Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Adequate adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display panel, preparation method of display panel and display device

The invention relates to the technical field of display, in particular to a display panel, a preparation method of the display panel and a display device. The display panel comprises a first substrate and a second substrate, wherein the first substrate and the second substrate are oppositely arranged, and the area, in contact with a framework sealant, of the first substrate and / or the second substrate is provided with a non-planar structure. The display panel has the advantages that the area, in contact with the framework sealant, of the first substrate and / or the second substrate is provided with the non-planar structure, so the contact area between the framework sealant and the first substrate as well as the second substrate is increased; in the premise of ensuring sufficient adhesion between the framework sealant and the first substrate as well as the second substrate, the width of the framework sealant is reduced, so the powerful technical support is provided for well realizing the narrow-edge framework; and meanwhile, the width of the framework sealant is reduced, the usage amount of framework sealant is reduced to a certain extent, and the production cost of the display panel is reduced.

Owner:BOE TECH GRP CO LTD

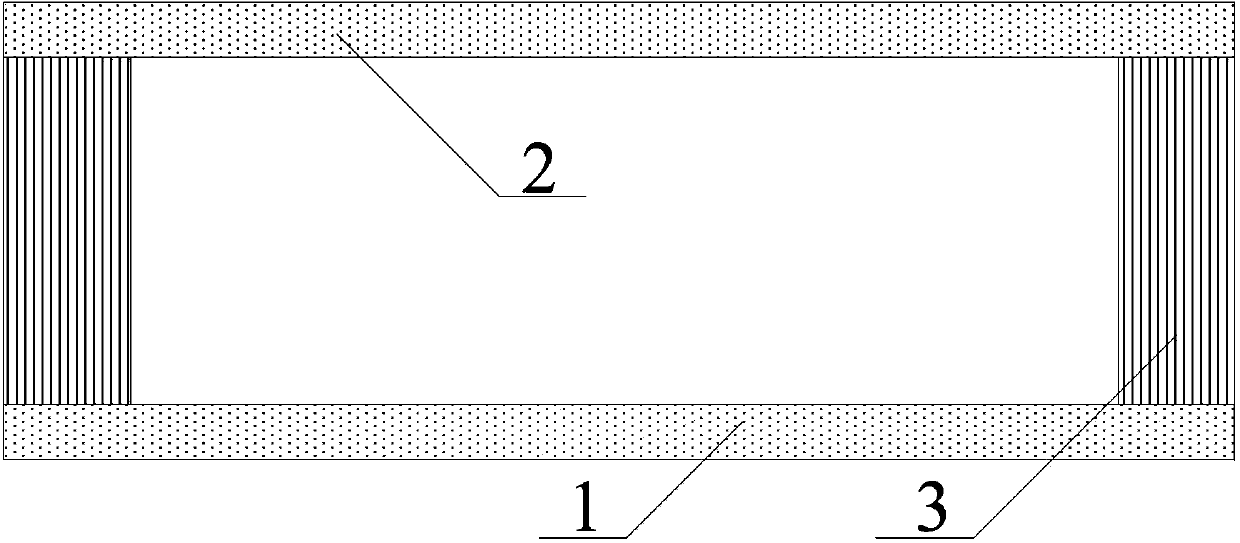

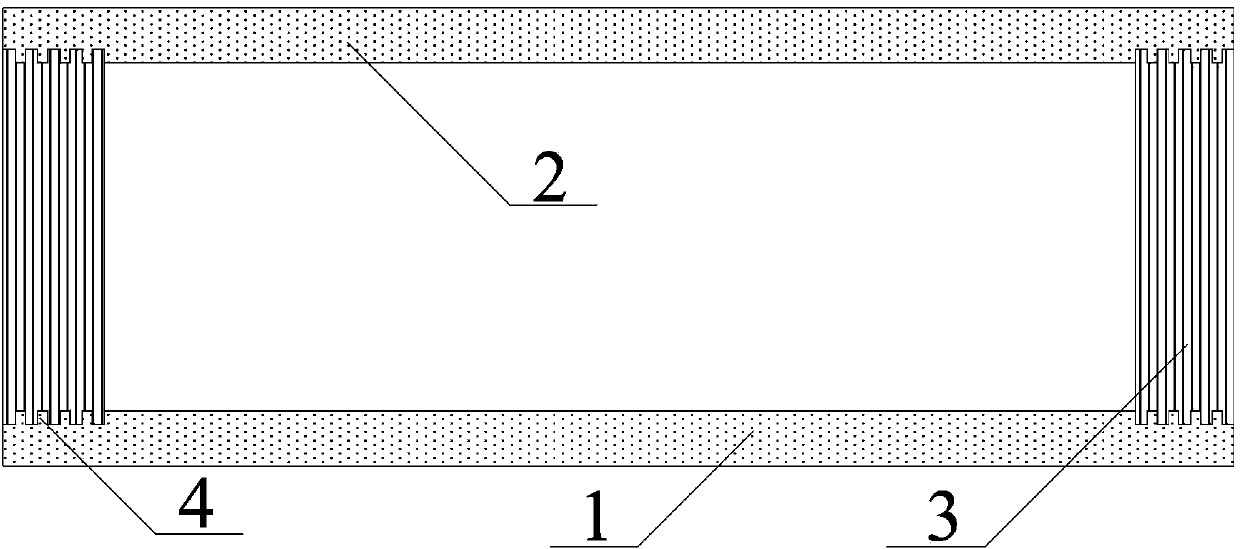

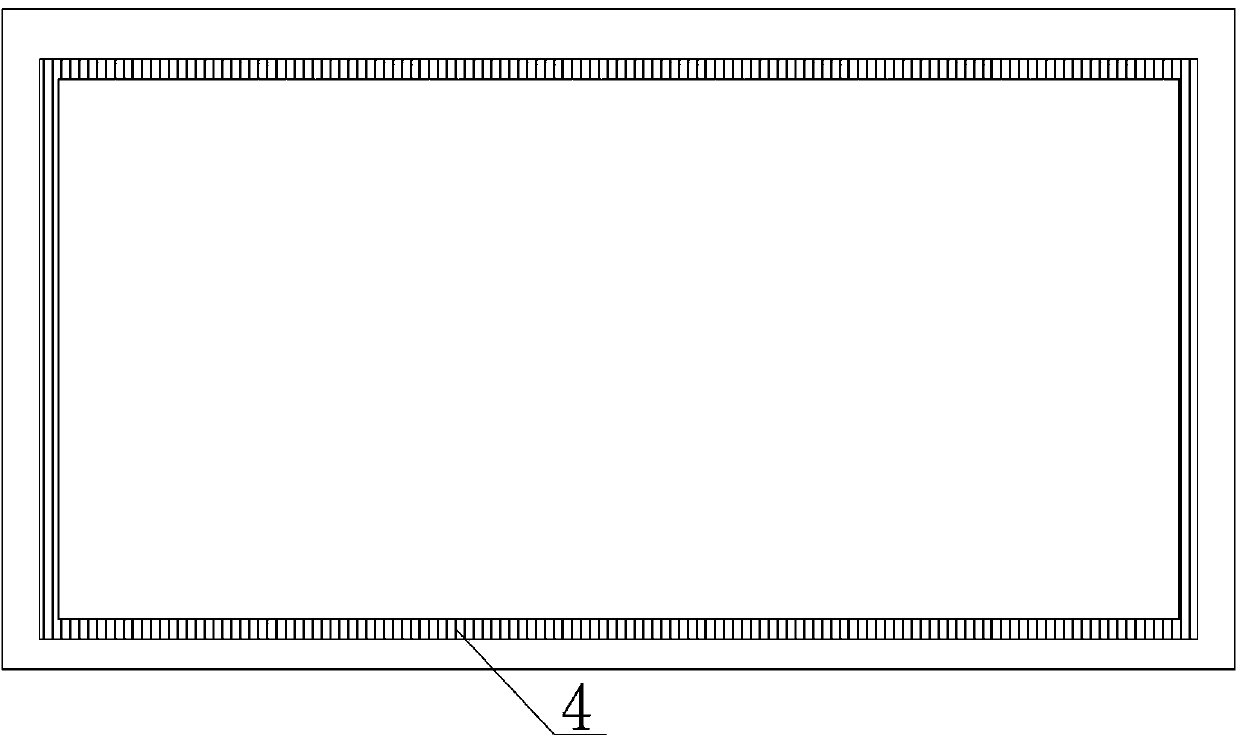

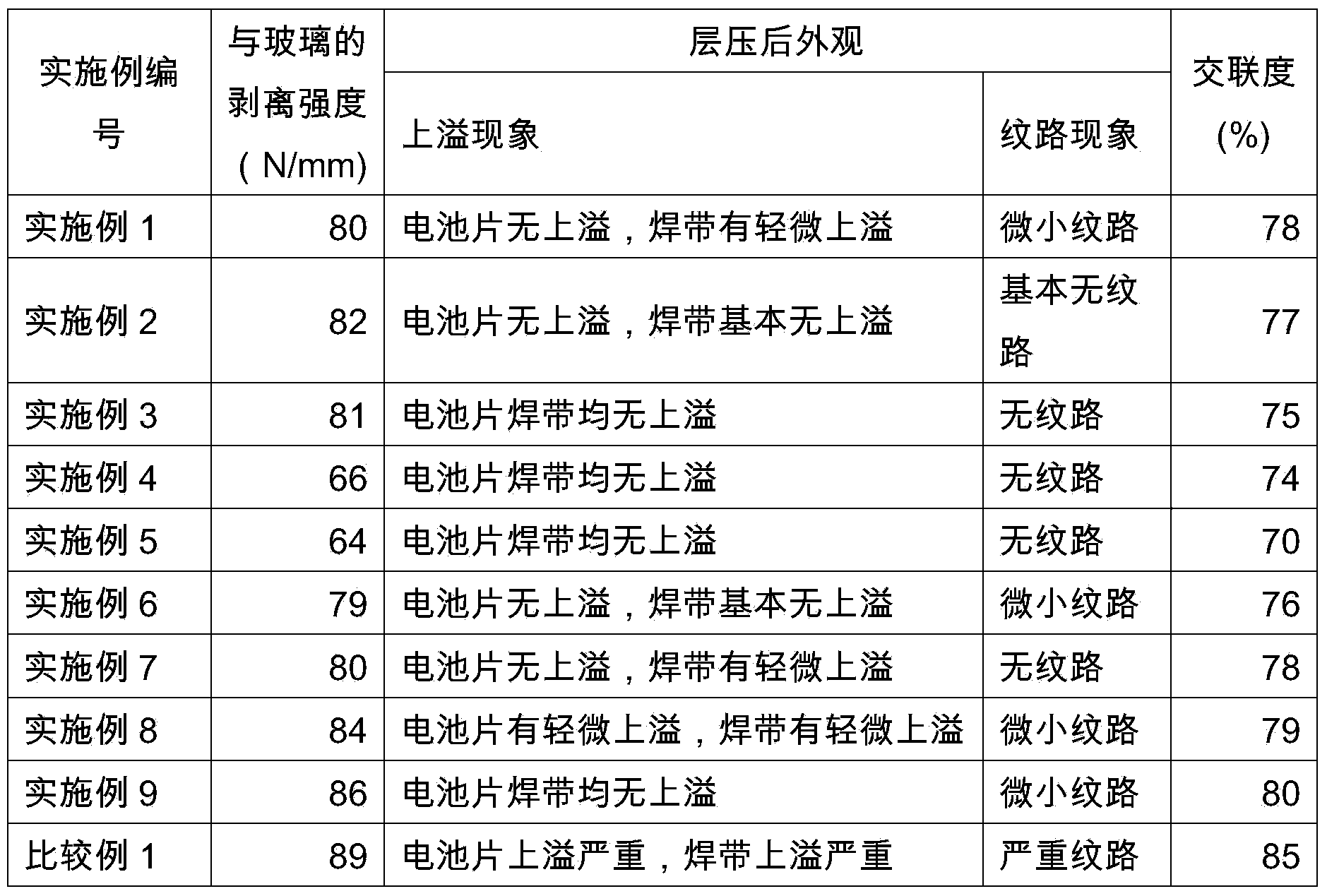

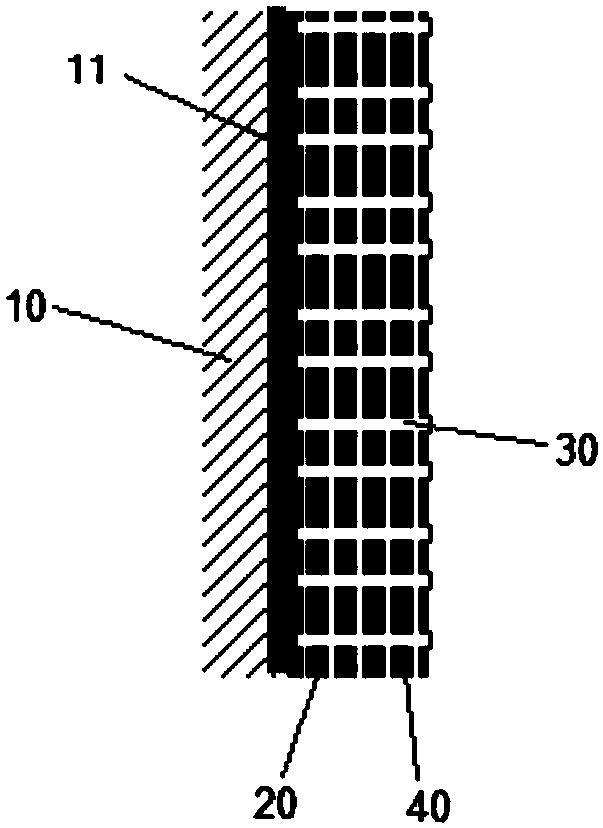

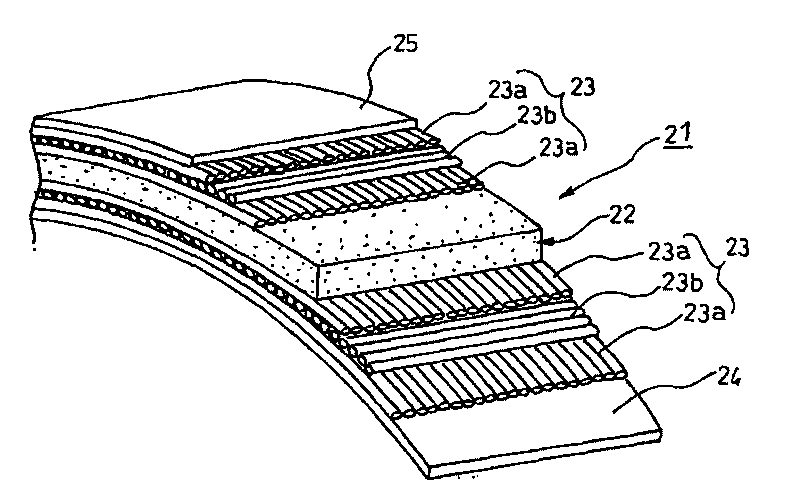

Solar battery piece packaging glue structure and preparation method thereof

ActiveCN103865420AAdhesion effectLow costFilm/foil adhesivesSynthetic resin layered productsCross-linkEngineering

The invention relates to a solar battery piece packaging glue structure and a preparation method thereof. The structure comprises a packaging glue layer and at least one partitioning membrane layer, or comprises a packaging glue layer, at least one layer of partitioning membrane and at least one adhesive layer distributed on one side, which is close to a battery piece, of the partitioning membrane, wherein the partitioning membrane is compounded with the packaging glue layer, or the partitioning membrane is compounded with the packaging glue layer and the adhesive layer; the flowability of the partitioning membrane is smaller than that of the packaging glue layer. According to the solar battery piece packaging glue structure, as one layer of the partitioning membrane with very low flowability is compounded with the packaging glue and the flowability of the partitioning membrane self is lower than that of the packaging glue, the packaging glue is harder to overflow, and moreover a good partitioning function is achieved for overflowing of the packaging glue with high flowability. When the structure is laminated, the packaging glue of a cross-linking system with high flowability at a lower layer can be fused with the partitioning membrane with low flowability at an upper layer at high temperature, so that sufficient binding force can be still maintained.

