Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

352 results about "Aluminum anode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Middle temperature sealant and closing process for aluminum anodized film

ActiveCN101323965AEasily biodegradableReduce pH variationSurface reaction electrolytic coatingNickel saltHeavy metals

The invention discloses a mesophilic sealing agent and a sealing technique of aluminum anodic oxide films and belongs to the technical field of the post sealing processing of the anodic oxide films of aluminum and aluminum alloys. The sealing agent of the invention is an aqueous solution that consists of alkali metals or salts of alkali earth metals, a complexing agent and a pH buffering agent; wherein, the concentration of the alkali metals or the salts of alkali earth metals is 5 to 15 g / L, the concentration of the complexing agent is 10 to 20 g / L,, the concentration of the pH buffering agent is 0 to 10 g / L, and the residual quantity is water; the pH value of the aqueous solution of the sealing agent is maintained between 5 and 6, the aluminum anodic oxide film is sealing processed by the sealing agent, the temperature of the aqueous solution of the sealing agent is 75 to 90 DEG C, and the soaking and sealing time lasts for 20 to 30 minutes. The sealing agent adopts the alkali earth metals or the salts of alkali metals with wide resource and low cost so as to replace heavy metal nickel salts or cobalt salts in the prior art and adopts the organic complexing agent that has biodegradability, low price and simple molecules so as to replace surface activating agents that contain giant molecules and benzene rings in the prior art, and consequently the aluminum anodic oxide film that is sealing processed by the sealing agent obtains excellent anti-pruina property, and the anti-corrosion and anti-pollution properties of the anodic oxide film of aluminum and aluminum alloys are generally improved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

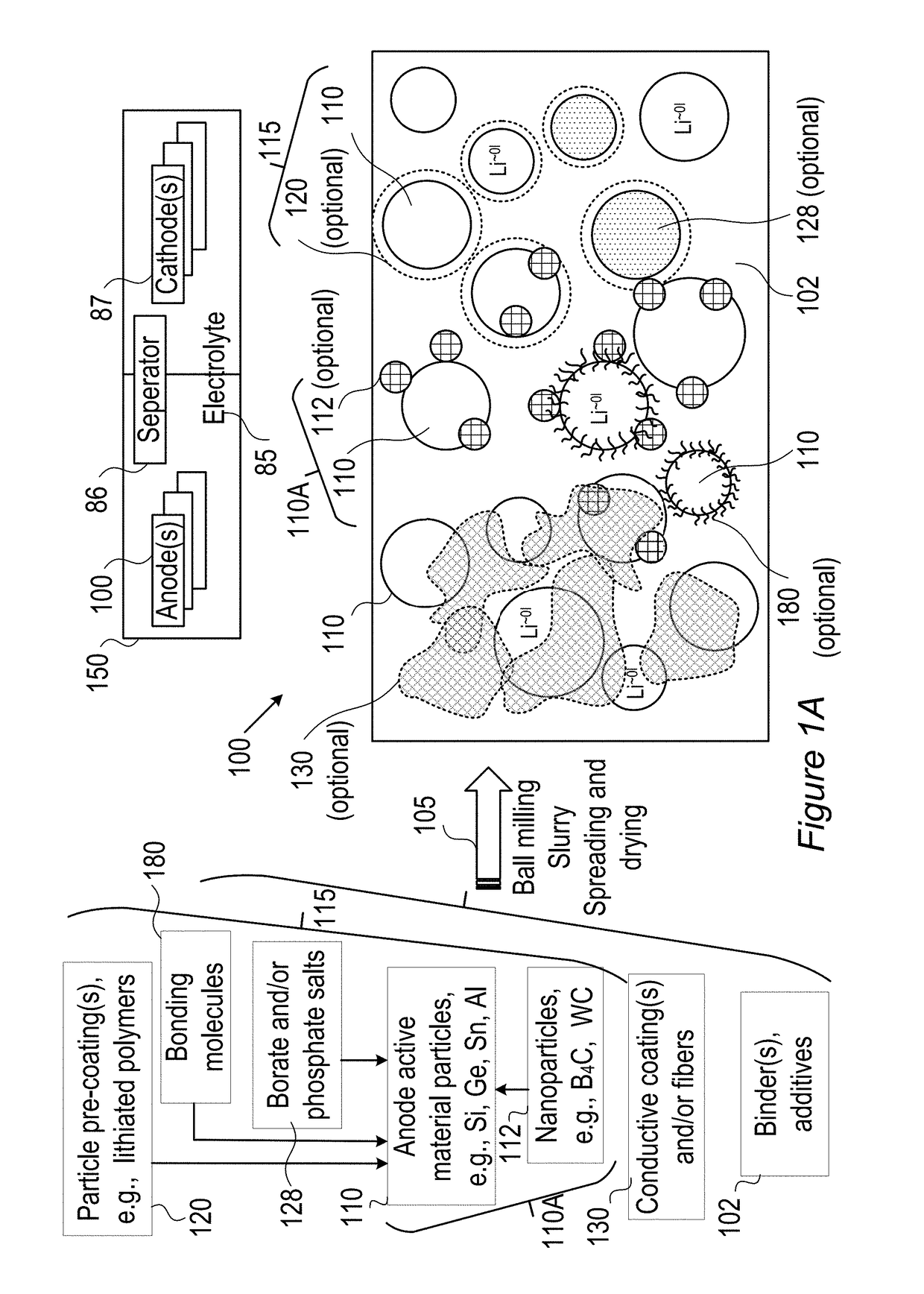

Aluminum anode active material

Improved anodes and cells are provided, which enable fast charging rates with enhanced safety due to much reduced probability of metallization of lithium on the anode, preventing dendrite growth and related risks of fire or explosion. Anodes and / or electrolytes have buffering zones for partly reducing and gradually introducing lithium ions into the anode for lithiation, to prevent lithium ion accumulation at the anode electrolyte interface and consequent metallization and dendrite growth. Various anode active materials and combinations, modifications through nanoparticles and a range of coatings which implement the improved anodes are provided.

Owner:STOREDOT

Method for producing aluminum anode by using waste cathode carbon block of aluminum cell

InactiveCN102146570AAchieving processing powerRealize comprehensive utilizationAluminum anodeElectrolysis

The invention relates to a method for producing an aluminum anode by using a waste cathode carbon block of an aluminum cell, belonging to the technical field of non-ferrous metallurgy environmental protection. The method comprises the following steps of: (1) crushing the waste cathode carbon block of the aluminum cell and sorting a steel rod, a refractory material, an electrolyte and the like in the waste cathode carbon block; (2) performing coarse crushing on the sorted waste cathode carbon block of the aluminum cell; (3) grinding into powder less than 0.075 millimeters; (4) separating impurities in the waste cathode carbon block of the aluminum cell by adopting methods including a floatation method, an acid method, an alkali method, an acid-alkali combination method and the like; (5) drying the treated waste cathode carbon block powder of the aluminum cell; (6) mixing according to the formula requirement of aluminum anode production; and (7) entering an aluminum anode production system and mixing the powder to produce a pre-baked anode. In the method, the waste cathode carbon block of the aluminum cell is taken as mixing powder for the aluminum anode, so that harmless treatment and comprehensive utilization of the waste cathode carbon block of the aluminum cell are realized, the using amount of petroleum coke is reduced, resources are saved, and the production cost is lowered.

Owner:王建军

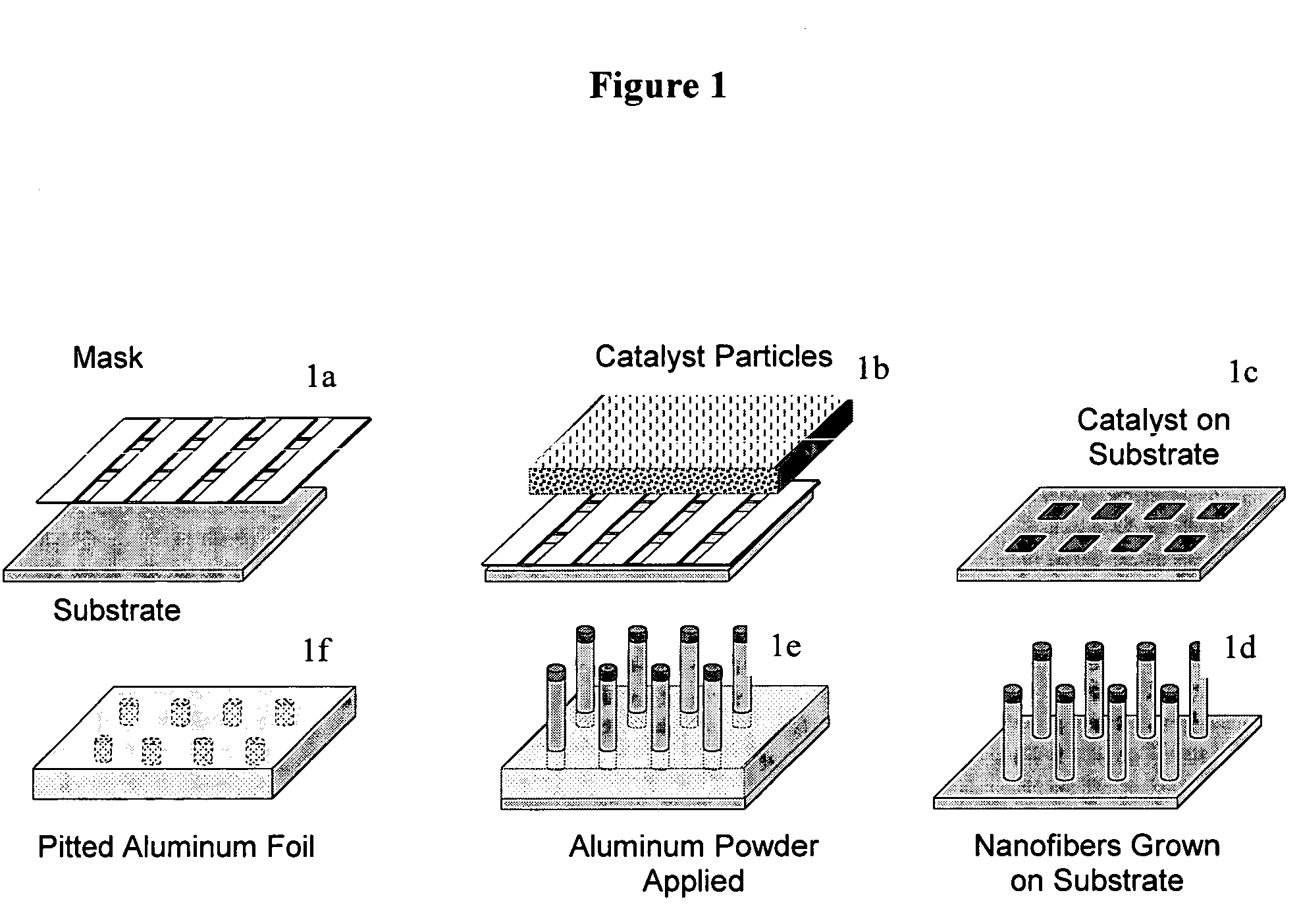

Aluminum electrolytic capacitor having an anode having a uniform array of micron-sized pores

A method for making an aluminum foil anode for an aluminum electrolytic capacitor. This invention also relates to an aluminum anode foil for use in an electrolytic capacitor as well as an aluminum electrolytic capacitor having increased capacitance and substantially uniform pore size distribution.

Owner:CATALYTIC MATERIALS

Laser marking of raw aluminum anode foil to induce uniform patterning etching

InactiveUS7452473B1Improve distributionHigh strengthElectrolysis componentsElectrolytic capacitorsCapacitanceAluminum anode

A method of producing a highly etched electrode for a capacitor from a foil is disclosed. The method comprises first applying a laser beam to the foil to form a plurality of marks on the foil surface and then etching the foil. Preferably, the laser marks facilitate etching of foil surface in areas near the marks and retard etching of foil surface inside the marks. After etching, the foil is further processed in a combination of optional steps such as forming and finishing steps. The laser marking of the foil allows for positional control of tunnel initiation, such that tunnel initiation density and the location of tunnel initiation is controlled. By controlling the position of tunnel initiation, foils are etched more uniformly and have optimum tunnel distributions, thus allows for the production of highly etched foils that maintain high strength and have high capacitance. The present invention further includes an electrolytic capacitor comprising etched aluminum anode foils, which have been prepared using the methods of the present invention.

