Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

214results about How to "Adjustable hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

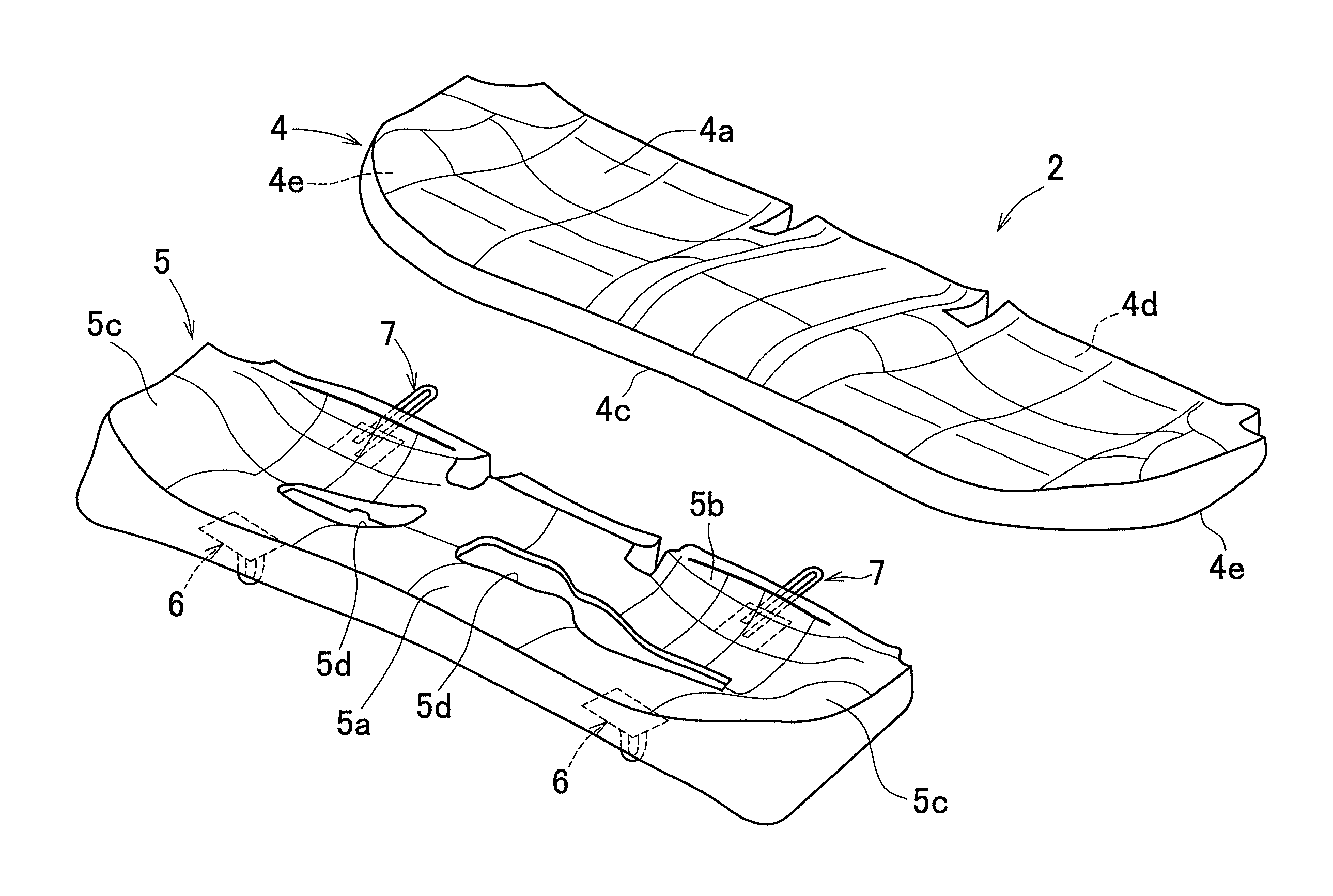

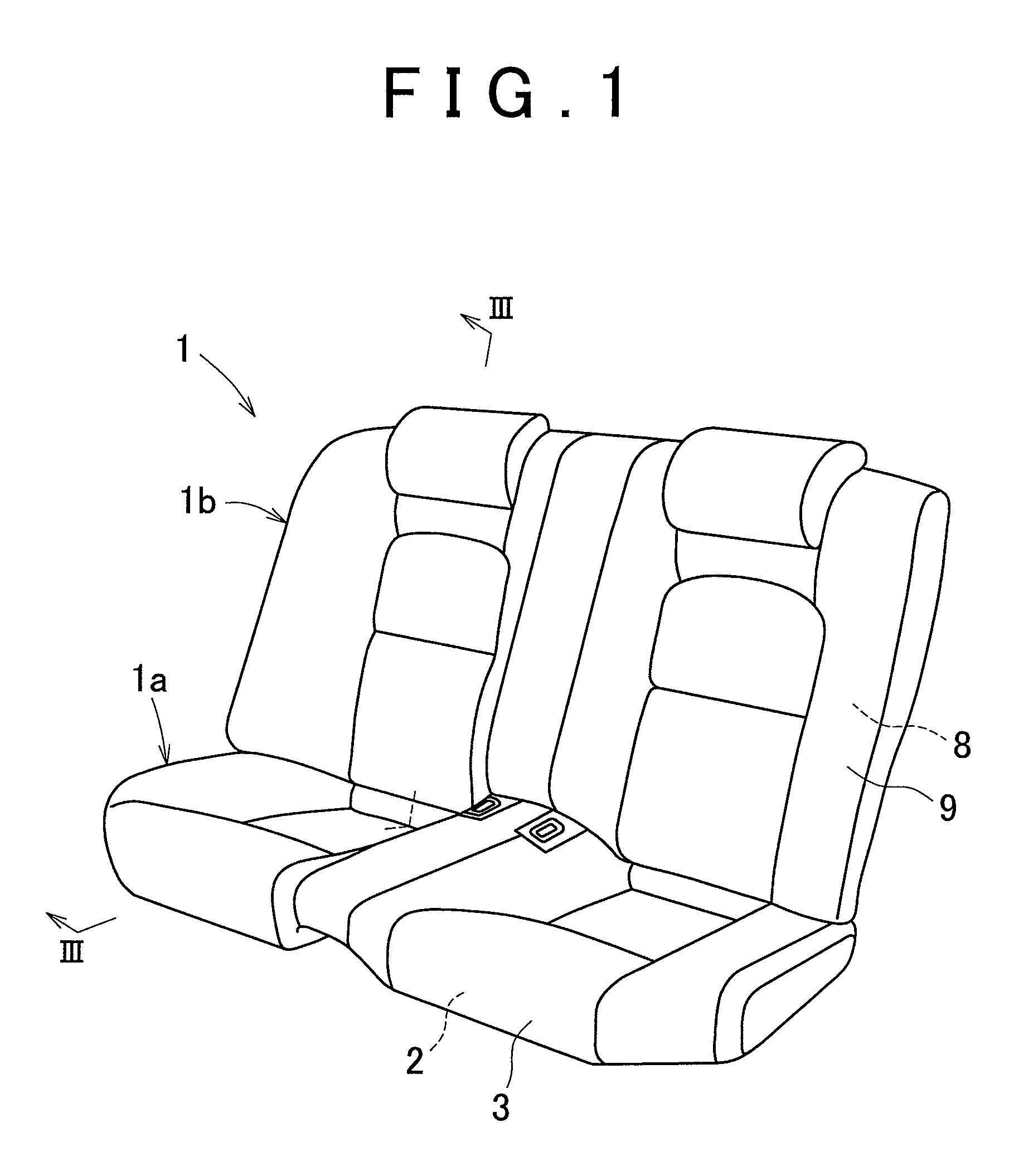

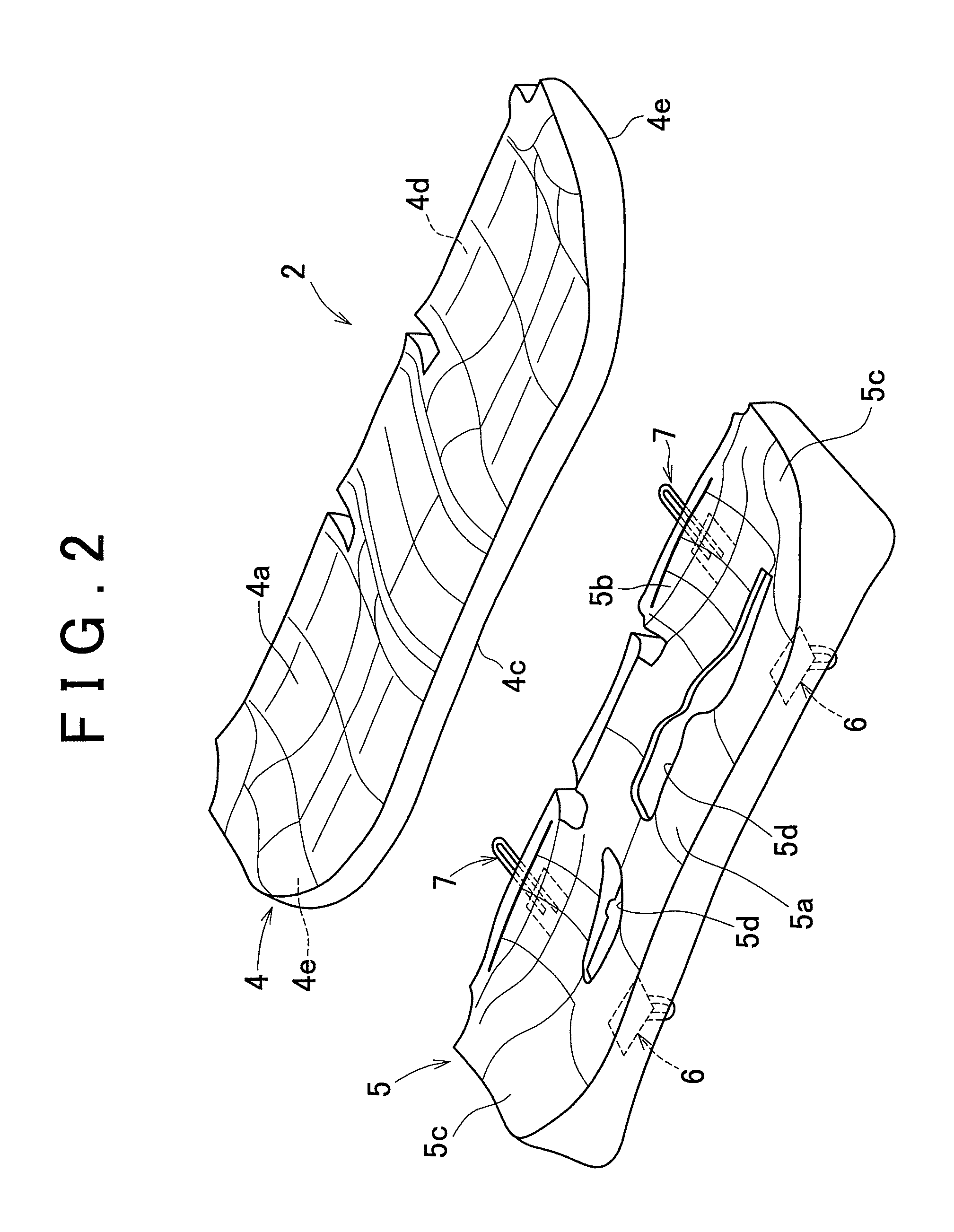

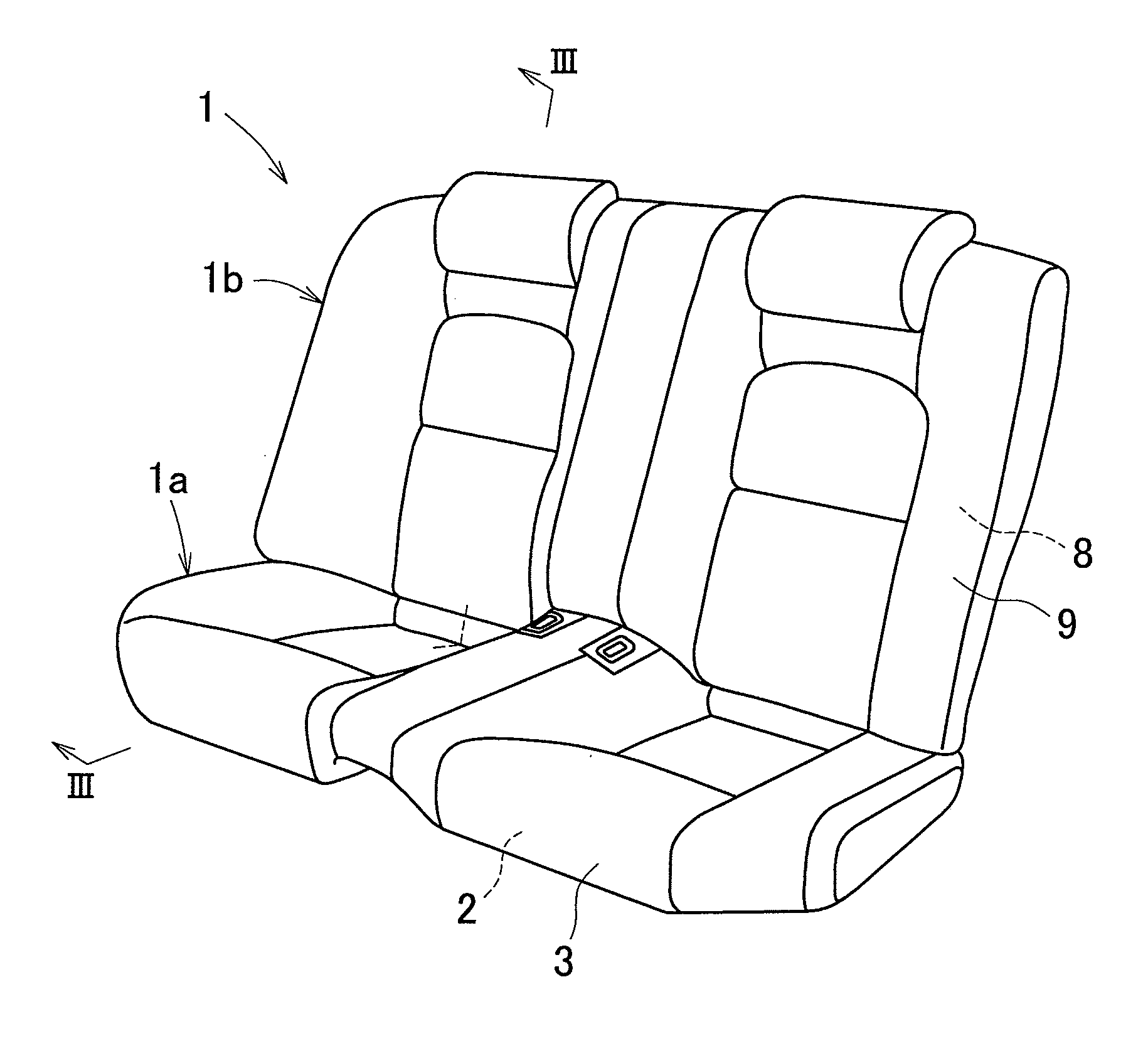

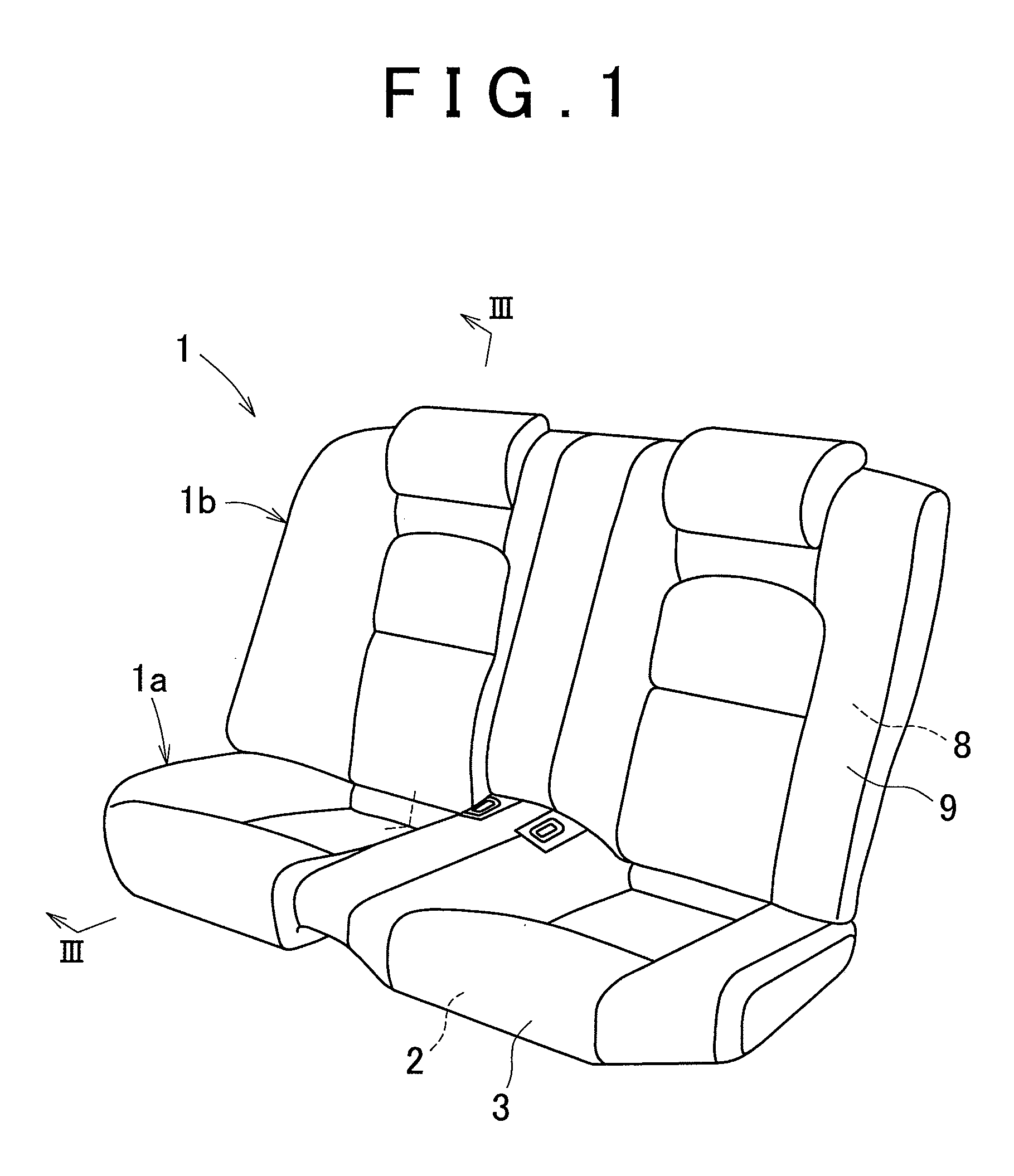

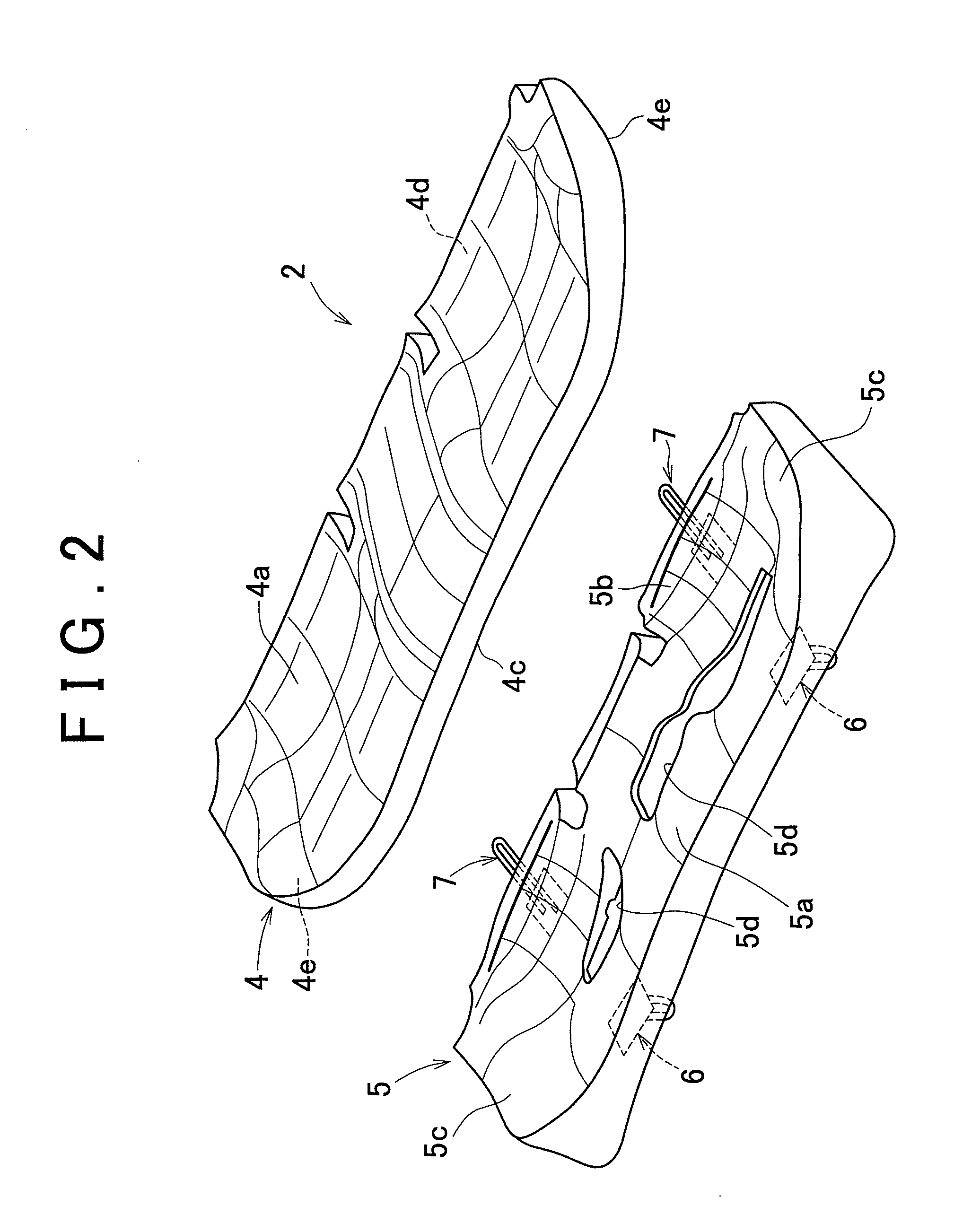

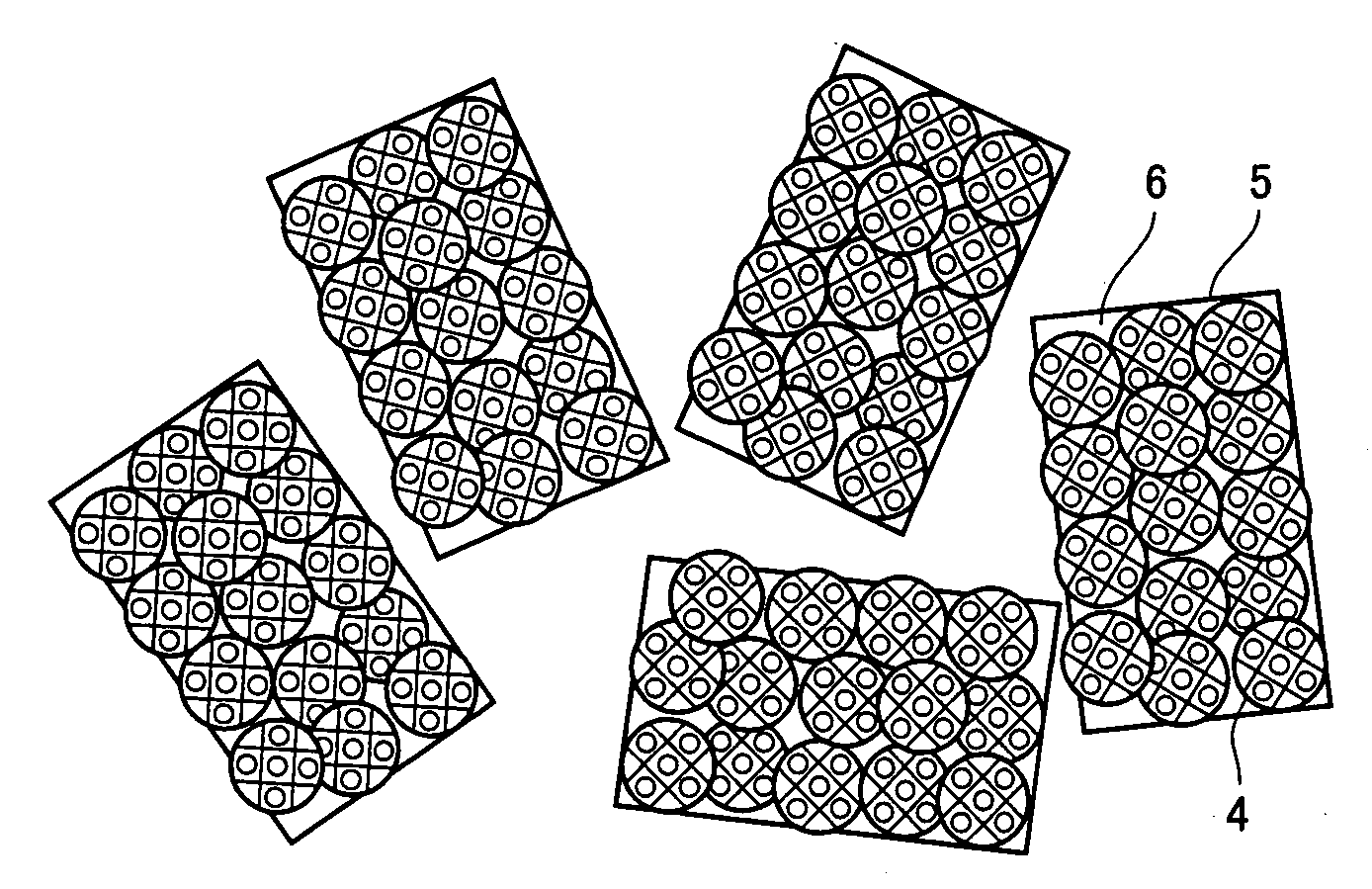

Vehicle seat

ActiveUS8360530B2Adjustable hardnessImprove comfortVehicle seatsStoolsSurface layerBiomedical engineering

