Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1297results about How to "Reduce toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant austenitic stainless steel and a production process thereof

InactiveUS20050194073A1Low costHigh-temperature strengthAustenitic stainless steelWorking temperature

Owner:DAIDO STEEL CO LTD

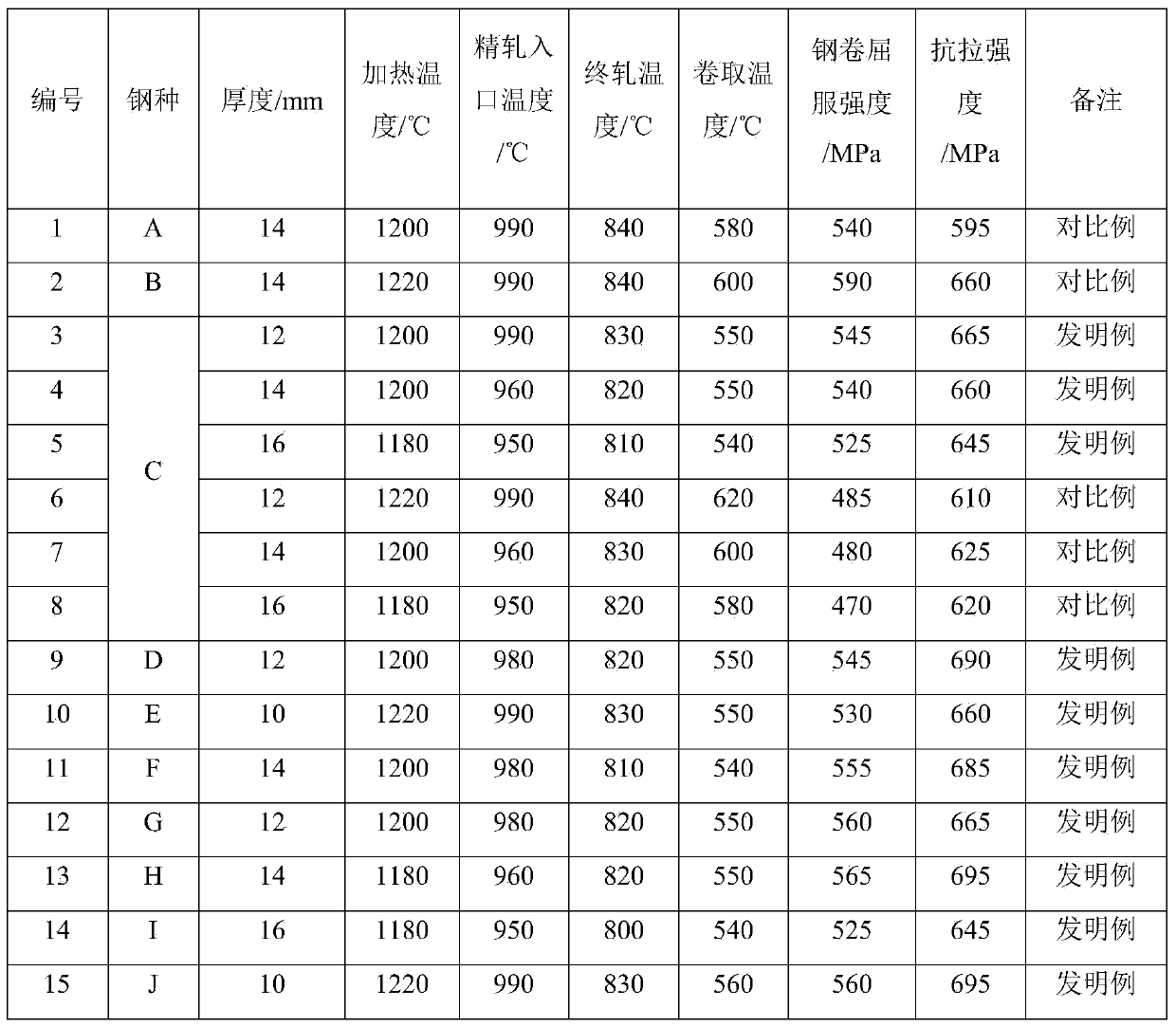

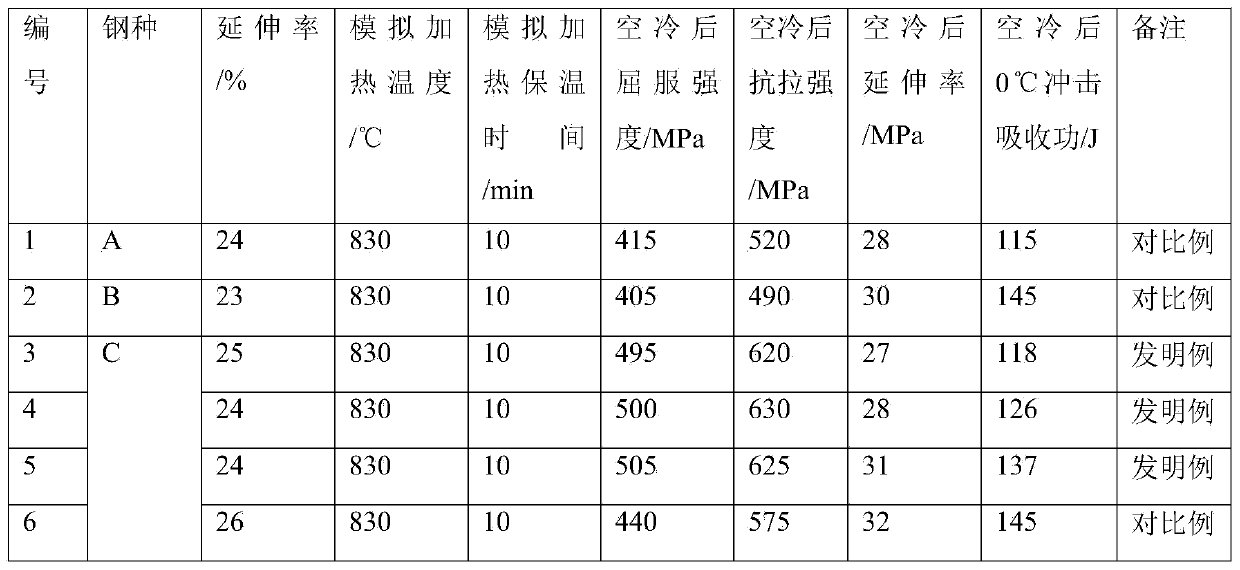

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

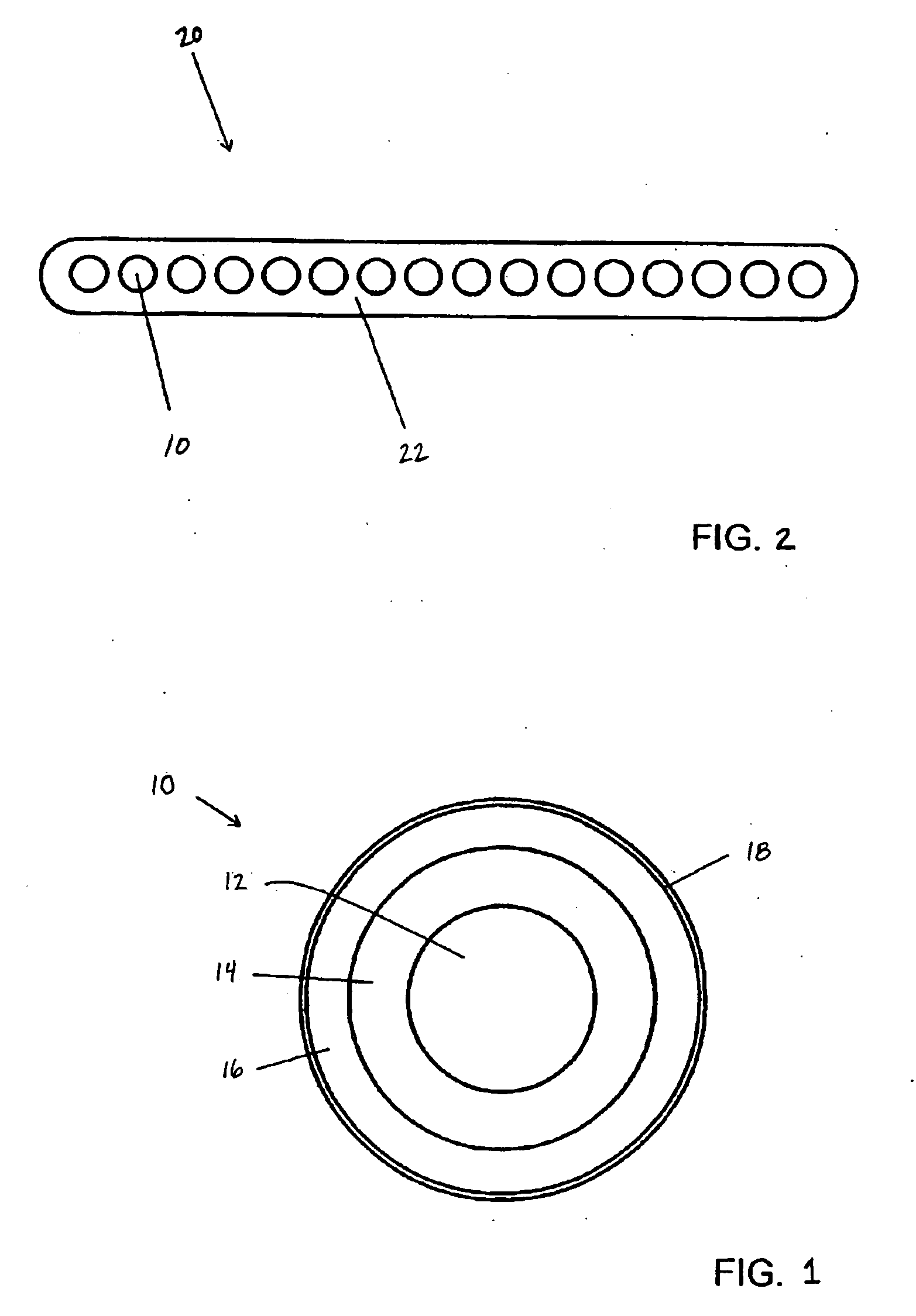

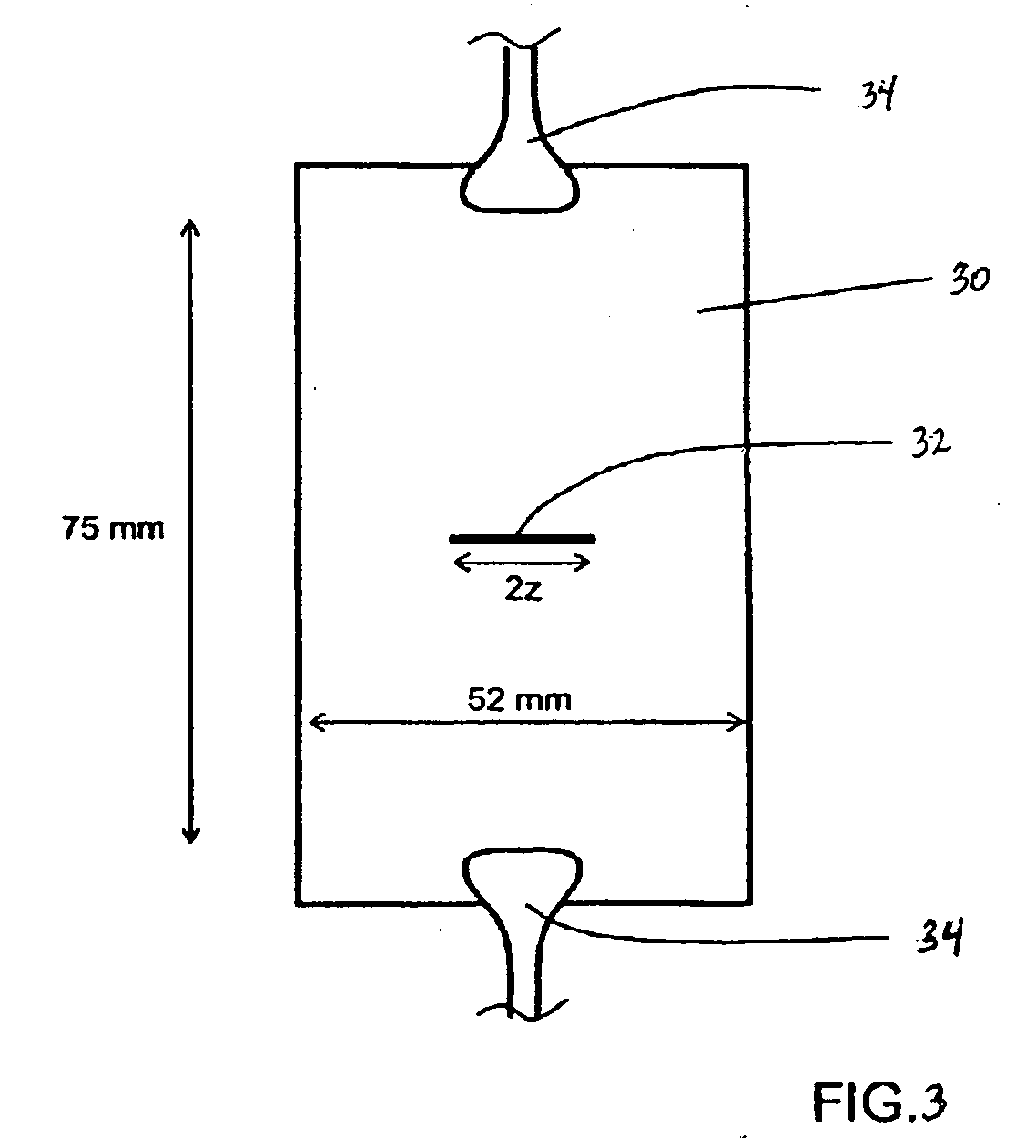

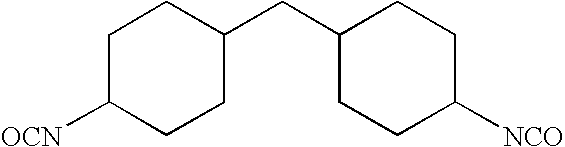

Non-reactive additives for fiber coatings

InactiveUS20070100039A1Easy to operateImprove performanceLayered productsPolyurea/polyurethane coatingsOligomerMonomer

The present invention relates to a curable composition having an oligomer, at least one monomer, and an amount of a substantially non-reactive oligomeric additive. The substantially non-reactive oligomeric additive is present in an amount effective to yield a cured product having a fracture toughness value that is higher than the fracture toughness value of a cured product of an otherwise identical composition lacking the non-reactive oligomeric additive. The present invention also relates to coated optical fibers, optical ribbons or bundles, and telecommunication systems having the curable composition.

Owner:CORNING INC

Flux Cored Wire for Duplex Stainless Steel and Method of Manufacturing the Same

ActiveUS20080093352A1Excellent pitting corrosion proofHigh strengthWelding/cutting media/materialsWelding/soldering/cutting articlesSilicon dioxideFluoride salt

A flux cored wire for duplex stainless steel and a manufacturing method thereof are provided. The flux cored wire can include a sheath and a flux filled into the sheath. The flux cored wire comprises about 24.0-30.0 wt % Cr, about 7.0-10.5 wt % Ni, about 2.0-4.0 wt % Mo, about 0.10-2.50 wt % Cu, about 0.40-1.00 wt % Si, about 1.5-3.0 wt % Mn, about 0.10-0.30 wt % N compound (converted value of N), and the remainder including Fe and inevitable impurities on the basis of the total weight of the wire. The flux comprises about 6.50-12.00 wt % of TiO2+SiO2+ZrO2+Al2O3, about 0.10-0.50 wt % of Li2O+K2O+Na2O, about 0.10-2.00 wt % of the other oxides, and about 0.10-0.50 wt % of metal fluoride (converted value of F) on the basis of the total weight of the wire. The flux can be filled into the sheath at a ratio of about 26-35%.

