Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

206 results about "Aluminum Carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The aluminum salt form of carbonic acid, an antacid with phosphate binding activity. Upon oral administration of aluminum carbonate, aluminum is able to bind to phosphate in the intestines, including the radionuclide phosphate P-32, thereby preventing phosphate uptake.

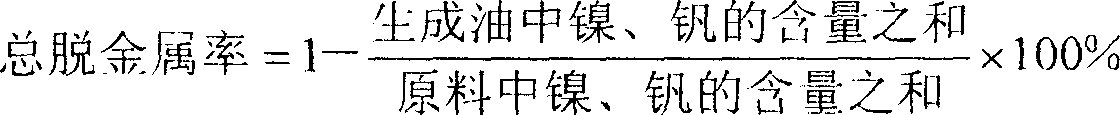

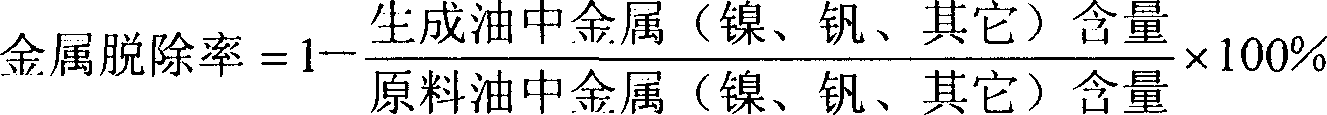

Slag oil hydro-demetallization catalyst and its preparing method

ActiveCN1782031AImprove performanceEasy to operateRefining to eliminate hetero atomsAluminum CarbonateAlumina hydrate

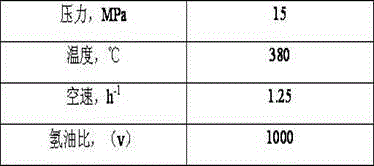

The slag oil hydrodemetallizing catalyst contains a kind of double-peak hole alumina carrier and supported Mo and / or W and Ni and / or Co metal components. The double-peak hole alumina carrier has pore volume of 0.8-1.6 ml / g, specific surface area 150-350 sq m / g, pore volume fraction of 10-30 nm size holes in 40-90 % and pore volume fraction of 100-2000 nm size holes in 10-60 %, and is prepared through mixing alumina hydrate and ammonium aluminum carbonate, forming and roasting. The slag oil hydrodemetallizing catalyst has simple preparation process and high hydrodemetallizing performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

A nano-modified highly stain-resistant elastic coating and its preparation method

InactiveCN102286233AOvercome sticking backImprove stain resistanceCoatingsPigment treatment with organosilicon compoundsColloidal silicaAluminum Carbonate

The invention provides a nano-modified highly stain-resistant elastic paint and a preparation method thereof, belonging to the technical field of building paint preparation. The composition and mass percent of the elastic coating provided by the present invention are: emulsion 40-50; water-based nano-colloidal silicon; 2-5; ultrafine aluminum carbonate; 15-25; modified nano-calcium carbonate 5-10; rutile titanium White powder; 8~15; pH regulator; 0.30~35; film-forming aid 0.50~0.65; elastic defoamer; 0.35~0.40; wetting agent 0.20~0.30; ; Leveling agent; 0.30~0.45; Bactericidal preservative; 0.10~0.15; Thickener; 0.10~0.20; Water; Balance. The nano-modified highly stain-resistant elastic paint provided by the present invention well achieves a balance among elasticity, stain resistance, water resistance, adhesion and practicability.

Owner:CHINA MCC17 GRP

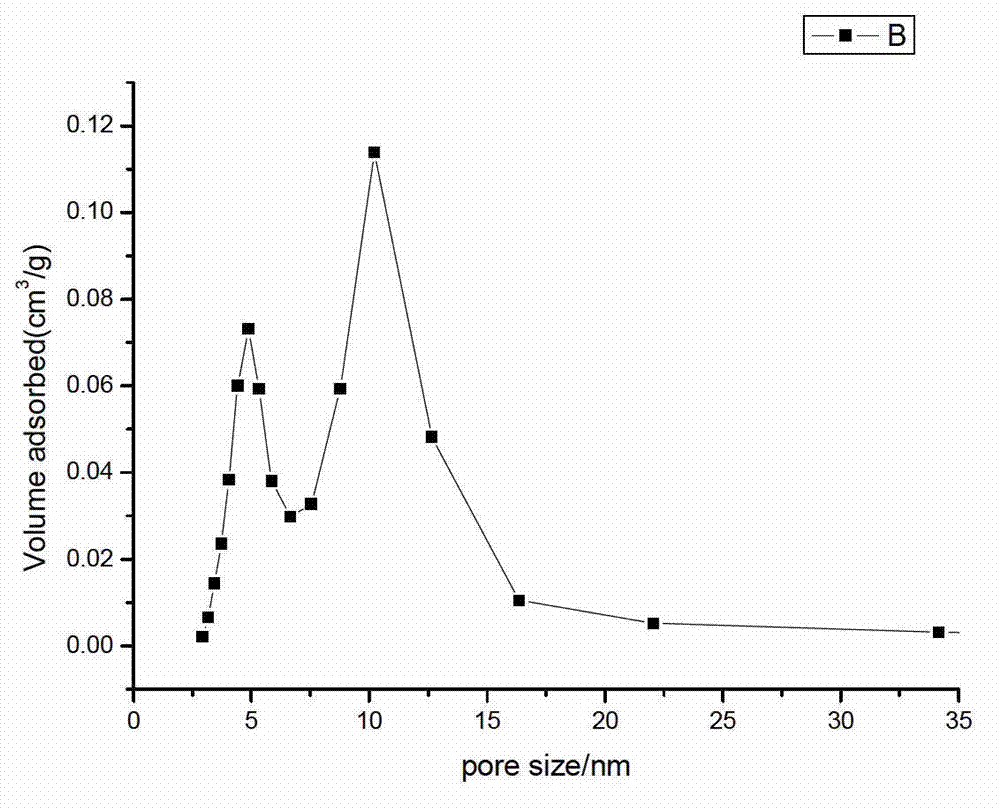

Solid phase preparation method for gamma-alumina with gradient distribution holes

InactiveCN102849763ALow costReduce manufacturing costCatalyst carriersAluminium oxide/hydroxide preparationAluminum CarbonateSolid reaction

The invention relates to a solid phase preparation method for gamma-alumina with gradient distribution holes. The method comprises: adopting a solid phase reaction to obtain a precursor ammonium aluminum carbonate hydroxide, and carrying out calcination to obtain gamma-alumina with a high specific surface area, gradient distribution holes and a large pore volume. The most prominent characteristic of the present invention comprises adopting a raw material solid phase reaction synthesis technology and controlling the property of the resulting gamma-alumina through synthesis conditions. In addition, the method of the present invention has characteristics of simpleness, easy operation, no requirement of addition of a pore-expanding agent, and cost saving, and is suitable for industrial mass production.

