Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133results about How to "Improve anti-stripping performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic/inorganic composite separator and electrochemical device containing the same

ActiveUS7695870B2Improve thermal stabilityRestrain electric short circuitFinal product manufactureConductive materialPorous substrateElectrochemistry

Owner:TORAY BATTERY SEPARATOR FILM +1

Organic/inorganic composite separator and electrochemical device containing the same

ActiveUS20090246613A1Improve thermal stabilityImprove stabilityCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous substrateElectrochemistry

An organic / inorganic composite separator includes a porous substrate having a plurality of pores; and a porous coating layer formed on at least one surface of the porous substrate with a plurality of inorganic particles and a binder polymer. The binder polymer is a copolymer including: (a) a first monomer unit having a contact angle to a water drop in the range from 0° to 49°; and (b) a second monomer unit having a contact angle to a water drop in the range from 50° to 130°. This organic / inorganic composite separator has excellent thermal stability, so it may restrain an electric short circuit between a cathode and an anode. In addition, the separator may prevent inorganic particles in the porous coating layer from being extracted during an assembling process of an electrochemical device, thereby improving stability of an electrochemical device.

Owner:TORAY BATTERY SEPARATOR FILM +1

Wearproof and tough quasi bainite points and rails and their production

A high-strength and high-toughness antiwear quasi-bainite rail for switch contains C (0.1-0.4 wt.%), Si (0.8-2.0), Mn (0.8-3.3), Cr (0-2.0), Mo (0.1-0.8), N (10-150 ppm), Al (0-0.005) and Fe (rest), and is made up through smelting in converter, reinfing, treating with RE, vacuum degassing, conticasting, rolling, air cooling to 400 deg.C, slow cooling to 200 deg.C and natural cooling. Its advantages are uniform hardness in cross section, high strength, toughness and stability, and high antiwear performance.

Owner:ANGANG STEEL CO LTD +1

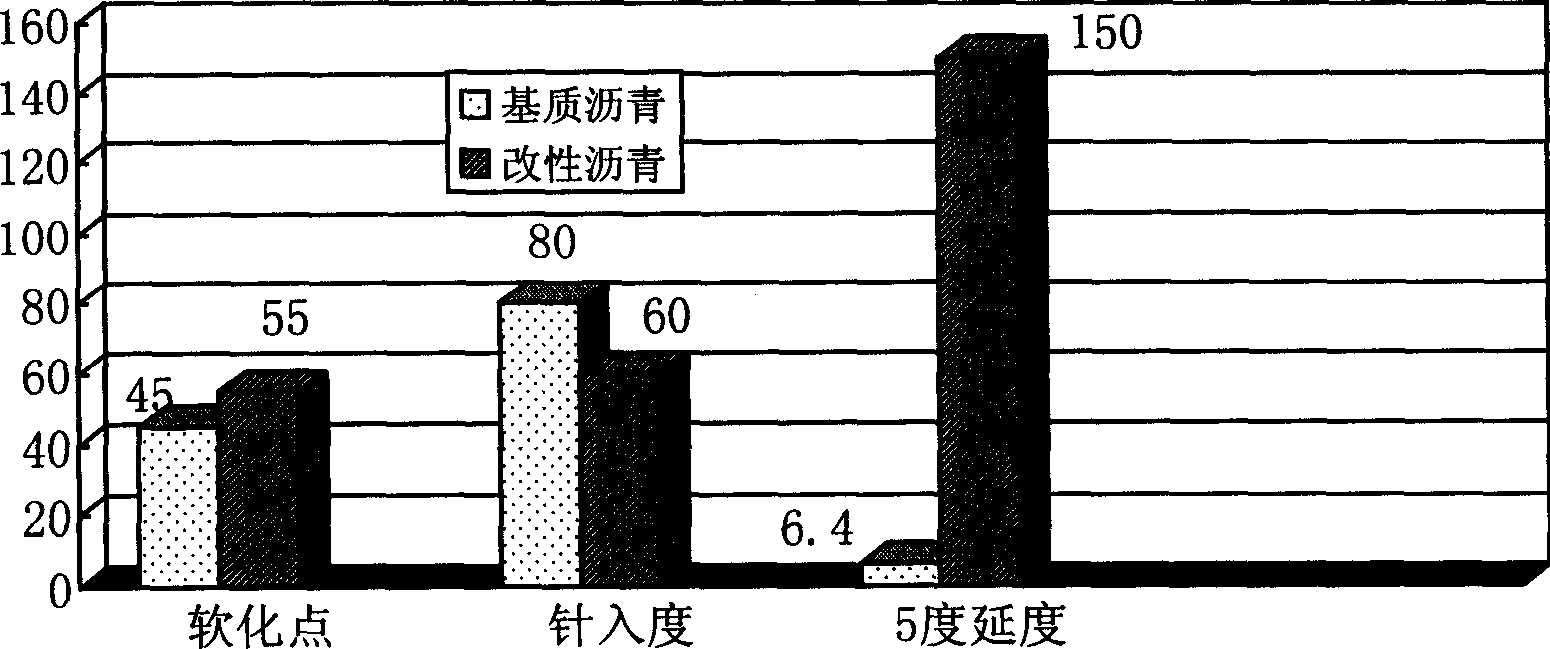

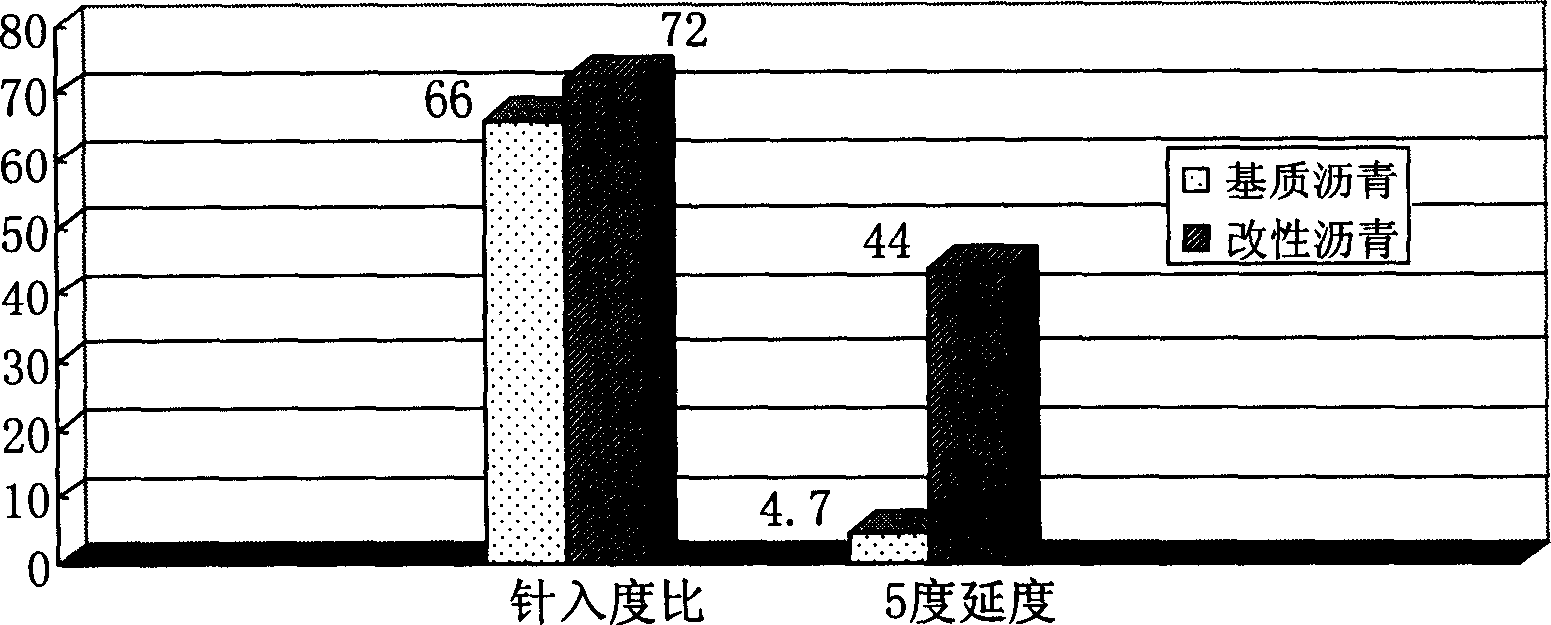

Modified asphalt material for road and its prepn

The present invention relates to one kind of modified asphalt material for road and its preparation. The modified asphalt material is prepared with asphalt with high wax content as base material and through adding powdered styrene-butadiene rubber, natural asphalite and organic metallic soap. The modified asphalt has the features of high temperature stability, low temperature crack resistance, fatigue resistance, peeling resistance, antiageing, etc. as well as improved comprehensive road use performance.

