Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

572results about How to "No delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

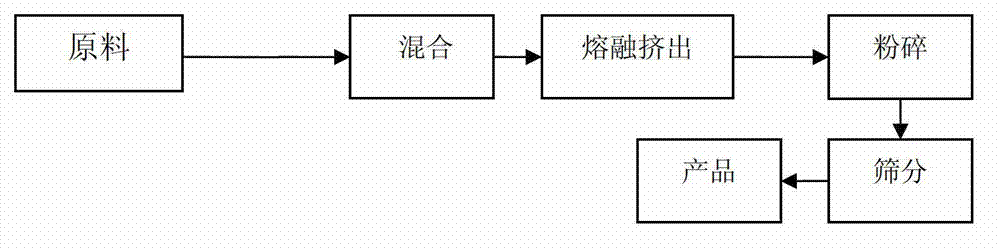

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

Pulp for lithium ionic cell electrode and manufacturing method thereof

ActiveCN101393978AEasy to useReduce dosageElectrode manufacturing processesActive material electrodesAdhesiveColloid

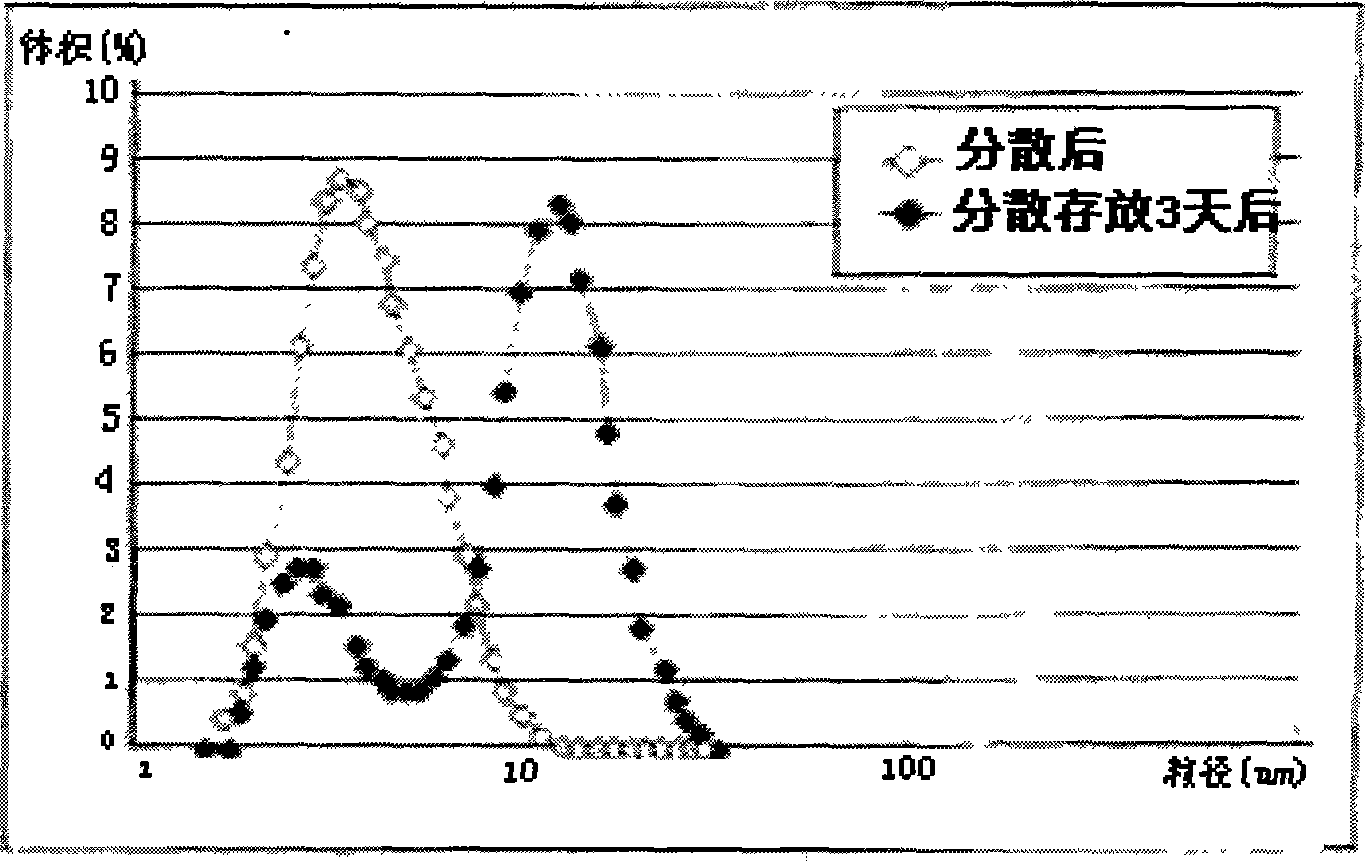

A sizing material for electrodes of a lithium ion battery mainly comprises an active material, a conductive agent, an adhesive and a solvent, and is characterized in that the distribution ratio of the active material, the conductive agent, the adhesive and the solvent is 100 : 0-4 : 1-7 : 35-100. The preparation process thereof comprises the following steps: 1) mixing the adhesive with partial solvent to prepare a glue body with the viscosity of 1 to 10 percent; 2) mixing the conductive agent weighed according to the distribution ratio with the glue body prepared in the step 1) and stirring to form a conductive glue; 3) mixing the active material and the rest solvent weighed according to the distribution ratio with the conductive glue and stirring to form a premixed sizing material; 4) introducing the premixed sizing material into a dispersion machine rotating at a high speed to conduct dispersion; 5) cooling and vacuumizing the dispersed sizing material to form the sizing material for the electrodes of the lithium ion battery. The sizing material has the better use performance, and the preparation method thereof solves the defect in the traditional mixture that the layering of the conductive agent is easily caused by a larger density difference when the conductive agent is mixed with the active material and the like, thereby ensuring the uniform distribution of each ingredient of the sizing material.

Owner:ZHENGZHOU BAK BATTERY CO LTD

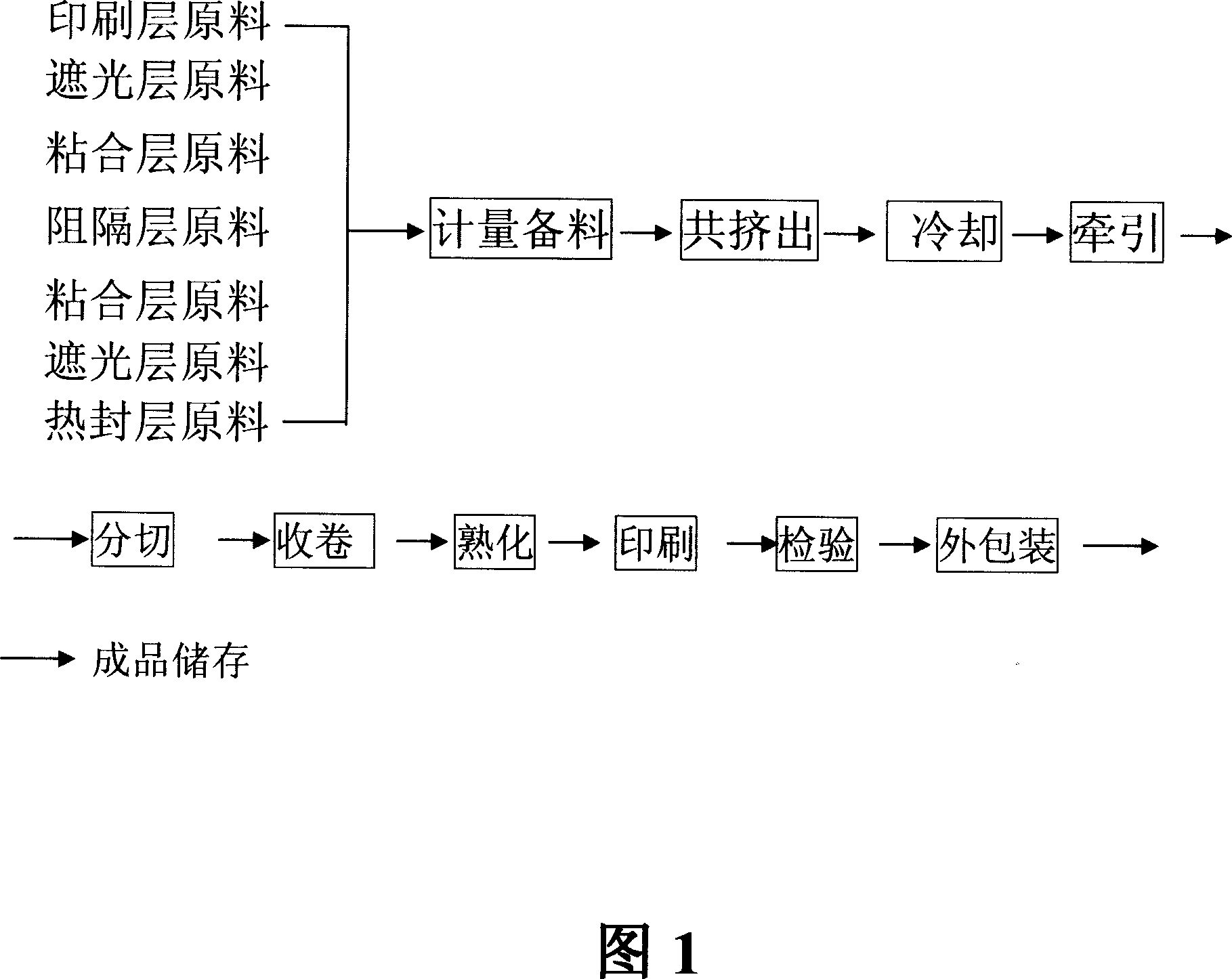

Seven-layer co-extrusion high-isolating packaging film

The seven layer high obstruct packing film includes the first printing layer made of LLDPE, LDPE and FSU; the second shading layer made of white color, LLDPE and LDPE; the third adhering layer of adhesive Tie; the fourth obstructing layer comprising EVOH; the fifth adhering layer of adhesive Tie; the sixth shading layer made of black color, LLDPE and LDPE; and the seventh thermal sealing layer made of LLDP, LDPE and FSU. The present invention possesses the advantages of non-toxicity, high humidity resistance, high oxygen resistance, high heat resistance, high flexibility, high cold resistance and high thermal sealing strength, and is used in packing milk without need of adding preservative and being cold stored.