Owner:仇桂芬

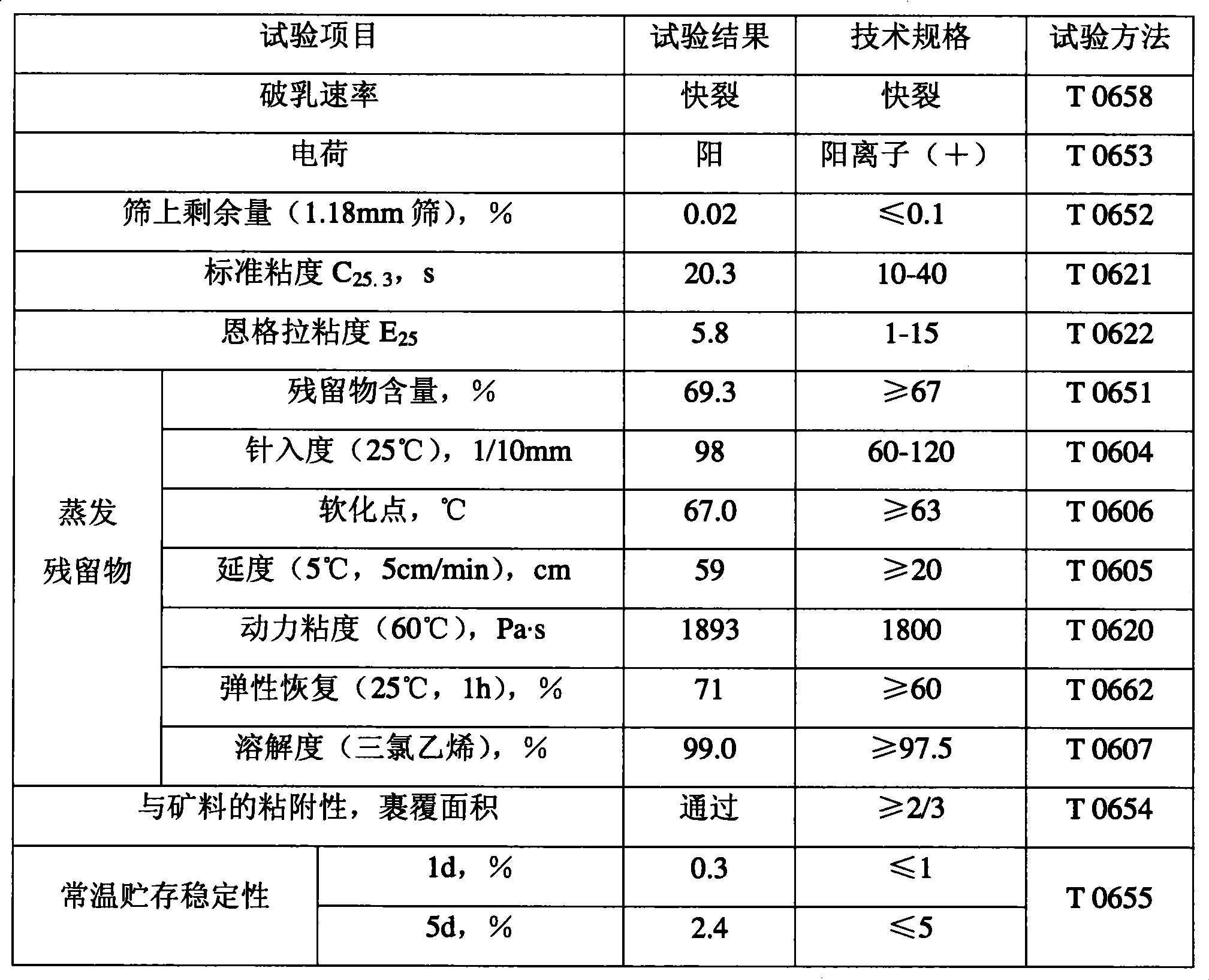

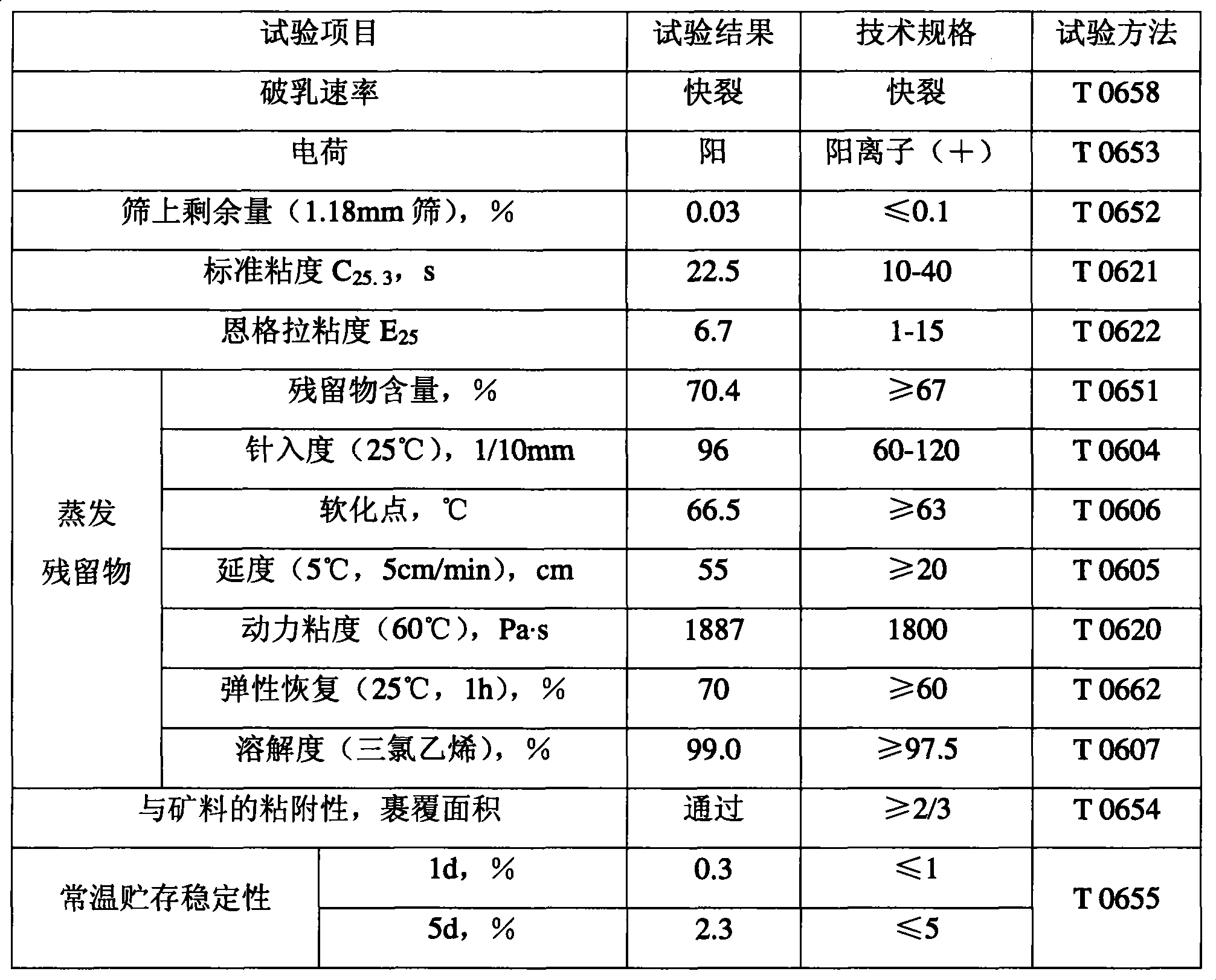

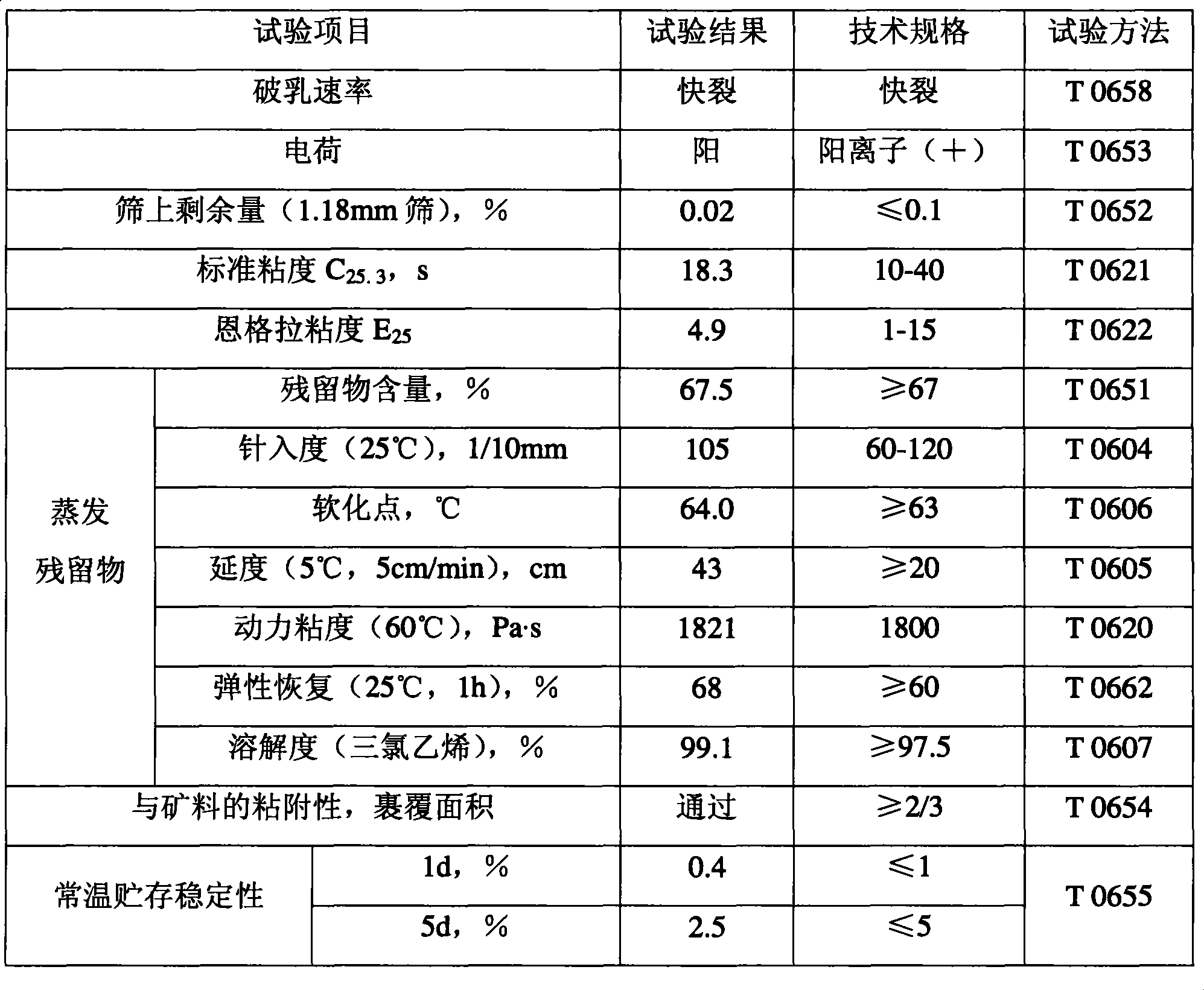

Modified emulsified bitumen for tie coat

The invention discloses modified emulsified asphalt for bonding layers, which comprises 65.0-68.0 wt% of asphalt, 3.0-4.0 wt% of modifier, 0.25-0.45 wt% of cation fast crack-typed emulsifier and 27.55-31.75 wt% of water. The solid content of the modified emulsified asphalt for bonding layers is more than 67%, a thicker asphalt film is produced after emulsion breaking, and excellent bonding performance and waterproof performance are provided, and the dynamic viscosity of evaporated residue at 60 DEG C is more than or equal to 1800Pa.s.

Owner:XIAMEN HUATE GROUP

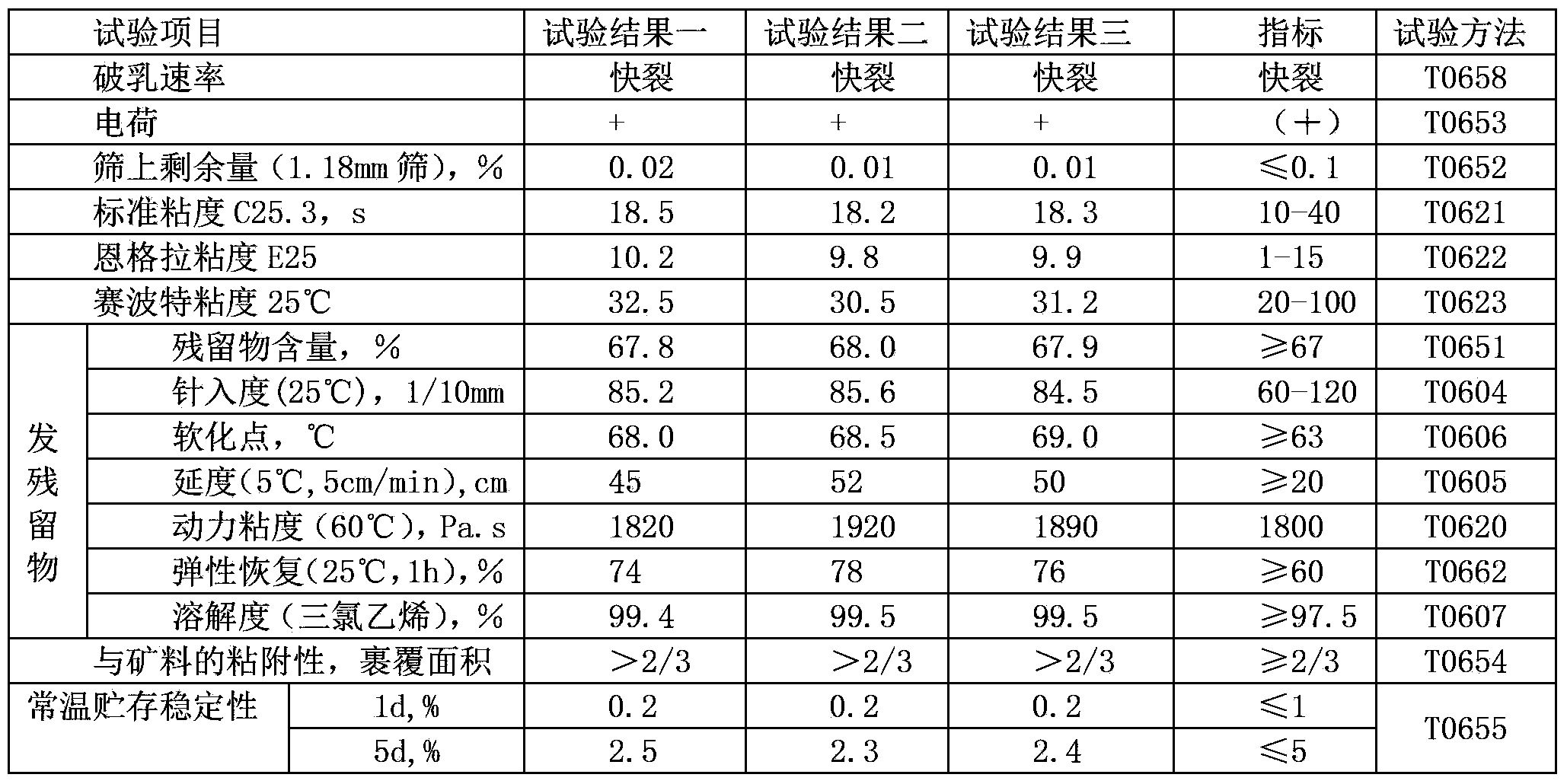

Preparation method of modified emulsified asphalt for ultra-thin wearing layer

InactiveCN104341603AImprove adhesionImprove low temperature resistanceBuilding insulationsEmulsionSolid content

The invention discloses a preparation method of modified emulsified asphalt for an ultra-thin wearing layer. The preparation method comprises the following steps: (1) preparing materials of asphalt, a modifying agent, a cationic quick-cracking type emulsifying agent and water according to the following matching ratio: 45.0-68.0% of asphalt, 3.0-4.0% of modifying agent, 0.25-0.45% of cationic quick-cracking type emulsifying agent, 0.5-2.0% of stabilizing agent, 1-5% of auxiliary agent and the balance of water; (2) rising the temperature of the asphalt to 160-189 DEG C, adding the modifying agent, stirring uniformly, grinding by a grinding machine, and controlling the particle size of the modifying agent to be less than 5mum, thereby preparing the modified asphalt; (3) adding the emulsifying agent and the stabilizing agent into water with the temperature of 40-60 DEG C, and adjusting the pH value to be 1.5-3 by using the auxiliary agent, thereby preparing soap liquid; and (4) preparing the modified asphalt obtained in the step (2) and the soap liquid in proportion by an emulsifying device. By virtue of the scheme, the obtained modified emulsified asphalt for the ultra-thin wearing layer has the advantages of strong adhesive property, high solid content and fast emulsion-breaking speed.