Owner:INST OF POLYMER NORTHWEST NORMAL UNIV

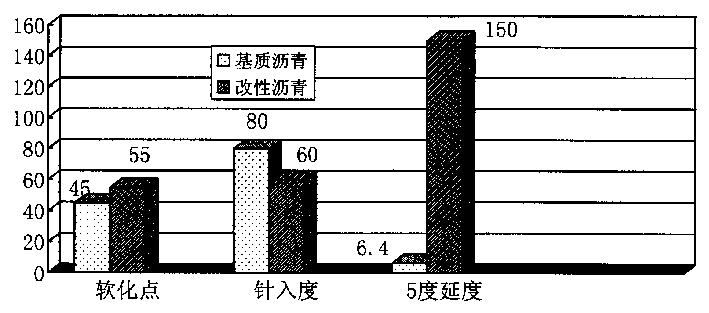

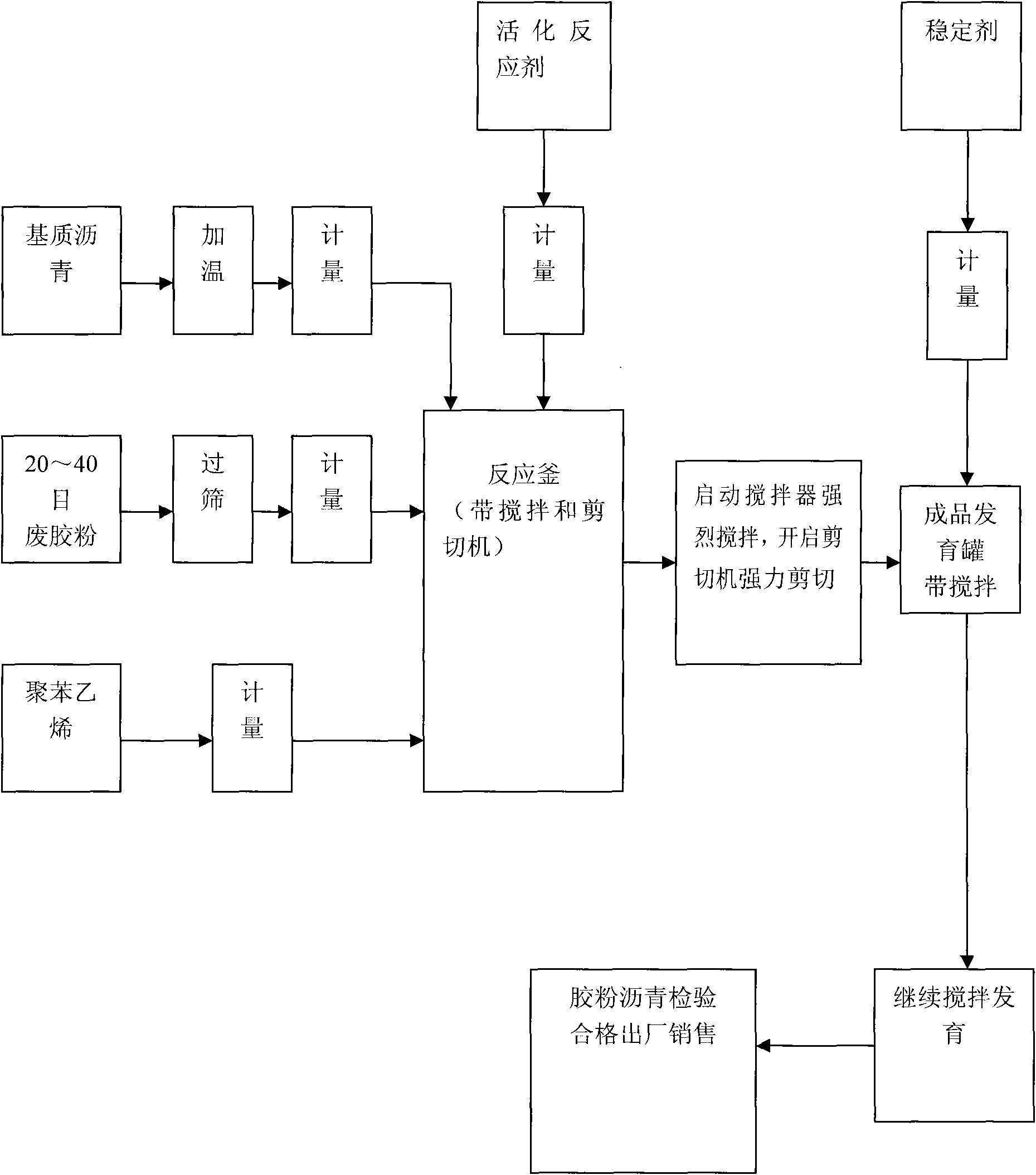

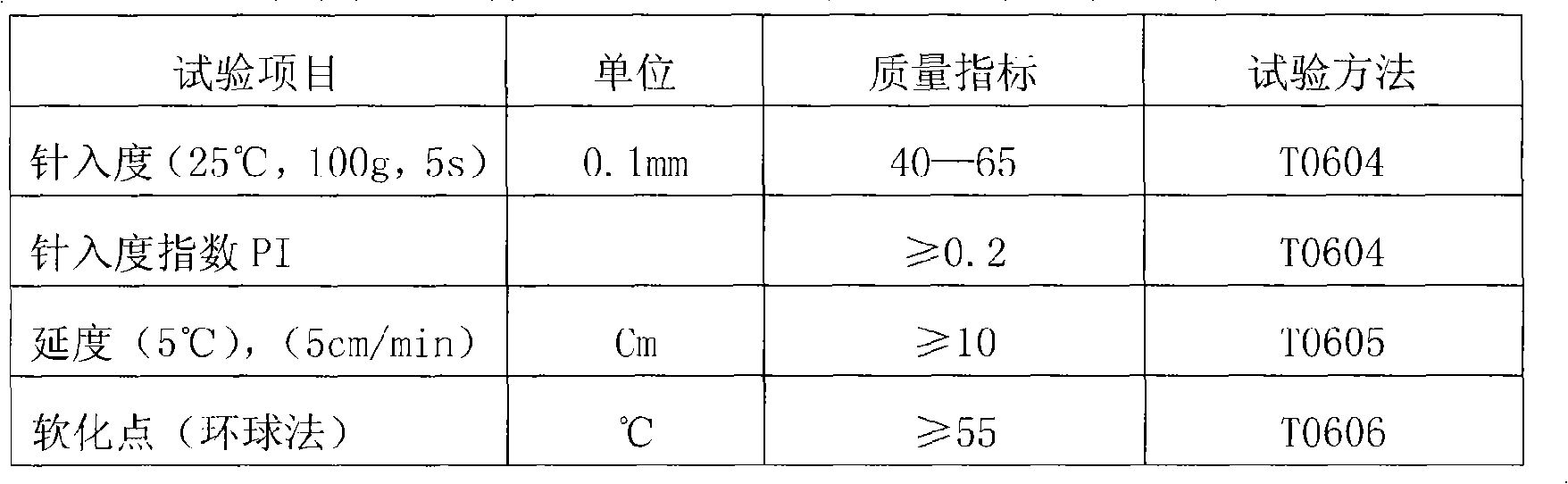

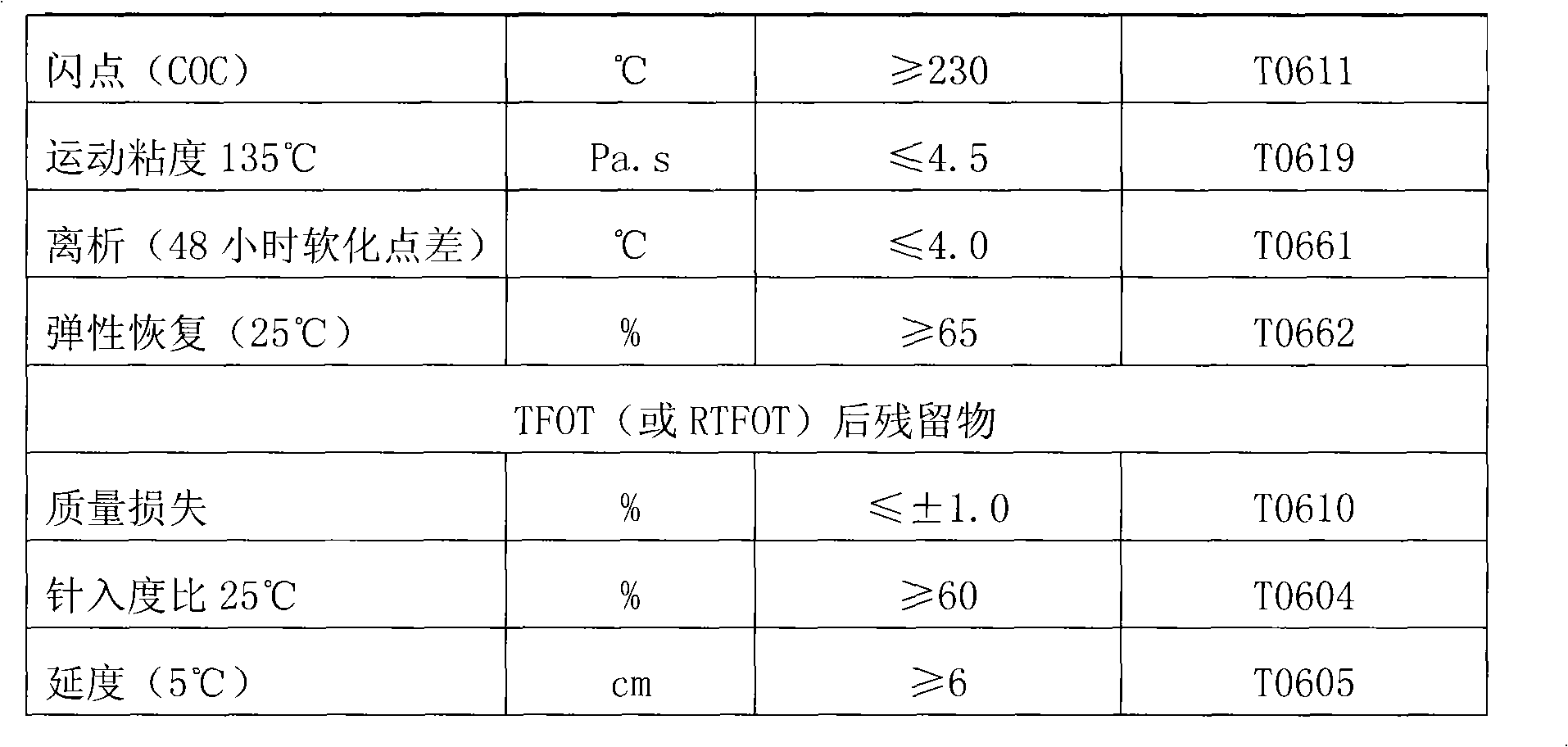

Crumb rubber modified asphalt and prepration method thereof

ActiveCN101550276AHas a linear plastic structureCut offPlastic recyclingBuilding insulationsPolymer scienceWaste rubber

