Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Paracrystalline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paracrystalline materials are defined as having short- and medium-range ordering in their lattice (similar to the liquid crystal phases) but lacking crystal-like long-range ordering at least in one direction. Ordering is the regularity in which atoms appear in a predictable lattice, as measured from one point. In a highly ordered, perfectly crystalline material, or single crystal, the location of every atom in the structure can be described exactly measuring out from a single origin.

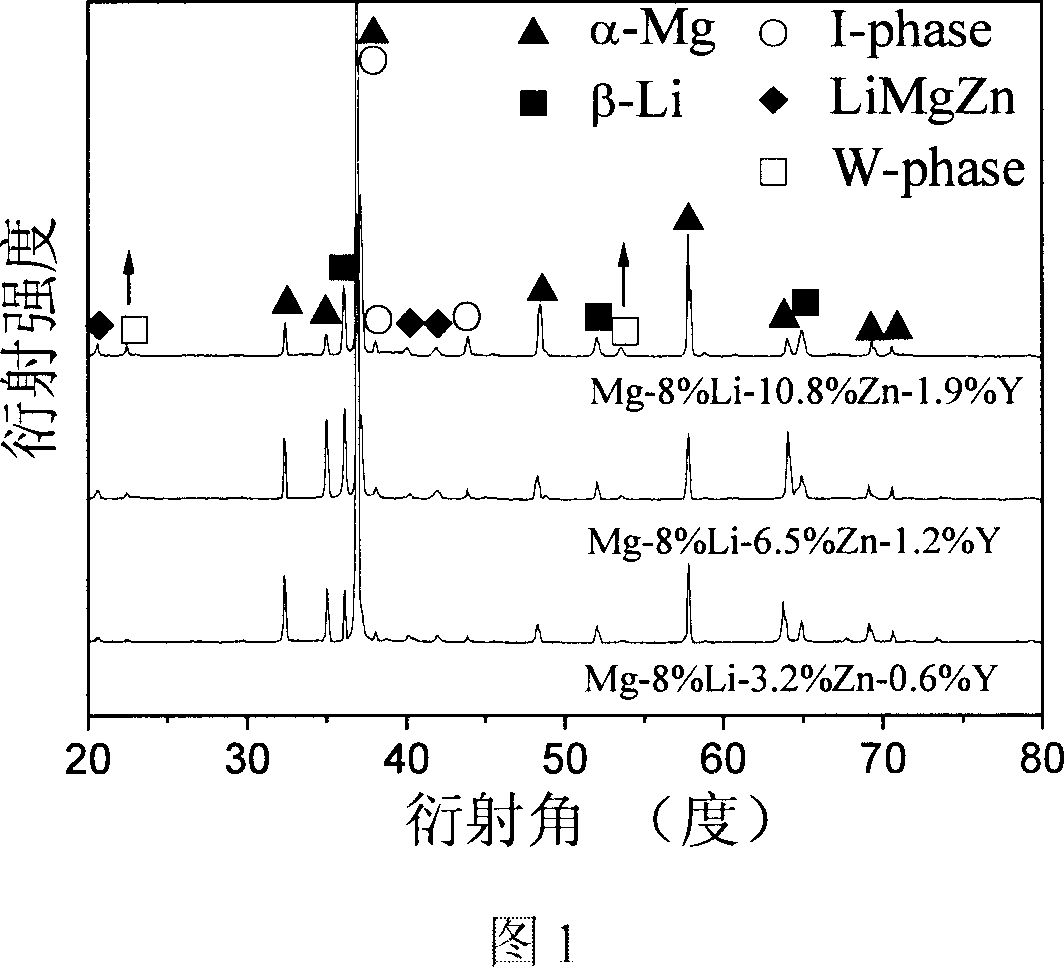

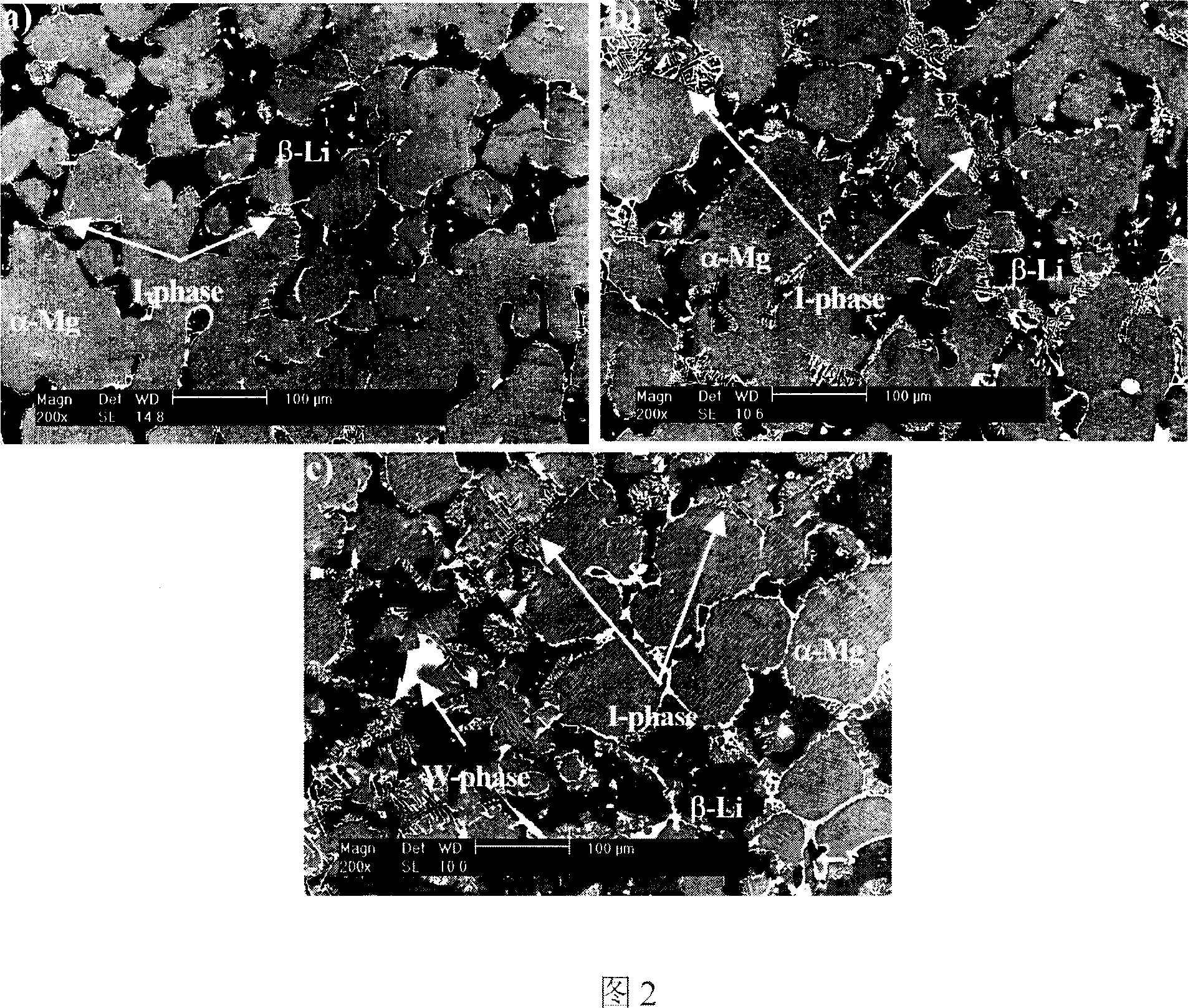

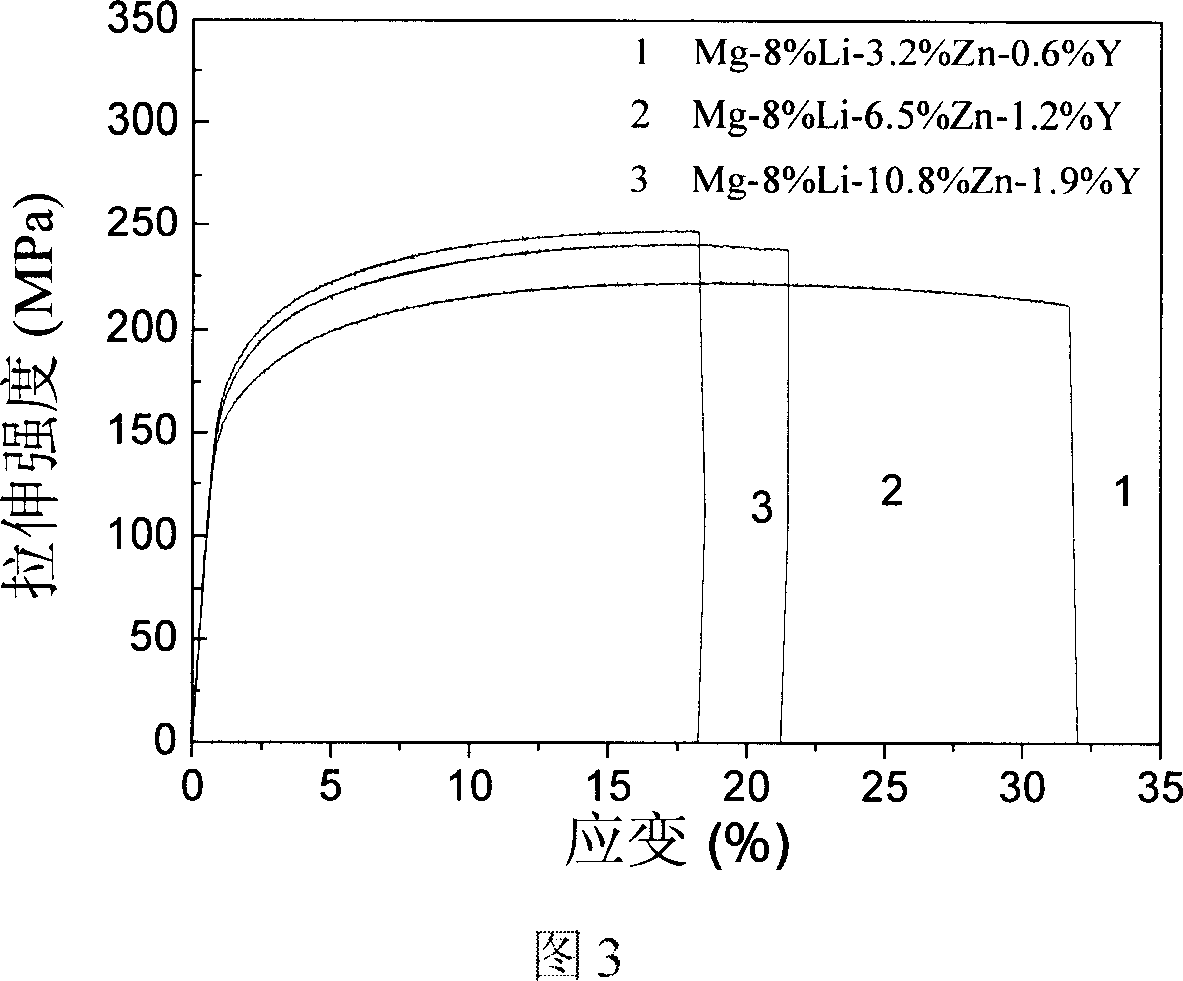

Quasi crystal phase fortified magnesium lithium alloy and its preparation method

The invention relates to Mg-Li alloy with high strength and its preparation techniques. It especially relates to Mg-Li alloy strengthened by quasi-crystalline phase and its preparation techniques, which can solve problems of alloy strengthening. Mg-Li alloy with low density, high strength and good plasticity is prepared by reasonable choosing of alloy elements and introducing quasi-crystalline phase into alloy base. The alloy is two-phase alloys of Mg-Li alloy in alpha-Mg and beta-Li phase areas. Component and content of the alloy are 5.5-11.5% Li, 0.5-15% Zn, 0.1-8% Y, and the allowances are Mg, in which percent is weight proportion. The alloy is made by melting and subsequent processing of hot extrusion and its crafts are simple and convenient to operate. Properties of materials are as follows: tensile strength is sigma b=200-300MPa, yield strength is sigma 0.2=150-260MPa, elongation percentage isdelta=17-65% and density is 1.34-1.83g / cm3.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

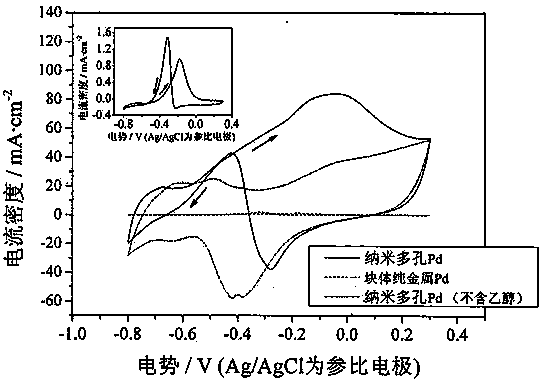

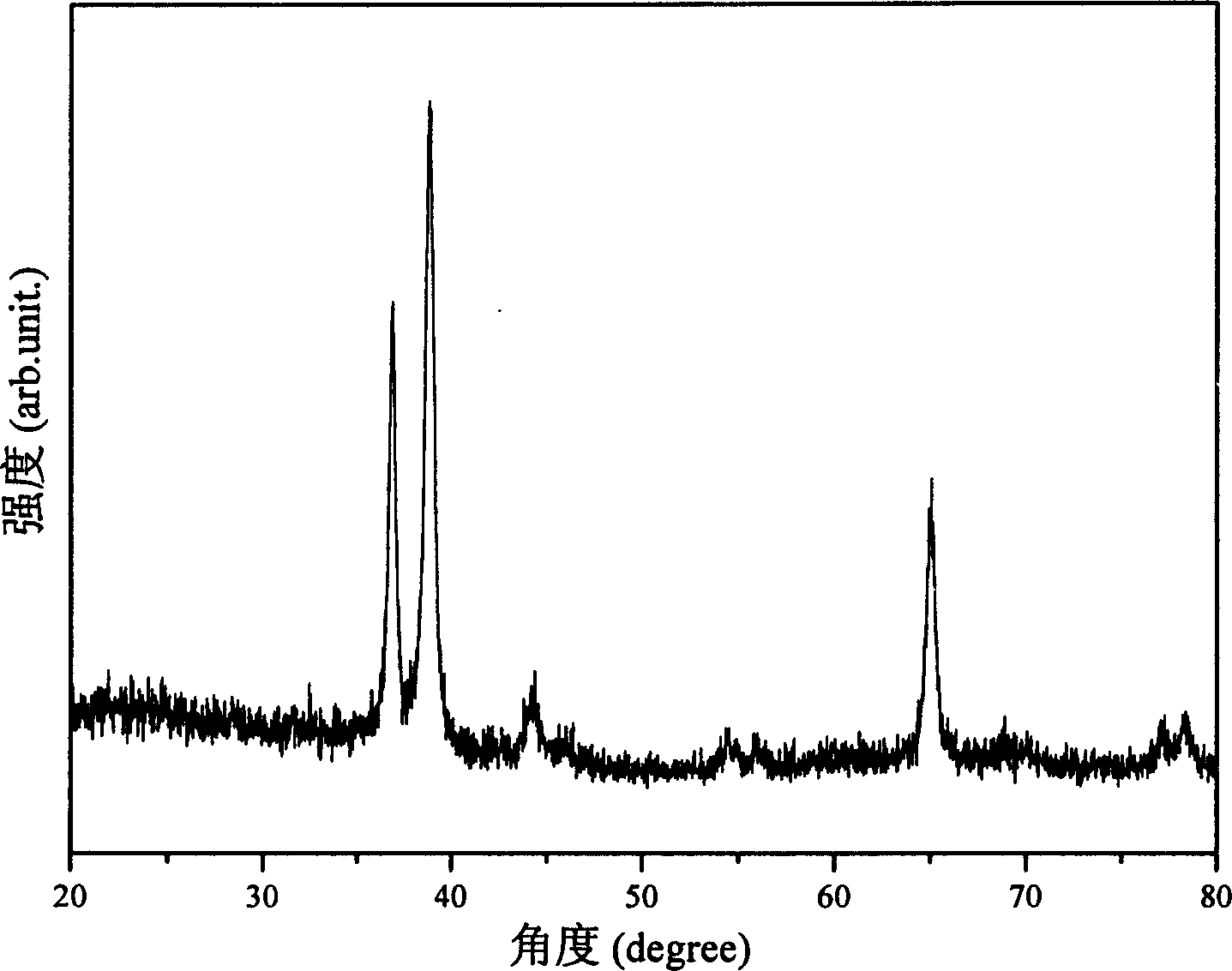