Owner:郭瑞林

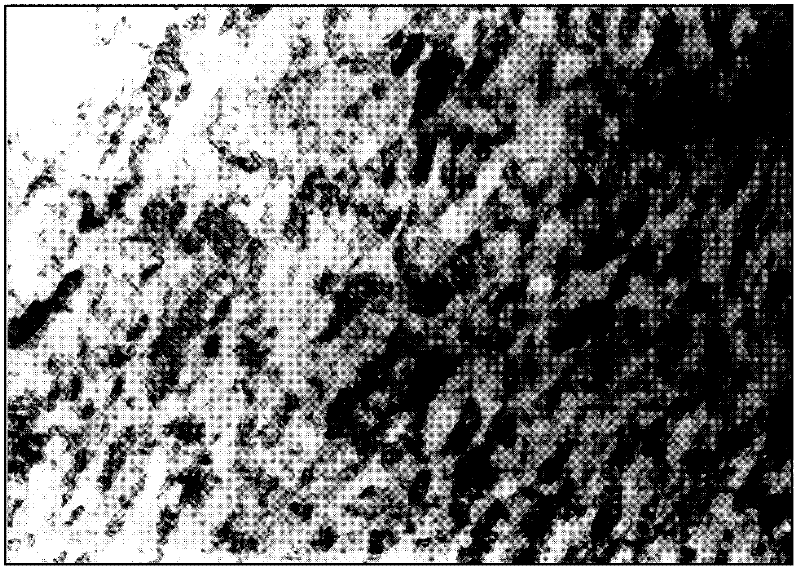

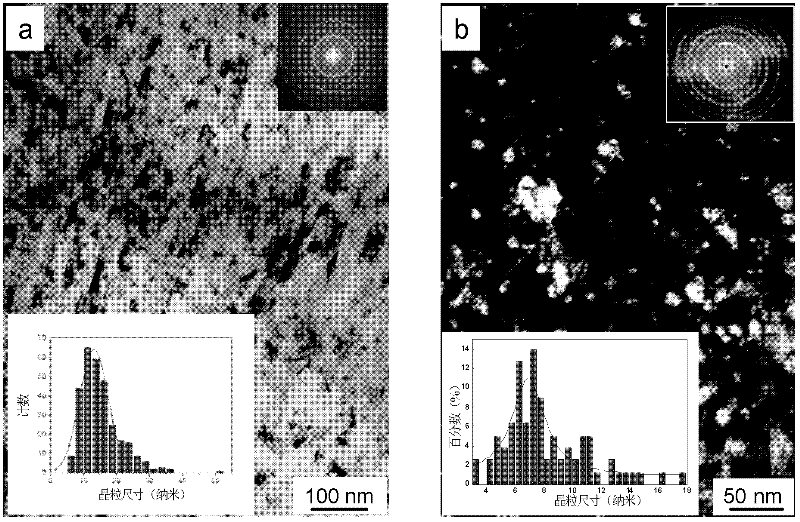

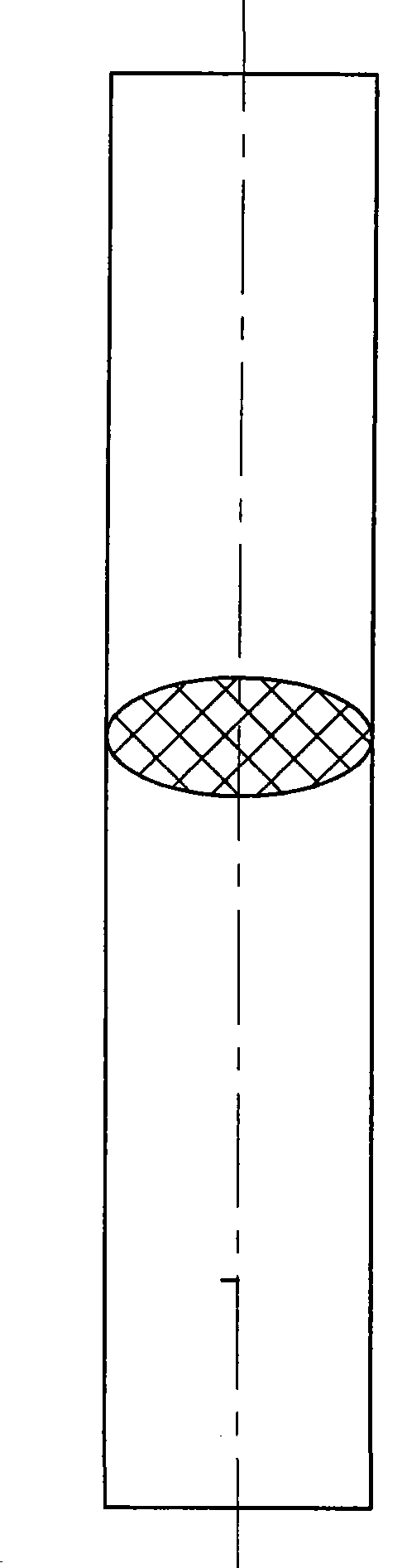

Method for forming nanometer gradient structure on surface layer of shaft metallic material

The invention relates to a surface treatment method for forming a nanometer gradient structure on a surface layer of a shaft metallic material. The invention aims to solve the problems that the surface roughness of the material to be treated is higher, the surface smoothness is not high and a nanometer crystal structure is difficult to form on the surface of a workpiece in the prior art. A spherical treatment tool is adopted to roll on the surface of the rotary shaft metallic material, and meanwhile, the spherical treatment tool moves along the axial direction of the workpiece, and plastic deformation is generated on the surface layer of the material, so that grains on the surface layer of a workpiece material are refined to form the nanometer gradient structure, wherein the depth of the deformation layer of the nanometer gradient structure reaches 100-300 micrometers; and the grains on the surface layer of the workpiece material are nanometer grains, submicron grains, deformation grains and initial grains in sequence in size from the surface to the inside. According to the processing method provided by the invention, the integral mechanical property of the material is improved through improving the microstructure of the surface layer, thereby, the service life of the material is prolonged. The processing method provided by the invention is small in investment and is simple and convenient in operation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

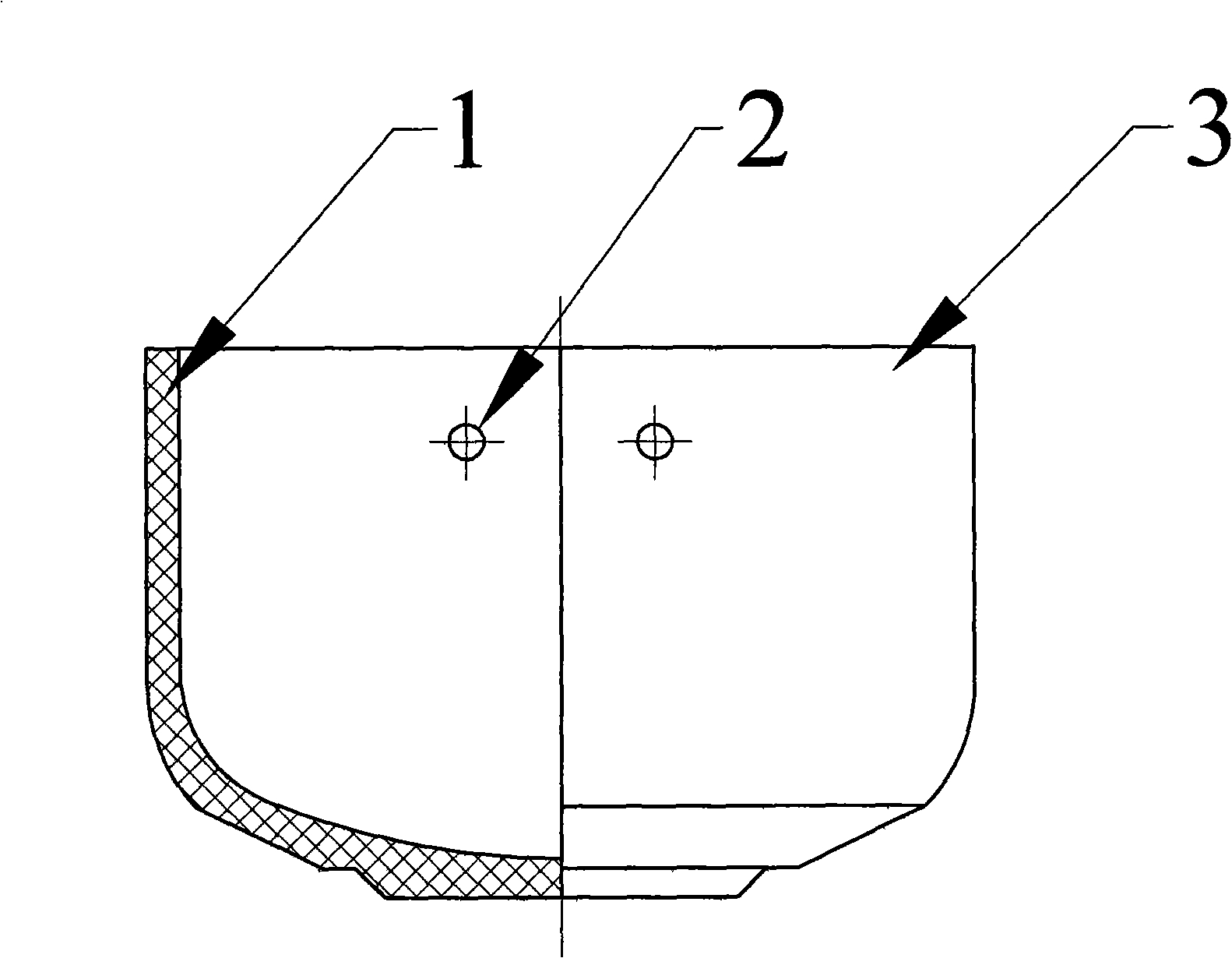

Carbon/carbon composite material crucible pot and preparing technique thereof

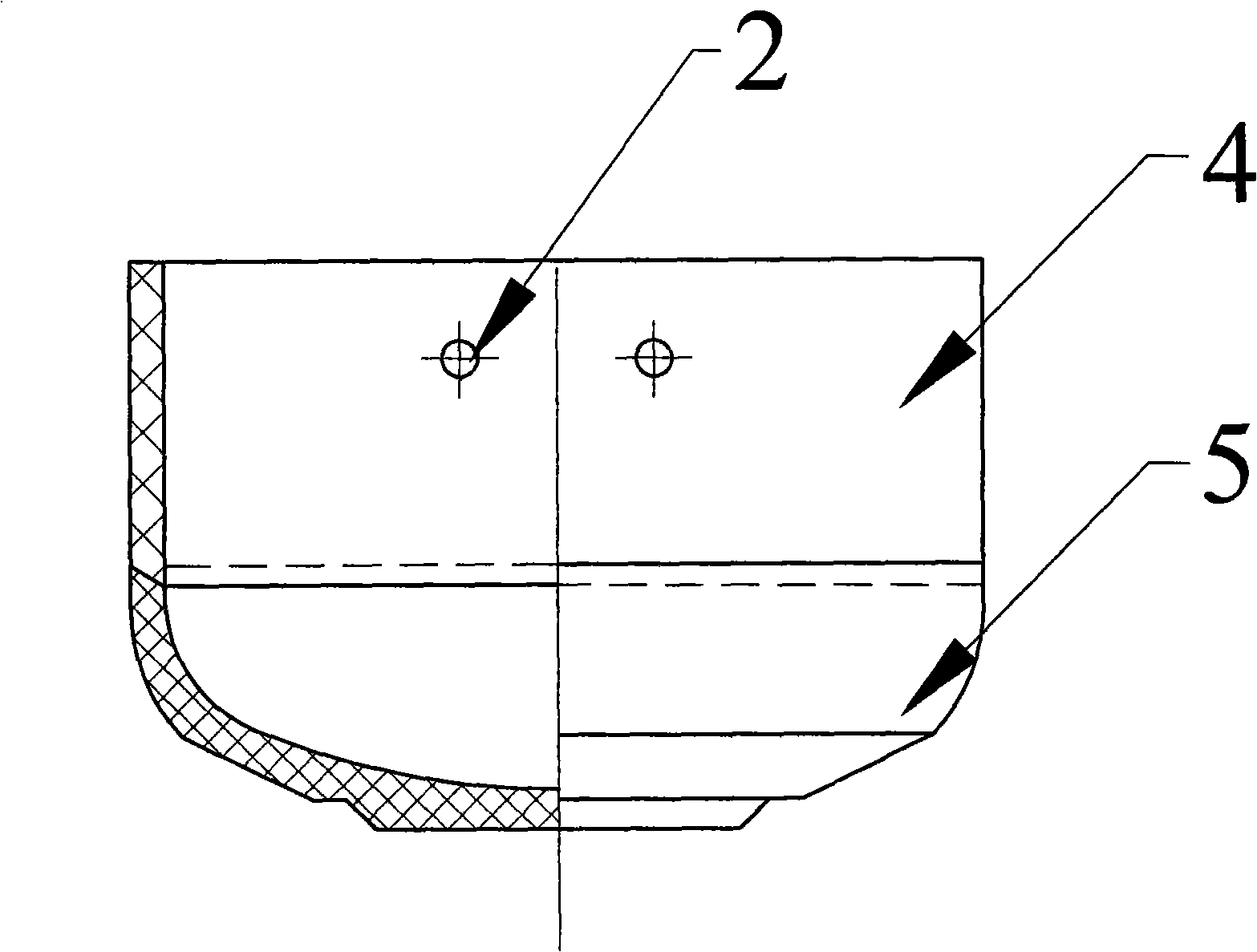

The invention discloses a carbon / carbon composite material crucible with simple technique and environmental protection and a technique for producing the same. The carbon / carbon composite material crucible can be prepared into a whole, or consists of 2 to 4 sections or consists of an upper part and a lower part which are relatively a bowl-shaped tray (5) and a cylinder (4). The technique for producing the carbon / carbon composite material crucible is as follows: the carbon / carbon composite material crucible is prepared through performing, densifying, purifying and machining of carbon fibers. The production technique has a simple technique; under the condition of performing, a mat which is formed by fluffy needlelike carbon fibers is adopted, thereby a quasi-three-dimensional prefabricated part is easy to obtain under the condition of needling; internal carbon fibers of the quasi-three-dimensional prefabricated part are interlaced, have strong cohesive force, can not be delaminated, and have stable structures; simultaneously, the pore space of the prefabricated part is small, which is convenient for accelerating the subsequent process of the densifying; and the purity of the crucible after the densifying is very high, and the carbon / carbon composite material crucible with an ash content less than 180 ppms can be produced only through high-temperature purification under the condition of vacuum or protective atmosphere; and the carbon / carbon composite material crucible is energy-saving and environment-friendly.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