A vehicle seat includes a pad that is made of resin foam, and that forms a seat cushion or a seatback. The pad has a layered structure formed of a surface layer pad that forms a seating surface-side portion of the pad and a back layer pad that is provided on the back side of the surface layer pad. The back layer pad is higher in hardness and lower in density than the surface layer pad.

Owner:TOYOTA BOSHOKU KK

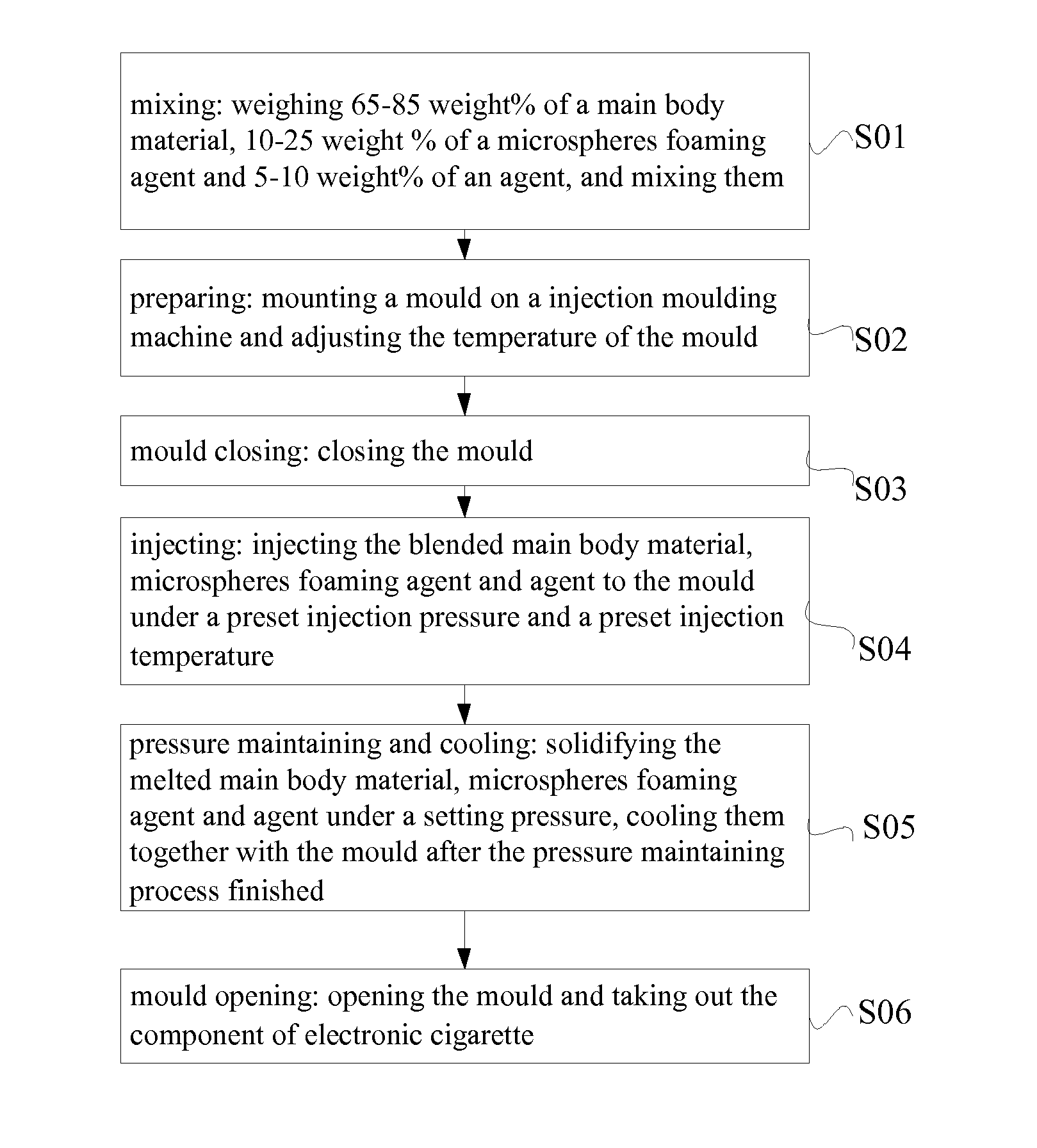

Thermoplastic elastomer composite, electronic cigarette component and method for producing the same

