Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "GLYCOL DIMETHACRYLATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

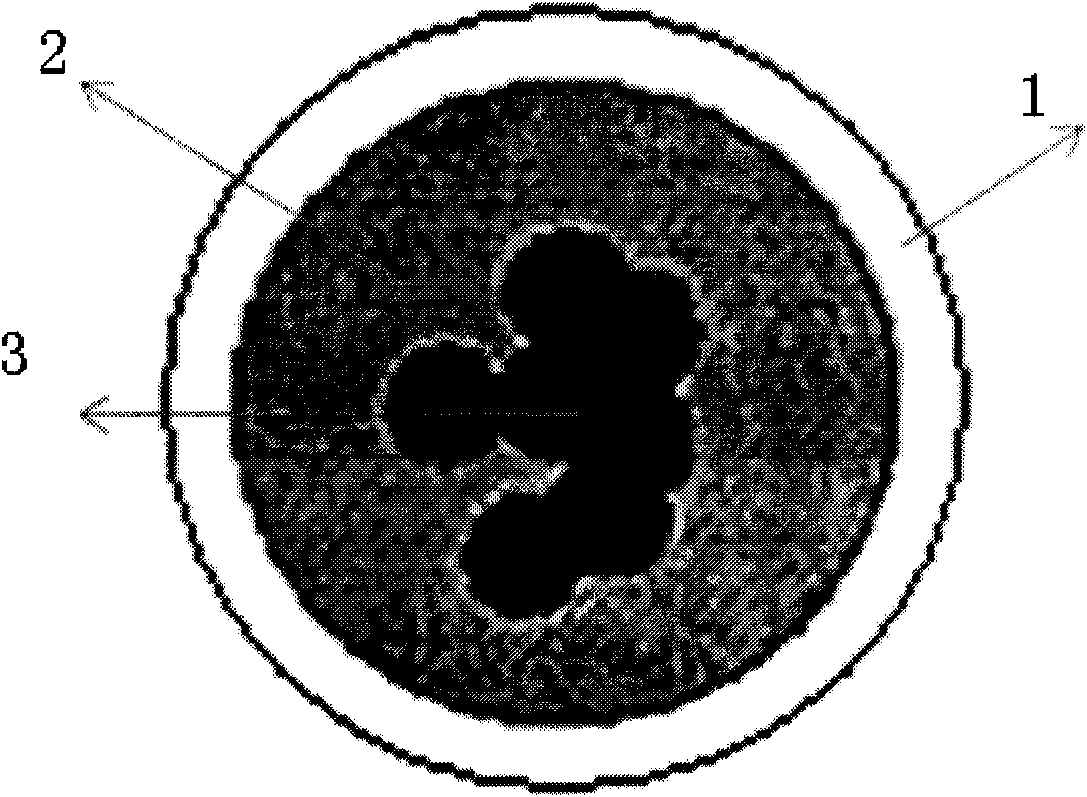

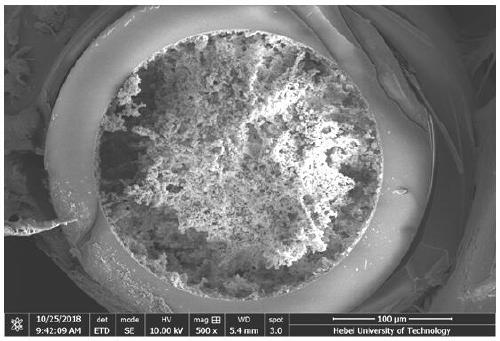

A method to prepare the phase-change material wrapped by microcapsule

InactiveCN101550328AMeet the needs of full-band camouflageInorganic material magnetismHeat-exchange elementsPotassium persulfateParaffin wax

A method to prepare the phase-change material wrapped by microcapsule, wherein, 1. Weigh paraffin and methyl methacrylate (MMA) at a mass ratio of 1:3; 2. Weigh 0.5% glycol dimethacrylate (GDMA), 1% methacrylic acid (MAA) and 1% sodium dodecyl sulfate (SDS), 1.5% potassium persulfate, 1%-15% ferrite and 400% deionized water (to the total mass of Item 1); 4. Add ferrite and molten paraffin into the solution of Item 3; 5. Emulsify the solution under ultrasonic sound and add MMA, GDMA and MAA; 6. Re-emulsify and transfer the obtained solution into a device with mechanical agitation, condenser tube, gas inlet and feed inlet; 7. Aerate and remove oxygen 0.5h, heat it in water bath to 70 DEG C, add potassium persulfate and cool the solution to room temperature to obtain the phase-change material wrapped by microcapsule. The material is used in such fields as building, heat-storing temperature-adaptable textile, and electronic equipment.

