Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1618 results about "Waste recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

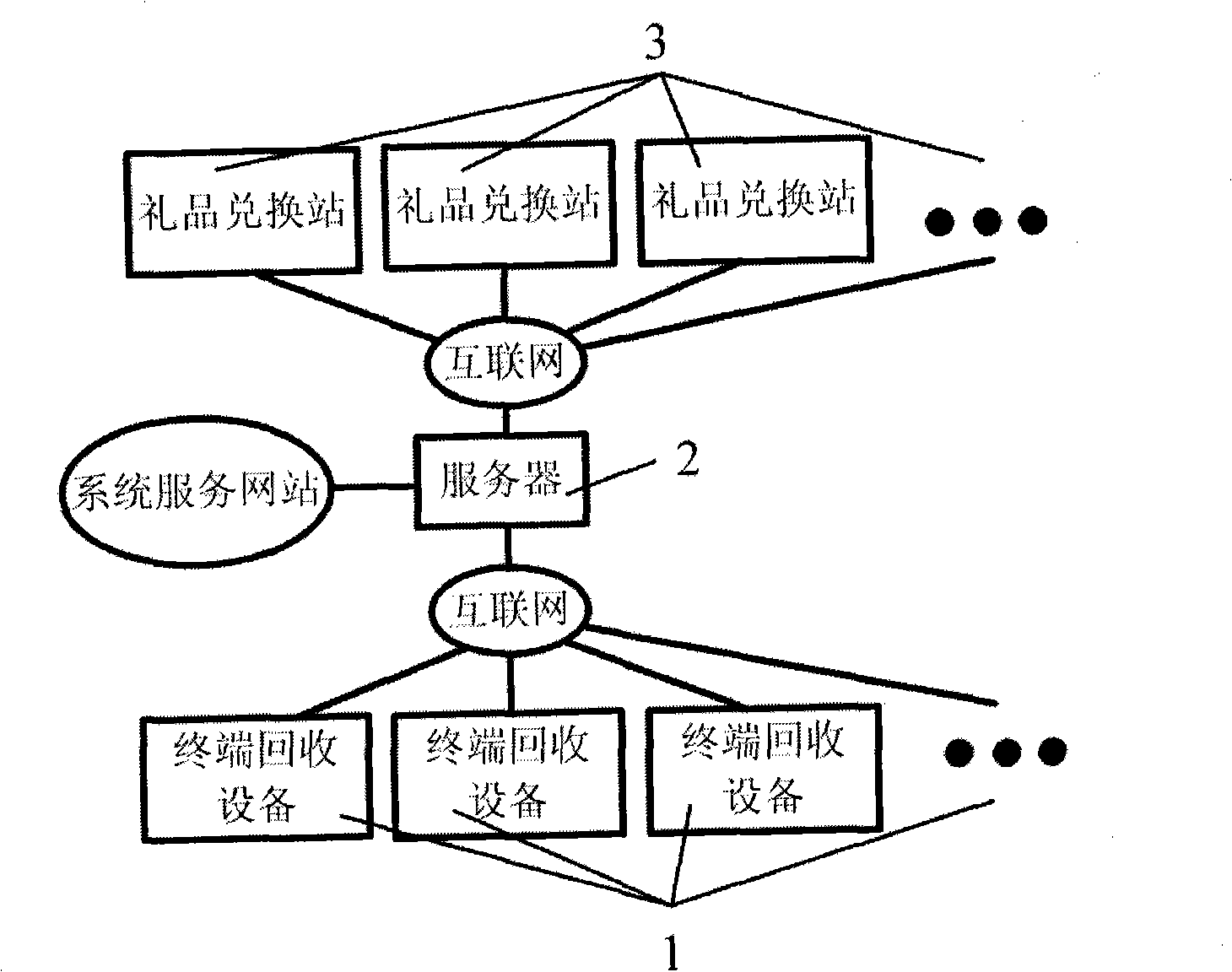

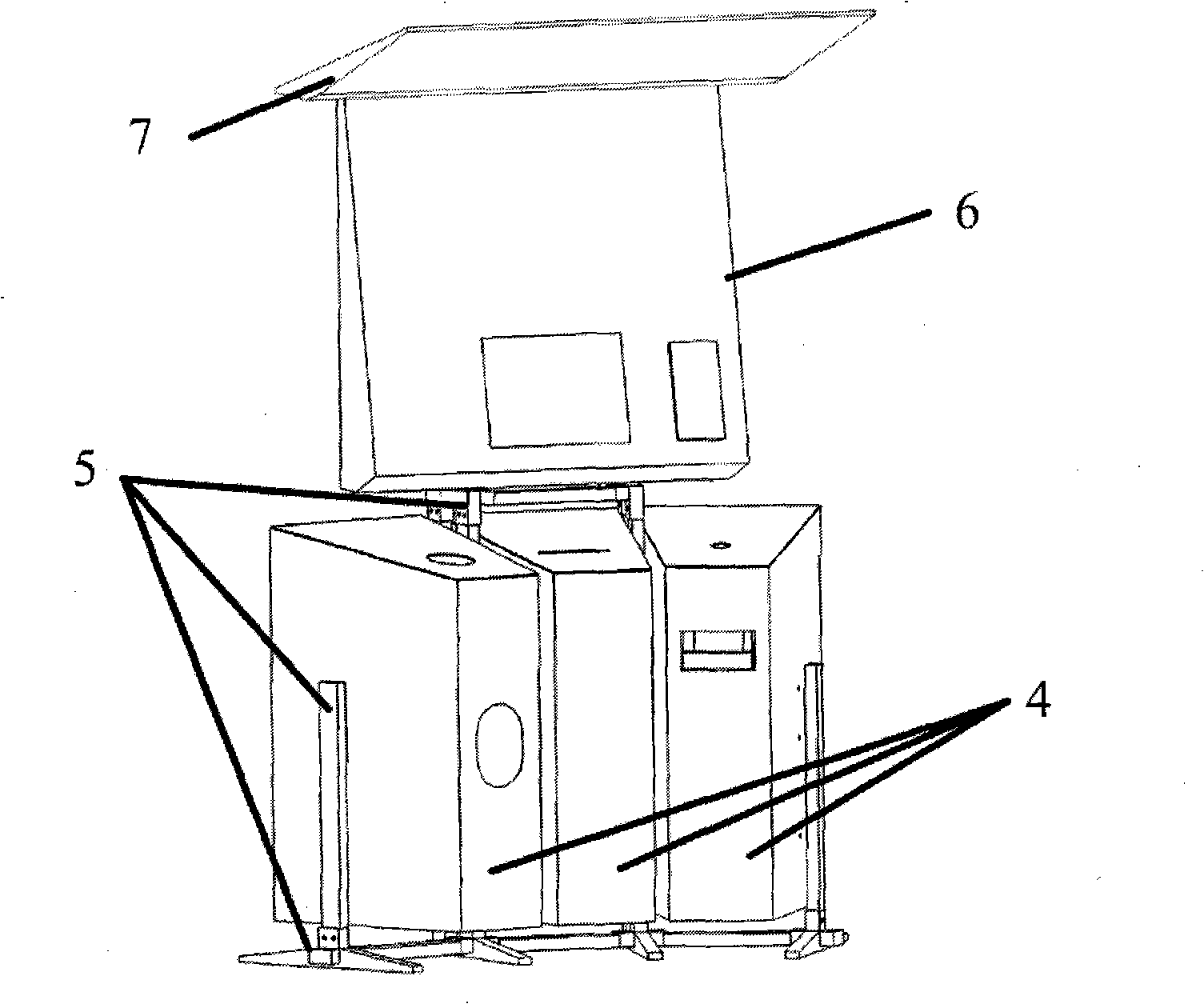

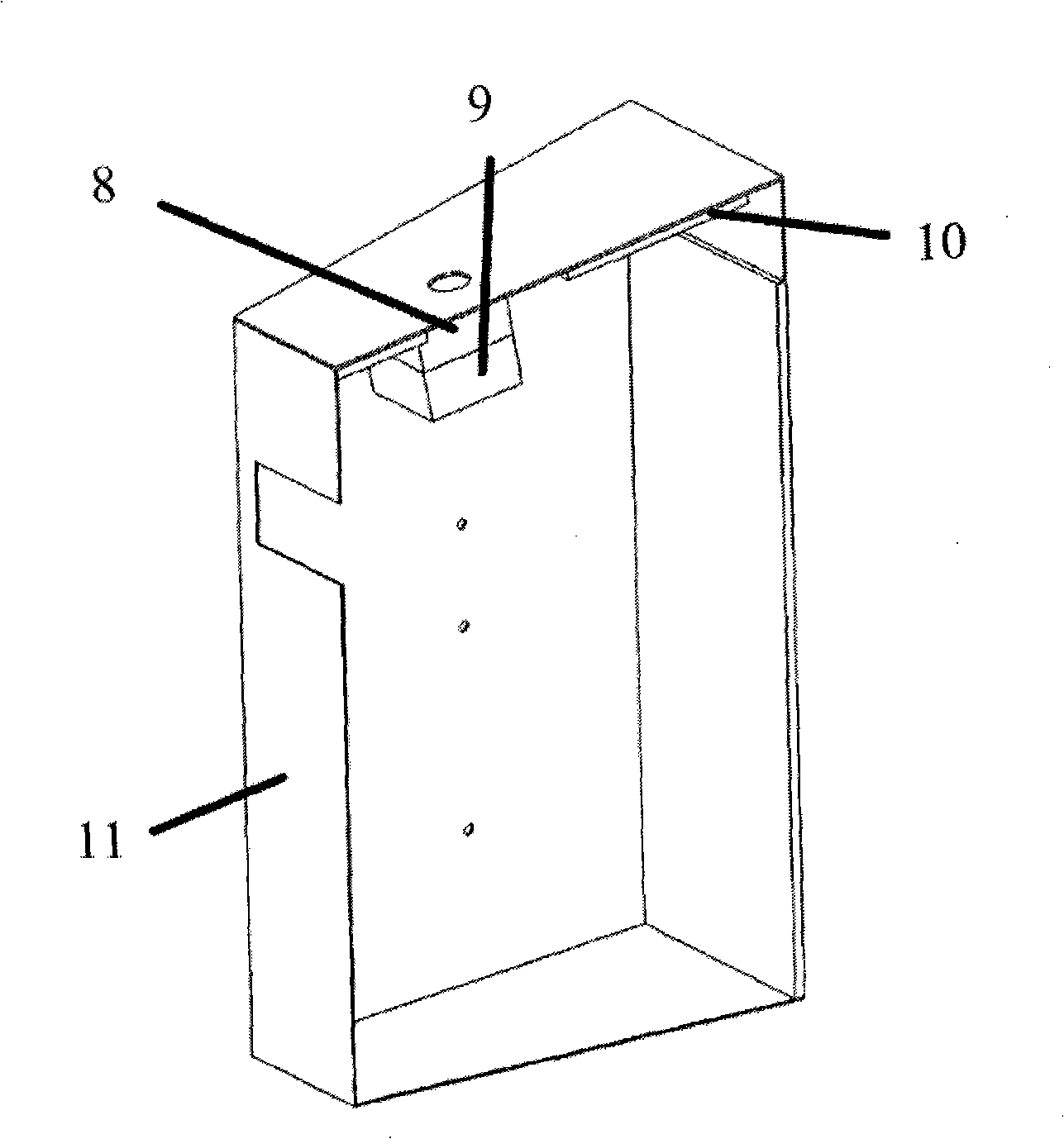

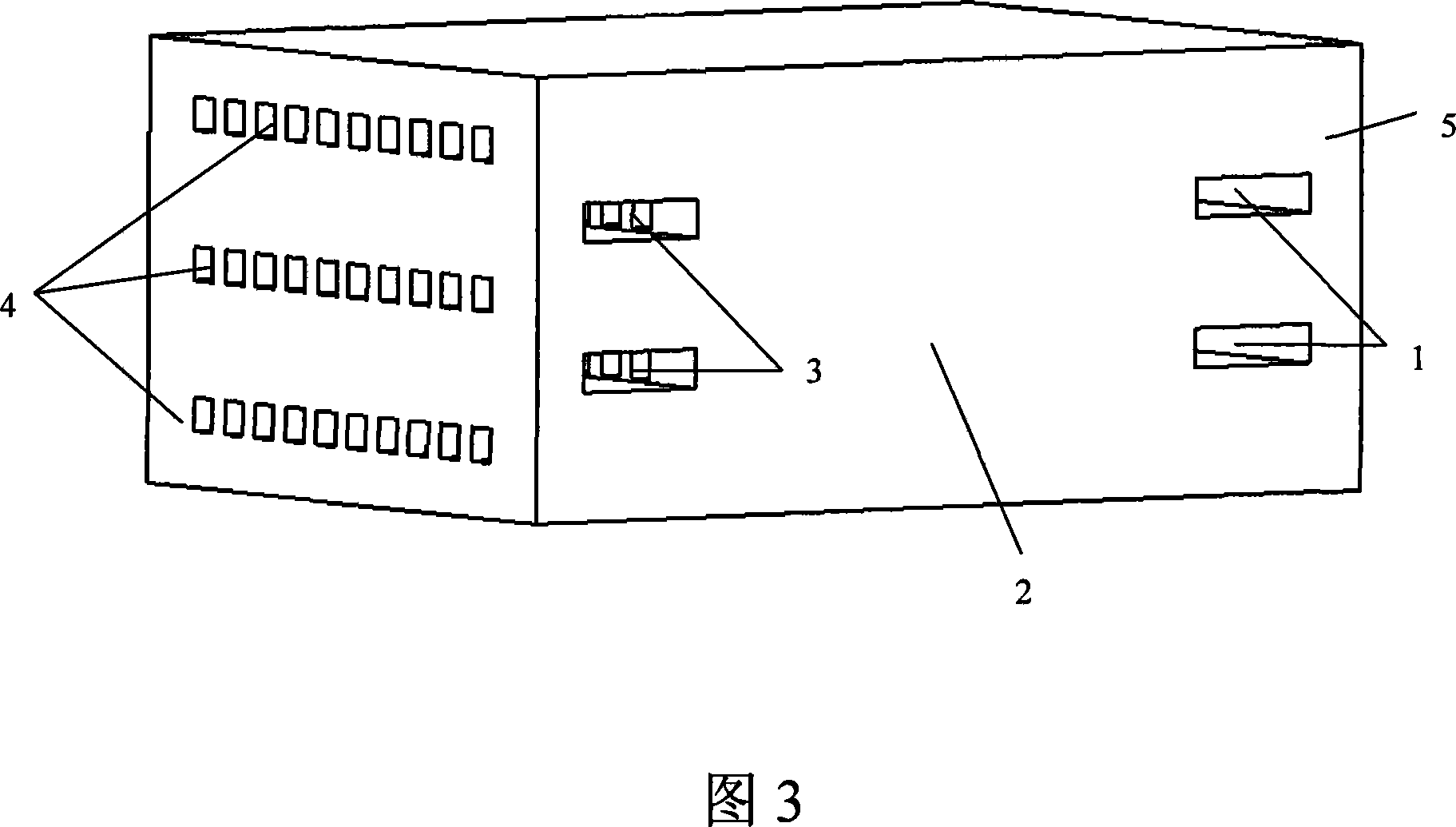

Solid garbage recovery system base on encouragement

InactiveCN101269739AReduce pollutionHigh recovery rateWaste collection and transferRefuse receptaclesUser needsTerminal equipment

A solid waste recovery system based on rewards as encouragement belongs to the technical field of environmental sanitation, and solves the problems of imperfect classification effect and low recovery rate of the existing recovery systems to develop accurate throwing habits of people who throw garbage. The invention is composed of a recovery terminal device, a server and a gift exchanging station, and the server is connected with the recovery terminal device and the gift exchanging station through the internet; the recovery terminal device is composed of a classification garbage bin, a supporting frame, a lamp box and a ceiling; the server stores the information such as accounts of users, the storage amount of garbage, addresses of the gift exchanging stations, etc., a system serving network station is erected on the internet to realize the functions of the registration of accounts of users, the addition, revision and deletion of the information of the accounts, gift exchanging by using points on a user network, etc.; the gift exchanging station is provided with a computer for obtaining and updating data in the server. The solid waste recovery system can give rewards according to the requirements of the users, can promote the users voluntarily to throw recovery garbage according to the requirements of classification, and reduce the environment pollution as well as increase the recovery rate.