Nano-porous Pd material prepared through quasi-crystal de-alloying and preparation process of nano-porous Pd material

InactiveCN103938014AStructural disorderThe preparation process is simple and environmentally friendlyMaterial nanotechnologyPtru catalystFuel cells

The invention discloses a nano-porous Pd material prepared through quasi-crystal de-alloying and a preparation process of the nano-porous Pd material, belonging to the technical field of new materials. The nano-porous Pd material contains 8-12at.% of Al, less than 1at.% of TM and the balance of Pd in percentage by atom. A precursor namely a quasi-crystal alloy required for preparing the material is low in cost, and the overall technological process is environment-friendly, simple and efficient; a prepared nano-porous structure is complete. The quasi-crystal alloy with special structures is used as the precursor, and the chemical composition of the quasi-crystal alloy is Al1-x-yPdxTMy (TM is Mn, Co, Fe, Cr, V or Mg, wherein x is more than or equal to 10at.% and is less than or equal to 25at.%, and y is more than or equal to 3at.% and is less than or equal to 15at.%); by putting the quasi-crystal alloy into a dilute saline solution under room temperature, the nano-porous Pd material can be obtained through an electro-chemical de-alloying process with a constant-voltage mode in a voltage range of 0-0.2V (a reference electrode is a saturated calomel electrode). Prepared nano-porous Pd is uniform in structure, stable in pore and ligament size and unordered in crystallographic orientation, shows excellent room-temperature ethanol / methanol electro-oxidation reaction catalytic performances in alkaline solutions, can keep the high catalytic performances after being used repeatedly for many times, and can be applied to an anode catalyst of a fuel cell such as an alkaline ethanol cell and the like.