Owner:PACESETTER INC

Electrolyte corrosion inhibitor for aluminum-air cell, electrolyte and preparation method

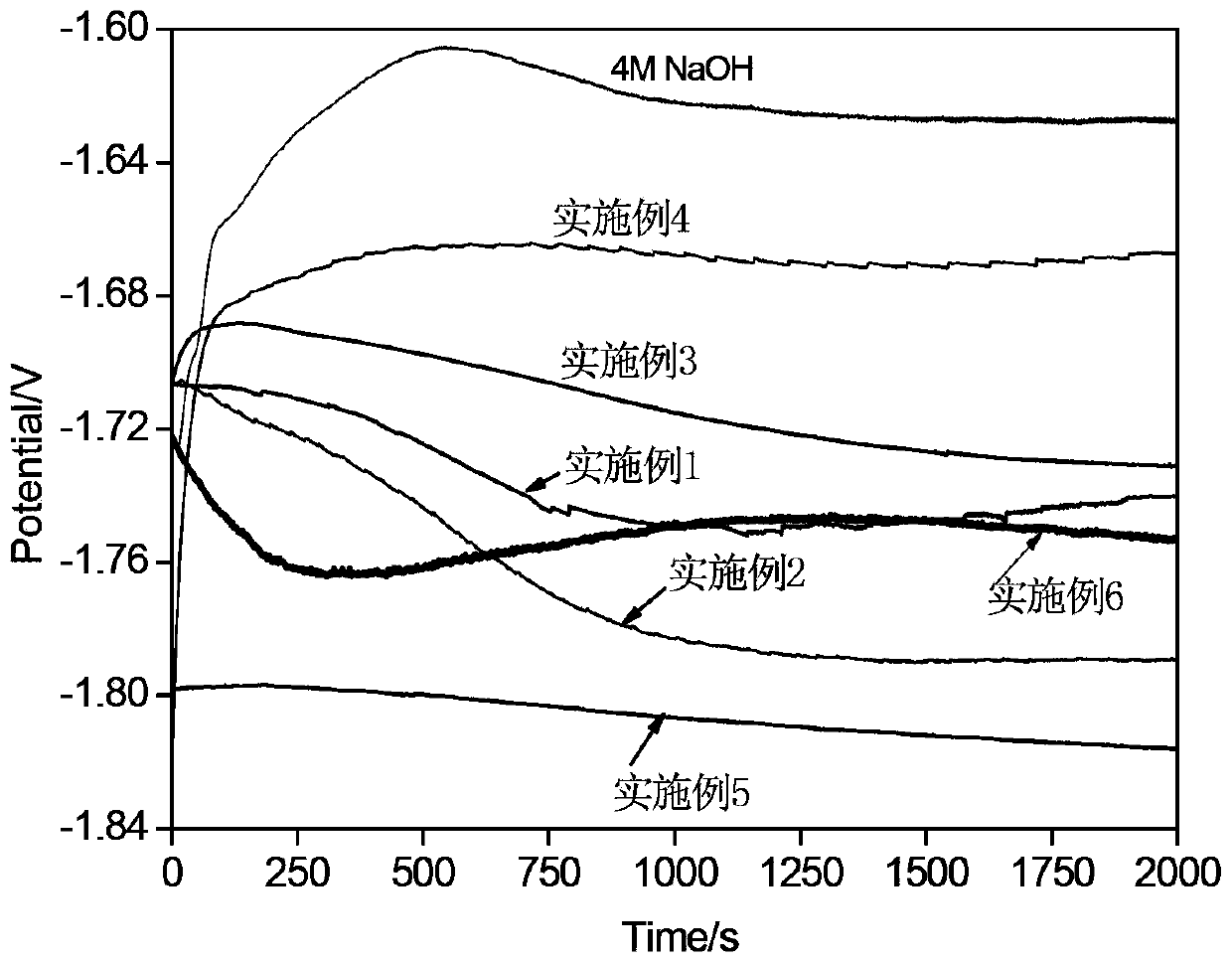

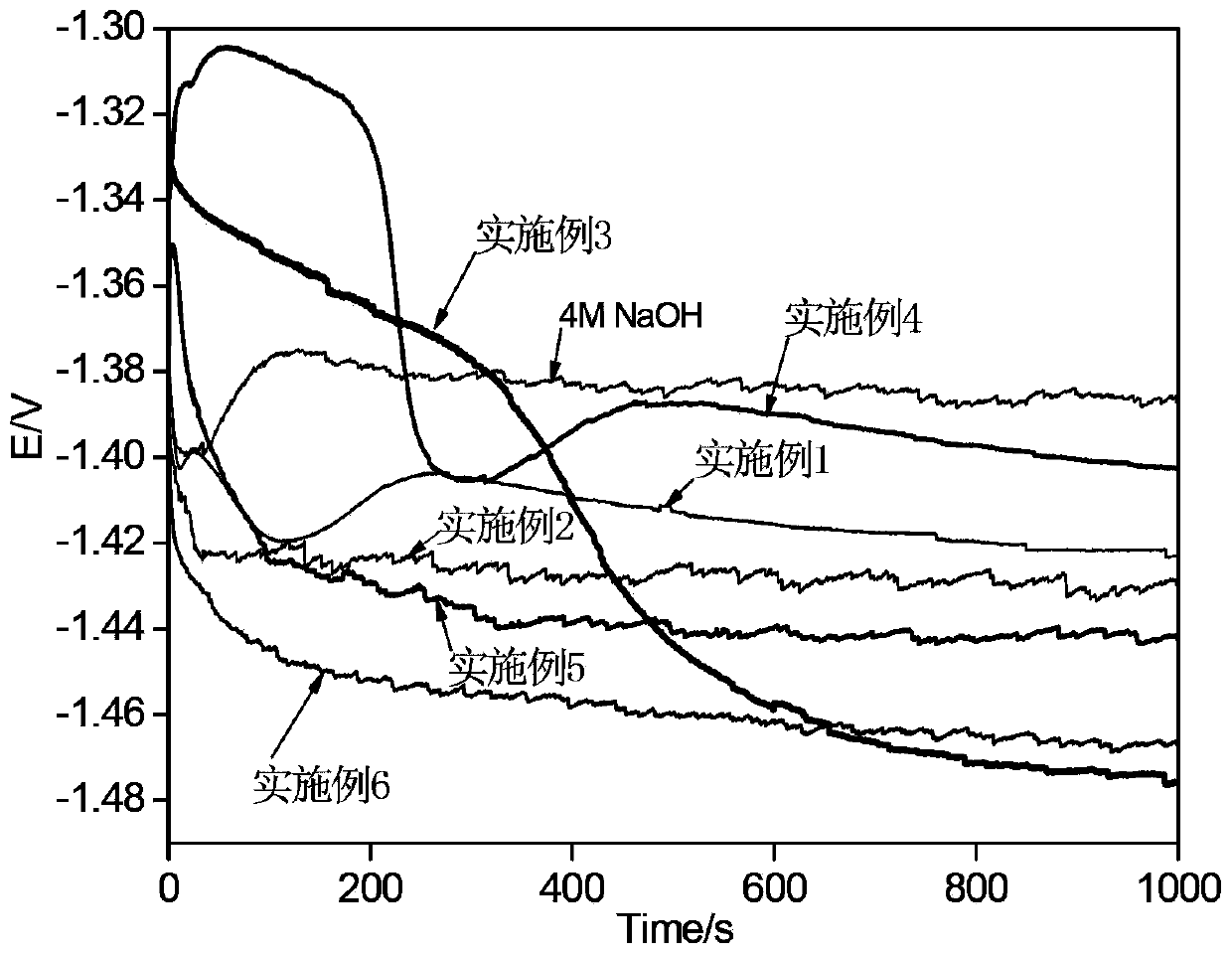

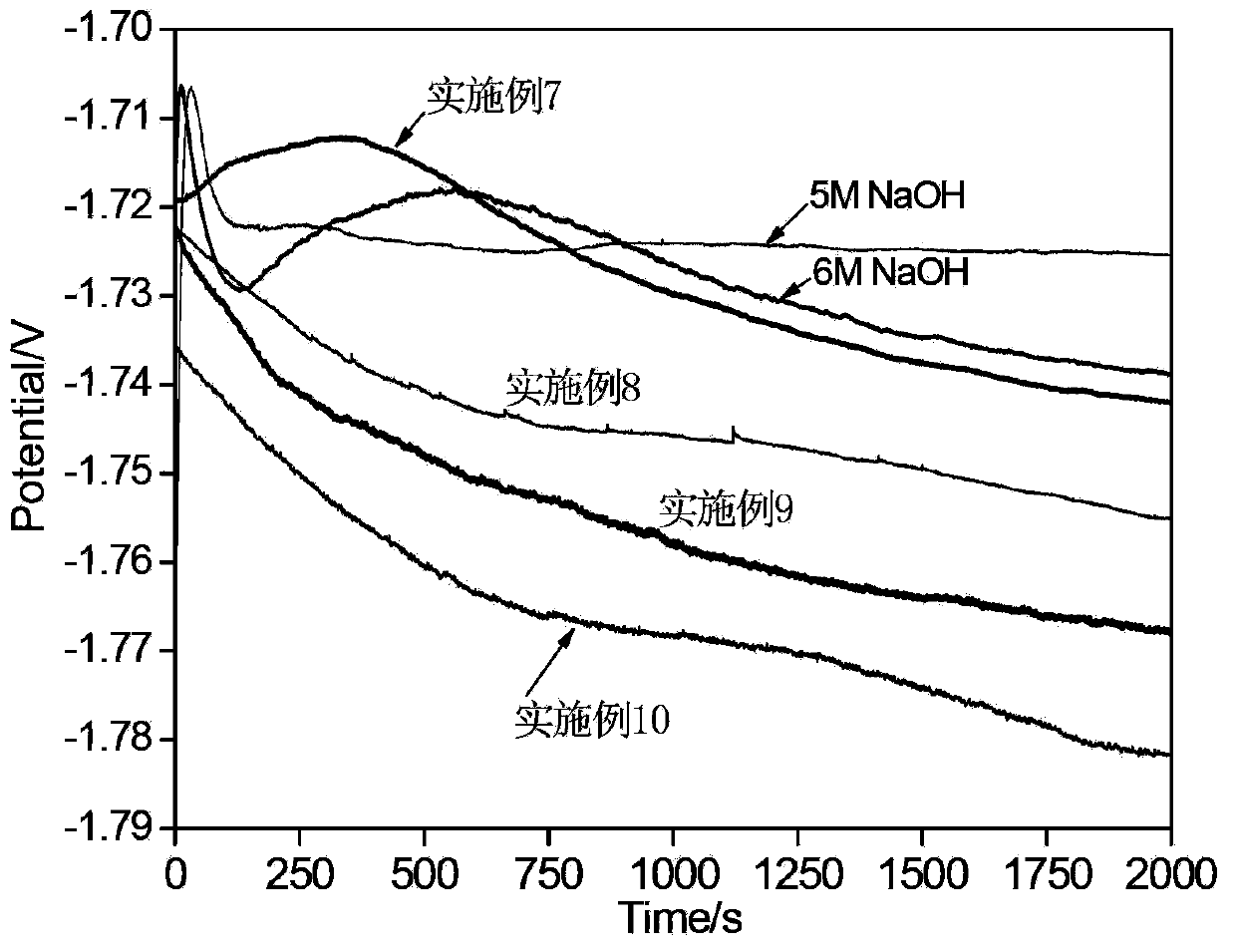

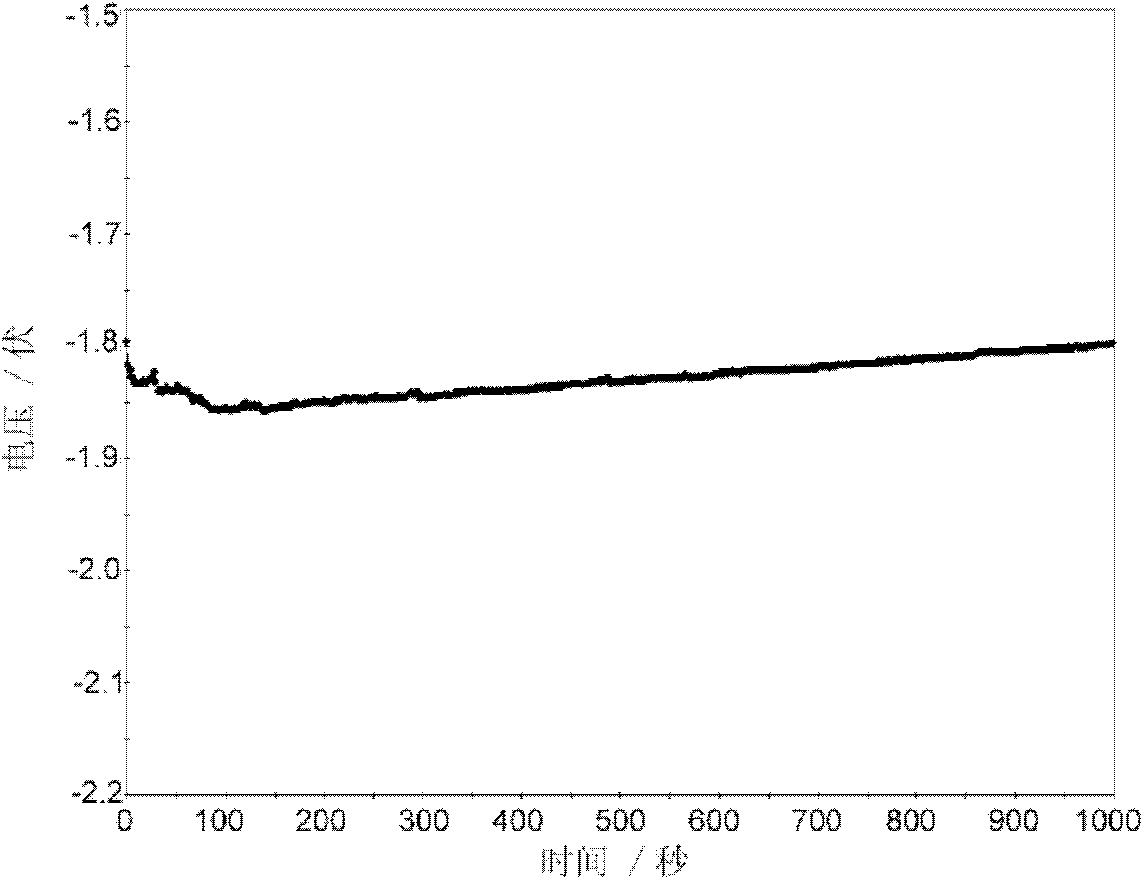

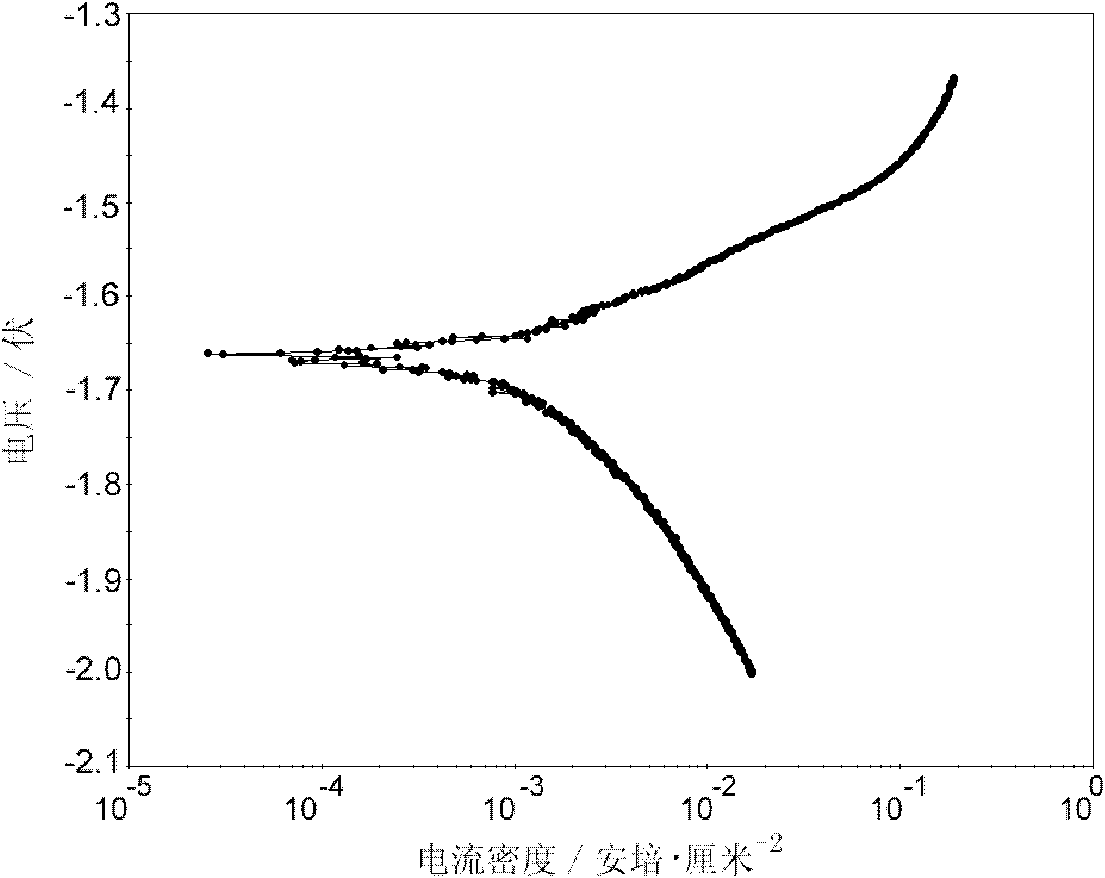

InactiveCN103633396AReduce hydrogen evolution self-corrosion rateProne to anodic polarizationFuel and primary cellsAluminum anodePhysical chemistry

The invention discloses an electrolyte corrosion inhibitor for an aluminum-air cell, an electrolyte and a preparation method, belonging to the technical field of chemical batteries. The electrolyte corrosion inhibitor mainly comprises sodium hyposulfite which has a concentration of 0.005 to 0.2 mol / L in the electrolyte and may further comprise the auxiliary additive sodium stannate which has a concentration of 0.01 to 0.03 mol / L in the electrolyte. The aluminum-air cell provided by the invention has the advantages of simple composition, low cost, safety and accordance with environmental protection requirements, can substantially reduce the hydrogen evolution self-corrosion rate of an aluminum anode, enables the open circuit potential of the aluminum anode and working potential under the condition of impressed current to undergo substantial negative transfer, allows an aluminum anode alloy to have good corrosion resistance and high electrochemical activity and meets the requirement of an alkaline aluminum-air cell for large current density discharging.

Owner:HENAN UNIV OF SCI & TECH

Aluminum-zinc-tin system sacrificial anode material and preparation method thereof

The invention discloses an aluminum-zinc-tin system sacrificial anode material and a preparation method thereof, wherein the material comprises the following components in percentage by weight: 5.0-8.0% of Zn, 0.05-0.2% of Sn, 0.01-0.05% of Ga, and the other is Al. Compared with an existing AlZn-Sn anode material, the aluminum-zinc-tin system sacrificial anode material briefly has the advantages that firstly, the aluminum-zinc-tin system sacrificial anode material of the invention has good activation performance, and reaches the reasonable range -1.0-1.1V(SCE) of protection potential, secondly, a minute quantity of Ga, Ga and Sn are added into the aluminum-zinc-tin system sacrificial anode material and are dissolved in solution in an ion state, tin ions are firstly restored to the original state, and deposit on the surface of an aluminum anode, and gallium ions also deposit on the deposited tin, thereby a Ga-Sn alloy active point with good flowing performance is continuously formed on the surface, oxidation film is partly separated, the aluminum anode has higher electric current efficiency and uniform surface dissolve performance, thirdly, the current efficiency of the aluminum-zinc-tin system sacrificial anode material of the invention can reach above 93% through micro-alloying, and the actual capacitance quantity reaches above 2620A.h.kg-1.