Owner:HUAZHONG UNIV OF SCI & TECH

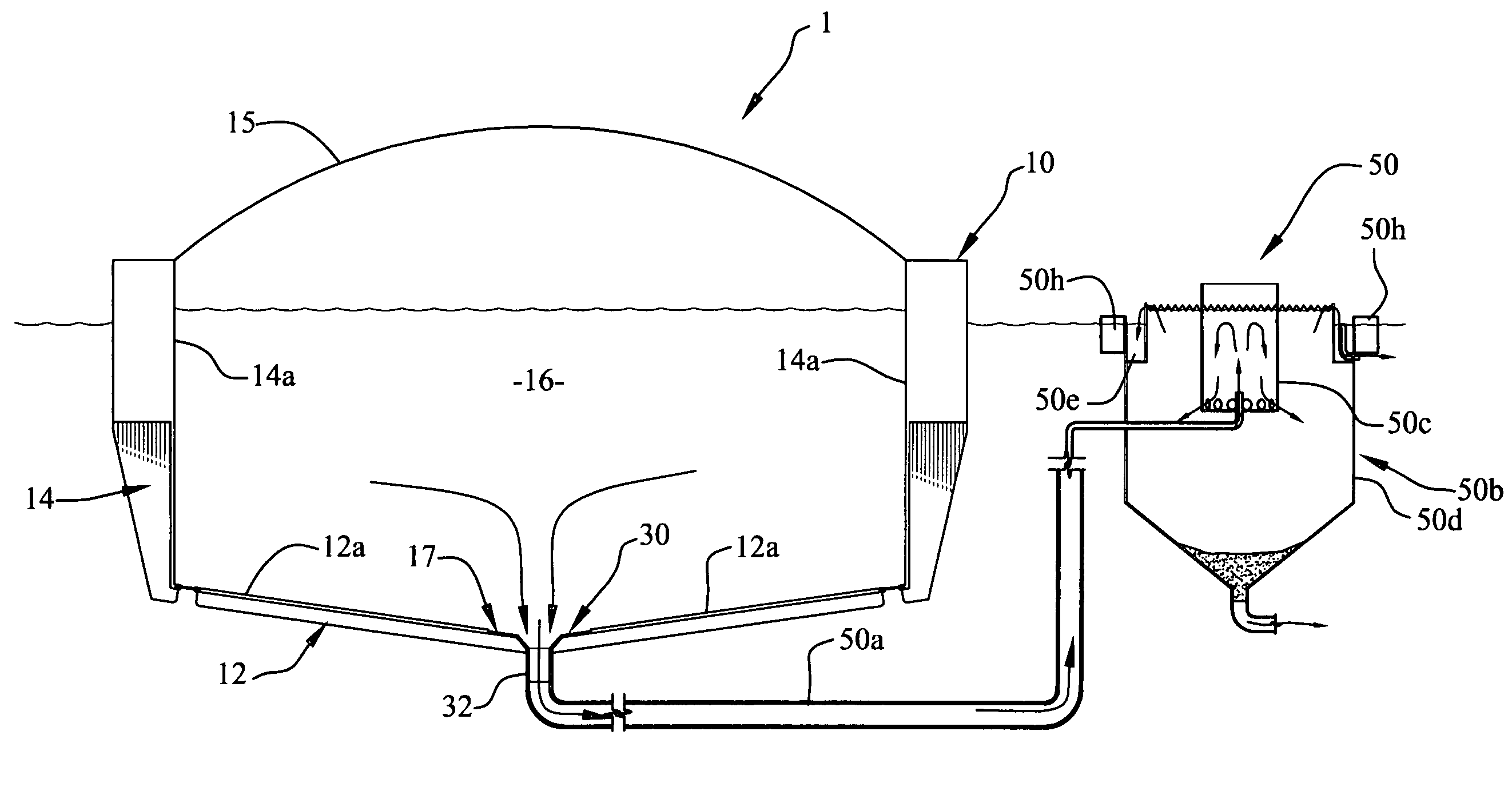

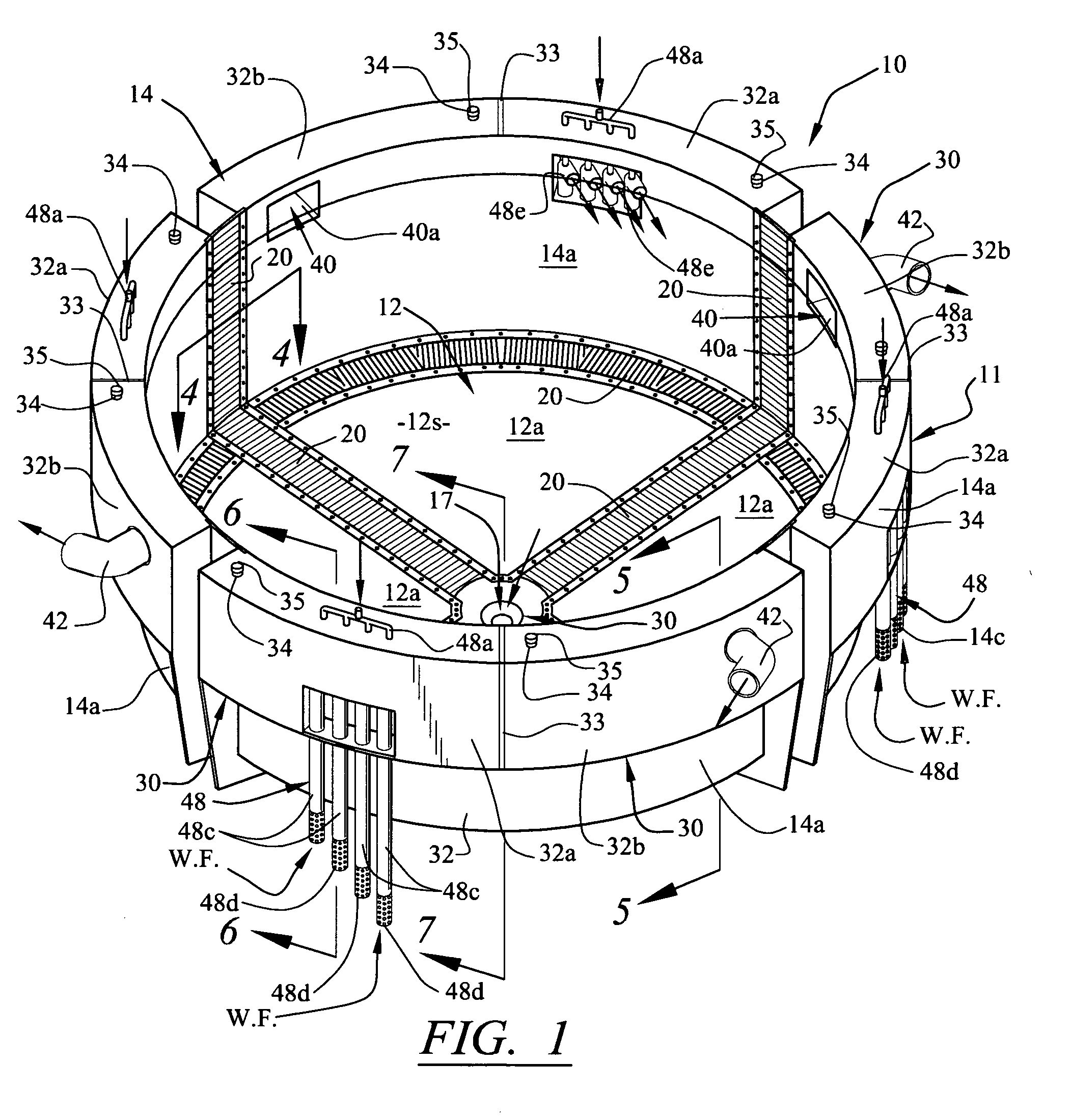

Aquaculture production system

InactiveUS20100224136A1Economically and environmentally superiorEconomically beneficialClimate change adaptationPisciculture and aquariaAquatic speciesSolid wall

A floating fish production system for placement within a body of water and being structured and disposed for containing fish and other aquatic animal, plant and algal species, the system including at least one primary containment tank having an arrangement of individual solid wall sections and an arrangement of individual solid floor sections. Flexible membranes span between and connect to adjacently positioned solid wall and floor sections to define flexible connecting joints that allow the individual solid wall and floor sections to move relative to one another in an articulating action. The flexible membranes allow the tank configuration to temporarily deform from a relaxed state in response to externally applied forces exerted on the tank (e.g., waves, wind, current) to thereby absorb the externally applied forces and reduce stress on the structural integrity on the tank. An air lift system including a high volume, low pressure blower and a spaced arrangement of vertically extending air lift pipes delivers water and oxygen from the exterior body of water and into the tank interior. A flexible main drain in a central area at the bottom of the tank connects to a waste recovery system for removing waste produced by the fish and other aquatic species.

Owner:PAPADOYIANIS ERNEST D +1

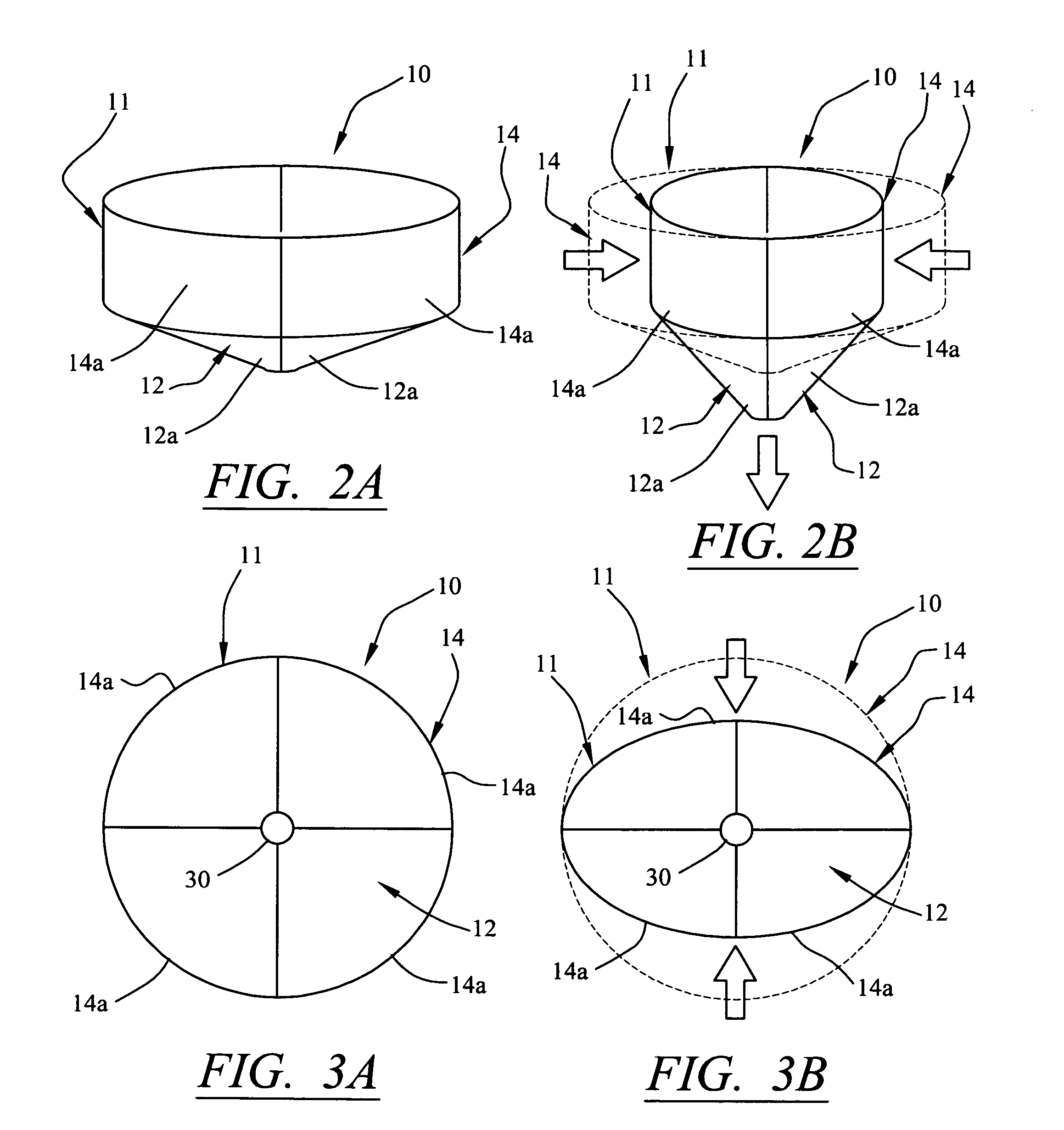

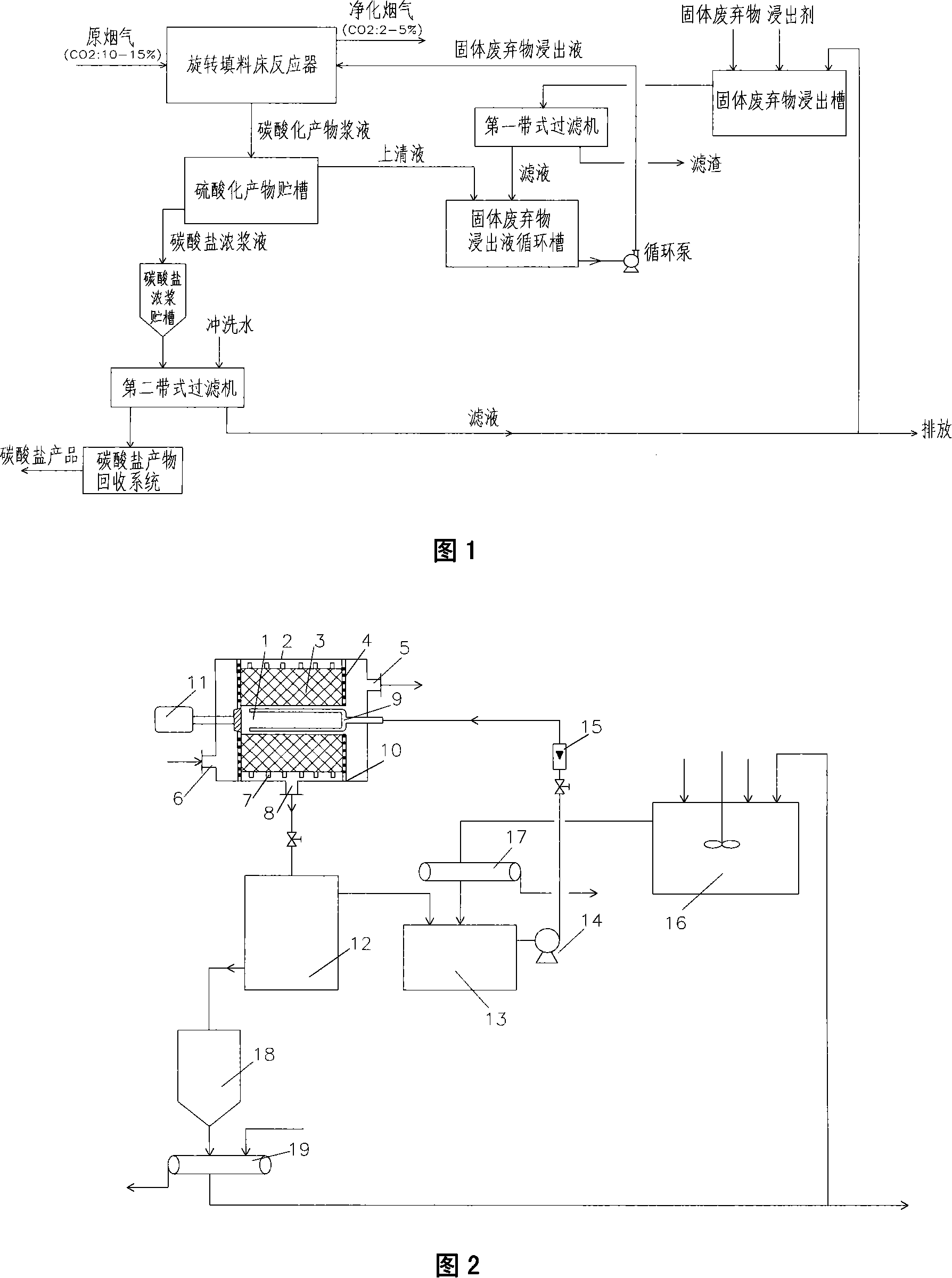

Method and device for fixing CO2 in stack gas by solid castoff carbonatation

InactiveCN101219330AIncrease mass transfer absorption rateIncrease carbon sequestration capacityDispersed particle separationBy chemical separationProcess integrationCentrifugal force

The invention provides a technique method for integrating coupling in-situ CO2 through utilizing a plurality of processes such as CO2 absorbing separation, carbonation fixation and solid wastes recovery in stack gas and a device thereof. A supergravity rotating packing bed reactor is used for intensifying transmission and multi-phase reacting process through utilizing powerful centrifugal force generated by the high-speed rotary packing bed, which is a breakthrough technology and can strengthen order of magnitude to the transmitting process of liquidoid-controlled CO2, etc., thus greatly improving mass transfer absorption rate of the CO2.