Owner:JIANGSU COING SPECIAL ASPHALT

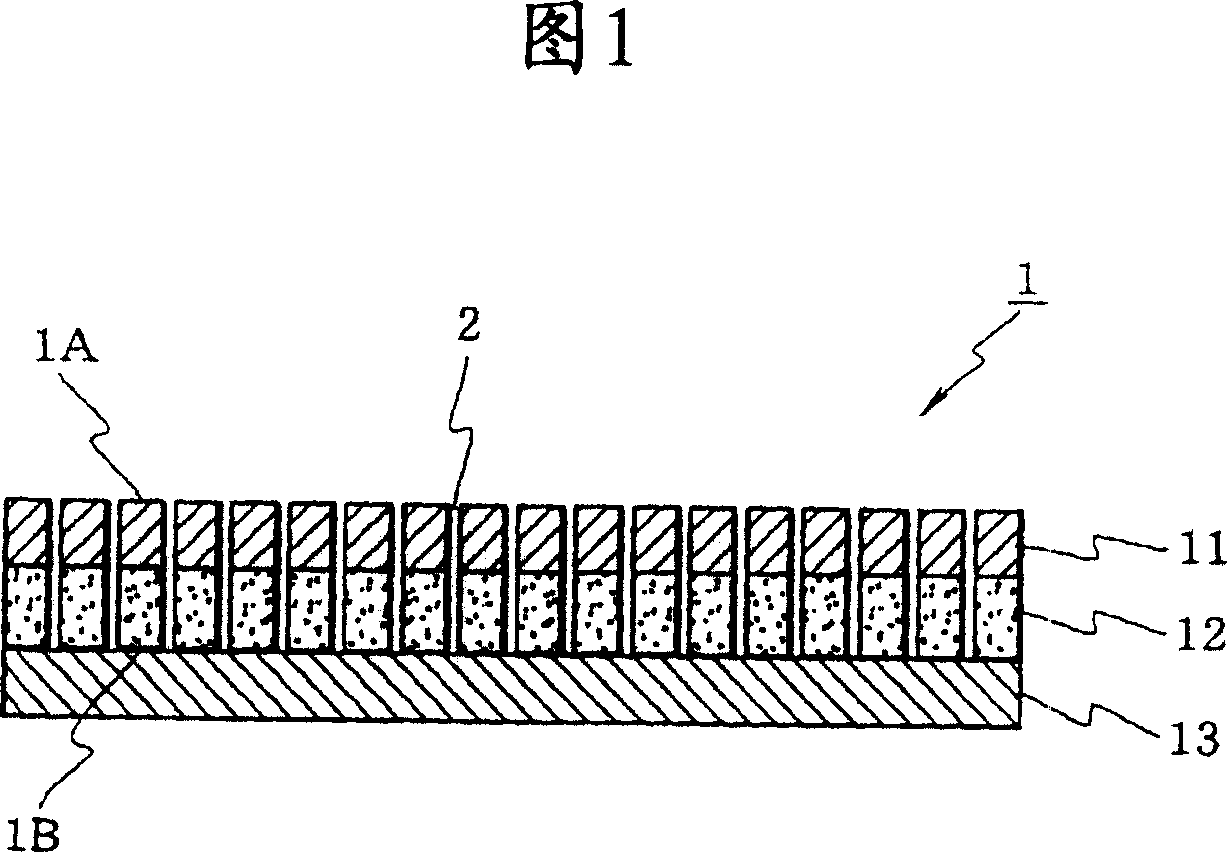

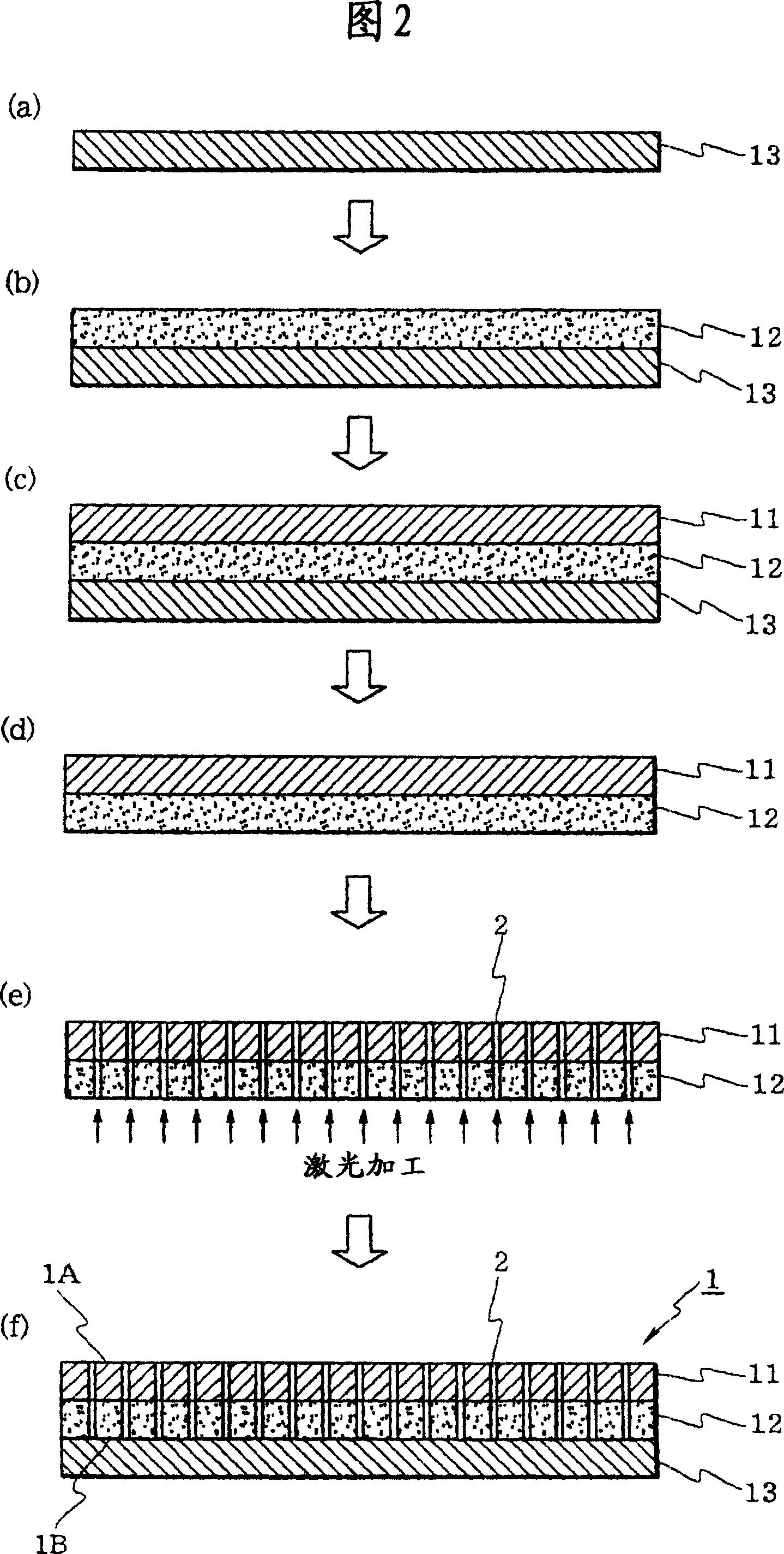

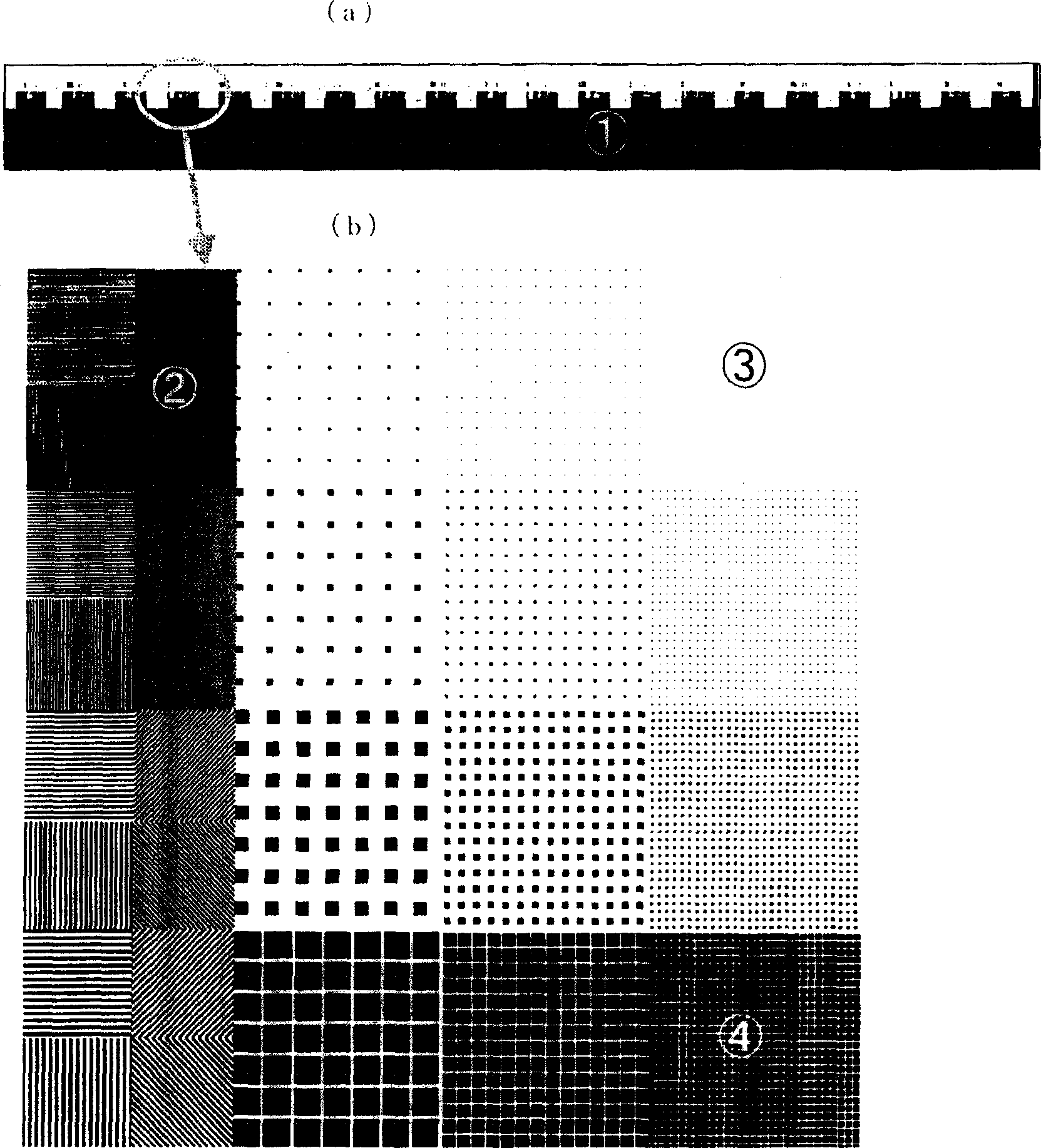

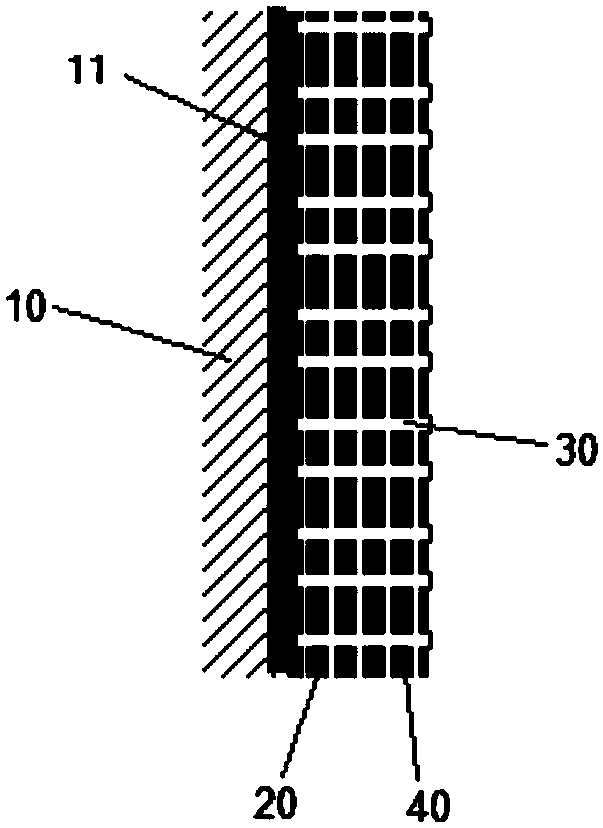

Adhesive sheet

InactiveCN1946821APrevent removalAdequate adhesionThin material handlingPressure sensitive film/foil adhesivesVolumetric Mass DensityMaximum temperature

The present invention provides an adhesive sheet in which a plurality of through holes (2) penetrating from one surface to the other are formed in an adhesive sheet (1) provided with a base material (11) and an adhesive layer (12). The diameter of the through holes (2) is set at 0.1-300 μm, and the hole density is set at 30-50,000 / 100 cm2. In addition, the storage modulus of the adhesive layer (12) at Tmax (the highest temperature that can be exposed after being attached to the adherend) is greater than or equal to 4.5×103Pa, and the adhesive layer (12) is at Tmax The loss tangent under is less than or equal to 0.78. The adhesive sheet (1) can prevent or remove air pockets or air bubbles while ensuring sufficient adhesive force without impairing the appearance. In addition, even if it is exposed to high temperature after being attached to the adherend, the Gas is also excellent.

Owner:LINTEC CORP

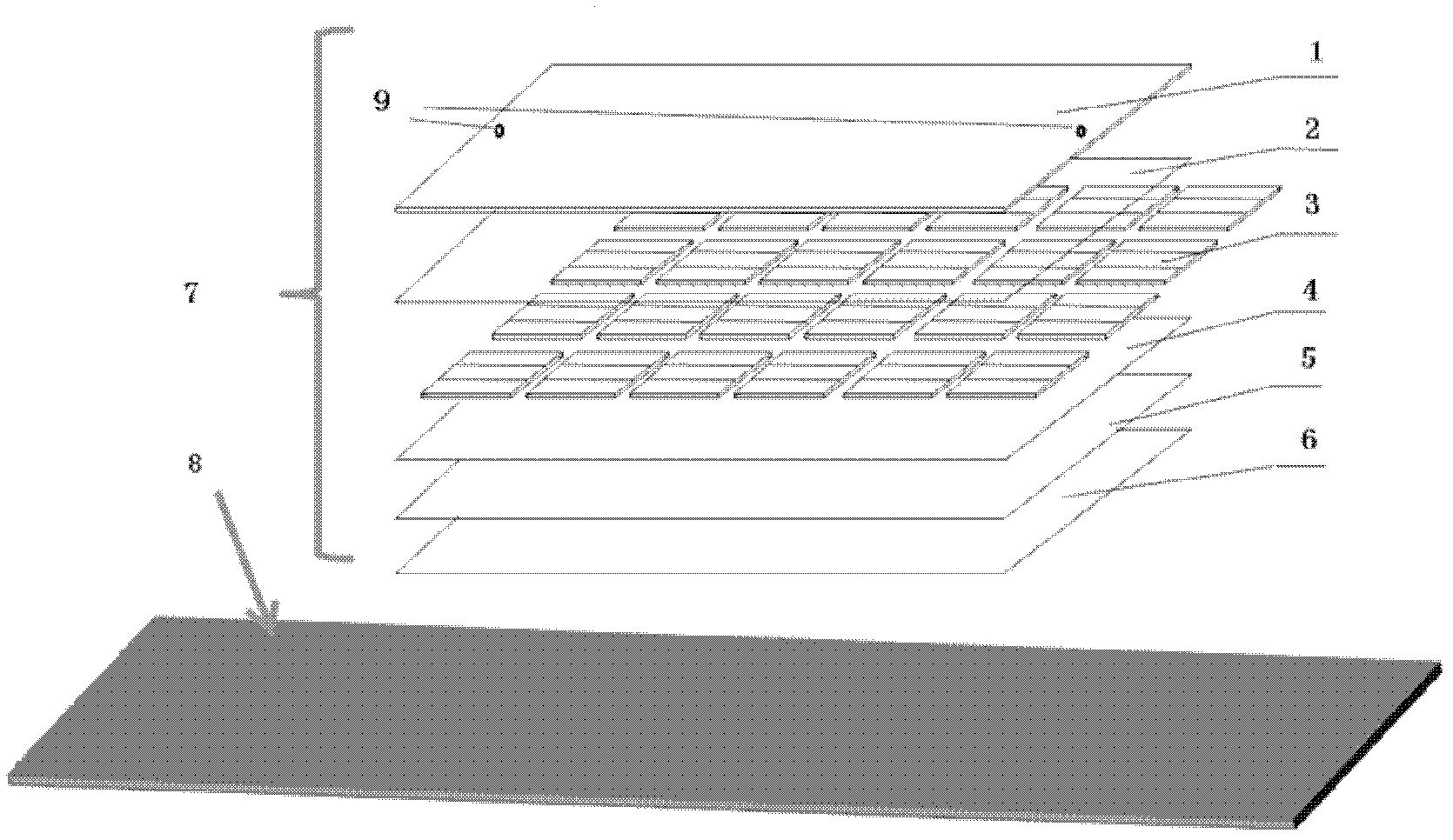

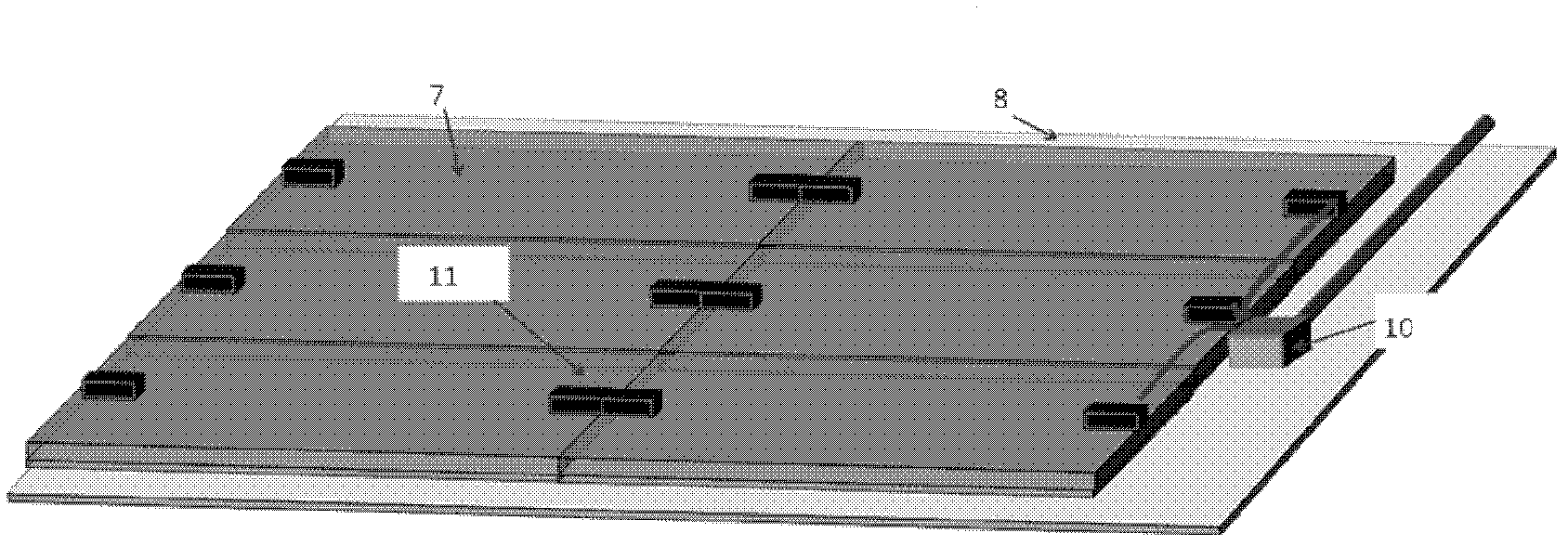

Self-adhesion modularized crystalline silicon solar cell component

ActiveCN102569467AHigh degree of freedom in constructionReduce processPhotovoltaic supportsRoof covering using slabs/sheetsPolyethylene terephthalateCrystalline silicon

The invention discloses a self-adhesion modularized crystalline silicon solar cell component, which is formed by laminating toughened glass, thermosol, a crystalline silicon cell sheet, thermosol, TPT (Tedlar / Polyethylene Terephthalate / Tedlar) and a self-adhesion adhesive layer in sequence. The self-adhesion modularized crystalline silicon solar cell component provided by the invention can be mounted on a roof of light steel structure; the irradiation of sunlight can be received to the greatest extent to generate power by combining the crystalline silicon solar cell component and the roof of light steel structure for use; the heat load of the roof in summer can be reduced by considering the roof bearing load and the wind load of the roof of light steel structure and storage of the original water proofing function; and the combination of the solar power generation function and the building water proofing function is realized.