Owner:HENAN UNIV OF SCI & TECH

Aluminum batteries comprising metal-oxide, metal-fluoride, metal-sulfide, or sulfur cathodes

InactiveUS8715853B1Silver accumulatorsElectrochemical processing of electrodesMetallic sulfideElectron

Variations of the invention provide an improved aluminum battery consisting of an aluminum anode, a non-aqueous electrolyte, and a cathode comprising a metal oxide, a metal fluoride, a metal sulfide, or sulfur. The cathode can be fully reduced upon battery discharge via a multiple-electron reduction reaction. In some embodiments, the cathode materials are contained within the pore volume of a porous conductive carbon scaffold. Batteries provided by the invention have high active material specific energy densities and good cycling stabilities at a variety of operating temperatures.

Owner:HRL LAB

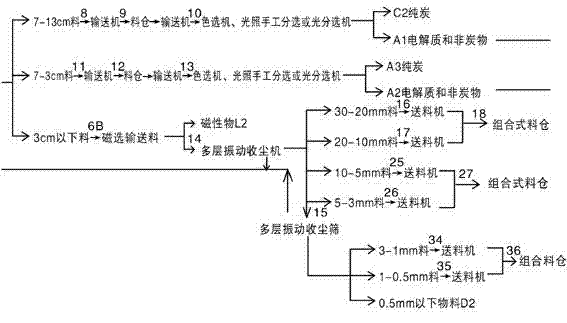

Electrolytic aluminum anode waste separating and recovering method

InactiveCN102389891AReduce sorting costsLabor demand is smallSievingScreeningChemical reactionChemical separation

An electrolytic aluminum anode waste separating and recovering method relates to the field of waste recovery and utilization. The method comprises the following steps: a, screening and classification are performed on waste materials; b, materials of which F is greater than F1 are divided into carbon objects and amorphous carbon objects through manual separation, and the separation of a color sorting machine or an optical separator; c, magnetic objects and nonmagnetic objects are separated during material conveying; d, carbon is extracted through respective electric separation equipment from the material of which the F is less than or equal to F3 and is less than or equal to F2 after screening and classifying; e, a material of which the F is less than the F3, and other amorphous carbon materials separated out from other links can be separated into carbon and amorphous carbon materials through crushing and flotation; f, the amorphous carbon materials in e is added with fluorine and chlorhydric acid for reaction so as to obtain cryolite; and g, purer cryolite is obtained after separation, water scrubbing, dewatering and drying. The invention has the benefits as follows: various material separation and purification from waste can be accomplished by using a series of processes such as optical separation, color selection, manual separation, magnetic separation, electric separation, floatation, chemical reaction and the like, so as to meet the requirements of industrial application. The separation cost during the entire process is low, the demand for labor force is low, and industrial automation continuous production is achieved.

