Low temperature co-fired microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and low-temperature co-firing technology, applied in ceramics, inorganic insulators, etc., can solve the problems of complex process, long manufacturing cost and long cycle, and achieve simple chemical composition and preparation process, low cost, and excellent microwave performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

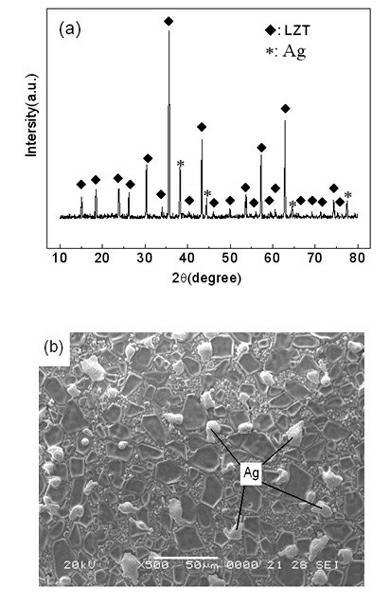

Embodiment 1

[0023] A preparation method of low-temperature co-fired microwave dielectric ceramic material, adding TiO in its composition 2 and LZB glass powder.

[0024] 1) Synthesis of Li 2 ZnTi 3 o 8 : Li 2 CO 3 (purity>97.5%), ZnO and TiO 2 (purity ≥ 99%) as raw material, according to the molar ratio Li 2 CO 3 :ZnO:TiO 2 = 1:1:3 Weigh the material, mix the prepared material with absolute alcohol as the medium, ball mill and mix for 12 h, dry and sieve, and then synthesize Li at 900°C for 4 h 2 ZnTi 3 o 8 main powder.

[0025] 2) Preparation of LZB glass powder: with Li 2 CO 3(purity>97.5%), ZnO and H 3 BO 3 (purity ≥ 99%) as raw material, according to aLi 2 O+ bZnO +cB 2 o 3 Carry out batching, wherein a=10%, b=37%, c=53% by weight percentage. Melt the batch material at 900°C for 1 hour, then pour it into cold water to form glass slag, and obtain D through ball milling 50 =10 μm LZB glass powder, the glass softening point is 490 ℃.

[0026] 3) Take a certain amount...

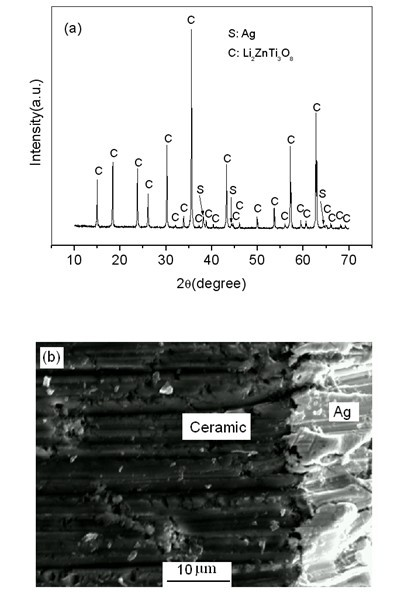

Embodiment 2

[0028] A preparation method of a low-temperature co-fired microwave dielectric ceramic material, in which LZB glass powder is added into the composition.

[0029] 1) Synthesis of Li 2 ZnTi 3 o 8 : Li 2 CO 3 (purity>97.5%), ZnO and TiO 2 (purity ≥ 99%) as raw material, according to the molar ratio Li 2 CO 3 :ZnO:TiO 2 = 1:1:3 Weigh the material, mix the prepared material with absolute alcohol as the medium, ball mill and mix for 12 h, dry and sieve, and then synthesize Li at 900°C for 4 h 2 ZnTi 3 o 8 .

[0030] 2) Preparation of LZB glass powder: with Li 2 CO 3 (purity>97.5%), ZnO and H 3 BO 3 (purity ≥ 99%) as raw material, according to aLi 2 O+ bZnO +cB 2 o 3 Carry out batching, wherein a=15%, b=40%, c=50% by weight percentage. Melt the batch material at 900°C for 1 hour, then pour it into cold water to form glass slag, and obtain D through ball milling 50 =8 μm LZB glass powder, the glass softening point is 480 ℃.

[0031] 3) Take a certain amount of syn...

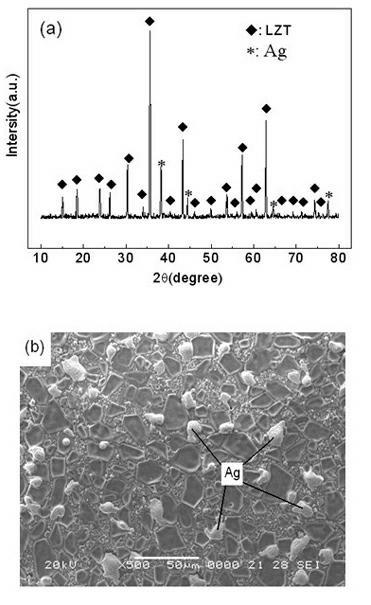

Embodiment 3

[0033] A preparation method of a low-temperature co-fired microwave dielectric ceramic material, in which LZB glass powder is added into the composition.

[0034] 1) Synthesis of Li 2 ZnTi 3 o 8 : Li 2 CO 3 (purity>97.5%), ZnO and TiO 2 (purity ≥ 99%) as raw material, according to the molar ratio Li 2 CO 3 :ZnO:TiO 2 =1:1:3 Weigh the material, mix the prepared material with anhydrous alcohol as the medium, ball mill and mix for 24 hours, dry and sieve, and then synthesize Li at 900°C for 4 hours 2 ZnTi 3 o 8 .

[0035] 2) Preparation of LZB glass powder: with Li 2 CO 3 (purity>97.5%), ZnO and H 3 BO 3 (purity ≥ 99%) as raw material, according to aLi 2 O+ bZnO +cB 2 o 3 Carry out batching, wherein a=10%, b=35%, c=55% by weight percentage. Melt the batch material at 900°C for 1 hour, then pour it into cold water to form glass slag, and obtain D through ball milling 50 =9 μm LZB glass powder, the glass softening point is 485 ℃.

[0036] 3) Take a certain amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com