Continuous heat-storage type fume residual heat recovering device

A recovery device and flue gas waste heat technology, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of high cost and maintenance costs, waste of fuel and energy, and easy wear and tear of the reversing system , to achieve the effect of convenient engineering management, long device life and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

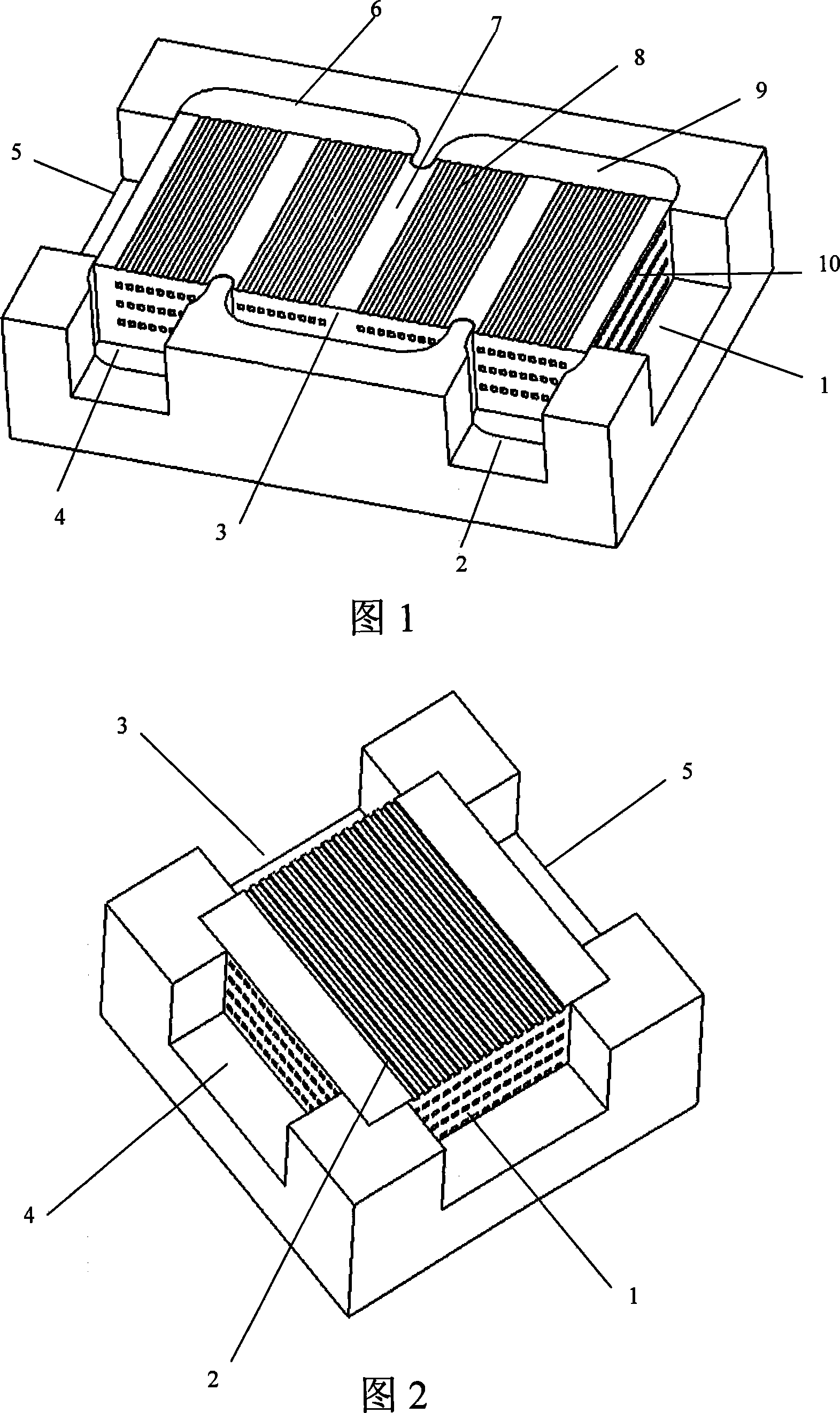

[0029] Embodiment 1 (wrong reverse flow)

[0030] The continuous regenerative flue gas waste heat recovery device is made of silicon carbide and is directly installed in the flue. After the flue gas enters through the inlet 1, it is evenly distributed to the flue gas channels 10 of each layer, and is directly discharged from the flue gas outlet 5 after passing through the heat storage body 7; after the same air (coal gas) enters through the inlet 4, it is evenly distributed to each layer of air ( In the gas) channel, it enters the gas collecting box 6 after passing through the regenerator vertically, and then turns back and reciprocates through the gas collecting boxes 7 and 9, and then is discharged from the air (gas) outlet 2; the heat in the flue gas is transferred to the The heat storage body, because the thermal resistance of the heat storage body made of high thermal conductivity material is very small, it will quickly conduct heat to the side of the air (gas) channel, a...

