Composite nanometer heat-preservation and thermal-insulation sheet and preparation method thereof

A thermal insulation, nano technology, applied in thermal insulation board and its preparation, composite nano thermal insulation board and its preparation field, can solve the problems of potential safety hazards, low flame retardant strength of thermal insulation board, etc., to improve the flame retardant , High flexural strength, compressive strength, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

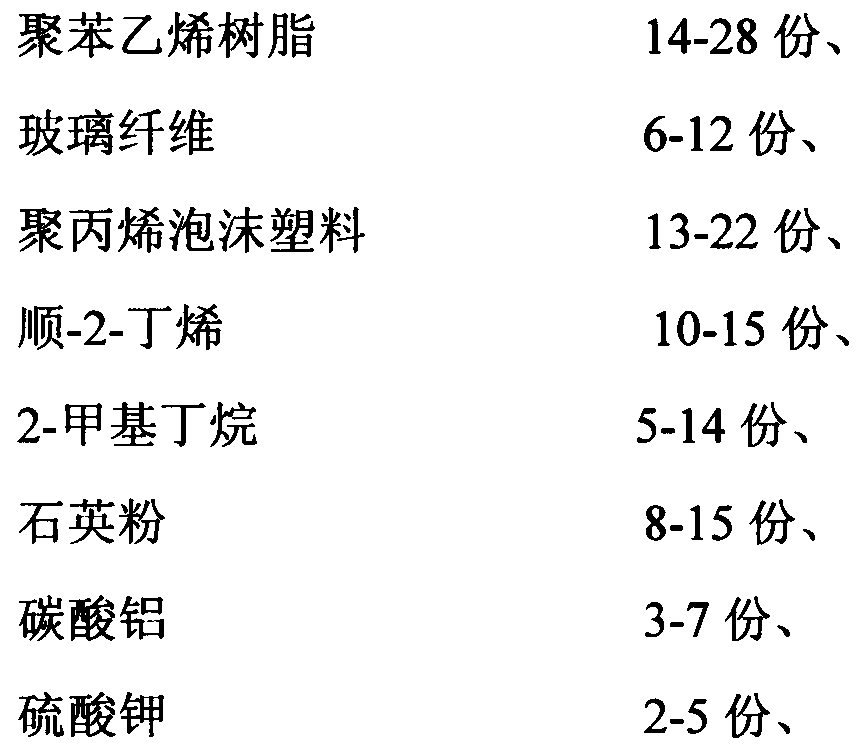

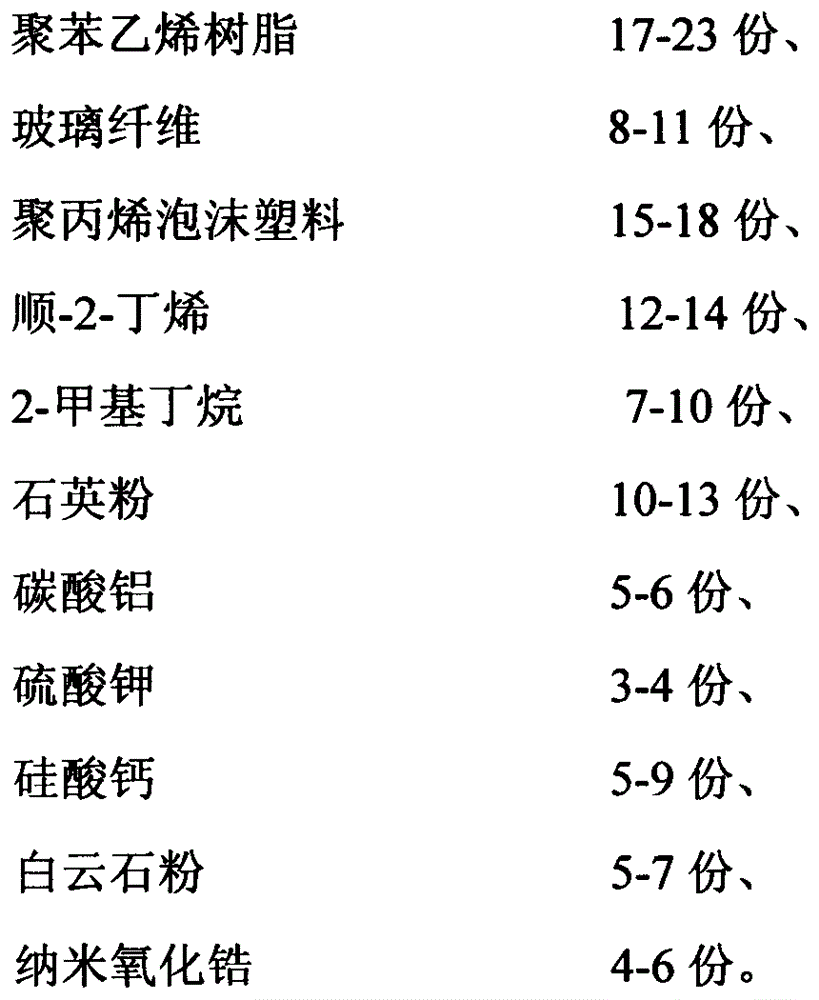

Method used

Image

Examples

Embodiment 1

[0019] (1) Take polystyrene resin 28Kg, glass fiber 6Kg, polypropylene foam plastics 22Kg, cis-2-butene 10Kg, 2-methylbutane 14Kg by weight, put the above-mentioned materials into a high-temperature reaction kettle for heating and stirring , stir until the above-mentioned various materials are mixed until uniform; (2) grind quartz powder, aluminum carbonate, potassium sulfate, calcium silicate, nano-zirconia, and dolomite powder respectively, and grind until the above-mentioned various powder mesh numbers are 200 order; (3) getting ground to 200 mesh quartz powder by weight is 15Kg, aluminum carbonate is 7Kg, potassium sulfate is 5Kg, calcium silicate is 4Kg, dolomite powder is 8Kg, adds nanometer zirconia to be 7Kg again, and above-mentioned material After mixing, add to the mixed material in step (1), stir while adding, and stir until uniform; (4) pour the mixed material stirred evenly in step (3) into a mold, and the pouring temperature is 150 ° C to prepare a composite nano...

Embodiment 2