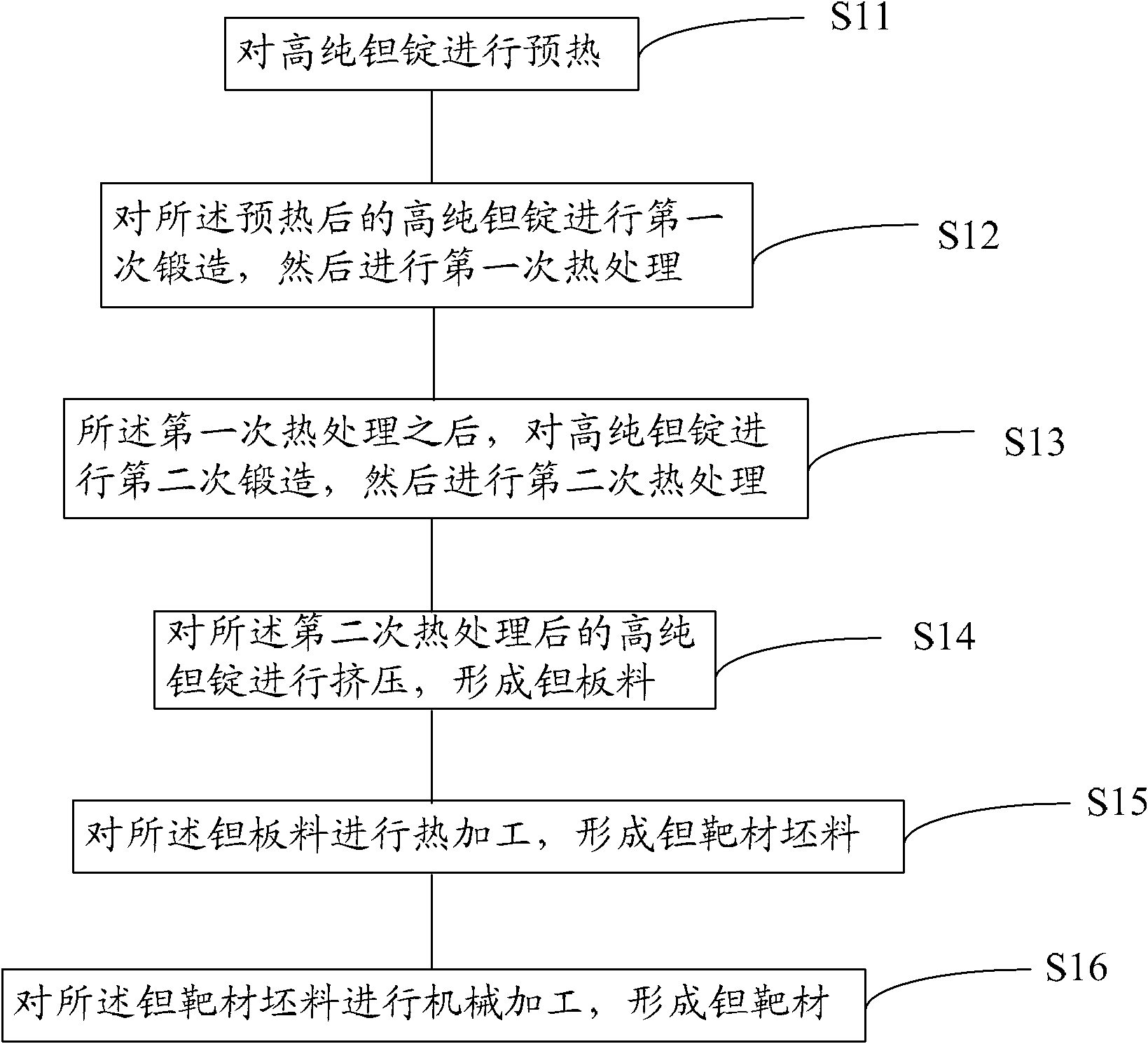

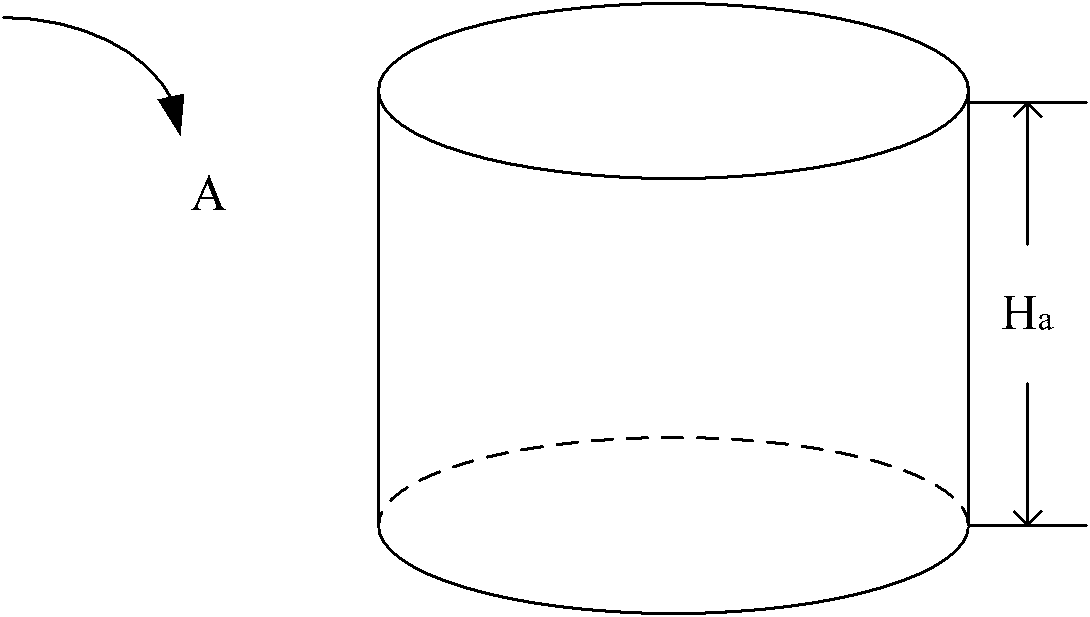

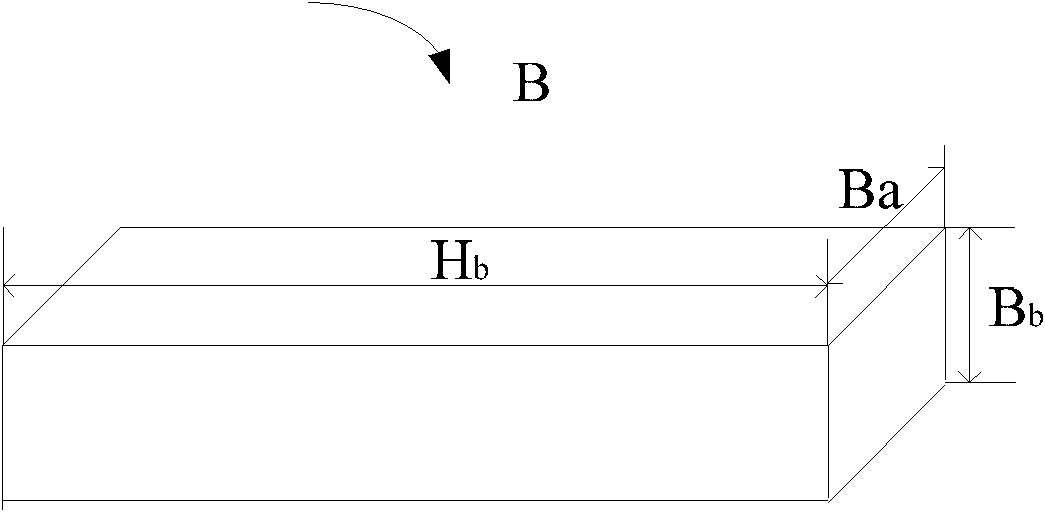

Method for preparing high-purity tantalum target

ActiveCN102517531ADense tissue structureFine and uniform grainVacuum evaporation coatingSputtering coatingSputteringCrystal orientation

A method for preparing a high-purity tantalum target comprises the following steps: preheating high-purity tantalum ingots; forging the preheated high-purity tantalum ingots by at least two times, wherein the high-purity tantalum ingots are heated after being forged each time; extruding the high-purity tantalum ingots after the high-purity tantalum ingots are heated for the last time, so as to obtain a tantalum board; heating the tantalum board to obtain a tantalum target blank; and machining the tantalum target blank to obtain the tantalum target. According to the process for preparing the tantalum target, the uniformity and the compactability of the tantalum target can be better, so as to meet the crystal particle requirements and the crystal orientation requirements of the tantalum target for semi-conductor sputtering.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Composite aerogel thermal insulation coating and preparation method thereof

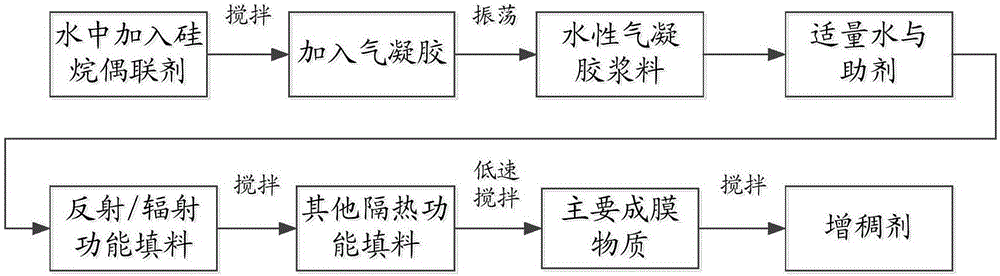

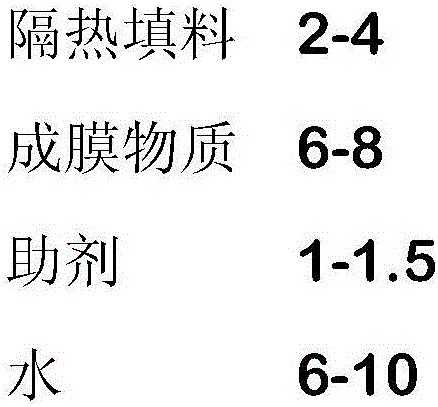

InactiveCN106752561AStable storageNo delaminationFireproof paintsAlkali metal silicate coatingsWater basedThermal insulation

The invention relates to composite aerogel thermal insulation coating and a preparation method thereof. The coating has good heat insulation performance, high reflection performance and high radiation performance, contains aerogel, and belongs to the technical field of heat insulation of building materials. The preparation method mainly comprises the steps of preparing water-based aerogel slurry, selecting filler with a high reflection / high radiation function, and selecting other filler with an auxiliary heat insulation function. The filler with the high reflection / high radiation function comprises one or more of high white aluminum silicate, titanium dioxide and zinc oxide; the filler with the auxiliary heat insulation function comprises one or more of glass microbeads, ceramic microbeads, expanded perlite and expanded vermiculite. Water glass and silicone acrylic emulsion (or pure acrylic emulsion) are used as film forming matters at the same time. In the step of preparing the water-based aerogel slurry, a silane coupling agent is taken as a dispersing agent.