Owner:巨锋

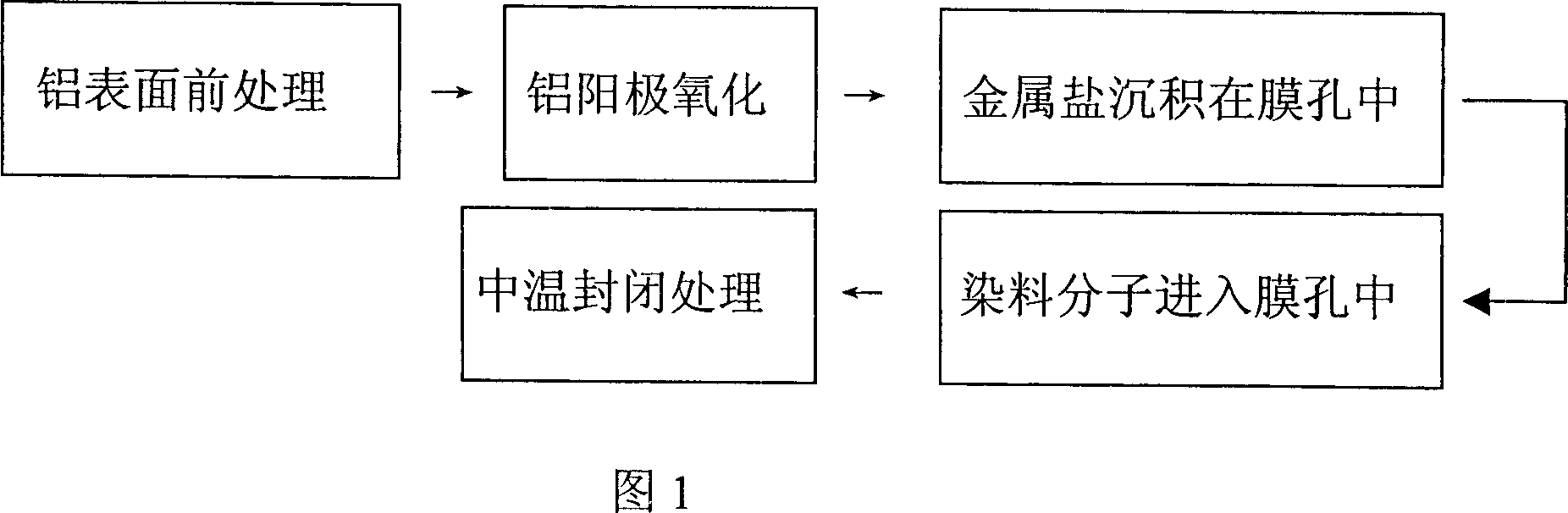

Composite coloration method of aluminium anode oxide film

ActiveCN1920111AImprove corrosion resistanceImprove light resistanceSurface reaction electrolytic coatingOrganic dyeNanotechnology

The invention discloses the composite coloration method for aluminum anodized film, comprising the following steps: 1 making the aluminum anodized film; 2 electrolyzation coloration, soaking into the electrolyzation coloration solution with metal salt, making metal salt deposit in the aluminum anodized film; 3 chemistry dyeing, making organic dye molecule enter into aluminum anodized film; 4 enclosing. The invention gets the colored film which has good corrosion resisting property, light resistance and decorative effect. The invention has the advantages of simple operation and easy production condition.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

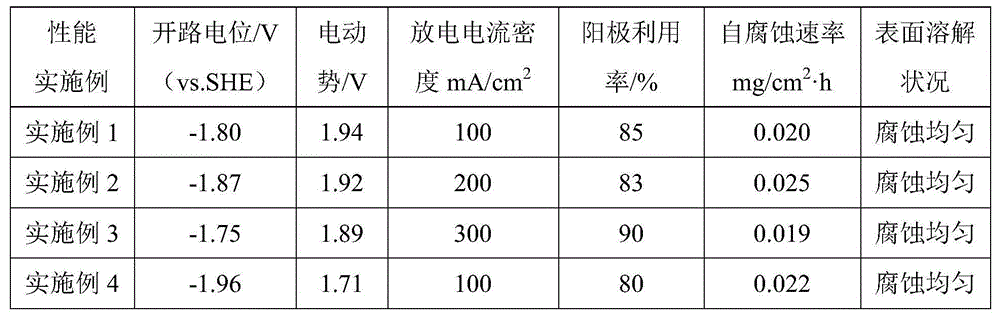

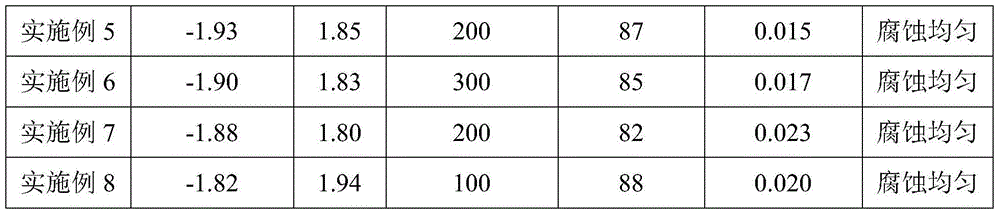

Rare earth-containing amorphous/nanocrystal aluminum anode composite material, preparation method and aluminum air battery

InactiveCN104372206AImprove electrochemical performanceAbundant resourcesFuel and primary cellsCell electrodesRare-earth elementDissolution

The present invention discloses a rare earth-containing amorphous / nanocrystal aluminum anode composite material, a preparation method and an aluminum air battery, and belongs to the techncial field of air batteries. The aluminum anode composite material comprises, by weight, 0.5-5% of Mg, 0.02-2% of Sn, 0.02-2% of Ga, 0.1-5% of La or Ce, and the balance of Al. According to the present invention, aluminum with the purity of more than or equal to 99.8% is adopted as the base, the trae amounts of Mg, Sn, Ga and the rare earth element La or Ce are added so as to reduce the self-corrosion rate and improve the electrochemical property and the surface dissolution uniformity of the alloy, especially the trae amount of the rare earth element is added to the aluminum alloy, and the addition of the rare earth element to the aluminum has effects of oxygen removing, hydrogen removing, desulfuration, melting rate accelerating, metal burning loss reducing, change of species distribution and refinement modification of iron and other harmful impurities, and the like so as to slow down the self-corrosion of the aluminum alloy, such that the anode utilization rate is improved.

Owner:HENAN UNIV OF SCI & TECH

Anti-oxidizing paint for electrolytic aluminum anode carbon blocks and preparation method thereof

The invention relates to an anti-oxidizing paint used in production of electrolytic aluminum anode carbon blocks and a preparation method thereof. The anti-oxidizing paint for electrolytic aluminum anode carbon blocks comprises, by weight percent, 35 to 40% of borax or boric acid, 10 to 15% of kaolin, 30 to 35% of industrial phosphoric acid, 0 to 5% of industrial aluminum sulfate and 10 to 15% of water. According to the invention, materials used in the invention are cheap and easily available, production cost is low, and it is simple to construct; application of the anti-oxidizing paint enables the weight loss rate of anode carbon blocks to reduce by 52% and consumption of anode carbon blocks to be substantially decreased, thereby benefiting electrolytic aluminum enterprises in achieving the goals of energy saving and emission reduction.

Owner:翟相文

Production method of low voltage aluminum anode foil for electrolytic condenser

ActiveCN104599845AExcellent dielectric propertiesImprove pressure resistanceElectrolytic capacitorsPrimary repairAluminum anode

The invention discloses a production method of a low voltage aluminum anode foil for an electrolytic condenser. The production method including the steps of: 1, adding aluminum foil into ammonium adipate solution for formation treatment; 2, performing secondary formation treatment; 3, performing third formation treatment; 4, performing fourth formation treatment; 5, performing fifth formation treatment; 6, performing sixth formation treatment; 7, performing depolarization treatment; 8, performing primary repair formation treatment; 9, performing secondary repair formation treatment; 10, performing aftertreatment; 11, performing thermal treatment: including putting the aluminum foil which is subjected to aftertreatment into a roasting furnace for roasting, then putting the roasted aluminum foil into a drying furnace for drying, and thereby the product is obtained. The aluminum foil manufactured according to the production method provided by the invention is improved in anti-hydration and wet-resistance of the oxide film.

Owner:华德士电子(东莞)有限公司

Method for preparing titanium dioxide/copper nano composite antibacterial coating on surface of aluminum material

InactiveCN101994142AAchieve closureImprove corrosion resistanceAnodisationPhosphoric acidCopper metal

The invention relates to a method for preparing a titanium dioxide / copper nano composite antibacterial coating on the surface of an aluminum material and provides a method for preparing a titanium dioxide / copper nano composite antibacterial coating on the surface of an aluminum anode oxidation film by nano composite plating technology. The method comprises the following steps of: firstly, preparing the aluminum anode oxidation film in solution of sulfuric acid or oxalic acid; secondly, soaking the aluminum anode oxidation film in phosphoric acid and chambering so as to remove a barrier layer; and lastly, electrically depositing nano titanium dioxide particles and copper metal in a film hole. The coating obtained by the method has high antibacterial property, strong interface bonding force, high corrosion resistance and high wearing resistance.

Owner:SHENYANG UNIV

High temperature calcination method of electrolytic aluminum anode scrap residue

The invention discloses a high temperature calcination method of electrolytic aluminum anode scrap residue. The method is characterized by comprising the following steps of: crushing and ball milling the electrolytic aluminum anode scrap residue; separating powdered carbon through floatation; then removing iron-containing impurities from the powdered carbon through magnetic separation; and calcining the powdered carbon by a calcining furnace to remove fluoride salt and sulfur from the powdered carbon, thus obtaining high-purity powdered carbon. According to the invention, through direct high temperature calcination of the powdered carbon recovered from the electrolytic aluminum anode scrap residue, the processes of asphalt blending, tar kneading and profiling are reduced, so that the method is simpler; and compared with calcined carbon blocks, the powdered carbon grains are small and quick in temperature rise, and can rapidly reach a high temperature over 1700 DEG C in the calcining furnace, so that sulfur and fluoride salt are gasified and released. Therefore, the calcination time is greatly reduced, and the calcination can be finished in 10-20 minutes, thus saving a large amount of heating time and electric energy. The calcined powdered carbon has the advantages of low volatile component, low sulfur, high purity and more balanced quality, and can be used as a high-quality carbon raw material.

Owner:周俊和 +1

Preparation method and device of nickel-cobalt-aluminum anode material precursor

InactiveCN106058244ACo-precipitated evenlyCo-precipitation realizationCell electrodesAluminum IonAluminum anode

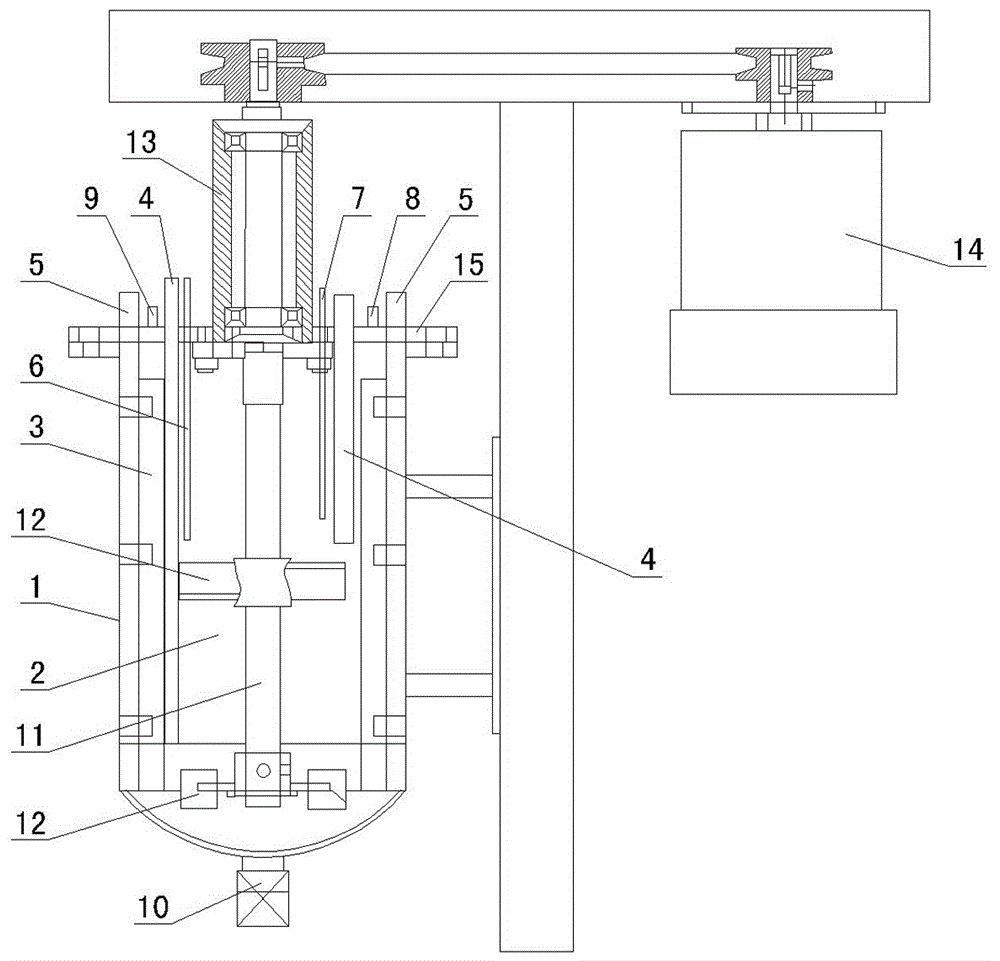

The invention discloses a preparation method and a preparation device of a nickel-cobalt-aluminum anode material precursor. The preparation method is characterized by comprising the following steps: preparing a nickel-cobalt-aluminum mixed salt solution containing a complexing agent and a strong base solution containing ammonia water; combining the nickel-cobalt-aluminum mixed salt solution with the strong base solution at a uniform flowing speed and synchronously filling into a reaction kettle with a base solution for co-precipitation reaction; after the nickel-cobalt-aluminum mixed salt solution is filled, stopping adding the strong base solution, and after the reaction is completed, aging the slurry, and further performing liquid-solid separation, thereby obtaining the nickel-cobalt-aluminum anode material precursor. According to the preparation method and the device, the complexing agent is directly added into an aluminum solution, and the complexing agent is complexed with aluminum ions before the co-precipitation reaction, so that aluminum can be prevented from nucleating and precipitating immediately after entering the reaction system; meanwhile, a mixed salt solution is prepared from nickel, cobalt and aluminum together, so that the ratio of nickel and cobalt to aluminum in the formed precursor is accordant with that of an expected nickel-cobalt-lithium aluminate material at any moment, nickel, cobalt and aluminum can be subjected to uniform co-precipitation reaction, and the nickel-cobalt-aluminum anode material precursor of which indexes such as the morphology, the granularity and the density are all higher than those of similar products can be prepared.