Owner:DALIAN UNIV OF TECH

Regular icosahedron titanium-base quasi-crystal material with hydrogen-storage function and its preparing method

InactiveCN1709564AStrong ability to form quasicrystalsEasy to operateOther chemical processesHigh energyTitanium

The invention provides a kind of single icosahedron quasicrystal material with hydrogen storing function. Its component is Ti100-x-y-zZrxNiyCuz, thereinto, 10 < x < 45, 5 < y < 20, 1 < z < 10. the forming ability of the alloy quasicrystal is strong, and the formed quasicrystal material is single icosahedron structure. It is thermodynamics is stable, and has good hydrogen storing function. It can be applied in gaseous state hydrogen storing material and battery cathode material; meantime, it provides a kind of producing method of the material: according to the count of the component formula of the quasicrystal material, choose powders of Ti, Zr, Ni, and Cu of 100 holes per cm2 chemical purity, encase them in the ball milling pot of the high energy ball mill, the ball material rate is 20 : 1, ball mill for 100 - 200 hours under the protection of argon, seal the ball milled alloy powders in the quartz tube, have heat processing at 1 í‡ 10-3 Pa, the heat processing temperature is 480 - 650 Deg. C, the time is 0.5 - 6 hours. Its craft is simple, the operational ability is strong, and it is easy to be industrialized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing dual special structure combined reinforced Mg-Zn-Y alloy

The invention relates to a method for preparing an icosahedral quasicrystalline phase and long-period stacking ordered structure combined reinforced Mg-Zn-Y alloy. The alloy prepared by the method contains the chemical elements in percentage by mass: 10wt% of Zn and Y and the balance of Mg, wherein Zn is added in the form of pure Zn, Y is added in the form of Mg-25wt%Y intermediate alloy, and Mg is industrial pure magnesium. According to the method, alloy structures, obtained after magnesium alloy is subjected to smelting, metal type molding and solid solution and grading aging treatment, are an alpha-Mg solid solution, an icosahedral quasicrystalline phase and a long-period stacking ordered structure phase; a quasi-crystal, which is formed through dispersion precipitation, depends on strong pinning on dislocation and forms a firm interface with a matrix, so that the magnesium alloy can be remarkably reinforced; a long-period structure and a matrix interface are in coherency, so that the thermal stability is very high, the coarsening is not easy, the dislocation motion and the extension of deformation twin crystals can be remarkably hindered, the mechanical properties of the alloy are improved obviously, the tensile strength can reach 352MPa to the maximum, and the elongation percentage can reach 7.5%. The method is beneficial to the promotion of the extensive application of high-strength magnesium alloy in many fields, such as automobiles, aviation and electronic communication.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy by means of equal channel angular pressing

ActiveCN107815579AImprove mechanical propertiesExpand the range of industrial applicationsFurnace temperatureThermal treatment

The invention discloses a method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy by means of equal channel angular pressing. The method includes the following steps that A, cast-state Mg-Zn-Y alloy is prepared according to the set atomic percentage composition ratio of all components and comprises 0.5%-6% of Zn, 0.08%-1.2% of Y and the balance Mg based on the set atomic percentage composition of all the components, and the atomic percentage composition specific value of the Zn to the Y is 5-7:1; B, the cast-state Mg-Zn-Y alloy is annealed for 8-20h at the temperature of 380-420 DEG C, and furnace cooling is conducted; C, the annealed Mg-Zn-Y alloy is subjected to hot extrusion after heat preservation lasts for 2-4h at the temperature of 300-400 DEG C, the extrusion temperature is300-400 DEG C, and the extrusion ratio is 9-60:1; D, the Mg-Zn-Y alloy processed through hot extrusion in the step C is put into a thermal treatment furnace, the furnace temperature rises to 540-600DEG C, heat preservation lasts for 5-20min, and quenching is performed; and E, the Mg-Zn-Y alloy obtained in the step D is subjected to equal channel angular pressing after heat preservation lasts for2-4h at the temperature of 180-330 DEG C, and accordingly the nano quasi-crystal reinforced Mg-Zn-Y alloy can be obtained. By adoption of the method, the high-performance magnesium alloy with good yield strength, tensile strength and ductility can be prepared.

Owner:SOUTHWEST JIAOTONG UNIV

Low-temperature diffusion bonding method for adding quasi-crystal interlayers to aluminum-steel-aluminum

InactiveCN104191085APrecise control of process parametersLow costWelding/soldering/cutting articlesNon-electric welding apparatusParacrystallineAlloy

The invention discloses a low-temperature diffusion bonding method for adding quasi-crystal interlayers to aluminum-steel-aluminum. The method includes the main steps that quasi-crystal aluminum silicon copper middle transition alloy foil sheets are arranged between contact interfaces to be welded of aluminum plates and contact interfaces to be welded of a low-carbon steel plate, vacuum diffusion bonding is conducted, processing parameters are that the bonding temperature is controlled in the range of 420 degrees to 490 degrees, the heat preservation time under the bonding temperature ranges from 15 min to 25 min, the pressure ranges from 0.3 MPa to 0.9 MPa, and the vacuum degree is 1.33*10<-3> Pa-1.33*10<-2> Pa. By means of the method, low-temperature diffusion bonding of the aluminum and the low-carbon steel can be achieved, the diffusion interfaces of the formed aluminum-steel-aluminum composite structure is firm in combination, reliable in bonding quality and high in production efficiency. The low-temperature diffusion bonding method for adding the quasi-crystal interlayers to aluminum-steel-aluminum has the advantages of being precise in processing parameter control, low in cost and the like, and the bonding temperature can be reduced.

Owner:SHANDONG UNIV

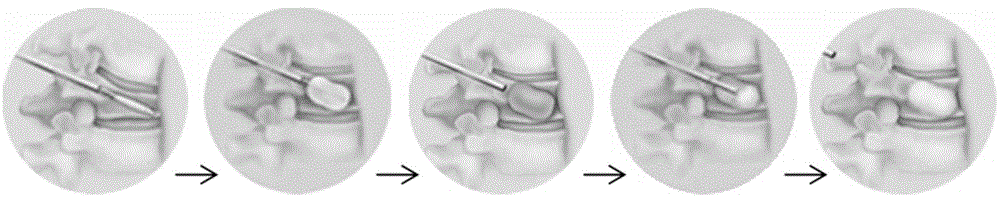

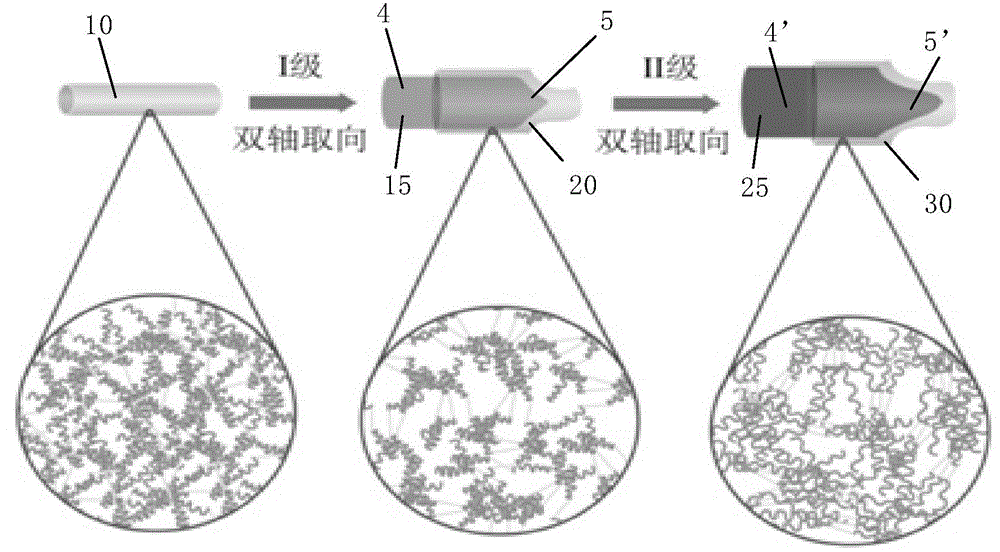

Self-enhanced thin-wall miniature balloon and manufacturing method thereof

The invention relates to a self-enhanced thin-wall miniature balloon and a manufacturing method of the self-enhanced thin-wall miniature balloon. The balloon is made of a thermoplastic elastomer, wherein the length of the balloon ranges from 12 mm to 22 mm, the outer diameter of the balloon ranges from 8 mm to 12 mm, and the ratio of annular strength to axial strength of the balloon is 1-2. A thermoplastic elastomer tube blank is dilated multiple times in the axial direction and the annular direction through a heating and dilating stick to obtain double-axis dilated orientation tube stock; a balloon die is arranged in an inner cavity of the double-axis dilated orientation tube stock, the two ends of the tube stock are pulled to stretch outwards after being heated, and then a balloon tube is obtained; the balloon tube is sleeved with a stainless steel gas tube, gas is fed into the balloon tube, the balloon tube is heated to expand, and the balloon is obtained after cooling and shaping. According to the method, a soft and hard embedded segment structure of the thermoplastic elastomer is utilized ingeniously, polymers are subjected to ordered orientation arrangement in the stress direction through multiple times of double-axis dilated orientation, hard segment phases form a paracrystalline or crystalline structure, the number of physical cross-links is increased, the tube stock is reinforced in the annular direction, and the tearing strength of the manufactured balloon is greatly enhanced.

Owner:EAST CHINA UNIV OF SCI & TECH

Laser holography interference method of similar-one-dimensional structure for preparation

The invention belongs to the technical field of laser holography interference and relates to a laser holography interference method of a similar-one-dimensional structure for preparation. The laser holography interference method comprises the steps of firstly taking five laser beams through a laser device and enabling the laser beams to be symmetrically distributed and converged in the vertical direction, adding a single dielectric film high-reflexivity mirror at the converged position of the five laser beams, reflecting the five laser beams through the single dielectric film high-reflexivity mirror to produce five mirror image light beams consistent to original laser beam parameters, and then selecting exposure quantity according to the selected laser beams to obtain a quasi-crystal-period three-dimensional model; then adopting a polarization adjusting technical method and utilizing a single-wave-length half-wave plate to adjust polarization angles of the five laser beams from 0 degree to 90 degrees, namely obtaining the similar-one-dimensional structure laminated structure. The laser holography interference method is simple, reliable in principle, controllable in process, simple and convenient to operate, low in cost, high in repeatability, easy to achieve and capable of being widely applied to preparation of multiple light-sensitive media.