Embodiment 2

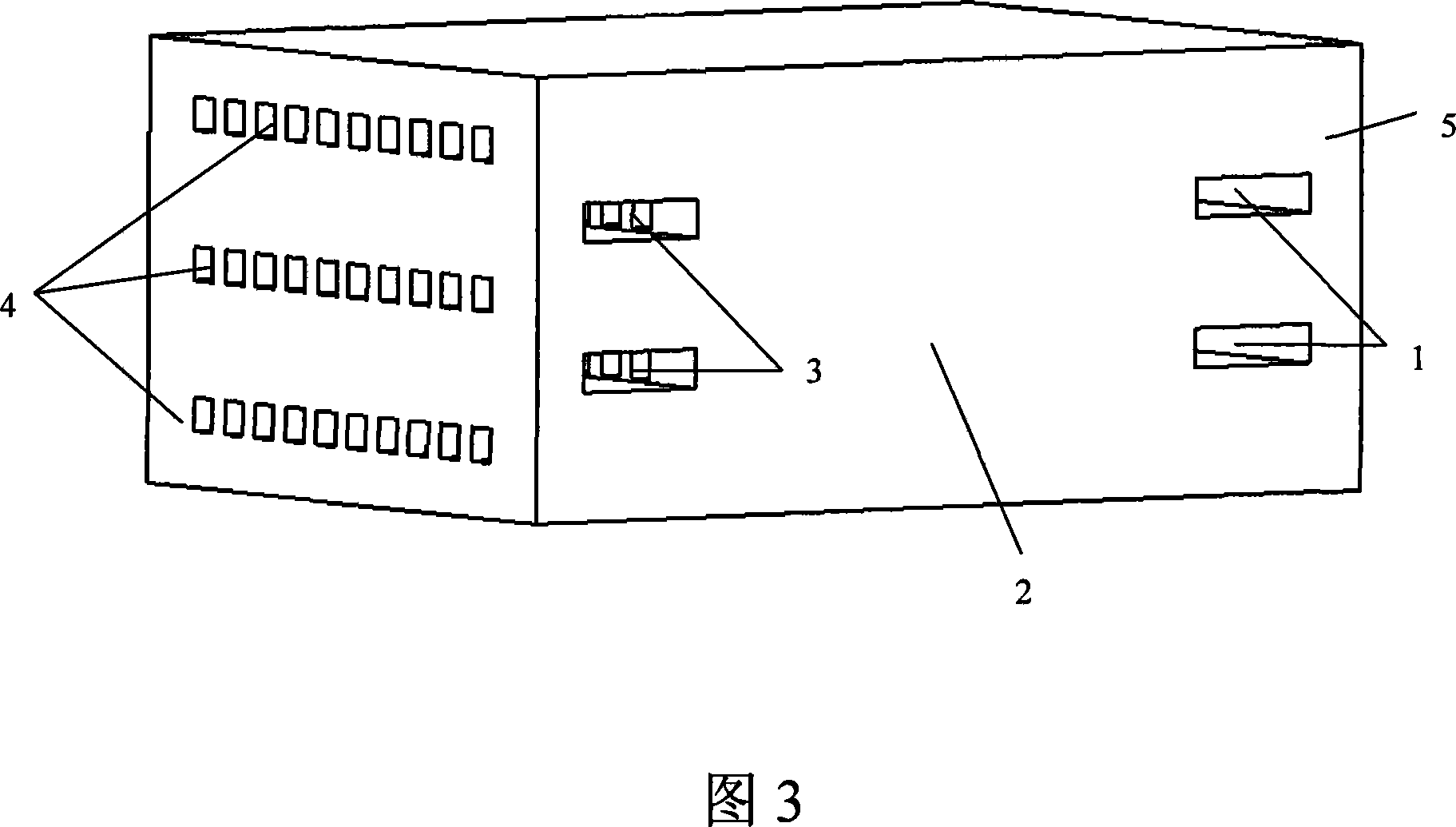

[0032] Embodiment 2 (vertical cross flow)

[0033] This continuous heat storage flue gas waste heat recovery device is made of silicon nitride material and is directly installed in the flue. The gas outlet 3 is discharged; after the same air (gas) enters from the inlet 4, it is evenly divided into the air (gas) channels of each layer, and is discharged from the air (gas) outlet 5 after passing through the regenerator; the heat in the flue gas is exchanged by convection. The heat is transferred to the heat storage body, and the heat storage body transfers the heat to the side of the air (gas) channel through heat conduction, and then the heat storage body transfers the heat to the cold air (gas) through convective heat exchange to complete the heat recovery process.

Embodiment 3

[0034] Example 3 (countercurrent)

[0035] This continuous heat storage flue gas waste heat recovery device is made of silicon nitride material and is directly installed in the flue. The gas outlet 3 is discharged; after the same air (gas) enters from the inlet 4, it is evenly divided into the air (gas) channels of each layer, and is discharged from the air (gas) outlet 5 after passing through the regenerator; the heat in the flue gas is exchanged by convection. The heat is transferred to the heat storage body, and the heat storage body transfers the heat to the side of the air (gas) channel through heat conduction, and then the heat storage body transfers the heat to the cold air (gas) through convective heat exchange to complete the heat recovery process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com