Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

326 results about "Microwave dielectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave dielectric ceramic and preparation method thereof

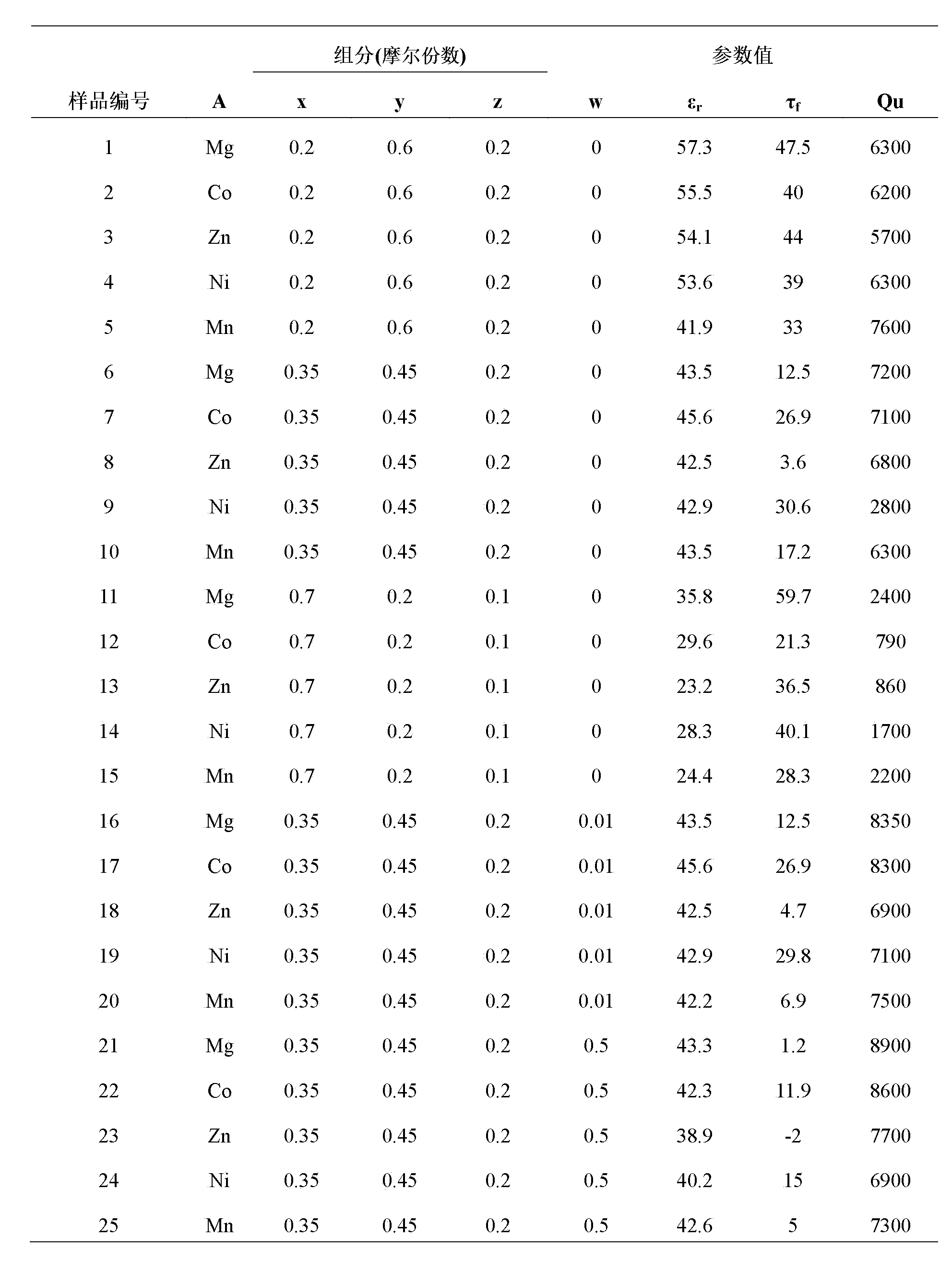

The invention discloses a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic is mainly composed of ZrO2, TiO2 and Nb2O5; the microwave dielectric property of the microwave dielectric ceramic can be improved by selectively adding MgO, CoO, ZnO, NiO and MnO2; the chemical constitution formula of the ceramic is xZrO3-YTiO2-zA(1+W) / 3Nb(2-w) / 2O3; in formula (I), A is one or more elements of Mg, Co, Zn, Ni and Mn; x, y and z are molar ratios, wherein x is between 0.2 and 0.7, y is between 0.2 and 0.6,, z is between 0.1 and 0.2, and, x plus y plus z is equal to 1; numerical range of w is l between 0 and 0.5. According to the microwave dielectric ceramic and the preparation method thereof, the ceramic has the characteristics that the dielectric constant is high, the loss is low, and the temperature coefficient is close to zero, and is liable to sinter; the preparation method has the characteristics that the price of raw materials is low, and a technology during production is simple.

Owner:HEFEI NORMAL UNIV

Molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and preparation method thereof

The invention discloses molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and a preparation method thereof. Based on a general structural formula of A4B3O12, a series of ceramic materials, which can be sintered at a temperature lower than 7,000 DEG C and have excellent microwave dielectrical properties ( a dielectric constant of 8.5 to 11.1 and a quality factor Qfof between 36,000 and 108,000GHz), can be obtained by using low-valence cation (such as Li<+>, Zn<2+>, Ca<2+>, Cu<2+>, Mg<2+>, Al<3+>, In<3+>, Cr<3+> and Ga<3+>) composite at a position A and a high-valence cation Mo<6+> at a position B and by using the conventional solid-phase reaction sintering method. The concrete structural expression of the ceramic material comprises Li2M<2+>2(MoO4)3(M<2+> may be Zn<2+>, Ca<2+>, Cu<2+> and Mg<2+>) and Li3M<3+>(MoO4)3(M<3+> may be Al<3+>, In<3+>, Cr<3+> and Ga<3+>).

Owner:XI AN JIAOTONG UNIV

Low temperature sintered microwave dielectric ceramic with medium dielectric constant and its prepn process

InactiveCN1609050AExcellent microwave dielectric propertiesFrequency temperature coefficient adjustableCeramicsSol-gelMicrowave dielectric properties

The present invention relates to low temperature sintered microwave dielectric ceramic with medium dielectric constant and its preparation process. The microwave dielectric ceramic has Ca(Li1 / 3Nb2 / 3)O3 and CaTiO3 as main crystal phase, B2O3, ZnO and ZnO-B2O3-SiO2 glass powder prepared through sol-gel process as sintering assistant. The present invention features the sintering temperature lowered through the synergistic effect of B2O3, ZnO and ZnO-B2O3-SiO2 glass powder, and regulated microwave dielectric performances; the technological process including twice calcining and twice ball milling for full synthesis of the main phase and improvement of powder characteristic; good microwave dielectric performance obtained through sintering at about 900 deg.c and stable technological process. The low temperature sintered microwave dielectric ceramic material may be used in various kinds of microwave devices.

Owner:ZHEJIANG UNIV +1

Mesomeric electric constant laminated microwave dielectric ceramic and producing method thereof

InactiveCN1848304AMiniaturizationEasy to serializeCeramicsResonatorsMiniaturizationDielectric permittivity

The present invention discloses an intermediate dielectric constant laminated microwave medium ceramic. It is a double-layer composite microwave medium ceramic formed from microwave medium ceramic A whose dielectric constant is 30-45 and microwave medium ceramic B whose dielectric constant is 75-90. Its general formula is (1-x) A / xB, in which x is volume percentage, x is greater than or equal to 0.2 and is less than or equal to 0.75. Besides, said invention also provides it preparation method and concrete steps.

Owner:ZHEJIANG UNIV

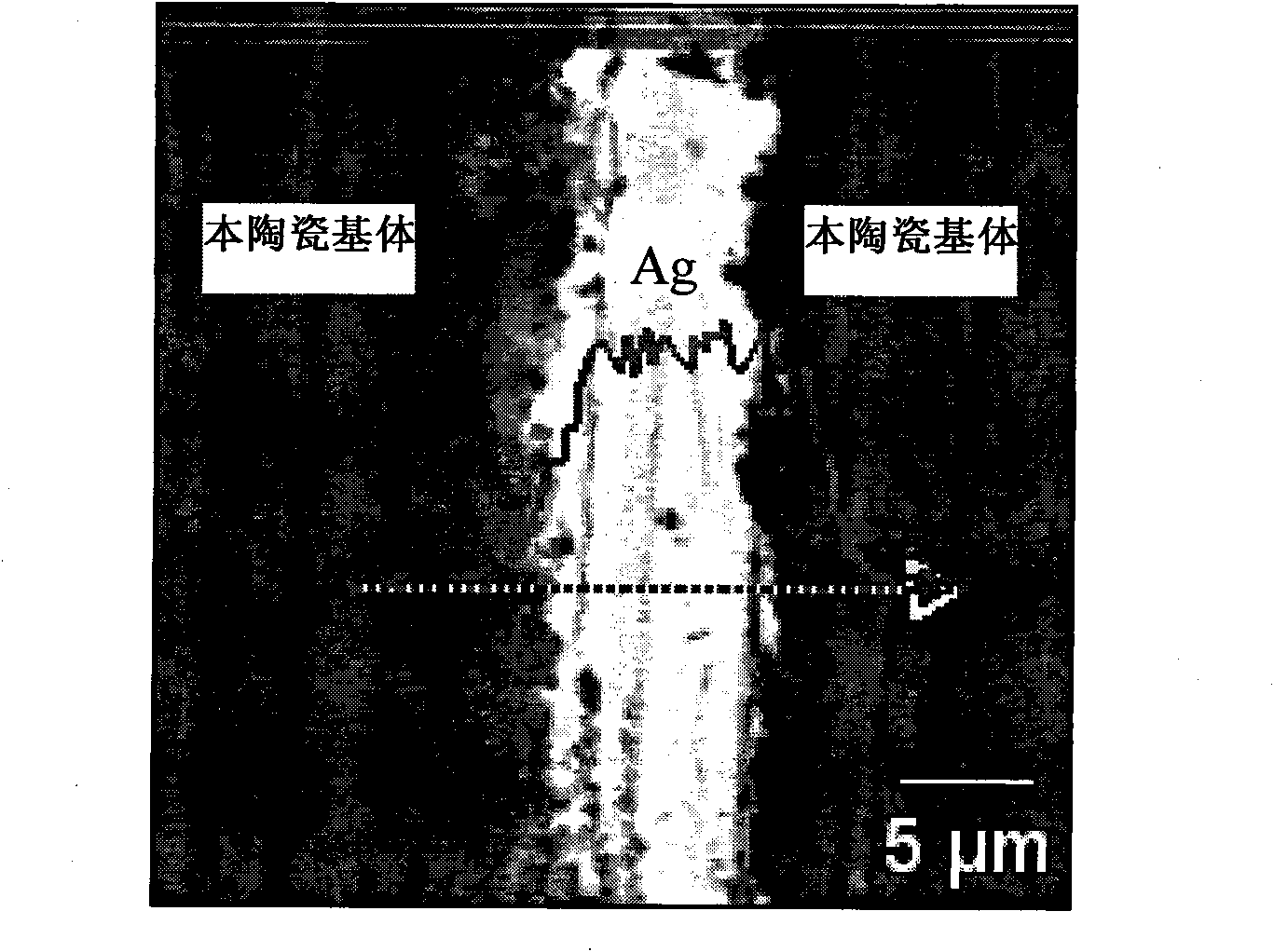

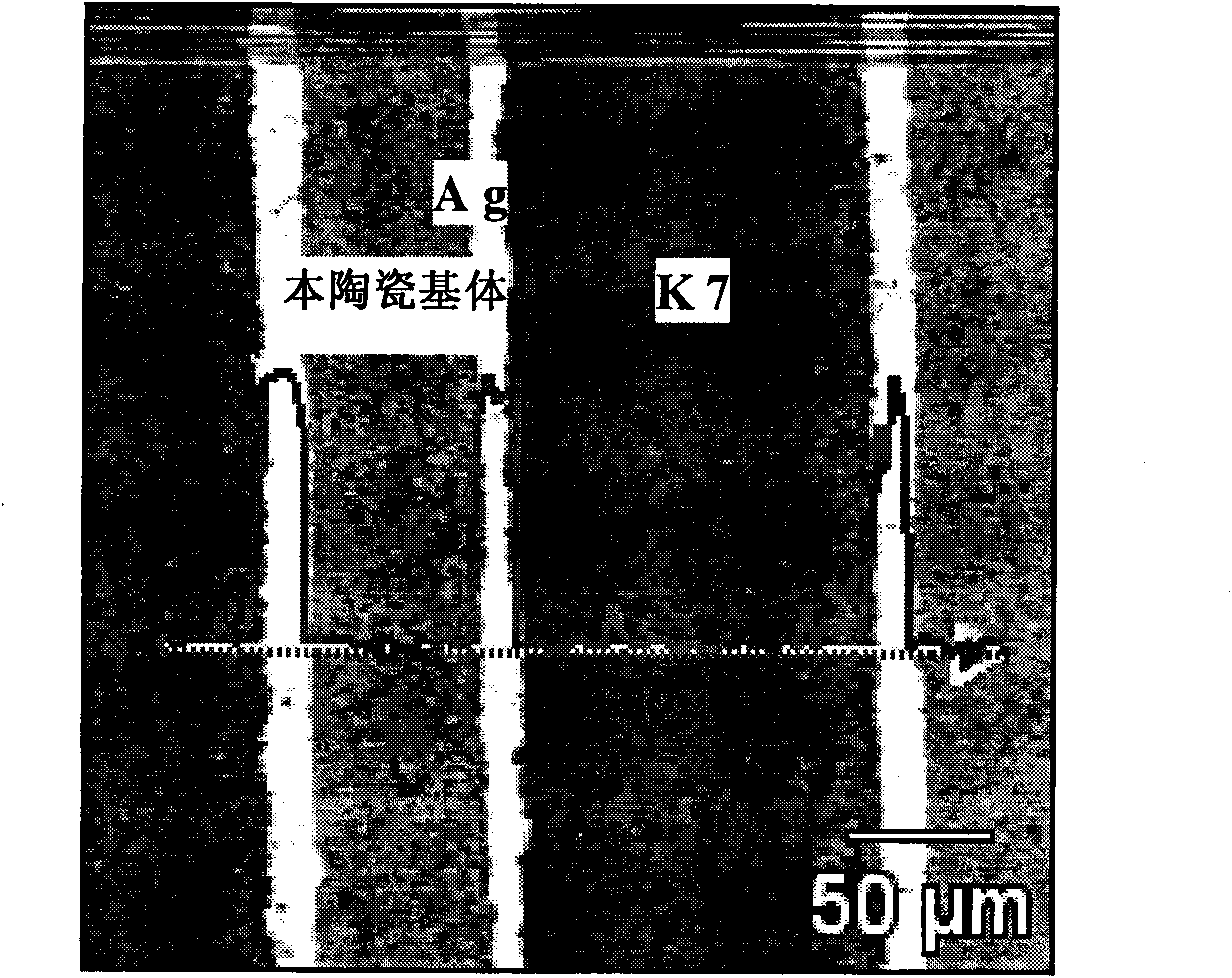

Low-temperature sintered LTCC microwave dielectric ceramics material and preparation method thereof

