Method for preparing TiO2 fixed film photocatalyst loaded on glass fiber net

A technology of glass fiber mesh and photocatalyst, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problem of stability, specific surface area, firmness and convenience of loading, which cannot meet the requirements of photocatalytic oxidation, degradation and dissolution The actual application requirements of sexual organic pollutants, the preparation method is not suitable for industrialized large-scale production, and the use of external light sources is unfavorable, so as to achieve good application prospects, high economic and practical value, and simplified structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The butyl titanate, absolute ethanol and concentrated nitric acid used in the present invention are commercially available and analytically pure. The specifications of the flexible base material glass fiber mesh are: Si content ≥ 96%, mesh size 1.5×1.5mm. Pretreatment of glass fiber mesh: put the glass fiber mesh directly into the muffle furnace, raise the temperature to 500°C at a rate of 2-4°C / min, then keep at this temperature for 0.5-1 hour, and cool naturally.

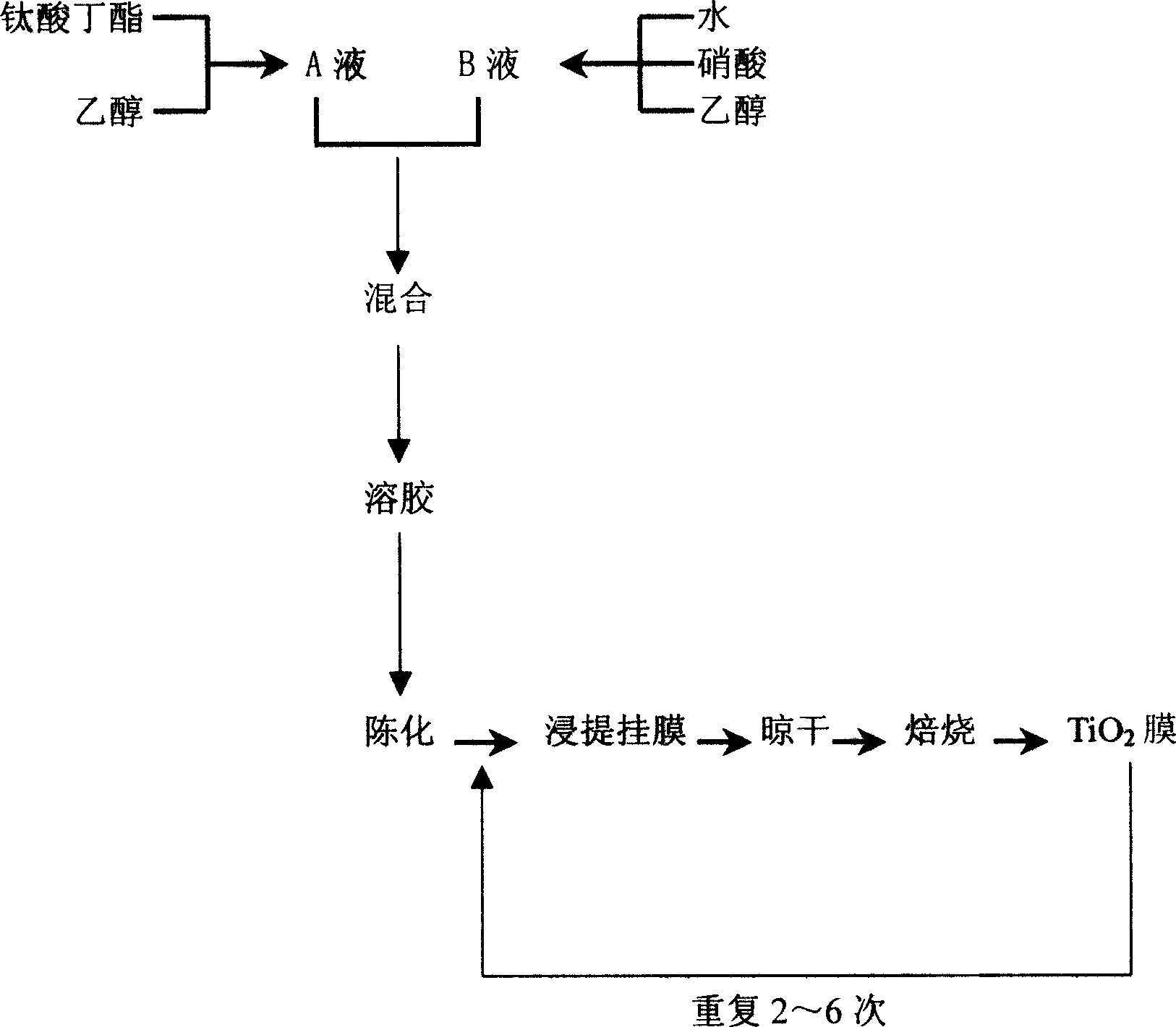

[0023] Preparation of sol-gel solution: 80ml tetra-n-butyl titanate T I (C 4 h 9 O) 4 Uniformly mix with 300-400ml absolute ethanol to form A liquid; uniformly mix 200-350ml absolute ethanol, 8ml water and 1-3ml nitric acid (concentration 1:4) to form B liquid; Slowly add liquid B into liquid A, and continue to stir vigorously for 30-60 minutes to form a transparent sol; finally let stand and age for 24-48 hours to form a gel for later use.

[0024] Membrane coating: immerse the glass fiber net in the ...

Embodiment 2

[0029] Pretreatment of glass fiber mesh: wash the glass fiber mesh with detergent to remove surface dirt, and then rinse with tap water; soak the fiber mesh with absolute ethanol for 3-5 minutes to remove fine debris on the mesh; wash repeatedly with distilled water 3-5 times; put it into a muffle furnace, raise the temperature to 300°C at a heating rate of 5-7°C / min, then keep at this temperature for 1-2 hours, and cool naturally.

[0030] Preparation of sol-gel solution: Mix 80ml of tetra-n-butyl titanate and 300-400ml of absolute ethanol evenly to form liquid A; mix 200-400ml of absolute ethanol, 8ml of water and 3-5ml of nitric acid (1:4) Mix to form liquid B; under the condition of vigorous stirring, slowly add liquid B to liquid A, and continue to stir vigorously for 30-60 minutes to form a transparent sol; finally stand and age for 24-72 hours to form a gel spare.

[0031] Membrane coating: immerse the glass fiber mesh in the glue solution for 2 to 3 minutes, lift the ...

Embodiment 3

[0036] Pretreatment of glass fiber mesh: wash the glass fiber mesh with detergent to remove surface dirt, and then rinse with tap water; soak the fiber mesh with absolute ethanol for 2-3 minutes to remove fine debris on the mesh; wash repeatedly with distilled water 3-4 times; put it into a muffle furnace, raise the temperature to 500°C at a rate of 3-5°C / min, then keep at 500°C for 1-2 hours, and cool naturally.

[0037] Preparation of sol-gel solution: uniformly mix 80ml tetra-n-butyl titanate with 300-400ml absolute ethanol to form liquid A; mix 250-350ml absolute ethanol, 8ml water and 6-8ml nitric acid (1:4) Mix to form liquid B; under the condition of vigorous stirring, slowly add liquid B to liquid A, and continue to stir vigorously for 60-90 minutes to form a transparent sol; finally stand and age for 12-24 hours to form a gel spare.

[0038] Membrane coating: immerse the glass fiber mesh in the glue solution for 3-5 minutes, lift the glass fiber mesh vertically at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com