Owner:GUANGDONG INST OF RARE METALS

Silicon-based heterojunction solar cell and preparation method thereof

ActiveCN102931267ACombination of good conductivityImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationHeterojunctionNiobium

The invention discloses a silicon-based heterojunction solar cell which comprises grid electrodes, a transparent conductive film, a boron-doped amorphous silicon, an intrinsic amorphous silicon, an N-type monocrystalline and a back electrode in sequence, wherein the back electrode is formed by a distributed Bragg reflector and an aluminum thin film, the distributed Bragg reflector is formed by arranging niobium-doped titanium dioxide thin films and aluminum-doped zinc oxide thin films at intervals, and the aluminum thin film is arranged on the surface layer of the aluminum-doped zinc oxide thin film on the outermost layer of the distributed Bragg reflector. The distributed Bragg reflector used as the back electrode consists of two transparent conductive films with different refraction indexes, so that the resistance of the cell device connected in series is reduced, the collection of current carriers is facilitated, and the photoelectric conversion efficiency of the cell is high; and by adopting the back-reflecting electrode formed by combining the distributed Bragg reflector and the aluminum anode, the long wave band of the near infrared part with characteristic wavelength can be reflected to the inside of the crystalline silicon wafer to be reabsorbed through the two layers of conductive films with different refractive indexes, so that both the current and the photoelectric conversion efficiency of the cell are improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Alumina anode steel claw protection ring and method for producing the same

The invention discloses an aluminum oxide anode steel paw protection ring and the production process, wherein the ring is made from 20-100% of aluminum oxide and right amount of binder through mixing, forming and hardening by the conventional methods.

Owner:邹建明 +1

Aluminum and solid alkali peroxide galvanic cell

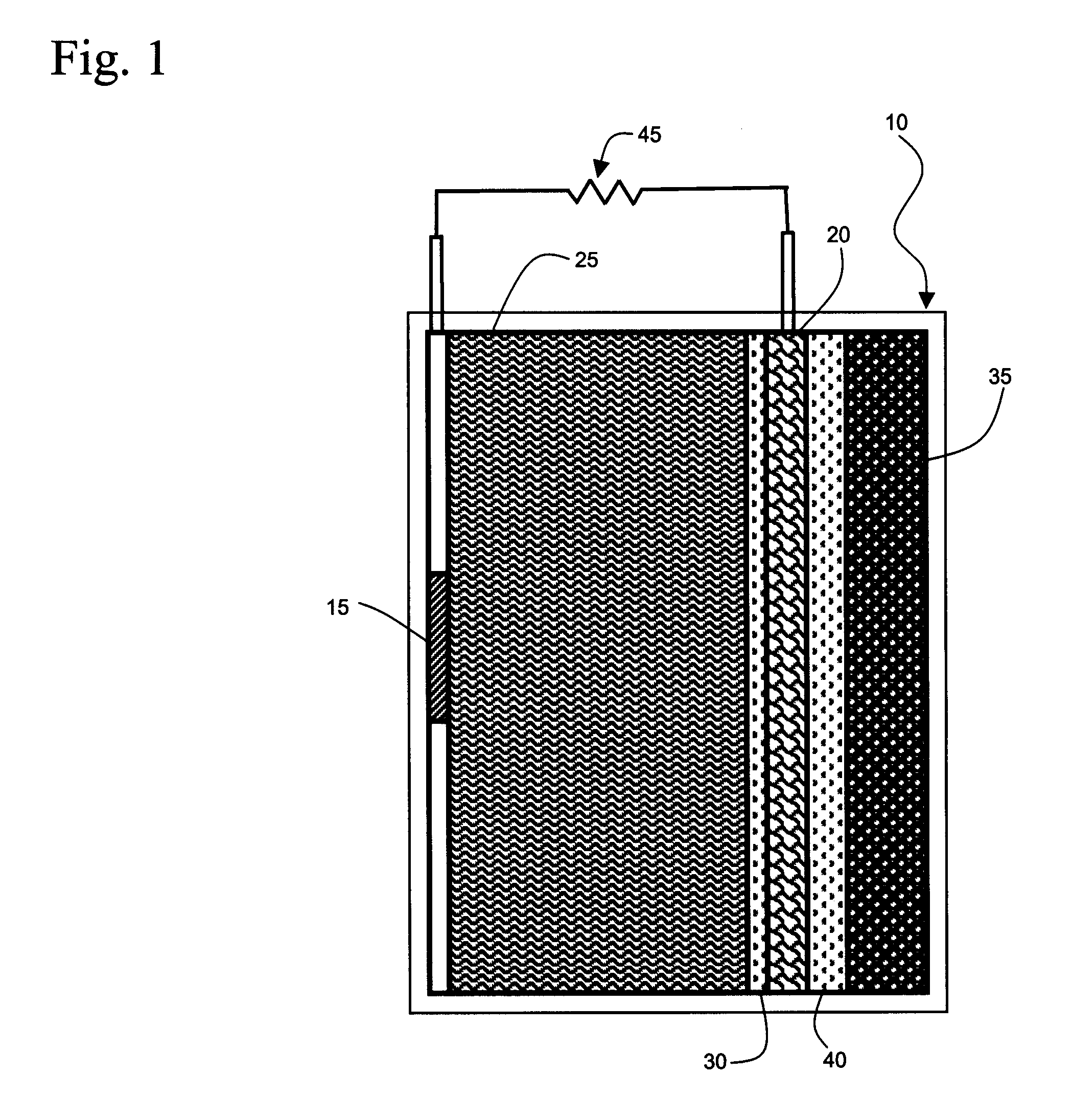

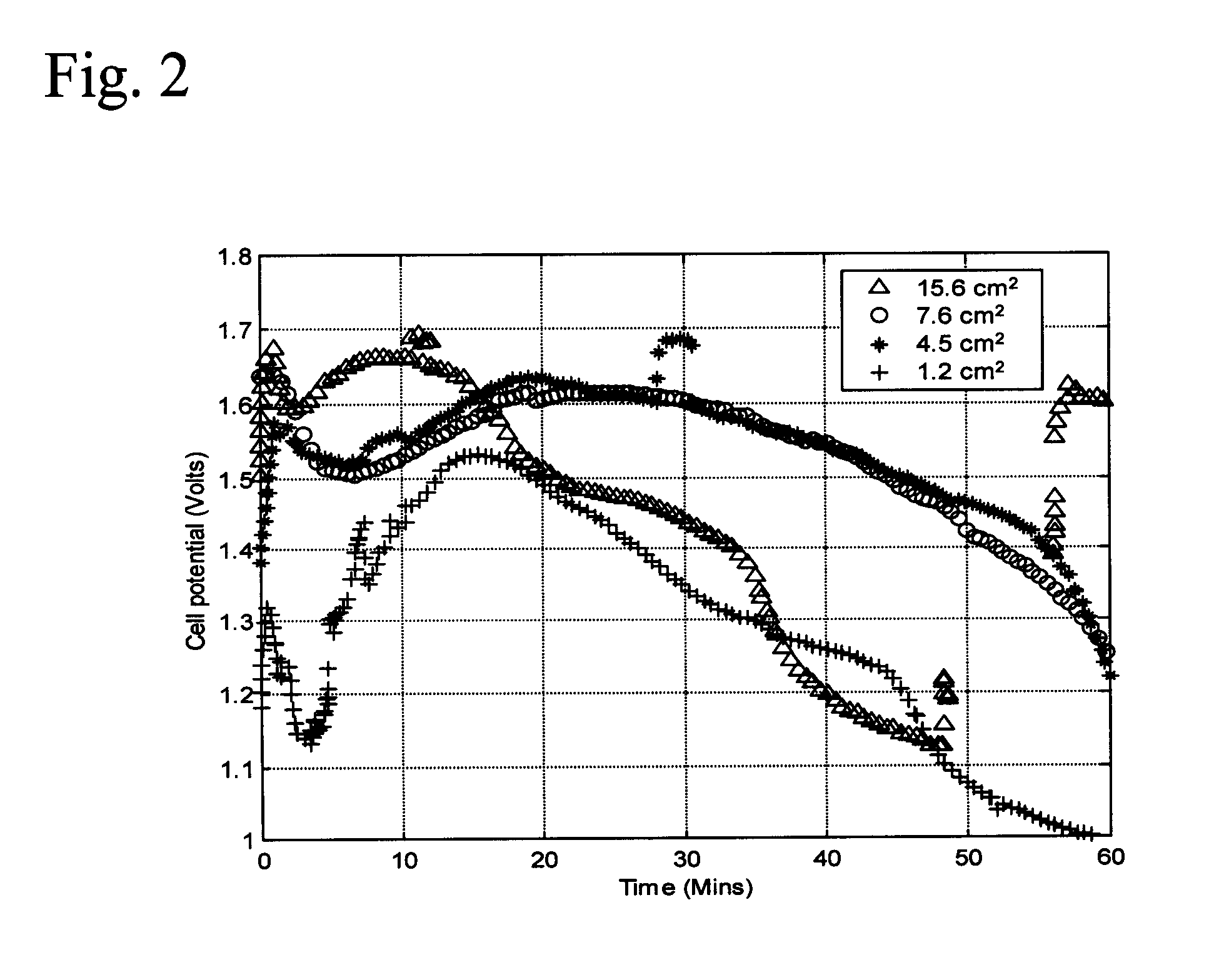

InactiveUS7855015B1Improvement in energy releasedFacilitated releaseSilver accumulatorsFuel and primary cellsElectrochemical responseGalvanic cell

The present invention provides a galvanic cell having an aluminum anode and a cathode compartment design suitable for carrying out the aqueous electrochemical reaction between solid aluminum metal and aqueous peroxide ions. The galvanic cell is activated when water, aqueous hydroxide solution, or an aqueous salt solution is added to the cell. This reaction releases a significant amount of electrochemical energy from a small size (mass or volume) cell. This cell reaction and design leads to an improvement in energy released over state-of-the-art aluminum / hydrogen peroxide galvanic cells.

