Method for preparing nitrogen-doped nano lamellar or Fe2O3 nanoparticle-loaded graphite structure

A nanosheet and graphite structure technology, applied in the field of materials, can solve the problems of low nitrogen content in nitrogen-doped graphene and the microwave absorption effect cannot meet the application needs, and achieve simple equipment, low production cost and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of N-doped nanosheet graphite structure by high temperature plasma arc evaporation technology:

[0041] In the plasma arc discharge evaporation process, the consumed anode target is a high-purity graphite rod with a diameter of 10 mm, and the distance between the graphite cathode and the anode target is 1.5 mm. Vacuum chamber up to 5×10 -3 After Pa, put 30ml of liquid acetonitrile into the vacuum chamber, turn on the DC power supply, adjust the voltage to 18V-24V, plasma arc discharge occurs between the anode target and the cathode, and the arc discharge current is 60A, and the adjustment work during the arc discharge process The current and voltage remain relatively stable, and the arc holding time is 90 minutes. N-doped nano-sheet graphite is prepared in the above atmosphere. After the reaction gas is extracted, the powdered N-doped nano-sheet is collected on the inner wall of the vacuum chamber. Graphite structure.

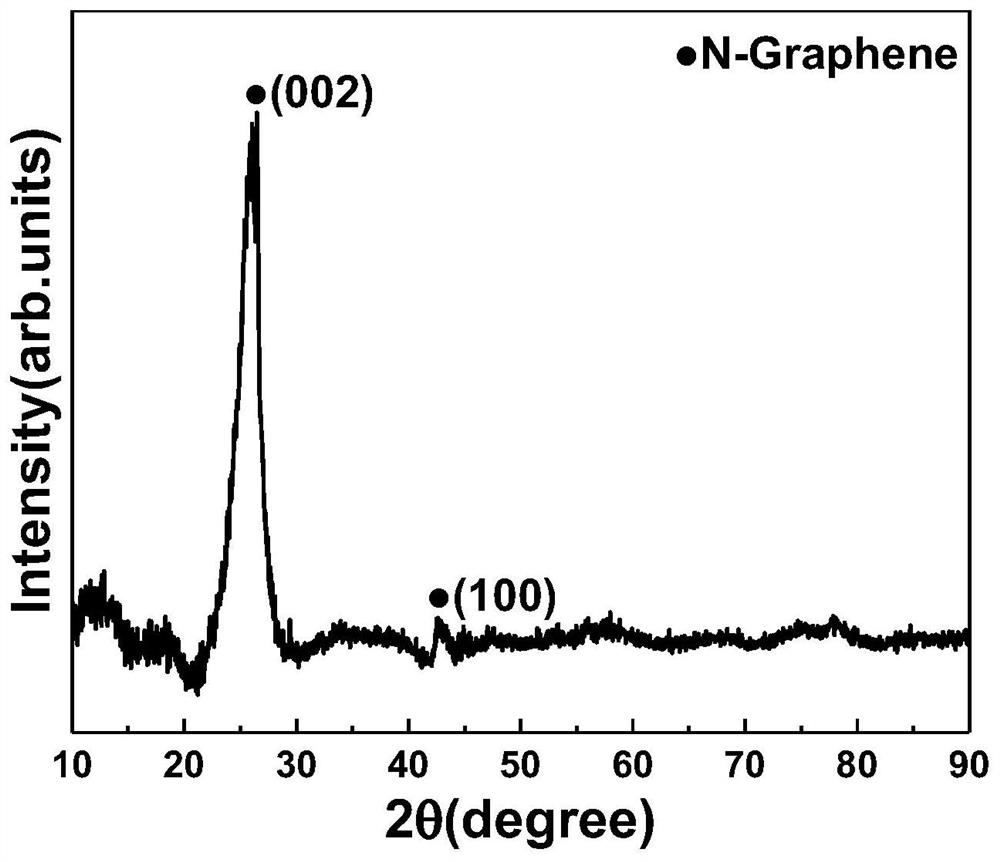

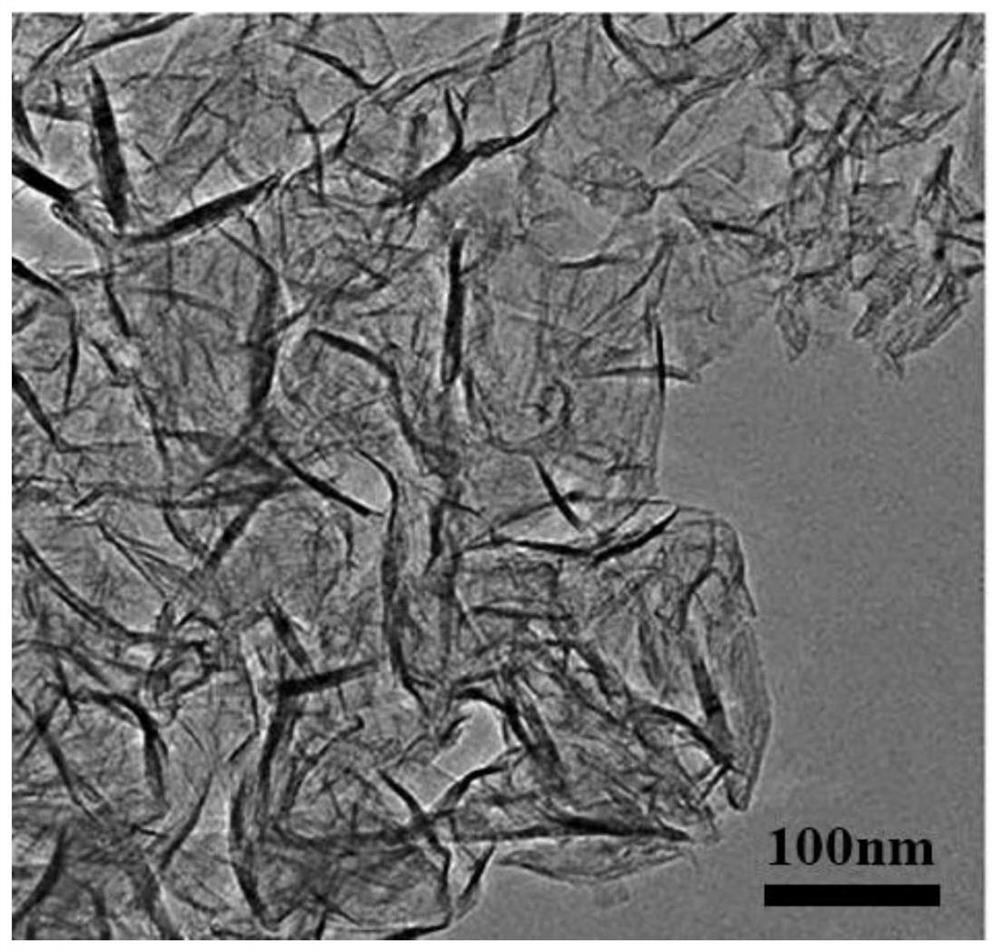

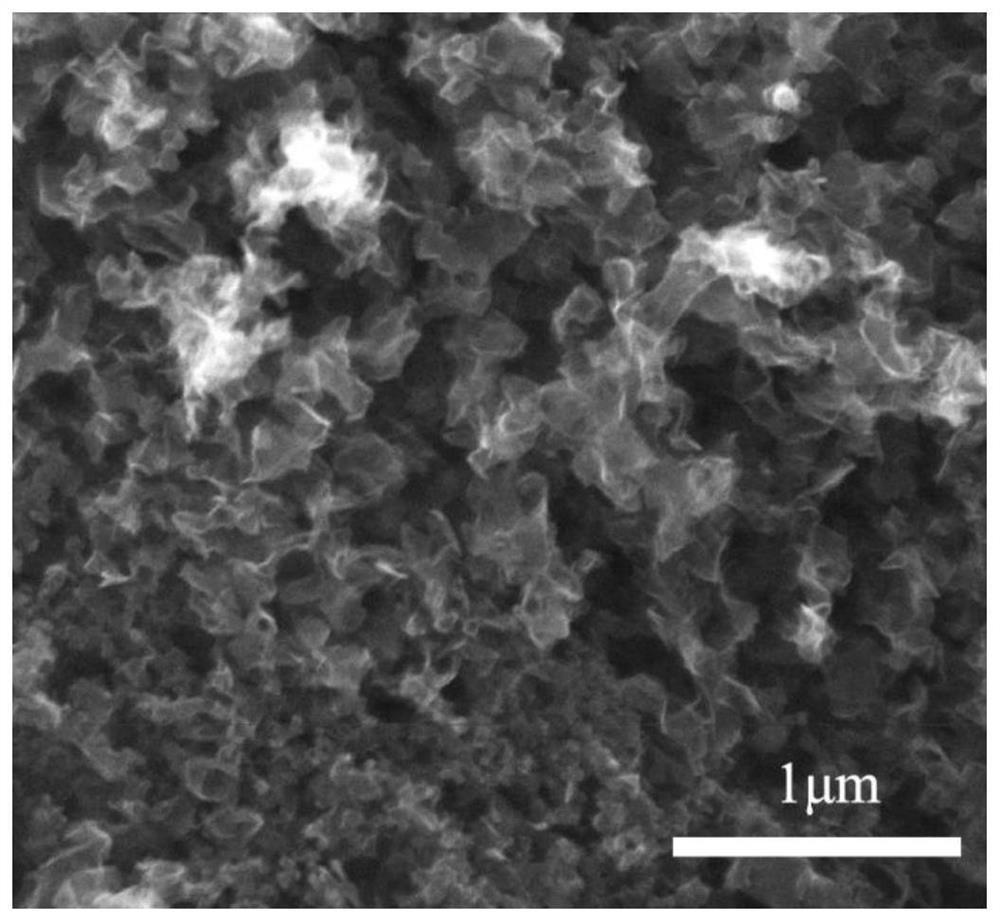

[0042] figure 1 Provide the X-ray d...

Embodiment 2

[0051] Preparation of surface-supported nano-Fe by high-temperature plasma-arc evaporation technique 2 o 3 Granular N-doped nanosheet graphite structure:

[0052] In the plasma arc discharge evaporation process, the consumed anode target is a cylinder with a diameter of 40mm and a thickness of 10mm formed by high-purity graphite powder (95at.%) and high-purity iron powder (5at.%). The graphite cathode and anode target The material spacing is 1.5mm. Vacuum chamber up to 5×10 -3 After Pa, put 30ml of liquid acetonitrile into the plasma arc discharge cavity, turn on the DC power supply, adjust the voltage to 22V-32V, arc discharge occurs between the anode target and the cathode, and the arc discharge current is 60A, during the arc discharge process Adjust the working current and voltage to keep relatively stable, and the arc holding time is 40 minutes. In the above reaction atmosphere, the surface-loaded nano-Fe 2 o 3 Granular N-doped nanosheet graphite, after the reaction g...

Embodiment 3

[0059] Preparation of surface-supported nano-Fe by high-temperature plasma-arc evaporation technique 2 o 3 Granular N-doped nanosheet graphite structure:

[0060] In the plasma arc discharge evaporation process, the consumed anode target is a cylinder with a diameter of 40mm and a thickness of 10mm formed by high-purity graphite powder (96at.%) and high-purity iron powder (4at.%). The graphite cathode and anode target The material spacing is 2mm. Vacuum the cavity up to 6.6×10 -3 After Pa, put 25ml of liquid acetonitrile into the plasma arc discharge chamber, connect the DC power supply, adjust the voltage to 18V-40V, arc discharge occurs between the anode target and the cathode, and the arc discharge current is 80A, during the arc discharge process Adjust the working current and voltage to keep relatively stable, and the arc holding time is 30 minutes. In the above reaction atmosphere, the surface-loaded nano-Fe 2 o 3 Granular N-doped nanosheet graphite, after the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com