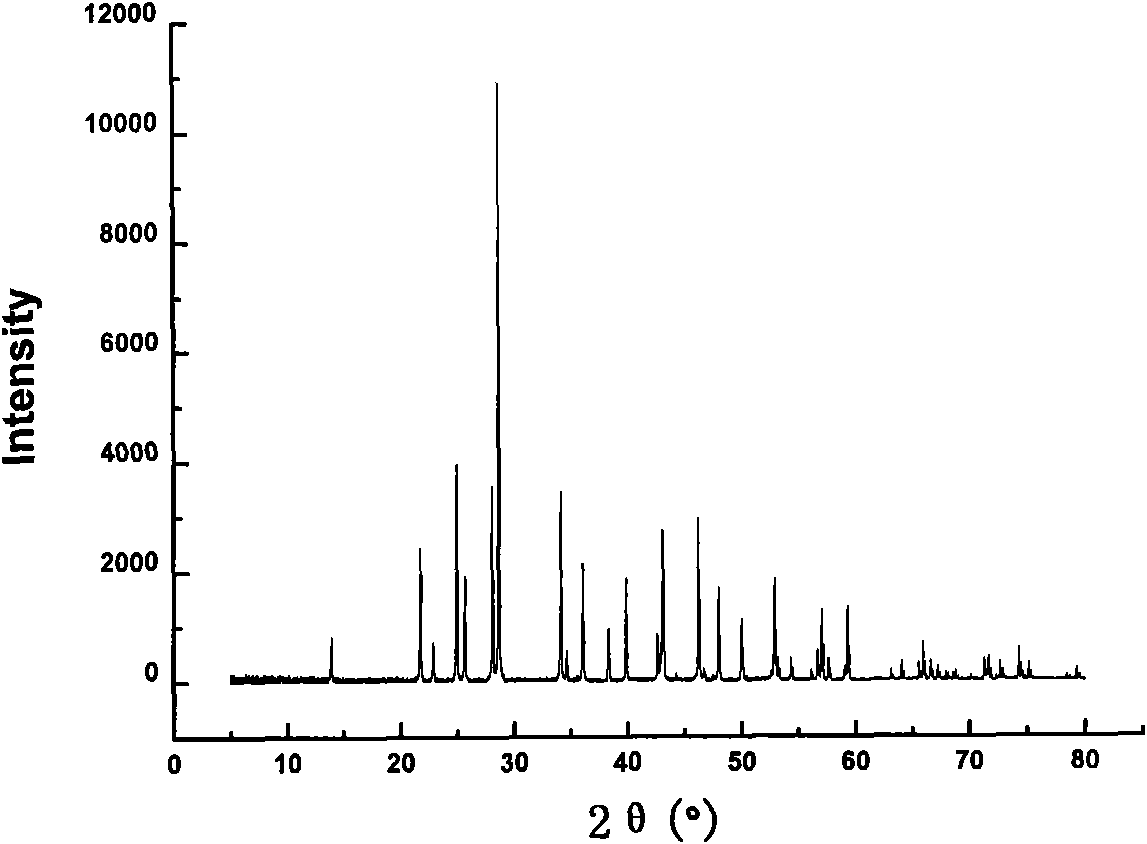

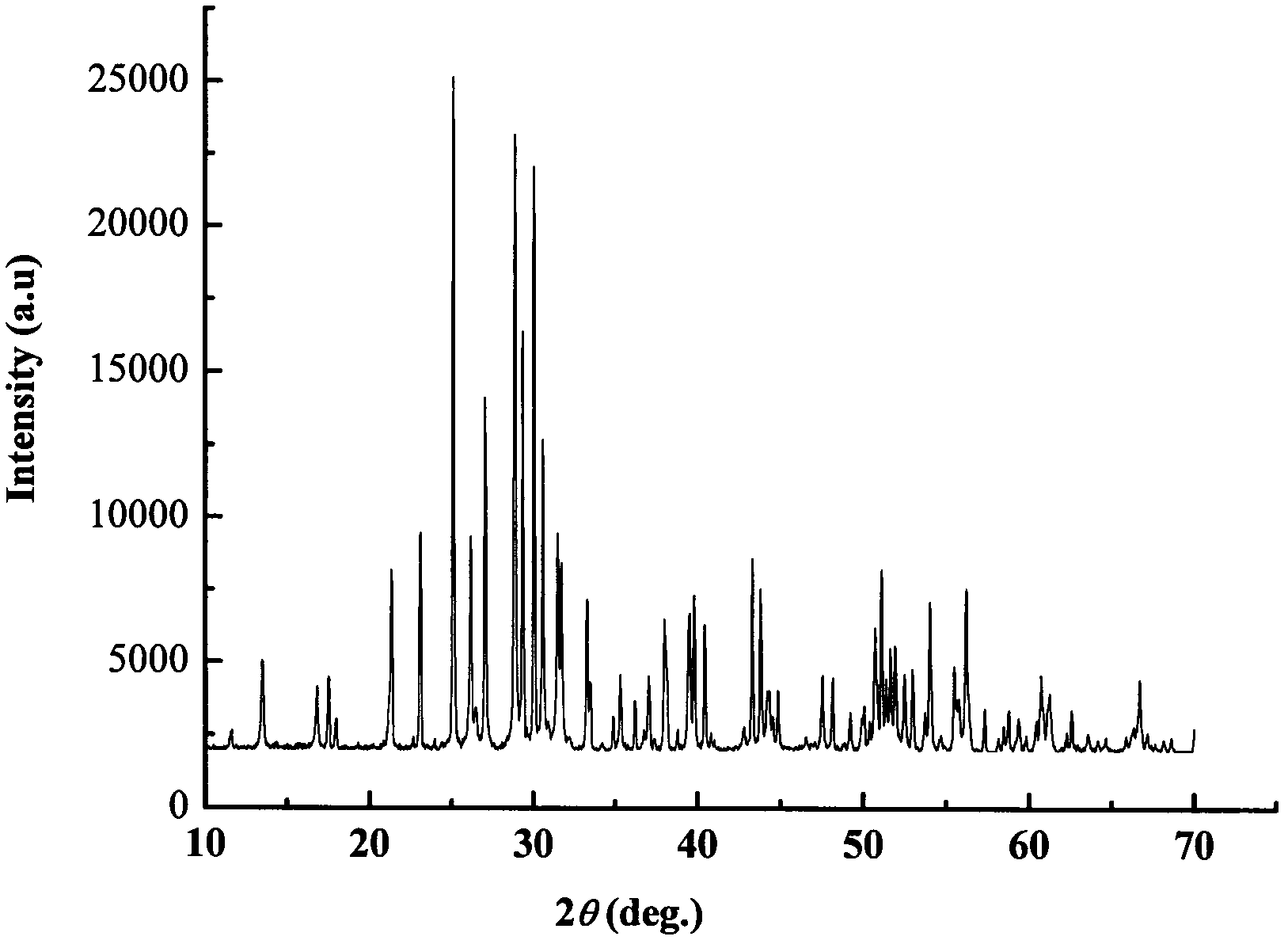

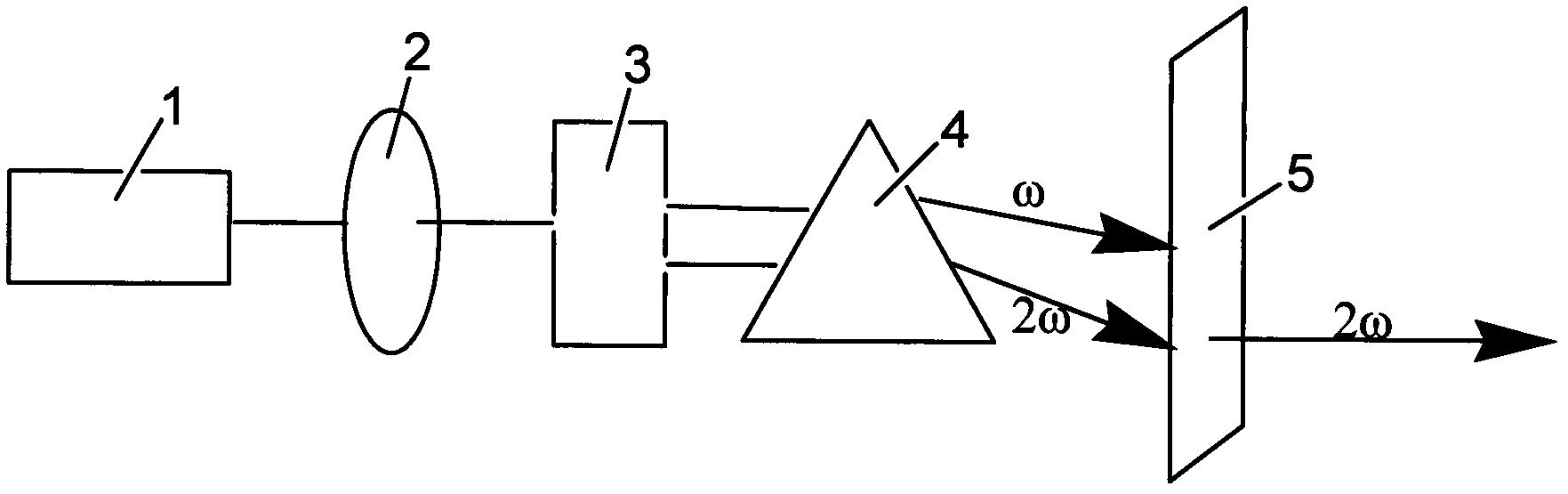

ActiveCN101914809APolycrystalline material growthFrom melt solutionsNonlinear optical crystalSpace group

The invention relates to a nonlinear optical crystal of a potassium borate chloride compound and a preparation method as well as application thereof. The chemical formula of the compound is K3B6O10Cl, and the molecular weight of the compound is 377.61. The crystal does not have a symmetric center and belongs to a trigonal system and a space group R3m, and cell parameters are as follows: a=10.0624(14), b=10.0624(14), c=8.8361(18), Z=3, and V=774.8 (2). The powder frequency-doubled effect reaches about 3 times of KDP(KH2PO4), the Mohs hardness is 4-5, and the light transmission waveband is 165nm-3460nm. A solid phase reaction method is used for synthesizing the compound, and a cosolvent method is used for growing the crystal. The crystal has the advantages of simple operation, low cost, large size, short growth cycle, few inclusion enclaves and larger mechanical hardness, and can be cut, polished, processed and saved easily. The crystal is used for generating twofold frequency or three-fold frequency or fourfold frequency or fivefold frequency harmonic light output for laser beams of which the wavelength is 1064nm.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