Owner:SOUTHEAST UNIV

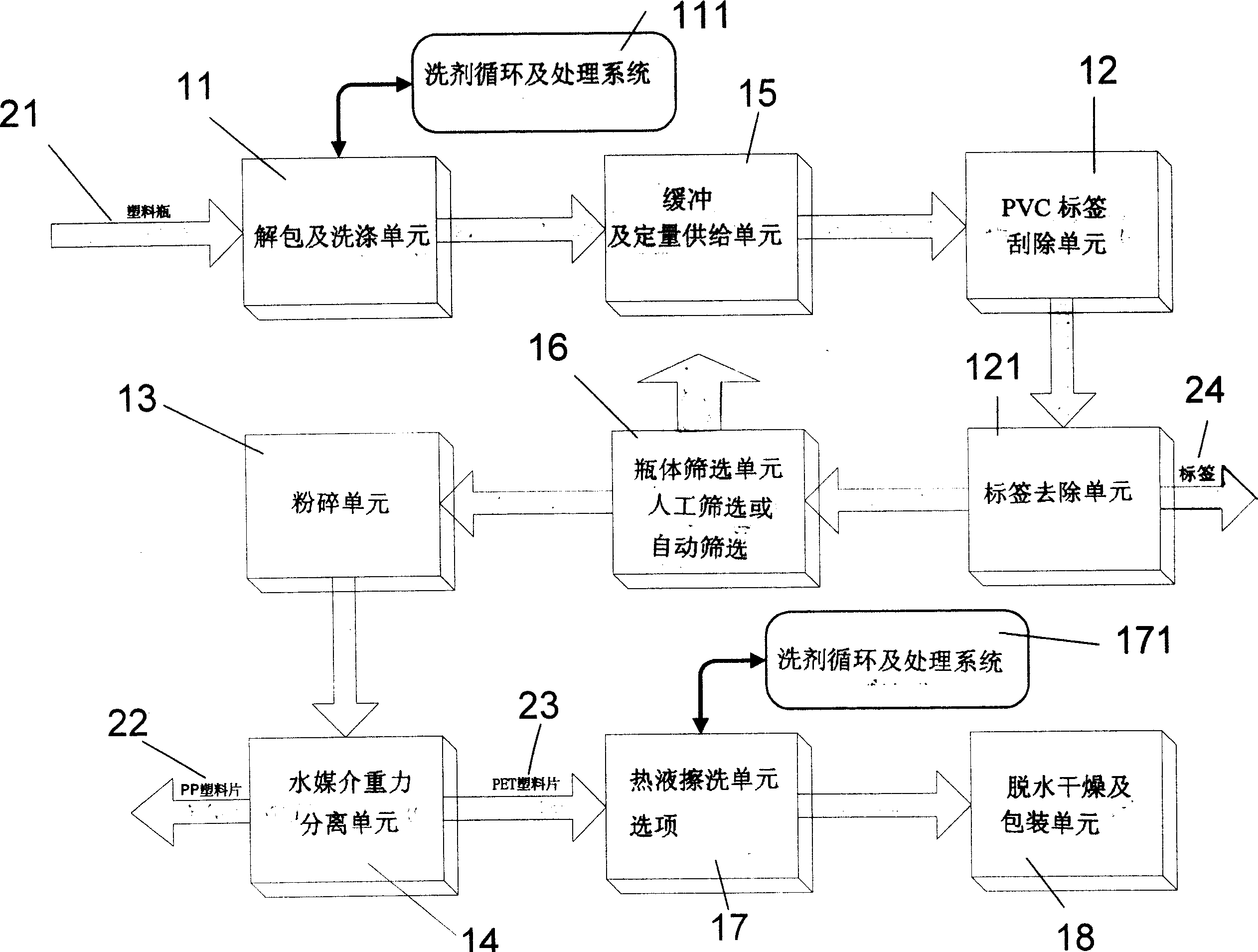

Plastic bottle reclaim treatment system

InactiveCN1765602ASimple structureEasy to operateSolid waste disposalPlastic recyclingEngineeringGravity separation

The invention relates to a plastic-bottle recovery processing system, belonging to the waste recovery system. The invention comprises: an open-washing unit; a PVC label-removing unit connected with open-washing unit; a crush unit connected to the PVC label-removing unit; and a water-medium gravitational separation unit connected to the crush unit. The invention has simple structure, easy operation, lower labor, automation recovery, and better benefits.

Owner:CITY RECYCLING

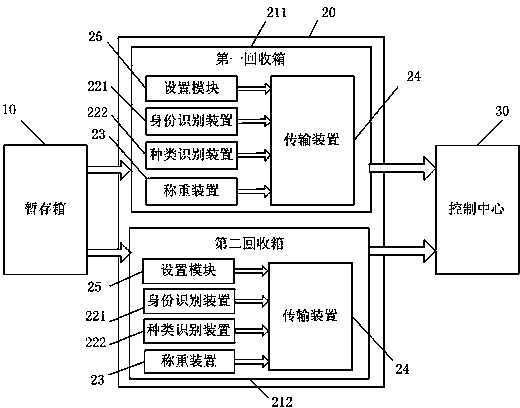

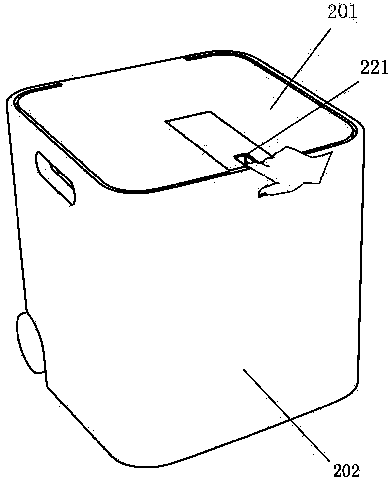

Intelligent waste classification and recovery system and recovery method thereof

InactiveCN104386388AConstrain delivery behaviorPromote civilized deliveryRefuse receptaclesRecovery methodIdentity recognition

The invention discloses an intelligent waste classification and recovery system and a recovery method thereof. The waste recovery information of each user is recorded through an identity recognition technology and a waste classification recognition technology; scoring is performed through a control center; a user waste throwing record is established in order that users can be rewarded correspondingly through a public service system; the waste classification and recovery efficiency is increased, and the recycling of resources is promoted through a reward mechanism; a temporary storage box and a recovery box of special structural designs are adopted, and are structurally matched with each other, so that waste can be thrown into the temporary storage box conveniently, and the throwing efficiency is increased; a temporary storage box structure for different types of waste is arranged, so that convenience is brought to temporary classification and storage of household waste and throwing of the waste into the recovery box, and disorder is avoided from source; meanwhile, the temporary storage box can be used repeatedly, so that the use of garbage bags is reduced, and the environmental pollution can be lowered greatly.

