Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1319 results about "Aluminum metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum is rarely used in its pure, unalloyed state. The most common metals alloyed with Aluminum are Silicon, Magnesium, Copper, Zinc, Nickel, Manganese and Tin. Among the less common are two Aluminum Alloys that contain about 1% Silver.

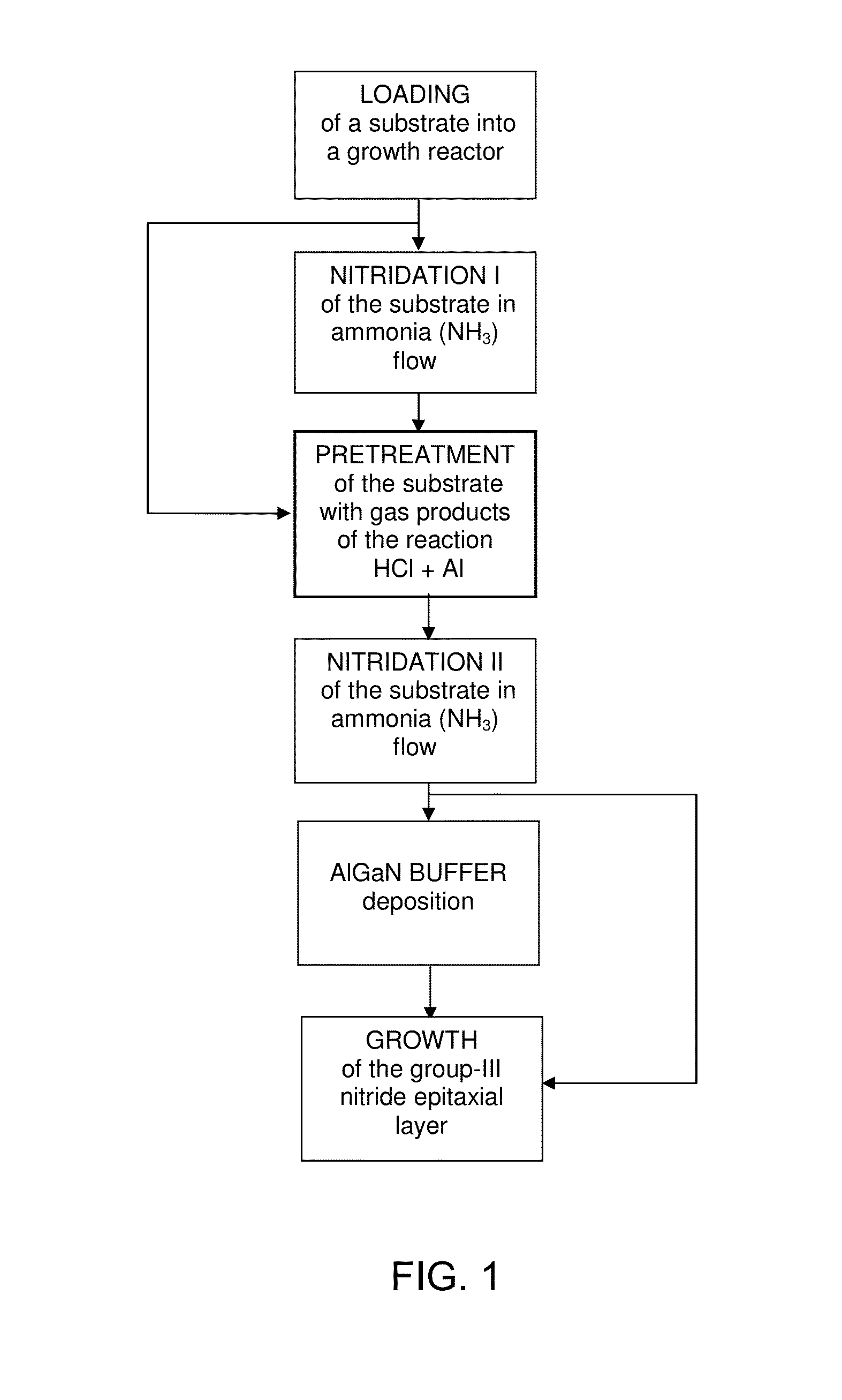

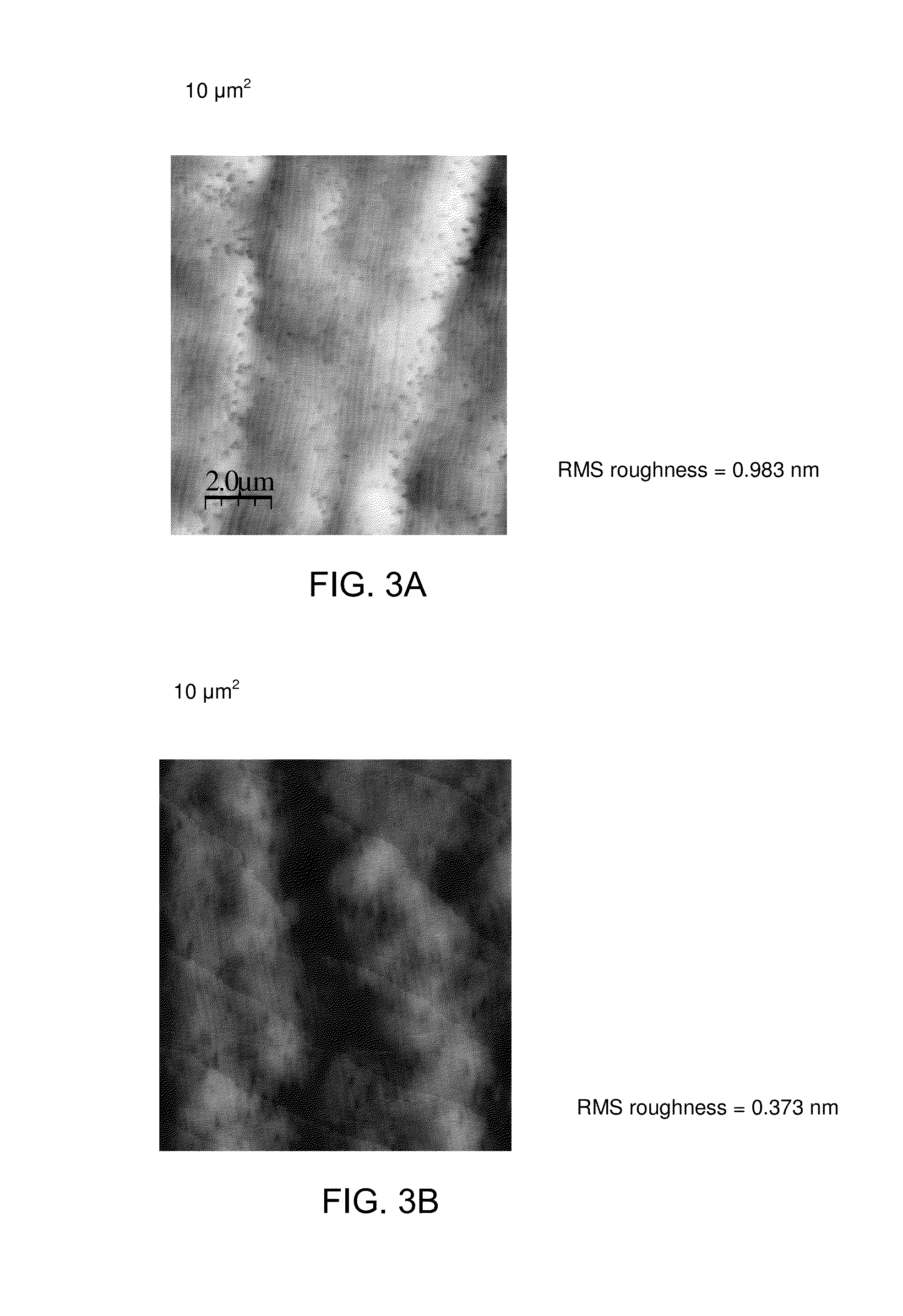

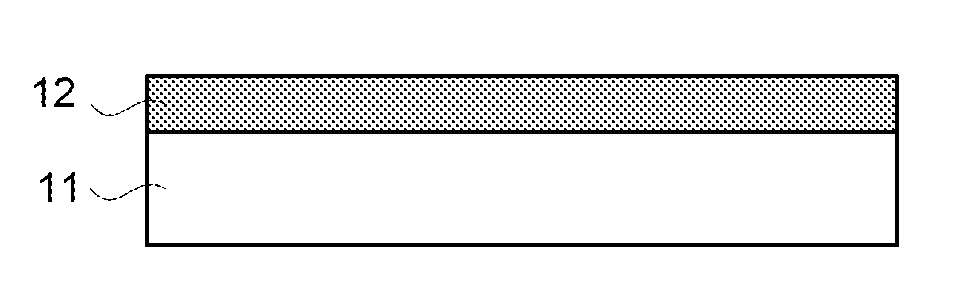

Method for Substrate Pretreatment To Achieve High-Quality III-Nitride Epitaxy

The present invention relates to a method for producing a modified surface of a substrate that stimulates the growth of epitaxial layers of group-III nitride semiconductors with substantially improved structural perfection and surface flatness. The modification is conducted outside or inside a growth reactor by exposing the substrate to a gas-product of the reaction between hydrogen chloride (HCl) and aluminum metal (Al). As a single-step or an essential part of the multi-step pretreatment procedure, the modification gains in coherent coordination between the substrate and group-III nitride epitaxial structure to be deposited. Along with epilayer, total epitaxial structure may include buffer inter-layer to accomplish precise substrate-epilayer coordination. While this modification is a powerful tool to make high-quality group-III nitride epitaxial layers attainable even on foreign substrates having polar, semipolar and nonpolar orientation, it remains gentle enough to keep the surface of the epilayer extremely smooth. Various embodiments are disclosed.

Owner:OSTENDO TECH INC

Aluminum Inks and Methods of Making the Same, Methods for Depositing Aluminum Inks, and Films Formed by Printing and/or Depositing an Aluminum Ink

InactiveUS20100022078A1Reduce minimize numberReadily apparentRadiation applicationsSolid-state devicesOrganic solventAluminum metal

Aluminum metal ink compositions, methods of forming such compositions, and methods of forming aluminum metal layers and / or patterns are disclosed. The ink composition includes an aluminum metal precursor and an organic solvent. Conductive structures may be made using such ink compositions by printing or coating the aluminum precursor ink on a substrate (decomposing the aluminum metal precursors in the ink) and curing the composition. The present aluminum precursor inks provide aluminum films having high conductivity, and reduce the number of inks and printing steps needed to fabricate printed, integrated circuits.

Owner:KOVIO

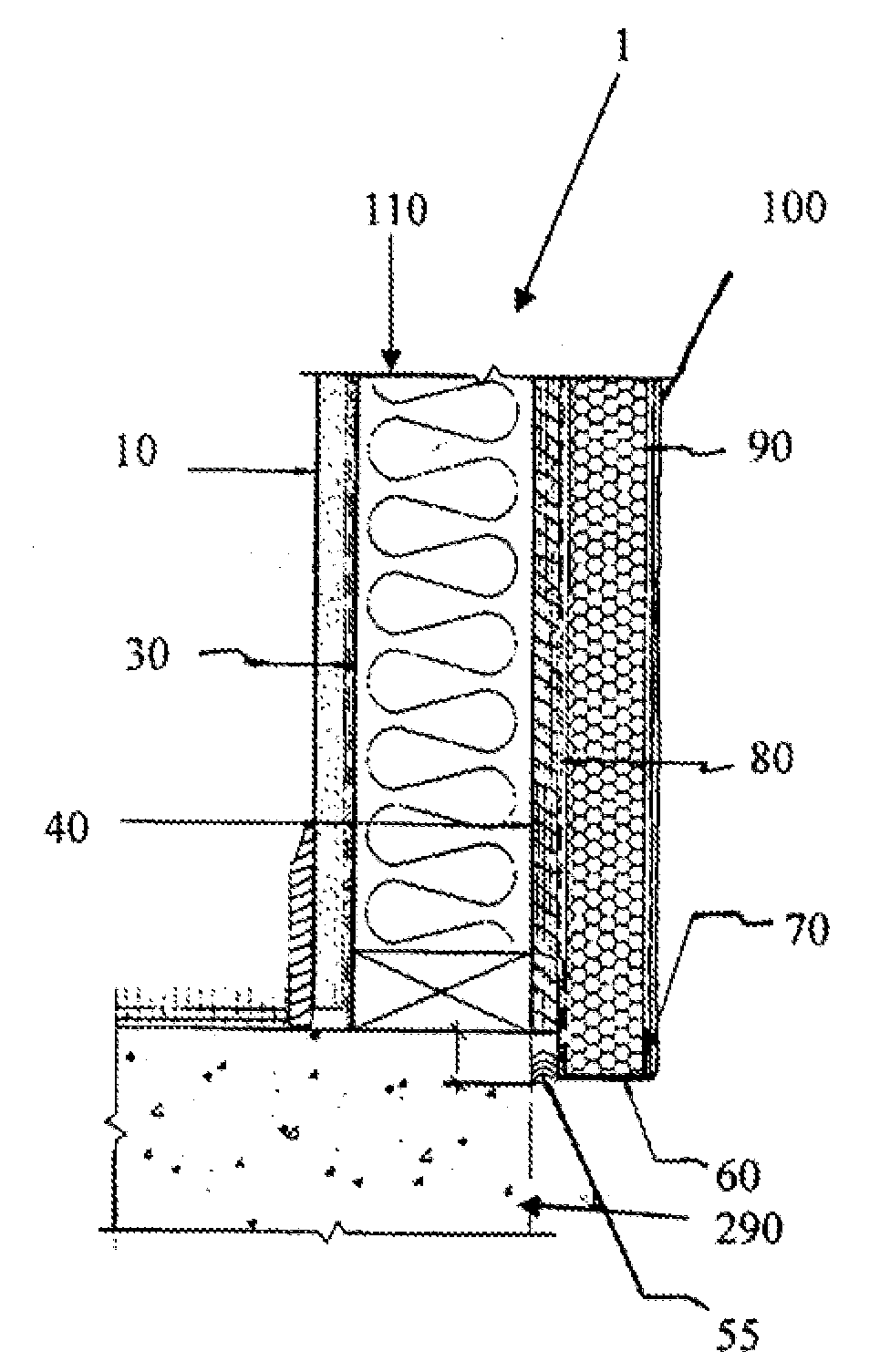

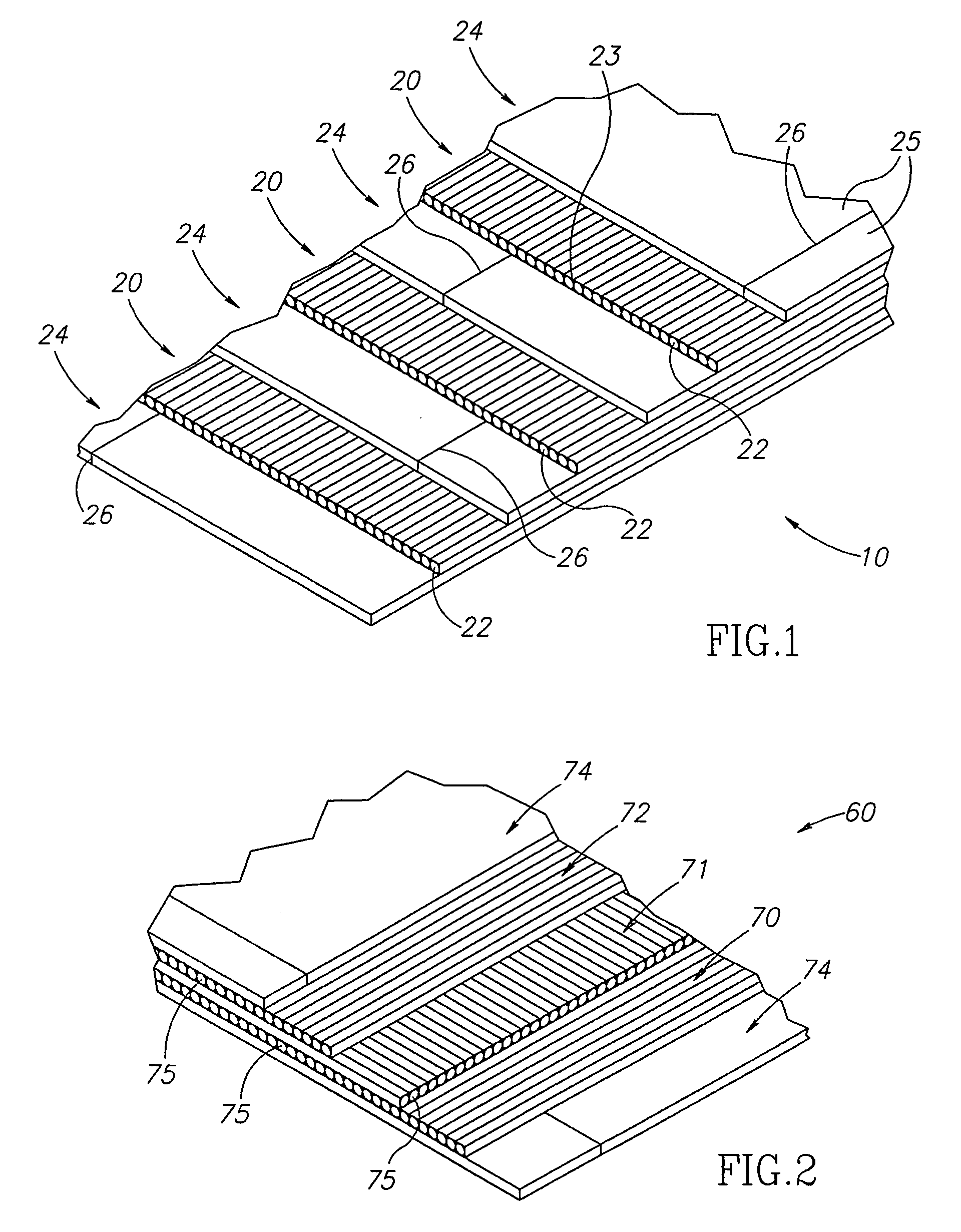

Gypsum wood fiber structural insulated panel arrangement

InactiveUS20080245007A1Low costHigh tensile strengthBuilding componentsMesh reinforcementCellulose fiber

A generally planar, structural insulated panel for building construction includes a pair of outer facings disposed on opposed surfaces of a plastic foam core. Both of the outer facings are gypsum cellulose fiber board such as gypsum wood fiber board. Disposed on the exterior surface of the gypsum wood fiber board on the exterior surface and between another expanded polystyrene insulation panel is a weather resistant barrier that is fastened to the gypsum wood fiber board. The exterior surface of the second insulation panel is fastened to the gypsum wood fiber board by mechanical fasteners. The insulation panels are then coated with a basecoat which has an embedded mesh reinforcement and then a finishing coat is applied to the base coating. Vinyl or aluminum metal siding can be fastened to the structural assembly by G screw fasteners or other mechanical fasteners.

