Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

381results about How to "Improve flexural performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dental complex color machinable zirconia ceramics and preparation method

InactiveCN102285795AHigh simulationFull aestheticsImpression capsDentistry preparationsAll ceramicAbutment

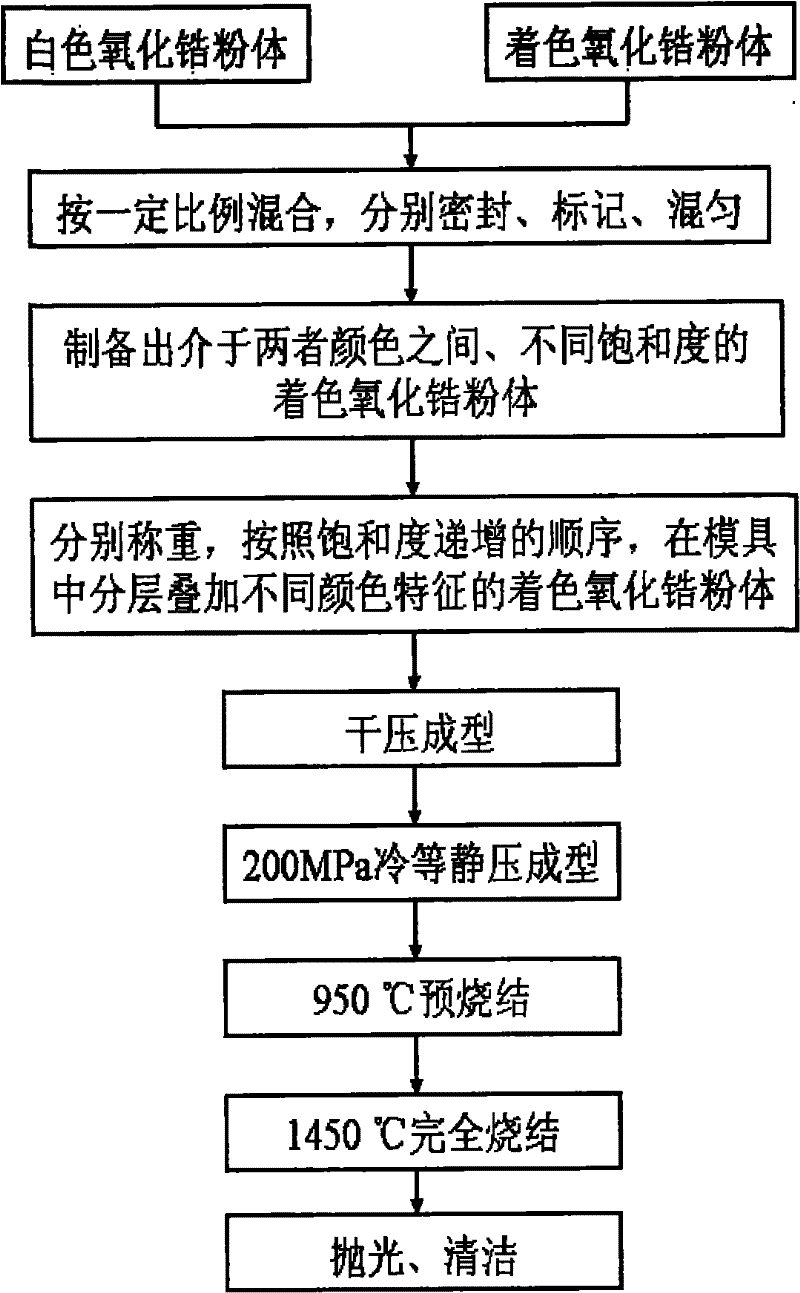

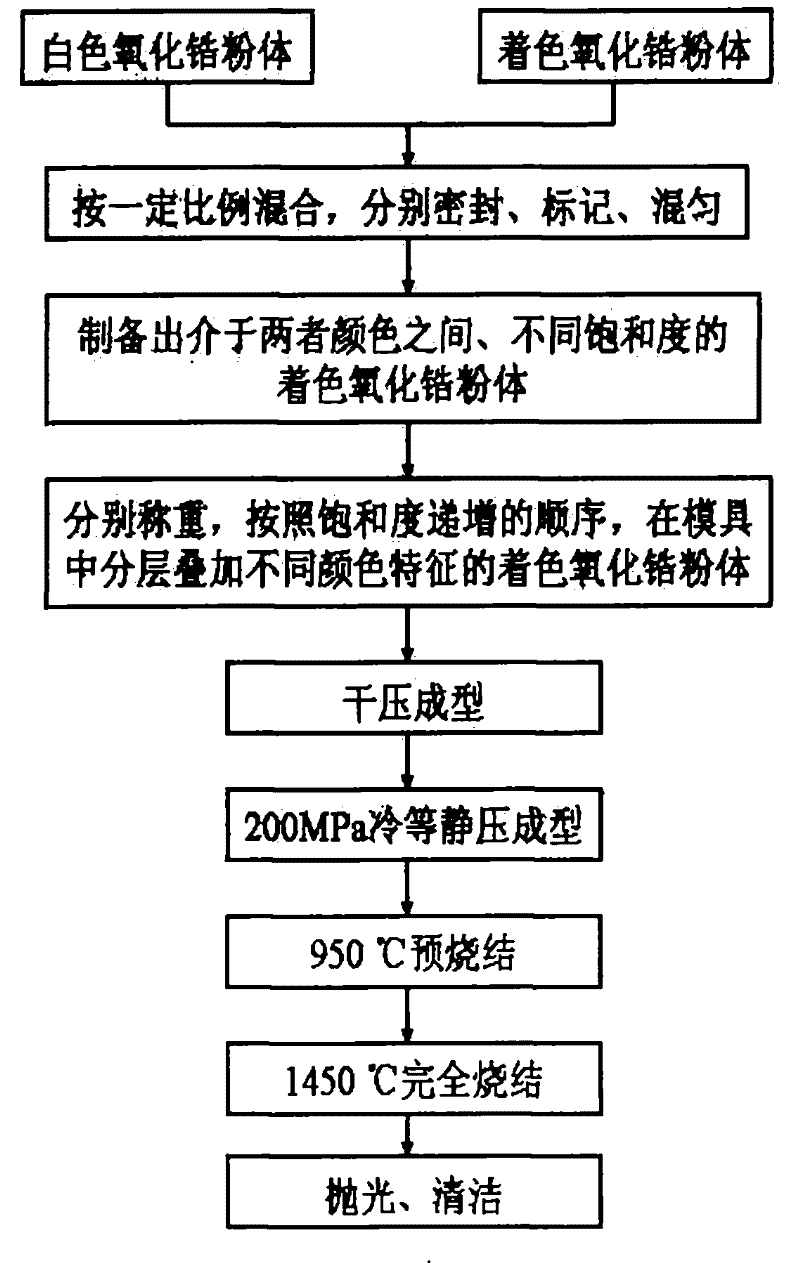

A dental multi-color machinable zirconia ceramic and its preparation method. The zirconia ceramic has the characteristics of translucence and color gradient, and contains more than five porcelain layers with the same hue and different saturation. The lightness gradually decreases from the top of the ceramic to the bottom layer, and the saturation The density gradually increases, and the color transitions naturally with a sense of hierarchy; the pre-sintered porous ceramic body of the zirconia ceramic is easy to cut and shape, and can be used to make personalized and beautiful dental zirconia all-ceramic restorations through the CAD / CAM system, which is conducive to preserving the abutment teeth. Improve the repair success rate. The preparation method of the dental complex color machinable zirconia ceramic is simple, effective and easy to popularize.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

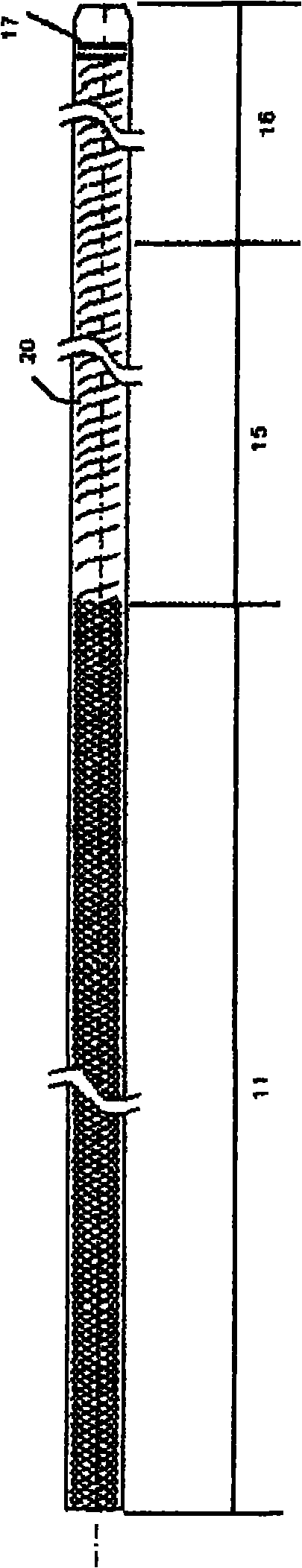

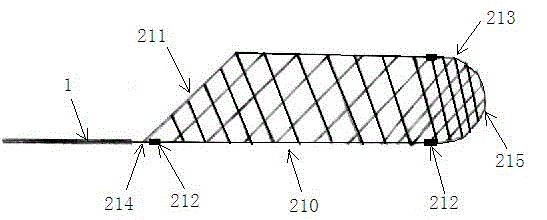

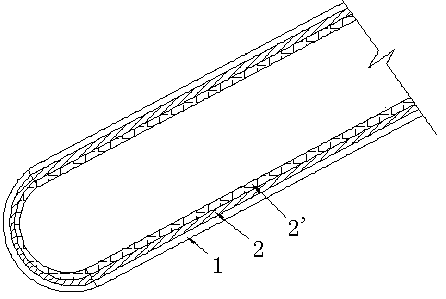

Mciro-catheter

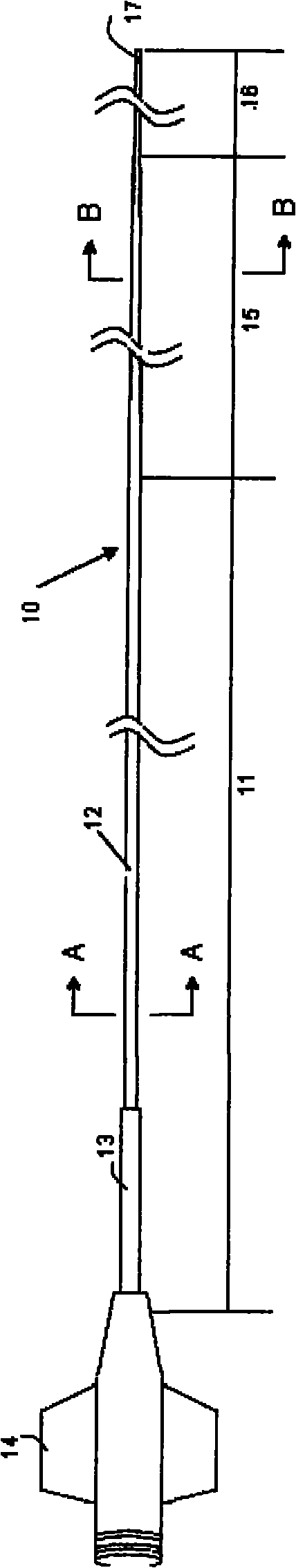

ActiveCN101933821ASafe and smooth crossingImprove flexibilitySurgeryMedical devicesBlood vesselPolymer

The invention relates to a catheter. A catheter wall thereof sequentially comprises a smooth layer, a strengthened layer and a jacket layer from inside to outside, wherein the smooth layer and the jacket layer are both formed by compounding polymer materials, and the strengthened layer is a support layer and is respectively connected with the smooth layer and the jacket layer, therefore, every two layers of the catheter are connected. The catheter also sequentially comprises a proximal end part and an extension part along the direction from the near to the distance. In addition, the strengthened layer is in a braided structure at the proximal end part and is in a spiral structure at the extension part. The invention has the advantages that the structure can enhance the flexibility, the torsional resistance, the tracing property, the supporting property and the anti-fold property of the catheter when reducing the size of the catheter, and therefore, the catheter is suitable for penetrating through a distal vessel in a cranium.