Owner:BEIJING JIAOTONG UNIV

Application of hyamine antibiont on dentistry antibacterial replacement material

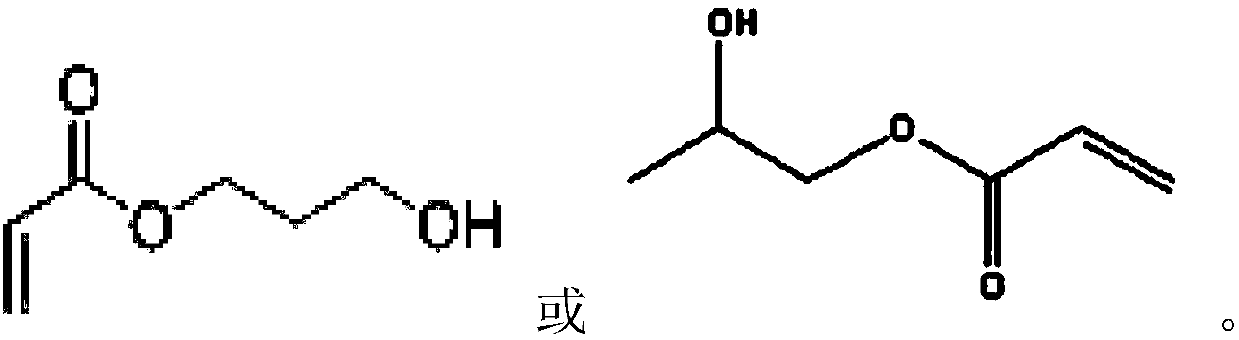

The invention discloses the application of an antibacterial quaternary ammonium salt monomer in dental antibacterial repairing material. The antibacterial quaternary ammonium salt monomer is inserted into a dental resin base material to enable the dental resin base material to have antibacterial property. The general molecular formula is shown in the right, wherein, R1=CH2CH2, R2= CH3, R4= CH3. One end of the structure is bisphenol A metacrylic acid glycidyl ester, carbamate bi-metacrylic acid ester or common polyradical group of the diluted triethylene - glycol dimethacrylate monomer molecule-a metacrylic acid ester group, and the other end is a functional group with antibacterial property, including N+ with positive electric charge, and a benzene ring, a meta- benzene ring and a long alkyl chain which are at the side chain.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Method for preparing extraction probe by means of micro-solid phase extraction based on polymer (methacrylic acid-ethyl glycol dimethacrylate)

InactiveCN102698720ALow detection limitSimple methodOther chemical processesSolid sorbent liquid separationEthyleneglycol dimethacrylateSolid phase extraction

The invention discloses a method for preparing an extraction probe by means of micro-solid phase extraction based on a polymer (methacrylic acid-ethyl glycol dimethacrylate), belonging to the field of micro-solid phase extraction. The extraction probe comprises a hollow fiber membrane and extracting filler; a membrane bag stops macromolecules and granular impurities by the hollow fibre membrane; the extraction material adsorbs the target micromolecular compounds; trace of organic solvent is used to resolve the target compounds. The extraction filler is polymer (methacrylic acid-ethyl glycol dimethacrylate) with acidic side groups and a hydrophobic skeleton, and has relatively strong adsorption performance for target substances in water; the hollow fibre membrane is a polypropylene membrane that prevents macromolecules and granular impurities form entering so as to eliminate interference of a matrix to a great extent. Therefore, the micro-solid phase extraction has purification function for samples and is used for direct analysis of samples with complicate matrixes; and the analysis range of a substrate is expanded.

Owner:HOHAI UNIV

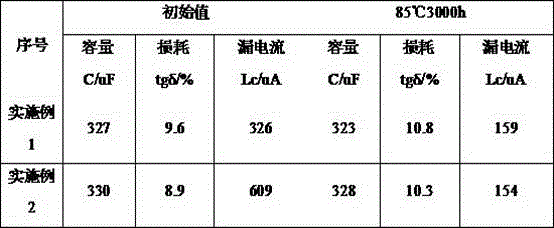

650V high-voltage aluminium electrolytic capacitor working electrolyte and preparation method thereof

InactiveCN106531443ALow viscosityLight weightLiquid electrolytic capacitorsDiethylene glycol monobutyl etherPolymer science

A 650V high-voltage aluminium electrolytic capacitor working electrolyte includes, in percentage by mass, 50% to 80% of a main solvent, 20% to 40% of auxiliary solvents, 5% to 15% of solutes, 1% to 8% of a sparking voltage enhancing agent; and the auxiliary solvents are two or more of a gamma-butyrolactone, DMF, polyethylene glycol 200, polyethylene glycol 400, a nano silica solution, glycerol, propylene carbonate, ethylene carbonate, tributyl phosphate, diethylene glycol monobutyl ether, trienthylene glycol dimethacrylate and diethylene glycol. The 650V high-voltage aluminium electrolytic capacitor working electrolyte has the advantages of low viscosity and high conductivity.