Owner:KISWEL LTD

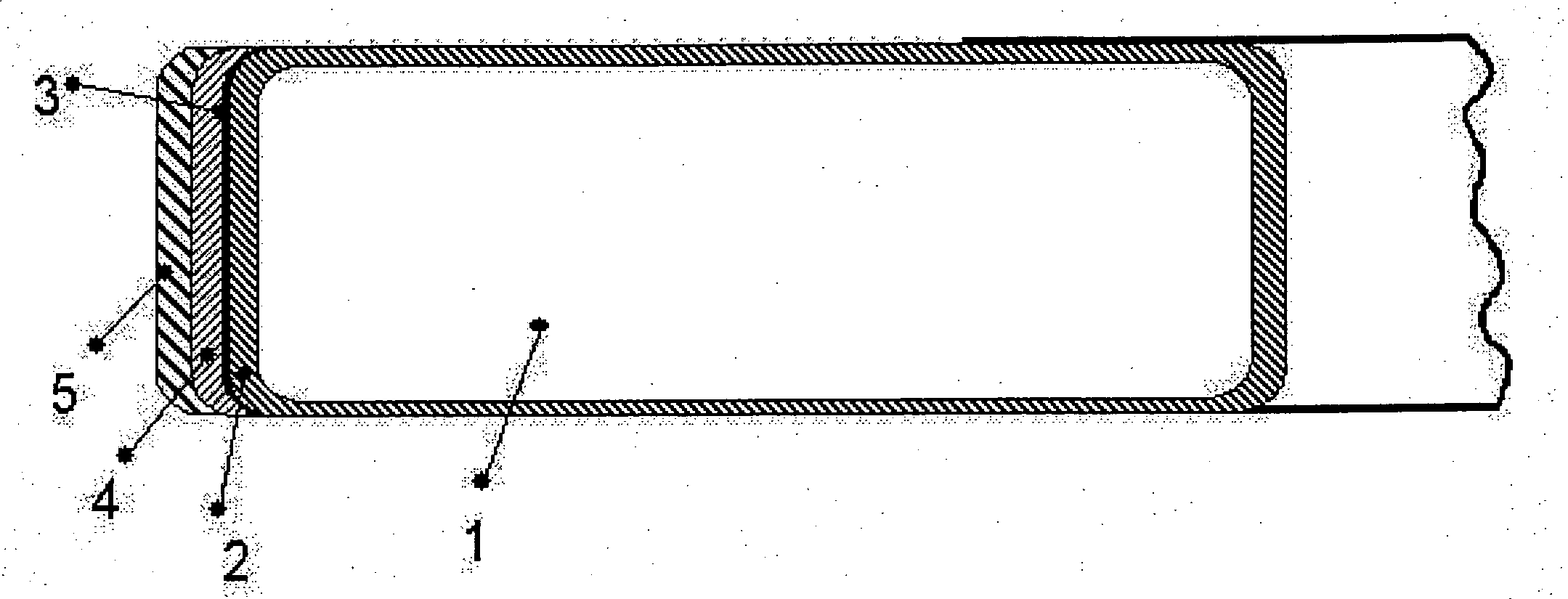

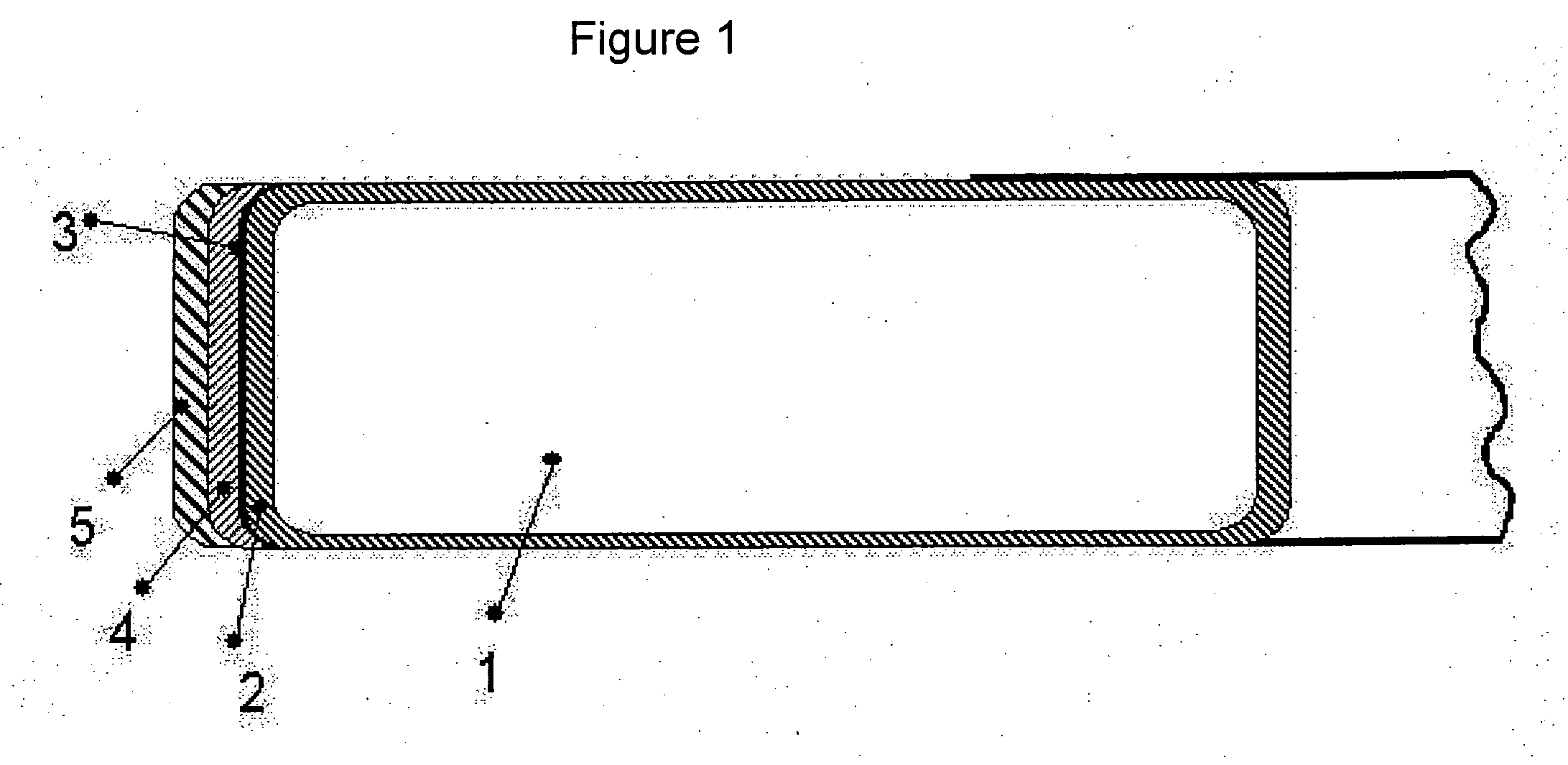

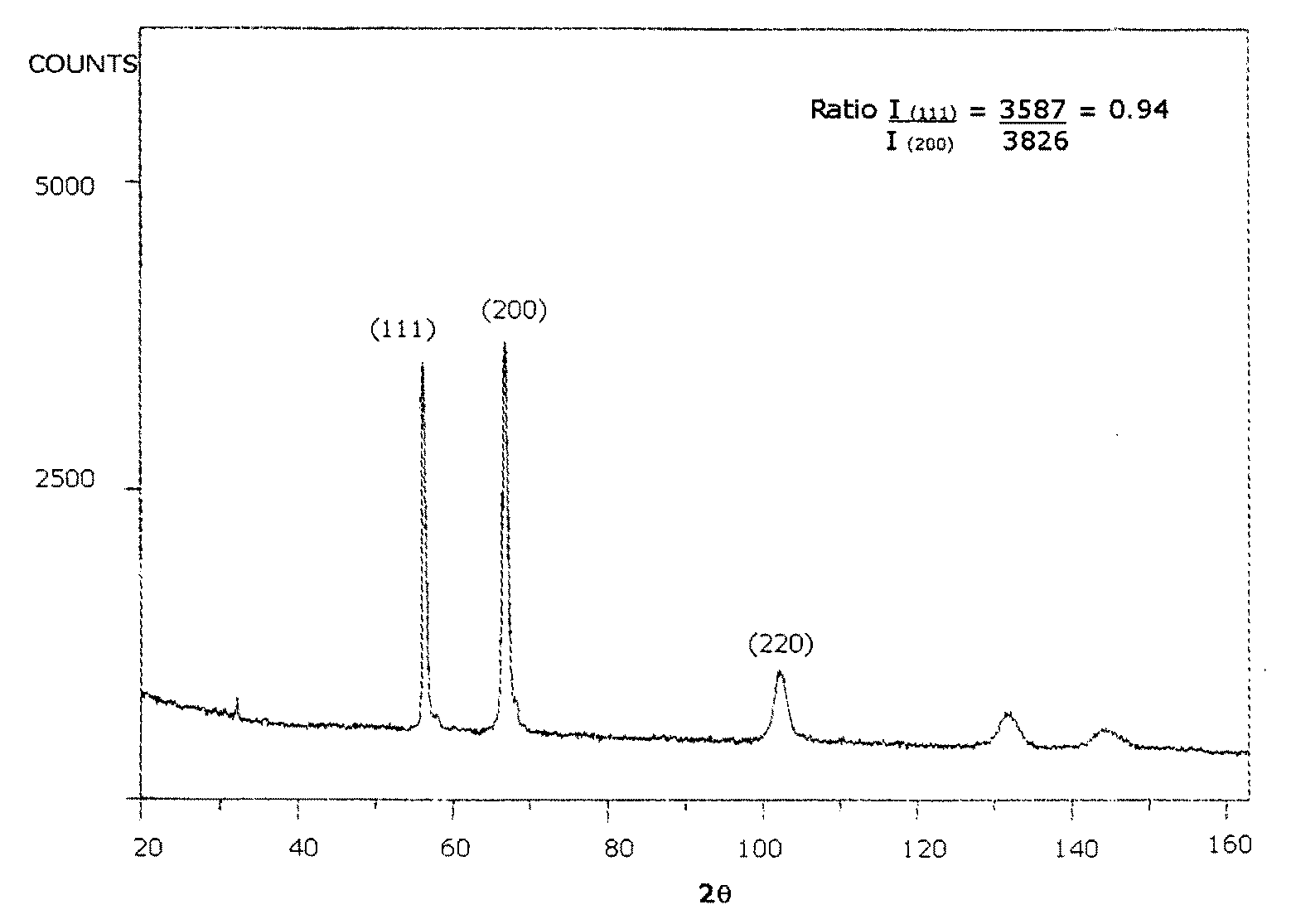

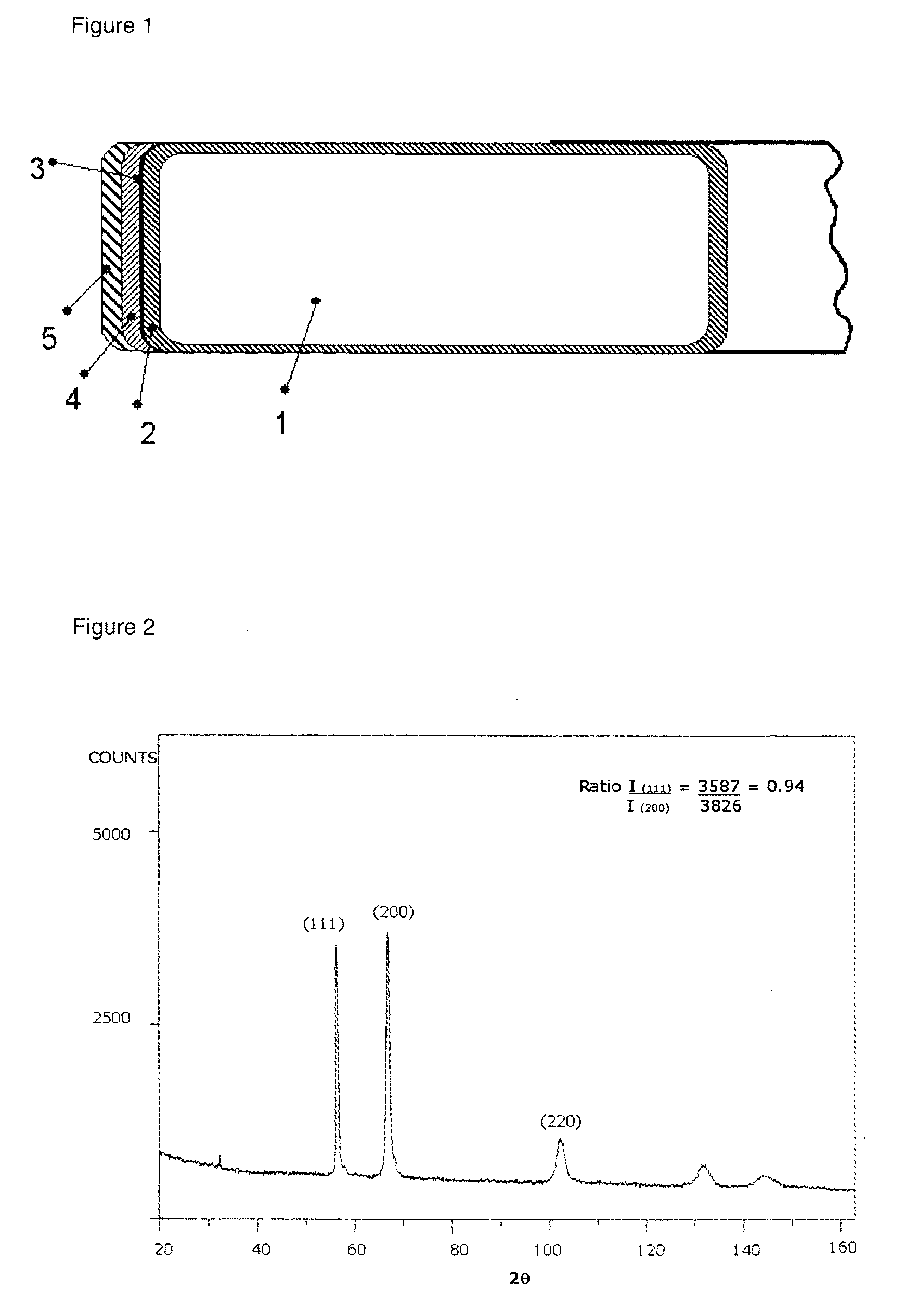

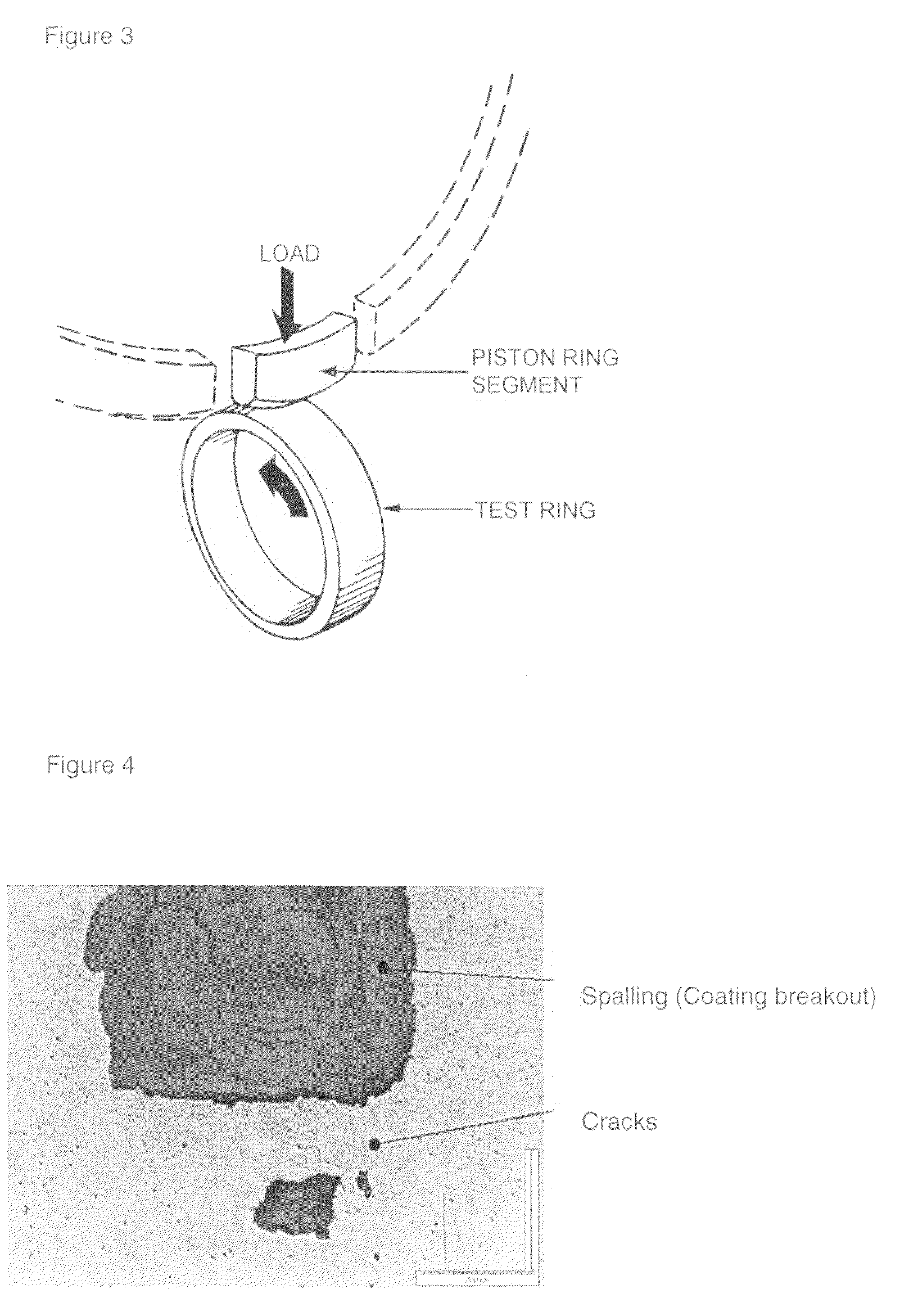

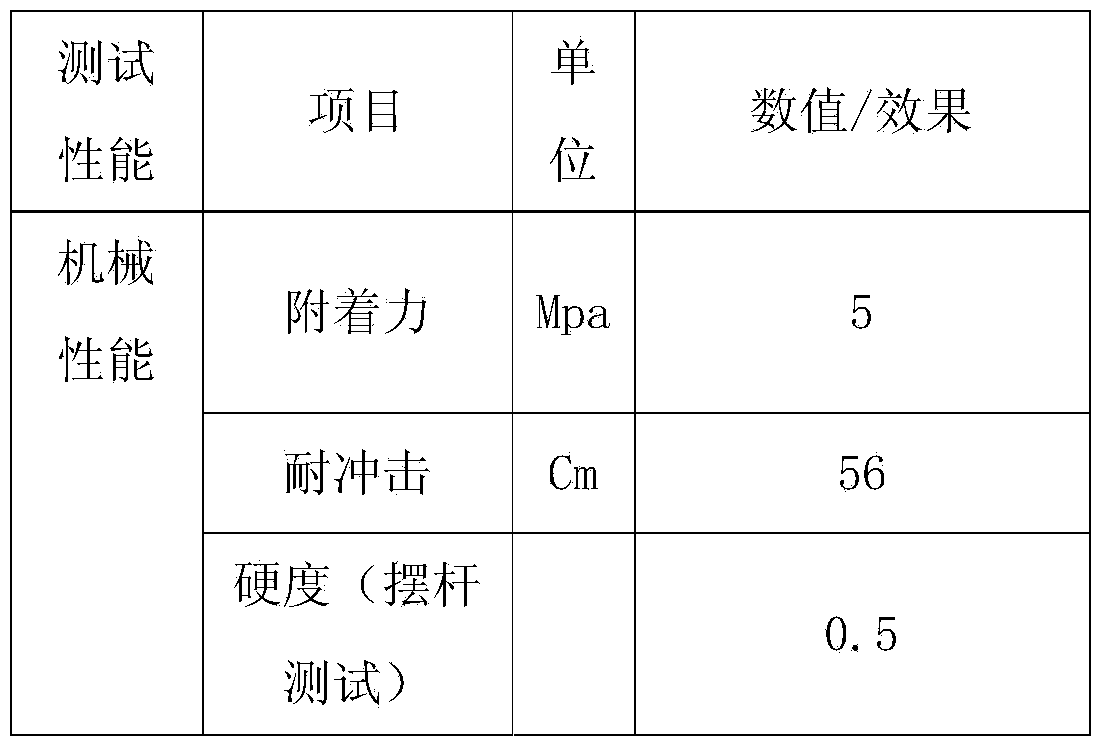

Piston ring for internal combustion engines

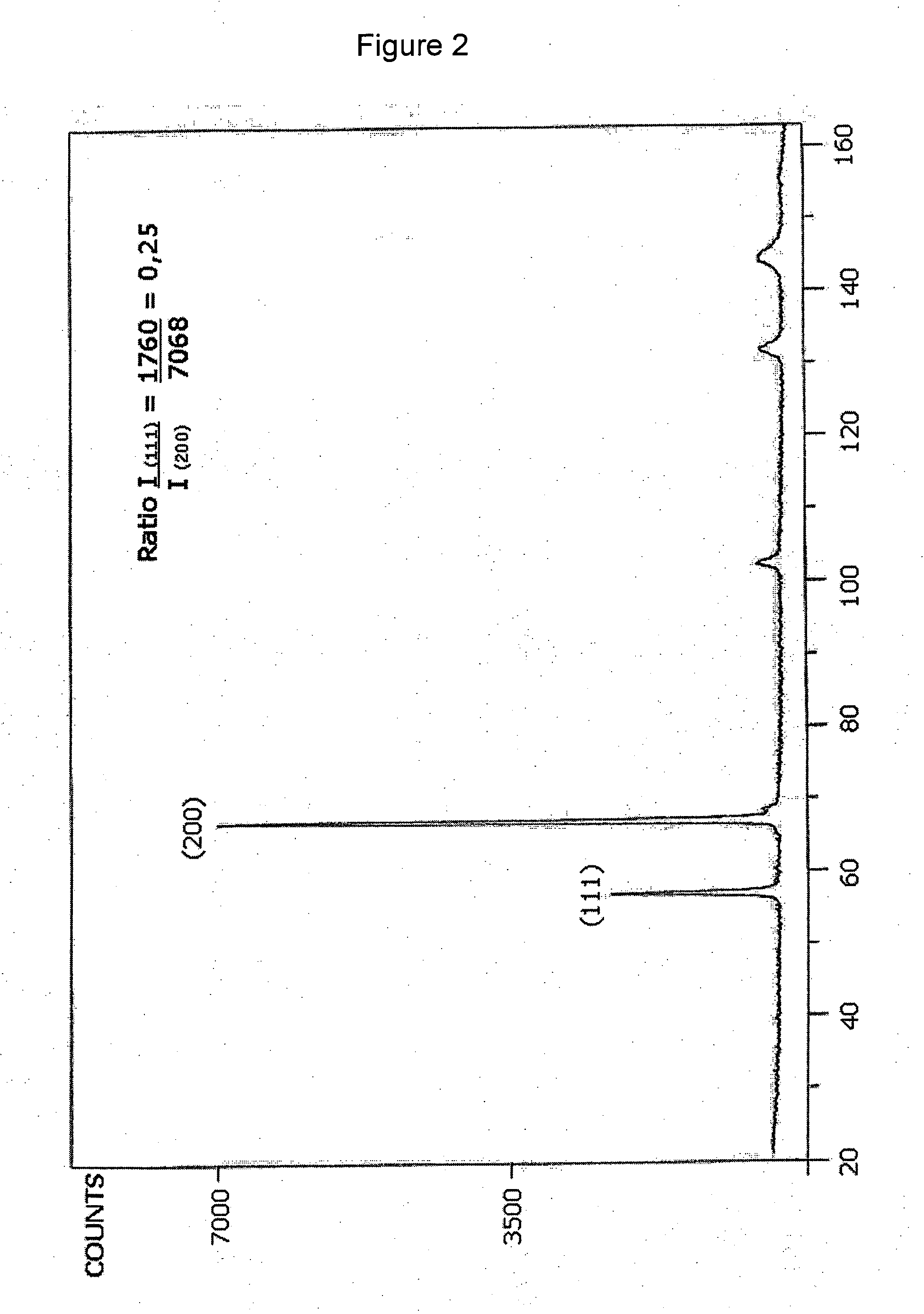

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

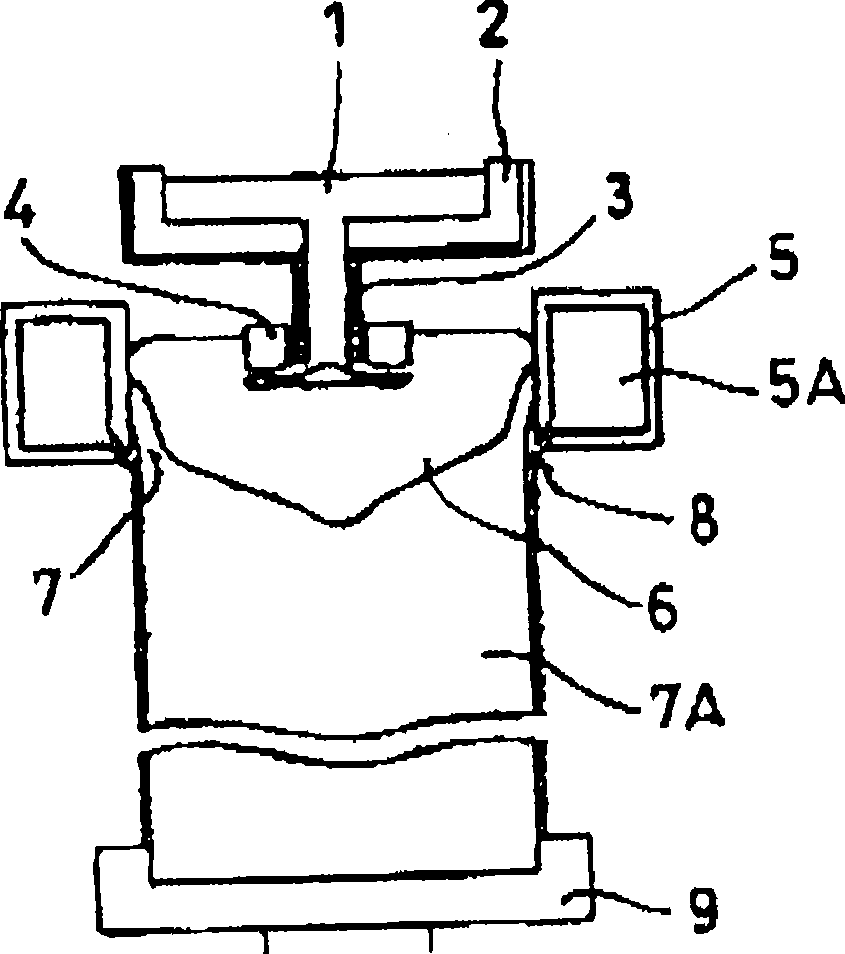

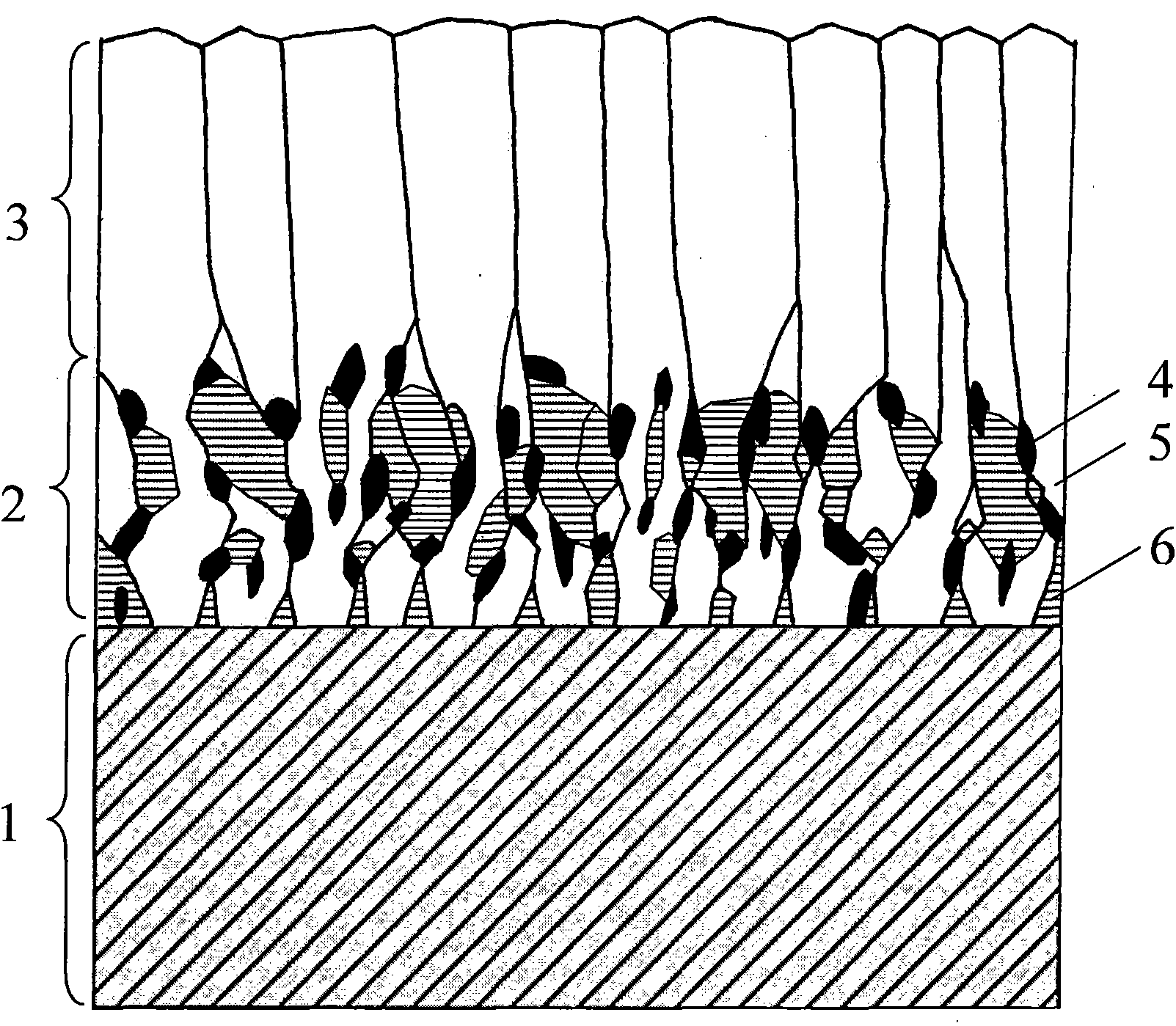

Method for comprehensively treating ecological environment of coal gangue hill

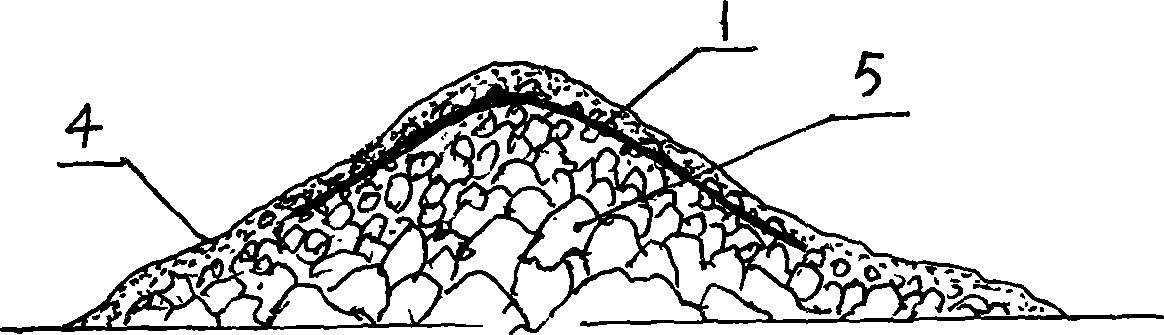

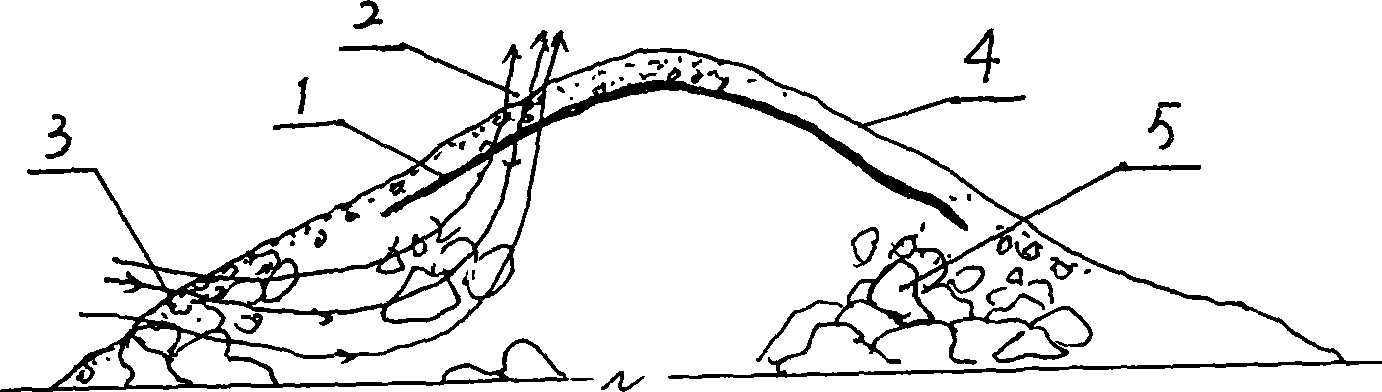

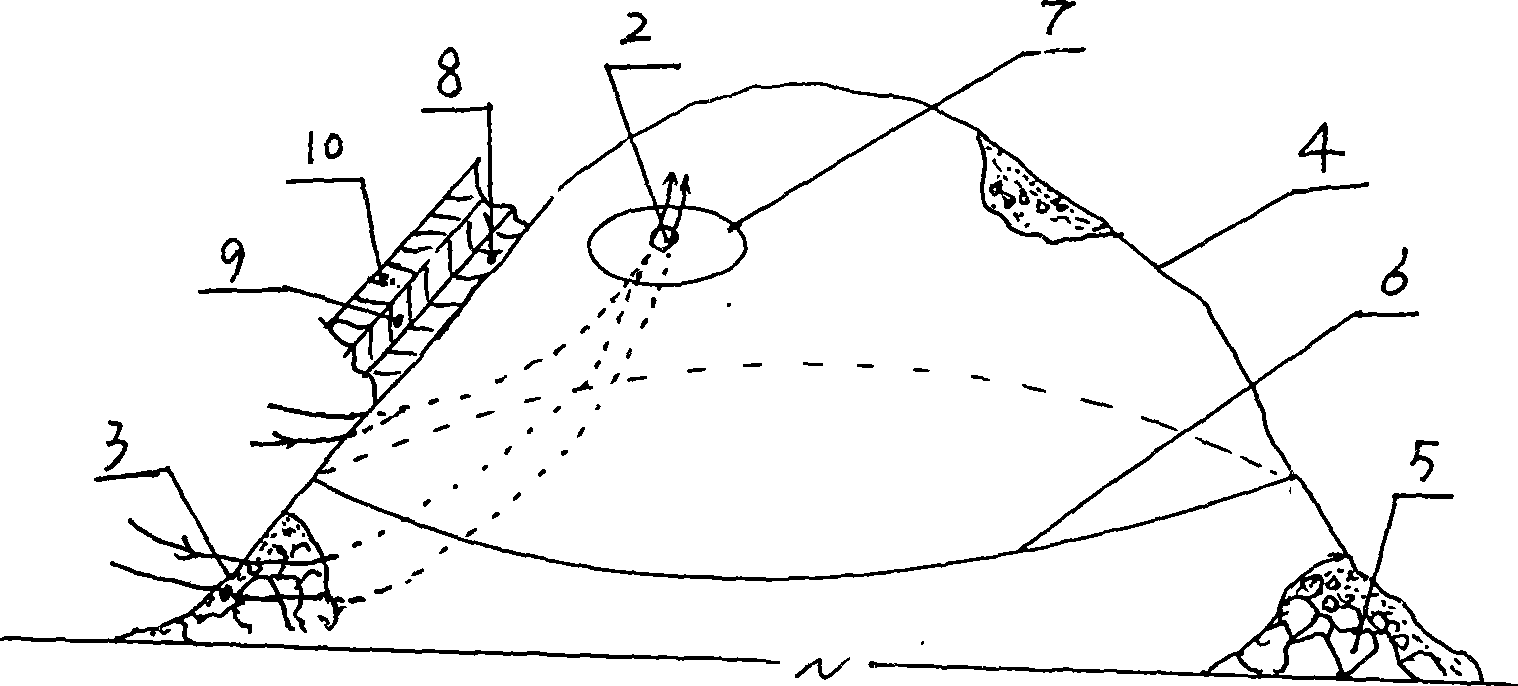

InactiveCN101519966AReduce flowAvoid formingUnderground miningSurface miningRevegetationEcological environment

The invention relates to a method for comprehensively treating the ecological environment of a coal gangue hill, which belongs to the field of mineral waste treatment and ecological environment restoration. The method mainly solves the problems of fire extinction, fire prevention and vegetation construction of the coal gangue hill. The method comprises the steps: the on-site reconnaissance of the coal gangue hill is carried out, and a construction operation plan is established; with fire prevention as principal and the combination of fire prevention and fire extinction, the fire prevention is crucial and is combined with the fire extinction, a thin layer of slurry is firstly sprayed on the coal gangue hill by a mechanical method to completely seal to form a sealing layer (8), transition slurry is sprayed on the sealing layer (8) to completely cover the sealing layer (8) to form a transition layer (9), slurry containing grass-shrub vegetation is spayed on the transition layer (9) to completely cover the transition layer (9) to form a planting layer (10); the contour line girdle band type operation in the spraying process is carried out from bottom to top to gradually and completely cover the hill, and different operating modes are selected according to practical conditions. The invention can not disturb the structure of the coal gangue hill, takes the fire prevention as the principal, combines the fire prevention with the fire extinction, has good and durable fire prevention effect, uses reliable and effective fire prevention and fire extinction measures as guarantee conditions to construct the planting layer, adopts grass-shrub plants, carries out hill sealing management and ensures vegetation restoration; in addition, the method uses the prior specialized mechanical devices to carry out construction operation, is easy to implement, has little difficulty, high efficiency and low investment and can ensure treatment effect.