InactiveCN101224977AImprove performanceInherently low sintering temperatureDielectric ceramicsCo-fired ceramic

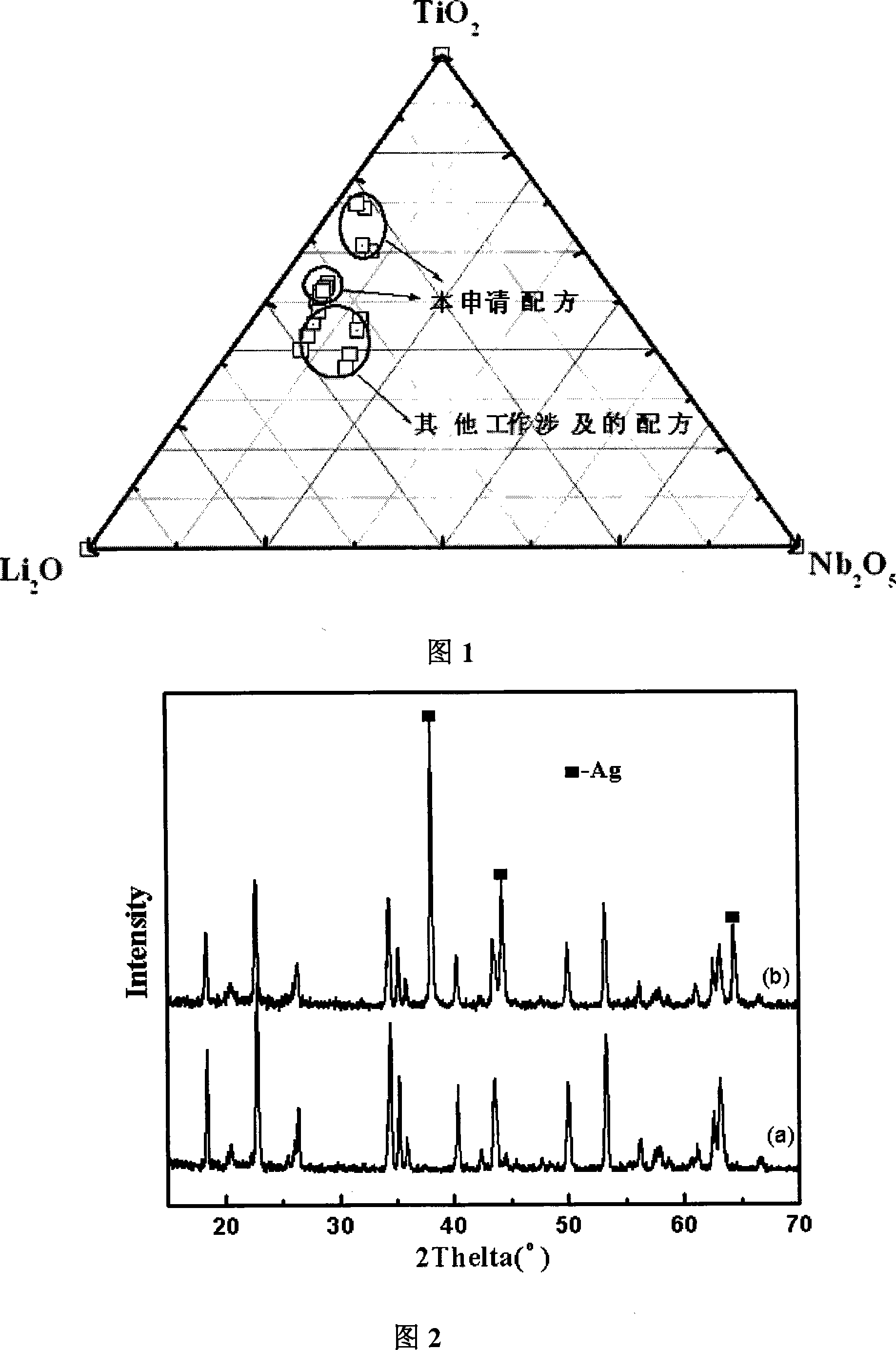

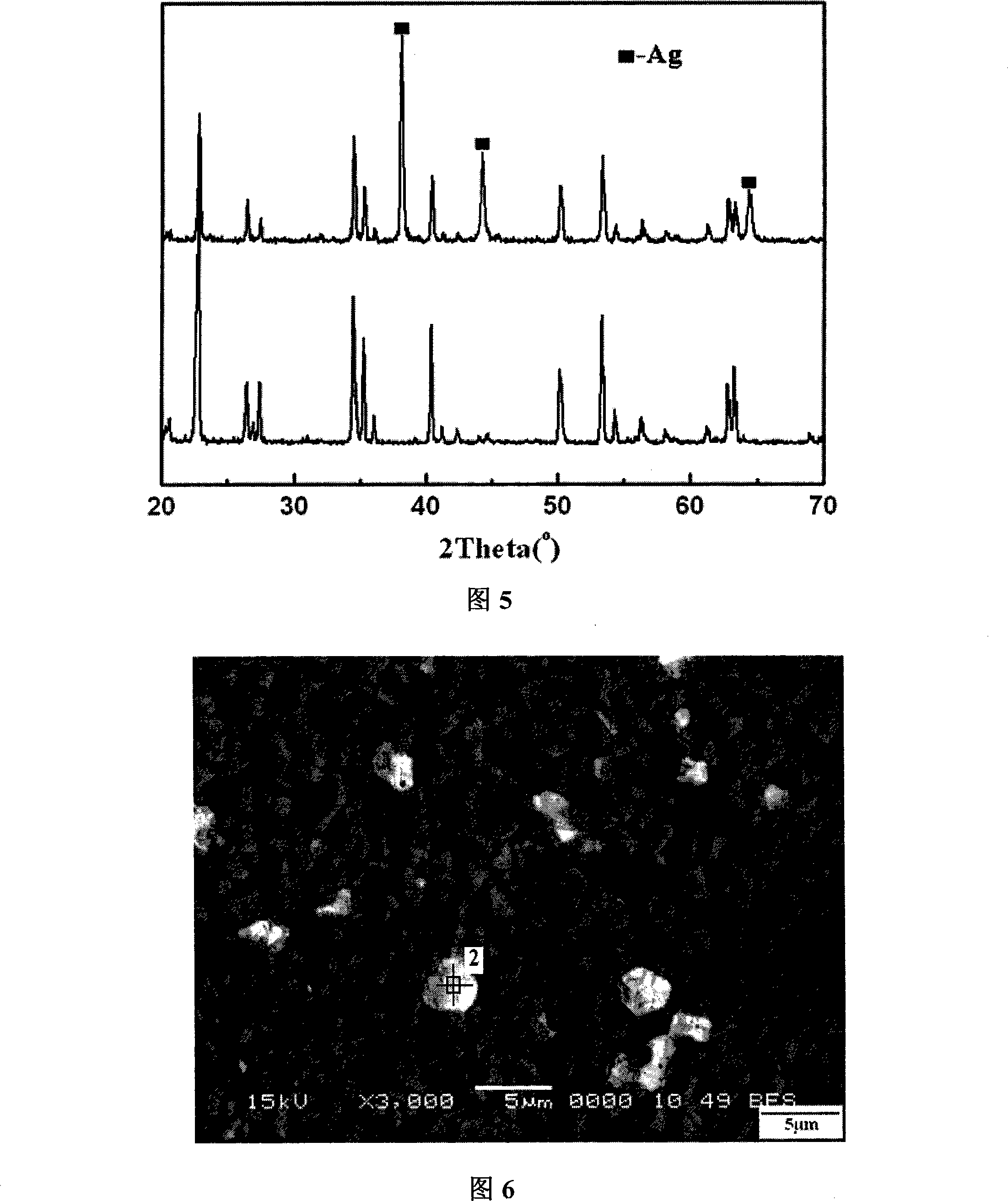

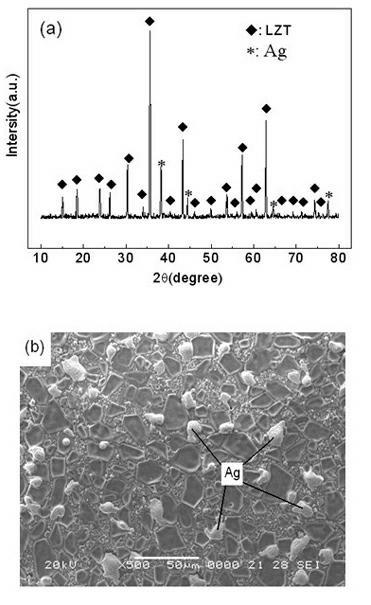

The invention discloses a low temperature co-fired ceramic LTCC microwave dielectric ceramic MWCD material, which is prepared by Li2CO3, Nb2O5 and TiO2 by the moral ratio that Li2CO5:Nb2O5:TiO2 = x:1:y, wherein, x is more than 5.5 and less than or equal to 6, y is more than 7 and is less than or equal to 7.5; the expression of structure for the made up modular is Li1+m-nNb1-m-3nTim+4nO3, wherein m is more than or equal to 0.1 and is less than or equal to 0.15, n is more than or equal to 0.2 and less than or equal to 0.25. The LTCC MWCD prepared by the invention has low sintering temperature (approx. 1,100 DEG C) and excellent microwave performance: the dielectric constant (Epsilon r) is that x is more than 32 and less than or equal to 52, Q multiplied by f value is high and Tf is small; the sintering temperature can be decreased to 900 DEG C and the microwave dielectric property can be maintained for excellence without any reaction to a Ag by adding a plurality of low melting point oxides. The pure silver can be taken as a electrode for sintering which can greatly reduce manufacturing cost for the components and applied in manufacturing of the microwave components such as a low temperature co-fired ceramic LTCC system, a multi-layer media resonator, a microwave antenna and a wave filter etc.

Owner:XI AN JIAOTONG UNIV

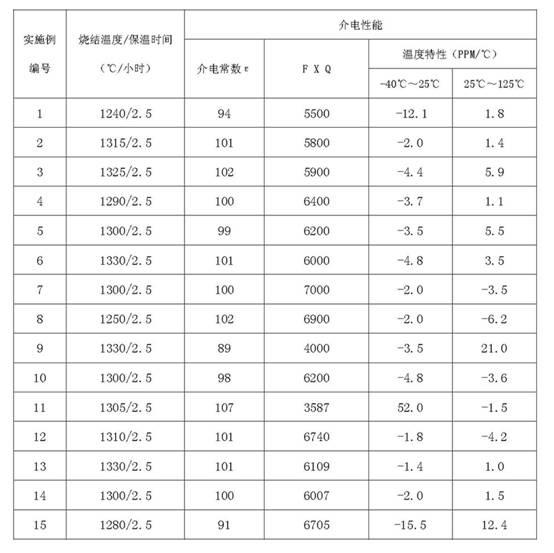

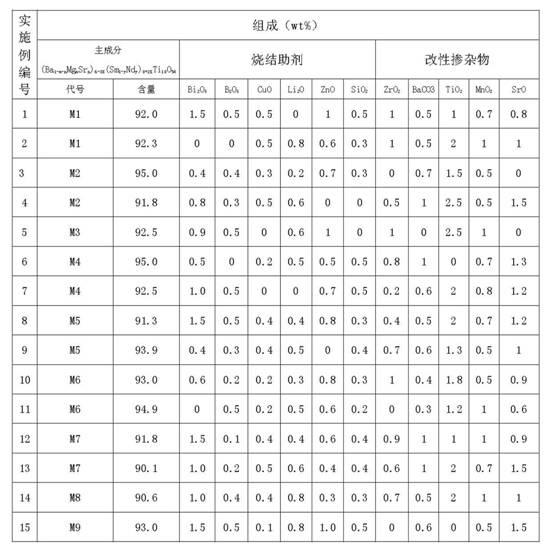

BaO-Ln2O3-TiO2-series microwave capacitor medium material and preparation method thereof

InactiveCN102093046AExcellent microwave dielectric propertiesMeet mobilityFixed capacitor dielectricCeramicsDopantCapacitor