Owner:MICROPORT NEUROTECH SHANGHAI

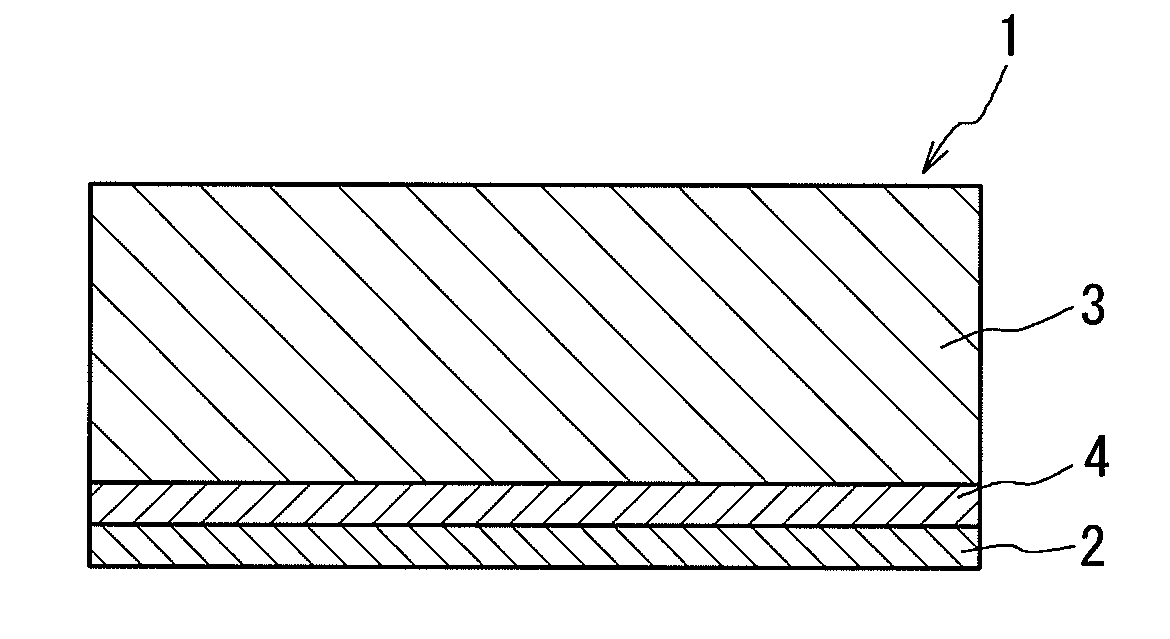

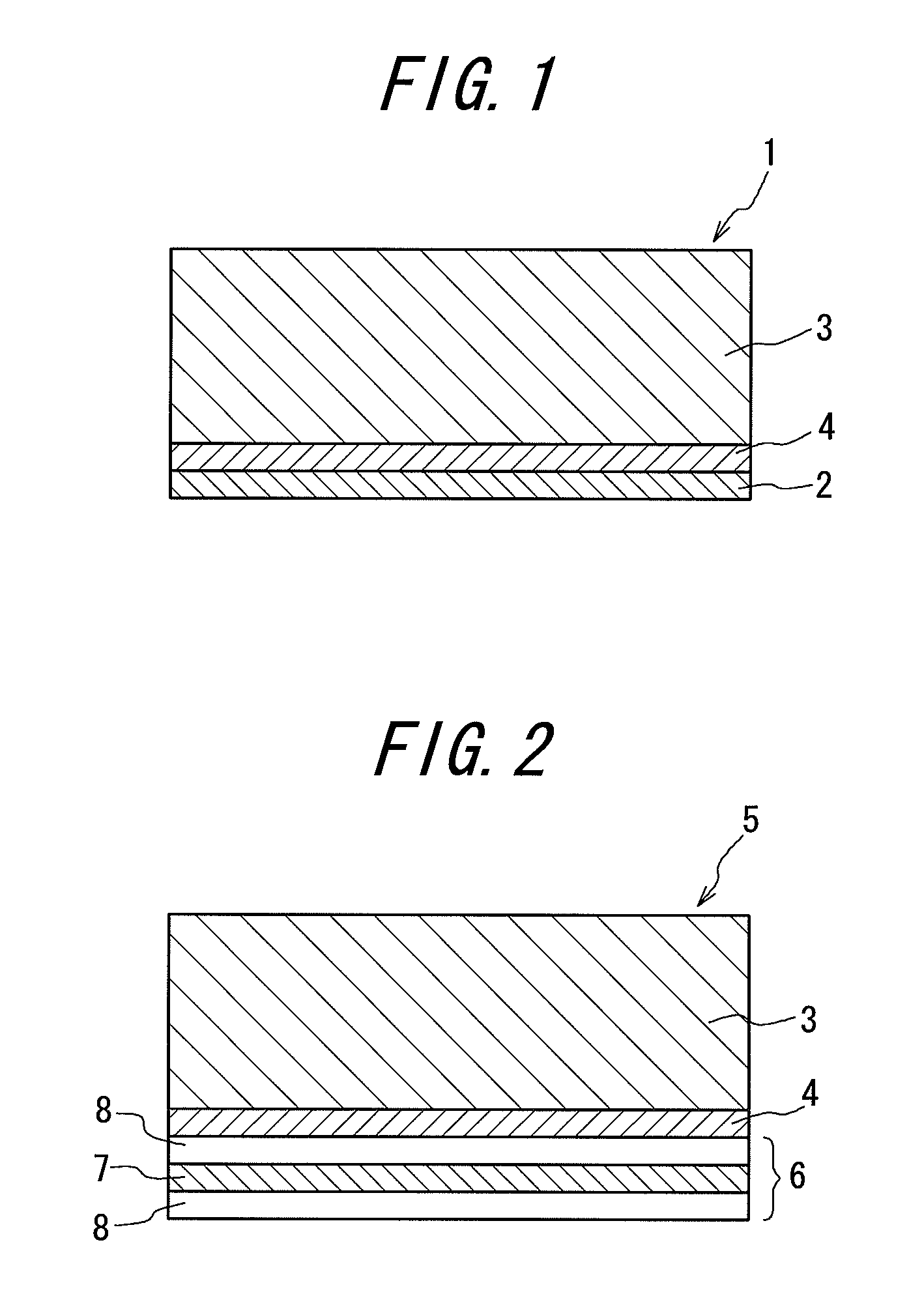

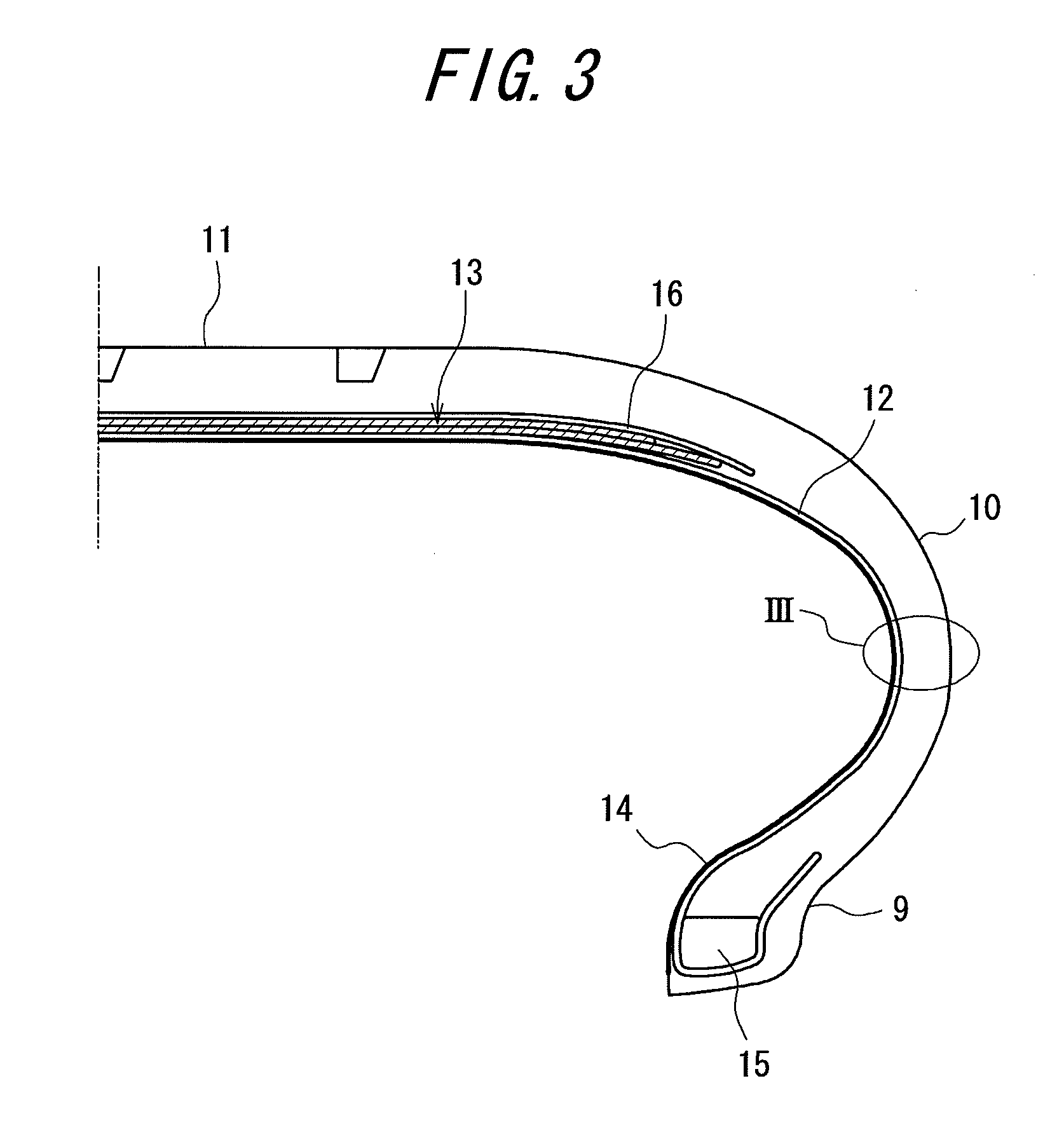

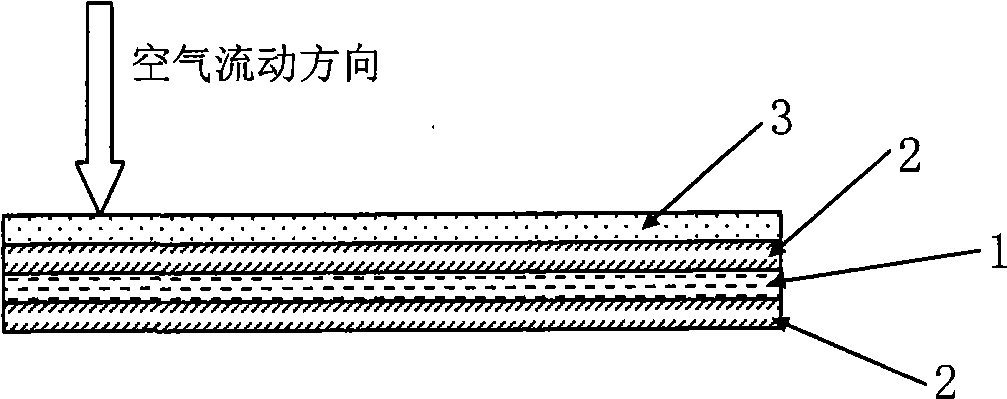

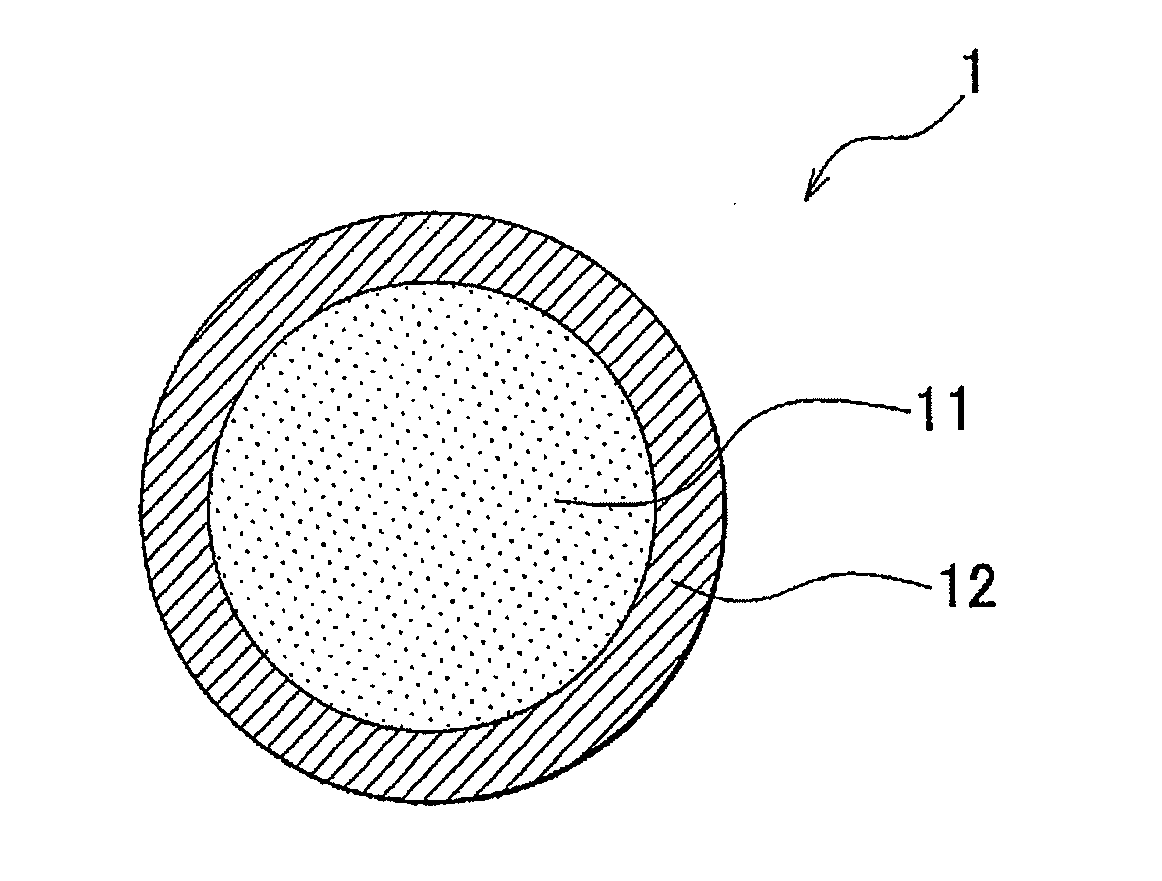

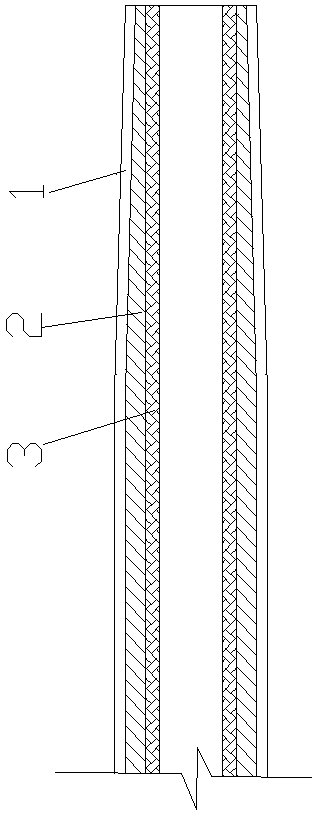

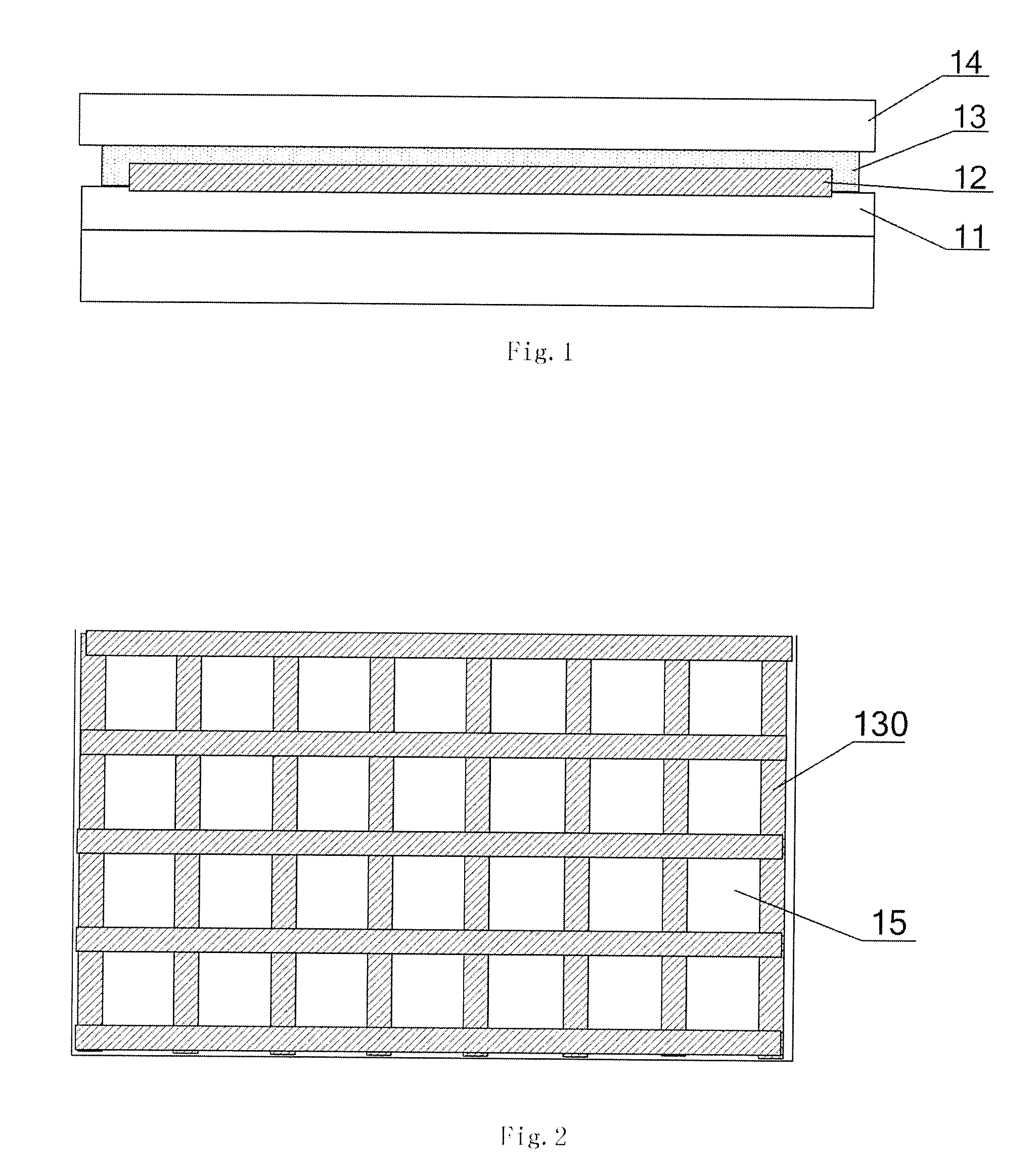

Laminated body and method of producing the same as well as innerliner for pneumatic tire and pneumatic tire

InactiveUS20090308517A1Improve machinabilityImprove anti-stripping performanceCoatingsWheelsElastomerYoung's modulus

The invention provides a laminated body (1) having a good workability during the production and an excellent peeling resistance, which is formed by joining a resin film layer (D) (2) comprising at least a layer composed of a resin composition (C) in which a soft resin (B) having a Young's modulus at 23° C. lower than that of a thermoplastic resin (A) is dispersed in a matrix made from the thermoplastic resin (A) and a rubbery elastomer layer (E) (3) through an adhesive layer (F) (4), wherein an adhesive composition (I) formed by compounding not less than 0.1 part by mass of at least one of a maleimide derivative (H) having not less than two reaction sites in a molecule thereof and poly-p-dinitrosobenzene based on 100 parts by mass of a rubber component (G) is applied to the adhesive layer (F) (4).

Owner:KURARAY CO LTD +1

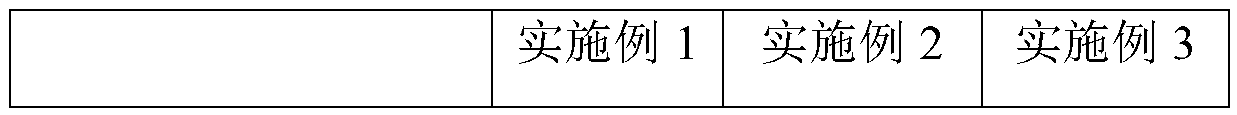

Water-borne epoxy resin modified cement grouting material

The invention provides a water-borne epoxy resin modified cement grouting material. The material is prepared by the following raw materials in parts by weight: 5-10 parts of water-borne epoxy resin, 30-50 parts of cement, 5-30 parts of quartz powder, 0-40 parts of quartz sand, 5-10 parts of calcium carbonate powder, 5-10 parts of a composite expanding agent, 0.01-0.03 parts of low-viscosity cellulose, 0.5-1 parts of asphalt powder, 0.2-0.6 parts of a water reducer, and 0.001-0.03 parts of a retarder. The material overcomes the deficiency in prior art, the composite expanding agent is used for compensating shrinkage in plastic stage, density of grouting is increased, and interspace structure is effectively filled; at the same time, fluidity is good, and settlement phenomenon disappears; the material is suitable for common cement grouting, and is suitable for repairing and strengthening, duct grouting, crack repairing, and other engineering occasions; furtherly, the materials has the advantages of good fluidity, adhesive property, shrinkage compensation performance and corrosion resistance.