Owner:赵平 +1

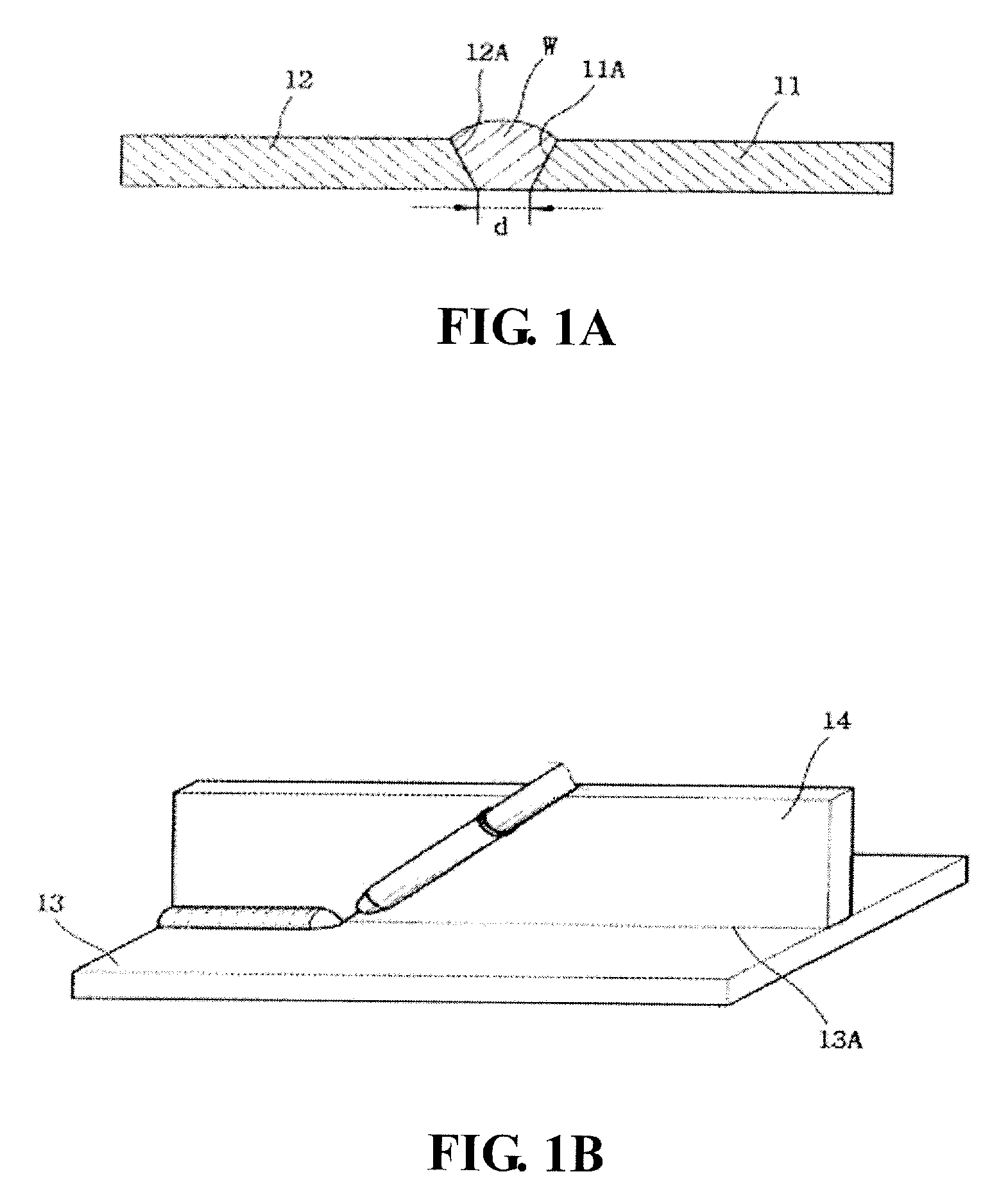

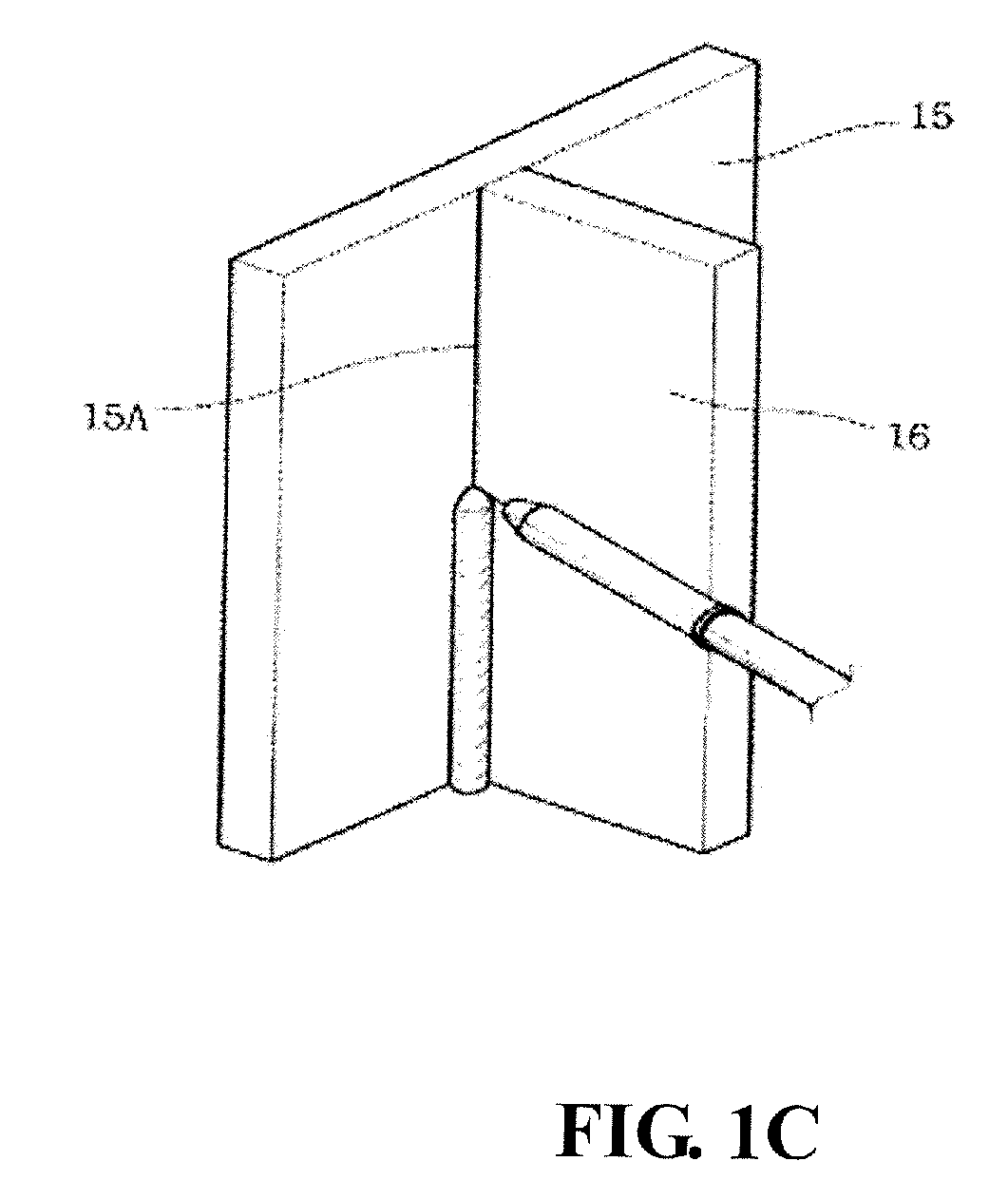

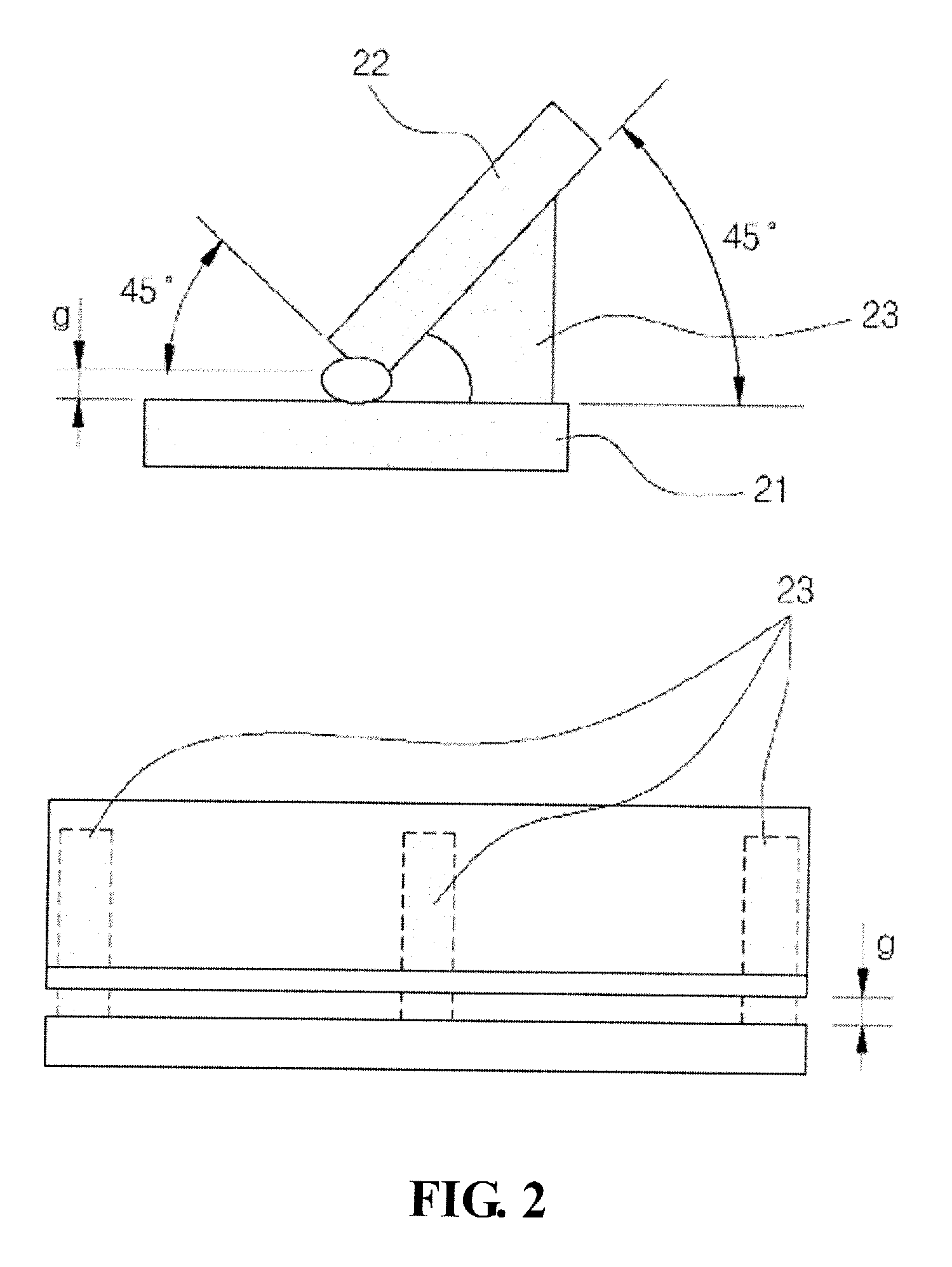

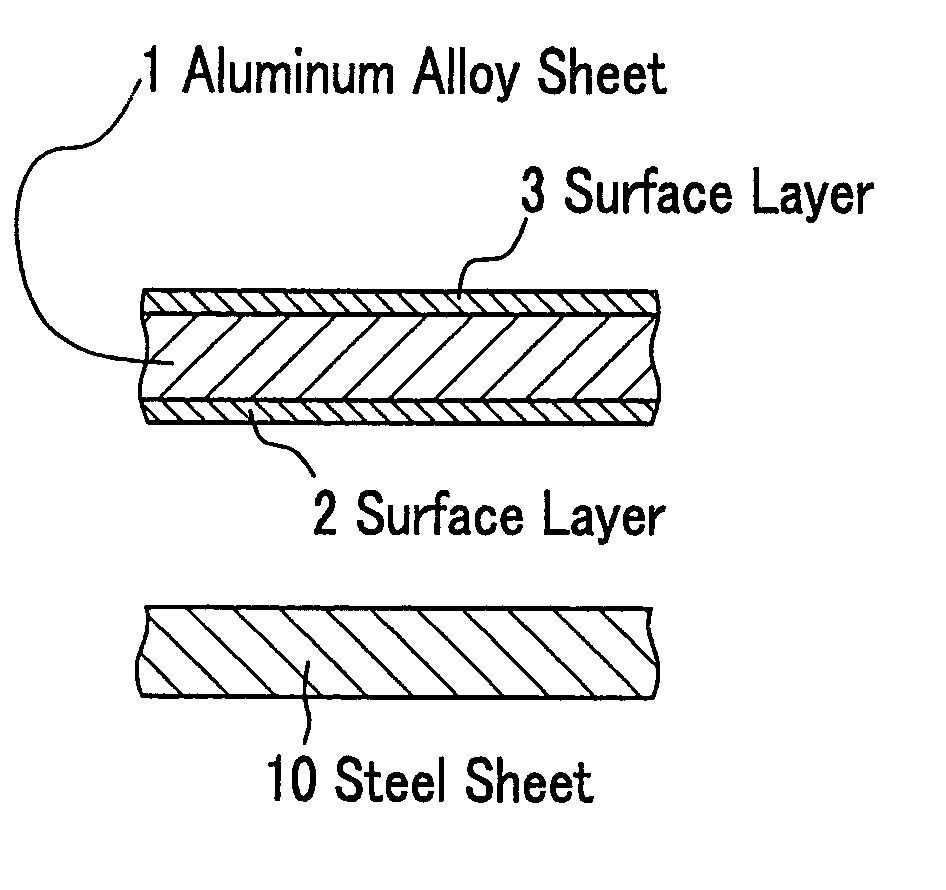

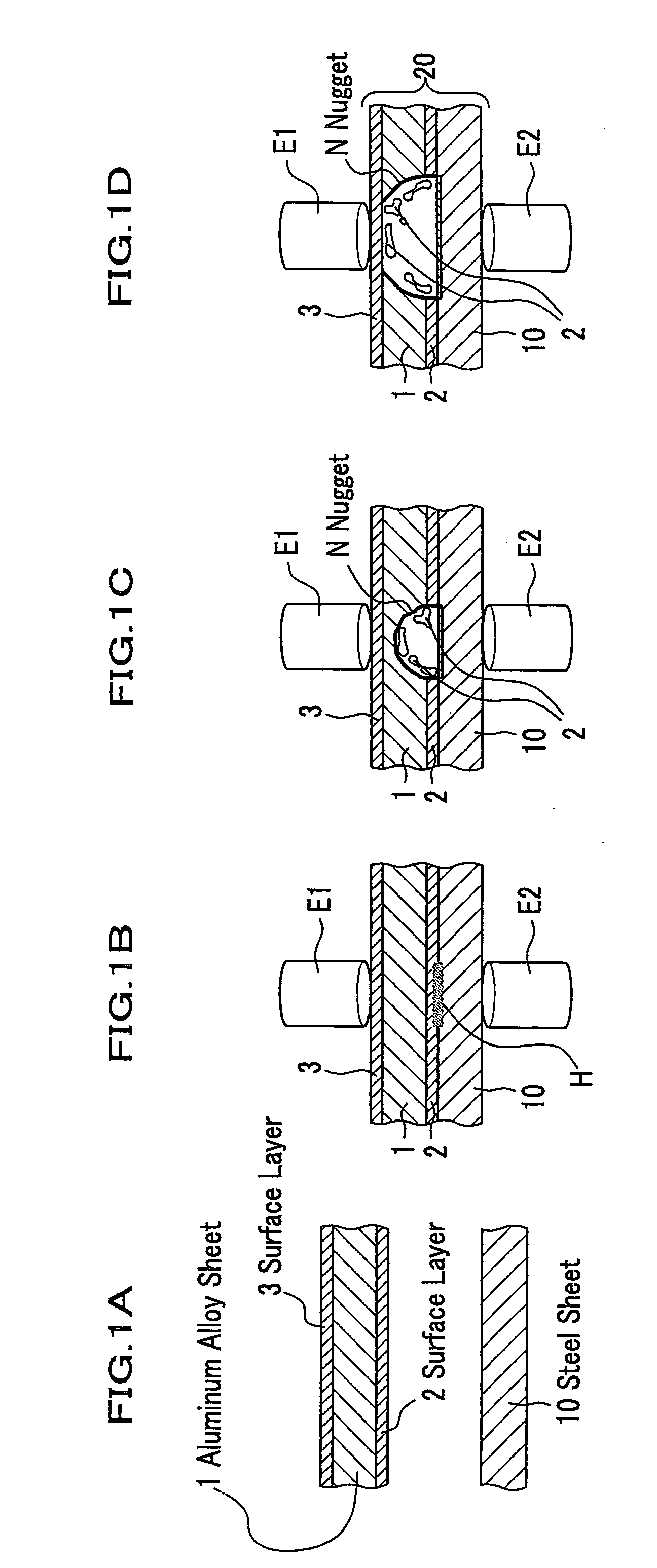

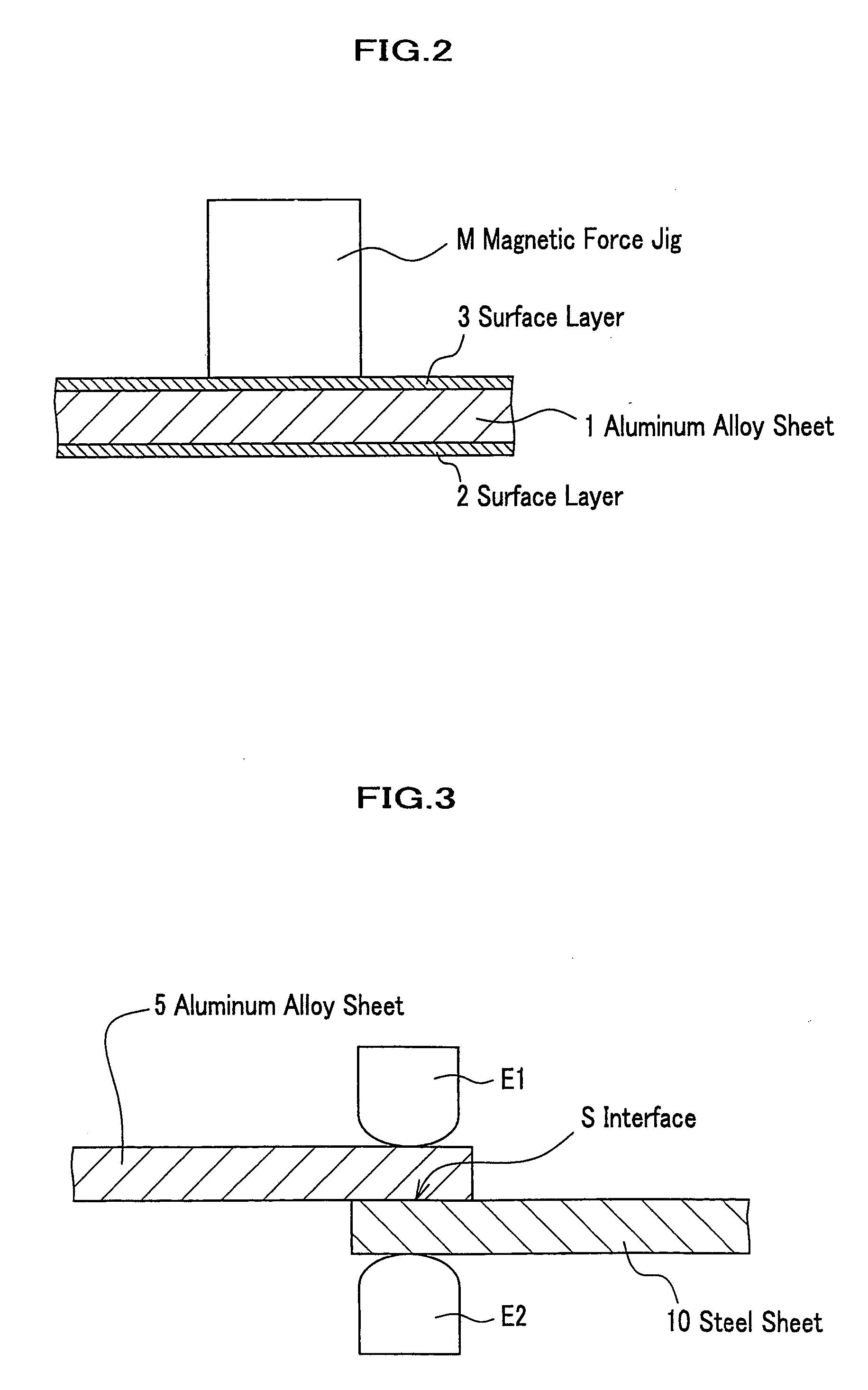

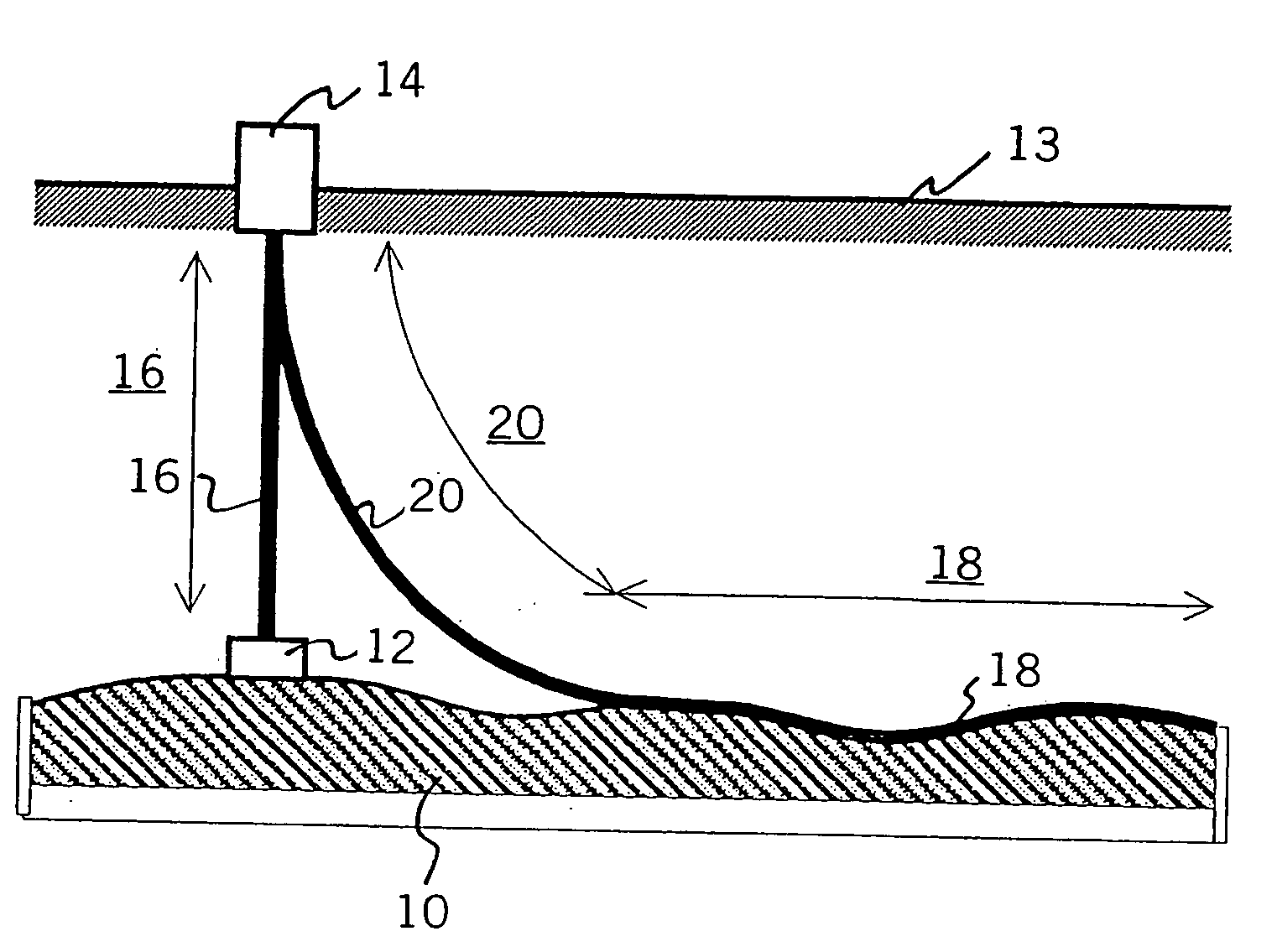

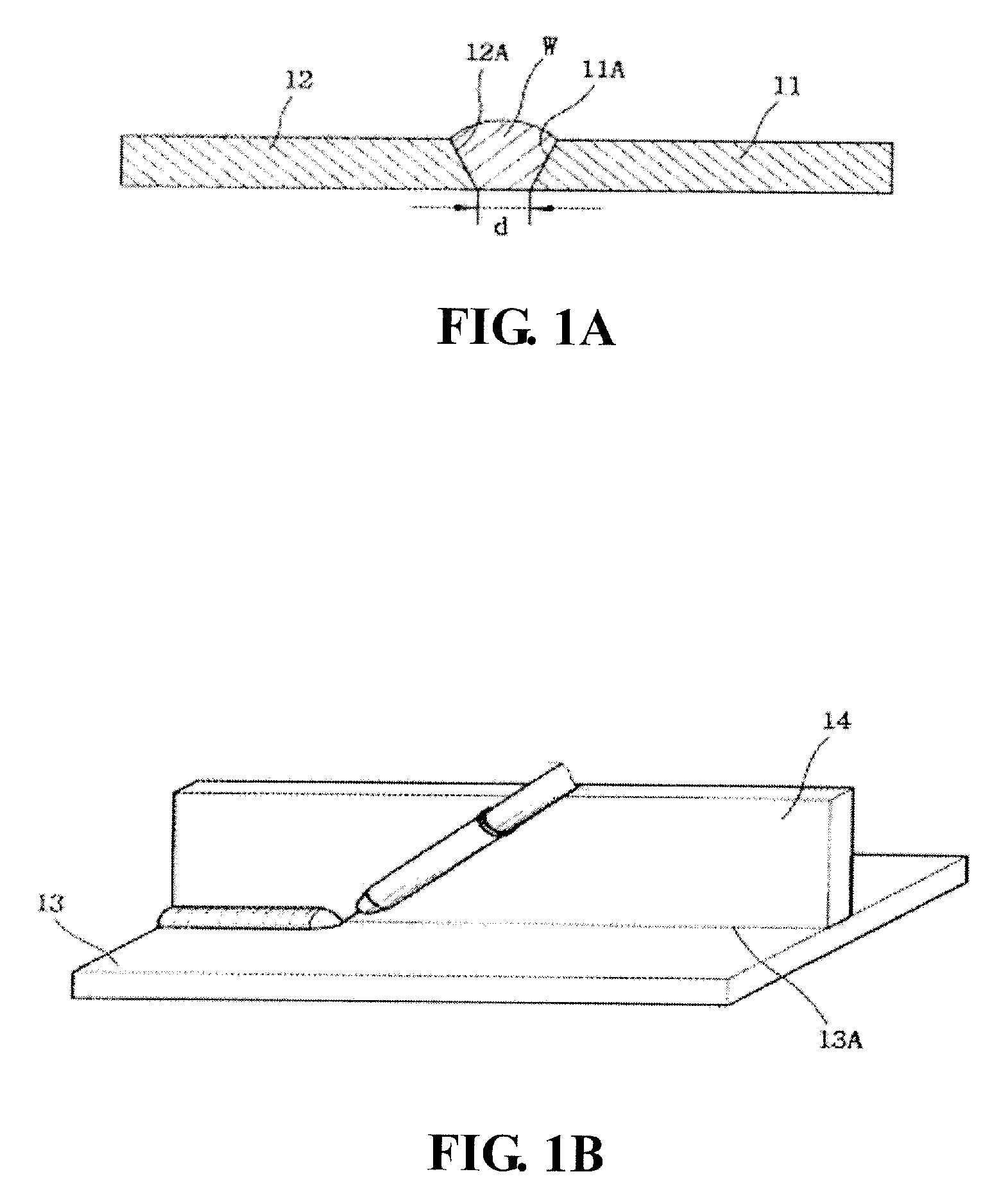

Resistance welding method of different kinds of materials, and resistance welding member of aluminum alloy material and different kind of material

InactiveUS20050218121A1Improve solderabilityEfficiency of manufacturing can not be realizedHot-dipping/immersion processesArc welding apparatusSurface layerSpot welding

The resistance welding method of different kinds of materials is the method for welding an iron material and an aluminum alloy material, and comprises the steps of: performing in advance a coating treatment at least to a portion of the aluminum alloy material, where resistance welding is performed, with any of iron and iron-base alloy and forming a surface layer; and performing resistance welding of the iron material and the aluminum alloy material through the surface layer, and the resistance welding may be any of spot welding and projection welding.

Owner:HONDA MOTOR CO LTD +1

Piston ring with chromium nitride coating for internal combustion engines

ActiveUS20090278320A1Improve the immunityHigher absorption of internal compressive stressesPiston ringsBraking action transmissionGas phaseX-ray

The invention relates to a piston ring for internal combustion engines, the piston ring comprises a steel or cast iron base material with a coating of chromium nitride deposited by a physical vapor deposition process on a sliding surface of the piston ring, wherein the coating is composed of a columnar crystal structure of CrN with the following features:(a) an oxygen content in solid solution of 0.5 to 2.5 wt %;(b) a content of uniformly dispersed micro-pores of less than 10% in volume of the coating; and(c) an X-ray diffraction intensity ratio of (111) planes to (200) planes parallel to the surface in the range of 0.80 to 1.20.