Owner:BEIJING SATELLITE MFG FACTORY

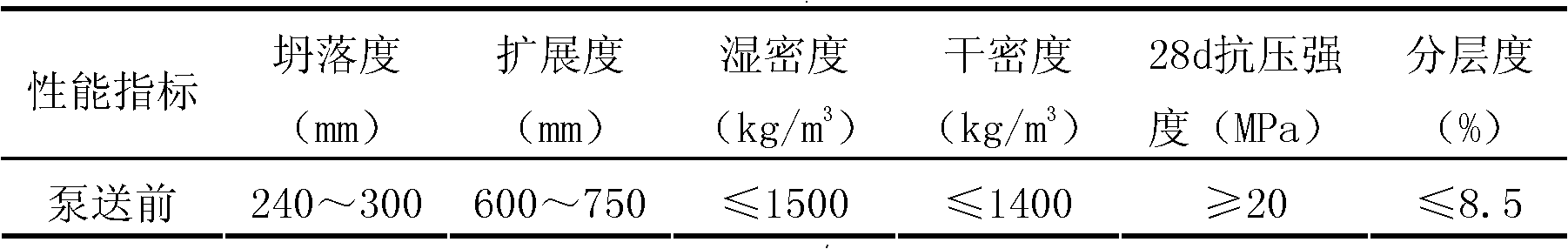

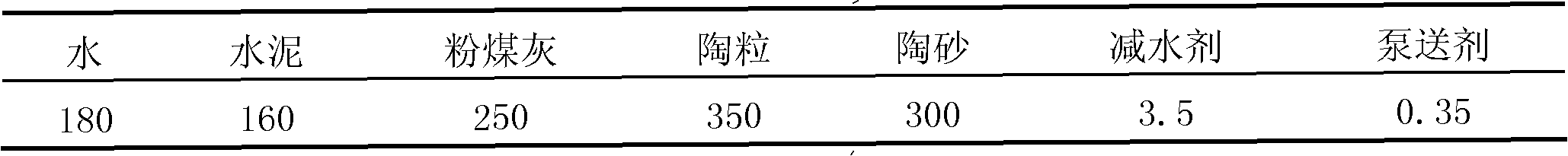

Super-light aggregate concrete for long-distance homogeneous pumping construction and preparation method thereof

InactiveCN101928127AConvenience to workImprove homogeneitySolid waste managementBuilding material handlingExpanded clay aggregateWater reducer

The invention belongs to the technical field of concrete and in particular relates to a super-light aggregate concrete for long-distance homogeneous pumping construction, a preparation method thereof and a pumping construction process. The super-light aggregate concrete for the long-distance homogeneous pumping construction is characterized by being prepared from water, a gel material, a fine aggregate, a coarse aggregate and an additive, wherein the gel material consists of cement and fly ash; the coarse aggregate is super-light ceramic particles; the fine aggregate is ceramic sand; the additive is a pumping agent and a water reducing agent; each cubic meter of concrete comprises 180 to 250kg of water, 160 to 250kg of cement, 250 to 320kg of fly ash, 350 to 450kg of super to light ceramic particle, 300 to 400kg of ceramic sand, 3.5 to 4.5kg of water reducing agent and 0.35 to 0.45kg of pumping agent. In a pumping process, the super-light aggregate concrete prepared by the method has relatively good working performance and homogeneity. The problems of easy blockage of a pump, high slump loss, layered concrete and the like in the pumping construction process of the super-light aggregate concrete are solved.

Owner:WUHAN HAIJIAN ENVIRONMENTAL PROTECTION MATERIALS CO LTD

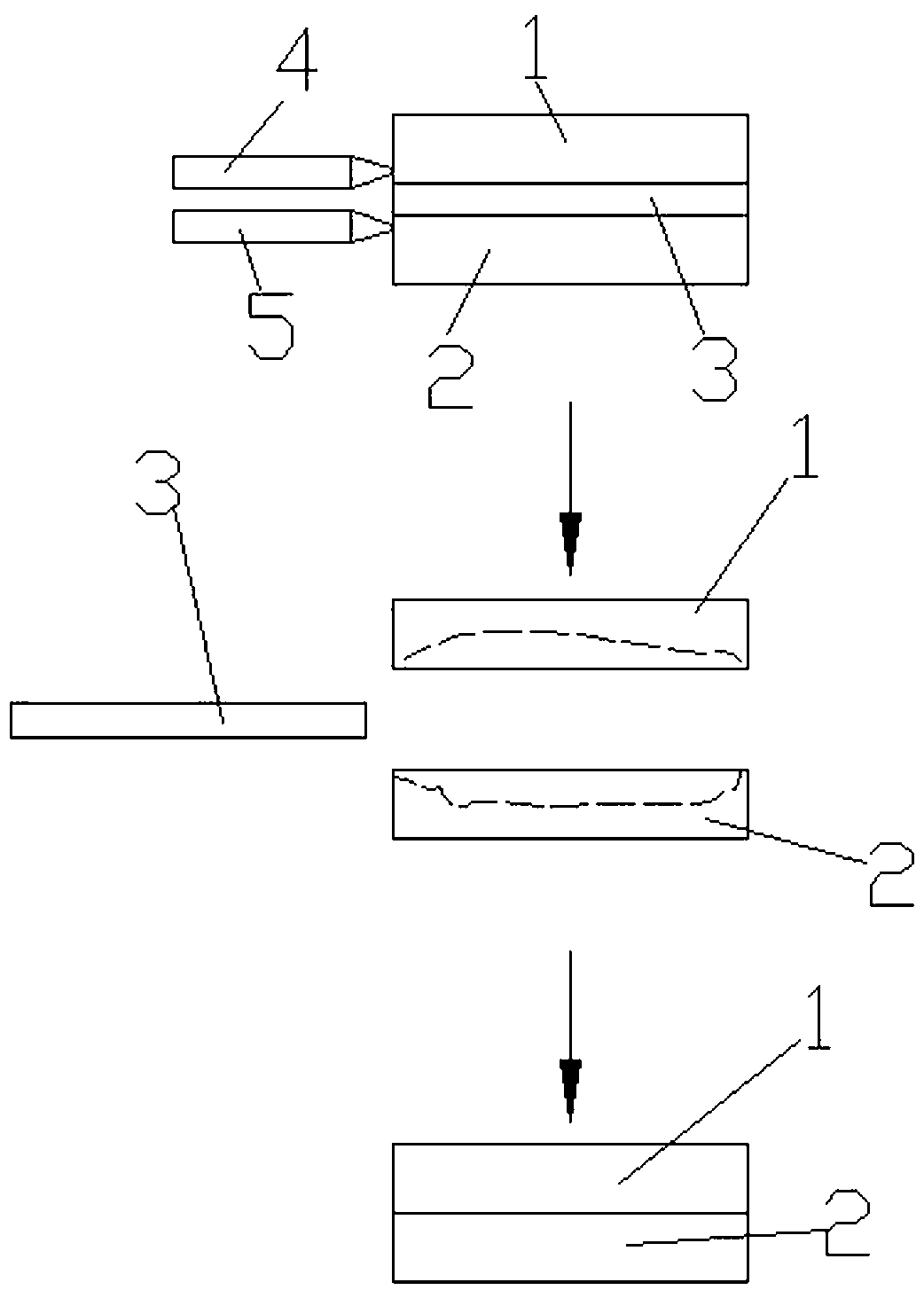

Forming technology and preparation method for double-color and double-hardness sole

ActiveCN103128978AEliminates manual hand gluing stepsSimple processDomestic articlesPlastic injection moldingHardness

The invention discloses a forming technology and a preparation method for a double-color and double-hardness sole. The forming technology and the preparation method for the double-color and double-hardness sole mainly includes the following steps: step 1, a mold is prepared, wherein a set of plastic injection mold is prepared; step 2, a plastic injection molding process is prepared, wherein a plastic injection molding machine is provided with two injection gun barrels which can be used for injecting plastics into the plastic injection mold simultaneously; step 3, the plastic injection molding process is carried out, wherein the plastic injection mold is placed on a mold frame of the plastic injection molding machine, the plastic injection molding machine is started, the two injection gun barrels are used for injecting the plastics into an upper mold body and a lower mold body of the plastic injection mold simultaneously, then the plastic injection mold is pre-pressed through a partition plate and then opened, the upper mold body and the lower mold body are separated, and then the partition plate is drawn out; and step 4, a bonding and cross-linked foaming forming process is carried out, wherein the upper mold body and the lower mold body are closed again, an upper-layer composite material and a lower-layer composite material are subjected to bonding and cross-linked foaming forming in a closed mold cavity, then the plastic injection mold is opened, and the double-color and double-hardness sole is obtained. According to the double-color and double-hardness sole produced through the preparation method, a shoe outsole portion and a shoe middle sole portion are not degummed when meeting water, do not separate from each other and are long in service live, the foaming forming process is fast, and a color bleeding phenomenon cannot happen.

Owner:JINJIANG CHENGCHANG SHOES

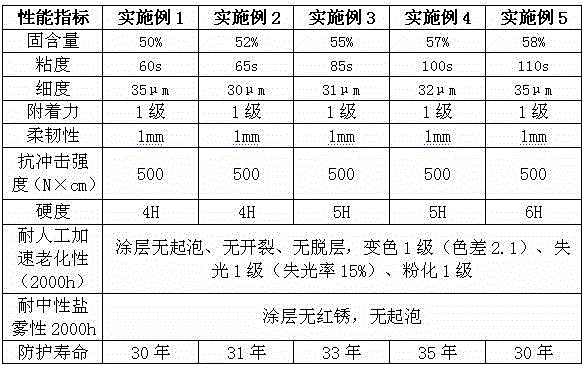

Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

ActiveCN104017480AImprove adhesionGood flexibilityAntifouling/underwater paintsPretreated surfacesPolymer scienceAcrylic resin

Owner:湖南惠电科技有限公司

Self-decomposition temporary plugging agent for workover fluid and using method of temporary plugging agent

InactiveCN105086973AWith self-blocking functionImprove protectionDrilling compositionFiberWater based

The invention discloses a self-decomposition temporary plugging agent for a workover fluid and a using method of the temporary plugging agent. The self-decomposition temporary plugging agent comprises 10-40 parts of particles I with the particle size ranging from 1 mm to 10 mm by mass, 20-60 parts of particles II with the particle size ranging from 20 meshes to 40 meshes by mass, 0.2-1 part of staple fibers with the length ranging from 3 mm to 10 mm by mass and 18-40 parts of superfine powder with the particle size ranging from 100 meshes to 300 meshes by mass; the particles I, the particles II, the staple fibers and the superfine powder are any one of or a mixture of several of polylactic acid, poly lactic-glycolic acid and polycaprolactone in any ratio. The using method of the agent comprises steps as follows: the staple fibers are evenly mixed in the water-based workover fluid, other components of the self-decomposition temporary plugging agent are added, and the mixture is evenly mixed. The self-decomposition temporary plugging agent for the workover fluid can be completely degraded into carbon dioxide and water in an aqueous solution and causes no damage to stratums, and the using method of the agent is suitable for on-site preparation.

Owner:CNPC BOHAI DRILLING ENG

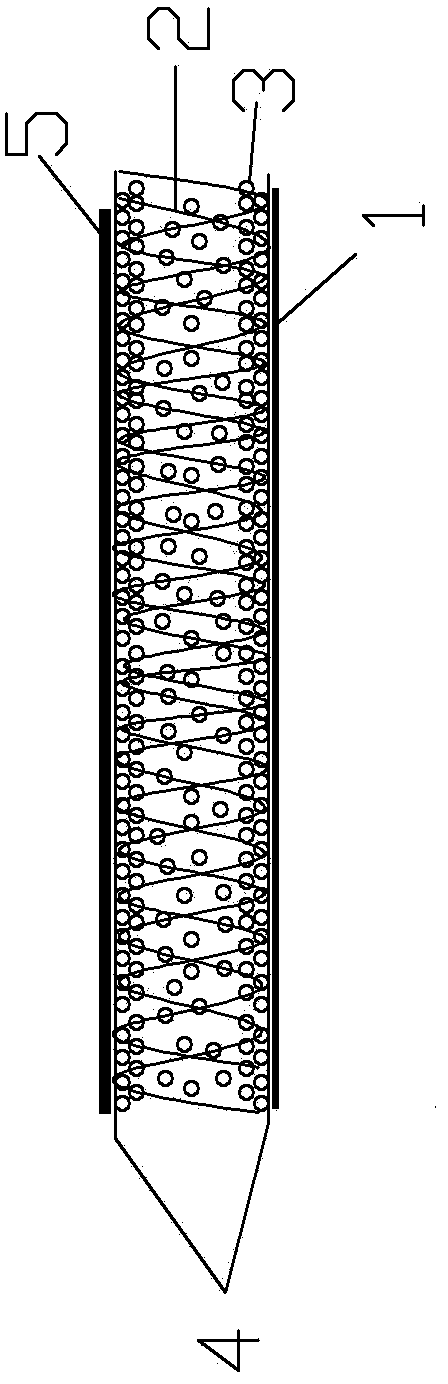

Carbon/carbon compound material heating element and production technology thereof

The invention discloses a simple-process environment-friendly carbon / carbon composite heating element and a production process thereof, which is characterized in that the heating element is prepared by making blank from carbon fibers, densifying, purifying, machining and purifying; the heating element is simple in process; as a net body formed by fluffy needle-like carbon fibers is adopted in the process of making the blank, a quasi-3D prefabricated part is easier to obtain in a needling process; the carbon fibers inside the prefabricated part are crisscrossed, strong in cohesive force, free from delamination and stable in structure; meanwhile, the prefabricated part is small in pore, which facilitates the acceleration of the subsequent densifying process; the heating element blank prepared through chemical vapor deposition densification consists of the carbon fibers and a carbon matrix, wherein the carbon matrix is formed by pyrolytic carbon obtained through a high temperature pyrolysis mode, which is high in purity; and a carbon / carbon composite product with the ash content less than 180 ppm can be obtained only through high-temperature purification in a vacuum or protective atmosphere, thereby saving energy and protecting environment.