Owner:PETROCHINA CO LTD +1

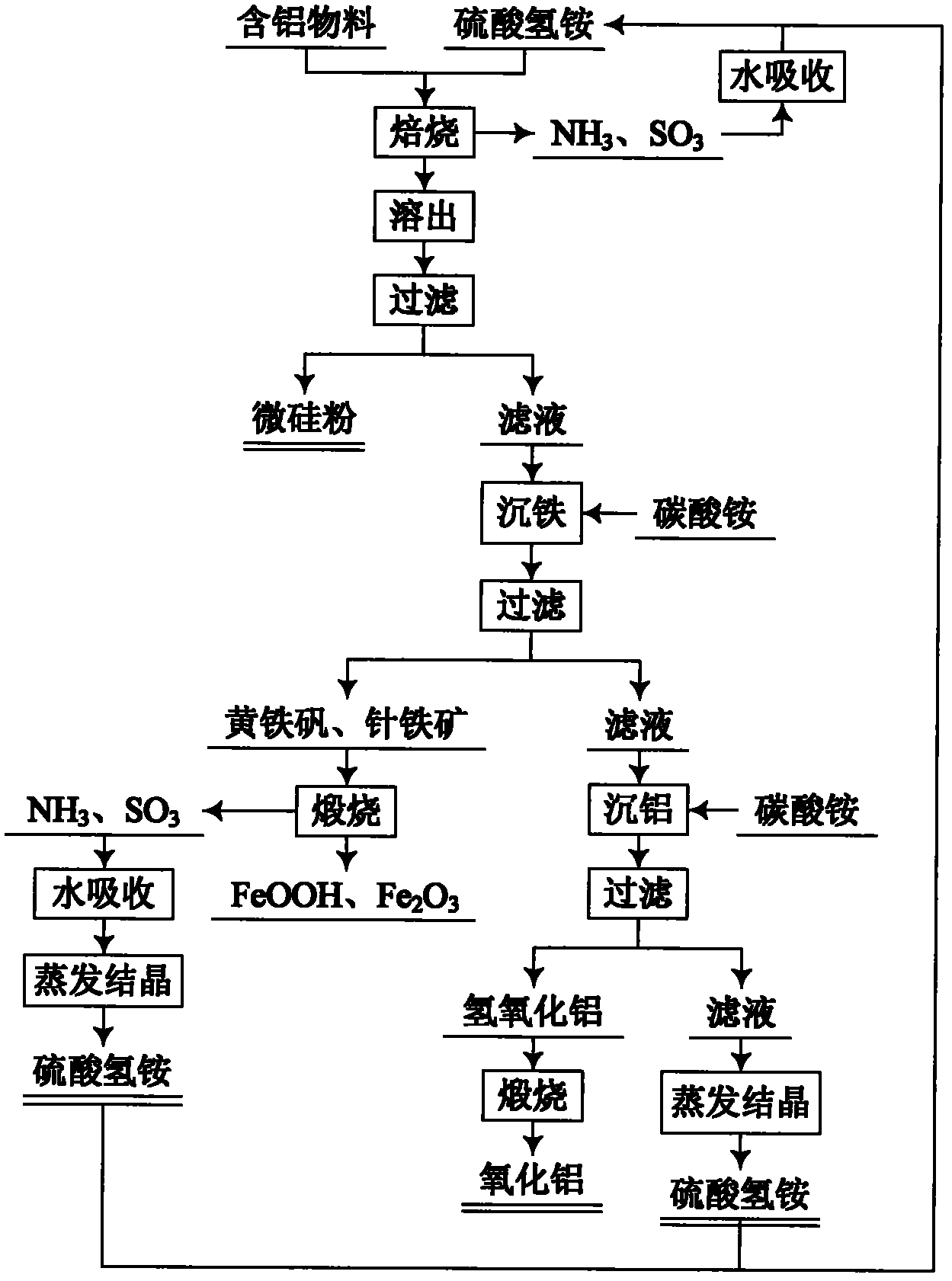

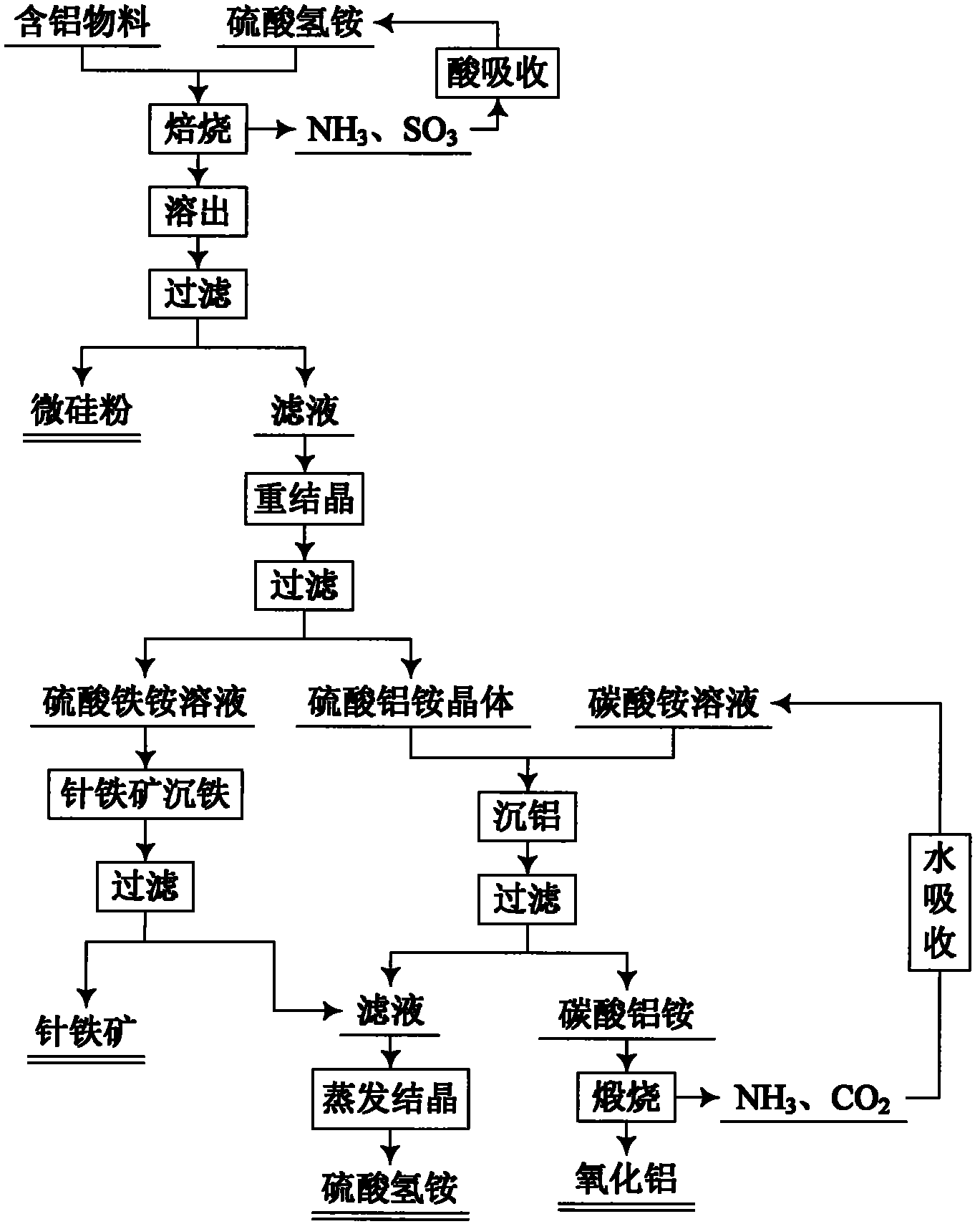

Method for comprehensive utilization of aluminum-containing material

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

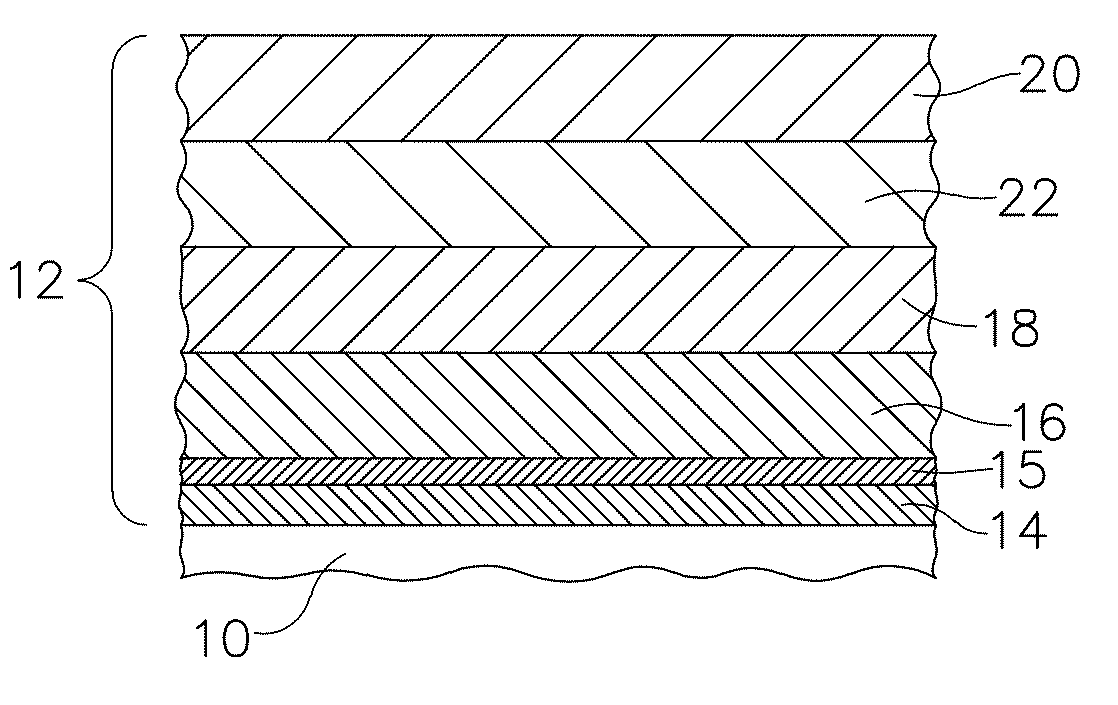

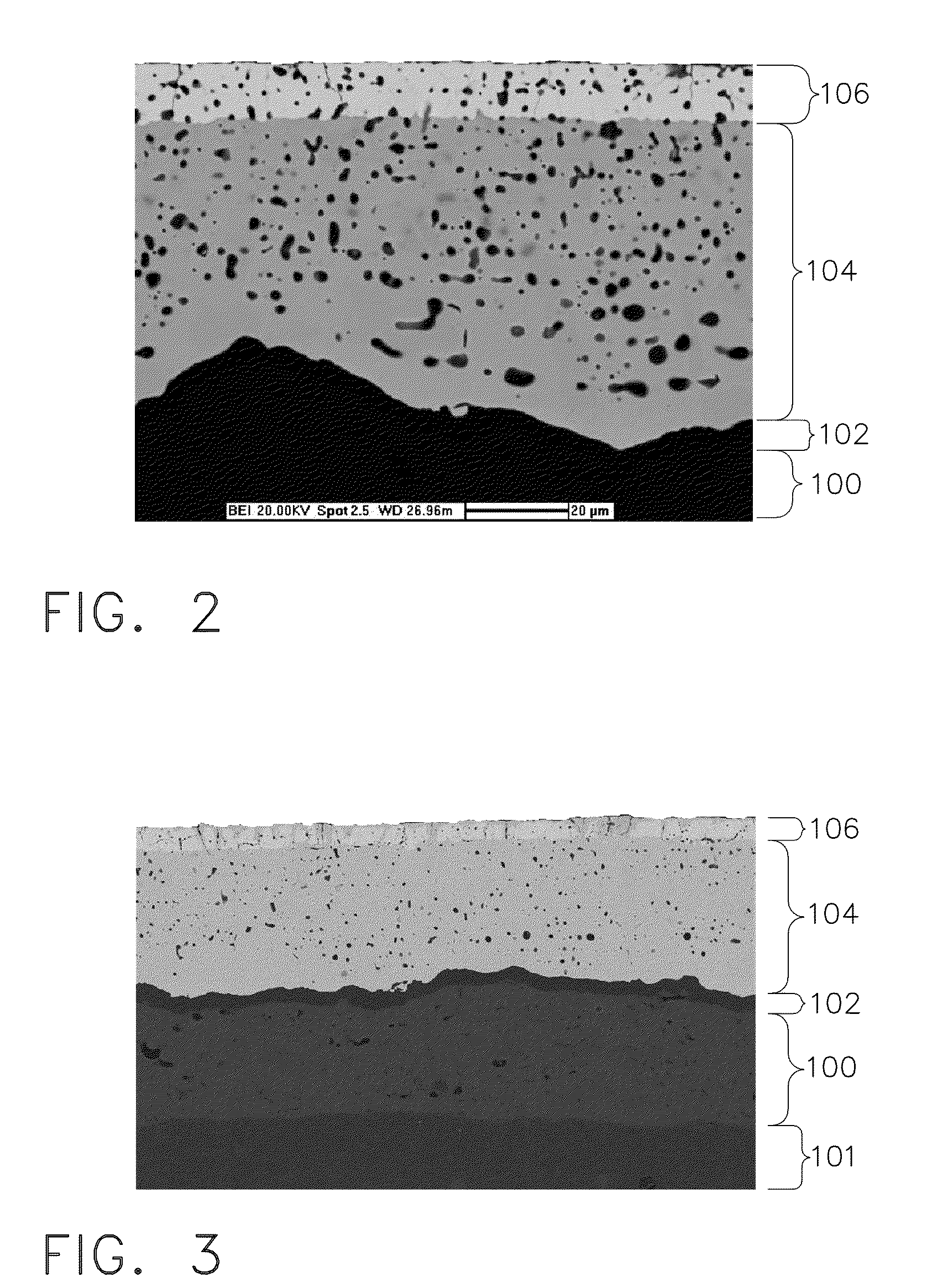

Methods of improving surface roughness of an environmental barrier coating and components comprising environmental barrier coatings having improved surface roughness

Methods for improving surface roughness of an environmental barrier coating including providing a component having a plasma sprayed environmental barrier coating; applying a slurry to the environmental barrier coating of the component, the slurry being a transition layer slurry or an outer layer slurry; drying the environmental barrier coating having the applied slurry; and sintering the component to produce a component having an improved surface roughness where the slurry includes a solvent; a primary transition material, or a primary outer material; and a slurry sintering aid selected from iron oxide, gallium oxide, aluminum oxide, nickel oxide, titanium oxide, boron oxide, alkaline earth oxides, carbonyl iron, iron metal, aluminum metal, boron, nickel metal, iron hydroxide, gallium hydroxide, aluminum hydroxide, nickel hydroxide, titanium hydroxide, alkaline earth hydroxides, iron carbonate, gallium carbonate, aluminum carbonate, nickel carbonate, boron carbonate, alkaline earth carbonates, iron oxalate, gallium oxalate, aluminum oxalate, nickel oxalate, titanium oxalate, solvent soluble iron salts, solvent soluble gallium salts, solvent soluble aluminum salts, solvent soluble nickel salts, solvent titanium salts, solvent soluble boron salts, and solvent soluble alkaline earth salts.

Owner:GENERAL ELECTRIC CO

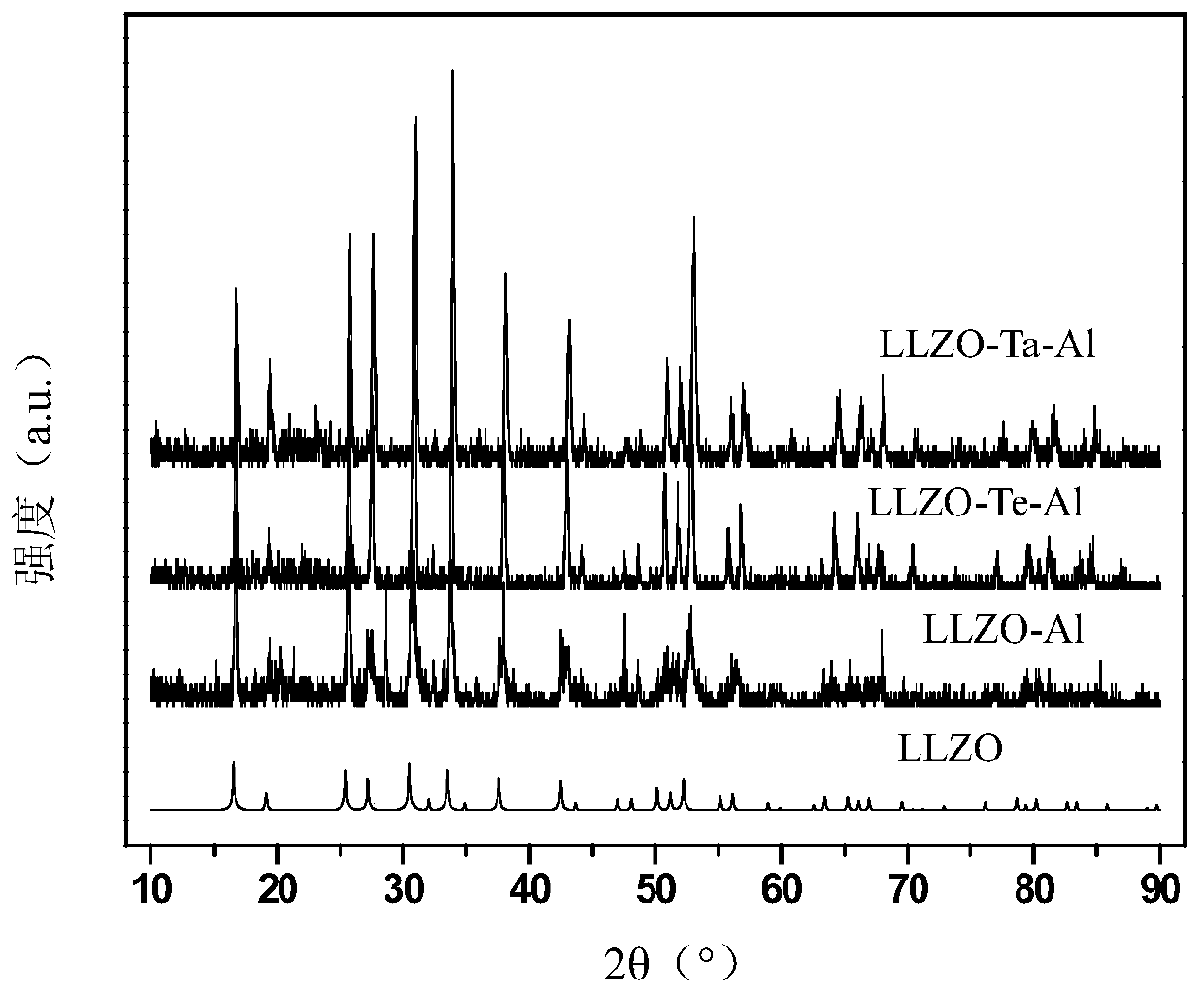

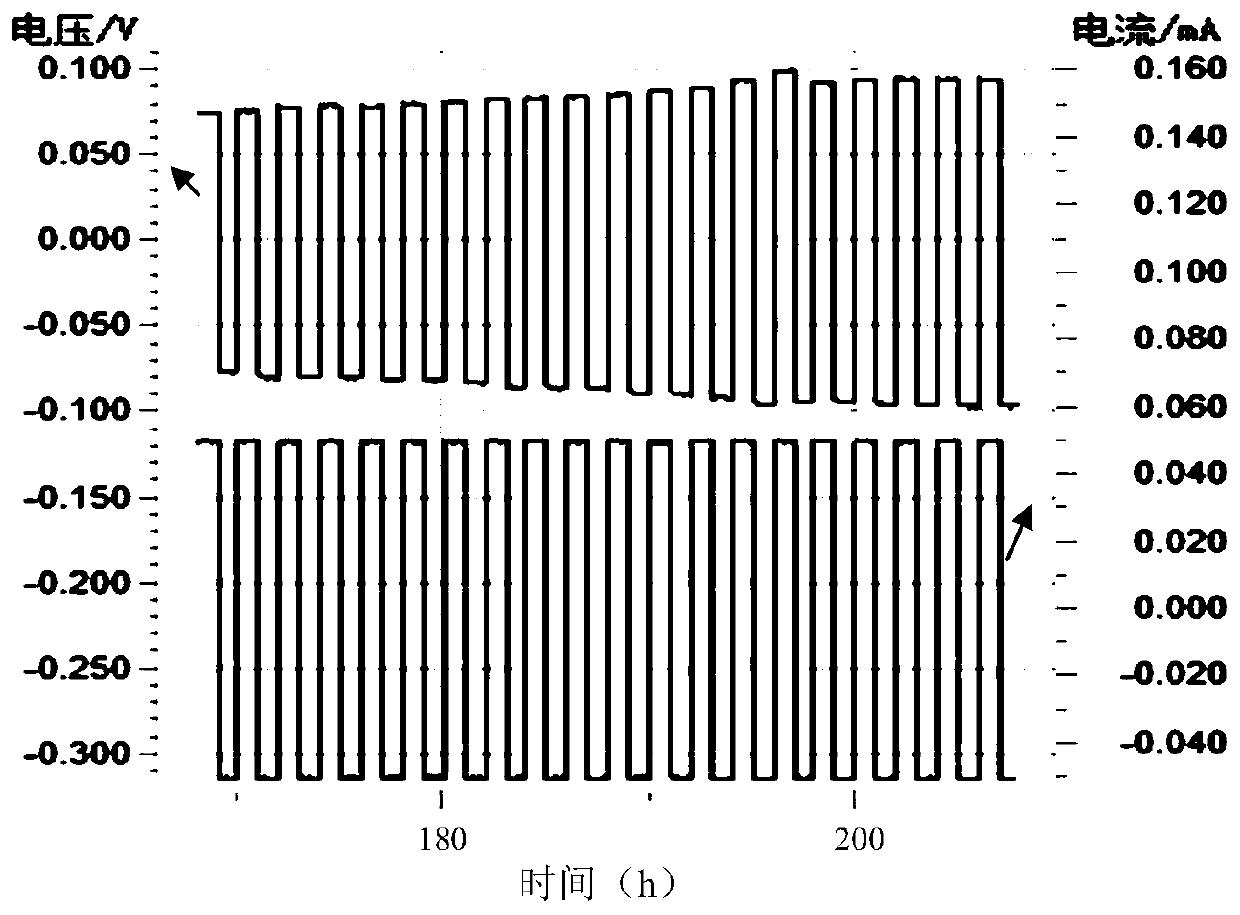

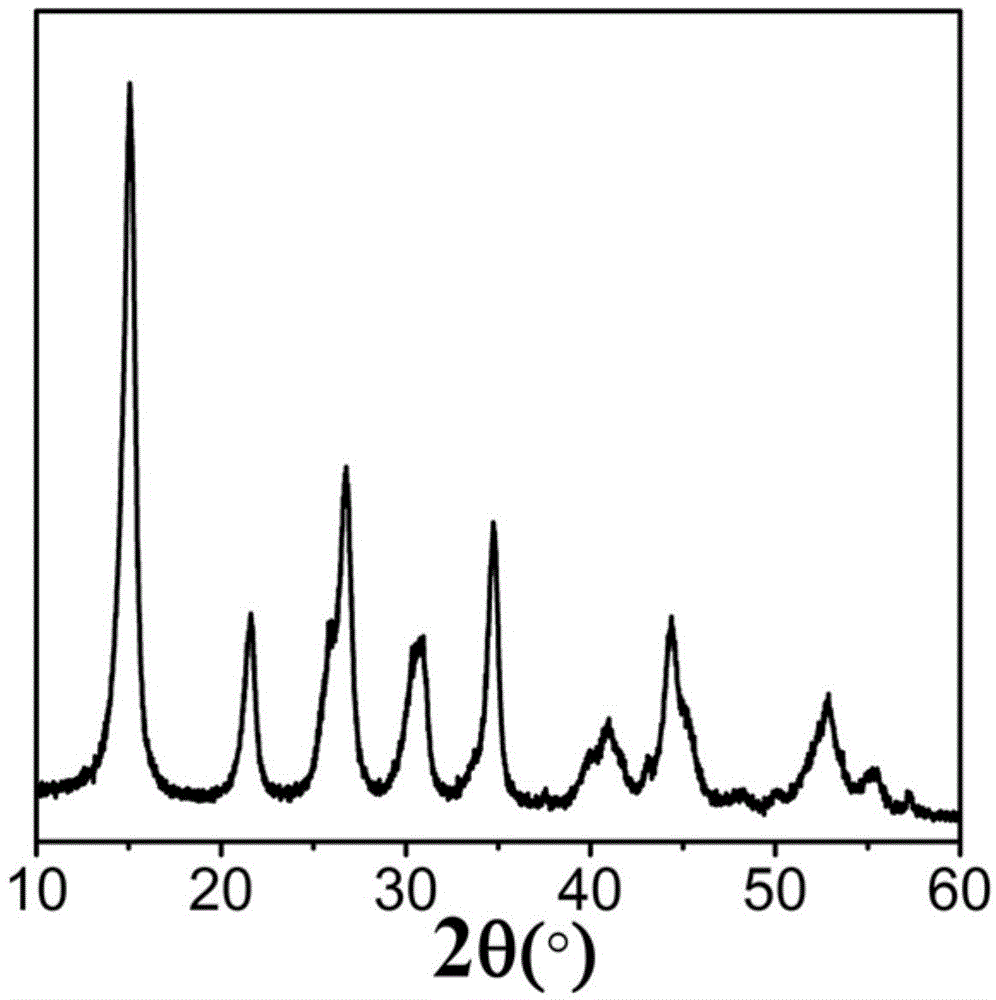

Multi-doping pomegranate-shaped solid electrolyte material and preparation method thereof

InactiveCN109888374AImprove electrochemical performanceLower sintering temperatureSecondary cellsAluminum CarbonateElectrochemistry

The invention belongs to the technical field of a solid electrolyte, and discloses a multi-doping pomegranate-shaped solid electrolyte material and a preparation method thereof. The constituent of themulti-doping pomegranate-shaped solid electrolyte material is A-Li<7-bX>La<3>Zr<2-x>M<x>O<12>, wherein M is more than one of Te, Ta, Ti, Nb, Ge, Ga, Gd and Bi, x is more than or equal to 0.1 but lessthan or equal to 1.5, the numerical value b is changed with the valence state of the M, and A is one or more of Al2O3, Al(NO3)3, aluminum carbonate, ZnO and MgO. The invention also discloses the preparation method of the solid electrolyte material. With the mode of multiple doping, the sintering temperature is reduced, the energy consumption is reduced, and the obtained pomegranate-shaped solid electrolyte material has relatively good electrochemical performance.