Owner:南通金丝楠膜材料有限公司

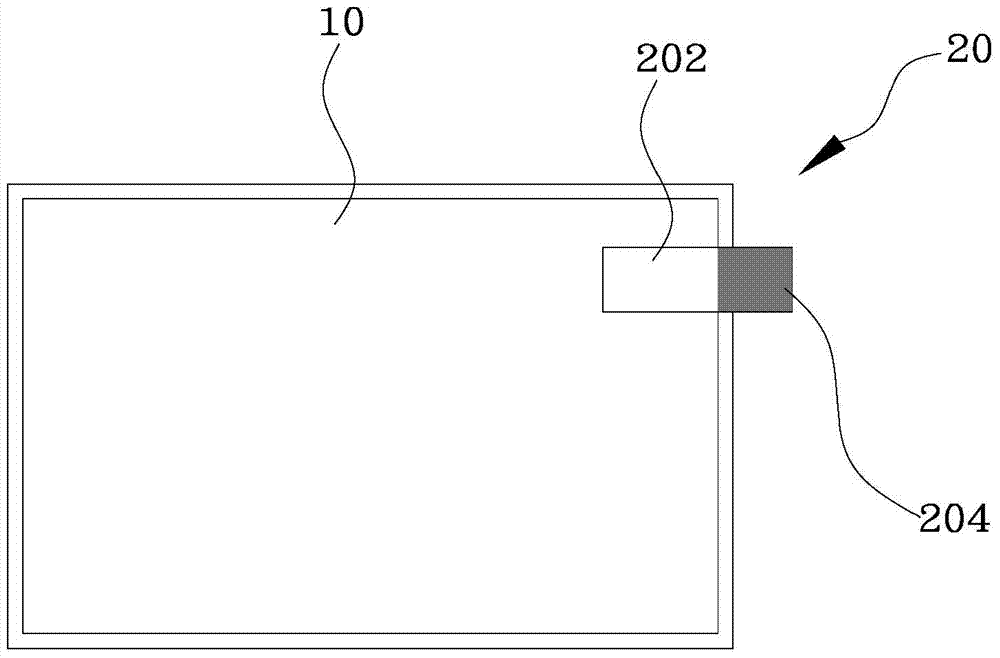

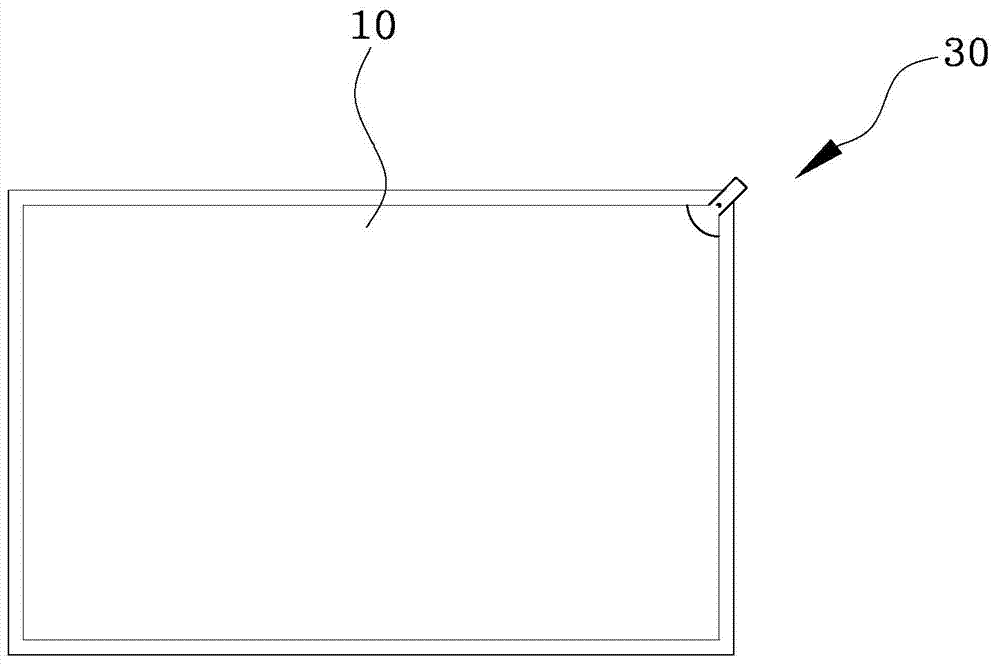

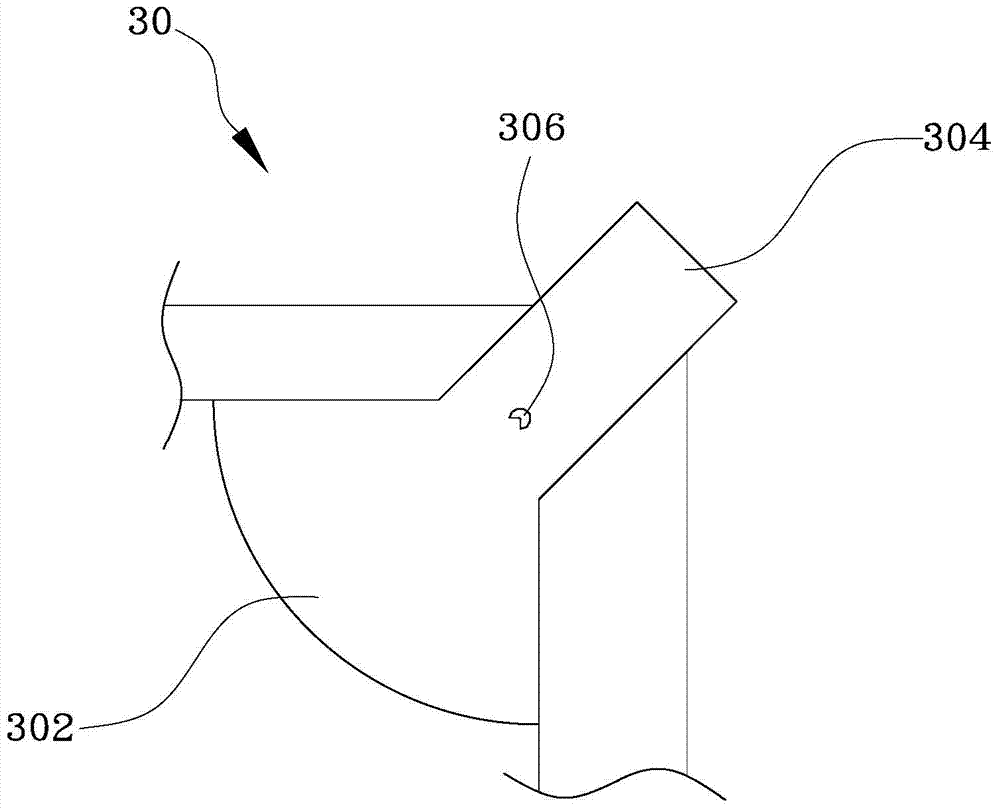

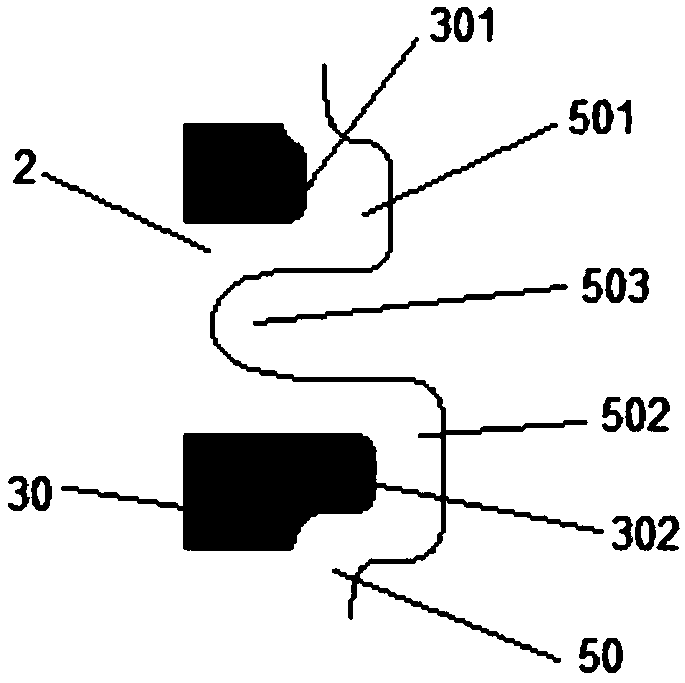

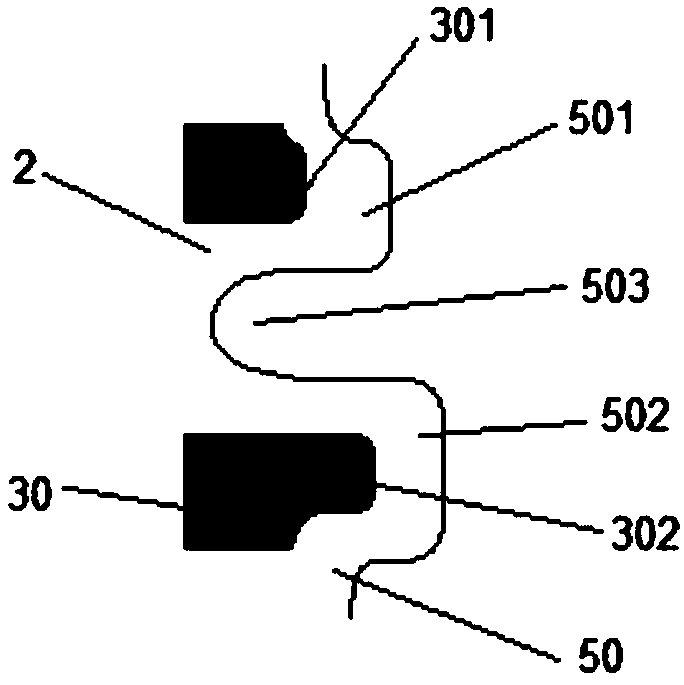

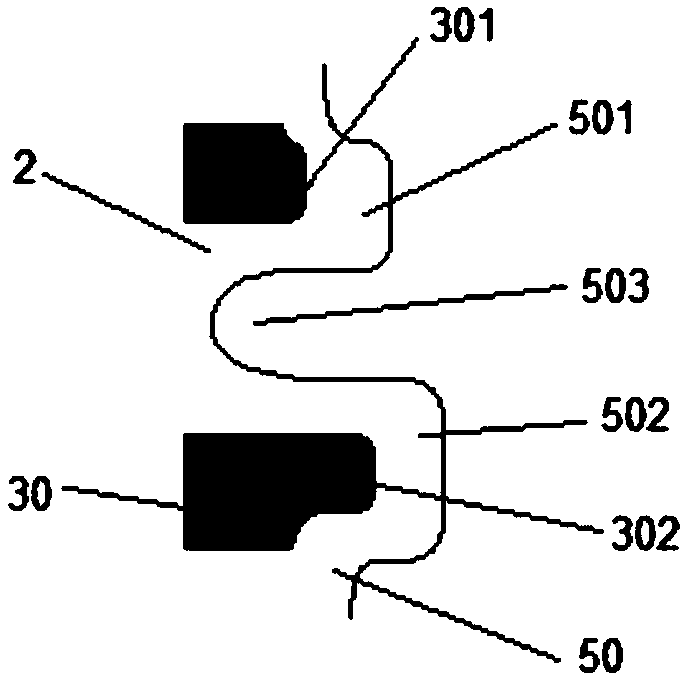

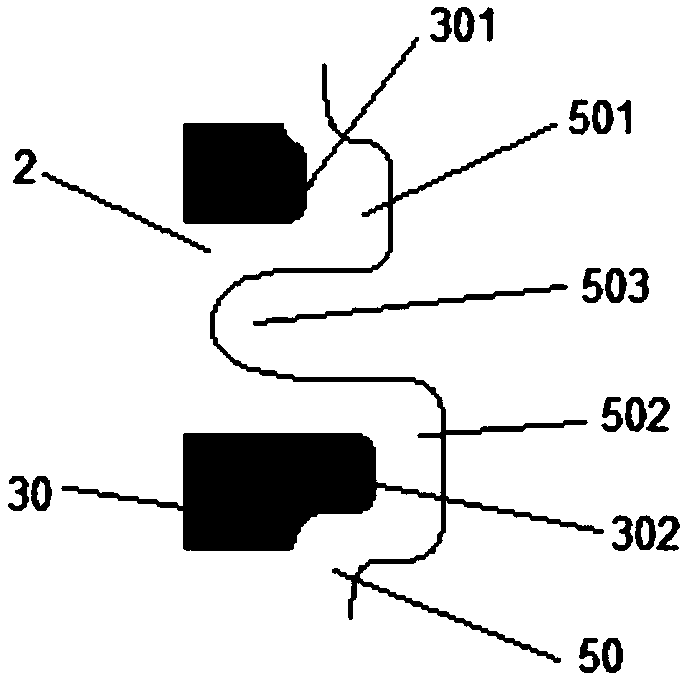

Adhesive tape structure for tearing off protecting film from panel

InactiveCN104263271AImprove alignment accuracyIncrease area sizeFilm/foil adhesivesEngineeringSurface plate

The invention provides an adhesive tape structure for tearing off a protecting film from a panel. The adhesive tape structure comprises a body, a tear-off handle and a positioning hole, wherein the body is arranged at the corner of the protecting film and comprises a first surface and a second surface; the protecting film is glued to the first surface; the tear-off handle and the body are integrally molded; the tear-off handle is arranged at one side, far away from the panel, of the adhesive tape structure; the positioning hole is formed between the body and the tear-off handle and is used for aligning the adhesive tape structure and the panel; and when the protecting film is torn off, the tear-off handle is lifted up, so that the body drives the protecting film to move together, so as to separate the protecting film from the panel. Compared with the prior art, the positioning hole is formed between the body and the tear-off handle, thus the alignment accuracy of the adhesive tape structure and the panel is improved and the problem that a glue preparation area is adhered to frame glue or an iron frame at the edge of the panel when a film-tearing adhesive tape is not adhered in place is avoided.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

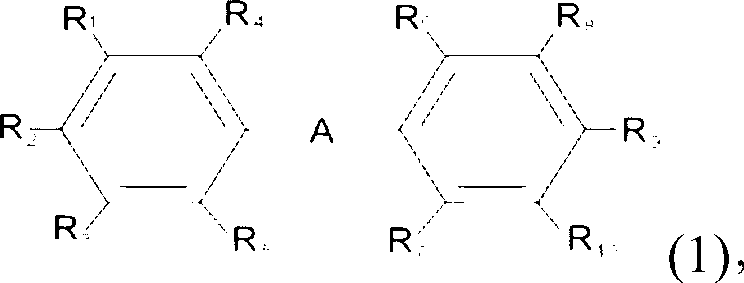

Positive-working photosensitive composition

Owner:THINK LABORATORY CO LTD

Spray hard phenolic foam

InactiveCN102268172ASmooth surface High tensile strengthHigh compressive strengthFireproof paintsPhenolformaldehyde foamPolymer science

The invention discloses a hard phenolic foam composition, a sprayed hard phenolic foam coating, a preparation process and an application. The rigid phenolic foam composition is obtained by mixing composite phenolic resin and mixed acid in a mass ratio of 1-10:1. The above-mentioned hard phenolic foam composition is completely atomized and mixed uniformly at a pressure of 100-200kg and a temperature of 20-50°C, sprayed from a spray gun, and evenly sprayed on the wall to form a spray-coated hard phenolic foam Insulation. The obtained spraying hard phenolic foam coating can be applied to the field of waterproof, fireproof or thermal insulation materials.