Owner:天津天盈新型建材有限公司

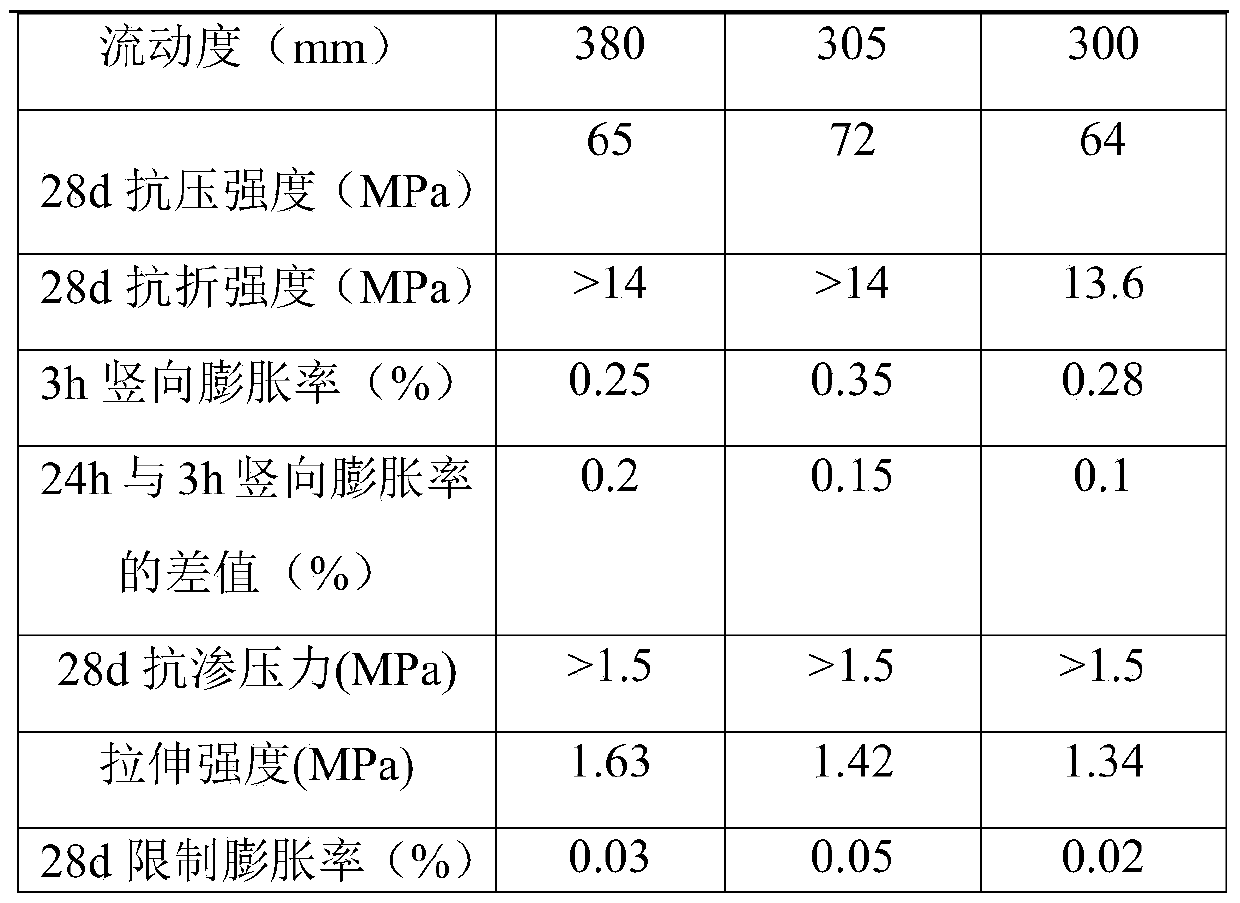

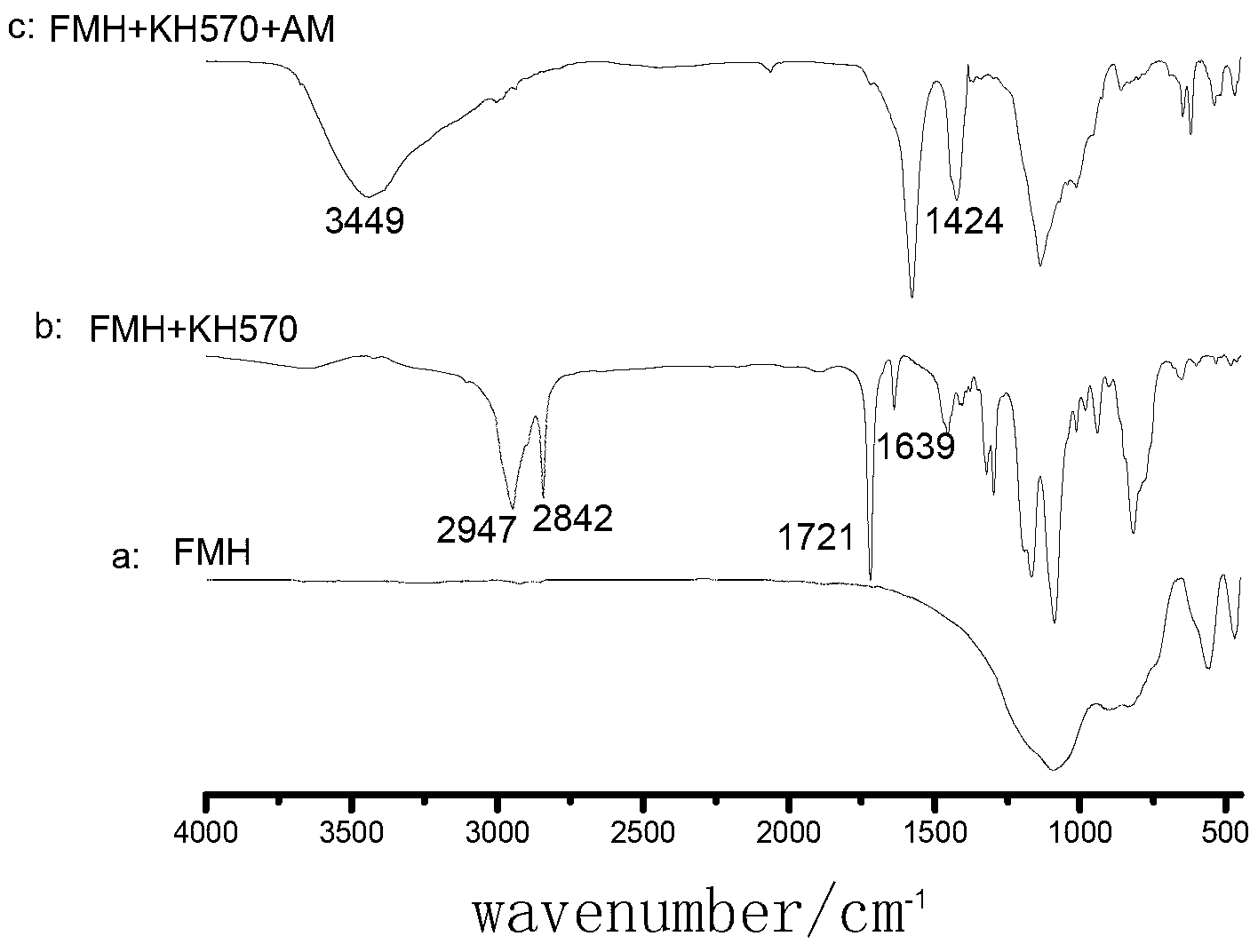

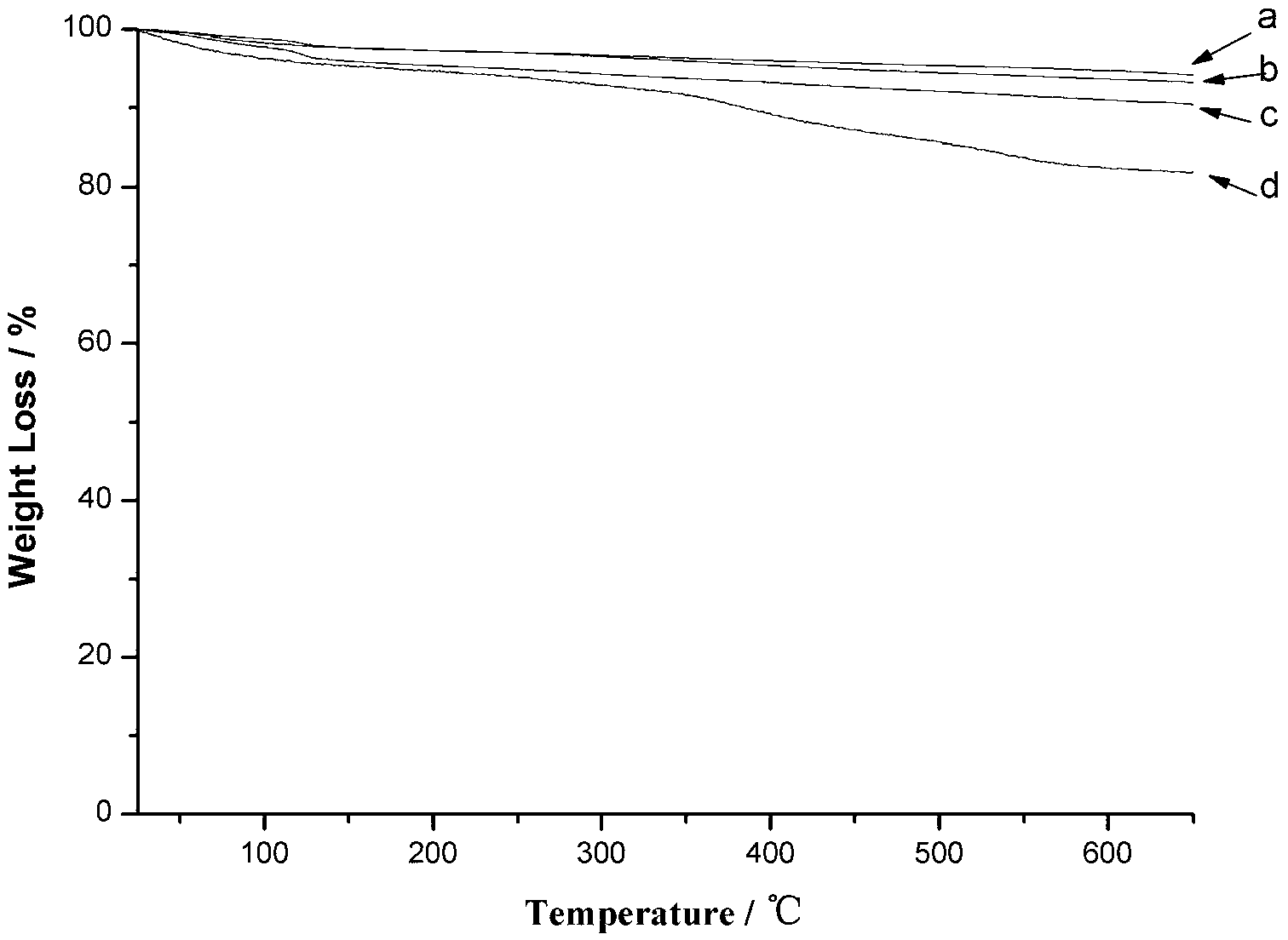

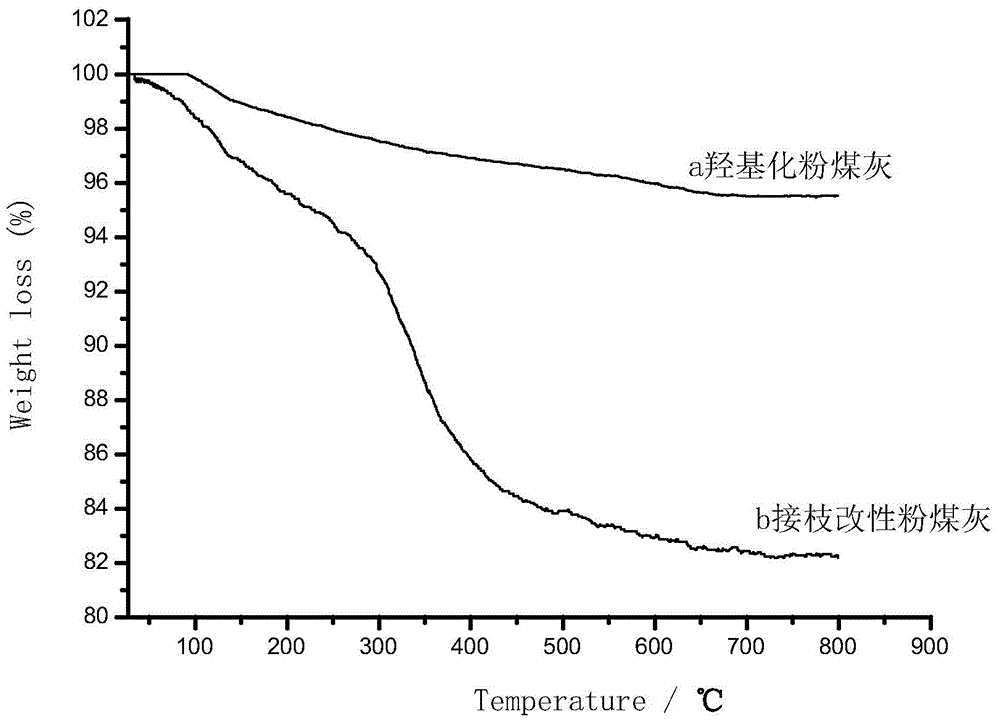

Preparation method of cationic surfactant modified fly ash

InactiveCN103304175AImprove adsorption capacityImprove flexural performanceAfter treatmentGraft reaction

The invention discloses a preparation method of cationic surfactant modified fly ash, which comprises the following steps of: firstly performing pretreatment and hydroxylation treatment on the surface of fly ash to obtain hydroxylated fly ash to obtain a grafting point; then modifying the fly ash by use of a coupling agent; and finally performing grafting reaction with a cationic surfactant polyacrylamide to obtain cationic surfactant modified fly ash. According to the preparation method disclosed by the invention, the polyacrylamide is grafted on the surface of the fly ash, and the adsorption property of the grafted fly ash is greatly changed; particularly the fly ash is applied to a cement-based composite material, and the fracture resistance of the cement-based composite material is obviously improved; and the preparation method disclosed by the invention has the advantages of low reaction temperature, mild conditions, simple after-treatment and low industrialization cost.

Owner:HEFEI UNIV OF TECH

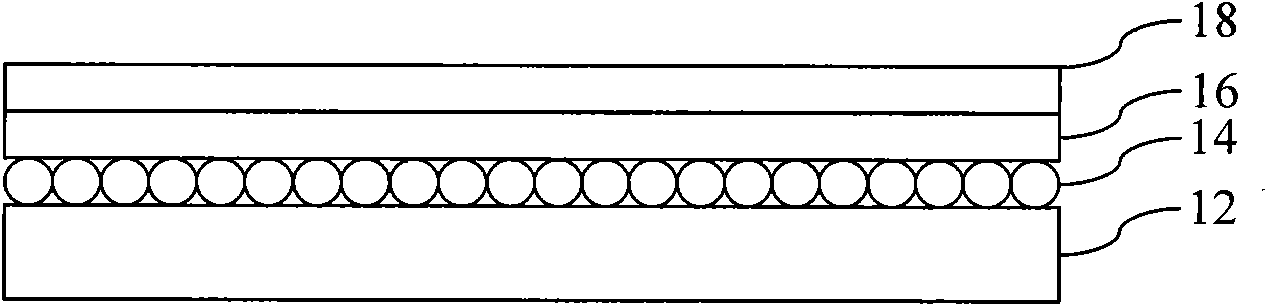

Reflective material, reflective membrane, reflective board and preparation method thereof

InactiveCN101819291AImprove flexural performanceReduce manufacturing costOptical elementsOrganic solventWhite powder

The invention provides a reflective material, a reflective membrane and a preparation method thereof. The reflective material comprises 30 to 50 weight percent of barium sulfate powder, 5 to 8 weight percent of titanium white powder, 5 to 10 weight percent of pearl powder, 10 to 20 weight percent of film forming aid and the balance of organic solvent. The reflective material provided by the invention has the advantages of high reflectivity, oxidation and corrosion resistance, low cost and the like.

Owner:王默文

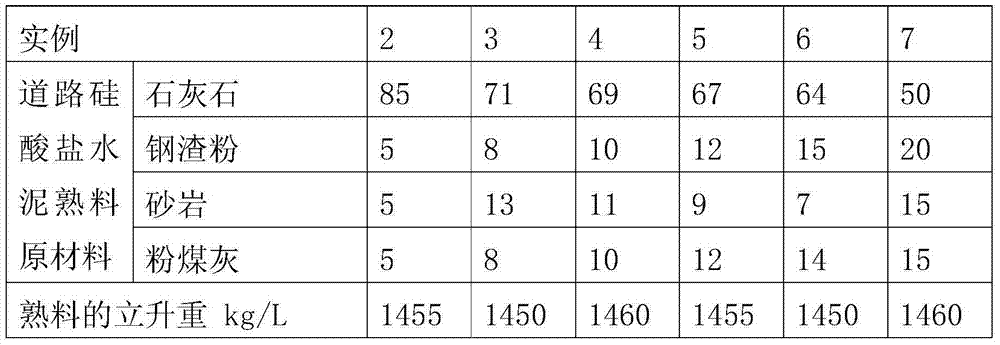

Road silicate cement clinker and preparation method thereof

InactiveCN104496228AImprove flexural performanceImprove wear resistanceCement productionHigh fractureShrinkage rate

The invention relates to road silicate cement clinker and a preparation method thereof. The preparation method for the road silicate cement clinker comprises the following steps: grinding and roasting a cement raw material, wherein the cement raw material consists of the following substances in parts by weight: 50-85 parts of lime stones, 5-20 parts of steel slag powder, 5-15 parts of sandstones and 5-15 parts of coal ash. The preparation method can be used for recycling the steel slag, grinding the steel slag into powder after drying, and adopting the prepared steel slag powder as a cement production raw material to prepare road silicate cement clinker with low heat and high fracture resistance, so that the sintering quality of the clinker can be effectively improved after the steel slag powder is added. On the basis of meeting the technical requirements specified in the road silicate cement national standards, the road silicate cement clinker can be used for improving the fracture resistance and wear resistance of the cement, and lowering the hydration heat evolution and the dry shrinkage rate.

