Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Resonant frequency temperature coefficient adjustable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature sintered composite microwave medium ceramic in series of lithium, niobium and titanium, and prepartion method

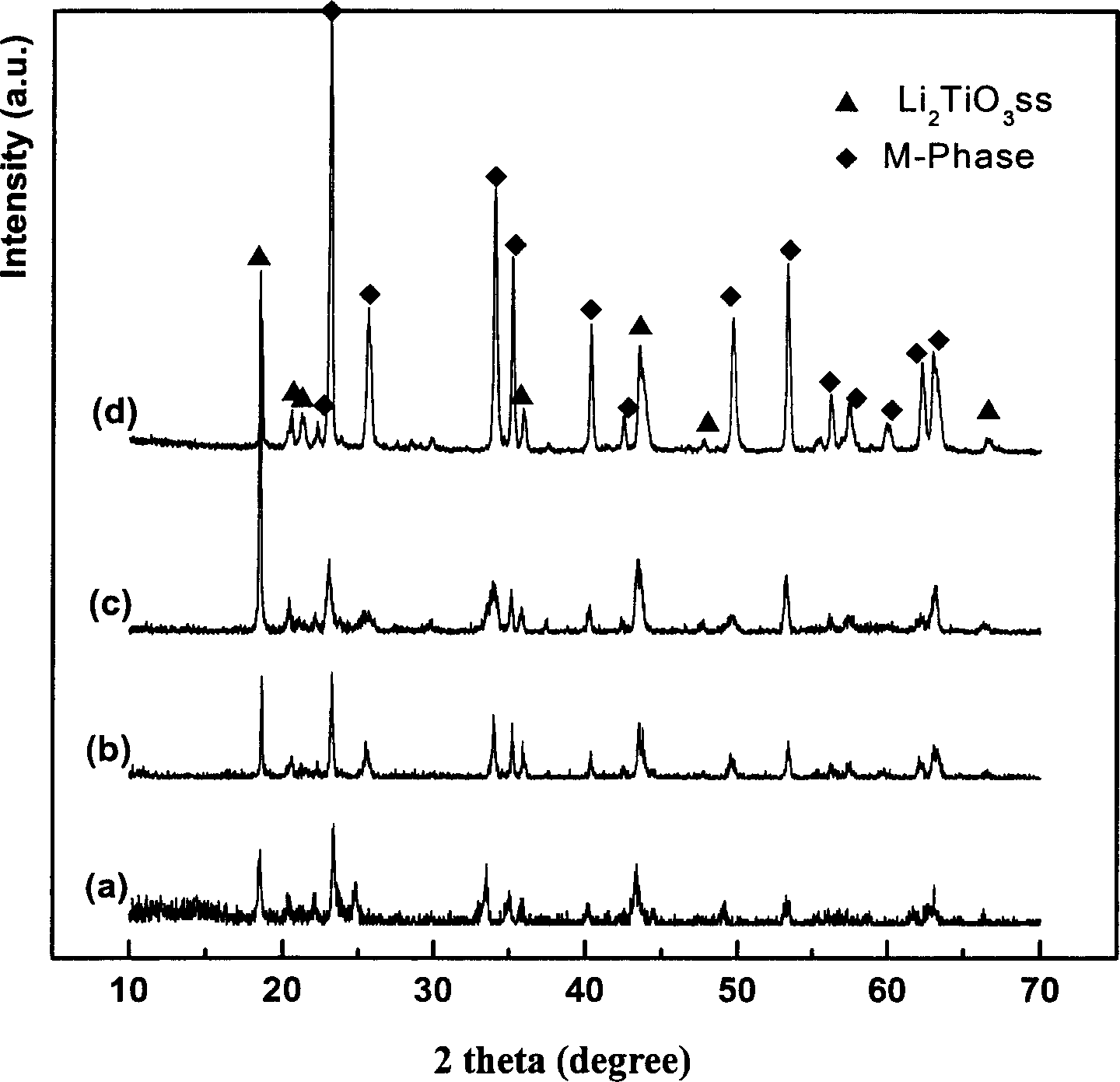

This invention relates to a method for preparing low-temperature-sintered lithium-niobium-titanate composite microwave dielectric ceramic, which is composed of Li2TiO3 solid solution and M-phase solid solution. The composite microwave dielectric ceramic is prepared from Li2CO3, Nb2O5 and TiO2 at a mol ratio of 5: x: y (x is in 1-2 and y in 4-6), and B2O3 or V2O5 0-5 wt. % by conventional solid-phase reaction. The composite microwave dielectric ceramic has a low sintering temperature (about 1100 deg.C), good dielectric property with a dielectric constant of 34-50, a high Q*f value (Q is quality factor), and a low resonance frequency temperature coefficient, and can be used in sheet dielectric resonator, filter, antenna, balun, etc. when added with a small quantity of low-melting-point oxide, the composite microwave dielectric ceramic has a lower sintering temperature of about 900 deg.C, while its good microwave dielectric property can be maintained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Bismuth-based molybdenum-based microwave dielectric ceramic material sintered at ultra low temperature and manufacture of the same

InactiveCN101318815ALower sintering temperatureLow dielectric lossCeramicsPermittivityStructural formula

The invention discloses a bismuthino molybdenum ultralow temperature sintering microwave medium ceramic material. A phase map of Bi2O3-MoO3 binary system is taken as a beginning, a single-phase compound is taken as a basis, and a series of microwave medium material which has good microwave dielectric property (the permittivity is between 10 and 45, and the Qf is between 4,000 and 25,000GHz) and can be sintered into ceramics at a low temperature of between 550 and 900 DEG C is prepared through the methods of adjusting the proportion of the binary system and substitution for equivalent and unequivalent ions. The structural formula is (1-x)[(Bi1-yAy)2O3]-x[(Mo1-zBz)O3], wherein, A is equal to La<3+>, Nd<3+>, and Sm<3+>, B is equal to W<6+>, Nb<5+>, Ta<5+>, Sb<5+>, Ti<4+>, Zr<4+>, and Sn<4+>, x is more than or equal to 0.01 and less than or equal to 1, y is more than or equal to 0 and less than or equal to 0.20, and z is more than or equal to 0 and less than or equal to 0.20.