The invention discloses a crumb rubber modified asphalt and a prepration method thereof, which aim at the deficiencies that the crumb rubber powder modified asphalt prepared by the prior art has low stability (appearing stratification phenomenon in storage) and special requirements on the fineness of crumb rubber powder. The proportioning by portions by weight of raw materials is as follows: 20-25 portions of waste rubber powder, 8-12 portions of polystyrene particles, 75-80 portions of based asphalt, 0.2-0.5 portion of high-efficient active reactant and 0.5-0.7 portion of stabilizer. The preparation method is as follows: the crumb rubber powder, the polystyrene particles, the based asphalt, the high-efficient active reactant and the stabilizer with the certain proportioning are added in the based asphalt at 180-190 DEG C and treated by special devices such as stirring, strong shearing and the like, thereby preparing an asphalt product with stable performance, no separation, convenient construction, good high-temperature and low-temperature performances, good anti-stripping performance, no excessive requirements on the fineness of the crumb rubber powder (only 20-40 meshes), good stability and ability of being applicable to large-scale factory production.

Owner:JIANGSU BAOLI INT INVESTMENT CO LTD

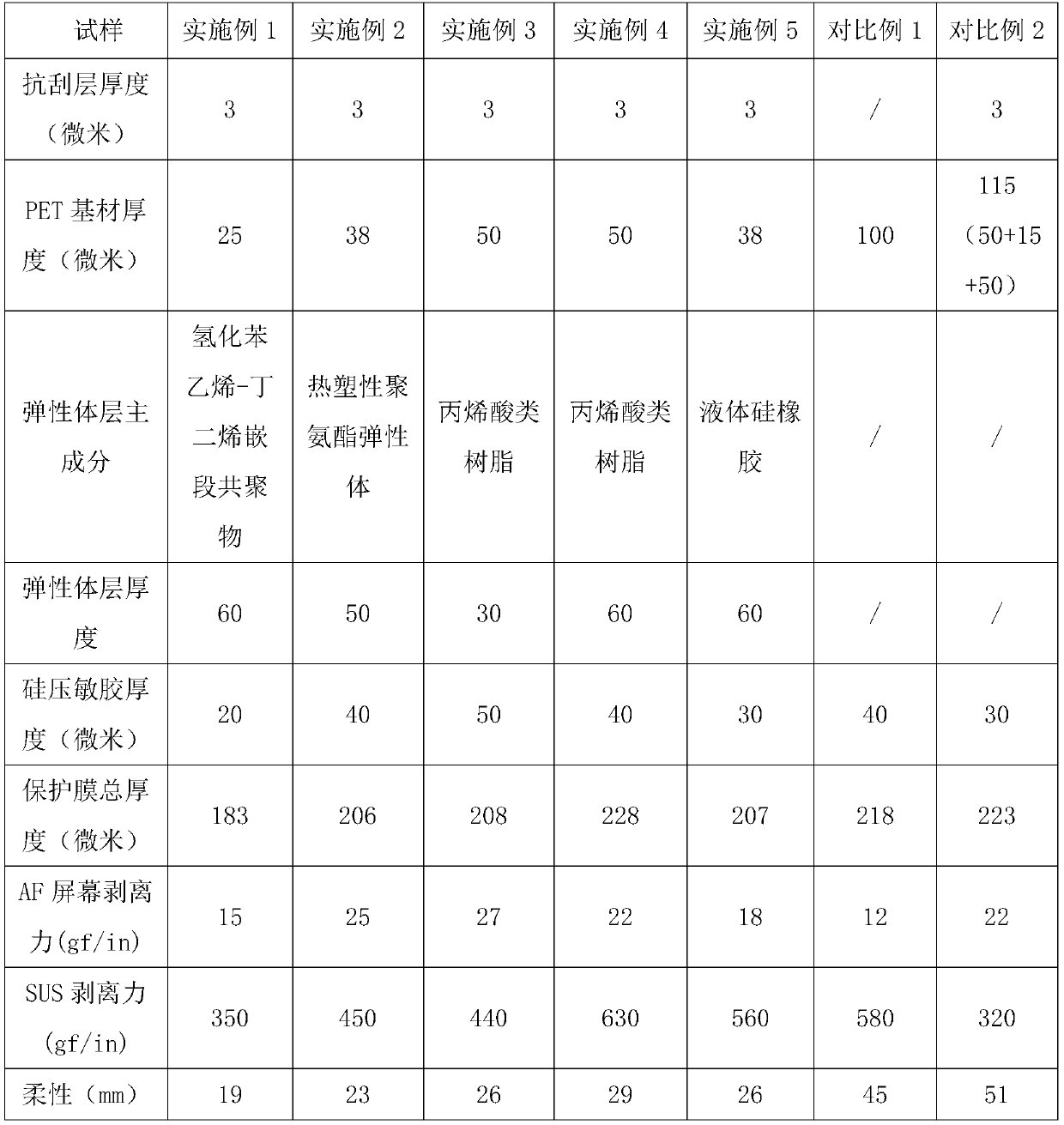

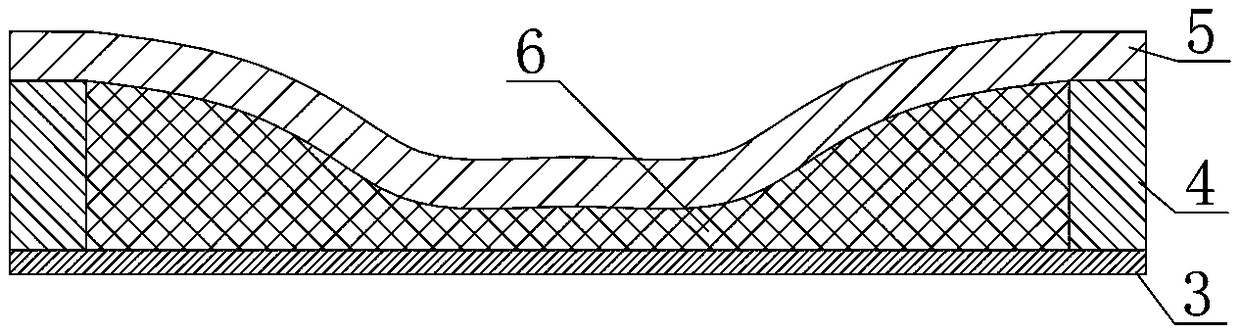

Curved screen protection film and preparation method thereof

ActiveCN110105896AImprove bendabilityImprove impact performanceFilm/foil adhesive primer layersPolyurea/polyurethane coatingsElastomerTectorial membrane

The invention relates to the technical field of curved screen protection films, in particular to a screen protection film for protecting curved liquid crystal screens and a manufacturing method of thescreen protection film. The curved screen protection film structurally comprises an anti-scratching layer, a PET base material, an elastomer layer, a silica gel layer and a fluorine release film which are sequentially arranged. According to the protection film, the arranged elastomer layer is beneficial to improving the bending property and drop resistance of the protection film, and under cooperation with the silica gel layer arranged on a protection film body, improvement of the fixing and fitting property of the protection film is facilitated, so that the problem of edge warping is effectively solved, and the protection film is suitable for the design of large angles and radians of the edge positions of mobile phone screens. Through the reasonable arrangement of the structure and thickness of each layer, the protection film has the basic performance of a PET screen protection film, and meanwhile, the flexibility, drop resistance and edge warping resistance of the protection film are further improved.

Owner:佛山固泰明科技有限公司

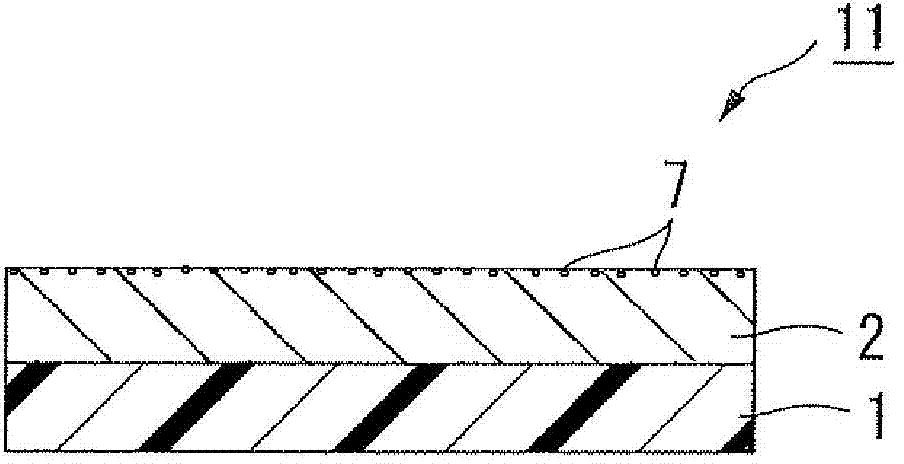

Surface protection film and optical component attached therewith

ActiveCN103382370ANo deterioration over timeExcellent anti-stripping performanceNon-macromolecular adhesive additivesLayered productsAntistatic agentEngineering

The invention provides a surface protection film and an optical component attached therewith. Specifically, a surface protection film which causes less pollution to an object the film is attached to, suffers no time degradation, and has excellent stripping-prevention electrified performance, and an optical component using the surface protection film are provided. In the surface protection film 10 where an adhesive layer 2 is formed on one surface of a transparent base material film 1 and a stripping film 5 is attached to the adhesive layer 2, the stripping film 5 is obtained by laminating a stripping agent layer 4 on one surface of a resin film 3 and the stripping agent layer 4 comprises stripping agent with dimethyl polysiloxane as the main component and silicone compound 7 which is liquid at the temperature of 20 DEG C. The adhesive layer 2 is formed by (meth)acrylic acid polymer obtained through copolymerization or blending of compound containing polyoxyalkylene groups and contains antistatic agent.