Owner:UNIV OF SOUTH FLORIDA

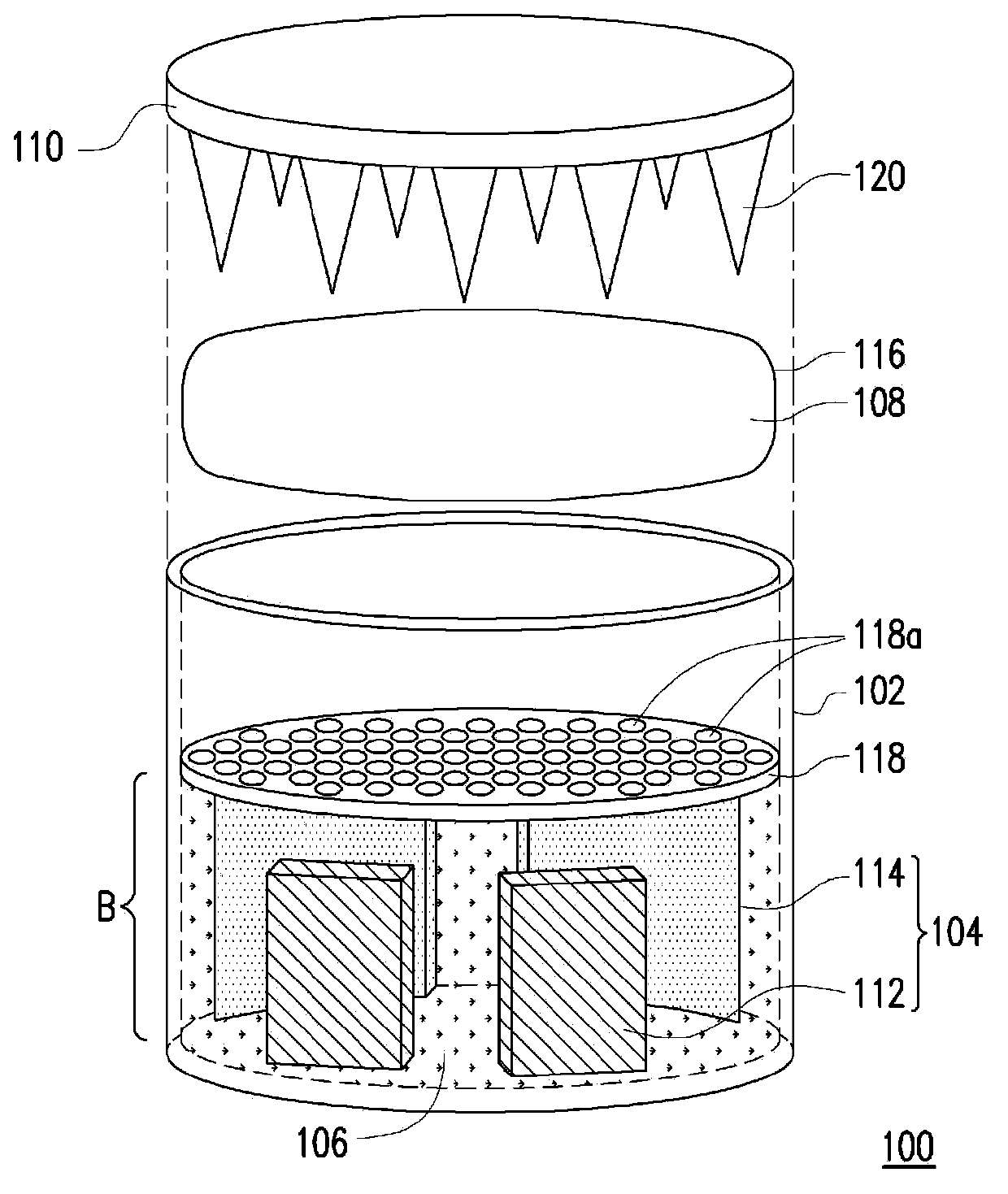

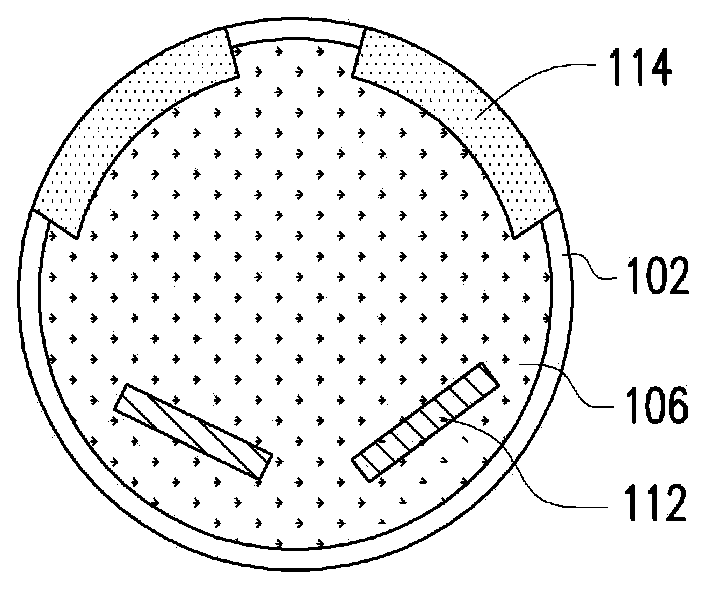

Primary aluminum air battery

ActiveCN103872349AFor long-term storageFuel and primary cellsDeferred-action cellsAluminum anodeAir cathode

The invention discloses a primary aluminum air battery, and the battery at least comprises a container, a battery pack, a water absorption material, an electrolyte, and an active-type starting device. The battery pack is put in the container, and consists of an aluminum anode and an air cathode. The water absorption material is put around the battery pack in the container. The electrolyte is put in the container, and does not contact with the battery pack. The active-type starting device is provided with a mechanism which enables the electrolyte to actively contact with the battery pack.

Owner:IND TECH RES INST

Embedded chip interconnecting and packaging method based on aluminum anodizing technology and structure

ActiveCN104157580ALow costHigh precisionSemiconductor/solid-state device detailsSolid-state devicesInterconnectionEmbedment

The present invention relates to an embedded chip interconnecting and packaging method based on an aluminum anodizing technology and a structure. The method comprises the steps of selecting a low-cost aluminum sheet as a chip embedded substrate, and making a double-face and porous alumina film by the aluminum anodizing technology; obtaining a cavity structure of an embedded chip by utilizing the aluminum chamber protection characteristic of a rectangular ring and the selective corrosion characteristic of the porous alumina film, and finishing the chip coplanar embedment; finishing the interconnection of the embedded chip by the technologies, such as a right side dielectric layer filling photoetching technology, a film metal layer wiring technology, etc. According to the present invention, the positioning precision is high, the size of an embedded cavity matches the chip very well, and the low-cost and coplanar embedment problem of the chips of different sizes is solved effectively. By designing the back side aluminum flux columns, the heat radiation problem of the chip can be solved very well. A dielectric layer having a low dielectric constant can be used as a surface protection film, an interlayer insulation film or a porous alumina depth groove filler of the chip, especially can solve the problems of flattening the surface of an aluminum substrate, improving the bending or warping of the substrate, and satisfies a film technology.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

High-temperature electrochemical cell and battery

A high-temperature electrochemical cell for use in applications such as downhole drilling comprises an anode, cathode and an electrolyte. The anode preferably includes either stabilized lithium / silicon intermetallic and / or lithium-tin / aluminum anode on a nickel-plated, copper substrate. The cathode contains sulfur and the electrolyte includes at least a high-boiling point glyme and lithium salt. The separator comprises one or more metal oxides with a polymer matrix, and is preferably flexible. A battery including one or more of the electrochemical cells has a high-temperature casing such as stainless steel.

Owner:MILLER MELVIN N +2

Aluminum air battery anode material, preparing method thereof and aluminum air battery

ActiveCN110484788AEasily brokenUniform dischargeFuel and primary cellsNegative electrodesAluminum anodeSurface oxidation

The invention relates to an aluminum air battery anode material, a preparing method thereof and an aluminum air battery, and belongs to the technical field of metal air batteries. The aluminum air battery anode material comprises 0.15 to 2.10% of Mg, 0.01 to 0.1% of Ga, 0.01 to 1.10% of Sn, 0.01 to 0.10% of In, 0.01 to 0.50% of Bi, 0.01 to 0.30% of Ti and the balance Al. Sn, Ga and In in the alloycan form low-temperature, in the discharge process, the eutectoid can be attached in a surface oxidation film of an aluminum anode plate to form holes, surface oxidation film fracturing is promoted,activation mass points are formed, current stable output is ensured, through the heat treatment and rolling process, anode plate components and a grain structure are uniform, aluminum air battery anode plate reaction uniformity is ensured, in the reaction process, the aluminum plate surface is not broken or opened, current stable output is achieved, and the anode use rate can be effectively improved.