InactiveUS20140353867A1Increase elasticityImprove user experienceTobacco devicesSolid ballsElastomerFoaming agent

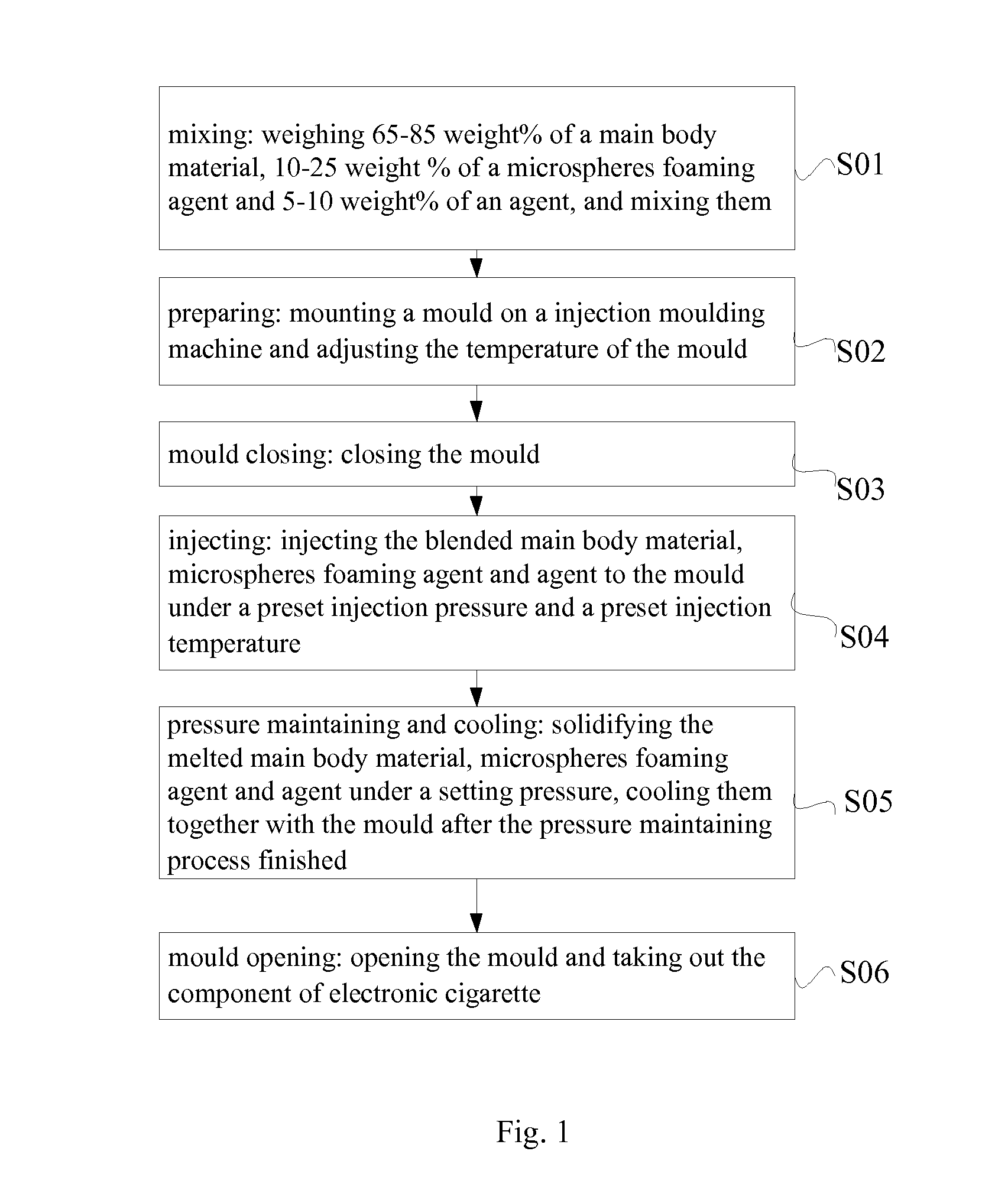

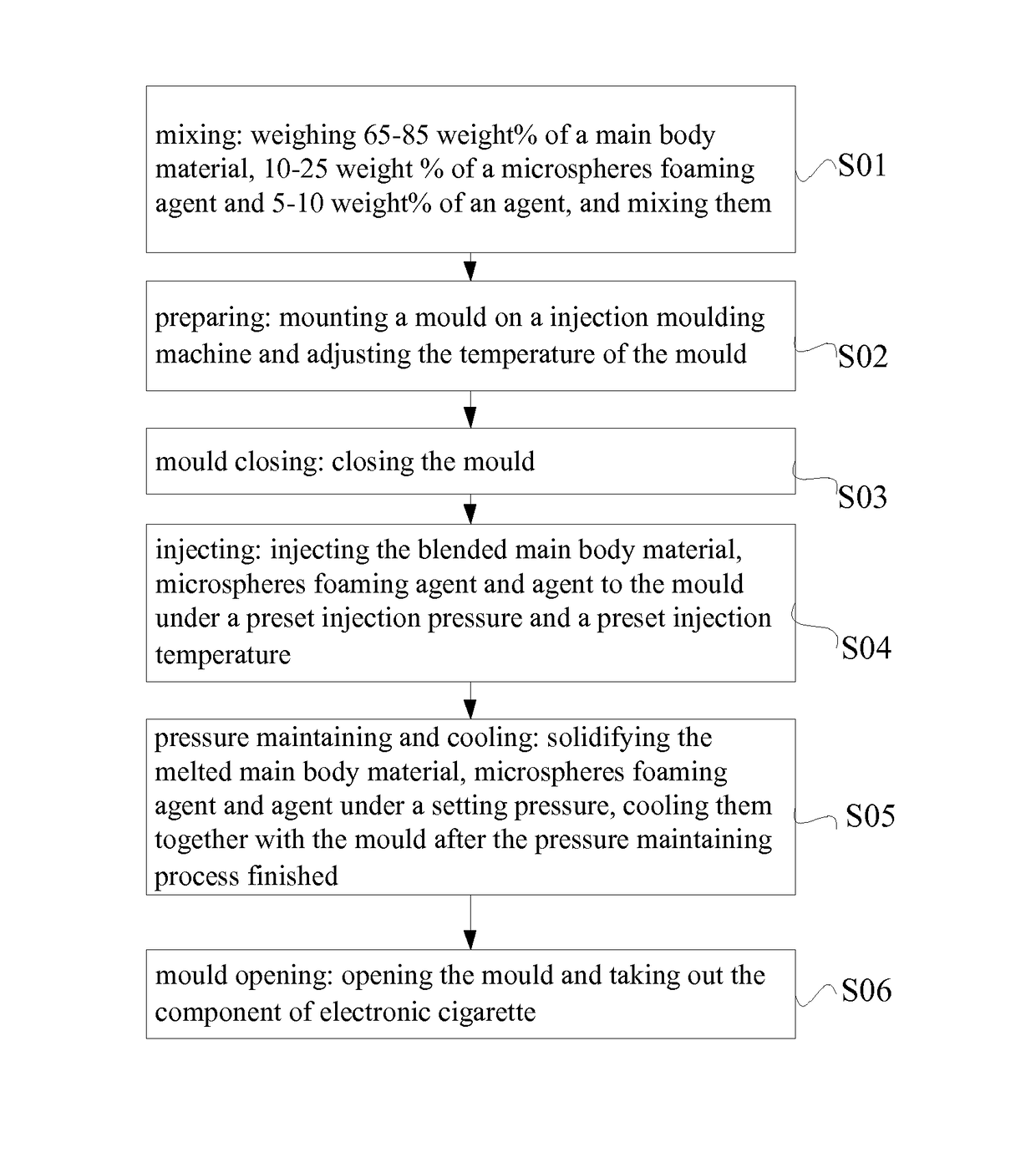

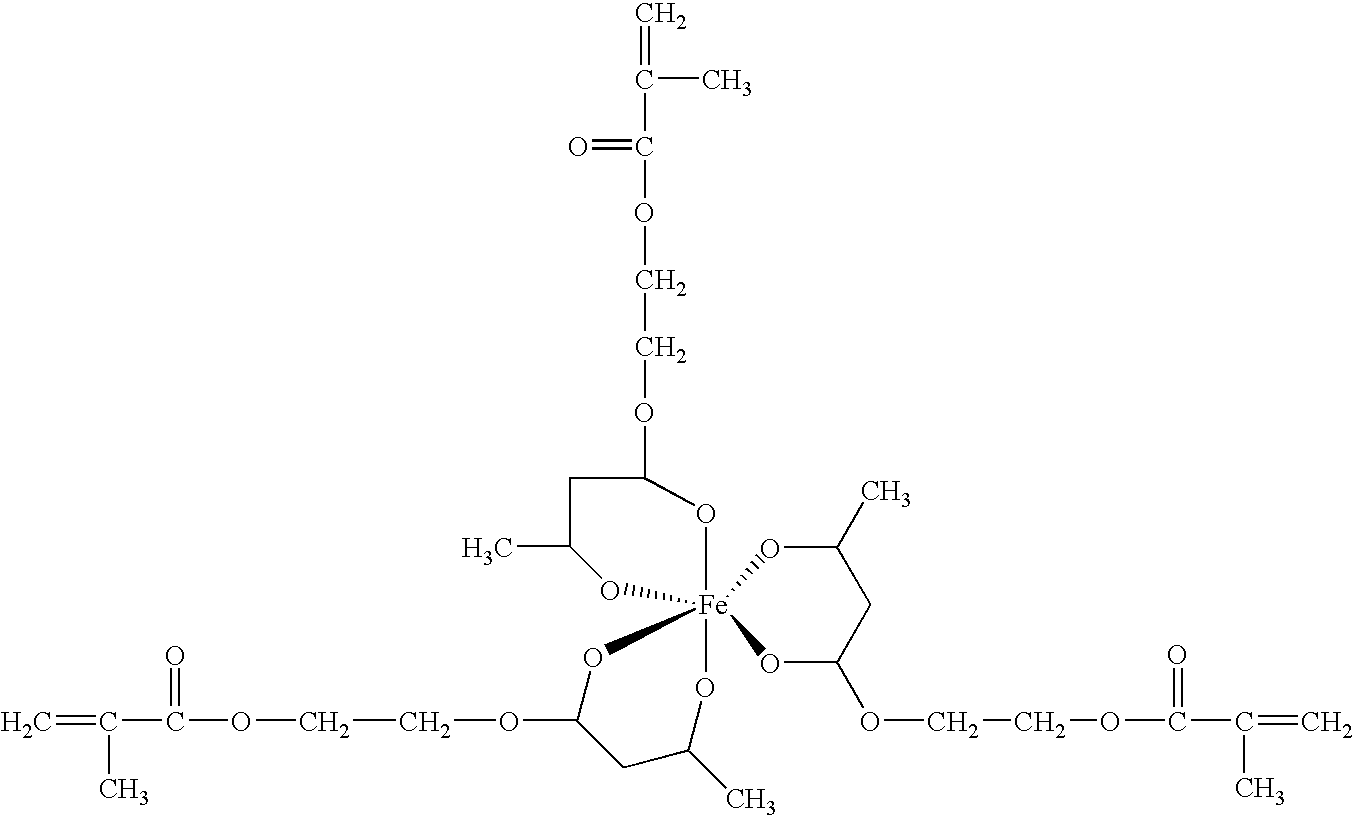

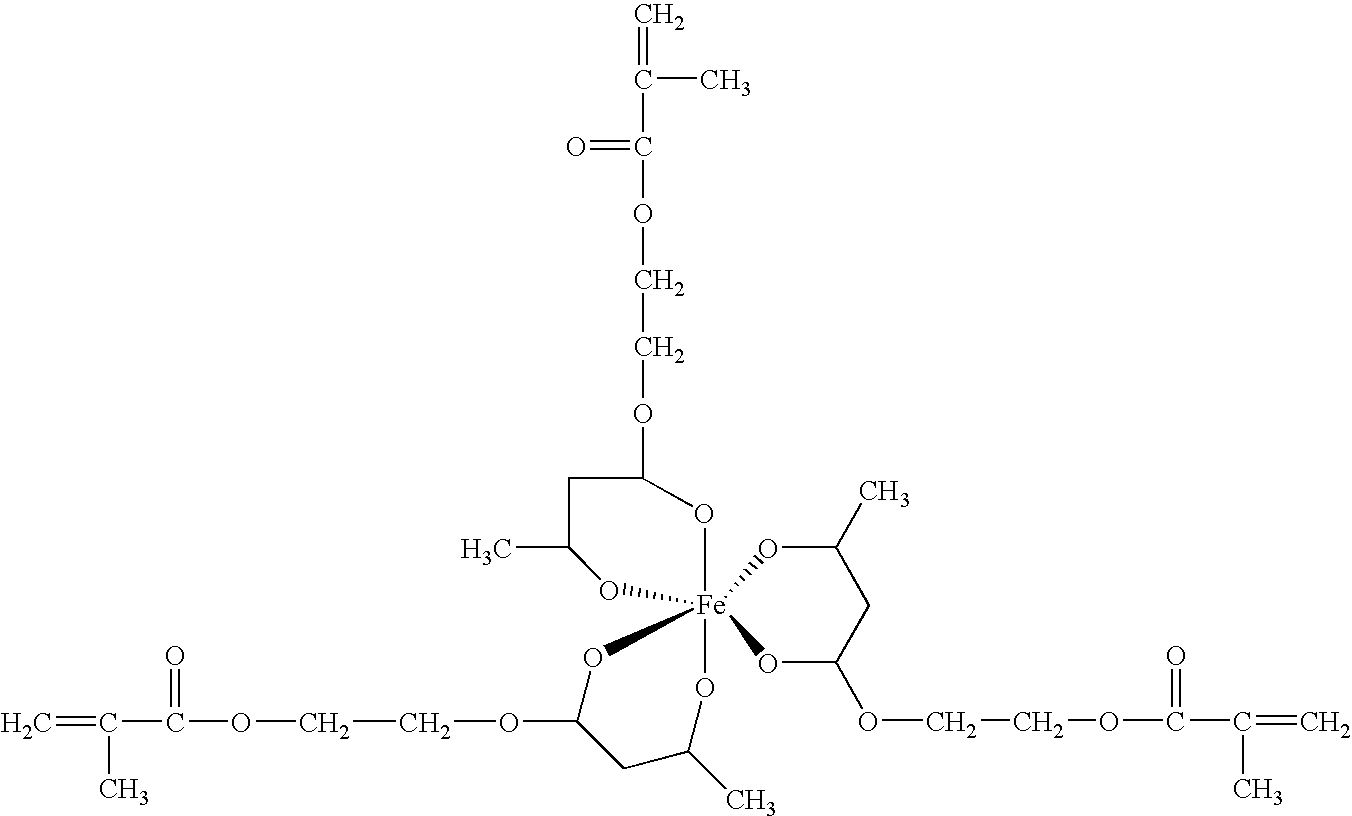

The invention discloses a thermoplastic elastomer composite, a component of electronic cigarette and a method of preparing the component of electronic cigarette. The thermoplastic elastomer composite comprises 65-85 weight % of a main body material, 10-25 weight % of a microspheres foaming agent and 5-10 weight % of an agent. The component of electronic cigarette made of the thermoplastic elastomer composite, has high elasticity and a wide hardness adjusting range, can be adjusted according to users' requirements, and has good taste and feel. The component can be provided with decorative patterns that are similar to tobacco leaves in production, and can simulate appearance of a real cigar and visual effects of real tobacco of cigarettes. The component has high elasticity, and it is non-toxic and non-pollution. The method can be carried out in a simple manner, and can improve the production efficiency.