Owner:HUNAN KINGBO CARBON CARBON COMPOSITES CO LTD

High-efficiency solar cell back film and preparation method thereof

InactiveCN102157589ASimple preparation processImprove performanceSynthetic resin layered productsPhotovoltaic energy generationCompound aPolyethylene terephthalate glycol

The invention relates to a high-efficiency solar cell back film. The back film is formed by compounding a modified high molecular weight high density polyethylene (HMWHDPE) film with the thickness of 0.08-0.10mm and a modified PET (polyethylene terephthalate) film with the thickness of 0.20-0.22mm. The back film has the following beneficial effects: the back film has a simple manufacturing process and excellent properties; and the solar cell panel packaged with the back film can resist high / low temperature (minus 60 DEG C-120 DEG C), water vapor and erosion of various corrosive gases and liquids, is free from delamination and crack and ensures the standard of stable use for many years.

Owner:诸暨市枫华塑胶科技有限公司

Double composite plastic steel composite pipe and manufacture method thereof

InactiveCN102620066ASave raw materialsLow costRigid pipesTubular articlesInternal pressureMaterial consumption

The invention provides a double composite plastic steel composite pipe and a manufacture method thereof, discloses a method for manufacturing a liquid conveying pipeline with the advantages of high annular rigidity, low material consumption, capability of bearing internal pressure, favorable sanitary performance, long service life, and better comprehensive performance. The basic process comprises steps of: manufacturing a plastic steel strip, manufacturing a plastic steel winding pipe stock by using the plastic steel strip, compounding and winding a metal wire, extruding a hot melt adhesive and coating on an outer surface of the pipe stock and coating a fused plastic on the outer surface of the plastic steel winding pipe stock. Thus both the anti-corrosion performance of plastic and the rigidity of steel belts are utilized; due to the adoption of the embedded steel wire, the internal pressure bearing performance of a buried pipe can be guaranteed; due to the composite structure of the pipe, the consumption of plastic is reduced, and the performance-price ratio of the pipe is greatly improved; and the manufacture method can be used for manufacturing large caliber liquid conveying pipelines, so as to solve the problem that the manufacture of large caliber plastic pipes is difficult in China.

Owner:山东天迈管业有限公司

Vegetable protein type non-dairy creamer and preparation method thereof

Belonging to the field of food processing, the invention in particular discloses a vegetable protein type non-dairy creamer and a preparation method thereof. The vegetable protein type non-dairy creamer is characterized by being prepared from the following raw materials by weight: 4-30 parts of vegetable oil, 1-8 parts of vegetable protein powder, 0.5-1 part of an emulsifier, 1-3 parts of a stabilizer, and 25-80 parts of syrup. The vegetable protein type non-dairy creamer provided by the invention cannot deteriorate after long-term preservation at room temperature, and has a stable state after brewing and is free of stratification phenomenon, thus being suitable for wide popularization and application.

Owner:菏泽大树生物工程科技有限公司

Wafer cutting method

ActiveCN103441104AAvoid or improve crackingNo delaminationSemiconductor/solid-state device manufacturingLaser cuttingEngineering

The invention provides a wafer cutting method. The wafer cutting method includes the steps that a wafer is provided, wherein the wafer comprises a front face and a back face corresponding to the front face; cutting is conducted from the front face of the wafer to the back face of the wafer through a laser cutting technology so that a plurality of cutting channels can be formed in the front face of the wafer; a grinding adhesive film is attached to the front face with the formed cutting channels of the wafer; back face grinding is conducted on the wafer which is provided with the grinding adhesive film in an attaching mode, the cutting channels are made to penetrate through the ground wafer, and therefore a plurality of separated chips can be formed. Due to the facts that laser cutting is used first, then the grinding process is adopted, and laser cutting can not generate cutting stress, the wafer cutting method not only can avoid rupture of thin wafers but also can be applied to cutting wafers with low dielectric constants.

Owner:北京中科微知识产权服务有限公司

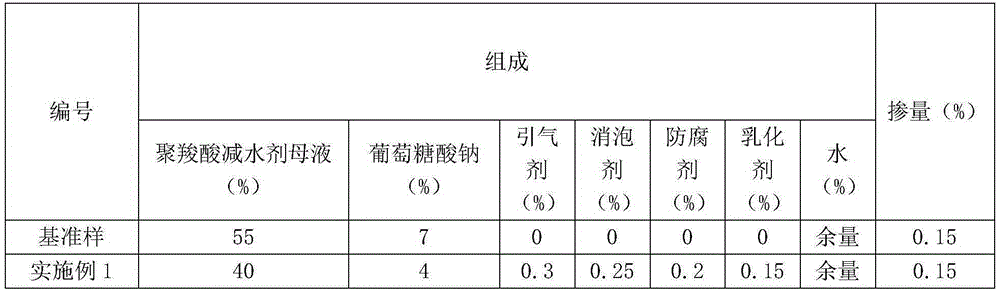

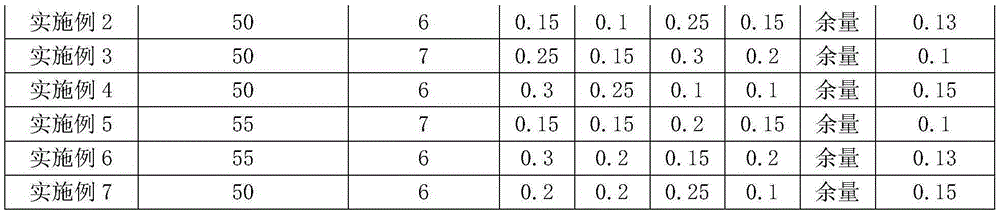

Anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and preparation method and application thereof

The invention relates to an anticorrosive composite polycarboxylate superplasticizer with high slump loss resistance, and a preparation method and application thereof. The composite polycarboxylate superplasticizer comprises, by mass, 40 to 55% of mother liquor of a polycarboxylate superplasticizer, 4 to 7% of sodium gluconate, 0.15 to 0.3% of an air entraining agent, 0.1 to 0.25% of an antifoaming agent, 0.05 to 0.2% of an emulsifying agent and 0.1 to 0.3% of an anticorrosive bactericide, with the balance being water, wherein the mass percents of every component sum to 100%. The composite polycarboxylate superplasticizer is prepared by placing the mother liquor of the polycarboxylate superplasticizer, sodium gluconate, the air entraining agent, the antifoaming agent, the anticorrosive bactericide and the water in a container together according to the above-mentioned mass percents under the conditions of normal temperature and normal pressure and carrying out uniform mixing under stirring. In use, the composite polycarboxylate superplasticizer is added into a concrete cementing material according to a mass ratio of the composite polycarboxylate superplasticizer to the concrete cementing material of 0.1-0.15: 100. Compared with the prior art, the composite polycarboxylate superplasticizer provided by the invention has the advantages of convenience in usage, stable performance, no phenomena of mildew, smelliness and layering due to long-term storage, capacity of introducing small bubbles when used in fresh mixed concrete, and excellent water-reducing and slump-retaining performances.

Owner:TONGJI UNIV

Preparation method of chitosan/titanium dioxide sol antibacterialpackaging film

InactiveCN104479155ALow reaction temperatureGood compatibilityFlexible coversWrappersAlcoholReaction temperature

The invention relates to a method for preparing anenvironment-friendlyhigh polymer material antibacterialpackaging film by mixing chitosan and titanium dioxide sol, and belongs to the technical field of preparation of a novel high polymer material taking renewablebiomass as a raw material. Tetrabutyltitanate, glacial acetic acid and a silane coupling agent (KH570) are slowly dropped in absolute ethyl alcohol respectively and stirred to prepare a precursor, deionized water and hydrochloric acid are sufficiently stirred and dropped in the absolute ethyl alcohol, a dropping liquid is prepared and then dropped in the precursor at a certain speed, modified titanium dioxide sol is obtained, added to a chitosan-acetic acid solution containing glycerin and uniformly stirred, and the chitosan / titanium dioxide sol antibacterialpackaging film is obtained after defoaming and film scraping. According to the preparation method, the titanium dioxide sol reaction temperature is low, the equipment investment is small, and uniform doping of the titanium dioxide sol and a chitosan solution in the molecular level can be realized in shorter time; and the compatibility of the titanium dioxide sol treated by the silanecoupling agentand chitosan is good.

Owner:BEIJING FORESTRY UNIVERSITY

Absorption product with core of double-layer structure and manufacturing method of absorption product

The invention belongs to the field of personal hygienic products, and discloses an absorption product with a core of a double-layer structure and a manufacturing method of the absorption product. The absorption product comprises a fluid permeability surface layer, a non-fluid-permeability bottom layer and the absorption core between the fluid permeability surface layer and the non-fluid-permeability bottom layer, wherein the absorption core comprises an upper layer and a lower layer; the upper layer is a double-combed and double-formed fluffy sheet; the fluffy sheet of the upper layer is divided into a dense surface and a fluffy surface; the lower layer of the absorption core is a dense sheet; the fluffy surface of the fluffy sheet and the dense sheet of the lower layer are bonded together; macromolecule water-absorbing particles or fibers of the absorption core are evenly distributed between the fluffy surface and the dense sheet of the lower layer. The absorption product has the advantages of being capable of rapidly absorbing liquid and diffusing liquid, good in air permeability and good in closed-fit performance.

Owner:湖南倍健卫生用品有限公司

Aluminium foil sealing film and preparation method thereof

ActiveCN102700819ADoes not affect ease of peelingImprove cooking temperatureSynthetic resin layered productsSealingPolymer sciencePolyethylene terephthalate glycol

The invention provides an aluminium foil sealing film and a preparation method thereof and belongs to the technical field of plastic packaging. The aluminium foil sealing film comprises a protective layer, a separation layer and a heat-seal layer, wherein the protective layer is a gloss oil layer or a PET (Polyethylene Terephthalate) film layer; the separation layer is an aluminium foil layer; and the heat-seal layer comprises the materials as follows: 15 to 25 wt% of polybutene, 25 to 35 wt% of ethylene-propylene copolymer and 40 to 60 wt% of HDPE (high-density polyethylene). As a sealing film for the bottle mouth of a polypropylene plastic bottle, the aluminium foil sealing film provided by the invention has the excellent properties of cooking resistance and easiness for uncovering, and when the cooking-resistant temperature is 121 DEG C, the sealing film is unchanged in color and is not stratified. The opening force is 5 to 25 N after the sealing film and the polypropylene bottle are heat-sealed at 200 DEG C, and the heat-seal strength of a heat-seal strip with the width of 15 mm is 5 to 25 N, which shows that the aluminium foil sealing film has the excellent properties of cooking resistance and easiness for uncovering at the same time.