Owner:QINGDAO UNIV OF SCI & TECH

SPR-based high-sensitivity photonic quasi-crystal fiber methane sensor

ActiveCN112945905AHigh sensitivityEasy to MiniaturizePhase-affecting property measurementsFiberParacrystalline

The invention relates to a methane sensor, in particular to a SPR-based high-sensitivity photonic quasi-crystal fiber methane sensor, the methane sensor is a photonic quasi-crystal fiber, a cladding of the methane sensor is composed of two layers of air holes arranged according to a sextuple Penrose type quasi-crystal structure, the first layer is provided with six inner layer air holes, and the surrounding area is a fiber core; the second layer comprises eight outer-layer air holes, wherein the diameters of four inner-layer air holes above and below the fiber core are smaller than the diameters of the other two inner-layer air holes; and the photonic quasi-crystal fiber is made of silicon dioxide, the two sides of the photonic quasi-crystal fiber are symmetrically and laterally polished, the two laterally polished surfaces are plated with silver films, the surfaces of the silver films are coated with methane sensitive films, and the double-sided structure can effectively enhance the surface plasma resonance effect. The methane sensor is simple in structure, easy to manufacture and high in sensitivity, and the detection difficulty is reduced.

Owner:NORTHEAST GASOLINEEUM UNIV

Method for manufacturing amorphous alloy thin strip through Mg-Zn-Gd quasi-crystal alloy

The invention relates to a method for preparing an amorphous alloy thin strip through Mg-Zn-Gd quasi-crystal alloy. The method is characterized in that on the basis of successfully preparing the Mg-Zn-Gd quasi-crystal alloy, components for forming quasi-crystals are selected for successfully preparing the amorphous alloy and include, by mass, 45.32-48.29% of Zn, 11.61-18.16% of Gd and the balance Mg. The method includes the steps that the Mg-Zn-Gd quasi-crystal alloy which is high in quasi-crystal content and even in texture is obtained; technology parameters of the quasi-crystal intermediate alloy are adjusted through a fast solidification method; and the amorphous alloy thin strip prepared through the Mg-Zn-Gd quasi-crystal alloy is obtained, wherein the maximum length of amorphous alloy thin strip samples obtained in experiments is 250 cm. According to the preparing method for the amorphous alloy thin strip through Mg-Zn-Gd quasi-crystal alloy, the obtained amorphous alloy thin strip has the characteristic of a melt of the quasi-crystal alloy and also has the typical steamed bread peak of amorphous alloy and the exothermic peak in the heating process of differential thermal analysis. The application range of magnesium alloy in practical production and life can be further improved through the amorphous alloy thin strip prepared through the method.

Owner:UNIV OF JINAN

Quasi-crystal coating, cooker and cooking appliance

ActiveCN110760778AGood non-stickStrong corrosion resistanceCooking-vessel materialsMolten spray coatingMetallurgyValence electron

The invention provides a quasi-crystal coating, a cooker and a cooking appliance. According to the embodiment of the quasi-crystal coating, the cooker and the cooking appliance, the quasi-crystal coating contains quasi-crystals, and the valence electron concentration of the quasi-crystals is 1.5-2.5. Therefore, the quasi-crystal content in the quasi-crystal coating is high, and non-stick performance, strength and corrosion resistance of the quasi-crystal coating can be greatly improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

A kind of quasicrystal strengthened casting magnesium-lithium alloy and preparation method thereof

ActiveCN110592449BGuaranteed uniformityImprove distribution uniformityFurnace temperatureParacrystalline

The invention discloses a quasi-crystal strengthened cast magnesium-lithium alloy and a preparation method thereof, belonging to the technical field of cast alloys. The invention aims to solve the problem that the uniform distribution of quasicrystals cannot be controlled when the number of quasicrystal phases is increased in the existing quasicrystal strengthened cast magnesium-lithium alloy. The quasicrystalline strengthened cast magnesium-lithium alloy of the present invention contains 8%-15% Li, 5%-8% Zn, 0-15% Al, 0-5% Y, and 0-5% in mass percent Gd, the rest is Mg. When preparing the quasi-crystalline strengthened cast magnesium-lithium alloy, the quasi-crystalline phase is added to the alloy melt in batches in the form of hollow spheres. After the addition, the melt is kept at 720-740°C for 30 minutes, and the furnace temperature is adjusted to 680-700°C before pouring into a mold to form an alloy ingot. The invention achieves the purpose of increasing the quasi-crystal content and simultaneously improving its distribution uniformity, and the distribution uniformity of the as-cast quasi-crystal strengthening phase is increased by more than 80%.

Owner:HARBIN INST OF TECH

Zirconium-based tough nanocrystalline alloy material and preparation method thereof

ActiveCN112522644AImprove thermal stabilityImprove toughnessMaterial nanotechnologyTemperature control deviceParacrystallineToughness

The invention discloses a zirconium-based tough nanocrystalline alloy material and a preparation method thereof. The zirconium-based tough nanocrystalline alloy material comprises following componentsas shown in the following expression of Zr65Al7.5Ni10CuaAub, wherein a and b respectively represent atomic percentages of Cu and Au elements, and a and b satisfy the following conditions: 2.5<=a <=11.5, 6<=b<=15, and a+b =17.5. According to the method, a zirconium-based amorphous alloy strip is rolled at the temperature of minus 200 to minus100 DEG C by an ultralow-temperature rolling method, sothat the alloy strip with a nano quasi-crystal / amorphous composite structure is obtained. The zirconium-based tough nanocrystalline alloy material obtained through the ultralow-temperature rolling method has good bending toughness and room-temperature stability, the defect that in the prior art, a quasicrystal composite structure material is usually brittle at the room temperature is overcome, andthe zirconium-based tough nanocrystalline alloy material can be used in the field of nanometer quasicrystal / amorphous composite structure materials with certain requirements for toughness and stability.