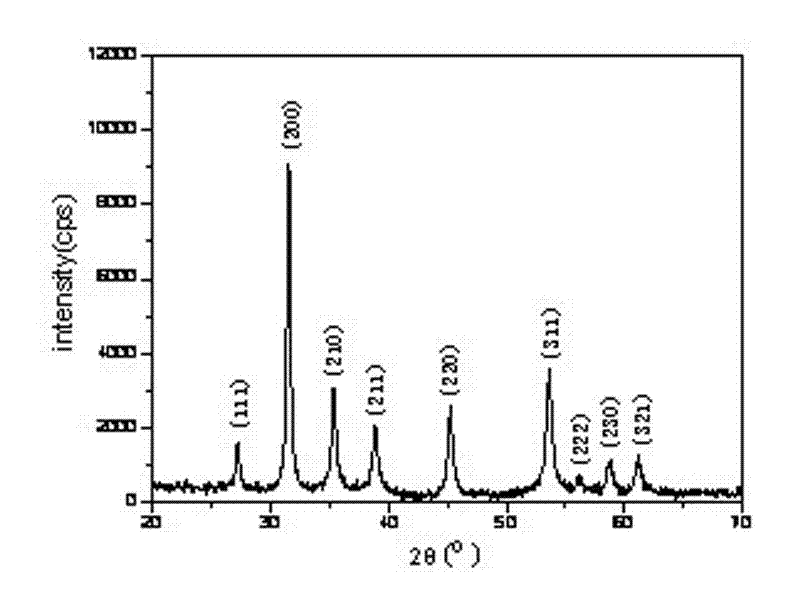

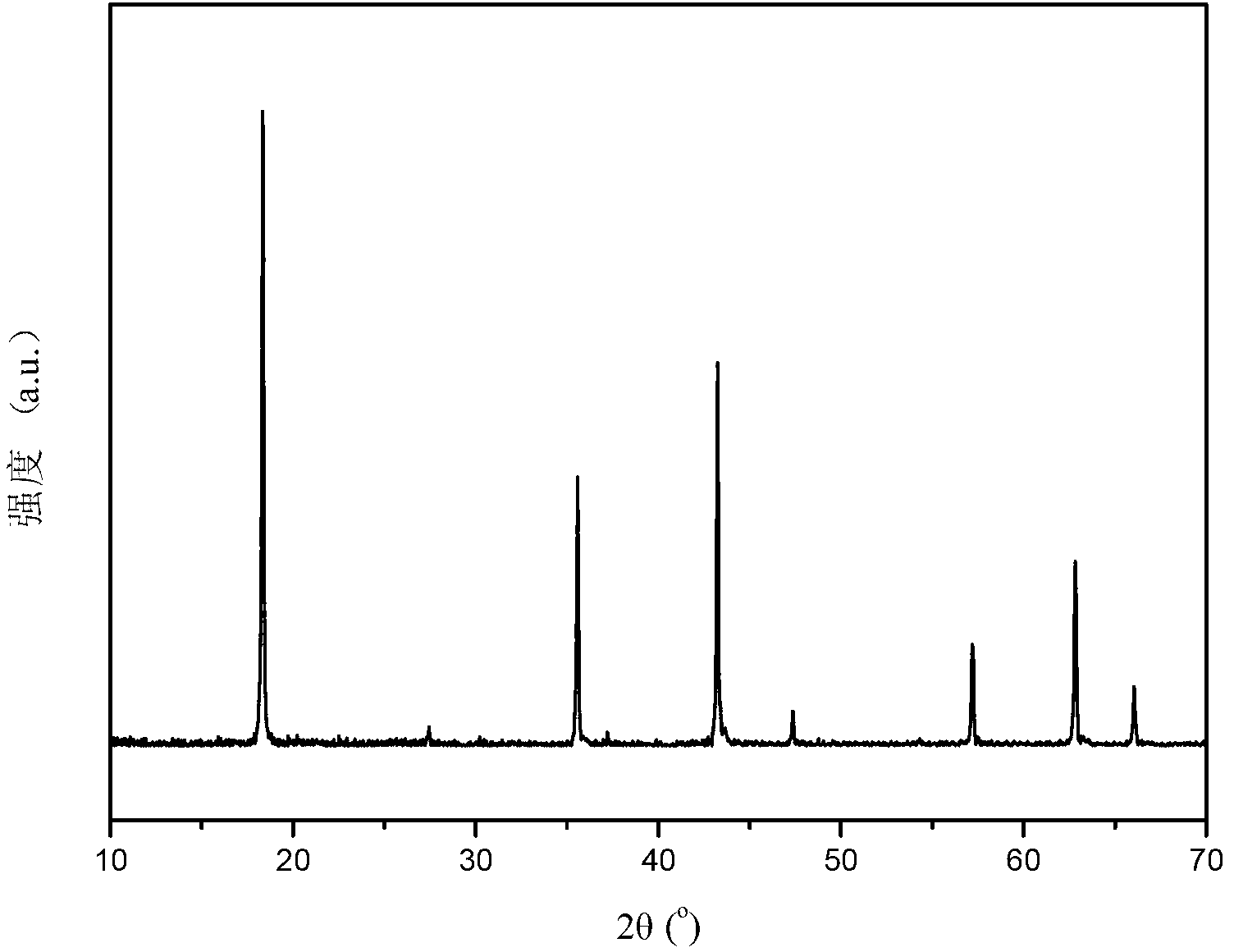

Preparation of stratified lithium ion anode material

ActiveCN101944610AHigh densityHigh activityElectrode manufacturing processesNickel compoundsManganeseSolid state reaction method

The invention relates to a preparation method of a stratified lithium ion anode material, which comprises the following steps: coating cobalt on the surface of a precursor containing nickel, manganese and a small amount of other metals by a chemical precipitation method; fully mixing with a lithium source; and then, adopting a solid reaction method to prepare the high nickel type lithium ion anode material. The chemical formula of the lithium ion anode material is as follows: LidNiaMnbMcCo1-a-b-c02, wherein 0.9<=d<=1.25, 0.5<=a<=1, 0<b<0.5, 0.9<=a+b+c<1, and M is one or a mixture of more than one of Al, Ti, Mg and Zn. The material has uniform chemical composition and high capacity. Besides, the cycle performance of the material is improved, and the operating voltage platform and the safety of a battery are enhanced, especially after the material is subject to doping and coating modification.

Owner:HENAN KELONG NEW ENERGY CO LTD

Hydrothermal preparation method for NiS2 with controllable shape

InactiveCN102633309AEasy to operateMild reaction conditionsNanotechnologyNickel sulfidesNickel saltReaction temperature

The invention discloses a hydrothermal preparation method for NiS2 with a controllable shape, and the method mainly comprises the following steps of: mixing nickel salt, a sulphur source and a complexing agent in a certain molar ratio, transferring the mixture into a high-pressure reactor, adding distilled water, and stirring to adequately dissolve soluble solids; adjusting the pH value of the reaction system, sealing the reactor, and reacting at a certain temperature; and washing the obtained product by use of distilled water and ethanol respectively, centrifugally separating, and drying. The hydrothermal preparation method for NiS2 with a controllable shape disclosed by the invention has the advantages of being simple in operation by using a hydrothermal method, moderate in reaction condition, narrow in particle size distribution, high in product purity, easy in industrial production, and the like. The particle shape and size of NiS2 can be controlled by adjusting the synthesis conditions such as hydrothermal reaction temperature, reaction time, complexing agent type and pH value, and the prepared NiS2 can be approximately-cube-shaped, spherical, sheet-shaped and the like. Compared with a solid-state reaction method, an ultrasonic spray pyrolysis method, a gamma-ray irradiation method and an organic solvent hot method, the NiS2 prepared by the hydrothermal method has the advantages of being low in reaction temperature and equipment demand, less in toxicity on a human body, high in safety factor, low in production cost, capable of meeting the requirements of energy conservation and emission reduction, and the like.

Owner:SHENYANG LIGONG UNIV

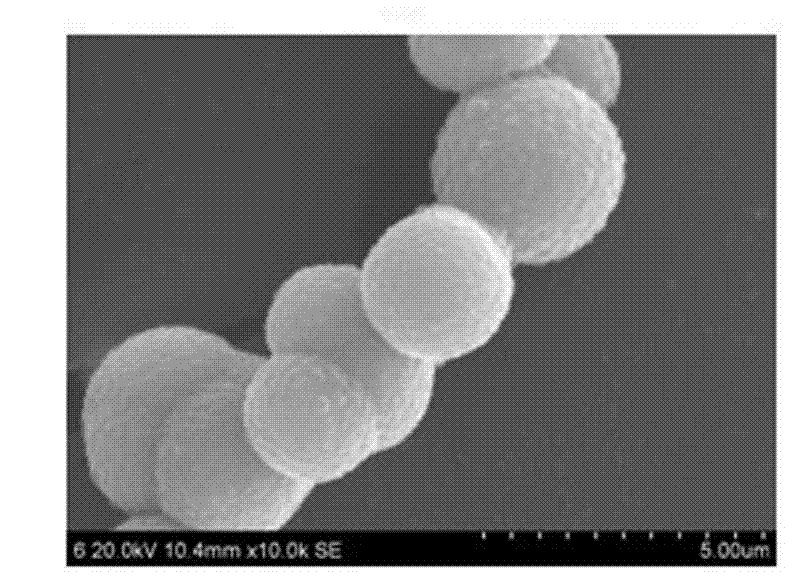

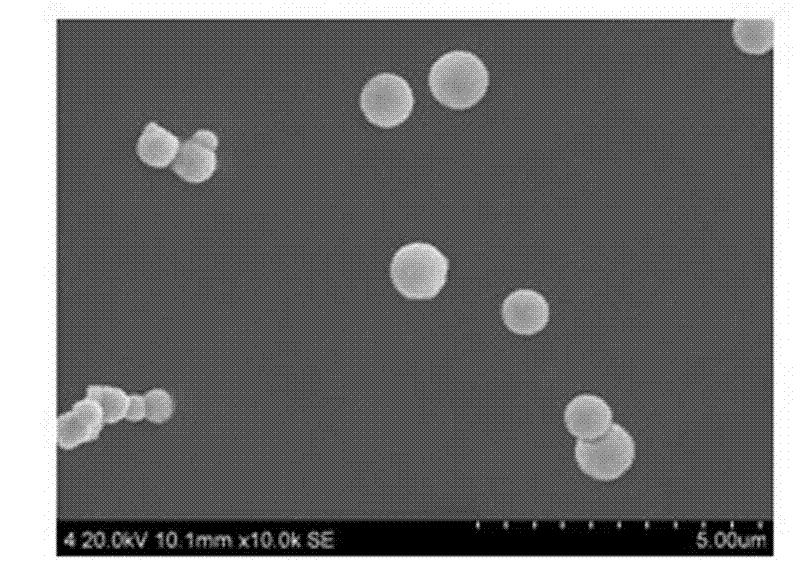

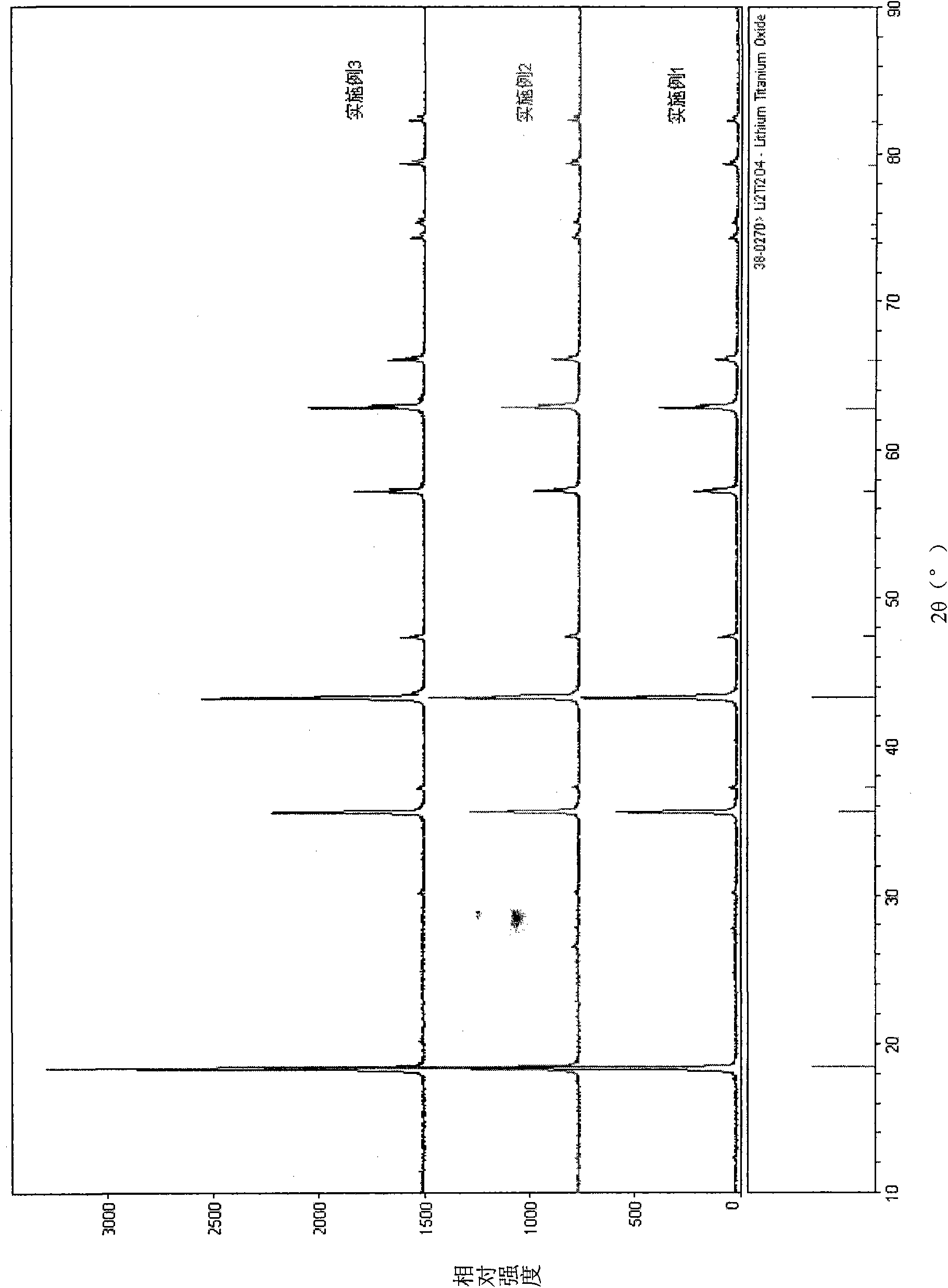

Preparation method for LiTiO/C compound electrode material

InactiveCN101587948APrevent volatilizationImprove conductivityElectrochemical generatorsElectrode manufacturing processesCapacitanceAir atmosphere

The invention discloses a preparation method for Li4Ti5O12 / C compound electrode material, using a solidifying phase reacting method of low temperature presintering firstly and further high temperature roasting. The method comprises following steps: (1) preparing compound containing Ti and inorganic lithium salts in a certain ratio, mixing and performing ball grinding in an organic solvent medium; (2) in the air atmosphere, increasing temperature to 300-700 DEG C and after keeping the temperature for 2-8h, cooling the mixture to the constant temperature with the furnace to obtain the intermediate product; (3) mixing and performing ball grinding on the intermediate product and carbon source; under the protection of inert gas atmosphere, increasing temperature to 780-950 DEG C and keeping the temperature for 2-20h, then cooling the mixture with the furnace to obtain the Li4Ti5O12 / C compound electrode material. The invention has low preparation cost and a characteristic easy to achieve scale production; the synthesized sample has a regular appearance and a stable structure, having high charging-discharging multiplying power and a great circulation performance, which can be used as the electrode material of super capacitor, lithium ion battery or super capacitor battery.