Owner:MAHLE INT GMBH +1

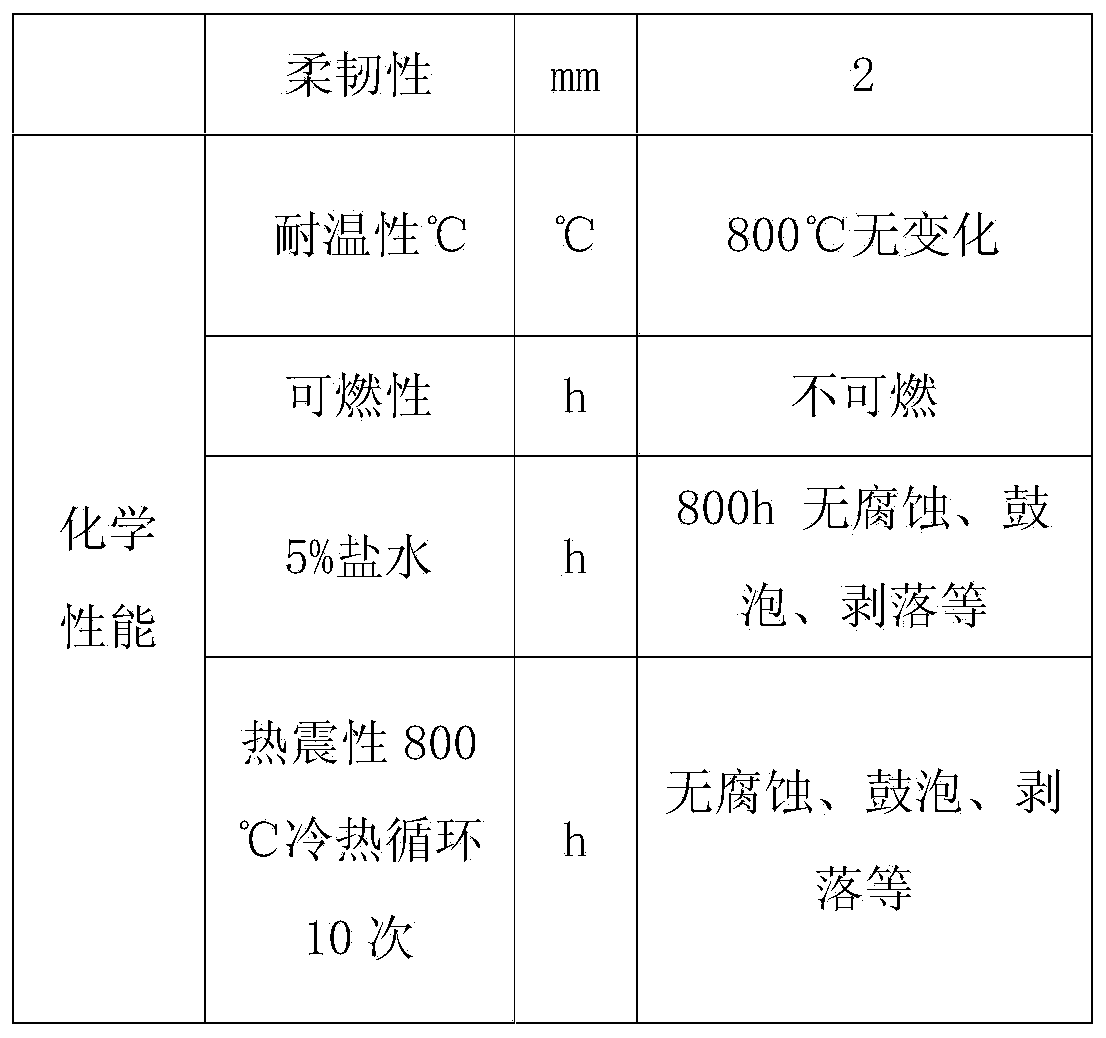

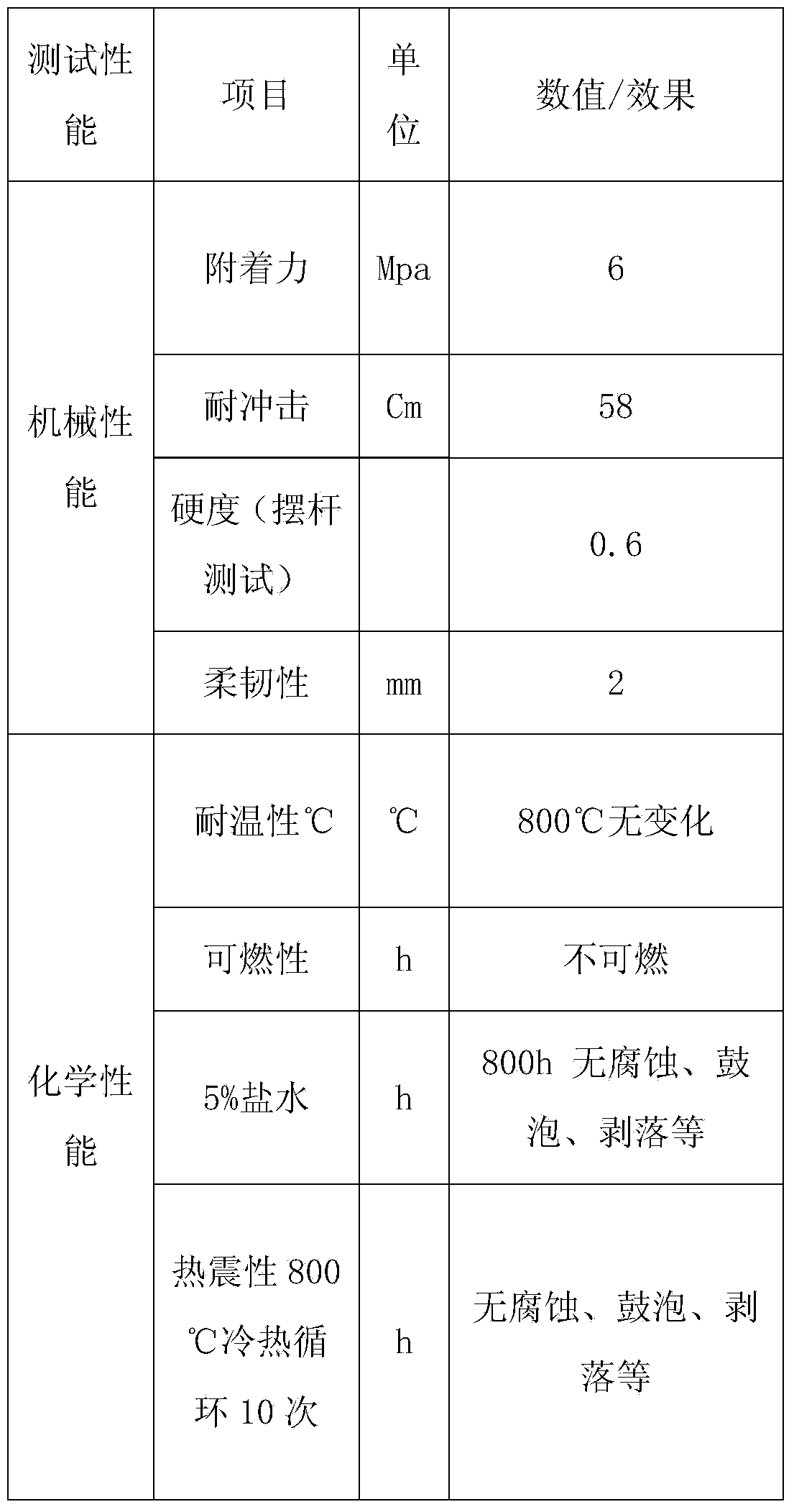

Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

The invention discloses a boron-modified organic silicon resin high-temperature-resistant coating which comprises the following components in percentage by mass: 45%-58% of boron-modified organic silicon resin, 35%-45% of heat-resisting pigment fillers and 2%-4% of auxiliary agents, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; and the mass ratio of nanometer silicon dioxide to barrier function fillers to aluminum powder which are contained in the heat-resisting pigment fillers is 1.5:1:1. The invention also discloses a preparation method of the boron-modified organic silicon resin high-temperature-resistant coating. The preparation method disclosed by the invention can be implemented on an existing coating preparation production line without increasing equipment investment; the prepared high temperature-resistant organic silicon coating can be coated by adopting a spray coating process and constructed by adopting a roll coating process, can be subjected to high temperature of 800 DEG C for a long time and has corrosion-resistant property.

Owner:JIANGSU MARINE VICTORY COATING

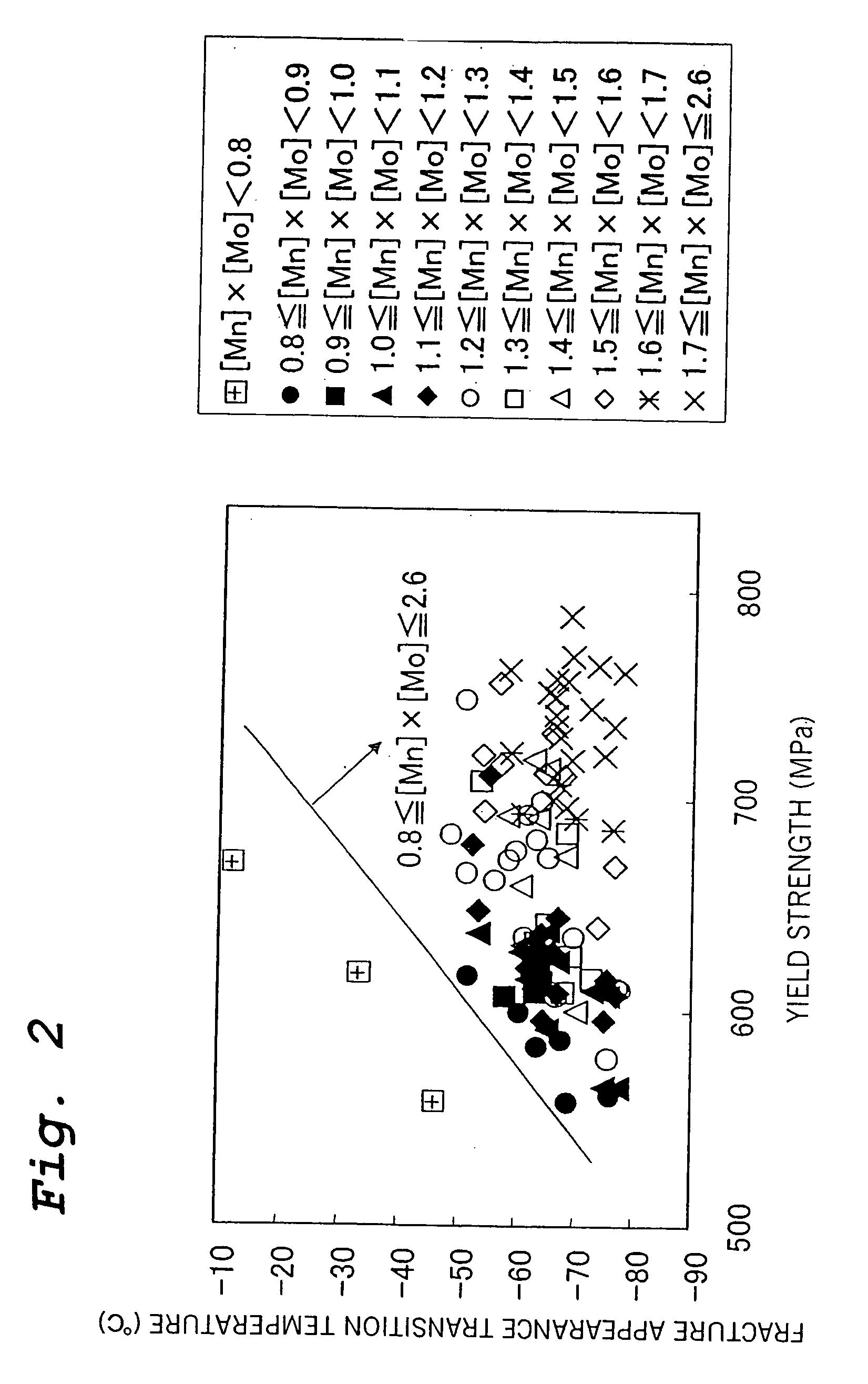

Seamless steel pipe for line pipe and a process for its manufacture

ActiveUS20080219878A1Stable supplyHigh strengthFurnace typesHeat treatment furnacesChemical compositionHigh intensity

A thick-walled seamless steel pipe for line pipe which has a high strength and improved toughness and corrosion resistance in spite of the thick wall and which is suitable for use as a riser and flow line has a chemical composition comprising, in mass percent, C: 0.02-0.08%, Si: at most 0.5%, Mn: 1.5-3.0%, Al: 0.001-0.10%, Mo: greater than 0.4%-1.2%, N: 0.002-0.015%, at least one of Ca and REM in a total amount of 0.0002-0.007%, and a remainder of Fe and impurities, with the impurities having the content of P: at most 0.05%, S: at most 0.005%, and O: at most 0.005%, the chemical composition satisfying the inequality: 0.8≦[Mn]×[Mo]≦2.6, wherein [Mn] and [Mo] are the numbers equivalent to the contents of Mn and Mo, respectively, in mass percent.

Owner:NIPPON STEEL CORP

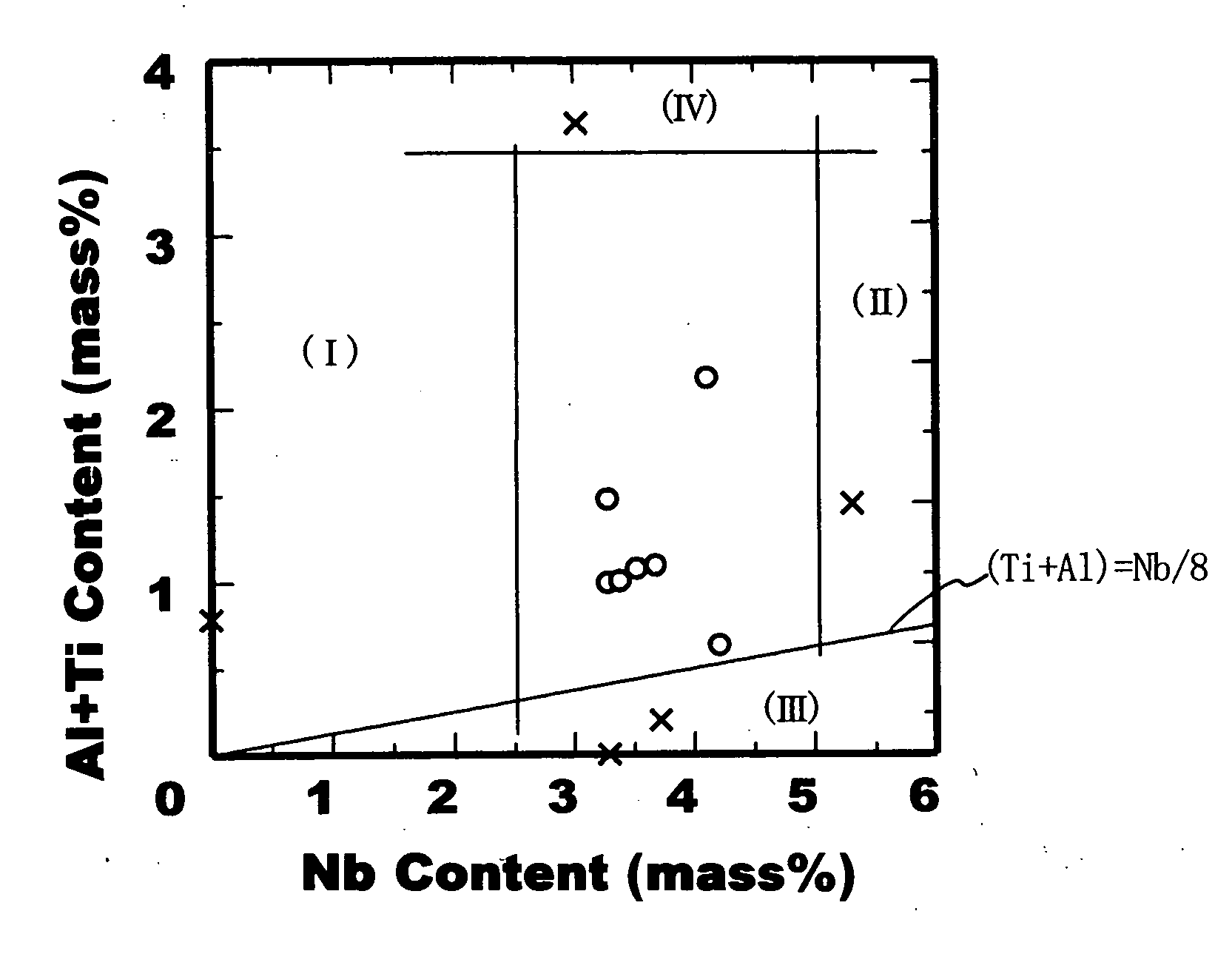

Welded joint made of an austenitic steel

InactiveUS20060191606A1High strengthIncrease resistanceArc welding apparatusMachines/enginesChemical compositionHigh pressure hydrogen

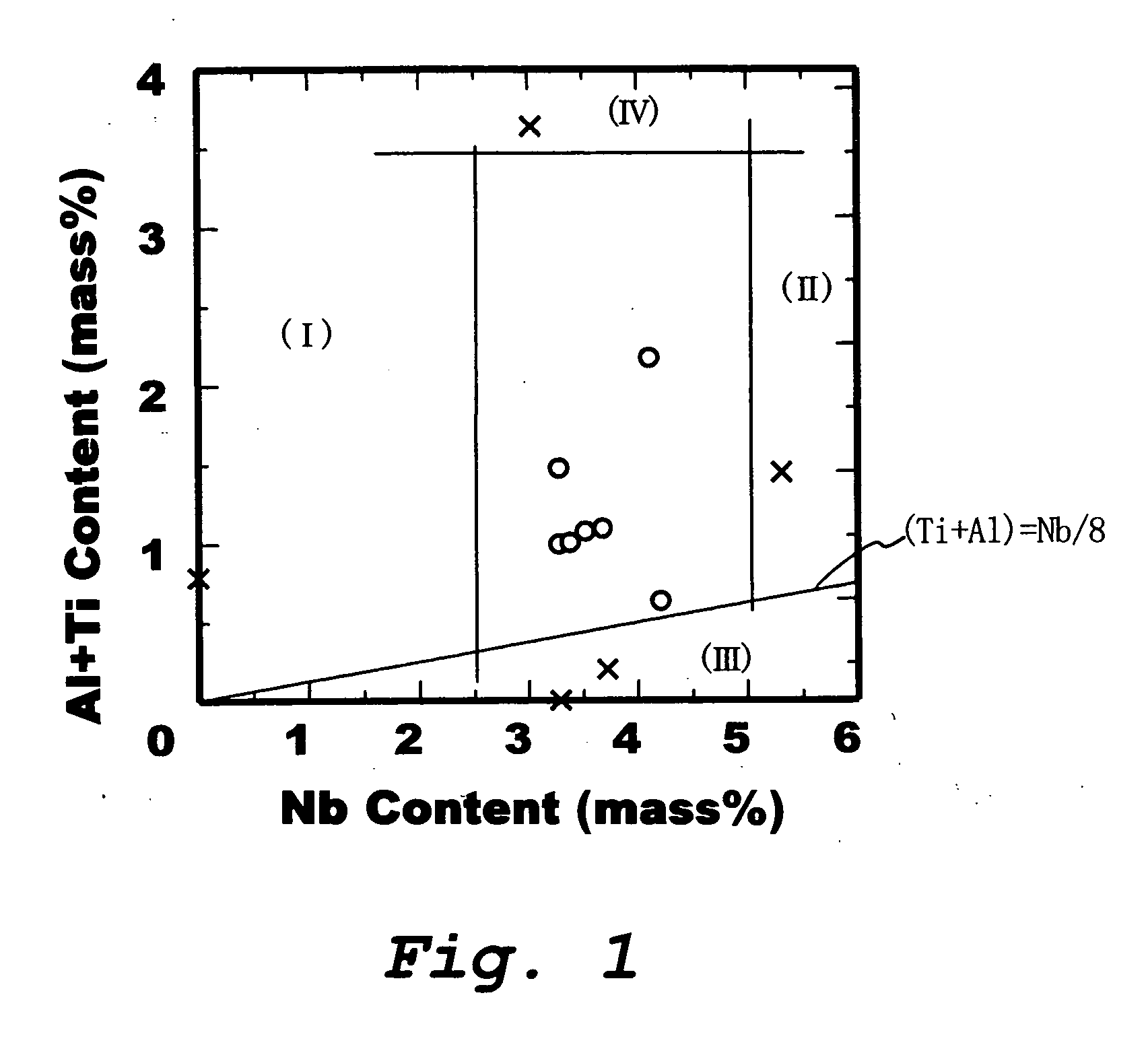

A weld joint having a base material and a weld metal both of an austenitic steel, wherein the weld metal has a chemical composition, in mass %, that C: 0.04% or less, Si: 1.0% or less, Mn: 3% or less, P: 0.02% or less, S: 0.005% or less, Cr: 15 to 25%, Ni: 30% or more, Mo: 10% or less, Nb: 2.5 to 5%, Al: 3.0% or less, Ti: 0.5% or less, and the balance: Fe and inevitable impurities, the contents of Al and Ti satisfying the following: (Ti+Al)>Nb / 8. The weld joint is a high strength austenitic steel weld joint which exhibits excellent toughness at a low temperature and excellent resistance to hydrogen embrittlement, which are required for a piping and a vessel for high pressure hydrogen, particularly also in a welded zone.

