Low temperature sintered composite microwave medium ceramic in series of lithium, niobium and titanium, and prepartion method

A microwave dielectric ceramic and low-temperature sintering technology, applied in ceramics, inorganic insulators, etc., can solve the problems of high sintering temperature, low temperature of materials and excellent microwave dielectric properties, and lower sintering temperature. Microwave dielectric properties, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Each raw material ratio (mol ratio) of the present embodiment is: Li 2 CO 3 : Nb 2 o 5 :TiO 2 =5:1.15:4.27. Analytical pure Li 2 CO 3 , Nb 2 o 5 and TiO 2 Weigh according to the above ratio, add deionized water according to the weight ratio of mixture and deionized water is 1:1.8, wet ball mill for 24~36h, dry at 100~150℃, put it into a high alumina crucible, Pre-fire at 700℃~1000℃ for 5h~8h to synthesize the main crystal phase. After pre-burning and synthesis, the powder is crushed again, and alcohol is directly added for wet ball milling for 24h-36h, then the material is discharged and dried, granulated with 4%-8% PVA, and pressed into small discs under a pressure of 100-200MPa. Debinding at 600-700°C, placing undoped ceramic samples in an alumina crucible for sintering at 1000-1200°C for 1-3 hours, and cooling naturally to obtain the material of the present invention. The ceramic samples are tested after being smoothed on both sides by sandpaper, and their...

Embodiment 2

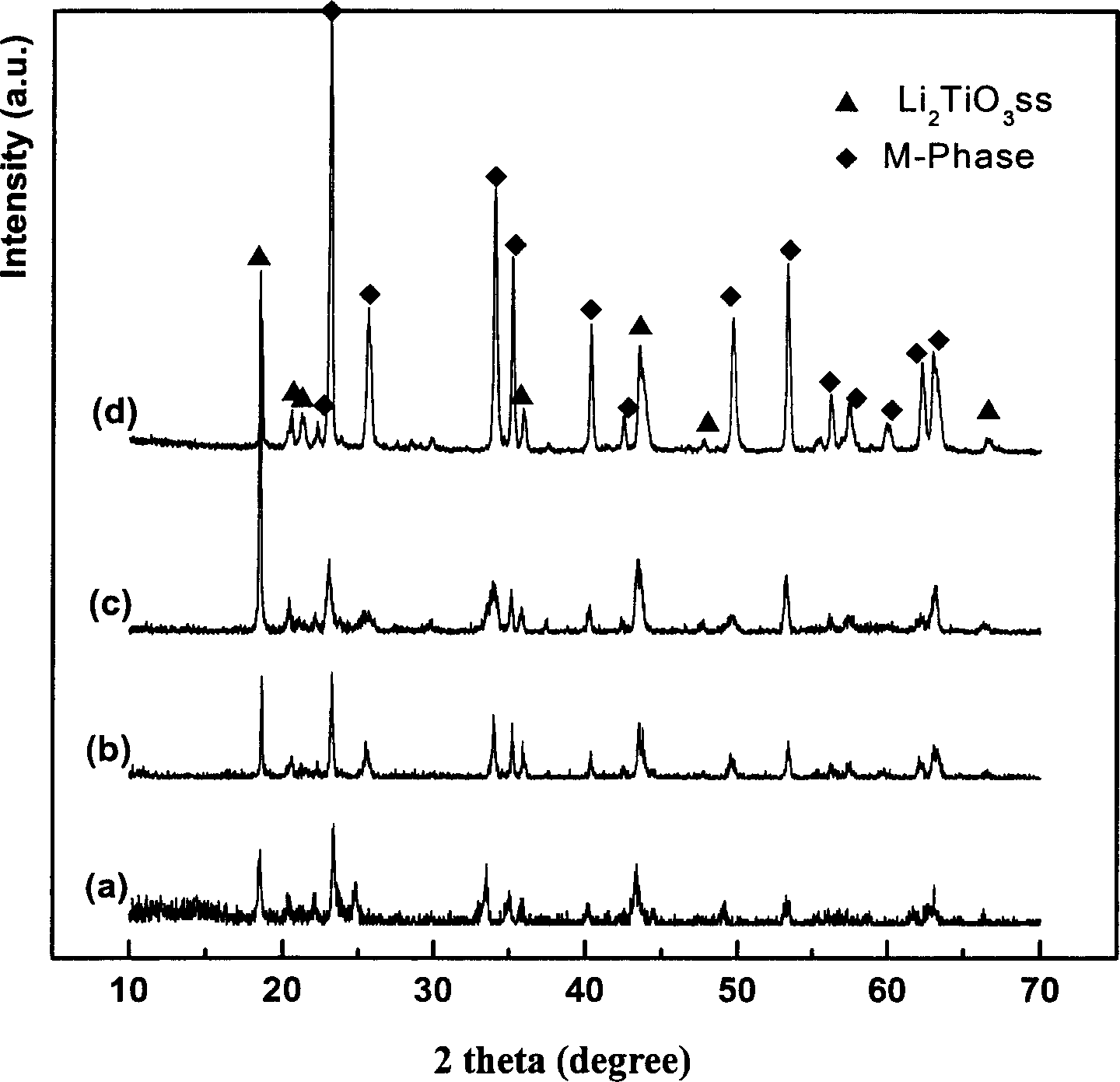

[0031] Each raw material ratio (mol ratio) of the present embodiment is: Li 2 CO 3 : Nb 2 o 5 :TiO 2 =5:1.05:4.85. Analytical pure Li 2 CO 3 , Nb 2 o 5 and TiO 2 Weighing was carried out according to the above-mentioned proportion, and the preparation process described in Example 1 was used to prepare the materials with the above composition. The ceramic samples were polished on both sides by sandpaper and then tested. Through the test of the microwave performance, the microwave dielectric properties of the composite ceramic material at different sintering temperatures are shown in Table 2, and the phase composition of the ceramic sheet sintered at 1100 ° C was identified by X-Ray ( figure 1 (b) shows the X-Ray diffraction pattern of the Example 2 sample at 1100 ° C sintered ceramics), XRD results show that the ceramics are made of Li 2 TiO 3 ss and M-phase two-phase composition, the volume fraction ratio of these two phases is about 0.91.

[0032] Sinteri...

Embodiment 3

[0035] Each raw material ratio (mol ratio) of the present embodiment is: Li 2 CO 3 : Nb 2 o 5 :TiO 2 =5:1:5. Analytical pure Li 2 CO 3 , Nb 2 o 5 and TiO 2 Weighing was carried out according to the above-mentioned proportion, and the preparation process described in Example 1 was used to prepare the materials with the above composition. The ceramic samples were polished on both sides by sandpaper and then tested. Through the test of the microwave performance, the microwave dielectric properties of the composite ceramic material at different sintering temperatures are shown in Table 3, and the phase composition of the ceramic sheet sintered at 1120 ° C was identified by X-Ray ( figure 1 (c) shows the X-Ray diffraction pattern of the sample of Example 3 at 1120 ° C sintered ceramics), XRD results show that the ceramic Li 2 TiO 3 ss and M-phase two-phase composition, the volume fraction ratio of the two phases is about 5.3. The microstructure photo of the sintered mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com