Owner:CENT SOUTH UNIV

Oil-absorbing resin and preparation method

ActiveCN103333286AImprove hydrophobicityImprove adsorption capacityOther chemical processesPolymer scienceDistilled water

The invention relates to an oil-absorbing resin and a preparation method thereof. The oil-absorbing resin comprises an oil phase: 5-15 parts of glycol dimethacrylate, 15-30 parts of isobornyl methacrylate, 20-40 parts of p-diphenyl sulfone methacrylate, 10-15 parts of triethylene glycol methacrylate, 10-20 parts of divinylbenzene, 20-30 parts of styrene, 50-200 parts of porogen, 0.5-2 parts of AIBN; and a water phase: 500-1000 parts of distilled water, 5-15 parts of PVA, and 20-50 parts of NaCl. According to the preparation method provided by the invention, the isobornyl methacrylate and the p-diphenyl sulfone methacrylate are used as main synthesis materials, and meanwhile, the non-polar crosslinking agents divinylbenzene and glycol dimethacrylate are used as crosslinking agents, and the styrene with higher hydrophobicity is used as a comonomer to synthetically prepare the oil-absorbing resin which can effectively absorb oil.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Halogen free releasable semiconductive insulation shielding material and production method thereof

InactiveCN102634108AImprove electrical performanceImprove securityPlastic/resin/waxes insulatorsPolymer scienceEthyleneglycol dimethacrylate

The invention relates to a halogen free releasable semiconductive insulation shielding material and a production method of the halogen free releasable semiconductive insulation shielding material, which belongs to the technical field of cable material production. The production method provided by the invention comprises the fowling steps: setting an internal mixer at the temperature range of 90-100DEG C; mixing EVA (ethylene-vinyl acetate copolymer), EPDM (ethylene-propylene-diene monomer), coupling agent-propyl trimethoxy silane, microstalline wax, glycol dimethacrylate, antioxidant, carbon black and copper inhibitor in the internal mixer for 8-10min; molding through hot cutting after extrusion by a mixing mill; and finally drying by air. According to the invention, the production process is simple and reasonable, the production and control is convenient, and the product stability is good; and the production method provided by the invention are suitable for insulating layer shielding materials produced at medium-high voltage power cable (6KV or above) and can improve electrical performance and safety of the cable in long-time running.

Owner:镇国广 +1

Starch-based absorbent resin and preparation method therefor

InactiveCN106366248AWith emission reductionImprove water absorptionSodium bicarbonatePotassium persulfate

The invention relates to starch-based absorbent resin and a preparation method therefor and belongs to the technical field of absorbent resin. The starch-based absorbent resin contains the raw materials in parts by weight: 40-50 parts of potato starch, 30-40 parts of methacrylic acid, 30-40 parts of acrylic acid, 5-10 parts of acrylonitrile, 1-2 parts of methylene-bisacrylamide, 0.5-1.0 part of glycol dimethacrylate, 1-3 parts of potassium persulfate, 1-3 parts of sodium bicarbonate, 80-100 parts of distilled water and 20-30 parts of 10% NaOH. The absorbent resin adopts a natural substance, i.e., the starch as a basic raw material and accordingly has the advantages of environment-friendliness, biodegradability, emission reduction, low cost, easiness in raw material obtaining, and the like. The water absorption power can reach 600g / g to 800g / g.

