Nano-porous Pd material prepared through quasi-crystal de-alloying and preparation process of nano-porous Pd material

A nanoporous, dealloying technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, can solve problems such as dealloying, achieve low cost, uniform interconnection size, structural integrity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Al 70 PD 20 mn 10 alloy

[0035] Step 1: Component weighing and alloy ingot melting

[0036] Will Al 70 PD 20 mn 10 The atomic percent composition of the alloy is converted to a weight percent composition:

[0037] Using industrial purity components, weighing ingredients according to the mass percentage of the alloy; mixing the weighed metal raw materials in a water-cooled copper crucible of a non-consumable arc melting furnace, melting under the protection of high-purity argon, and then Flip the alloy ingot up and down, and smelt it repeatedly for 3 times to obtain an alloy ingot with uniform composition;

[0038] Step 2: Preparation of broadband samples

[0039] The alloy ingot is crushed and put into a quartz tube. The size of the nozzle of the quartz tube is: length 8mm×width 1mm. Put the charged quartz tube in the induction heating coil, use the vacuum copper roll stripping technology, under the protection of high-purity argon, melt the alloy s...

Embodiment 2

[0049] Example 2 Al 72 PD 25 V 3 alloy

[0050] Step 1: Component weighing and alloy ingot melting

[0051] Same as Step 1 in Embodiment 1.

[0052] Step 2: Preparation of broadband samples

[0053] Same as Step 2 in Embodiment 1.

[0054] Step 3: Microstructure analysis of the precursor alloy

[0055] With the step 3 in the embodiment 1, the result shows that Al 72 PD 25 V 3 The alloy is a nearly single-phase three-dimensional icosahedral quasicrystal structure. The grain size is about 0.5-3 μm.

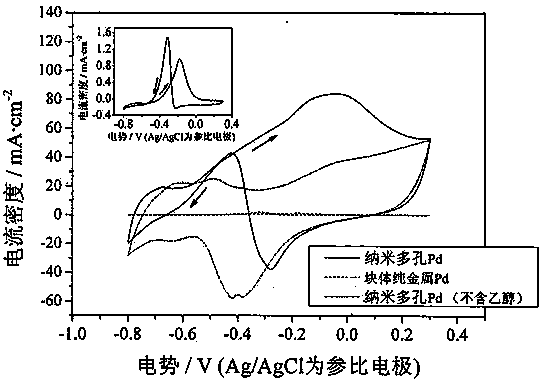

[0056] Step 4: Electrochemical performance test and dealloying test

[0057] Same as Step 4 in Embodiment 1, the measured critical potential is about 0 V. A nanoporous Pd material that can be obtained by dealloying with a constant voltage in the range of 0.0-0.2V.

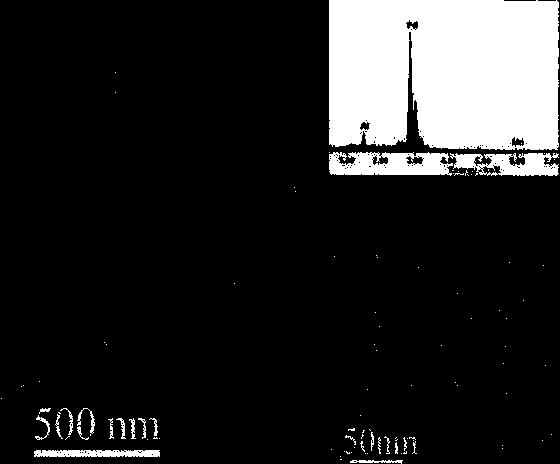

[0058] Step 5: Structure Characterization and Component Testing of Nanoporous Materials

[0059] Same as Step 5 in Example 1, it is found that the size of the alloy broadband sample before and after deal...

Embodiment 3

[0062] Example 3 Al 74 PD 21 Mg 5 alloy

[0063] Step 1: Component weighing and alloy ingot melting

[0064] Same as Step 1 in Embodiment 1.

[0065] Step 2: Preparation of broadband samples

[0066] Same as Step 2 in Embodiment 1.

[0067] Step 3: Microstructure analysis of the precursor alloy

[0068] With the step 3 in the embodiment 1, the result shows that Al 74 PD 21 Mg 5 The alloy is a nearly single-phase two-dimensional tenth order quasicrystal structure, containing a small amount of Al 3 Pd phase. The grain size is about 1-3 μm.

[0069] Step 4: Electrochemical performance test and dealloying test

[0070] Same as Step 4 in Embodiment 1, the measured critical potential is about 0 V. A nanoporous Pd material that can be obtained by dealloying with a constant voltage in the range of 0.0-0.2V.

[0071] Step 5: Structure Characterization and Component Testing of Nanoporous Materials

[0072] Same as Step 5 in Example 1, it was found that: the dealloying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com