Owner:FUJIMORI KOGYO CO LTD

Gelatine powder and liquid cement for quickly mixing putty or cement

InactiveCN103555226ANon-toxicNo pollution in the processAmide/imide polymer adhesivesCellulose adhesivesAdhesive cementAlcohol

The invention belongs to the technical field of building adhesives and relates to gelatine powder and liquid cement for quickly mixing putty or cement. The gelatine powder mainly comprises the following components in parts by weight: 20-65 parts of PVA (Polyvinyl Alcohol), 10-42 parts of PAM (Polyacrylamide) and 4.0-18 parts of HPMC (Hydroxy Propyl Methyl Cellulose). The liquid cement is prepared by adding alcohol or deionized water to the gelatine powder. Compared with the existing gelatine powder and liquid cement, the product disclosed by the invention has the advantages that the preparation process is simple and convenient, the preparation process can be finished within one hour, the open time is 30 seconds, the liquid cement is transparent, the viscosity can be freely adjusted according to application demands, the cost is low, the storage is stable, and the like. If being used for mixing cement, building putty and the like, the gelatine powder and the liquid cement can accelerate the initial set of the cement and the putty, improve the binding power of the cement and the putty on a base material and improve the working efficiency.

Owner:熊静雯

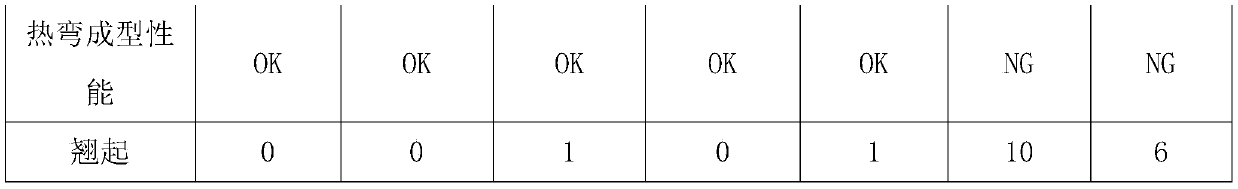

Wet base surface treating agent

Wet base surface treating agent comprises a component A and a component B, wherein the component A comprises the following raw materials in percentage by weight as follows: 50%-80% of emulsified asphalt, 10%-40% of modified emulsion and 1%-5% of an auxiliary; and the component B comprises the following raw materials in percentage by weight as follows: 50%-70% of cement, 10%-35% of graded sand, 10%-30% of filler and 1%-5% of an auxiliary. The wet base surface treating agent has the advantages of rapid drying, low cost, good waterproof performance, high sealing capacity and the like; experiments prove that the surface drying time of the wet base surface treating agent ranges from 13 min to 15 min; the wet basesurface primer is mainly applied to a building basement, a road or bridge surface and a wet tunnel base surface for basic layer processing, and can improve the adaptability of self-adhesive roll materials, SBS (styrene butadiene styrene) modified asphalt roll materials and high polymer roll materials to construction of the wet base surface.

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

Surface protection film and optical component attached with the film

ActiveCN104745116AReduce stripping voltageImprove anti-stripping performanceNon-macromolecular adhesive additivesLayered productsAntistatic agentMeth-

The invention provides a surface protection film and an optical component attached therewith. Specifically, a surface protection film which causes less pollution to an object the film is attached to, suffers no time degradation, and has excellent stripping-prevention electrified performance, and an optical component using the surface protection film are provided. In the surface protection film 10 where an adhesive layer 2 is formed on one surface of a transparent base material film 1 and a stripping film 5 is attached to the adhesive layer 2, the stripping film 5 is obtained by laminating a stripping agent layer 4 on one surface of a resin film 3 and the stripping agent layer 4 comprises stripping agent with dimethyl polysiloxane as the main component and silicone compound 7 which is liquid at the temperature of 20 DEG C. The adhesive layer 2 is formed by (meth)acrylic acid polymer obtained through copolymerization or blending of compound containing polyoxyalkylene groups and contains antistatic agent.

Owner:FUJIMORI KOGYO CO LTD

Low-temperature thermosetting light-tight ink and preparation method thereof

The invention discloses a low-temperature thermosetting light-tight ink and a preparation method thereof. The light-tight ink is prepared by blending new carries and taking the carriers as raw materials and then re-adjusting the proportions of talc powder, barium sulfate, titanium white, insulating carbon black and the carriers; the obtained light-tight ink, compared with the present existing similar products, is greatly reduced in surface dry temperature and thereby greatly saves electric energy; the hardness of the solidified light-tight ink is capable of reaching up to 3H, and the light-tight performance thereof is greatly improved; the light-tight ink is applied to the insulation protection of products such as a photoelectric touch module, a touch screen, an electronic housing and the like; and compared with the present existing similar products, the usability of the light-tight ink is greatly improved.

Owner:SUZHOU XIREN NEW MATERIAL TECH

Air permeable and ion rich medium temperature hot melt leather

The invention relates to an air permeable and ion rich medium temperature hot melt leather. The preparation technology of the hot melt leather includes: fully stirring 25-35 parts by weight of a negative ion / diatom mud composite material and 15-25 parts by weight of deionized water evenly, then adding 45-55 parts by weight of emulsion resin, conducting mixing for 25-35min to make the prepared slurry fully mixed uniformly, then subjecting non-woven fabric to dip padding in a rubber dipping groove, carrying out 175-185DEG C drying tentering shaping, and then performing cooling shaping. The air permeable and ion rich medium temperature hot melt leather provided by the invention contains organobentonite, and the moisture absorption and air permeability of the air permeable and ion rich medium temperature hot melt leather can be significantly improved. Tests find that the ageing resistance and antistripping performance are also greatly improved.

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

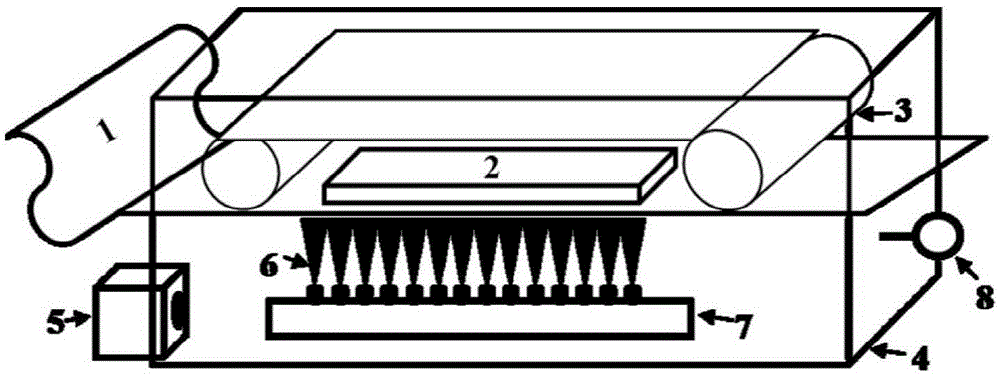

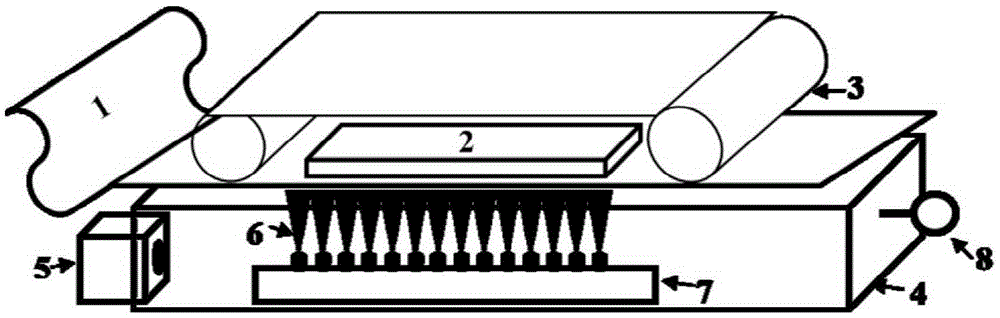

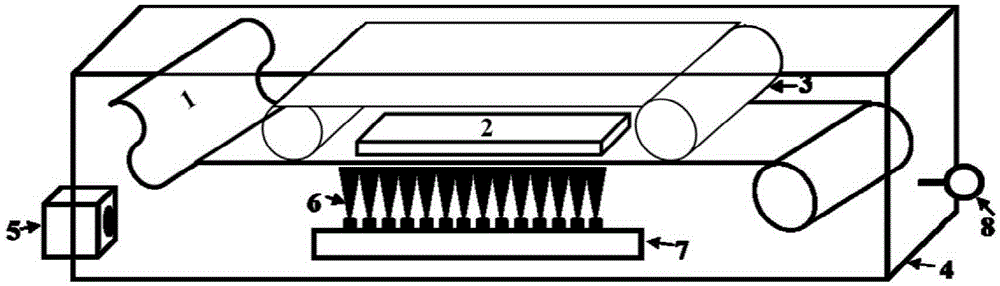

A kind of high wear-resisting and anti-stripping electrostatic spinning nanofiber composite filter material and its spinning method