Owner:TIANJIN UNIV

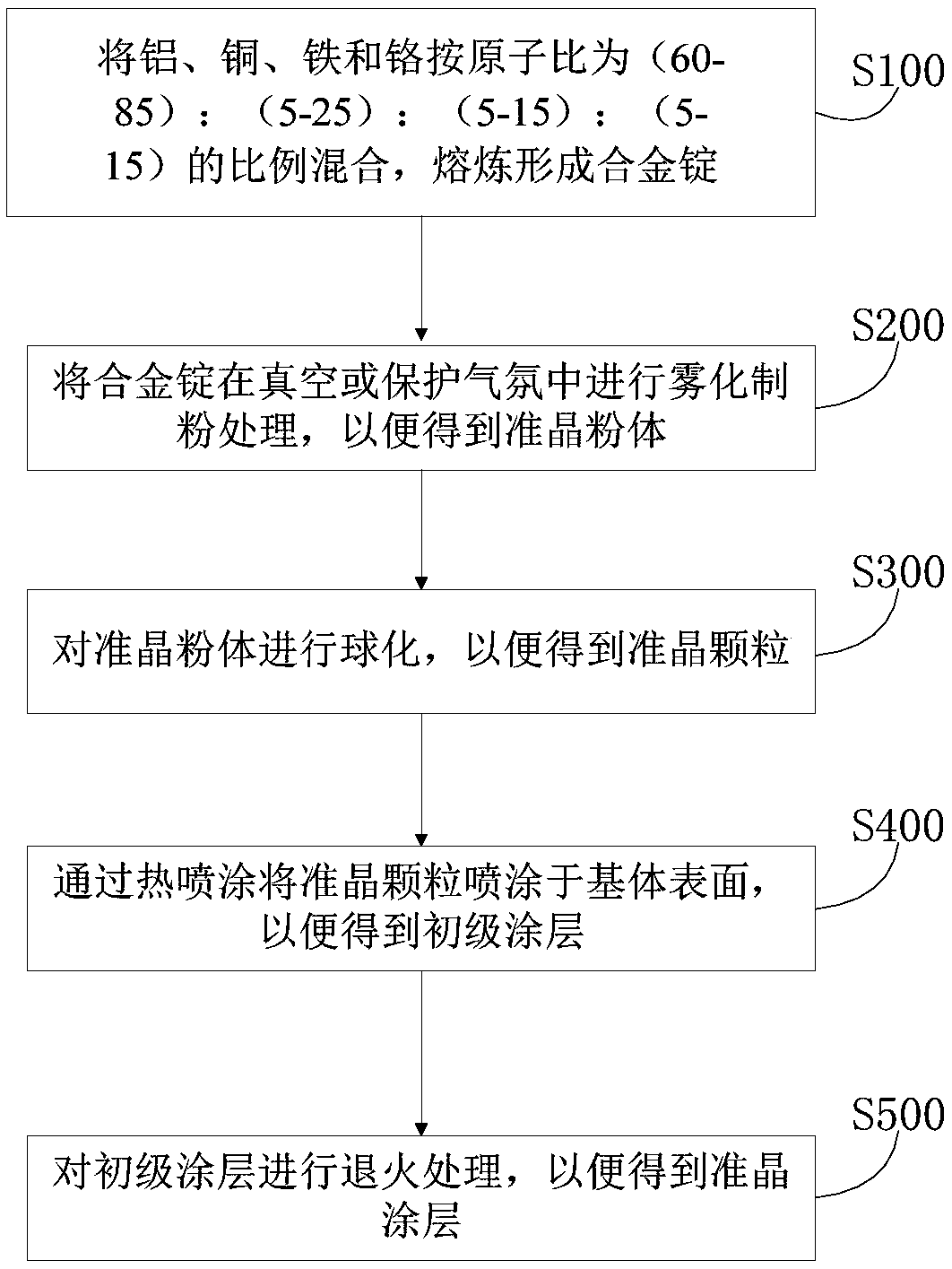

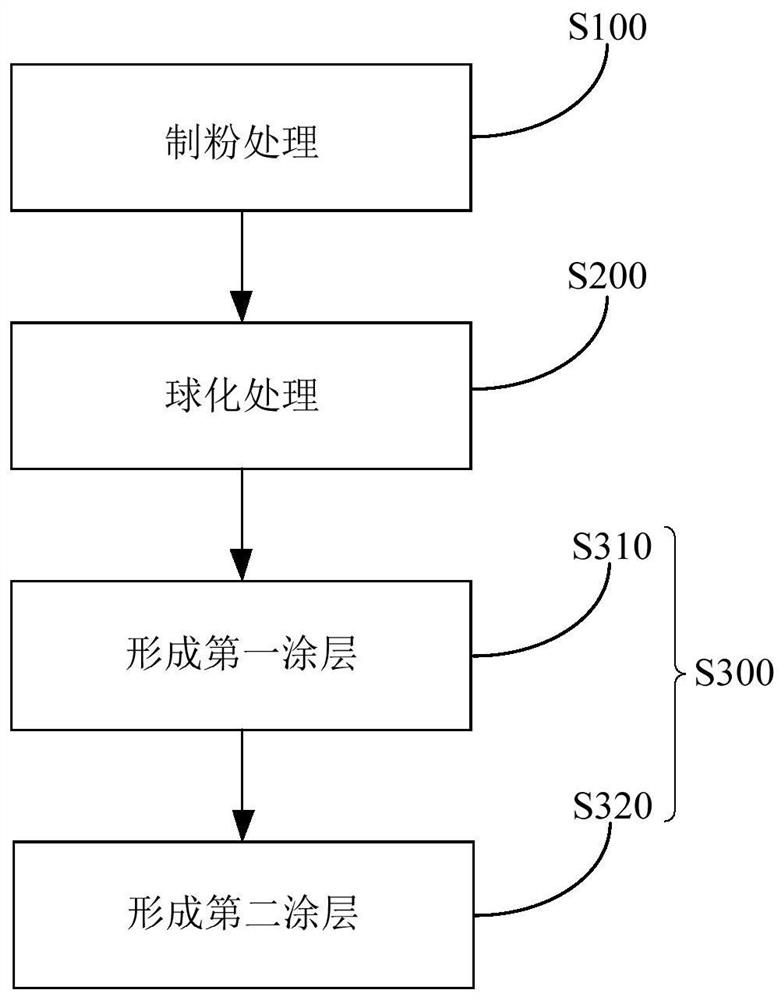

Method and system for forming quasi-crystal coating and cookware

ActiveCN110756816AIncreased quasicrystal contentHigh hardnessCooking-vessel materialsMolten spray coatingCrystallographyMetallurgy

The invention discloses a method and a system for forming a quasi-crystal coating and cookware. The method for forming the quasi-crystal coating comprises the steps as follows: (1), a primary coatingis formed on a substrate on the basis of quasi-crystal powder; and (2), the primary coating is subjected to annealing treatment to obtain the quasi-crystal coating. According to the method for formingthe quasi-crystal coating, the primary coating formed by the quasi-crystal powder is subjected to the annealing treatment, so that the surface properties of the quasi-crystal coating can be effectively improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

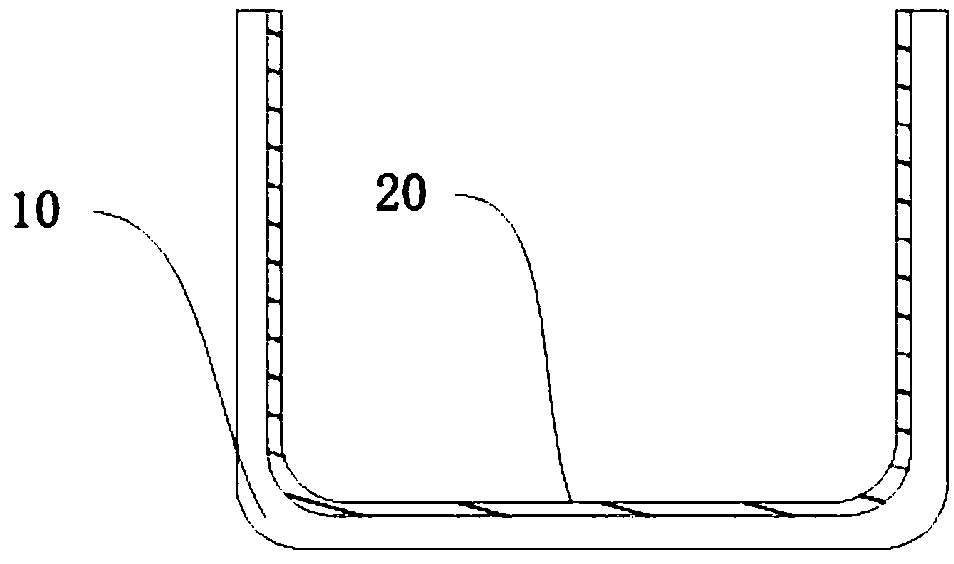

Pot and cooking utensil

ActiveCN113455912AImprove uniformityImprove hydrophobicityCooking-vessel materialsPressure-cookersParacrystallinePhysical chemistry

The invention provides a pot and a cooking utensil. The pot comprises a pot body; and a titanium-based crystal coating which is arranged on the inner surface of at least one part of the pot body and comprises an icosahedron quasicrystal phase. Therefore, the titanium-based crystal coating has better corrosion resistance and non-stickiness, so that pitting corrosion can be effectively avoided when the cookware is used in an acidic aqueous solution containing more chloride ions, the corrosion resistance of the cookware is improved, and the service life of the cookware is prolonged; in addition, due to the icosahedron quasicrystal phase, the surface energy of the titanium-based crystal coating is low, and the non-stickiness of the titanium-based crystal coating can be further improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

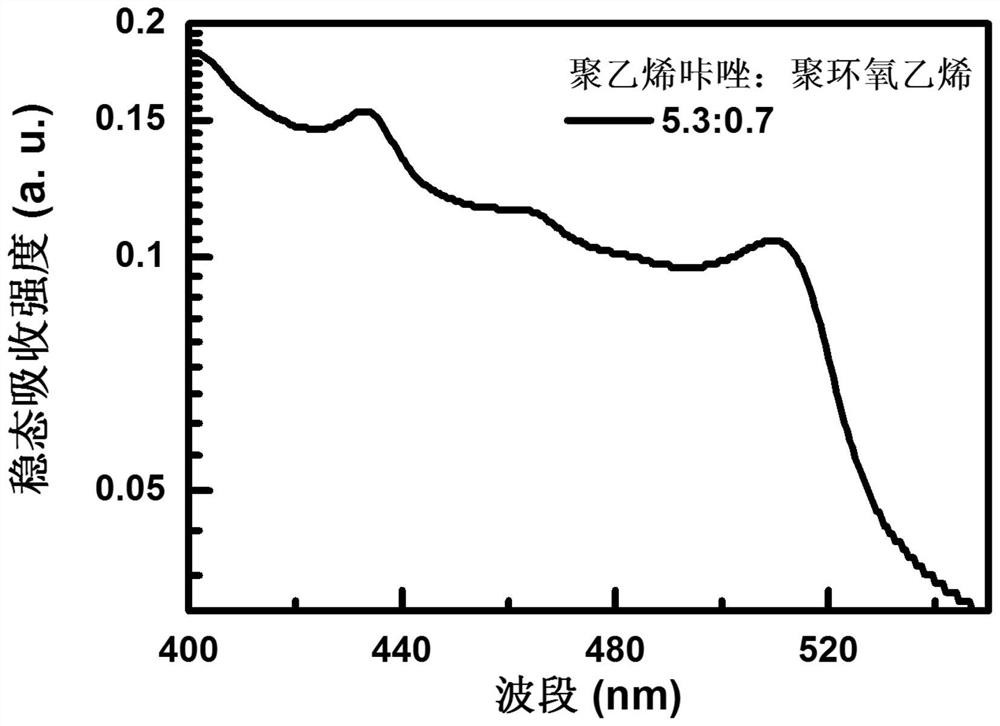

Modified hole transport layer perovskite light emitting diode and preparation method thereof

PendingCN111933814AReduce defectsImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyElectron hole

The invention discloses a modified hole transport layer perovskite light emitting diode and a preparation method thereof, relates to the field of photoelectric devices, and solves the problem of low performance of an existing perovskite light emitting diode photoelectric device. The light emitting diode comprises a hole transport layer used in the perovskite light emitting diode device. The hole transport layer is made of a blended solution comprising polyvinylcarbazole and polyepoxyethylene, and the hole transport layer is used as an attachment for rotary coating of a PEABr DMSO solution. ThePEABr DMSO solution forms a two-dimensional quasi-crystal structure on the hole transport layer. The brightness of the prepared photoelectric device is obviously improved, the lumen efficiency of theprepared photoelectric device is obviously improved, the external quantum efficiency of the prepared photoelectric device is obviously improved, and meanwhile, compared with all literatures reportedat present, the optimal performance effect is achieved.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Cooker and preparation method thereof and cooking utensil