Owner:胡级轮

Strongly basic carbon nanotube composite resin and its preparation method

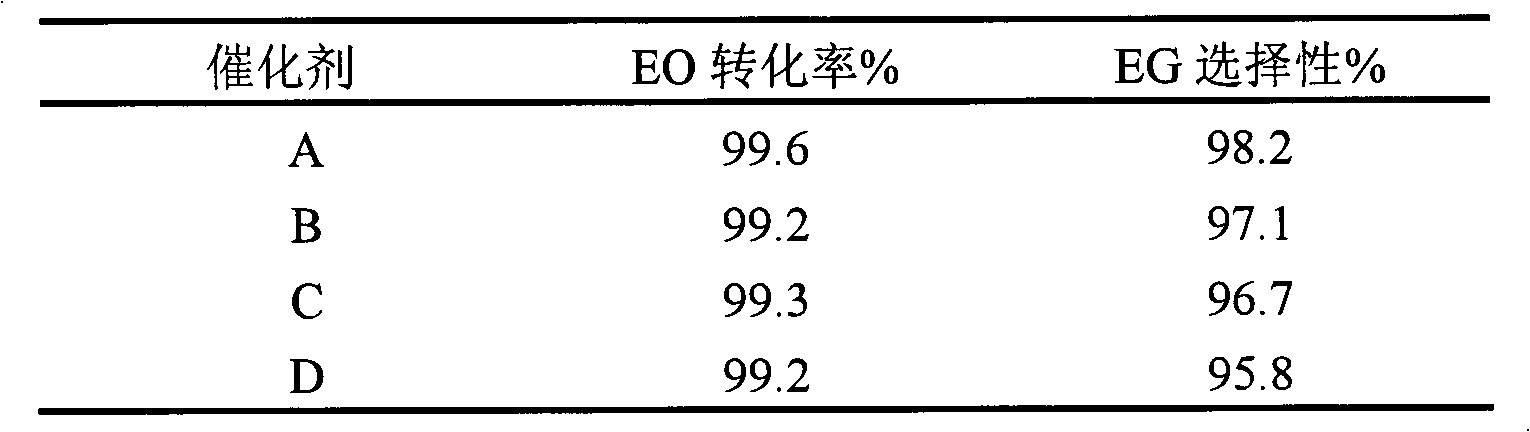

The invention relates to strongly basic carbon nanotube composite resin and its preparation method, and mainly aims to solve the problems of poor heat resistance and swelling resistance of ion exchange resin involved in previous technologies. The composite resin of the invention comprises: (1) 75-90% of a monomer; (2) 5-15% of a comonomer; (3) 0.1-5% of a nano-material; (4) 0.1-10% of an initiator. Specifically, the monomer is at least one of p-chloromethyl styrene, 4-(3-chloropropyl) styrene, 4-(3-bromopropyl) styrene, 4-(4-chlorobutyl) styrene, 4-(4-brombutyl) styrene, 4-(5-chloropentyl) styrene or 4-(5-bromopentyl) styrene; the comonomer is at least one of glycol dimethacrylate, 2-propenylbenzene, divinyl phenylmethane, and divinylbenzene;the nano-material is at least one of a multi-walled carbon nanotube, a single-walled carbon nanotube, C60 or C70 etc. fullerene; and the initiator is at least one of benzoyl peroxide, azodiisobutyronitrile, lauroyl peroxide, and cumene hydroperoxide. The composite resin and its preparation method of the invention well solves the above problems, and can be used in the industrial production of oxirane catalytic hydration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of multicomponent composite materials used for single paste type cavity filling

InactiveCN101569593AImprove toughnessNot easy to peel offImpression capsDentistry preparationsMethacrylateApatite

The invention relates to a preparation method of multicomponent composite materials used for single paste type cavity filling, belonging to the field of preparation for dental use. The technical proposal aims at solving the problem that current dental composite resin materials used for cavity filling urgently need to be further improved in the aspects of wear-resisting properties and toughness. The method comprises the following steps: silane coupling agent is adopted to carry out surface modification on inorganic nano powder; the modified inorganic nano powder is evenly mixed with monomers such as bisphenol A glycidyl methacrylate, thinners such as triethylene- glycol dimethacrylate, light initiators such as camphorquinone, coinitiators such as dimethylamino ethyl methacrylate and the like in the absence of light; bubbles are eliminated in vacuum. The technical proposal has the key point that the inorganic nano powder contains short-rod like nano-particle hydroxyapatite accounting for 10-80% of the inorganic nano powder by weight. The short-rod like nano-particle hydroxyapatite added in the multicomponent composite materials helps to improve the wear-resisting properties and toughness of the materials.

Owner:中国人民解放军南京军区福州总医院四七六临床部

Resin lens with ultraviolet photocuring refractive index of 1.56 and production method thereof

The invention relates to a resin lens with ultraviolet photocuring refractive index of 1.56, and the resin lens comprises the following raw material components by mass: 15%-20% of methyl styrene, 35%-60% of poly(propyleneglycol)dimethacrylate, 20%-40% of tri methylol propane tri methacrylate, 15%-30% of poly pentyl glycol dimethacrylate, 0.002 to 0.05% of an UV agent, 0.01-0.04% of a pigment and 0.06-0.1% of a light curing initiator. The invention provides a method for manufacturing the resin lens with the ultraviolet photocuring refractive index of 1.56, and the method is a new and efficient method for producing the resin lenses that can be cured by ultraviolet ray.

Owner:SHANGHAI WEIXING OPTICAL

Molecularly imprinted polymer for m-p-cresol separation and preparation method thereof

The invention discloses a molecularly imprinted polymer for m-p-cresol separation and a preparation method of the polymer. The molecularly imprinted polymer for m-p-cresol separation is synthesized by taking 4-vinyl pyridine, acrylamide and alpha-methyl methacrylate as functional monomers, glycol dimethacrylate as a cross-linking agent, azo diisobutyronitrile as an initiator and acetonitrile as a solvent.

Owner:ANQING FULLTIME CHEM INDAL +1

Sodium hyaluronate contained flexible hydrophilic contact lens and method for producing the same

ActiveCN101482625AImprove dehydrationReduce evaporationOptical articlesOptical parts(Hydroxyethyl)methacrylateGlycidyl methacrylate

The invention discloses a flexible hydrophilic contact lens containing sodium hyaluronate and preparing method thereof, the flexible hydrophilic contact lens consists of comonomers composed of methyl methacrylate, ethyl methacrylate, N-ethenyl pyrrolidone, glyceryl methacrylate, (bi)glycol dimethacrylate, UV absorbing agent, azo-bis-iso-heptonitrile and reduction blue rinsing dye, also comprises 0. 1-0. 2(volume) of sodium hyaluronate water solution, when being preparing, mixing the above substances; arranging in a mould for heat polymerization and additional vulcanization; then machining, hydrating, extracting and cleaning to obtain the flexible hydrophilic contact lens. The sodium hyaluronate adopted in the invention is high hydrotropic substance and has high wetting property and moisture-keeping property. The sodium hyaluronate is added in the traditional flexible hydrophilic contact lens material system, which can improve the water content of the material and can improve the wetting property and the moisture-keeping property of the material surface, the wearing time of the wearer can be prolonged.