Owner:CHINA BUILDING MATERIALS ACAD

Non-woven filter felt combining air-laid web with pinprick reinforcement and production method

ActiveCN101530698AHigh temperature resistantAnti-acid and alkali corrosionLayered productsFiltration separationSurface layerPunching

The invention provides a non-woven filter felt combining air-laid web with pinprick reinforcement, wherein, the non-woven filter felt has a layered structure, the intermediate layer is high-tenacity and low-elongation type base cloth, and the upper surface and the lower surface of the high-tenacity and low-elongation type base cloth are symmetrically glued with a fiber surface layer or an extra fine fiber surface layer. The production method essentially comprises the technology of producing the surface layer air-laid web: producing the base cloth; producing the needled-punched felt; impregnating; calendering; coating; preliminary drying; solidifying in a way of curing; trimming; winding; and finishing a product. The invention has the advantage that the technology combining the air-laid web with the pinprick reinforcement is used for producing the non-woven filter felt, thereby combining the respective advantage of the two technologies, improving the service life of filter materials, and having high filtration efficiency, high physical and mechanical properties, as well as low cost. Compared with the normal method for filtrating materials with needle punching, the invention can obviously improve the wearing resistance, the fold-resistance capability and the tensile strength, and can bear hyperfiltration load, wherein, the filtering rate can reach more than 1.0 m / min, and the running resistance is low.

Owner:SHANGHAI BG INDAL FABRIC

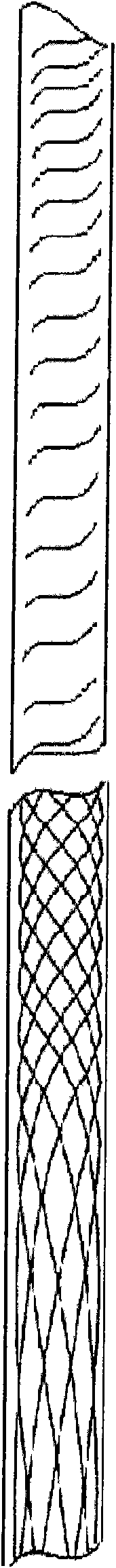

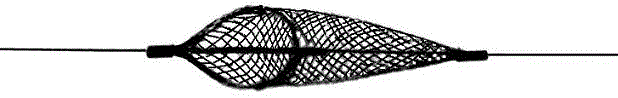

Micro-invision intervened thrombus taking system

The invention discloses a micro-invision intervened thrombus taking system, which comprises a conveyor guide wire, a thrombus catching device, a microcatheter and a guide catheter; the thrombus catching device is a net-shaped bracket formed by knitting one or more wires, a remote end of the bracket is closed or necked, a near end thereof is opened and in the shape of cone. The net-shaped bracket can sleeve relatively big main thrombus and also catch stripped small thrombus, so as to prevent small thrombus flowing to the blood vessel at remoter end and largely reduce the possibility of secondary stroke. The head end of the guide catheter is soft and can be expanded by the thrombus to obtain larger thrombus. The fracture resistance and the flexibility of the remote end of the guide catheter are largely improved, therefore, the guide catheter can be conveyed to the blood vessel at remoter end. The net-shaped bracket is also used as a bracket and reserved in a narrow-section blood vessel to expand the blood vessel and dredge the blood flow, therefore, the additional function of the disease is eased. By using the system, the operation time can be saved to win the treatment time for patients with acute cerebral apoplexy stoke, thus the success rate of the revascularization of the patients is improved.