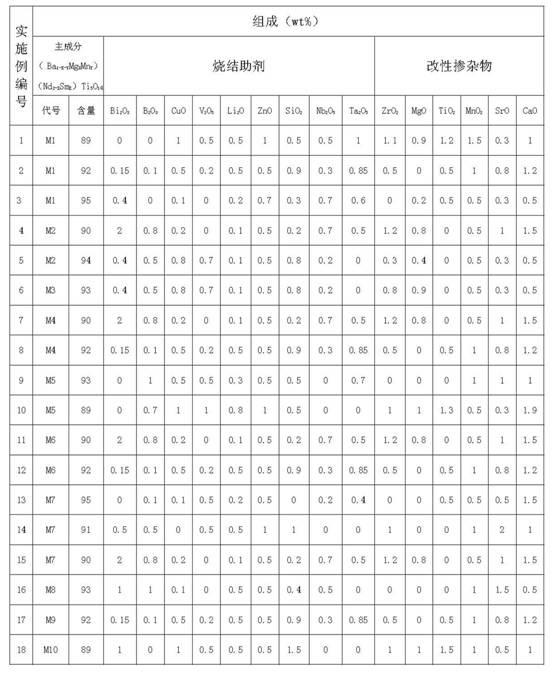

The invention discloses a BaO-Ln2O3-TiO2-series microwave capacitor medium material and a preparation method thereof. The microwave capacitor medium material is characterized by consisting of (Ba1-X-YMgXMnY) (Nd2-ZSmZ) Ti5O14 serving as a main component, a sintering additive and a modification dopant, wherein X is equal to 0 to 0.02, Y is equal to 0 to 0.05 and Z is equal to 0.002 to 0.025; the sintering additive comprises one or the mixture of low-melting-point oxides such as Bi2O3, B2O3, CuO, V2O5, Li2O, ZnO, SiO2, Nb2O5, Ta2O5 and the like and low-melting-point glass powder; and the modification dopant comprises one or the mixture of different metal oxides such as ZrO2, MgO, TiO2, MnO2, SrO, CaO and the like. By adopting the method, the uniform microwave capacitor medium material which can be sintered at the temperature of between 1,250 DEG C and 1,330 DEG C and has high microwave dielectric property is prepared, wherein epsilon r is equal to 90 to 100, Q.f is more than or equal to 5,500 GHZ (3.5 to 4.5 GHZ), and tau f (at the temperature of between 40 DEG C below zero and 25 DEG C or between 25 DEG C and 125 DEG C) is less than or equal to 10 PPM / DEG C.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

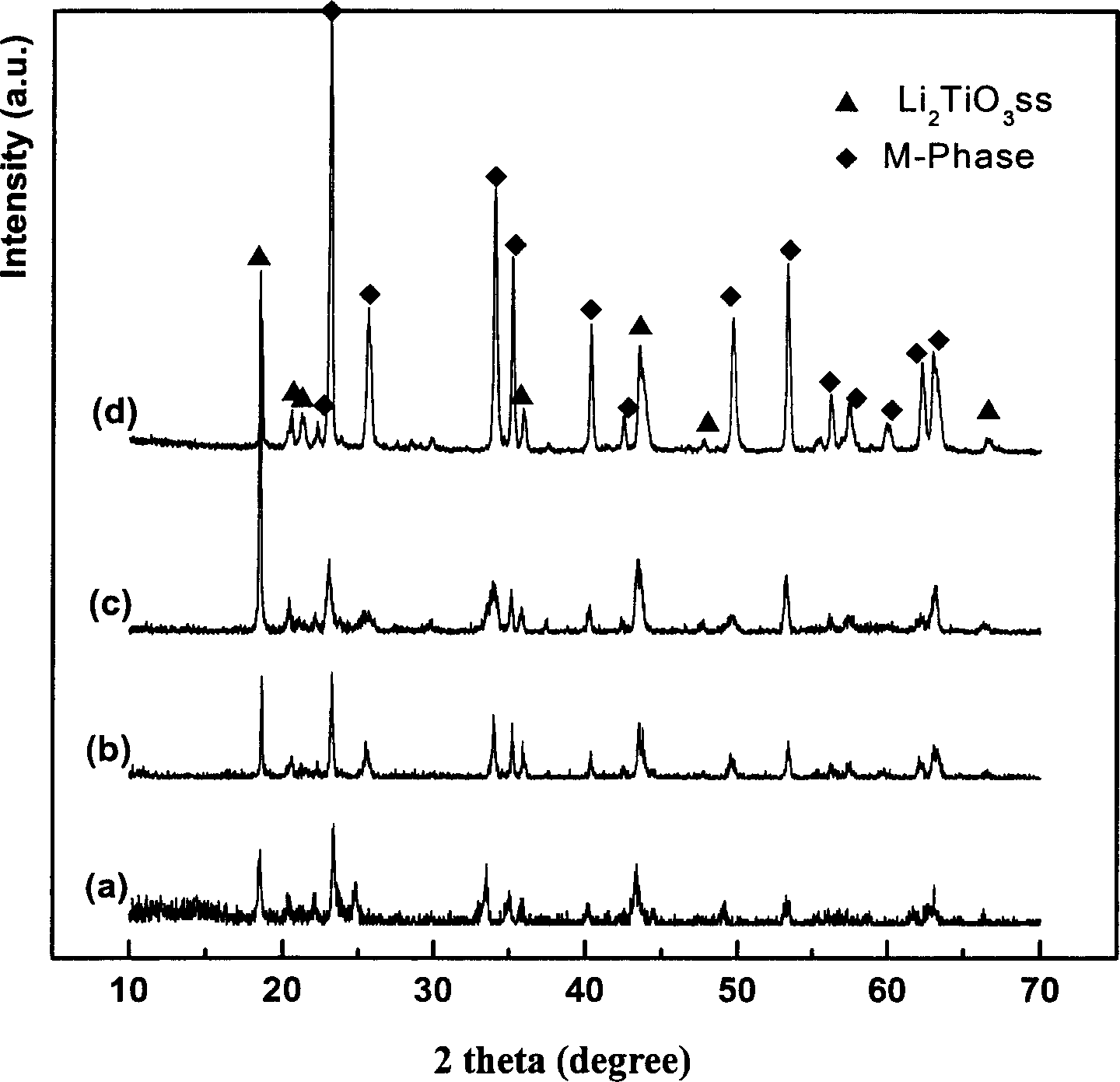

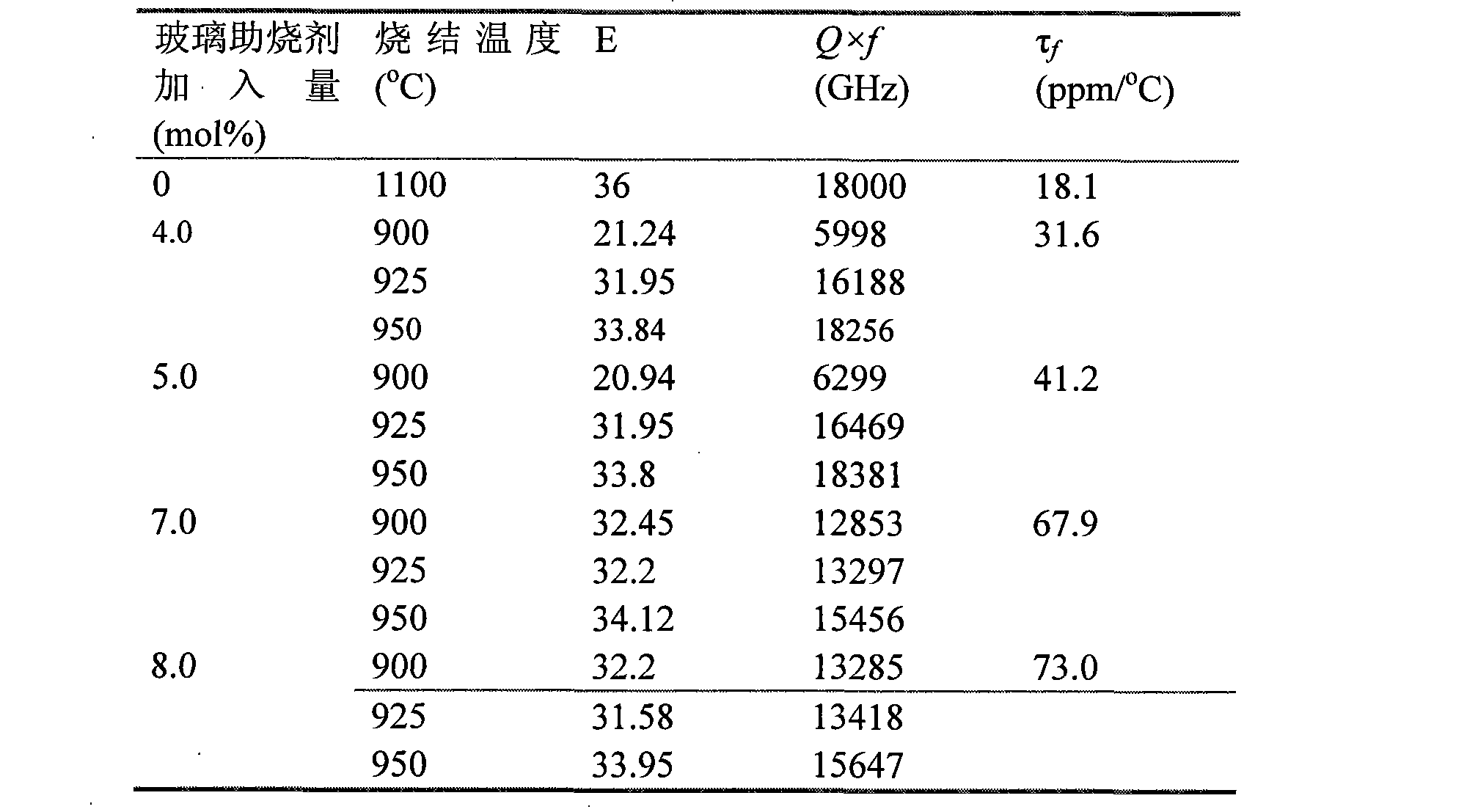

Low temperature sintered composite microwave medium ceramic in series of lithium, niobium and titanium, and prepartion method

This invention relates to a method for preparing low-temperature-sintered lithium-niobium-titanate composite microwave dielectric ceramic, which is composed of Li2TiO3 solid solution and M-phase solid solution. The composite microwave dielectric ceramic is prepared from Li2CO3, Nb2O5 and TiO2 at a mol ratio of 5: x: y (x is in 1-2 and y in 4-6), and B2O3 or V2O5 0-5 wt. % by conventional solid-phase reaction. The composite microwave dielectric ceramic has a low sintering temperature (about 1100 deg.C), good dielectric property with a dielectric constant of 34-50, a high Q*f value (Q is quality factor), and a low resonance frequency temperature coefficient, and can be used in sheet dielectric resonator, filter, antenna, balun, etc. when added with a small quantity of low-melting-point oxide, the composite microwave dielectric ceramic has a lower sintering temperature of about 900 deg.C, while its good microwave dielectric property can be maintained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Low-temperature sintered microwave medium ceramic material and preparation method thereof

ActiveCN101613200AImprove performanceExcellent microwave dielectric propertiesCeramicsCombustionSilver electrode

The invention discloses a low-temperature sintered microwave medium ceramic material and a preparation method thereof. The material comprises the raw materials with the mol ratio: BaCO3:ZnO:TiO2:Q=1:x:(4+y):z, wherein x=0.01-0.5, y=0.01-0.5, z=0.01-0.1, and Q is glass combustion-supporting agent or BaCu (B2O5); the glass combustion-supporting agent comprises the raw materials with the mol ratio being Li2O:ZnO:B2O3=1:2:7 or Li2O: B2O3-1:2:7=3:2:5. The material can be obtained through traditional solid phase reaction synthesis. The material has lower sintering temperature (is capable of being fired at the temperature below 900 DEG C to form ceramics), is capable of being fired at the temperature of 900 DEG C to form ceramics and has better microwave dielectric property, wherein Epsilon r is equal to 25-35, Q*F is larger than 12,000, and Pi f is equal to -10ppm / DEG C to +30ppm / DEG C; in addition, the material has stable process and good repeatability and can be better co-fired and matched with a silver electrode. The low-temperature sintered microwave medium ceramic material can be used for manufacturing microwave devices, such as lower temperature co-fired ceramic (LLCC) systems, multilayer medium resonators, microwave antennae, wave filters, and the like.

