One-component acrylic ester matte core-shell emulsions with good anti-water-white performance and preparation method and application thereof

An acrylate, core-shell emulsion technology, applied in the direction of biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve problems such as poor stability, achieve improved stability, simple and feasible process, and simple and easy raw materials the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

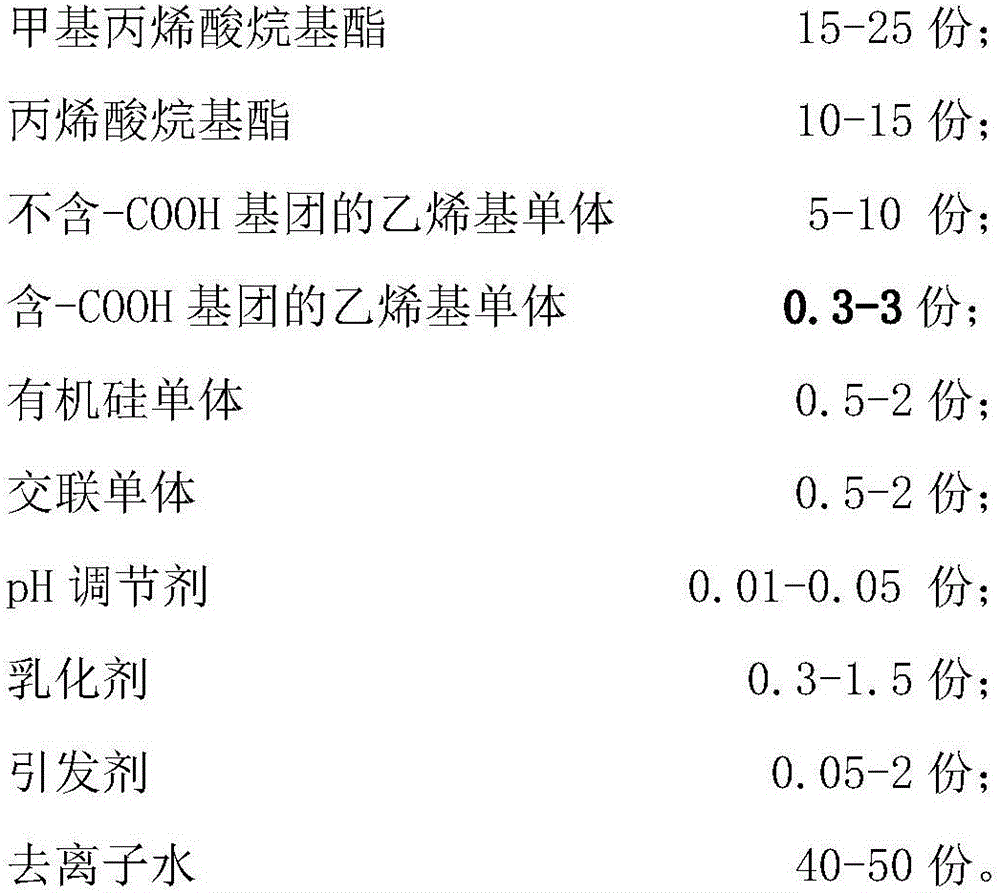

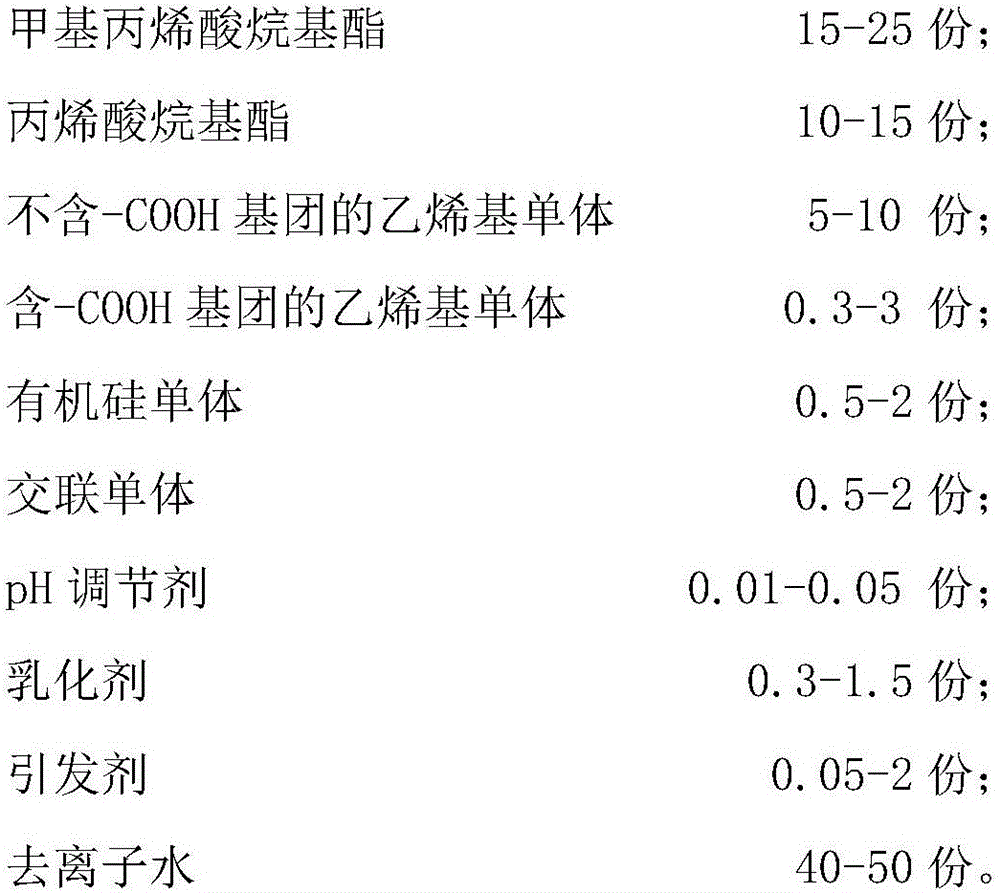

[0038] A kind of one-component acrylate matte core-shell emulsion with excellent water whitening resistance, its raw material includes the following components in parts by weight: 20 parts of alkyl methacrylate (including methyl methacrylate and butyl methacrylate ester); 12 parts of alkyl acrylate (including isooctyl acrylate and butyl acrylate); 6.5 parts of vinyl monomers without -COOH groups (including styrene and acrylamide); vinyl monomers containing -COOH groups 1 part of base monomer (acrylic acid); 0.5 part of silicone monomer (vinyltrimethylsilane); 1 part of crosslinking monomer (including ethylene glycol dimethacrylate and trimethylolpropane triacrylate) 0.03 part of pH regulator (sodium hydroxide); 0.8 part of emulsifier (comprising sodium lauryl sulfate, alkyl polyoxyethylene ether (EO=10) and allyl ether sodium hydroxypropyl sulfonate); 1 part of agent (ammonium persulfate); 40 parts of deionized water.

[0039] The preparation method of the above-mentioned one...

Embodiment 2