Owner:UNITED STATES GYPSUM CO

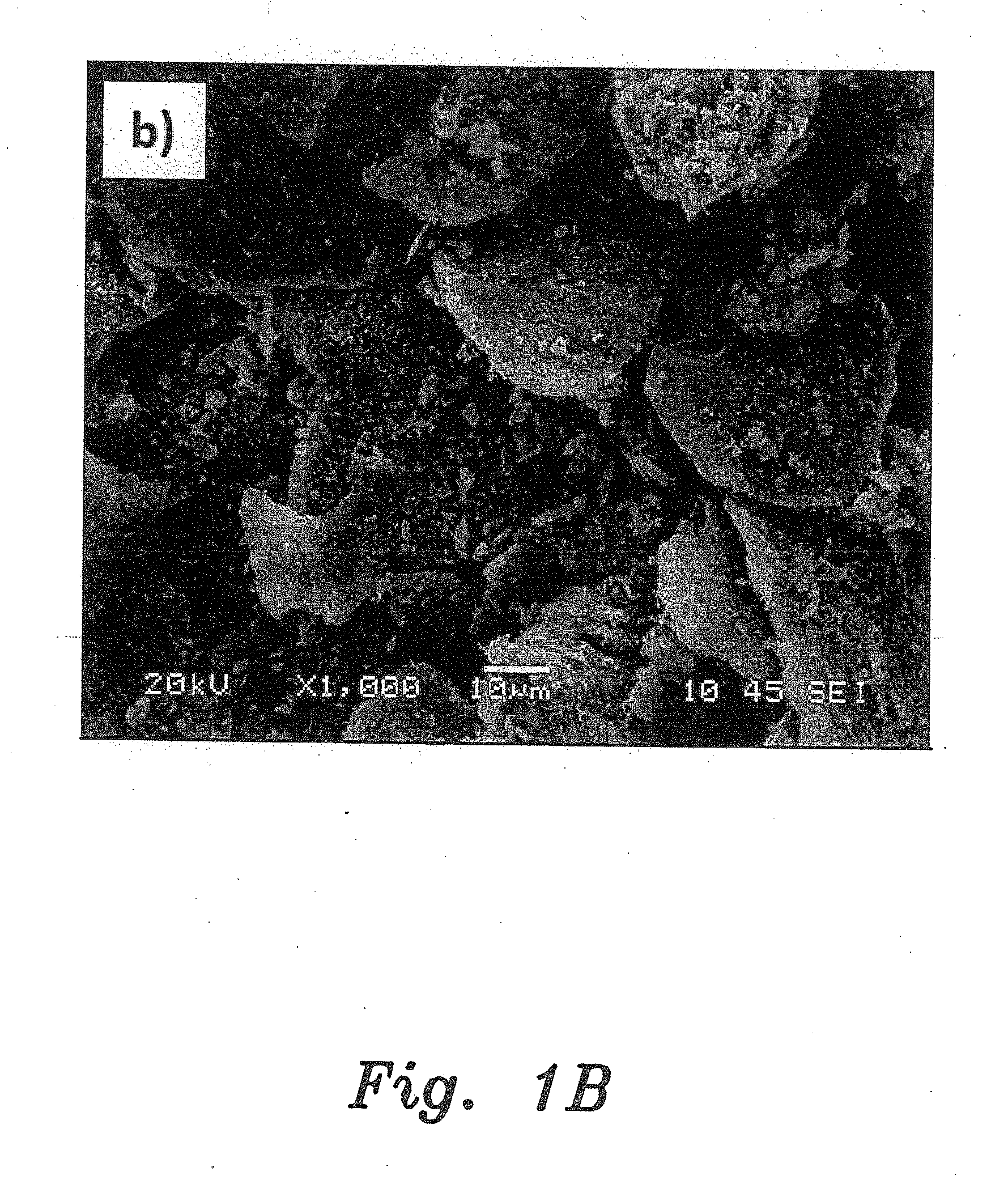

Titanium alloy based dispersion-strengthened composites

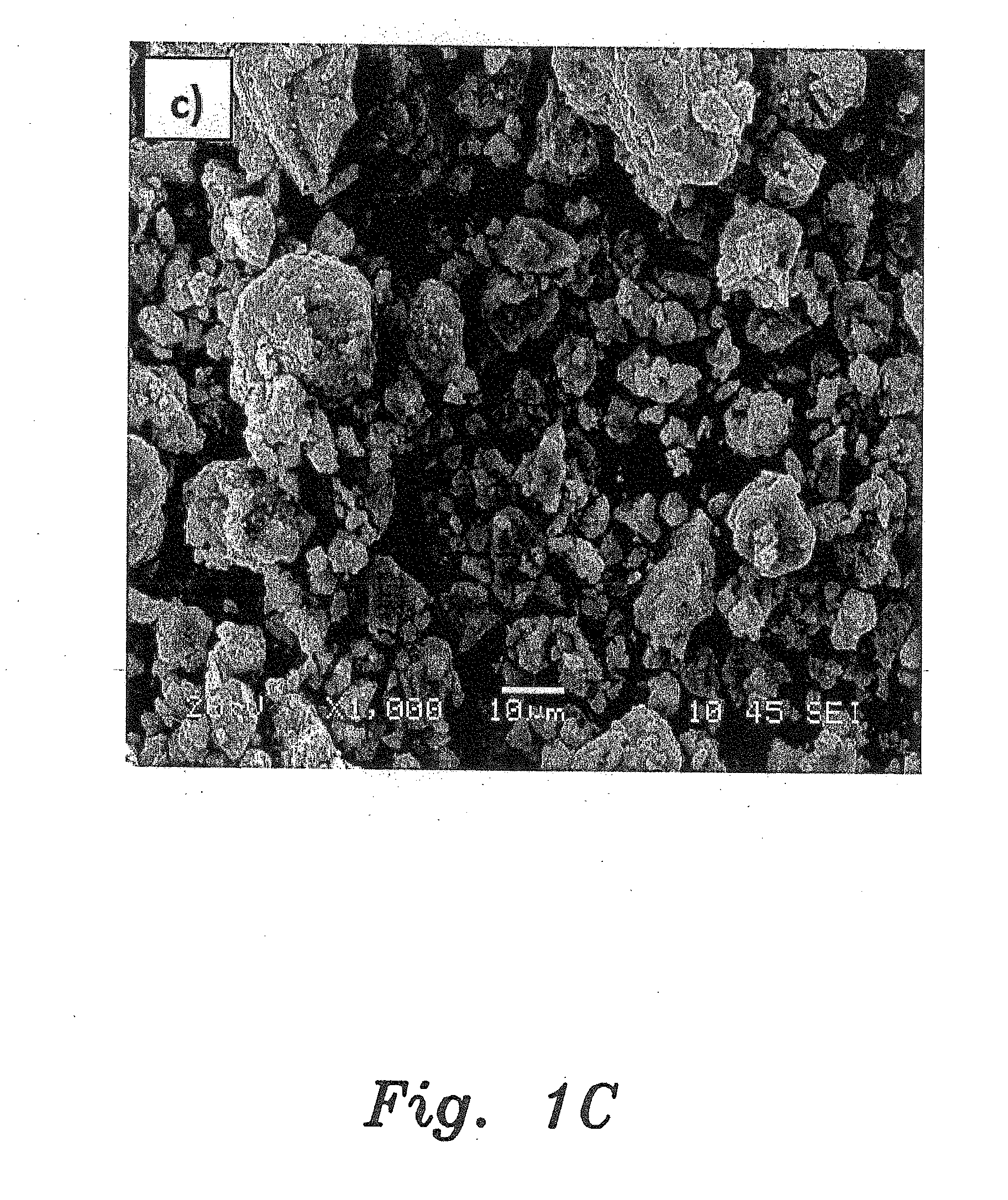

Titanium based metal matrix composites reinforced with ceramic particulate are well known, based on a blend of titanium alloy powders with ceramic powders, e.g., aluminum oxide powders, utilizing a low energy ball milling process, followed by cold compacting and sintering to produce an appropriate composite. This prior art process is disadvantaged from the point of view that there are virtually no particles in the blend below the micrometer size range, which lack has a deleterious effect on the subsequent processing of the composite. This problem has been overcome by utilizing dry high energy intensive milling in the process, which has the effect of providing the necessary number of small particles below the micrometer size range as well as enhancing the reactivity of different particles with one another. In order to produce a titanium base alloy alumina metal matrix composite, titanium dioxide powder is blended with aluminum powder and subjected to dry high energy intensive milling until the separate particle phases achieve a size of 500 nanometers maximum. The intermediate powder product is then heated to form the titanium alloy / amumina metal matrix composite in which the ceramic particles have an average diameter of no more than 3 mu, and the oxide consists of more than 10% and less than 60% by volume fraction of the total composite. The composites have extensive application to tough and strong engineering alloys.

Owner:TITANOX DEV

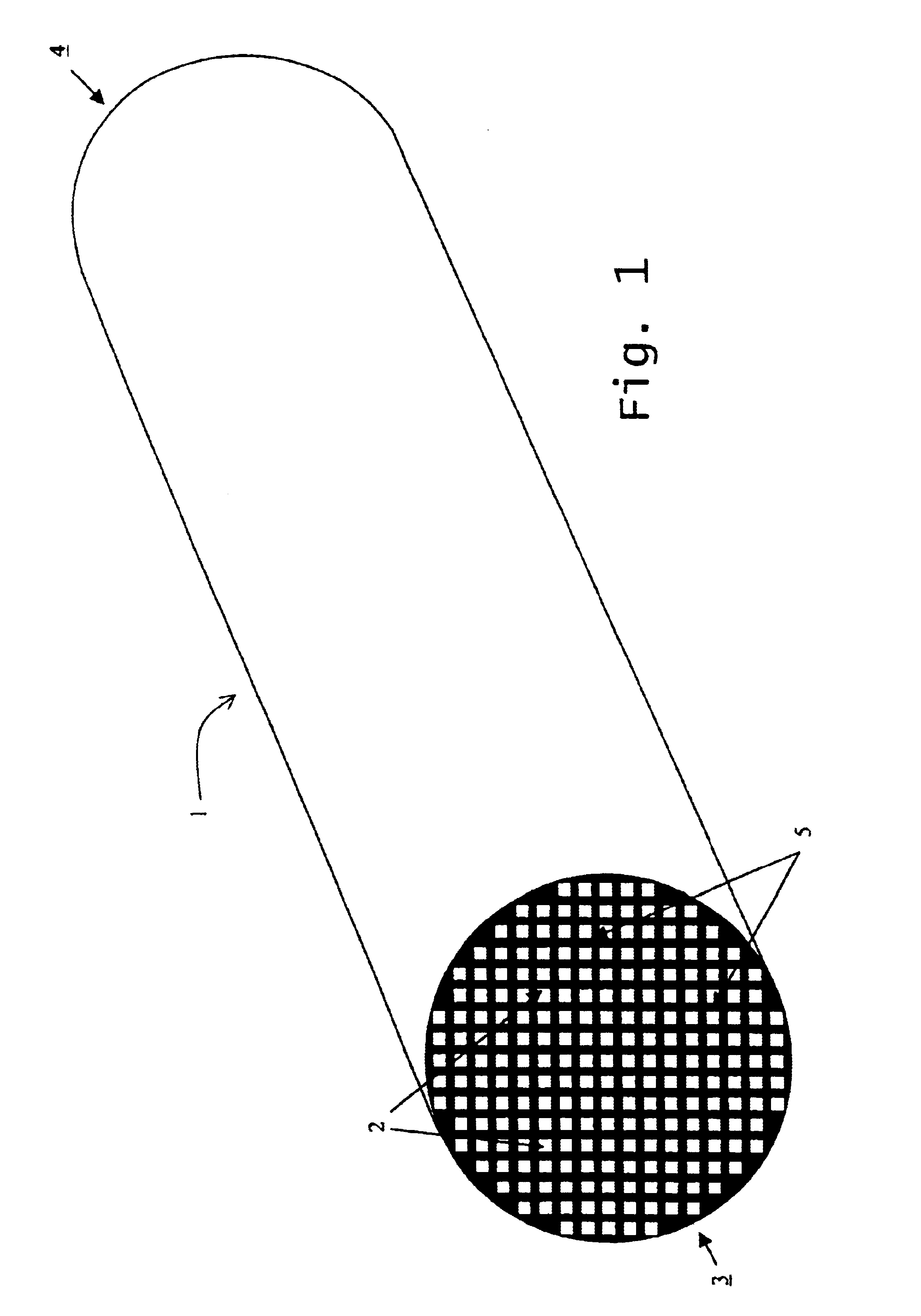

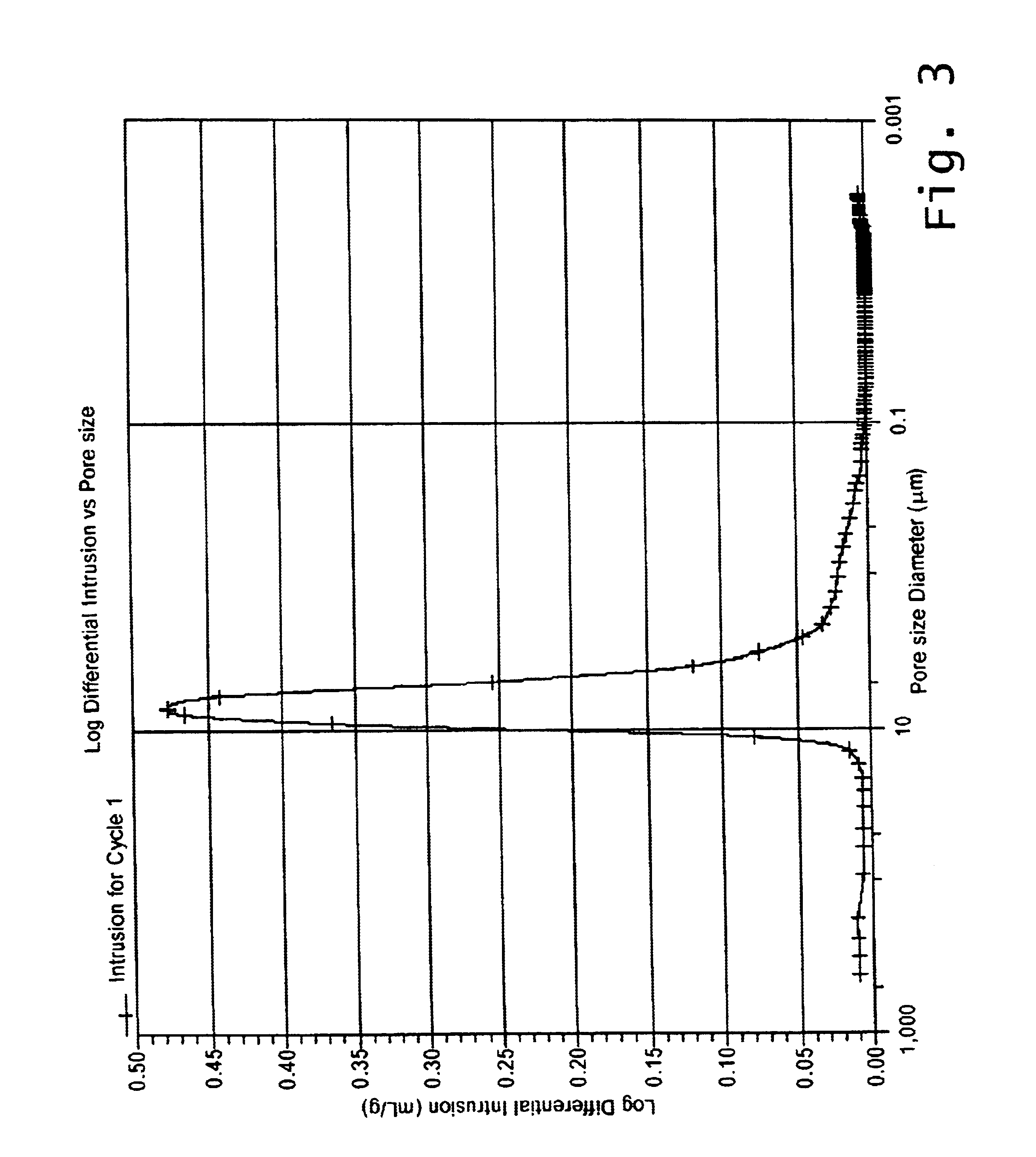

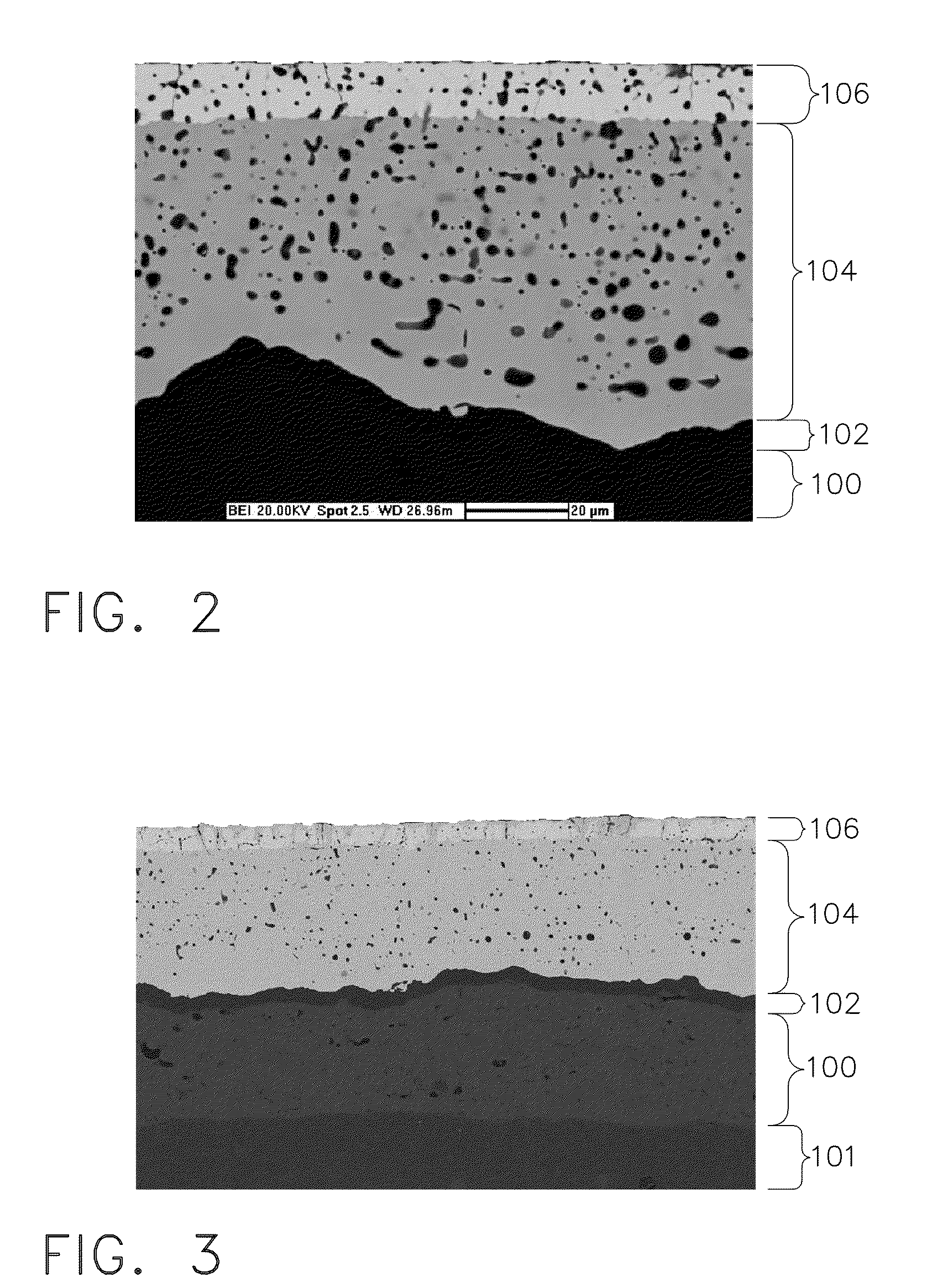

Reaction bonded alumina filter and membrane support

InactiveUS6695967B2Minimize changesIncrease the volume ratioSemi-permeable membranesDispersed particle filtrationAluminum metalMaterials science

A reaction-bonded alpha-alumina filter element is provided. The filter element includes a monolith of porous material having multiple passageways extending from one end face to an opposing end face. The monolith is extruded from a mixture containing at least aluminum metal and alumina powders in a proportion such that on sintering the volume change of the monolith is minimized. The filter body can be used as a filter or as a membrane support for crossflow or dead end flow filter elements. A method for making the filter element is also provided.