Owner:XI AN JIAOTONG UNIV

Potassium-based vanadium-based low-temperature sintered microwave dielectric ceramic material and preparation method thereof

InactiveCN102249664AImprove performanceLow and low frequency dielectric lossElectricityDielectric loss

The invention discloses potassium-based vanadium-based low-temperature sintered microwave dielectric ceramic materials and a preparation method thereof. Based on the structure of typical scheelite of ABO4, low-valent K+ ions and Bi3+ are selected to occupy an A site jointly, and high-valent Mo6+ and V5+ composite cations are selected to occupy a B site; a series of ceramic materials are obtained by a solid state reaction sintering method, wherein the ceramic materials can be sintered in a temperature range below 800 DEG C, have a high dielectric constant (34<=epsilon r<=80), an adjustable temperature coefficient of resonant frequency (-260 ppm / DEG C<=TCF<=+116 ppm / DEG C), and a low microwave dielectric loss (high quality factor Qf value, 4,000 GHz<=Qf<=9,700 GHz) in microwave frequency band. The specific structure expression is (K0.5xBi1-0.5x)(MoxV1-x)O4, wherein 0.05<=x<=0.99.

Owner:XIAN TECH UNIV

Silicate low-temperature co-fired ceramic substrate material and preparation method thereof

The invention discloses a silicate low-temperature co-fired ceramic substrate material and a preparation method thereof. The principal crystalline phase of the ceramic substrate material is Zn2SiO4, and the paracrystalline phase is CaTiO3. The dielectric constant [epsilon]r of the ceramic substrate material is 6.1-8.2, the quality factor Q*f is 9600-16000 GHz, and the resonance frequency temperature coefficient [Tau]f is -52 ppm / DEG C to 28 ppm / DEG C. The preparation method includes grinding the Zn2SiO4 and the CaTiO3 respectively into powder, mixing the CaTiO3 and the Zn2SiO4 with Bi2O3-CuO-B2O3 or Li2CO3-Bi2O3-CuO-B2O3 according to a ratio, adding absolute ethanol or deionized water, ball milling, drying, granulating, and sintering at 900-975 DEG C in a furnace. According to the preparation method, a product has the advantages of high purity, good quality, simple technology and low sintering temperature, and can be co-fired with Ag having high conductivity.

Owner:SHANDONG UNIV OF SCI & TECH

Microwave ceramic medium and its preparing process

InactiveCN1342623AHigh dielectric constantReduce lossFixed capacitor dielectricResonatorsDielectricMicrowave

A microwave ceramic medium has its formula: mBaO.n[(1-y)Nd2O3.ySm2O3].p[(1-z)TiO2.zSnO2], where m=13.8-18 mole%, n=16-18 mole%, y=0.1-0.9, p=66-68 mole%, z=0-0.1 and m+n+p=100 mole%. Its advantages include high dielectric constant up to 80-82, low loss (Qf=7500-11000 GH2), and adjustable temp. coefficient of resonance frequency.

Owner:ZHEJIANG UNIV

Microwave medium ceramic and preparing method thereof

InactiveCN1528705AReduce lossResonant frequency temperature coefficient adjustableCeramicsElectricityMicrowave

The invention disclose a microwave medium ceramic, including main component: p[m(aCaO.bNd2O3) .cMgO.TiO2].q[1 / 4Li2O.1 / 4Sm2O3.TiO2], where according to mol percent, p+q=100mol%, m+c=1, a+3b=1, q is not less than 30 mol% and not greater than 55 mol%, a not less than 0.3 mol and not greater than 0.75 mol, and m not less than 0.8 mol and not greater than 0.95 mol; auxiliary component ZnO, 0.5-20wt% of the main component. It also provides preparing method. Its dielectric constant is 90-120, and it has low-loss and adjustable harmonic frequency temperature coefficient, and can make microwave devices such as medium resonator and filter adaptive to higher frequency. It can be applied to high frequency ceramic capacitor or temperature compensating capacitor, and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

Low temperature sintering high-dielectric constant microwave-medium ceramics material and preparation method thereof

ActiveCN101381230AReduce manufacturing costImprove conductivityDielectric resonatorLow melting point

The invention discloses a low temperature sintered high dielectric constant microwave dielectric ceramic material. The component of the microwave dielectric ceramic material is [(1-x)(Ca0.61Nd0.26)(Ti1-ySny)O3+x(Li1 / 2 Nd1 / 2)TiO3]+a(H3BO3-CuO)+b Li2CO3, wherein x is more than or equal to zero and less than or equal to 0.7, y is more than or equal to zero and less than or equal to 0.1, a is more than zero and less than or equal to 15 percent, b is more than or equal to zero or less than or equal to 5 percent, and a and b represent, respectively, the weight percent of H3BO3-CuO and weigh percent of Li2CO3 against the weight of [(1-x)(Ca0.61Nd0.26)(Ti1-ySny)O3+x(Li1 / 2 Nd 1 / 2)TiO3]. The invention also discloses a method for preparing the ceramic material. By adding a small amount of low melting point sintering assistant, the method reduces the sintering temperature to between 850 and 1,100 DEG C and maintains excellent microwave dielectric property and, therefore, meets the requirement for cofiring with low cost Ag electrodes. The method can be used to manufacture multilayer dielectric resonators, microwave antennae, filters and other microwave elements and greatly reduce the manufacture costs of the microwave elements.