Owner:HUIZHOU KIMREE TECH

Thermoplastic elastomer composite, electronic cigarette component and method for producing the same

InactiveUS9623592B2Increase elasticityImprove user experienceTobacco devicesInhalatorsElastomerFoaming agent

Owner:HUIZHOU KIMREE TECH

Two-component polyurethane / vinyl ester hybrid foam system and its use as a flame retardant material and material for filling openings in buildings with foam

ActiveUS8217093B2Increase crosslink densityImprove rigidityFoundry mouldsFoundry coresFire protectionPolyol

A two-component polyurethane / vinyl ester hybrid foam system is formed of a polyol component (A), which contains at least one polyol, a catalyst for the reaction of the polyol with the polyisocyanate, at least one polymerizable vinyl monomer and water or a blowing agent on the basis of a compressed or liquefied gas as foam-forming agent, and a polyisocyanate component (B), which contains at least one polyisocyanate and a catalyst for the polymerization of the vinyl monomer, and is designed for use as a flame retardant material and material for filling openings, cable and pipe bushings in walls, floors and / or of buildings for the purpose of fire protection.

Owner:HILTI AG

Vehicle seat

A vehicle seat includes a pad that is made of resin foam, and that forms a seat cushion or a seatback. The pad has a layered structure formed of a surface layer pad that forms a seating surface-side portion of the pad and a back layer pad that is provided on the back side of the surface layer pad. The back layer pad is higher in hardness and lower in density than the surface layer pad.

Owner:TOYOTA BOSHOKU KK

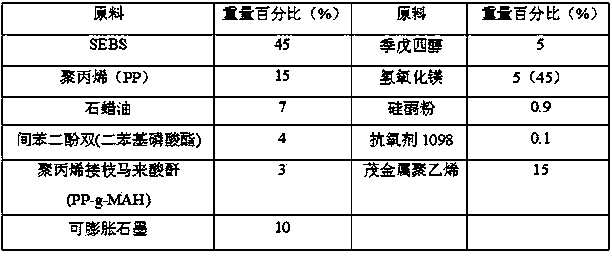

Halogen-free flame retardant thermoplastic elastomer composite material and preparation method thereof

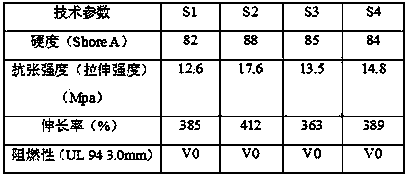

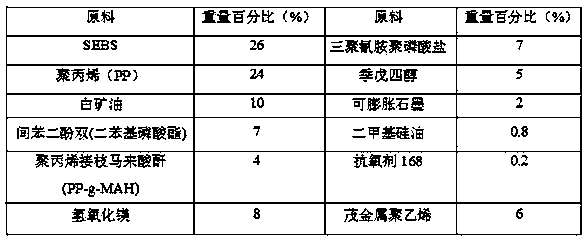

ActiveCN103435955AImprove mechanical propertiesImprove heat resistancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention belongs to the technical field of high polymer materials and particularly relates to a halogen-free flame retardant thermoplastic elastomer composite material. The halogen-free flame retardant thermoplastic elastomer composite material comprises the following components in percentage by weight according to a raw material formula: 25-45 percent of SEBS (Styrenic Block Copolymer), 15-25 percent of polypropylene, 5-15 percent of metallocene polyethylene, 5-15 percent of a flame retardant synergist, 5-15 percent of a soften plasticizer, 15-25 percent of a flame retardant, 3-5 percent of a compatilizer, 0.1-1 percent of an antioxidant and 0.5-2 percent of a processing aid, wherein the flame retardant is a mixture of an inorganic flame retardant and an organic flame retardant; the organic flame retardant is at least one of melamine cyanurate, melamine pyrophosphate, organic hypophosphite and pentaerythritol; the inorganic flame retardant is at least one of zinc borate, magnesium hydroxide and expansible graphite; the mass ratio of the inorganic flame retardant to the organic flame retardant is (0.1-10):1. The composite material disclosed by the invention has the advantages of favorable flame-retardant performance and mechanical property and easiness for processing and forming.

Owner:ADVANCED THERMOPLASTIC POLYMER TECH

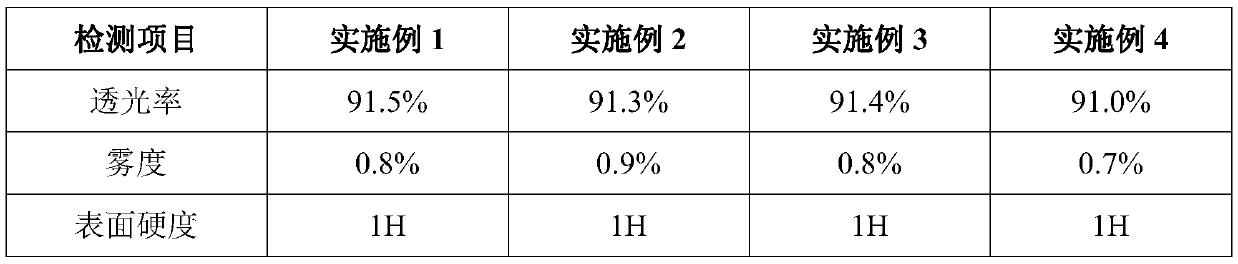

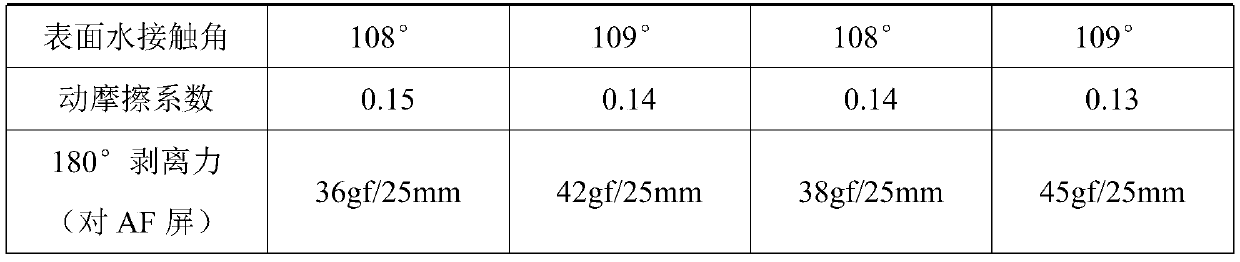

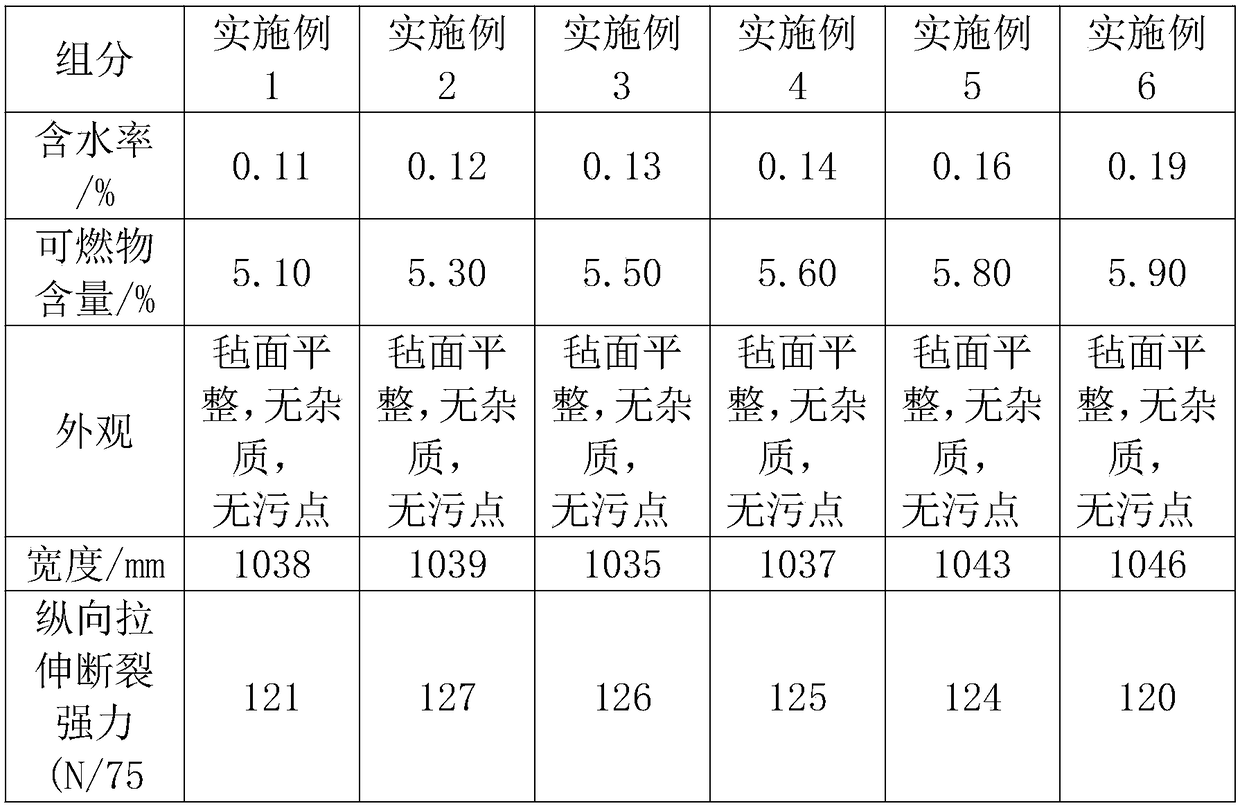

Anti-fingerprint TPU protective film for 3D curved screen and preparation method of anti-fingerprint TPU protective film

PendingCN111484810AGood optical performanceImprove smoothnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterColloidal silica

The invention discloses an anti-fingerprint TPU protective film for a 3D curved screen. The protective film comprises a low-viscosity protective film, an anti-fingerprint UV hardening coating, an optical hard TPU resin film layer, an optical-grade high-viscosity silica gel pressure-sensitive adhesive layer and a fluorine element release film which are attached from top to bottom; the anti-fingerprint UV hardening coating is formed by coating an anti-fingerprint UV hardening coating; the optical hard TPU resin film layer is formed by coating optical hard TPU glue, the optical-grade high-viscosity silica gel pressure-sensitive adhesive layer is formed by coating an optical-grade high-viscosity silica gel pressure-sensitive adhesive; the anti-fingerprint UV hardening coating is prepared fromthe following components: UV prepolymer resin, an acrylate reactive diluent, a photoinitiator, a slipping aid and a first solvent, the optical-grade hard TPU glue is formed by polymerizing polyisocyanate, polyester polyol and a chain extender in a second solvent under the action of a first catalyst; the optical-grade high-viscosity silica gel pressure-sensitive adhesive is composed of silica gel resin, a cross-linking agent, an anchoring agent and a second catalyst. The anti-fingerprint TPU protective film for a 3D curved screen has the properties of fingerprint resistance, scratch resistance,difficulty in bursting and good fitting property of the curved screen.

Owner:GUANGDONG BANGGU FILM COATING INNOVATION ACAD CO LTD

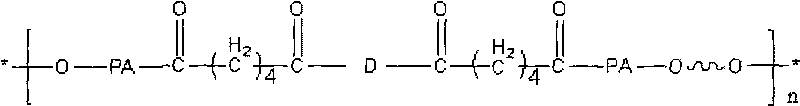

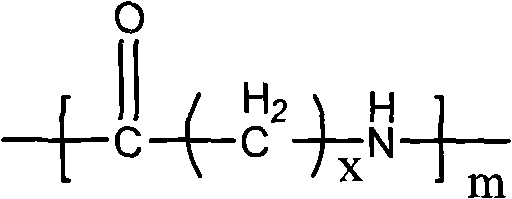

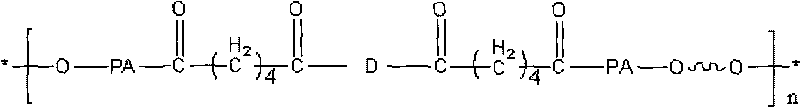

PA6 (polyamide 6) type thermoplastic elastomer and preparation method thereof

ActiveCN101747510AImprove the noise reduction effectAdjustable hardnessElastomerThermoplastic elastomer

The invention relates to a PA6 (polyamide 6) type thermoplastic elastomer and a preparation method thereof, in particular to a PA6 type thermoplastic elastomer containing polyether and diisocyanate blocks and a preparation method thereof, more particularly to a method for preparing a block copolymer thermoplastic elastomer by firstly preparing PA6 and diisocyanate hard blocks by adopting a hydrolysis ring-opening polymerization method and then carrying out esterification and polycondesation with polyether soft blocks. The PA6 type thermoplastic elastomer comprises the hard blocks consisting of the PA6 and the diisocyanate blocks, polyol soft blocks, hard blocks and soft blocks, which alternately exist in the thermoplastic elastomer; and the hard blocks consisting of the PA6 and the diisocyanate blocks comprise two PA6 segmers and one diisocyanate block. The PA6 type thermoplastic elastomer has high tenacity, strong abrasive resistance and good elasticity. The preparation method of the PA6 type thermoplastic elastomer has simple process, one-step hydrolysis of reaction, higher molecular weight, good elasticity, adjustable Shore hardness, good abrasive resistance, good erasure effect and reduced damp attenuation.