Owner:XI AN JIAOTONG UNIV

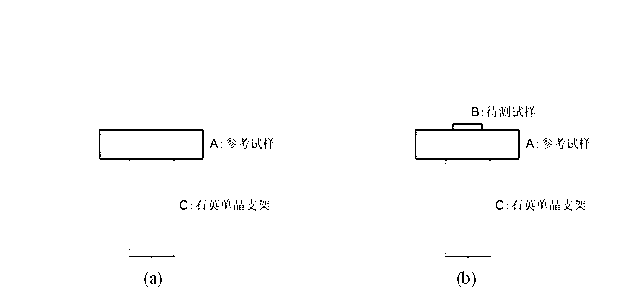

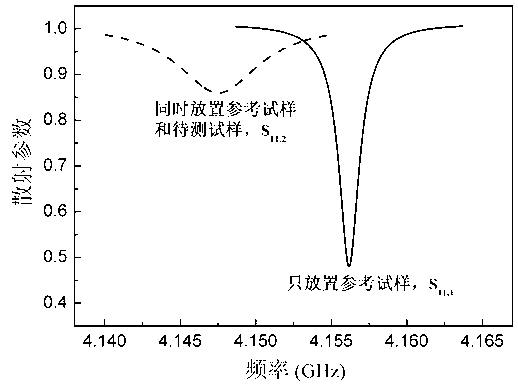

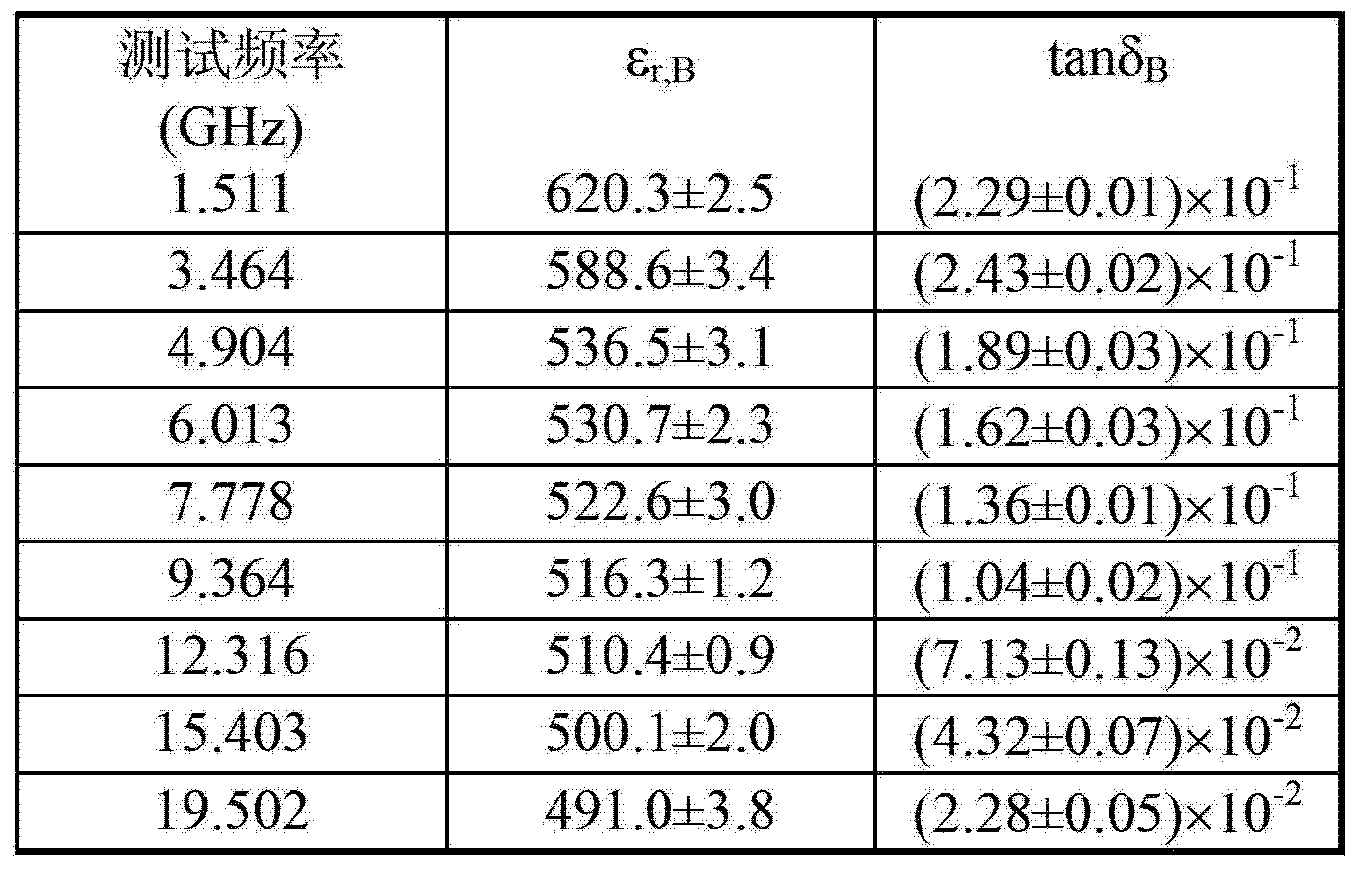

Method for testing microwave dielectric property of high-loss dielectric substance

ActiveCN102798766AOvercome the defect of low test accuracyReduce lossResistance/reactance/impedenceReference sampleElement analysis

The invention discloses a method for testing microwave dielectric property of a high-loss dielectric substance. According to the method, a small-size sample to be tested is used, and a large-size and low-loss reference sample is introduced, so that the high loss of the sample to be tested is reduced, and the resonance peak is ensured to be observed. According to the changes of the resonance peak of a TE01 delta model when only the reference sample is arranged in a resonant cavity and the reference sample and the sample to be tested are simultaneously arranged in the resonant cavity, and the distribution of an electromagnetic field under the two conditions can be simulated by using finite element analysis, so that the dielectric constant and the dielectric loss of the sample to be tested at the resonance frequency can be obtained. According to the method, the characteristics of high test precision of the microwave resonance method is utilized, and the influence on the distribution of the electromagnetic field caused by the introduction of the sample to be tested, is considered, so that the defects of low precision of other conventional methods can be overcome from the test principle, and the accurate test of the microwave dielectric property of the high-loss substance can be realized. Meanwhile, the resonance frequency is decided by the reference sample with large size, so that the frequency conversion test can be realized by changing the dielectric constant or the size of the reference sample.

Owner:ZHEJIANG UNIV

Bismuth-based molybdenum-based microwave dielectric ceramic material sintered at ultra low temperature and manufacture of the same

InactiveCN101318815ALower sintering temperatureLow dielectric lossCeramicsPermittivityStructural formula

The invention discloses a bismuthino molybdenum ultralow temperature sintering microwave medium ceramic material. A phase map of Bi2O3-MoO3 binary system is taken as a beginning, a single-phase compound is taken as a basis, and a series of microwave medium material which has good microwave dielectric property (the permittivity is between 10 and 45, and the Qf is between 4,000 and 25,000GHz) and can be sintered into ceramics at a low temperature of between 550 and 900 DEG C is prepared through the methods of adjusting the proportion of the binary system and substitution for equivalent and unequivalent ions. The structural formula is (1-x)[(Bi1-yAy)2O3]-x[(Mo1-zBz)O3], wherein, A is equal to La<3+>, Nd<3+>, and Sm<3+>, B is equal to W<6+>, Nb<5+>, Ta<5+>, Sb<5+>, Ti<4+>, Zr<4+>, and Sn<4+>, x is more than or equal to 0.01 and less than or equal to 1, y is more than or equal to 0 and less than or equal to 0.20, and z is more than or equal to 0 and less than or equal to 0.20.

Owner:XI AN JIAOTONG UNIV

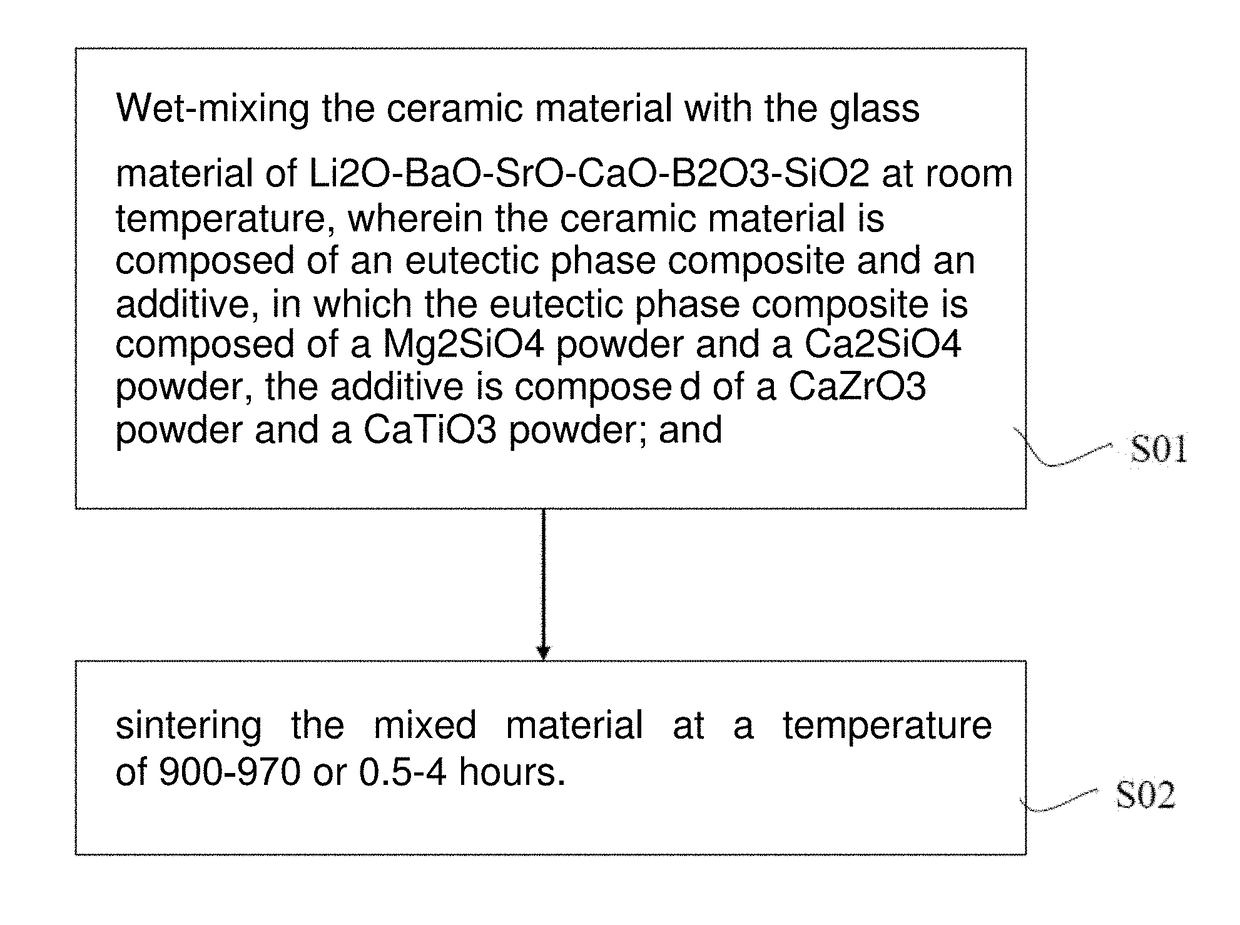

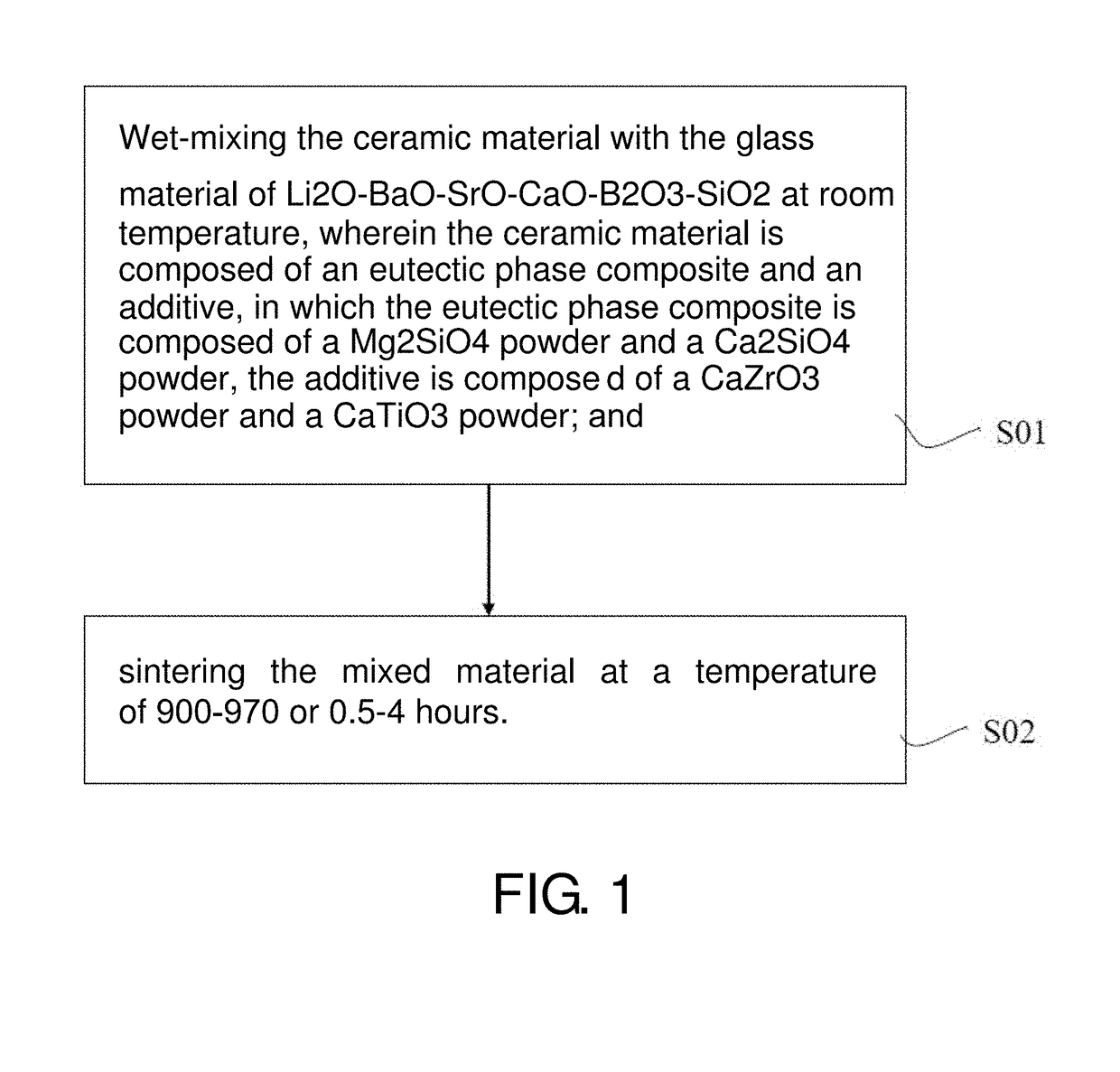

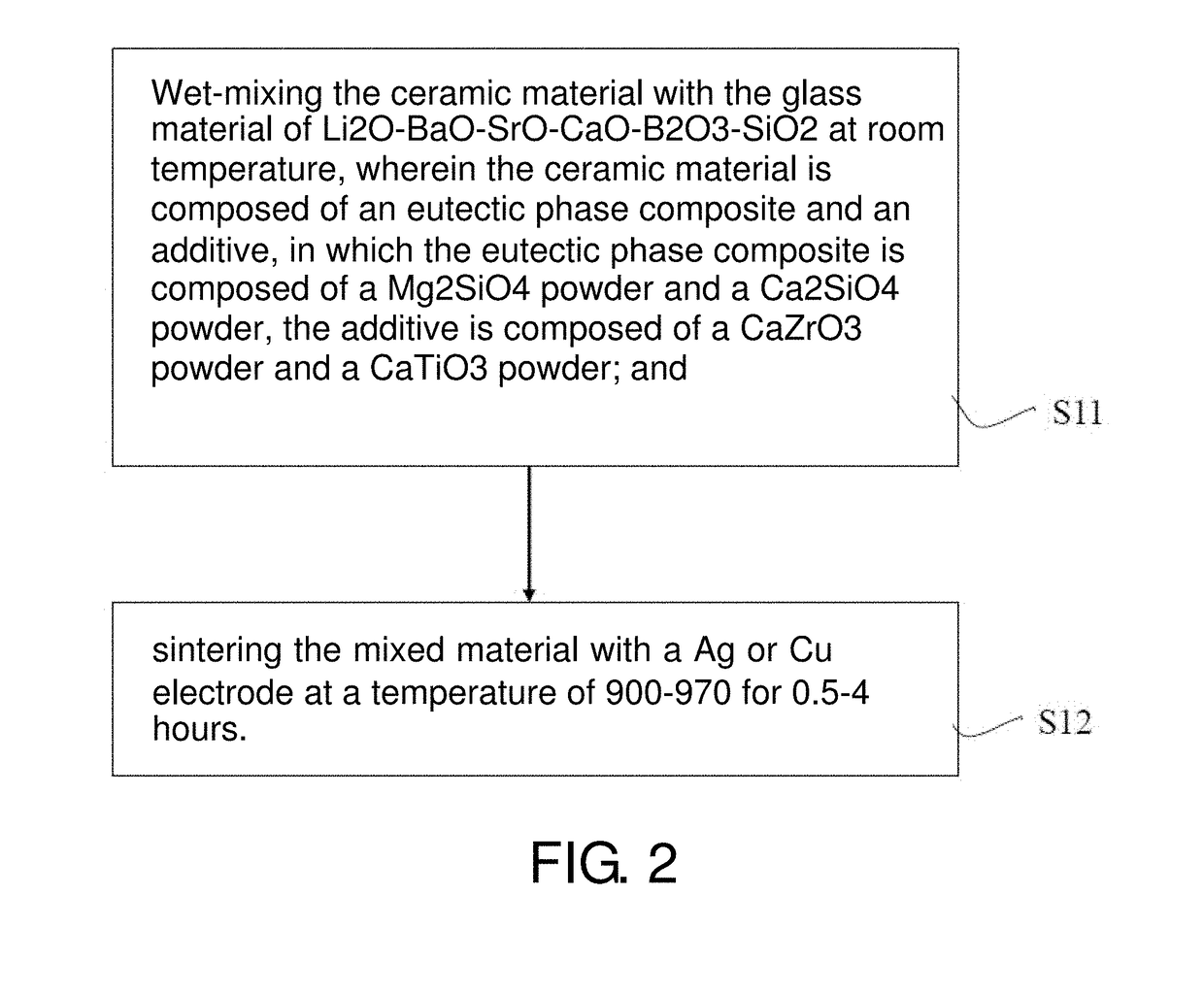

Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

InactiveUS20170334785A1Maintain good propertiesLow dielectric constantCeramicsWaveguide type devicesGlass compositesDielectric loss