Owner:GUANGZHOU BAOSHINING OPTICAL PROD

Organic one-component inserted bar glue and preparation method thereof

InactiveCN104762052AFor long-term storageLow viscosityNon-macromolecular adhesive additivesModified epoxy resin adhesivesPolymer scienceAcrylic adhesive

The invention discloses an organic one-component inserted bar glue and a preparation method thereof, and belongs to the technical field of anaerobic adhesives. The organic one-component inserted bar glue is prepared from the following raw materials: methacrylic acid epoxide, triethylene-glycol dimethacrylate, acrylic acid, ethylenediamine tetraacetic acid, cumene hydroperoxide, acidified saccharin and hydracetin. By virtue of an anaerobic curing mechanism, the target of one-component inserted bar glue is reached; and the acrylic adhesive can be relatively permanently stored in a liquid state when oxygen exists, and can be cured into an insoluble and non-fusible solid at a room temperature after being isolated from air.

Owner:DALIAN UNIV OF TECH

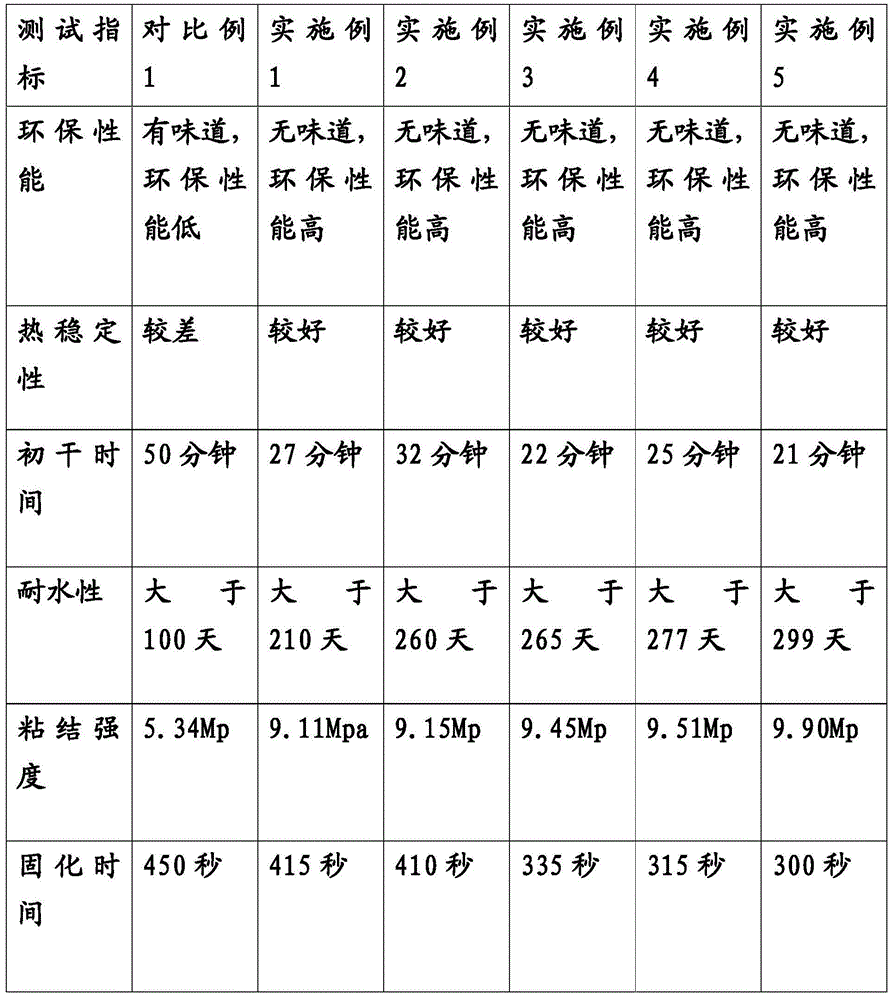

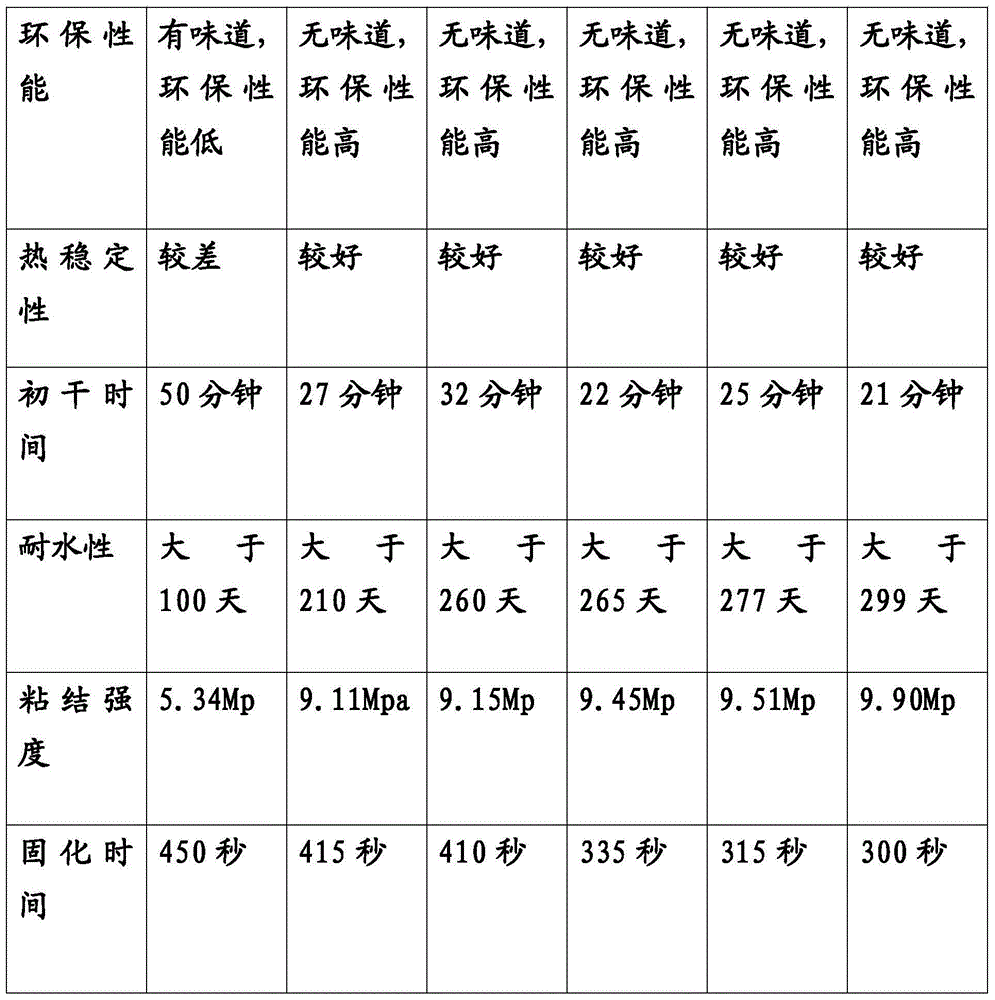

Strong white latex

ActiveCN104673146AImprove thermal stabilityExcellent dry timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonateWaxy corn

The invention provides strong white latex. The strong white latex comprises the following components in parts by weight: 900 parts of polyvinyl acetate, 330 parts of vinyl acetate, 130 parts of polyvinyl alcohol, 85 parts of dibutyl phthalate, 30 parts diethylene glycol dibenzoate, 13 parts of octanol, 37 parts of isopropanol, 19 parts of allyl methacrylate, 8 parts of glycol dimethacrylate, 5 parts of toluene diisocynate, 41 parts of sodium bicarbonate, 1460 parts of water, 46 parts of an emulsifying agent, 8 parts of an initiator, 27 parts of hydroxymethyl