Aluminum air battery anode material, preparing method thereof and aluminum air battery

A technology for aluminum-air batteries and anode materials, applied in battery electrodes, fuel cell half-cells, primary battery-type half-cells, negative electrodes, etc., can solve environmental pollution, large pieces of aluminum are difficult to clean, and aluminum anode plates are prone to occurrence Breakage and other problems, achieve uniform distribution, help to stabilize output, and solve the effect of component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the second aspect, the embodiment of the present application proposes a method for preparing the above-mentioned anode material for an aluminum-air battery, including:

[0037] The batching method adopted in the embodiment of the present application is: Mg, Ga, Bi, In and Al are added in the form of pure substances, Sn is added in the form of Al-50Sn master alloy, Ti is added in the form of Al-10Ti master alloy, and the burning loss of Mg is as follows: 5% calculation, the above metal purity requirement is above 99.95%. In this application, Sn is added in the form of Al-50Sn master alloy, which effectively avoids the specific gravity segregation in the casting process, and the uniformity of composition also plays a vital role in the stability of the discharge current.

[0038] Casting. Put the aluminum block into the graphite crucible and heat it with an intermediate frequency furnace. When the temperature rises to 690°C-710°C, add the Ai-10Ti alloy and stir slowly ev...

Embodiment 1

[0048] This embodiment provides an anode material for an aluminum-air battery and a preparation method thereof, including:

[0049] 1. According to the following alloy composition (mass percentage): Mg: 0.50%, Ga: 0.07%, Sn: 0.03%, In: 0.02%, Bi: 0.16%, Ti: 0.05%, and the rest is Al;

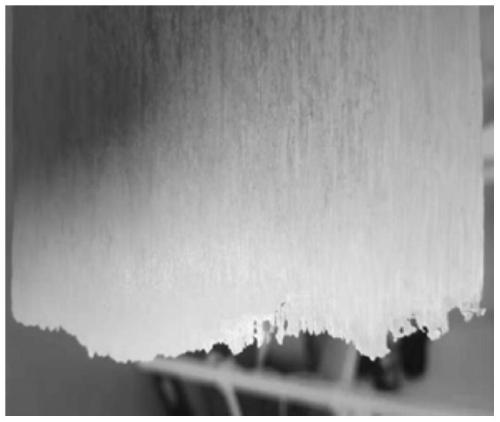

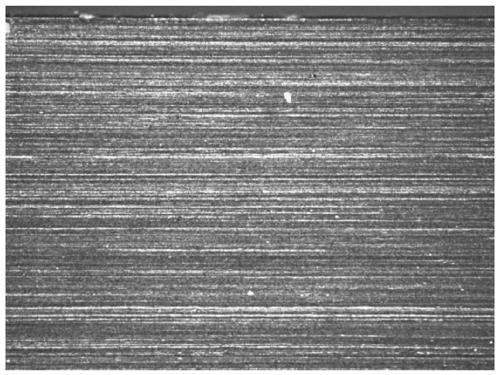

[0050] 2. Put the aluminum block into the graphite crucible and heat it with an intermediate frequency furnace. When the temperature rises to 690°C, add the Ai-Ti alloy and stir evenly. When the temperature rises to 710°C, add Mg, and the temperature drops to 700°C Add Al-Sn, Bi, Ga and In metals at the same time, and slowly introduce argon inert gas into the melt, keep it at 710-720°C for 5 minutes to remove the scum on the surface of the melt, and cast it in a water-cooled copper mold. Cool naturally to room temperature to obtain ingots, and the tool materials such as stirring and slag removal used above are titanium alloys;

[0051] 3. Place the ingot in a suspension furnace at 540°C for 10 ...

Embodiment 2

[0056] This embodiment provides an anode material for an aluminum-air battery and a preparation method thereof, including:

[0057] 1. According to the following alloy composition (mass percentage): Mg: 0.65%, Ga: 0.05%, Sn: 0.01%, In: 0.04%, Bi: 0.10%, Ti: 0.05%, and the rest is Al;

[0058] 2. Put the aluminum block into the graphite crucible and heat it with an intermediate frequency furnace. When the temperature rises to 700°C, add the Ai-Ti alloy and stir evenly. When the temperature rises to 710°C, add Mg, and the temperature drops to 695°C Add Al-Sn, Bi, Ga and In metals at the same time, and slowly introduce argon inert gas into the melt, keep it at 710-720°C for 5 minutes to remove the scum on the surface of the melt, and cast it in a water-cooled copper mold. Cool naturally to room temperature to obtain ingots, and the tool materials such as stirring and slag removal used above are titanium alloys;

[0059] 3. Place the ingot in a suspension furnace at 540°C for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com