Self-adhesion modularized crystalline silicon solar cell component

A technology of solar cells and crystalline silicon cells, applied in the support structure of photovoltaic modules, photovoltaic modules, electrical components, etc., can solve the problems of difficult solar module installation costs, difficult installation of photovoltaic products, and difficult consumer acceptance, etc. The effect of adding roof load, large construction freedom and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The inventive spirit of the present invention can be better understood in conjunction with the accompanying drawings and the embodiments. The embodiments are only used to illustrate how the present invention can be better realized, and do not limit the present invention to be implemented only by the following methods. Changes, substitutions, equivalent transformations, etc. made by those skilled in the art on the basis of understanding the essence and spirit of the present invention still belong to the protection scope of the present invention.

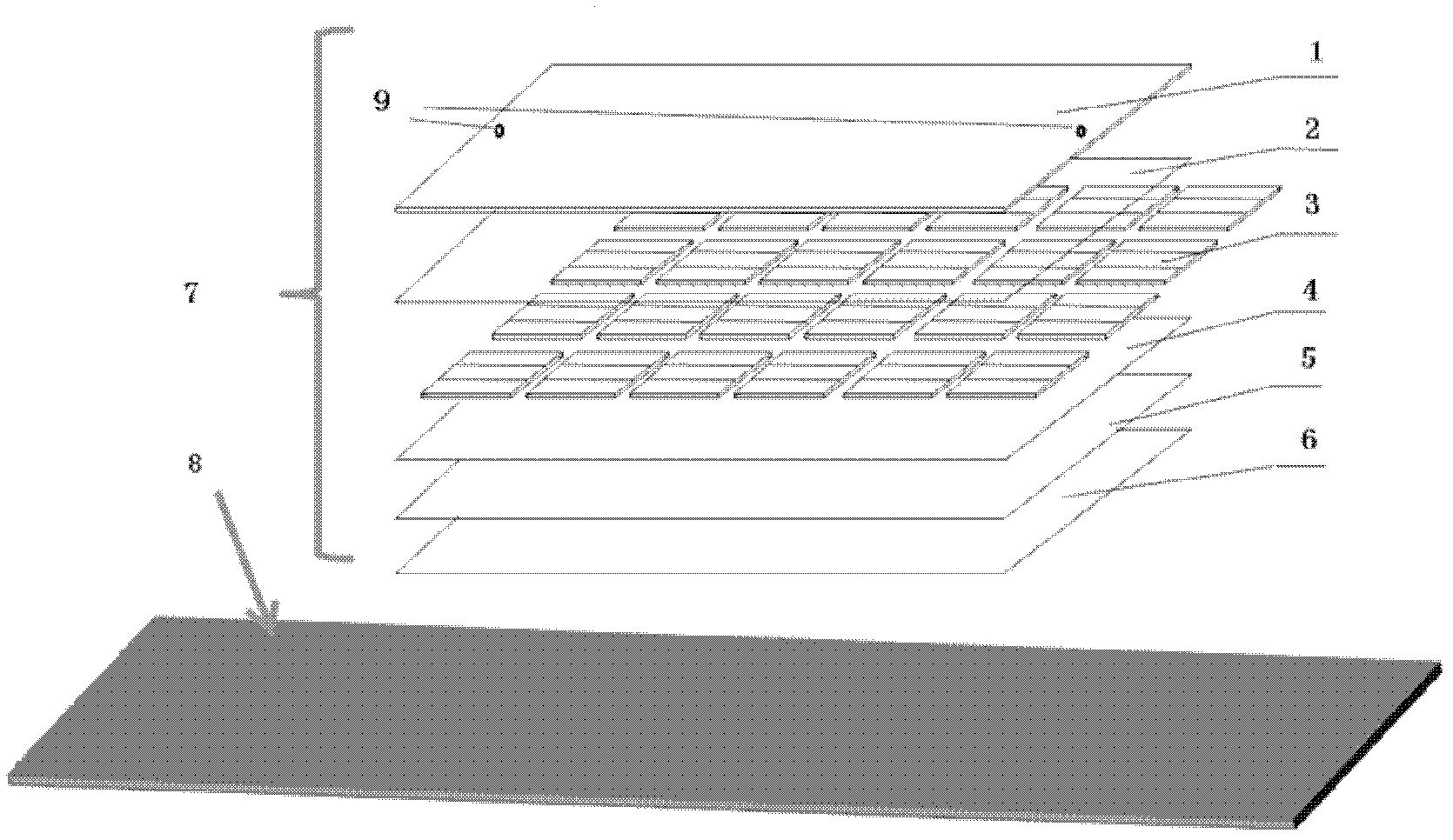

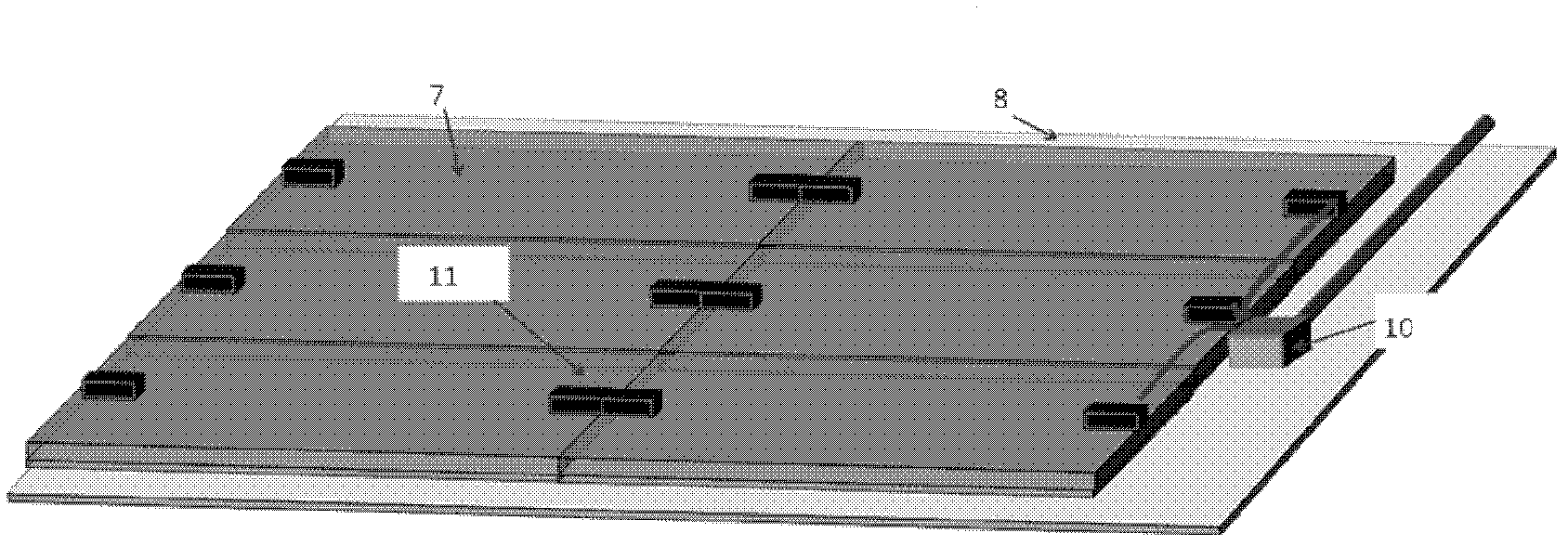

[0029] refer to figure 1, discloses the decomposition structure of the self-adhesive modular solar cell module of the present invention, which is installed on the light steel structure roof 8, wherein the bottom of the self-adhesive modular solar cell module 7 is composed of creep rubber The self-adhesive layer 6, the self-adhesive layer 6 is covered with TPT (polyvinyl fluoride composite film) 5, on the TPT is provided with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com