Owner:吕文峰

Long fiber glass reinforced hydrophobic perlite thermal baffle for buildings and method for manufacturing same

InactiveCN101718122ASimple structureImprove flexural performanceConstruction materialHeat proofingAluminium chlorideFireproofing

The invention relates to a novel fireproofing and heat preservation material for buildings, in particular to a long fiber glass reinforced hydrophobic perlite thermal baffle for the buildings. The long fiber glass reinforced hydrophobic perlite thermal baffle for the buildings is characterized by comprising the following raw materials in percentage by weight: 25 to 50 percent of expanded perlite, 30 to 55 percent of paste or white cement, 5 to 15 percent of filler, 0 to 10 percent of silicate cotton, 0 to 3 percent of retarding agent, 1 to 5 percent of inflating medium, 0.5 to 5 percent of polyaluminum chloride and 1 to 3 percent of water repellent. Due to good fire resistance, good heat insulation and preservation property, mechanical property and construction property, the product of the invention meets the fire resisting and energy saving requirements of the modern buildings, belongs to an environmentally-friendly material and has no pollution to the environment.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Heating yarn and woven or knitted fabric using this heating yarn

InactiveUS20120100386A1High flex resistanceHigh elasticitySeat coveringsWarp knittingConductive yarnElectrical and Electronics engineering

A heating yarn includes an insulating yarn and a conductive yarn that is wound around the insulating yarn. The conductive yarn has an insulating core yarn and a plated layer (such as a copper plated layer) formed on a peripheral surface of the core yarn, and the core yarn is a high elasticity yarn (such as an aramid fiber) with an initial tensile resistance of 4.9 GPa or higher. Moreover, the heating yarn is woven in or knitted into the woven or knitted fabric as part of the constituent yarn.

Owner:TOYOTA BOSHOKU KK

High-strength case plank of transfer case

InactiveCN101219718AHigh strengthNot easy to layerBio-packagingWood veneer joiningGlass fiberFiberglass mesh

The invention relates to a high strength plate of a turnover box, which is a plate or a multilayer plate manufactured by mixing fragment wood fiber and glue under high temperature and high pressure; a stiffener is positioned inside the wood fiber-glue mixed plate or between plate layers. The stiffener which is positioned inside the wood fiber- glue mixed plate or between the plate layers is a metal net inside the wood fiber-glue mixed plate or between the plate layers and the metal net can preferably be a plastic net or a glass fiber net; as the plastic net and the glass fiber net are compatible with wood glue so that the high strength plate with high density is generated; besides, the plastic net and the glass fiber net is not easy to be layer and separated from a body. In this way, the invention gets rid of the habit that the stiffener is not put inside the wood fiber plate by people; the invention greatly enhances the strength, especially anti-bending and anti-deformation capability.

Owner:郭泽和

Technically simple method for modifying fly ash

InactiveCN104961368AImprove performanceReduce brittlenessSolid waste managementBreaking strengthALLYL SUCROSE

The invention discloses a technically simple method for modifying fly ash. The method includes hydroxylating the surface of the fly ash to obtain hydroxylated fly ash; grafting the hydroxylated fly ash. The method has the advantages that polyacrylic acid is grafted on the surface of the fly ash, accordingly, the brittleness of cement-based composite materials can be reduced, the toughness of the cement-based composite materials can be improved, water consumption and cement consumption can be decreased, the breaking strength can be evidently improved, and the requirement of the high-performance cement-based composite materials on the breaking strength can be completely met; the modified fly ash contains large quantities of water-soluble groups and accordingly is good in dispersibility, and the problem of agglomeration of mineral admixtures can be effectively solved.

Owner:HEFEI UNIV OF TECH

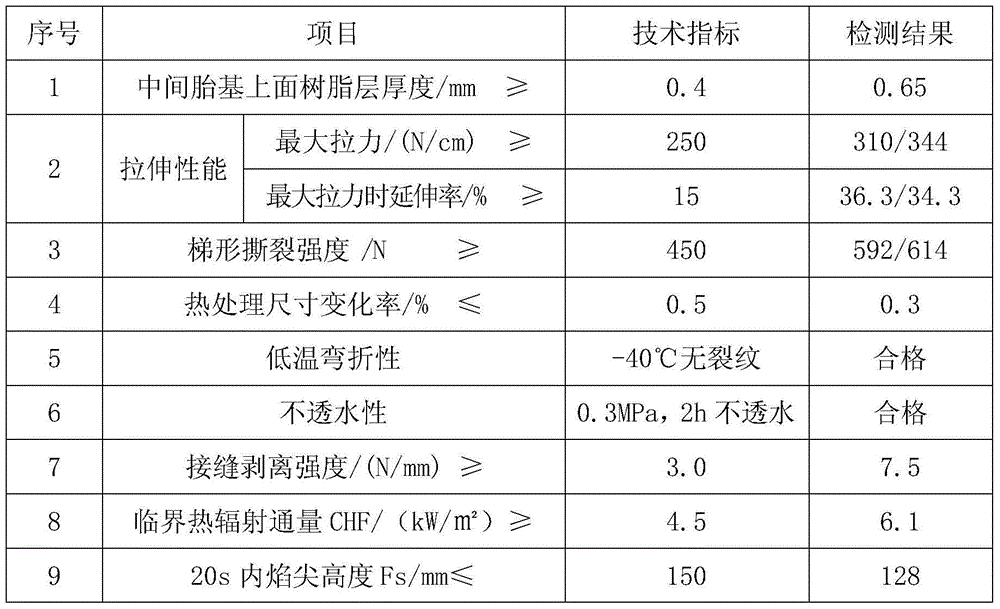

Fire-retardant thermoplastic polyolefin waterproof roll and preparation method thereof

InactiveCN104441887AImprove flame retardant performanceHave synergistic effectSynthetic resin layered productsGlass/slag layered productsFiberPolyolefin

The invention discloses a fire-retardant thermoplastic polyolefin waterproof roll, which is of a three-layer composite structure, wherein a middle layer is a fiber fabric layer; an upper surface layer and a lower surface layer are fire-retardant TPO roll layers; a fire-retardant TPO resin layer is prepared from TPO resin as a base material, a composite fire retardant as an assistant and other auxiliary materials; the composite fire retardant is composed of decabrominated dipheny ethane (DBDPE), magnesium hydrate, antimonous oxide and zinc borate; and the auxiliary materials are selected from one or a mixture of more than one of packing, titanium dioxide, a compatilizer, an antioxidant, an ultraviolet absorbent, a light stabilizer and black master batches. According to the waterproof roll disclosed by the invention, through use of the composite fire retardant, the defect that an existing TPO waterproof roll is inflammable is solved; the fire-retardant target is achieved under the premise of ensuring the welding construction and waterproof effect reliability of the product; and through use of the composite fire retardant, the combustion performance of the TPO roll belonging to inflammable materials can be up to A grade maximally, and reaches the non-inflammable grade.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

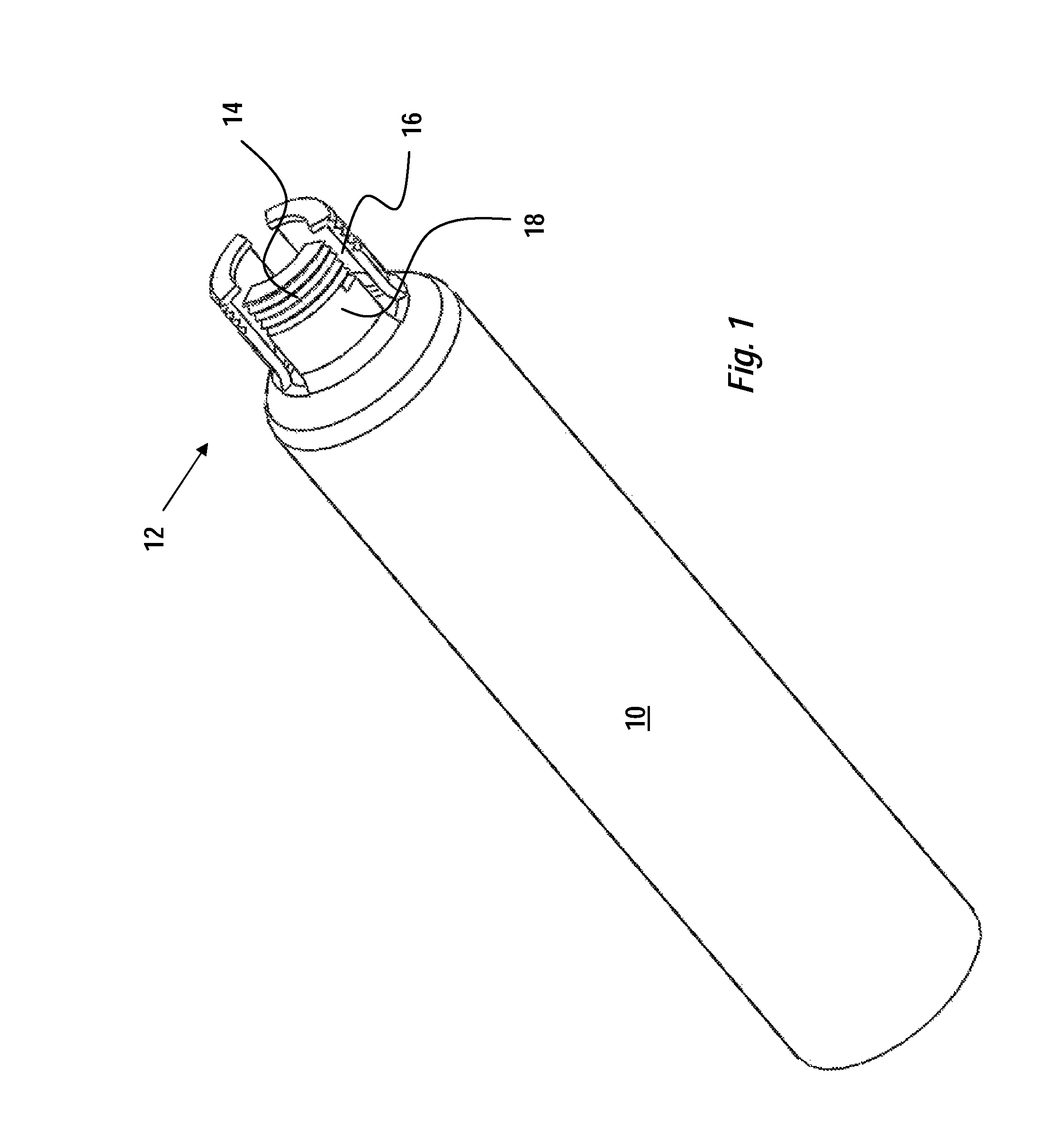

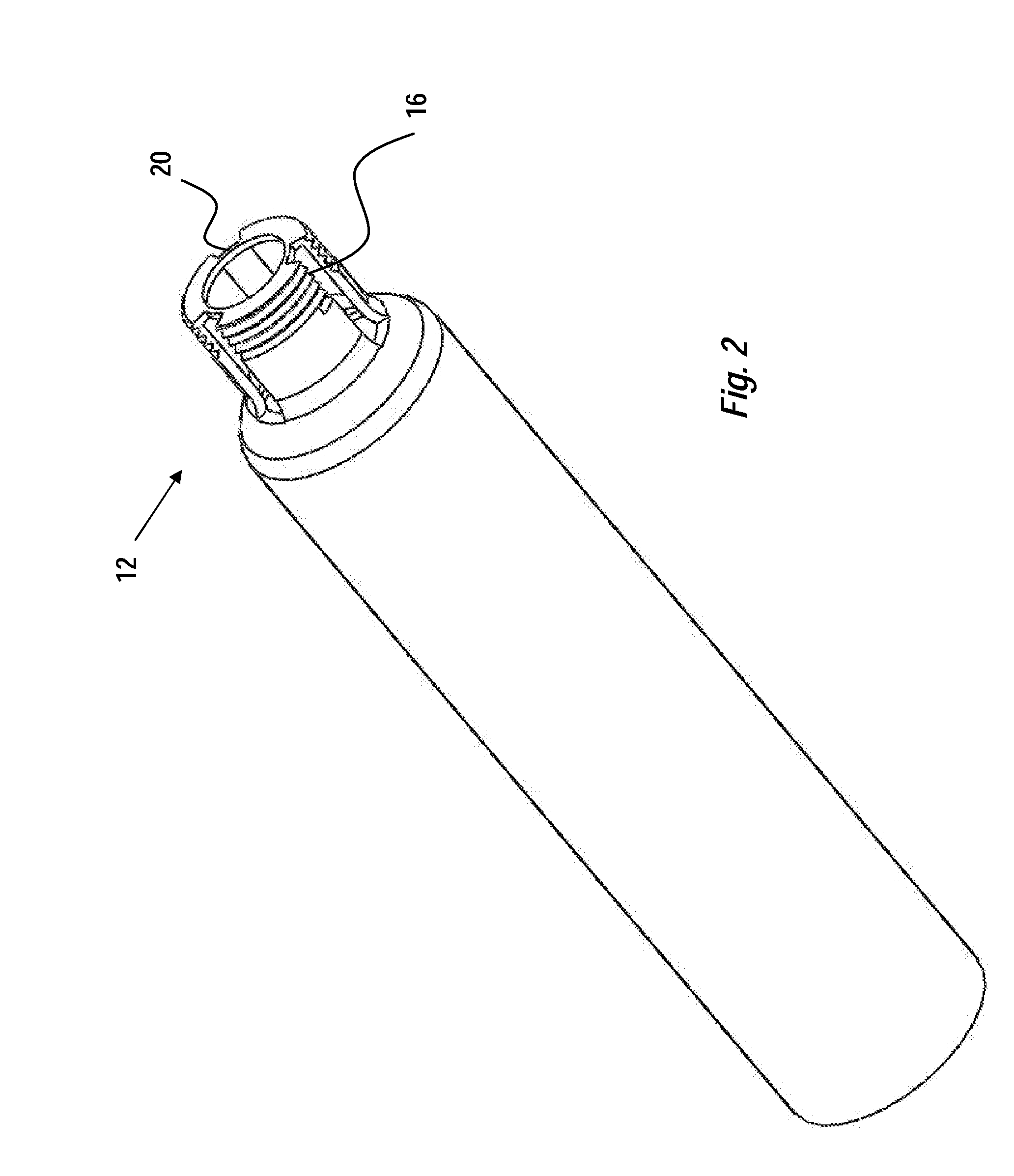

Delivery member attachment device

ActiveUS8876785B2Improve flexural performanceGood adhesionAmpoule syringesMedical atomisersBiomedical engineering