InactiveCN111139433AGood non-stickNon-stick panCooking-vessel materialsVacuum evaporation coatingMetallurgyParacrystalline

The invention provides a cooker and a preparation method thereof and a cooking utensil. The cooker comprises a cooker body and a quasi-crystal coating film. The quasi-crystal coating film is arrangedon the inner surface of the cooker body, and the quasi-crystal coating film is prepared through magnetron sputtering or multi-arc ion plating. Thus, the quasi-crystal coating film is high in density,and good heat conductivity is achieved while the non-stick performance is met. The quasi-crystal coating film serves as the inner surface coating of the cooker, heat can be transferred to conditionedmatter (food in contact with the cooker), and therefore the cooker has good non-stick performance, hardness and corrosion resistance; the quasi-crystal coating film is smooth in surface, the non-stickperformance of the cooker can be further improved, and cleaning is convenient; and in addition, the quasi-crystal coating film is dense and can be attached to the surface of the cooker body forcefully.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Pot and cooking utensil comprising same

InactiveCN110754955AGood non-stickExcellent and long-lasting non-stickCooking-vessel materialsParacrystallineFood science

The invention discloses a pot and a cooking utensil comprising the same. The pot comprises a pot body and a quasi-crystal layer, wherein the quasi-crystal layer is formed on the inner surface of the pot body, and the surface of the quasi-crystal layer is a silver quasi-crystal reflecting surface. The pot not only has the excellent and lasting non-stick performance, but also facilitates uniform heating of food during food cooking and achieves the effect of energy saving.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Frying pan and preparation method thereof

ActiveCN110754915AExcellent anti-rustFunction increaseCooking-vessel materialsCoatingsParacrystallineSS - Stainless steel

The invention discloses a frying pan and a preparation method thereof. The frying pan comprises a pan body formed by an iron-based material and a quasi-crystal coating formed by a quasi-crystal material and formed on the inner surface of the pan body. According to the frying pan in the embodiment, the quasi-crystal coating is formed on the inner surface of the pan body, the quasi-crystal coating has good bonding force with the pan body and is not prone to falling off, and the quasi-crystal coating also has the non-stick performance, so that the shortcomings that an iron frying pan is easy to rust and sticky are overcome. In addition, the inventor also discovers that the quasi-crystal coating is sprayed on the iron frying pan made of a carbon steel material, and the corrosion resistance ofthe quasi-crystal coating is close to that of 304 austenitic stainless steel and is obviously superior to that in an existing nitriding process. According to the frying pan in the embodiment, nitriding treatment of the iron frying pan can be omitted, the frying pan also has good non-stick performance and corrosion resistance, and the performance is obviously superior to that of the existing iron frying pan.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

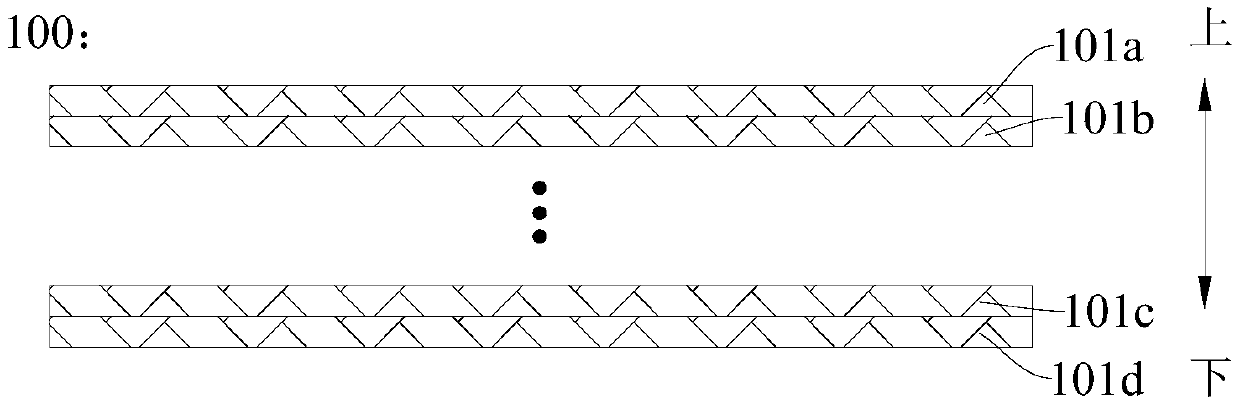

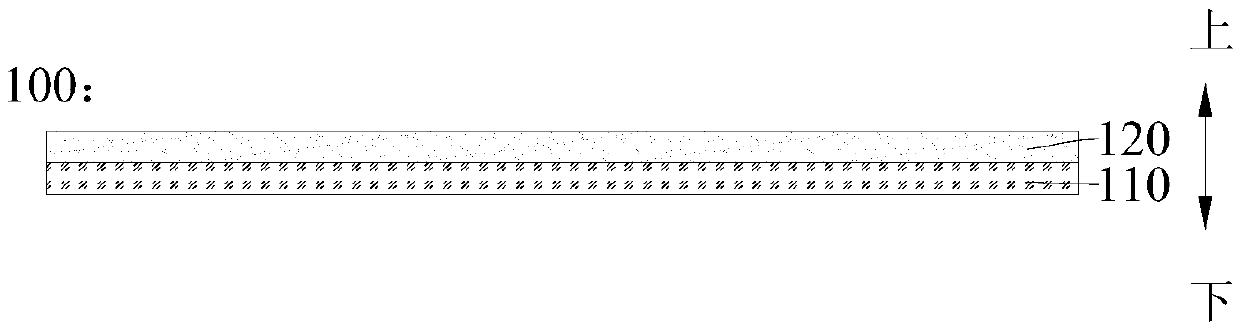

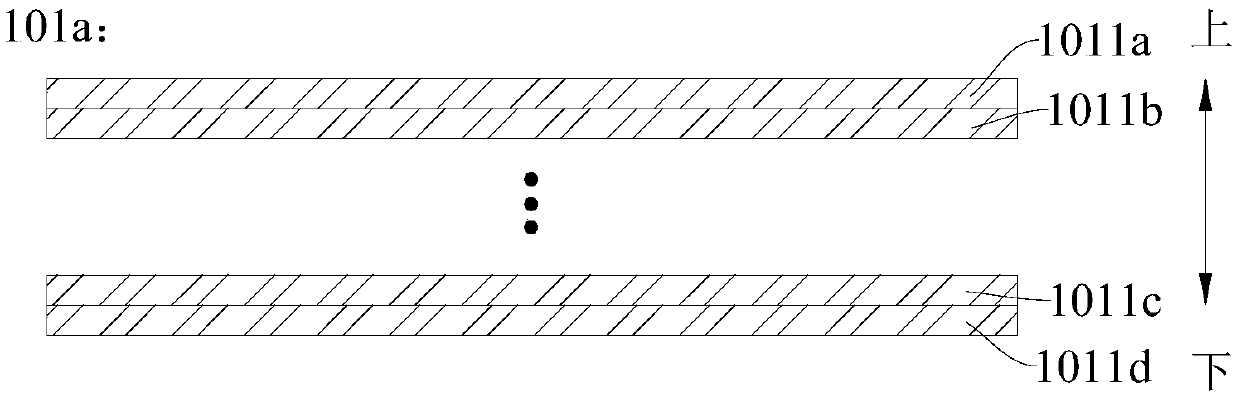

Coating and cooking utensil

ActiveCN110754951AGood non-stickSimple preparation processCooking-vessel materialsPressure-cookersPolymer scienceParacrystalline

The invention relates to a coating, a preparation method thereof and cooking utensil. The coating comprises multiple sub-coatings containing quasi-crystal materials, wherein the multiple sub-coatingsare sequentially stacked from bottom to top, and the particle size of the quasi-crystal material in at least one coating is greater than that of the quasi-crystal material in at least one above sub-coating. The coating disclosed by the invention is good in non-stickness, low in cost, simple in preparation process, easy to industrialize, and especially suitable for the cooking utensil.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Preparation method of terrace-shaped appearance Al-Cu-Fe quasi crystal block material

A preparation method of a terrace-shaped appearance Al-Cu-Fe quasi crystal block material mainly includes the steps of mixing and pressing 52-57% of high-purity Al powder, 40-42% of Cu powder and 3-6% of Fe powder into a prefabricated blank, putting the prefabricated blank in a crucible in a graphite composite heating body, sealing the crucible with pyrophyllite, putting the crucible in a drying box at the temperature of 180 DEG C to remove adsorbed moisture, putting the dried h-BN crucible and the graphite composite heating body in a cavity of a hinge type cubid press, conducting synthesizing at pressure of 3-6 GPa, keeping the temperature at 1273 K to 1373 K for 30-60 minutes, lowering the temperature to 973-1073 K, and keeping the temperature for 2-3 hours to obtain the terrace-shaped appearance Al-Cu-Fe quasi crystal block material. The method is simple, effective and stable in process, the prepared quasi material is dense, extremely-high condensation speed required for reaction is decreased, and the terrace-shaped appearance quasi crystal block material can be obtained within a wide component range.