Owner:田瑞军

Microwave curing method for block

ActiveCN110936485AUniform temperatureDimensionally stable materialCeramic shaping apparatusChemistryMicrowave frequency

The invention provides a microwave curing method for a block. The method includes steps that (1) slurry is injected into a test mold, covered by a film, and is subjected to standing and pre curing for2-4 hours, and the temperature is controlled at 30-45 DEG C; (2) after pre curing, a steel wire is used to cut an uncured block, and then the film is utilized to re-cover and transferred to a microwave reaction chamber for 1-2 hours, the temperature is controlled at 50-70 DEG C, and the microwave frequency is 433-2450 MHz; and (3) after microwave heating and curing, the block is naturally cooledto room temperature, and curing is completed. The method is advantaged in that a microwave source with the specific frequency of 433-2450 MHz has the characteristics of deep acting depth, which can realize synchronous heating of the whole block inside and outside so that the temperature of each part of the block is uniform, and the stress damage caused by temperature difference is avoided, and themethod can realize fast curing of the block, improve production efficiency, and realize energy conservation and environmental protection.

Owner:GUANGXI ACAD OF SCI +2

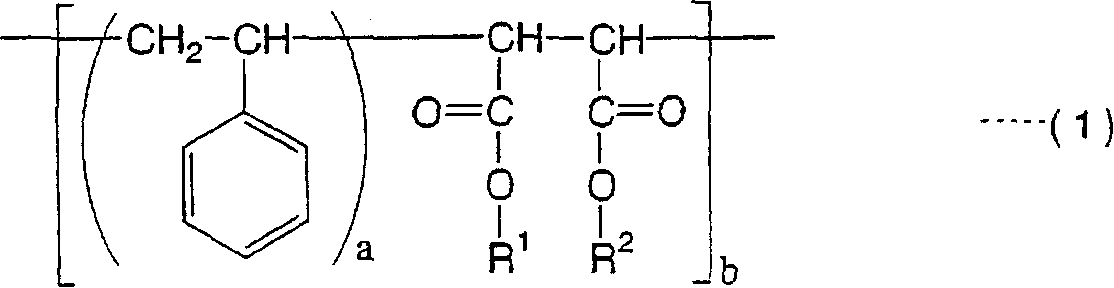

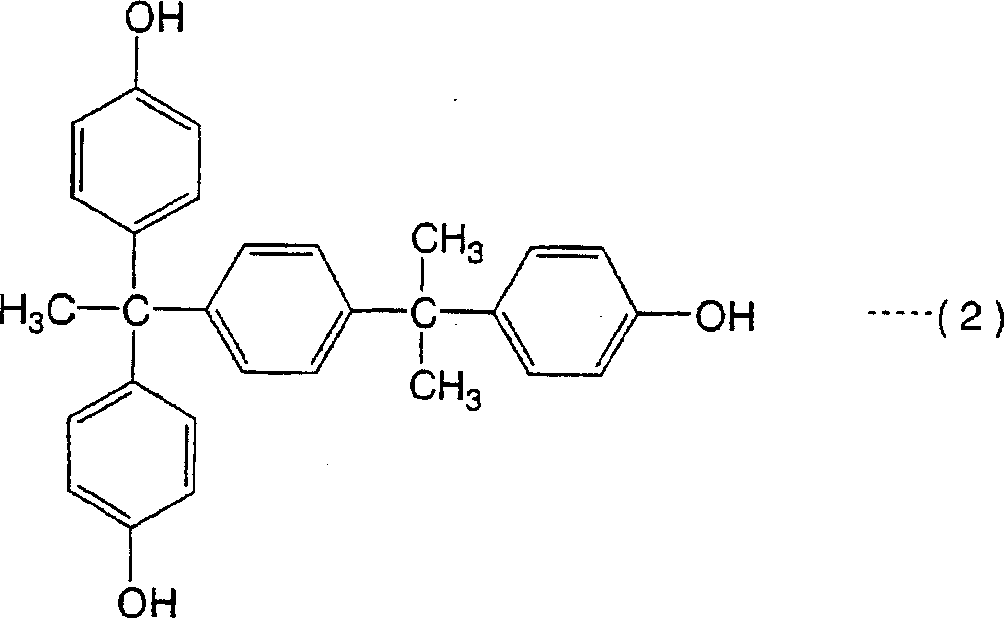

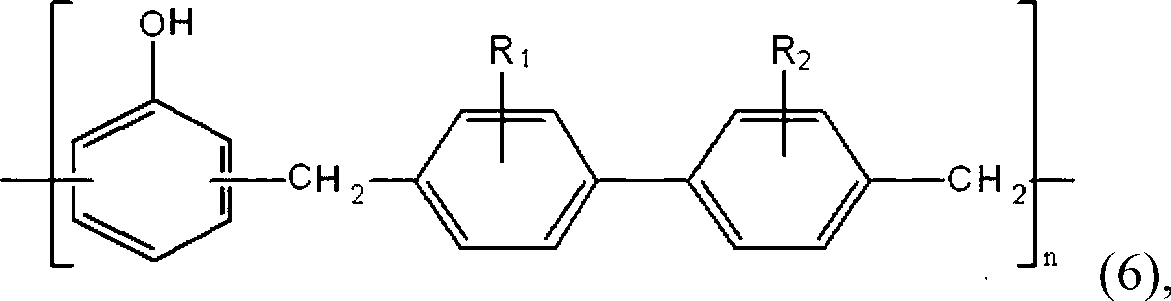

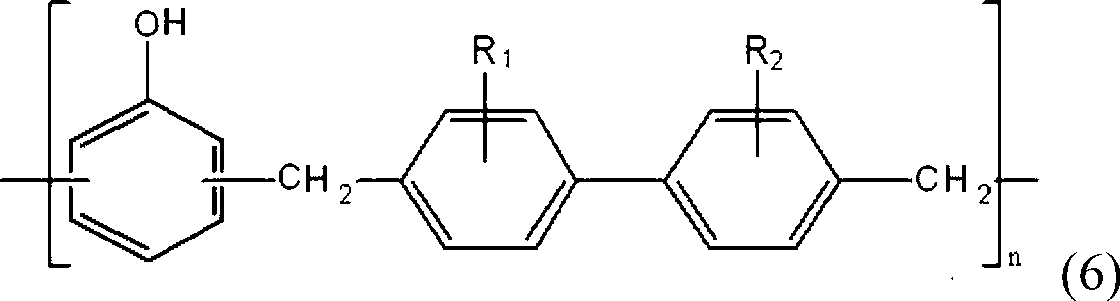

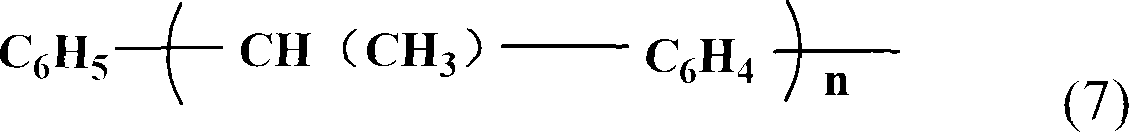

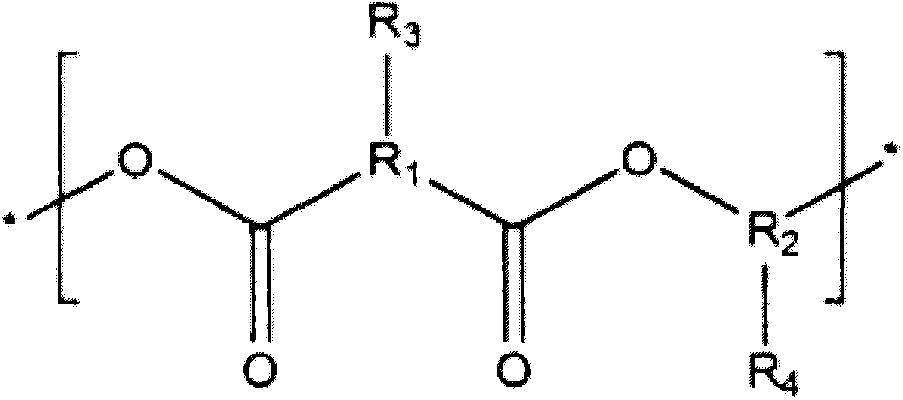

Adhesive composition for semiconductor, adhesive film and semiconductor device

InactiveCN103184014APlasma process omittedAdequate adhesionNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsAdhesion processSemiconductor

The invention relates to an adhersive composition for a semiconductor, an adhesive film and a semiconductor device. More specifically, the invention relates to the adhersive composition. Through highly adhersive features of the adhersive composition, a PCB curing process and a PCB plasma process can be omitted through improvement of the curing rate, and partial curing, if being applied to an on-line process, can be conducted during a lead adhesion process so as to reduce the process time, so that a curing process (or a semi-curing process or a B step) can be omitted or minimized. For the adhersive composition, phenolic film and amine-cured resin both serve as curing agents to allow the curing process to be omitted or minimized, and an imidazole curing agent or a micro-capsule potential curing agent is adopted to serve as the curing agent so that the curing rate is improved.

Owner:CHEIL IND INC

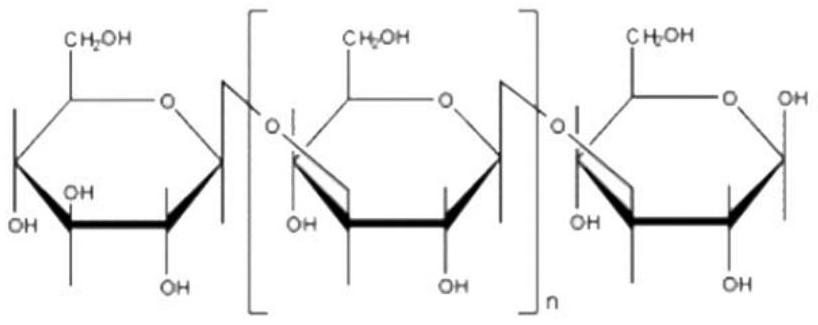

Aqueous dispersion, method for producing same, and method for bonding shaped article made of ethylene-alpha-olefin copolymer

ActiveCN1894293AHigh bonding strengthImprove stabilityMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsOrganic solventAlpha-olefin

Disclosed is an aqueous dispersion containing (A) an ethylene-alpha-olefin copolymer, (B) a modified ethylene-vinyl acetate copolymer, (C) a photopolymerization initiator and (D) an ethylenically unsaturated monomer, and if necessary (E) an ethylene-vinyl acetate copolymer and (F) a nonaqueous organic solvent.

Owner:MITSUI CHEM INC

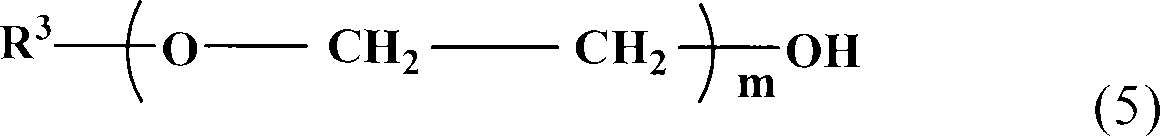

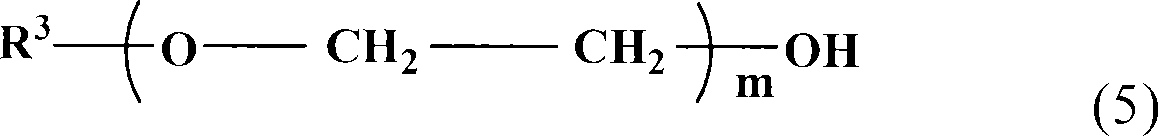

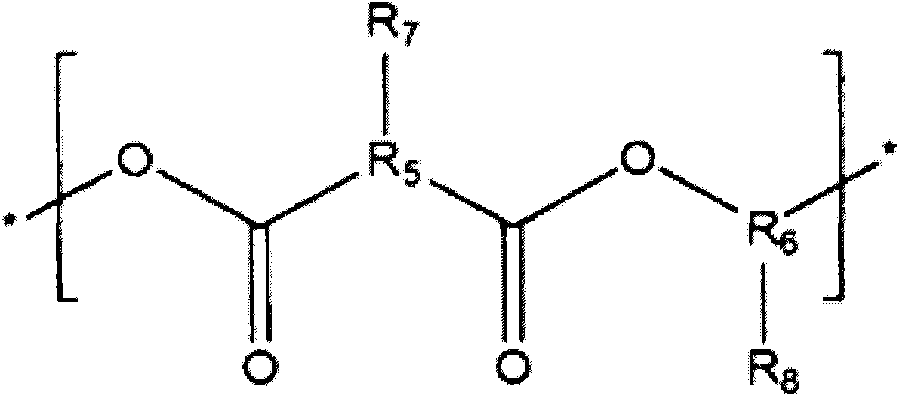

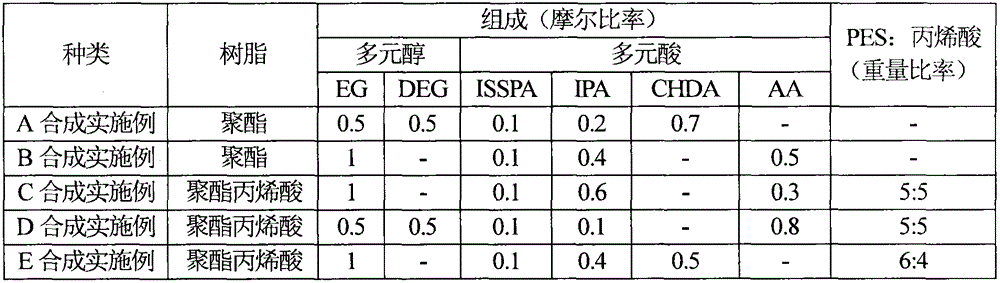

Optical film comprising primer layer containing polyester resin and polarizing plate using same

ActiveCN105765423AAdequate adhesionImprove adhesionSynthetic resin layered productsPolarising elementsRainbowPolyol

The present invention relates to an optical film comprising: a base film; and a primer layer formed on at least one surface of the base film and containing a polyester resin and water-dispersive microparticles, the difference in the refractive index between the base film and the polymer layer being 0.03 or smaller, wherein the polyester resin contains polyester glycol formed by a reaction of polybasic acid and polyol, the polybasic acid containing an aromatic carboxylic acid compound and an aliphatic carboxylic acid compound at a mole ratio of 1:9 to 9:1. Superior adhesive strength and a small refractive index difference between the optical film and a functional coating layer lead to a reduction in the rainbow phenomenon, and excellent optical properties.