Owner:SHENZHEN UNIV

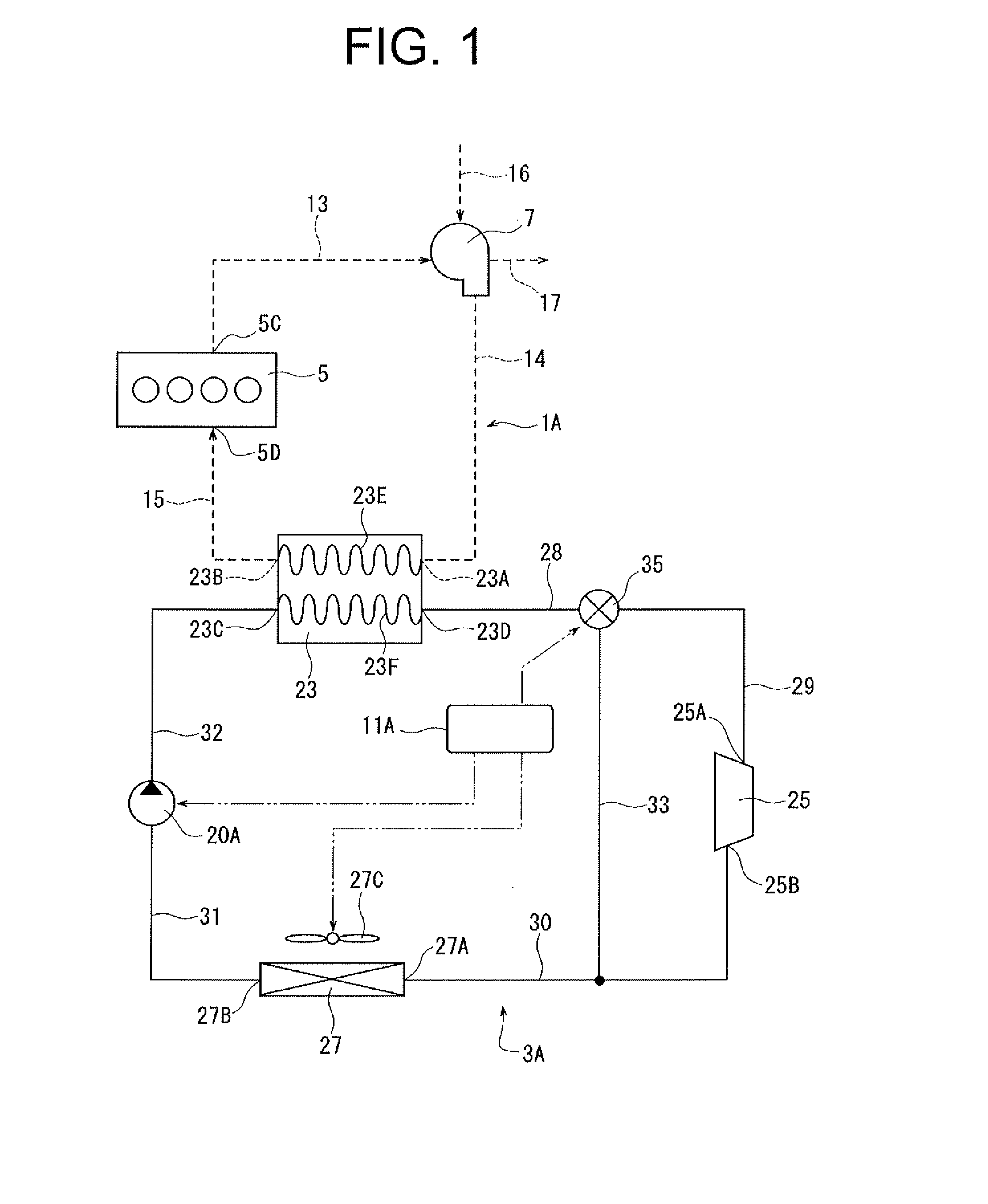

Waste heat recovery system

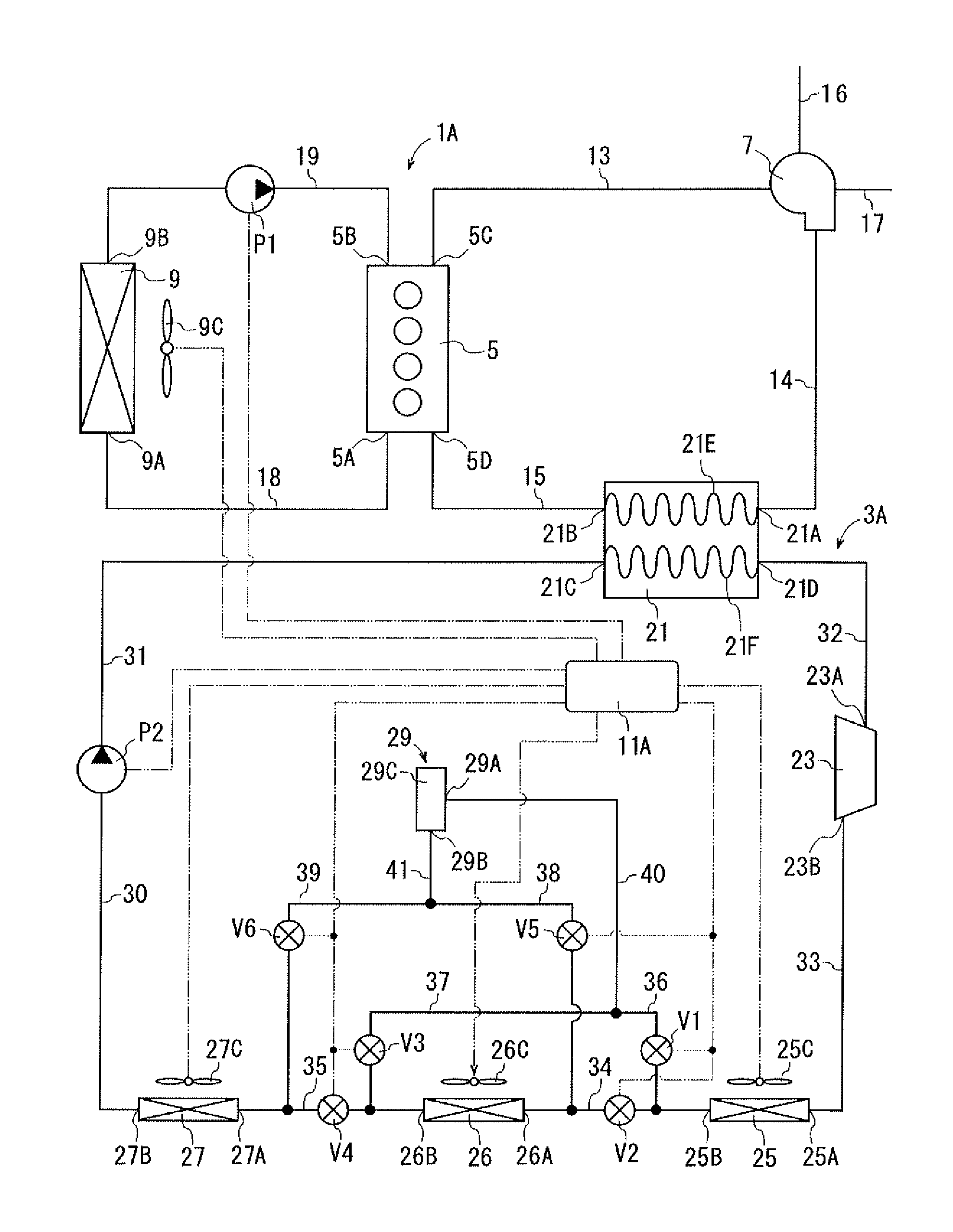

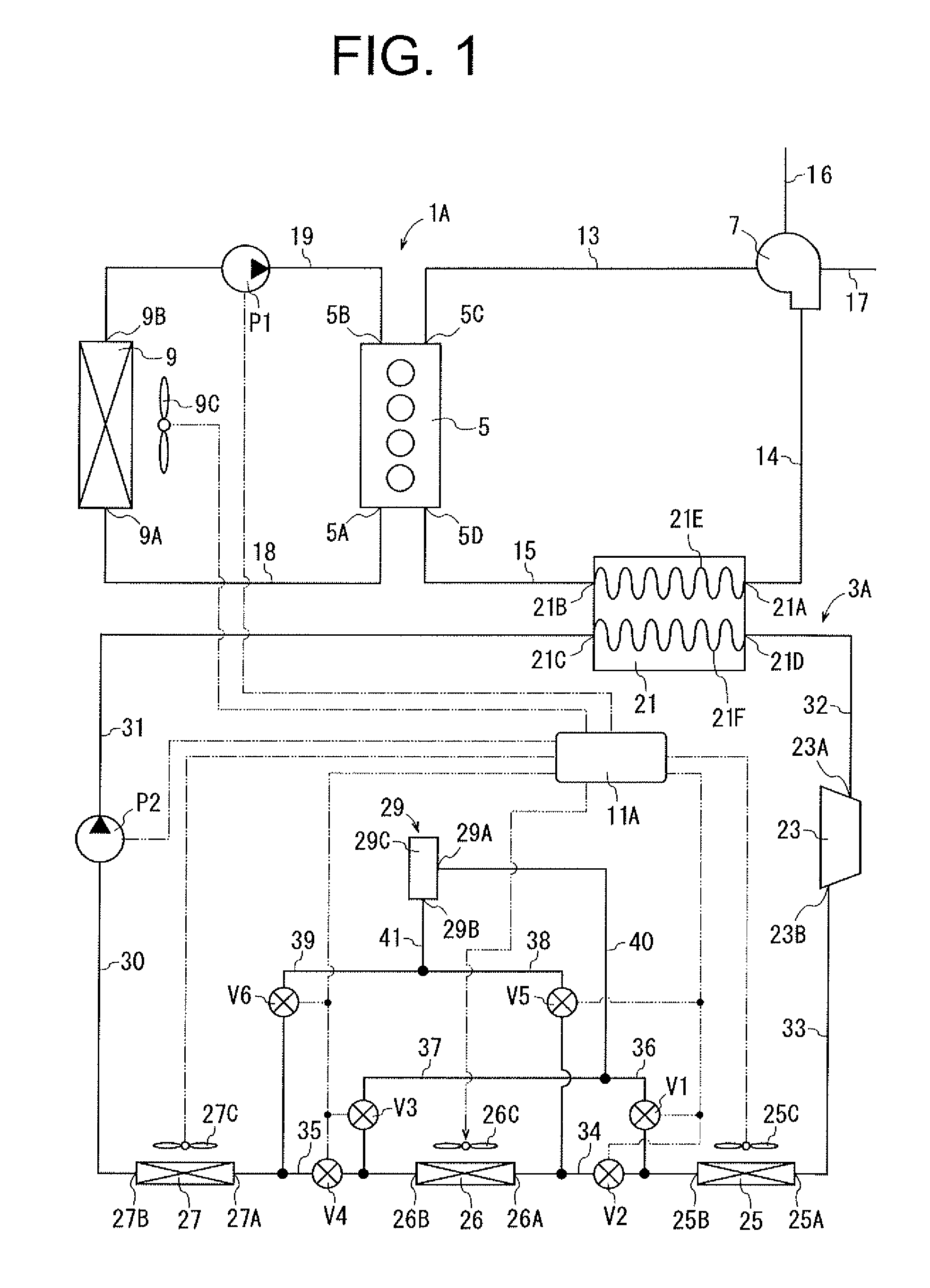

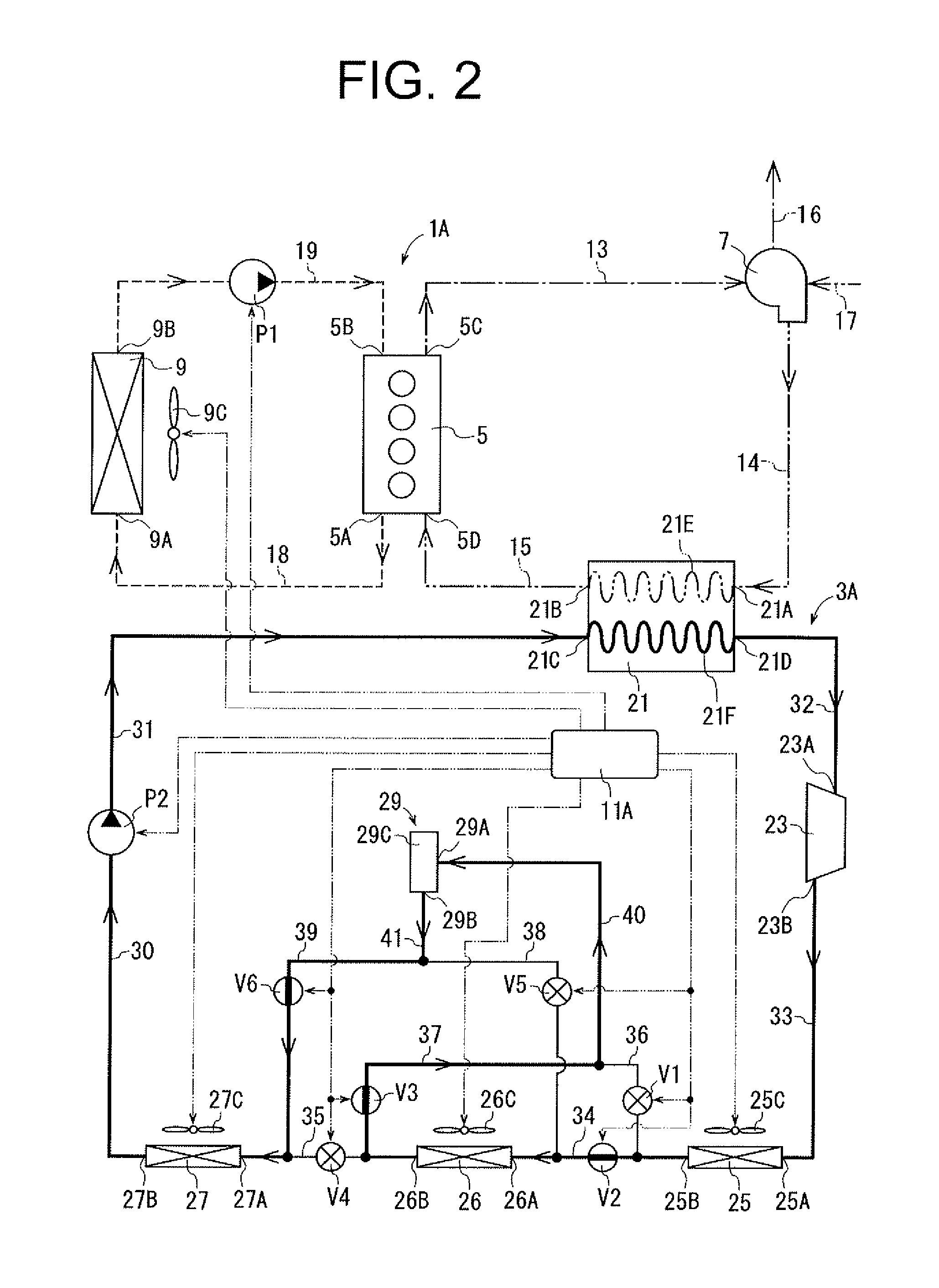

InactiveUS20130067910A1Non-fuel substance addition to fuelInternal combustion piston enginesWaste heat recovery unitWorking fluid

The waste heat recovery system includes a Rankine cycle device in which working fluid circulates through a pump, a boiler, an expander and then through a heat exchanging device, heat exchange occurs in the boiler between the working fluid and intake fluid that is introduced into an internal combustion engine while being cooled. The heat exchanging device includes a condenser condensing the working fluid, a receiver connected downstream of the condenser and storing liquid-phase working fluid, a subcooler connected downstream of the receiver and subcooling the liquid-phase working fluid, and a selector device serving to change the ratio of the condenser to the subcooler. The waste heat recovery system further includes a determination device for determining required cooling load for the intake fluid, and a controller for controlling the selector device depending on the required cooling load determined by the determination device.

Owner:TOYOTA IND CORP

Process for Making Integrated Layered Urethane Products

InactiveUS20090212454A1Increase loadExtended and controlled releaseSemi-permeable membranesAbsorbent padsWound dressingPolyethylene oxide

Polyurethane shapes containing a core layer of a water soluble polymer such as polyethylene oxide (PEO) are produced by casting onto a surface an aqueous mixture containing a pre-polymer of a hydrophilic polyurethane as a first layer of uncured polyurethane, covering the uncured first layer with release paper and compressing the layer, uncovering the uncured first layer and distributing PEO on the uncured surface, applying a second layer of uncured polyurethane on top of the PEO while the polyurethane is still uncured, then covering the resulting mass with release paper and compressing it to form an integrated, layered shaped article containing a core region enriched in PEO that when wetted releases PEO over an extended period. The second layer is applied by adhering about one-half of the first uncured foam layer to the release paper as the first uncured layer is uncovered and then recombining the adhered material on top of the PEO and further compressing the resulting mass to produce an integrated, layered shaped article. The second layer can be applied, alternatively, by independently casting a second layer of uncured polyurethane foam after distributing the PEO and then compressing and curing. The PEO containing shapes are useful in making improved comfort strips for wet shaving razors. Shape products of the process where the core region contains other specified working ingredients are useful in applications including bandages and wound dressings, cosmetic sponges, cleaning and polishing sponges, dry cleaning and anti-static sheets, and in household, industrial and environmental clean up and waste recovery.

Owner:EDGEWELL PERSONAL CARE BRANDS LLC

Waste heat recovery system

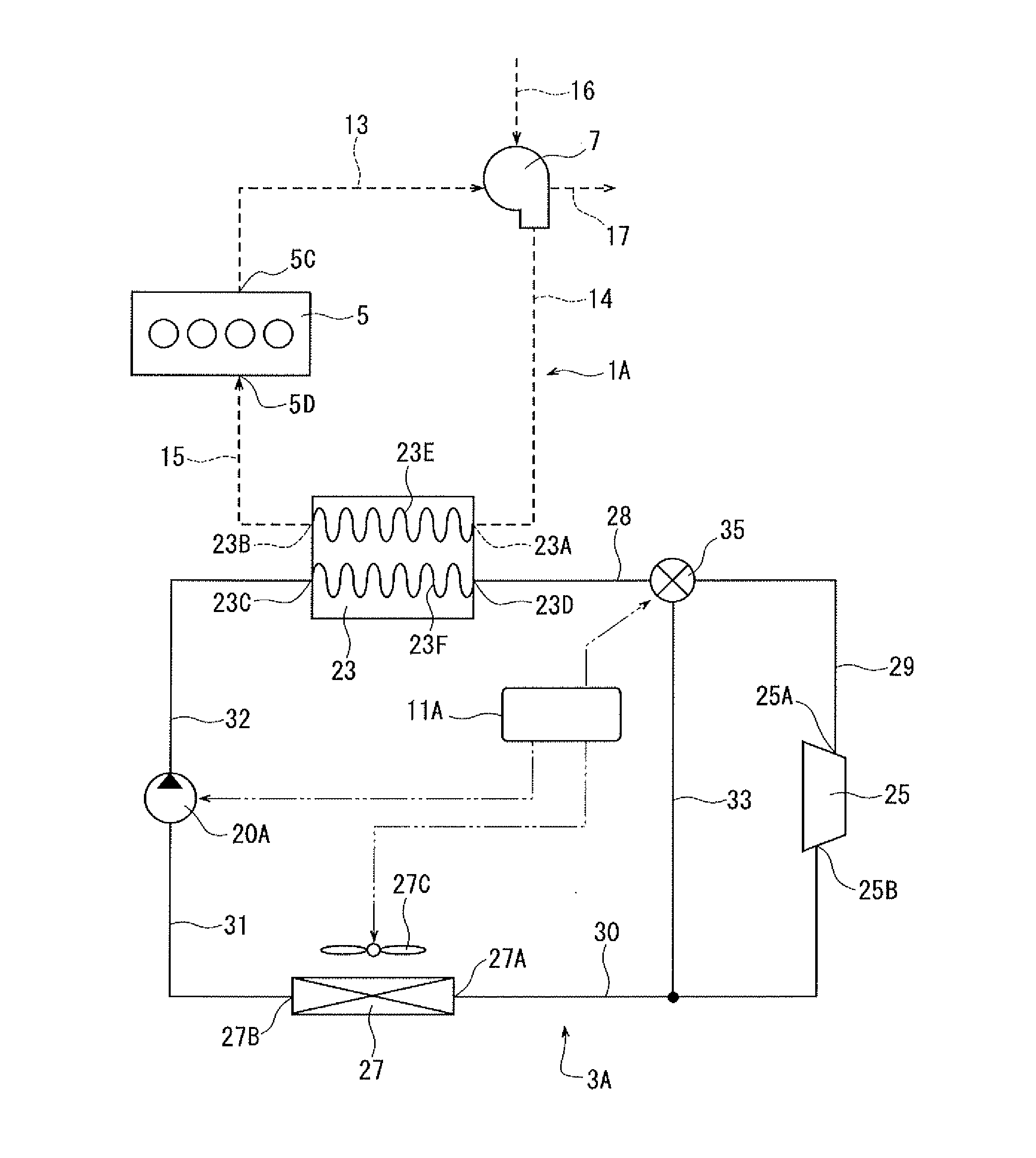

InactiveUS20130074497A1Reduce evaporating pressureNon-fuel substance addition to fuelInternal combustion piston enginesWorking fluidExternal combustion engine

A waste heat recovery system is for use with a power unit that includes an internal combustion engine. The waste heat recovery system includes a Rankine cycle device in which working fluid circulates through a pump, a boiler, an expander and then through a condenser, heat exchange occurs in the boiler between the working fluid and intake fluid that is introduced into the internal combustion engine while being cooled, a determination device for determining required cooling load for the intake fluid, a pressure reducing device for reducing evaporation pressure in the Rankine cycle device, and a controller for controlling the pressure reducing device so as to reduce the evaporation pressure below a predetermined evaporation pressure if the required cooling load determined by the determination device exceeds a threshold.

Owner:TOYOTA IND CORP

Method for recovering lithium from waste lithium ion batteries

ActiveCN107058742AOvercoming the problem of introducing new pollution factorsOvercome the problems of complex process and difficult operationProcess efficiency improvementLithium carbonatePhysical chemistry

The invention relates to the field of solid waste recovery treatment, and specifically discloses a method for recovering lithium from waste lithium ion batteries. The method comprises the following steps: (1) detaching the waste lithium ion batteries to obtain a battery powder; (2) dissolving the battery powder with an acid to obtain a dissolution liquid; (3) extracting non-ferrous metals from the dissolution liquid to obtain a lithium-containing feed liquid; (4) obtaining a lithium salt reverse-extraction liquid from the lithium-containing feed liquid through the steps of pH adjustment, extraction, washing and reverse extraction; and (5) obtaining an anhydrous lithium salt from the lithium salt reverse-extraction liquid through oil removal, evaporation, cooling crystallization, filtering and drying. Recovery for lithium in the waste lithium ion batteries is carried out through applying the method disclosed by the invention; the problems of complex process and high operation difficulty in an existing recovery technology are effectively overcome; the extraction recovery rate of lithium can achieve more than 99.5%; the content of lithium carbonate precipitate products obtained through the recovery can achieve more than 99.2%, and the standards of GB / T11075-2013 industrial-grade products or YS / T582-2013 battery-grade products are achieved; and the recovery rate is high, and the recovered lithium products are high in quality.

Owner:赣州吉锐新能源科技股份有限公司

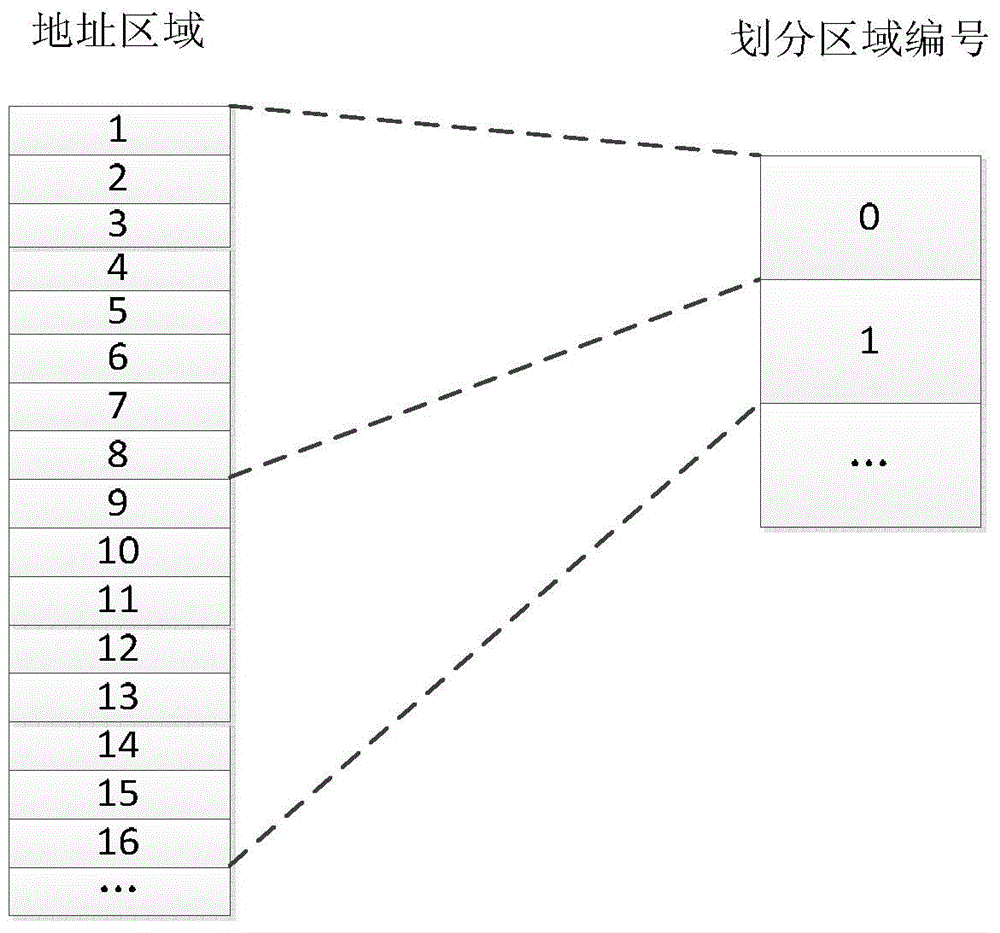

Wiping and writing management method and system for non-volatile flash memory

InactiveCN104156317AExtended service lifeImprove recycling efficiencyMemory adressing/allocation/relocationManagement systemWaste recovery

The invention discloses a wiping and writing management method and system for a non-volatile flash memory and relates to Flash wiping and writing technologies. The method includes the steps that the flash memory is divided into multiple storage regions which are the same in size according to a flash memory address; according to the frequency of writing operation of each storage region, the heat weight value of each storage region is counted; when a writing request for one storage region is received, it is determined that the storage region is within a preset heat data region range in the sequence of the heat weight values of all the storage regions, data of the writing request are written into any one storage region beyond the heat data region range, and otherwise the data of the writing request are directly written into the storage region. The invention further discloses the wiping and writing management system for the non-volatile flash memory. According to the technical scheme, a layering mechanism is used for managing Flash wiping and writing, the balance of non-volatile Flash medium loss is guaranteed, the efficiency of waste recovery is improved, and the service life of media is prolonged.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