Owner:CENT SOUTH UNIV +1

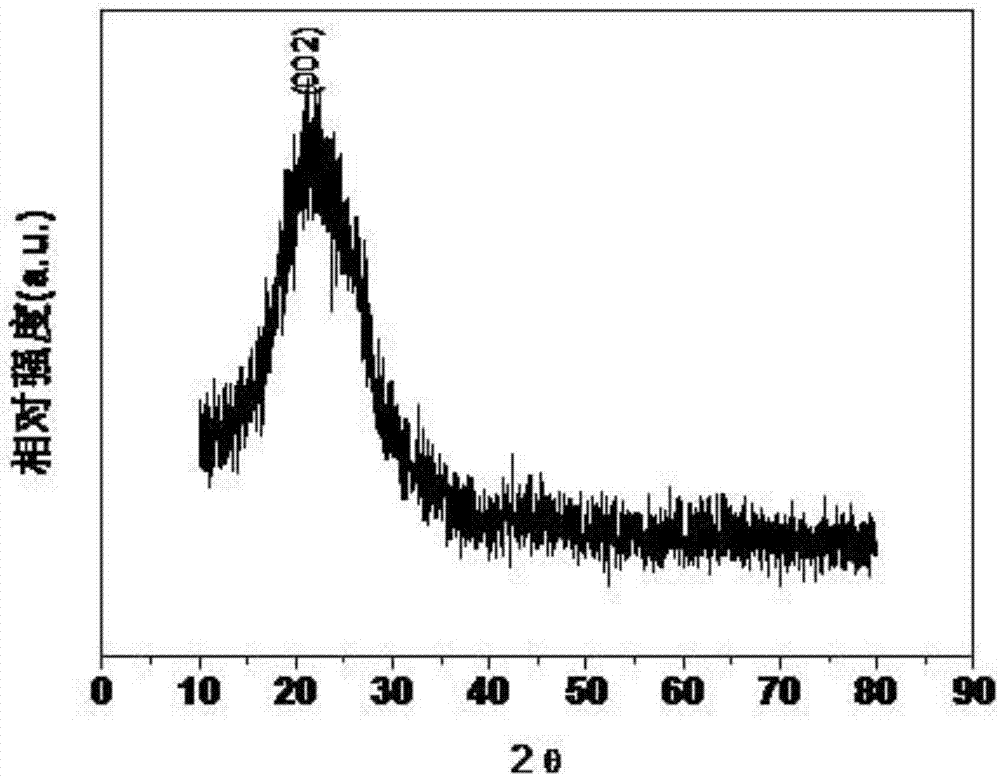

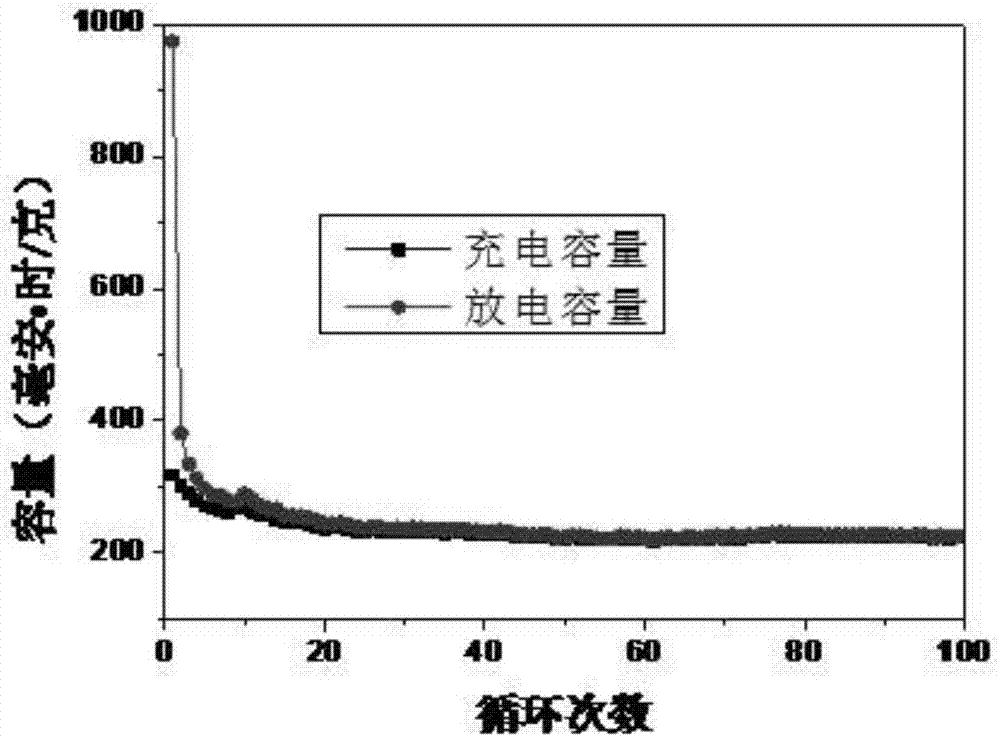

Method for preparing nitrogen-doped porous carbon material used as sodium ion battery cathode

ActiveCN107331867AImprove cycle stabilityOvercome the disadvantage of low specific capacityCell electrodesSecondary cellsPorous carbonSynthesis methods

The invention provides a method for preparing a nitrogen-doped porous carbon material used as a sodium ion battery cathode, and belongs to a method for preparing nitrogen-doped porous carbon. The nitrogen-doped carbon material is controlled and synthesized by regulating and controlling each parameter in the reacting process by means of a simple and feasible high-temperature solid phase reaction method, and is applied to a sodium ion battery cathode material. The method comprises the following steps: dissolving a selected nitrogen source in a solvent to form a transparent solution A; adding a proper amount of carbon source into the solution A, and constantly adding into solvent to sufficiently disperse the nitrogen source under a stirring state; drying the materials in a lyophilizer for 2-12 hours; putting a proper amount of the materials into a crucible, heating to 300-1100 DEG C and insulating for 1-6 hours in a vacuum tube furnace under an argon atmosphere at a speed of 2-8 DEG C / minute; and separating and purifying the generated product to obtain a product. The preparation method has the advantages of low-price and easily available raw materials, simple synthesis method and high controllability of operation steps, and is easy for expanded production. The nitrogen-doped porous carbon material can be used as a sodium ion battery cathode material, and shows excellent electrochemical performance.

Owner:CHINA UNIV OF MINING & TECH

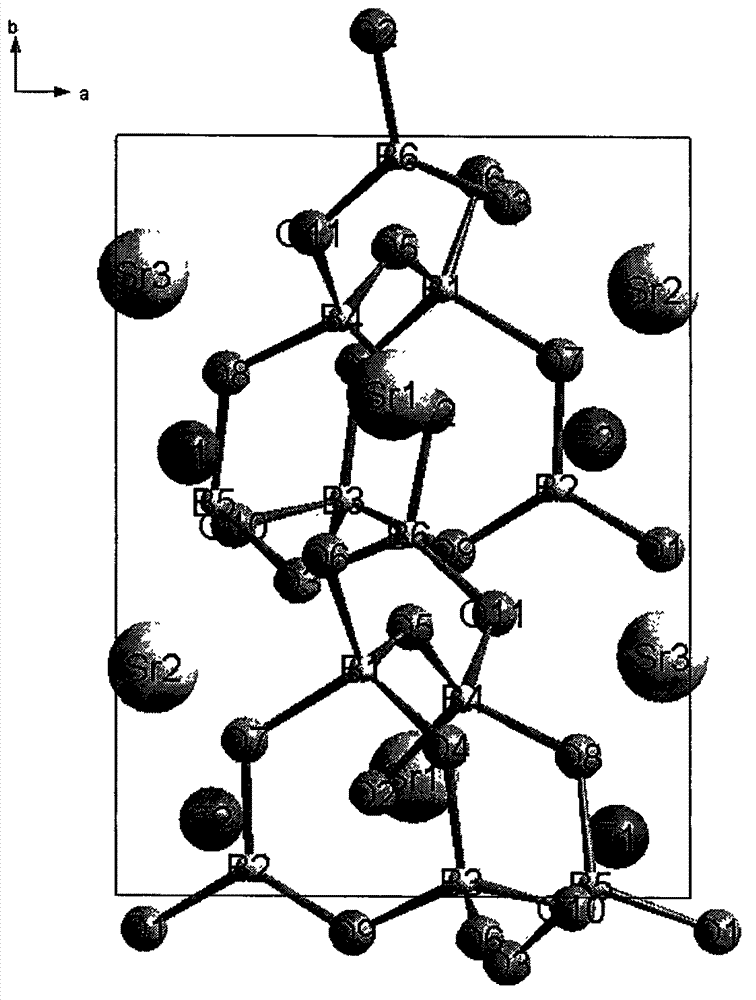

Compound potassium lead borophosphate nonlinear optical crystal as well as preparation method and application thereof

InactiveCN101876772AHigh birefringenceBroaden the field of studyPolycrystalline material growthFrom frozen solutionsNonlinear optical crystalPhosphate

The invention relates to a compound potassium lead borophosphate nonlinear optical crystal as well as a preparation method and application thereof. The compound has the chemical formula of KPbBP2O8. The preparation method comprises the following steps of: after uniformly mixing a raw material containing K, Pb, B and P by adopting a solid-phase reaction method, heating for carrying out solid-phase reaction to obtain a compound of the potassium lead borophosphate; and growing a crystal on the compound by adopting a melt method to obtain the potassium lead borophosphate nonlinear optical crystal. The compound is the centimeter-grade large size nonlinear optical crystal of a tetragonal crystal system; a space group is I-42d; cell parameters comprise a=7.1764(7), b=7.1764(7), c=13.9483(13), Z=4 and V=718.35; the powder frequency doubling effect of the compound is equivalent to that of KDP (Potassium Dihydrogen Phosphate); the Mohs hardness is 4 to 5; and the potassium lead borophosphate nonlinear optical crystal has the advantages of easy cutting, polishing processing and storage, no deliquescence, high preparation speed, simple operation, low cost, good mechanical performance, difficult cracking, stable physicochemical property, and the like and is suitable for manufacturing an nonlinear optical device.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

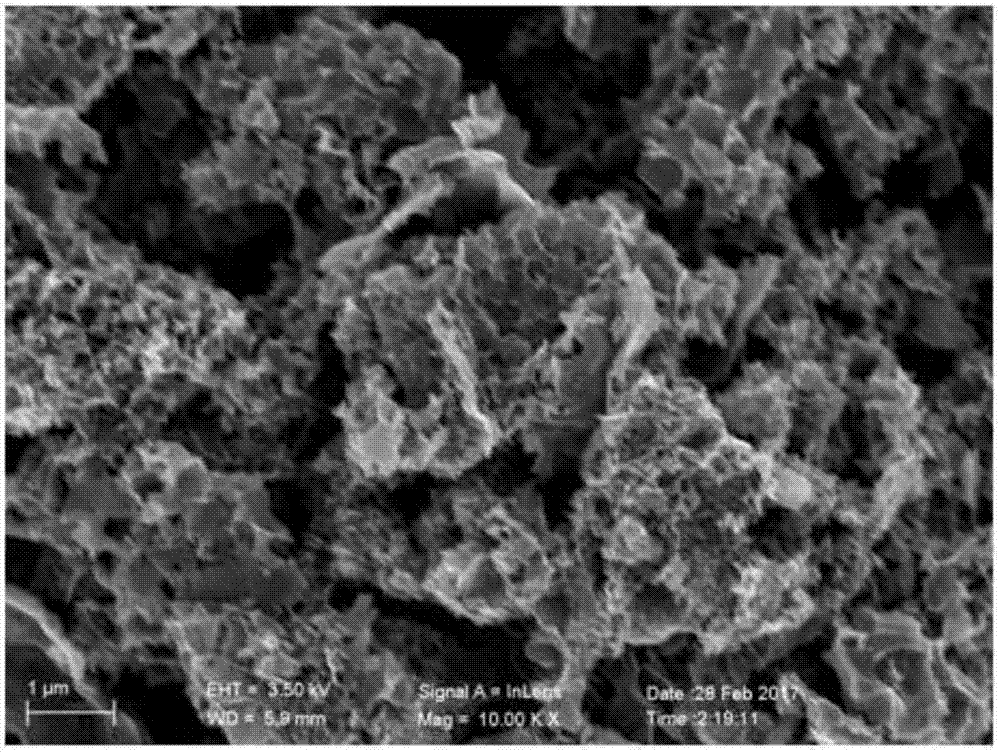

Li4Ti5O12/ grapheme composite electrode material and preparation method thereof

InactiveCN103219168AEase of industrial productionInhibition of agglomerationHybrid capacitor electrodesCell electrodesCarbon layerSodium-ion battery

The invention relates to a Li4Ti5O12 / grapheme composite electrode material, which is prepared by combining the following components: carbon-coated titanium dioxide, grapheme and a lithium source, wherein in a mixture of the carbon-coated titanium dioxide and the lithium source, the molar ratio of lithium to titanium is 0.8-0.88:1; and the grapheme accounts for 1.0 percent-15 percent of the total weight of lithium titanate / grapheme composite electrode materials. The invention also provides a preparation method of the composite electrode material. The method comprises the following steps of: on the basis of coating carbon on raw material nano TiO2, compositing the lithium source and the grapheme with the TiO2 through ball-milling; and preparing the composite electrode material under inert atmosphere through an in-situ solid-phase reaction method. According to the method, the agglomeration of Li4Ti5O12 at high temperature is effectively inhibited, the combination between the coated carbon layer and the grapheme is closer, and the stable and uniform composite material is formed. Tests show that the composite material has favorable electrochemical performance when being used as the electrode material of a lithium ion battery and a supercapacitor, is an ideal electrode material for the lithium ion battery and the supercapacitor, has simple combination process, and is easy to produce in large scale.

