Process for production of aluminum alloy formings, aluminum alloy formings and production system

A manufacturing method and technology for aluminum alloys, applied in metal processing equipment, machines/engines, mechanical equipment, etc., can solve the problem of lack of research on mechanical properties, improve high-temperature fatigue strength, improve fatigue strength characteristics, suppress primary Si the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

[0144] 〔Manufacturing conditions〕

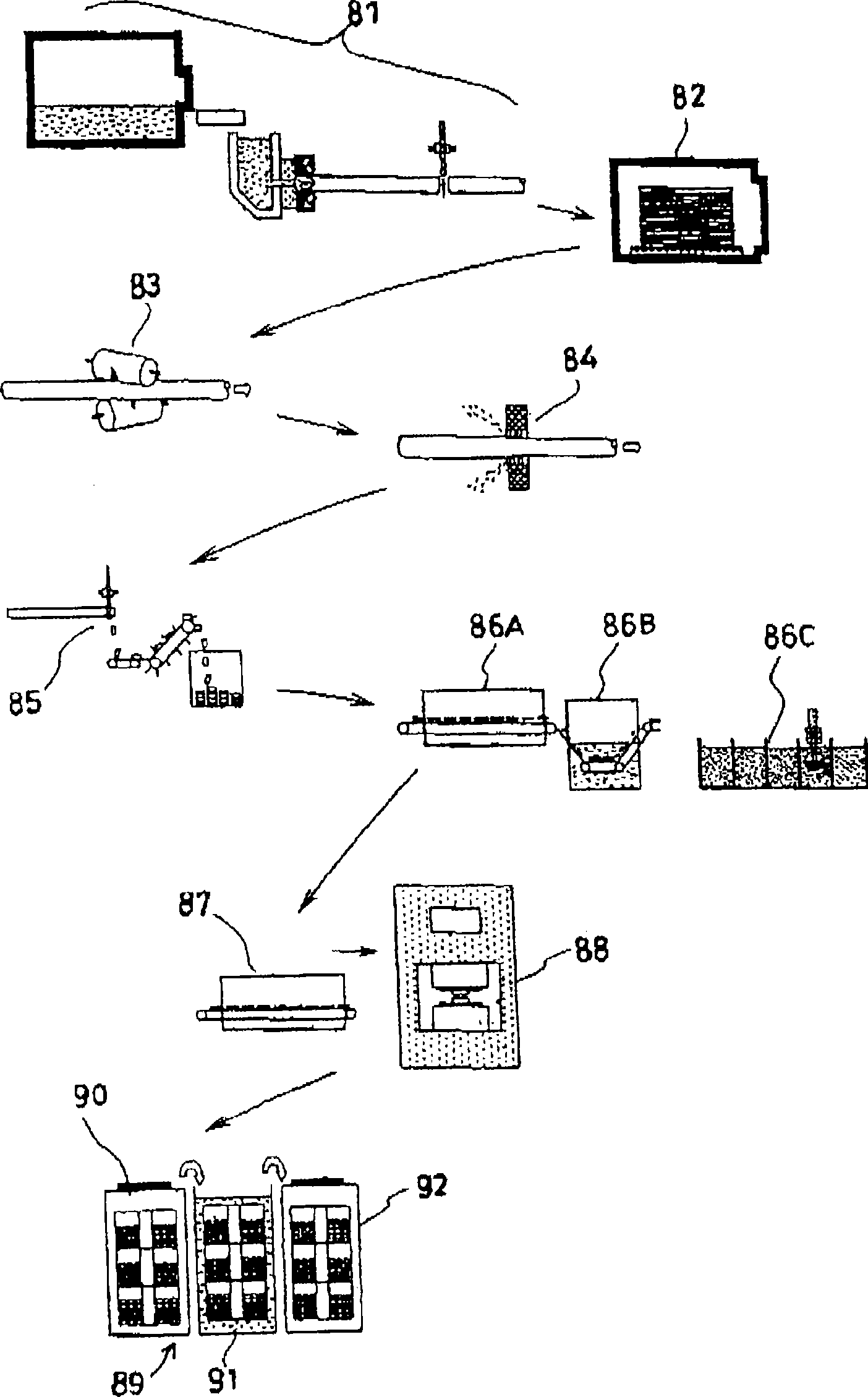

[0145] Using the production system shown in FIG. 1 , aluminum alloy molded products of Examples 1 to 16 shown in Table 1 and Comparative Examples 1 to 10 shown in Table 2 were produced.