ActiveCN104028047BCompact structureSimple processSynthetic resin layered productsLaminationElectrospun nanofiberSpinning

The invention relates to a high-wear-resistant anti-stripping electrostatic spinning nanofiber composite filter material and a spinning method thereof. The preparation method comprises the following step: in the electrostatic spinning process, performing one-step forming by controlling and regulating the solvent concentration / pressure difference / melting points of two different polymers / an electrostatic spray solvent, so as to obtain dense three-dimensional arc-hole structural composite filter material fully adhered to fiber lapping points, wherein the gram weight of a fiber layer is 0.01 to 30 g / m<2>, the wear resistance of the composite filter material is 600 to 3,000 circles, the anti-stripping intensity is 5 to 100 MPa, the filter efficiency to 0.008-2-mircon particles reaches more than 99.99%, the resistance pressure drop is below 25 Pa, and the clogging capacity is 100 to 3,000 g / m<2>. The spinning method has the advantages of simple preparation process and low cost, and the prepared composite filter material has wide application prospects in the fields of engine filtration, air compressor filtration, gas turbine filtration, indoor air purification and filtration, high-efficiency filtration and the like.

Owner:SHANGHAI XUNJIANG TECH CO LTD

Preparation method of one-way water-permeable and breathable type fibrosis fiberboard

ActiveCN105437698AHigh utility valueTo promote metabolismSynthetic resin layered productsWoven fabricPolymer chemistry

The invention relates to a preparation method of a one-way water-permeable and breathable type fibrosis fiberboard. The method includes the steps of firstly, evenly stirring 25-35 weight parts of anion / diatom ooze composite material and 15-25 weight parts of deionized water, adding 45-55 weight parts of emulsion resin to be mixed and stirred for 25-35 min, conducting pad-rolling on non-woven fabric through a glue soaking tank, conducting drying, stentering and shaping at a temperature of 175-185 DEG C, and conducting cooling and shaping to obtain a water-permeable and breathable type semi-finished product material; secondly, conducting pad-rolling after waterproof emulsion resin treatment is conducted on spunlace non-woven fabric 0.6 mm thick, punching holes vertically by means of high pressure through a drying box, conducting drying, stentering and shaping at a high temperature of 175-185 DEG C, and obtaining a waterproof semi-finished product material after cooling and shaping, wherein the mass ratio of emulsion resin to spunlace non-woven fabric is 1:(3-5); thirdly, attaching and forming the water-permeable and breathable type semi-finished product material and the waterproof semi-finished product material through a polyurethane hot melt mesh film by means of high temperature and high pressure, and obtaining the one-way water-permeable and breathable type fibrosis fiberboard. The moisture absorption performance, breathability, ageing resistance and stripping resistance of the prepared product are greatly improved.

Owner:HANGZHOU KAIYUE NEW MATERIAL CO LTD

Method for preparing lead dioxide electrode with porous matrix

InactiveCN105887131AImprove performanceUnique three-dimensional internal structureElectrolytic inorganic material coatingWater/sewage treatmentElectricityElectrical resistance and conductance

The invention relates to a method for preparing a lead dioxide electrode with a porous matrix. The method includes the following steps that a porous material serves as the matrix, the matrix is subjected to surface treatment, and a mud-crack-free middle coating and a lead dioxide surface layer are prepared on the treated surface of the matrix sequentially. The method has the beneficial effects that the lead dioxide electrode with the porous matrix is of a unique three-dimensional internal structure, and the middle layer can be closely combined with the porous matrix as a solid solution or in other forms, and forms a compact mud-crack-free covering layer, so that the matrix is effectively protected, and the service life of the electrode is greatly prolonged; an active layer and the matrix can be firmly combined, and high bonding force and high anti-stripping capacity are achieved; the special internal meshed communication mechanism of the porous matrix material improves the overall performance of the electrode and plays a significant role in assisting in electrocatalytic oxidation; and the prepared lead dioxide electrode with the porous matrix has the advantages of high oxygen evolution potential, good catalytic activity, large electrode specific surface area, and small interface resistance and internal stress.

Owner:CHANGZHOU UNIV

Electronic device and method for manufacturing the electronic device

InactiveUS20070023911A1Improve reliabilityImprove productivitySemiconductor/solid-state device detailsSolid-state devicesMulti materialInsulation layer

A method for manufacturing an electronic device in which a bonding pad composed of a foundation layer and a surface layer is formed on an Si layer or an Si-base insulation layer, comprises: forming, on the Si layer or Si-base insulation layer and by a droplet discharging method, the foundation layer using liquid material including one or more material(s) selected from Ni, Cr, and Mn or a compound thereof; and forming, on the foundation layer and by the droplet discharging method, the surface layer.

Owner:SEIKO EPSON CORP

Three-dimensional relief processing method of toilet lid

InactiveCN109080361AIncrease productivityImprove aestheticsOrnamental structuresEngineeringColor matching

The invention discloses a three-dimensional relief processing method of a toilet lid. The three-dimensional relief processing method of the toilet lid comprises the steps that step one, an upper lid base plate is trimmed; step two, a theoretical route of a relief protrusion and color systems needed to be reflected on a picture are determined; step three, a relief protrusion route is manufactured by a UV machine; and step four, color matching is carried out by the UV machine, and mixed UV ink is sprayed and painted onto the base surface of the upper lid base plate to form a color pattern layer.According to the three-dimensional relief processing method of the toilet lid, a technical means similar to 3D printing is adopted, patterns with different heights are formed through multiple spraying, and thus the relief effect is achieved. In addition, the monochromatic relief protrusion route is determined firstly and creatively, the relief protrusion route is used as the thickest position ofthe relief, on the one hand, an outline of the whole relief is delineated, the three-dimensional effect of the relief is improved, on the other hand, the series flow of color ink is avoided, and the function of stabilizing colors is achieved. The rugged relief effect id formed according to the colors of the color pattern layer and different spraying times.