Owner:ZHEJIANG UNIV

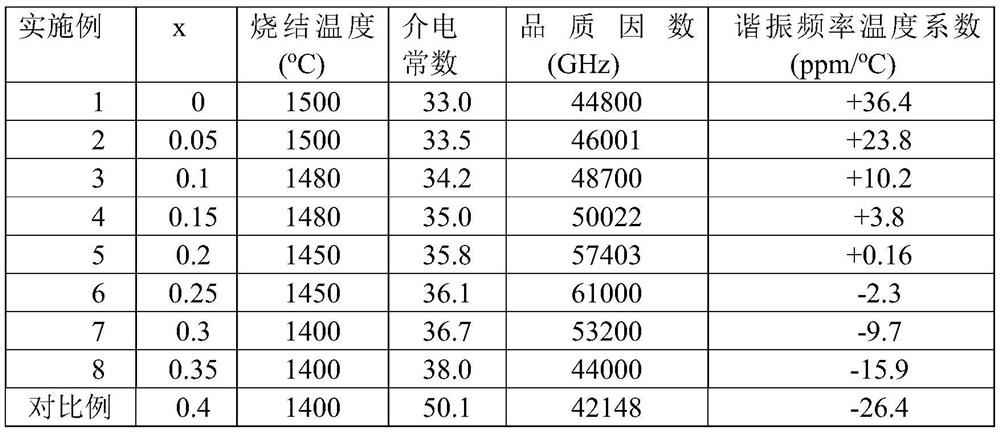

High-Q-value lithium-based microwave medium material prepared through Mg/Nb-codoping

The invention discloses a high-Q-value lithium-based microwave medium material prepared through Mg / Nb-codoping. A chemical formula of the material is Li<2>Ti<1-x>(Mg<1 / 3>Nb<2 / 3>)xO3, x = 0.05-0.4. The preparation method includes the steps of: 1) dosing Li2CO3, TiO2, MgO and Nb2O5 according to the stoichiometric equation, ball-milling and drying the mixture, and pre-sintering the mixture at 700-900 DEG C; 2) adding 0.7 wt% of a PVA powder, mixing and granulating the mixture, and pressing the mixture powder into a green body through a powder tablet machine; and 3) sintering the green body at 1200-1300 DEG C to obtain the high-Q-value lithium-based microwave medium material with Mg / Nb-codoping. Under microwave frequency band, the product reaches 94,010-115,424 GHz in Qf value and has low dielectric consumption. The preparation method is simple and is free of a high oxygen pressure atmosphere during sintering. The product has controllable dielectric constant (16.12-21.92) and temperature coefficient of resonance frequency (-36.61 to +7.96 ppm / DEG C), so that a microwave filter produced therefrom has great application prospect.

Owner:TIANJIN UNIV

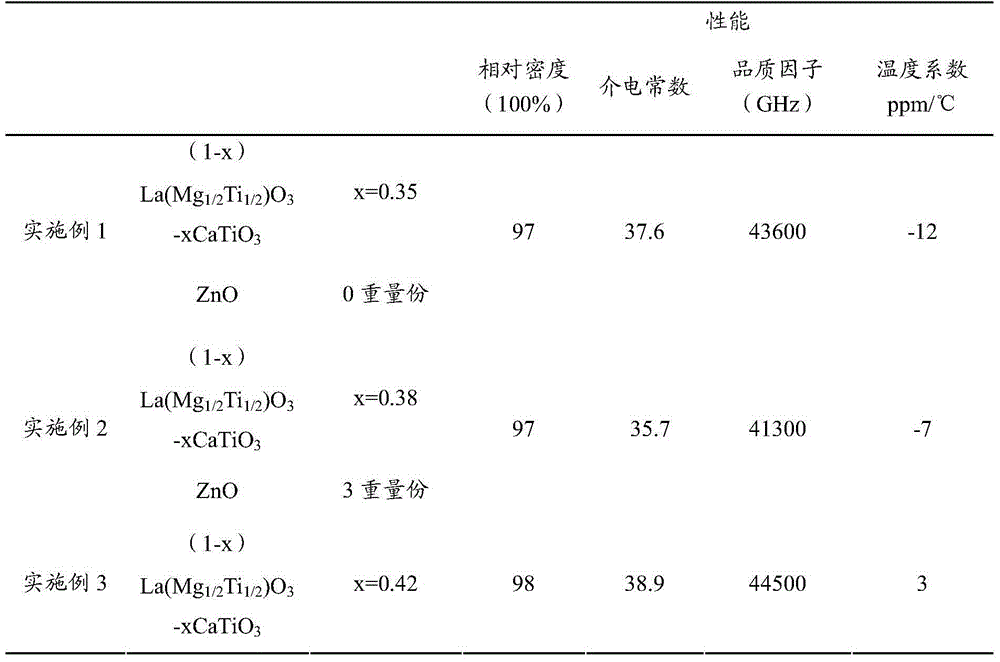

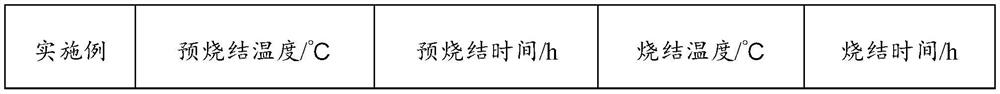

High-performance microwave dielectric ceramic material and preparation method thereof

InactiveCN104261818AHigh quality factorResonant frequency temperature coefficient adjustableDielectricMicrowave

The invention provides a high-performance microwave dielectric ceramic material which is prepared from xMO-yLn2O3-zTiO2 and a metal nanoscale additive, wherein M comprises Ba and further comprises one or two of Ca or Sr; Ln comprises La and further comprises one or more of Sm, Pm, Nd, Pr or Eu; the metal nanoscale additive comprises Zn and further comprises one or more of Zr, Sn, Mg, Ni, Co or W; and x+y+z is equal to 1. The invention further provides a preparation method of the ceramic material. According to the microwave dielectric ceramic material provided by the invention, the dielectric constant is 46-48, and meanwhile has a relatively high quality factor of 35000-50000GHz, and the temperature coefficient of resonance frequency can be adjusted within a range from -12ppm / DEG C to +12ppm / DEG C.