Owner:NIPPON STEEL CORP

Heat resistant austenitic stainless steel

InactiveUS6485679B1High creep rupture strengthGood steam oxidation resistanceRigid pipesHeat exchange apparatusAustenitic stainless steelTungsten

A heat resistant austenitic stainless steel with high strength at elevated temperatures, good steam oxidation resistance, good fire side corrosion resistance, and a sufficient structural stability, suitable for use in boilers operating at high temperatures has a composition (by weight) of. 0.04 to 0.10% carbon (C), not more than 0.4% silicon (Si), not more than 0.6% manganese (MN), 20 to 27% chromium (Cr), 22.5 to 32% nickel (Ni), not more than 0.5% molybdenum (Mo), 0,20 to 0.60% niobium (Nb), 0.4 to 4.0% tungsten (W), 0.10 to 0.30% nitrogen (N), 0.002 to 0.008% boron (B), less than 0.05% aluminium (Al), at least one of the elements Mg and Ca in amounts less than 0.010% Mg and less than 0.010% Ca, and the balance being iron and inevitable impuities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Preparation and application methods of selective laser sintering polypropylene powdery material

The invention relates to the technical field of high molecular materials and particularly relates to preparation and application methods of a selective laser sintering polypropylene powdery material. The method comprises the following steps: obtaining polypropylene powder by a freeze grinding method; grading and collecting by an airflow screening machine, selecting polypropylene powder with the granularity in a range of 200-800 meshes and returning coarse materials which do not meet the fineness requirement to a stock bin and continuously smashing; and adding 100 parts of polypropylene powder, 0.1-1 part of graphite powder, 0.01-0.5 part of antioxidant and 0.5-6 parts of metallic soap salt and uniformly mixing in a high speed mixer, wherein the granularity of the graphite powder is 1000-5000 meshes and the antioxidant is a compound antioxidant consisting of phenols and phosphonate or thioester in a weight ratio of 1:1. The polypropylene powder prepared by the invention has excellent sintering performance and the SLS (Selective Laser Sintering) formed piece prepared by the polypropylene powder has high mechanical property and dimensional precision.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Flux cored wire for duplex stainless steel and method of manufacturing the same

ActiveUS8153935B2Improve corrosion resistanceLow elongationWelding/cutting media/materialsWelding/soldering/cutting articlesOxide

A flux cored wire for duplex stainless steel and a manufacturing method thereof are provided. The flux cored wire can include a sheath and a flux filled into the sheath. The flux cored wire comprises about 24.0-30.0 wt % Cr, about 7.0-10.5 wt % Ni, about 2.0-4.0 wt % Mo, about 0.10-2.50 wt % Cu, about 0.40-1.00 wt % Si, about 1.5-3.0 wt % Mn, about 0.10-0.30 wt % N compound (converted value of N), and the remainder including Fe and inevitable impurities on the basis of the total weight of the wire. The flux comprises about 6.50-12.00 wt % of TiO2+SiO2+ZrO2+Al2O3, about 0.10-0.50 wt % of Li2O+K2O+Na2O, about 0.10-2.00 wt % of the other oxides, and about 0.10-0.50 wt % of metal fluoride (converted value of F) on the basis of the total weight of the wire. The flux can be filled into the sheath at a ratio of about 26-35%.

Owner:KISWEL LTD

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

Propylene Copolymers In Soft Thermoplastic Blends

ActiveUS20090270545A1Physical improvementImproved processing propertyPlastic/resin/waxes insulatorsPolymer sciencePolyolefin

Thermoplastic polyolefins (TPOs) and / or thermoplastic vulcanizates (TPVs) are blended with low molecular weight propylene-dominated copolymers to provide polymeric compositions with an improved balance between processability and toughness. The compositions have improved processability by facilitating the ease with which a TPO or TPV, usually difficult to melt process, can be processed at high line speeds, which in turn improves the formation of the composition into articles.

Owner:EXXONMOBIL CHEM PAT INC

Formulation providing a low carbohydrate cereal based system including a novel dough and a pizza crust or bread product having open cell structure

InactiveUS20050276896A1Enhance manufacturing characteristicReduce the amount requiredDough treatmentBaking mixturesFiberCompound (substance)

A novel dough composition for improved dough can be used to produce a baked, high protein, low carbohydrate bread product. The formulation and process can be used to make low carbohydrate dough that can be used to manufacture bread and other bread-like products of high quality and consumer acceptance. The bread is characterized by low nutritive carbohydrate content, bread-like open cell structure and a high quality nutrition, texture and flavor. The dough comprises an aqueous leavened dispersion that comprises an effective but low amount of wheat flour for texture and flavor, an effective amount of gluten, in excess of the flour content, and an effective amount of a protein source along with an effective amount of an edible fiber to provide high protein content, low carbohydrate content and bread-like texture.

Owner:SCHWANS GLOBAL SUPPLY CHAIN

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Antioxidant, anti-wear and antirust lubricating oil for automobile gear and preparation method thereof

The invention discloses antioxidant, anti-wear and antirust lubricating oil for an automobile gear. The lubricating oil is characterized by being prepared from the following raw materials: base oil, a clearing agent, a dispersing agent, a preservative, an extreme-pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirust agent, a pour point depressant and an antifoaming agent, wherein in the base oil of the lubricating oil, the kinematic viscosity below 100 DEG C is 1.5-40mm<2> / s, the viscosity index is over 100, the pour point is below -25 DEG C, and the sulfur content is below 0.01% by mass. The lubricating oil for an automobile gear, disclosed by the invention, has the advantages of simple composition, low cost, relatively good viscosity index, high anti-wear property and long service life; the compatibility between the lubricating oil additive and the base oil is relatively good, and the lubricating oil is of relatively high stability; and compared with existing automobile lubricating oil, the automobile lubricating oil disclosed by the invention has high corrosion resistance, the preparation technology of the lubricating oil is simple, and the steps are simple and environment-friendly and easy to implement.

Owner:高安市超鹰科技有限公司

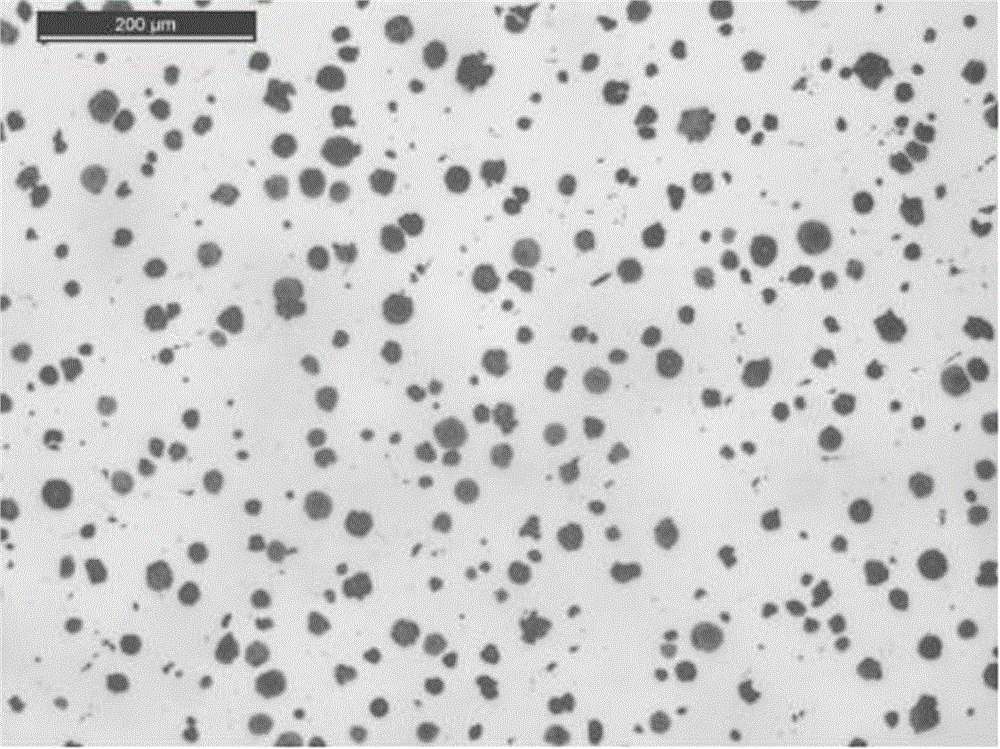

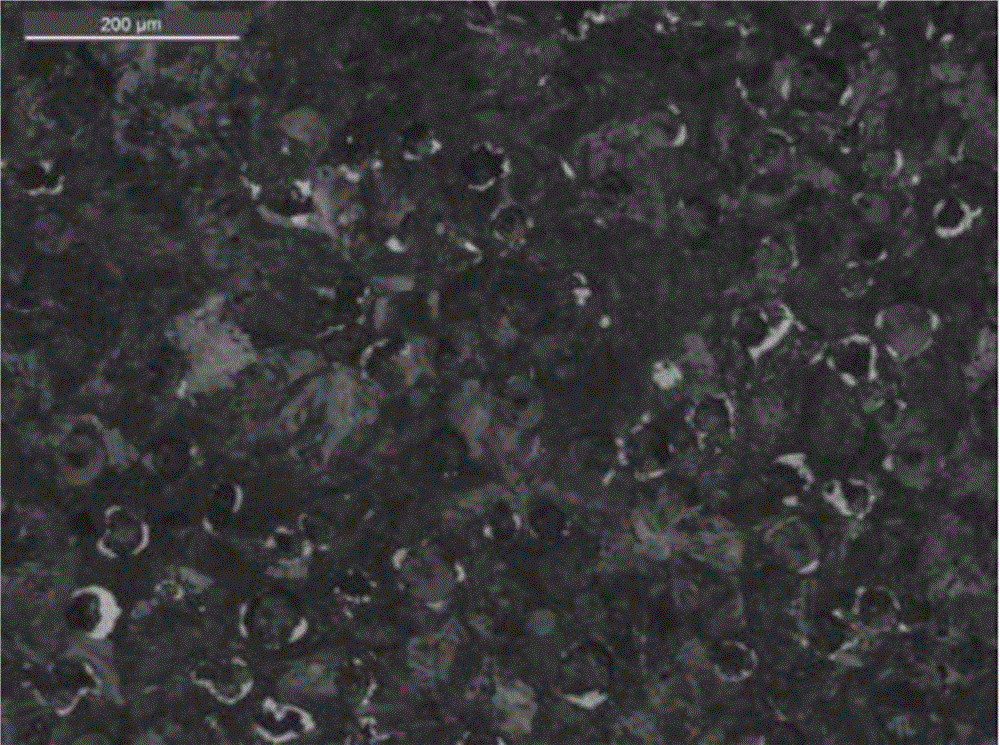

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

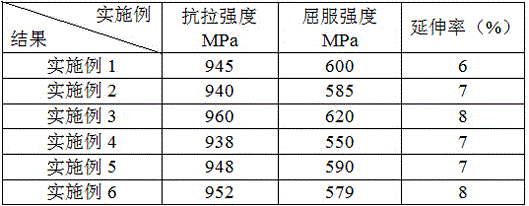

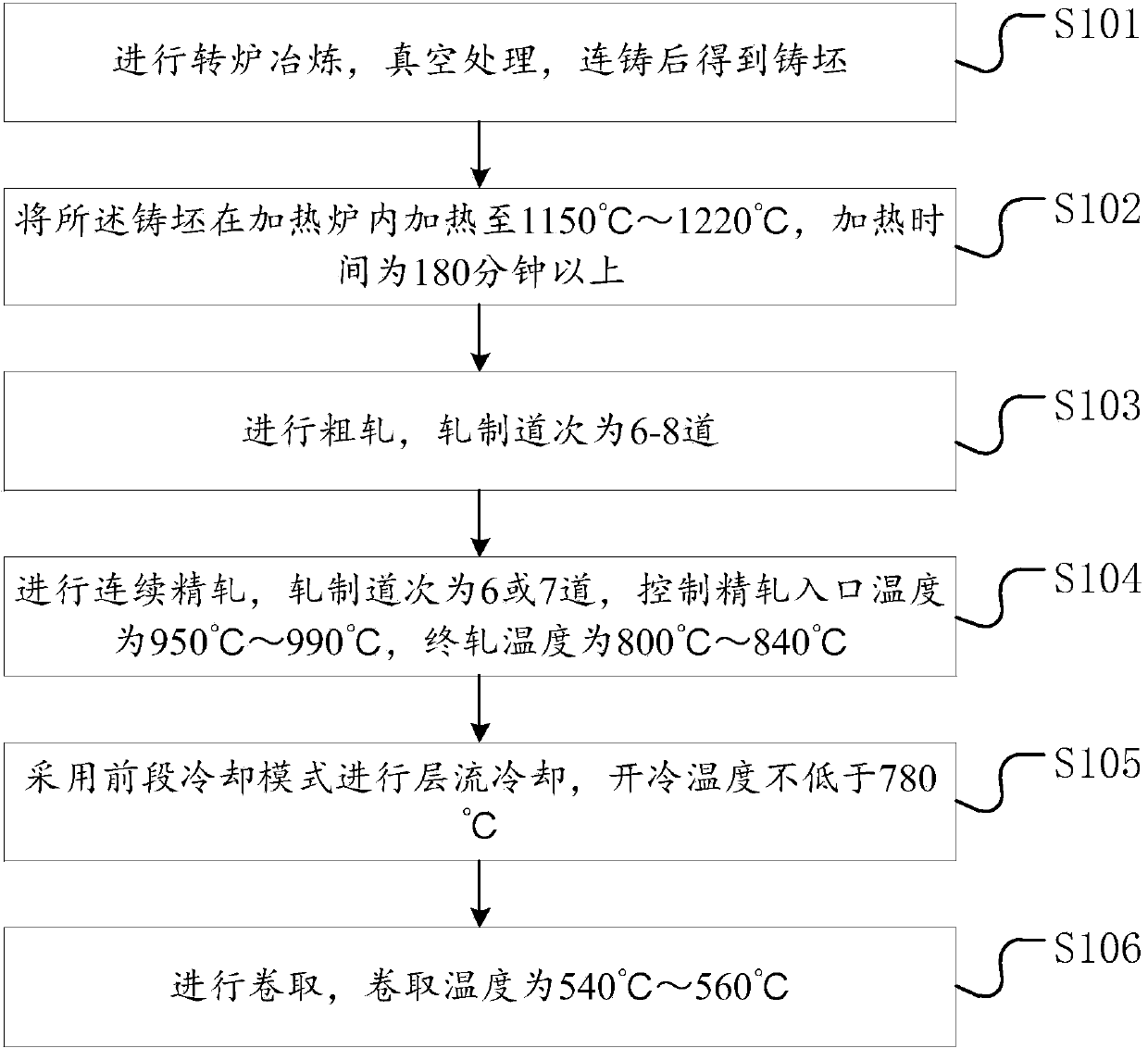

600 MPa level automobile axle housing steel and production method thereof

The invention discloses 600 MPa level automobile axle housing steel and a production method of the 600 MPa level automobile axle housing steel. Compositions of the steel comprise, by weight, 0.21 percent to 0.26 percent of C, 0.51 percent to 0.6 percent of Si, 1.1 percent to 1.5 percent of Mn, 0.01 percent to 0.06 percent of Al, P smaller than or equal to 0.02 percent, S smaller than or equal to 0.01 percent, 0.05 percent to 0.06 percent of V, 0.012 percent to 0.016 percent of N, and the balance Fe and inevitable impurities. The ratio of V to N is smaller than or equal to 5:1. According to the method, the accurate V content, the accurate N content and the controlled rolling and controlled cooling process window are designed, hot rolling strip steel for a 600 MPa level automobile axle housing is produced, the strip steel has the good strength and toughness, and meanwhile various mechanical performance indexes of the axle housing after hot forming at the temperature more than 800 DEG C can be ensured. The method can be applied to automobile axle housing production, the thickness of materials can be effectively reduced, and on the premise that the safety of an automobile is ensured, the lightweight aim can be effectively achieved.

Owner:SHOUGANG CORPORATION

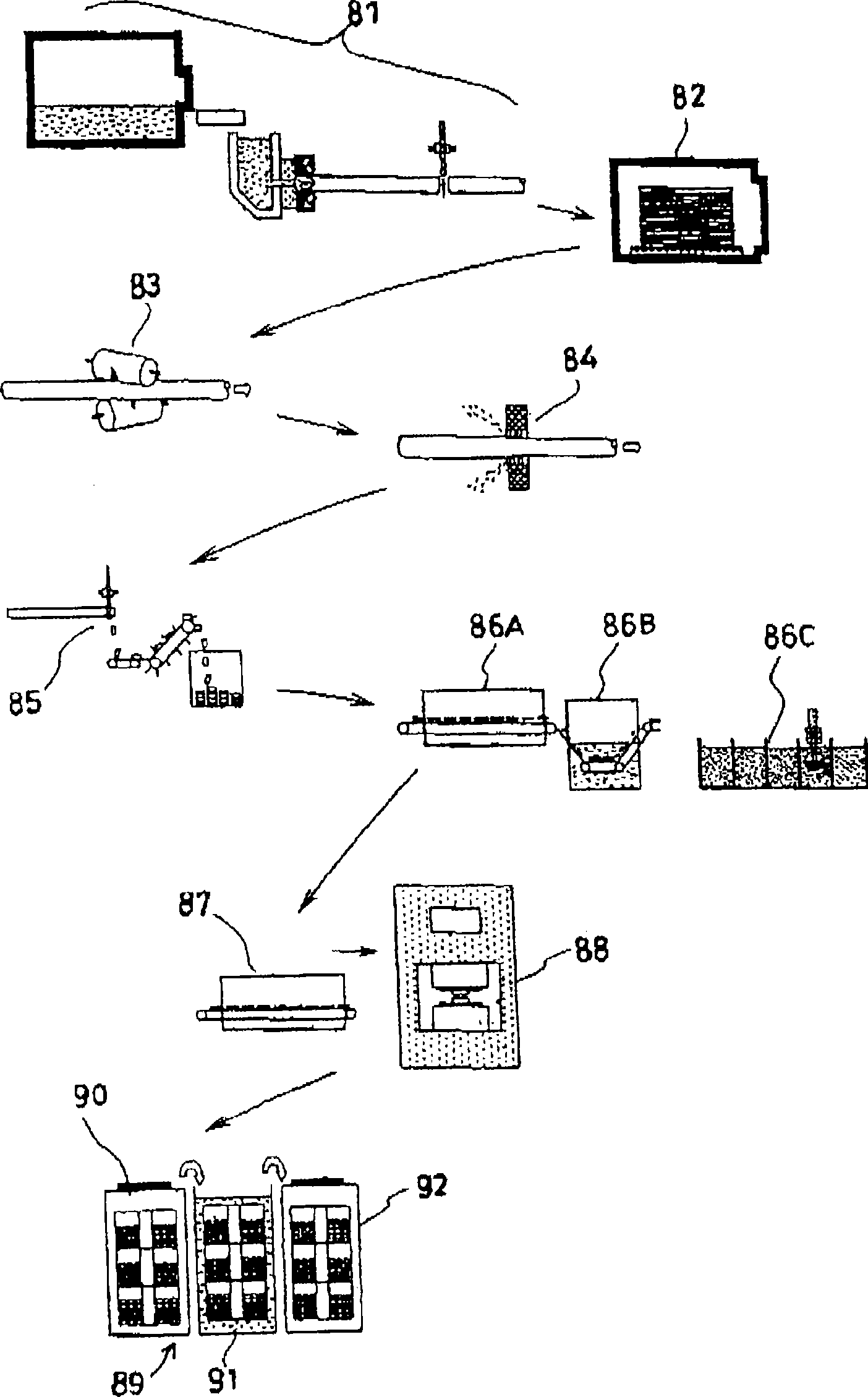

Process for production of aluminum alloy formings, aluminum alloy formings and production system

InactiveCN101522935ABoth ductilityToughnessMetal-working apparatusMachines/enginesUltimate tensile strengthMaterials science

The invention provides a process for production of aluminum alloy formings superior to conventional aluminum alloy forgings in mechanical strength at high temperature. A process for production of aluminum alloy formings by forging a stock consisting of a continuously cast rod made of an aluminum alloy, in which the aluminum alloy contains 10.5 to 13.5% by mass of Si, 2.5 to 6% by mass of Cu, 0.3 to 1.5% by mass of Mg, and 0.8 to 4% by mass of Ni and satisfies the relationship: Ni (% by mass) = [-0.68 OECu(% by mass) + 4.2(% by mass)] and which comprises the step (82) of preheat treatment of the stock, the heating step (87) of forging the stock, and the step (89) of postheat treatment of an aluminum alloy forming as the heat treatment / heating steps, with the step (82) involving the treatment of keeping the stock at -10 DEG C to 480 DEG C for 2 to 6 hours.