Owner:ZHEJIANG HENGYUAN SANITARY WARE

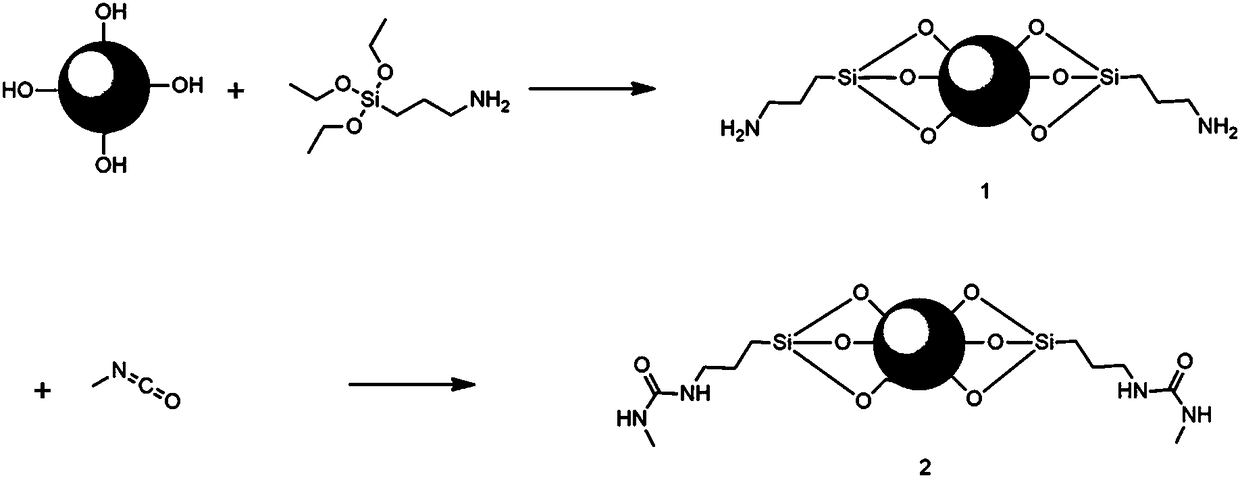

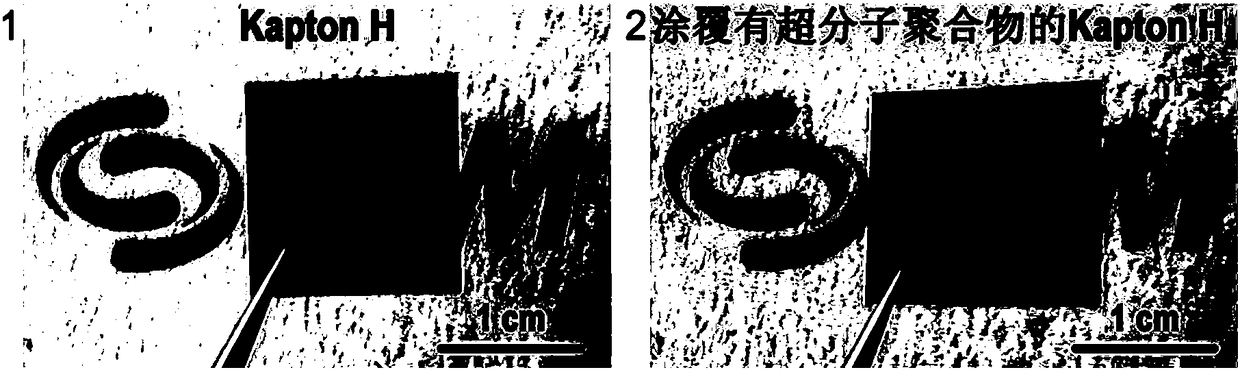

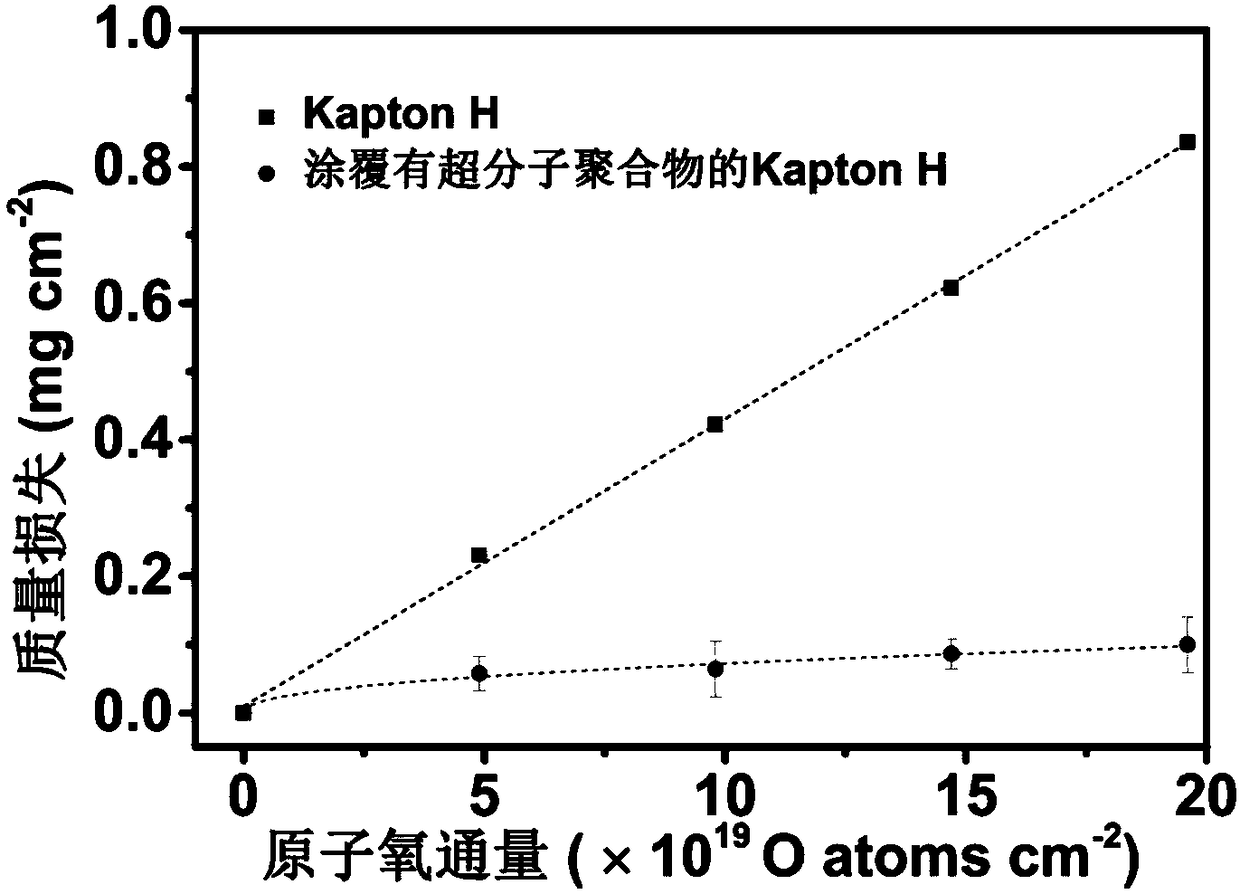

Atomic oxygen protective coating with physical damage spontaneous repairing function and preparation method thereof

The invention discloses an atomic oxygen protective coating with a physical damage spontaneous repairing function and a preparation method thereof, belonging to the field of spontaneous repairing technology of coatings. The preparation method comprises the steps of firstly, chemically modifying component materials of a traditional atomic oxygen protective coating, deriving chemical groups capableof producing supra-molecular interaction, thereby forming a supra-molecular polymer, with both atomic oxygen protective capability and spontaneous repairing capability, through self-assembling; and then, washing and processing substrate material, and preparing a supra-molecular polymer on the substrate, thereby finishing the preparation of a protective coating described in the invention. The coating provided by the invention has the advantages of good transparency, good atomic oxygen protective effect, strong anti-stripping capability and the like. The coating, after passing through a ground-based simulated atomic oxygen exposure test that approximately runs in a low-earth orbit for half a year, can still maintain good transparency and repairing capability. The atomic oxygen protective coating provided by the invention is simple in process, easily available for materials and low in cost. Therefore, the atomic oxygen protective coating provided by the invention is expected to apply to structural components such as heat insulation materials of spacecrafts, optical elements and flexible substrates of solar panels.

Owner:JILIN UNIV

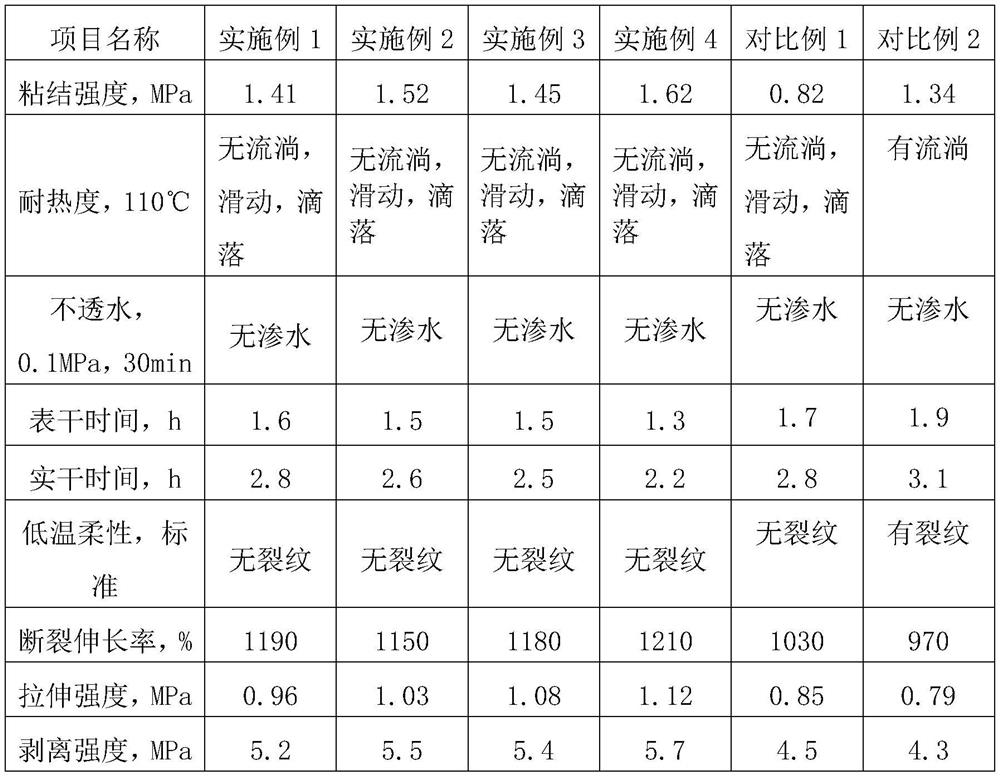

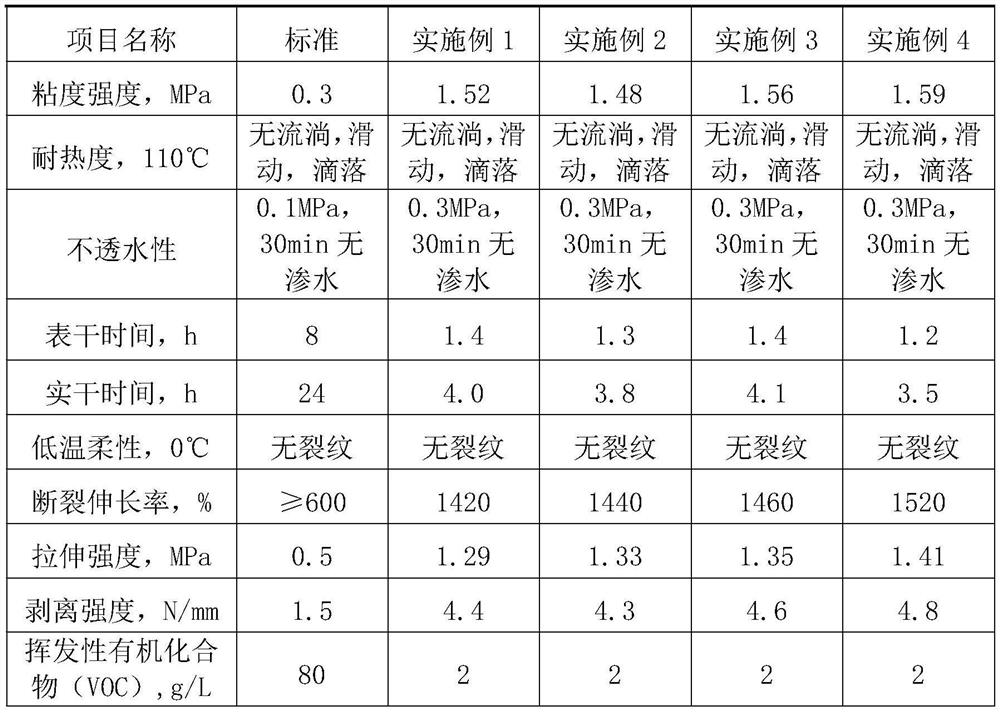

High-viscosity water-based asphalt waterproof coating and preparation method thereof

