Perfluoro alkyl ethyl acrylic ester-modified single-component acrylic resin and preparation method as well as application thereof

A technology of perfluoroalkyl ethyl acrylate and perfluoroalkyl ethyl acrylic acid is applied in the field of one-component perfluoroalkyl ethyl acrylate modified acrylic resin and its preparation, and can solve harsh reaction conditions, operation High technical requirements and increased resin production costs, etc., to achieve the effects of low surface energy, simple construction and operation, and strong water and oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

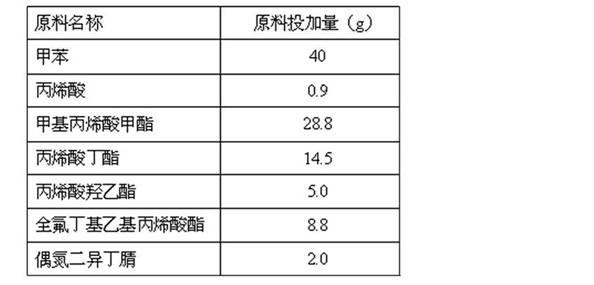

[0025] Raw material distribution table

[0026]

[0027] (1) First add toluene into the reactor according to the raw material dosage table, and raise the temperature to 60°C;

[0028] (2) Mix acrylic acid, methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, perfluorobutyl ethyl acrylate and azobisisobutyronitrile evenly, and add dropwise for 2 hours;

[0029] (3) keep warm for 1 hour;

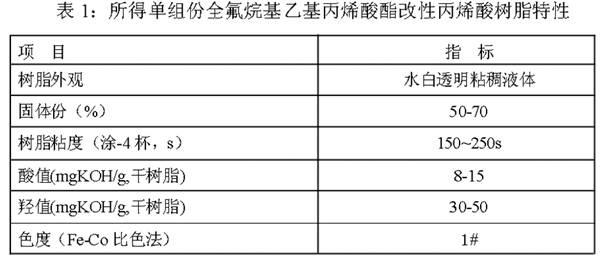

[0030] (4) Then cool down to 40°C and discharge to produce a one-component perfluoroalkyl ethyl acrylate modified acrylic resin with a molecular weight of 55,000. The obtained one-component perfluoroalkyl ethyl acrylate modified Acrylic resin properties are shown in Table 3.

[0031] The application of the one-component perfluoroalkyl ethyl acrylate modified acrylic resin as a coating raw material, its preparation process is as follows:

[0032] (1) Use toluene to adjust the viscosity of one-component perfluoroalkyl ethyl acrylate modified acrylic resin, and apply it to a -4 cup f...

Embodiment 2

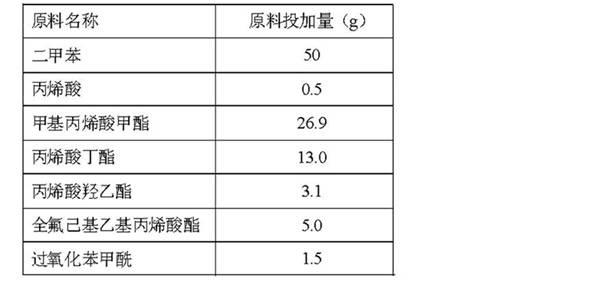

[0037] Raw material distribution table

[0038]

[0039] (1) Add toluene into the reactor according to the raw material dosage table, and raise the temperature to 75°C;

[0040] (2) Mix acrylic acid, methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, perfluorobutyl ethyl acrylate and azobisisobutyronitrile evenly, and add dropwise for 3 hours;

[0041] (3) Keep warm for 0.5 hours;

[0042] (4) Then cool down to 50°C and discharge to produce a one-component perfluoroalkyl ethyl acrylate modified acrylic resin with a molecular weight of 50,000. The obtained one-component perfluoroalkyl ethyl acrylate modified Acrylic resin properties are shown in Table 3.

[0043] The application of the one-component perfluoroalkyl ethyl acrylate modified acrylic resin as a coating raw material, its preparation process is as follows:

[0044] (1) Use toluene to adjust the viscosity of one-component perfluoroalkyl ethyl acrylate modified acrylic resin, apply it to a -4 cup and meas...

Embodiment 3

[0049] Raw material distribution table

[0050]

[0051] (1) First add toluene into the reactor according to the raw material dosage table, and raise the temperature to 70°C;

[0052] (2) Mix acrylic acid, methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, perfluorobutyl ethyl acrylate and azobisisobutyronitrile evenly, and add dropwise for 2 hours;

[0053] (3) Keep warm for 0.5 hours;

[0054] (4) Then cool down to 60°C and discharge to produce a one-component perfluoroalkyl ethyl acrylate modified acrylic resin with a molecular weight of 50,000. The obtained one-component perfluoroalkyl ethyl acrylate modified Acrylic resin properties are shown in Table 3.

[0055] The application of the one-component perfluoroalkyl ethyl acrylate modified acrylic resin as a coating raw material, its preparation process is as follows:

[0056] (1) Use toluene to adjust the viscosity of one-component perfluoroalkyl ethyl acrylate modified acrylic resin, and use it as a film-form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com