Construction waste recycling and reusing process

A technology of construction waste and construction, applied in the direction of construction, building structure, construction materials, etc., can solve the problems of waste of resources, large environmental pollution, etc., and achieve less manpower and material resources, significant economic benefits, and simple method steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

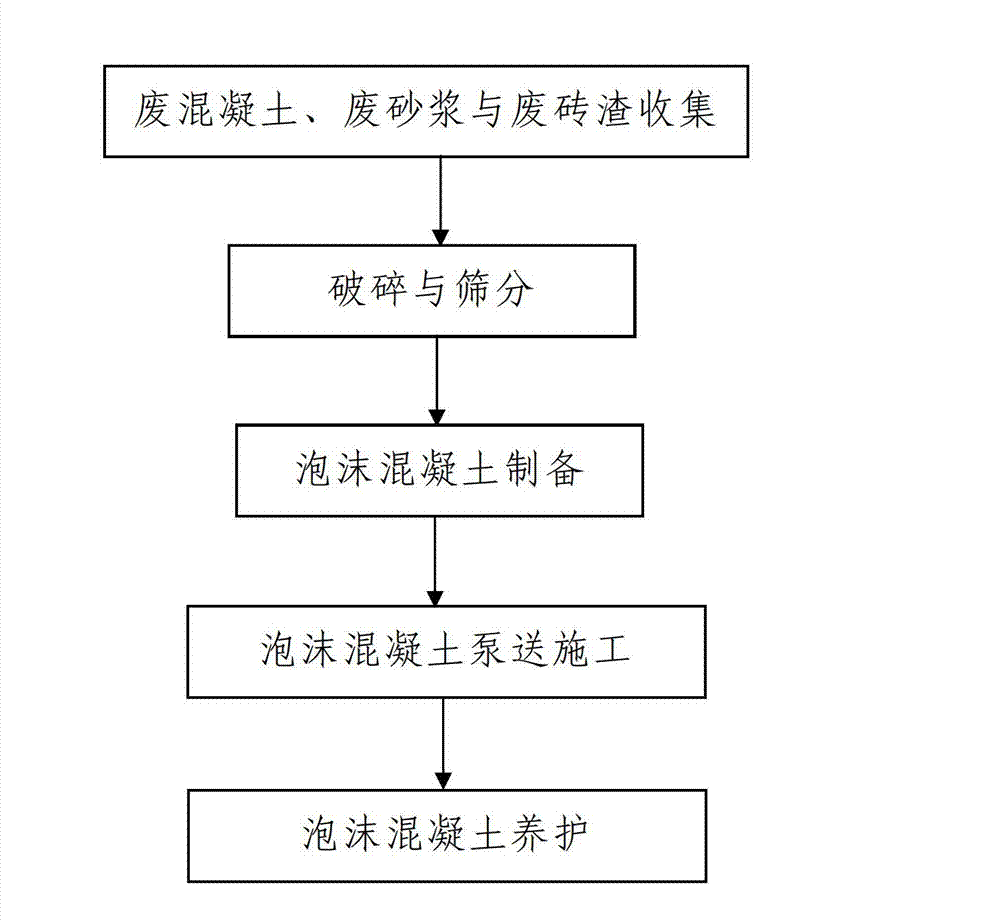

Method used

Image

Examples

Embodiment 2

[0092] In this example, the difference from Example 1 is: the weight ratio of cement, water, recycled coarse aggregate and recycled fine aggregate in the cement slurry described in step 301 is 280:160:320:260; in step 302 The weight ratio of foaming agent to water in the foam diluent is 1:36, and the weight ratio between the foaming agent and the cement in step 301 is 2.2:280.

[0093] In this embodiment, the remaining process steps and process parameters are the same as those in Example 1.

Embodiment 3

[0095] In this example, the difference from Example 1 is: the weight ratio of cement, water, recycled coarse aggregate and recycled fine aggregate in the cement slurry described in step 301 is 280: 150: 310: 250; in step 302 The weight ratio of foaming agent to water in the foam dilution liquid is 1:35.5, and the weight ratio between the foaming agent and the cement in step 301 is 2.1:280.

[0096] In this embodiment, the remaining process steps and process parameters are the same as those in Example 1.

Embodiment 4

[0098]In this example, the difference from Example 1 is: the weight ratio of cement, water, recycled coarse aggregate and recycled fine aggregate in the cement slurry described in step 301 is 280:129:300:255; in step 302 The weight ratio of foaming agent to water in the foam dilution liquid is 1:33, and the weight ratio between the foaming agent and the cement in step 301 is 1.8:280.

[0099] In this embodiment, the remaining process steps and process parameters are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com