Owner:HPD

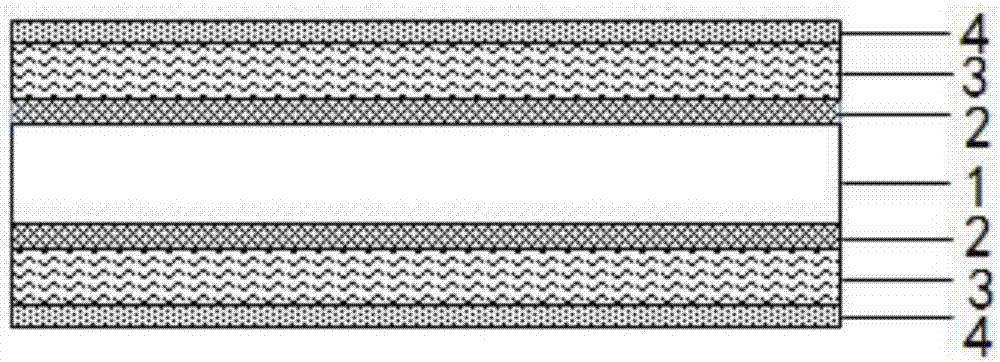

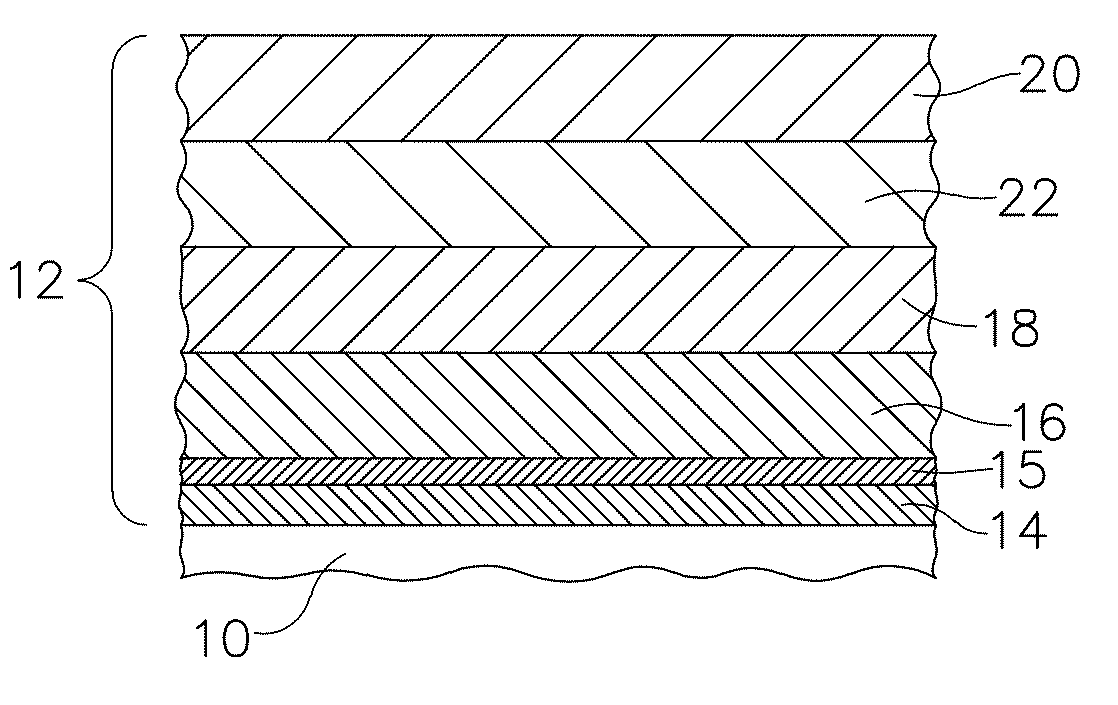

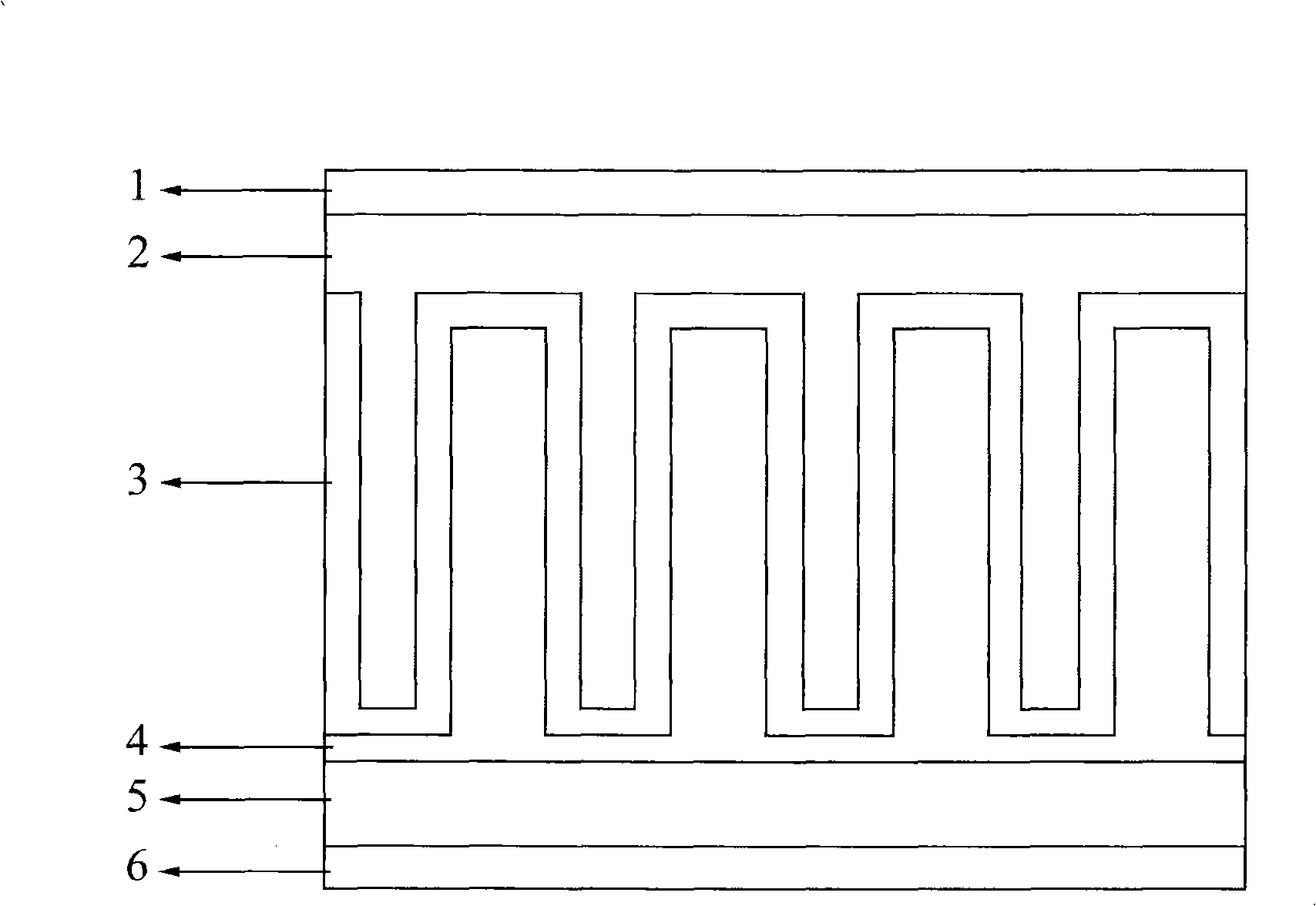

Positive electrode current collector and preparation method and application thereof

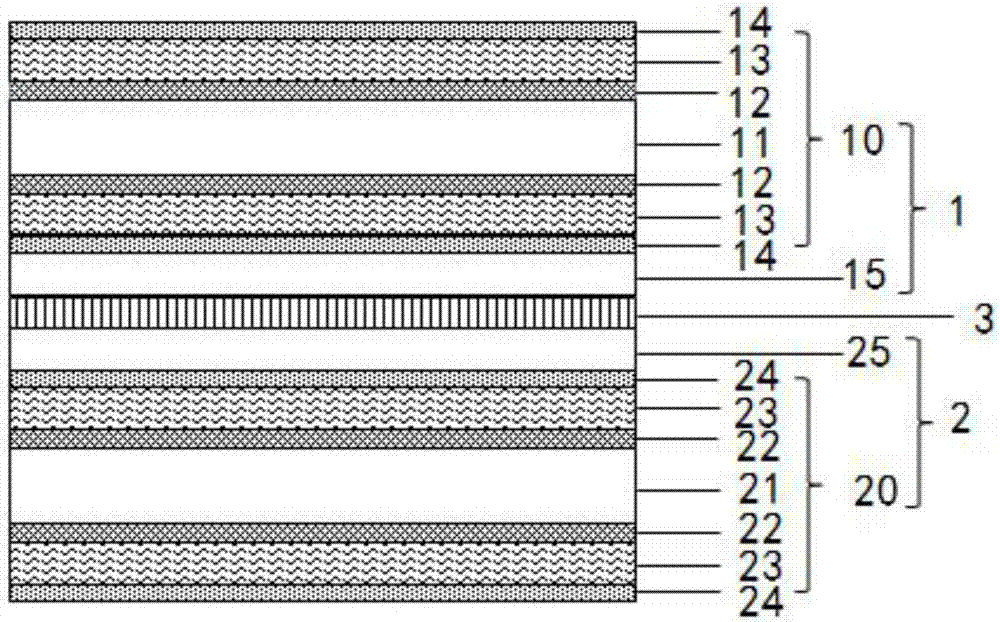

ActiveCN107123812AIncrease energy densityReduce thicknessFinal product manufactureElectrode carriers/collectorsEvaporationAluminum metal

The invention discloses a positive electrode current collector and a preparation method and an application thereof. The positive electrode current collector is of a multilayered structure and comprises a plastic thin film, wherein the upper and lower surfaces of the plastic thin film are coated with a bonding force enhancement layer, an aluminum metal coating layer and an anti-oxidization layer in sequence. The preparation method comprises the steps of coating the bonding force enhancement layer, the aluminum metal coating layer and the anti-oxidization layer through an evaporation film-coating process in sequence. The application of the positive electrode current collector mainly refers to an application in a lithium ion battery. By virtue of the positive electrode current collector, light weight of the battery can be realized, energy density can be improved, the aluminum coating layer does not fall off easily, and easy oxidization can be avoided.

Owner:CONTEMPORARY AMPEREX TECH CO +1

High performance aluminum nanocomposites

InactiveUS20150252451A1Readily apparentTransportation and packagingMetal-working apparatusParticulatesNanoparticle

The high performance aluminum nanocomposites are formed by a combination of mechanical alloying and Spark Plasma Sintering (SPS) in order to obtain reinforced nanostrutured aluminum alloys, The nanocomposites are formed from aluminum metal reinforced with silicon carbide (SiC) particulates, wherein the SiC particulates have a particle diameter between about 20 and 40 nm. The nanocomposites are prepared by mixing aluminum-based metal, e.g., Al-7Si-0.3Mg, (Al=92.7%, Si-7% and Mg=0.3%), with SiC nanoparticles in a conventional mill to form a uniformly distributed powder, which is then sintered at a temperature of about 500° C. for a period up to about 20 hours to consolidate the silicon carbide particulates in order to obtain the reinforced aluminum metal-based silicon carbide nanocomposite.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Ceramic cores for casting superalloys and refractory metal composites, and related processes

A rare earth-based core for use in the casting of a reactive metal is described. The core contains a ceramic composition which includes at least about 10% by weight of monoclinic rare earth aluminate (RE4Al2O9), wherein RE represents at least one rare earth element; and at least about 10% by weight of at least one free rare earth oxide. The ceramic phase of the composition may include a microstructure which comprises a multitude of substantially spherical pores which are formed as a result of the removal of aluminum metal from the core composition during a heat treatment step. Additional embodiments relate to a method for the fabrication of a ceramic core, employing a rare earth oxide, aluminum metal, and a binder. Methods for removing cores from a cast part are also described.

Owner:GENERAL ELECTRIC CO

Lithium battery with novel current collectors and preparation method of lithium battery with novel current collectors

ActiveCN107154499AAchieve weight lossReduce thicknessElectrode carriers/collectorsSecondary cellsCopper platingEngineering

The invention discloses a lithium battery with novel current collectors and a preparation method of the lithium battery with the novel current collectors. The lithium battery comprises a positive pole piece, a diaphragm and a negative pole piece. The positive pole piece comprises a novel positive pole current collector in a multi-layer structure, the positive pole current collector comprises a first plastic film, and each of upper and lower surfaces of the first plastic film is coated with a first adhesion reinforcement layer, an aluminum metal plating layer and a first antioxidant layer sequentially. The negative pole piece comprises a novel negative pole current collector in a multi-layer structure, the negative pole current collector comprises a second plastic film, and each of upper and lower surfaces of the second plastic film is coated with a second adhesion reinforcement layer, a copper metal plating layer and a second antioxidant layer sequentially. The preparation method includes: laminating the positive pole piece, the diaphragm and the negative pole piece, packaging through aluminum-plastic films, injecting an appropriate amount of electrolyte, and subjecting the aluminum-plastic films to hot-press packaging. The lithium battery has advantages that light weight, energy density improvement and cost reduction of the battery can be realized, and copper / aluminum plating layers are less prone to shedding and oxidization.

Owner:CONTEMPORARY AMPEREX TECH CO

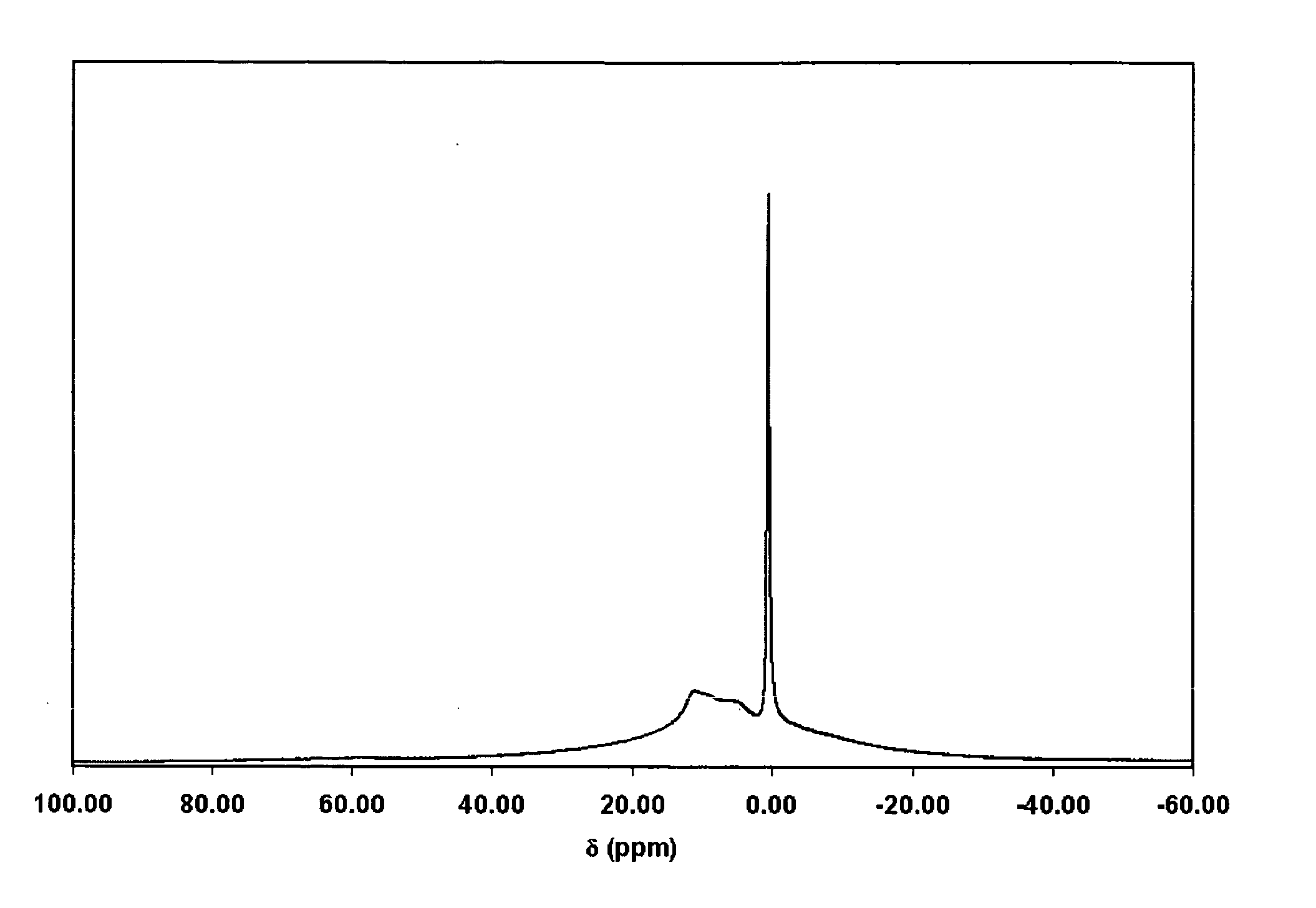

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

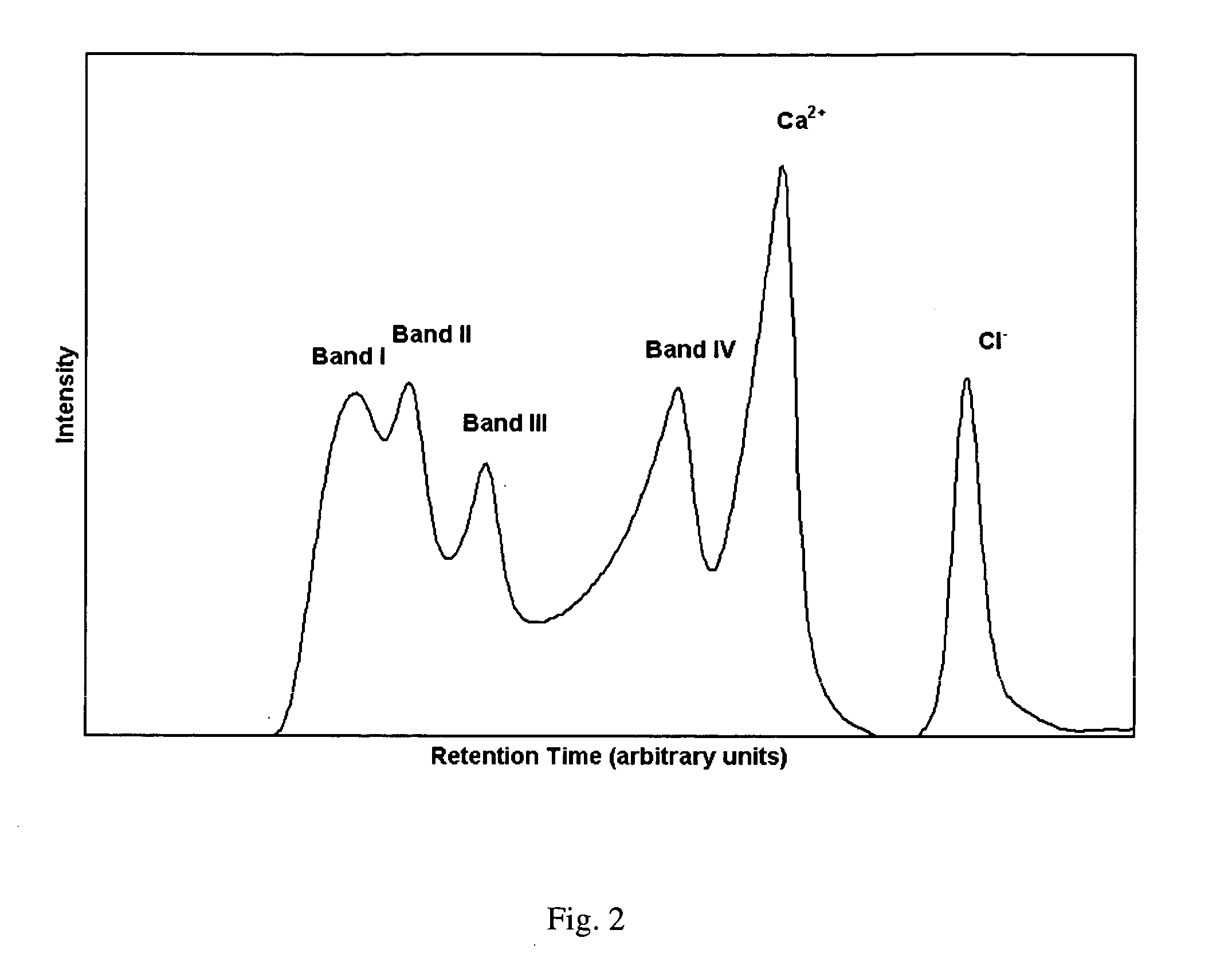

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

Nanostructure aluminum fiber metal laminates

InactiveUS20050271859A1Reduce property damageEffective solution to strength character issuesVehicle componentsThin material handlingFiber metal laminateAluminum metal