Owner:HEFEI UNIV OF TECH

Lithium iron phosphate anode material for lithium ion battery and modification method

InactiveCN101315981AUniform structureEasy to processElectrode manufacturing processesChemical/physical/physico-chemical processesSolid state reaction methodLithium-ion battery

The invention provides a lithium iron phosphate anode material used for lithium ion batteries; the lithium iron phosphate which is prepared by a water heating method is taken as a precursor which is then uniformly mixed with a conductive matter precursor and metal ion salt, and finally baked in inert gas to obtain the lithium iron phosphate anode material which is coated by the conductive matter and doped by the metal ions. Compared with a pure solid phase reaction method, the method of the invention has small energy dissipation, the chemical uniformity of the synchronized outcome is good, the dimension and the appearance of the outcome are uniform, and the electromechanical performance and the processing performance have good stability and repeatability. Compared with the a pure water heating method, as the coating of the conductive matter, the doping and modifying performance of the metal ions are added during the anaphase, the electric conductivity of the material is greatly improved, and the high magnification electromechanical performance of the material is excellent; wherein, under the 10C discharging magnification, the discharging content of the lithium iron phosphate anode material with the copper ion doped is kept at 107mAh / g. After circulation for 50 times, the discharging content of the material is kept unchangeable basically, which can certify that the material has good circulation performance.

Owner:HEFEI UNIV OF TECH

Compound barium borofluoride, barium borofluoride non-linear optical crystal, and preparation method and use of the barium borofluoride non-linear optical crystal

ActiveCN102978702APolycrystalline material growthBy pulling from meltNonlinear optical crystalHardness

The invention discloses a compound barium borofluoride, a barium borofluoride non-linear optical crystal, and a preparation method and a use of the barium borofluoride non-linear optical crystal. The compound barium borofluoride and the barium borofluoride non-linear optical crystal have the same chemical formula of Ba3B6O11F2. The barium borofluoride non-linear optical crystal belongs to a monoclinic system, has a space group P2(1), has cell parameters shown in the patent specification, wherein beta is equal to 101.351(4)deg., and has the molecular weight of 690.88. The powder frequency-doubling effect of the barium borofluoride non-linear optical crystal is 3 times that of KDP (KH2PO4). The compound barium borofluoride is synthesized by a solid-phase reaction method. The barium borofluoride non-linear optical crystal grows by a high-temperature melting method. The barium borofluoride non-linear optical crystal has large mechanical hardness, can be cut, polished and stored easily, and can be widely used in preparation of nonlinear optical devices such as a frequency multiplication generator, an upper frequency converter, a lower frequency converter and an optical parameter resonator.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Mullite-whisker-reinforced anorthite porous ceramic and preparation method thereof

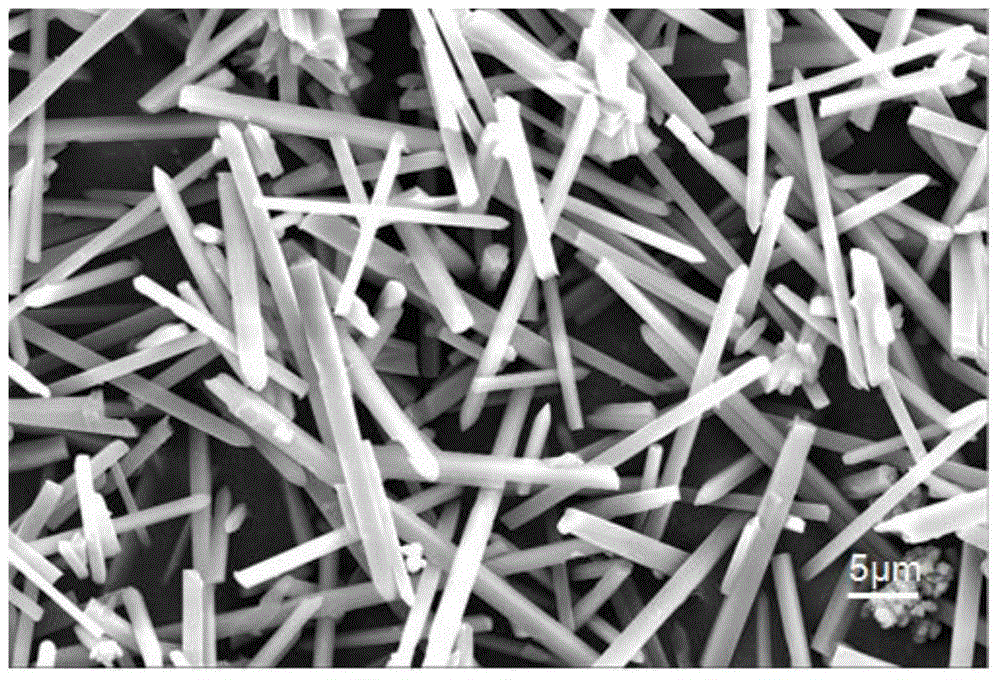

InactiveCN105198478ARaw materials are easy to getGood lookingCeramicwareSolid state reaction methodSilicon dioxide

The invention provides a mullite-whisker-reinforced anorthite porous ceramic and a preparation method thereof. The preparation method comprises the following steps: preparing pure-phase high-length-diameter-ratio high-dispersibility mullite whisker by a solid reaction process, preparing a porous ceramic billet from the mullite whisker, alpha-aluminum oxide, silicon dioxide and calcium carbonate powder by a foam gelcasting process, and finally, sintering at 1450 DEG C for 5 hours to obtain the mullite-whisker-reinforced anorthite porous ceramic. The material prepared by the method has the advantages of high porosity, low thermal conductivity and high strength. The apparent porosity of the sample, in which the addition amount of the mullite whisker is 50 wt.%, is up to 90%; the room-temperature vacuum thermal conductivity is only 0.045 W / m.K; and the compression strength is up to 1.1 MPa. The research shows that the added mullite whisker inhibits the growth of the anorthite grains, and the high porosity, complicated pore structure and fine grains are main reasons for low thermal conductivity. The tight combination between the added whisker and base greatly enhances the strength of the material.

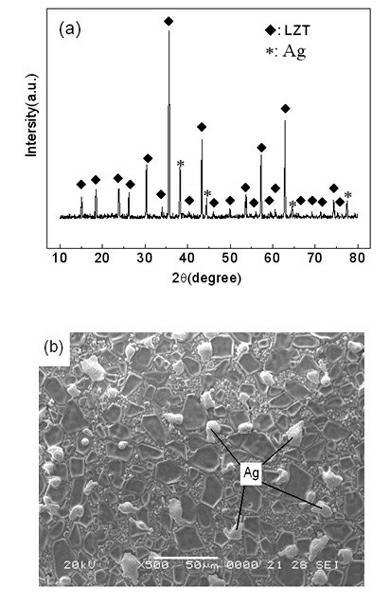

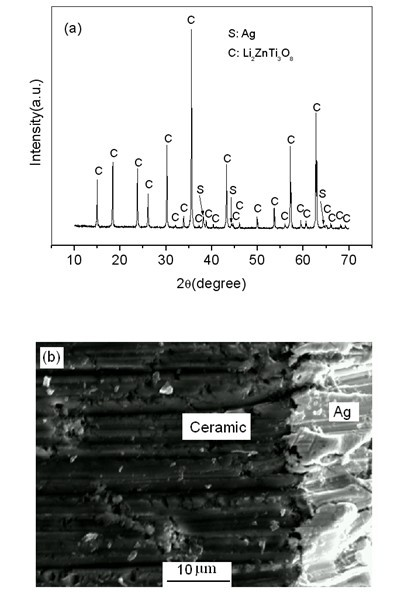

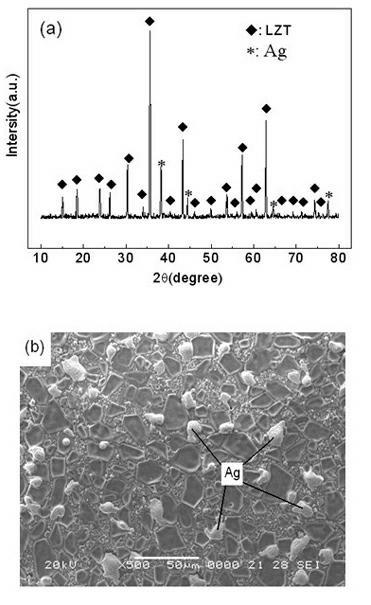

Low temperature co-fired microwave dielectric ceramic material and preparation method thereof

InactiveCN102381874ALower sintering temperatureThe sintering temperature drops toCeramicsDielectric resonatorSolid state reaction method

The invention discloses a low temperature co-fired microwave dielectric ceramic material and a preparation method thereof. The ceramic material comprises a main powder material Li2ZnTi3O8, an auxiliary component TiO2 and low-melting-point LZB (Li2O-ZnO-BiO2) or LBS (Li2O-B2O3-SiO2) glass powder. The preparation method comprises the following steps of: adding TiO2 and the glass powder into the Li2ZnTi3O8 powder in a powder form; and then evenly mixing in a ball mill, drying, pelleting and sintering so as to obtain the ceramic material. In the invention, based on the Li2ZnTi3O8 powder as a reference, batching is carried out according to the proportions that the mass of the glass powder is 0.5-3wt% of that of Li2ZnTi3O8 and the mass of the TiO2 powder is 0-5wt% of that of Li2ZnTi3O8; and thematerial of the invention can be obtained by a traditional solid phase reaction method. The low temperature co-fired microwave dielectric ceramic material prepared by the method of the invention has low sintering temperature (about 875 DEG C) and good microwave dielectric property, and can be well co-fired with a Ag electrode; pure silver with high electricity conductivity and low cost is used asan electrode material, thus the manufacturing cost of a device can be greatly reduced; and the low temperature co-fired microwave dielectric ceramic material can be used for a low temperature co-fired ceramic (LTCC) system and manufacturing of microwave devices such as multilayer dielectric resonators, microwave antennas, filters and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

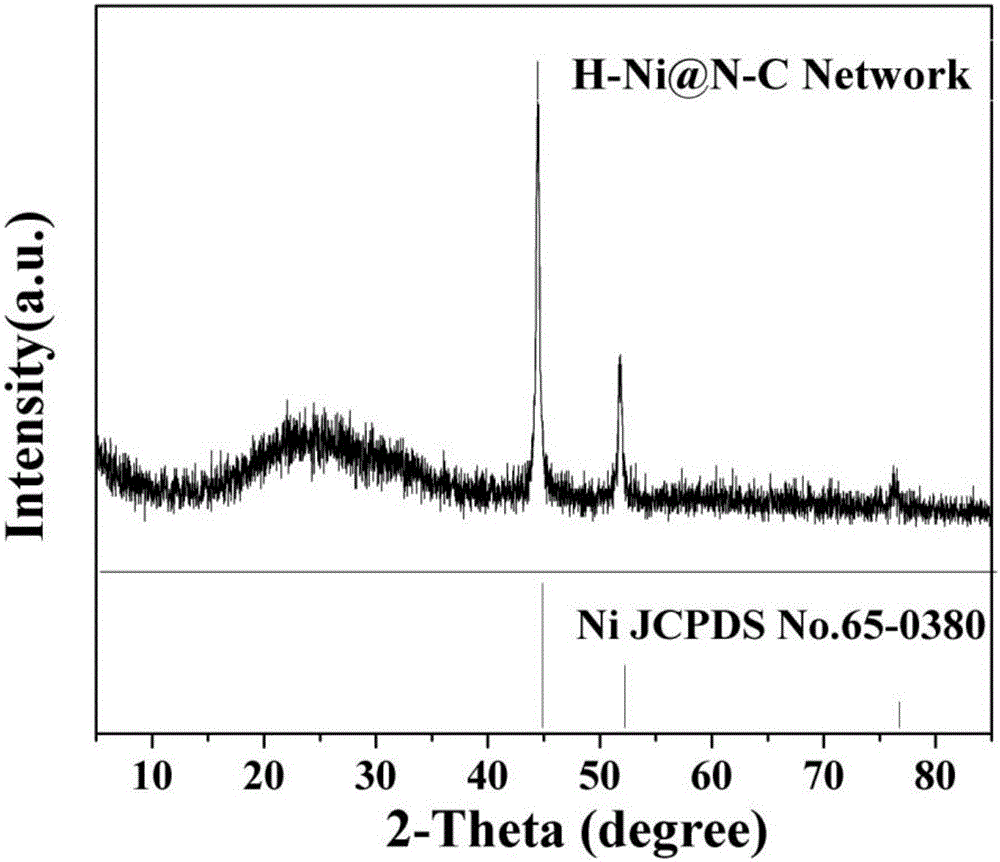

Preparation method for hollow porous carbon composite material

InactiveCN105776130AEasy to prepareUniversalMaterial nanotechnologyCell electrodesCarbon compositesNew energy

The invention discloses a preparation method for a hollow porous carbon composite material. The preparation method comprises the following steps that 1, solid phases are self-assembled to synthesize a metal complex; 2, the metal complex is subjected to in-situ thermolysis and carbothermic reduction to synthesize the hollow porous carbon composite material with embedded metal or metal oxide nano-particles. Furthermore, the carbon composite material is modified and reacts with proper acid, the metal or metal oxide nano-particles in the carbon composite material are removed, and then a graded porous carbon composite material is further obtained. According to the preparation method, a simple one-pot solid-phase reaction method is adopted, step-by-step temperature control is carried out, and then the hollow porous carbon composite material with the evenly embedded metal or metal oxide nano-particles is obtained. Various carbon composite materials synthesized through the method have the advantages of being good in charge and discharge capacity stability, high in specific capacity, excellent in rate capability and the like, and can be applied to lithium ion batteries, electrochemical capacitors and new energy fields.

