Metal substrate of heat conducting aluminium-based core and preparation method thereof

A metal substrate and metal technology, which is applied in the manufacture of metal core circuits, circuit substrate materials, printed circuit components, etc., can solve the problem that the heat dissipation requirements of high-density component assembly circuit boards cannot be met, and the high thermal conductivity metal substrates cannot be fully promoted and used. Affecting the performance and reliability of the substrate and other issues, achieving the effect of light weight, high performance reliability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

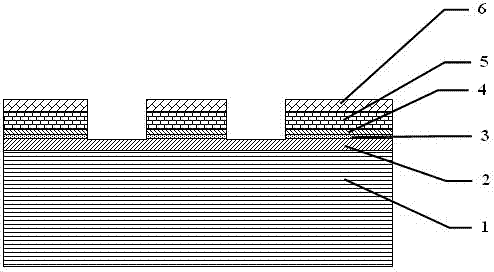

[0031] Use oxalic acid system, add acetic acid, glycerol organic additives and anodic oxidation solution of yttrium sulfate inorganic additives to anodize the aluminum substrate to form a 10μm aluminum oxide insulating layer, and evaporate a layer of buffer layer - molybdenum and titanium alloy 300 ?, and then magnetron sputtering metal silver 800 ? to realize its electrical conductivity, and then electroplate copper 40μm, thicken the conductive layer, and test the thermal conductivity to 23W / m·K. Then, stick a film on the surface of the metal copper plating layer and perform etching treatment to obtain the required circuit; finally, electroless silver plating of 13 μm can obtain an aluminum-based core metal substrate with high thermal conductivity.

Embodiment 2

[0033] Using a sulfuric acid system, add malic acid, sulfosalicylic acid, ethylenediaminetetraacetic acid organic additives and anodic oxidation solution of cerium nitrate and lanthanum nitrate inorganic additives to anodize the aluminum substrate to form a 100μm aluminum oxide insulating layer. Magnetron sputtering a layer of buffer layer - tungsten and titanium alloy 500?, then ion-plating iron-nickel alloy 500? to realize its electrical conductivity, and then electroplating copper 50μm to thicken the conductive layer. The test thermal conductivity is 20W / m· K. Then, stick a film on the surface of the metal copper plating, etch to obtain the required circuit; finally electroless nickel / immersion gold 8μm, you can get an aluminum-based core metal substrate with high thermal conductivity.

Embodiment 3

[0035] Use oxalic acid-phosphoric acid system, add lactic acid, citric acid, ethylenediaminetetraacetic acid organic additives and anodic oxidation solution of yttrium sulfate, lanthanum nitrate inorganic additives, anodize the aluminum substrate to form a 35μm aluminum oxide insulating layer, ion plating A 500? metal tungsten buffer layer is placed on it, and then 600? Then, stick a film on the surface of the metal silver plating, etch to obtain the required circuit; finally, electroless tin plating of 10 μm can obtain an aluminum-based core metal substrate with high thermal conductivity.

[0036] The aluminum-based core metal substrates with high thermal conductivity prepared in the above three embodiments were baked at 300°C for 10 minutes, and there was no peeling phenomenon between the multilayer metal layers, and the performance reliability was extremely high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com