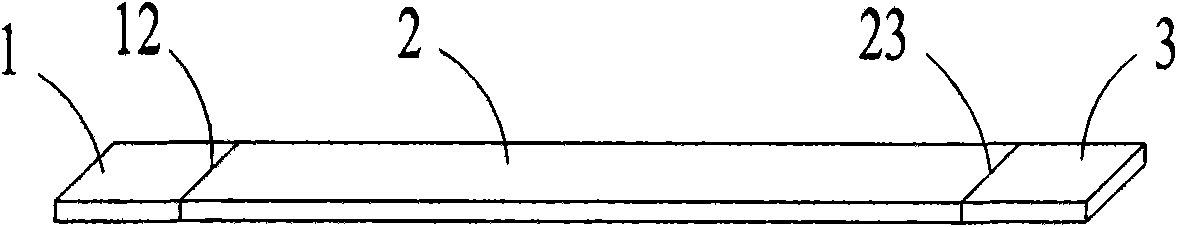

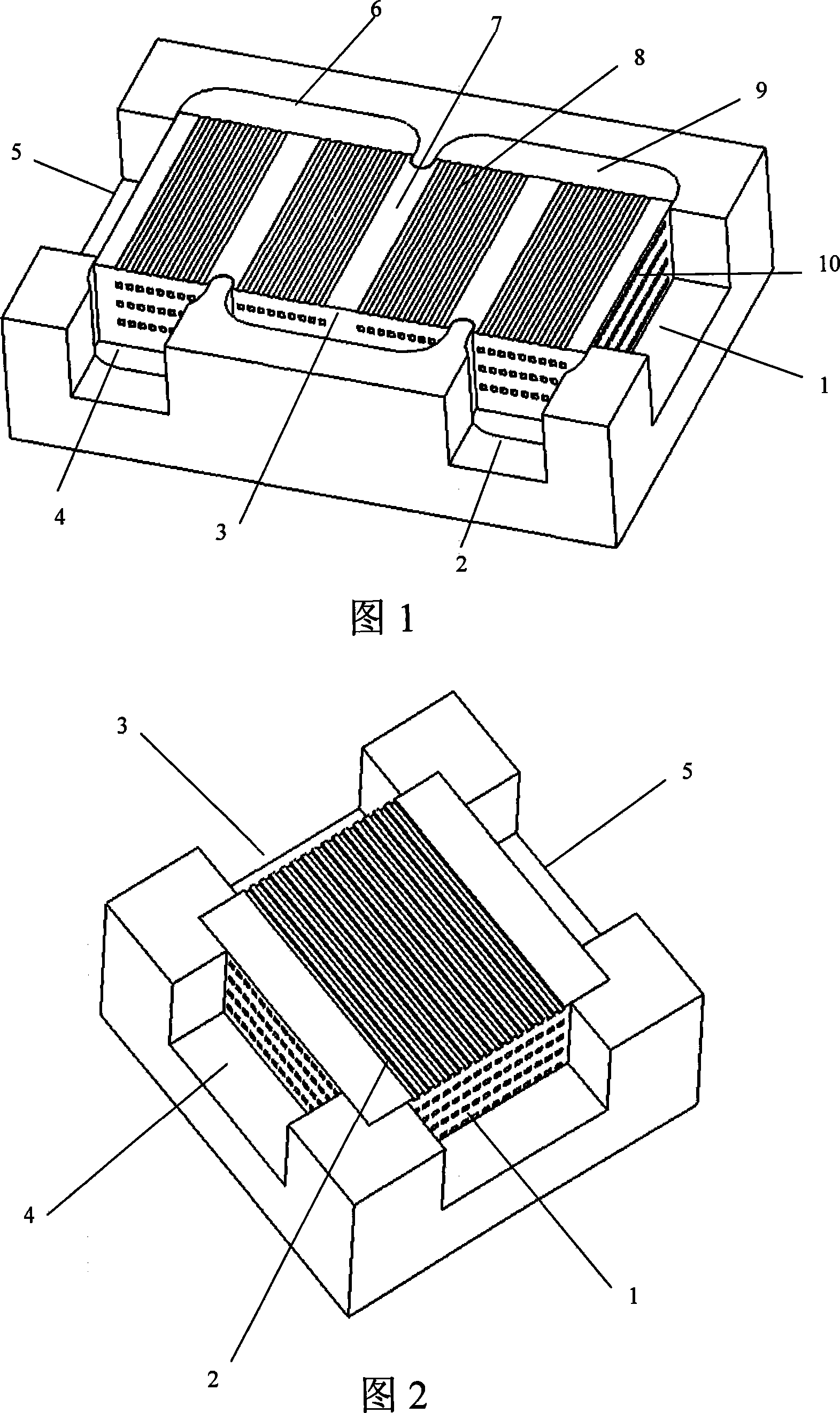

Conductive connecting sheet with side composite metal structure and production method thereof

ActiveCN102035080AReduce contact resistanceHigh recycling valueContact member manufacturingSingle bars/rods/wires/strips conductorsMetal stripsLap joint

A conductive connecting sheet with a side composite metal structure comprises at least two foreign metal sheets. Each metal sheet comprises at least one copper metal sheet or nickel metal sheet, and the rest is a metal sheet at the price lower than the price of copper and nickel. Each metal sheet is arranged along the length direction of the conductive connecting sheet. The adjacent metal sheets are combined closely on an end face, and lap joint does not exist among the adjacent metal sheets. The production method comprises the following steps that: in the at least two metal strips, the adjacent metal strips are firmly combined on the adjacent side to form a side composite board strip by side composite technology; and the produced board strip is subjected to rolling and process annealing treatment to produce a final board strip with thickness the same as that of the conductive connecting sheet, and then is punched and formed along the transverse direction. The invention makes the bestof the advantages of combination of the side composite metal board strips, can ideally meet the requirement of the overall high-conductivity and the transition welding component, prevent the negativeeffect of the traditional lap joint and obviously save scarce metal and improve the waste recovery value.

Owner:徐卓辉 +1

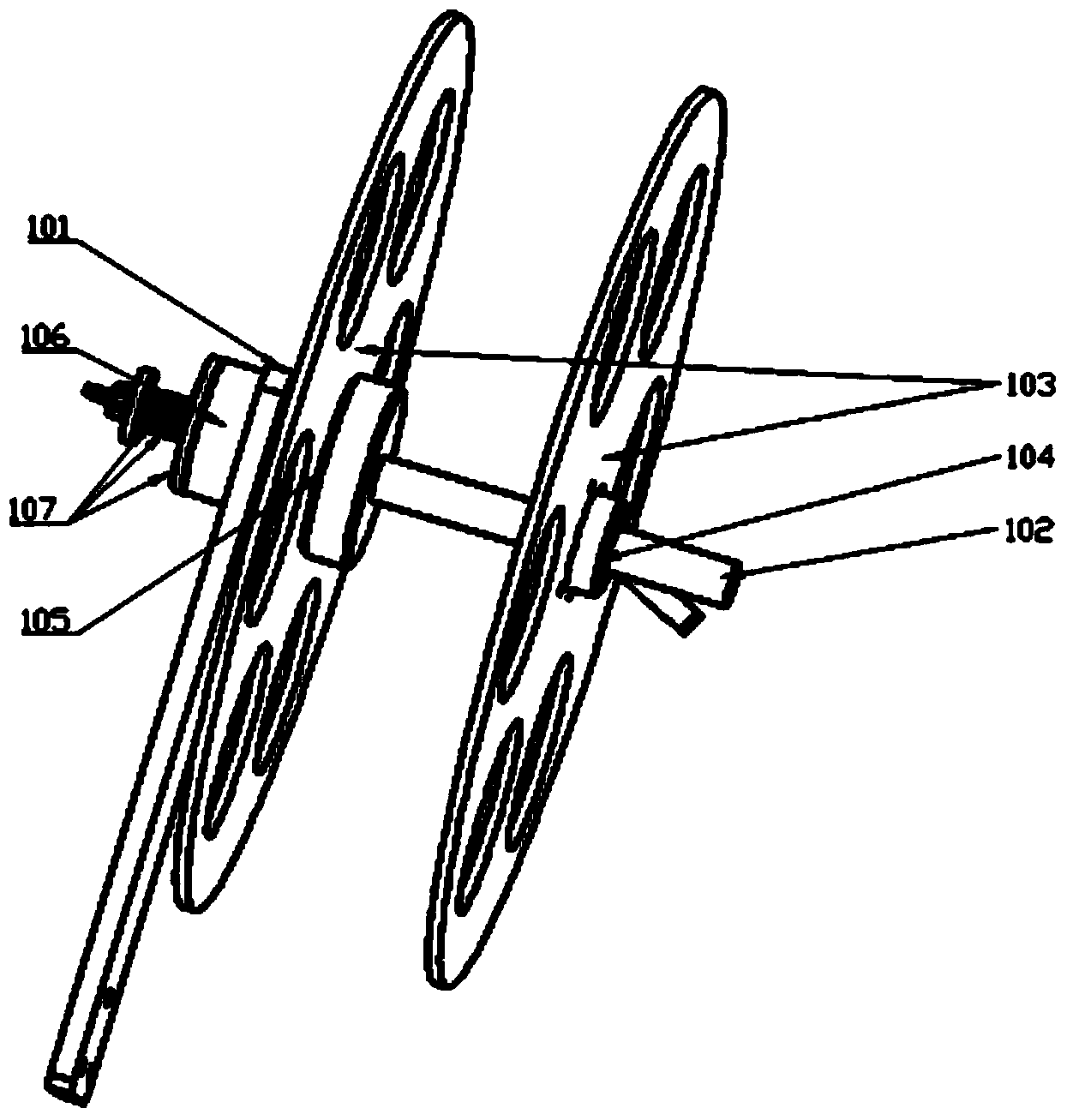

Laser cutting system for pole piece of power battery

InactiveCN101692489AUniform sizeReduce consumption costLaser detailsElectrode manufacturing processesPower batteryPunch press

The invention discloses a laser cutting system for a pole piece of a power battery, which comprises an automatic loading subsystem, a laser cutting subsystem, an automatic finished product sorting subsystem and a control clip subsystem. The automatic loading subsystem conveys a partitioned pole piece material to the laser cutting subsystem, the laser cutting subsystem cuts the conveyed pole piece material according to a given size, the automatic finished product sorting subsystem fills the cut pole pieces and the rim charges into a finished product box and a waste recovery box, and the control clip subsystem intensively controls the automatic loading subsystem, the laser cutting subsystem and the automatic finished product sorting subsystem. The non direct contact and flexible processing of the laser cutting system thoroughly solve the problems of burrs and rim charge falling produced after cutting in modes of cutting of the prior punch cutting die and the like, the quality of the produced pole pieces is high, the sizes of the cut pole pieces are uniform, the equipment are easy to be maintained, the production cost is low and the efficiency is high. The laser cutting system is widely applied to a cutting process for the pole piece of the power battery.

Owner:广州瑞通激光科技有限公司

Method for preparing organic fertilizer through tobacco extracting solution

InactiveCN102924183APromote absorptionPromote reproductionFertilizer mixturesMicrobial agentPotassium

The invention discloses a method for preparing organic fertilizer through tobacco solution. By adopting the method, the tobacco extracting solution can be subjected to waste recovery and prepared into organic fertilizer, and the method for processing the extracting solution by degrading through a large number of devices at present is replaced. According to the method, a microbial agent is added to the tobacco extracting solution for fermenting, and the prepared organic fertilizer includes a plurality of organic acid, peptides and rich nutrient elements such as nitrogen, phosphorus and potassium, so that the organic fertilizer can be used for providing comprehensive nutrition to crops, and the plant can be absorbed well; and furthermore, the organic matters in the soil can be increased and updated, so that the microbial proliferation can be promoted, and the physicochemical property and biological activity of the oil can be improved. The tobacco extracting solution includes nicotine which can be used for disinfesting, and the nicotine is remained in the finally obtained organic fertilizer during the processing of the method, so that the organic fertilizer has the effect of disinfesting.

Owner:SHANGHAI JUHUA TECH

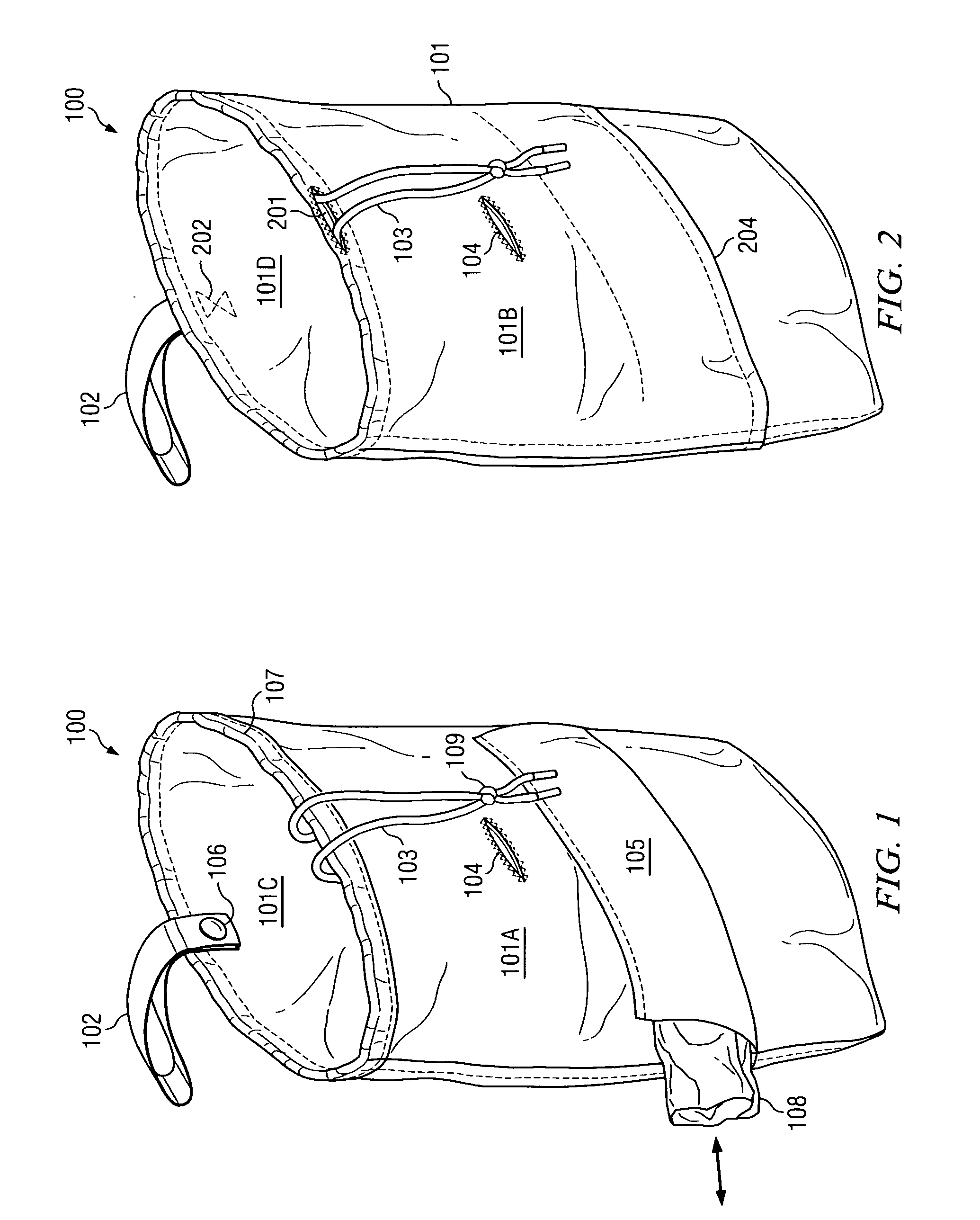

Pet waste recovery, storage and disposal apparatus

A pet waste recovery and disposal apparatus, including a reusable soft-sided container in the general construction of a sleeve, having a closable top and a closable bottom adapted to receive a disposable bag therein, said disposable bag, in a preferred embodiment, having a closure means, such as a drawstring to close the top of the bag. A further embodiment of the invention includes the reusable soft-sided container in combination with the disposable bag having a drawstring closure means, the reusable soft-sided container having a second aperture through which the ends of the drawstrings of the disposable bag are threaded, the disposable bag having its inside surface outwardly exposed when the reusable soft-sided container is in the right side out position and the disposable bag being in the interior of the reusable soft-sided container when in the reusable soft sided container is in the wrong side out position. The reusable soft-sided container is washable and stylish and has, on an outside portion thereof, a pocket adapted to receive at least one unused disposable bag.