Owner:武汉凡谷陶瓷材料有限公司

Low-loss high-strength microwave medium ceramic and preparing method thereof

The invention discloses low-loss high-strength microwave medium ceramic. The composition expression of the ceramic is xCaTiO3-ySmAlO3-(1-x-y)CaSmAlTiO6, wherein x, y and (1-x-y) each represent a molarratio, x is 0.6, y is larger than or equal to 0 and smaller than 0.4. The invention further discloses a preparing method of the low-loss high-strength microwave medium ceramic. In the microwave medium ceramic, SmAlO3 is partly or overall replaced with CaSmAlTiO6, and therefore the dielectric constant can be reduced, and the temperature stability can be improved; by increasing the sintering temperature, the processing intensity of the ceramic is increased; the CaSmAlTiO6 and the SmAlO3 have the similar dielectric constants, but the CaSmAlTiO6 has the resonant frequency temperature coefficientcloser to zero and the higher hardness, so the high-hardness ceramic material with the dielectric constant of about 35, the low loss and the resonant frequency temperature coefficient close to zero can be obtained by partly or overall replacing the SmAlO3 with the CaSmAlTiO6 and adjusting the ratio of the components.

Owner:无锡鑫圣慧龙纳米陶瓷技术有限公司

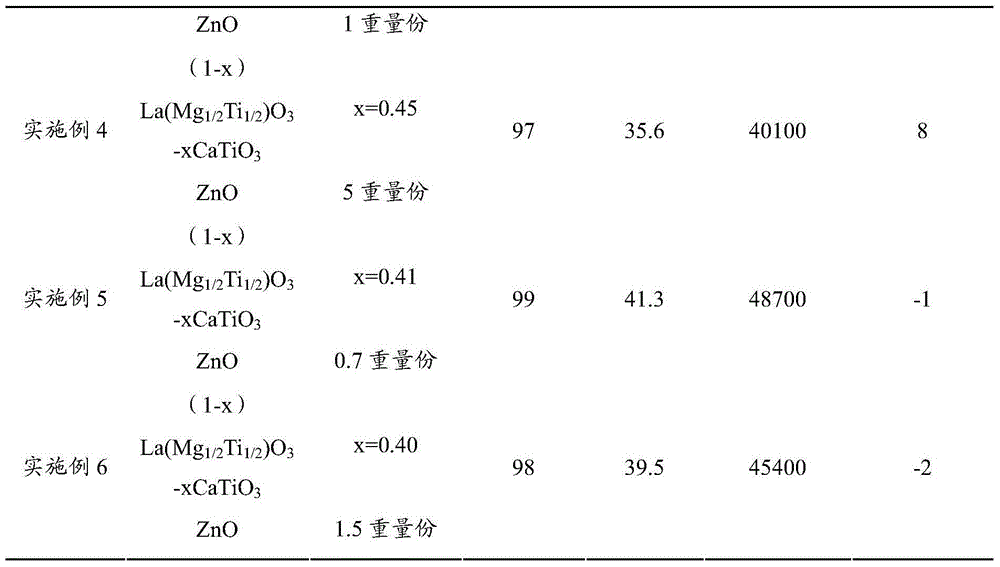

Mediated high-Q microwave medium material for mobile communication and preparation method of mediated high-Q microwave medium material

InactiveCN104261833AHigh quality factorResonant frequency temperature coefficient adjustableElectricityMicrowave

The invention provides a mediated high-Q microwave medium material for mobile communication. The mediated high-Q microwave medium material comprises x MO-y Ln2O3-z TiO2 and a nano-sized metal additive, wherein M comprises Ca, and one or two of Ba or Sr; Ln comprises La, and one or more of Sm, Dy, Nd, Er or Eu; the nano-sized metal additive comprises Mg, and one or more of Zr, Sn, Zn, Ni, Co or W; and x+y+z is equal to 1. The invention also provides a preparation method of the microwave medium material. The microwave medium material disclosed by the invention has a dielectric constant being 44-46, and simultaneously has a relatively high quality factor being 40,000-52,000GHz; and the temperature coefficient of resonance frequency is adjustable within the range of -12ppm / DEG C to +12ppm / DEG C.

Owner:武汉凡谷陶瓷材料有限公司

Microwave dielectric materials capable of burning with copper electrodes together, preparation method and application thereof

ActiveCN103146345AModerate dielectric constantHigh quality factorOther chemical processesDielectricCopper electrode