Owner:ZHEJIANG GOLDSTONE PACKING

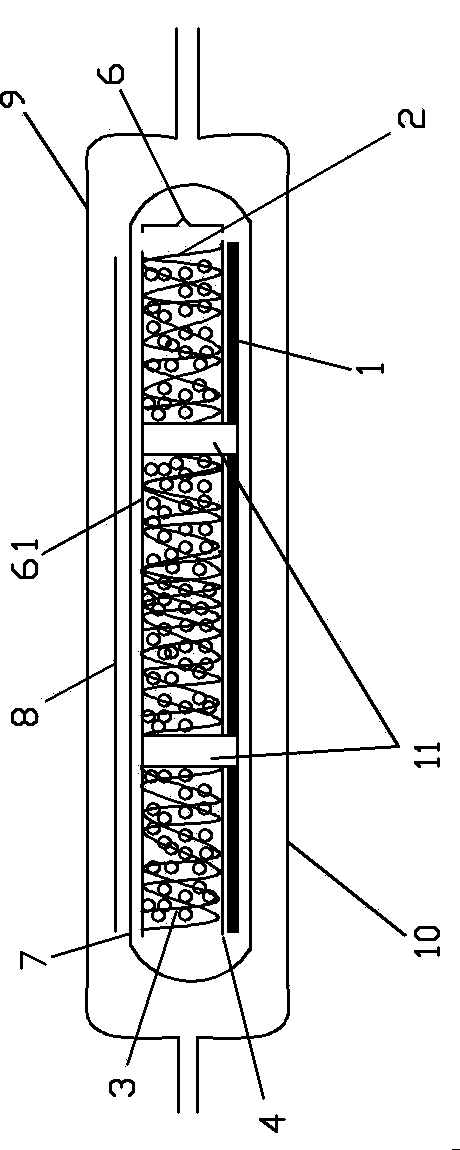

Method for preparing bimetallic seamless steel pipe for alkali recovery boiler

InactiveCN102039326AFine grainNo delaminationRoll force/gap control deviceExtrusion control devicesHigh pressureRecovery boiler

The invention relates to a method for preparing a bimetallic seamless steel pipe for an alkali recovery boiler. The method for preparing the bimetallic seamless steel pipe comprises the following steps of: selecting and treating a pipe blank, namely selecting a bimetallic composite pipe blank which is combined in a metallurgical mode and performing primary annealing; and extruding, namely extruding at an extrusion ratio of more than 10 and performing secondary annealing, wherein the heating temperature of the blank before extrusion is between 1,180 and 1,220 DEG C. The method has the characteristics that: an outer metal layer of the prepared composite pipe is resistant against alkali liquor corrosion, and an inner metal layer of the composite pipe is resistant against high pressure; meanwhile, the composite pipe avoids layering of two metal layers after tests such as flattening, bending and the like.

Owner:BEIJING CHANGXING KAIDA COMPOSITE MATERIAL TECH DEV

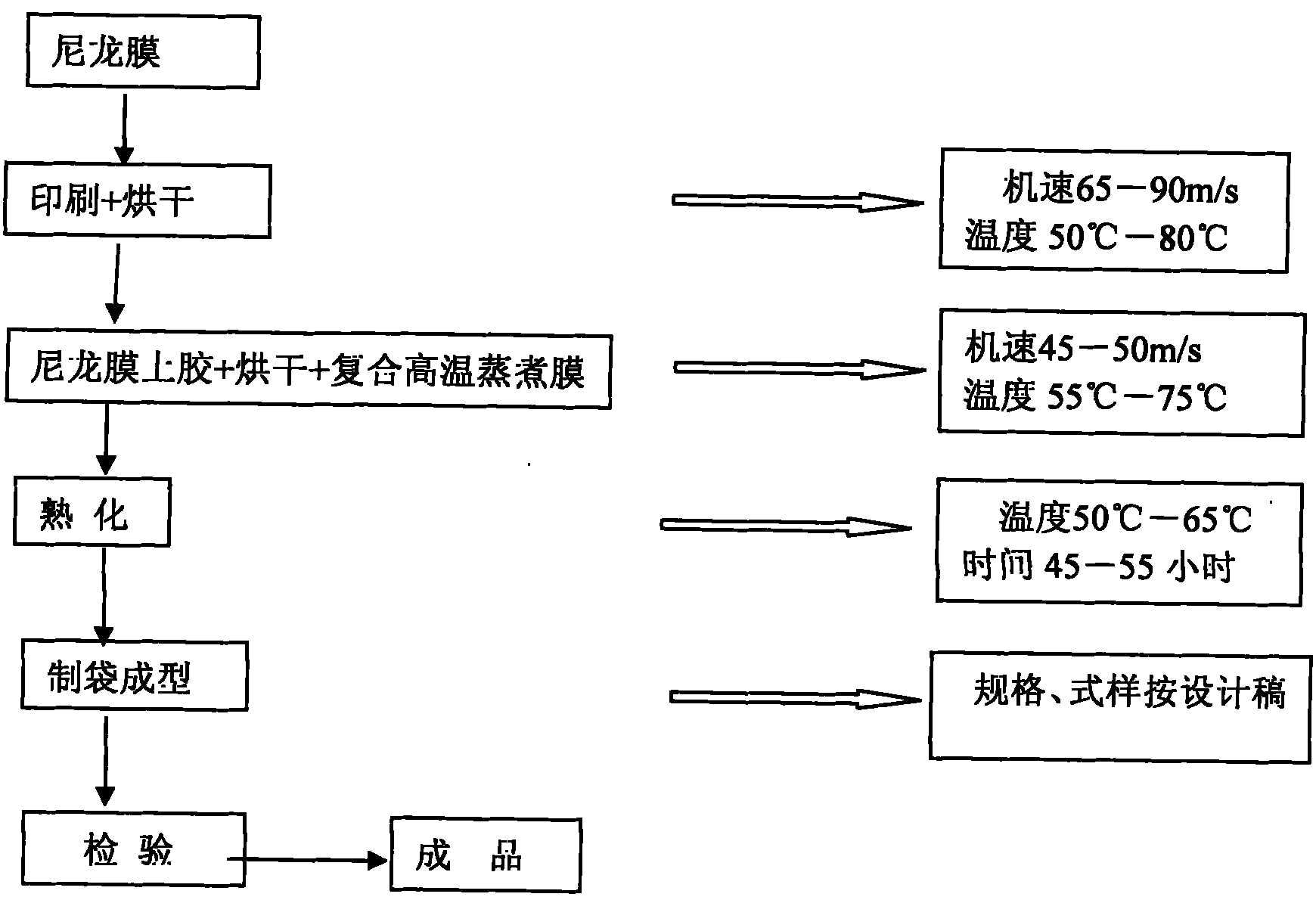

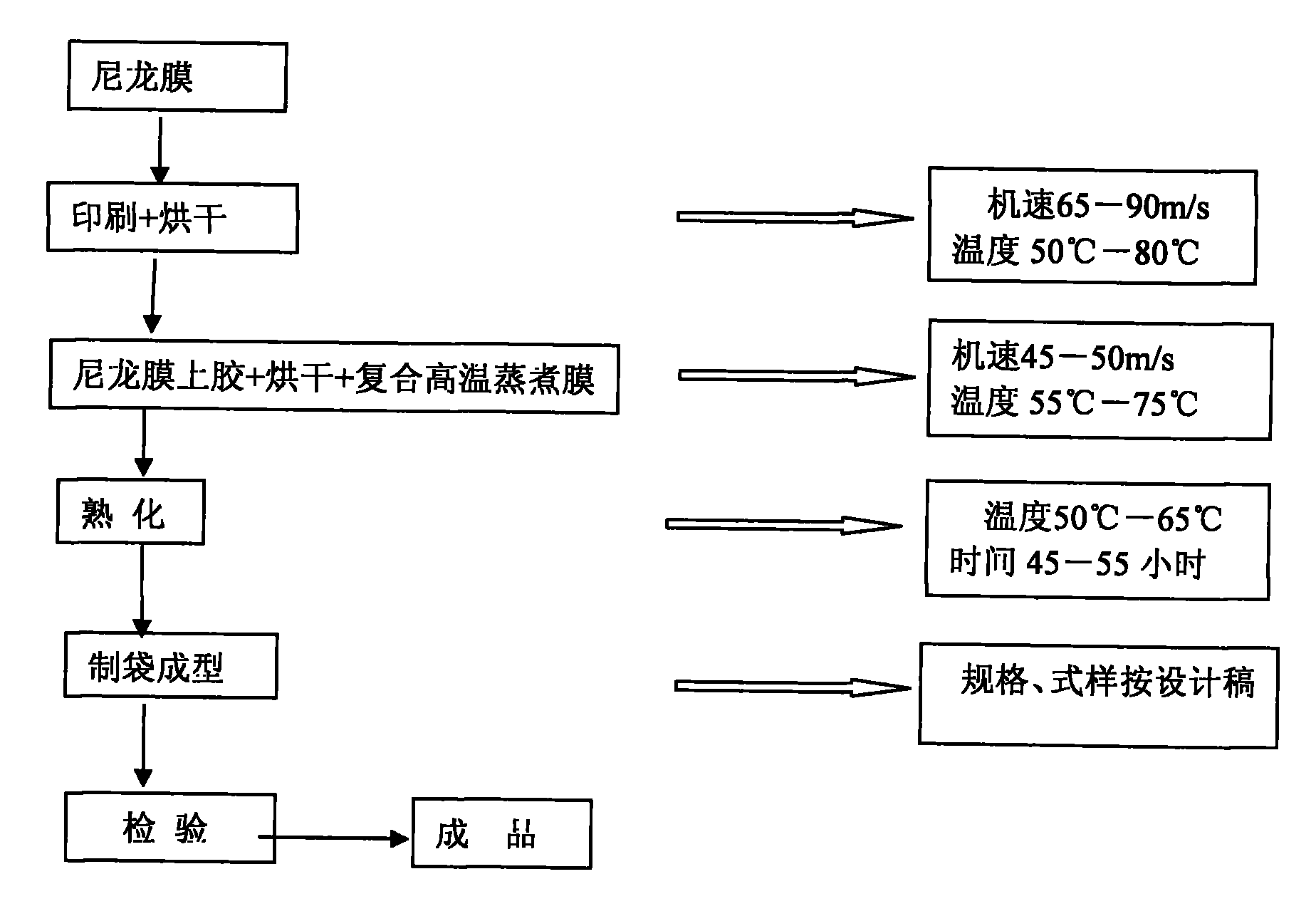

Manufacturing method of vacuum cooking and packaging bag for food

InactiveCN101837855AIncrease air flowImprove toughness and strengthLamination ancillary operationsBagsCompound aEngineering

The invention relates to a manufacturing method of a vacuum cooking and packaging bag for food, which comprises the following steps: selecting and proportioning raw materials and controlling the process flow; compounding a BOPA with an RCPP; firstly, delivering the printed BOPA into a compounding process; and proportioning a polyurethane glue and a solvent by weight; stirring uniformly and gluing on the BOPA; and manufacturing and forming a bag by heating in a drying tunnel, aging at constant temperature and heat sealing. After the food is packaged in vacuum, the vacuum package can resist high-temperature cooking and sterilizing at 135 DEG C for 30 minutes, and the packaging bag can not loose or leak air, can ensure the quality of the food and prolong the preservation and quality guarantee period of the food.

Owner:赵秀雄

High-temperature resistant rubber conveyer belt and preparation method thereof

ActiveCN104495215AImprove high temperature resistanceNo aging cracksConveyorsPackagingPolyesterPolymer science

The invention relates to a high-temperature resistant rubber conveyer belt and a preparation method thereof. Cover rubber takes silicone rubber, fluororubber or Levapren rubber as a matrix, employs a peroxide crosslinking agent and is added with a mixed bonding system and other proper additives, wherein the mixed bonding system comprises maleimide, a methylene donor, a methylene acceptor and the like; a frame material adopts polyester canvas or aramid fiber canvas, which is not subjected to surface treatment; and the prepared cover rubber has better high-temperature resistance than ethylene propylene diene monomer, can be bonded with the frame material and still keeps higher bonding strength after being aged at 200 DEG C for a long time. The prepared high-temperature resistant rubber conveyer belt can be applied in a conveying environment where the material temperature is extremely high, and has a longer service life than an ethylene propylene diene monomer high-temperature resistant conveyer belt.