Owner:SLY INNOVATIONS

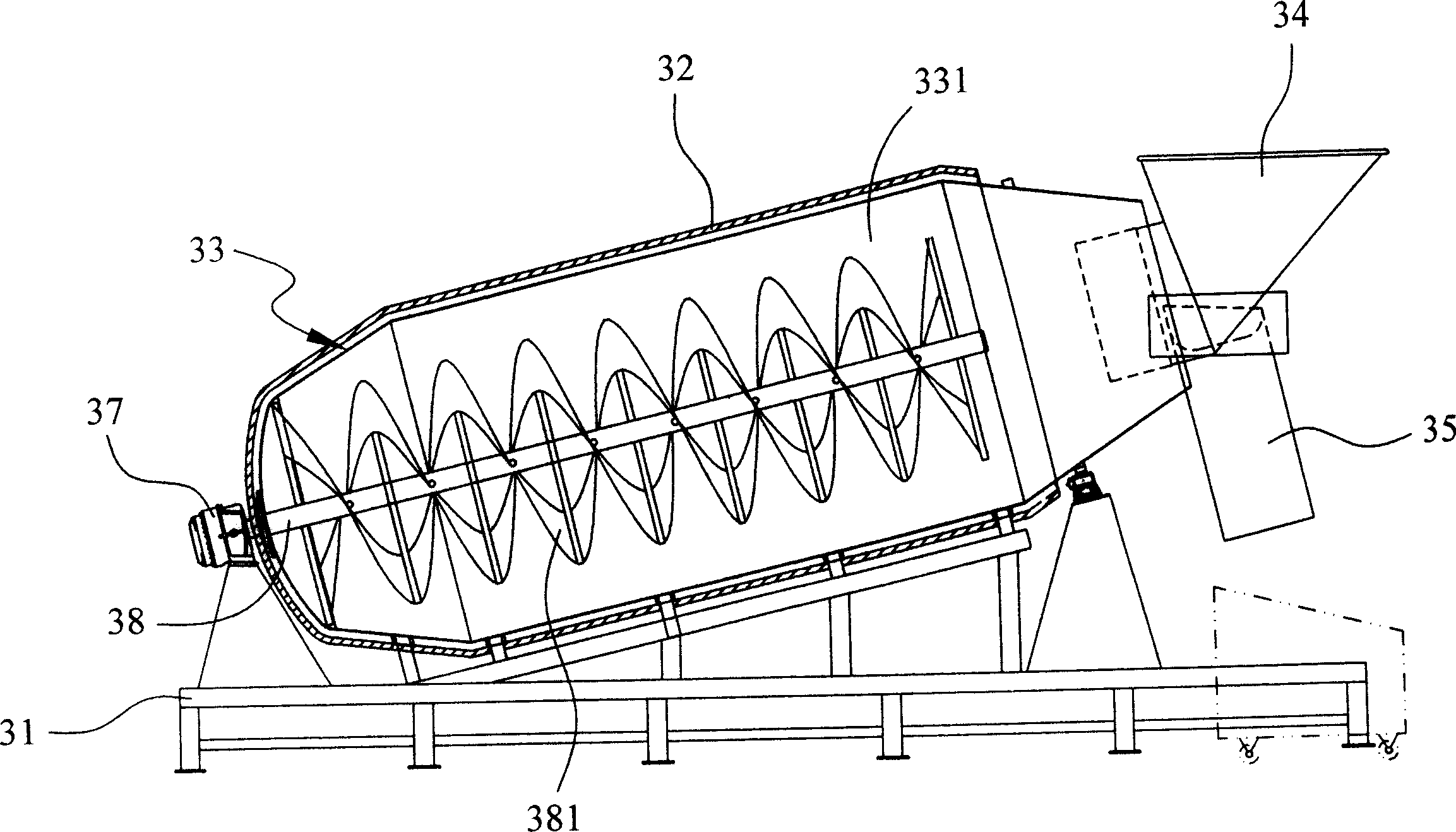

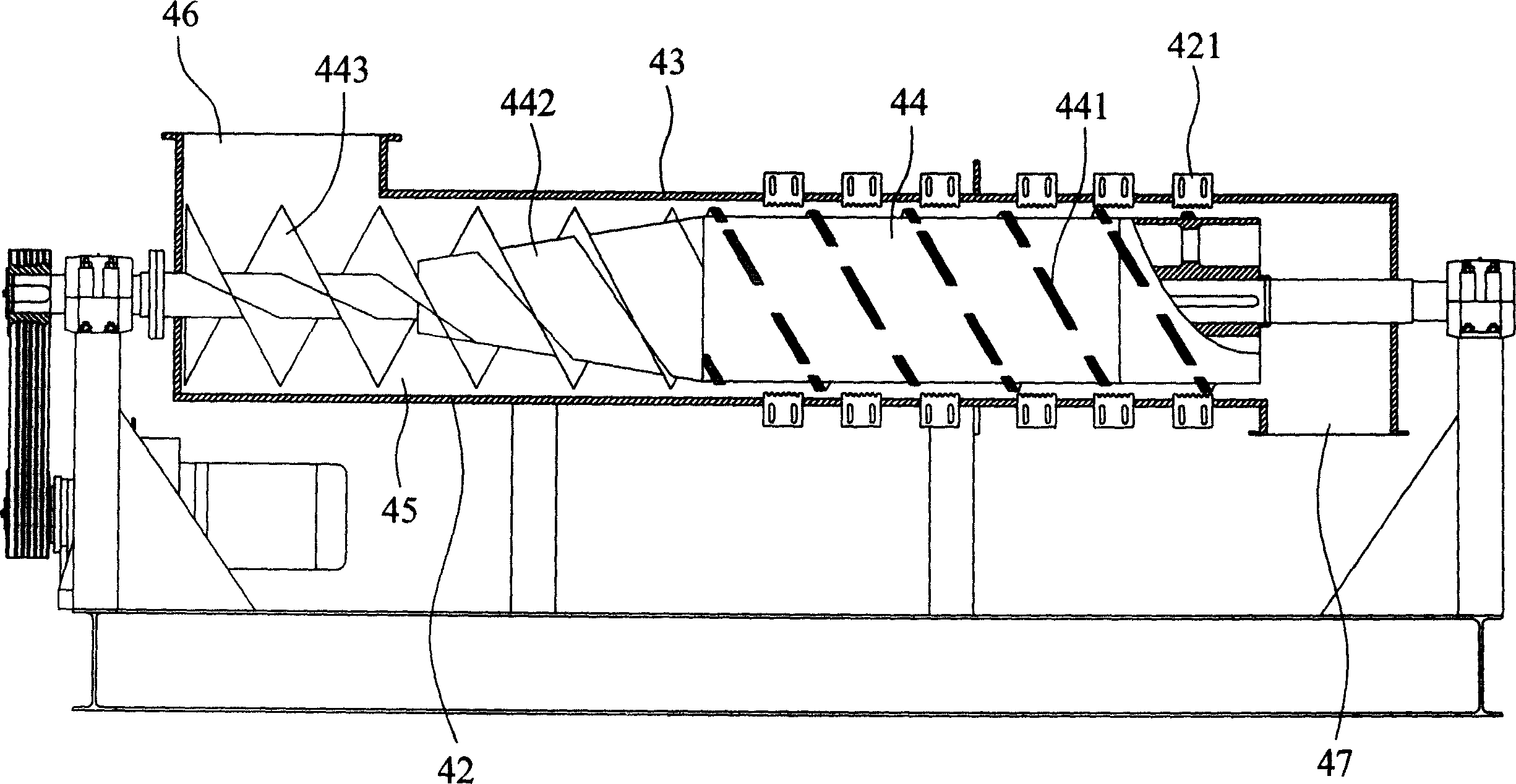

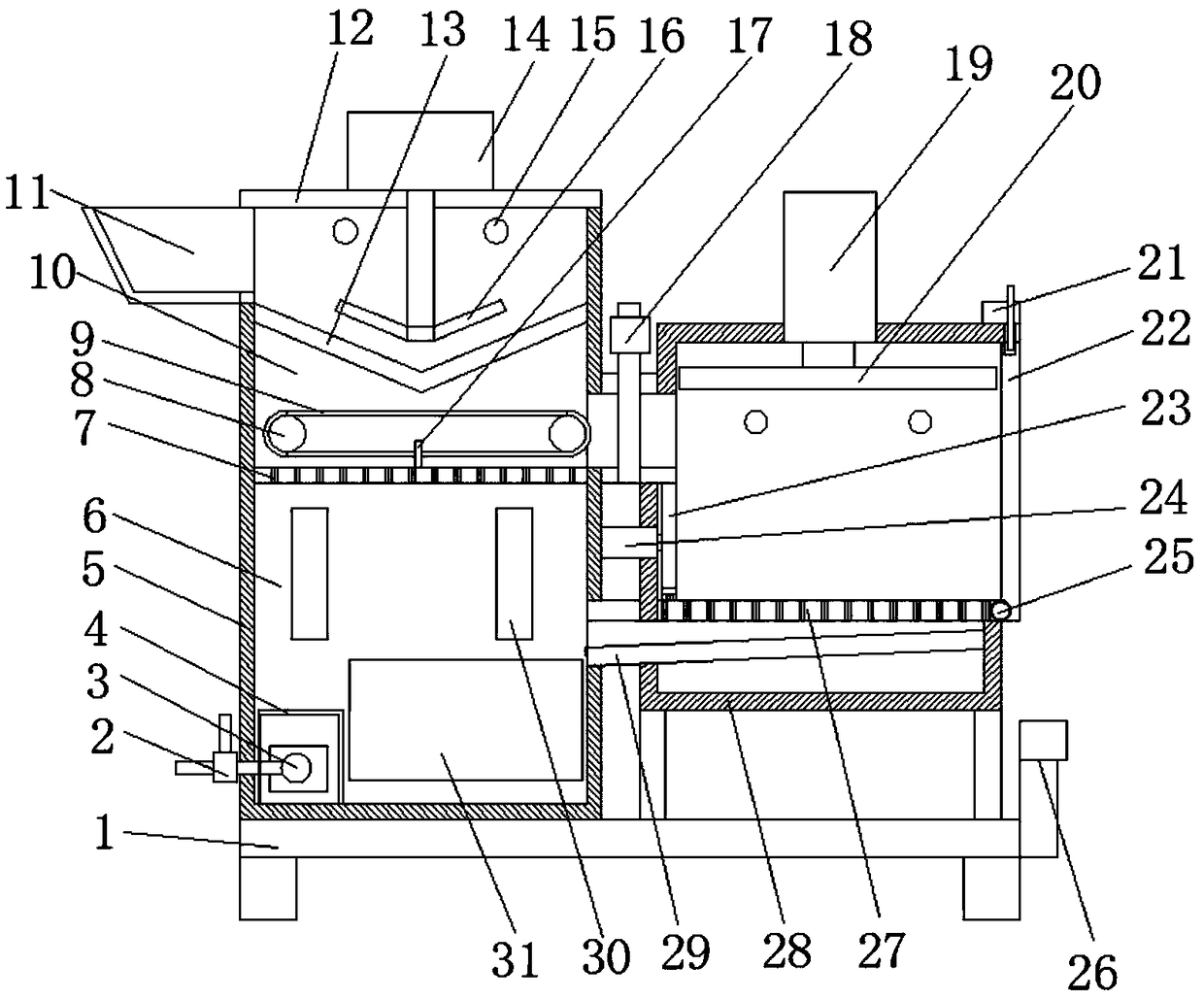

Waste recovery device facilitating unloading for processing of agricultural and sideline products

PendingCN109078956AEasy to recycleImprove recycling efficiencySolid waste disposalGrain treatmentsSlagEngineering

The invention belongs to the technical field of agricultural and sideline product processing, and particularly relates to a waste recovery device facilitating unloading for processing of agriculturaland sideline products. Aiming at the problems that when an existing waste recovery device is used, unloading is inconvenient, and consequently, the waste recovery efficiency is low, the following scheme is put forwards, specifically, the waste recovery device comprises a base; a first box is connected to one side of the top of the base through bolts, and a second box is connected to the other sideof the top of the base through bolts; and a communicating pipe of a rectangular structure is connected to the top of the junction of the second box and the first box through a flange. According to the waste recovery device facilitating unloading for processing of the agricultural and sideline products, initial separation of solid and liquid is completed, juice in a juice accumulating cavity is conveyed and recovered through a conveying pump, slag liquid is separated and recovered, recycling of waste is facilitated, and the recovering efficiency is improved; and a linear electric pushing rod and a pushing plate are utilized to slidably push caky residues into an unloading trolley along a sealing plate, thus unloading of the waste recovery device is easy and convenient, and the waste recovery efficiency is high through continuous operation.

Owner:ANHUI HUARUI PHARMA TECH DEV CO LTD

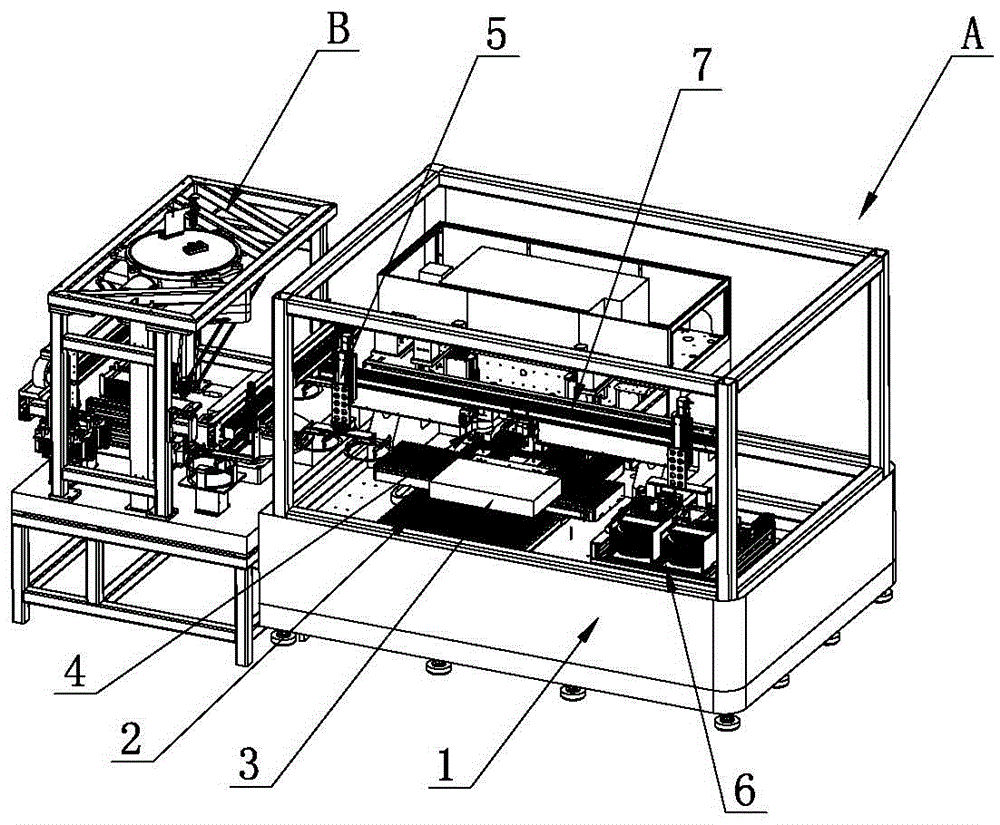

Fully-automatic laser cutting production workstation

ActiveCN105689899AReduce labor costsIncrease productivityLaser beam welding apparatusLaser cuttingEngineering

The invention relates to the technical field of laser cutting equipment, and particularly relates to a fully-automatic laser cutting production workstation. The fully-automatic laser cutting production workstation comprises a fully-automatic scribing machine and an automatic blanking-sorting machine which are mutually connected, wherein the fully-automatic scribing machine comprises a scribing rack; a slide table of the rack is provided with a scribing fixed-distance compression jig; the scribing rack is provided with a fixed slide rail; a double-end laser system is arranged above the scribing fixed-distance compression jig; the fixed slide rail is slidably connected with an automatic loading-unloading device; the scribing rack is provided with a scribing loading pre-location device; the automatic blanking-sorting machine is provided with a four-station index plate; a cleaning mechanism and a waste recovery mechanism are arranged at the sides of the four-station index plate respectively; a taking manipulator is arranged between each of the cleaning mechanism and the waste recovery mechanism, and the corresponding station; a high-speed sorting parallel robot is arranged above the four-station index plate; and a blanking-sorting rack is provided with a CCD visual scanning mechanism. According to the fully-automatic laser cutting production workstation disclosed by the invention, production efficiency is improved, and the human cost of enterprises is greatly reduced.