Owner:SHANGHAI YITAN NEW MATERIAL CO LTD +1

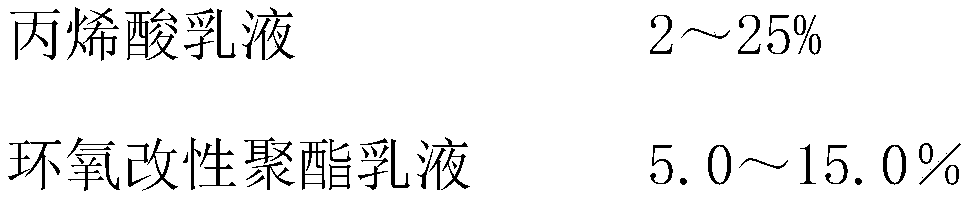

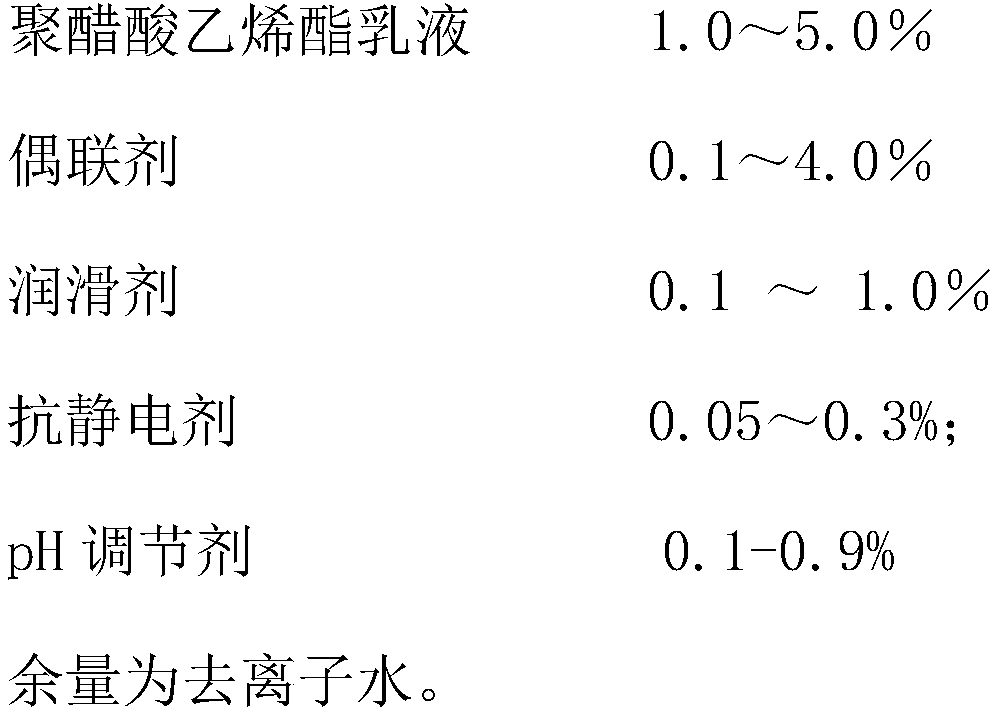

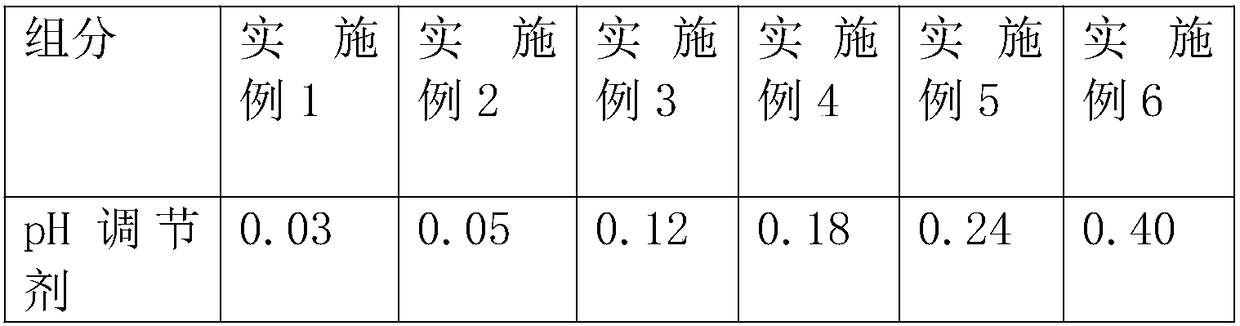

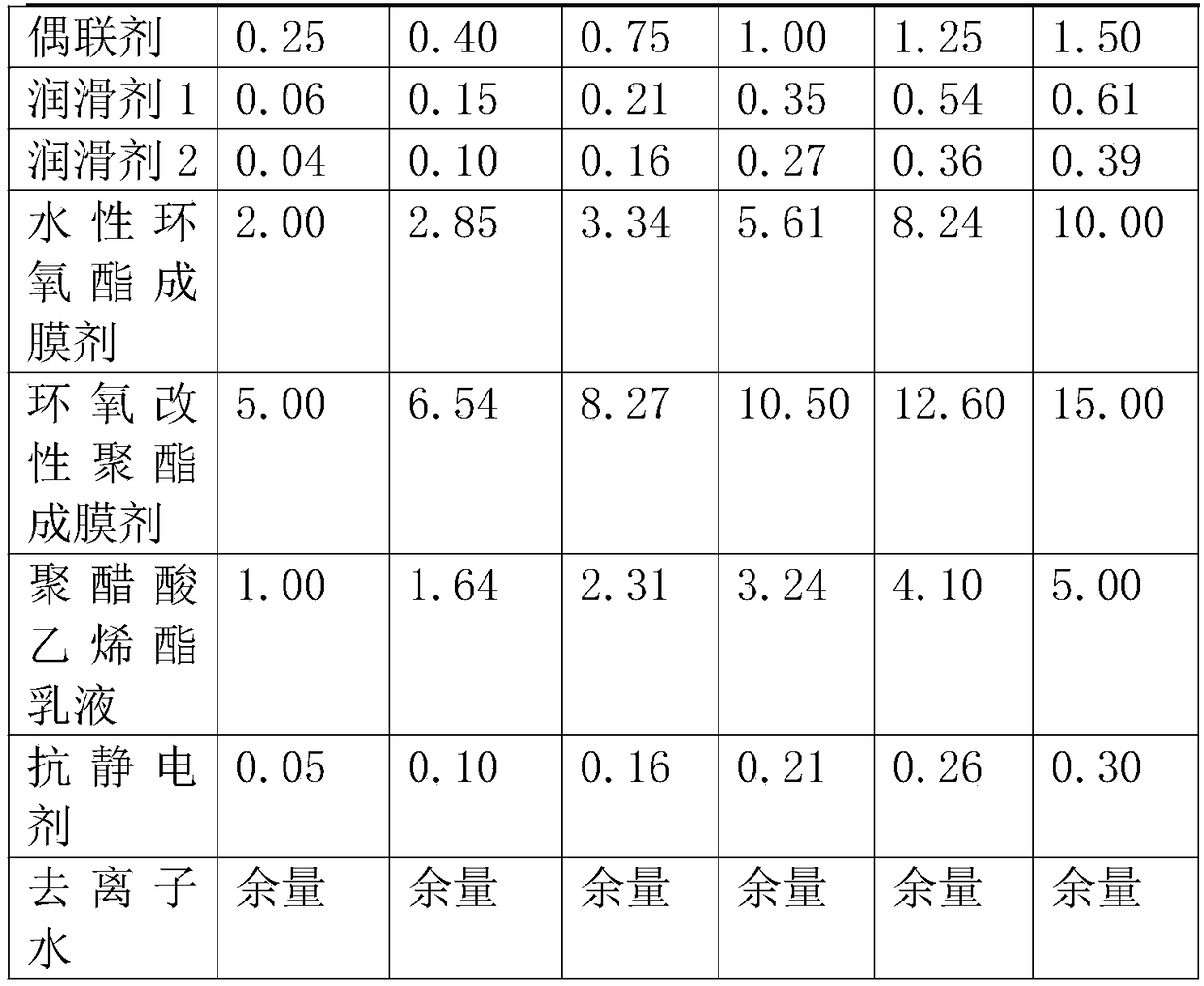

Impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn

The invention relates to an impregnating compound for enhancing polypropylene plastic-glass fiber chopped yarn. The impregnating compound is prepared from components in percentage by total mass of theimpregnating compound as follows: 3%-22% of an acrylic emulsion, 5.0%-15.0% of epoxy modified polyester emulsion, 1.0%-5.0% of a polyvinyl acetate emulsion, 0.1%-1.0% of a lubricating agent, 0.05%-0.3% of an antistatic agent, 0.1%-0.9% of a pH regulator and the balance of deionized water. Compared with the prior art, the provided impregnating compound can have a good compatibility with polypropylene plastic resin, the plasticity and stiffness of the glass fiber are enhanced, and the impregnating compound has small static electricity and adjustable hardness, can be compatible with multiple resin, is high in resin permeation speed and good in bondability with resin and endows a composite with excellent mechanical properties.

Owner:SHANDONG FIBERGLASS GRP

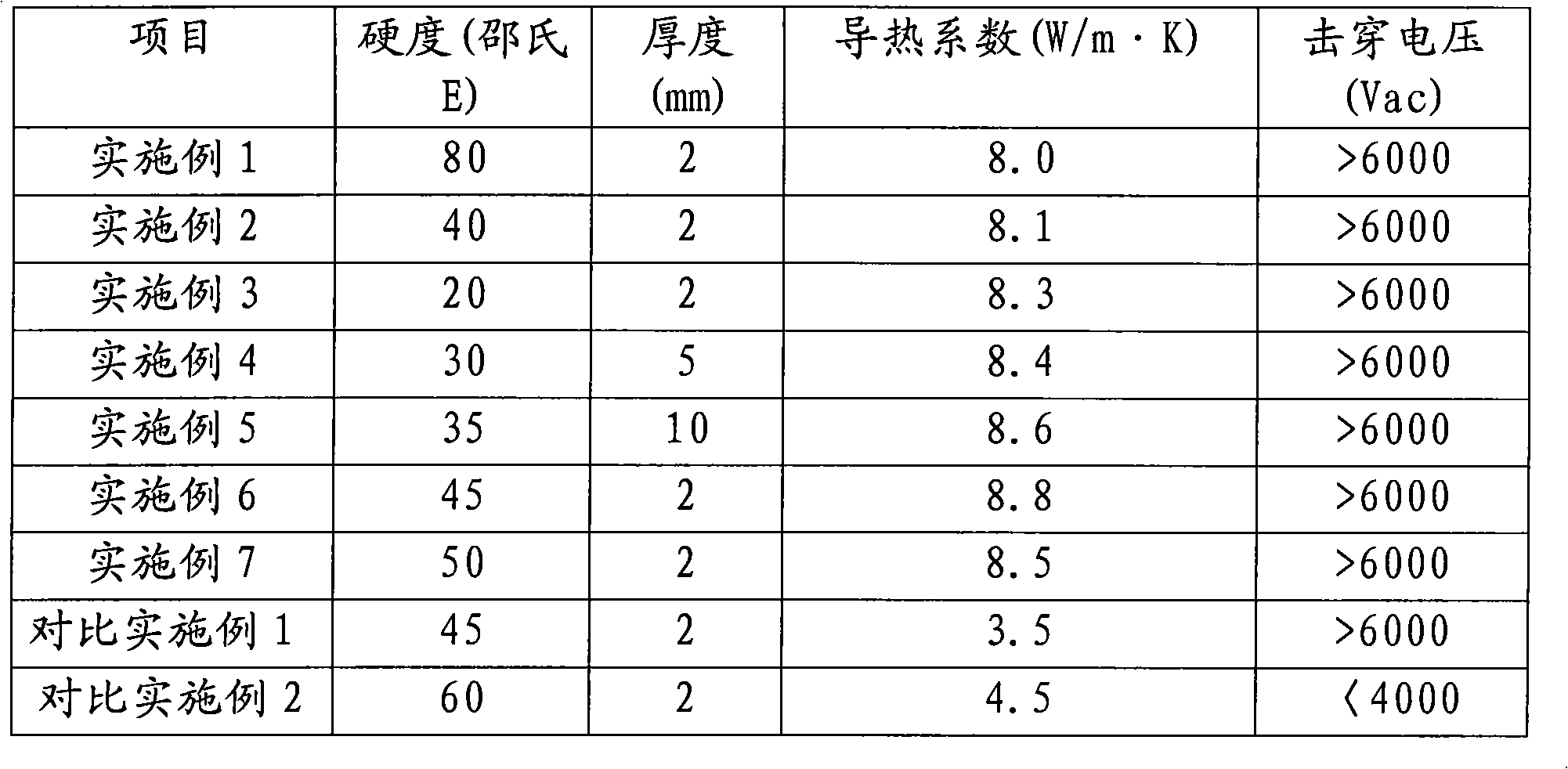

Macromolecule thermal-conducting composite material and preparation method thereof

InactiveCN101921489AGood thermal conductivity performanceLow costHeat-exchange elementsPolyresinRaw material

The invention relates to a macromolecule thermal-conducting composite material and a preparation method thereof. The macromolecule thermal-conducting composite material comprises two parts of matrix resin and a heat conductive filler with the weight proportion of 100:700-110:1100. The matrix resin comprises the following raw materials in percentage by weight: 95-99 percent of organic silicon resin, 1-4 percent of curing agent and 0.1-1 percent of catalyst; and the heat conductive filler comprises the following raw materials in percentage by weight: 70-95 percent of spherical filler and 5-30 percent of needle-like filler. The preparation method comprises the steps of: sequentially adding the organic silicon resin, the curing agent and the catalyst into a mixer, mixing to obtain the matrix resin; then mixing the matrix resin with the heat conductive filler by the proportion of 100:700-100:1100, wherein in the process of the heat conductive filler addition, 70-95 percent of the spherical filler is added firstly and the 5-30 percent of needle-like filler is added subsequently; and stirring for mixing, smearing to form a film, and curing to obtain the composite material.

Owner:YANTAI DARBOND TECH

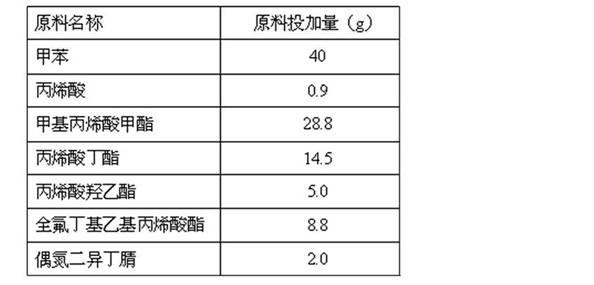

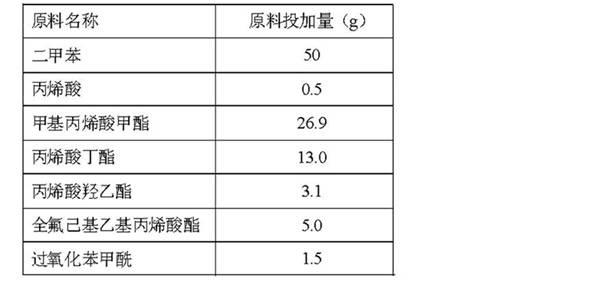

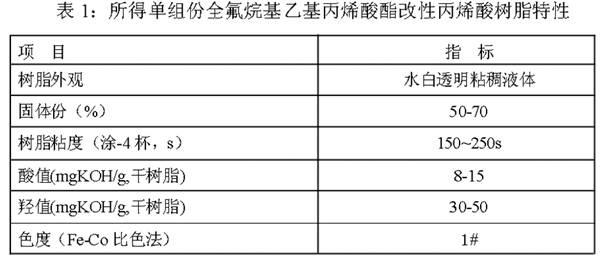

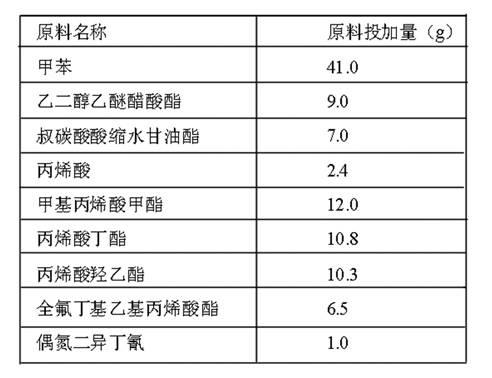

Perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin and preparation method as well as application thereof

ActiveCN102250280AReduce surface propertiesAccelerated corrosionCoatingsPolymer scienceAcrylic resin

The invention relates to a perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin and a preparation method as well as application thereof. The perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin has the structural formula which is shown in the specification, wherein n is equal to 4, 6 or 8; and the molecular weight is 40,000-55,000. The preparation method comprises the following steps of: adding a solvent into a reaction vessel and heating to 60-80 DEG C; uniformly mixing methyl methacrylate, acrylic acid, butyl acrylate, hydroxyethyl acrylate and perfluoro alkyl ethyl acrylic ester type monomer with an initiator and dropwise adding for 2-3 hours; preserving heat for 0.5-1 hour; and cooling to 40-70 DEG C and discharging. The resin prepared by the invention has high thermal stability and chemical resistance stability and low surface energy and is used as a main raw material of a paint; and a coating also has low surface energy, strong water-proof and oil-proof capacities and high weather resistance, corrosion resistance and aging resistance, has superior mechanical performance and high glossiness of an acrylic ester paint, can be cured at normal temperature and is easy and convenient to use.