[0050] A kind of single-component acrylate matte core-shell emulsion with excellent water whitening resistance, its raw materials include the following components in parts by weight: 15 parts of alkyl methacrylate (including methyl methacrylate and butyl methacrylate ester); 15 parts of alkyl acrylate (including ethyl acrylate and butyl acrylate); 5 parts of vinyl monomers without -COOH groups (including styrene and methacrylamide); 2 parts of vinyl monomer (methacrylic acid); 1 part of silicone monomer (methacryloxypropyl trimethoxysilane); 0.5 parts of crosslinking monomer (including allyl methacrylate and trihydroxy Methylpropane triacrylate); 0.05 parts of pH regulator (ammonia); 0.3 parts of emulsifier (including alkyl polyoxyethylene ether sodium sulfate, alkyl polyoxyethylene ether (EO=40), allyl ether hydroxypropyl Sodium sulfonate and sodium lauryl sulfate); 0.05 parts of initiator (sodium persulfate); 45 parts of deionized water.

[0051] The preparation method of t...

Embodiment 3

[0062] A one-component acrylate matte core-shell emulsion with excellent water whitening resistance, its raw materials include the following components in parts by weight: 25 parts of alkyl methacrylate (including ethyl methacrylate, butyl methacrylate esters and isooctyl methacrylate); 10 parts of alkyl acrylates (including methyl acrylate and butyl acrylate); 10 parts of vinyl monomers without -COOH groups (including styrene and N-isopropyl acrylamide); 3 parts of vinyl monomers containing -COOH groups (methacrylic acid and maleic anhydride); 2 parts of silicone monomers (vinyl tris(β-methoxyethoxy)silane); 2 parts of monomers (including allyl methacrylate and hydroxyethyl methacrylate); 0.01 parts of pH regulator (potassium hydroxide); 1.5 parts of emulsifier (including sodium dodecylbenzenesulfonate, alkyl Polyoxyethylene ether (EO=10), allyl ether sodium hydroxypropyl sulfonate and the SR-10 emulsifier of Japan Addico Corporation); 2 parts of initiator (potassium persulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com