Owner:THE BOEING CO

Wire bonding of aluminum-free metallization layers by surface conditioning

InactiveUS20090166861A1Reduce contact failureHigh similaritySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

In sophisticated semiconductor devices including copper-based metallization systems, a substantially aluminum-free bump structure in device regions and a substantially aluminum-free wire bond structure in test regions may be formed on the basis of a manufacturing process resulting in identical final dielectric layer stacks in these device areas. Moreover, reliable wire bond connections may be obtained by providing a protection layer, such as an oxide layer, after exposing the respective contact metal, such as copper, nickel and the like, thereby providing highly uniform process conditions during the subsequent wire bonding process. The number of process steps may be reduced by making a decision as to whether a substrate is to become a product substrate or test substrate for estimating the reliability of actual semiconductor devices. For example, nickel contact elements may be formed above copper-based contact areas wherein the nickel may provide a base for wire bonding or forming a bump material thereon.

Owner:GLOBALFOUNDRIES INC

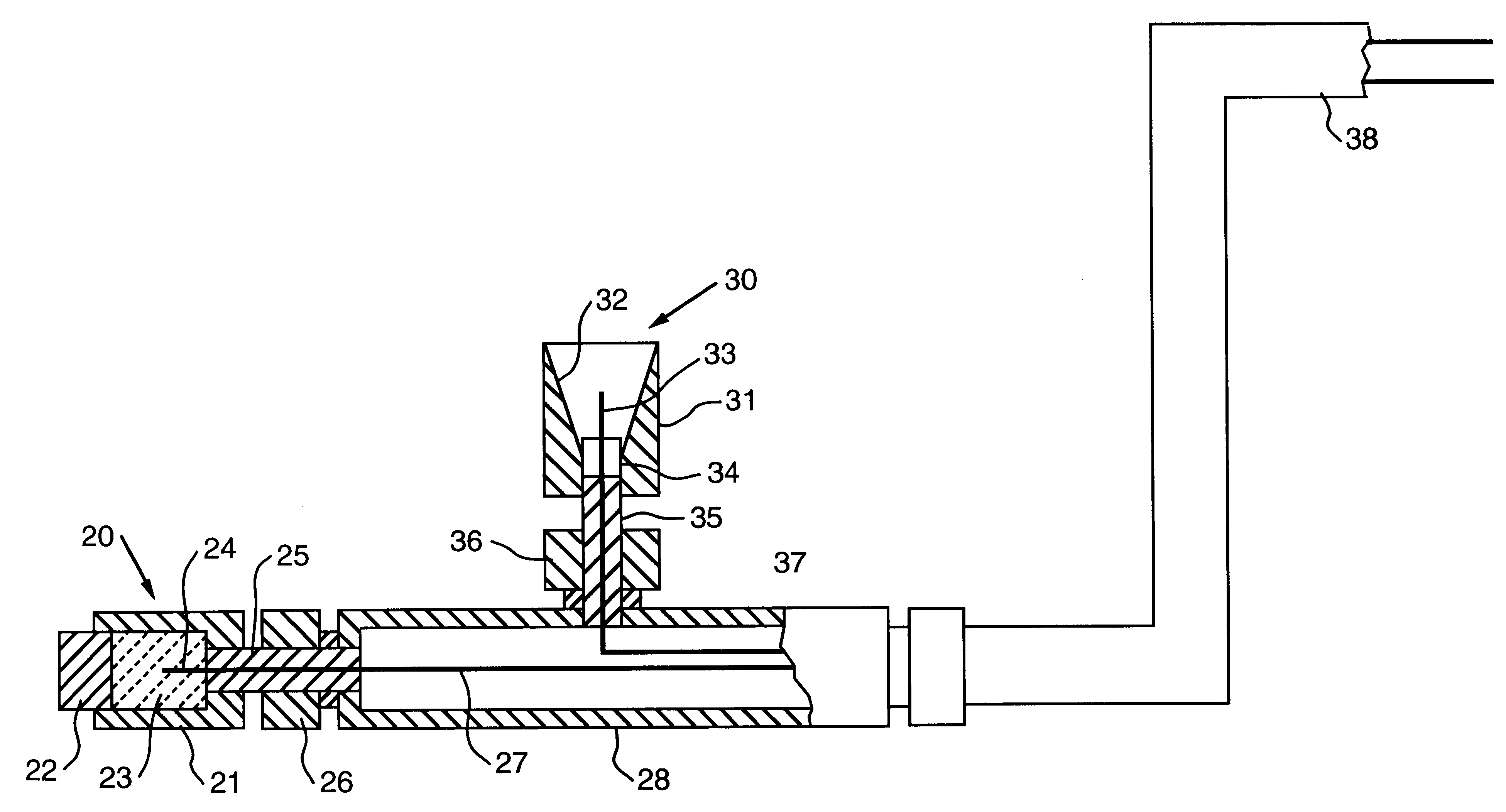

Method and apparatus for testing material utilizing differential temperature measurements

A method and apparatus for timely and accurate measurement of material parameters are disclosed. A test sensor measures the temperature of a sample of material as it is heated up and / or cooled down. A reference sensor is used to obtain differential temperature measurements as the temperature of the test sample is varied. A differential temperature trace is generated and analyzed in order to determine various characteristics of the material being tested. In one embodiment, the sodium fluoride to aluminum fluoride ratio (NaF:AlF3) and alumina concentration in a Hall bath aluminum smelting operation are determined in order to efficiently control smelting of aluminum metal. In this embodiment, bath temperature and liquidus temperature may be measured and compared in order to determine the amount of superheat of the bath and to prevent the operation of smelters at higher temperatures than necessary.