Owner:JINZHOU DPF TH CHEM CO LTD

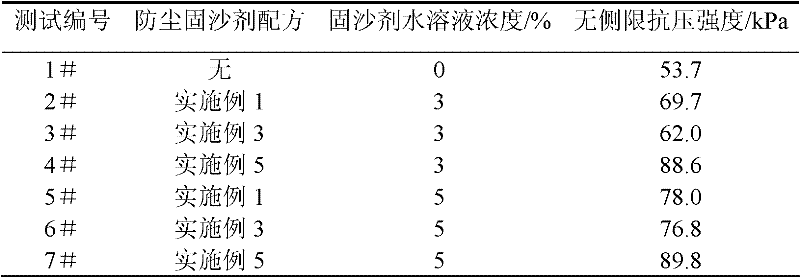

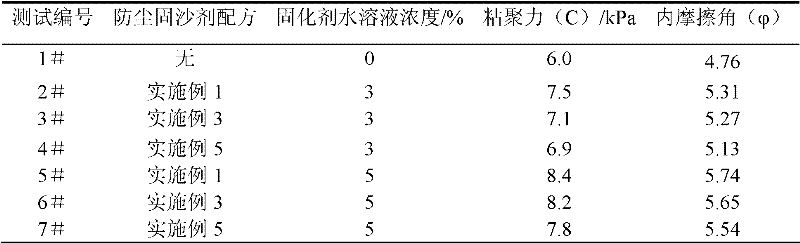

Polyurethane-based ecological sand-fixing agent and preparation method thereof

ActiveCN102226088AGood strength bearing capacityEasy to adjustOrganic fertilisersSoil conditioning compositionsPolymer sciencePolyol

The invention relates to a polyurethane-based ecological sand-fixing agent and a preparation method thereof. The sand-fixing agent comprises the following components: 25-29 parts of polyurethane prepolymer, 0.5-2.1 parts of dispersion stabilizer and 27-36 parts of solvent, wherein the polyurethane prepolymer is obtained by polycondensation reaction of polymer polyol and diisocyanate, the polymer polyol comprises polypropylene oxide diol, polyoxyethylene diol and easily-degradable polymer diol, the mass ratio of polypropylene oxide diol to polyoxyethylene diol is (1:3)-(5:1), and the easily-degradable polymer diol accounts for 13-23wt% of the polymer polyol; and the mass ratio of the polymer polyol to diisocyanate is (4:1)-(7:1). The preparation method comprises the following steps: controlling the temperature at 85-100 DEG C under nitrogen gas protection, allowing reaction between the polymer polyol and diisocyanate to obtain a polyurethane prepolymer, and homogeneously mixing the polyurethane prepolymer, the dispersion stabilizer and the solvent to obtain the polyurethane-based ecological sand-fixing agent.

Owner:NANJING UNIV

Method for synthesizing p-phenylene diisocyanate

InactiveCN1687022ANo pollution in the processNo toxicityIsocyanic acid derivatives preparationOrganic compound preparationRoom temperatureNitrogen gas

The present invention relates to a method for synthesizing p-phenylene diisocyanate. Said method includes the following steps: adding inert organic solution of di(trichloromethyl) carbonate into reaction flask, introducing nitrogen gas to make protection, under the condition of cooling slowly adding inert organic solution of p-phenylene diamine, making reaction for 2-4 hr, at 15-200 deg.C and 0-0.3 MPa, after the reaction is completed, removing solvent, filtering and washing so as to obtain solid product p-phenylene diisocyanate.

Owner:杭州崇舜化学有限公司

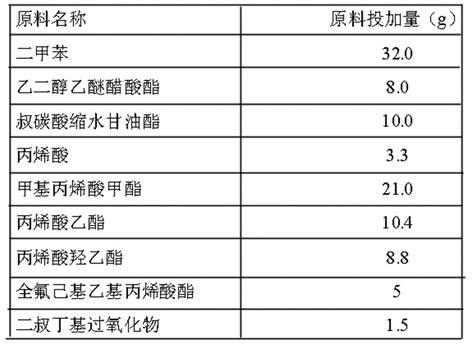

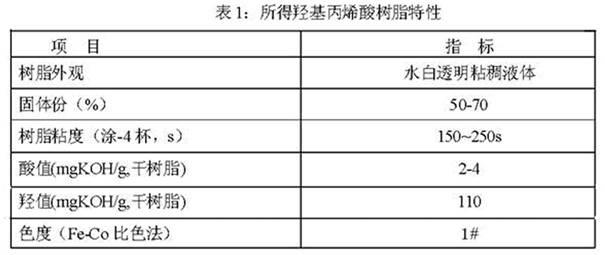

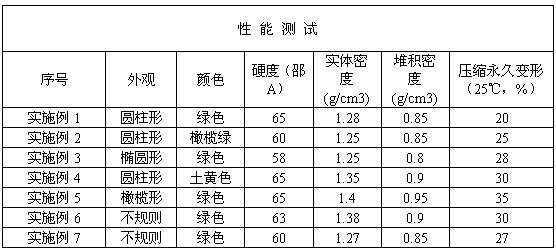

Hydroxylated acrylic resin as well as preparation method and application thereof

The invention relates to hydroxylated acrylic resin as well as preparation method and application thereof. The hydroxylated acrylic resin has a structural formula, wherein n is equal to 4, the sum of C number in 6, 8, R1 and R2 is 9, and the molecular weight is 10,000-20,000; the preparation method comprises the steps of: adding solvent and reactive solvent into a reaction vessel under protectionof nitrogen gas environment, and increasing temperature to 150-160 DEG C; evenly mixing acrylic acid, methyl methacrylate, ethyl acrylate, hydroxyethyl acrylate and perfluoroalkylethyl acrylate monomer with initiator, and carrying out dropwise addition for 3-4 hours; carrying out heat insulation for 1.5-2 hours; and reducing temperature to 40-70 DEG C for discharging, thus obtaining hydroxylated acrylic resin. A paint film formed by the hydroxylated acrylic resin and a curing agent has properties of both acrylic polyurethane and fluorocarbon coating. The prepared hydroxylated acrylic resin can carry out reaction smoothly at normal temperature and normal pressure, has low production cost, can be cured at normal temperature and be applied in the fields of ships, containers, drilling platforms, anticorrosion of steel structures, outer wall coating of high-rise buildings and the like.

Owner:JINZHOU DPF TH CHEM CO LTD

Thermoplastic elastomer material for artificial lawn and preparation method thereof

The invention provides a thermoplastic elastomer material for an artificial lawn and a preparation method thereof. The material can meet environment-friendly requirements and simultaneously ensure the good performances of the artificial lawn, and the material can further improve the resilience of the artificial lawn and is environment-friendly. The material comprises the following components in parts by weight: 10-30 parts of styrene type thermoplastic elastomer, 1-5 parts of PP (polypropylene) or PE (polyethylene) or a mixture with the weight ratio of PP / PE of (0.5-3):1, 2-10 parts of novel metallocene-catalyzed propylene-ethylene copolymer, 5-20 parts of mineral oil, 4-10 parts of stearic acid, 20-200 parts of active calcium carbonate, 0.1-2 parts of antioxidant, 0.1-2 parts of anti-ultraviolet agent and 0.1-5 parts of pigment.

Owner:金海兰

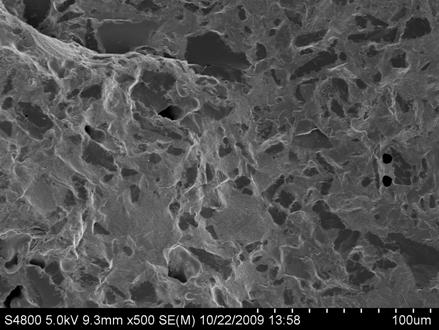

B4C/SiC whisker/SiC multiphase ceramic matrix composite and preparation method thereof

InactiveCN102219536AHigh bonding strengthImprove overall performanceCeramic matrix compositeWhiskers

The invention which belongs to the technical field of ceramic matrix composites concretely relates to a ceramic matrix composite containing multiple ceramic phases of SiC whiskers, SiC particles and B4C particles and a preparation method of a product thereof. The B4C / SiC whisker / SiC multiphase ceramic matrix composite is prepared through carrying out a Si or Si alloy infiltration reaction on a prefabricated member, and the prefabricated member is prepared through carrying out compression molding on raw materials containing at least one of SiC and carbon, SiC whiskers and B4C powder. The B4C / SiC whisker / SiC multiphase ceramic matrix composite containing the multiple ceramic phases of the SiC whiskers, the SiC particles and the B4C particles prepared in the invention allows integrated performances of the composites to be improved. In the invention, the spontaneous infiltration reaction method is employed, each advantage of the spontaneous infiltration reaction method is inherited, and the compact multiphase ceramic matrix composite and the product thereof are obtained by carrying out infiltration and reaction sintering on the porous prefabricated member which is composed of B4C and rice hull silicon carbide whiskerizing products containing abundant SiC with Si or the Si alloy.

Owner:ZHEJIANG UNIV

Biodegradable bionic fishing bait material and preparation method thereof

The invention discloses a biodegradable bionic fishing bait material and a preparation method thereof and relates to the technical field of artificial fishing baits. A main raw material of the biodegradable bionic fishing bait material is a blend of two or a plurality of types of degradable thermoplastic materials, such as polyurethane (TPU), polyhydroxyalkanoate (PHA), polylactic acid (PLA), polyhydroxypropionic acid-glycolide (PLGA) and capryl glycol polycitrate (POC); an environment-friendly plasticizer is one or more of a compound of citrate, isosorbide, epoxidized soybean oil and the like; feeding characteristics of fish varieties are matched with a plurality of types of fish attracting components including corn starch, a plurality of types of amino acids, minerals, protein and the like, and an antioxidant for a bionic fishing bait, and the components are blended and granulated; a mixture is subjected to injection molding to obtain the bionic fishing bait with various colors and fish, shrimp and insect shapes. The bionic fishing bait prepared by the invention has advantages of a food fishing bait and the bionic fishing bait, and has a great attraction force on the taste senseof fishes; a product is adjustable in hardness and can be completely biodegraded, and is an ecological environment-friendly bionic fishing bait for attracting the fishes.

Owner:ANHUI UNIVERSITY

PA6 type thermoplastic elastomer and preparation method thereof

The invention provides a PA6 type thermoplastic elastomer with high molecular weight, good elasticity and adjustable hardness, and a preparation method thereof. The method comprises the following steps: adding 4-40 parts by weight of polyetheramine, 50-94 parts by weight of caprolactam, 0.5-2 parts by weight of diacid and 1-8 parts by weight of a ring opening agent to a reactor, reacting under 0.25-0.55Mpa for 4-7h, reacting under normal pressure for 5-8h, reacting under 0-0.05Mpa for 1-3h, controlling the reaction temperature to be always in a range of 240-270DEG C, carrying out boiling water extraction, and carrying out vacuum drying to obtain the PA6 type thermoplastic elastomer. Certain temperature maintenance and pressure change of amino-terminated polyether, the diacid and caprolactam are carried out under the action of the ring opening agent, so the method has the advantages of simple process and high production efficiency, and the obtained PA6 type thermoplastic elastomer has the advantages of high molecular weight, good elasticity and adjustable Shore hardness.

Owner:FUJIAN JINJIANG TECH

Molding material, molded part, and method for manufacturing them

InactiveUS20080036119A1High affinityGood mixing propertiesFilament/thread formingWood working apparatusCross-linkShell molding

A method for manufacturing a molded part with an improved convenience and a high degree of efficiency in molding is provided, the molded part containing a biodegradable resin composite, which has the heat resistance in a wide temperature range and which is provided with the flexibility and the elongation in accordance with the use. A kneaded product of a biodegradable resin component and a cross-linkable monomer is prepared. The biodegradable resin component is cross-linked and ground to prepare a biodegradable resin cross-linking product powder. An impregnant at a temperature of 60° C. or higher, and lower than or equal to the melting point or degradation temperature of the biodegradable resin component is impregnated to prepare a molding material composed of a biodegradable resin composite powder. The molding material is heated to a temperature higher than or equal to the melting point of the biodegradable resin component to mold into pellets.

Owner:SUMITOMO ELECTRIC FINE POLYMER INC

Nano-composite coating with low surface energy and preparation method thereof

The invention discloses a nano-composite coating with low surface energy and a preparation method thereof. The nano-composite coating consists of a transition layer and a surface layer, wherein the thickness of the transition layer is between 2 and 200 mu m, and the transition layer consists of more than one layer of mixture of bulbs, clubs and flakes; and the thickness of the surface layer is between 2 and 40 mu m, and the surface layer consists of a reticulated silica glassy substance. The method comprises the steps of: performing cleaning and roughing treatment on the surface of a substrate first, then mixing the bulbs, the clubs, the flakes, a slurry forming agent and a solvent to obtain slurry of the transition layer, using the slurry of the transition layer to coat the substrate, placing the coated substrate at a temperature of between 180 and 250 DEG C to obtain the transition layer, then mixing organosiloxane water solution and alcohol solution of ethyl orthosilicate to obtain hydrolytic polycondensation reaction solution first, then dripping acid into the hydrolytic polycondensation reaction solution to obtain coating solution of the surface layer, coating the substrate coated with the transition layer by the coating solution of the surface layer, and then placing the substrate at a temperature of between 180 and 250 DEG C to obtain the nano-composite coating with low surface energy. The coating has the characteristics of low surface energy, high density, adjustable hardness, good flexibility and strong adhesion force.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

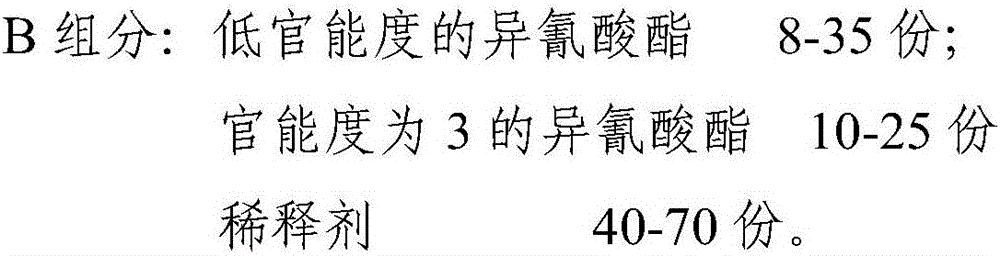

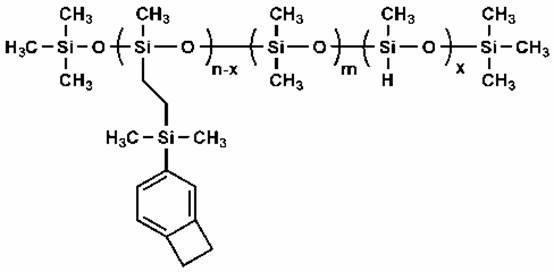

Benzocyclobutene polysiloxane polymer monomer or resin and preparation method thereof

The invention relates to a benzocyclobutene polysiloxane polymer monomer or resin and a preparation method thereof. The invention discloses a dimethyl-4-benzocyclobutene silicon-based ethylmethyl cyclotetrasome disclosed as Formula (III) and a preparation method thereof. The preparation method of the polysiloxane polymer monomer comprises the following steps:Sequentially adding a tetramethyl-tetravinyl-cyclosiloxane solution diluted by solvent methylbenzene and 4-(1-H-1,1-methyl)silicon benzocyclobutene into a reactor, adding a platinum catalyst after applying a nitrogen atmosphere, and reacting at 60-90 DEG C for 20-40 hours; and adding triphenylphosphine, heating under reflux for 3 hours, cooling, filtering, concentrating the filtrate by distillation, adding methanol, mixing, precipitating, filtering, repeatedly precipitating the solid with methanol, and drying the solid to obtain the polysiloxane polymer monomer product. The product has excellent thermal properties, mechanical properties, electric properties and film-forming properties, and has wide development and application prospects as a high-performance dielectric film material or packaging material in the fields of micro-electronics, aerospace, national defence and the like. (III).