Owner:YANSHAN UNIV

A kind of preparation method of quasi-single crystal perovskite thin film

ActiveCN110534654BEasy to operateSuitable for large-area industrial applicationsSolid-state devicesSemiconductor/solid-state device manufacturingParacrystallinePhysical chemistry

The invention discloses a method for preparing a quasi-single-crystal perovskite film, comprising: step 1, preparing a small-grain perovskite ABX3 film with a grain size less than or equal to 300 nm on the surface of a substrate; step 2, comprising step 1 The prepared small-grain perovskite ABX3 film substrate is transferred to a closed device containing a saturated atmosphere of AX, heated to a temperature of 50-400°C and kept for 5-90min; Rapid growth occurs under the condition of the quasi-single crystal perovskite thin film. In the present invention, the prepared small-grain perovskite film is placed in a closed environment containing the saturated vapor pressure of AX, so that the perovskite film is dissolved and crystallized into a quasi-single crystal perovskite film in the saturated vapor of AX, greatly reducing the Defects are eliminated, and the defect density is reduced. Moreover, surface and grain boundary defects caused by organic cations or halide anions escaping from perovskite during the preparation of quasicrystalline perovskite are avoided.

Owner:杨冠军

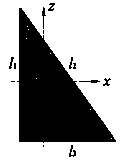

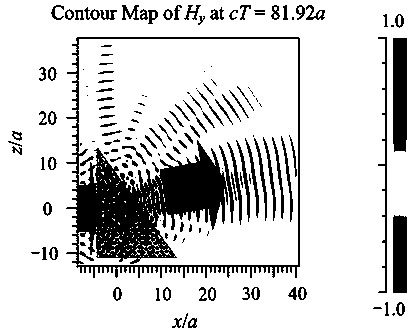

Double-linear track detecting method of refraction effect of two-dimensional photonic quasi-crystal wedge lens

InactiveCN102749189BEquivalent Refractive IndexTesting optical propertiesPhotonic crystalParacrystalline

The invention provides a double-linear track detecting method of a refraction effect of a two-dimensional photonic quasi-crystal wedge lens, which relates to a double-linear track detecting method. According to the invention, the double-linear track detecting method comprises the following steps of: arranging two linear tracks parallel to a bevel edge of the two-dimensional photonic quasi-crystal wedge lens; and according to opposite positions of the two tracks and the bevel edge as well as maximum strength positions detected on the two tracks, determining a refraction angle and effective index of a refracted beam as well as an emission position and emission position offset of the refracted beam through a geometrical relationship and a refraction law, so as to determine the refraction effect of the two-dimensional photonic quasi-crystal wedge lens. The double-linear track detecting method provided by the invention can be applied to any electromagnetic wave and any two-dimensional N-fold quasi-crystal wedge lens. The double-linear track detecting method provided by the invention is suitable for the field of photonic crystals, in particular photonic quasi-crystals. Meanwhile, according to the invention, a problem that the refraction angle and the effective index cannot be accurately detected or calculated by the traditional single circular arc track detecting method is also solved.

Owner:HARBIN INST OF TECH

A kind of ER-containing quasicrystal strengthened magnesium-lithium alloy and preparation method thereof

ActiveCN108456814BPlay a reinforcing rolePlay the role of fine grain strengtheningSolution treatmentSmelting process

The invention discloses an Er-contained quasi-crystal reinforced magnesium-lithium alloy and a preparation method thereof. The magnesium-lithium alloy comprises, by weight, the following components: 10-16% of Li, 0.5-6% of Zn, 0.2-4% of Er, 0-0.6% of Zr and the balance being Mg and inevitable impurities. The preparation method of the quasi-crystal reinforced magnesium-lithium alloy comprises the following steps of two processes of smelting and heat treatment, wherein the smelting process comprises the following steps of: melting, stirring, standing and preserving heat and casting; and the heattreatment process comprises solution treatment and aging treatment. According to the invention, Zn and Er are introduced to form a quasi-crystalline phase, the mass ratio of Zn and Er is 1:1-8:1, thestrength and the thermal stability of the magnesium-lithium alloy can be obviously improved, and trace ZrCl4 mixed salt ZrCl4-LiCl-LiF-CaF2 is added into the alloy, so that the alpha-Mg grains are obviously refined.

Owner:SHANGHAI JIAO TONG UNIV

A method for preparation of nano-quasicrystalline reinforced mg-zn-y alloy by equal channel angular extrusion

The invention discloses a method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy by means of equal channel angular pressing. The method includes the following steps that A, cast-state Mg-Zn-Y alloy is prepared according to the set atomic percentage composition ratio of all components and comprises 0.5%-6% of Zn, 0.08%-1.2% of Y and the balance Mg based on the set atomic percentage composition of all the components, and the atomic percentage composition specific value of the Zn to the Y is 5-7:1; B, the cast-state Mg-Zn-Y alloy is annealed for 8-20h at the temperature of 380-420 DEG C, and furnace cooling is conducted; C, the annealed Mg-Zn-Y alloy is subjected to hot extrusion after heat preservation lasts for 2-4h at the temperature of 300-400 DEG C, the extrusion temperature is300-400 DEG C, and the extrusion ratio is 9-60:1; D, the Mg-Zn-Y alloy processed through hot extrusion in the step C is put into a thermal treatment furnace, the furnace temperature rises to 540-600DEG C, heat preservation lasts for 5-20min, and quenching is performed; and E, the Mg-Zn-Y alloy obtained in the step D is subjected to equal channel angular pressing after heat preservation lasts for2-4h at the temperature of 180-330 DEG C, and accordingly the nano quasi-crystal reinforced Mg-Zn-Y alloy can be obtained. By adoption of the method, the high-performance magnesium alloy with good yield strength, tensile strength and ductility can be prepared.

Owner:SOUTHWEST JIAOTONG UNIV

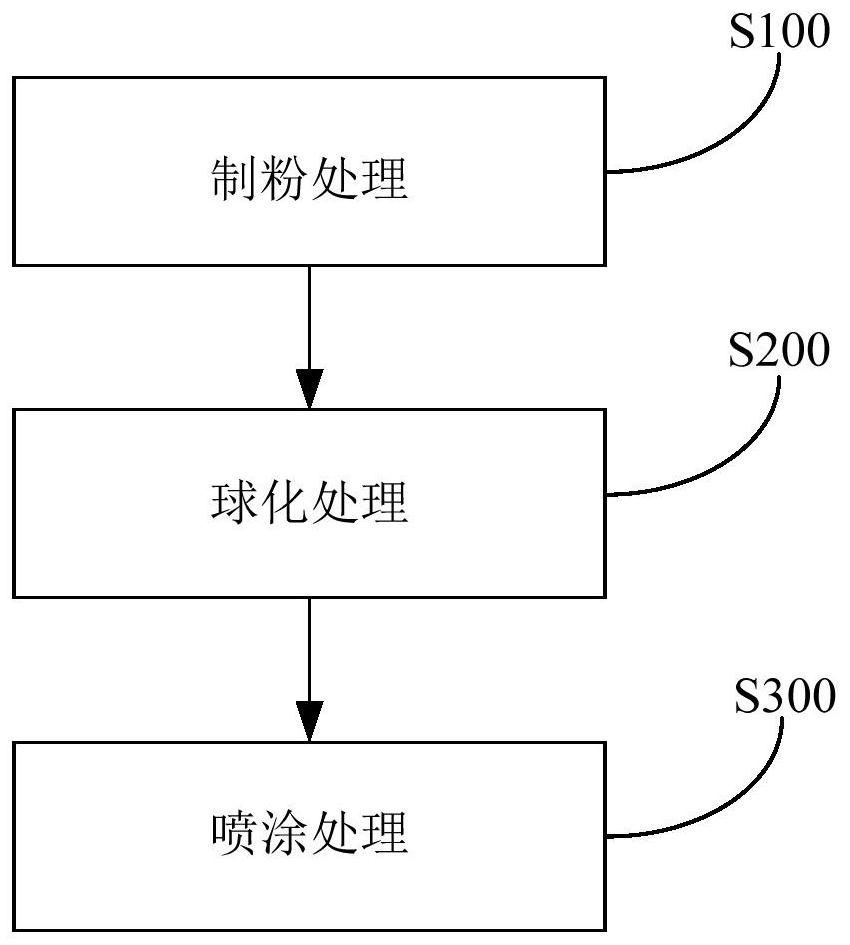

Method and system for forming quasicrystal coating and pot

The invention discloses a method and system for forming a quasicrystal coating and a pot. The method for forming the quasicrystal coating comprises the following steps: (1) carrying out powder processing on a quasicrystal alloy ingot so as to obtain quasicrystal powder; (2) carrying out annealing treatment on the quasi-crystal powder so as to obtain annealed powder; and (3) forming the quasicrystal coating on a substrate based on the annealed powder. According to the method for forming the quasicrystal coating, the quasicrystal coating is formed by using the annealed quasicrystal powder, and the surface performance of the quasicrystal coating can be effectively improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Ultrasonic laser welding method and metal material

PendingCN114589390AHigh strengthImprove toughnessFinal product manufactureLaser beam welding apparatusParacrystallineMetallic materials

The invention provides an ultrasonic laser welding method and a metal material.The welding method comprises the following steps that S10, a first plate and a second plate are obtained; wherein the first plate comprises a first surface and a second surface which are opposite to each other, the second plate comprises a third surface and a fourth surface which are opposite to each other, and the first surface and the third surface are subjected to surface treatment; s20, the third face is subjected to texturing treatment; s30, the first plate and the second plate are oppositely placed, so that the first face and the third face are attached; wherein a middle metal layer is arranged between the first surface and the third surface; and S40, the first plate and the second plate are welded in an ultrasonic laser welding mode, so that a quasi-crystal structure is generated between the first plate and the second plate. According to the method, generation of a brittle phase is reduced in an ultrasonic laser mode, meanwhile, grains are refined, a quasi-crystal structure is formed, and the strength of a welding seam is improved by means of the characteristic that quasi-crystals enhance dispersion distribution.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