Owner:SHOWA DENKO KK

Aluminum alloys for casting, aluminum alloy castings and manufacturing method thereof

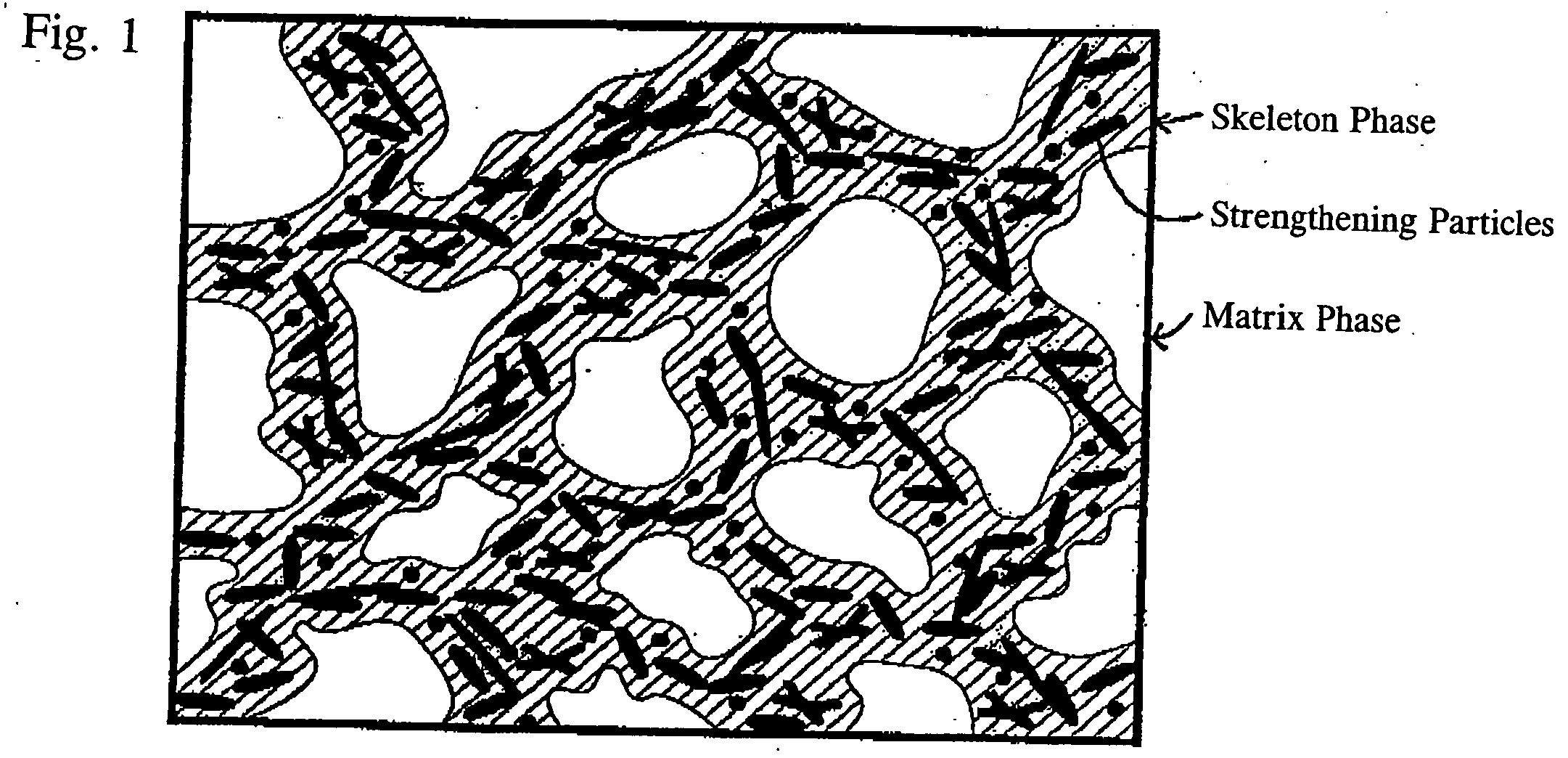

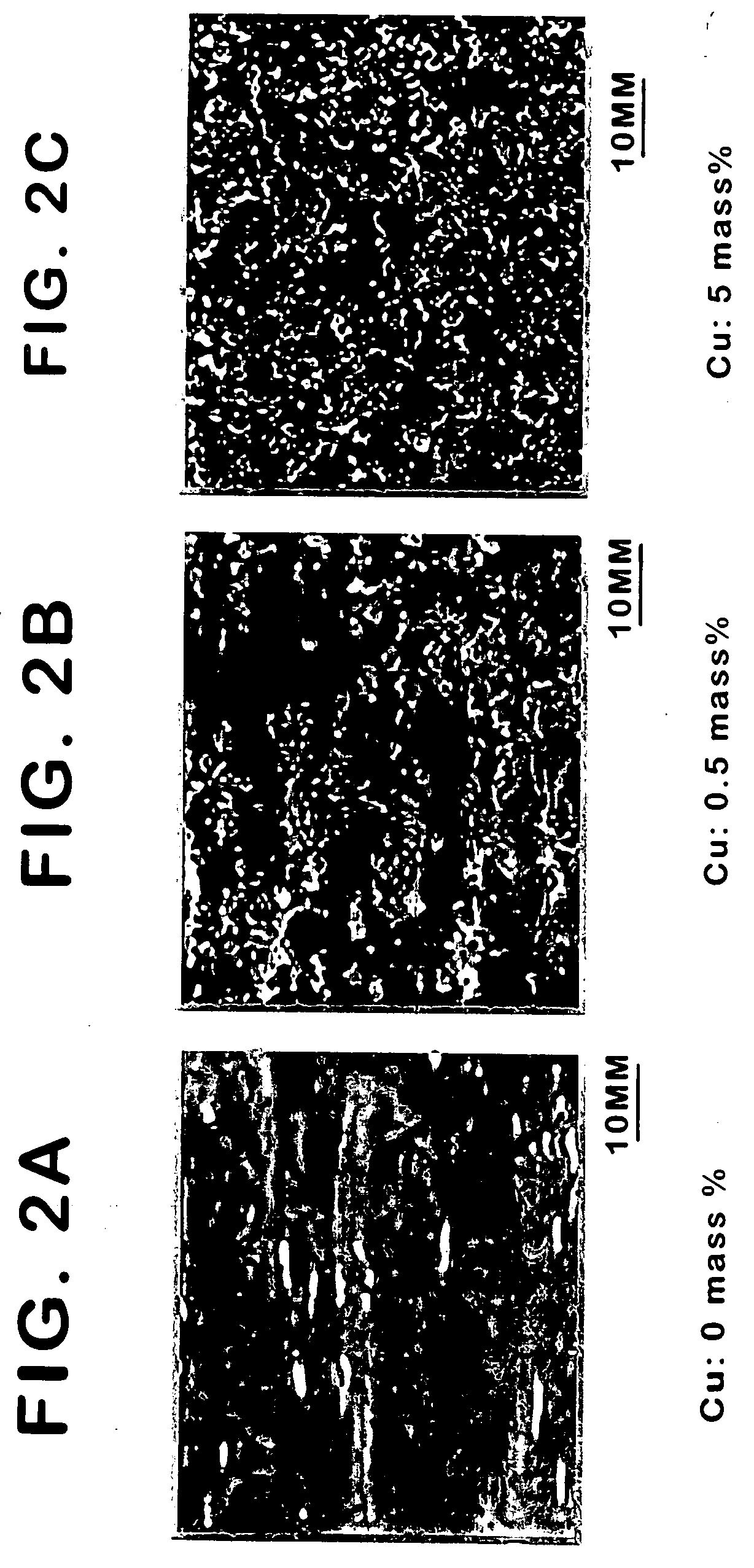

Aluminum alloys and castings are provided that have excellent practical fatigue resistances. The alloy includes, based upon 100 mass %, 4-12 mass % of Si, less than 0.2 mass % of Cu, 0.1-0.5 mass % of Mg, 0.2-3.0 mass % of Ni, 0.1-0.7 mass % of Fe, 0.15-0.3 mass % of Ti, and the balance of aluminum (Al) and impurities. The alloy has a metallographic structure, which includes a matrix phase primarily of α-Al and a skeleton phase crystallizing around the matrix phase in a network shape. The matrix phase is strengthened by precipitates containing Mg. Because of the strengthened matrix phase, and the skeleton phase that surrounds it, the castings have high strength, high fatigue strength, and high thermo-mechanical fatigue resistance.

Owner:TOYOTA CENT RES & DEV LAB INC

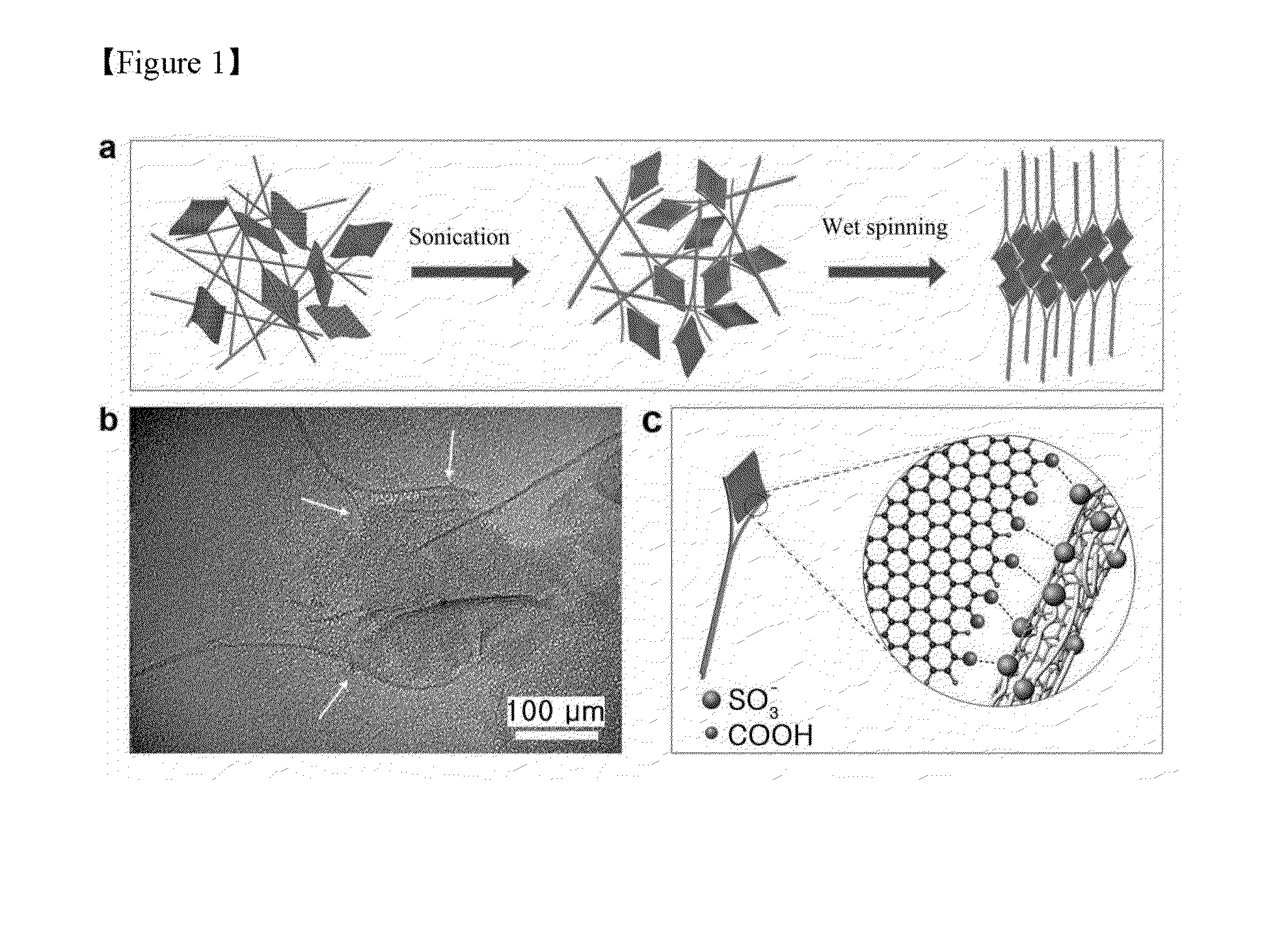

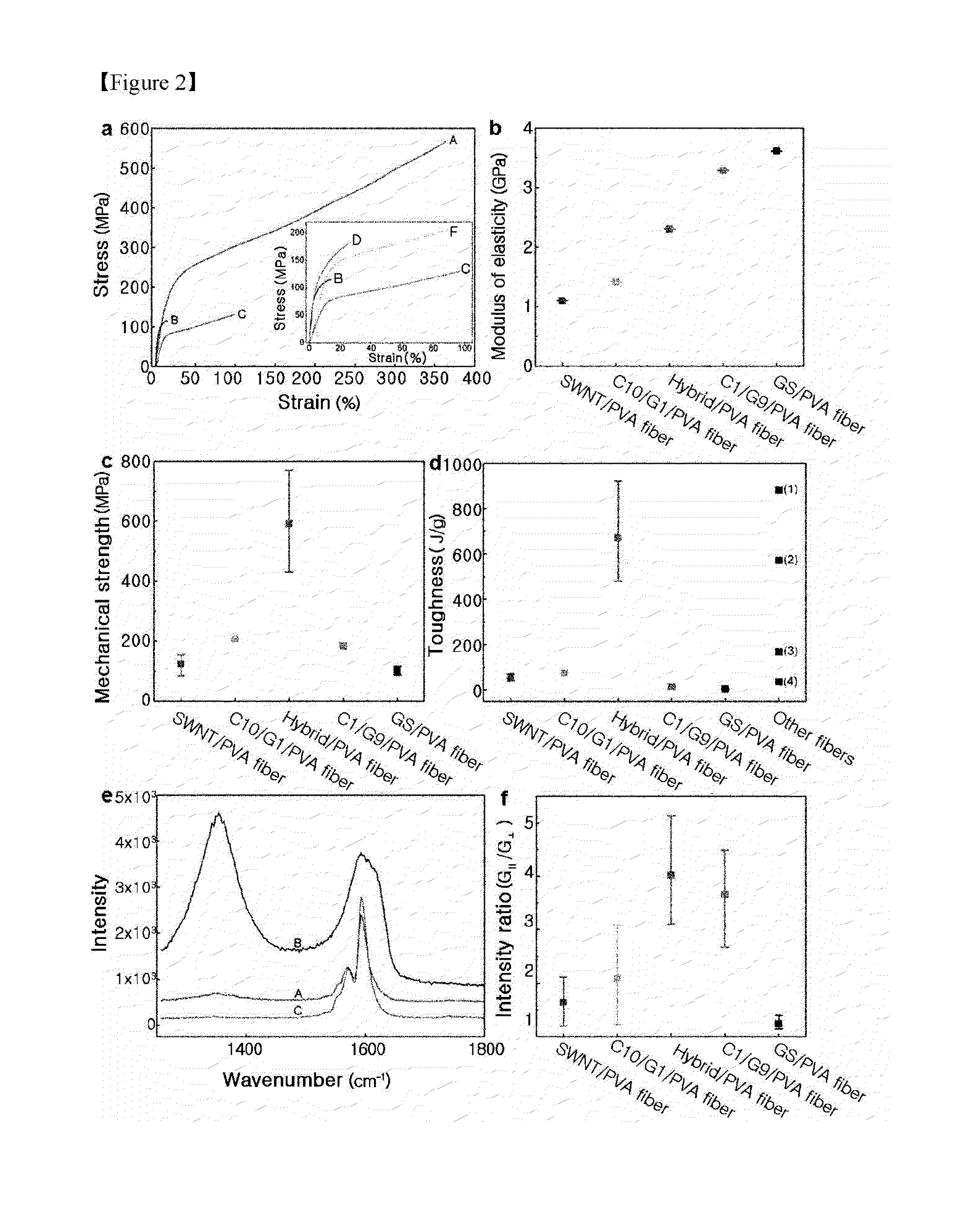

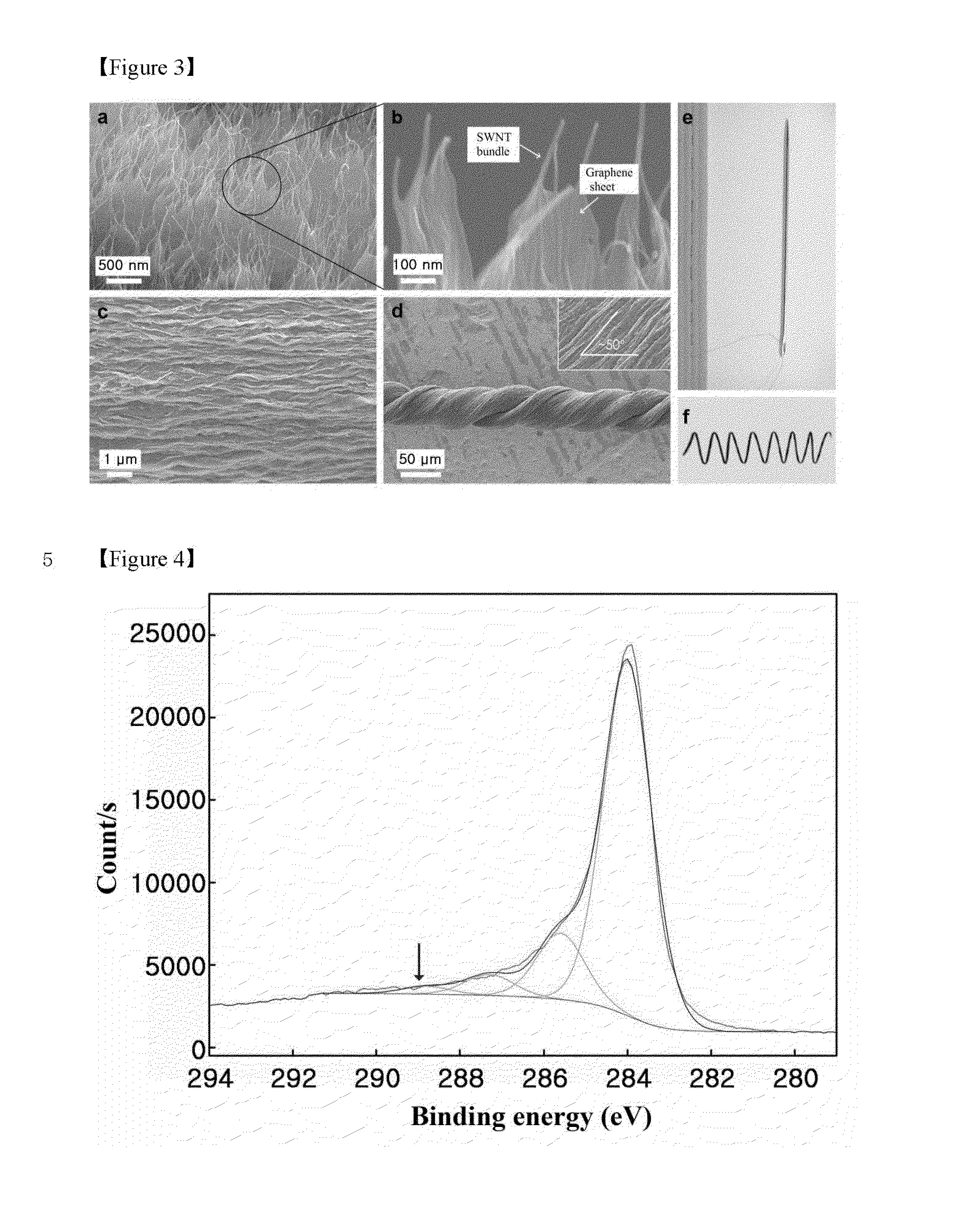

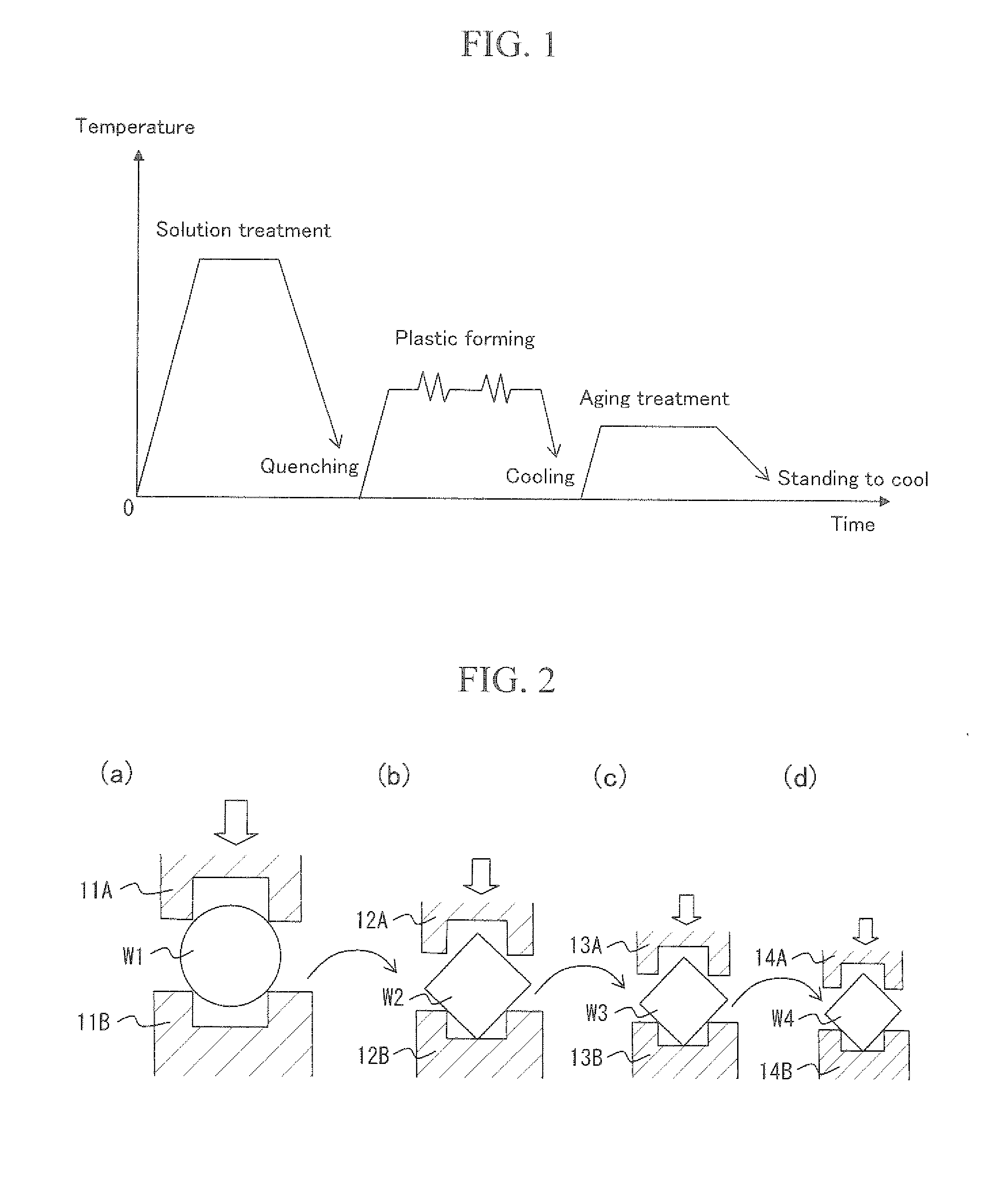

Hybrid polymer composite fiber including graphene and carbon nanotube, and method for manufacturing same

ActiveUS20140001417A1Improve toughnessEliminate needNon-metal conductorsMaterial nanotechnologyFiberHydrogen

The present invention relates to a graphene-based hybrid polymer composite fiber and a method for manufacturing same, and more particularly, to a hybrid composite fiber including the graphene, a carbon nanotube, and a polymer, wherein the graphene and the carbon nanotube are combined by means of self-organization through hydrogen bonding, so as to be very tough and flexible, without involving stretching, and to a method for manufacturing the hybrid composite fiber.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

Microcapsule preparation method of phase change material

InactiveCN102676123AImprove stabilityGood coating effectHeat-exchange elementsMicroballoon preparationBuilding energyPhase change

The invention discloses a microcapsule preparation method of a phase change material. The defects of containing of methanol, poor environment friendliness, easiness in cracking in a capsule energy storing process and poor energy storing effect exist in a phase change microcapsule prepared with the conventional method. The method comprises the following steps of: emulsifying a phase change material into a nuclear phase by adopting an interface polymerization method, wherein the phase change material accounts for 20-60 percent; preparing styryl and acrylate monomers into a shell phase; and mixing the two phases, polymerizing at the temperature of 80-160 DEG C, reacting for 2-6 hours, preserving heat for 1-4 hours, cooling and drying to obtain a phase change microcapsule. Formaldehyde is not required to be added in a preparation process, and a production process is environment-friendly; after a capsule is prepared, the capsule wall coating property is high, and reaction time is shortened; the method is low in preparation cost, has a simple and convenient process and contributes to industrial production; and the obtained product can be widely applied in the fields of building energy storage, energy saving, consumption reduction, spinning and the like.