Owner:ANHUI HEMEI MATERIALS TECH CO LTD

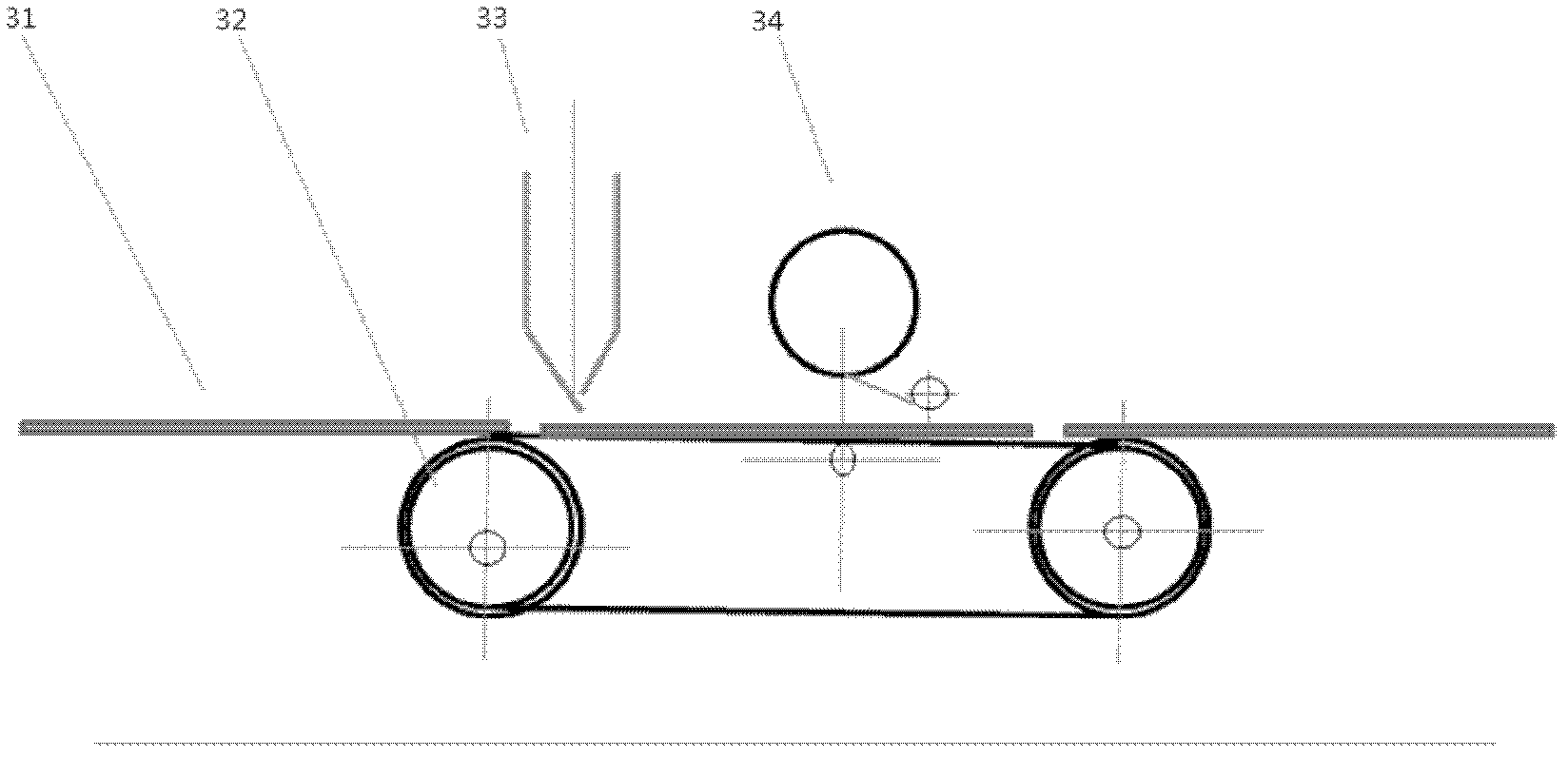

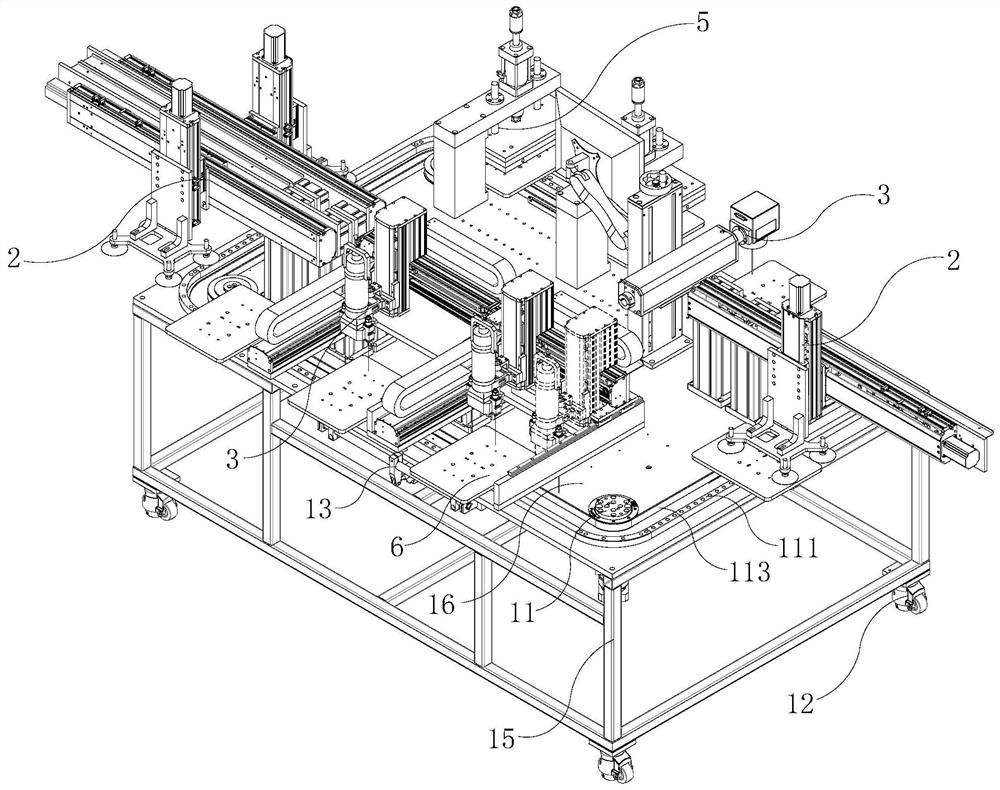

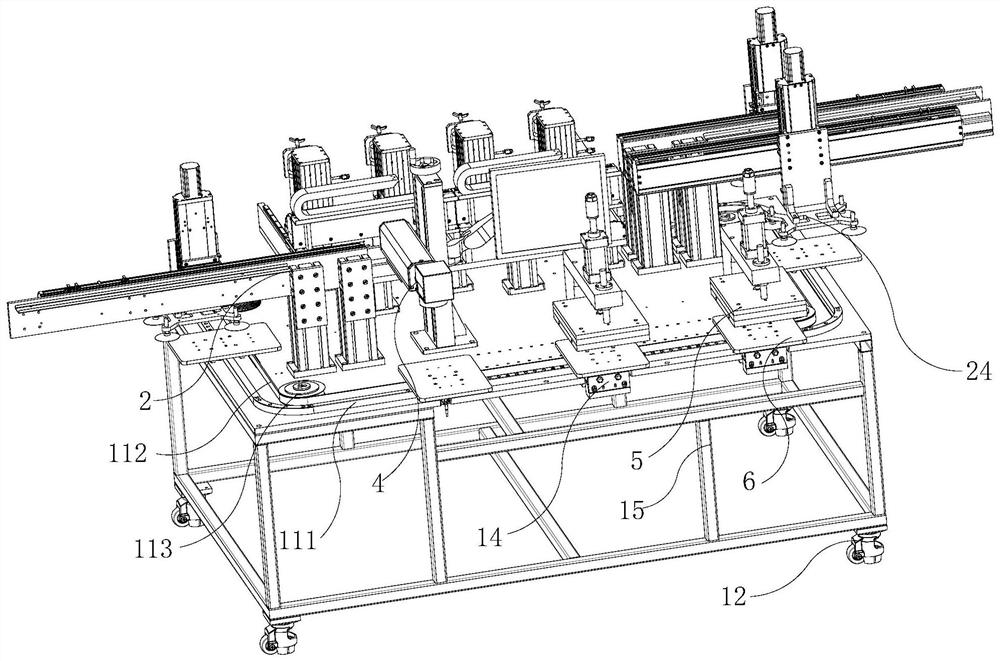

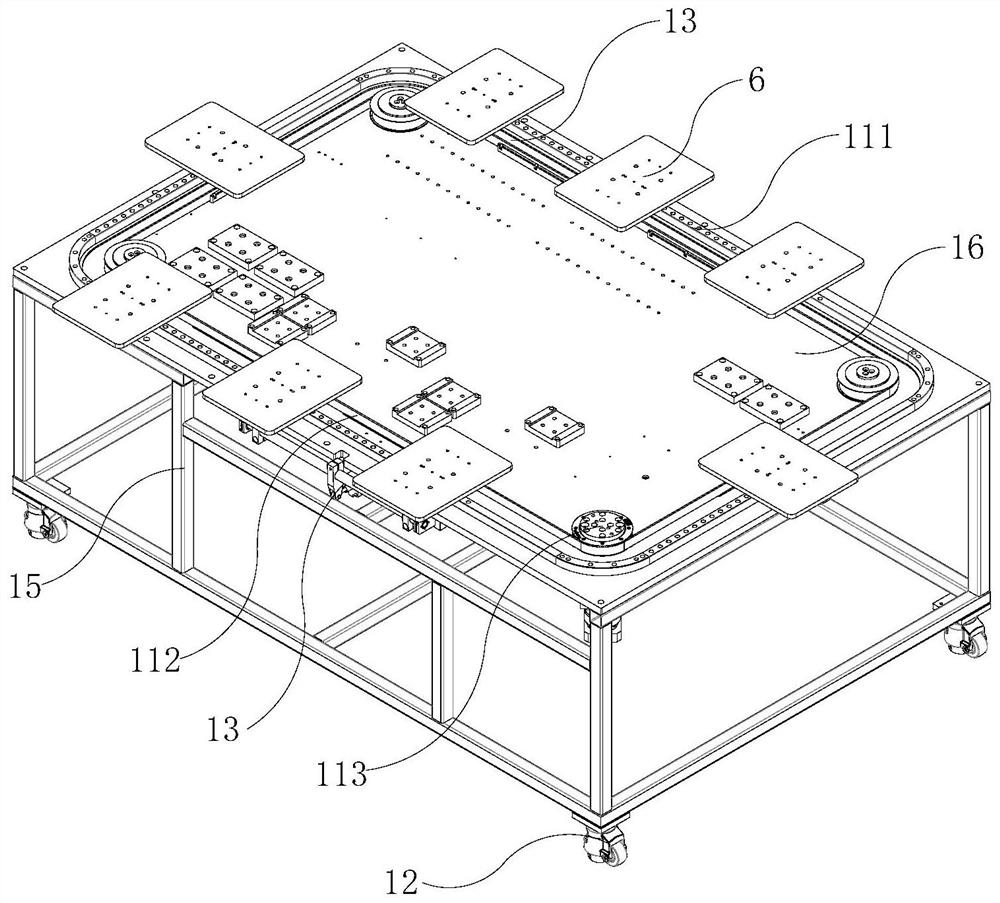

Slow-curing gluing process and device for panel and frame

PendingCN112157918AEasy to pressStable positionDomestic articlesLaser beam welding apparatusPolyurethane adhesiveAdhesive glue

The invention discloses a slow-curing gluing process and device for a panel and a frame. The gluing device comprises a supporting table, manipulators, glue dispensing devices, a laser marking device and pressing devices, wherein the manipulators comprise the frame feeding manipulator, the panel feeding manipulator and the discharging manipulator, the number of the glue dispensing devices is two, and the pressing devices comprise the hot pressing device and the cold pressing device. The two glue applying devices are arranged to apply glue to the frame twice, and the two pressing devices are also used after glue applying for hot pressing and cold pressing on the panel and the frame after covering separately. Slow-curing moisture polyurethane glue can be melted when heated through hot pressing, and better bonding is achieved under the action of pressure; and meanwhile, the slow-curing glue after bonding is instantly cured through the cold pressing device, and the bonding efficiency is improved while the bonding quality is improved.