Owner:SOUTH CHINA UNIV OF TECH

Slag oil hydro-demetallization catalyst and its preparing method

ActiveCN1782033AImprove performanceEasy to operateRefining to eliminate hetero atomsAluminum CarbonateHydrogen

The slag oil hydrogen de-metallizing catalyst contains a kind of macroporous alumina carrier and supported Mo and / or W and Ni and / or Co metal components. The alumina carrier has medium pore size of 25-35 nm, pore volume of 1.2-2.0 ml / g, and specific surface area 200-350 sq m / g, and is prepared through mixing ammonium aluminum carbonate and one kind of nitrogen containing compounds except acid, forming and roasting. Compared with available slag oil hydrogen de-metallizing catalysts, the catalyst of the present invention has high hydrogen de-metallizing performance and simple preparation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

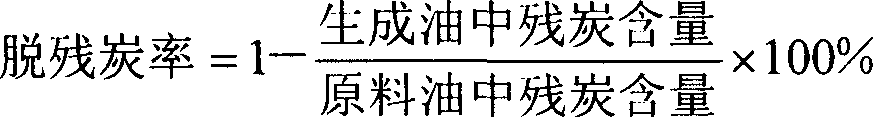

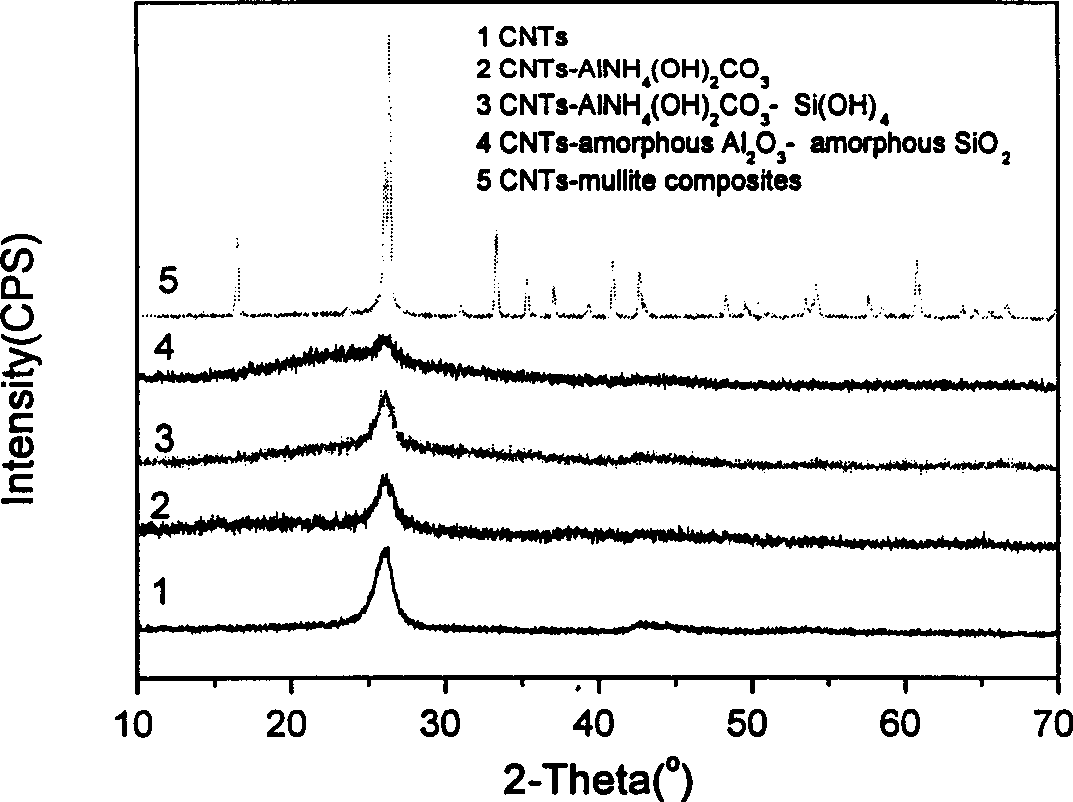

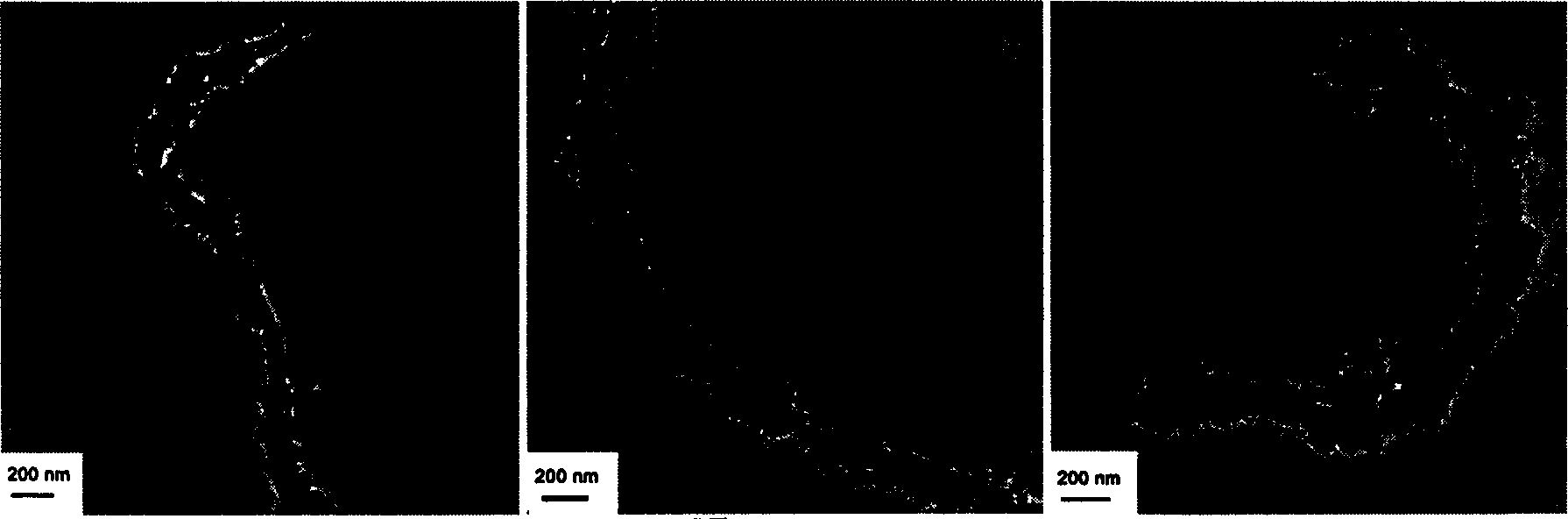

Preparation method of composite powder of mullite precursor in situ enveloped carbon nanometer tube

The invention provides a method of preparing composite powder through coating carbon nano-tube by mullite-predecessor. It is characterized by: put carbon nano-tube after surface working to aqueous solution to synthesize composite powder of carbon nano-tube-ammonium aluminum carbonate-silicon oxide sol, wash, dry, riddle and burn it to get composite powder of carbon nano-tube coated by mullite-predecessor. The construction feature is: the mollite-predecessor is on the wall of carbon nano-tube which could accomplish total coating to carbon nano-tube in optimum condition. We could get composite powder of carbon nano tube-mollite predecessor with different ratio through controlling solution strength. The convention accomplishes the tight bond of mollite predecessor and carbon nano tube in the way of original position coating synthesis, which is an effective approach of preparing carbon nano tube / mollite composite material. Said composite material is the predecessor of preparing carbon nano tube / mollite composite material, also, could be used as reinforced body of other material with wide application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

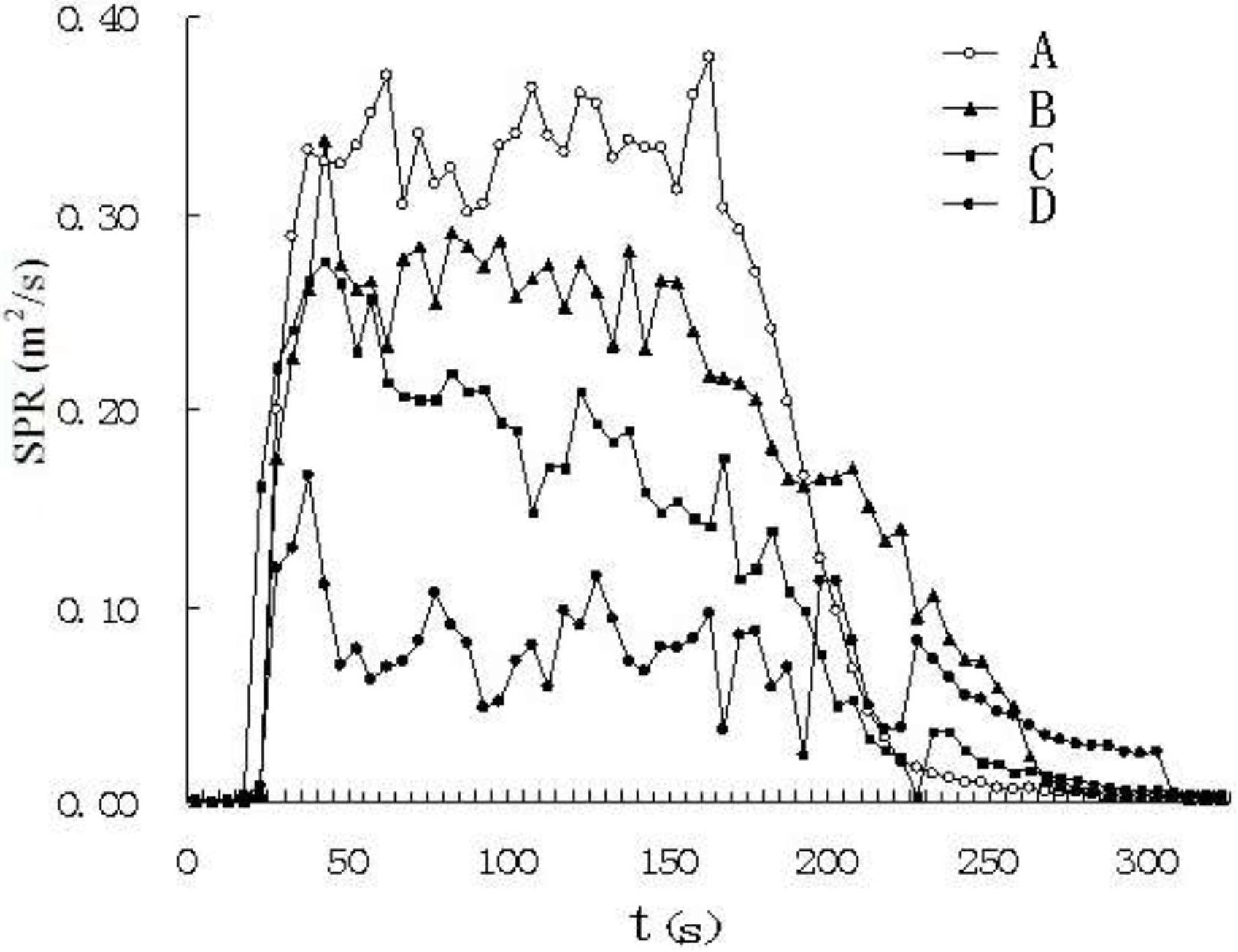

Low-smoke flame-retardant acrylonitrile butadiene styrene (ABS) alloy material

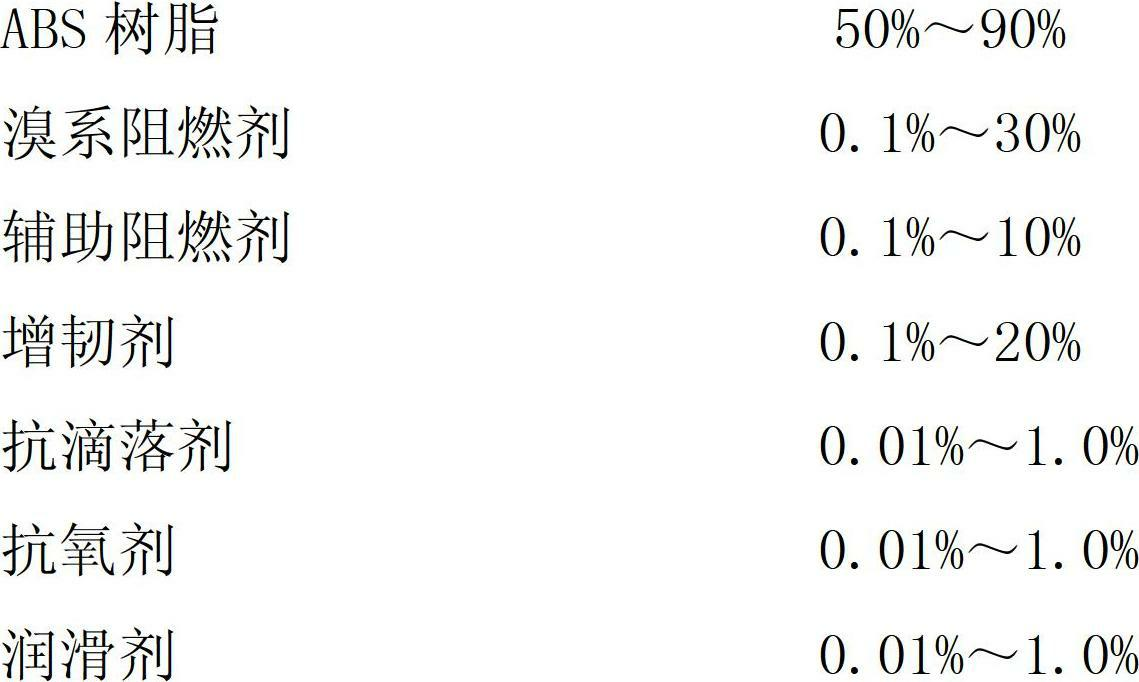

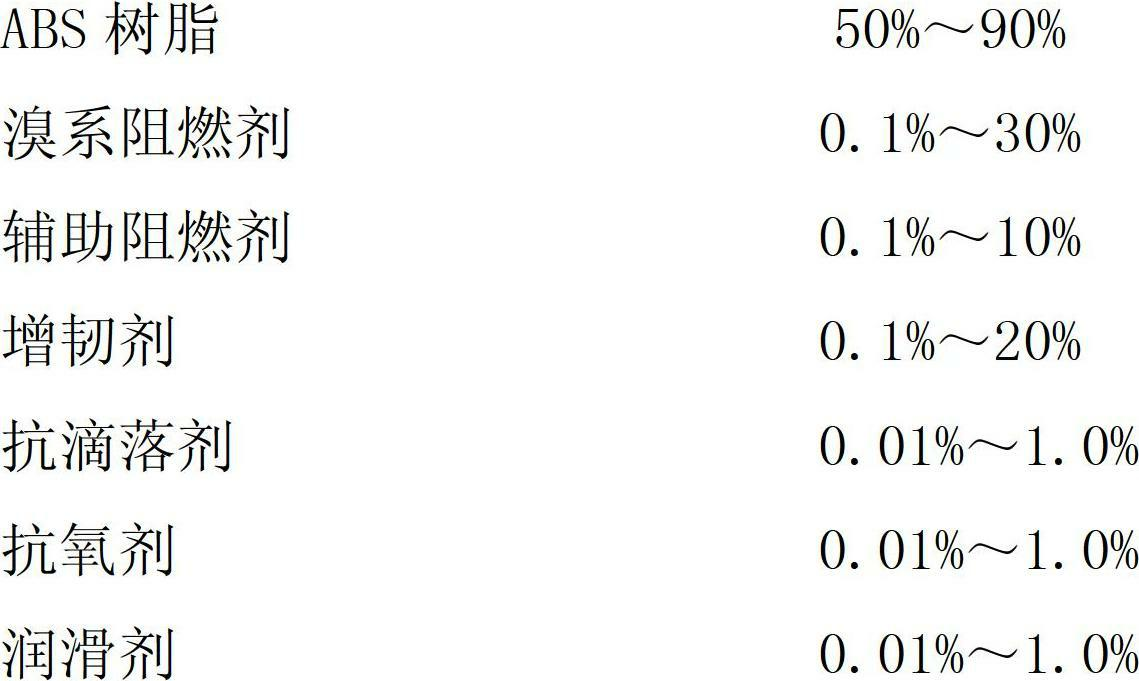

The invention relates to the technical field of the high polymer material, in particular to a low-smoke flame-retardant acrylonitrile butadiene styrene (ABS) alloy material. The ABS alloy material comprises the following components in percentage by weight: 50-90% of ABS resin, 0.1-30% of brominated flame retardant, 0.1-10% of auxiliary flame retardant, 0.1-20% of toughening agent, 0.01-1% of anti-dripping agent, 0.01-1% of antioxidant and 0.01-1% of lubricating agent. The auxiliary flame retardant in the low-smoke flame-retardant ABS alloy material is antimony sodium silicon composite flame retardant, zinc borate, aluminium magnesium carbonate compound and antimonous oxide or combination of several of the antimony sodium silicon composite flame retardant, the zinc borate, the aluminium magnesium carbonate compound and the antimonous oxide. According to the auxiliary flame retardant, the use amount of antimony white can be lowered, the production cost of the flame-retardant ABS alloy material is lowered, the smoke release rate and the smoke release amount in the material burning process are lowered, and the low-smoke flame-retardant ABS alloy material has the advantages of good flame-retardant effect and obvious social benefit and industrial application value.