[0146]

[0147]

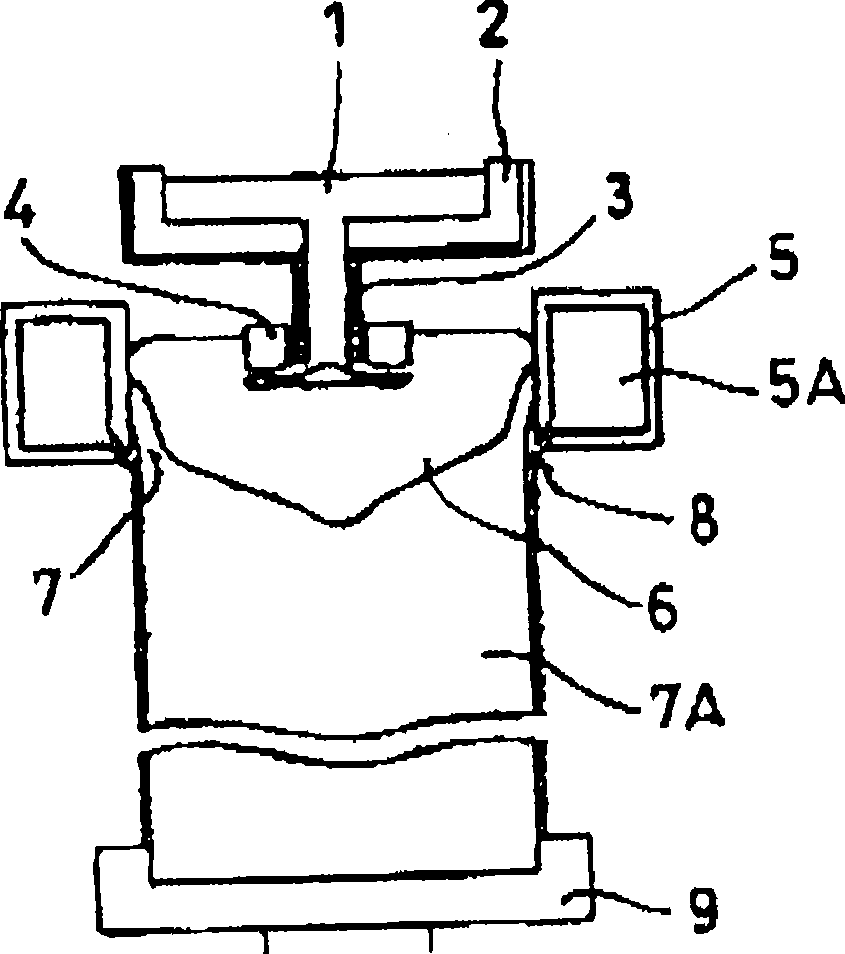

[0148] As the continuous casting device 81 constituting this production system, using the hot top continuous casting machine shown in FIG. 85Φ (mm) continuous casting round bar of 10 aluminum alloy. The above-mentioned hot top continuous casting machine is a casting machine using a gas pressurized hot top casting method, and is configured to introduce gas and lubricating oil into the gap between the end plate and the mold so that the pressure of the molten alloy supplied to the mold and the lubricating oil and The gas formed by the vaporization of lubricating oil is well balanced. According to this configuration, the area where the molten aluminum comes into contact with the casting mold becomes narrow, so that the molten alloy can...

Embodiment 17、18

[0173] 〔Manufacturing conditions〕

[0174] Examples 17 and 18 and Comparative Examples 11 and 12 were produced by the same production method as in Examples 1 to 16 and Comparative Examples 1 to 10 under the compositions and production conditions shown in Table 5, respectively. In addition, Comparative Example 13 was produced by the same production method as Comparative Examples 11 and 12 except that it was formed from a powdered squeeze-cast material, and was not formed from a continuous casting round bar of aluminum alloy, and was not subjected to homogenization treatment. Examples 17, 18, and Comparative Examples 11 to 13, as shown in Fig. 7 (a) to (c), are formed into aluminum alloy molded products having the shape of a piston 1 having a crown surface 10 having a diameter of 80 mm and a thickness of 8 mm. .

[0175] 〔Fatigue Strength Evaluation〕

[0176] About Examples 17 and 18 and Comparative Examples 11-13, the fatigue strength was evaluated by the following method.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com