Owner:SHENZHEN GUNUOTAI TECH

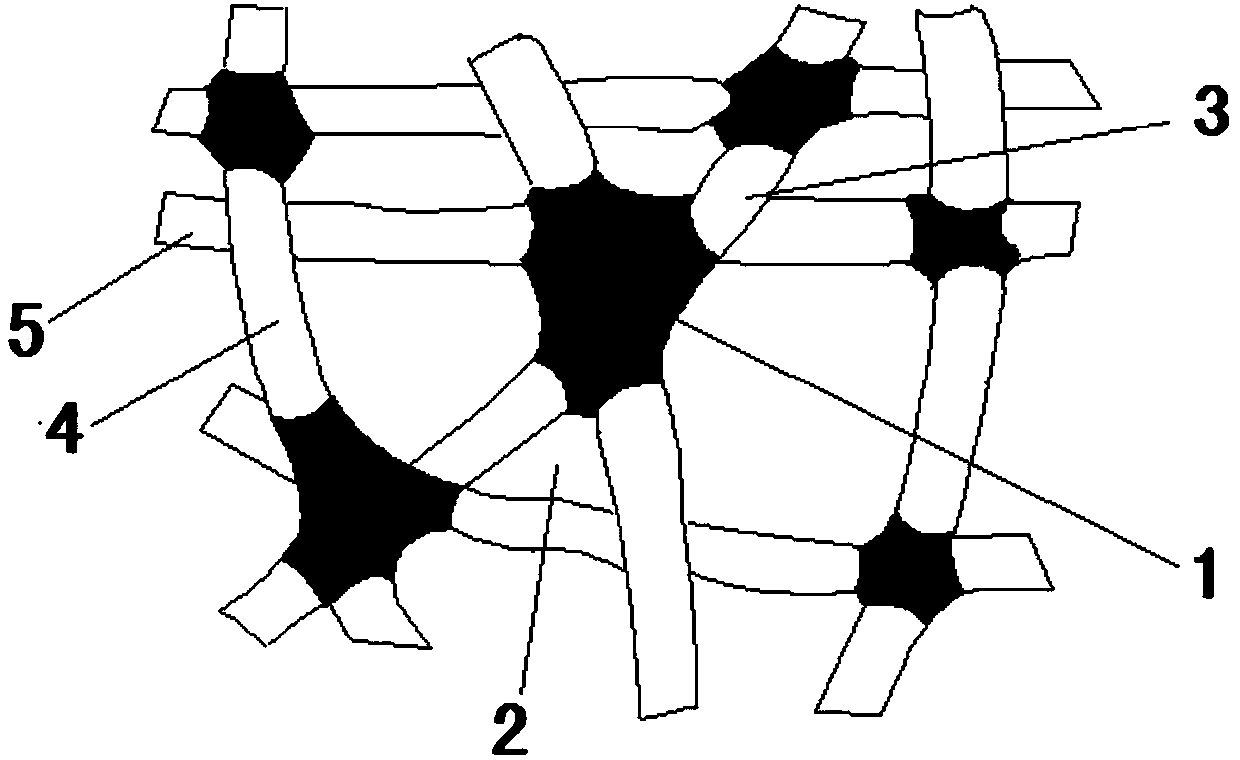

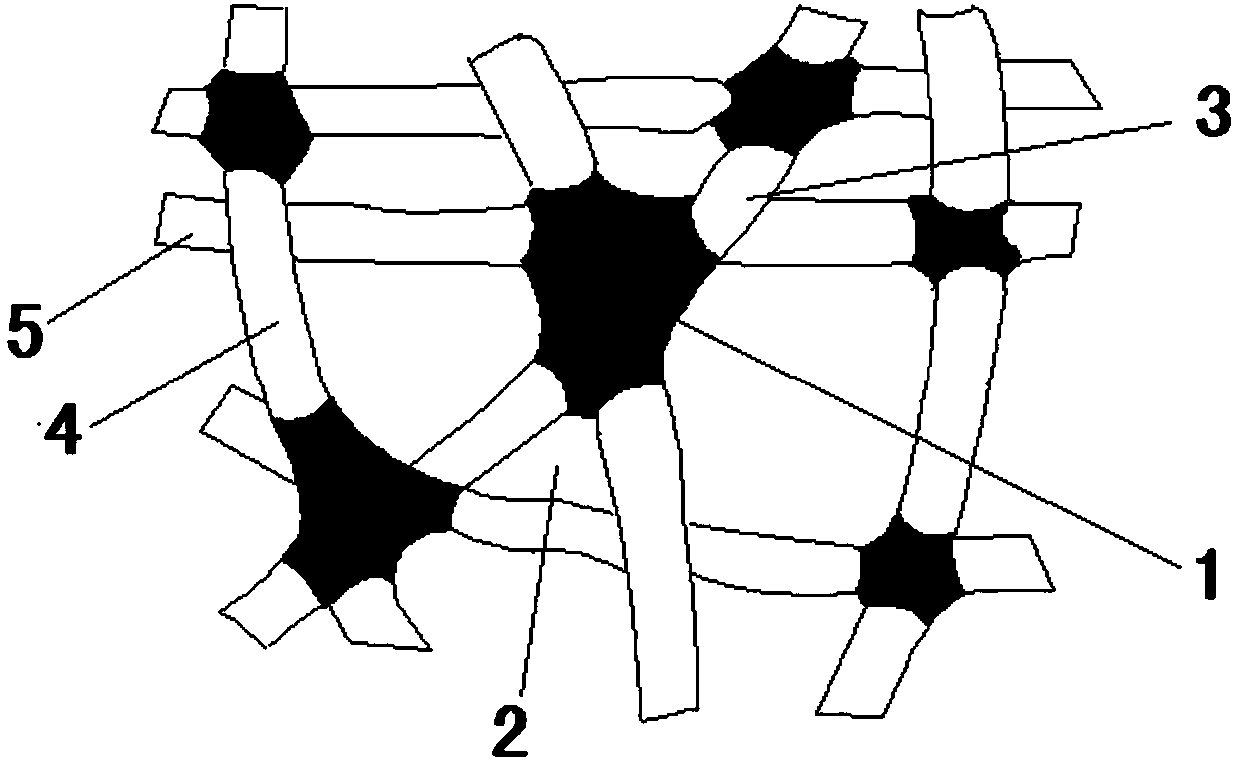

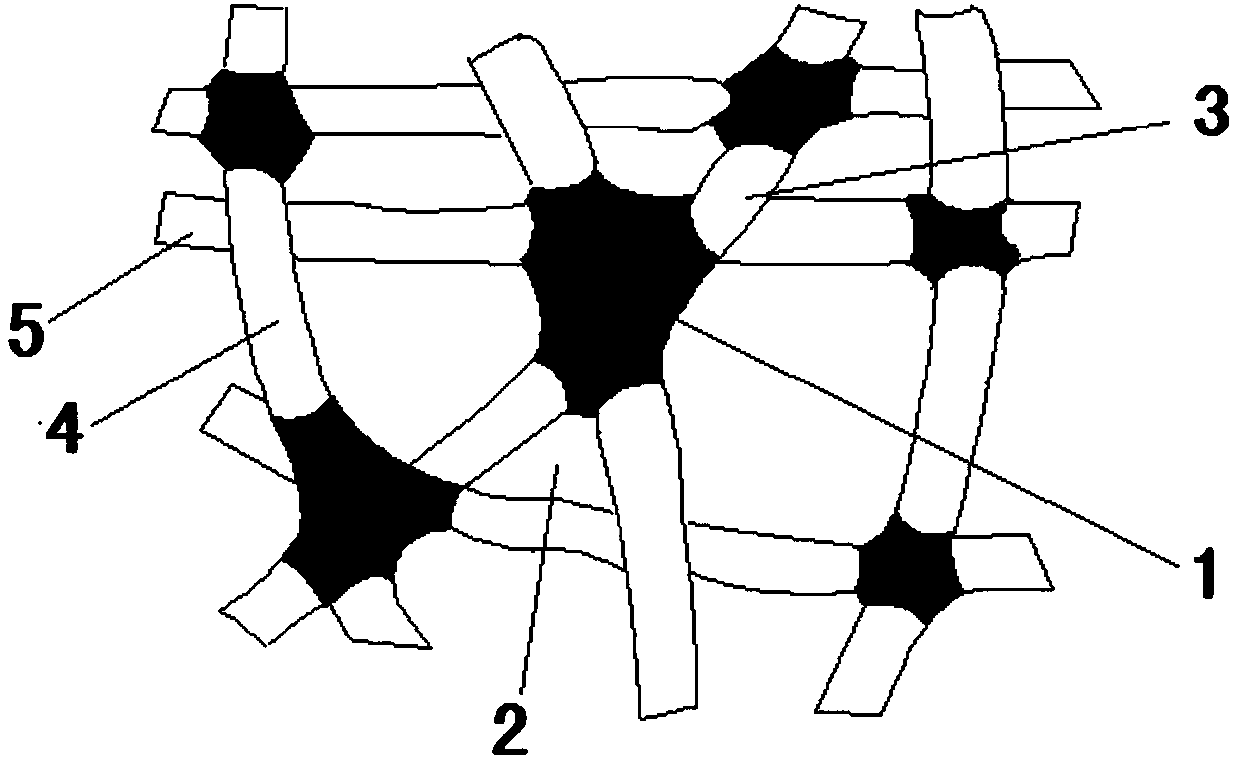

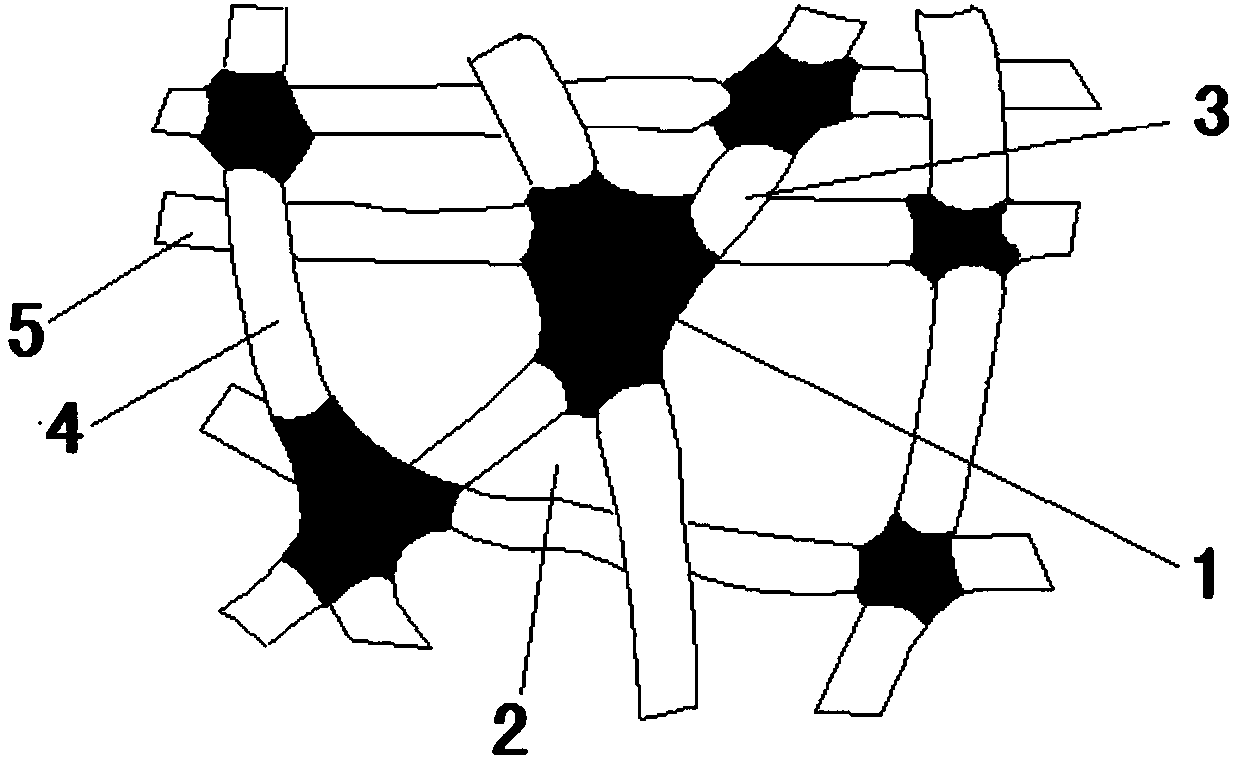

Phase change energy storage infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides a phase change energy storage infiltration coating sandwich wall cloth, and a method for manufacturing the phase change energy storage infiltration coating sandwich wall cloth,or an object decoration method. The phase change energy storage infiltration coating sandwich wall cloth comprises a bottom coating and an infiltration coating composite sandwich coating compound coated on the surface of the bottom coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; the second coating penetrates into meshes of the network structure; and one or more of the second coating, the bottom coating and the fiber texture network sandwich can have a phase change energy storage function. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Fireproof infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158892AAdequate adhesionObvious connection seamCovering/liningsCoatingsFiberCoated surface

The invention provides a fireproof infiltration coating sandwich wall cloth and a method for manufacturing the fireproof infiltration coating sandwich wall cloth or an object decoration method. The fireproof infiltration coating sandwich wall cloth comprises an undercoat layer and an infiltration coating composite sandwich coating composite body, wherein the surface of the undercoat layer is coated with the infiltration coating composite sandwich coating composite body, the infiltration coating composite sandwich coating composite body comprises a transparent or semitransparent second coatinglayer and a fiber texture network sandwich covered with the second coating layer, the fiber texture network sandwich contains a network structure formed by fibers, the second coating layer penetratesinto meshes of the network structure, and one or more of the second coating layer and the undercoat layer can be a fireproof coating layer. The wall cloth with skin textures and / or patterns can be produced in a standardized and large-scale mode, and good crack resistance, air permeability and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Heat-conducting silicone grease and preparation method thereof

The invention provides heat-conducting silicone grease and a preparation method thereof. The heat-conducting silicone grease is prepared from the following components in parts by mass: 100 parts of polydimethylsiloxane, 5-20 parts of modified silicone oil, 1300-1800 parts of modified heat-conducting composite powder and 2-10 parts of a thermal gel additive. Through grading of spherical aluminum oxide with different particle sizes and by utilizing the characteristics of strong surface effect and small-size effect of nano quantum dots, cavity gaps dispersed among aluminum oxide particles are uniformly filled, so that the thermal resistance of the product is effectively reduced, the thixotropic index of the heat-conducting silicone grease is improved, and the heat-conducting silicone grease is endowed with a shear thinning characteristic; and meanwhile, the heat-conducting silicone grease has enough binding power, and the aging property of the heat-conducting silicone grease is improved.Meanwhile, the particle size distribution of the filler is strictly controlled, and the selected filler is very narrow in particle size distribution and has good monodispersity; the filler with the particle size larger than 20 microns is screened out through sieving processing, so that it is ensured that the filler grading effect is good, and gaps are avoided; and the heat-conducting silicone grease is low in thermal resistance value and excellent in aging performance.

Owner:SHENZHEN FRD SCI & TECH

Polyurethane modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047949AGood storage stabilityImprove high temperature resistanceFireproof paintsAntifouling/underwater paintsBituminous waterproofingPolyvinyl alcohol

The invention relates to a polyurethane modified asphalt waterproof paint, which is composed of the following raw materials by weight: 25-30 parts of a polyurethane prepolymer; 70-75 parts of 90# petroleum asphalt; 40-60 parts of water; 20-25 parts of polychloroprene latex; 4-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 1-2 parts of polypropylene glycol;3-5 parts of trihexyl o-acetylcitrate; 0.1-0.5 part of pentaerythritol ester of hydogenated rosin; 1-3 parts of polyacrylamide; and 10-15 parts of modified nano calcium carbonate. The polyurethane modified asphalt waterproof paint prepared by the method provided by the invention has good film compactness and high stability, a waterproof layer formed by the waterproof paint in a building has largebonding strength with a building base surface and good waterproof effect, moreover, after modification, the product has substantially improved water tolerance, aging resistance, acid and alkaline resistance and the like, has a simple making process, and overcomes the disadvantages of tedious making, poor film compactness, poor waterproofness and aging resistance in previous water emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047952AImprove physical performanceImprove waterproof performanceAnti-corrosive paintsBituminous coatingsBituminous waterproofingPolyvinyl alcohol

The invention relates to a modified asphalt waterproof paint for buildings. The modified asphalt waterproof paint is composed of the following raw materials by weight: 50-65 parts of 90# petroleum asphalt; 60-70 parts of water; 25-28 parts of styrene butadiene latex; 5-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 5-7 parts of polyoxypropylene glycerol ether; 3-5 parts of triethyl citrate; 0.1-0.5 part of rosin glycerin ester; 1-3 parts of sodium polyacrylate; and 10-15 parts of modified nano calcium carbonate. The modified asphalt waterproof paint for buildings prepared by the method provided by the invention has good film compactness and high stability, can be used for buildings to form a waterproof layer, which has large bonding strength with the base surfaces of buildings and has good waterproof effect, moreover, after modification, the product has greatly improved water resistance, aging resistance, acid and alkali resistance and other properties, the making process is simple, and the modified asphalt waterproof paint overcomes the shortcomings of tedious making, poor film compactness, poor water resistance and aging resistance in previous water-emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

Heat insulation infiltration coating sandwich wall cloth and manufacturing method thereof

PendingCN110158891AAdequate adhesionObvious connection seamCovering/liningsSpecial surfacesFiberCrack resistance

The invention provides a heat insulation infiltration coating sandwich wall cloth, and a method for manufacturing the heat insulation infiltration coating sandwich wall cloth, or an object decorationmethod. The heat insulation infiltration coating sandwich wall cloth comprises a heat insulation coating and an infiltration coating composite sandwich coating compound covering the surface of the heat insulation coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the secondcoating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of the network structure. The wall cloth with textures and / orpatterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Alkali-resistant infiltration coating sandwich wall cloth and manufacturing method thereof

The invention provides an alkali-resistant infiltration coating sandwich wall cloth, and a method for manufacturing the infiltration coating sandwich wall cloth, or an object decoration method. The alkali-resistant infiltration coating sandwich wall cloth comprises a closed bottom coating, a bottom color coating covering the surface of the closed bottom coating and an infiltration coating composite sandwich coating compound covering the surface of the bottom color coating; the infiltration coating composite sandwich coating compound comprises a transparent or semi-transparent second coating and a fiber texture network sandwich wrapped by the second coating; the fiber texture network sandwich contains a network structure formed by fibers; and the second coating penetrates into meshes of thenetwork structure. The wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale mode, and has good crack resistance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

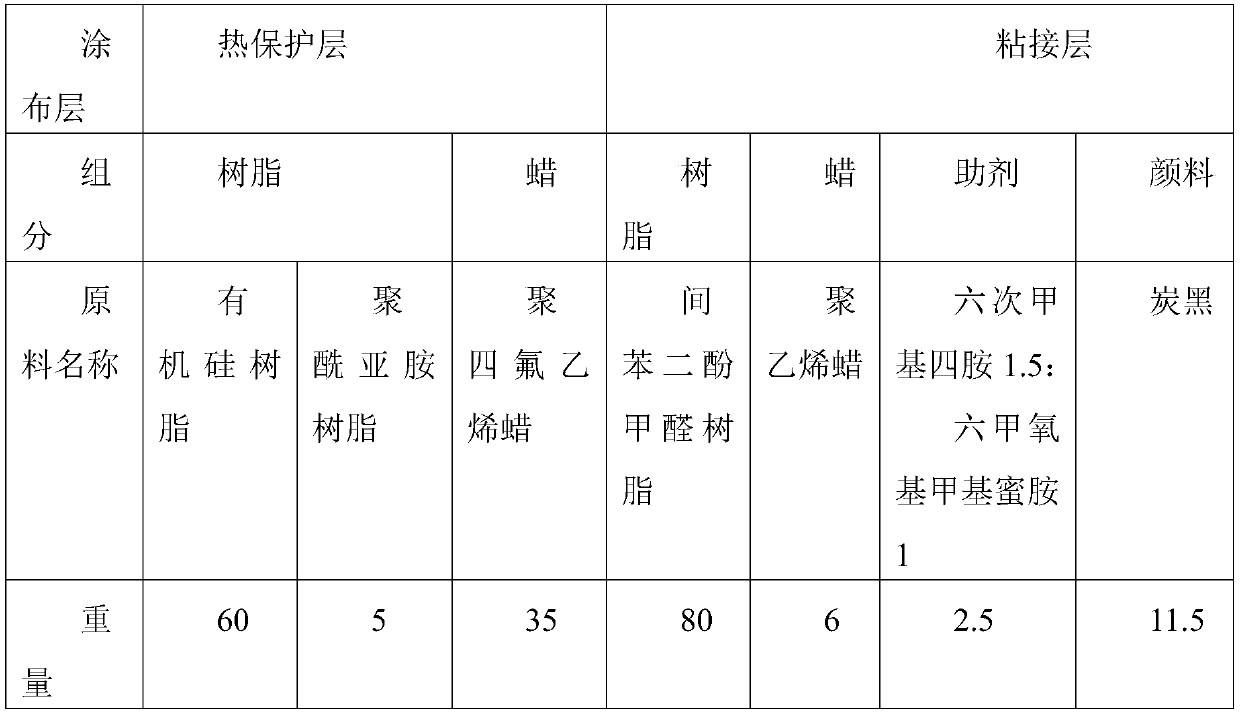

Marking film for surface of hard smooth substrate

ActiveCN110776835AAvoid damageAdequate bond strengthNon-macromolecular adhesive additivesFilm/foil adhesive primer layersEtchingThin membrane

The invention aims at the limitation that a thermal transfer ribbon is difficult to apply to the surfaces of substrates such as metal in the prior art, and provides a marking film for the surface of ahard smooth substrate. A method for preparing the marking film comprises the following steps: printing marking information on the surface of a TPU thin film through heat transfer printing via a thermal transfer ribbon, then carrying out heating and pressurizing to enable the TPU thin film to be melted and to be bonded with the surface of metal, and carrying out cooling to obtain the marking film.The thermal transfer ribbon comprises a ribbon base, wherein the two sides of the ribbon base are coated with a back coating and a thermal transfer layer respectively, and the thermal transfer layeris sequentially composed of a protective layer and a bonding layer from inside to outside from the surface of one side of the ribbon base. The marking film can reach the bonding strength required in application, is good in corrosion resistance, and avoids damage caused by chemical etching.

Owner:JIAOZUO ZHUOLI STAMPING MATERIAL CO., LTD.

Impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides an impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, and the second coating permeates into net holes of the network structure. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

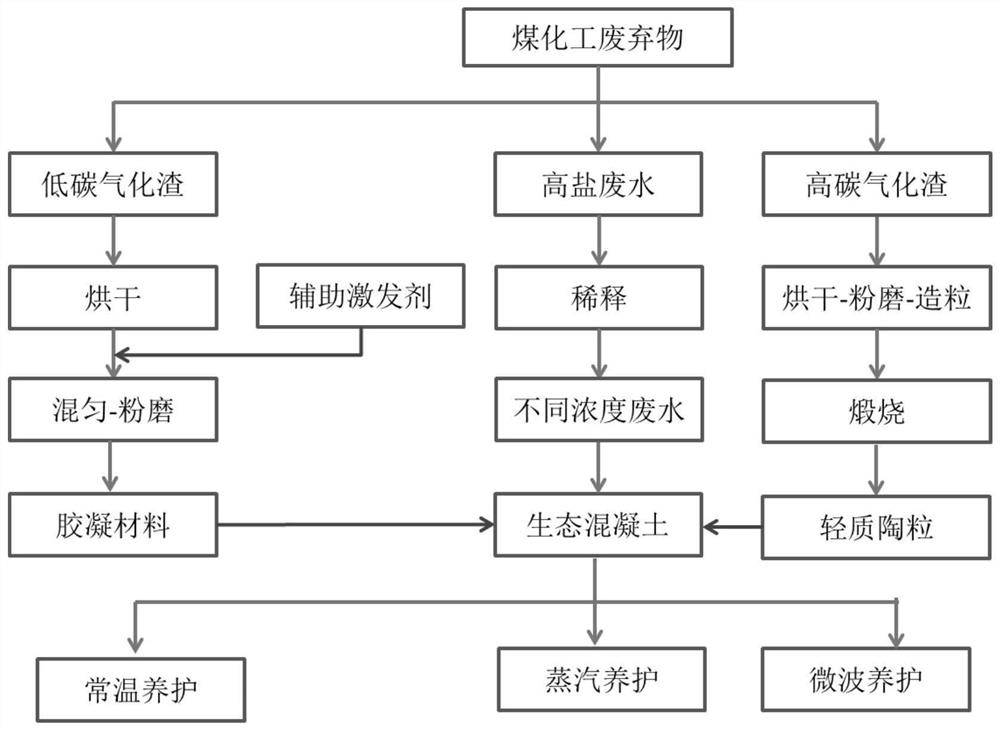

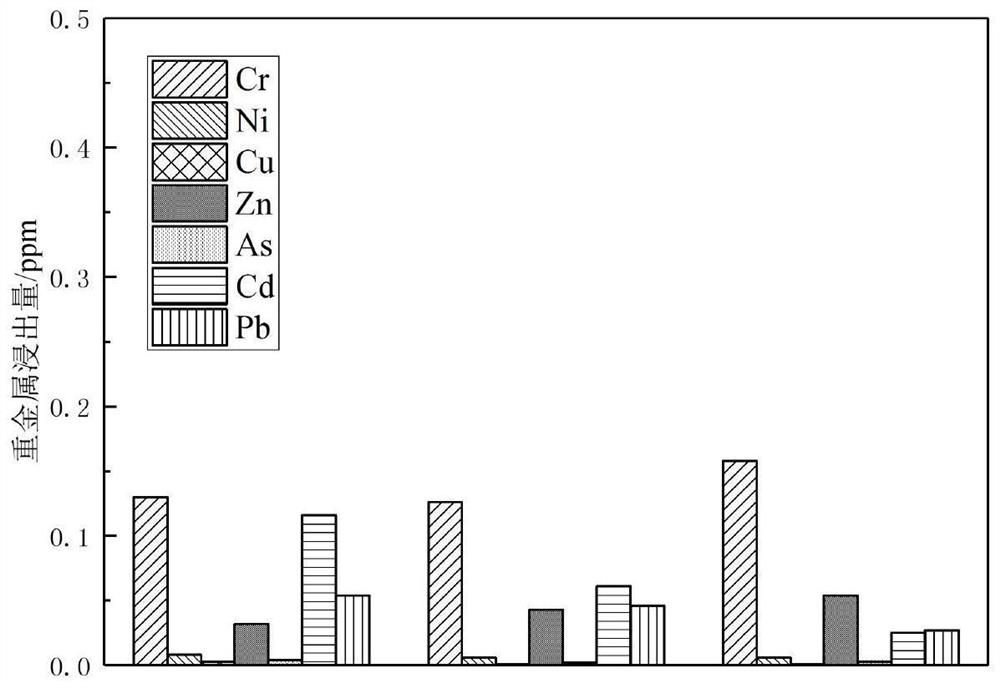

Method for preparing ecological concrete by synergistically utilizing coal chemical industry waste residues and waste water