Owner:ARCONIC INC

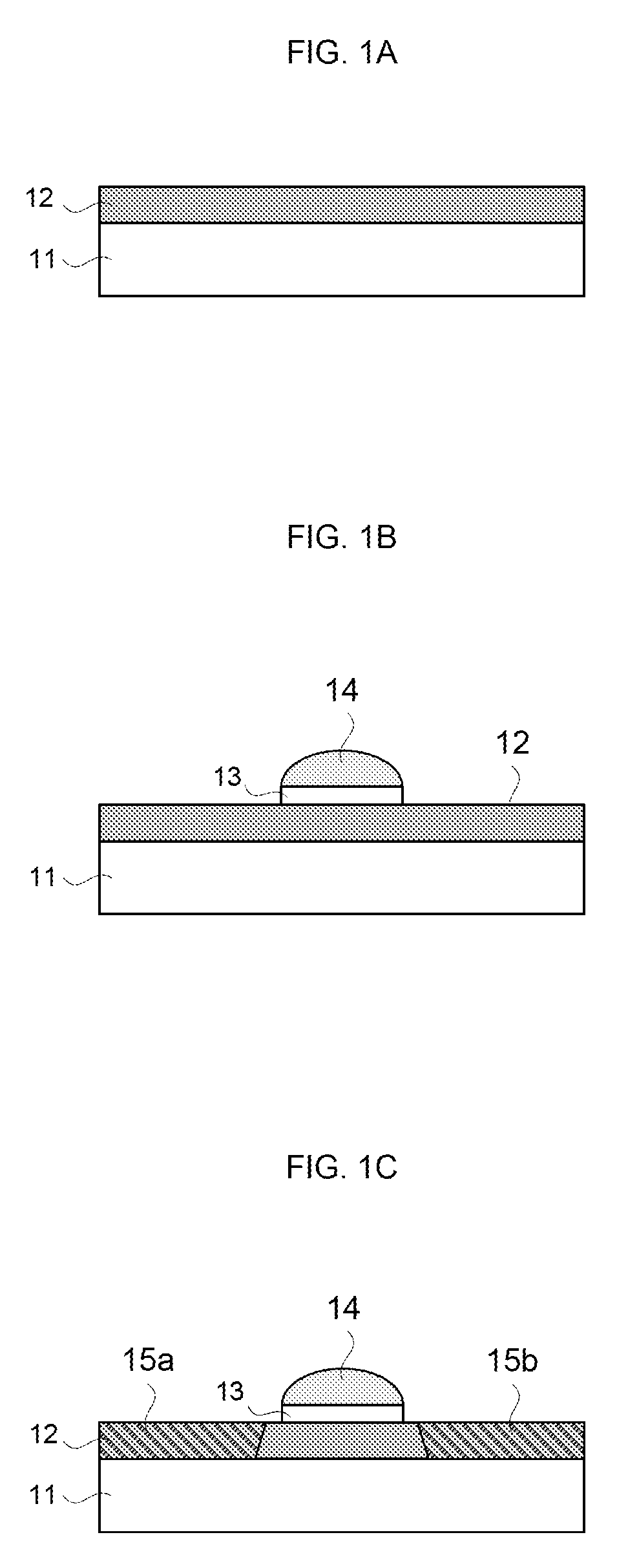

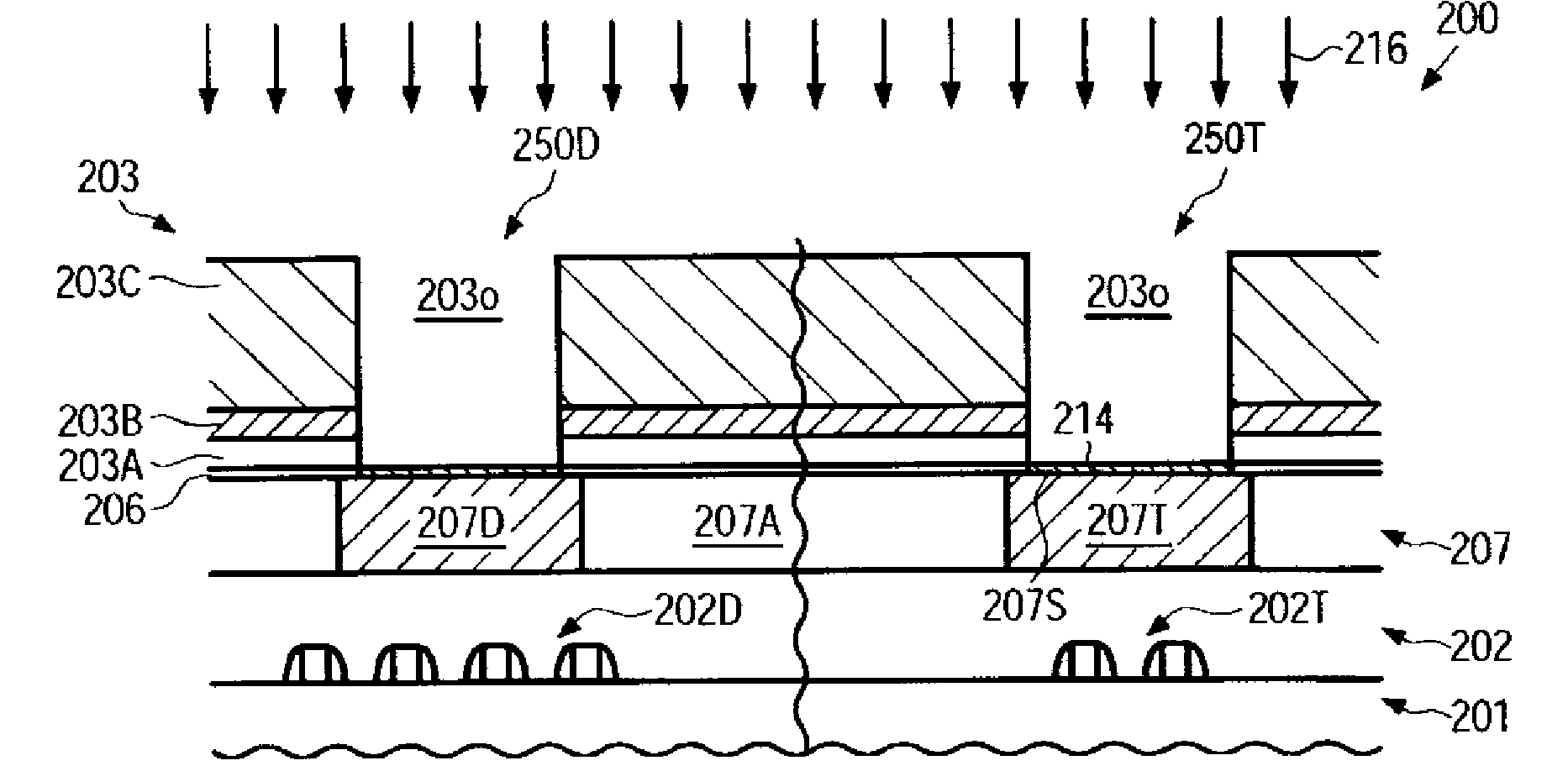

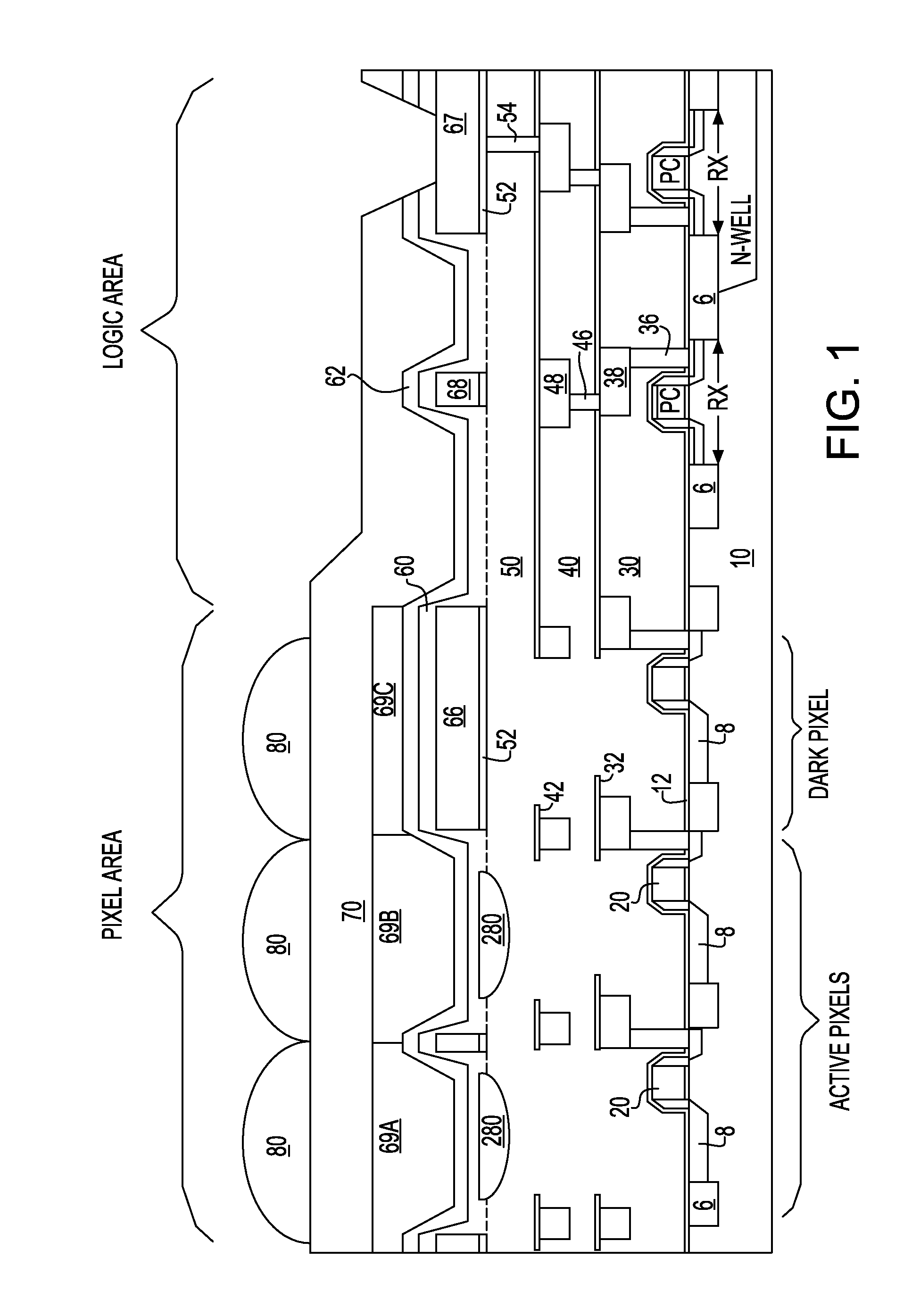

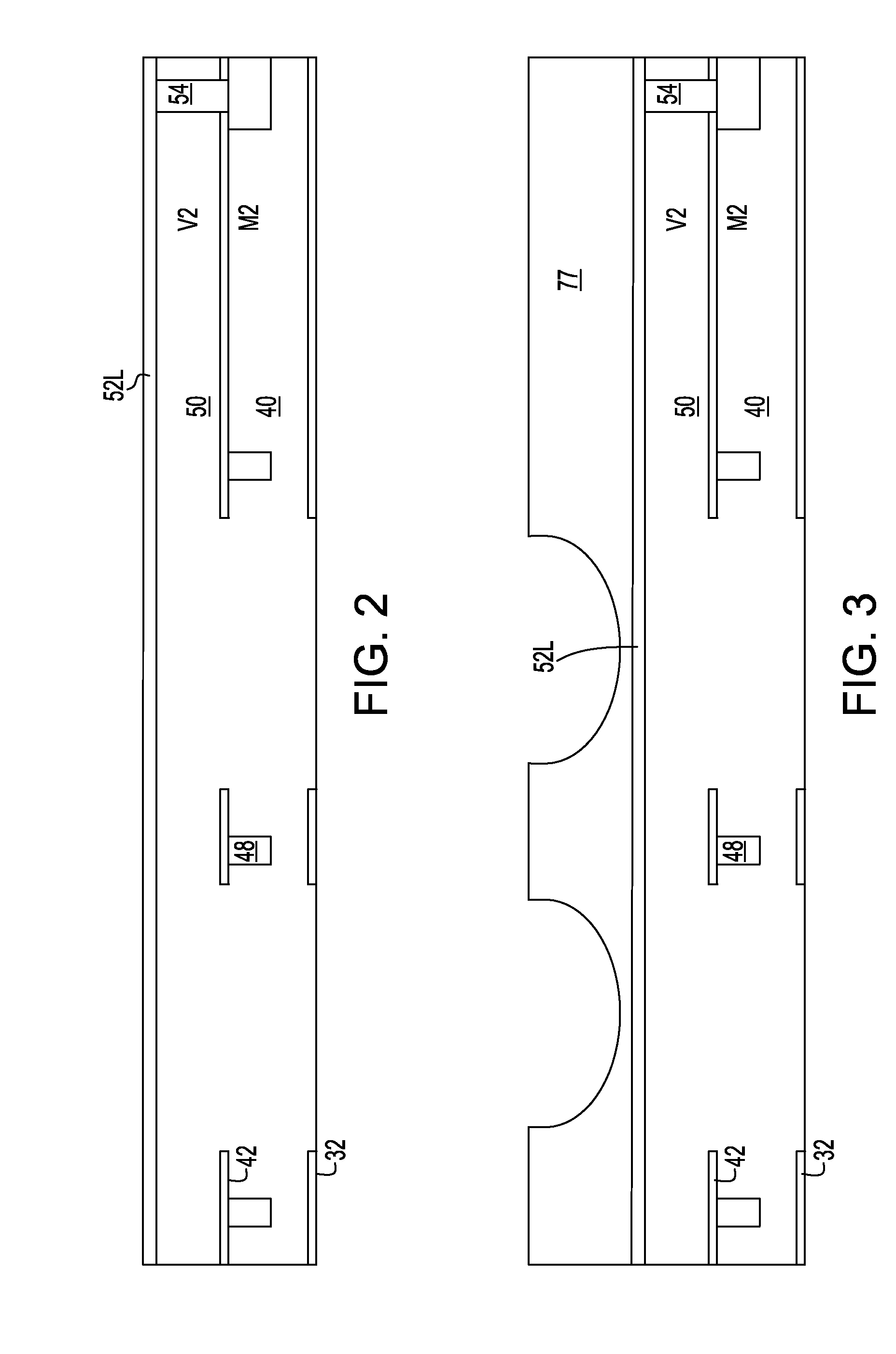

Method of forming an inverted lens in a semiconductor structure

InactiveUS20090242948A1Light capacityLight efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureRefractive index

A flat-top convex-bottom lower lens is formed by first applying a positive tone photoresist over a silicon oxide layer and an optional metallic barrier layer thereupon in a back-end-of-line (BEOL) metallization structure. The positive tone photoresist is exposed under defocused illumination conditions and / or employing a half-tone mask so that a cross-sectional profile of the positive tone photoresist after exposure contains a continuous and smooth concave profile, which is transferred into the underlying silicon oxide layer to form a concave cavity therein. After removing the photoresist, the cavity is filled with a high refractive index material such as silicon nitride, and planarized to form a flat-top convex-bottom lower lens. Various aluminum metal structures, a color filter, and a convex-top flat-bottom upper lens are thereafter formed so that the upper lens and the lower lens constitute a composite lens system.

Owner:IBM CORP

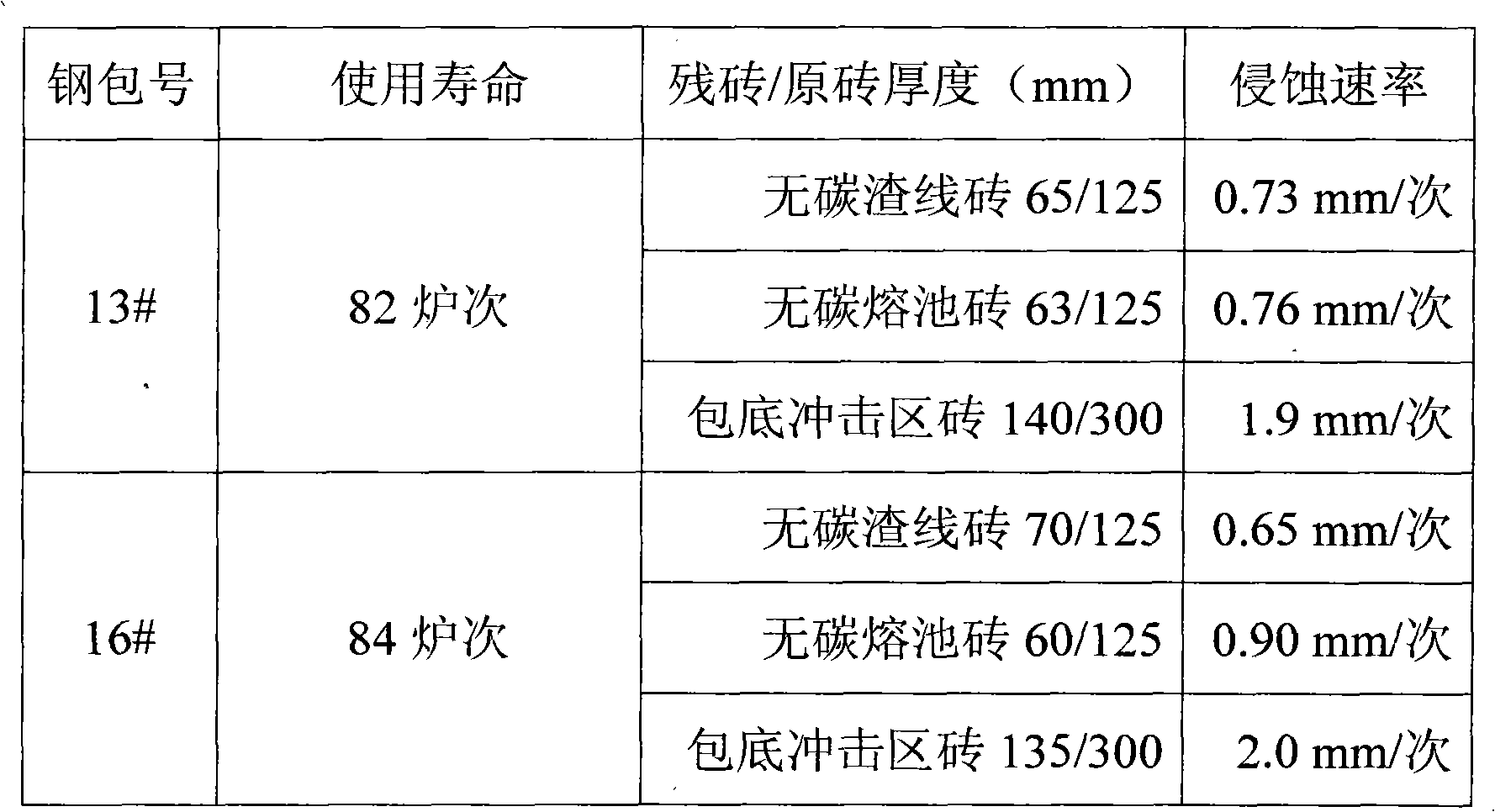

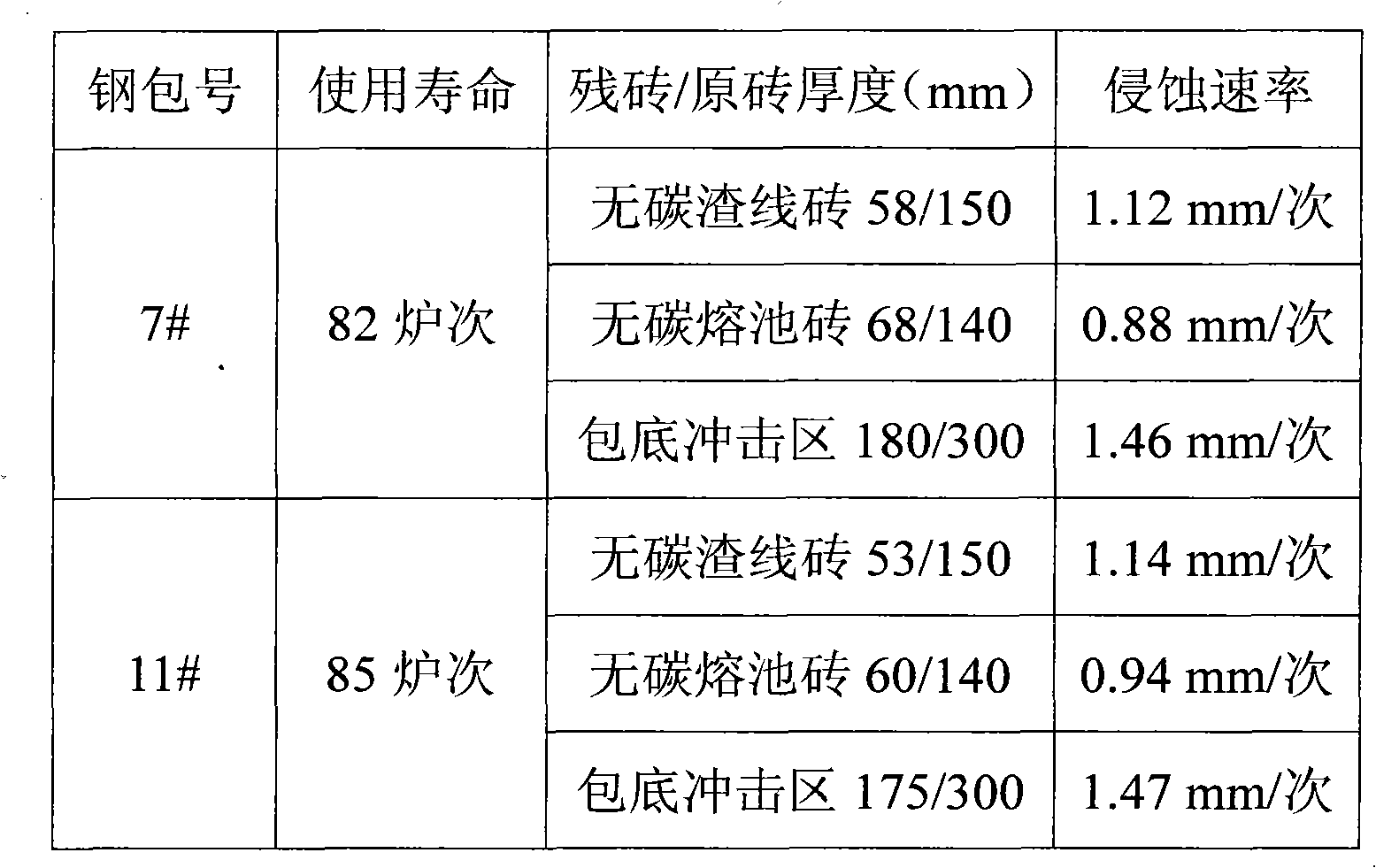

Non-carbon residue feather edge brick for refining steel ladle and preparation method thereof

The invention relates to a refractory and mainly provides a non-carbon residue feather edge brick for a refining steel ladle and a preparation method thereof. The non-carbon residue feather edge brick is formed by taking corundum grains, electrofused spinel grains and electrofused magnesia grains as aggregate, taking corundum fine powder, high-temperature alumina micropowder, electrofused magnesia, chromium sesquioxide, aluminum metal powder and other powders as base components and adopting a mode of compounding and adding inorganic and organic bonding agents and a mode of machine pressing. The obtained non-carbon residue feather edge brick has the advantages of high strength of generated blanks, no firing, favorable thermal shock stability, strong capability of resisting acid and alkali molten slag, no pollution on molten steel and the like and can be applied to residue line parts of the steel ladle under the conditions of RH and specified LF / VD refining.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