acrylamide, 13 parts of waxy corn starch and 5 parts of sodium hypochlorite. The environmental-friendly performance of the strong white latex is fundamentally improved; meanwhile, the strong white latex has excellent representation on indexes of thermal stability, initial drying time, water resistance, bonding strength and curing time and has excellent overall performance.

Owner:江苏中丽新材料有限公司

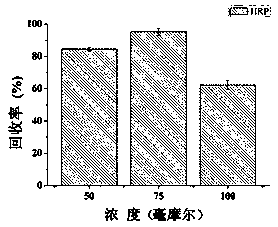

Octavinyl-POSS and ethylene glycol dimethacrylate co-crosslinked boron affinity monolithic column and preparation method thereof

ActiveCN109400823AImprove permeabilityHigh recovery rateOther chemical processesRelative standard deviationSolid-phase microextraction

The invention relates to anoctavinyl-POSS and ethylene glycol dimethacrylate co-crosslinked boron affinity monolithic column and a preparation method thereof. The octavinyl-POSS ethylene glycol dimethacrylate co-crosslinked boron affinity monolithic column is prepared from 1.63 percent of octavinyl-POSS, 4.05 percent of ethylene glycol dimethacrylate, 0.26 percent of azobisisobutyronitrile, 3.08 percent of 3-acryloylaminophenylboronic acid, 81.98 percent of chloroform and 9.00 percent of dimethyl sulfoxide. The boron affinity monolithic column is prepared by co-crosslinking octavinyl-POSS andethylene glycol dimethacrylate, and is applied to solid-phase microextraction of horse radish peroxidase. Compared with aboron affinity monolithic column without the octavinyl-POSS, the boron affinitymonolithic column containing a proper amount of octavinyl-POSS as a crosslinking agent has the advantages that the recovery rate during solid-phase microextraction of the horse radish peroxidase is improved twice or more, being 90 percent or more, and the relative standard deviation (RSD) is less than 5 percent.