Owner:东莞市盛雄激光先进装备股份有限公司

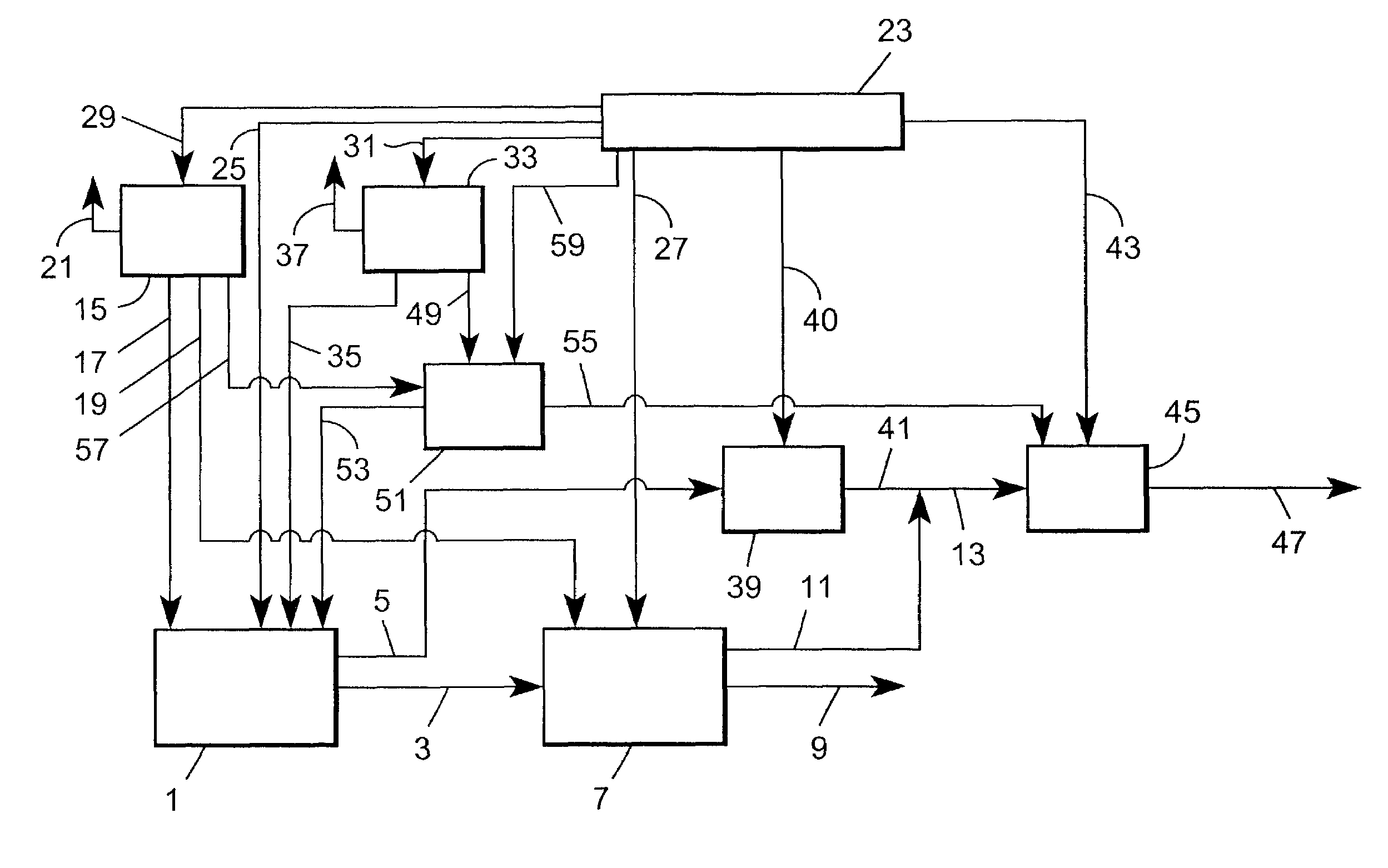

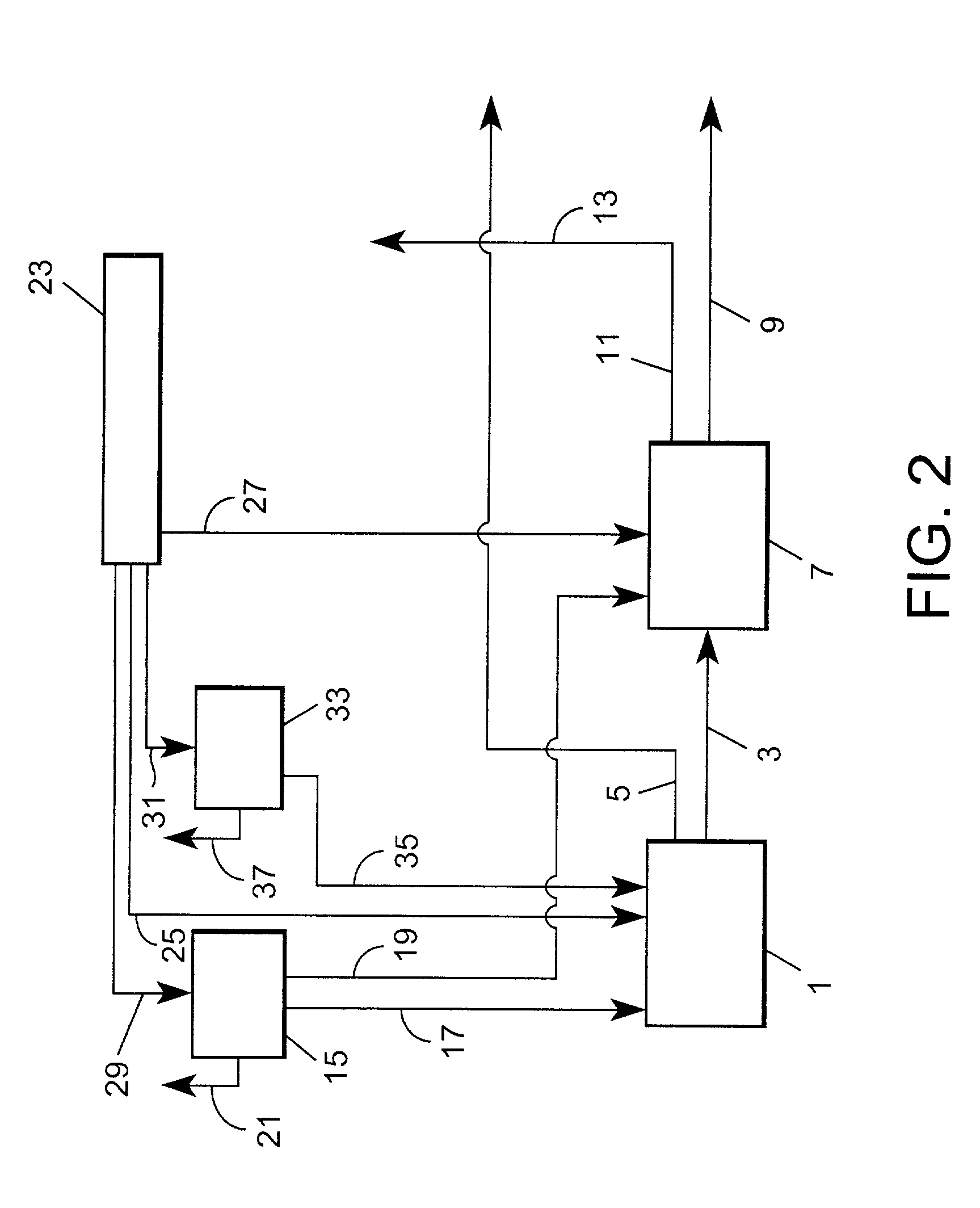

Waste recovery cogenerator

InactiveUS20110036320A1Easy to remove waterImprove filtering effectInternal combustion piston enginesExhaust apparatusThermal energyParticulates

A waste-to-energy cogeneration system is described in various embodiments. The system can convert certain fuel-laden waste to thermal energy and electrical power. In certain embodiments, fuel-laden waste which has not been pre-filtered or pre-treated to remove particulates and water is deposited in the cogeneration system and prepared by the system for combustion in an unmodified diesel engine. The fuel-laden waste can comprise oils, greases and fats from food preparation which are contaminated with water and particulates. Thermal and mechanical energy produced by the engine are utilized to provide thermal energy and electrical power external to the cogeneration system.

Owner:UNIV OF MIAMI

Method for producing environment-friendly type plasticiser using waste oil and oil foot

ActiveCN101372539AImprove the defects in the production processShort reaction timePlasticizerWaste oil

The invention discloses a method for recycling waste, and more particularly relates to a method for producing an environmental-protection plasticizer by waste oil and bottom oil. The method comprises the steps as follows: waste oil reacts with methanol, and the reacted ester reacts with hydrogen peroxide and further reacts with the methanol to finally obtain the product, namely an epoxy fatty acid methyl ester plasticizer. The method has the advantages of carrying out ester exchange by one step without decolorization, adding no stabilizer in the epoxidization process, reducing the reaction time and energy consumption by using a high-efficiency mixed reactor, simplifying the process, and being more environment-friendly. The method can be widely applied to various occasions where waste oil is generated.

Owner:浙江嘉澳环保科技股份有限公司

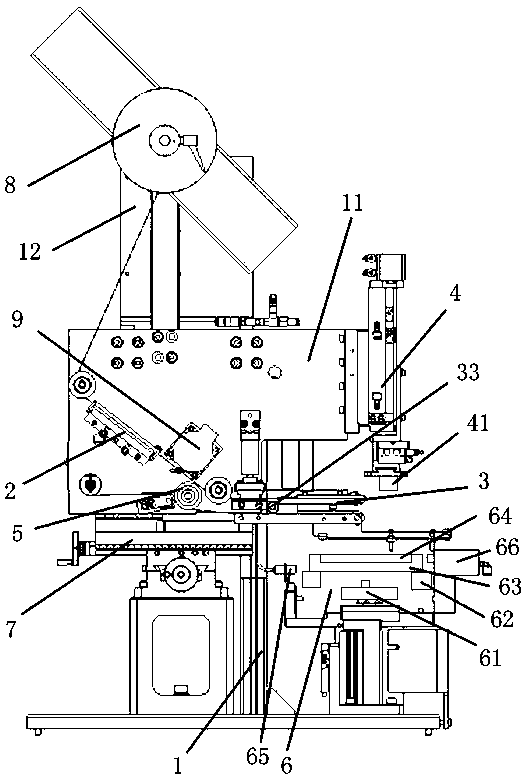

Automatic labeling machine

ActiveCN104354944AReduce utilizationControl speedLabelling machinesWebs handlingEngineeringFully automated

The invention discloses an automatic labeling machine and belongs to the field of labeling machines. The automatic labeling machine comprises a base, a mounting plate and a jig, wherein the mounting plate and the jig are mounted on the base; a label conveying path, a driven roller wheel set and a slide rail fixing frame are arranged on the mounting plate; the label conveying path and the driven roller wheel set are arranged on the front surface of the mounting plate; a discharging device, a sucking plate, a stripping plate, a main drive wheel module and a waste recovery device are arranged on the label conveying path in sequence from a starting point to an ending point; the roller wheels of the driven roller wheel set are arranged between the discharging device and the sucking plate, between the sucking plate and the stripping plate and between the stripping plate and the main drive wheel module respectively; a label sucking and moving mechanism capable of moving between the stripping plate and the jig is mounted on the slide rail fixing frame. As the whole labeling process is fully automated and the working process is accurate, the labeling stability and accuracy are really improved.

Owner:SHENZHEN DAYUCNC TECH

Waste circuit board hook pulling and dismounting device

InactiveCN101733631AImprove dismantling rateAvoid damageSolid waste disposalMetal working apparatusCratePrinted circuit board

The invention discloses a waste circuit board hook pulling and dismounting device, belonging to the technical field of waste recovery and reuse. The waste circuit board hook pulling and dismounting device comprises a crate, a heating system, a double-chain delivery mechanism, a hook pulling mechanism and a double-rolling brush mechanism, wherein the heating system divides the crate into a pre-heating region and a high temperature region; and a circuit board is arranged on the double-chain delivery mechanism, is preheated by the preheating region, and is subjected to dismounting of components and solder by the hook pulling mechanism and the double-rolling brush mechanism in the high temperature region. The air-out inclined planes of two lower high temperature bellows arranged at the lower part of the high temperature region inclines at a large angle facing to the center of the high temperature region, extension type hot air nozzles on the air-out inclined planes are a group of hot air spray pipes, the diagonal fault planes of the hot air spray pipes inclining upwards and the spray pipe outlets not only enable the circuit board to be heated evenly and rapidly, but also can ensure that all dismounted components and solder can enter collection trays of components and solder without entering the spray pipe outlets. The invention is a device which can pull and dismount the components from the printed circuit board with no damage and integrity, and is used for waste recover and reuse enterprises in electronic industry.

Owner:TSINGHUA UNIV

Building ecological heat-insulation mortar and preparation method thereof

The invention relates to a building ecological heat-insulation mortar and a preparation method of the heat-insulation mortar, belonging to the technical field of buildings heat-insulation mortar materials. The preparation method mainly comprises the steps of organically combining phase change material, material for regulating environment humidity and adsorbing harmful gas, and foaming heat-insulation inorganic cementing material, and fully building an ecological environment of human and buildings. The raw materials are cheap and easily available, thus being conducive to waste recovery, environment friendliness and energy conservation. The product is convenient to produce, package, store, transport and construct. Heat-insulation inner wall mortar, heat-insulation outer wall mortar, heat-insulation building mortar, heat-insulation floor heating mortar and heat-insulation wall pouring mortar can be prepared by regulating different formulas. The construction modes include manual scraping, pouring and mechanical spraying.

Owner:武汉优特斯节能建材研究所

Automatic waste collecting device for stamping die

InactiveCN104308027ARealize automatic collectionAvoid damageMetal-working feeding devicesPositioning devicesCouplingWorking environment

The invention provides an automatic waste collecting device for a stamping die. The automatic waste collecting device comprises a conveyer, a waste recovery box, a power device and an auxiliary structure positioned on the stamping die, wherein the conveyer comprises a fixed pulley support, a support, a belt and a belt shaft which are fixed on a stamping workbench; the support is connected with the belt shaft through a bearing; the fixed pulley support is provided with a fixed pulley capable of rotating around the fixed pulley support; the fixed pulley is connected with the belt shaft through the belt; the right side of the damping die is provided with an inclined chute; the other end of the inclined chute is connected with the waste recovery box; the power device comprises a motor; a supporting table is arranged below the motor; the output shaft of the motor is connected with the belt shaft through a coupling. The automatic waste collecting device is simple in structure, stamping waste can be automatically collected, halt is not required for cleaning the waste, the working efficiency is improved, the working environment is improved, and the damage of the die caused by the blockage of the waste is avoided.

Owner:TIANJIN YINGHAO ELECTRONICS

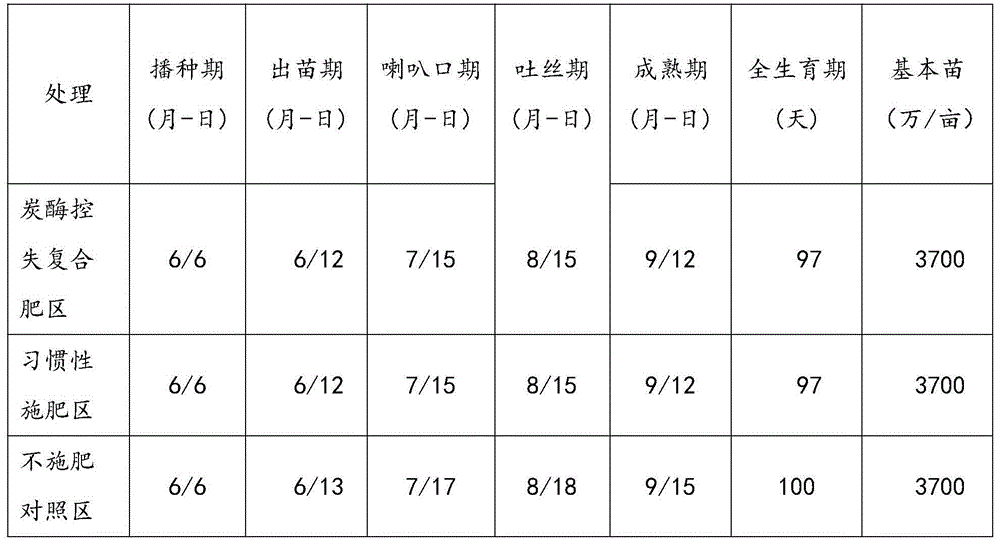

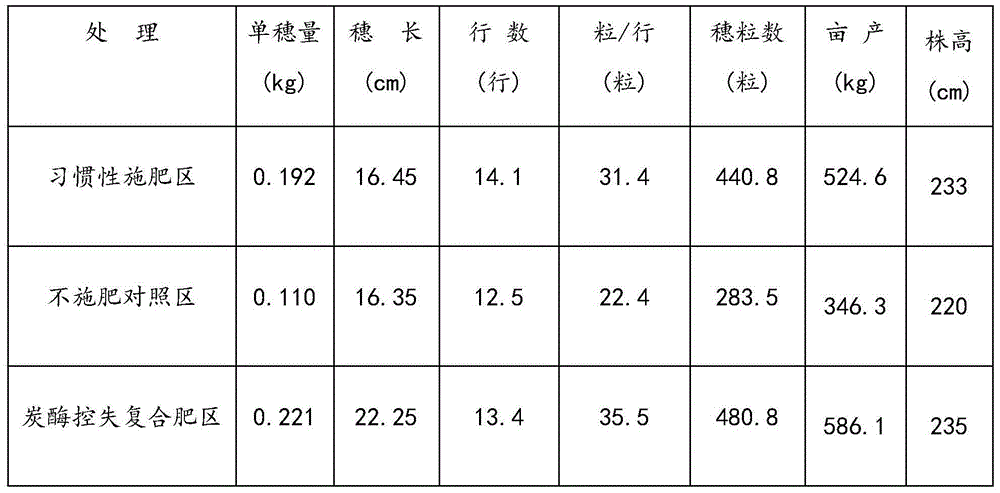

Organic biochar enzyme inhibiting slow-release fertilizer and production method thereof

ActiveCN104609949APromote reproductionIncrease productionClimate change adaptationAgriculture gas emission reductionPhosphateNitrification inhibitors

The invention provides an organic biochar enzyme inhibiting slow-release fertilizer and a production method thereof, and relates to the technical field of fertilizer production. The organic biochar enzyme inhibiting slow-release fertilizer is prepared from the following raw materials in parts by weight: 10 parts of potassium sulfate, 10 parts of monoammonium sulfate, 40 parts of urea, 18 parts of ammonium sulfate, 10 parts of a biochar enzyme inhibiting material, 5 parts of humic acid, and 7 parts of biochar powder, wherein the biochar enzyme inhibiting material is prepared from the following raw materials in parts by weight: 500 parts of polyaspartic acid, 400 parts of biochar powder, 5 parts of phosphate solubilizing bacteria, 5 parts of potassium bacteria, 60-80 parts of a nitrification inhibitor and 60-80 parts of a urease inhibitor. The organic biochar enzyme inhibiting slow-release fertilizer contains a certain amount of organic matters, and also comprises phosphate solubilizing bacteria, potassium bacteria, polyaspartic acid and urease inhibitor; with the biochar powder, propagation of microorganisms in soil is facilitated, the soil is improved, phosphate and potassium are solubilized, and loss of the slow-release fertilizer is controlled, so that not only is crop yield increased, but also waste recovery is realized, and the environmental pollution is reduced; the organic biochar enzyme inhibiting slow-release fertilizer belongs to environmental-friendly fertilizers.