Owner:JIANGSU AGT TECH DEV +1

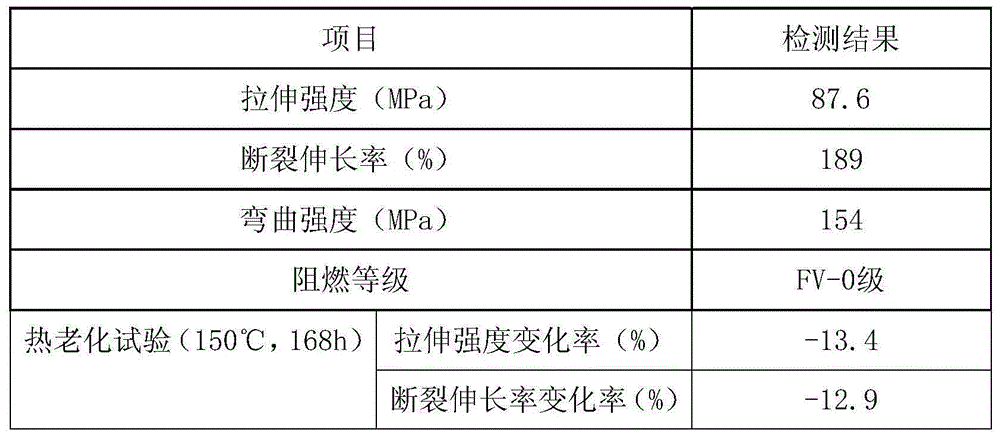

Flame retardant cable sheath material with high malleability and preparation method

ActiveCN103524967AImprove ductilityIncrease elasticityRubber insulatorsInsulated cablesCarbon blackDicumyl peroxide

The invention discloses a flame retardant cable sheath material with high malleability and a preparation method. The cable sheath material is prepared from the following raw materials, by weight, 60-80 parts of acrylate rubber, 20-30 parts of polyurethane rubber, 10-15 parts of EVA, 5-10 parts of EVA-g-MAH, 4-8 parts of basic sodium aluminum carbonate, 5-10 parts of ammonium polyphosphate, 8-12 parts of zinc borate, 3-6 parts of ammonium molybdate, 15-20 parts of carbon black N550, 3-5 parts of salt basic magnesium carbonate, 2-3 parts of zinc stearate, 1.5-2.5 parts of bis[3-(triethoxysilyl)propyl]tetrasulfide, 1-2 parts of anti-scorching agent CTP, 4-6 parts of polyethylene wax, 0.4-0.8 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 10-15 parts of nano potash feldspar, 5-10 parts of potassium titanate whiskers and 3-6 parts of composite filling materials. The sheath material has high malleability, high elasticity, good flexibility, high breaking elongation and tensile strength, good flame retardant effects, and has incombustibility and self-extinguishing property. The generated smoke is little during burning. No harmful gases are generated. The sheath material is durable, safe and environmentally friendly, and has wide application prospects.

Owner:滁州三界外信息科技有限公司

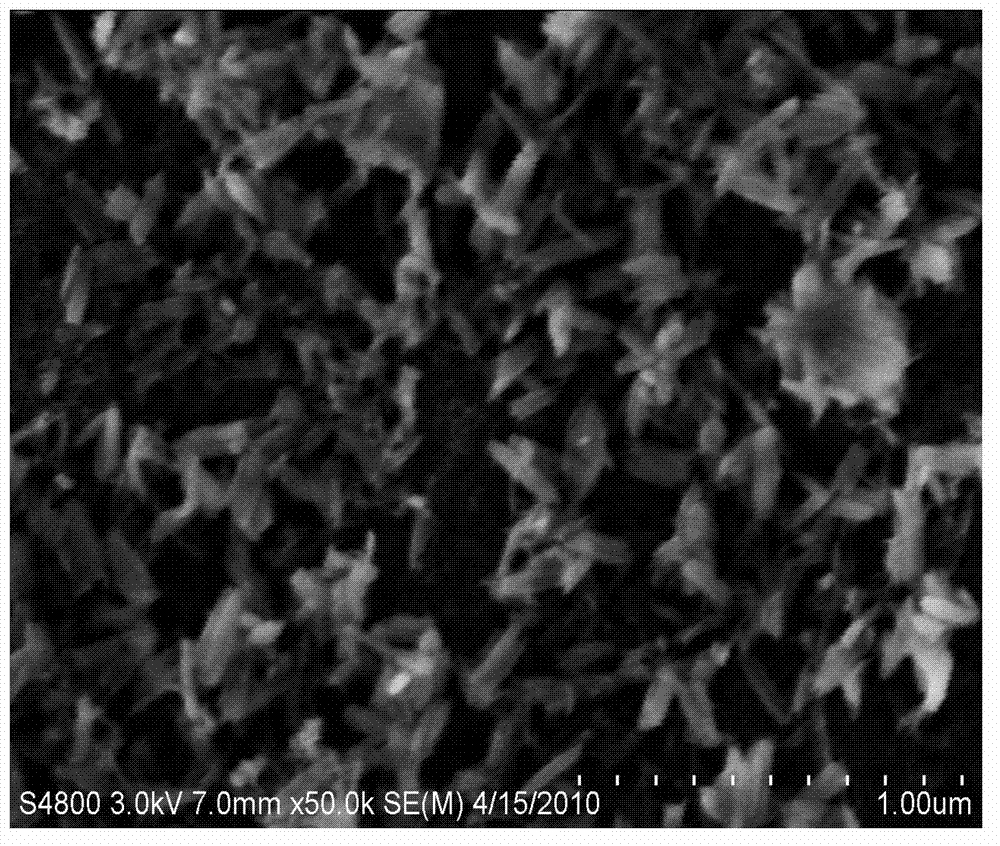

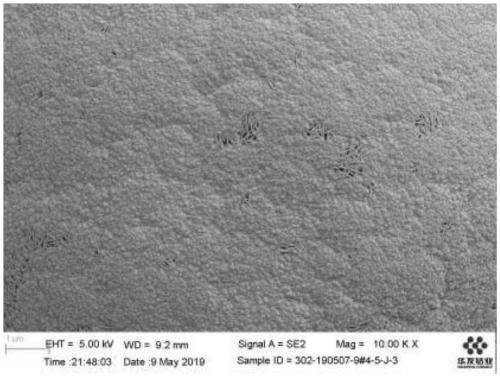

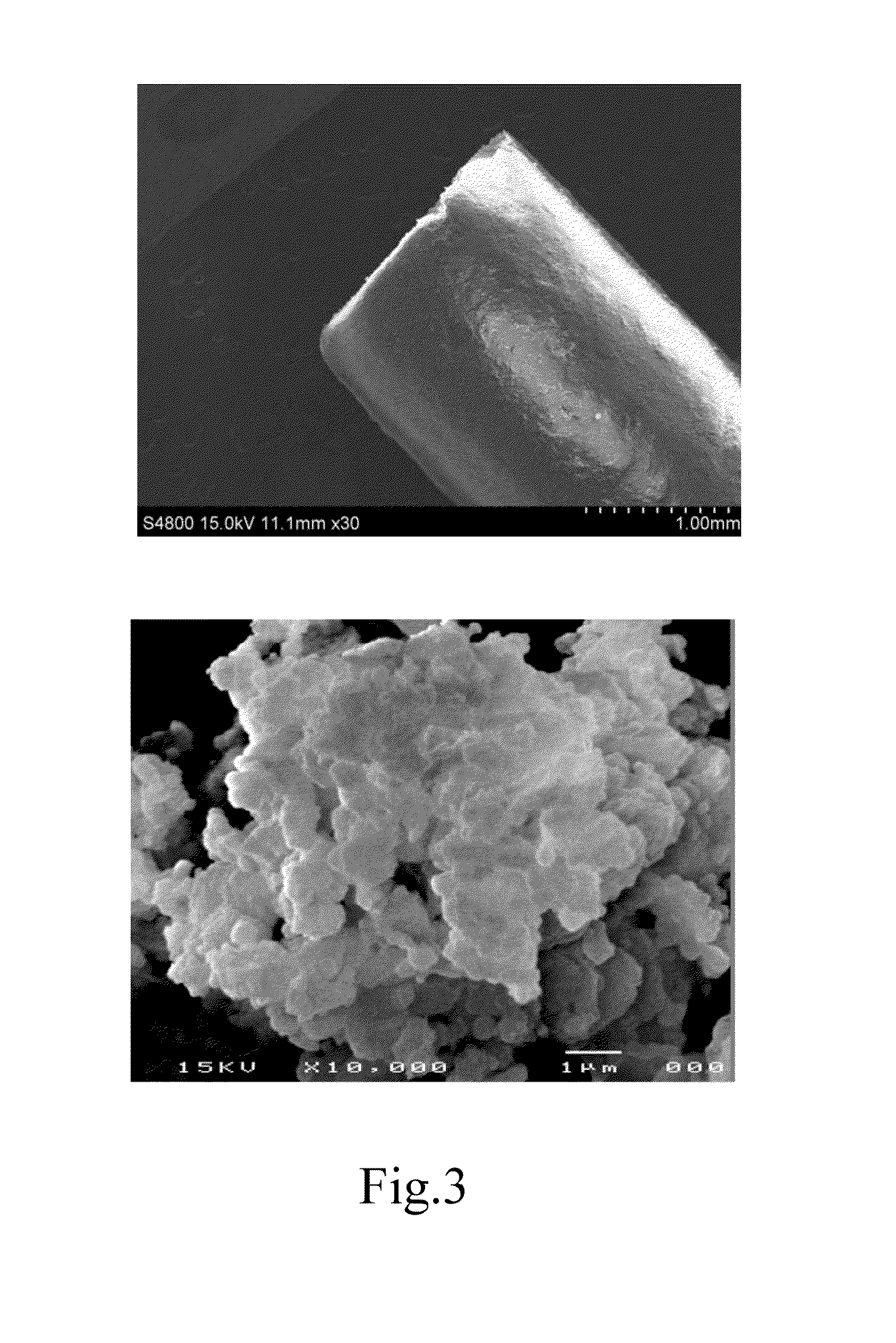

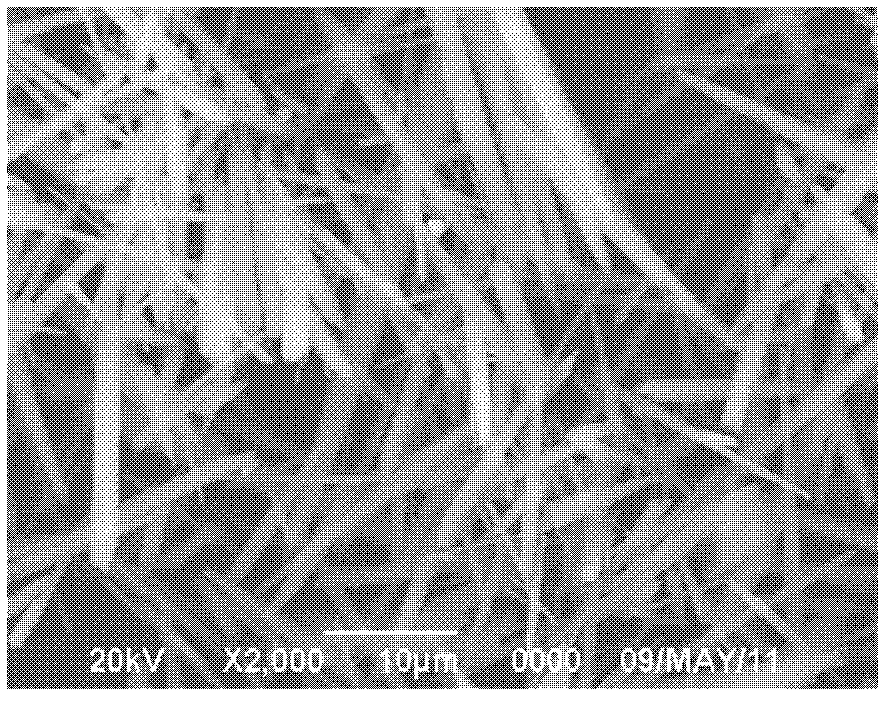

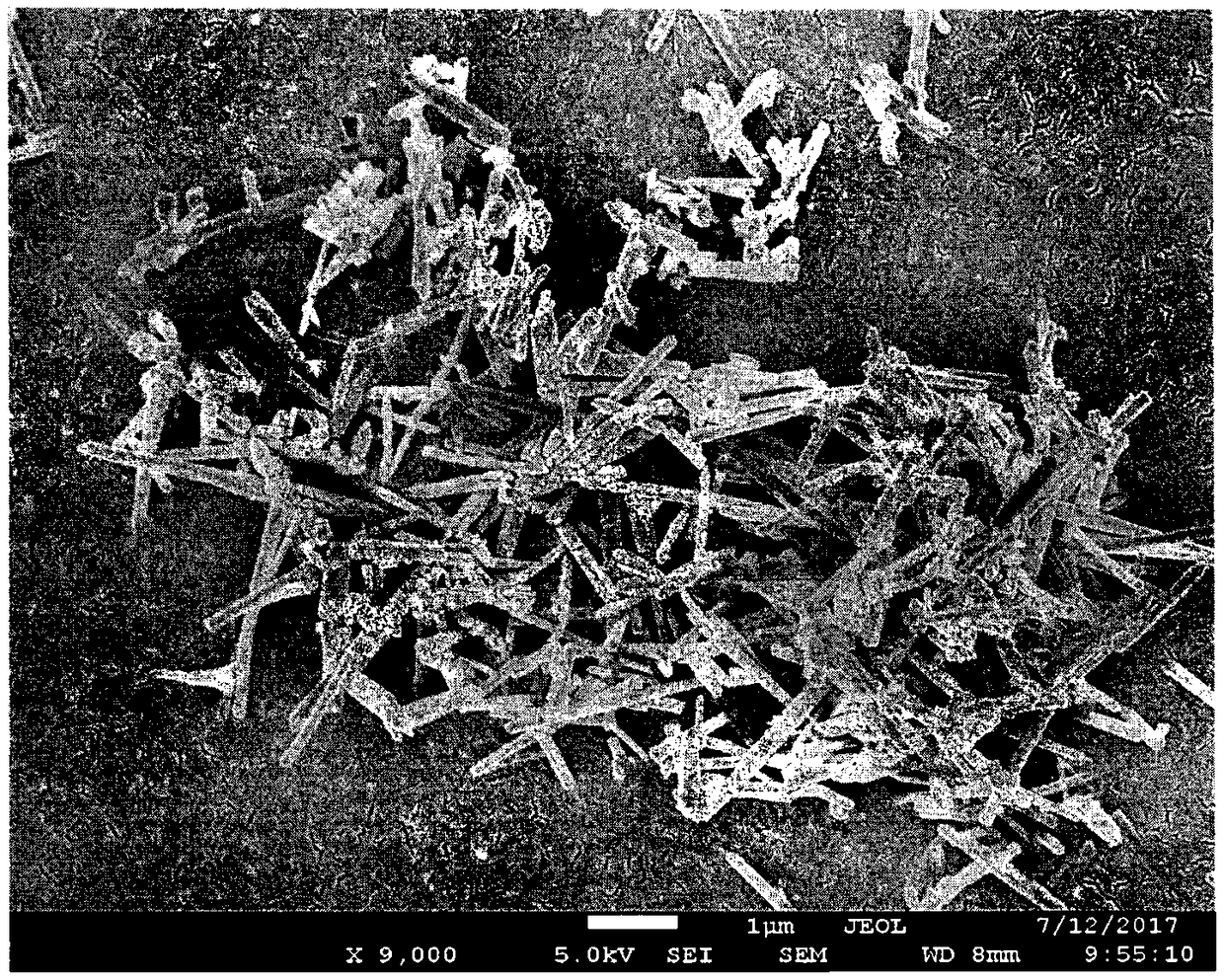

Preparation method for ammonium aluminum carbonate hydroxide fiber with high length-diameter ratio

InactiveCN103911686ACorrosion resistanceHigh temperature resistantInorganic material artificial filamentsFiberWater baths

The invention discloses a preparation method for an ammonium aluminum carbonate hydroxide fiber with a high length-diameter ratio. The preparation method comprises the following steps: (1) measuring distilled water with a measuring cylinder, adding the distilled water into a beaker and carrying out heating to a temperature of 60 to 80 DEG C in a in water bath; (2) measuring distilled water with a transfer pipette, adding the distilled water into another beaker, carrying out magnetic stirring, weighing aluminum nitrate and urea, adding weighed aluminum nitrate and urea into the beaker and allowing aluminum nitrate and urea to be completely dissolved so as to obtain a component A; (3) measuring a part of distilled water in a water-bath kettle with the transfer pipette, adding the distilled water into a small beaker, adding a surfactant and carrying out uniform mixing under stirring so as to obtain a component B; (4) slowly adding the component B into the component A and carrying out uniform mixing under magnetic stirring; (5) pouring a mixed liquid obtained in the step (4) into a hydro-thermal reaction vessel so as to obtain a white precipitate; and (6) washing the white precipitate with distilled water and absolute ethyl alcohol a plurality of times and successively carrying out ultrasonic treatment, pumping filtration, drying and grinding so as to obtain the ammonium aluminum carbonate hydroxide fiber with a high length-diameter ratio. The prepared ammonium aluminum carbonate hydroxide fiber has the advantages of no corrosion, low viscosity, combustion resistance, environment friendliness, easy dispersion in a solution and a high length-diameter ratio.