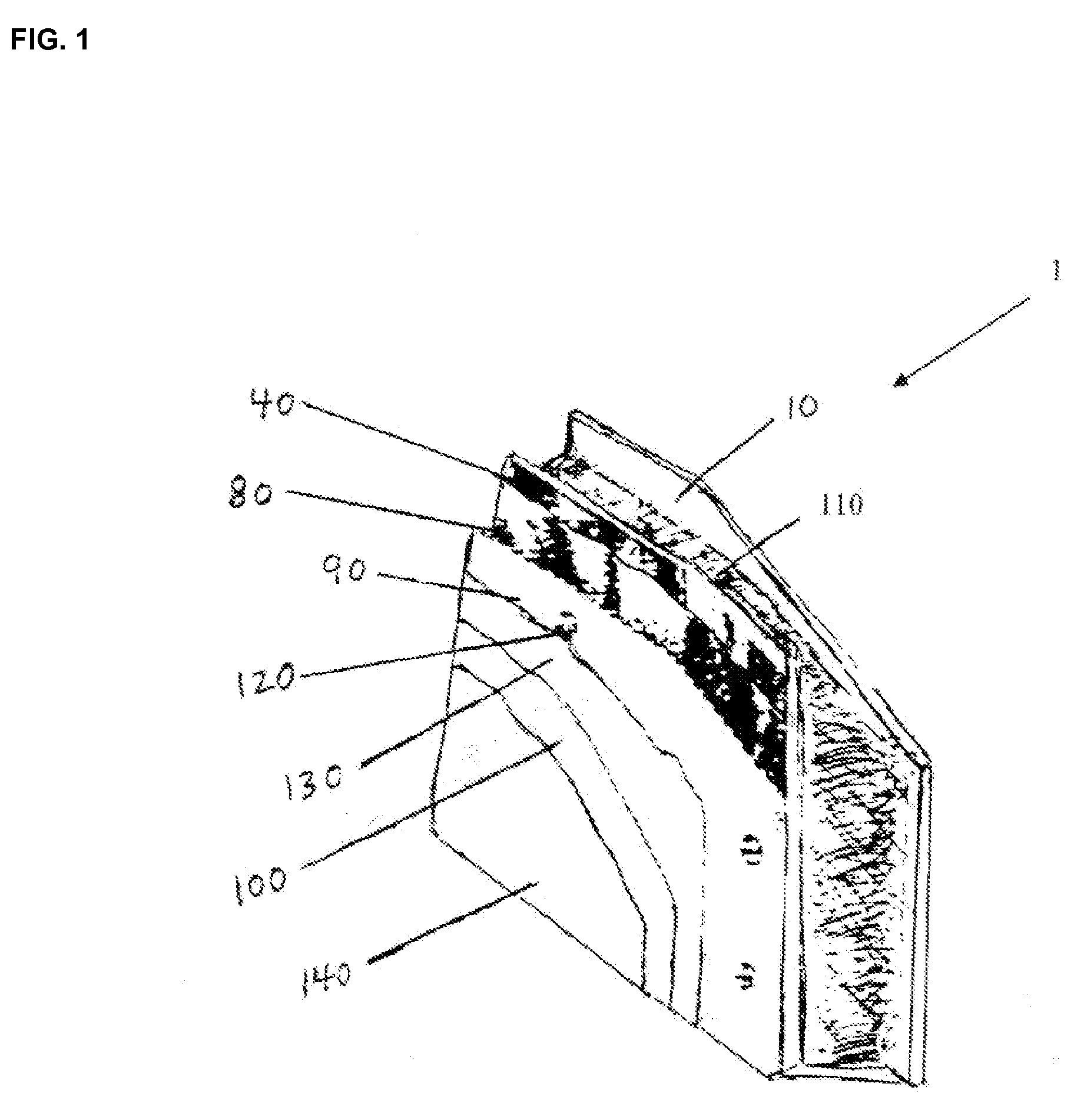

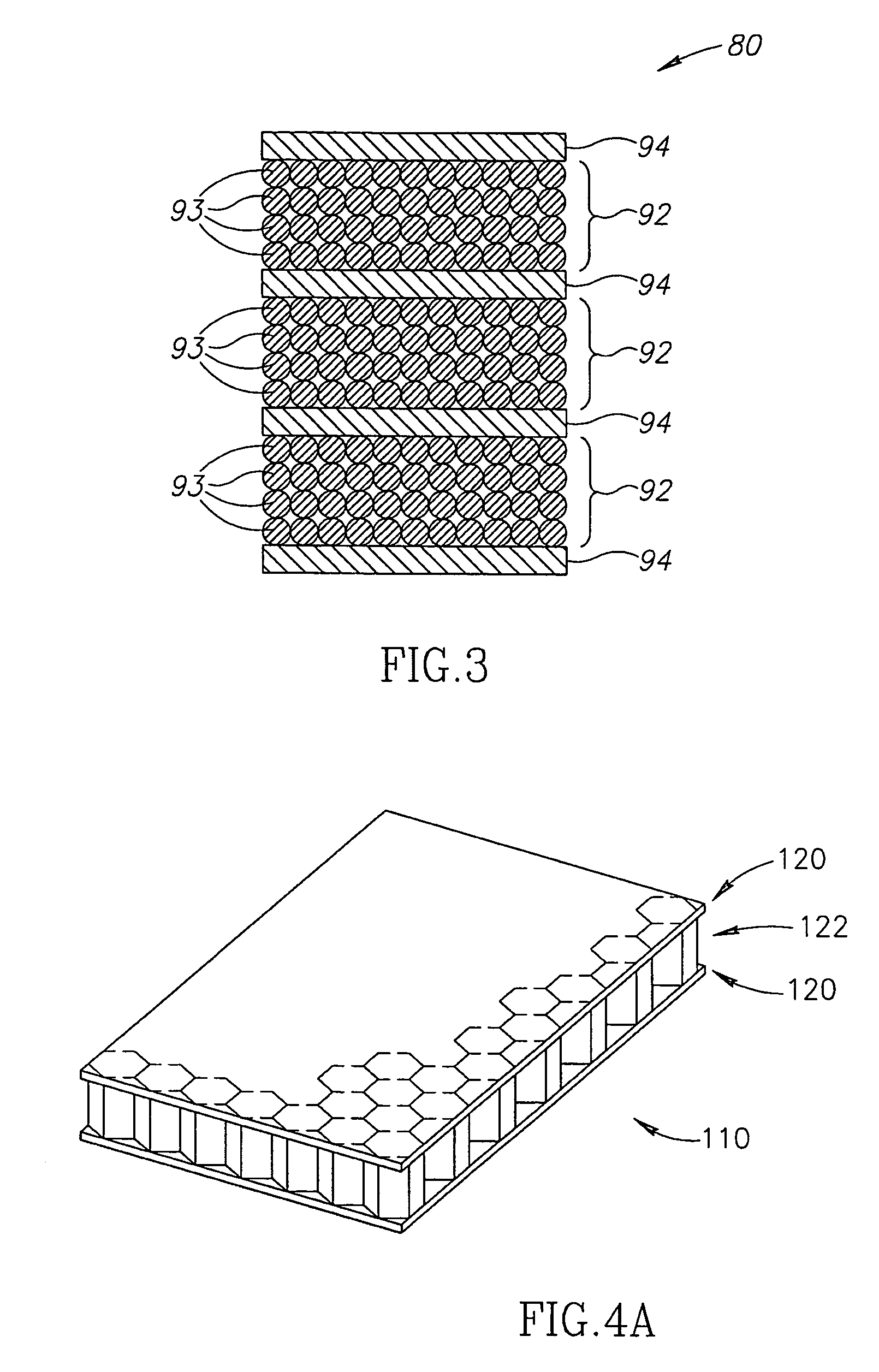

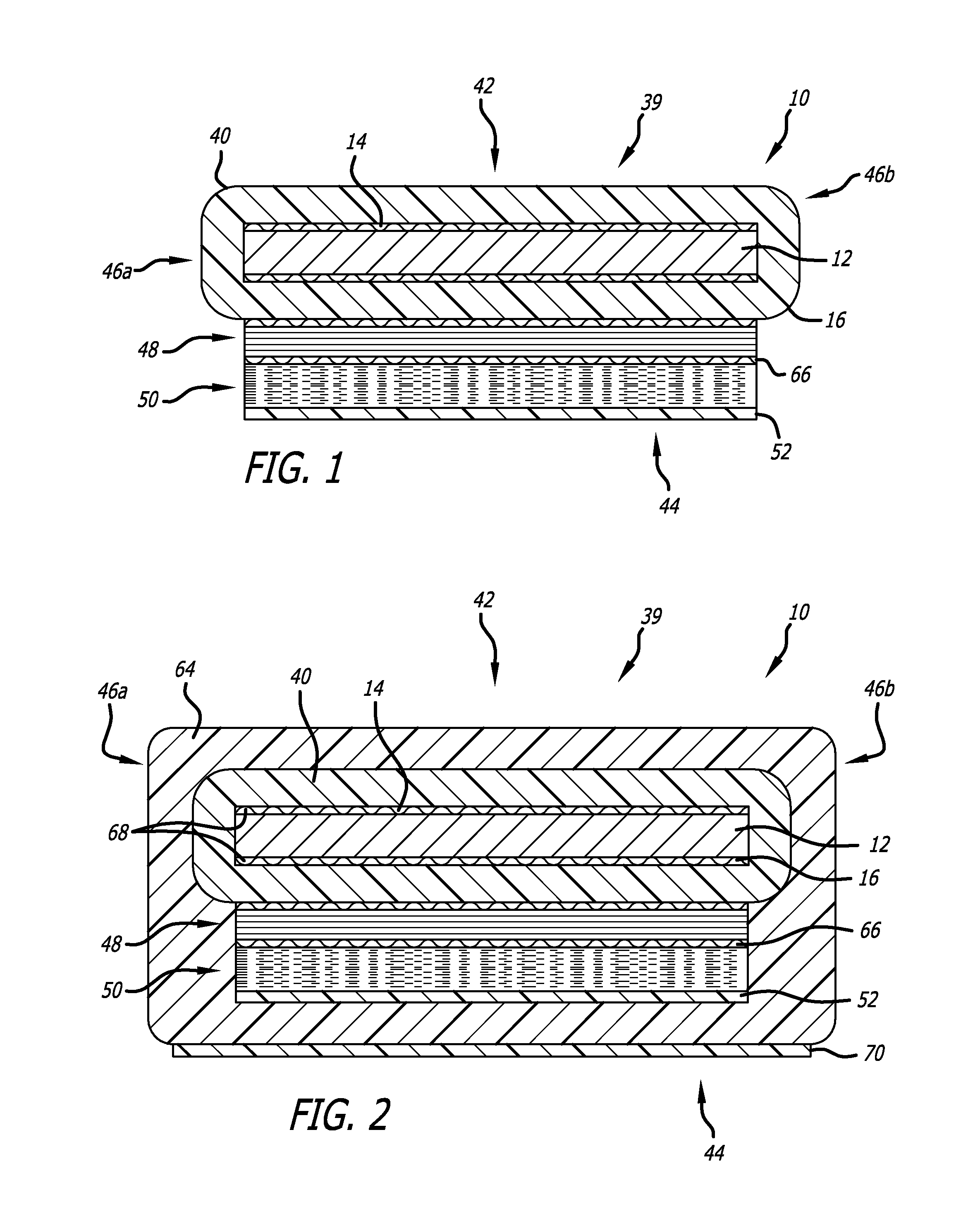

Multi-layered ballistics armor

ActiveUS20110192274A1Minimize fragmentationImprove protectionArmour platesParticulatesCarbon composites

The multi-layered ballistics armor includes one or more containment layers covering at least a portion of an impact absorbing layer formed of a fragmenting material to minimize and contain fragmentation of the impact absorbing layer. The one or more containment layers may include one or more primary containment envelopes, and the fragmenting material may be a ceramic such as silicon carbide, carbon / carbon composites, carbon / carbon / silicon carbide composites, boron carbide, aluminum oxide, silicon carbide particulate / aluminum metal matrix composites, or combinations thereof. The multi-layered armor may include one or more adhesive layers over the impact absorbing layer, one or more composite backing layers, an energy absorbing layer, and a flame resistant layer. A secondary containment envelope can be provided over the one or more primary containment envelopes, composite backing layers, and energy absorbing layer.

Owner:INT COMPOSITES TECH

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

Cement-free refractory

InactiveUS20120142518A1Shorten drying timeIncrease refractorinessBlast furnace componentsWood working apparatusRefractoryLiquid metal

A cement free refractory mixture contains aluminum oxide, silicon carbide, fumed silica, aluminum metal, an anti-oxidant, reactive alumina, and a carbon-bearing material. The mixture can be formed by conventional techniques to create refractory articles to contain or direct the flow of liquid metals. Refractory articles formed by the mixture do not require firing to achieve an initial cure.

Owner:VESUVIUS USA CORP

Aluminum metal-core weld wire and method for forming the same

InactiveUS6933468B2Reduce porosityImprove permeabilityWelding/cutting media/materialsSoldering mediaAluminum metalNitride

An aluminum metal-core weld wire, the sheath being aluminum, the metal-core having a composition that contains primarily metallic alloying powders e.g. Manganese nitride and / or barium. A method for manufacturing aluminum metal-core wire, the method including depositing a core composition onto strip of aluminum, forming strip of aluminum into a tube containing core composition, and applying an inorganic lube to surface of tube, and drawing tube through reducing dies.

Owner:HOBART BROS

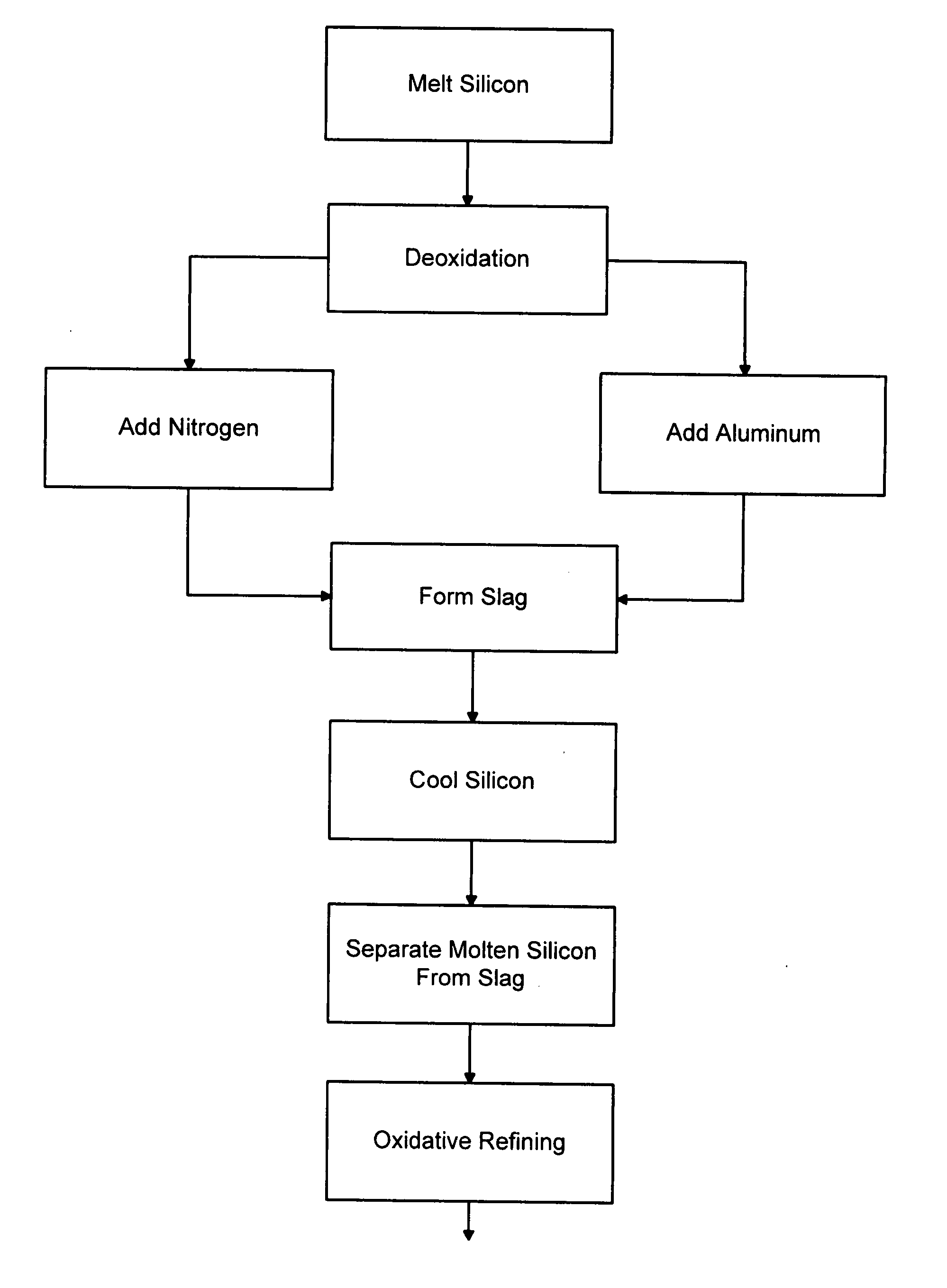

Silicon refining process

Nitrogen and aluminum and fluxing agents (Al2O3, SiO2, CaO and MgO) are added to molten silicon to create an oxy-nitride slag that acts as a sink for dissolved boron and phosphorus. The nitrogen can be added by bubbling nitrogen gas through the molten silicon; the aluminum can be added as aluminum metal or as Al2O3. Normally, the silicon must initially be deoxidized to allow the boron and phosphorus refining reactions to occur. The process may be followed by oxidative refining, SiC settling, the Silgrain process and directional solidification to remove other impurities and produce silicon suitable for use in solar cells. In an alternative version of the process, the molten silicon is passed through a particulate bed formed of a nitrogen-containing compound and an aluminum-containing compound.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Aluminum composite material of low-thermal expansion and high-thermal conductivity and method of producing same

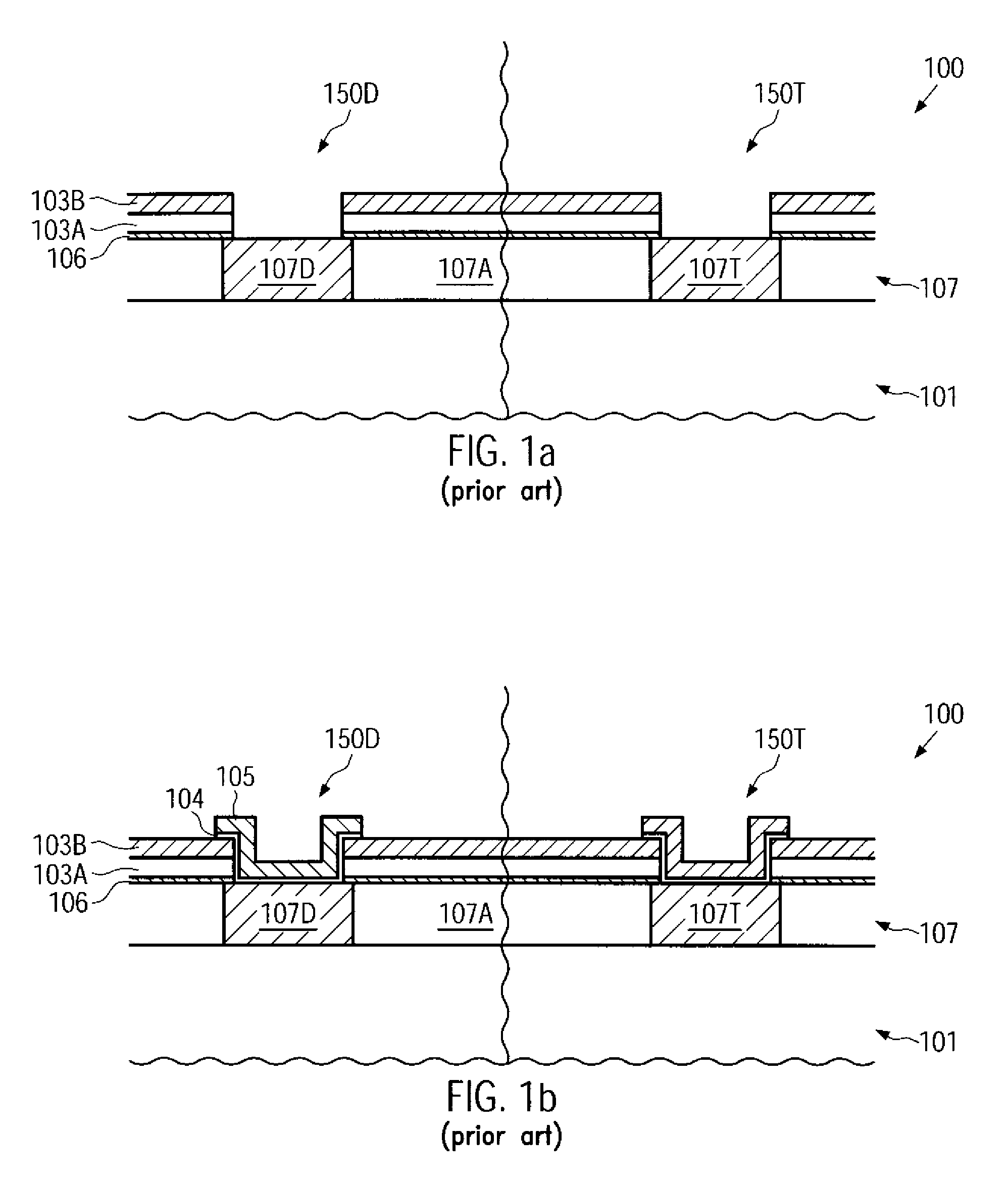

InactiveUS6077327ATransportation and packagingSemiconductor/solid-state device detailsAlloyThermal expansion

There is disclosed a method of producing an aluminum composite material in which the content of silicon carbide can be made higher as compared with conventional methods, and the production cost is low, and the method can be carried out easily. An aluminum composite material of low-thermal expansion and high-thermal conductivity is produced by this method. A mixture of powder of aluminum metal or an alloy thereof and silicon carbide powder is pressurized and compacted to form a green compact. Subsequently, this green compact is charged into a mold, and is heated and compacted into a predetermined shape at a temperature not less than a melting point of the aluminum metal or the alloy thereof.

Owner:HITACHI METALS LTD

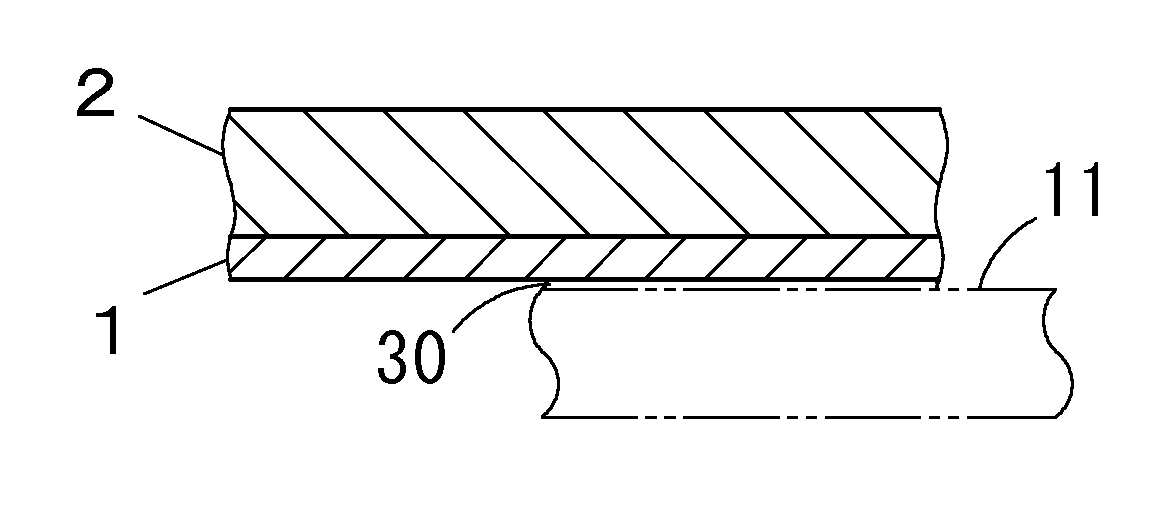

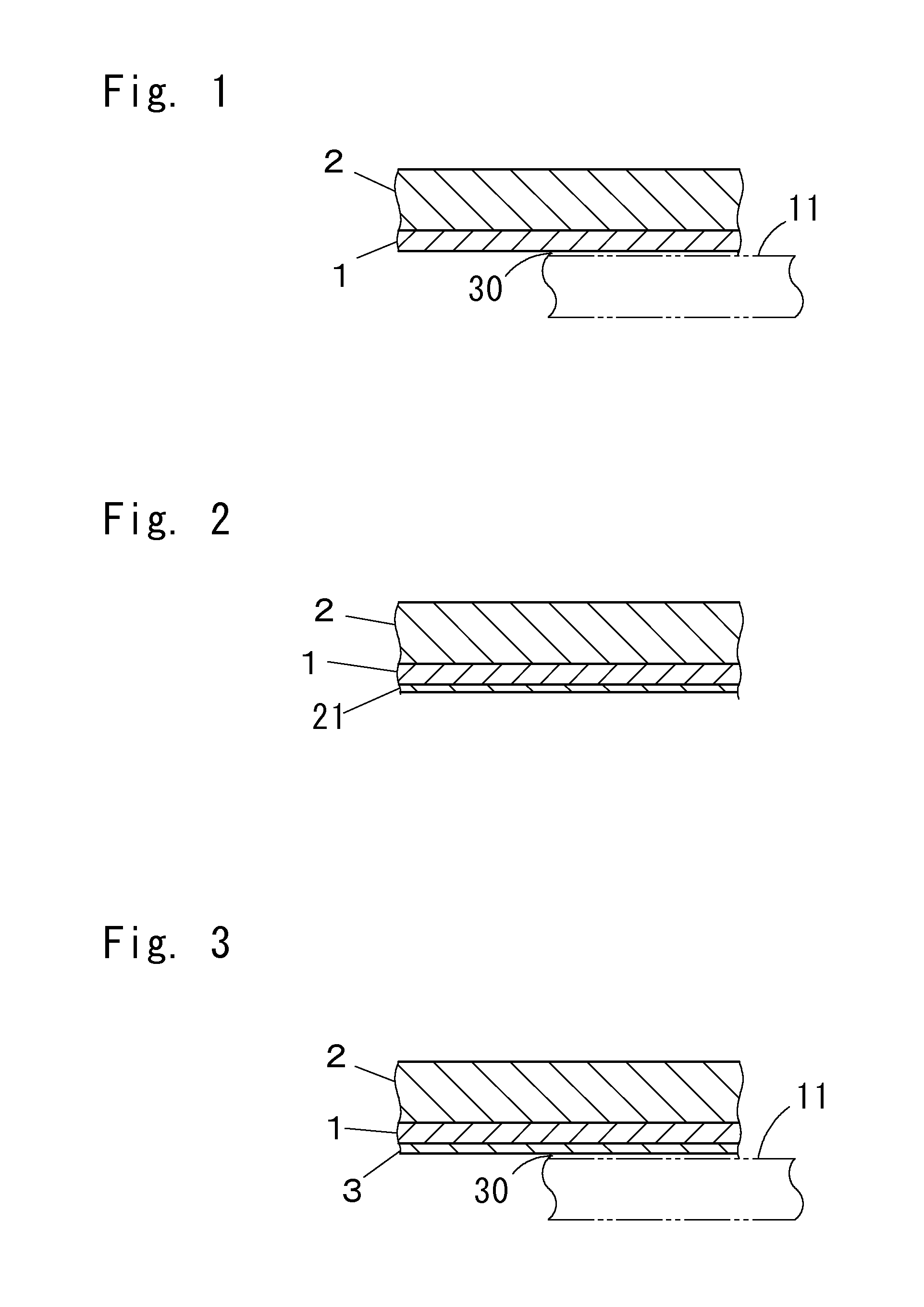

Aluminum bonding alloy, and clad material and aluminum bonding composite material each having bonding alloy layer made of the alloy