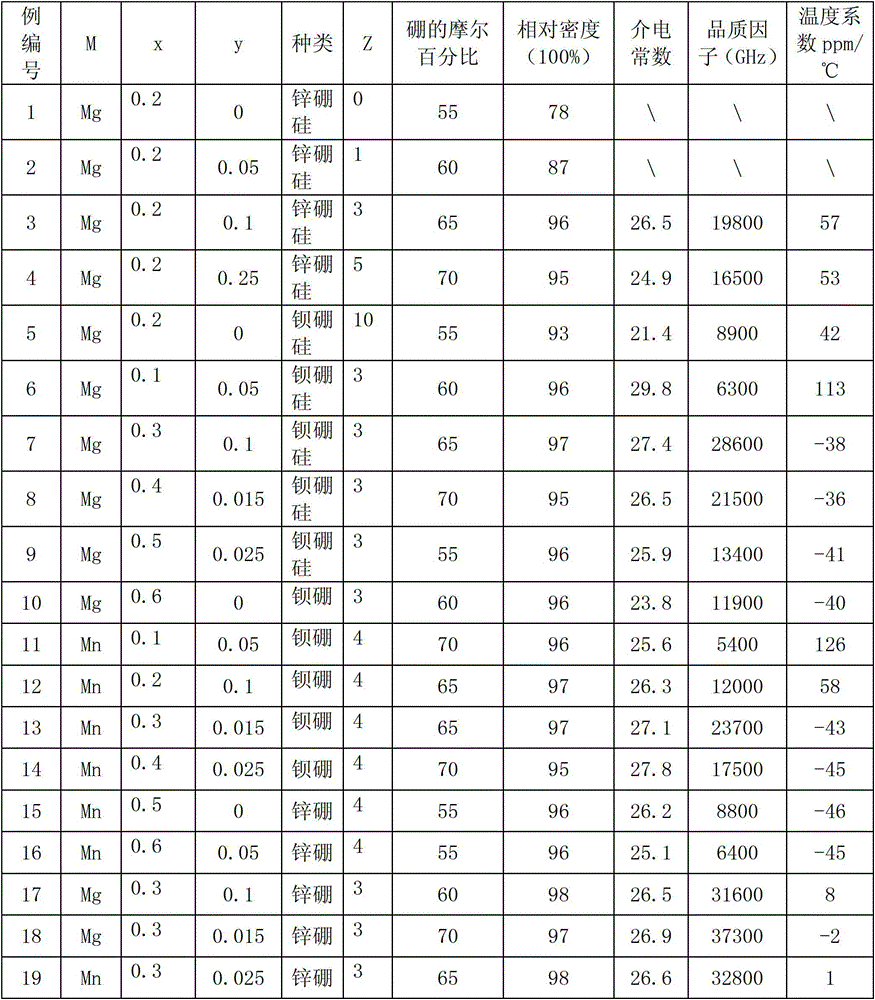

The invention discloses microwave dielectric materials capable of burning with copper electrodes together, a preparation method and application thereof. The microwave dielectric materials comprise: (1-z) wt% ((ZnxM (1-x) (Til-y / 2Mgy) O3)) + zwt% low-melting-point glass, wherein the M is magnesium or manganese; 0<x <=0.6, 0<y <=0.1, 0<z <=10. According to the microwave dielectric material, dielectric constant is moderate, a quality factor is high, temperature coefficient of resonance frequency is adjustable, burning with the copper electrodes can be achieved. Ceramic materials are insoluble in solvents such as water and ethanol and do not occur gelation reaction with binders such as poly vinyl alcohol (PVA) and polyvinyl butyral (PVB), and ceramic diaphragm with high density can be obtained, and firing density of ceramic can not be reduced, the direction of microwave communication frequency developing to higher frequency can be satisfied. The microwave dielectric materials capable of burning with the copper electrodes together is low in cost and suitable for multi-layer microwave medium components and industrialization production of base plates.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Molybdenum-base low-temperature-sintered microwave dielectric ceramic material and preparation method thereof

InactiveCN103232240ASintered denseExcellent microwave dielectric propertiesCeramicsDielectricMicrowave

The invention discloses a molybdenum-base low-temperature-sintered microwave dielectric ceramic material and a preparation method thereof. The formula of the ceramic material is Bi1-x / 3(MoxV1-x)O4, wherein 0.02<=x<=0.95. The molybdenum-base low-temperature-sintered microwave dielectric ceramic disclosed by the invention has the characteristics of adjustable relative dielectric constant (24.5-74), favorable microwave behavior (Qf=7200GHz-10700GHz), lower sintering temperature (620-840 DEG C), adjustable temperature coefficient of resonance frequency (-380 to +135ppm / DEG C) and simple chemical composition. By adopting the solid-phase reaction sintering method, the invention is simple in technological operation, environment-friendly and suitable for industrial production.

Owner:XI AN JIAOTONG UNIV

High Q value microwave dielectric ceramic with adjustable temperature coefficient of resonance frequency

InactiveCN109912306APorcelain with high densityResonant frequency temperature coefficient adjustableTemperature coefficientDielectric

The invention discloses high Q value microwave dielectric ceramic with adjustable temperature coefficient of resonance frequency. The high Q value microwave dielectric ceramic has chemical formula: Li(2-2x+y)Ti(1-x-4y)(MgxNby)3O3, wherein x=0.022, and x:y=(1-3):(1-3). Li2CO3, TiO2, MgO and Nb2O5 are prepared according to the chemical formula, the mixture is pre-sintered at the temperature of 800 DEG C after ball milling, drying and sieving, regranulation is performed, secondary ball milling is performed, and a green body is prepared through pressing; the green body is sintered at the temperature of 1,200-1,280 DEG C, and the compact high Q value microwave dielectric ceramic is prepared. Compared with pure-phase Li2TiO3, the dielectric constant of the system has is not changed significantly, epsilon r is 17.3-20.2, the Q*f value is increased by about 125% to the highest extent, and the temperature coefficient of resonance frequency is adjustable. The preparation process is simple, the process is environmentally friendly, and the ceramic is excellent in performance and is a prospective high Q value microwave dielectric ceramic.

Owner:TIANJIN UNIV

Preparation method of modified BaO-TiO2-La2O3 dielectric ceramics

InactiveCN109534815AMeet application requirementsImprove sintered densityAdditive ingredientDistilled water

The invention discloses a preparation method of modified BaO-TiO2-La2O3 dielectric ceramics, and belongs to the technical field of functional ceramics. The method comprises the following steps of taking BaO, TiO2, La2O3 and modifying agents, wherein the modifying agent is prepared from MnO2, WO3 and Fe2O3 according to the weight ratio of 2:2:1; performing wet ball milling mixing for more than 12 hours, wherein the ball milling media is distilled water; performing drying after the ball milling; performing sintering on the mixed powder after the ball milling for 4 to 8 hours in atmosphere being860 to 890 DEG C; adding bonding agents into the prepared powder; performing granulation and pressing shaping; finally performing sintering for 4 to 6 hours in atmosphere being 940 to 980 DEG C. The BaO-TiO2-La2O3 is used as a basic system; through doping with the modifying agents with the specific ingredients, the sintering performance and the stability are improved; the sintering temperature islow; the dielectric constant is improved, but the Q value reduction is not obvious; meanwhile, the resonant frequency temperature coefficient is adjustable.