Owner:WUYI UNIV

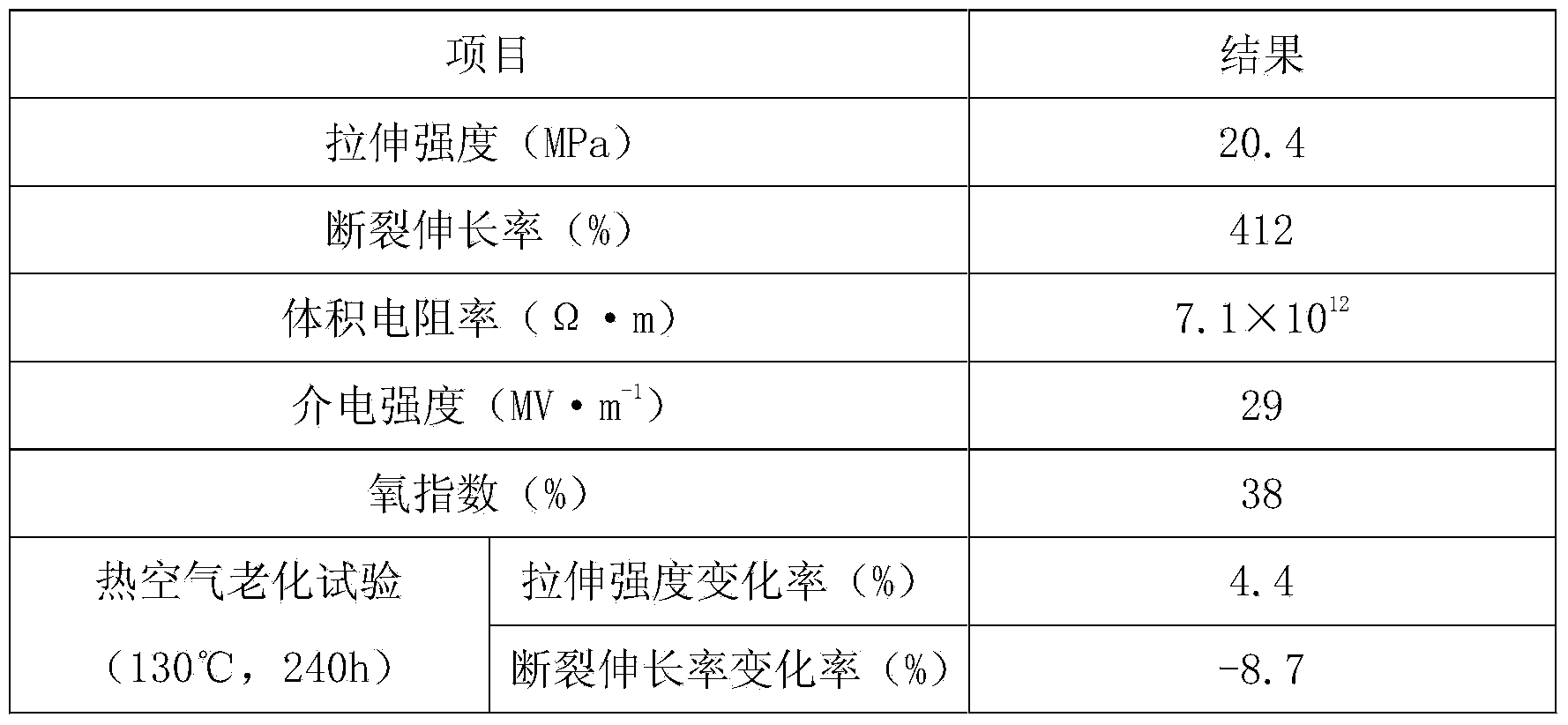

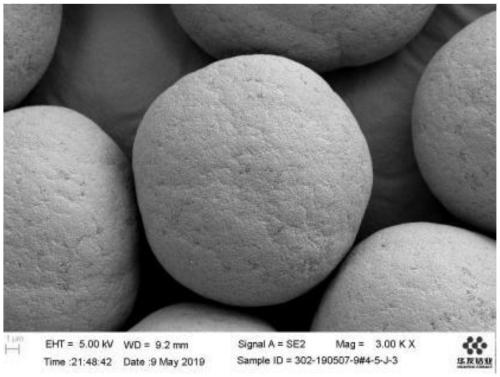

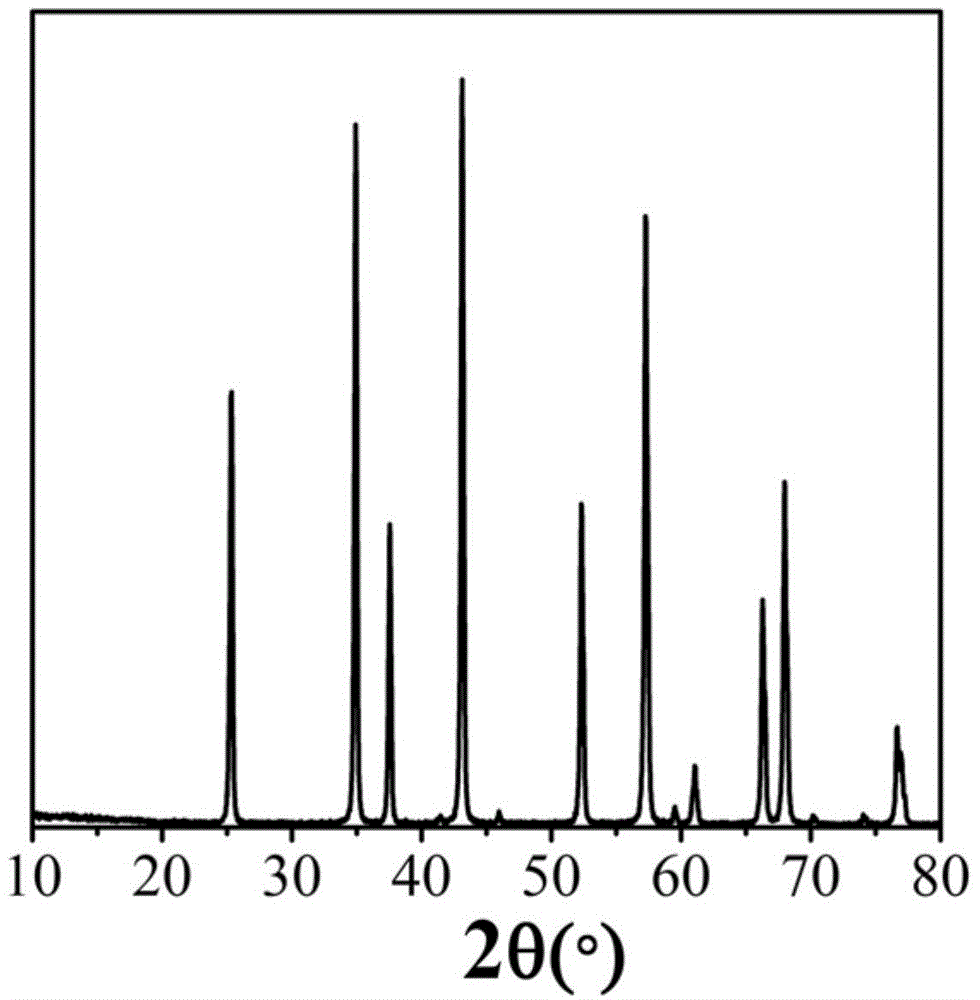

Nano basic aluminum cobalt carbonate/cobalt carbonate composite spherical precursor

ActiveCN111082007AGood dispersionGood sphericityMaterial nanotechnologySecondary cellsAluminum CarbonatePhysical chemistry

The invention relates to the technical field of precursors of lithium cobalt oxide serving as a positive electrode material of a lithium ion battery, and particularly relates to an aluminum cobalt carbonate / cobalt carbonate composite spherical precursor and a preparation method thereof. The nano basic aluminum cobalt carbonate / cobalt carbonate composite spherical precursor is composite material formed by taking spherical cobalt carbonate as a main body material and uniformly distributing nano basic aluminum cobalt carbonate crystal particles in a bulk phase of the main body material, the expression of the composite material is (1-x)[CoCO3].x [Co6Al2CO3(OH)16.4H2O], and x is greater than or equal to 0.001 and less than or equal to 0.04. The product obtained by the invention has better aluminum distribution uniformity, is applied to the preparation of lithium cobalt oxide (LCO), is easier to uniformly dope Al into LCO crystal lattices, and has excellent high-voltage cycle performance.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

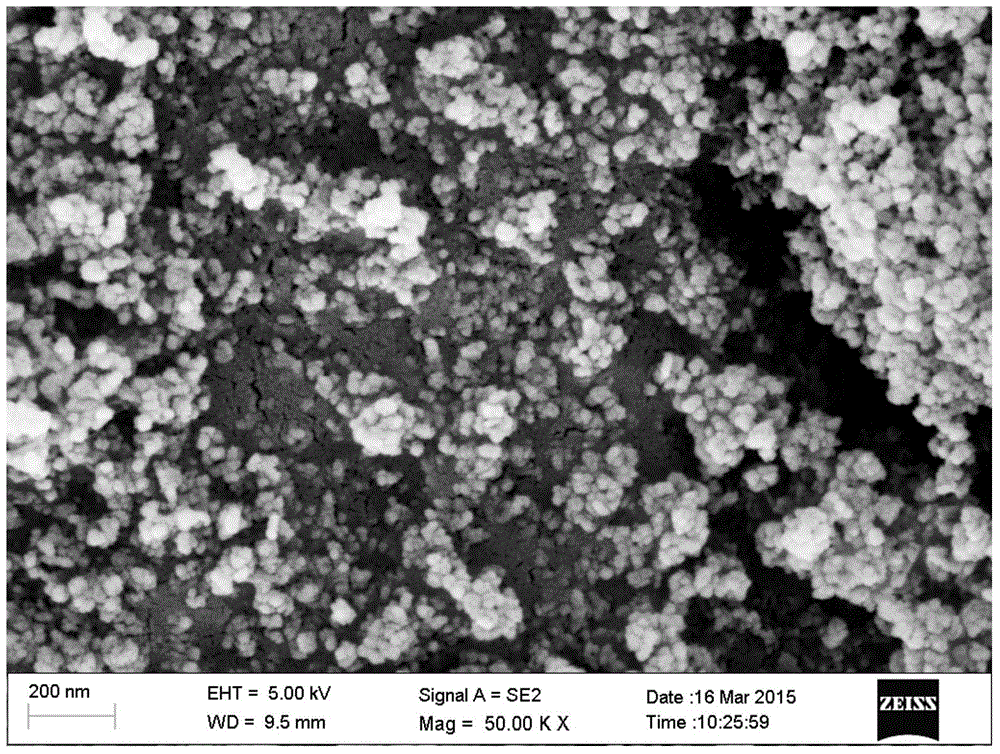

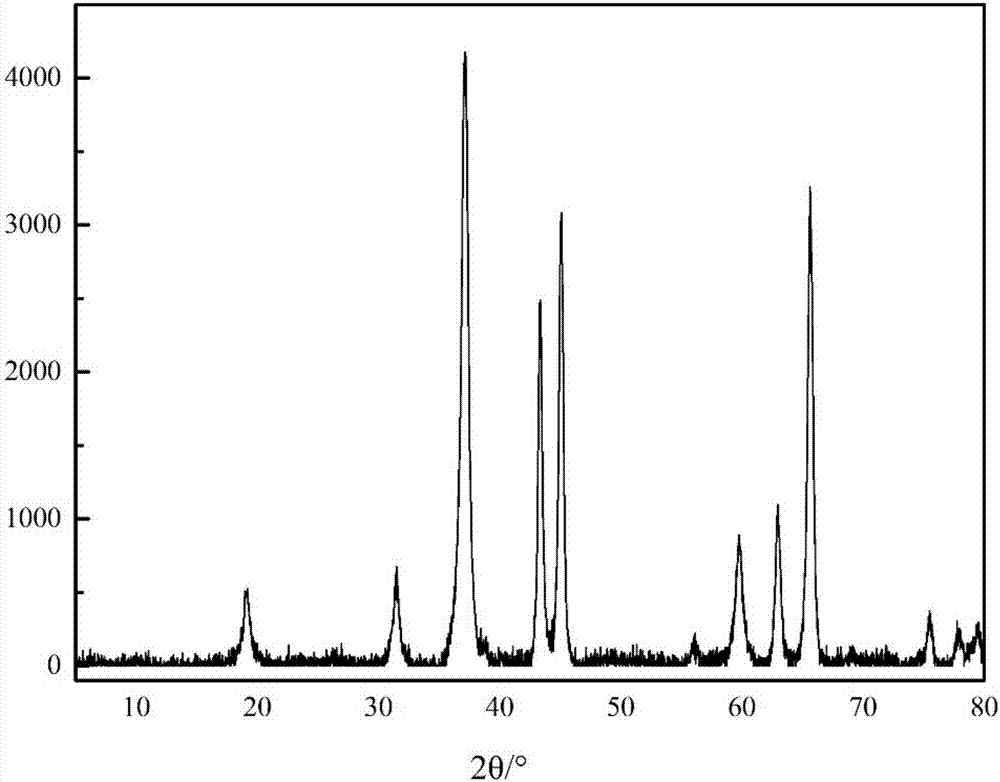

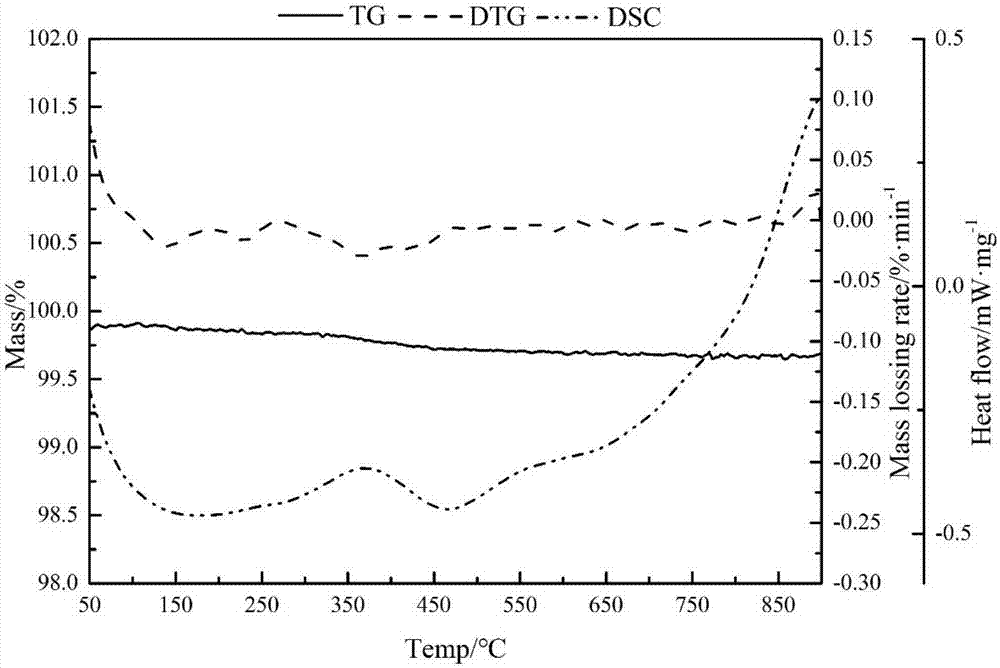

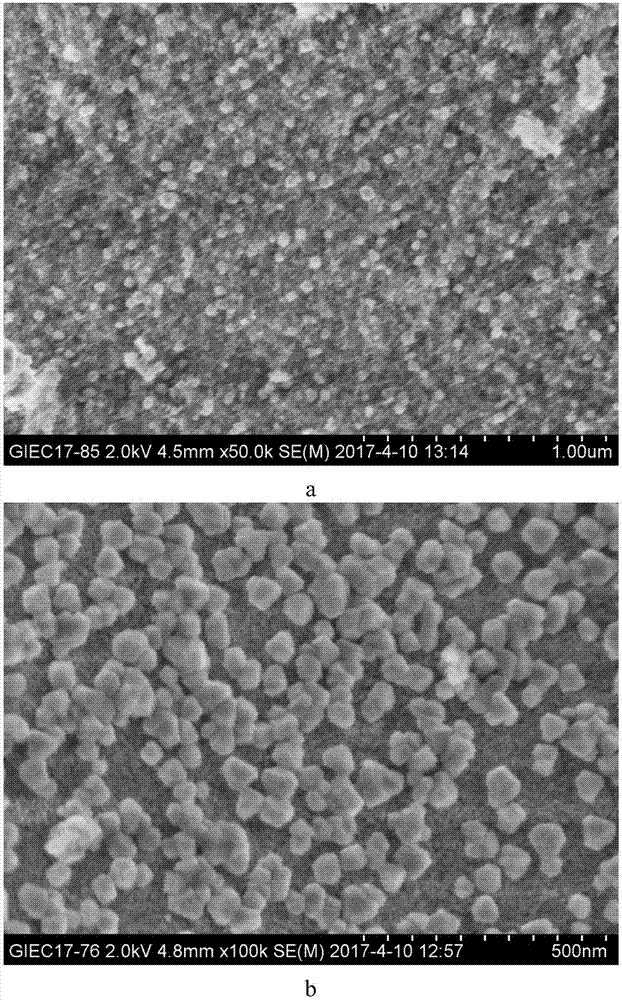

Preparation method of ultrafine alpha-Al2O3 powder

ActiveCN104891542AInhibition of agglomerationAccelerate emissionsAluminium oxides/hydroxidesAluminum CarbonateChemical reaction