Owner:SHL MEDICAL AG

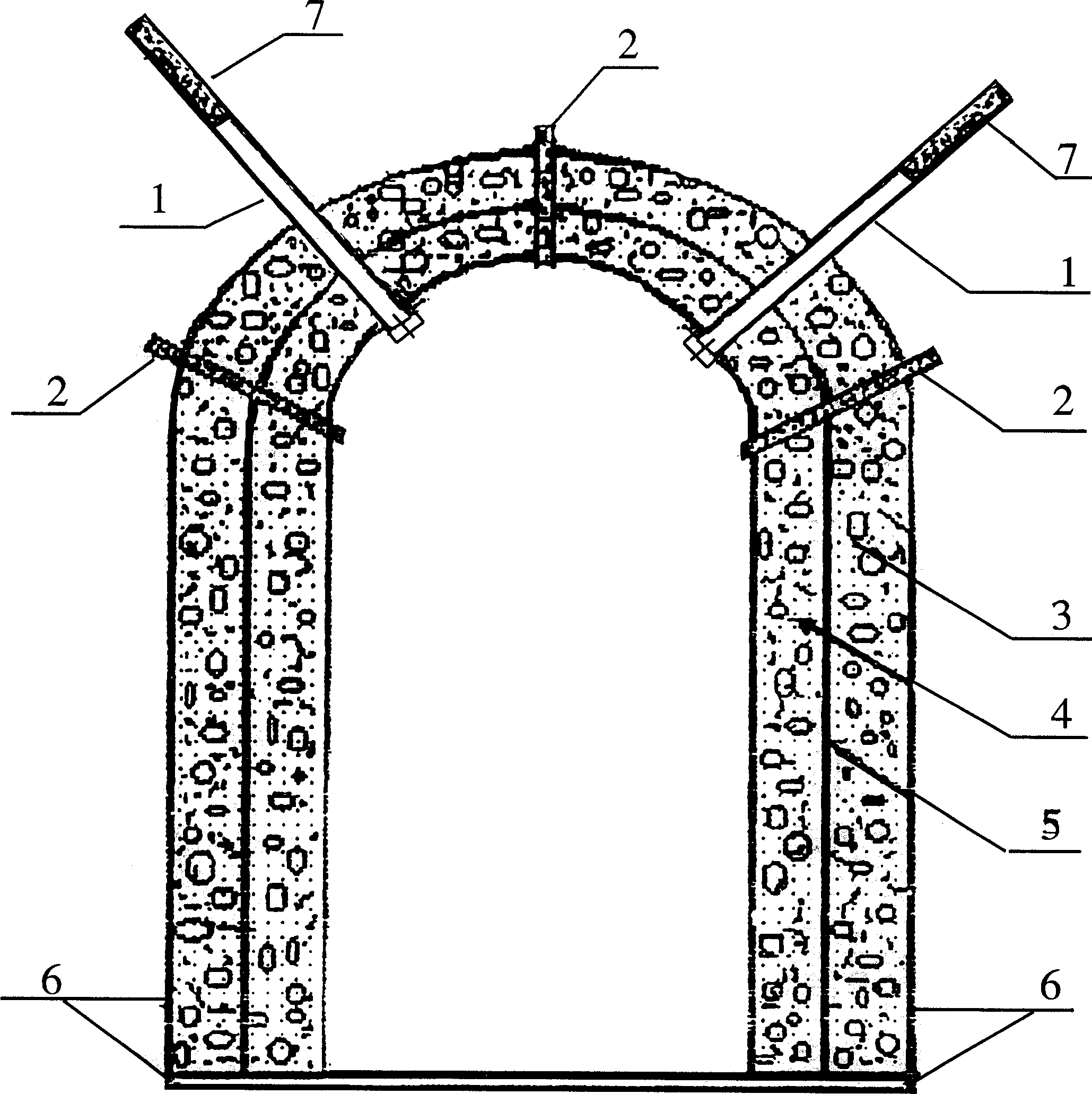

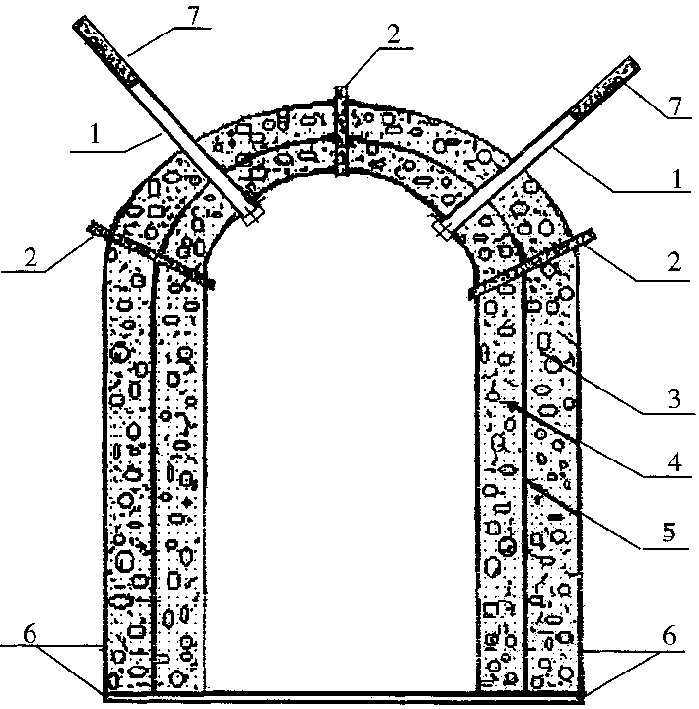

Anchor-spraying concrete for treating water and support

InactiveCN1381651ASolve construction technical problemsAchieve governanceArtificial islandsUnderground chambersShotcreteUltimate tensile strength

An anchoring-sprayed prop for controlling water in constructing underground engineering features direct use of anchorage and spraying concrete. Its construction technology includes such steps as drilling weep holes, setting up weep pipes, primary spraying, drilling anchor holes, installing anchor rods, hanging net, spraying again, blocking drainage pipes, and curing. If the bed rock encounters fault, it is necessary to spray concrete for the third time.

Owner:王衡

Pouring material for cement kiln tertiary air duct

The invention relates to a pouring material for a cement kiln tertiary air duct. The pouring material comprises aggregate and a matrix material according to a weight ratio of 2-8: 1-3. The aggregate has particle sizes of 1-10mm and the matrix material has the particle sizes of 0.1-0.5mm. The aggregate comprises, by weight, 28-50 parts of fused magnesia, 25-45 parts of modified white alundum, 5-15 parts of zirconium mullite and 8-20 parts of magnesium aluminate spinel. The matrix material comprises magnesia powder, silicon oxide fine powder, mullite powder, alumina fine powder and andalusite. The pouring material utilizes appropriate aggregate and the matrix material and has wear resistance and corrosion resistance, a uniform degree of expansion and good thermal shock stability. Through use of a fiber additive, pouring material integrality is improved, and pouring material flexural performances and anti-erosion performances are improved. The cement kiln tertiary air duct has the advantages of long service life, long replacement period, small production cost and high production efficiency under bad conditions.

Owner:长兴兴鹰新型耐火建材有限公司

Polyamide laminated film

InactiveUS6294263B1Excellent gas barrier performanceIncrease resistanceSynthetic resin layered productsDomestic articlesElastomerXylylene

The present invention is to provide a polyamide laminated film comprising a resin layer A and a resin layer B formed on at least one surface of the resin layer A,the resin layer A being composed mainly of a m-xylylene group-containing polyamide polymer (a-1) which is one prepared from monomer components containing a xylylenediamine compound as a main diamine component and an alpha,omega-aliphatic dicarboxylic acid having from 6 to 12 carbon atoms as a main dicarboxylic acid component, the xylylenediamine compound being m-xylylenediamine alone or a mixture of m-xylylenediamine and p-xylylenediamine, andthe resin layer B being mainly composed of a mixed polymer (b-3) which is a mixture of from 99 to 80% by weight of an aliphatic polyamide (b-1) and from 1 to 20% by weight of an elastomer (b-2).The laminated film is good in a gas barrier property and also in a flexural fatigue resistance and a transparency.

Owner:TOYO TOYOBO CO LTD

A high durability and high bearing capacity concrete pipe pile

The invention discloses a high-durability and high-bearing-capacity concrete pipe pile, which is characterized by comprising the following raw material in part by mass: 685 to 760 parts of common silicate cement, 170 to 200 parts of silicon powder with an average particle size of 0.30 mu m and a SiO2 content of more than or equal to 92 percent, 1,100 to 1,190 parts of quartz sand with a particle size between 0.16 to 1.25mm, 13 to 15 parts of superplasticizer, 165 to 190 parts of water, and 90 to 150 parts of copper-plated steel fibers with a diameter between 0.18 and 0.25mm and a length between 11 and 15mm. The preparation process of the pipe pile is to uniformly stir the steel fiber and fine quartz sand and the concrete, silicon powder, water and superplasticizer in turn to obtain a mixture, fill the mixture into a mold, form with vibrating, cure in a steam environment with a temperature between 75 and 95 DEG C and a humidity of not less than 95 percent for 36 to 48 hours and demold. The pipe pile has the advantages of high antifatigue performance and corrosion-resistance performance and small cross section thickness.

Owner:黄贺明

Delivery Member Attachment Device

ActiveUS20110288493A1Improve flexural performanceGood adhesionAmpoule syringesMedical atomisersBiomedical engineeringEngineering

Owner:SHL MEDICAL AG

Catheter of composite structure

The invention discloses a catheter of composite structure. The catheter comprises a high-molecular pipe on the outer layer, a tubular woven net or spring net on the middle layer and a smooth inner layer. The high-molecular pipe on the outer layer is made of nylon, nested polyetheramide elastomer, polyurethane or silicone rubber; the wall thickness of the far end of the woven net or spring net on the middle layer is smaller than or equal to the wall thickness of a woven net body or spring net body; the inner layer is made of polytetrafluoroethylene or high-density polyethylene or nested polyetheramide elastomer containing a friction coefficient reducing additive. Compared with a conventional plastic catheter, the composite catheter has the advantages that the same mechanical performance requirement is met, and the wall thickness can be greatly reduced; the passing performance, folding resistance and controllability of the composite catheter are greatly improved, the composite catheter can be pushed to deeper and smaller blood vessels under the same conditions, and the operative successful rate is increased.