Owner:BEICHUAN RUIHUI SCI & TECH CO LTD

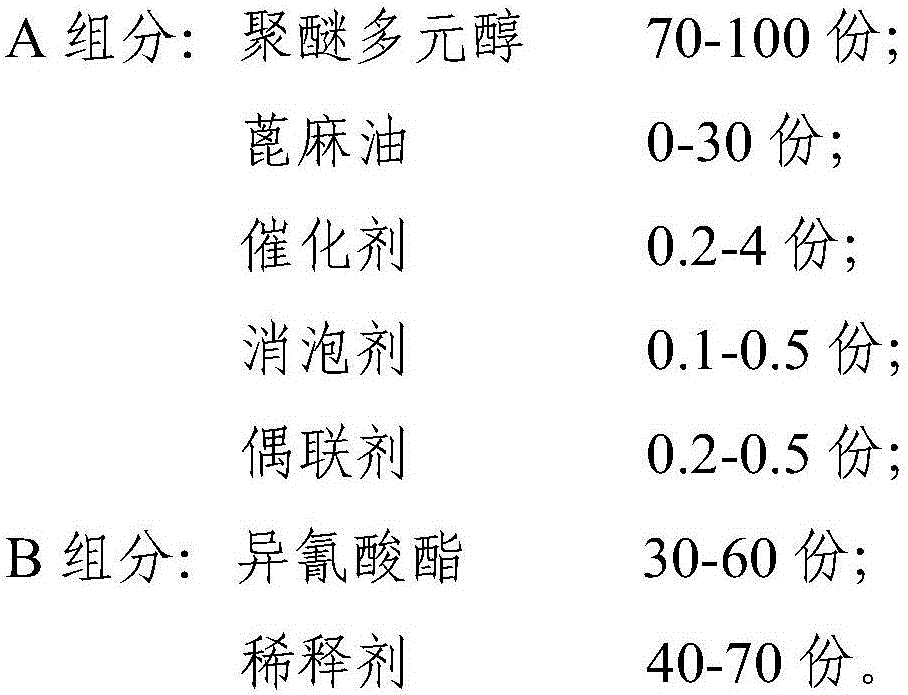

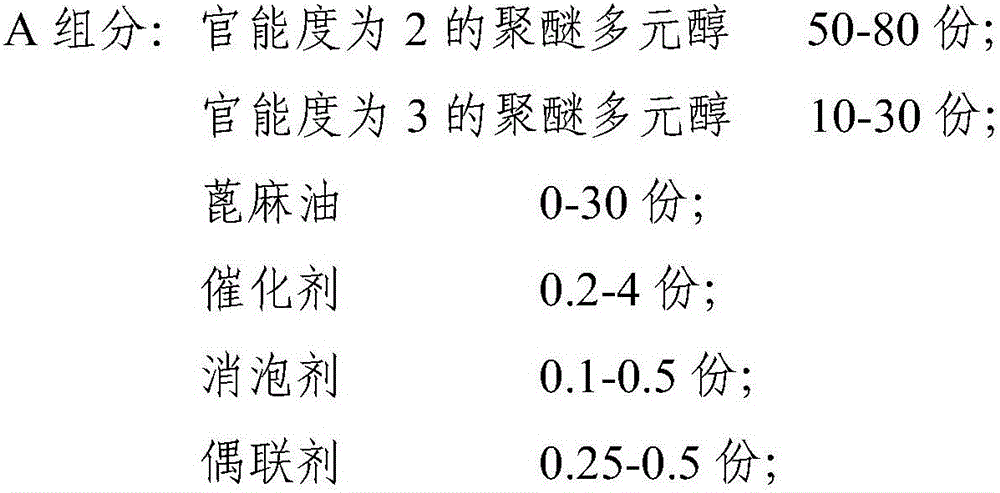

Expediting setting polyurethane pouring sealant material and preparing method thereof

The invention relates to a polyurethane pouring sealant material and a preparing method thereof. The polyurethane pouring sealant material contains a component A and a component B, wherein the component A is prepared from, by mass, 70-100 parts of polyether polyol, 0-30 parts of castor oil, 0.2-4 parts of catalyst, 0.1-0.5 part of defoamer and 0.2-0.5 part of coupling agent, and the component B is prepared from, by mass, 30-60 parts of isocyanate and 40-70 parts of diluents. The polyurethane pouring sealant material has the advantages that setting speed is high, matching operation is easy, environment friendliness is realized, hardness is adjustable, line repair can be achieved conveniently, and preparing process is simple.

Owner:BEIJING POLYSTAR HITECH CO LTD

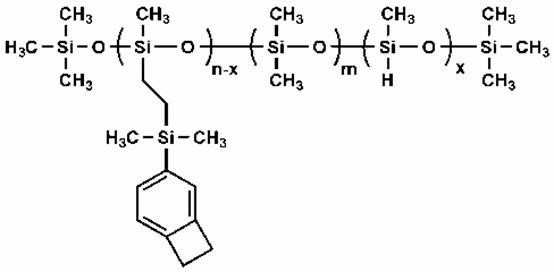

Benzocyclobutene silicone oil resin and preparation method thereof

InactiveCN102516547AImprove mechanicsGood thermal propertiesOther chemical processesMethyl benzenePlatinum catalyst

The invention discloses dimethyl-4-benzocyclobutene silicon-based vinyl-grafted modified hydrogen-containing silicone oil shown as a formula (IV) and a preparation method thereof. The preparation method of benzocyclobutene silicone oil resin comprises the following steps of: putting solvent-toluene-diluted hydrogen-containing silicone oil and 4-(1,1-dimethyl-1-vinyl) silicon benzocyclobutene intoa reactor, adding a platinum catalyst after being protected by N2, and stirring and carrying out reaction for 20-40 hours at the reaction temperature of 60-90 DEG C; and adding triphenylphosphine, heating to reflux for 3 hours, cooling, filtering, adding methanol and mixing after a filtrate is concentrated, carrying out precipitation, filtering, carrying out repeated precipitation on solids for 1-2 times by using methanol, and then, drying to obtain a product. The product, i.e. benzocyclobutene silicone oil resin, has excellent thermal properties, mechanical properties, electrical properties and film forming properties and has wide development and application prospects in fields, such as microelectronics industry, aerospace and national defense and the like.

Owner:BEICHUAN RUIHUI SCI & TECH CO LTD

Piston ring

ActiveUS8273469B2Adjustable hardnessPiston ringsBraking action transmissionPiston ringWear resistant

Disclosed is a piston ring comprising a supporting material and a wear-resistant coating. The wear-resistant coating is composed of a ternary system A-B—N which is applied using a PVD process and in which A and B each represent an element form the group encompassing Ti, Zr, Hf, V, Nb, Ta, Cr, Mo W, Al, Si and C, wherein A≠B and N represents nitrogen. The thickness of the wear-resistant coating amounts to ≧3 μm.