The invention belongs to the field of inorganic nonmetallic materials, and particularly relates to a preparation method of ultrafine alpha-Al2O3 powder. The preparation method of the ultrafine alpha-Al2O3 powder comprises the following steps of using solid powder of aluminum salt and ammonium salt as raw materials; uniformly mixing reaction materials by a synergistic effect of high-speed mechanical stirring and ultrasonic dispersion; synthesizing the reaction materials into ammonium aluminum carbonate hydroxide through chemical reaction; using the ammonium aluminum carbonate hydroxide as a precursor; and preparing the ultrafine alpha-Al2O3 powder through roasting and mechanical grinding. The obtained ultrafine alpha-Al2O3 powder is high in dispersibility and fine in granularity; diameters of particles are 100-200 nanometers; grain fineness distribution is narrow; and particle volume distribution is as follows: D50= 0.2 micrometer, and D90= 0.42 micrometer. In a whole preparation technological process, conditions are gentle, the technology is easy to control, energy-saving and environment-friendly, the quality of ultrafine powder is stable, and the ultrafine alpha-Al2O3 is suitable to be produced in batches.

Owner:SHANDONG UNIV

Preparation method for nanometer aluminum nitride powder

InactiveCN109019536AImprove stabilityHigh purityMaterial nanotechnologyNitrogen compoundsAir atmosphereAluminum Acetate

The invention discloses a preparation method for nanometer aluminum nitride powder. The preparation method comprises the following steps: uniformly mixing a solid aluminum sourcesuch as aluminum nitrate, aluminum carbonate, aluminum isopropoxide, aluminum sulfate, aluminum acetate, basic aluminum acetate and alkaline aluminum acetate with a solid nitrogen source such as urea and melamine accordingto a molar ratio of elemental aluminum to the solid nitrogen source of 1: 1 to 1: 6; and carrying out calcining at 600 to 1000 DEG C for 1 to 6 h in a baking atmosphere; and then performing decarburization treatment in an air atmosphere at 300 to 650 DEG C for 1 to 4 h to obtain the high-purity aluminum nitride powder. The aluminum nitride powder prepared by using the method of the invention hashigh purity and a particle size distribution range of 15 to 90 nm; the preparation method is simple in process and easy to operate; the raw materials are widely available; synthesis cost is low; and the method is environmental friendly, economic and practicable and is a green process capable of realizing large-scale industrial production.

Owner:SHAANXI NORMAL UNIV +1

Slag oil hydro-demetallization catalyst and its preparing method

ActiveCN100363470CImprove performanceEasy to operateRefining to eliminate hetero atomsAluminum CarbonateAlumina hydrate

The slag oil hydrodemetallizing catalyst contains a kind of double-peak hole alumina carrier and supported Mo and / or W and Ni and / or Co metal components. The double-peak hole alumina carrier has pore volume of 0.8-1.6 ml / g, specific surface area 150-350 sq m / g, pore volume fraction of 10-30 nm size holes in 40-90 % and pore volume fraction of 100-2000 nm size holes in 10-60 %, and is prepared through mixing alumina hydrate and ammonium aluminum carbonate, forming and roasting. The slag oil hydrodemetallizing catalyst has simple preparation process and high hydrodemetallizing performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

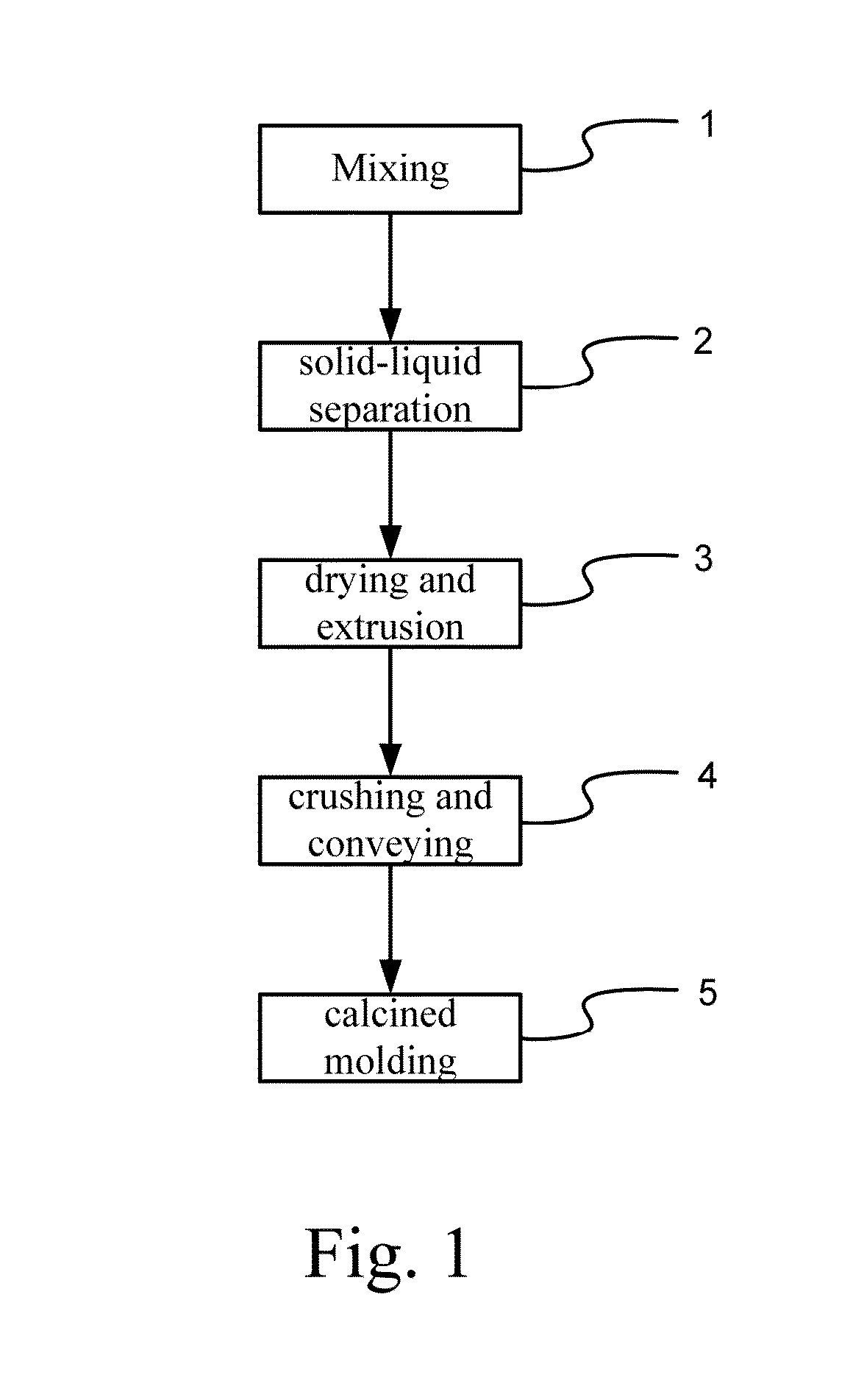

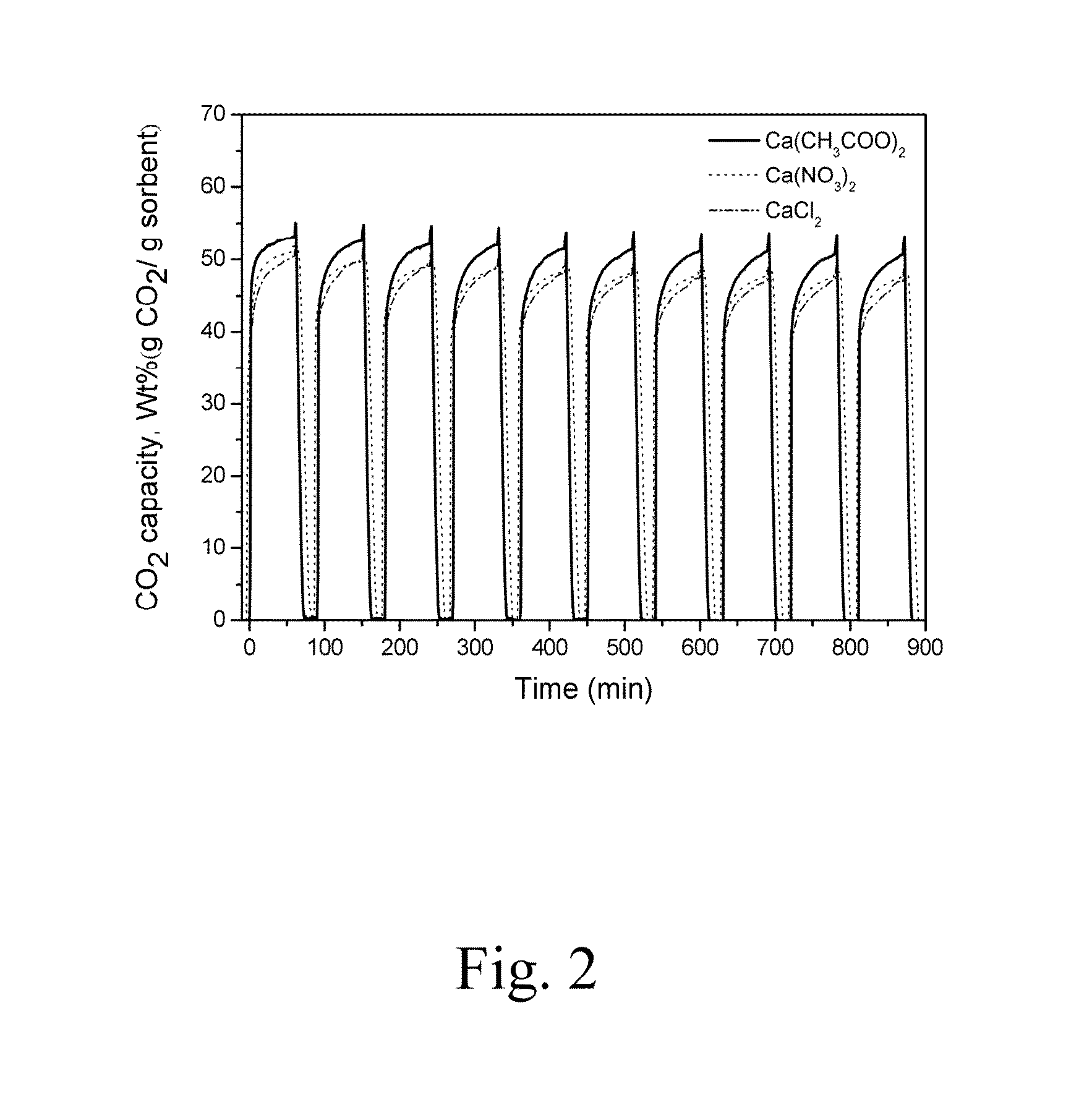

Engineered process of manufacturing calcium aluminate carbonates for medium-high temperature co2 capture

An engineered process of manufacturing a carbon capturing agent calcium aluminum carbonate Ca—Al—CO3 includes steps of mixing, solid-liquid separation, drying and extrusion, crushing and conveying, and calcined molding. The acid bath of Ca+2 and Al+3 is mixed with the alkaline bath of Na2CO3 and NaOH while stirring to form slurry which are then subject to solid-liquid separation to obtain a filtrated cake. The filtrated cake is place into a drying and extrusion device to obtain granular material. The granular material is placed in a conveying and crushing equipment to obtain a powder material. The powder material is calcined at furnace for forming a Ca—Al—CO3, which is nano-layered composite with high porosity. Thereby, the preparation of a solid sorbent can be scale up under systematically controlled with yield of at least batches of kilograms used in medium-high temperature (400˜800° C.) CO2 capture.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Preparation method of nano-alumina fibers

InactiveCN104451954AHigh purityHigh aspect ratioMaterial nanotechnologyInorganic material artificial filamentsFiberAluminum Carbonate

The invention discloses a preparation method of nano-alumina fibers, and particularly relates to a preparation method of nano-alumina fibers. The preparation method comprises the following steps: by adopting a hydrothermal-pyrolysis method, preparing AACH (ammonium aluminum carbonate hydroxide) nanofiber by taking aluminum nitrate nonahydrate as a raw material through adopting a hydrothermal synthesis method, and preparing the nano-alumina fibers by adopting a high-temperature pyrolysis method. The prepared nano-alumina fiber has the advantages of being high in purity, high in length-diameter ratio, uniform in particle size and the like, and the preparation method has the advantages that I. the preparation processes are simple and controllable, and II. the prepared particles are uniform in dimension, and the fibrous alumina is high in length-diameter ratio.

Owner:广东华科新材料研究院有限公司 +1

Composite epoxy asphalt pavement material and preparation method thereof

InactiveCN103773039AAccelerated corrosionImprove heat resistanceBuilding insulationsBenzoic acidStearic acid

The invention relates to a composite epoxy asphalt pavement material and a preparation method thereof. The composite epoxy asphalt pavement material is composed of following components in parts by weight: 50-55 parts of coal tar asphalt, 24-29 parts of phenolic resin, 15-17 parts of bisphenol F-type epoxy resin, 3-5 parts of stearic acid diethanolamide, 6-12 parts of benzoic anhydride and 5-9 parts of aluminum carbonate. According to the composite epoxy asphalt pavement material, the composition materials are heated and fused, agitated, crushed and reacted to prepare the composite epoxy asphalt pavement material; the prepared composite epoxy asphalt pavement material has good corrosion resistance and heat resistance; the composite epoxy asphalt pavement material serves as a bonding layer so that the corrosion stability and the heat stability of a road can be improved.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Flexing-resistant nylon material for cable jacket and preparation method of flexing-resistant nylon material

InactiveCN105086435AImprove mechanical propertiesImprove flame retardant performanceISOCETYL PALMITATEEpoxy

The invention discloses a flexing-resistant nylon material for a cable jacket and a preparation method of the flexing-resistant nylon material. The flexing-resistant nylon material is prepared by, by weight, 30-45 parts of nylon 11, 223-36 parts of thermoplastic polyurethane elastomer, 15-25 parts of styrene-isoprene-butadiene terpolymer, 18-26 parts of nano diamond, 10-15 parts of basic sodium and aluminum carbonate, 17-24 parts of brominated epoxy resin, 3-6 parts of isocetyl palmitate, 5-10 parts of N,N-dimethyl-p-toluenesulfonamide, 8-14 parts of tributoxyethyl phosphate ester, 3-5 parts of magnesium oleate, 2-4 parts of stannous fluoborate, 4-8 parts of barium molybdate, 10-15 parts of PPTA pulp and 2.5-4.5 parts of assistant. The nylon 11 is taken as a main material, and the thermoplastic polyurethane elastomer and styrene-isoprene-butadiene terpolymer are added to perform blending modification on the nylon 11, so that flexing resistance and fatigue resistance of the flexing-resistant nylon material are improved.