Owner:BEIJING UNIV OF CHEM TECH +1

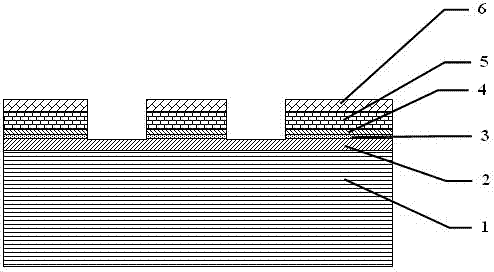

Metal substrate of heat conducting aluminium-based core and preparation method thereof

InactiveCN102256441ARaw materials are easy to obtainStable production processCircuit susbtrate materialsMetal core circuit manufactureMetallic aluminumHeat conducting

The invention discloses a metal substrate of a heat conducting aluminium-based core and a preparation method thereof. The metal substrate is composed of a metal aluminium substrate, an alumina insulating layer, a buffer layer, a first conducting layer, a second conducting layer and a weldable layer, wherein the metal aluminium substrate, the alumina insulating layer, the buffer layer, the first conducting layer, the second conducting layer and the weldable layer are superposed successively. According to the preparation method, a surface of the aluminium substrate is processed by using an anodization solution to generate the alumina insulating layer; the buffer layer and the first conducting layer are coated on the alumina insulating layer by a physical deposition method and then the second conducting layer is coated by an electrochemical deposition method; pad pasting and etching processes are carried out on the surface of the second conducting layer to obtain a needed circuit; at last, the weldable layer metal is coated on the second conducting layer by the electrochemical deposition method. According to the invention, the metal substrate has advantages of light weight, high heat radiation efficiency, long service life, and high reliability of performance; moreover, the metal substrate completely meets packaging requirements of various components and has low production cost; therefore, the metal substrate provided in the invention satisfies a condition of large-scale industrial application.

Owner:SUN YAT SEN UNIV

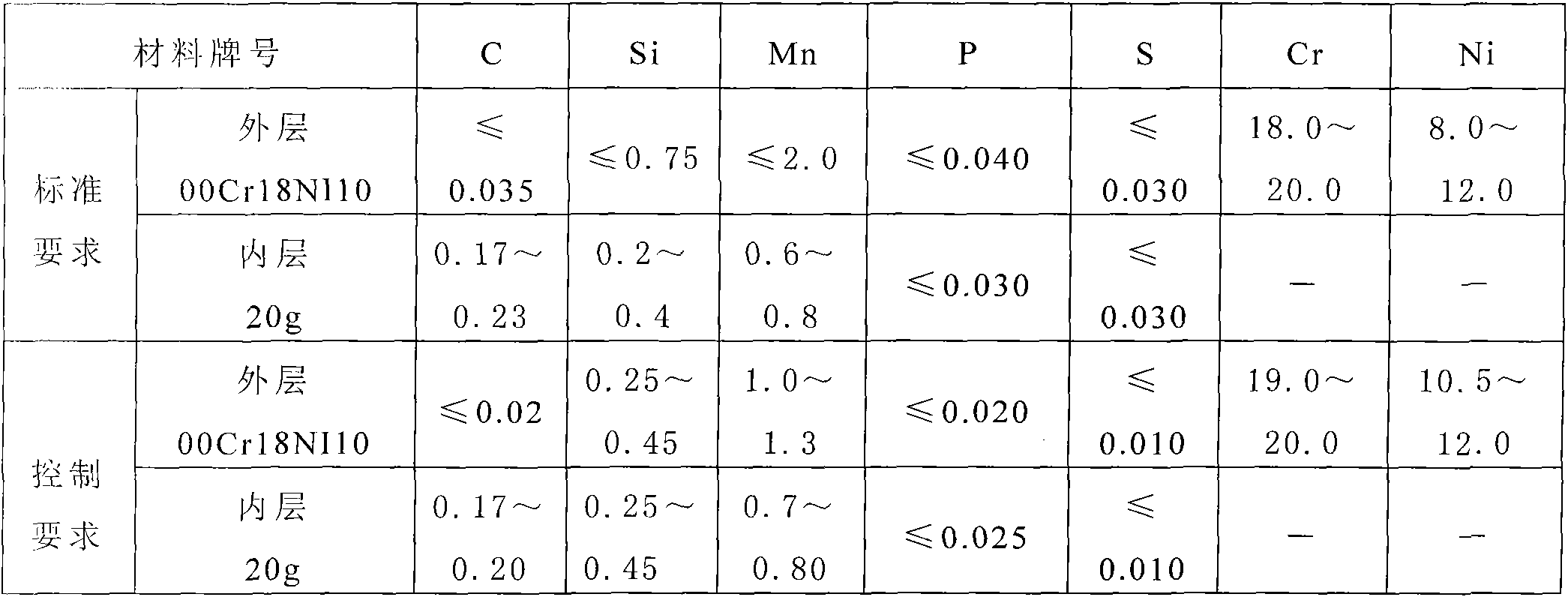

Preparation method for stainless steel clad plate

InactiveCN103157959AOmit the vacuum stepReduce investmentNon-electric welding apparatusVacuum extractionMaterials science

The invention discloses a preparation method for a stainless steel clad plate, and aims at solving the problem that through an existing vacuum rolling method for a metal clad plate, the time needed for vacuum extraction is long, and therefore the production cycle of the metal clad plate is quite long. The preparation method for the stainless steel clad plate includes the following steps: step 1, a first clad surface of a base material is subjected to surface treatment; step 2, a stainless steel plate is cut and shaped, a second clad surface is subjected to polishing treatment, and at the same time, a third surface is well cleaned, coated with a mold releasing agent and is ready for use; step 3, two stainless steel plates are combined together for form a cladding blank; step 4, base materials are arranged on the cladding blank and under the cladding blank, inlaid bars are arranged around the cladding blank, and a pressure welding machine is used for welding an initial blank to obtain a welding blank; and step 5, after the welding blank is heated, the welding blank is subjected to rolling and straightening, and then sides are further cut to obtain the stainless steel clad plate. According to the preparation method for the stainless steel clad plate, a vacuum extraction process is not needed, and the investment on vacuum extraction equipment can be effectively reduced; and meanwhile, production efficiency is improved, the production cycle is shortened, and the production cost of the stainless steel clad plate is lowered.

Owner:SICHUAN YOUQI DUEL METAL COMPOSITE MATERIALS CO LTD

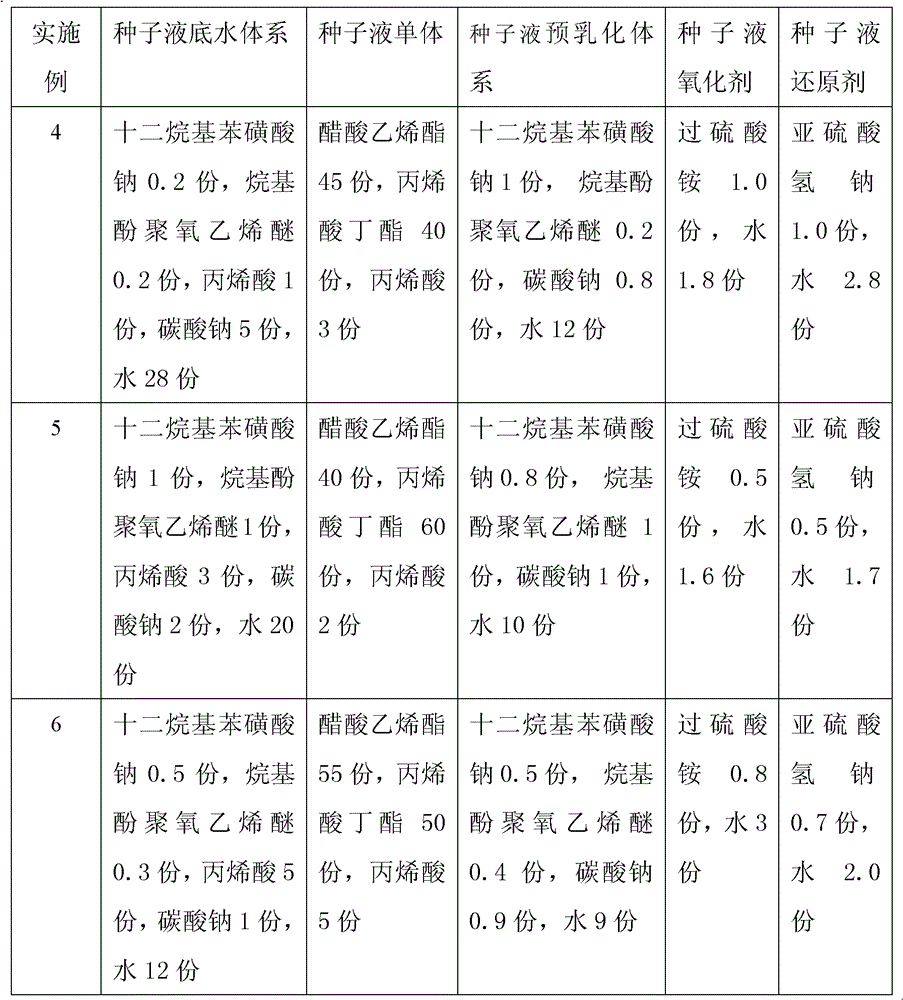

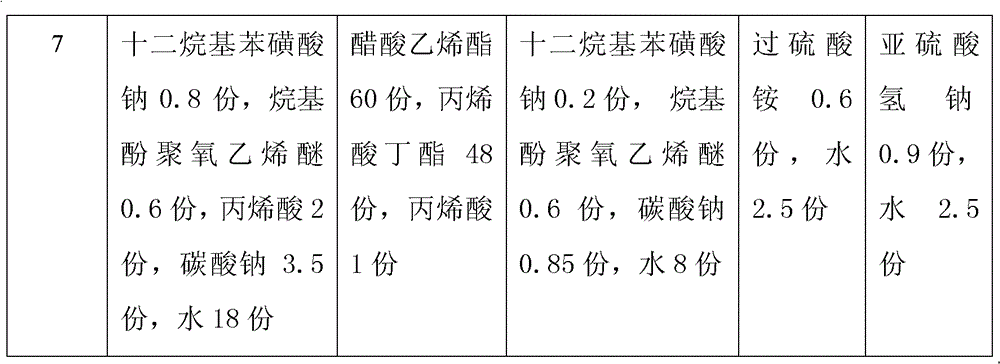

Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

ActiveCN103059211ALow coating viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesAdhesiveSynthesis methods

The invention relates to a vinyl acetate-acrylate copolymer emulsion, which is prepared by adopting OP-10, SDBS, SVS, water, acrylic acid and a seed emulsion as the bottom water system, taking VAc, BA and AA as the monomer, employing ammonium persulfate as the oxidant, and using sodium bisulfite as the reducing agent. Specifically, the seed emulsion in the bottom water system is prepared by using SDBS, OP-10, AA, sodium carbonate and water as the base solution, adopting VAc, BA and AA as the monomer, employing SDBS, OP-10, sodium carbonate and water as the pre-emulsification system, taking ammonium persulfate as the oxidant, and adopting sodium bisulfite as the reducing agent. The emulsion provided in the invention has a solid content of 40%-45%, viscosity (in terms of a 4-cup application amount) of 20S-26S, bonding peel strength (N / 2.5cm) of 1.4-2.5, a surface tension force of 32-37 dyne, and a film contact angle of 25-29 degrees, thus being particularly suitable for application in dry paper-plastic or plastic-plastic composite adhesives. The preparation method of the vinyl acetate-acrylate copolymer emulsion has the characteristics of mild reaction conditions and safety reaction system, thus being conducive to factory mass production.