Owner:FEDERAL MOGUL BURSCHEID

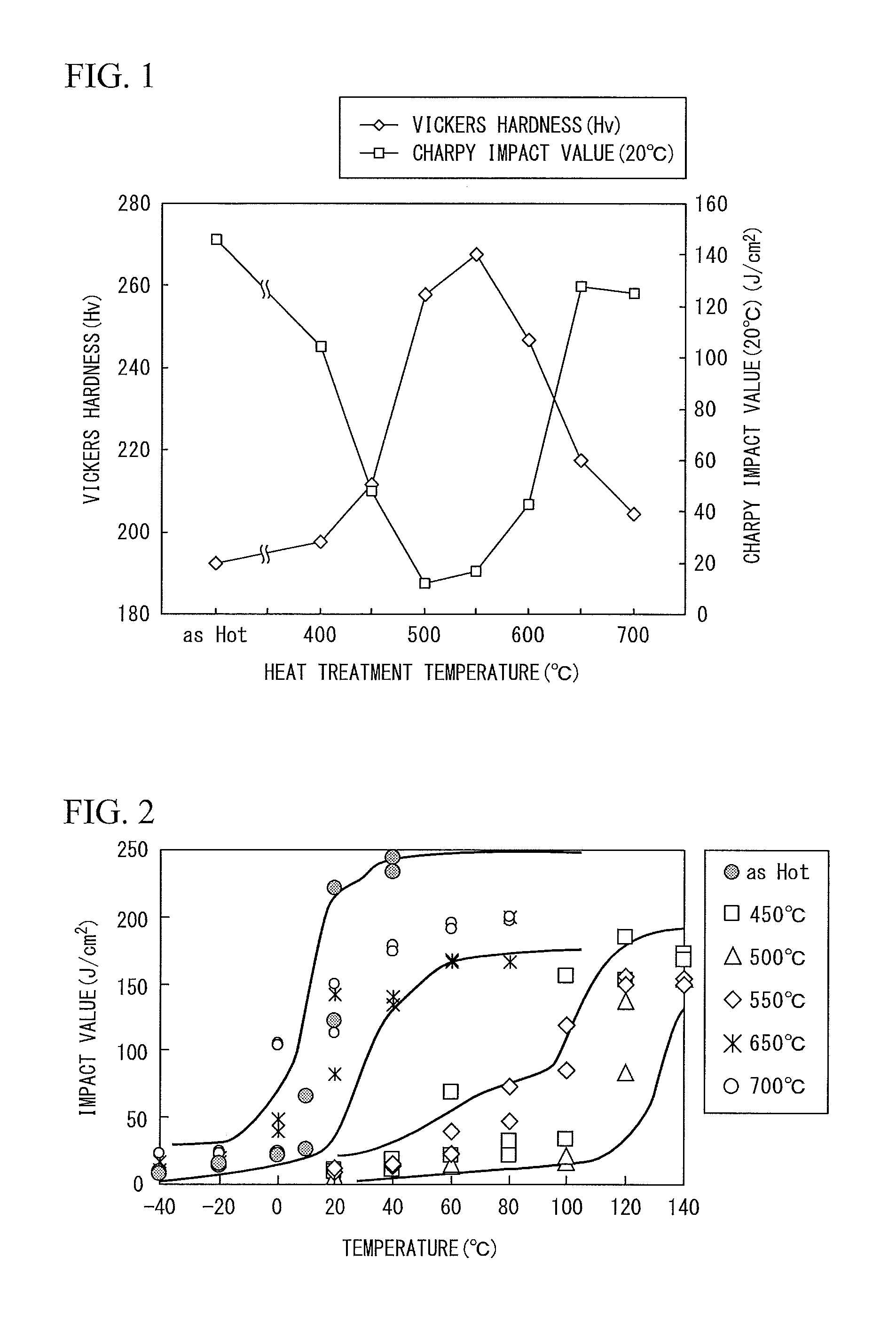

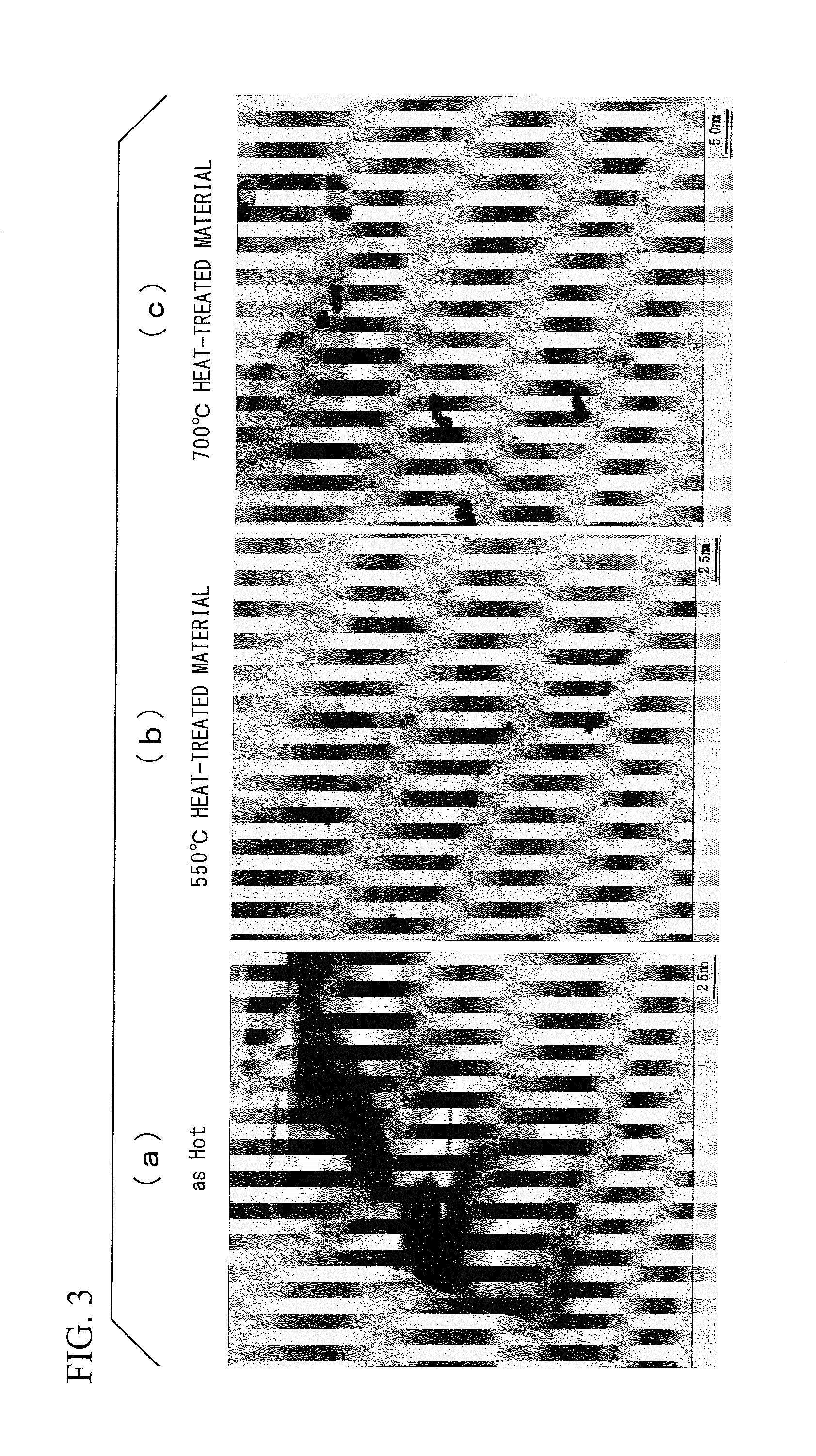

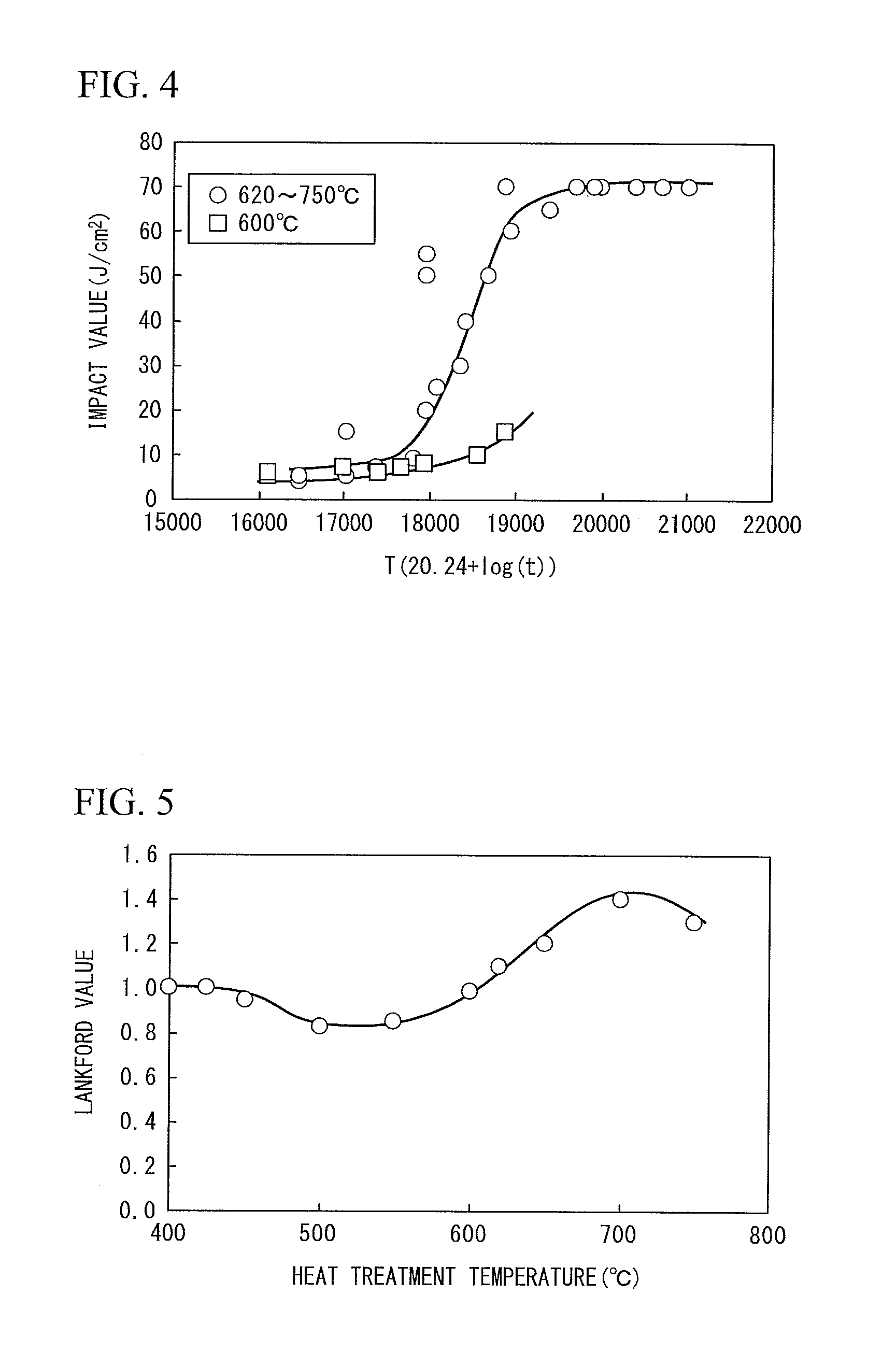

Hot rolled ferritic stainless steel sheet, method for producing same, and method for producing ferritic stainless steel sheet

ActiveUS20130306204A1Improve heat resistanceAdjustable hardnessFurnace typesMetal rolling arrangementsMetallurgyMaterials science

This hot-rolled ferritic stainless steel sheet has a steel composition containing, in terms of % by mass: 0.02% or less of C; 0.02% or less of N; 0.1% to 1.5% of Si; 1.5% or less of Mn; 0.035% or less of P; 0.010% or less of S; 1.5% or less of Ni; 10% to 20% of Cr; 1.0% to 3.0% of Cu; 0.08% to 0.30% of Ti; and 0.3% or less of Al, with the balance being Fe and unavoidable impurities, and the hot-rolled ferritic stainless steel sheet has a Vickers hardness of less than 235 Hv.

Owner:NIPPON STEEL STAINLESS STEEL CORP

Efficient flame retardant cable sheath material

InactiveCN103897400AGuaranteed completenessHigh strengthRubber insulatorsInsulated cablesAluminium hydroxideAluminum silicate

The invention discloses an efficient flame retardant cable sheath material which comprises the following raw materials in parts by weight: 80-100 parts of methyl vinyl silicone rubber, 16-23 parts of fumed silica, 11-17 parts of precipitated white carbon black, 1.3-2.2 parts of octamethylcyclotetrasiloxane, 30-40 parts of diatomite, 2-3 parts of titanium dioxide, 1.5-2.5 parts of titanium dioxide, 0.13-0.25 part of ferric oxide, 0.3-1 part of peroxidized bi(2, 4-dicholorbenzoyl), 0.5-0.9 part of 2, 5-dimethyl-2, 5-bi(tertiary butyl peroxy) hexane, 0.0015-0.002 part of platinum flame retardant, 15-20 parts of aluminum hydroxide, 20-30 parts of magnesium hydrate, 1-1.5 parts of dioctahedron alkaline aluminum silicate and 0.4-0.7 part of trioctahedron alkaline aluminum silicate. The efficient flame retardant cable sheath material disclosed by the invention is free from pollution, excellent in flame retardant effect and good in high-temperature self-extinguishing effect, and has certain strength and supporting capacity after combustion.

Owner:ANHUI DINGXING CABLE

Food-grade safe biomimetic simulated fish bait capable of being completely degraded

ActiveCN104304205ATaste sensory allureReduce pollutionBaitOther angling devicesCelluloseAdditive ingredient

The invention provides a food-grade safe type biomimetic simulated fish bait capable of being completely degraded, and relates to the technical field of fishing. The bait is prepared from the following components in parts by weight: 0.5-1 part of polyvinyl alcohol resin, 5-10 parts of edible gelatine, 5-10 parts of corn protein powder, 1-2 parts of hydrolyzed protein, 3-5 parts of aloe gel, 1-3 parts of corn peptide, 2-4 parts of microlite cellulose, 2-4 parts of dihydroxy acetone, 1-3 parts of a phagostimulant, 0.5-1 part of shea butter, 0.5-1 part of hyaluronic acid, 0.5-1 part of tea polyphenol, 2-4 parts of talcum powder, 1-2 parts of linseed gum, and 0.5-1 part of soybean lecithin. According to the bait disclosed by the invention, the corn protein powder, the edible gelatine and the aloe gel are used as main raw materials, the dihydroxy acetone is used as a plastifier, fish luring components of natural silk peptide, pit soil, esterified enzyme composite bacterial liquid and the like are added, according to the feeding characteristics of different fish varieties, the biomimetic bait with authentic features of various forage fish and shrimps is prepared, the bait can be completely biodegraded in natural environment, and pollution to the environment is little.

Owner:界首市猎钓渔具有限公司

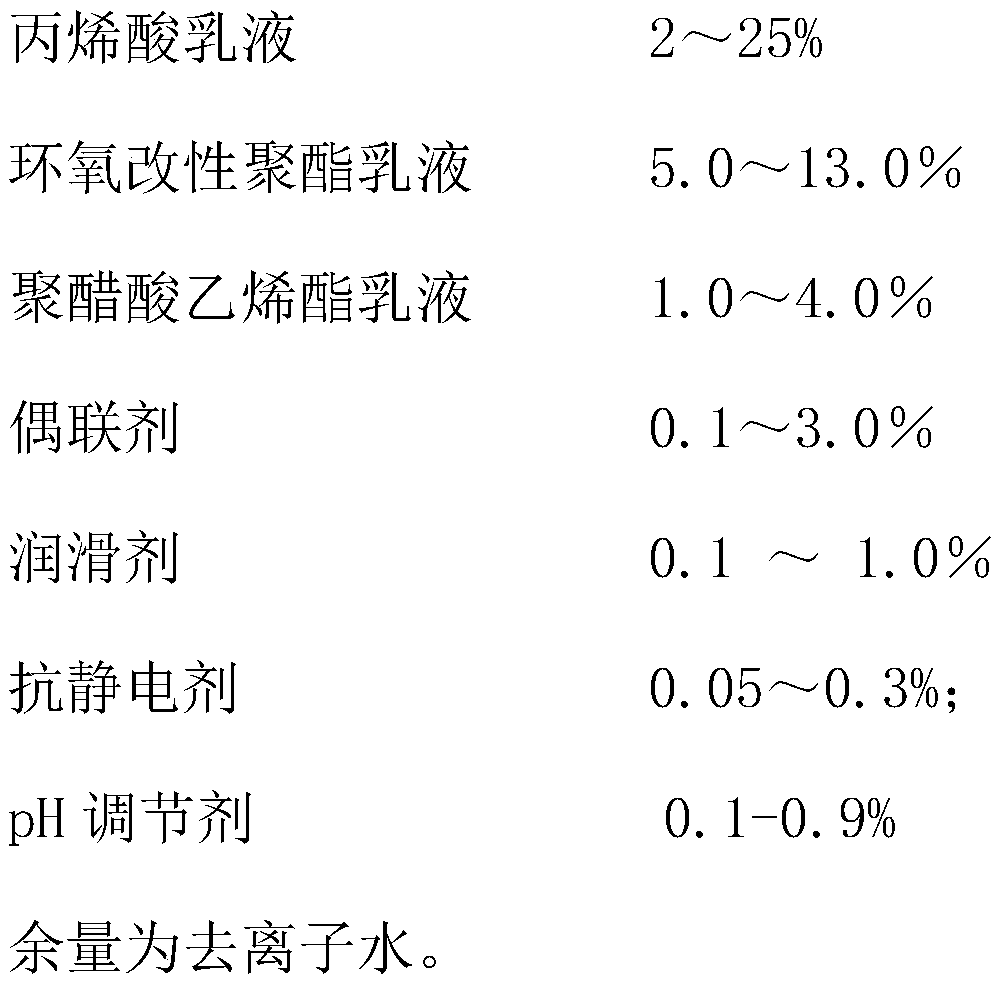

Glass fiber continuous strand mat impregnating agent

The invention relates to a glass fiber continuous strand mat impregnating agent. The glass fiber continuous strand mat impregnating agent is prepared from a silane coupling agent, a lubricating agent,a main film-forming agent, an auxiliary film-forming agent, a pH regulator, an anti-electrostatic agent and deionized water, wherein the film-forming agent comprises water-based epoxy ester emulsion,epoxy modified polyester emulsion and polyvinyl acetate emulsion; the solid content of the impregnating agent is 4.0 to 12.0 percent. A glass fiber original tow coated with the impregnating agent haslittle static electricity and adjustable hardness, can be compatible with various types of resin, is high in resin penetration velocity and has high bondability with the resin. Continuous felt with different solubility can be obtained by adjusting the proportion of the film-forming agent, and the glass fiber continuous strand mat impregnating agent is suitable for various processes such as pultrusion, injection molding and GMT processes.

Owner:SHANDONG FIBERGLASS GRP

Scratch resistance waterborne polyurethane coating and preparation method thereof

ActiveCN102559023AAdjustable hardnessToughness can be adjustedPolyurea/polyurethane coatingsExtensibilityHardness

The invention discloses a scratch resistance waterborne polyurethane coating. The scratch resistance waterborne polyurethane coating comprises the following raw materials in percentage by weight: 20-50 of waterborne acrylic acid resin, 10-30 of curing agent, 10-25 of nanometer calcium carbonate, 20-50 of waterborne polyurethane, 1-5 of reactive organic silicon and 1-3 of cosolvent. Correspondingly, the invention also discloses a preparation method of the scratch resistance waterborne polyurethane coating. According to the preparation method, the scratch resistance waterborne polyurethane coating is prepared by uniformly mixing the waterborne acrylic acid resin, the nanometer calcium carbonate, the waterborne polyurethane, an organic silicon solution and the curing agent. After the coating prepared by the method is cured, a coating film formed on the surface of a base material has scratch resistance and good extensibility and lubricative appearance; and simultaneously, a proportion of the hardness to toughness of the coating can be adjusted according to different applications of the coating; and the scratch resistance waterborne polyurethane coating has wide range of application and is low in cost.

Owner:ANHUI TIANAN NEW MATERIAL CO LTD

High temperature sealing coating and making method thereof

ActiveCN104404514AHigh bonding strengthImprove bindingMolten spray coatingSuperimposed coating processBraze alloyHigh pressure

The invention provides a high temperature sealing coating and a making method thereof. The high temperature sealing coating comprises a sealing coating bottom layer and a sealing coating surface layer; the material of the sealing coating bottom layer is NiCoCrWMoSiB high temperature brazing alloy or NiCrCoSiB high temperature brazing alloy; and the material of the sealing coating surface layer comprises 5-12wt% of polyphenyl ester, 5-10wt% BaF2 / CaF2, and the balance of NiCrAlYSi alloy or NiCrAlY alloy or NiCoCrAlTaY alloy or CoCrAlY alloy. The making method of the high temperature sealing coating comprises the following steps: making the sealing coating bottom layer on a substrate through cold gas dynamic spraying; making the sealing coating surface layer through plasma spraying; carrying out heat insulation on the substrate sprayed with the high temperature sealing coating at 500DEG C to obtain a pre-product; and carrying out vacuum diffusion treatment on the pre-product at 1150-1250DEG C for 15-30min to complete the production of the high temperature sealing coating. The high temperature sealing coating has the characteristics of low hardness, self lubrication, low friction coefficient and long life, can work at a temperature of 1150DEG C, and can be used for sealing gas paths of aeroengines and ground gas turbine high pressure turbines.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com