Owner:宁波烯铝新能源有限公司

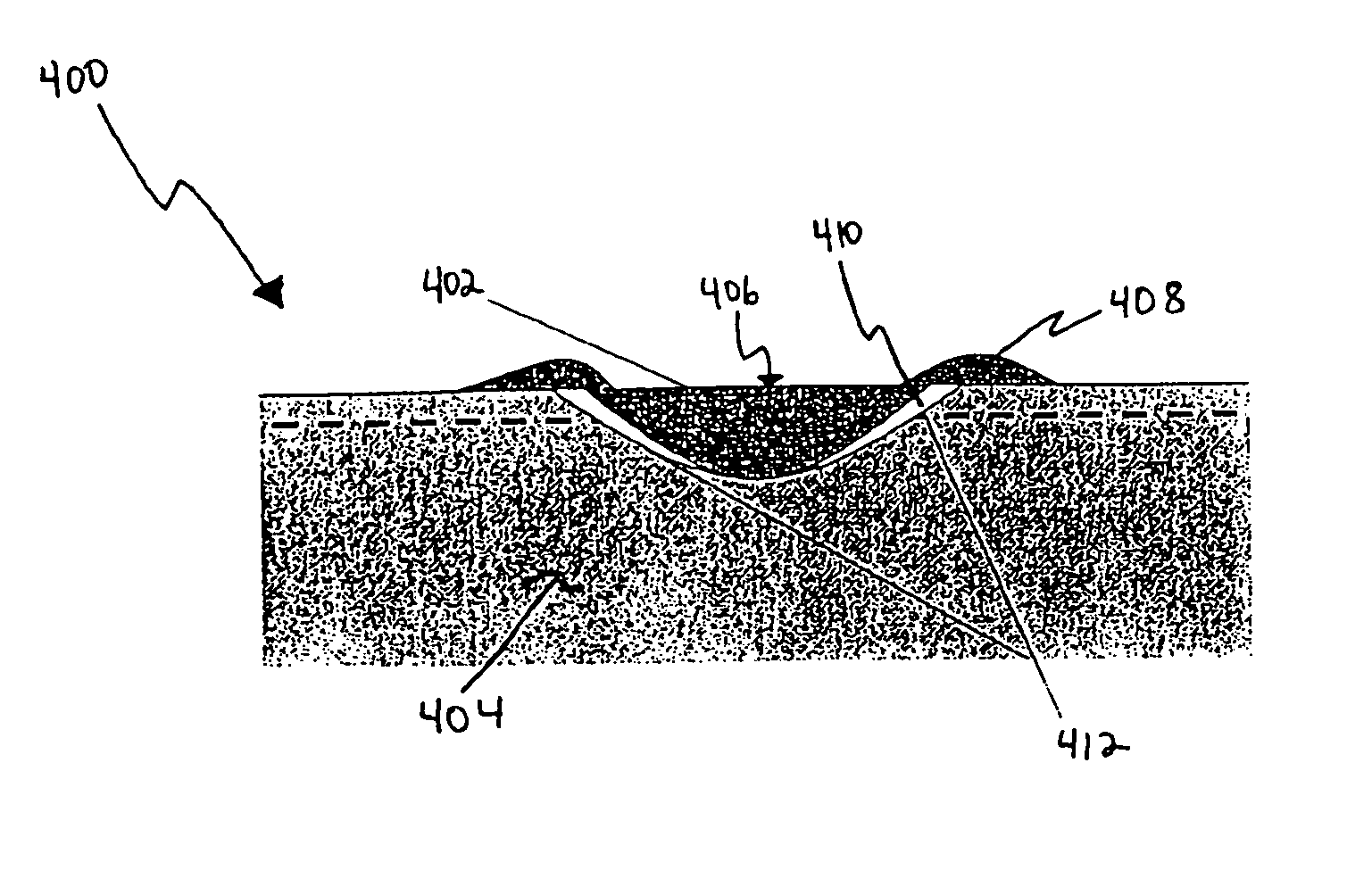

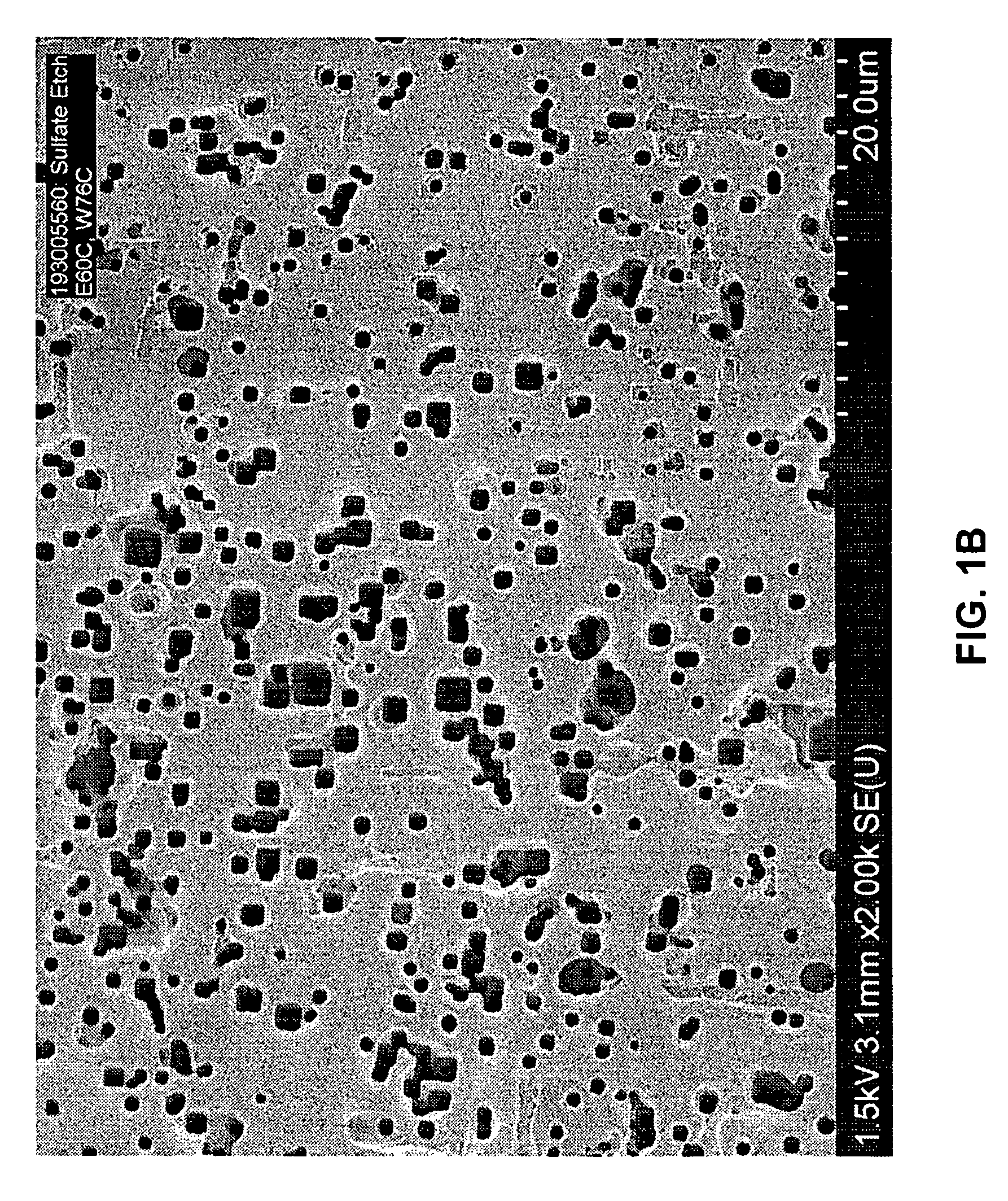

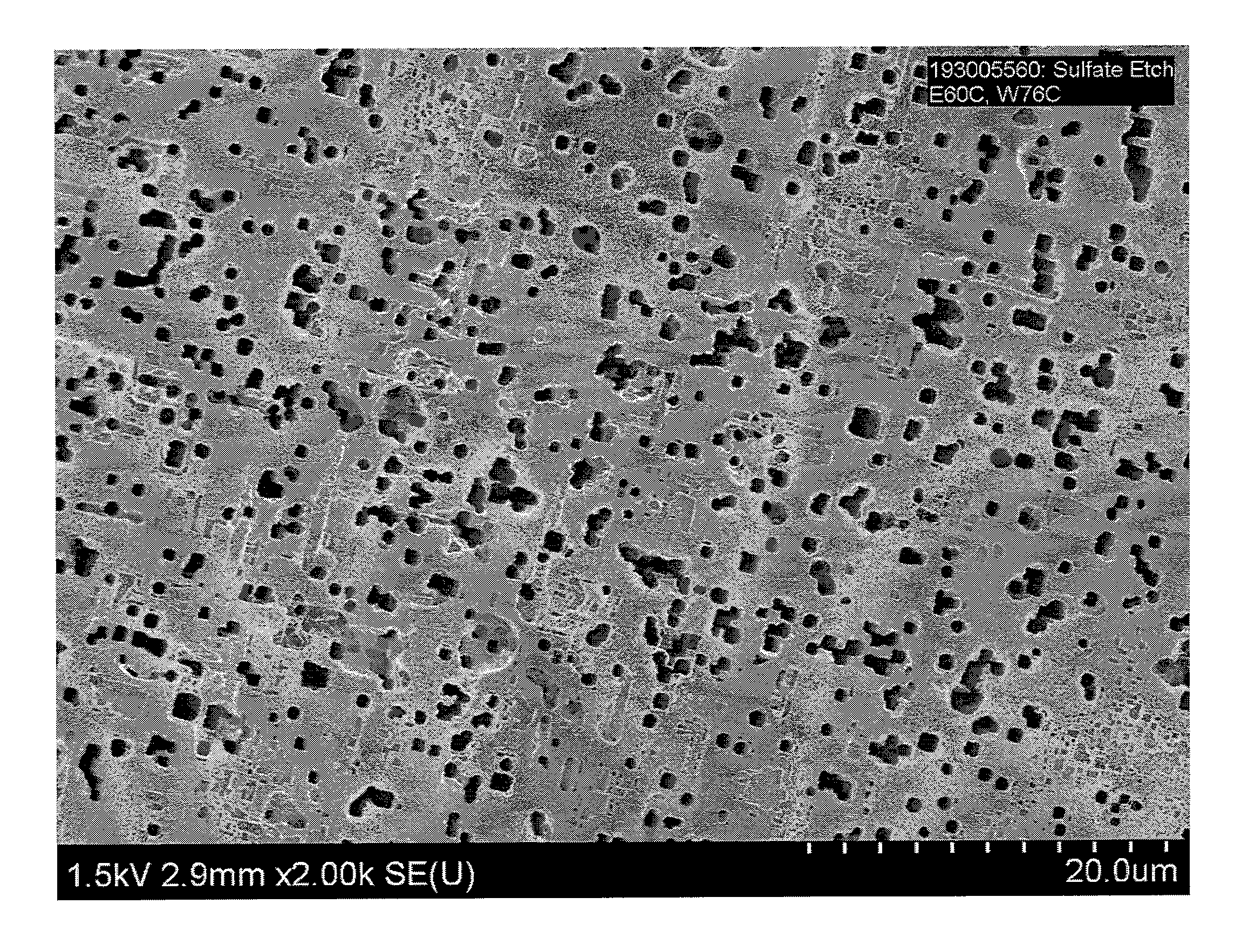

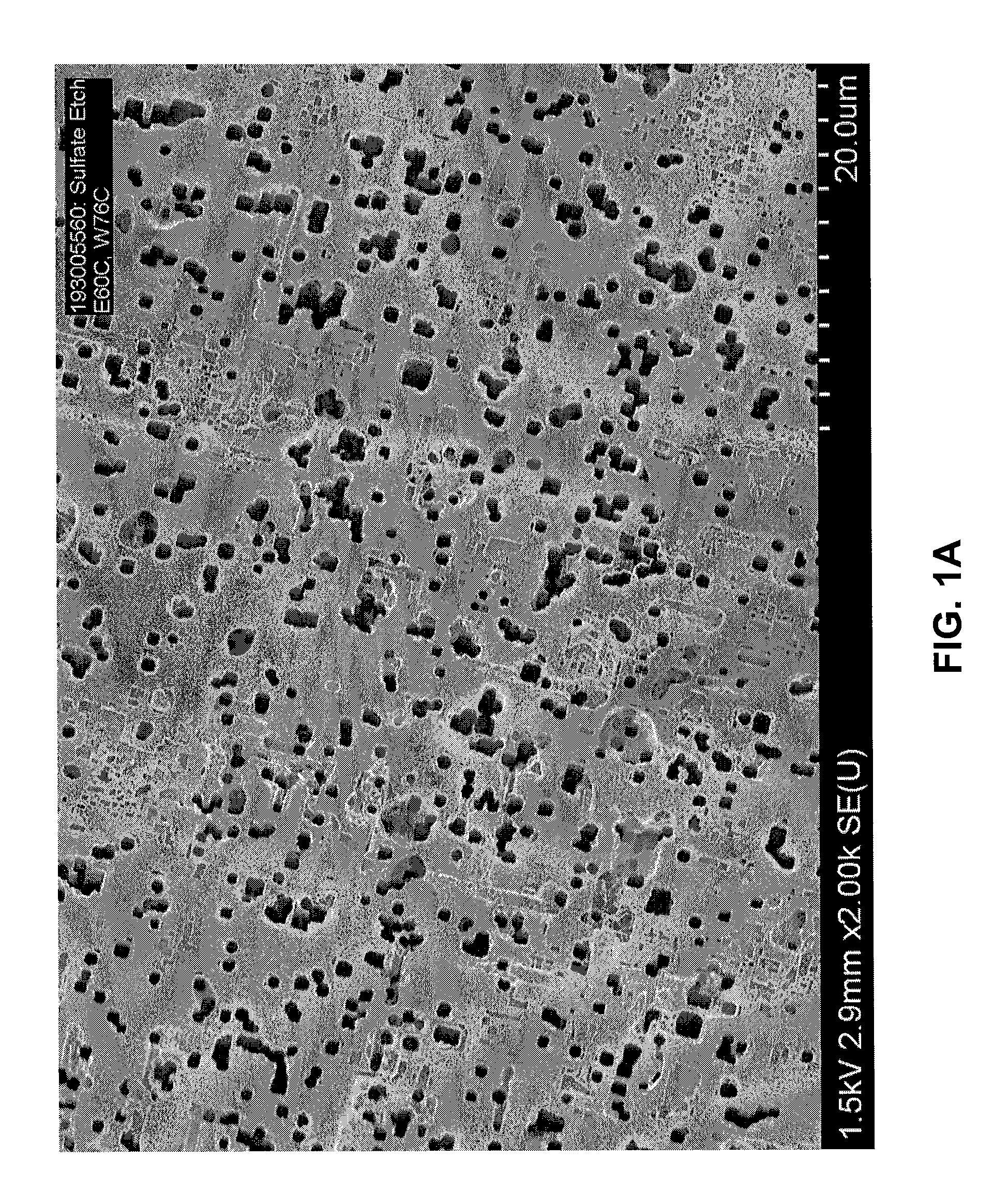

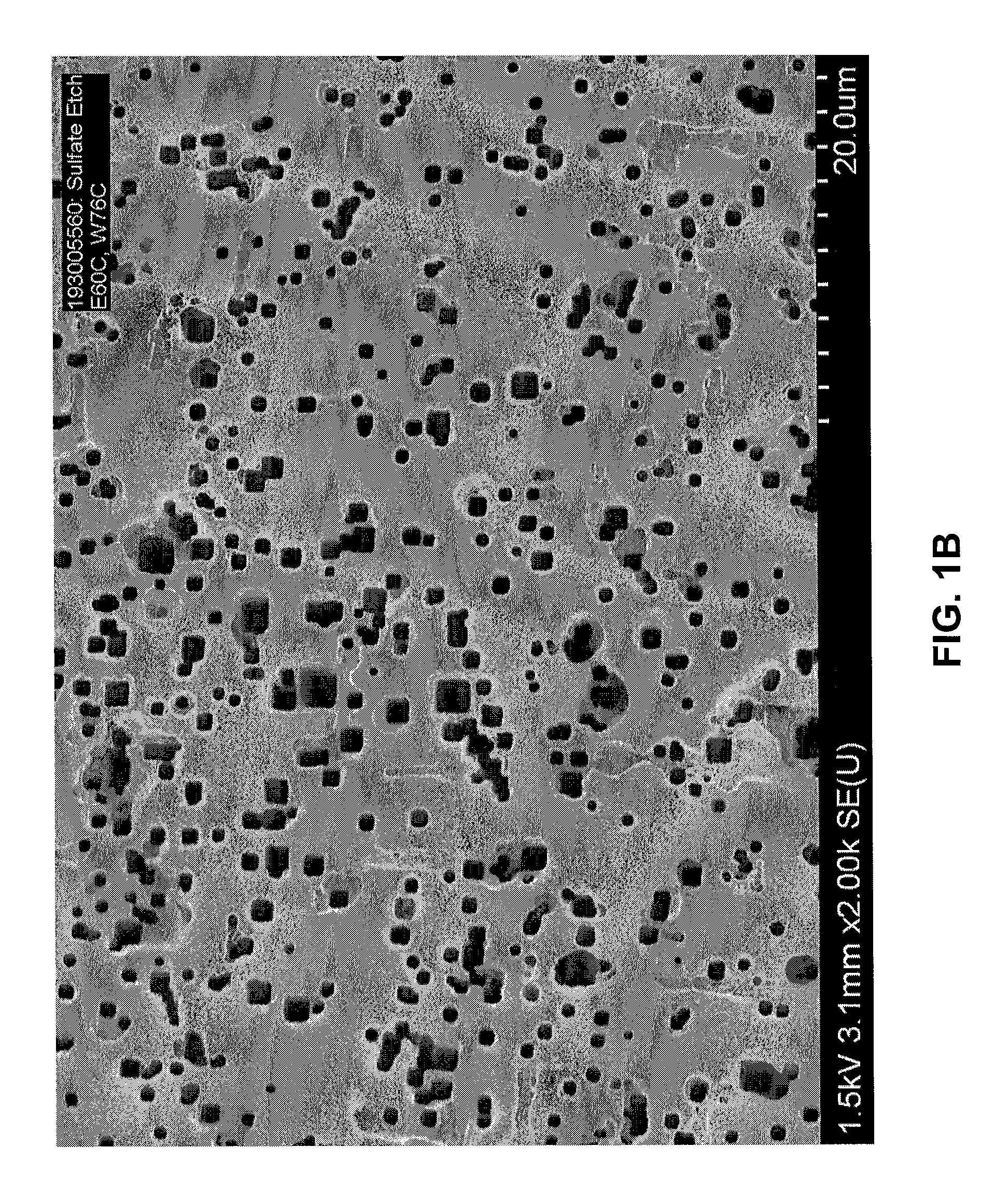

Process for producing high etch gains for electrolytic capacitor manufacturing

ActiveUS7578924B1Easy maintenanceHigh yieldElectrolysis componentsConductive material chemical/electrolytical removalAluminum anodeElectrolysis

Anode foil, preferably aluminum anode foil, is etched using a process of treating the foil in an electrolyte bath composition comprising a sulfate and a halide, such as sodium chloride. The anode foil is etched in the electrolyte bath composition by passing a charge through the bath. The etched anode foil is suitable for use in an electrolytic capacitor.

Owner:PACESETTER INC

Process for producing high etch gains for electrolytic capacitor manufacturing

InactiveUS20090273885A1Electrolysis componentsLiquid electrolytic capacitorsAluminum anodeElectrolysis

Anode foil, preferably aluminum anode foil, is etched using a process of treating the foil in an electrolyte bath composition comprising a sulfate and a halide, such as sodium chloride. The anode foil is etched in the electrolyte bath composition by passing a charge through the bath. The etched anode foil is suitable for use in an electrolytic capacitor.

Owner:PACESETTER INC

Electrolytic capacitor

InactiveCN109326447AInhibition of dissolutionLower impedanceLiquid electrolytic capacitorsCapacitanceAluminum anode

The invention relates to the field of capacitors, and provides an electrolytic capacitor for prolonging service life of capacitors. The electrolytic capacitor comprises an aluminum foil anode, an aluminum foil cathode, a partition and electrolyte; surfaces of the aluminum foil anode and the aluminum foil cathode are covered with alumina membrane; the partition is arranged in the electrolyte between the anode and the cathode; the electrolyte comprises, by mass, 65-70 parts of ethanediol, 1-6 parts of modifiers, 8-10 parts of ammonium sebacate, 1-2 parts of ammonium dodecanedioate, 5-8 parts ofpolyethylene glycol, and 2-4 parts of additives. The anode or cathode made of the aluminum foil can suppress dissolving of aluminium effectively, reduce impedance of the capacitor, and prolong servicelife of the capacitor; combination of the aluminum anode and aluminium cathode and the electrolyte can prolong the service life of the capacitor further.

Owner:广州金立电子有限公司

Antimony-Based Anode on Aluminum Current Collector

ActiveUS20150349338A1Improve adhesionImprove compatibilityElectrode thermal treatmentIron cyanidesGalliumAntimony

An electrochemical battery is provided with an aluminum anode current collector and an antimony (Sb)-based electrochemically active material overlying the aluminum current collector. The Sb-based electrochemically active material may be pure antimony, Sb with other metal elements, or Sb with non-metal elements. For example, the Sb-based electrochemically active material may be one of the following: Sb binary or ternary alloys of sodium, silicon, tin, germanium, bismuth, selenium, tellurium, thallium, aluminum, gold, cadmium, mercury, cesium, gallium, titanium, lead, carbon, and combinations thereof. The aluminum current collector may additionally include a material such as magnesium, iron, nickel, titanium, and combinations thereof. In one aspect, the anode further composed of a coating interposed between the aluminum current collector and the Sb-based electrochemically active material. This coating may be a non-corrodible metal or a carbonaceous material. The cathode is may be composed of a number of different active materials including sodium-based Prussian Blue analogues.