Owner:安庆市泽烨新材料技术推广服务有限公司

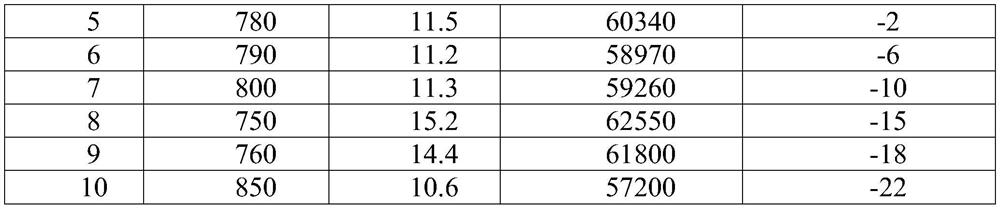

Low-temperature co-fired ceramic material and preparation method thereof

The invention provides a low-temperature co-fired ceramic material, the chemical expression of the ceramic material is Li3Mg2NbxV1-x (O1-y / 2Fy) 6, x is more than or equal to 0.75 and less than or equal to 1, and y is more than or equal to 0.03 and less than or equal to 0.25. The invention also provides a preparation method of the low-temperature co-fired ceramic material, which comprises the following steps: a pre-sintering step: proportioning and pre-sintering reactant raw materials according to the stoichiometric ratio of the chemical expression Li3Mg2NbxV1-x (O1-y / 2Fy) 6 to obtain mixed material powder; a granulation step: adding a binder and a release agent into the mixed material powder, fully mixing, and carrying out spray granulation to obtain granulated powder; and a sintering step: carrying out dry pressing on the granulation powder to prepare a green body, sintering the green body, and cooling to obtain the low-temperature co-fired ceramic material. Therefore, the low-temperature co-fired ceramic material disclosed by the invention can realize low-temperature sintering on the premise of not adding a sintering aid, so that the performance of the ceramic material is greatly improved, and the preparation method is simple in process, low in cost and suitable for large-scale industrial production.

Owner:无锡市高宇晟新材料科技有限公司

A kind of microwave dielectric ceramic powder and its preparation method

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

A kind of nanometer microwave dielectric ceramic material and preparation method thereof

The invention provides a nano-microwave dielectric ceramic material prepared from a mixture comprising a composite oxide and a sintering aid; the composite oxide has a general formula shown in formula (I): xLn 2 o 3 ‑yBaO‑zAl 2 o 3 ‑wTiO 2 ; In formula (I), 0<x≤10, 0≤y≤10, 0≤z≤1, 0<w≤20. Compared with the prior art, the nano-microwave dielectric ceramic material provided by the present invention takes the composite oxide of the above-mentioned specific general formula as the main component, and its crystal structure changes from the perovskite structure as the ratio of x, y, z, and w changes. Transforming to the composite perovskite structure and then to the black bronze structure, the BaO‑Ln 2 o 3 -TiO 2 (Ln: La\Sm\Nd) system microwave dielectric ceramic material is effectively improved; the nano-microwave dielectric ceramic material also has a high dielectric constant, extremely low dielectric loss and good sintering stability, and at the same time resonant The frequency temperature coefficient is adjustable, and it has very broad application prospects in the field of microwave communication.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

Low temperature sintered microwave dielectric ceramics and its preparing method

InactiveCN100378031CExcellent microwave dielectric propertiesLow costCeramicsDielectric ceramicsCeramic chemistry

The present invention relates to low temperature sintered microwave dielectric ceramic and its preparation process, and belongs to the field of microwave dielectric ceramic technology. The material has the composition of Li2+xNb3xTi1-4xO3+yB2O3, where 0 C04B 35 / 462 C04B 35 / 622 H01B 3 / 12 1 8 2 2006 / 3 / 9 1821171 2006 / 8 / 23 100378031 2008 / 4 / 2 2008 / 4 / 2 2008 / 4 / 2 Shanghai Inst. of Ceramic Chemistry and Technology, CAS Shanghai 200050 Li Wei Zeng Qun Shi Jianlin Wu Wenjun Guo Jingkun

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Bismuth-based molybdenum-based microwave dielectric ceramic material sintered at ultra low temperature and manufacture of the same

InactiveCN101318815BLower sintering temperatureLow dielectric lossCeramicsPermittivityStructural formula

The invention discloses a bismuthino molybdenum ultralow temperature sintering microwave medium ceramic material. A phase map of Bi2O3-MoO3 binary system is taken as a beginning, a single-phase compound is taken as a basis, and a series of microwave medium material which has good microwave dielectric property (the permittivity is between 10 and 45, and the Qf is between 4,000 and 25,000GHz) and can be sintered into ceramics at a low temperature of between 550 and 900 DEG C is prepared through the methods of adjusting the proportion of the binary system and substitution for equivalent and unequivalent ions. The structural formula is (1-x)[(Bi1-yAy)2O3]-x[(Mo1-zBz)O3], wherein, A is equal to La<3+>, Nd<3+>, and Sm<3+>, B is equal to W<6+>, Nb<5+>, Ta<5+>, Sb<5+>, Ti<4+>, Zr<4+>, and Sn<4+>,x is more than or equal to 0.01 and less than or equal to 1, y is more than or equal to 0 and less than or equal to 0.20, and z is more than or equal to 0 and less than or equal to 0.20.