Owner:巢启 +1

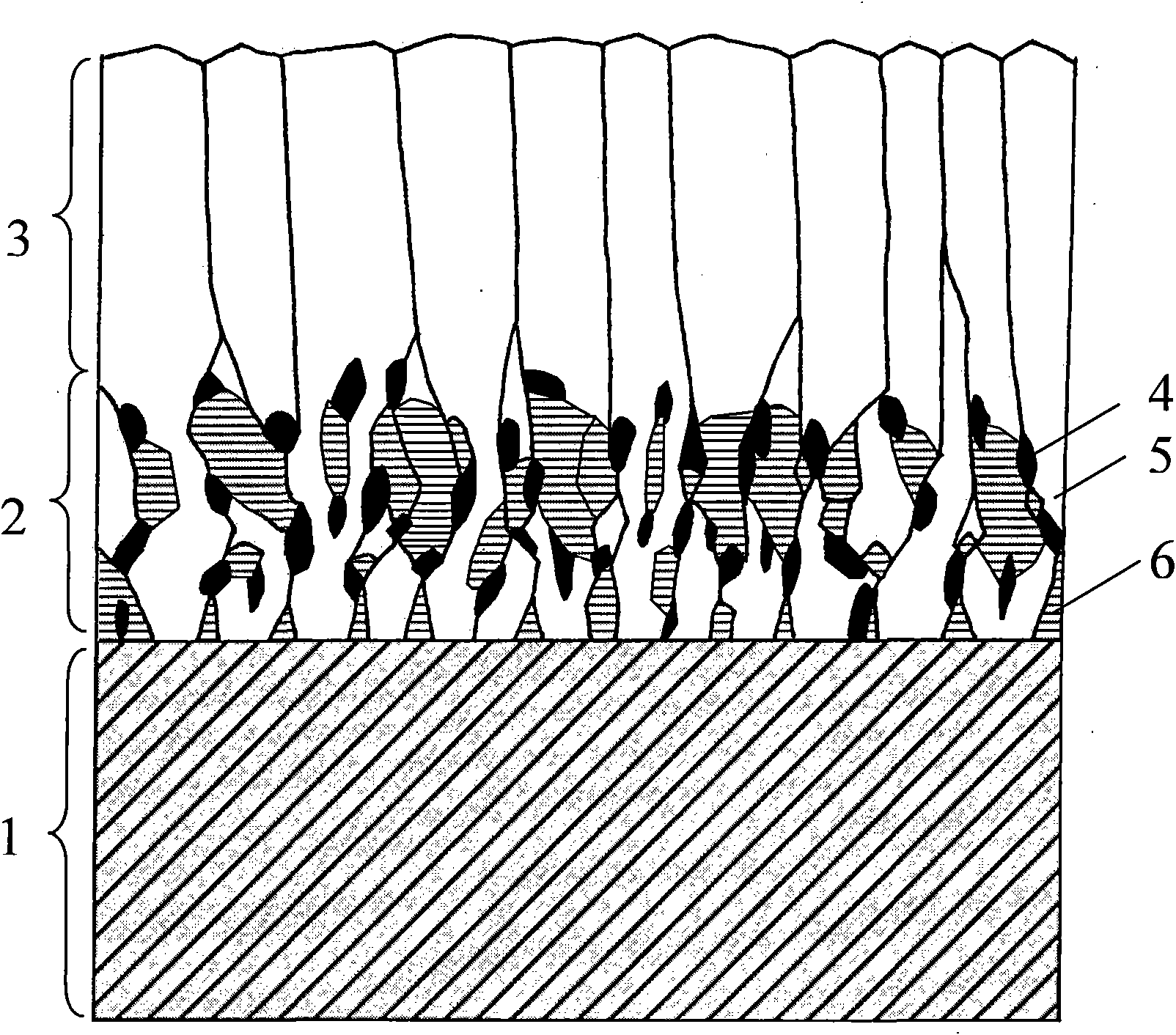

Process for producing aluminum alloy material and heat treated aluminum alloy material

InactiveUS20100319820A1Reduction in aluminum alloy material strengthInhibition of recrystallizationSolution treatmentUltimate tensile strength

According to the present invention, a process for producing an aluminum alloy material, whereby reduction in toughness and in fatigue strength of the aluminum alloy material can be inhibited even after solution treatment is provided. Also, the following is provided: a process for producing an aluminum alloy material comprising at least the steps of subjecting a heat treatable aluminum alloy material to solution treatment and applying aging treatment to the aluminum alloy material subjected to solution treatment, which further comprises the following step between the solution treatment step and the aging treatment step: the step of subjecting the aluminum alloy material to plastic forming in a manner such that a given amount of equivalent strain is imparted to the aluminum alloy material from at least two directions while the aluminum alloy material subjected to solution treatment is maintained under temperature conditions that do not cause softening of the aluminum alloy material by over-aging.

Owner:TOYOTA JIDOSHA KK

Method for preparing diamond-silicon carbide-cobalt disilicide composite interlayer of diamond coating on hard alloy

ActiveCN101880866ALow elastic modulusGood plasticityChemical vapor deposition coatingCemented carbideAlloy substrate

The invention discloses a method for preparing a diamond-silicon carbide-cobalt disilicide composite interlayer of a diamond coating on a hard alloy and belongs to the technical field of diamond coatings. The method is characterized in that: direct current plasma-assisted hot filament chemical vapor deposition (CVD) technology is adopted, hydrogen, methane and tetramethylsilane are used as reactant gases, the diamond-silicon carbide-cobalt disilicide composite interlayer is deposited on the hard alloy of which the surface is etched for removing cobalt, the composite interlayer is subjected to isothermal treatment in an atmosphere of methane and hydrogen in a volume ratio of 1 percent, and a diamond thin film is deposited on the composite interlayer. The method has the advantages that: the cobalt disilicide generated in the composite interlayer improves the adhesive force between a CVD diamond coating and a hard alloy substrate and the toughness of the CVD diamond coating obviously. The process of the invention is easy to control, can be applied to hard alloy CVD diamond coating tools and parts and large-area CVD diamond coatings and has a promising industrial prospect.

Owner:DALIAN UNIV OF TECH

Chewing soft capsule shell, chewing soft capsule drug and prepration method thereof

ActiveCN101628117ALow mechanical strengthReduce toughnessCapsule deliveryMacromolecular non-active ingredientsCarrageenanPolyvinyl alcohol

The invention relates to a chewing soft capsule shell, a chewing soft capsule drug and a prepration method thereof. The soft capsule shell consists of the following raw materials: 25-35 wt% of gelatin, 15-25 wt% of glycerol, 35-50 wt% of purified water, 0.1-1 wt% of sodium alginate, 0.1-1 wt% of carrageenan, 0.1-1 wt% of pectin, 1.5-2.5 wt% of sorbitol and 2-5 wt% of polyvinyl alcohol 400. The chewing soft capsule shell further comprises the following components: 0.1-0.3 wt% of sweetener, 0.2-0.4 wt% of acidifier, 0.001-0.01 wt% of spice, 0.001-0.01 wt% of preservative and 0.001-0.01 wt% of pigment. The soft capsule shell prepared by the raw materials has the advantages of small mechanical strength and toughness, and the invention further provides the method for preparing the chewing soft capsule drug.

Owner:BEIJING HANGYANG CAPSULE TECH

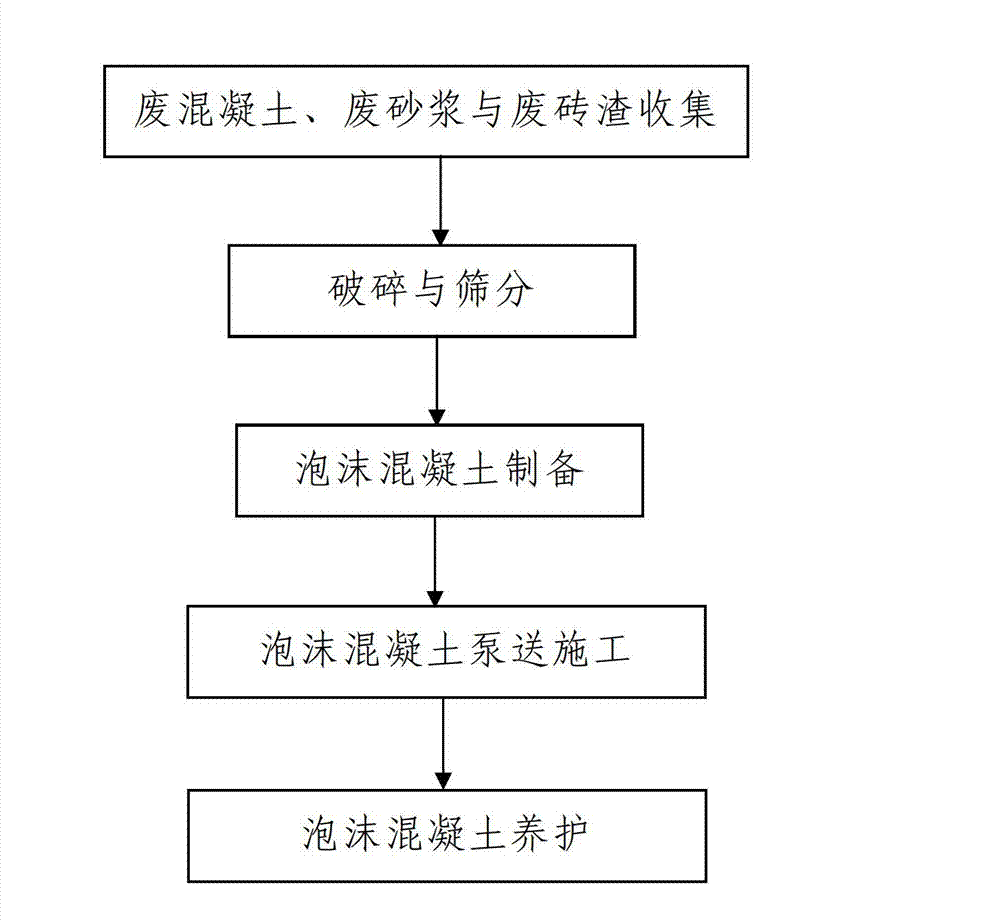

Construction waste recycling and reusing process

InactiveCN102815964AThe method steps are simpleReasonable designSolid waste managementBuilding material handlingFoam concreteBrick

The invention discloses a construction waste recycling and reusing process, which comprises the following steps of: 1, collecting waste concrete, waste mortar and waste brick slag; 2, smashing and screening, namely smashing and screening the collected waste concrete, the collected waste mortar and the collected waste brick slag to obtain regenerative rough aggregates and regenerative fine aggregates; and 3, preparing foam concrete, namely firstly preparing cement slurry, namely uniformly stirring concrete, water, the regenerative rough aggregates and the regenerative fine aggregates to obtain the cement slurry, and secondly adding a foam dilution solution, namely adding the foam dilution solution formed by uniformly mixing a foaming agent and water into the cement slurry, and uniformly stirring to obtain the foam concrete. The steps of the process are simple; the investment cost is low; the process is simple, feasible and high in operability; the waste concrete, the waste mortar and the waste brick slag can be effectively reused; the economical benefit is outstanding; the produced foam concrete material is high in heat preservation performance; and the problems that the construction waste is abandoned and stacked randomly and occupies the land, the waste of resources is severe, and the environment pollution is severe are solved.

Owner:陕西建工集团有限公司

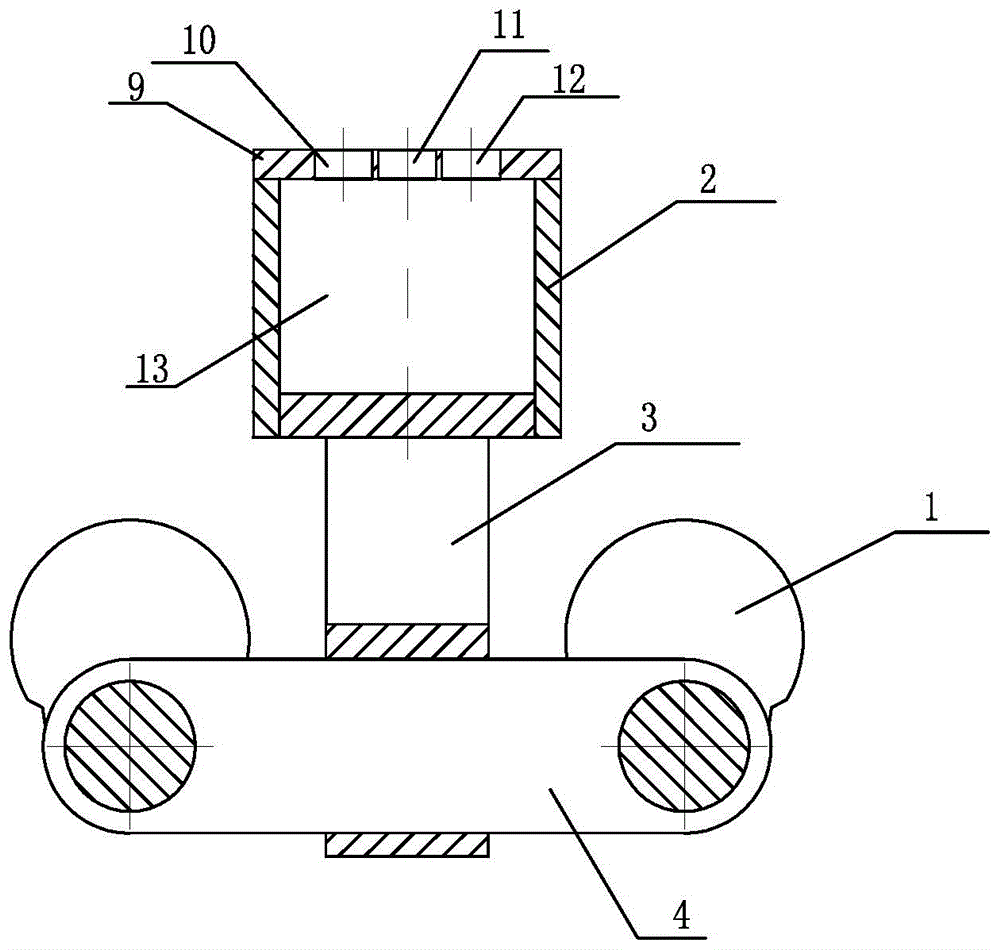

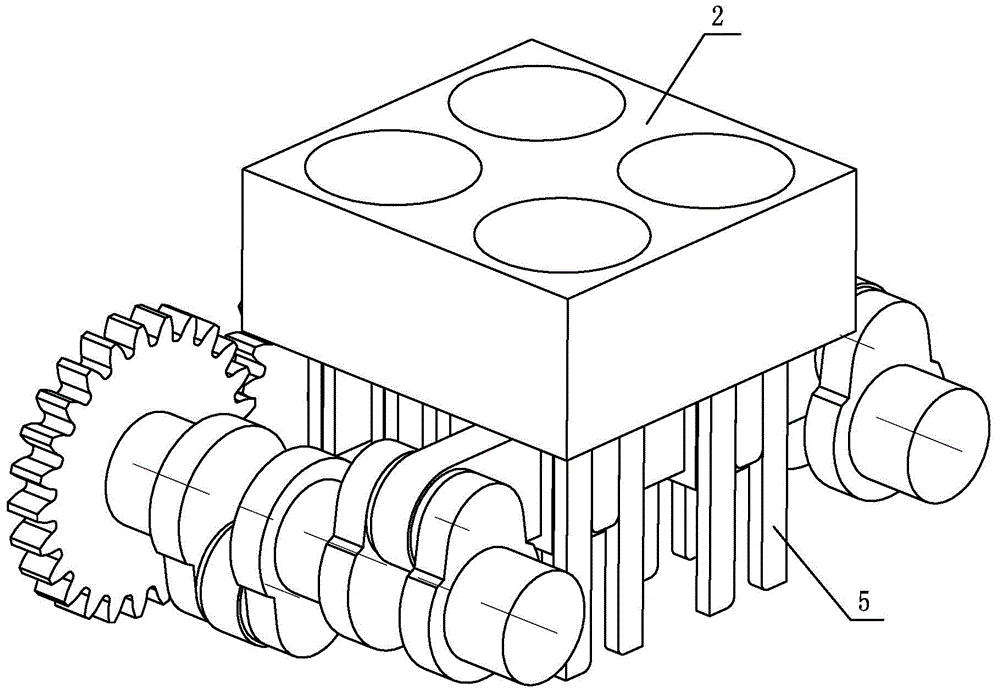

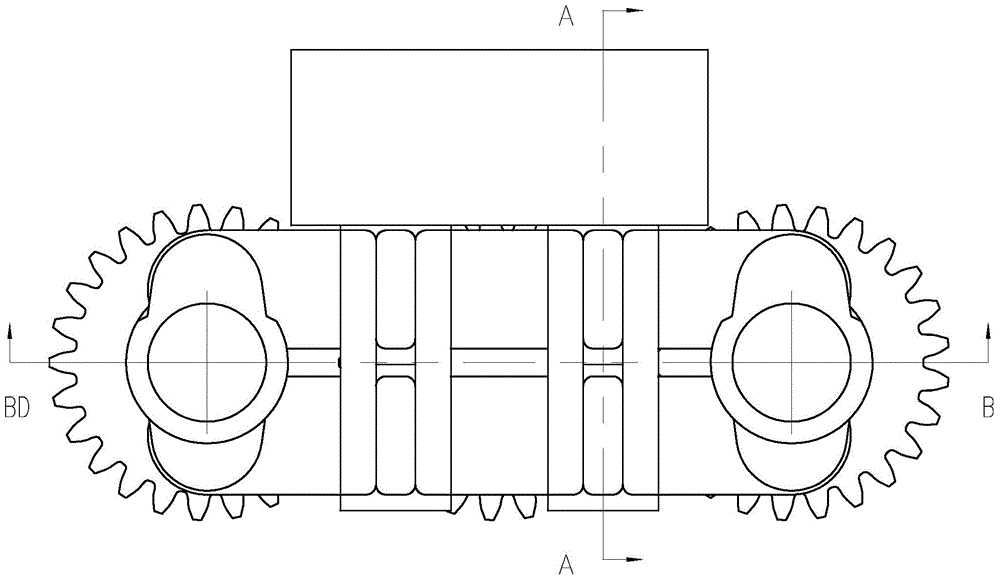

Double-crank mechanism engine

ActiveCN104481689AReduce toughnessReduce manufacturing costCylinder headsCylindersGas cylinderReciprocating motion

The invention discloses a double-crank mechanism engine, belonging to the technical field of engines. The double-crank mechanism engine comprises a gas cylinder and a piston capable of performing straight reciprocating motion in the gas cylinder, wherein two parallel crankshafts are arranged at the two sides of the gas cylinder; a connecting rod is hinged between corresponding crankshaft pins of the two crankshafts to form a double-crank mechanism; a connecting rod insertion slot and a slide block are arranged on a piston rod on the rear end of the piston, the connecting rod is inserted to the connecting rod insertion slot in a sliding manner, a guide block is fixed in the engine; a guide rail for sliding the slide block is formed on the guide block; the slide block is inserted to the guide rail; transmission gears are arranged on the end parts of the crankshafts; an output gear is engaged between the two transmission gears; and an output shaft is arranged on the output gear. The double-crank mechanism engine can be used for effectively lowering the abrasion and the impact of the piston and a cylinder sleeve, improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com