Owner:SHARP KK

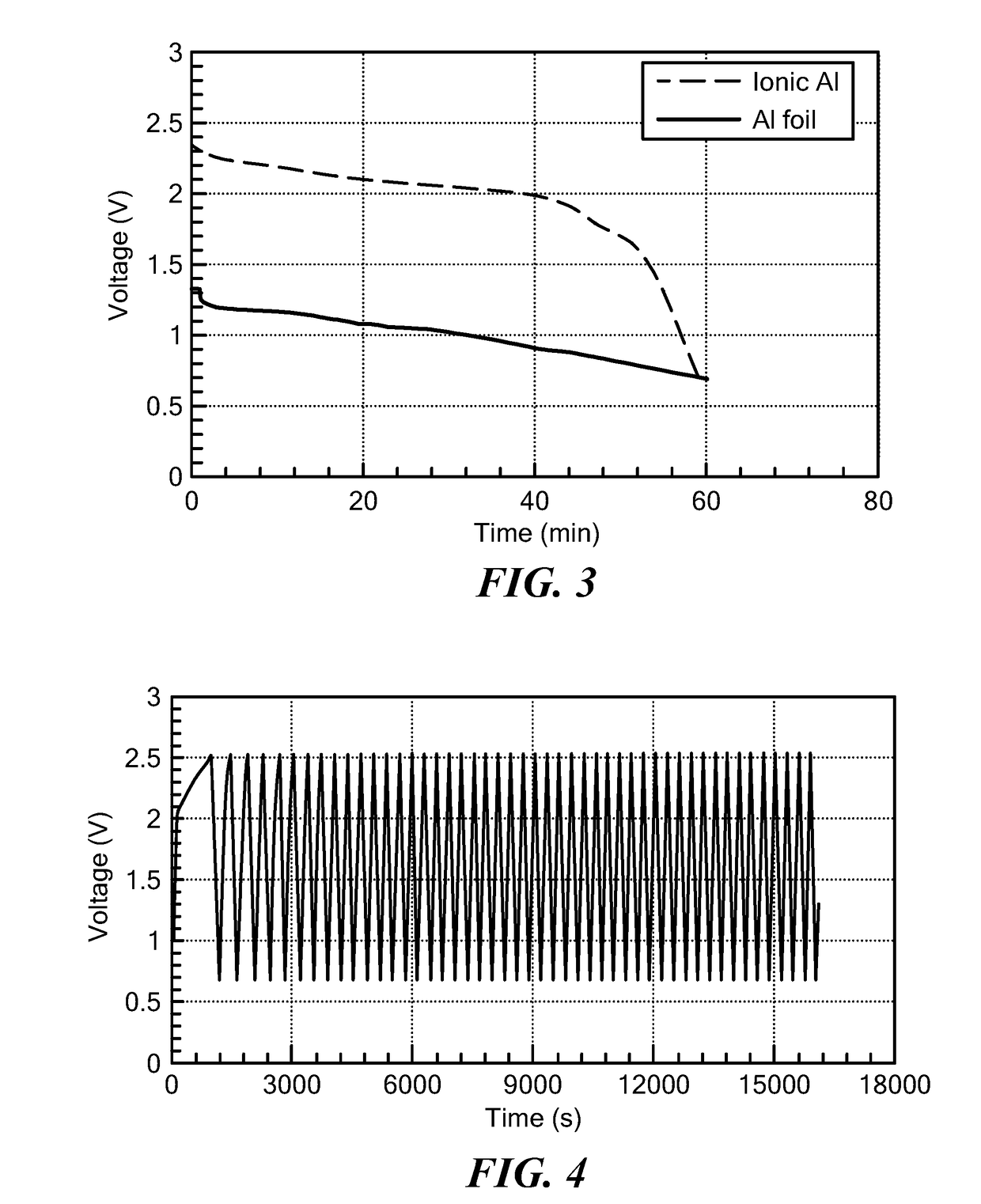

Battery having aluminum anode and solid polymer electrolyte

ActiveUS20180175372A1Large capacitySolid electrolytesAlkaline accumulatorsPolymer electrolytesAluminum anode

A battery, having polyvalent aluminum metal as the electrochemically active anode material and also including a solid ionically conducting polymer material.

Owner:IONIC MATERIALS INC

Section aluminum anode oxide film copper salt electrolytic coloring production process

ActiveCN109056027APrevent fadingChange structureSurface reaction electrolytic coatingElectrolysisPyrophosphate

The invention discloses a section aluminum anode oxide film copper salt electrolytic coloring production process. The section aluminum anode oxide film copper salt electrolytic coloring production process comprises the following treatment steps of oil removing, washing, washing, anodizing, washing, washing, an activation working procedure, an electrolytic coloring, washing, washing, hole sealing and a washing treatment working procedure and is characterized in that an electrolytic coloring agent in the electrolytic coloring step comprises, by weight percent, 2%-8% of copper sulfate, 20%-40% ofmagnesium sulfate, 4%-6% of sulfuric acid, 1%-3% of a dispersing agent, 5%-10% of pyrophosphate, 3%-7% of EDTA and the balance water, a bath solution in an electrolytic coloring trough is composed of30g / L-50g / L of the electrolytic coloring agent, 18 g / L-25 g / L of free sulphuric acid, 5g / L-25 g / L of copper sulfate pentahydrate and the balance water, and in the electrolytic coloring treatment step, the temperature of the bath solution in the electrolytic coloring trough is 20 DEG C-22 DEG C, the voltage is 16v-19v, and the coloring time is 0.5min-0.8min. A coloring film layer color system of section aluminum prepared through the coloring production process is complete, uniform, stable and good in quality, a color fading problem does not exist in the using process, relatively high corrosionresistance is achieved, and volume production can be formed.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

Aluminum anode material for seawater power battery

InactiveCN101814595AImprove electrochemical activityLittle electrochemical activityPrimary cell electrodesSeawaterTin

The invention discloses an aluminum anode material for a seawater power battery, which adopts aluminum as a base body, and comprises the following components in percentage by weight: 0.01 to 1.0 percent of activating element mercury, 0.05 to 2.0 percent of gallium, 0.05 to 2.0 percent of magnesium, 0.01 to 1.0 percent of tin and 0.01 to 1.0 percent of zinc. By designing the alloy composition and researching the electrochemical performance and the element activating mechanism, the alloy elements and compositions which can reduce the passivation and polarization of the aluminum anode and can improve the electrochemical activity and corrosion resistance of the aluminum anode material are selected, and the aluminum anode material for the large-power seawater-activating power battery with the advantages of short activating time, high current efficiency, stable discharging, less hydrogen evolution quantity, long service life and the like is prepared.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com