Owner:NANJING NORMAL UNIVERSITY

Preparation method of strontium fluoroborate nonlinear optical crystals, and applications of strontium fluoroborate nonlinear optical crystals

ActiveCN103590106APolycrystalline material growthFrom melt solutionsNonlinear optical crystalFlux growth

The invention relates to a preparation method of strontium fluoroborate nonlinear optical crystals, and applications of the strontium fluoroborate nonlinear optical crystals. Compound synthesis is realized via solid phase reaction, and crystal growth is realized via flux growth method. The preparation method is simple in operation, and low in cost. The obtained strontium fluoroborate nonlinear optical crystals will not deliquesce in the air, possesses excellent mechanical properties and stable physico-chemical properties, is unbreakable, is convenient for processing, and is suitable for preparation of nonlinear optical devices. Frequency-doubled effect of the strontium fluoroborate nonlinear optical crystals obtained by the preparation method is three times of that of KDP, and the strontium fluoroborate nonlinear optical crystals can be widely used in nonlinear optical devices such as double frequency converters and optical parametric oscillators.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Low temp, sintered bismuth base microwave medium ceramic material and preparation process thereof

InactiveCN1793035ALower sintering temperatureResonant frequency temperature coefficient is smallCeramicsMicrowaveSolid state reaction method

The invention discloses a low temperature sintering bismuth based microwave medium ceramic material. The expression of the material is Bi(Nb1-xVx)O4, of which 0.001<=x<=0.064. Traditional solid phase synthesis compounding technology is adopted, and the sintering temperature range is between 810 degree centigrade and 980 degree centigrade. The material has low sintering temperature, suitable dielectric constant, and simple manufacturing structure. It could be used to make LTCC, multilayer medium resonator, microwave antenna, filter, etc.

Owner:XI AN JIAOTONG UNIV

Method for preparing intermediate-tmeperature solid oxide electrolyte superfine powder for fuel cell

InactiveCN1471188ALarge specific surface areaHigh sintering activityFinal product manufactureOxide conductorsSolid state reaction methodComposite oxide

First, complexing metal ion by complexing agent, then adding organic gel-forming agent also as auxiliary complexing agent and fuel, and finally adding proper amount of NH4NO3. With being concentrated under 40-100 DEG C, the glue is heated till drastic combustion reaction similar to explode happens so as to generate superfine precursory powder of composite oxides. The method can synthesize electrolytical micropowder material possessing favorable sintering character with granularity in tens nano for solid oxide fuel cell. The method makes phasing temperature(superfine LSGM powder with granularity less then 100 nano is obtained) of La0.9 Sr0.1 Ca0.8 Mg0.2O[3-delta](LSGM9182) reduce to 1120 DEG C from 1500 DEG C by using solid state reaction method.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lanthanum-zirconium-doped lead titanate ferroelectric thick film ceramic material and preparation method thereof

The invention discloses a lanthanum-zirconium-doped lead titanate ferroelectric thick film ceramic material and a preparation method thereof, wherein the composition of the material is (Pb1-XLax)(Zr1-YTiy)zO3, x is 0.03-0.15, y is 0.05-0.50, and z is 0.50-1.00. According to the present invention, lanthanum-zirconium-doped lead titanate powder is synthesized from raw materials such as PbO, La2O3, ZrO2 and TiO2 according to a solid-phase reaction method, a raw film is prepared through a casting molding process, and the raw film is subjected to glue removing sintering to obtain the lanthanum-zirconium-doped lead titanate ferroelectric thick film ceramic; and the thickness of the prepared PLZT thick film ceramic is 20-70 [mu]m, the prepared lanthanum-zirconium-doped lead titanate ferroelectric thick film ceramic has the properties of the relaxation type ferroelectric material, can bear the high electric field strength, has the excellent electrothermal effect, and can meet the electrothermal refrigeration device preparation requirements.

Owner:GUANGDONG UNIV OF TECH

Method for preparing magnesia-alumina spinel powder through low-temperature solid reaction process

The invention discloses a method for preparing magnesia-alumina spinel powder through the low-temperature solid reaction process. Raw material containing aluminum and magnesium is weighted according to the stoichiometric proportion of magnesia-alumina spinels, the weighted raw material is subject to dry-process pretreatment, wet-process pretreatment, saline hydrolysis process pretreatment or saline precipitation process pretreatment to obtain mixture powder as a precursor, the precursor is subject to the heat treatment or roasting at the temperature of 900 to 1,200 DEG C to obtain the magnesia-alumina spinel powder with better dispersibility and pure phase, and part of particles takes the shape of an octahedra. According to the invention, fluorochemicals are taken as mineralizing agents, the effective control on the solid-phase reaction of alumina (or aluminum hydroxide) and marmag (or magnesium hydroxide) at a high temperature is achieved, and the characteristics that the reaction temperature is low, the pure-phase or almost pure-phase magnesia-alumina spinel powder can be manufactured, the chemical purity of the powder can keep the same level with that of the powder before the solid-phase reaction, the granularity of the powder is micron-grade or submicron-grade, and the raw material particles of the powder take the shape of a regular octahedra sometimes are achieved.