ActiveCN113667404AHigh bonding strengthHigh tensile strengthAntifouling/underwater paintsPaints with biocidesPolymer scienceBituminous waterproofing

The invention relates to a high-viscosity water-based asphalt waterproof coating and a preparation method thereof. The high-viscosity water-based asphalt waterproof coating comprises the following raw materials in parts by weight: 50-70 parts of anionic emulsified asphalt, 10-30 parts of an acrylic emulsion, 5-25 parts of neoprene latex, 1-2 parts of a defoaming agent, 1-3 parts of a thickening agent, 0.5-1 part of a sterilizing agent, 3-5 parts of a wetting agent, 1-3 parts of a dispersing agent, 10-30 parts of filler, 1-2 parts of a cosolvent and 5-15 parts of water. The thickening agent is prepared from water-based associated polyurethane, silica gel and polyhydroxy polyacrylamide according to a mass ratio of 1:(0.45-0.68):(0.6-0.9). The coating has high bonding strength, high tensile strength, high elongation rate and excellent low-temperature flexibility, and solves the problem of blistering during construction.

Owner:河北三棵树涂料有限公司

Anti-stripping cyanoacrylate adhesive and preparation method thereof

ActiveCN105315933AImprove impact resistanceImprove anti-stripping performanceNon-macromolecular adhesive additivesProtein adhesivesEthyl cyanoacrylateGelatin

The invention discloses an anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is prepared from, by weight, 30-50 parts of alpha-ethyl cyanoacrylate, 0.5-4 parts of EVA, 2-5 parts of beta-propiolactone, 0.5-1 part of modified titanium oxide, 8-12 parts of gelatin, 5-10 parts of polyacrylate, 2-8 parts of galactomannan, 3-8 parts of hydroxyethyl cellulose and 1-1.5 parts of coupling agent. The invention further discloses a preparation method of the anti-stripping cyanoacrylate adhesive. The anti-stripping cyanoacrylate adhesive is high in curing speed, good in water resistance, high in impact resistance, large in bonding strength, good in anti-stripping performance, small in use amount, free of toxicity and beneficial to environmental protection.

Owner:ZHEJIANG TIME NEW MATERIAL

Method for manufacturing high strength galvanized steel sheet and high strength galvanized steel sheet

ActiveUS20150044503A1Good coating appearanceImprove corrosion resistanceHot-dipping/immersion processesFurnace typesChemical compositionHigh intensity

A method for manufacturing a high strength galvanized steel sheet and a high strength galvanized steel sheet are provided. A base steel sheet having a chemical composition comprising C: 0.03% to 0.35%, Si: 0.01% to 0.50%, Mn: 3.6% to 8.0%, Al: 0.001% to 1.000%, P≦0.10%, S≦0.010%, and the balance comprising Fe and incidental impurities, on a percent by mass basis, is subjected to annealing and galvanization treatment, wherein the maximum steel sheet temperature in an annealing furnace is 600° C. or higher and 700° C. or lower, the steel sheet transit time in a temperature region of the maximum steel sheet temperature of 600° C. or higher and 700° C. or lower is specified to be 30 seconds or more and 10 minutes or less, and the dew point in an atmosphere is specified to be −45° C. or lower.

Owner:JFE STEEL CORP

Environment-friendly water-based asphalt waterproof coating and preparation method thereof

ActiveCN113683958AHigh bonding strengthStrong peel resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceBituminous waterproofing

The invention relates to an environment-friendly water-based asphalt waterproof coating and a preparation method thereof. The environment-friendly water-based asphalt waterproof coating is composed of the following raw materials in parts by weight: 60 to 80 parts of emulsified silane modified asphalt, 10 to 25 parts of an acrylic emulsion, 5 to 25 parts of neoprene latex, 1 to 3 parts of a defoaming agent, 1 to 2 parts of a thickening agent, 0.5 to 1 part of a composite sterilizing agent, 10 to 30 parts of an inorganic filler, 2 to 4 parts of a solubilizer, 1 to 3 parts of a dispersing agent and 10 to 20 parts of water. The emulsified asphalt is modified at normal temperature by adding a proper amount of acrylic emulsion and neoprene latex, then the thickening agent, the bactericide, the defoaming agent, the filler and the solubilizer are added, and all the components interact with one another, so that the water-based asphalt waterproof coating has excellent bonding strength, is good in bonding property when being used for a base layer, has excellent anti-stripping capability and anti-sliding performance, and has good anti-sagging performance.

Owner:河北三棵树涂料有限公司

High-toughness anti-stripping epoxy resin adhesive

InactiveCN106047243ASmall particle sizeLarge particle sizeNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAcrylonitrile

The invention discloses a high-toughness anti-stripping epoxy resin adhesive. The high-toughness anti-stripping epoxy resin adhesive is prepared from, by weight, 20-50 parts of phenolic modified epoxy resin, 5-15 parts of resorcinol diglycidyl ether type epoxy resin, 20-35 parts of E-12 epoxy resin, 15-30 parts of modified wheat gluten, 1-8 parts of polyimide modified epoxy resin, 1-2 parts of carboxyl-terminated butadiene acrylonitrile rubber, 1-2 parts of polybutadiene-polymethyl methacrylate, 1-10 parts of methylene bicyclohexyl amine, 2-6 parts of epoxidized SBS (styrene butadiene styrene), 1-4 parts of vinyl triamine, 1-2 parts of triethanolamine, 5-15 parts of calcined clay, 1-5 parts of sodium carboxymethylcellulose and 20-50 parts of diglycidyl ether. The high-toughness anti-stripping epoxy resin adhesive is excellent in toughness, favorable in anti-stripping effect, high in thermal stability and long in storage time even at a high temperature and is safe, environment friendly and free of environment pollution.

Owner:HEFEI DONGCAI PRINTING TECH

Support foot apparatus and methods

ActiveUS8300406B2Improve anti-stripping performanceDetails for portable computersStands/trestlesEngineeringHandling system