Owner:ANHUI ANLAN MOLD

Building energy-saving heat preservation material and preparing technology thereof

ActiveCN106316332AImprove insulation effectImprove flame retardant performanceCeramicwareStress concentrationCross-link

The invention discloses a building energy-saving heat preservation material and a preparing technology thereof. Polyphenyl fibers, ammonium aluminum carbonate hydroxide fibers and polypropylene fibers are added, long chains of fiber molecules are wound together and cross-linked into a network structure, and a fine structure similar to steel bars is formed so that after the heat preservation material is solidified, the cross-linked network structure can be solidified, and integral fastening can be achieved. The cross-linked net-shaped fibers can perform the effects of enhancing, cracking preventing and toughening after being foamed, stress concentration can be prevented, the dry shrinkage and cracking probability of the building energy-saving heat preservation material can be reduced, and the heat preservation effect and the flame retardance of the building energy-saving heat preservation material can be improved while the strength is improved; meanwhile, by means of the structure, more foaming holes can be allowed in the heat preservation material, and the heat preservation effect of the heat preservation material is enhanced.

Owner:江苏攀越建筑劳务有限公司

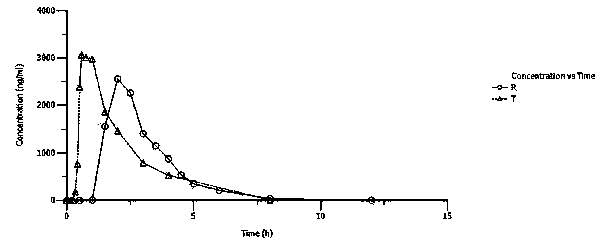

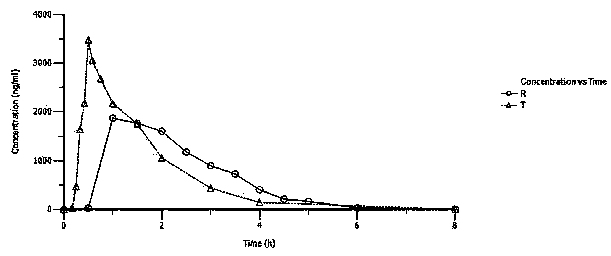

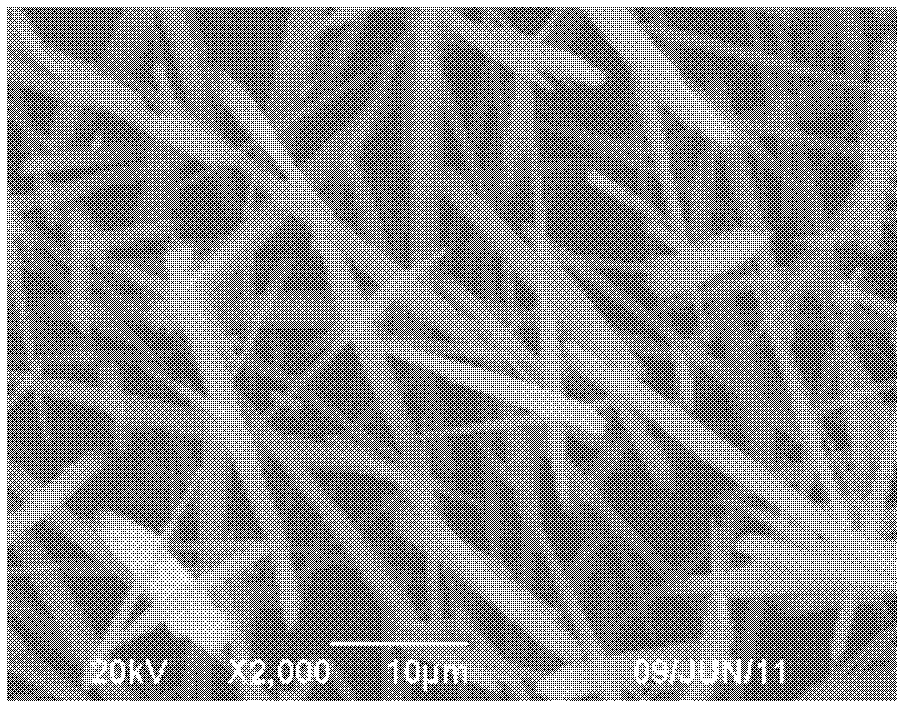

Esomeprazole pharmaceutical composition and preparation thereof

InactiveCN103845734AAvoid degradation damageRaise the pHOrganic active ingredientsDigestive systemAluminium hydroxideStrong acids

The invention provides an esomeprazole pharmaceutical composition with stronger acid resistance and a preparation thereof. The esomeprazole pharmaceutical composition comprises esomeprazole, one or more antacids and common pharmaceutical adjuvants, wherein the esomeprazole comprises esomeprazole salt, particularly esomeprazole magnesium salt and esomeprazole lithium salt; and the antacids comprise sodium bicarbonate, sodium carbonate, potassium carbonate, potassium bicarbonate, calcium carbonate, aluminum carbonate, magnesium carbonate, magnesium hydroxide, magnesium oxide, aluminium hydroxide, magnesium aluminum carbonate and the like. The preparation of the esomeprazole pharmaceutical composition is prepared by adding the antacids via interior addition and exterior addition; and in an optimized preparation method, the weight ratio of the antacids in the interior addition and the exterior addition is 2: 3, so that the antacids play double efficacies, the dosage of acid neutralization agent is reduced and the acid resisting effect is better.

Owner:LIAONING YILING KECHUANG BIOLOGICAL MEDICAL TECH +1

Concrete with excellent durability

The invention discloses a concrete with excellent durability. The concrete is prepared from the following raw materials in parts by weight: 100-120 parts of ordinary Portland 42.5 cement, 3-6 parts of epoxy resin, 3-5 parts of chlorinated polyethylene, 1-4 parts of polydimethylsiloxane, 4-8 parts of modified chopped carbon fiber, 2-5 parts of carboxymethyl cellulose, 1-4 parts of vinyl triamine, 3-6 parts of resorcinol, 2-5 parts of silane coupling agent KH-560, 1-5 parts of polyvinyl alcohol, 2-4 parts of ammonium phosphate, 2-5 parts of borax, 3-6 parts of macadam, 5-15 parts of river sand, 3-9 parts of magnesium aluminum carbonate hydrotalcite, 1-4 parts of fly ash limestone flour, 3-6 parts of metakaolin, 2-5 parts of magnesium oxide, 1-3 parts of polycarboxylic acid water reducing agent, 1-3 parts of defoaming agent and 3-9 parts of water. The concrete has excellent fatigue resistance.

Owner:蚌埠市方阵商品混凝土有限公司

Method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite

ActiveCN102618932ANo waste dischargeReduce manufacturing costPolycrystalline material growthAlkali metal silicatesSodium BentoniteSurface-active agents

The invention discloses a method for preparing basic ammonium aluminum carbonate hydroxide whisker and aluminum oxide whisker co-production liquid sodium silicate from bentonite, which comprises the following steps of: adding sulfuric acid solution to bentonite mineral powder which is taken as an initial raw material; reacting; then performing filtering separation; collecting an acid-leached filtrate and acid-leached filter cakes; adding salpeter solution and isoamyl alcohol to the acid-leached filtrate; performing liquid separation and collecting an aqueous phase to obtain aluminum salt solution; adding urea and a surface active agent to the aluminum salt solution; reacting; then, separating, washing and drying to obtain basic ammonium aluminum carbonate hydroxide whiskers; and calcining the basic ammonium aluminum carbonate hydroxide whiskers to obtain aluminum oxide whiskers. Aluminum oxide and silicon dioxide which are required by the method disclosed by the invention respectively come from bentonite ore, and other industrial raw materials do not need to be adopted, so that the production cost can be effectively reduced. The method disclosed by the invention has the advantages that the recovery rate is high; the yield of the aluminum oxide in the bentonite can reach at least 90 percent; and the yield of the amorphous silicon dioxide can reach at least 95 percent.

Owner:HEFEI UNIV OF TECH

Materials and method used for preparing calcium aluminum titanate electronic functional ceramic using laser

The invention discloses materials and a method used for preparing calcium aluminum titanate electronic functional ceramic using laser. The preparation method comprises following steps: calcium carbonate, aluminum carbonate, and titanium dioxide are taken according to a molar ratio of (1-x):x:1, are mixed and dried, are subjected to dry grinding using a ball miller for 2h, and are subjected to wet grinding for 3h after adding of an appropriate amount of deionized water; an obtained mixture is collected and are dried; a binder is added for plasticization and granulation, an obtained material is subjected to pressed compact under a pressure of 35MPa, and the pressure is maintained for 8min; obtained green body is dried for 2h at a temperature of 70 DEG C, is dried for 5h at a temperature of 250 DEG C, and is subjected to furnace cooling; an obtained sample is collected, and is subjected to sintering using broadband carbon dioxide laser directly so as to obtain the calcium aluminum titanate electronic functional ceramic; wherein x is used for representing molar mass fraction, and 0

Owner:沈新荣

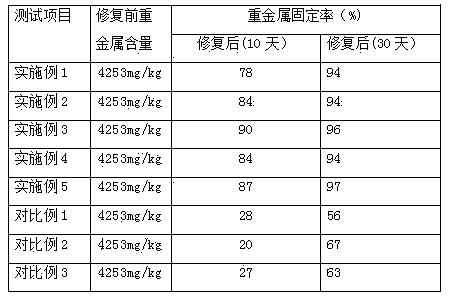

Heavy metal contaminated acidic soil remediation agent, and preparation method and application method thereof

InactiveCN105368455AGood restorativeShort repair timeOrganic fertilisersSoil conditioning compositionsSodium dithioniteSodium metasilicate

The invention discloses a heavy metal contaminated acidic soil remediation agent, and a preparation method and an application method thereof. The heavy metal contaminated acidic soil remediation agent contains the following materials by weight: 20-30 parts of fly ash, 20-28 parts of bentonite, 18-25 parts of hydroxyapatite, 4-9 parts of magnesium aluminosilicate, 3-6 parts of sodium aluminum carbonate, basic, 2-3 parts of zirconium potassium fluoride, 1-2 parts of sodium metasilicate, 1-2 parts of coal gangue, and 0.8-2 parts of sodium dithionite. The present invention also provides a preparation method of the heavy metal contaminated acidic soil remediation agent.

Owner:JIANGSU GAIYA ENVIRONMENTAL SCI & TECH CO LTD

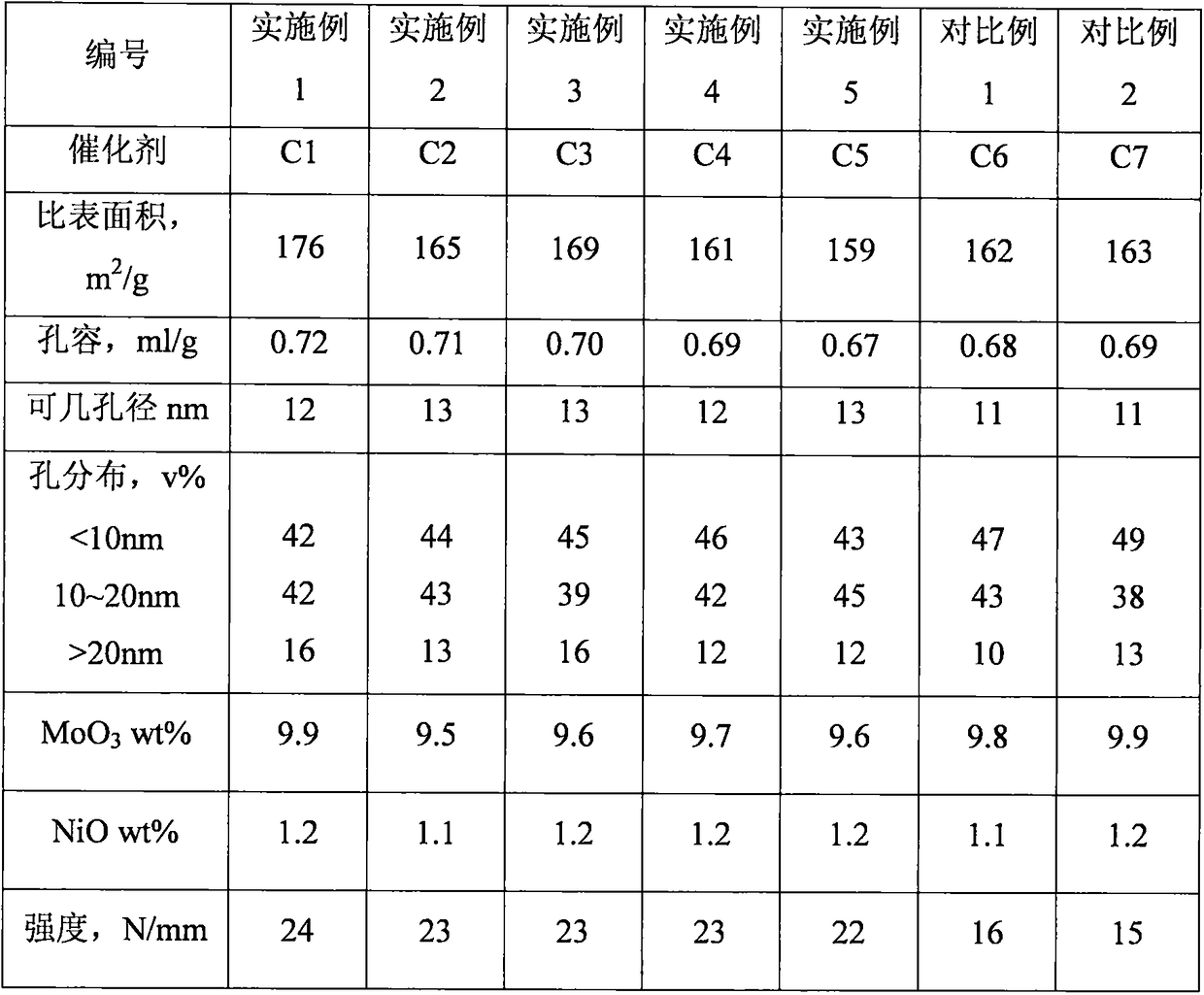

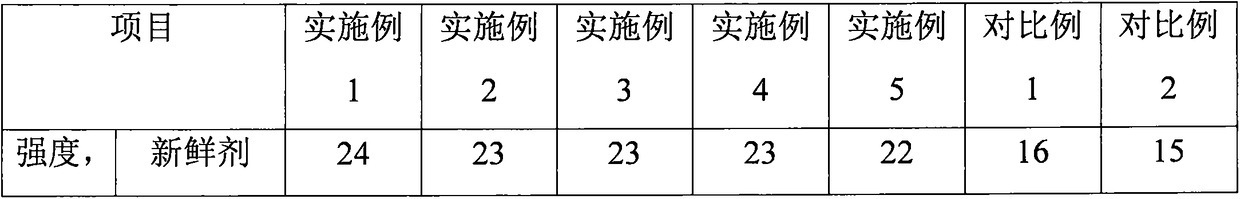

Preparation method of catalyst for hydrotreating of fluidized bed

ActiveCN108970628ATune chemical propertiesHigh activityPhysical/chemical process catalystsBulk chemical productionAluminum CarbonateFluidized bed

The invention discloses a preparation method of a catalyst for hydrotreating of a fluidized bed. The preparation method includes the following steps: (1) kneading and forming pseudo-boehmite and alkaline ammonium aluminum carbonate of a adsorption carbon precursor solution, and drying a formed product; (2) spraying the material obtained in step (1) by a solution containing carbon precursors, and drying and roasting the soaked material to obtain an alumina carrier; (3) impregnating the alumina carrier obtained in step (2) by impregnation liquid containing hydrogenation active components, and drying and roasting the alumina carrier after impregnation to obtain the catalyst for hydrotreating of the fluidized bed. The catalyst prepared by the method has higher strength and wear resistance, andis particularly applicable to the hydrotreating process of heavy-oil fluidized beds.