A low-temperature, high stability co-fired microwave dielectric composite of ceramic and glass, including 85-99 wt % microwave dielectric ceramic of formula [1-y-z[(1−x)Mg2SiO4−xCa2SiO4]−yCaTiO3−zCaZrO3, wherein 0.2≦x≦0.7,0.05≦y≦0.3 and 0.02≦z≦0.15], and 1 to 15 wt % with Li2O—BaO—SrO—CaO—B2O3—SiO2 glass respectively made at a low sintering temperature of ceramic for co-firing with Ag or Cu electrode, employing eutectic phase of ceramic oxides to reduce its melting temperature, a low melting-point glass material with high chemical stability as a sintering aid added to oxides and raw material powders of Li2O, BaO, SrO, CaO, B2O3 and SiO2, obtained by combining and melting the ingredients in the temperature range between 1000 to 1300° C., quenching and crashing, and then adding it to the main ceramic oxides to form the final composition. This ceramic / glass composite material may be co-fired with an Ag and Cu electrode at 900° C.-970° C. for 0.5-4 hours in a protective atmosphere. After sintering, this dielectric material possesses efficacious microwave dielectric properties, dielectric constant between middle-K to low-K at 8−15, high quality factors, low dielectric loss, low temperature-capacitance coefficient and superior chemical stability suitable for manufacture of multilayer ceramic devices.

Owner:WALSIN TECHNOLOGY CORPORATION

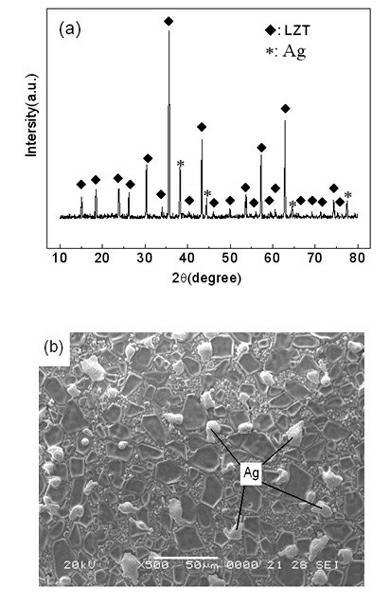

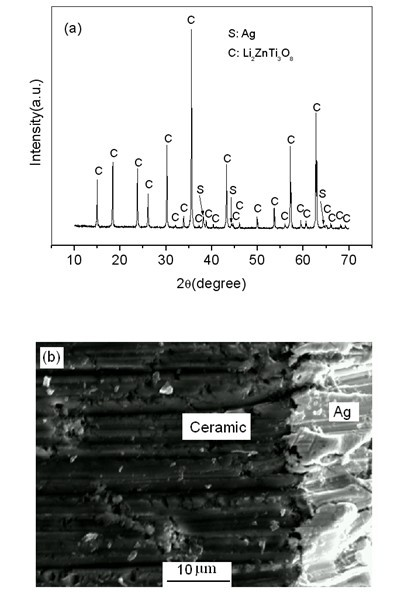

Low temperature co-fired microwave dielectric ceramic material and preparation method thereof

InactiveCN102381874ALower sintering temperatureThe sintering temperature drops toCeramicsDielectric resonatorSolid state reaction method

The invention discloses a low temperature co-fired microwave dielectric ceramic material and a preparation method thereof. The ceramic material comprises a main powder material Li2ZnTi3O8, an auxiliary component TiO2 and low-melting-point LZB (Li2O-ZnO-BiO2) or LBS (Li2O-B2O3-SiO2) glass powder. The preparation method comprises the following steps of: adding TiO2 and the glass powder into the Li2ZnTi3O8 powder in a powder form; and then evenly mixing in a ball mill, drying, pelleting and sintering so as to obtain the ceramic material. In the invention, based on the Li2ZnTi3O8 powder as a reference, batching is carried out according to the proportions that the mass of the glass powder is 0.5-3wt% of that of Li2ZnTi3O8 and the mass of the TiO2 powder is 0-5wt% of that of Li2ZnTi3O8; and thematerial of the invention can be obtained by a traditional solid phase reaction method. The low temperature co-fired microwave dielectric ceramic material prepared by the method of the invention has low sintering temperature (about 875 DEG C) and good microwave dielectric property, and can be well co-fired with a Ag electrode; pure silver with high electricity conductivity and low cost is used asan electrode material, thus the manufacturing cost of a device can be greatly reduced; and the low temperature co-fired microwave dielectric ceramic material can be used for a low temperature co-fired ceramic (LTCC) system and manufacturing of microwave devices such as multilayer dielectric resonators, microwave antennas, filters and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Aluminum oxide microwave dielectric ceramic and preparation method thereof

InactiveCN105948723AImprove pressure resistanceLower sintering temperatureBreakdown strengthSilicon oxide

The invention discloses an aluminum oxide microwave dielectric ceramic and a preparation method thereof. The aluminum oxide microwave dielectric ceramic comprises aluminum oxide, yttrium oxide, zirconium oxide and a CMS mixture, wherein the mass percent of aluminum oxide is 95%-98%, the mass percent of yttrium oxide is 0.25%-0.75%, the mass percent of zirconium oxide is 0%-3%, and the mass percent of the CMS mixture is 1.25%-3.25%; the CMS mixture comprises magnesium oxide, calcium oxide and silicon oxide, wherein the mass percent of magnesium oxide is 18.6%, the mass percent of calcium oxide is 50.1%-56.0% and the mass percent of silicon oxide is 25.4%-31.3%. The preparation method comprises: mixing aluminum oxide, yttrium oxide, zirconium oxide and the CMS mixture in proportion, performing ball-milling and pelleting, forming blank pieces by pressing, performing rubber discharging and sintering to prepare the ceramic. By adding the combined oxide, the ceramic is endowed with high microwave dielectric properties and high breakdown strength.

Owner:HUAZHONG UNIV OF SCI & TECH

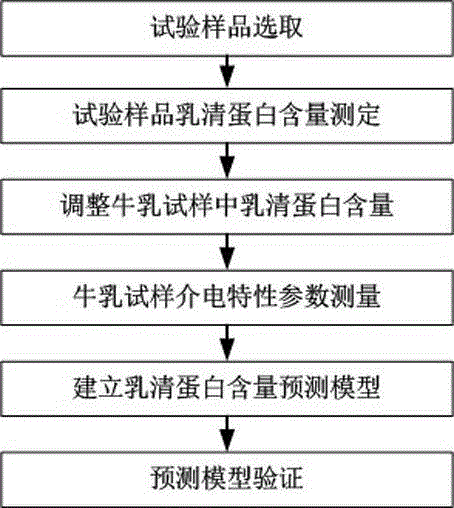

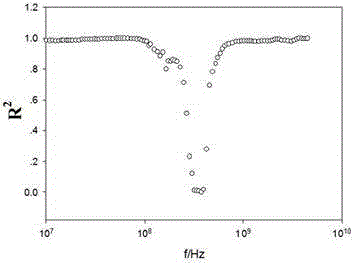

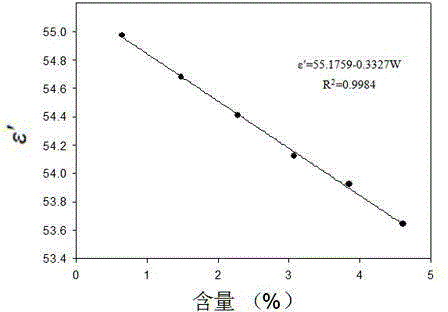

Whey protein content predication models based on cow milk dielectric property and establishment method thereof

InactiveCN103558259AEfficient measurementMeasurement time is shortMaterial impedanceElectricityCow milking

The invention belongs to the technical field of food detection, and particularly relates to whey protein content predication models based on a cow milk dielectric property and an establishment method thereof. In order to overcome the disadvantages of a traditional whey protein content measuring method and lay a foundation for development of a quick, efficient, accurate and online milk quality detection instrument, the mutual relation of the cow milk whey protein content and dielectric parameters (namely relative dielectric constant and dielectric lose factor) of milk whey protein is researched based on the cow milk radio frequency / microwave dielectric property, and the cow milk whey protein content predication models are established on the basis of the mutual relation. The two whey protein content predication models based on the cow milk dielectric property are provided, and the establishment method of the models is given. Verification results show that determination coefficients of the two models reach to 0.998 and 0.997 respectively. The new method is provided for related instrument development, and has the characteristics of high speed, high efficiency, accuracy and online measurement.

Owner:NORTHWEST A & F UNIV

Middle-low temperature sintering middle-dielectric constant microwave medium ceramics and preparation method thereof

InactiveCN101391890AExcellent microwave dielectric propertiesMeet environmental protection requirementsCeramicsResonanceCeramic capacitor

The invention discloses medium dielectric constant microwave medium ceramics sintered by medium-low temperature, and a preparation method thereof. When in preparation, ZnO and Nb2O5 are mixed and added with grinding aid for ball milling; after being dried, the mixture is presintered at the temperature of 900 to 1000 DEG C for 2 to 8 hours; then the presintered powder lot is dried after being ball-milled with TiO2, a sintering auxiliary agent, and the grinding aid; afterwards, an adhesion agent is added, granulation and pressing molding are carried out, and sintering is carried out for 2 to 8 hours within the range of 900 to 1000 DEG C, thus obtaining the microwave medium ceramics. The microwave medium ceramic material provided by the invention has good microwave dielectric property: the dielectric constant is 35 to 50, Q multiplied by f equals to 10000 to 30000GHz, temperature coefficient of resonance frequency is small and adjustable and insulating resistivity is high, therefore, the material can be used for preparing resonators, filters, phase shifters and the like, and can also be used as the dielectric material of multilayer chip ceramic capacitors, thus having important industrial application value.

Owner:SOUTH CHINA UNIV OF TECH

Device and technology for industrial waste salt multi-level harmless treatment

InactiveCN107892928AReduce processing costsImprove cracking efficiencyDispersed particle separationSpecial form destructive distillationElectricityDecomposition

The invention discloses a device and technology for industrial waste salt multi-level harmless treatment. A first inlet is formed in a rotary kiln drying desorption device, the desorption device is connected with a mixing device, and an outlet of the mixing device is connected with a microwave splitting decomposition device; the microwave splitting decomposition device is connected with a refiningdevice, a second output of the refining device is connected with the microwave splitting decomposition device, and after waste salt enters the rotary kiln drying desorption device and the microwave splitting decomposition device, a large amount of organic matter is removed, and the waste salt flows into the refining device; an inlet of a tail gas treatment device is connected with an outlet of asecond-level incineration device, and a second outlet of the refining device is connected with a second inlet of the microwave splitting decomposition device. The technology comprises the processes offirst-level thermal desorption, second-level splitting decomposition, third-level salt refining, tail gas treatment and the like. According to the device and technology for industrial waste salt multi-level harmless treatment, refined salt is obtained after treated by the refining device, the device is simple in structure, residual microwave dielectric property substances can be recycled, the treatment cost is lowered, the waste salt is subjected to second-level harmless treatment, and the organic matter and water in the waste salt can be removed.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

Preparation method of single phase nano-CaTiO3 powder using collosol-gel low temperature synthesis

The present invention discloses a preparation method of low-temperature synthetic single-phase nano CaTiO3 ceramic powder body by using sol-gel process. Said method includes the following steps: dissolving inorganic salt of calcium in anhydrous ethyl alcohol; dissolving butyl titanate in the mixed solution of anhydrous ethyl alcohol and acetic acid; drop-adding nitric acid and acrylic acid to regulate pH value; according to mole ratio of 1:1 of calcium: titanium mixing the above-mentioned two solutions, adding proper quantity of dispersing agent; uniformly stirring the obtained solution, sealing and standing still to obtain gel, drying and grinding said gel, calcining so as to obtain the invented nano ceramic powder body.

