Method for preparing ecological concrete by synergistically utilizing coal chemical industry waste residues and waste water

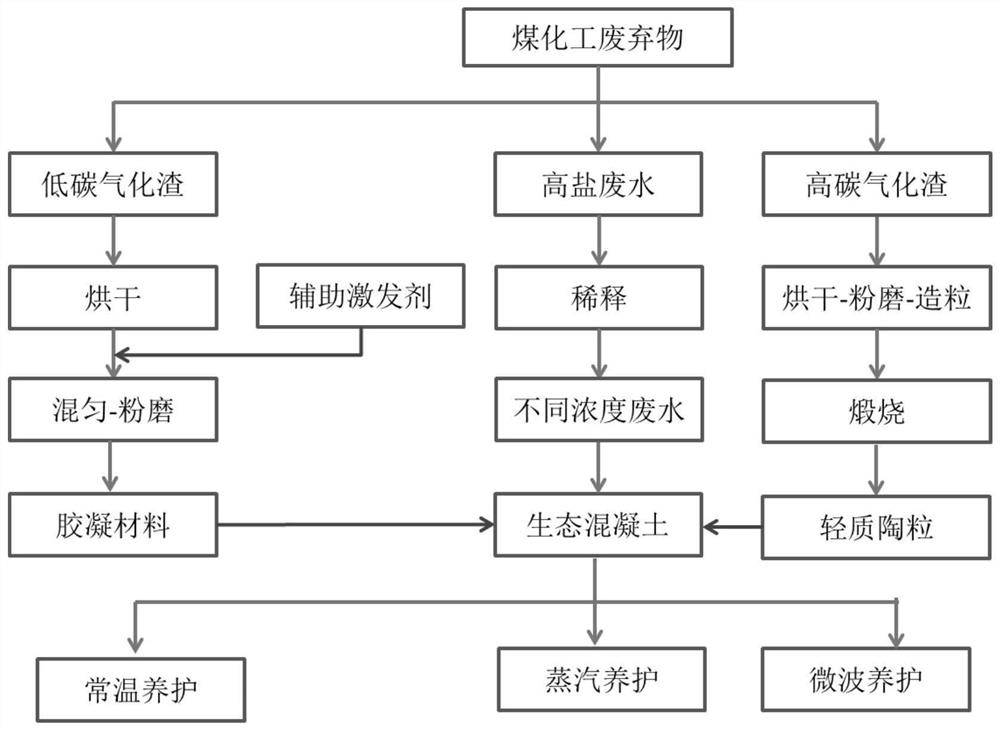

A technology of ecological concrete and coal chemical industry, which is applied in the field of solid waste resource utilization and new building materials, and can solve the problems affecting the utilization technology of building materials and low concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for synergistically utilizing coal chemical waste residue and waste water to prepare ecological concrete, comprising the following steps:

[0038] (1) Dry the low-carbon gasification slag in a drying oven at 105°C, and grind it until the specific surface area is 320m 2 After / kg, add calcium hydroxide, low-carbon gasification slag and calcium hydroxide mass ratio are 19:1, obtain cementitious material;

[0039] (2) Dry the high-carbon gasification slag in a drying oven at 105°C, and grind it until the specific surface area is 320m 2 / kg, put it into a disc granulator for granulation treatment, and make raw meal balls with a diameter of 10mm. After aging for 24 hours, carry out two-stage calcination, specifically: heat up to 600°C at a rate of 10°C / min , keep warm for 30min; heat up to 1120°C at a rate of 20°C / min, keep warm for 30min; then cool naturally to below 50°C to obtain a bulk density of 928kg / m 3 , cylinder compressive strength 11.59MPa, light cerams...

Embodiment 2

[0042] A method for synergistically utilizing coal chemical waste residue and waste water to prepare ecological concrete, comprising the following steps:

[0043] (1) Dry the low-carbon gasification slag in a drying oven at 105°C, and grind it until the specific surface area is 320m 2 After / kg, add calcium hydroxide and sodium hydroxide, low-carbon gasification slag and calcium hydroxide and sodium hydroxide mass ratio are 9:1, obtain cementitious material;

[0044] (2) Dry the high-carbon gasification slag in a drying oven at 105°C, and grind it until the specific surface area is 320m 2 / kg, put it into a disc granulator for granulation treatment, and make raw meal balls with a diameter of 10mm. After aging for 24 hours, carry out two-stage calcination, specifically: heat up to 550°C at a rate of 10°C / min , keep warm for 30min; heat up to 1130°C at a rate of 20°C / min, keep warm for 30min; then cool naturally to below 50°C to obtain a bulk density of 920kg / m 3 , cylinder com...

Embodiment 3

[0047] A method for synergistically utilizing coal chemical waste residue and waste water to prepare ecological concrete, comprising the following steps:

[0048] (1) Dry the low-carbon gasification slag in a drying oven at 105°C, and grind it until the specific surface area is 320m 2 After adding Portland cement and sodium hydroxide, the mass ratio of low-carbon gasified slag to Portland cement and sodium hydroxide is 9:1 to obtain a cementitious material;

[0049] (2) Dry the high-carbon gasification slag in a drying oven at 105°C, and grind it until the specific surface area is 320m 2 / kg, put it into a disc granulator for granulation treatment, and make raw meal balls with a diameter of 10mm. After aging for 24 hours, carry out two-stage calcination, specifically: heat up to 550°C at a rate of 10°C / min , keep warm for 30min; heat up to 1130°C at a rate of 20°C / min, keep warm for 30min; then cool naturally to below 50°C to obtain a bulk density of 920kg / m 3 , cylinder com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com