Owner:XI AN JIAOTONG UNIV

Low temperature sintering high-dielectric constant microwave-medium ceramics material and preparation method thereof

The invention discloses a low temperature sintered high dielectric constant microwave dielectric ceramic material. The component of the microwave dielectric ceramic material is [(1-x)(Ca0.61Nd0.26)(Ti1-ySny)O3+x(Li1 / 2 Nd1 / 2)TiO3]+a(H3BO3-CuO)+b Li2CO3, wherein x is more than or equal to zero and less than or equal to 0.7, y is more than or equal to zero and less than or equal to 0.1, a is more than zero and less than or equal to 15 percent, b is more than or equal to zero or less than or equal to 5 percent, and a and b represent, respectively, the weight percent of H3BO3-CuO and weigh percent of Li2CO3 against the weight of [(1-x)(Ca0.61Nd0.26)(Ti1-ySny)O3+x(Li1 / 2 Nd 1 / 2)TiO3]. The invention also discloses a method for preparing the ceramic material. By adding a small amount of low melting point sintering assistant, the method reduces the sintering temperature to between 850 and 1,100 DEG C and maintains excellent microwave dielectric property and, therefore, meets the requirement for cofiring with low cost Ag electrodes. The method can be used to manufacture multilayer dielectric resonators, microwave antennae, filters and other microwave elements and greatly reduce the manufacture costs of the microwave elements.

Owner:ZHEJIANG UNIV

Scheelite type molybdenum-based ultralow temperature-sintered microwave dielectric ceramic material and preparation method thereof

InactiveCN101823879BLower sintering temperatureAdjustable dielectric constantChemical compositionMicrowave

The invention discloses a scheelite type molybdenum-based ultralow temperature-sintered microwave dielectric ceramic material and a preparation method thereof. The structure expression of the ceramic material is (Li0.5-0.5MxBi0.5-0.5x)MoO4, wherein M is equal to Ca2+, Zn2+, Sr2+ or Ba2+, 0.0(x(1.0. The scheelite type molybdenum-based ultralow temperature-sintered microwave dielectric ceramic material has the characteristics of adjustable relative dielectric constant (10.8 to 44), low dielectric loss under low frequency (tan delta(5*10-4, 1 MHz), high microwave performance (Qf is equal to 3,200 GHz to 84,000 GHz), low sintering temperature (560 to 1,050 DEG C), adjustable temperature coefficient of resonance frequency (-55 to +250 ppm / DEG C) and simple chemical composition and preparation process.

Owner:XI AN JIAOTONG UNIV

Microwave medium ceramic and preparing method thereof

InactiveCN1267377CReduce lossResonant frequency temperature coefficient adjustableCeramicsElectricityMicrowave

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of modified BaO-TiO2-Sm2O3 dielectric ceramic

InactiveCN109665843AImprove sintered densityImprove sintering performance and stabilityTemperature coefficientCeramic

The invention discloses a preparation method of a modified BaO-TiO2-Sm2O3 dielectric ceramic and belongs to the technical field of functional ceramics. The preparation method of the modified BaO-TiO2-Sm2O3 dielectric ceramic comprises the following steps of in a wet mode ball-milling BaO, TiO2, Sm2O3 and modifier in a medium of distilled water, and then drying the ball-milled powder; uniformly mixing the ball-milled and dried mixed power with bonding agent for press forming; sintering the press-formed powder in the atmosphere at 950-980 DEG C, and keeping the temperature for 3-5 hours; annealing the sintered powder at 820-860 DEG C for 3-5 hours to obtain the modified BaO-TiO2-Sm2O3 dielectric ceramic. As a microwave dielectric ceramic, the modified BaO-TiO2-Sm2O3 dielectric ceramic has afoundation system of BaO-TiO2-Sm2O3, and by means of the modifier doped with specific components, improves the dielectric constant without significant reduction of Q value and meanwhiles achieves adjustability of temperature coefficient of resonance frequency.

Owner:安庆市泽烨新材料技术推广服务有限公司

A low-loss high-strength microwave dielectric ceramic and its preparation method

ActiveCN110451952BReduce lossResonant frequency temperature coefficient near zeroDielectric ceramicsUltimate tensile strength

Owner:无锡鑫圣慧龙纳米陶瓷技术有限公司

Low-temperature sintered microwave dielectric ceramic material, preparation method and microwave device

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Microwave dielectric ceramic and its preparing process

InactiveCN1125792CHigh dielectric constantReduce lossFixed capacitor dielectricResonatorsDielectric ceramicsCapacitor

The expression of the microwave dielectric ceramic of the present invention is: mBaO.n [(1-y) Nd 2 o 3 .ySm 2 o 3 ].p[(1-z)TiO 2 .zSnO 2 ], the content of each component is respectively: Let the content of BaO be m, 13.8 mol%≤m≤18.0 mol%, (1-y)Nd 2 o 3 .ySm 2 o 3 The content is n, 16.0 mol%≤n≤18.0 mol%, where 0.10≤y≤0.9, (1-z)TiO 2 .zSnO 2 The content of is p, 66.0 mol%≤p≤68.0 mol%, wherein 0<z≤0.1, m+n+p=100 mol%. The microwave dielectric ceramic of the present invention has a high dielectric constant of 80-82, low loss (Qf=7500-11000 GHz) and adjustable resonant frequency temperature coefficient. The microwave dielectric ceramics provided by the invention can adapt microwave components such as dielectric resonators and filters to higher frequencies. At the same time, the ceramics provided by the invention can also be applied to high-frequency ceramic capacitors or temperature compensation ceramic capacitors. Therefore, the present invention has great industrial value.