Owner:ZHEJIANG UNIV

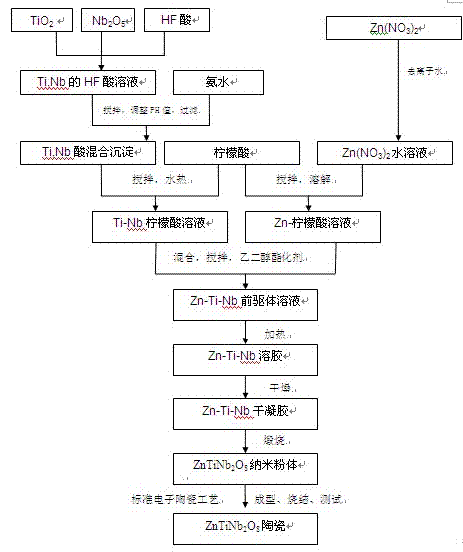

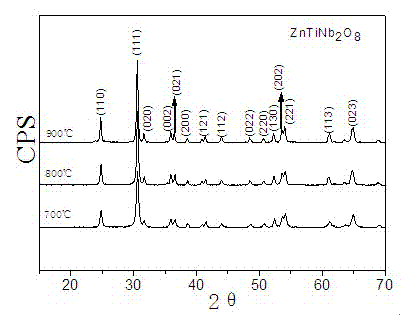

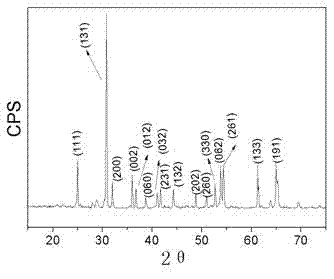

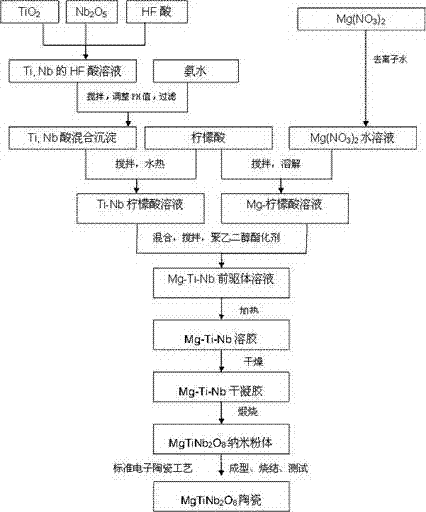

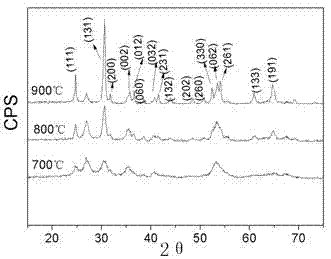

Method for finely synthesizing ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramics by wet chemical process

InactiveCN102775141ASynthesis temperature is lowImprove sintering propertiesSpecific surface energyMicrowave dielectric properties

The invention belongs to the technical field of preparation and application of electronic ceramics, and particularly relates to a method for finely synthesizing ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramics by a wet chemical process. The technical scheme is as follows: the method comprises the following steps: 1) preparing a Zn ion citric acid water solution; 2) preparing a Ti and Nb ion citric acid water solution; and 3) synthesizing a ternary ZnO-Nb2O5-TiO2 microwave dielectric ceramic precursor, and preparing the ceramics. The invention has the advantages of low synthesis temperature, uniform ceramic particles, favorable dispersity, pure phase, nano particle size of powder, high specific surface energy, high activity and the like, can implement low-temperature sintering, and maintains favorable microwave dielectric properties, thereby satisfying the application requirements for LTCC (low temperature co-fired ceramic).

Owner:UNIV OF JINAN

Stable-temperature medium-temperature-sintering microwave dielectric ceramic and preparation method thereof

InactiveCN104944939ASimple preparation processExcellent microwave dielectric propertiesChemical measurementGreen body

The invention discloses a stable-temperature medium-temperature-sintering microwave dielectric ceramic and a preparation method thereof. The preparation method comprises the following steps: proportioning MgO, TiO2 and CaCO3 according to the stoichiometric formula 0.93MgTiO3-0.07CaTiO3, carrying out ball milling, drying, screening and presintering at 900-1150 DEG C; proportioning La2O3 and Al2O3 according to the stoichiometric formula LaAlO3, carrying out ball milling, drying, screening and presintering at 1100-1300 DEG C; and mixing the two presintered powders in a mole ratio of 99:1, adding 1-3 wt% of ZnO and 1-3 wt% of B2O3, carrying out ball milling, drying, screening, granulating, compacting into a green compact, and sintering at 1075-1175 DEG C to prepare the stable-temperature medium-temperature-sintering microwave dielectric ceramic. The Qf value is up to 33000-57000 GHz, tau<f> reaches -9.1 to -2.6 ppm / DEG C, and the optimal sintering temperature is lowered to 1125 DEG C. The stable-temperature medium-temperature-sintering microwave dielectric ceramic has the advantages of simple preparation technique and excellent microwave dielectric properties, and has wide application prospects.

Owner:TIANJIN UNIV

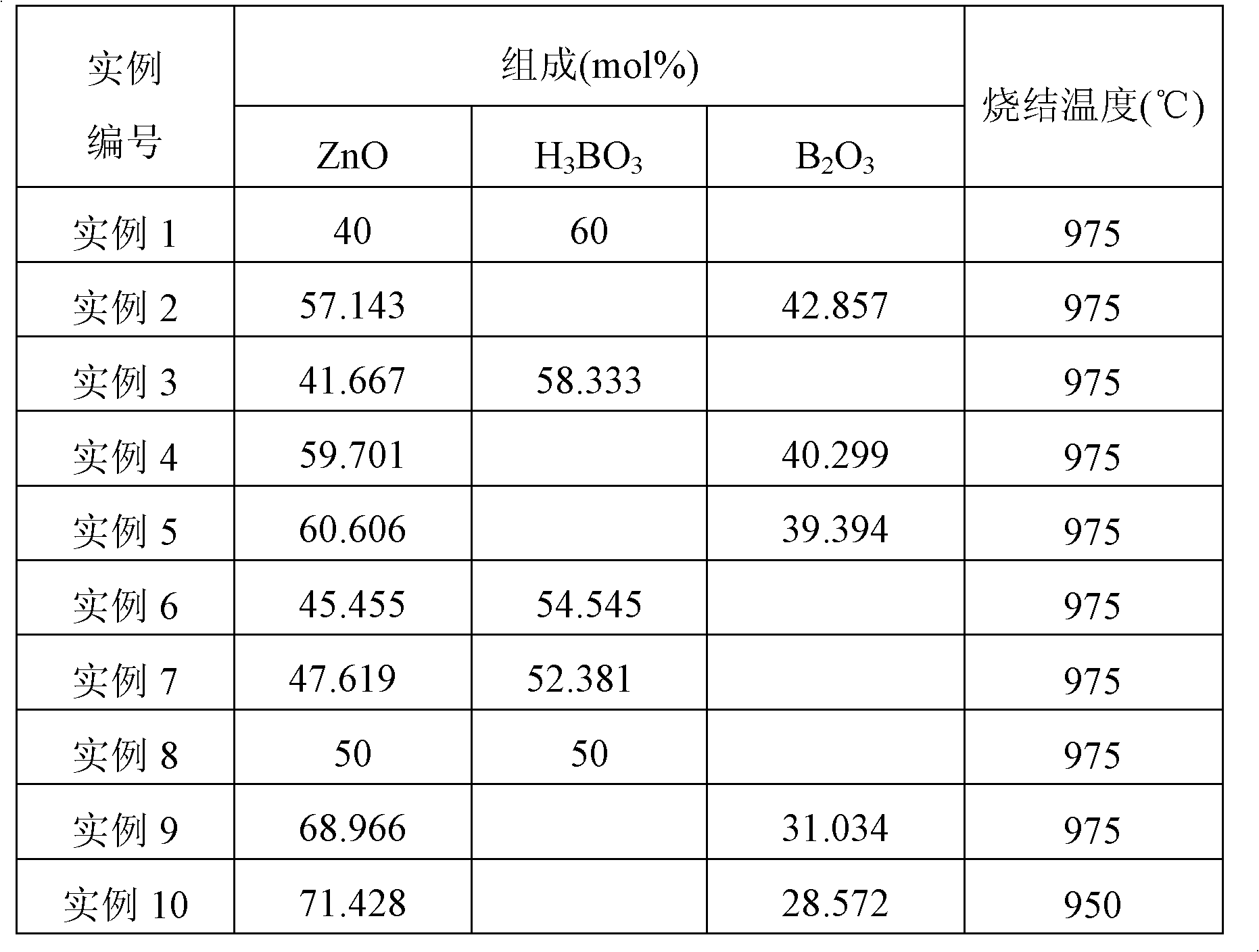

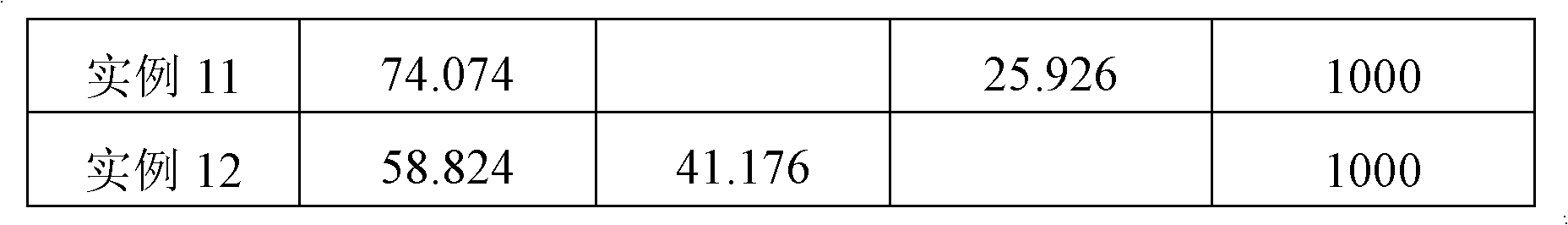

Low-temperature co-fired ceramic substrate material and preparation method thereof

The invention discloses a low-temperature co-fired ceramic substrate material and a preparation method thereof. The ceramic substrate material is zinc borate ceramic of which the main crystalline phase is 3ZnO.B2O3. The ceramic raw material consists of the components of ZnO and H3BO3, wherein the mole percent of the H3BO3 is 60-41.176%, or the raw material consists of chemical components of ZnO and B2O3, wherein the mole percent of the B2O3 is 42.857-25.926%. The preparation method of the ceramic substrate material comprises the steps of firstly presintering to combine 3ZnO.B2O3 powder, then adding deionized water, ball milling, drying, granulating, tableting and sintering. The material disclosed by the invention has a low sintering temperature (950-1000 DEG C) and good microwave dielectric performances: dielectric constant epsilon r = 6.5-6.9, Q*f = 26400-44600 GHz, and the resonant frequency temperature coefficient = -66 to -94 ppm / K, and the dielectric performance requirement of a high-frequency high-speed circuit on the substrate material can be met.

Owner:威海圆环先进陶瓷股份有限公司

Low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and preparation method thereof

InactiveCN102674829ALower sintering temperatureImprove Microwave PerformanceCeramicsDielectric resonatorAg electrode

The invention discloses a low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and a preparation method thereof. The material comprises a main powder material Li2MgTi3O8 and low-melting-point Li2O-MgO-B2O3 (LMB) glass powder. The glass powder is added into Li2MgTi3O8 powder in the form of powder and then the mixture is evenly mixed in a ball mill and is dried, granulated and fired to obtain the material. The proportions of components for preparing the material are determined by taking the Li2MgTi3O8 powder as a reference, wherein the weight of the glass powder accounts for 0.5-3 percent of the weight of Li2MgTi3O8 powder. The material can be obtained through the traditional solid-phase reaction synthesis method. The low-temperature co-fired microwave dielectric ceramic material prepared by adopting the preparation method has the advantages that the firing temperature is low (approximate 875 DEG C), the microwave dielectric performance is excellent, the dielectric constant (epsilon r) is large, the quality factor (Q-f) is high, the resonant frequency-temperature factor (tf) is close to zero, the effect of co-firing with an Ag electrode is good, high-conductivity low-cost pure silver can be used as an electrode material, the manufacturing cost of devices can be greatly reduced, and the low-temperature co-fired microwave dielectric ceramic material can be used for manufacturing microwave devices such as low-temperature co-fired ceramic (LTCC) systems, multilayer dielectric resonators, microwave antennas and filters.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Temperature frequency characteristic regulator of microwave medium ceramic and LTCC material thereof

ActiveCN106927804AStable phase structureExcellent microwave dielectric propertiesAlkaline-earth metal silicatesPrinted circuitsDielectric permittivityMicrowave dielectric properties

The invention discloses a microwave dielectric ceramic, a temperature frequency characteristic regulator of the microwave medium ceramic and an LTCC material thereof. The microwave dielectric ceramic comprises a principal crystalline phase. The chemical formula of the principal crystalline phase is BaSixO2(x+1)(x is greater than or equal to 1.56 but less than or equal to 1.85). The ceramic has a low dielectric constant (epsilon r is equal to 7.1-7.9), a relatively high quality factor (Q*f is equal to 10973-20350GHz) and a relatively wide sintering temperature (750-1250 DEG C). Meanwhile, the principle crystalline phase which is sintered in a reductive atmosphere N2-1vol%H2 still has an excellent microwave dielectric property and is the microwave dielectric material with good reduction resistance. The microwave dielectric material can be used as the temperature frequency characteristic regulator of the microwave medium ceramic and can keep a stable phase structure and a good microwave dielectric property (reduction resistance) in the reductive atmosphere. Compared with a conventional adjustor, the microwave dielectric ceramic has an obvious advantage and is a novel temperature frequency characteristic regulator which can be applied to BME-MLCC.

Owner:HUAZHONG UNIV OF SCI & TECH

Low temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and preparation thereof

InactiveCN101475371ALow costExcellent electrical performanceCeramicsDielectric antennasCeramic capacitor

The invention discloses a low-temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and a preparation method thereof. The formula of raw materials of the ceramic material comprises the following compositions: 30 to 45 percent of zinc oxide, 2 to 14 percent of magnesium oxide, 50 to 60 percent of titania and an auxiliary sintering agent. The preparation method comprises: taking the zinc oxide, basic magnesium carbonate and the titania as raw materials, mixing the raw materials, adding a grinding aid for ball milling, drying, sieving and presintering, and obtaining clinker; and mixing the obtained clinker with the titania, the auxiliary sintering agent and an additive, performing drying, granulation and press forming after secondary ball milling, finally sintering the mixture for 2 to 8 hours at a temperature of between 900 DEG C and 1,000 DEG C, and obtaining the ceramic material. The ceramic material prepared by the method has the advantages of superior microwave dielectric property, low sintering temperature, low cost and the like, and is suitable for microwave devices such as multi-layer ceramic capacitors, filters, resonators and dielectric antennas.