Owner:DALIAN JIAOTONG UNIVERSITY +1

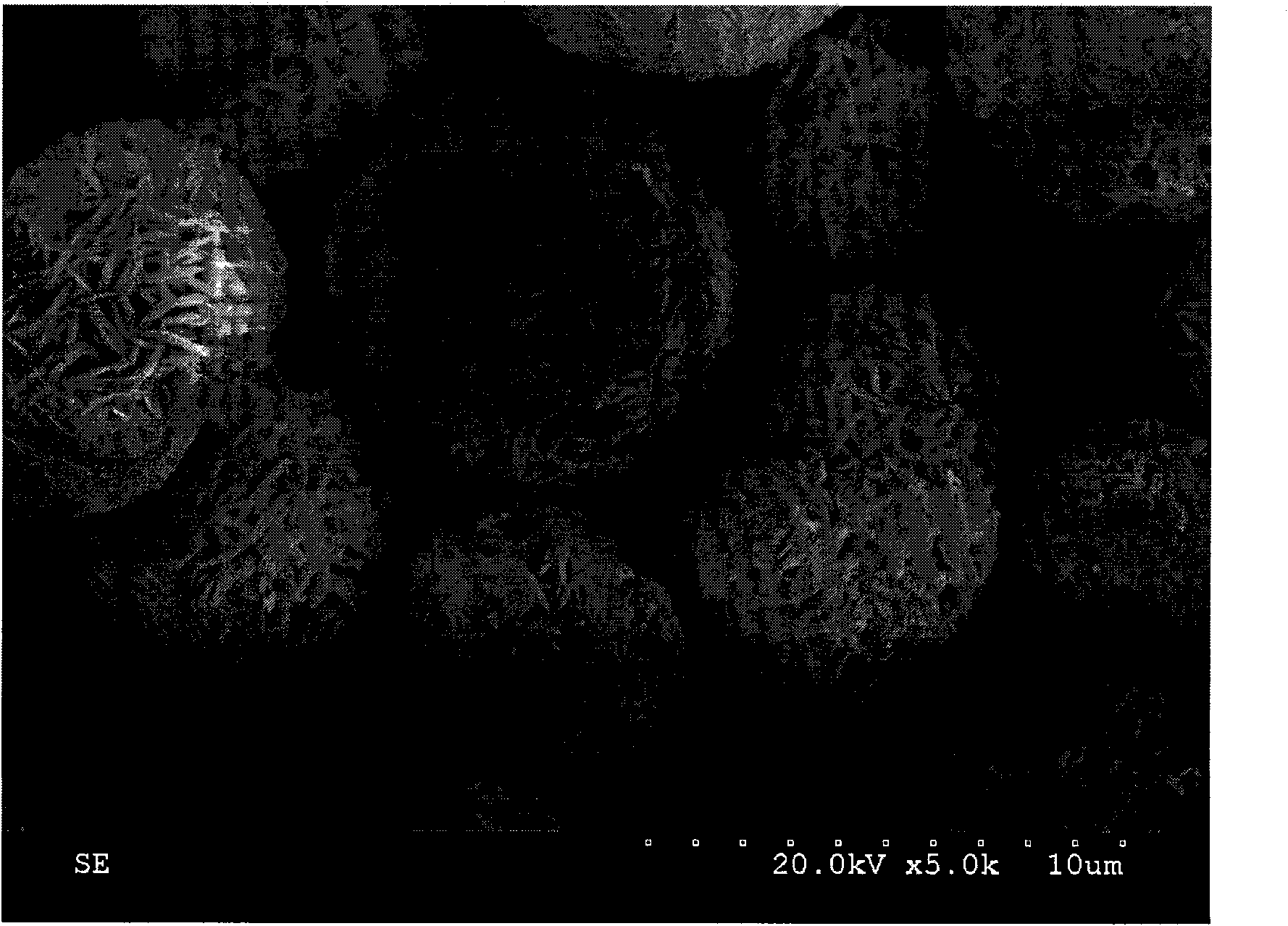

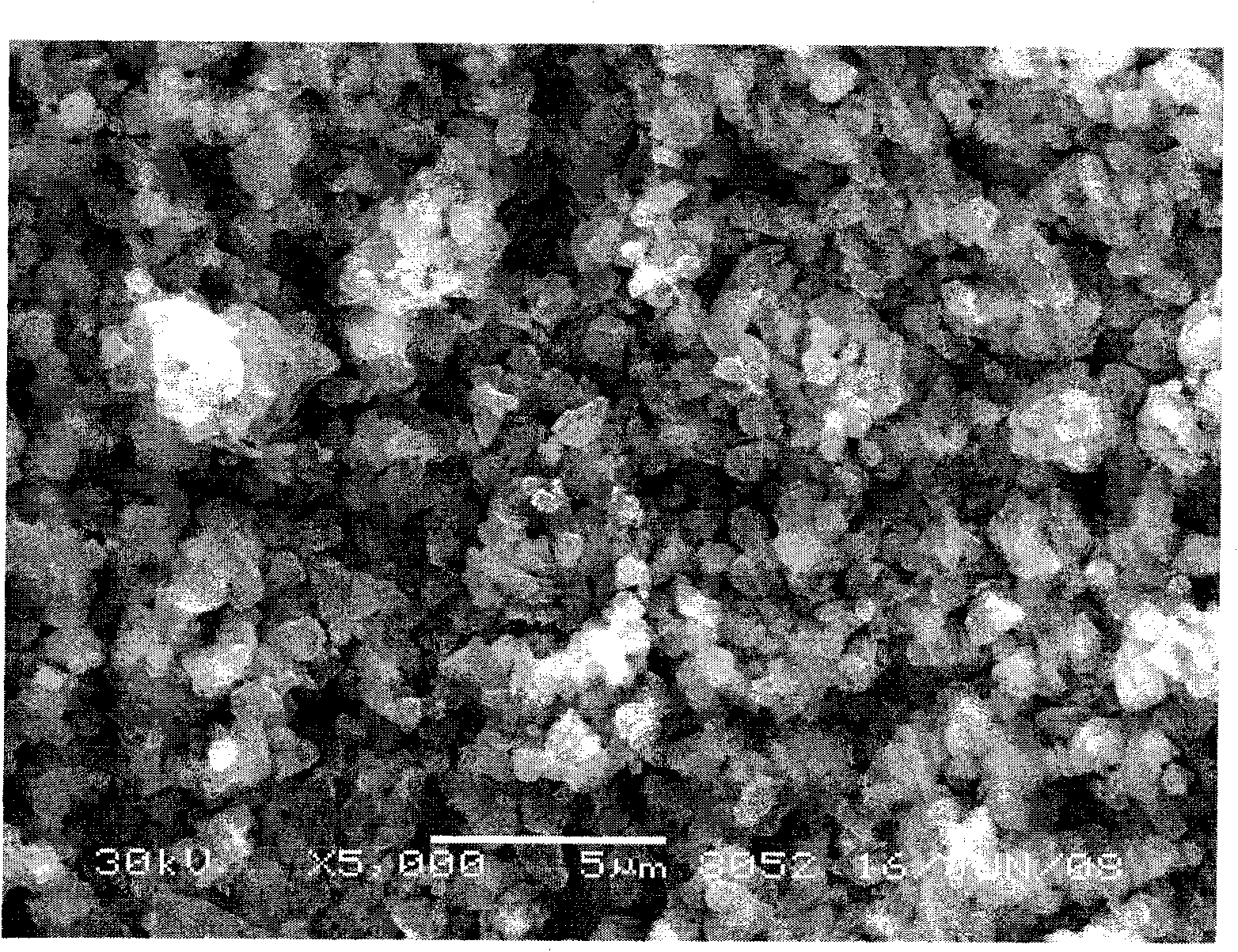

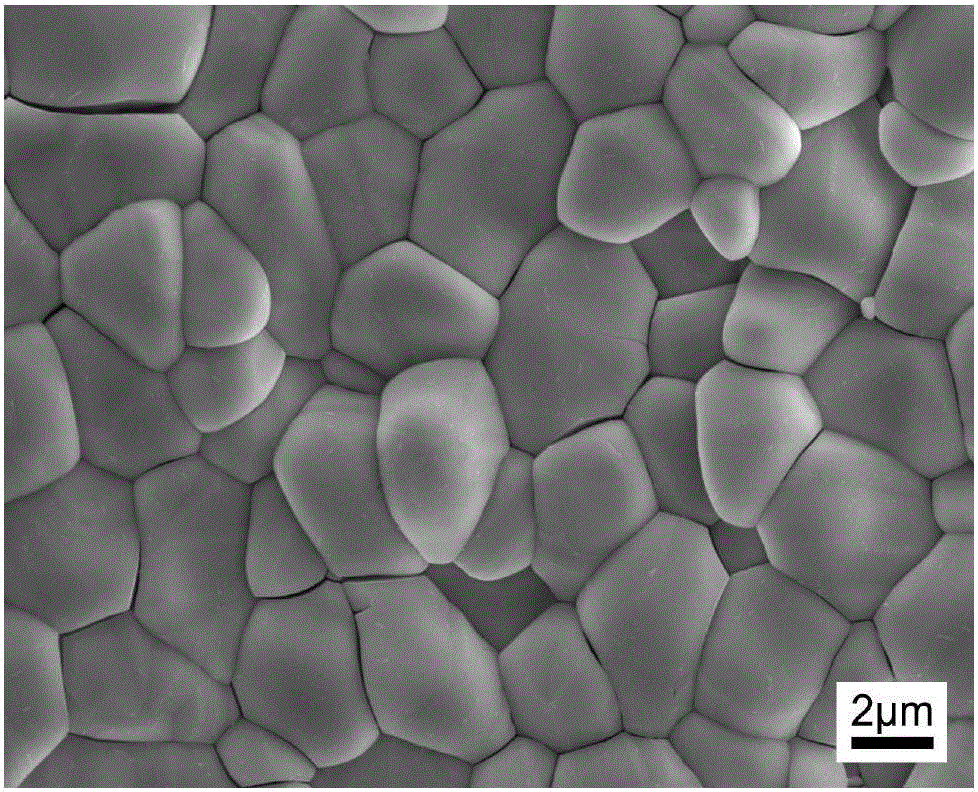

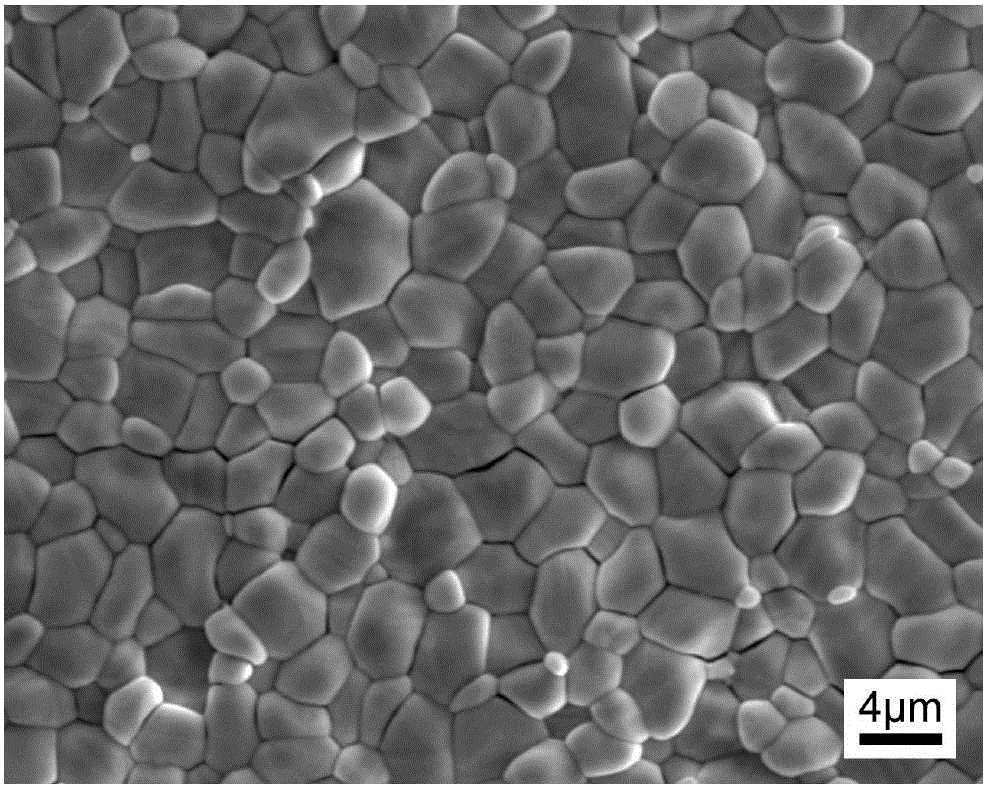

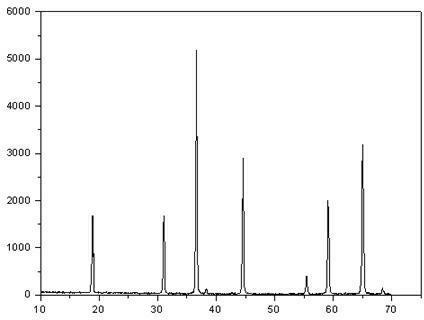

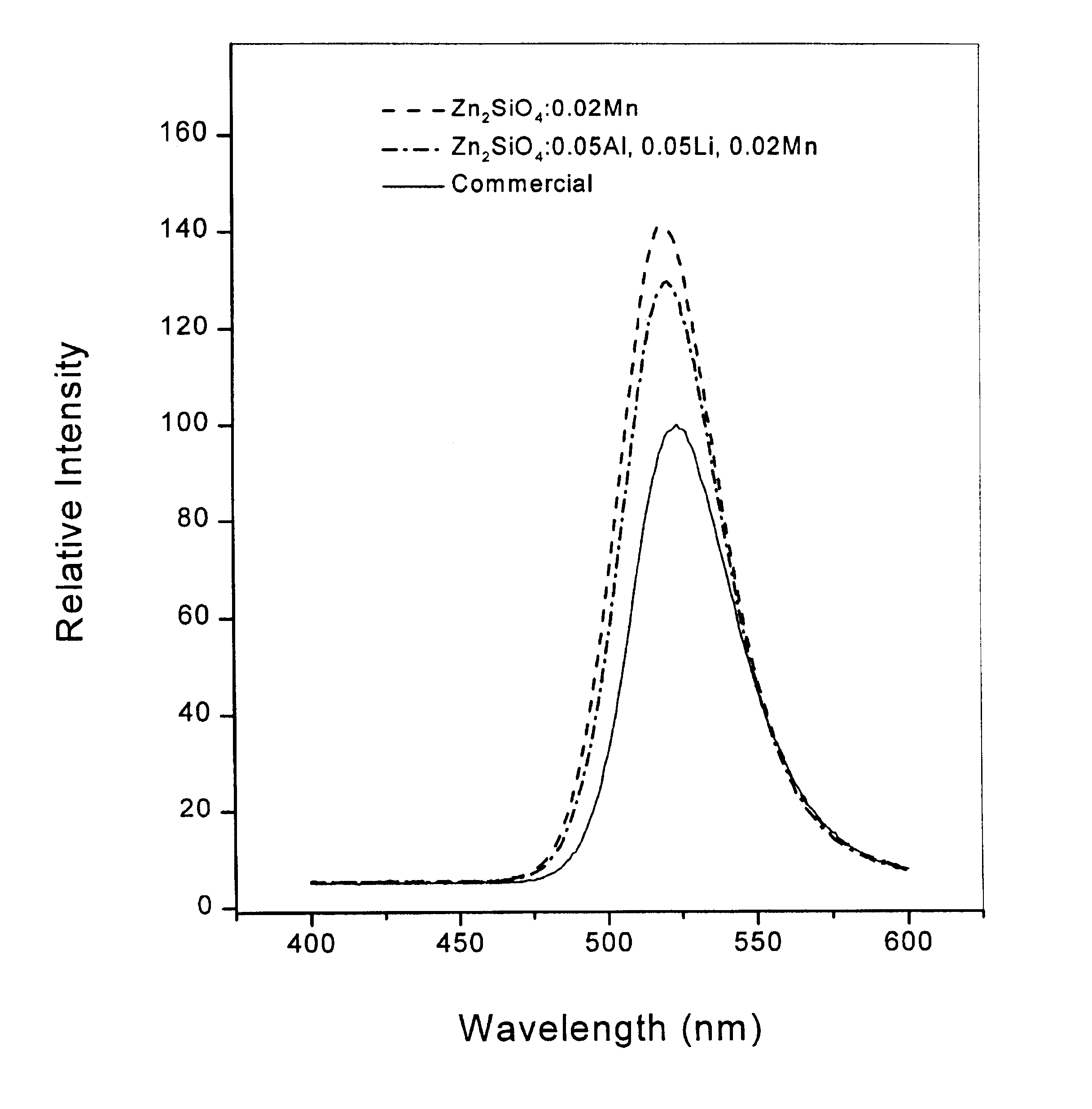

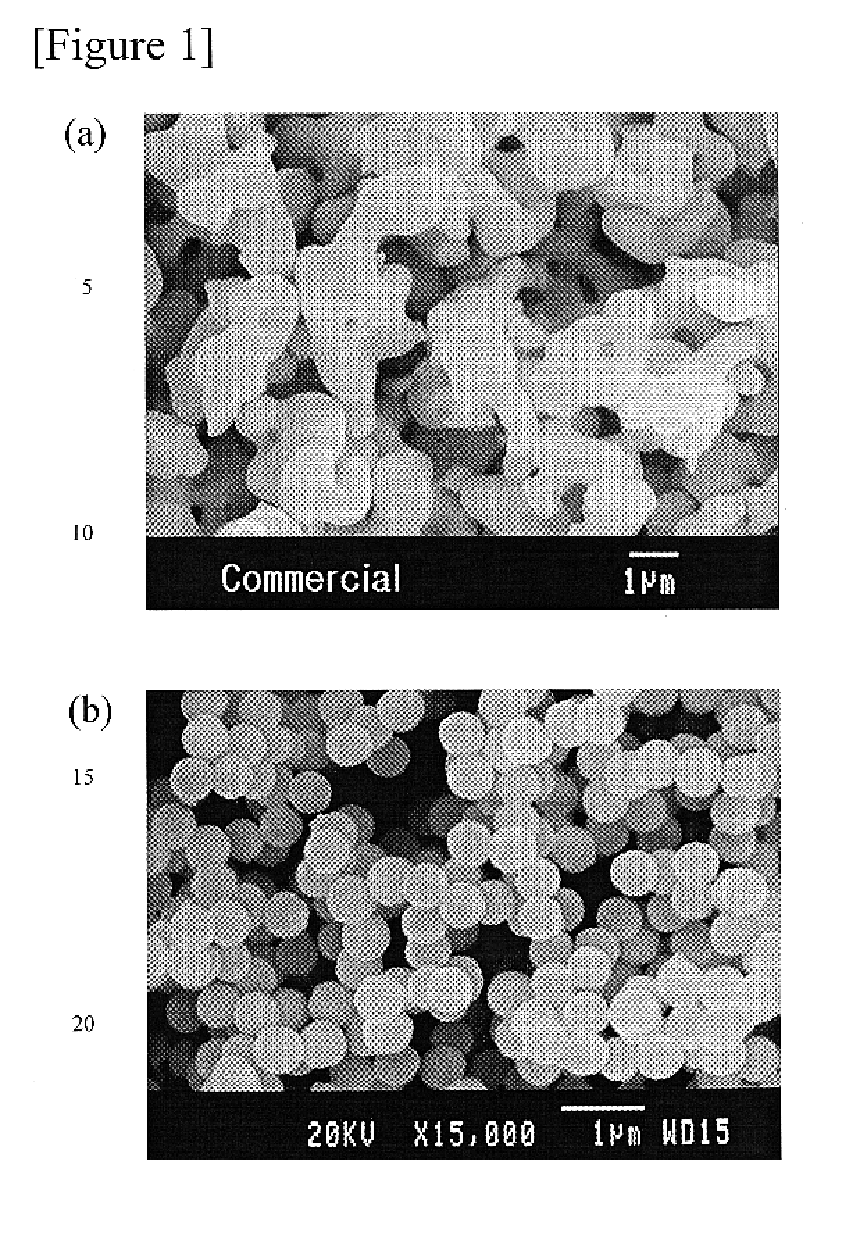

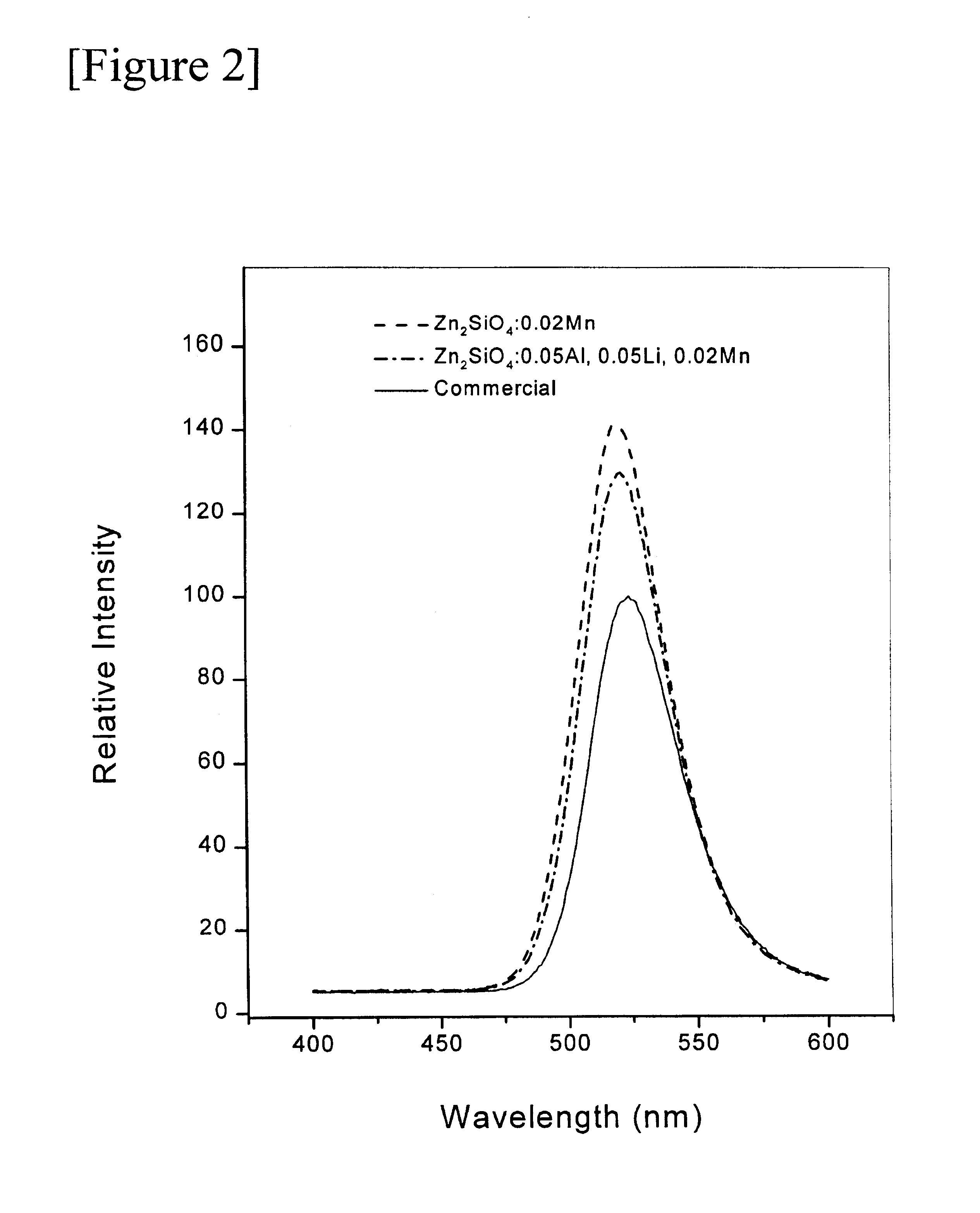

Preparing green phosphor based on zinc orthosilicate

This invention relates to a process for preparing a spherical green-emitting phosphor based on zinc orthosilicate and more particularly, to the process for a zinc orthosilicate-based green-emitting phosphor demonstrating an emission spectrum at visible regions, when excited by electron beam, via a new application of 'the homogeneous precipitation method' comprising the following steps such as i) a solution of tetraethylorthosilicate (TEOS) diluted in ethanol is hydrolyzed to obtain a hydrated silica, ii) said hydrated silica is dispersed together with the solution containing zinc and manganese components, iii) a precipitant selected from oxalic acid and oxalates is added to said dispersed solution together with a basic solution, while precipitating zinc and manganese components, iv) said admixture precipitate, so filtered off and dried, is calcined in the air and reheated under the reducing atmosphere to generate a phosphor powder; hence, the above-described phosphor particle is quite effective in a variety of display fields of industry including PDP, since it has a spherical shape with less agglomeration and homogeneous distribution of manganese, an activator, thus proving superior to the conventional phosphor prepared by the solid state reaction method in terms of brightness.

Owner:KOREA RES INST OF CHEM TECH

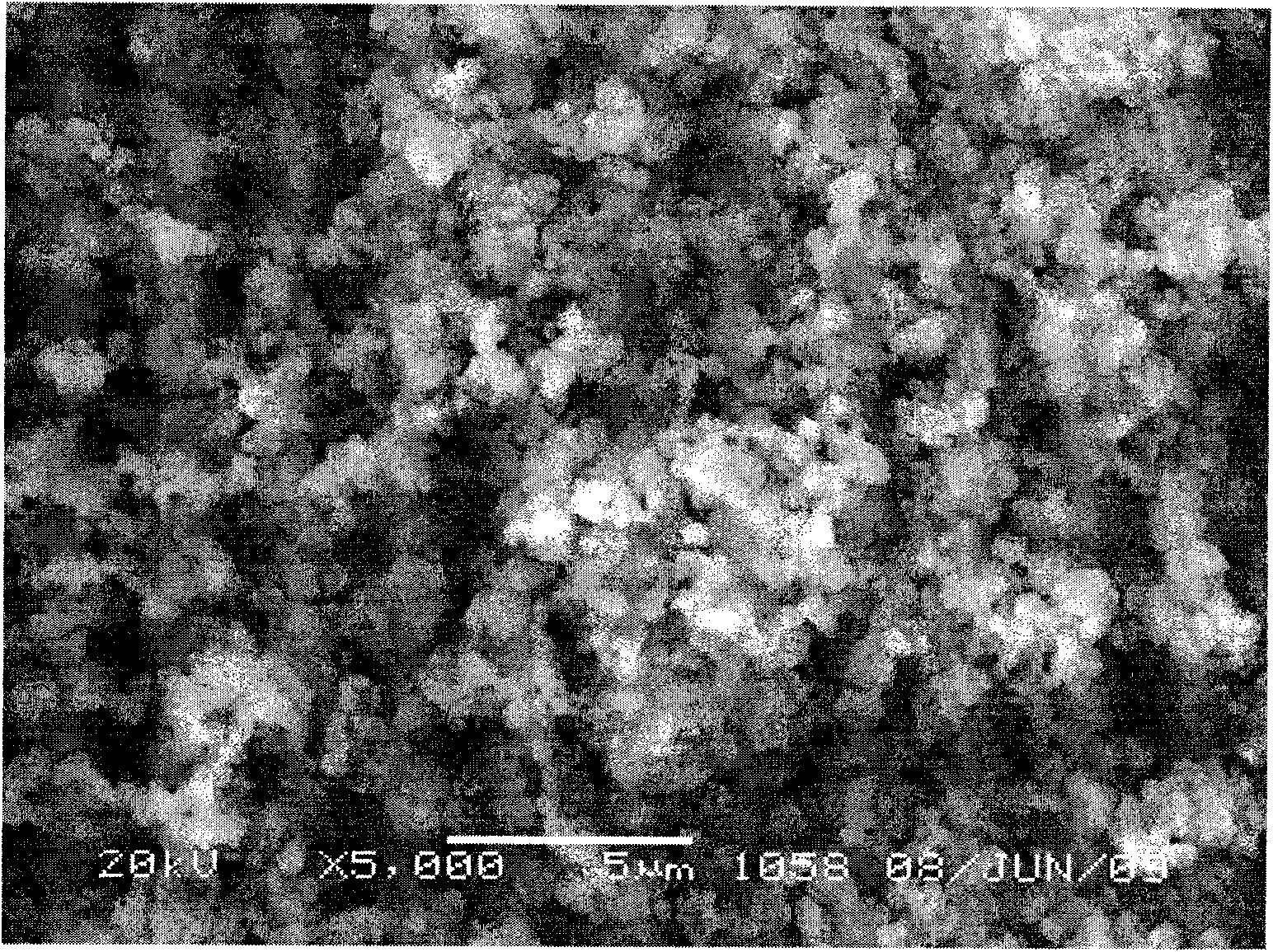

Process for preparing nano zinc oxide material