Owner:南京普微森医疗科技有限公司

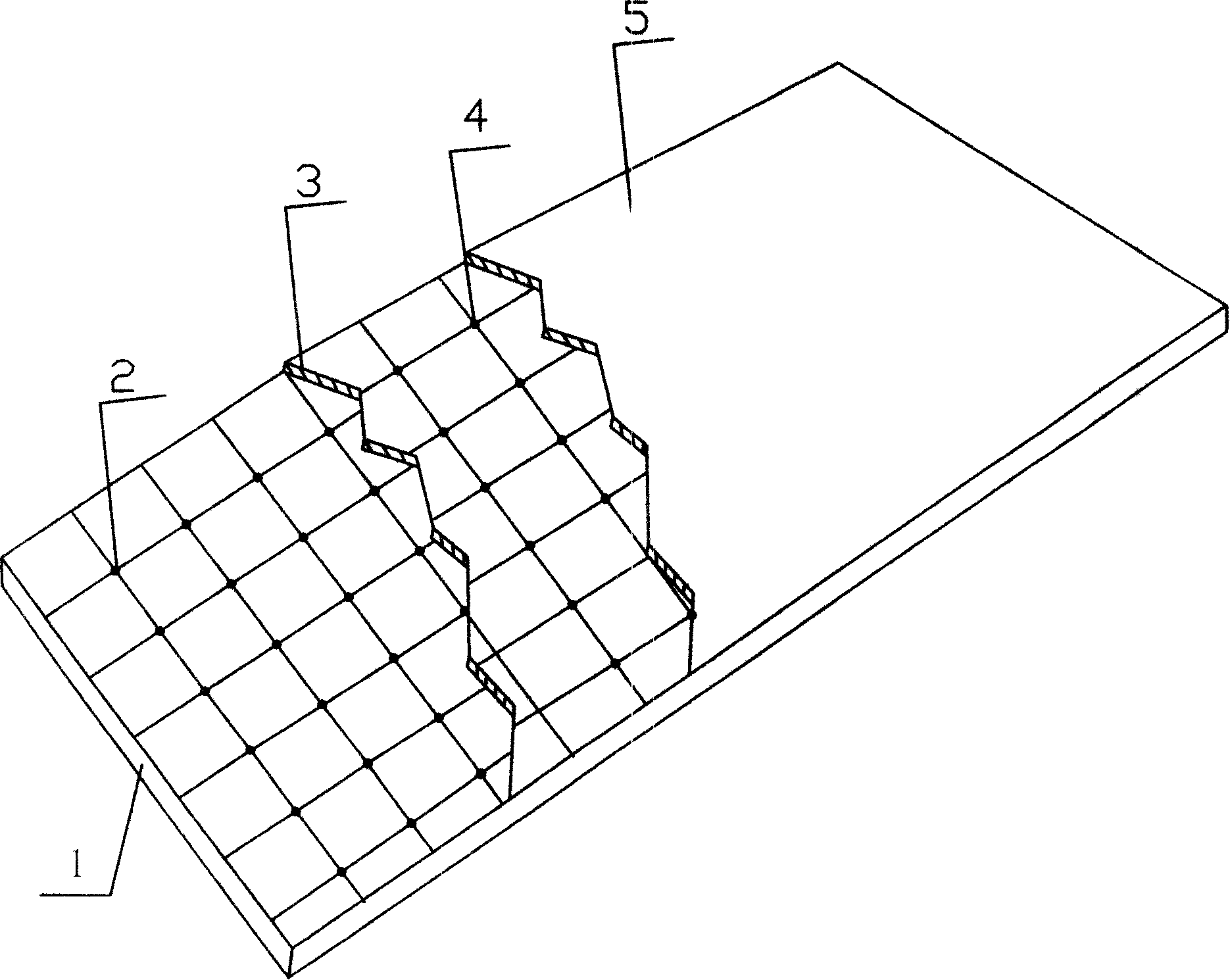

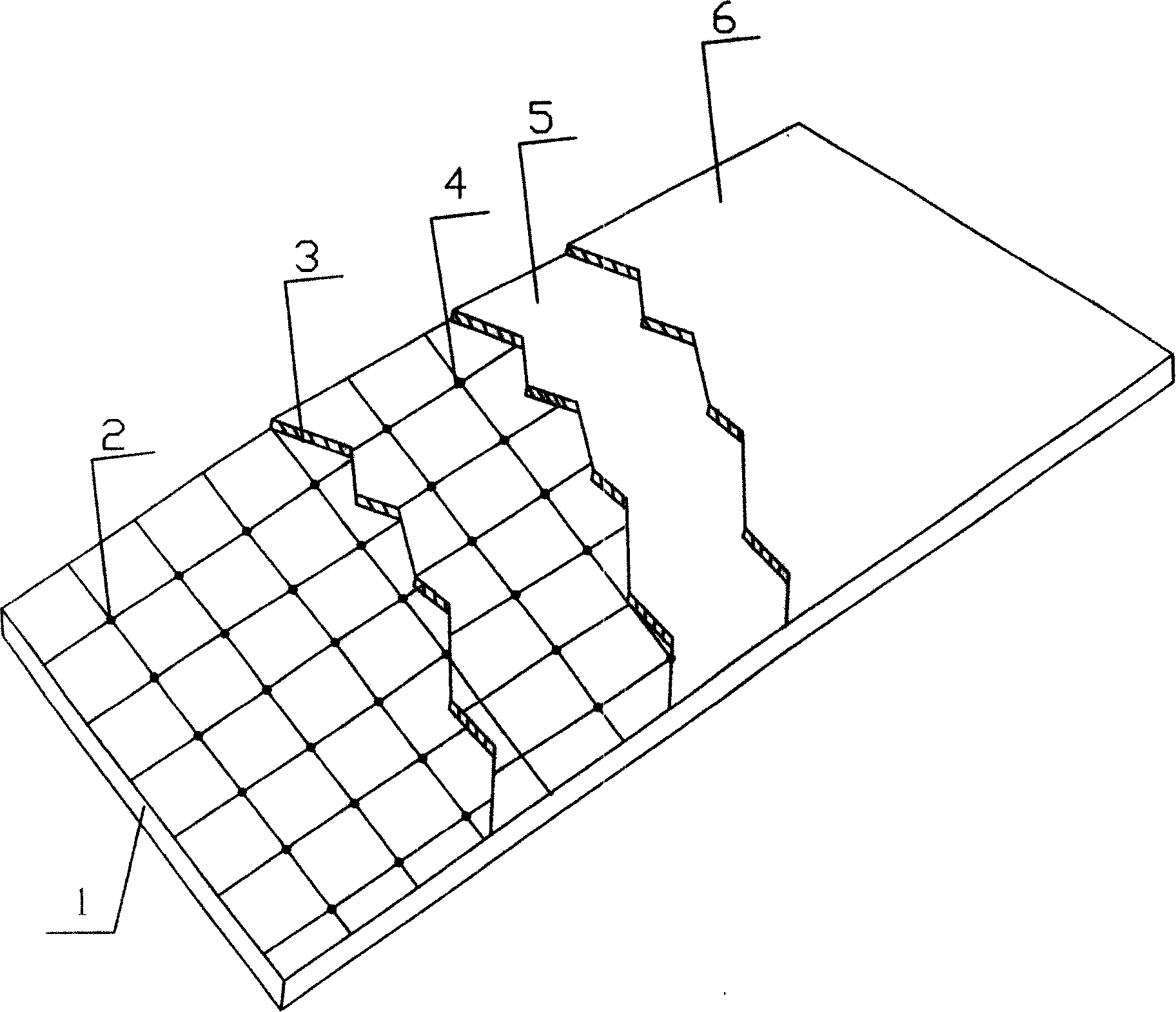

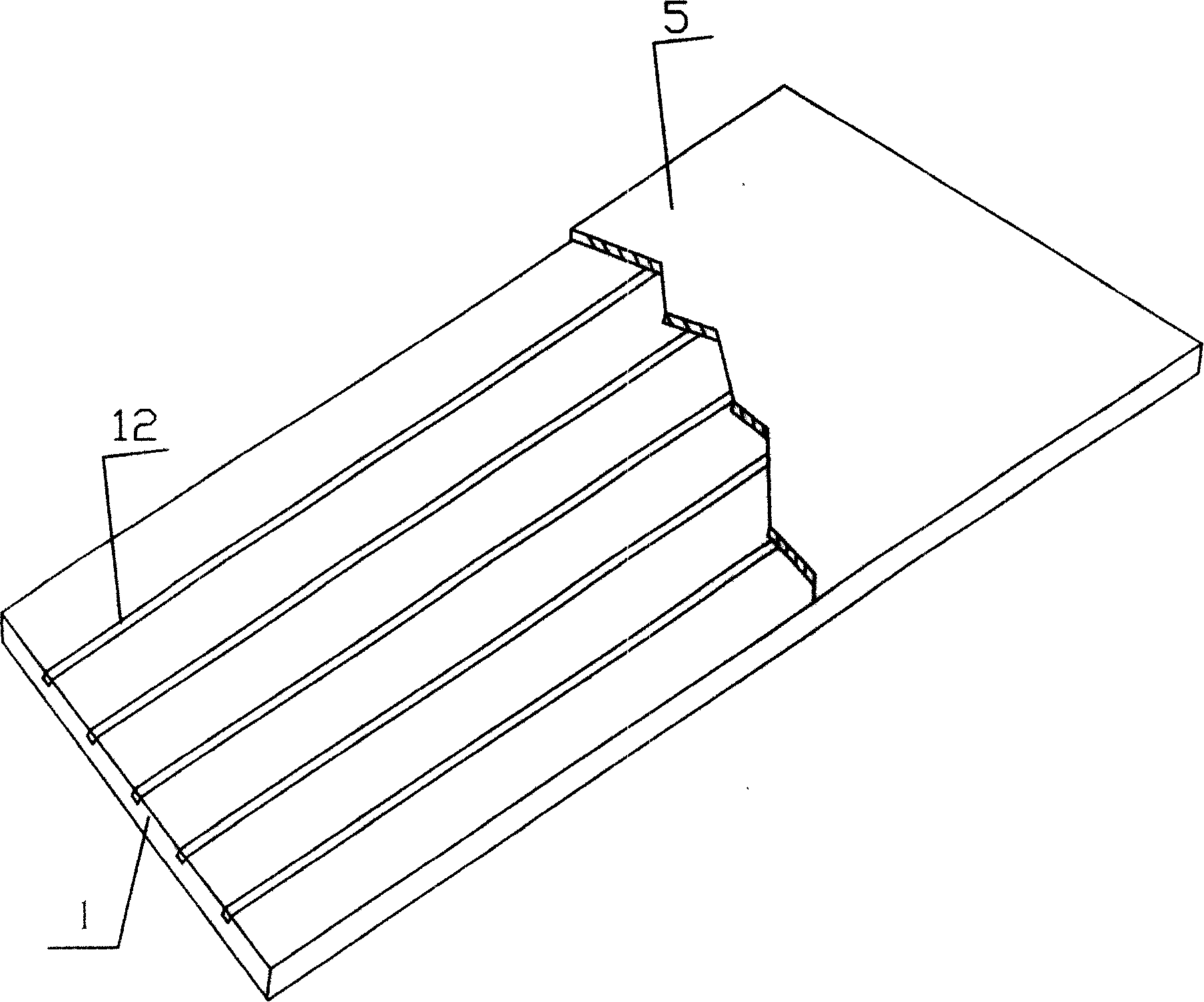

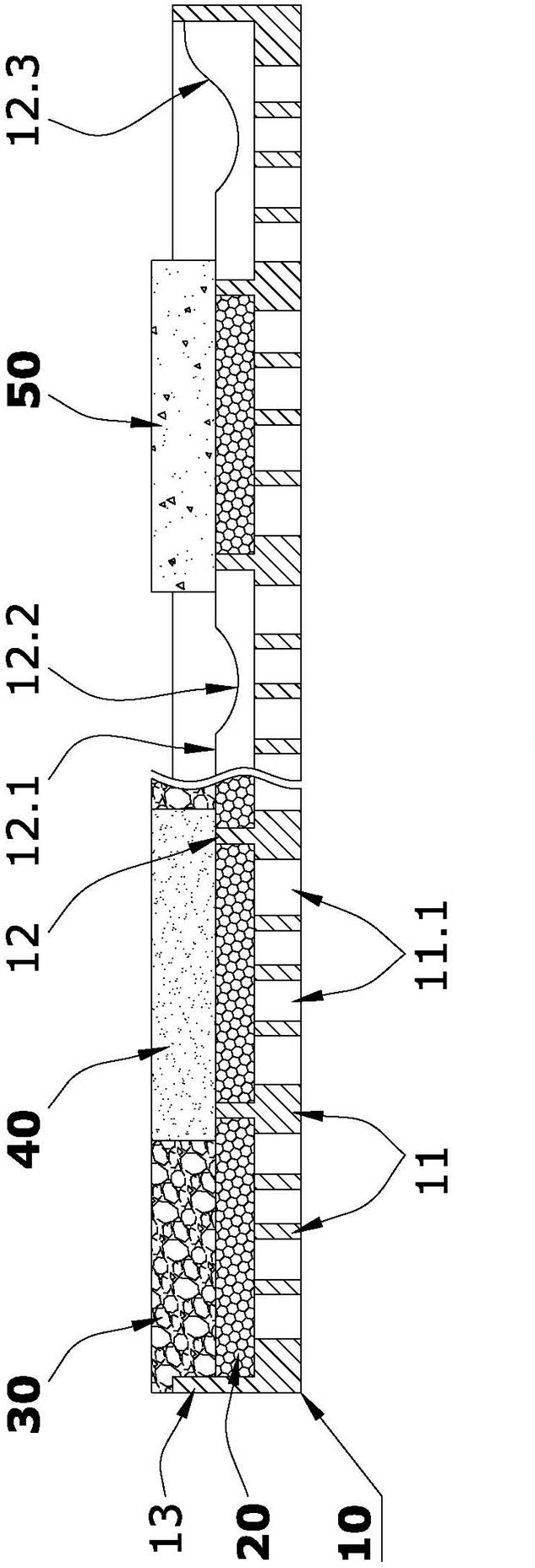

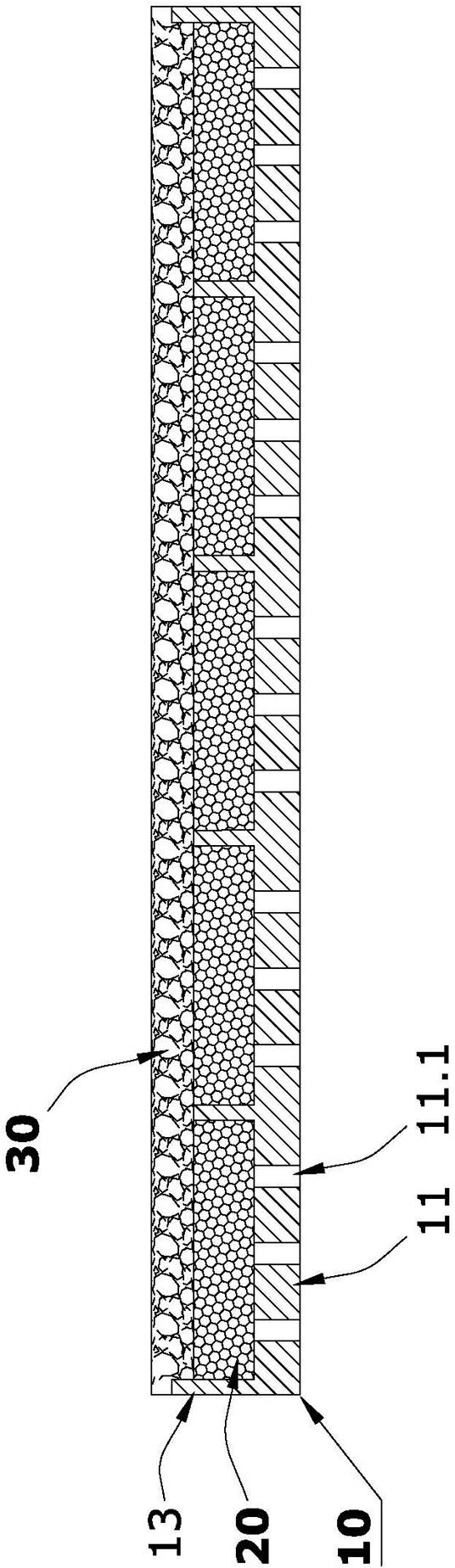

Water permeable stone paving block

InactiveCN102587256AImprove stress resistanceImprove flexural performanceSingle unit pavingsSidewalk pavingsAdhesiveMesh grid

The invention discloses a water permeable stone paving block, which comprises a flat water permeable grid plate frame, a water permeable cushion layer that is filled in the water permeable grid plate frame and made of stones bonded with adhesive, a colored stone water permeable surface layer that is bonded on the stone water permeable cushion layer and bonded with contacts, or a colored stone water permeable surface layer that is bonded on the stone water permeable cushion layer and bonded with water permeable and non-water permeable paving blocks. Compared with the traditional water permeable stone paving block, the water permeable stone paving block disclosed by the invention has greatly increased level, greatly prolonged service life and excellent water permeability, and can be produced in a factory; and the construction with the water permeable stone paving block is not affected by climatic conditions.

