Modified hole transport layer perovskite light emitting diode and preparation method thereof

A technology of hole transport layer and light-emitting diode, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of low performance and achieve the effects of reducing defects, improving external quantum efficiency, and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing a perovskite light-emitting diode with a modified hole transport layer, comprising the following steps:

[0046] Step A, blending the polyvinylcarbazole material solution and the polyethylene oxide material solution, and stirring at room temperature to form a mixed solution;

[0047] Step B, preparing the mixed solution into a thin film by coating, and the thin film is a hole transport layer;

[0048] Step C, spin-coating a perovskite solution on the film described in step B to prepare a perovskite light-emitting diode with a modified hole transport layer.

[0049] Further, the following detailed steps are included:

[0050] SA1, blend polyvinyl carbazole and polyethylene oxide at a mass ratio of 5:1 to 6:0 to form a 6 mg / ml solution, stir until it is evenly mixed, and stir at room temperature for 2 hours to form a blend solution;

[0051] SB1, the mixed solution is spin-coated at 4000rpm / min for 60s, and heated in a glove box at 150°C for 15min ...

Embodiment 1

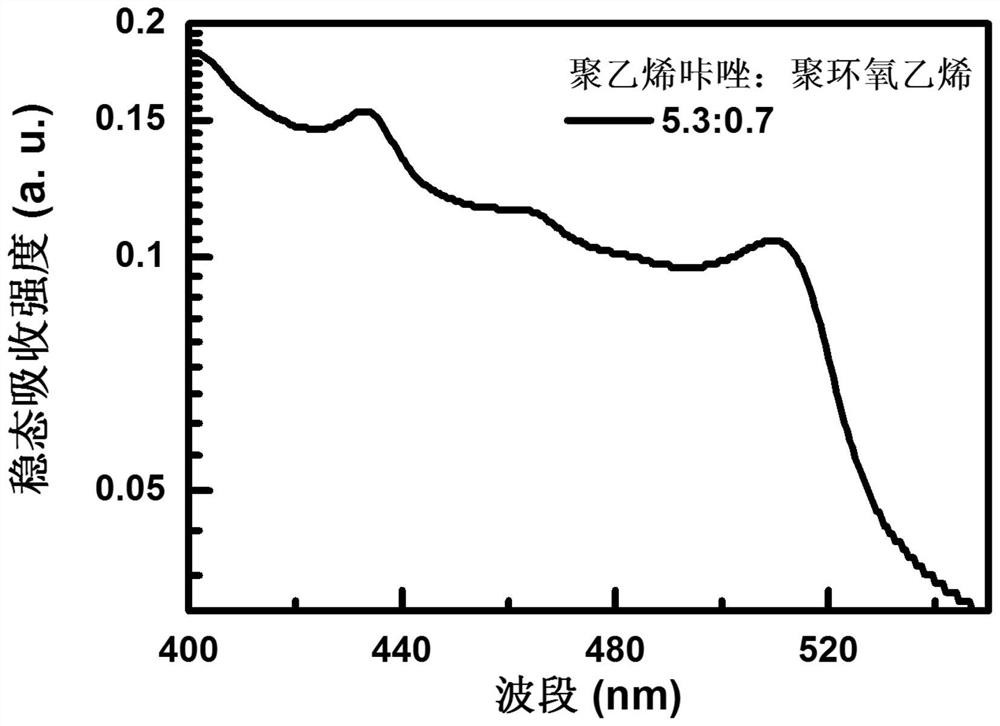

[0057] This embodiment provides a method for preparing a perovskite light-emitting diode comprising a modified hole transport layer, such as figure 1 As shown, the photoelectric device hole transport layer is made of polyvinyl carbazole and polyethylene oxide solution blended and then coated. The specific preparation steps are as follows:

[0058] Step 1, preparing a blend solution of polyvinylcarbazole and polyethylene oxide hole transport material:

[0059] Blend polyvinyl carbazole and polyethylene oxide at a mass ratio of 5.3:0.7 to form a 6 mg / ml solution, stir until it is evenly mixed, and stir at room temperature for 2 hours to form a blended solution;

[0060] Step 2, prepare the mixed solution into a thin film by coating, spin coating at 4000rpm / min for 60s, and heat in the glove box at 150°C for 15min:

[0061] Step 3, the CsBr:PbBr 2 Prepare a 12 mg / ml PEABr DMSO solution at a molar ratio of 1.2:1, and stir for 12 hours. The solution obtained was continued to be ...

Embodiment 2

[0064] The difference between this embodiment and embodiment 1 is that in step 2, the gold nanoparticle aqueous solution and the 3,4-ethylenedioxythiophene: polystyrene sulfonate solution are sequentially set to six groups of different proportioning relationships according to the volume ratio , as shown in Table 1 below.

[0065] Table 1 The highest brightness, highest lumen efficiency and highest external quantum efficiency of the modified hole transport layer under different mass ratio conditions

[0066]

[0067] One, the film performance test result prepared by the present embodiment:

[0068] Different mass ratios (polyvinylcarbazole: mass ratio of polyethylene oxide), measure the highest brightness, the highest lumen efficiency and the highest external quantum efficiency of the modified hole transport layer, and the test results are shown in Table 1;

[0069] Two, the performance of the film prepared in this embodiment and the polyfluorene derivative film is analyzed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com