ActiveUS20120202090A1Improve corrosion resistanceImprove workabilityHot-dipping/immersion processesWelding/cutting media/materialsTitaniumAluminum metal

An aluminum bonding alloy is an Ni—Mg alloy for bonding aluminum and a non-aluminum metal selected from steel, copper, nickel or titanium. The Ni—Mg alloy consists essentially of 0.08-0.90 mass % Mg, and the balance of Ni and inevitable impurities. A clad material includes a non-aluminum metal layer made of the non-aluminum metal and a bonding alloy layer made of the aluminum bonding alloy. The non-aluminum metal layer and the bonding alloy layer are bonded together by pressure welding and diffusion bonding.

Owner:NEOMAX MATERIALS

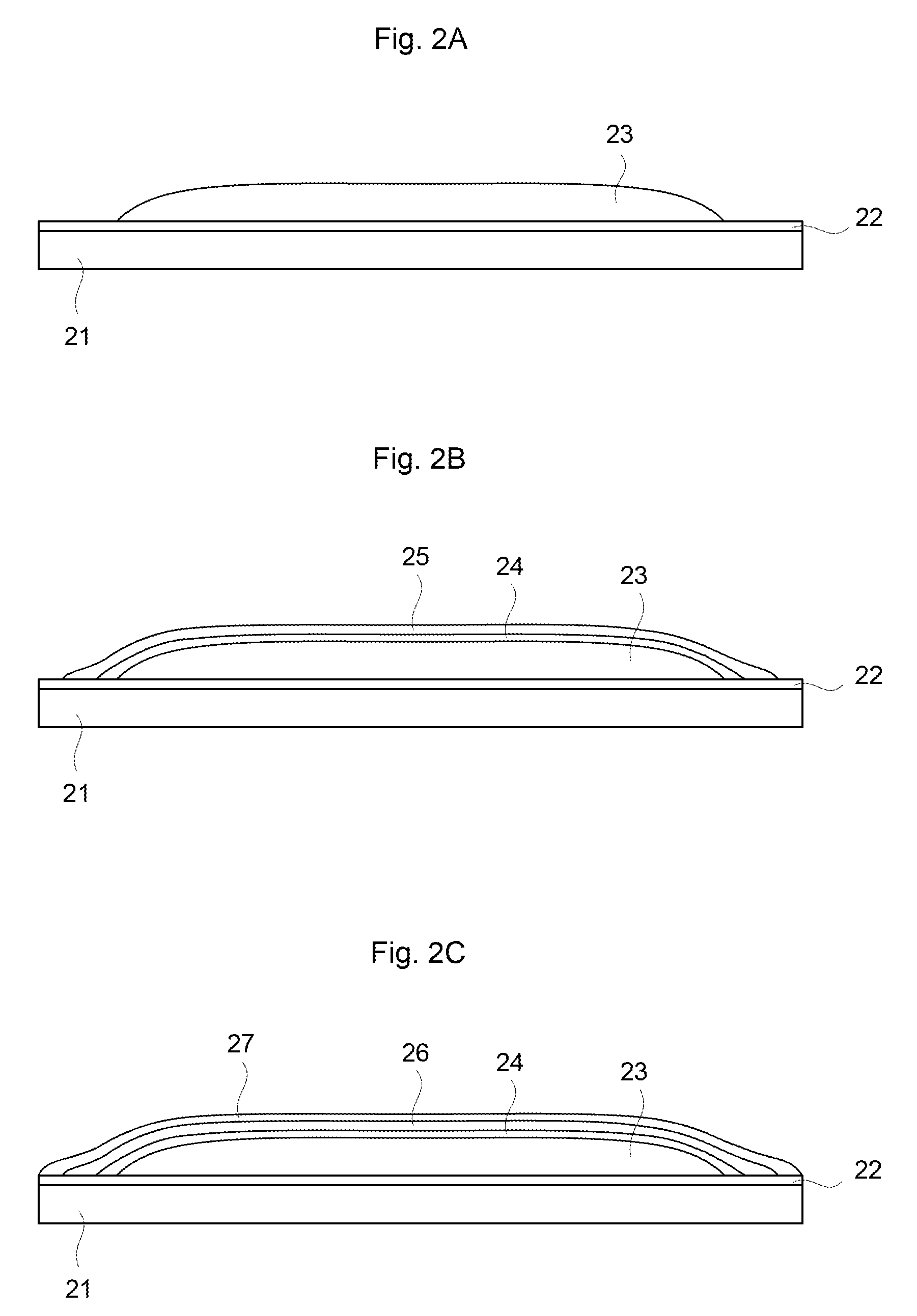

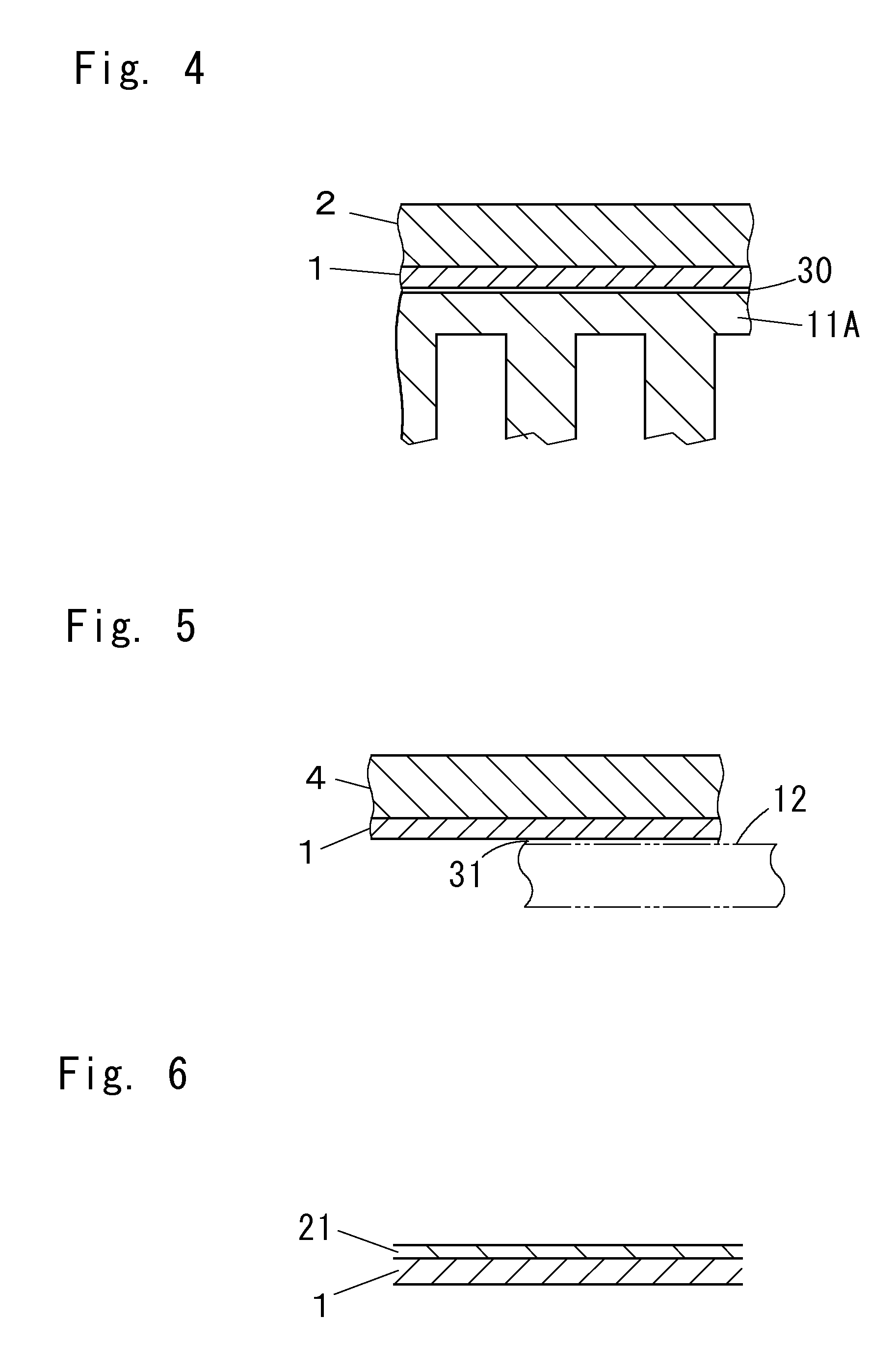

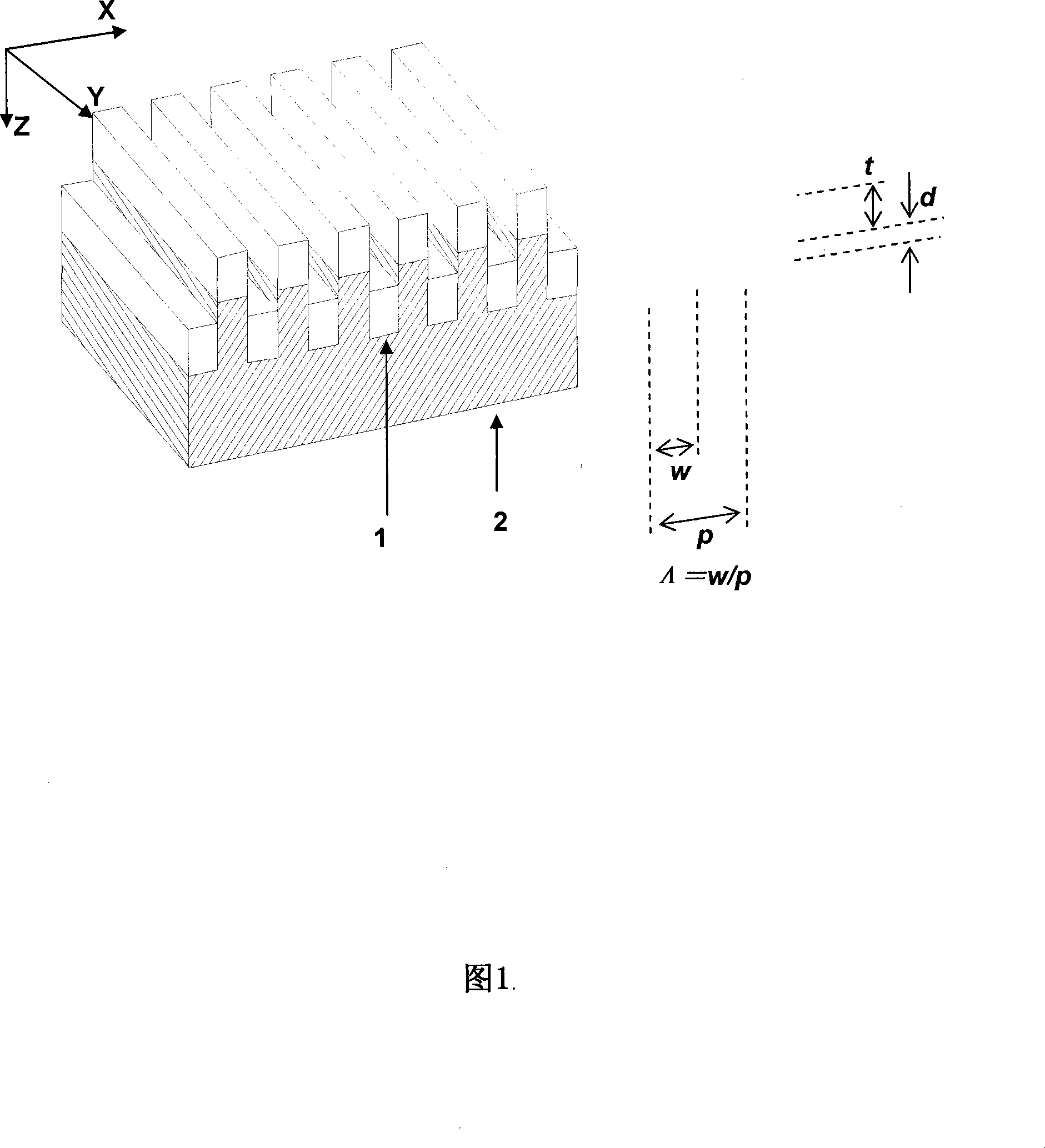

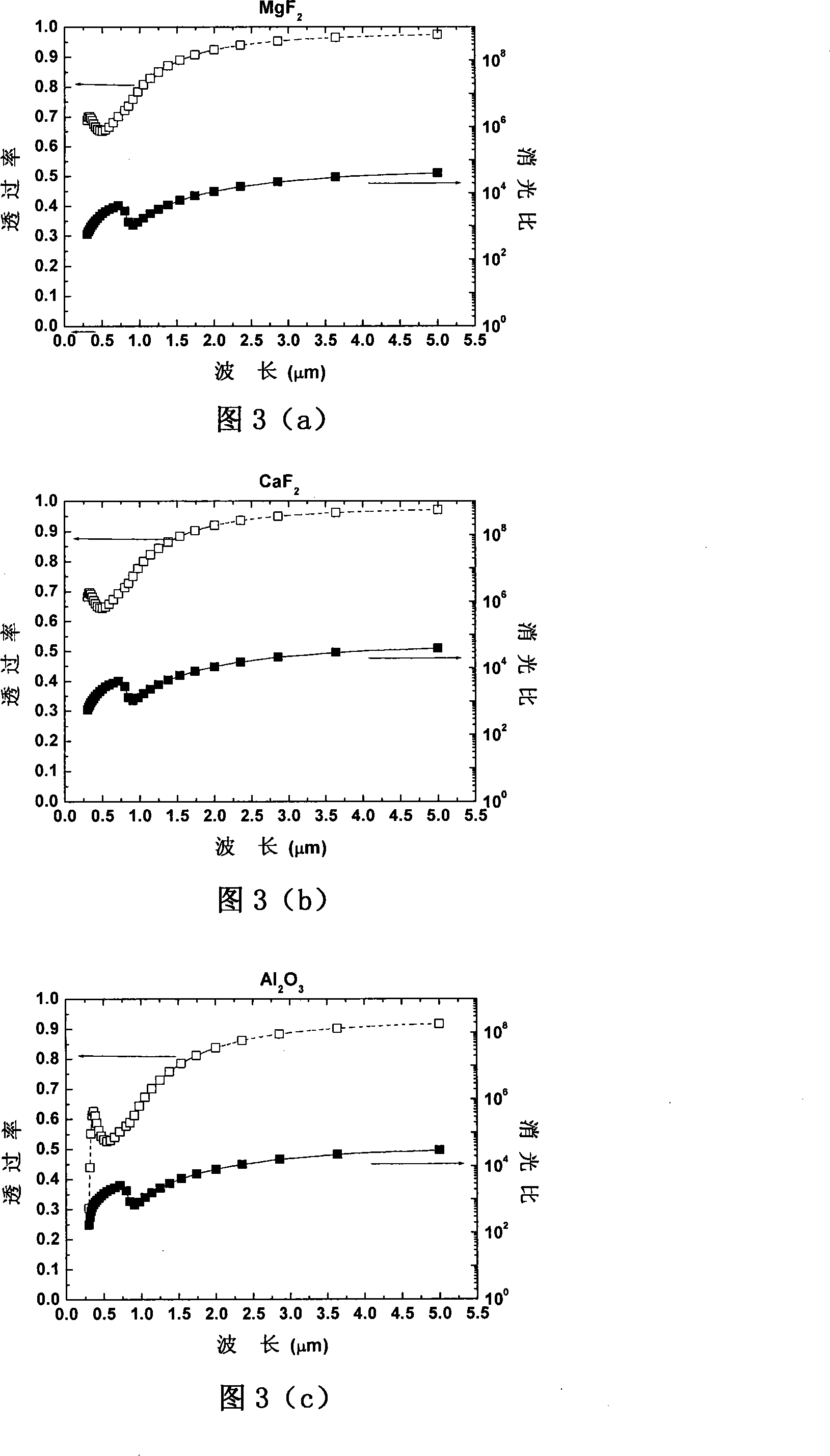

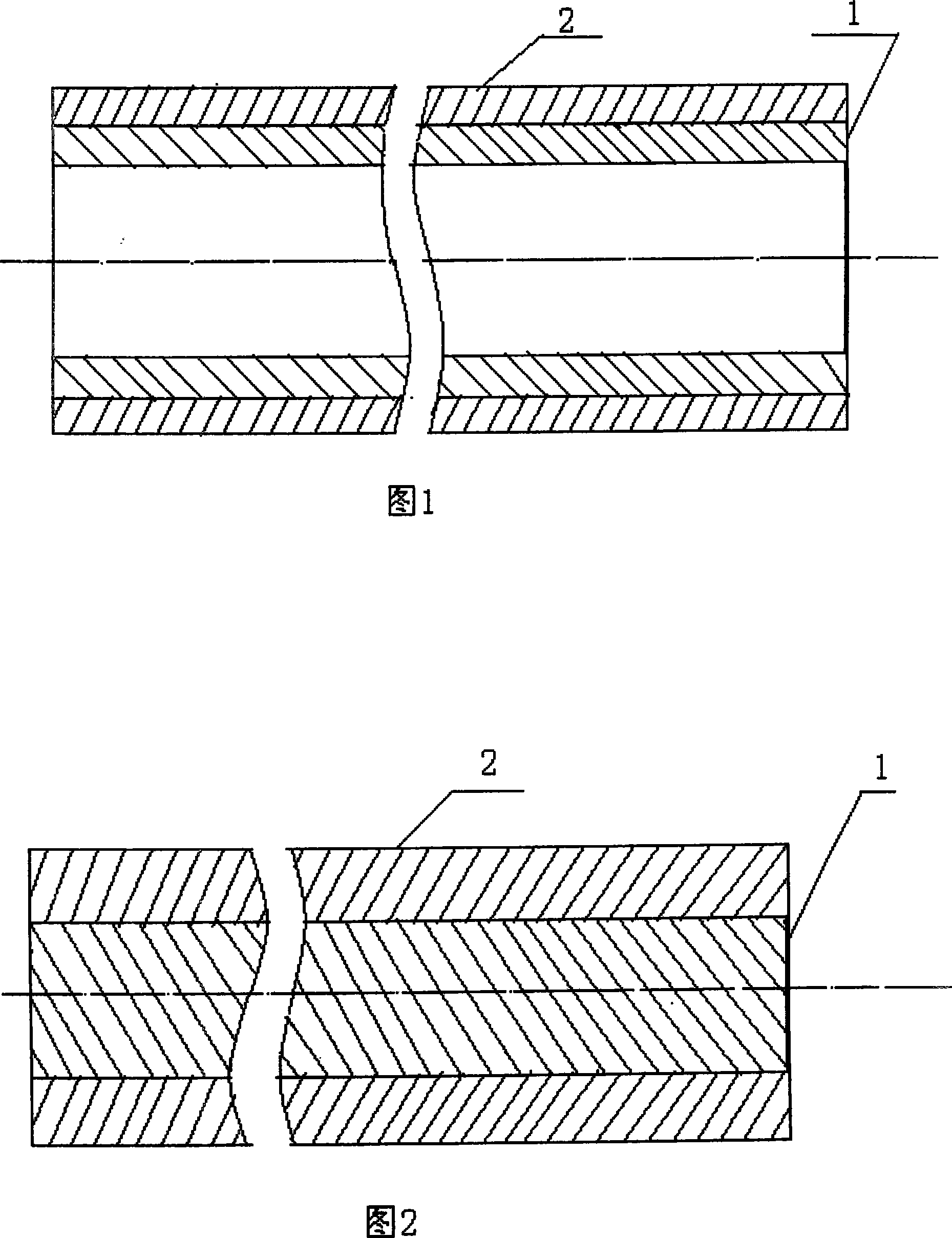

Wire grating wideband polarizer and method of producing the same

InactiveCN101183158ASimple structureVacuum evaporation coatingSputtering coatingTectorial membraneGrating