Owner:ANHUI HUILONG AGRI TECH

Intelligent waste classifying and recovering equipment

InactiveCN104355017AEfficient sorting and recyclingEasy to useWaste collection and transferRefuse receptaclesHeat sensitiveEngineering

The invention discloses intelligent waste classifying and recovering equipment which mainly comprises a waste type identification module used for identifying the types of wastes thrown by users and the identity information of the users, a waste classifying and throwing unit used for classifying and throwing the wastes by the users, a waste classifying and recovering unit used for classifying and recovering the wastes by waste recovery workers, a human body sensing module used for sensing pedestrians close to the equipment, a voice module used for playing an operation prompt voice and a publicity voice, an IC (integrated card) reading module used for reading user information, and a heat-sensitive printer used for printing the identity information of the users and the type information of the thrown wastes. Due to the adoption of the technical scheme, the equipment has the functions of sensing the pedestrians close to the equipment, making a voice prompt in the whole operation, intelligently identifying the waste types, automatically classifying and recovering the wastes and the like, and is easy and convenient to use and relatively high in waste classifying and recovering efficiency.

Owner:张志勇

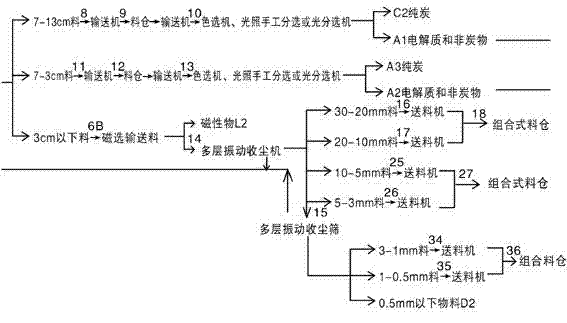

Electrolytic aluminum anode waste separating and recovering method

InactiveCN102389891AReduce sorting costsLabor demand is smallSievingScreeningChemical reactionChemical separation

An electrolytic aluminum anode waste separating and recovering method relates to the field of waste recovery and utilization. The method comprises the following steps: a, screening and classification are performed on waste materials; b, materials of which F is greater than F1 are divided into carbon objects and amorphous carbon objects through manual separation, and the separation of a color sorting machine or an optical separator; c, magnetic objects and nonmagnetic objects are separated during material conveying; d, carbon is extracted through respective electric separation equipment from the material of which the F is less than or equal to F3 and is less than or equal to F2 after screening and classifying; e, a material of which the F is less than the F3, and other amorphous carbon materials separated out from other links can be separated into carbon and amorphous carbon materials through crushing and flotation; f, the amorphous carbon materials in e is added with fluorine and chlorhydric acid for reaction so as to obtain cryolite; and g, purer cryolite is obtained after separation, water scrubbing, dewatering and drying. The invention has the benefits as follows: various material separation and purification from waste can be accomplished by using a series of processes such as optical separation, color selection, manual separation, magnetic separation, electric separation, floatation, chemical reaction and the like, so as to meet the requirements of industrial application. The separation cost during the entire process is low, the demand for labor force is low, and industrial automation continuous production is achieved.

Owner:巨锋

Integral blocks, chemical delivery systems and methods for delivering an ultrapure chemical

InactiveUS7334708B2Easy to addLow costElement comparisonSpecial dispensing meansFiltrationCompound (substance)

Integral blocks, chemical delivery systems and methods for delivering an ultrapure chemical to a point of use or to another integral block are provided. More particularly, the integral blocks include a recharge container block, a pressurization gas block, a purge gas block, a waste recovery block, a vacuum block, a solvent supply block, a degas block, a control block, and a filtration block. Various integral blocks may be selected to form a chemical delivery system, which is particularly suited for a given application. A chemical delivery system will typically comprise a chemical container block, a chemical delivery block, and a point of use in line with the chemical container block and chemical delivery block, as well as one or more integral blocks. The invention also relates to a method for delivering an ultrapure chemical from a chemical container to a point of use, by connecting a chemical container block, containing an ultrapure chemical, to a chemical delivery block and introducing the ultrapure chemical to a point of use. The methods may also include the use of one or more integral blocks. The chemical delivery systems and methods of the invention may be used in a variety of applications. In particular, the invention may be used in electronics fabrication, optical fiber manufacture or semiconductor manufacture.

Owner:AIR LIQUIDE AMERICA CORP +1

Continuous heat-storage type fume residual heat recovering device

InactiveCN101122446AImprove thermal conductivityIncrease the heat transfer specific surface areaStationary plate conduit assembliesFailure riskThermal transmittance

A continuous regenerative flue gas residual heat recycle device belongs to the industrial furnace energy saving field. The device is made from high heat resistance and conduction materials. A gas passage in the device is separated into mutually independent multistory spaces. Flue gas passages and air (gas) passages are arranged in a stratified and staggered way (that is a layer of flue gas passage is connected with a layer of air (gas) passage in the height direction, a staggered arranged sandwich structure). Every layer of gas flow passage is a honeycomb channel, which is made from high thermal conductivity materials. The hest recycle device has the advantages mentioned below. First, the heat exchange rate is fast. The thermal conductivity rate of a regenerator is high. And heat exchange between flue gas and air can be done rapidly. Second, the device can work continuously. Communication is not required in the wind supply and the smoke exhaust. And the system is simple. Third, utmost waste recovery is really realized. No heat and fuel loss caused by volume effect is made during the communication. Fourth, with a long service life, the device can be flexibly arranged. And the device has relative small relevance with the furnace, which makes the failure risk lowered and is convenient for the engineering management.

Owner:UNIV OF SCI & TECH BEIJING

Kitchen waste treatment process

InactiveCN105753100AEliminate negative effectsReasonable useFatty/oily/floating substances removal devicesSolid waste disposalGutter oilBiodiesel

The invention belongs to the technical field of kitchen waste recovery treatment and particularly relates to a kitchen waste treatment process. The kitchen waste treatment process comprises the following steps: treatment adopting an oil-water separator, kitchen waste treatment, treatment in a small sewage treatment station and manufacture of organic fertilizer in a treatment plant. The kitchen waste treatment process has the beneficial effects as follows: kitchen waste and gutter oil of restaurants, hotels and the like can be prevented from flowing into the society with adoption of the kitchen waste treatment process, the problem of body health of the masses caused by consumption of the kitchen waste and the gutter oil can be avoided, adverse impact of the gutter oil on the society is eliminated, source control is realized, each link is monitored in the whole process by a monitoring center, all the kitchen waste and the gutter oil are enabled to enter to the treatment plant, the organic fertilizer and biodiesel are prepared respectively, and the waste is used reasonably.

Owner:山东京蕴腾辉环境科技发展有限公司

Production method of mixed binary acid with long carbon chain

ActiveCN102795984AReduce pollutionImprove efficiencyPreparation from carboxylic acid saltsHydroxy compound separation/purificationCarbon chainTower

The invention belongs to the technical field of solid waste recovery and regeneration, and in particular relates to a production method of mixed binary acid with a long carbon chain. The method comprises the following steps of: with heavy constituents remained after ethanol obtained in the dodecanedioic acid refining process is recovered as raw materials, enabling the heavy constituents to react with and a superfluous alkali solution at the temperature of 95-100 DEG C to generate sodium binary acid with a long carbon chain and ethanol; recovering the ethanol in the reaction process by using an alcohol fog recovery tower; and after the reaction is ended, carrying out aftertreatment on the obtained sodium salt to obtain the mixed binary acid with the long carbon chain. According to the invention, the heavy constituents remained after the ethanol obtained in the dodecanedioic acid refining process is recovered as raw materials and reacts with the superfluous alkali solution to generate the binary acid with the long carbon chain, and thus not only are wastes utilized, but also the environment pollution is reduced, and the benefit is increased.

Owner:山东广通新材料有限公司

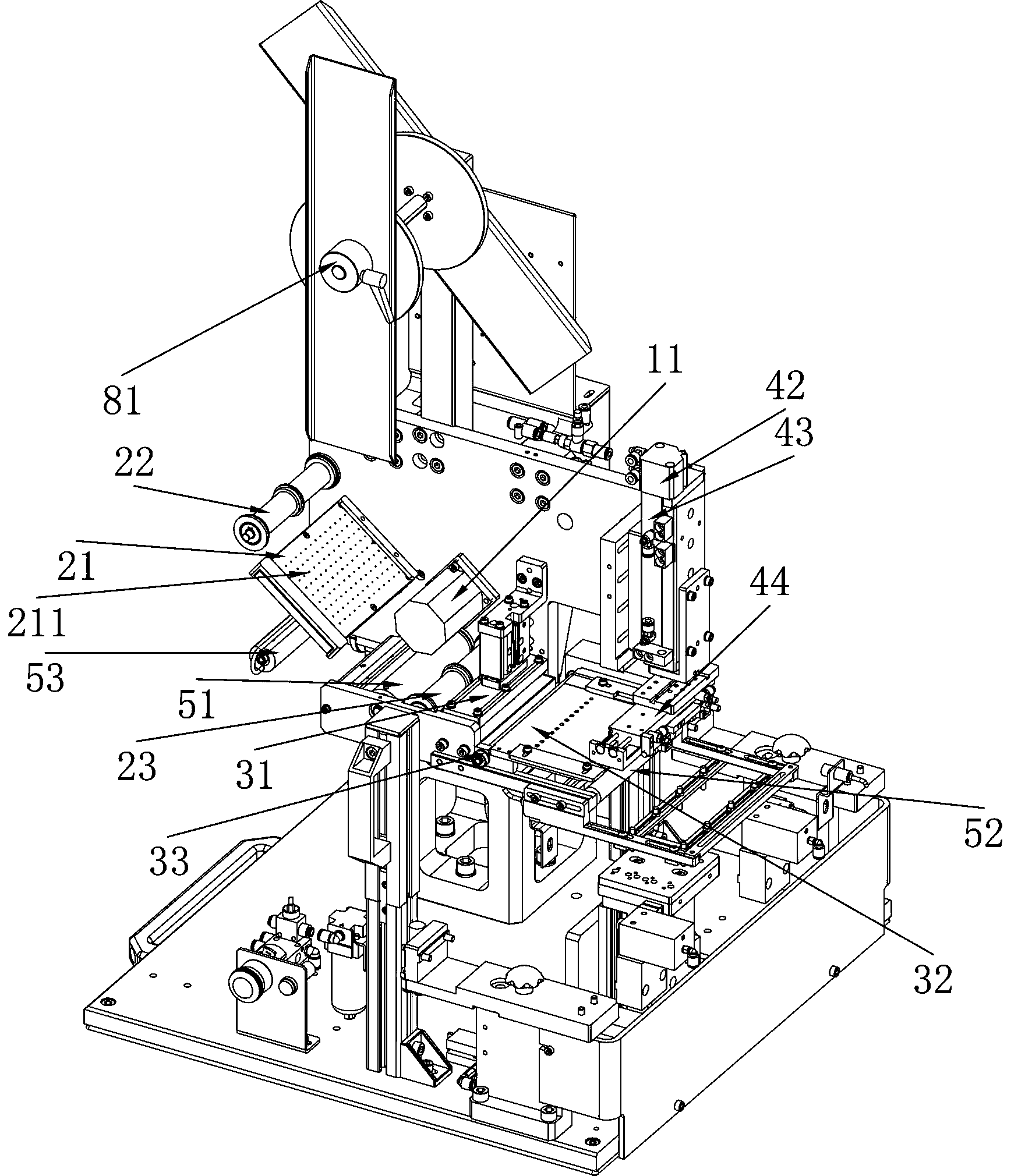

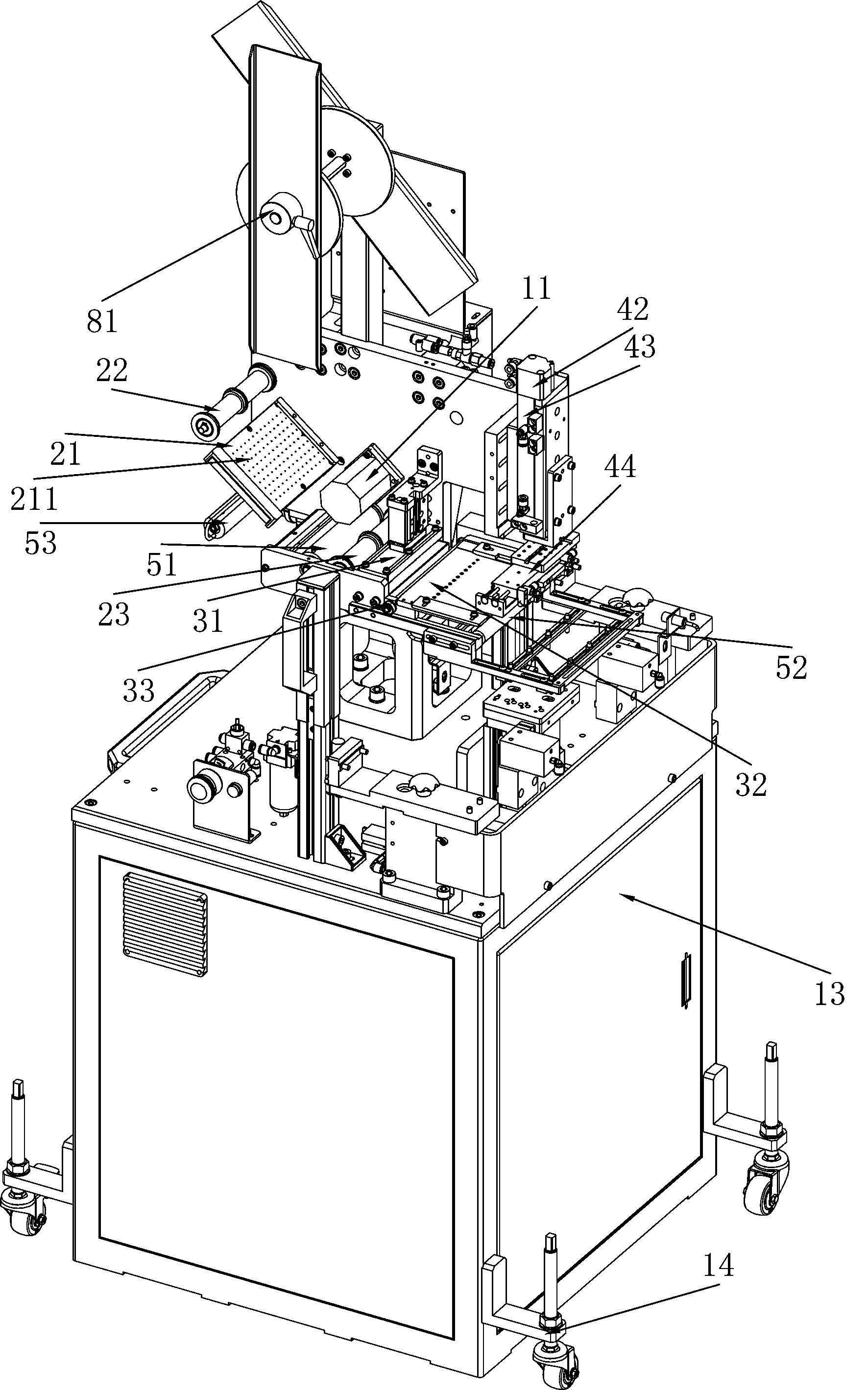

Full-automatic laminator

InactiveCN104309848AIncrease usageReduce dosagePackaging automatic controlArticle deliveryProduction lineStripping membrane

The invention relates to the field of lamination equipment, in particular to a full-automatic laminator. The full-automatic laminator comprises a frame. A feeding mechanism used for conveying material membranes is arranged on the frame. A membrane stripping mechanism used for stripping membranes to be pasted among the material membranes is arranged on the frame and located at the output end of the feeding mechanism. A membrane transfer mechanism used for transferring the stripped membranes to be pasted is arranged on the frame and located at the output end of the membrane stripping mechanism. A waste recovery mechanism used for recovering stripped waste is further arranged on the frame and located at the output end of the membrane stripping mechanism. The frame is further provided with a membrane pasting mechanism used for pasting the membranes to be pasted onto workpieces in cooperation with the transfer mechanism. Compared with manual membrane pasting and membrane pasting through an existing laminator, the full-automatic laminator has the advantages that manual intervention is not needed, manual membrane pasting on a production line is replaced, and the labor cost is lowered; the membrane pasting speed is increased, and the productivity of the production line is improved; the use number of single auxiliary material pieces is reduced; the bad phenomena of deviation, pasting missing, scratches, damage, unevenness (wrinkles) and the like in the manual membrane pasting process are avoided, waste of auxiliary materials is reduced, and the utilization rate of the auxiliary materials is increased.

Owner:SHENZHEN BORWIN PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com