Owner:SOUTH CHINA UNIV OF TECH

Ku frequency band environment friendly microwave dielectric ceramic

The Ku frequency band environment friendly microwave dielectric ceramic is prepared with CaO, Ln2O3, TiO2 and Al2O3, where Ln is La, Nd and Sm, as material and has the chemical expression of xCaO-y(mNd2O3-nLa2O3-pSm2O3)-z(aTiO2+bAl2O3), where x is 20-45 mol%, y is 5-20 mol%, z is 45-60 mol%, x+y+z=100 mol%, m+n+p=1, a+b=1. The Ku frequency band environment friendly microwave dielectric ceramic contains no components harmful to environment and human health, and has the microwave dielectric performance including dielectric constant of 30-70, high of value of 16,000-47,000 GHz and near zero temperature coefficient of resonant frequency. It may be used in resonator, filter, capacitor and other key electronic elements and devices for Ku frequency band satellite communication and has important industrial application value.

Owner:FUZHOU UNIV

Microwave dielectric ceramic material as well as preparation method and application thereof

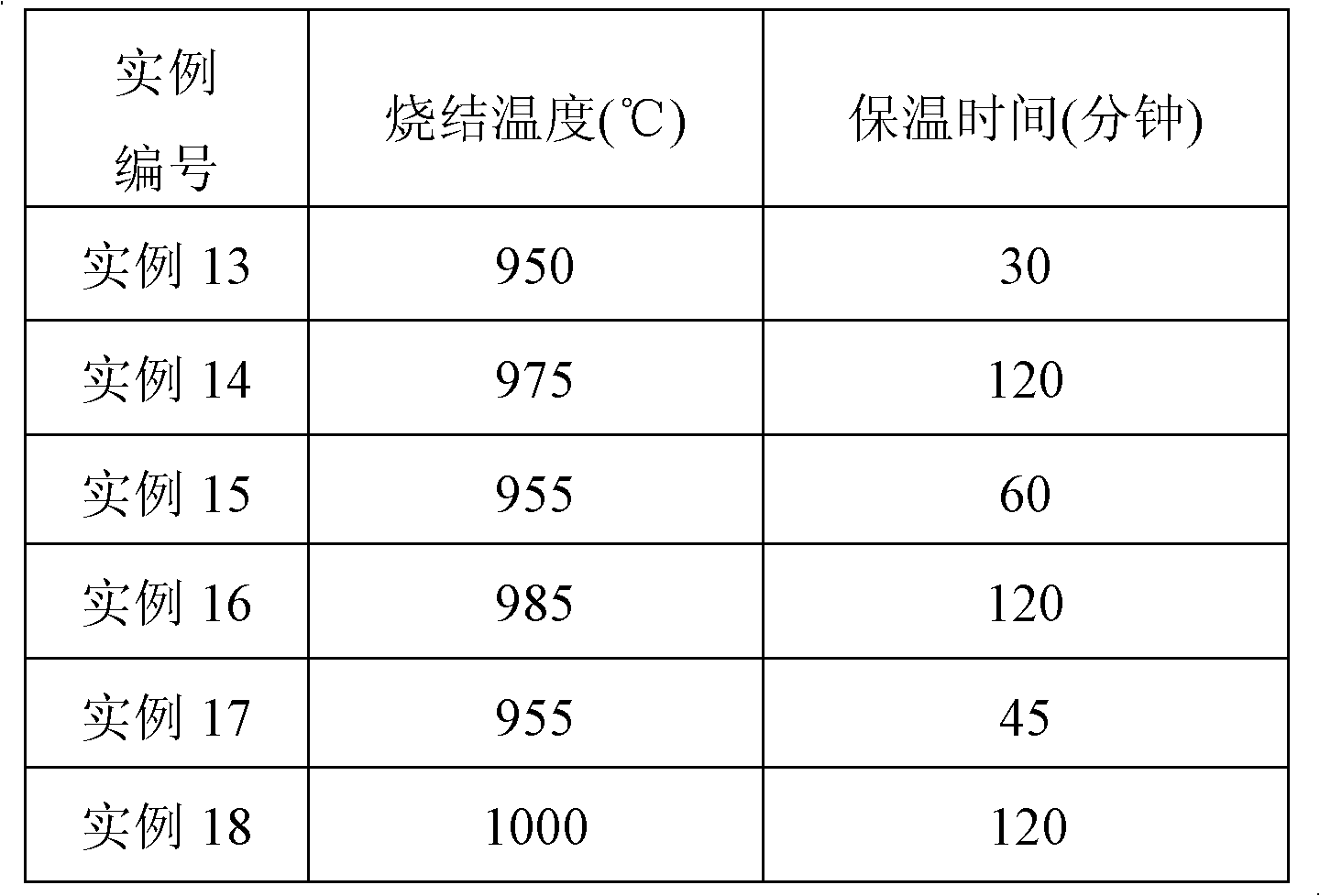

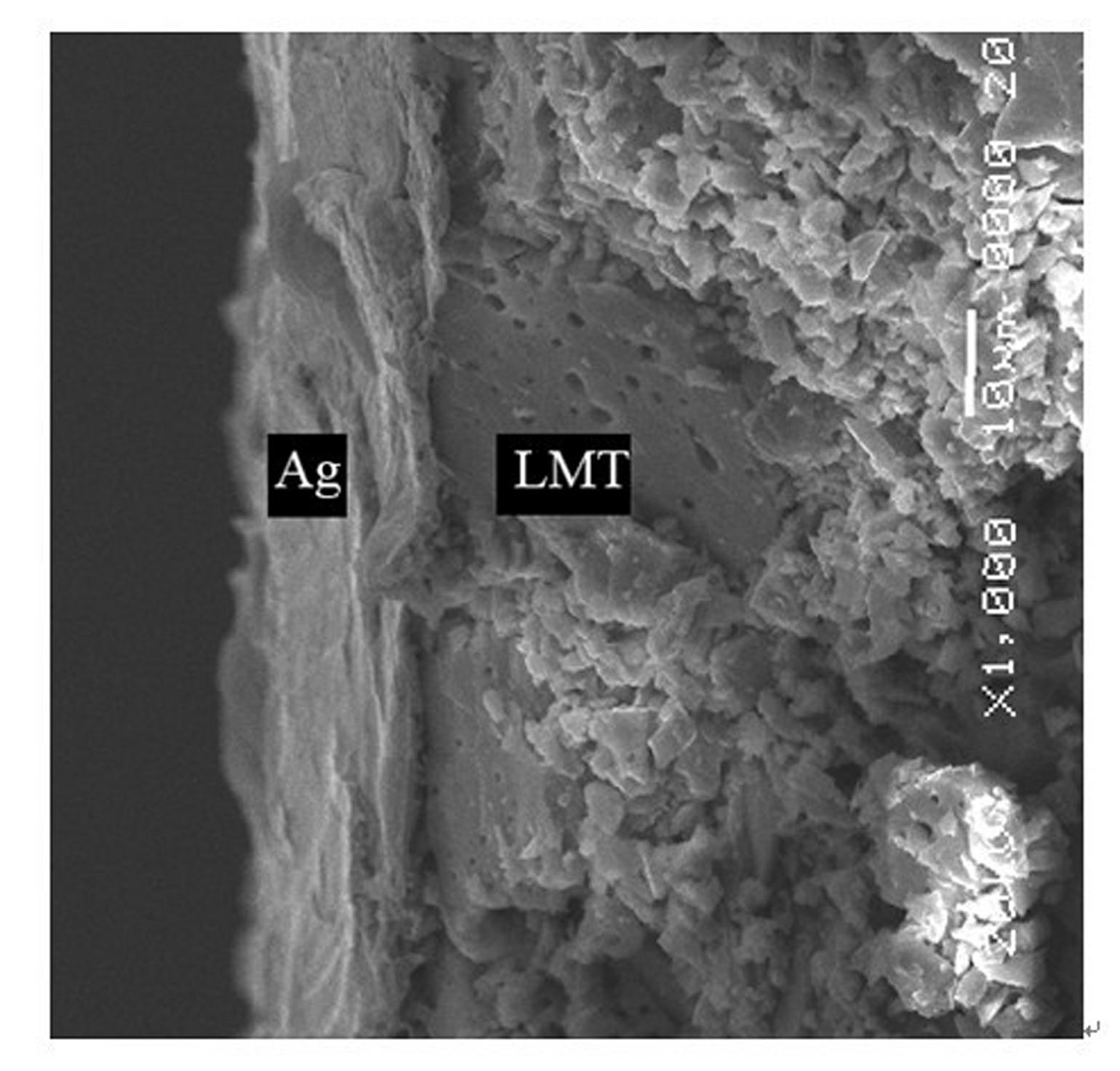

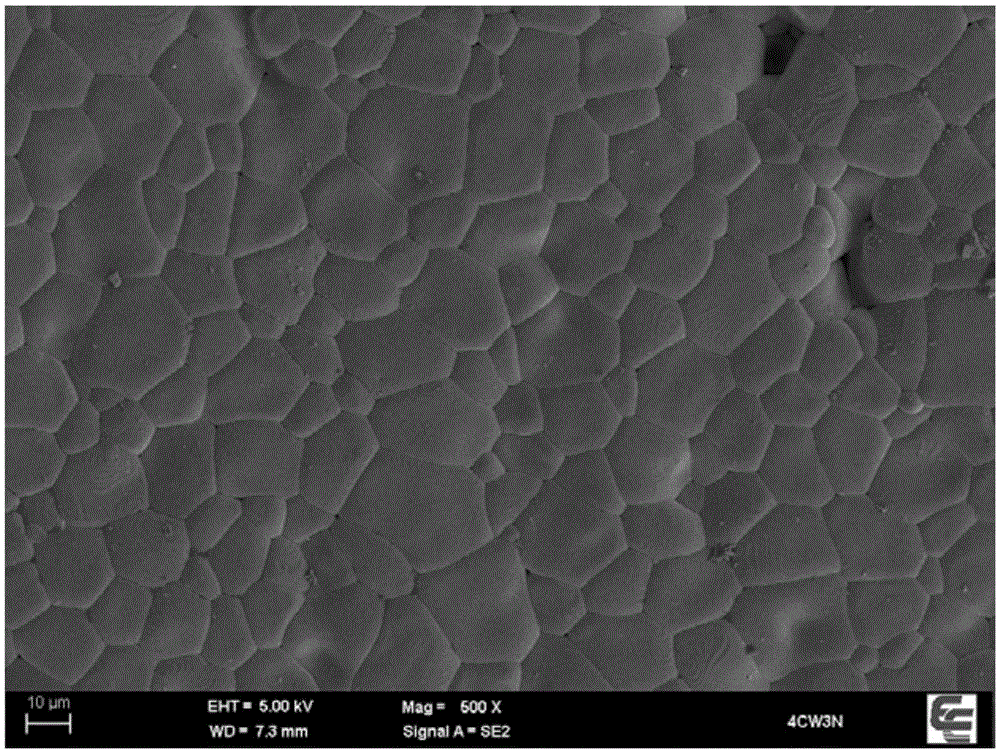

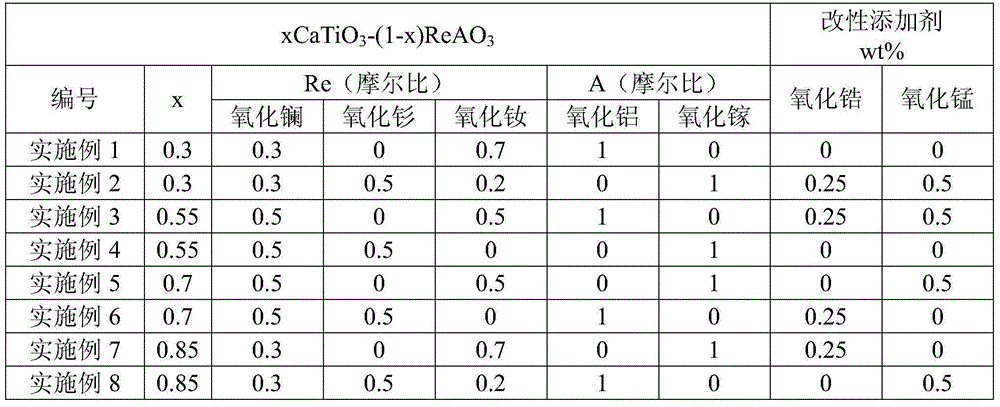

The invention belongs to the field of new materials and microwave communication, and particularly relates to a microwave dielectric ceramic material as well as a preparation method and application thereof. The principal crystalline phase of the microwave medium ceramic material adopts the structure of xCaTiO3-(1-x)ReAO3; Re refers to at least one of La, Ns and Sm, and A refers to at least one of Al and Ga; x is less than or equal to 1 and is greater than or equal to 0; the microwave dielectric ceramic material further comprises a modified additive. According to the invention, the microwave dielectric ceramic material is prepared through steps of compounding, sanding, presintering and adding the modified additive, sanding, pelletizating, pressing for formation and sintering. The material has the characteristics of low cost and excellent microwave dielectric property, is high in electric inductivity, high in Q, has a frequency temperature coefficient close to zero temperature excursion and is continuously adjustable in accessories within a certain range, and can be used for manufacturing microwave components such as dielectric resonators, all-dielectric filters, cavity filters, antennas and the like in a communication system.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Low temperature sintering lithium-base microwave dielectric ceramic material and preparation thereof

The invention discloses a lithium-based low-temperature sintering microwave dielectric ceramic material and a preparation thereof. A series of microwave dielectric materials which have great microwave dielectric properties, the dielectric constant of 7.7 to 16, the quality factor Qf of 13,366GHz to 55,009GHz, the resonance frequency temperature coefficient of minus 24.2ppm / DEG C to minus 55ppm / DEG C and can be sintered to ceramics under the lower temperature are obtained by starting from a phase diagram of a Li2O-M2O5 (M is equal to Nb<5+>, Ta<5+> or Sb<5+>) binary system, being based on a single-phase compound Li3MO4 of which and adding B2O3 to reduce the sintering temperature. The expression formula of the low-temperature sintering microwave dielectric ceramic structure is: Li3MO4 plus x percent by weight of B2O3, wherein, M is equal to Nb<5+>, Ta<5+> or Sb<5+>, x is not less than 0 and not more than 1.0.