[0021] (1) Take polystyrene resin 14Kg, glass fiber 12Kg, polypropylene foam 13Kg, cis-2-butene 15Kg, 2-methylbutane 5Kg by weight, put the above-mentioned materials into a high-temperature reactor and heat and stir , stir until the above-mentioned various materials are mixed until uniform; (2) grind quartz powder, aluminum carbonate, potassium sulfate, calcium silicate, nano-zirconia, and dolomite powder respectively, and grind until the above-mentioned various powder mesh numbers are 300 order; (3) getting ground to 300 mesh quartz powder by weight is 8Kg, aluminum carbonate is 3Kg, potassium sulfate is 2Kg, calcium silicate is 10Kg, dolomite powder is 4Kg, adds nanometer zirconia to be 3Kg again, and above-mentioned material After mixing, add to the mixed material in step (1), stir while adding, and stir until uniform; (4) pour the mixed material stirred evenly in step (3) into a mold, and the pouring temperature is 180 ° C to prepare a composite nanometer Thermal insulatio...

Embodiment 3

[0023] (1) Take polystyrene resin 17Kg, glass fiber 8Kg, polypropylene foam 18Kg, cis-2-butene 12Kg, 2-methylbutane 10Kg by weight, put the above-mentioned materials into a high-temperature reactor and heat and stir , stir until the above-mentioned various materials are mixed until uniform; (2) grind quartz powder, aluminum carbonate, potassium sulfate, calcium silicate, nano-zirconia, and dolomite powder respectively, and grind until the various powder mesh numbers above are 250 order; (3) getting ground to 250 mesh quartz powder by weight is 10Kg, aluminum carbonate is 5Kg, potassium sulfate is 4Kg, calcium silicate is 5Kg, dolomite powder is 7Kg, adds nanometer zirconia to be 4Kg again, and above-mentioned material After mixing, add to the mixed material in step (1), stir while adding, and stir until uniform; (4) pour the mixed material stirred uniformly in step (3) into a mold, and the pouring temperature is 170 ° C to prepare a composite nanometer Thermal insulation panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com