Owner:BEIJING ZHONGZHI INNOVATION SCI & TECH DEV

Method for preparing nano nickel oxide / nickel aluminum spinel oxygen carrier

ActiveCN107460019APromote formationRich pore structureNanotechnologyFuel additivesGel preparationCalcination

The invention discloses a method for preparing a nano nickel oxide / nickel aluminum spinel oxygen carrier. The method comprises the steps of solution preparation; coprecipitation gel preparation; segmented temperature control aging; preheating forming; and calcination at high temperature. Co-gel of nickel-aluminum carbonate and nitrate is prepared by a partial coprecipitation method, the growth process of the crystal is controlled by controlling drying and aging temperature and time, the forming temperature and calcination temperature are controlled by utilizing the characteristics that metallic oxides decompose when heated and generate oxygen, micro oxygen enrichment conditions favorable for formation of spinel are created, and the nano-NiO / NiAl2O4 oxygen carrier can be obtained under simple conditions. The preparation process is simple, equipment requirements are low, and the process is easy to control, and mass production can be implemented. The oxygen carrier shows very strong redox capacity in chemical chain combustion. Therefore, the method has great potential when used for carbon dioxide capture in chemical chained combustion or raw water hydrogen production.

Owner:SOUTH CHINA AGRI UNIV

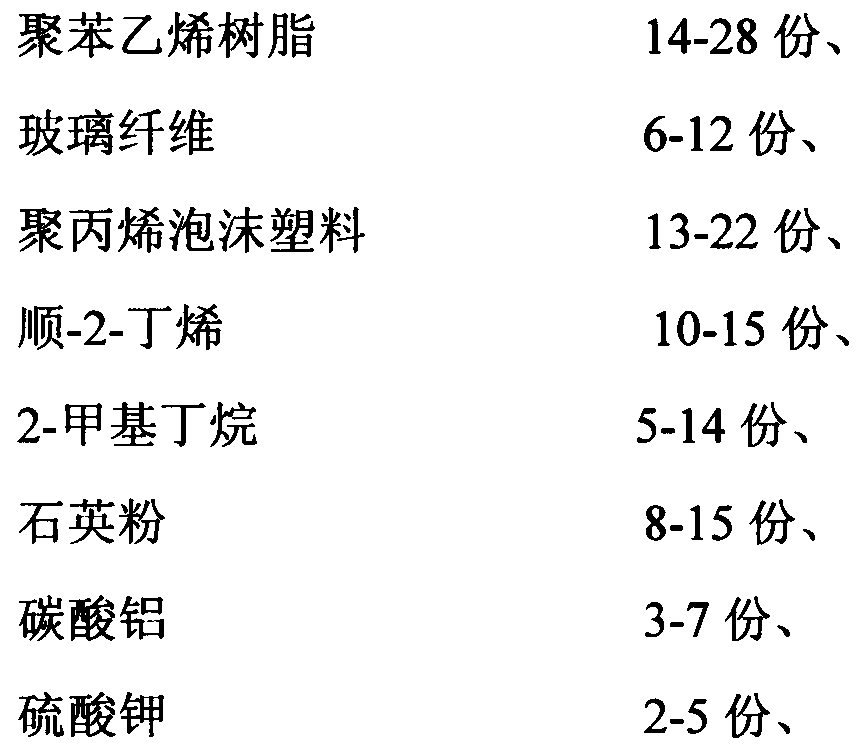

Composite nanometer heat-preservation and thermal-insulation sheet and preparation method thereof

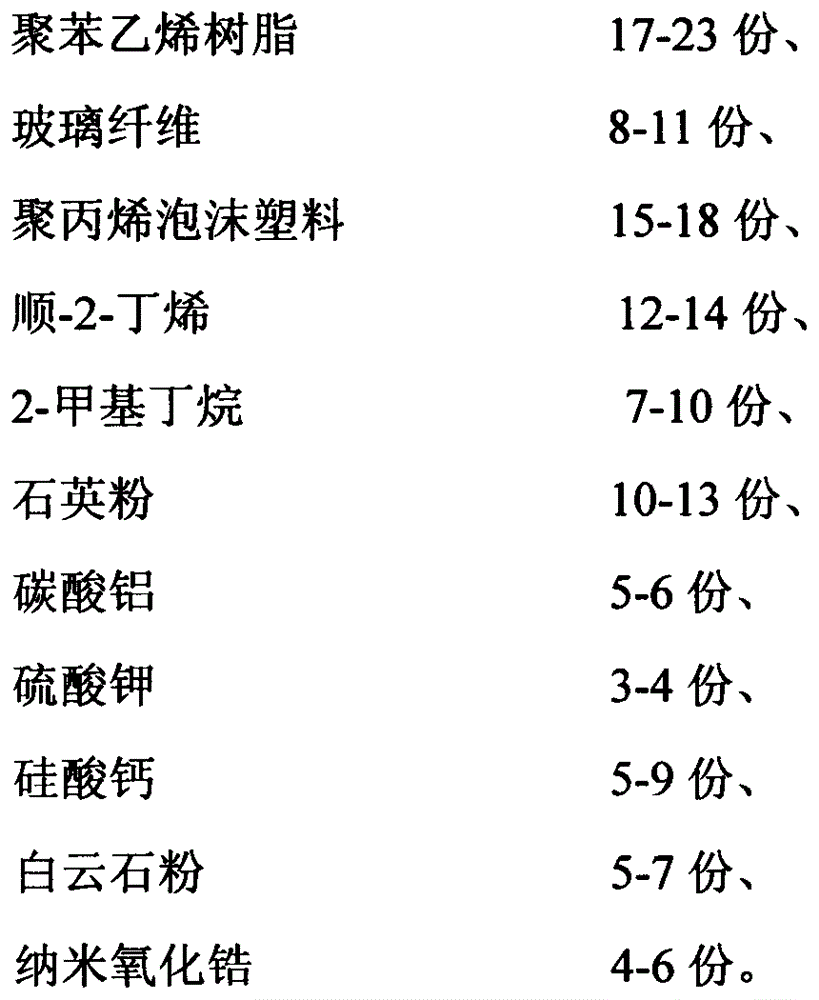

The invention belongs to the field of heat-preservation sheets and discloses a composite nanometer heat-preservation and thermal-insulation sheet. The sheet is prepared from polystyrene resin, glass fibers, quartz powder, aluminum carbonate and other materials. The preparation method comprises the following steps: (1) stirring polystyrene resin, the glass fibers, polypropylene foamed plastic, cis-2-butene and 2-methylbutane until the materials are uniformly mixed to obtain a mixed material; (2) grinding quartz powder, aluminum carbonate, potassium sulfate and the like; (3) mixing and adding the ground material into the mixed material obtained in the step (1) while uniformly stirring; and (4) molding the mixed material which is uniformly stirred in the step (3) by casting to prepare the composite nanometer heat-preservation and thermal-insulation sheet.

Owner:SUZHOU RUNJU DECORATION ENG

Porous aluminium oxide micro/nanospheres and preparation method thereof

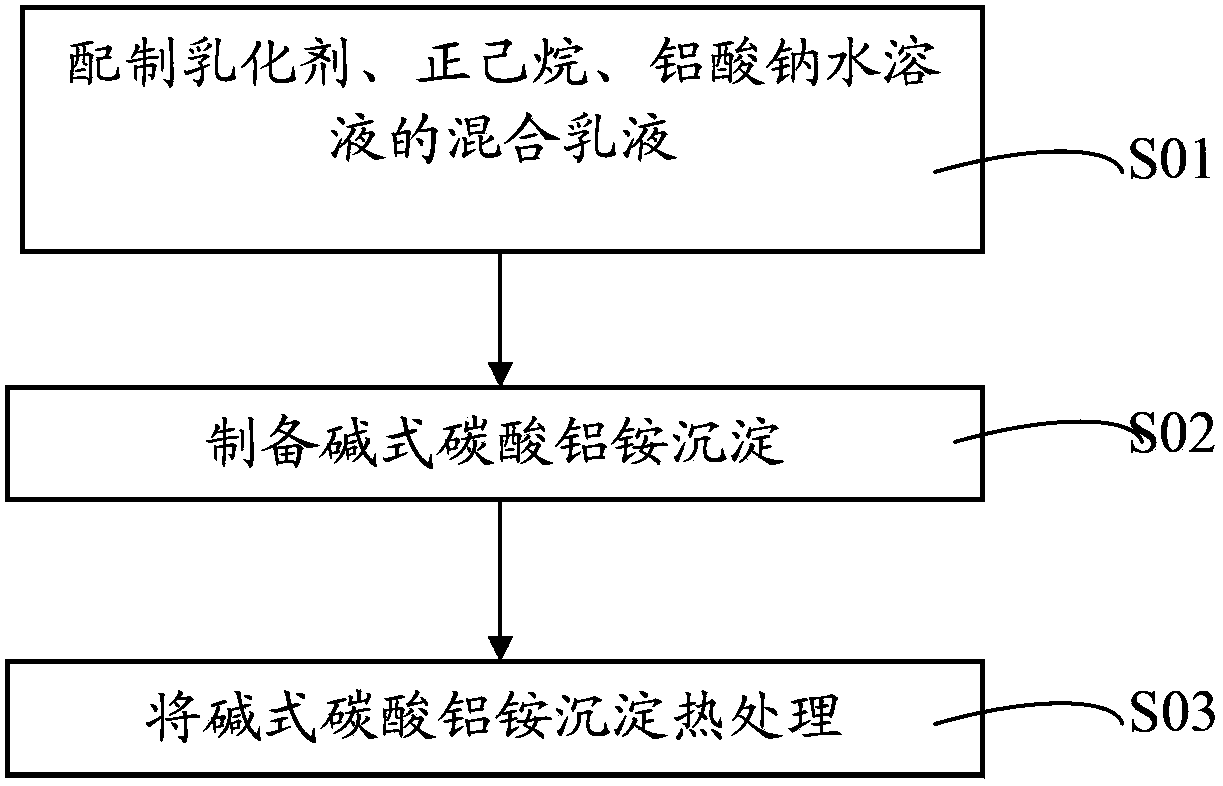

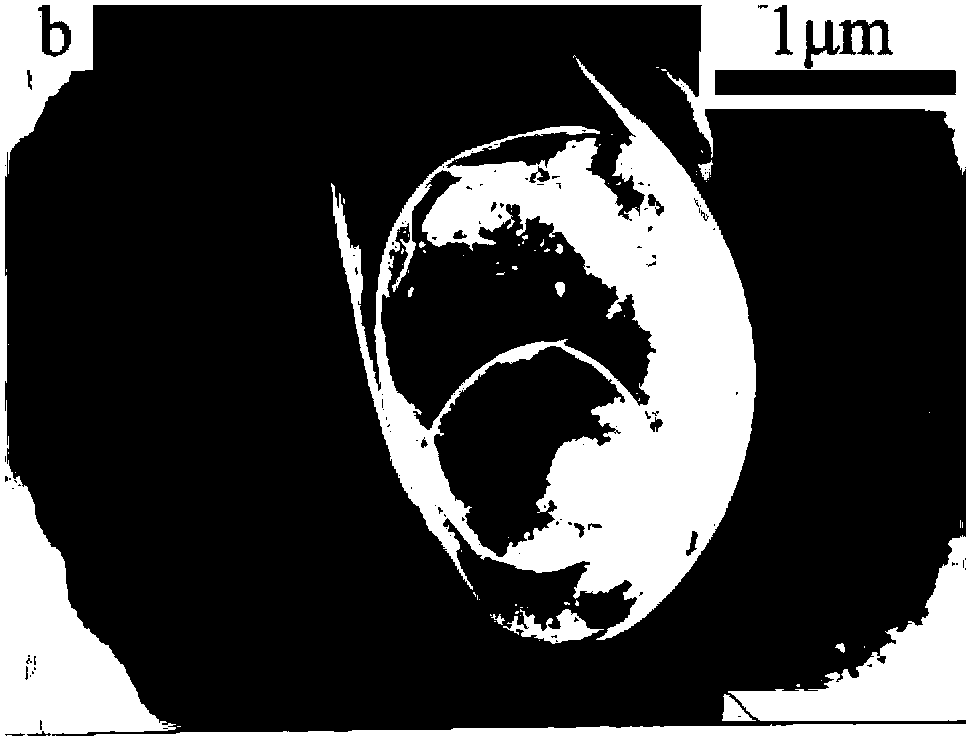

InactiveCN103449490ASimple processProcess conditions are easy to controlMaterial nanotechnologyAluminium oxide/hydroxide preparationAluminum CarbonateEmulsion

The invention discloses a porous aluminium oxide micro / nanosphere and a preparation method thereof. The preparation method of the porous aluminium oxide micro / nanospheres comprises the steps of mixing an emulsifier, normal hexane and the aqueous solution of sodium aluminate together and then carrying out emulsifying treatment on the mixed solution to prepare a mixed emulsion, preparing ammonium aluminum carbonate basic precipitate and performing heat treatment on the ammonium aluminum carbonate basic precipitate to prepare the porous aluminium oxide micro / nanospheres. The preparation method of the porous aluminium oxide micro / nanospheres is characterized in that hollow or solid micro / nanospheres with an ammonium aluminum carbonate porous structure are prepared successfully in a W / O / W emulsion system with the aqueous solution of sodium aluminate as an aluminium source and ammonium bicarbonate as a precipitator, and then the heat treatment is performed on the hollow or solid micro / nanospheres to obtain hollow or solid micro / nanospheres with an aluminium oxide porous structure. The preparation method is simple in process, easily controllable in condition, low in requirements for equipment and suitable for batch production. The prepared porous aluminium oxide micro / nanospheres are hollow and solid spheroidal particles with a porous structure; with the porous structure, the porous aluminium oxide micro / nanospheres are large in specific surface area, good in stability and excellent in surface infiltration capacity.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

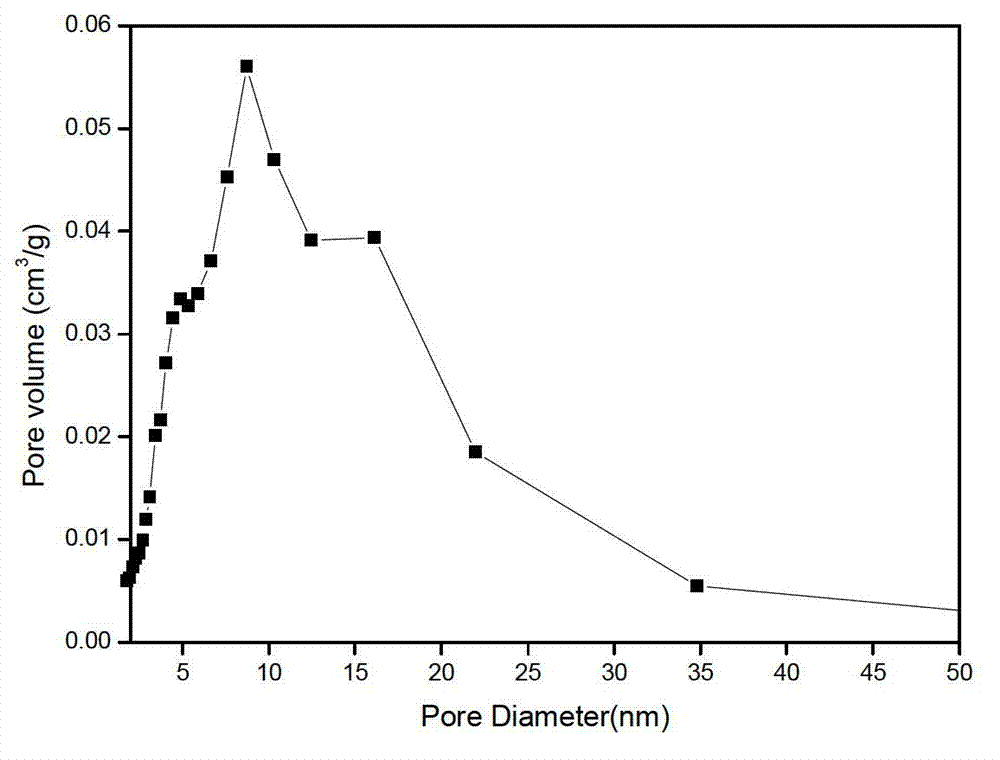

Method for preparing hydrodemetallization catalyst

ActiveCN105521793AIncrease profitImprove connectivityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsAluminum CarbonateMetal catalyst

The invention discloses a method for preparing hydrodemetallization catalyst. The method comprises the following steps: 1) partial active ingredient impregnation liquid is used for impregnating to ammonium aluminum carbonate hydroxide powder to obtain the active ingredient-modified ammonium aluminum carbonate hydroxide, then ammonium aluminum carbonate hydroxide is dried for standby; 2) the material obtained in the step 1), pseudo-boehmite dry glue powder, a chemical pore-expanding agent, an extrusion aid, and a peptizing agent are shaped, striped, dried, and calcinated to obtain an alumina carrier; and 3) the alumina carrier obtained is loaded with residual active ingredient, is dried, and calcinated to obtain the hydrodemetallization catalyst. The content of the prepared catalyst active metal is high at a macroporous place, and is low at a porous place, and the catalyst has wide application prospect in hydrodemetallization of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com