The present invention uses gas-solid phase reaction method as main preparation measure, uses Zn(NO3)2 and NaOH as main raw material and adopts the following stesp: grinding and mixing them at normal temp., making the undergo the process of thermal decomposition to obtain mixed solution, adding deionized water, washing with water, adding alcohol and washing with alcohol, filtering, drying filter cake, roasting so as to obtain the nano zinc oxide powder material. Said nano zinc oxide material can be used in the products of fibre, glass, ceramic and cosmetics, fields, and can greatly change the light, electric and magnetic properties of these original products.

Owner:大连创博科技发展有限公司

Single-phase rare earth vanadium phosphate white fluorescent powder for mercury lamp and preparation method thereof

InactiveCN101974334AGood chemical stabilityImprove thermal stabilityGas discharge lamp usageLuminescent compositionsAlkaline earth metalLuminous intensity

Owner:XIAN UNIV OF TECH

Leadless piezoelectric ceramics and method for preparing the same

InactiveCN101323522ARaise the depolarization temperatureLow costPiezoelectric/electrostrictive/magnetostrictive devicesPhase boundarySolid state reaction method

The invention discloses a leadless piezoelectric ceramics and a corresponding preparation method. The chemical formula of the leadless piezoelectric ceramics is as follows: 0.94Bi0.5Na0.5TiO3-(0.06-x)BaTiO3-xK0.5Na0.5NbO3, wherein, x is larger than 0 and less than 0.06. The leadless piezoelectric ceramics is manufactured through a solid state reaction method, and the structure of the ceramics is similar to a tripartite-orthogonal morphotropic phase boundary and has better ferroelectric and piezoelectric capability, and a residual polarization is about 30 Mu C / cm<2> and a saturation polarization is about 40 Mu C / cm<2> without depending on the contents, and the coercive field alters from 4.2 to 5.5kV / mm and increases as the increase of parameter x; and a piezoelectric coefficient d33 and an electro-mechanical coupling factor Kp decrease as the increase of parameter x, d33 alters from 86 to 118pC / N and kp alters from 0.26 to 0.29. A depolarization temperature (T<d>) increases from 108 to 146 DEG C as the increase of KNN.