Owner:XI AN JIAOTONG UNIV

High dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material and preparation method thereof

The invention provides a high dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material and a preparation method of the high dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material. The high dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material is composed of a major component (namely, (Ba1-m-nMgmSrn)6-3X(Sm1-yNdy)8+2XTi18O54), a sintering aid and a modified dopant. The major component, namely the (Ba1-m-nMgmSrn)6-3X(Sm1-yNdy)8+2XTi18O54 is solid solution, wherein the X is equal to 0-0.02; Y is equal to 0-0.05; m is equal to 0.002-0.025; and n is equal to 0.05-0.03. The sintering aid comprises one of or a mixture of more than one of low-melting-point oxides of Bi2O3, B2O3, CuO, Li2O, ZnO, SiO2, and the like and low-melting-point glass dust. The modified dopant comprises different metallic oxides and carbonate, such as one of or the mixture of more than one of ZrO2, BaCO3, TiO2, MnO2, SrO, and the like. The microwave dielectric material finally prepared through reasonable formula, optimized synthesis and ball-milling process can be sintered in the temperature range of 1250 DEG C to 1330 DEG C. The produced microwave capacitor has excellent microwave dielectric properties, wherein epsilon r is equal to 100; Q*f is more than or equal to 5500GHZ(3.5-4.5GHZ); and tau f(-40 DEG C-25 DEG C / 25 DEG C-125 DEG C) is less than or equal to 10PPM / DEG C.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

High-Q-value medium-dielectric-constant microwave dielectric ceramic and preparation method thereof

ActiveCN102531571AExcellent microwave dielectric propertiesResonant frequency temperature coefficient continuous adjustmentCompound aMicrowave dielectric properties

The invention discloses a high-Q-value medium-dielectric-constant microwave dielectric ceramic and a preparation method thereof and relates to a microwave dielectric ceramic. According to the invention, a novel material system is adopted as follows: xCaTiO3-(1-x)LaGaO3 (x is 0.66-0.62) microwave dielectric ceramic is obtained by compounding a calcium titanate (CaTiO3) phase with a lanthanum gallate (LaGaO3) phase; the microwave dielectric ceramic comprises the following components by weight percent: 25-35% of CaCO3, 15-30% of TiO2, 20-35% of La2O3 and 10-25% of Ga2O3, wherein the purities of CaCO3 and TiO2 are more than or equal to 99.0%, and the purities of La2O3 and Ga2O3 are more than or equal to 99.9%. The high-Q-value medium-dielectric-constant microwave dielectric ceramic disclosed by the invention is good in microwave dielectric property, simple in production technical process and good in repeatability, can be widely applied to preparation of good-property microwave devices such as a dielectric resonator, a filter and a duplexer and meets the technical requirements of systems such as a communication base station.

Owner:HUAZHONG UNIV OF SCI & TECH +1

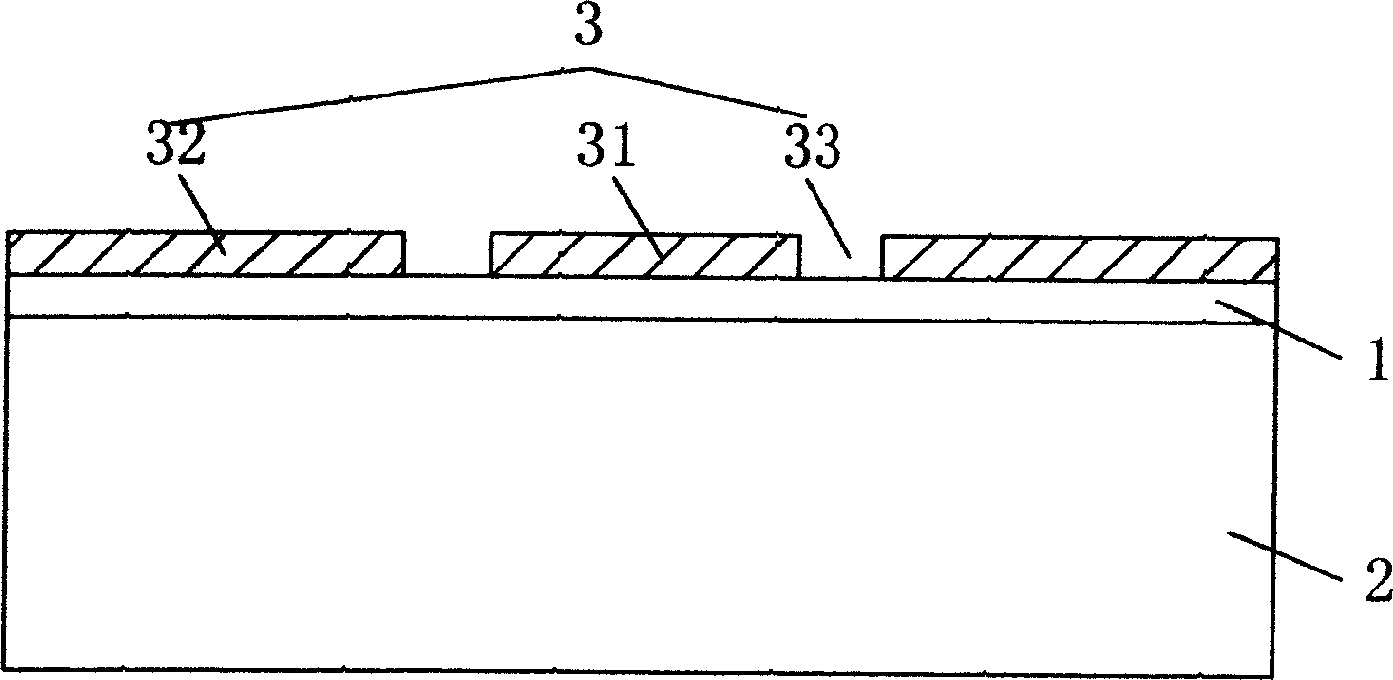

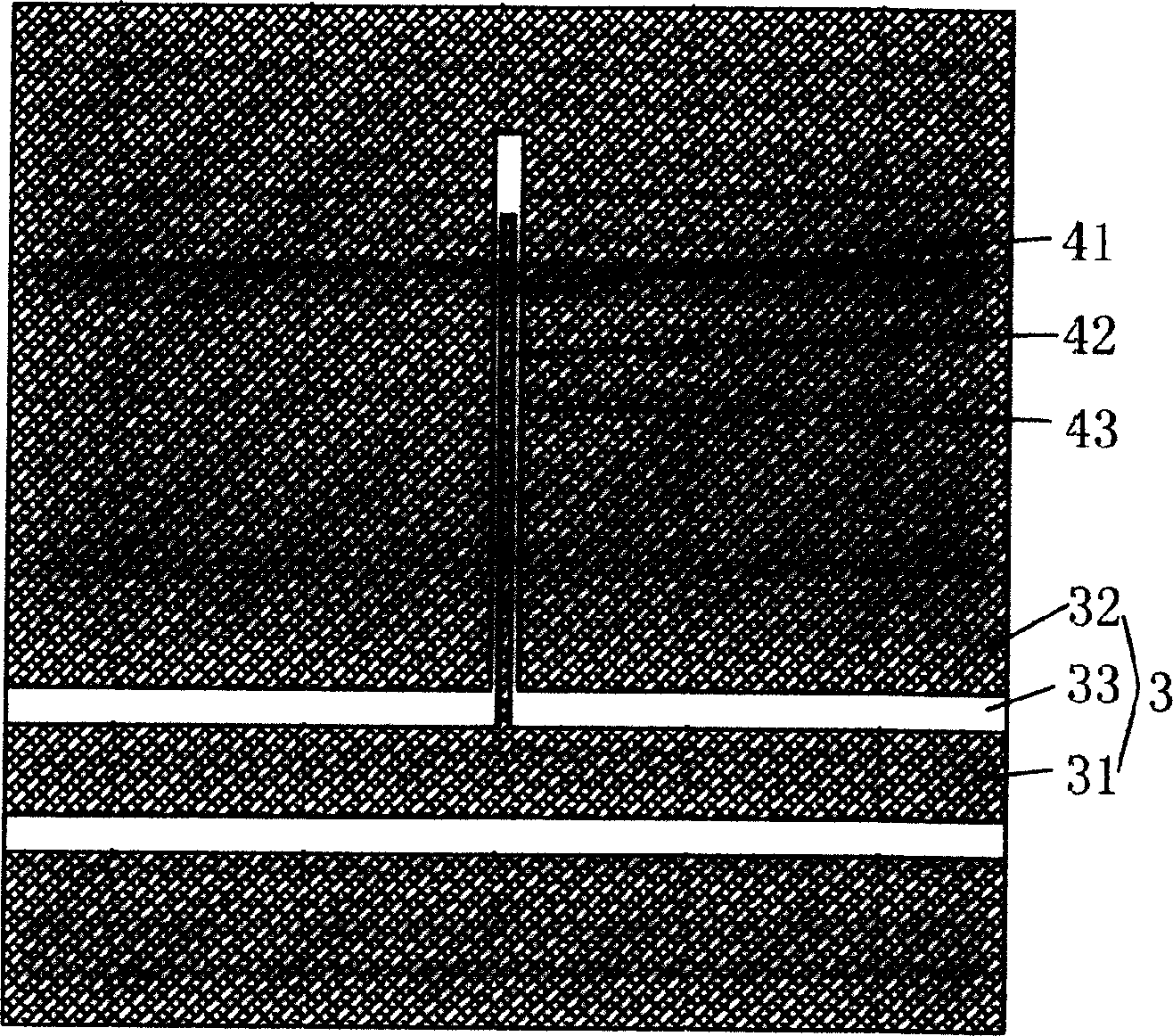

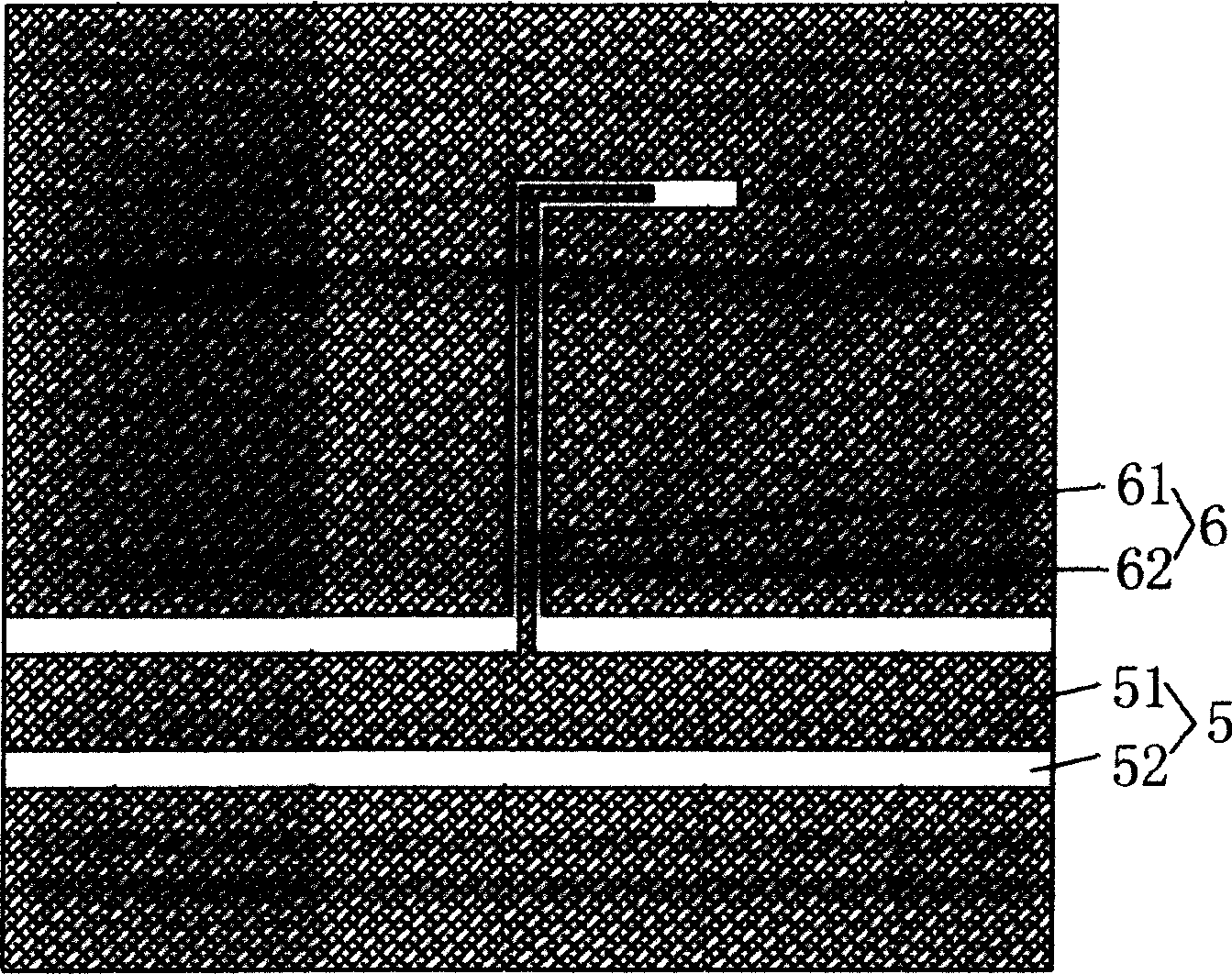

Method and device for detecting ferro-electric film microwave dielectric property

The present invention is method and device for detecting the microwave dielectric characteristic of ferroelectric film. The device includes substrate, measured ferroelectric film on the substrate, coplanar waveguide line including main transmission line and earthing areas separated on two sides on the film, and coplanar quarter-wave open-circuited line on the film and including transmission line connected to the main transmission line and earthing areas separated on two sides. Owing to the coplanar quarter-wave open-circuited line to form the resonant peak, the dielectric characteristic of the measured film may be obtained easily. The pattern for detection of the ferroelectric film may be formed in once forming process. Therefore, compared with available technology, the present invention has simple principle and easy device making and assembling, and is convenient and practical.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com