The present invention provides a metal wire grating polarizer and a preparation method thereof, which belongs to optical devices. The object is that the present invention is of high polarized light extinction ratio, high luminous flux, simple structure and the wide range of working wavelength. The polarizer of the present invention deposits a metal aluminum nanometer wire gating on a substrate. The substrate is optical materials which are transparent from ultraviolet band to infrared band. The structure parameter of the metal aluminum nanometer wire gating is as follows: the wire gating cycle length ranges from 40 to 80 nanometers; the wire gating duty cycle is 40 percent to 60 percent; the interlayer distance is 10 to 20 nanometers. The method steps of the present invention are as follows: the substrate is cleaned; a protection film is deposited on the surface of the substrate; a photoresist is spin coated; the nanometer wire gating structure is formed on the surface of the photoresist; the nanometer wire gating structure is carved on the protection film; nanometer wire gating structure is carved on the substrate; the rest protection film is eliminated; an aluminum metal film is coated on the vertical surface of the substrate; a parallel strip nanometer wire gating is formed. The polarization extinction ratio of the wideband polarizer of the present invention can reach 33 to 37dB in the wave band range of 300 to 5000 nanometers, and the polarized light transmittance can reach 68 percent to 94 percent.

Owner:HUAZHONG UNIV OF SCI & TECH

SiC nanowire reinforced aluminum matrix composite and preparing method thereof

The invention discloses an SiC nanowire reinforced aluminum matrix composite and a preparing method thereof and relates to aluminum matrix composites and preparing methods thereof. The problem that preparing of an existing SiC nanowire reinforced aluminum matrix composite is complex in process, high in cost and long in consumed time is solved. The SiC nanowire reinforced aluminum matrix composite is prepared by SiC nanowires and aluminum metal. The preparing method comprises the steps of firstly, weighing; secondly, preparing an SiC nanowire prefabricating body; thirdly, preparing the preheated SiC nanowire prefabricating body, and melting the aluminum metal; and fourthly, infiltrating molten aluminum, cooling, releasing a mold, obtaining an ingot casting, and completing the preparing. A pre-dispersion and prefabricated body forming one-step method technology of the SiC nanowires shortens the technological process, consumed time is shortened by one day, the preparing efficiency of the composite is improved, and the cost is reduced. A method combining low-surface tension and large external pressure is adopted, and infiltration of molten Al is promoted. The preparing method is simple, and easy to operate and control, and the composite has the beneficial effects of being low in density and high in compactness.

Owner:HARBIN INST OF TECH

Method for manufacturing titanium base composite pipe-rod materials

InactiveCN101121184AUniform forceReduce manufacturing costFurnace typesHeat treatment process controlTitaniumCopper

The present invention relates to a titanium-base multiunit tube rod manufacturing method; the metal pipe rod such as copper or aluminum metal pipe rod is taken as the material core with the adopted manufacturing method; the material core is covered with a titanium layer and the material core is closely clung to the titanium pipe by techniques such as extrusion, drawing, etc. and rolled into titanium composite material with a cross section of various shapes such as rectangle, tympaniform, polygon, etc. and various sizes. Because the titanium layer is closely clung to the copper, aluminum and other metal material core, the technical process is simple and efficient, which saves the titanium material and promote the production efficiency; at the same time, the production cost is reduced.

Owner:BAOJI AATI NEW METAL

Silicon nano line/non crystal heterogeneous agglomeration solar battery

InactiveCN101262024AEnhanced light absorptionImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesSilicon nanowiresAmorphous silicon

The invention discloses a solar battery device of a silicon nanowire array, which pertains to the technical field of solar batteries and is characterized in that a p-type silicon nanowire / an n-type three-dimensional amorphous silicon heterogenous junction layer is contained between a transparent indium tin oxide conductive film and a P-type silicon base layer. A solar conversion device comprises layers that are overlapped in sequence, namely, a Ti / Pd / Ag gridiron electrode serving as a frontal extraction electrode, a transparent ITO conductive film layer playing a role in transparence and serving as a frontal extraction electrode, an n-type amorphous silicon which is positioned above the p-type silicon nanowire forms a p-n heterogenous junction together with the P-type silicon nanowire; the P-type silicon nanowire is positioned above the P-type silicon base layer and forms the three-dimensional heterogenous junction together with the n-type amorphous silicon as well as serves as an antireflection layer of the solar battery, the P-type silicon base layer serves as a base area of the solar battery, the back electrode of an aluminum metal film serves as a back extraction electrode. The solar conversion device with the novel structure provided by the invention has strong capacity of light absorption and high photoelectric conversion efficiency.

Owner:BEIJING NORMAL UNIVERSITY

Method of improving copper pad adhesion

InactiveUS7026721B2Increasing area occupiedReduce contact resistanceSemiconductor/solid-state device detailsSolid-state devicesTantalum nitrideLead bonding

This invention relates to a new improved method and structure in the fabricating of aluminum metal pads. The formation special aluminum bond pad metal structures are described which improve adhesion between the tantalum nitride pad barrier layer and the underlying copper pad metallurgy by a special interlocking bond pad structure. It is the object of the present invention to provide a process wherein a special grid of interlocking via structures is placed in between the underlying copper pad metal and the top tantalum nitride pad barrier layer providing improved adhesion to the aluminum pad metal stack structure. This unique contact bond pad structure provides for thermal stress relief, improved wire bond adhesion to the aluminum pad, and prevents peeling during wire bond adhesion tests.

Owner:TAIWAN SEMICON MFG CO LTD

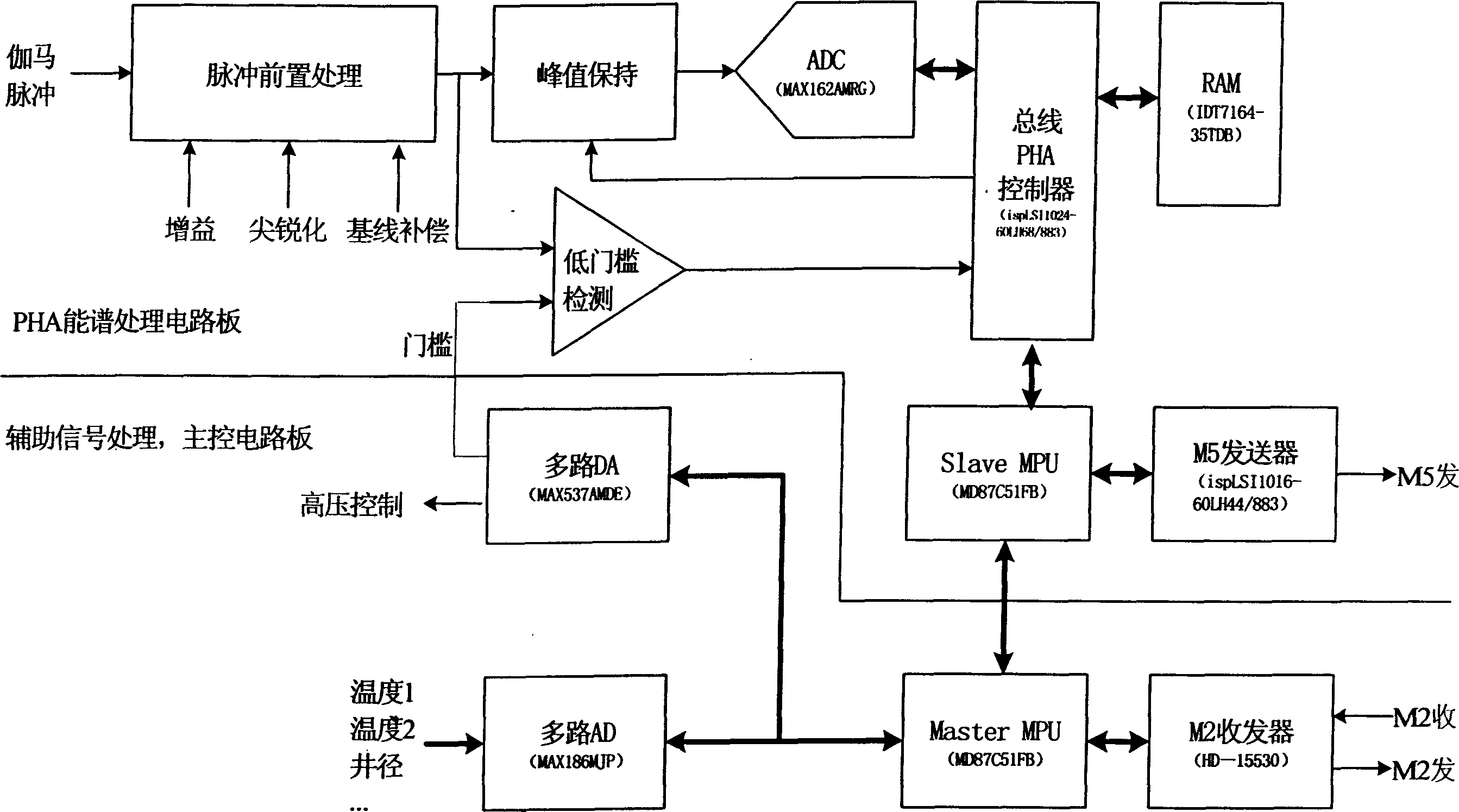

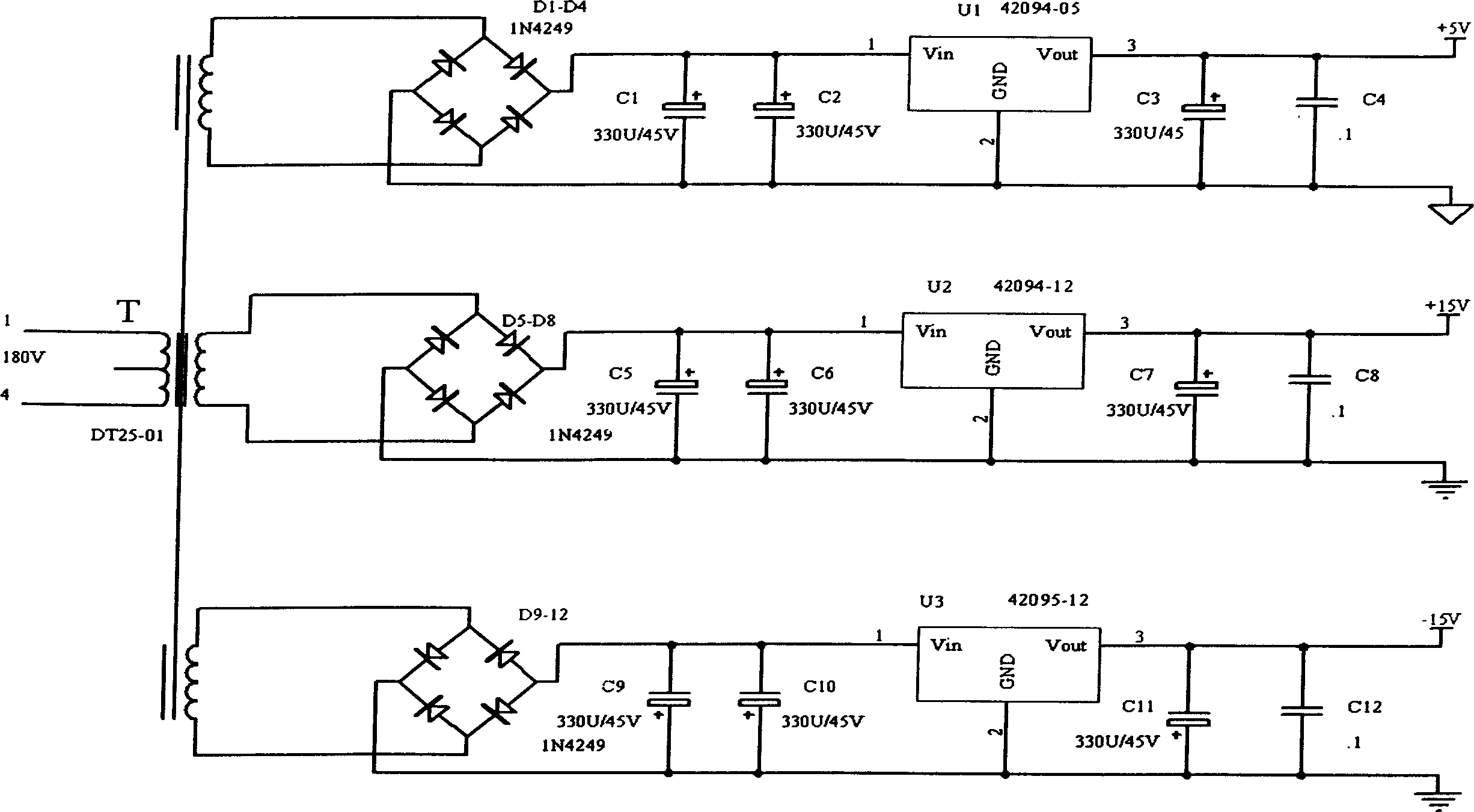

Well logger of natural ganmma energy specntrum

InactiveCN1760507AEasy to handleGuaranteed Conversion AccuracyBorehole/well accessoriesGamma energyAlloy

The present invention relates to a logging unit which can be used for measuring radioactive gamma energy spectrum naturally-existed in the borehole. Its technical scheme includes probe portion, mechanical structure portion and circuit portion, in which the mechanical structure portion mainly includes upper connector, external shell, power supply skeleton, circuit skeleton, scale mark and lower connector. The circuit portion mainly includes power supply plate, main control plate and PHA plate, the power supply plate is mounted on the aluminum alloy skeleton, and the main component of the probe portion includes a cesium iodide crystal, an optically-coupled piece and a photomultiplier, on the pins of photomultiplier are welded a voltage-dividing resistor and a filter capacitor, the described component is packaged in an aluminum metal cylinder, and the upper end of the probe is equipped with three lead-out wires which respectively are high-voltage power supply wire, signal output wire and grounding wire. The circuit composition of main control plate and PHA plate includes energy spectrum preamplifier circuit, energy spectrum communication interface, energy spectrum measurement and control circuit, pulse height analysis circuit and M5 data remote transmission control circuit. Besides, said invention also provides the concrete application field and range.

Owner:中国石化集团胜利石油管理局测井公司

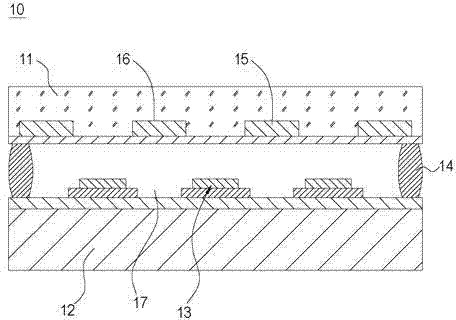

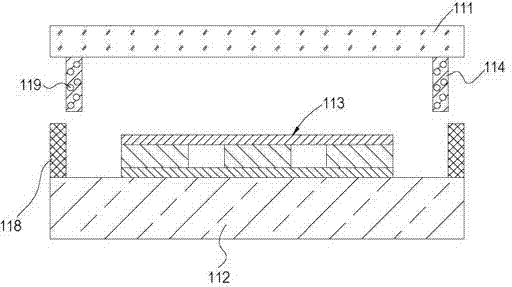

Organic light-emitting diode encapsulation structure and manufacturing method thereof

InactiveCN102447077AAvoid accessExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingPlastic materialsAluminum metal

Owner:CPTF VISUAL DISPLAY (FUZHOU) LTD +1

Method for preparing graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials

The invention discloses a method for preparing a graphene reinforced aluminum-based composite with multi-layer graphene nanoplatelets as raw materials, and relates to a method for the graphene reinforced aluminum-based composite. The method aims to solve the problems that the dispersion difficulty of single-layer or few-layer graphene is high in the preparation method of a graphene reinforced aluminum-based composite at present and the cost of the graphene reinforced aluminum-based composite is high. The preparation method comprises the steps that the multi-layer graphene nanoplatelets, aluminum metal and commercial pure aluminum blocks are weighed; secondly, the multi-layer graphene nanoplatelets are dispersed, and precast blocks are molded; thirdly, the aluminum metal is infiltrated; fourthly, severe plastic deformation treatment is conducted; and fifthly, composition homogenization treatment is conducted. The low-cost multi-layer graphene nanoplatelets are used as reinforcement raw materials, so that the cost is obviously lowered compared with composites with few-layer graphene as reinforcements directly; and the prepared graphene reinforced aluminum-based composite is excellent in comprehensive performance, and industrialization production and application can be achieved easily. The method is suitable for preparation of the graphene reinforced aluminum-based composite.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com