Owner:NANJING UNIV

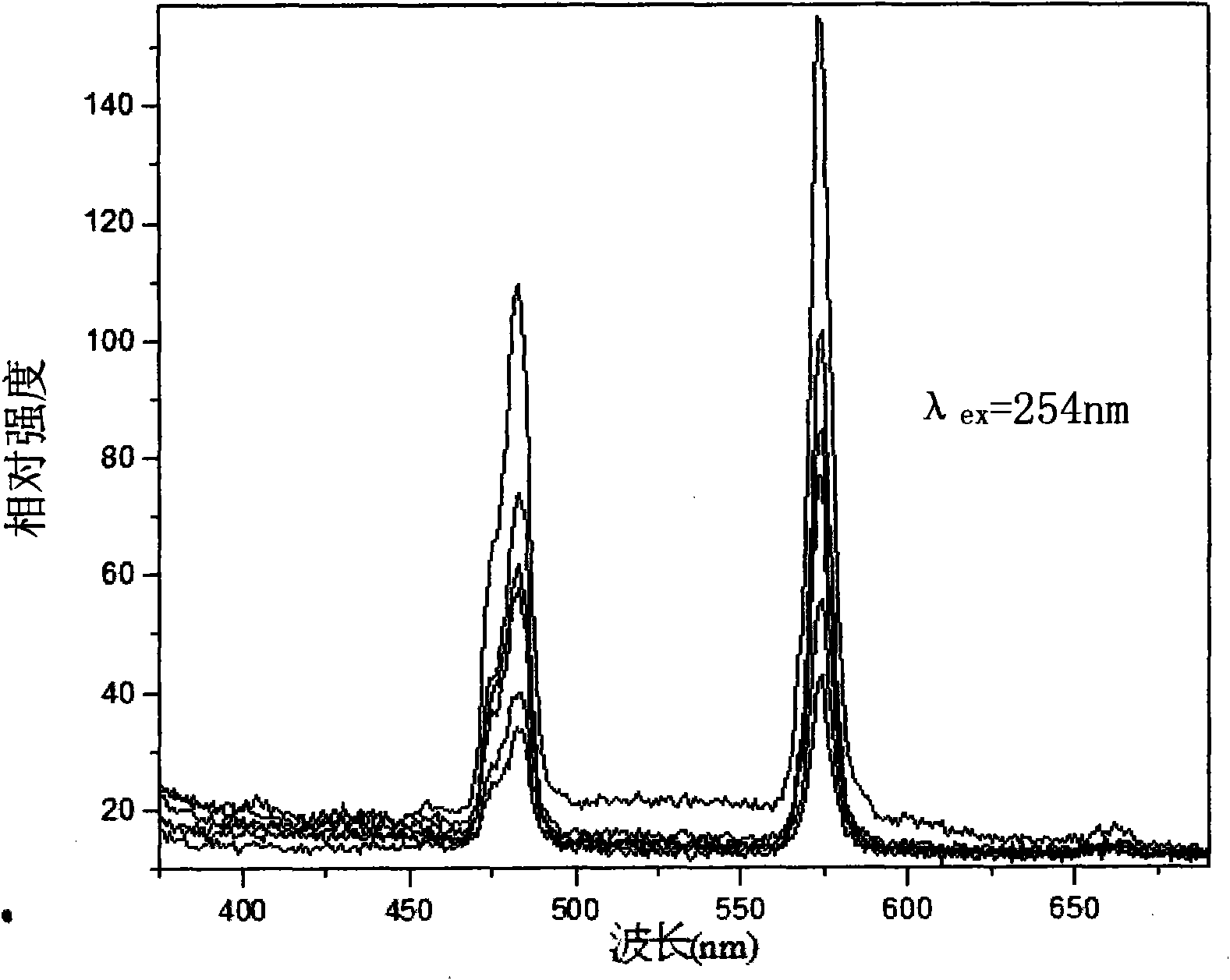

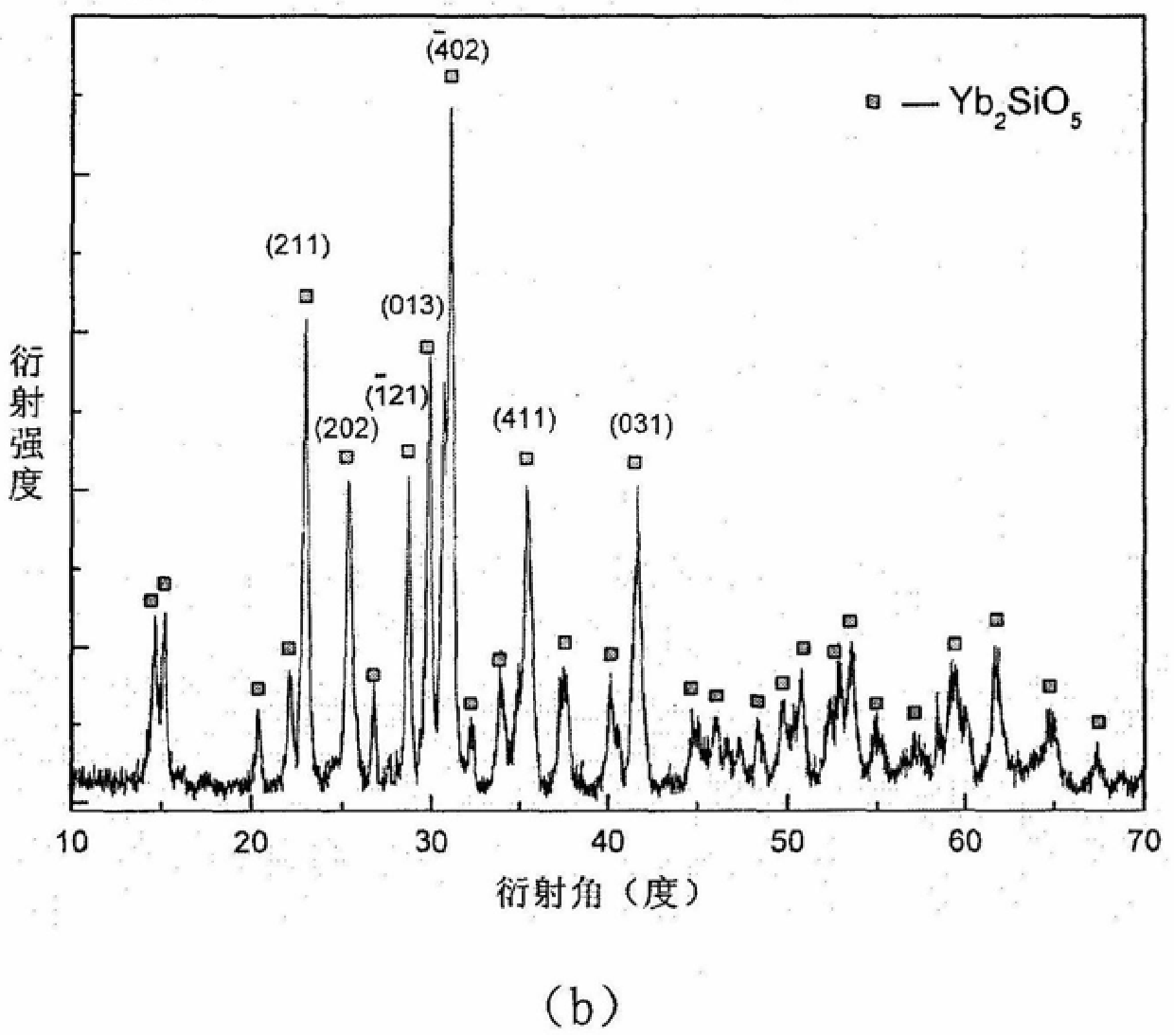

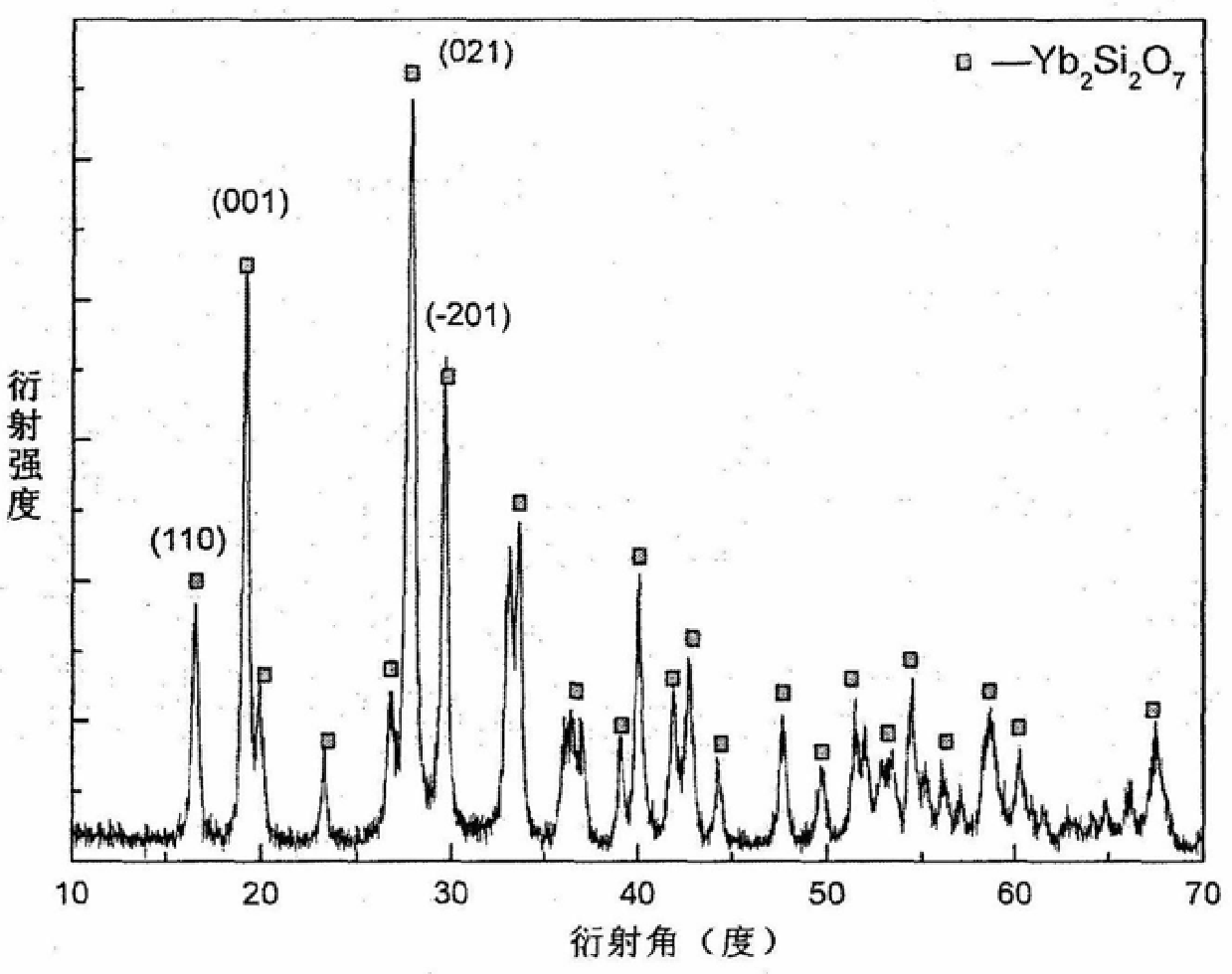

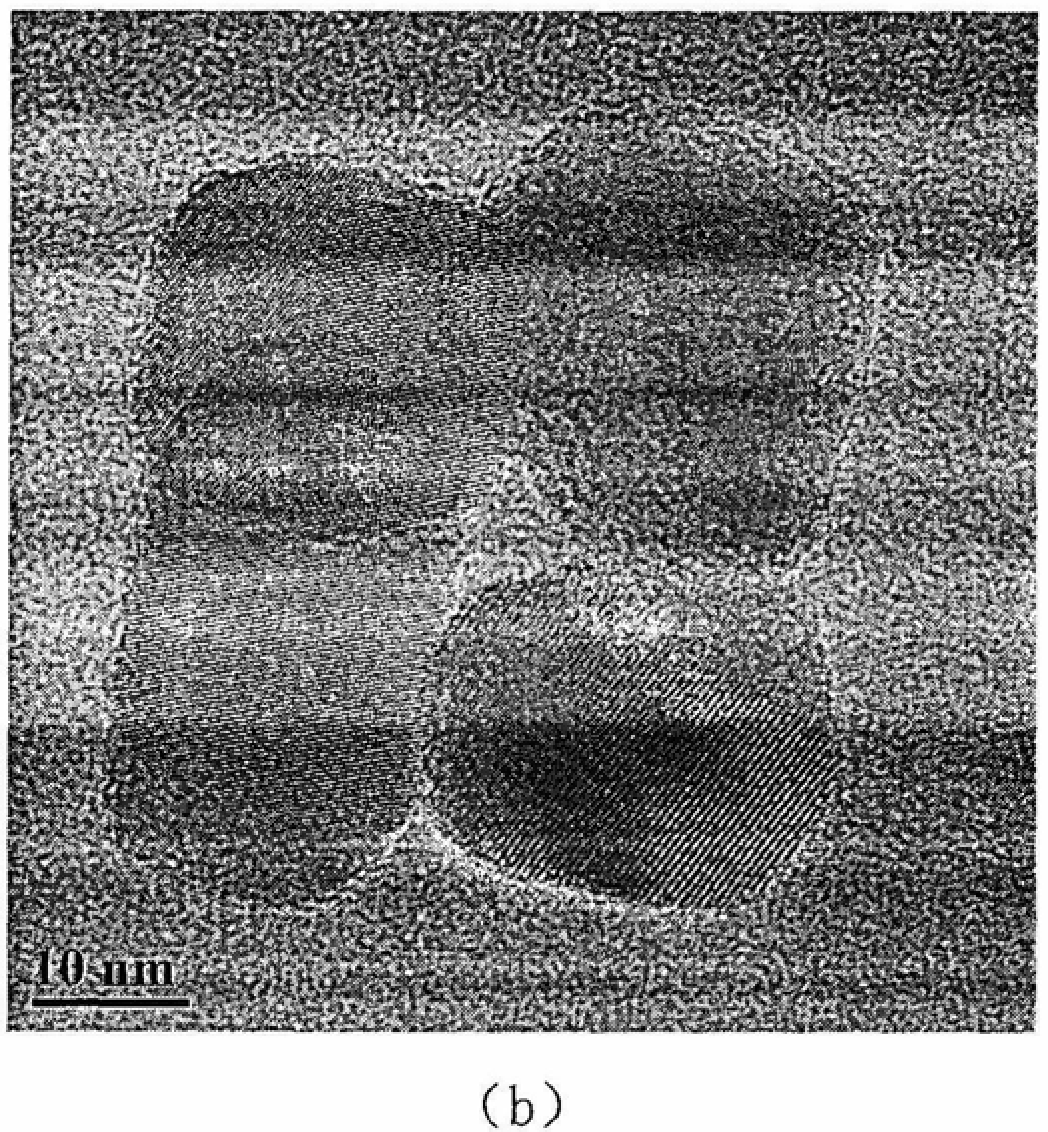

Preparation method of nanometer rare earth silicate powder

InactiveCN106342075BGood heat insulationNarrow particle size distributionRare earth metal compoundsSilicon compoundsFiltrationSynthesis methods

The invention relates to a preparation method of nano-rare earth silicate powder, which is characterized in that a certain stoichiometric ratio of rare earth oxides or rare earth soluble salts and silicon sources are formulated into solutions respectively, and the two solutions are mixed, and continuously After reacting for 6-24 hours, filtering and drying, monodisperse particles with a particle diameter of 20-30 nm can be obtained. Compared with the commonly used solid-phase reaction method and co-precipitation-calcination method, the synthesis method provided by the present invention has a synthesis temperature lowered by 1000-1300°C, which is more environmentally friendly and energy-saving; the obtained product has good oxidation resistance and compatibility with the substrate Physical and chemical compatibility of materials. The powder obtained by the method of the invention can be used to prepare the anti-oxidation coating on the surface of C / C composite materials and non-oxide silicon-based ceramic materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Compound lead borate and nonlinear optical crystal of lead borate, preparation method thereof and purpose thereof

ActiveCN103046113APolycrystalline material growthFrom frozen solutionsNonlinear optical crystalSpace group

The invention relates to a compound lead borate and a nonlinear optical crystal of the lead borate, a preparation method thereof and a purpose thereof. Chemical formulas of the compound lead borate and the nonlinear optical crystal of the lead borate are all Pb4O(BO3)2, wherein the crystal is an orthorhombic system, a space group is Aba2, the cell parameters comprise: a=15.4598(16) Angstrom, b=10.8050(11) Angstrom, c=9.9452(11) Angstrom, V=1661.3(3) Angstrom<3>, a molecular weight is 962.38, a powder frequency multiplication effect of the compound is 3 times that of KDP (KH2PO4), and a translucent band is 280 to 3300 nm. The compound lead borate is prepared by using a solid phase reaction method, and the nonlinear optical crystal of the lead borate is grown by using a melt method or a high-temperature melt method. The nonlinear optical crystal of the lead borate is moderate is mechanical hardness, easy to cut, polish and preserve, and can be widely applied for preparing nonlinear optical devices such as frequency multiplication generators, upper frequency converters, lower frequency converters, optical parametric oscillators, etc.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com