Owner:厦门市闽长鹭科技发展有限公司

A flexible display apparatus and an encapsulation method thereof

InactiveUS20170012237A1Improve performanceReduce possibilityConstructionsSolid-state devicesEngineeringMultiple function

The disclosure describes a flexible display apparatus and an encapsulation method thereof, which are capable of solving the problem of easily producing cracks with the existing encapsulating film layer and improving the performance of flex resistance of the flexible display apparatus. The flexible display apparatus according to the disclosure comprises: an LED device, and a protective layer arranged on a cathode of the OLED device, wherein the protective layer comprises a water oxygen barrier region and a multi-functional region, the multi-functional region has dual functions of a water oxygen barrier and stress blocking, and the thickness of the film layer in the multi-functional region is less than that of the film layer in the water oxygen barrier region, and / or the film texture in the multi-functional region is looser than that in the water oxygen barrier region.

Owner:BOE TECH GRP CO LTD

High-efficient needle punched filter felt for purifying Pm 2.5 fine particles and manufacturing method thereof

InactiveCN103055605ASimple methodEasy to implementFibre treatmentLiquid/gas/vapor removalYarnGlass fiber

The invention relates to a high-efficient needle punched filter felt for purifying Pm 2.5 fine particles and a manufacturing method thereof, relating to a high-efficient needle punched filter felt for purifying Pm 2.5 fine particles in industrial smoke gas and a manufacturing method thereof. The product is used for iron and steel, smelting, carbon black, cement and waste incineration, and belongs to industrial environmentally-friendly filtering material. A needle punched filter felt is composed of surface layer yarn, inner layer yarn and middle chemical fiber base cloth; the surface layer yarn of the needle punched filter felt is made of superfine fiber; and the inner layer yarn is made of large diameter ordinary fiber. The method is simple and easy to implement; the dedusting efficiency of the needle punched filter felt manufactured by the invention can reach 99.99%, and Pm 2.5 fine particles dust can be efficiently purified. The materials of the surface layer yarn and the inner layer yarn are reasonably matched, and are used according to different characteristics and features of microfiber, coarse fiber, glass fiber and chemical fiber. The effect of filtering smoke gas is improved, and the service life of a filter bag is also prolonged. The production and use costs are greatly reduced. The problem existing in the existing filtering material is solved.

Owner:MELONG ENVIRONMENTAL PROTECTION FILTER MATERIAL TECH YINGKOU CO LTD +2

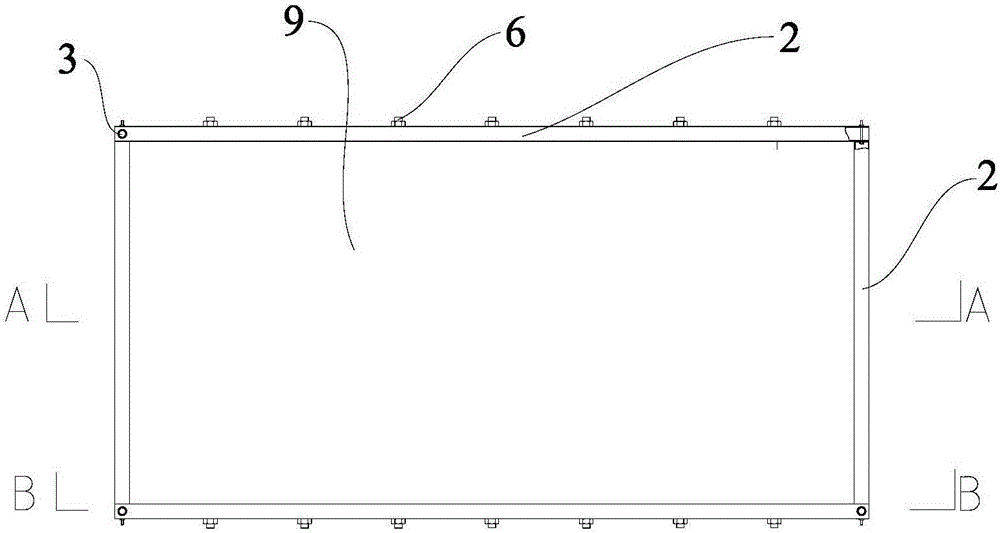

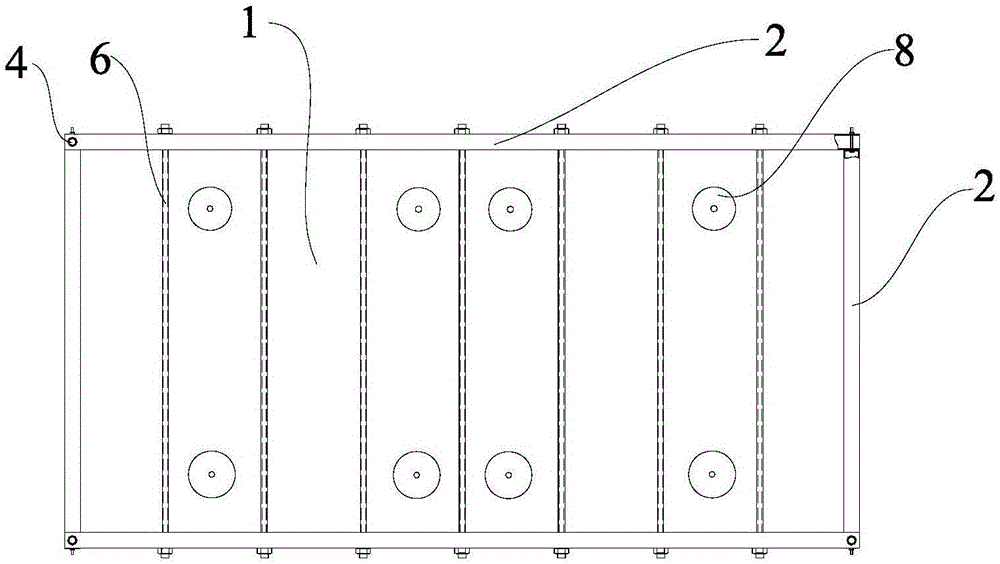

Production line for concrete prefabricated piece

PendingCN106738290ASmall footprintSave heatDischarging arrangementCeramic shaping plantsProduction lineEngineering

The invention belongs to the field of building part production and particularly discloses a production line for a concrete prefabricated piece. The production line comprises a mould pretreatment station, a material distribution station, a mould combination station and a demoulding station. The mould combination station is used for stacking and combining moulds after material distribution is completed, connecting portions are arranged at the bottoms and on the upper portions of the moulds, and the vertically-arranged moulds are fixed through the connecting portions. An independent curing space is formed between the vertically-arranged moulds, and the prefabricated piece is cured in the curing space. According to the production line for the concrete prefabricated piece, a curing kiln or other curing rooms are not needed in the curing link, only the moulds are conveyed to stock dump after being stacked and combined, and demoulding can be conducted after curing is conducted for a certain time; the technological process is simplified, a stacking frame or other supports are not needed in the curing process, and production efficiency is improved while production cost is reduced; and meanwhile, due to the fact that the curing kiln and the like does not need to be used, cost is reduced, energy consumption is lowered, maintenance cost of facilities is reduced, and the occupied area of the whole technological production line is greatly reduced.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

Water-proof, high-strength, weather resistance, flame-retardant and environment-friendly thermal insulation board and preparation method thereof

InactiveCN108358589AHigh tensile strengthImprove flexural performanceCeramicwareCellulosePolyvinyl alcohol

The invention discloses a water-proof, high-strength, weather resistance, flame-retardant and environment-friendly thermal insulation board and a preparation method thereof. The thermal insulation board is prepared from the following raw materials in parts by weight: 30-40 parts of modified straw, 6-8 parts of fly ash, 7-9 parts of calcined gypsum powder, 10-14 parts of ore filler, 8-12 parts of silica sol, 6-8 parts of thermal insulation additive, 7-9 parts of polyvinyl alcohol, 4-6 parts of acrylic emulsion, 3-5 parts of modified nano additive, 5-7 parts of a gel material, 0.3-0.5 part of cellulose ether and 7-9 parts of fire-proof and flame-retardant additive. The thermal insulation board disclosed by the invention adopts a large amount of wastes, saves the resources, protects the environment, is high in material compressive strength, superior in weather resistance and excellent in humidity resistance, low in heat conductivity coefficient and good in thermal insulation effect, and also has a certain sound insulation effect at the same time; and furthermore, the preparation method disclosed by the invention has the advantages that the material cost is lower, the raw materials areeasy to obtain, the process is concise, the practical value is higher, and the application prospects are good.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

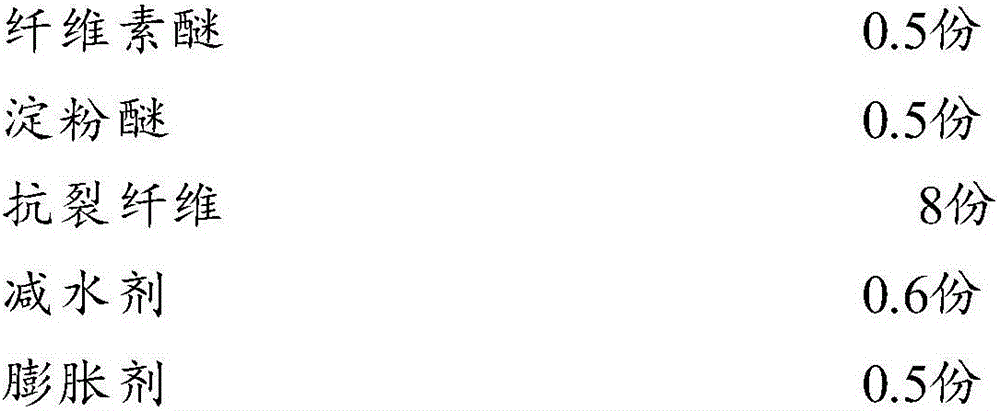

Concrete repairing dry-mixed mortar and preparation method thereof

The invention discloses concrete repairing dry-mixed mortar being prepared from the components including, by mass, 100 parts of Portland cement, 80-120 parts of ferrous aluminate cement, 220-280 parts of fine aggregate, 30-40 parts of fly ash, 60-90 parts of silicon micro-powder, 0.5-1 part of methyl cellulose ether, 0.5-1 part of starch ether, 8-12 parts of anti-cracking fibers, 0.6-1.5 parts of a water reducing agent, and 0.5-2 parts of an expanding agent. The invention also relates to a preparation method of the mortar. The mortar has strong adhesive property, can be effectively bond with concrete, is anti-corrosion and has good anti-cracking performance, and prolongs service life of concrete.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Polymer mortar and mixing method thereof

The invention relates to polymer mortar. The polymer mortar comprises the following components in percentage by weight: 5.0-10.0% of fly ash, 0.3-0.8% of silicon powder, 0.5%-0.8% of redispersible latex powder, 0.2-0.3% of thickening and water-retaining agent, 0.8-1.2% of water reducing agent, 0.1-0.3% of coagulation accelerator, 0.1-0.2% of anti-crack fiber, 0.1-0.2% of wood fiber, 45.0-50.0% of quartz sand and 40.0-45.0% of cement. The invention also discloses a mixing method of the polymer mortar. The mixing method comprises the following steps: firstly stirring and mixing the fly ash, the thickening and water-retaining agent, the water reducing agent, the coagulation accelerator, the anti-crack fiber, the wood fiber, the redispersible latex powder and the silicon powder according to a proportion to obtain a mixture which is uniformly stirred; then weighing, mixing and uniformly stirring the mixture, the cement and the quartz sand to obtain the polymer mortar. By applying the technical scheme of the invention, the performance index parameters of the polymer mortar are as follows: the splitting tensile strength is 7.2MPa, the compressive strength is 58.8MPa, the flexural strength is 12.2MPa and the positive pulling bond strength is 2.5MPa.

Owner:NANJING HULIAN NEW BUILDING MATERIAL

Foamed concrete and preparation method thereof

InactiveCN108947398AImprove mechanical propertiesImprove thermal insulation performanceCeramicwareFoam concreteGlass fiber

The invention discloses foamed concrete and a preparation method thereof. The foamed concrete contains aerogel powder, foamed concrete and fibers, wherein the aerogel powder contains an internal hydrophobic layer and a surface hydrophilic layer, and the thickness of the surface hydrophilic layer is 0.1-100 microns; and a fiber felt is one or more of a glass fiber felt, a basalt fiber felt, an aluminum oxide fiber felt, a carbon fiber felt and a polyvinyl chloride fiber felt. According to the preparation method, the fibers are compounded with the foamed concrete, the fibers are uniformly distributed in the foamed concrete, and the foamed concrete still remains a nano-porous structure; and compared with existing foamed concrete in the market, the foamed concrete has relatively excellent mechanical property and heat insulation property, the fracture resistance and pressure resistance of the foamed concrete can be remarkably improved, the foamed concrete can be endowed with certain flexibility, and the drying shrinkage value of the foamed concrete can be decreased.

Owner:苏州郎旭志远科技有限公司

Novel noodles

The invention discloses novel noodles. The noodles comprise more than two noodles connected side by side, all the noodles are connected into a row, and the width of the connection face of every two adjacent noodles is smaller than the thickness of each noodle, so that the mutually connected noodles can be manually separated from each other in the cooking process. By adopting the structure, the noodles have low probability of breakage, so that both the graded product rate and the production efficiency are improved, the production cost is lowered, and wastes caused when the noodle is packaged, transported and selected by customers are reduced; the noodles are easy to cook thoroughly and be tasty, and people can cook patches or noodles according to different food requirements; as more than two noodles are connected into a row side by side, the cross section can be elliptic, round or rhombic or in other novel shapes, so that the purchase desire and the appetite of people can be easily aroused; and more choices are provided by the masses to purchase noodles, the life of the masses is enriched and the life quality is improved; and the novel noodles provided by the invention have a broad market prospect and can be successful commercially.

Owner:CHENZHOU CHENGSHI FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com