Owner:ZHEJIANG UNIV

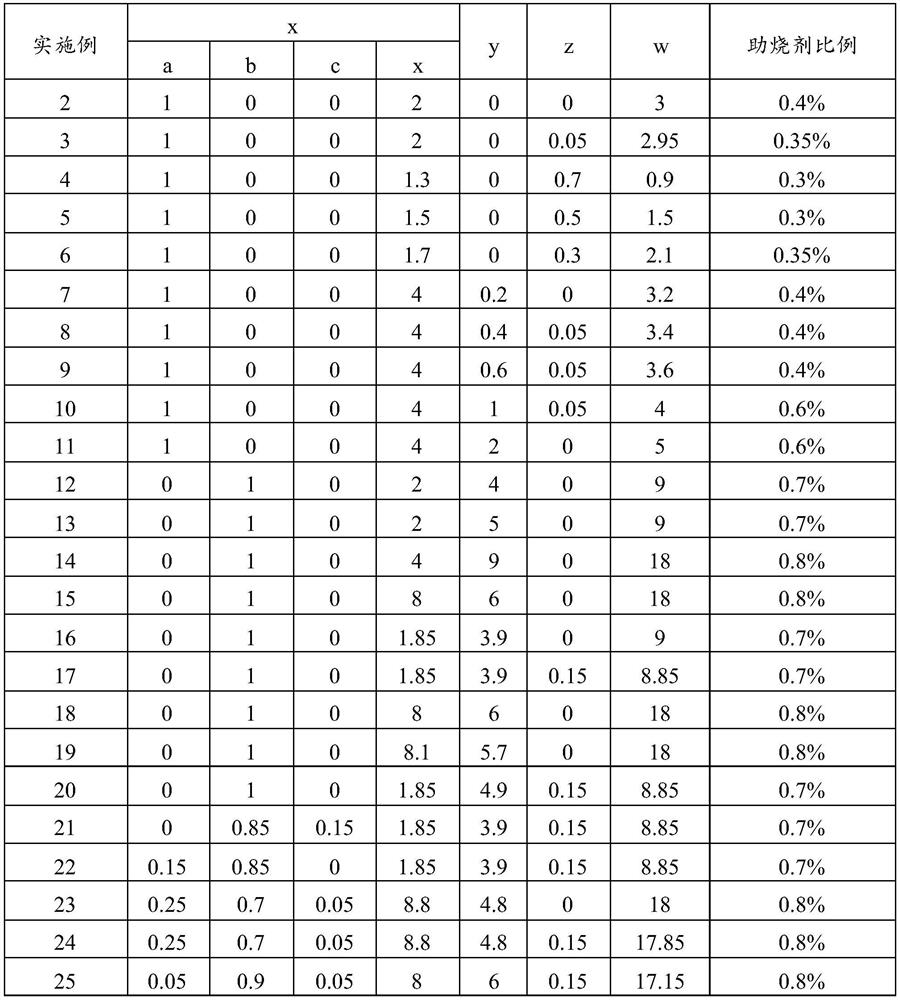

High-performance ceramic material and preparation method thereof

InactiveCN109485412AHigh quality factorResonant frequency temperature coefficient adjustableMicrowaveMetal

The invention provides a high-performance ceramic material. The material is prepared from mMO-yLn2O3-zTiO2 and metal nano-grade additives, wherein M includes Ba and one or two of Ca and Sr; Ln includes La and one or more of Sm, Pm, Nd, Pr and Eu; the metal nano-grade additive includes Zn and one or more of Zr, Sn, Mg, Ni, Co and W; and the sum of x, y and z is 1. The invention further provides a preparation method of the ceramic material. The microwave medium ceramic material has a dielectric constant of 46-48, a relatively high quality factor of 35000-50000GHz, and has the resonance frequencytemperature coefficient being adjustable between negative 12-12ppm / DEG C.

Owner:嘉兴实新企业服务有限公司

Low-temperature sintering Ti-base microwave medium ceramic material and preparation thereof

InactiveCN100591641CLower sintering temperatureHigh dielectric constantCeramicsDielectric lossDielectric resonator

The invention discloses a Ti-based microwave medium ceramics material by low-temperature sintering. The Ti-based microwave medium ceramics material takes rutile TiO2 as a main phase. The general formula of the prescription of the invention is that: (AxM2x)(NyTi1-y)1-3xO2, (BxM3x)(NyTi1-y)1-4xO2, (CxMx)(NyTi1-y)1-2xO2 or (1-m) TiO2-mBi2Ti4O11, wherein, the A is one of bivalent ions such as Zn<2+>,Cu<2+>, Ni<2+>, the B one of univalent ions such as Li<+>, the C one of trivalent ions such as Al<3+>, Fe<3+>, M is one of pentavalent ions such as Nb<5+>, Ta<5+>, Sb<5+>, N one of quadrivalent ions such as Zr< 4+ >, Sn< 4+ >, Mn< 4+ >; the X is more than or equal to 0 and less than or equal to 0.25, the Y more than or equal to 0 and less than or equal to 0.5, the m more than or equal to 0 and less than or equal to 0.15, the n is more than or equal to 0 and less than or equal to 2. The microwave medium ceramics material by low-temperature sintering has the advantages of high dielectric constant, low dielectric loss, wide covering range of temperature coefficient of resonant frequency, low sintering temperature, simple preparation technique and adjustable temperature coefficient of resonantfrequency according to materials. The invention can be used for Low Temperature Co-fired Ceramics System (LTCC system) and used for producing microwave devices such as multi-media resonators, filters, etc.

Owner:XI AN JIAOTONG UNIV

Microwave dielectric materials capable of burning with copper electrodes together, preparation method and application thereof

ActiveCN103146345BModerate dielectric constantHigh quality factorOther chemical processesDielectricCopper electrode

The invention discloses microwave dielectric materials capable of burning with copper electrodes together, a preparation method and application thereof. The microwave dielectric materials comprise: (1-zwt% ) ((ZnxM (1-x) (Til-y / 2Mgy) O3)) + zwt% low-melting-point glass, wherein the M is magnesium or manganese; 0<x <=0.6, 0<y <=0.1, 0<z <=10. According to the microwave dielectric material, dielectric constant is moderate, a quality factor is high, temperature coefficient of resonance frequency is adjustable, burning with the copper electrodes can be achieved. Ceramic materials are insoluble in solvents such as water and ethanol and do not occur gelation reaction with binders such as poly vinyl alcohol (PVA) and polyvinyl butyral (PVB), and ceramic diaphragm with high density can be obtained, and firing density of ceramic can not be reduced, the direction of microwave communication frequency developing to higher frequency can be satisfied. The microwave dielectric materials capable of burning with the copper electrodes together is low in cost and suitable for multi-layer microwave medium components and industrialization production of base plates.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com