Owner:CHINA PETROCHEMICAL CORP +2

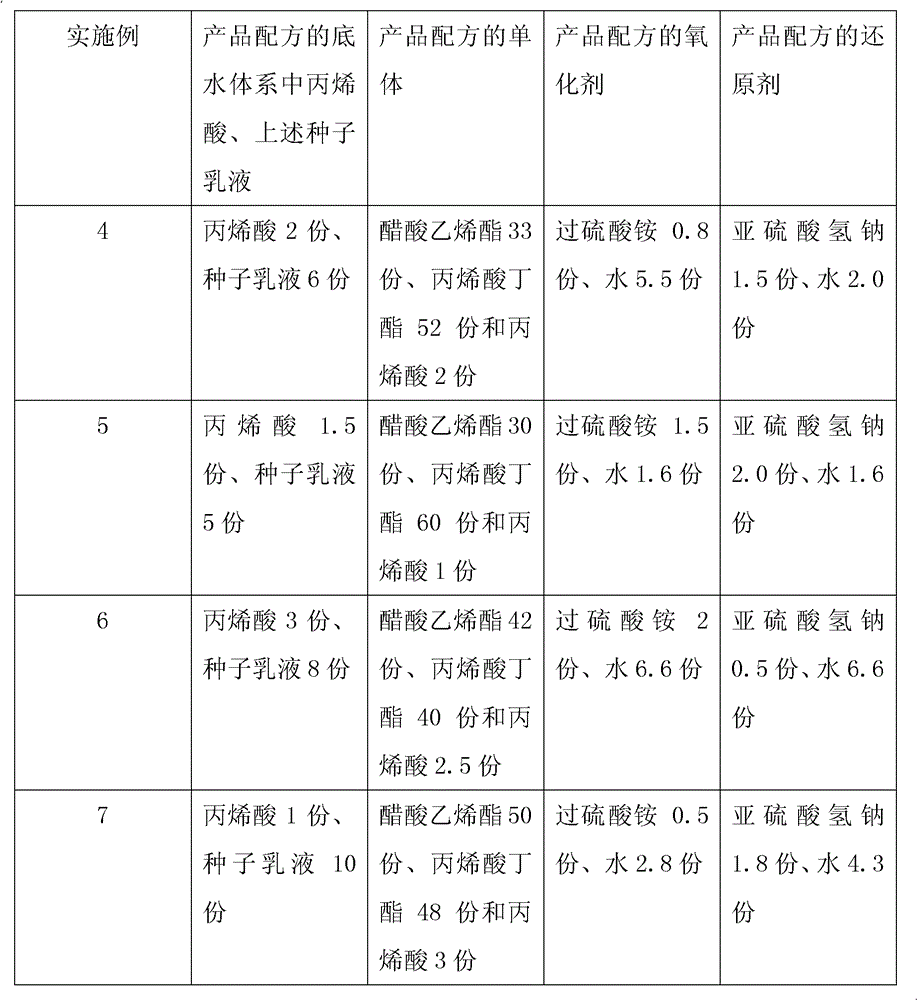

UV transfer printing in-mold-transfer printing decoration method

The present invention belongs to a process for electronic and electrical appliance shell surface treatment, and specifically relates to a UV transfer printing in-mold-transfer printing decoration method, which comprises the following steps: (1) preparing an IMT film, and carrying out acrylic UV line forming on the other surface of the film material non-PET diaphragm; (2) placing the line-formed IMT film in a vacuum optical electroplating device, and carrying out electroplating to increase transparent plating or color plating; (3) placing the printed IMT film on a hot pressing mold to heat and stretch into a shape required by a customer by using a hot pressing machine; (4) adopting a stamping mold to stamp the redundant part on the edge of the stretched IMT film sheet material; (5) peeling the IMT film PET protection film on the surface of the stamped sheet material to only leave the acrylic UV layer and the printing layer; and (6) placing in an injection mold to carry out injection molding. According to the UV transfer printing in-mold-transfer printing decoration method, the surface of the product is the ultra-thin acrylic UV, and can bear a high temperature (350 DEG C) injection molding material during injection molding, ink can not punch through the glue inlet during injection molding, the ultra-thin product can be produced, and problems of product deformation, layering and the like can be solved when temperature limit testing is performed.

Owner:东莞市崇康电子有限公司

Liquid package composite membrane and preparation method thereof

ActiveCN102673882AHigh heat sealing strengthExcellent drop resistance and pressure resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a liquid package composite membrane and a preparation method thereof and belongs to the technical field of plastic package. The composite membrane comprises a surface layer, an obstruction layer, a reinforced layer and a heat seal layer, wherein the surface layer is a polyethylene terephthalate film layer; the obstruction layer is an aluminum foil layer; the reinforced layer is a polyethylene terephthalate film layer; and the heat seal layer consists of the following materials: 40-60wt% of eight-carbon linear low-density polyethylene, 35-50wt% of polyvinyl acetate and 5-10wt% of low-density polyethylene. The liquid package composite membrane provided by the invention has excellent break-resistant and pressure-resistant performances; break-resistant performance test shows that the liquid package composite membrane does not break while falling to a cement floor from a height of 10 meters once; and pressure-resistant performance test shows that the liquid package composite membrane has no leakage within 24 hours when the static pressure is 20MPa.

Owner:ZHEJIANG GOLDSTONE PACKING

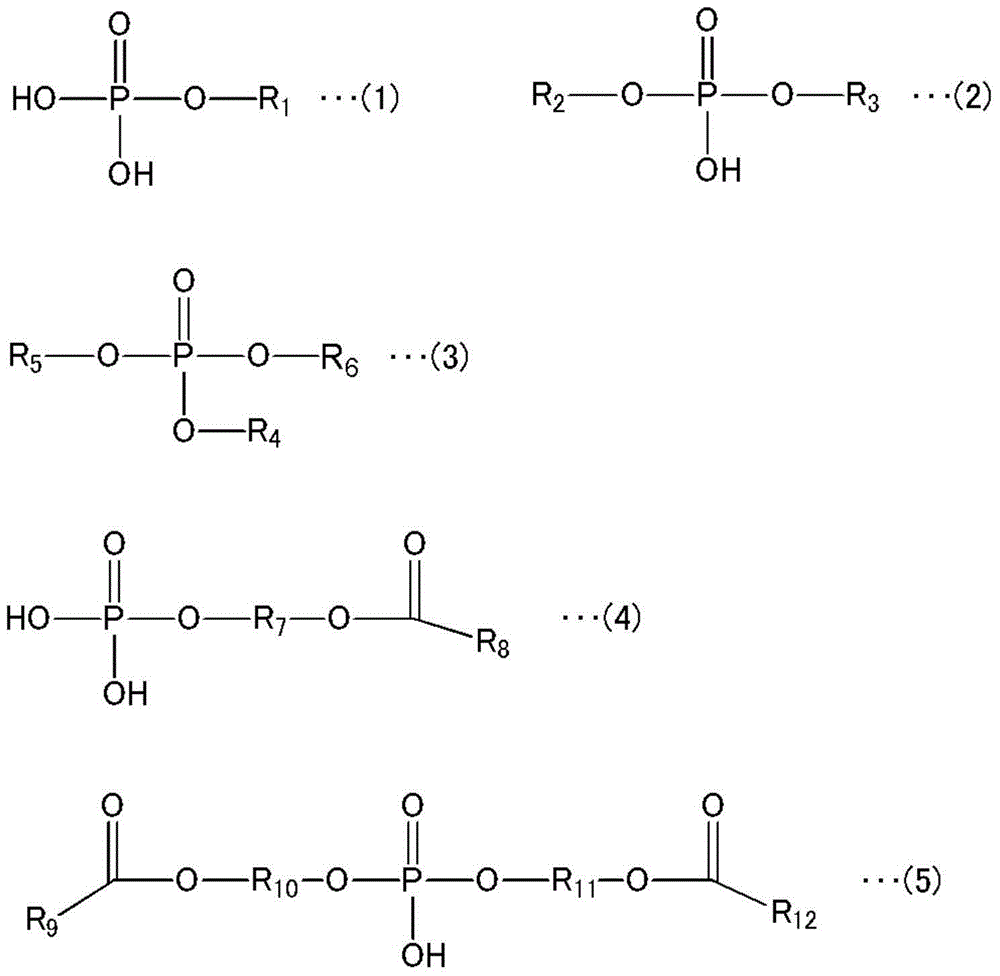

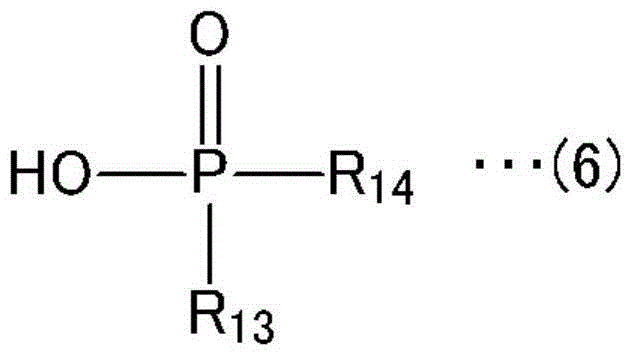

Laminate adhesive, and laminate and rechargeable battery using same

ActiveCN104662114AImprove moisture resistanceImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyolefin

[Problem] To provide a laminate adhesive composition that: has excellent adhesion properties with respect to metal layers and plastic layers; provides moisture-proof properties, heat resistance, insulating properties, durability, and the like; further provides electrolyte resistance; and in which delamination does not occur over time. To further provide a laminate and rechargeable battery in which the laminate adhesive is used. [Solution] Provided are: a laminate adhesive composition characterized by containing a modified polyolefin resin (A), a phosphoric acid-modified compound (B), and preferably, an epoxy resin, and a polyisocyanate compound; and a laminate and rechargeable battery in which the laminate adhesive is used.

Owner:DIC CORP

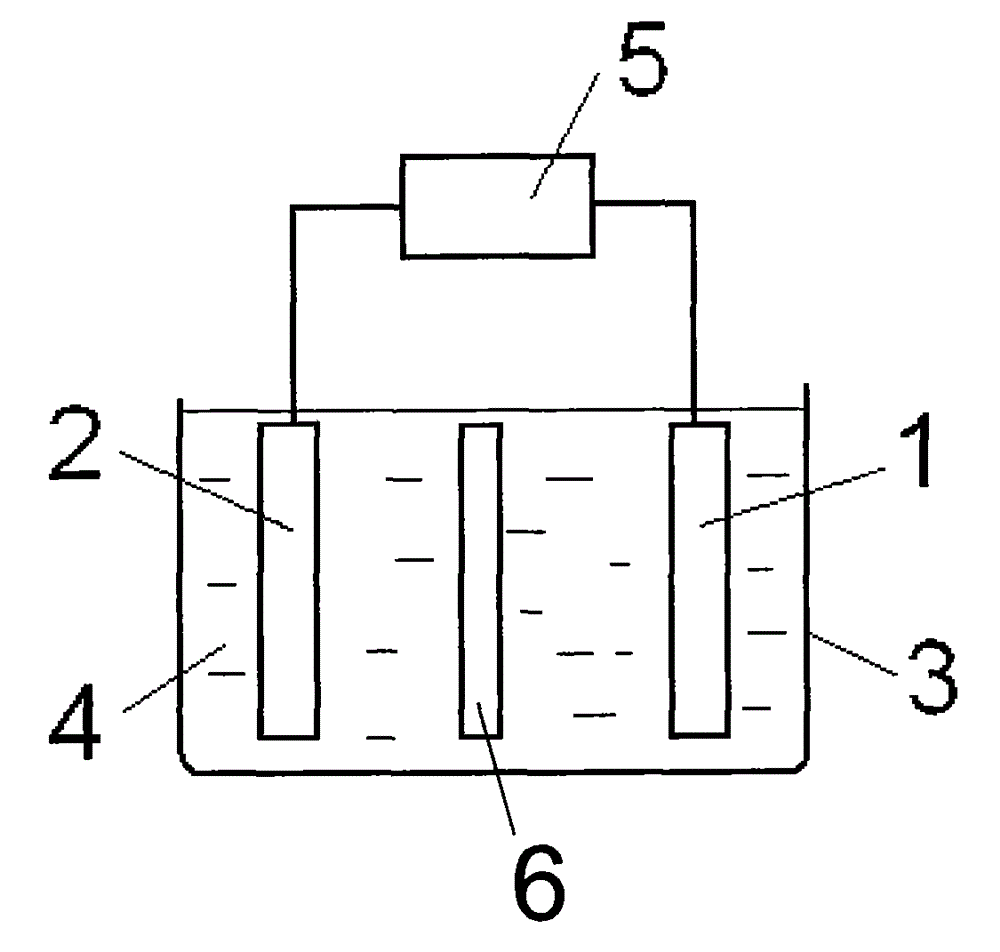

Method for preparing nanometer powdered carbon for fertilizer

InactiveCN104591855AImprove stabilityNo precipitationMaterial nanotechnologySurface reaction electrolytic coatingImpulse frequencyPulse power supply

The invention relates to a method for preparing nanometer powdered carbon for fertilizer. The method comprises the following steps of providing a system comprising an anode, a cathode, a separator plate and an electrolyte aqueous solution, wherein the anode, the cathode and the separator plate are prepared from high-purity graphite, connecting the anode and the cathode to a pulsed power supply with impulse frequency of 40-60Hz and effective voltage of 12-20V so that nanometer carbon sol is obtained, wherein effective current density formed between the anode and the cathode is in a range of 50 to 100A / m<2>, adding 0.3-1wt% of a potassium-containing compound into the nanometer carbon sol to obtain potassium ion-containing nanometer carbon gel, and drying the potassium ion-containing nanometer carbon gel to obtain the nanometer powdered carbon. The method can control nanometer powdered carbon particle size and yield by adjusting voltage and current so that the method is suitable for industrial production of fertilizer.

Owner:刘广安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com