Quasi-crystal coating, cooker and cooking appliance

A quasicrystal and coating technology, which is applied in special materials, coatings, cooking utensils and other directions of cooking utensils, and can solve the problem that the research of quasicrystal non-stick coating needs to be further developed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

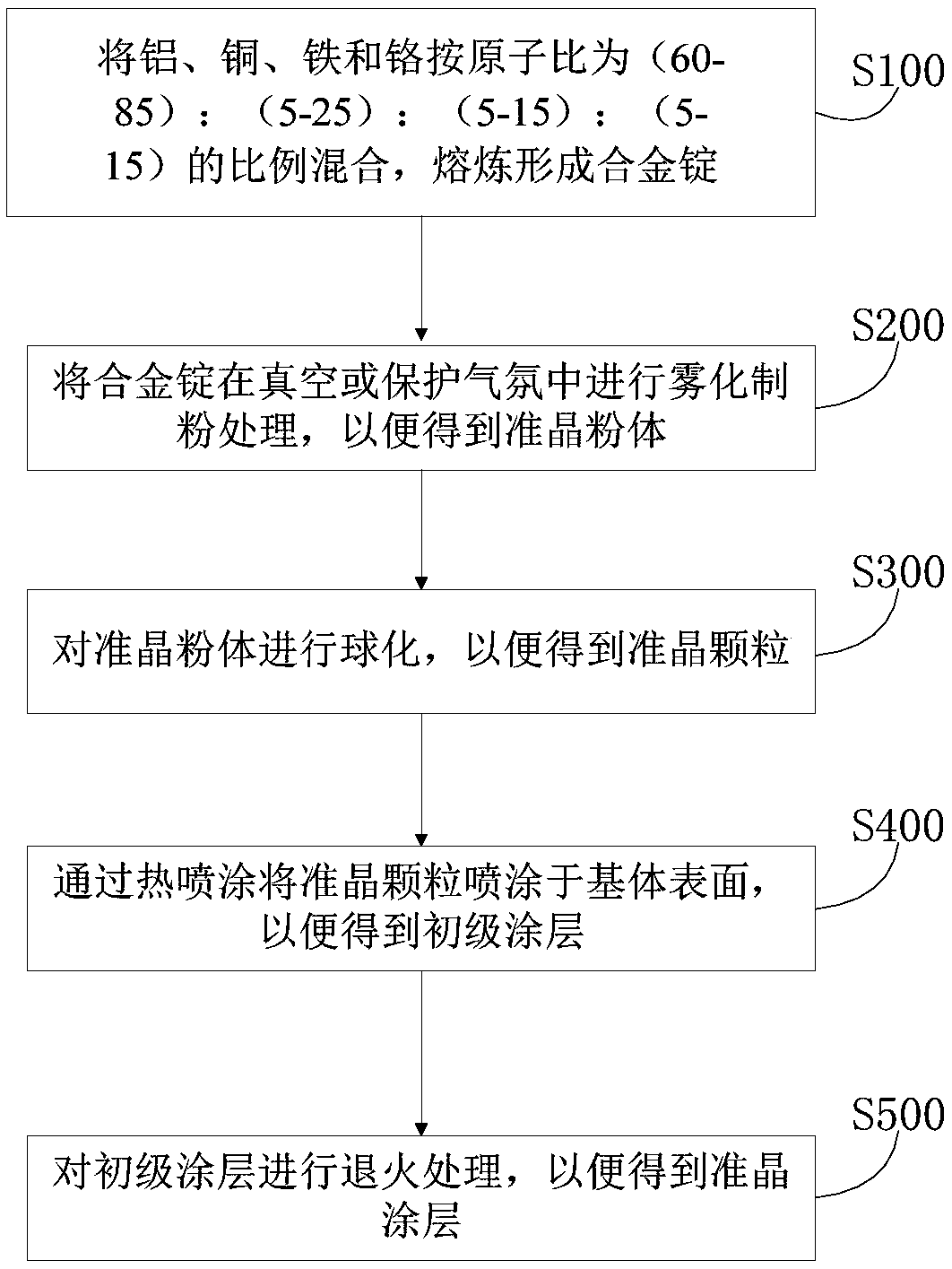

[0080] The steps for preparing the quasicrystalline coating are:

[0081] 1. According to the atomic number ratio of Al: Cu: Fe: Cr = 64: 20: 8: 8, the alloy raw material is melted to form an alloy ingot;

[0082] 2. Atomization pulverization: Under vacuum or protective atmosphere, use pulverization equipment to make quasi-crystalline powder.

[0083] 3. Spheroidization: spheroidize and sieve the quasicrystalline powder to obtain quasicrystalline particles with a particle size of less than 150 μm.

[0084] 4. Substrate surface cleaning: Use alcohol, trichlorethylene or pure water plus ultrasonic waves to clean and dry the substrate surface so that there is no rust on the substrate surface before plasma spraying, and then perform sandblasting to roughen the substrate surface.

[0085] 5. Plasma spraying: Use plasma spraying to spray on the surface of the above substrate to form a primary coating. The spraying power is 30-50KW, the main air flow is 50-60L / min, the auxiliary air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com