Wok and its preparation method

ActiveCN110754915BExcellent anti-rustFunction increaseCooking-vessel materialsCoatingsParacrystallinePhysical chemistry

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Binary nano-crystalline super-lattice material and preparation method thereof

InactiveCN112745849AUniform structureThickness is easy to adjustMaterial nanotechnologyNanoopticsMicron scaleUpconversion luminescence

The invention provides a binary nano-crystalline super-lattice material. The binary nano-crystalline super-lattice material is a UCNPs-Au super-lattice with a quasi-crystal structure, and the UCNPs-Au super-lattice is formed by self-assembly of lanthanide doped up-conversion luminescent nano-crystalline UCNPs and Au nano-particles. The invention also provides a preparation method of the binary nano-crystalline super-lattice material. The binary super-lattice material is uniform in structure, the thickness is easy to regulate and control, the range of the two-dimensional quasi-crystal structure can reach the micron level, and the regulation and control effect of the plasma effect of Au nano-particles on the up-conversion luminescence property can be researched in the quasi-crystal structure.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

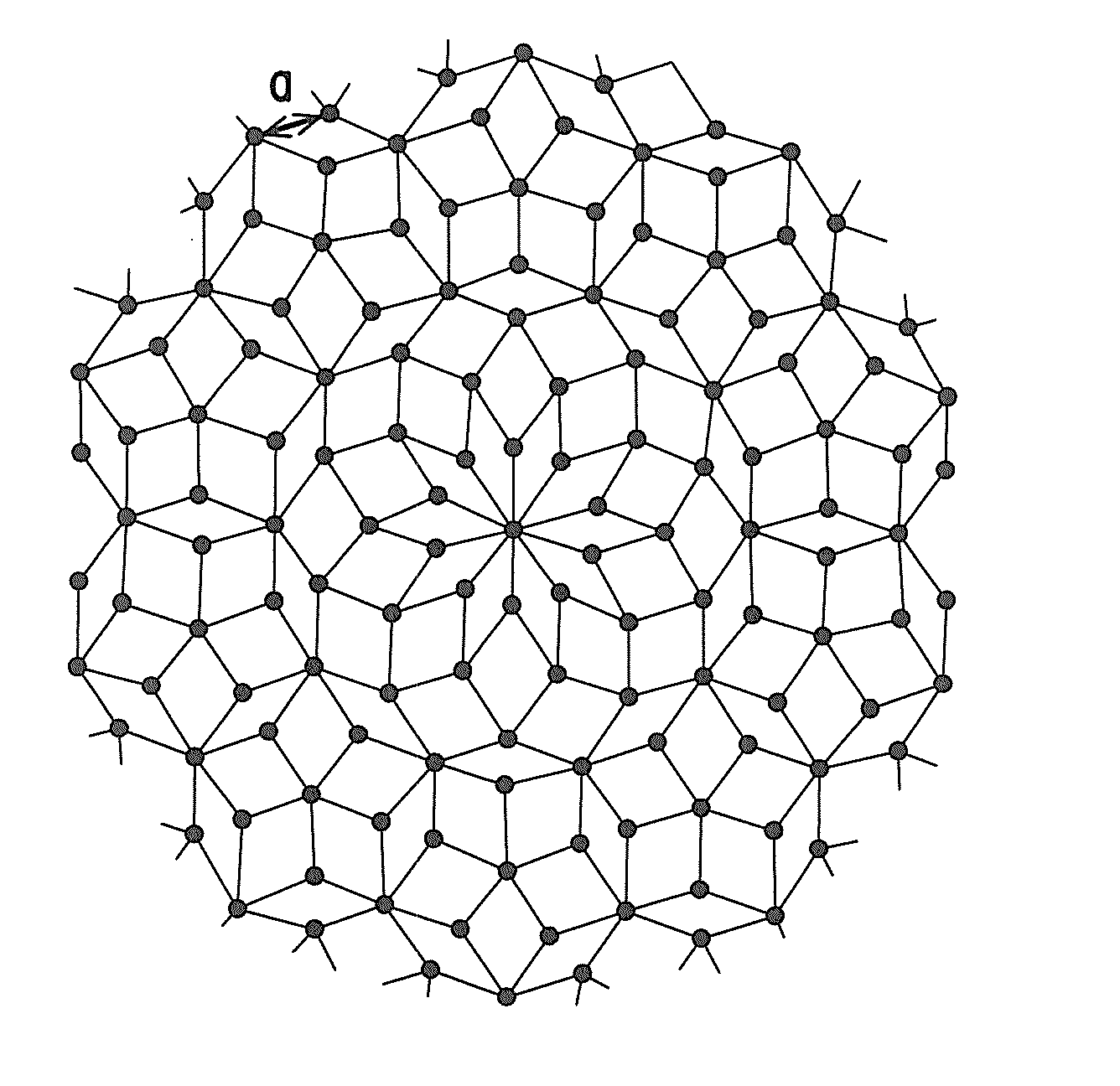

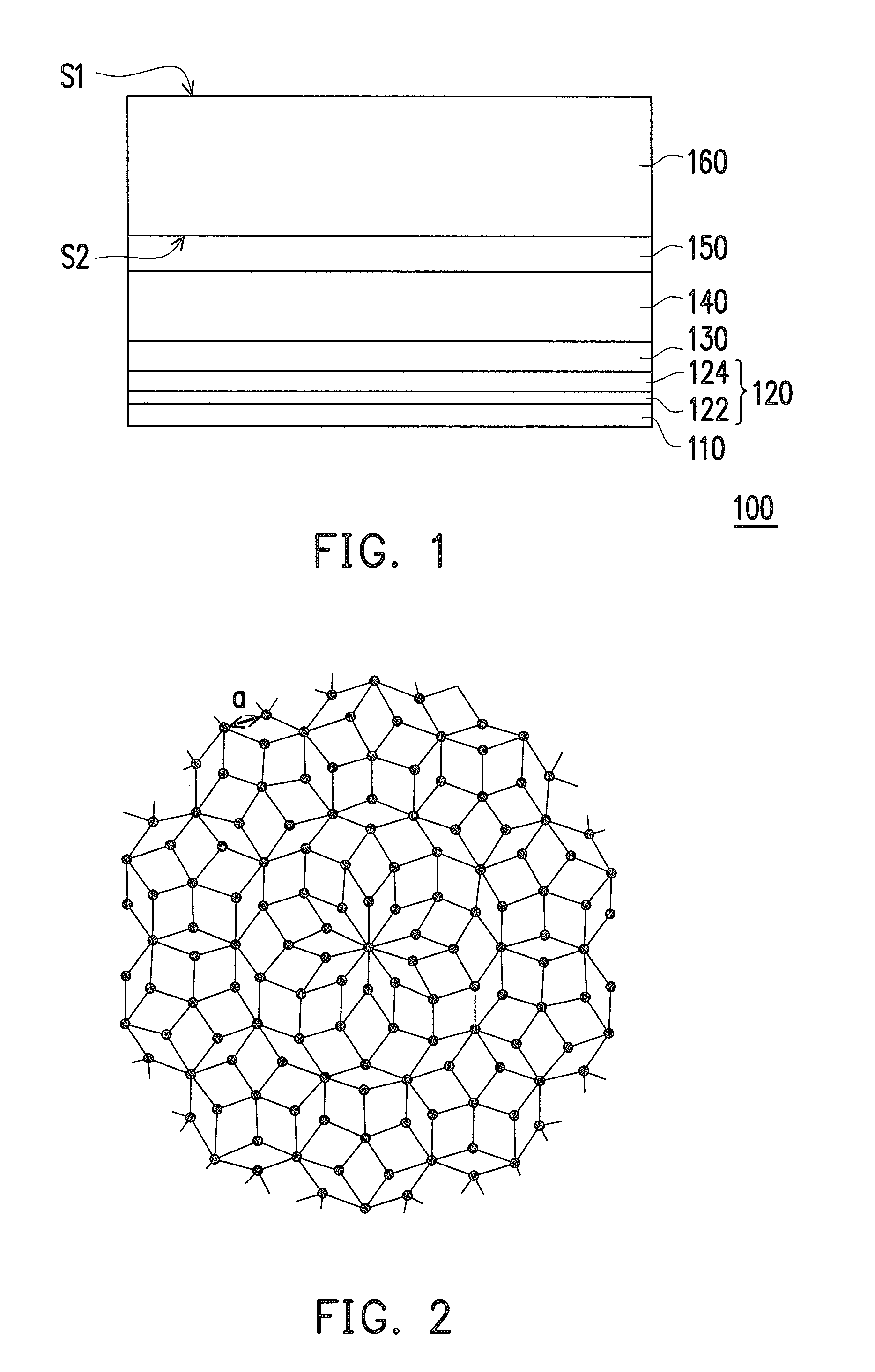

Quasi-crystal organic light-emitting display panel and method for simulating optical efficiency of the same

ActiveUS20160099436A1Improve optical efficiencyImprove light extractionStatic indicating devicesSolid-state devicesParacrystallineQuasicrystal

A quasi-crystal organic light-emitting display panel including a first electrode layer, an organic light-emitting layer, a second electrode layer, a buffer layer, a 10-fold quasi-crystal layer and a package cover is provided. The organic light-emitting layer is located on the first electrode layer. The second electrode layer is located on the organic light-emitting layer. The buffer layer is located on the second electrode layer. The 10-fold quasi-crystal layer is located on the buffer layer. The package cover is located on the 10-fold quasi-crystal layer. A method for simulating optical efficiency of the quasi-crystal organic light-emitting display panel is also provided.

Owner:WINBOND ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com