Owner:DELL PROD LP

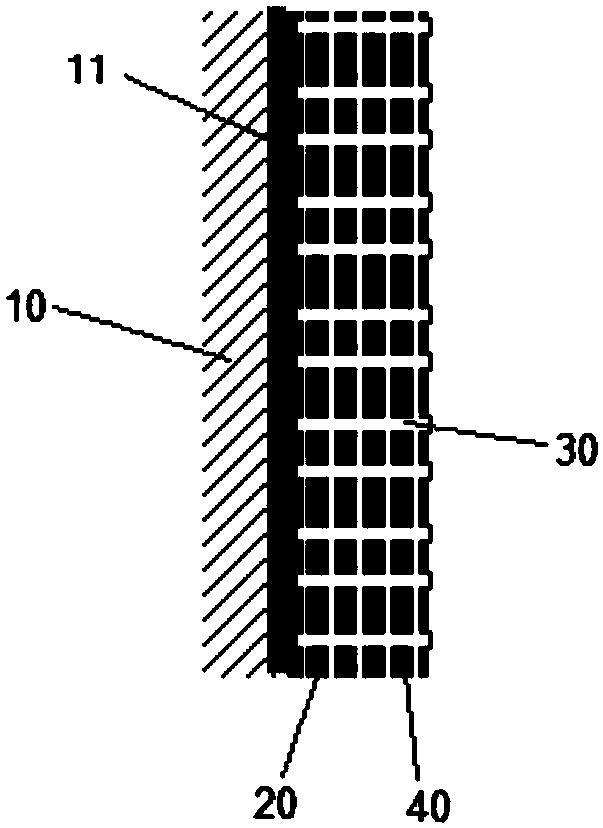

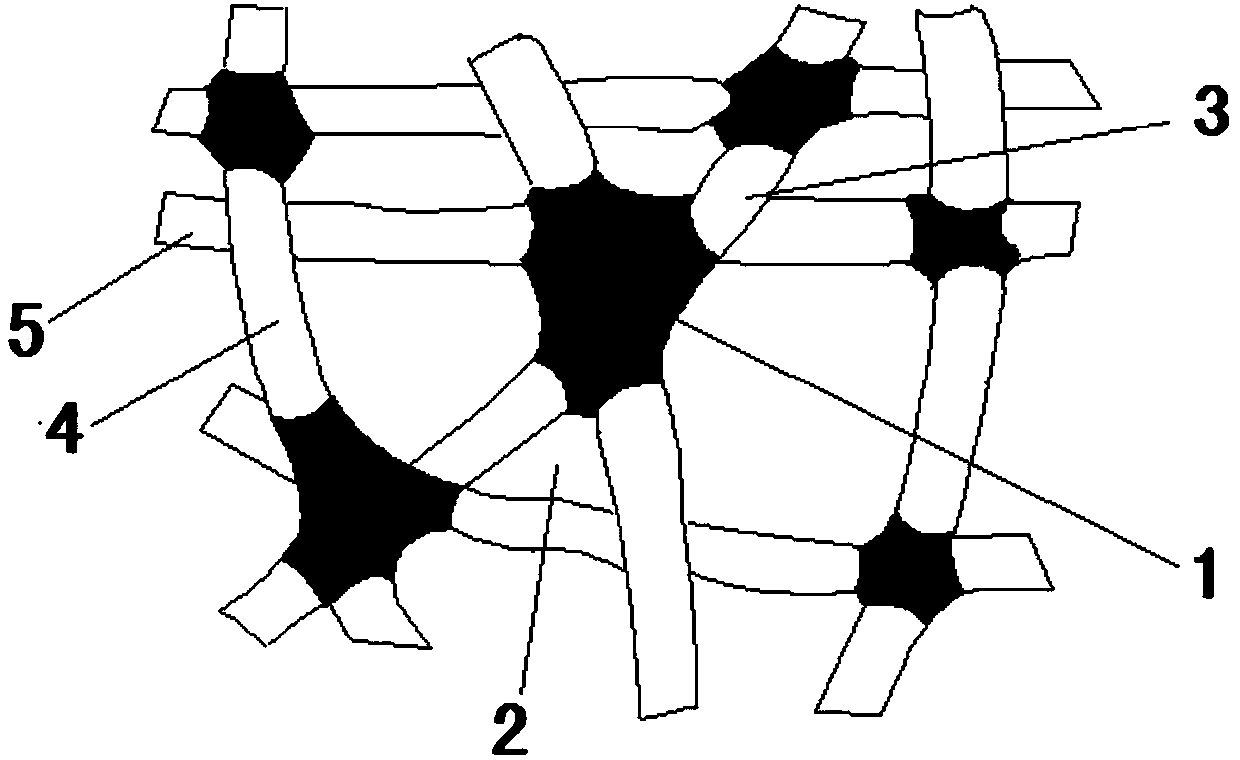

Phase change energy storage infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides a phase change energy storage infiltration coating sandwich wall cloth, and a method for manufacturing the phase change energy storage infiltration coating sandwich wall cloth,or an object decoration method. The phase change energy storage infiltration coating sandwich wall cloth comprises a bottom coating and an infiltration coating composite sandwich coating compound coated on the surface of the bottom coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; the second coating penetrates into meshes of the network structure; and one or more of the second coating, the bottom coating and the fiber texture network sandwich can have a phase change energy storage function. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Fireproof infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158892AAdequate adhesionObvious connection seamCovering/liningsCoatingsFiberCoated surface

The invention provides a fireproof infiltration coating sandwich wall cloth and a method for manufacturing the fireproof infiltration coating sandwich wall cloth or an object decoration method. The fireproof infiltration coating sandwich wall cloth comprises an undercoat layer and an infiltration coating composite sandwich coating composite body, wherein the surface of the undercoat layer is coated with the infiltration coating composite sandwich coating composite body, the infiltration coating composite sandwich coating composite body comprises a transparent or semitransparent second coatinglayer and a fiber texture network sandwich covered with the second coating layer, the fiber texture network sandwich contains a network structure formed by fibers, the second coating layer penetratesinto meshes of the network structure, and one or more of the second coating layer and the undercoat layer can be a fireproof coating layer. The wall cloth with skin textures and / or patterns can be produced in a standardized and large-scale mode, and good crack resistance, air permeability and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

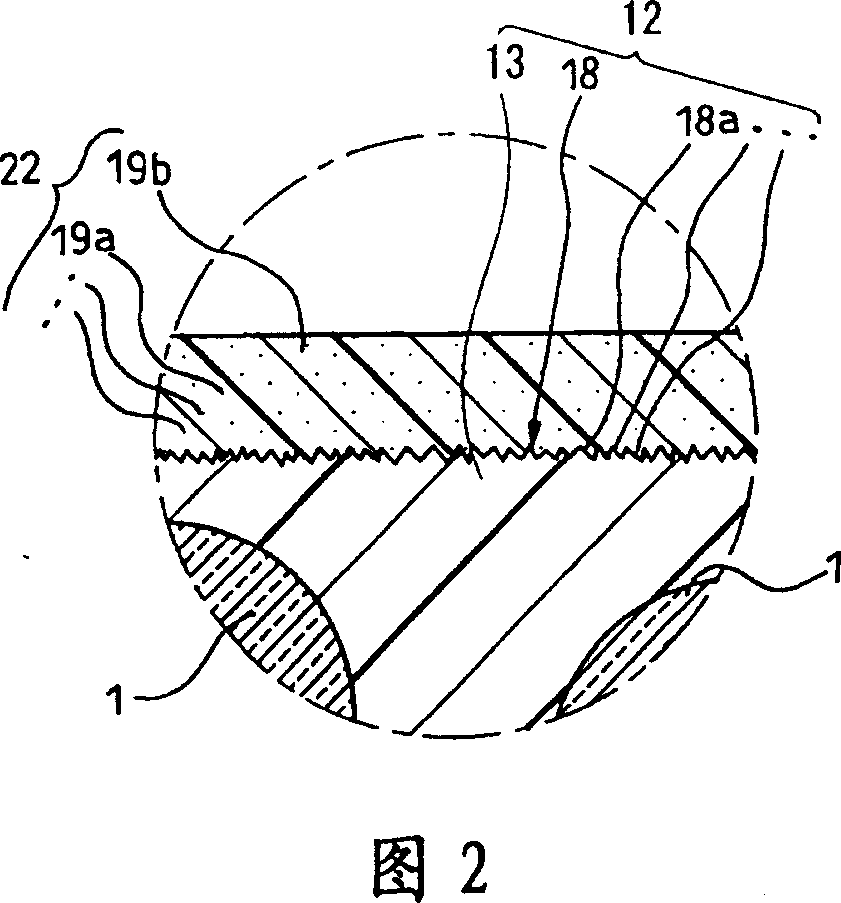

Synthetic crosstie and manufacturing method for the same

ActiveCN101046076AGood flame retardancyIncrease bonded areaBallastwaySpecial surfacesFilling materialsParent material

The present invention provides a synthetic crosstie having excellent fire resistance and a method manufacturing synthetic crosstie. The synthetic crosstie comprises synthetic crosstie body (12), a fire resistance layer (22) formed on its surface. Sand paper (15) with roughness concentration less than or equal to #120 is used for grinding parting agent (9f) attached on the surface of the syntheticcrosstie, and a part surface (13a) of the frothing parent material (13). In the grinding layer (18) formed by grinding, innumerable unevennesses (18a) are formed corresponding to the roughness concentration of the sand paper. And, on the surface side of the grinding layer (18), the fire resistance layer (22) is formed by using the spray gun (21d) coat urethane resin dope appended with inorganic filling material.

Owner:SEKISUI CHEM CO LTD

Solid-color quick-drying water-based nail polish

InactiveCN104352360AAnti-strippingLarge particle sizeCosmetic preparationsToilet preparationsWater basedMixing ratio

The invention relates to solid-color quick-drying water-based nail polish. The solid-color quick-drying water-based nail polish is characterized by comprising the following components: a pigment and filler, water-based emulsion, a film-forming auxiliary agent and a functional auxiliary agent, wherein the pigment and filler is one or a mixture of titanium dioxide, kaolin and a colorant paste; the water-based emulsion is water-based polyurethane emulsion; the film-forming auxiliary agent is one or a mixture of DPM, DPnB and medical alcohol; the functional auxiliary agent is a mixture of a wetting agent, a defoamer, a dispersant and an anti-settling directional agent in a mixing ratio of (0.1-0.2)% : (0.1-0.3)% : (0.2-0.4)% : (0-1.5)%. A preparation method of the solid-color quick-drying water-based nail polish is characterized by comprising the following steps: sufficiently and uniformly dispersing the pigment and filler, the water-based emulsion, the film-forming auxiliary agent and the functional auxiliary agent till the fineness of the mixture is smaller than 15 microns, and packaging to obtain a finished product. The solid-color quick-drying water-based nail polish has the advantages as follows: the solid-color quick-drying water-based nail polish has good wear resistance, water resistance, fullness and peeling resistance and excellent drying speed; the solid-color quick-drying water-based nail polish is simple in nail beautifying process, can be dried within 5 minutes at room temperature or dried within one minute by a dryer, and is simple and safe to use; the solid-color quick-drying water-based nail polish can be widely applied to nail beautification.

Owner:上海展辰涂料有限公司 +4

Stable high-adhesive aluminum alloy surface conditioning agent

InactiveCN104109849AImprove stabilityStrong weather resistanceMetallic material coating processesPhosphoric Acid EstersAdhesive

The invention discloses a stable high-adhesive aluminum alloy surface conditioning agent. The agent is composed of the following raw materials in parts by weight: 0.4 to 1 part of calcium hexafluoroacetylacetonate, 0.7 to 1 part of lauryl alcohol phosphoric acid ester potassium, 1 to 2 parts of formamide, 0.5 to 1 part of polyisobutenyl succinimide, 1 to 2 parts of itaconic acid, 0.4 to 1 part of magnesium hydroxide, 1 to 2 parts of N-methylolacrylamide, 0.2 to 0.4 part of mica powder, 0.1 to 0.2 part of tung oil, 0.1 to 0.3 part of triethanolamine borate, 2 to 4 parts of film-forming auxiliary agent, 13 to 20 parts of (3-Aminopropyl)trimethoxysilane, and 120 to 140 parts of deionized water. The added calcium hexafluoroacetylacetonate can effectively improve the stability of the coating, and furthermore, the raw materials are reasonably compounded, so the prepared coating has the advantages of weatherability, acid and alkali resistance, strong salt fog resistant performance, good anti-peeling property, and enduring protection effect on metal tools.

Owner:RUIZHAN TONGLING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com