ActiveCN113072313AHigh strengthReduce carbon residueSolid waste managementCement productionWastewaterCoal chemical industry

The invention discloses a method for preparing ecological concrete by synergistically utilizing coal chemical industry waste residues and wastewater. The method comprises the following steps: preparing a cementing material by using low-carbon coal gasification residues generated in a coal chemical industry process as a main cementing material and a small amount of excitant as an auxiliary material, sintering high-carbon coal gasification residues to prepare lightweight aggregate with light weight and high strength, adopting coal chemical industry high salinity wastewater as mixing water, proportioning according to a certain ratio to prepare the ecological concrete, and curing by using different curing systems to treat waste with waste so as to achieve the purposes of harmless treatment and resource utilization of coal chemical industry waste.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Waterproof impregnated coated sandwich wall cloth and manufacturing method thereof

The invention provides a waterproof impregnated coated sandwich wall cloth and a method for manufacturing the impregnated coated sandwich wall cloth, or an object decoration method. The waterproof impregnated coated sandwich wall cloth comprises a bottom coating and an impregnated coated composite sandwich coating complex, wherein the surface of the bottom coating is coated with the impregnated coated composite sandwich coating complex; and the impregnated coated composite sandwich coating complex comprises a transparent or translucent second coating and a fiber texture network sandwich wrapped by the second coating, wherein the fiber texture network sandwich contains a network structure formed by fiber, the second coating permeates into net holes of the network structure, and one or moreof the second coating and the bottom coating can be waterproof coatings. The wall cloth with textures and / or patterns can be manufactured in standardized and large-scale modes, and the waterproof impregnated coated sandwich wall cloth has good anti-cracking performance, air-permeable performance and decoration performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

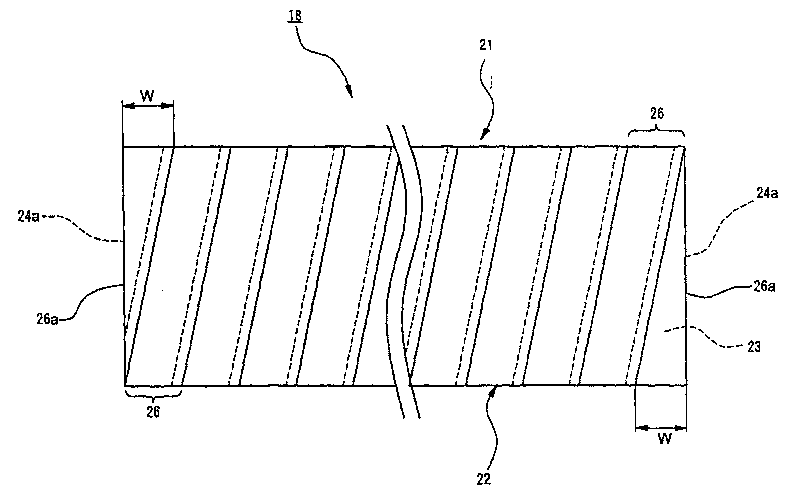

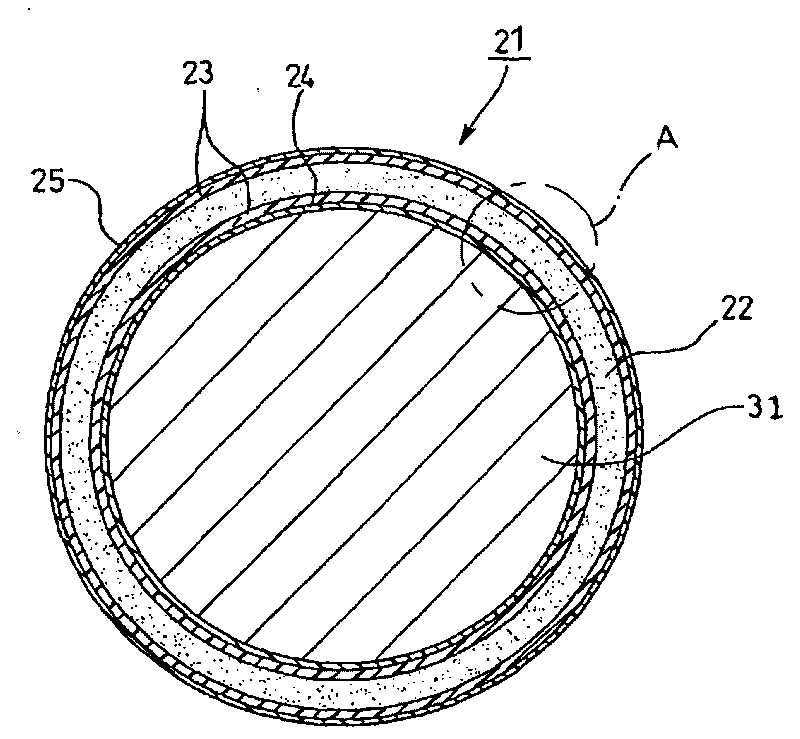

Reinforced compound pipe and manufacture device thereof

ActiveCN101694252AReduce the ratio of air bubblesExpected watertightnessSynthetic resin layered productsRigid pipesFiberInorganic materials

The invention provides a reinforced compound pipe with uniform thickness and a manufacture device thereof. The reinforced compound pipe comprises an inner resin soaking stiffener layer, a resin mortar layer and an outer resin soaking stiffener layer, wherein the inner resin soaking stiffener layer is formed by winding fibers soaked with resin; the resin mortar layer is formed in a such way that a mixture mixed with the resin in sand materials or particle inorganic materials are limited in a thickness direction dimension and a width direction dimension to form strip-shaped resin mortar, the strip-shaped resin mortar is spirally winded on the outer surface of the inner resin soaking stiffener layer; and the outer resin soaking stiffener layer is formed by winding the fibers soaked with the resin outside the resin mortar layer. The inner resin soaking stiffener layer, the resin mortar layer and the outer resin soaking stiffener layer are laminated together.

Owner:SEKISUI CHEM CO LTD

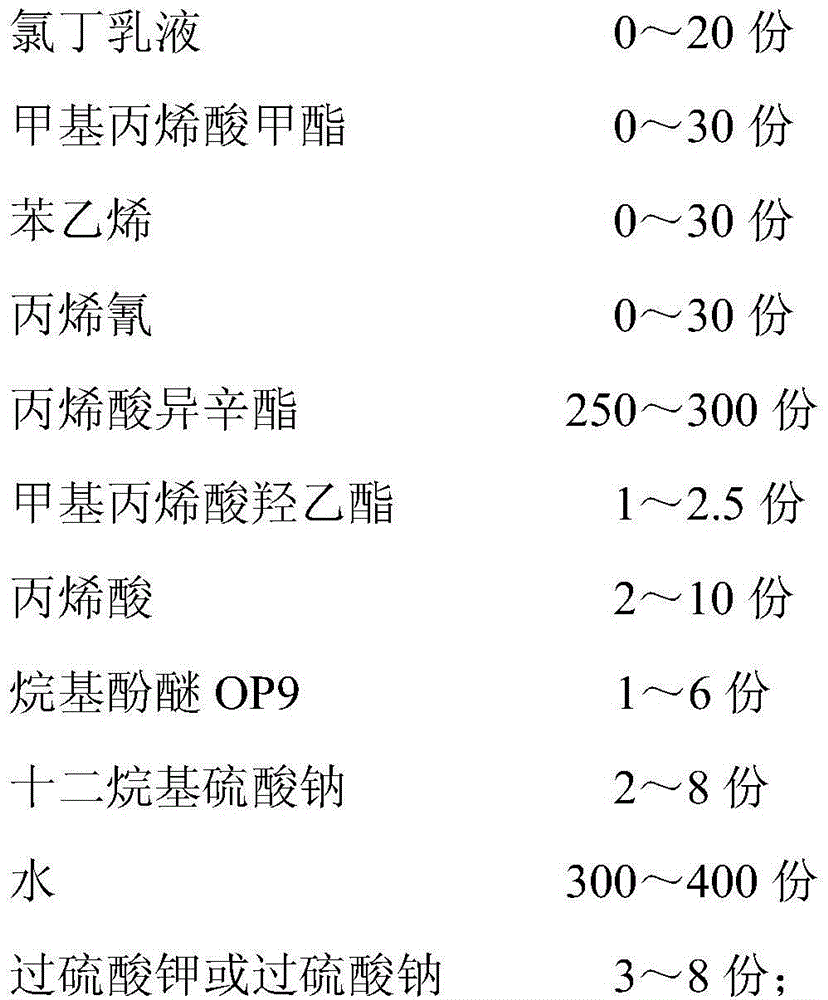

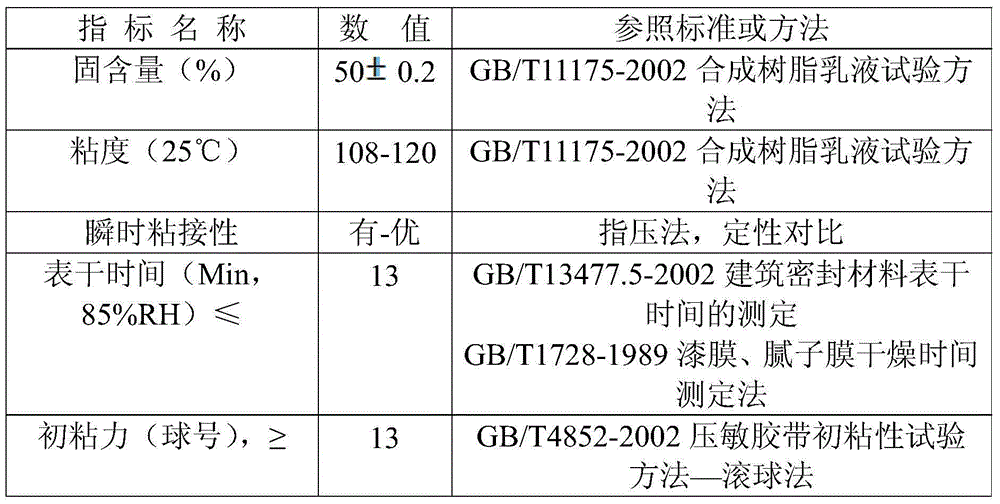

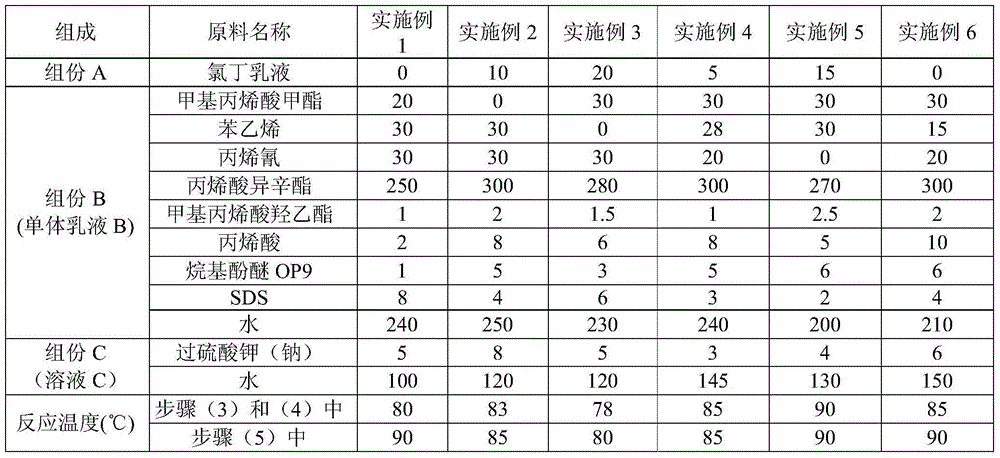

Quick-sticking type modified chloride butyl acrylic emulsion as well as preparation method and application thereof

InactiveCN104448152AFast bondingAdequate adhesionGraft polymer adhesivesIsooctyl acrylatePotassium persulfate

The invention belongs to the technical field of emulsion adhesives and particularly relates to a quick-sticking type modified chloride butyl acrylic emulsion as well as a preparation method and an application thereof. The emulsion is prepared from the following components in parts by mass: 0-20 parts of chloride butyl emulsion, 0-30 parts of methyl methacrylate, 0-30 parts of styrene, 0-30 parts of acrylonitrile, 250-300 parts of ethylhexyl acrylate, 1-2.5 parts of hydroxyethyl methylacrylate, 2-10 parts of acrylic acid, 1-6 parts of alkylphenol ether OP, 2-8 parts of lauryl sodium sulfate, 300-400 parts of water, 3-8 parts of potassium persulfate or sodium persulfate, wherein the solid content of the chloride butyl emulsion is 50%. The preparation method of the quick-sticking type modified chloride butyl acrylic emulsion has the advantages of being convenient and quick, relatively high in reaction efficiency, small in monomer residue and uniform in product appearance. The obtained modified chloride butyl acrylic emulsion has the advantages of being stable, quick in sticking and strong in adhesive strength, capable of meeting the comprehensive requirements of a high-performance chloride butyl acrylic emulsion adhesive.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Electromagnetic shielding impregnation coating sandwich wall cloth and manufacturing method thereof

The invention provides an electromagnetic shielding impregnation coating sandwich wall cloth and a method of manufacturing the electromagnetic shielding impregnation coating sandwich wall cloth or anobject decoration method. The electromagnetic shielding impregnation coating sandwich wall cloth comprises a bottom coating and an impregnation coating composite sandwich coating composite body applied to the surface of the bottom coating; and the impregnation coating composite sandwich coating composite body comprises a transparent or semitransparent second coating and a fiber texture network sandwich wrapped in the second coating, the fiber texture network sandwich comprises a network structure formed through fibers, the second coating permeates into net holes of the network structure, and one or more of the bottom coating, the second coating and the fiber texture network sandwich have an electromagnetic shielding function. According to the electromagnetic shielding impregnation coatingsandwich wall cloth and the method, the wall cloth with textures and / or patterns can be manufactured in a standardized and large-scale manner, and the wall cloth has the good anti-cracking performance, air permeability and decorative performance.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Scrawling preventing infiltration coating sandwiched wall cloth and manufacturing method thereof

PendingCN110158885AAdequate adhesionAvoid crackingLiquid surface applicatorsCovering/liningsCoated surfaceFiber

The invention provides scrawling preventing infiltration coating sandwiched wall cloth and a method for manufacturing the scrawling preventing infiltration coating sandwiched wall cloth or an object decoration method. The scrawling preventing infiltration coating sandwiched wall cloth comprises a bottom coating and an infiltration coating composite sandwiched coating composite body applied to thesurface of the bottom coating. The infiltration coating composite sandwiched coating composite body comprises a transparent or semitransparent scrawling preventing coating and a fiber texture networksandwiched core wrapped by the scrawling preventing coating, wherein a network structure formed by fiber is contained in the fiber texture network sandwiched core, and the scrawling preventing coatingseeps into meshes of the network structure. By means of the method, the wall cloth with texture and / or patterns can be manufactured in a standard and large-scale manner, and good crack resisting performance, ventilation performance and decoration performance are achieved.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and manufacturing method thereof

The invention provides a magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth and a manufacturing method thereof or an object decorating method. The magnetic attracting wall-mounted infiltrated and coated sandwich wall cloth comprises a bottom coating and an infiltrated and coated compound sandwich painting complex coated on the surface of the bottom coating; the infiltratedand coated compound sandwich painting complex comprises a transparent or semitransparent second coating and a fiber texture mesh sandwich wrapped by the second coating, wherein the fiber texture meshsandwich includes a mesh structure formed by fibers inside; the second coating infiltrates into mesh openings of the mesh structure; and one or several of the second coating, the bottom coating and the fiber texture mesh sandwich can possess magnetic attracting performance. The manufacturing method disclosed by the invention is capable of manufacturing the wall cloth with textures and / or patternson a large scale in a standardizing manner, and the wall cloth has good anti-cracking ability, air permeability and decorating property.

Owner:SUZHOU HONGNI NEW MATERIAL TECH LTD CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com