Owner:TIANJIN MEDICAL UNIV

Preparation method of white latex

InactiveCN104628960AImprove thermal stabilityExcellent dry timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonateOctanol

The invention provides a preparation method of white latex. The method comprises the following steps: taking water and vinol, mixing and increasing the temperature; taking an emulgator, adding the emulgator and residual water to the solution under the condition of stirring, then slowly adding vinyl acetate and an initiator, increasing the temperature and preserving heat; cooling; after that adding residual vinyl acetate and residual initiator; adding the emulgator and polyvinyl acetate; adding sodium bicarbonate, dibutyl phthalate, diethylene glycol dibenzoate, octanol and isopropanol; adding residual emulgator, allyl methacrylate, glycol dimethacrylate, toluene diisocynate, N-hydroxymethyl acrylamide, waxy maize starch and sodium hypochlorite to obtain the white latex. The content of vinyl acetate in the white latex prepared by the preparation method is greatly reduced, the environmental protection property of a product is improved fundamentally, and the white latex is superior in combination property.

Owner:江苏中丽新材料有限公司

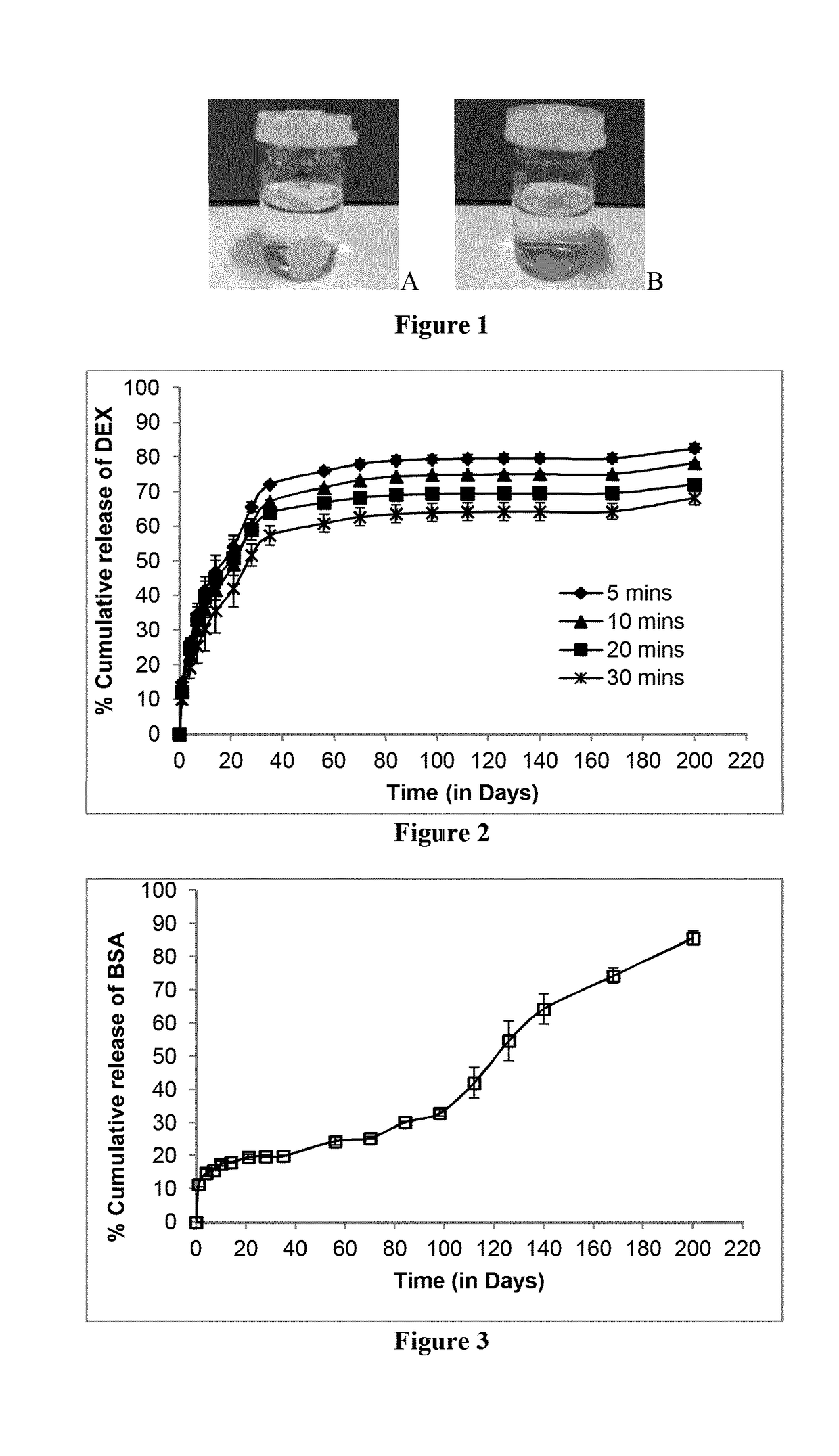

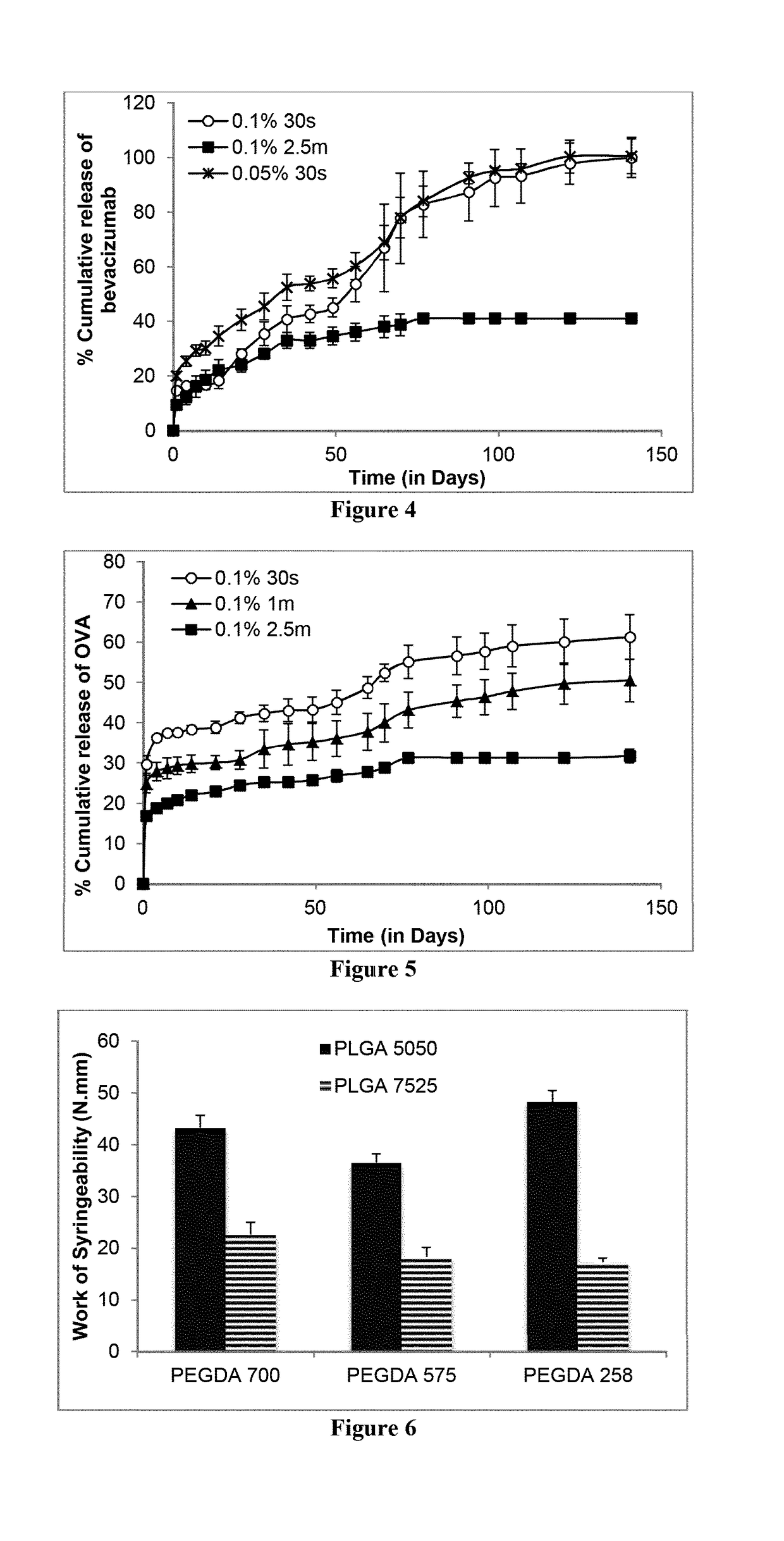

Ocular compositions

InactiveUS20180325812A1Maintain activityOrganic active ingredientsSenses disorderPolyesterMethacrylate

The invention provides an ocular composition comprising: 99 to 60% (w / w) of a photopolymerizable composition selected from the group of fragments or monomers consisting of polyalkylene glycol diacrylate and polyalkylene glycol dimethacrylate, wherein the photopolymerizable composition has a molecular weight in the range of 100 to 20,000 Dalton; a biodegradable polymer selected from the group consisting of aliphatic polyester-based polyurethanes, polylactides, polycaprolactones, polyorthoesters and mixtures, copolymers, and block copolymers thereof; a photoinitiator; and a therapeutic agent. The composition can be used to form an ocular implant and an in situ ocular implant.

Owner:RE VANA THERAPEUTICS LTD

Macroporous adsorbent resin for treating phenol-containing industrial wastewater and preparation method of macroporous adsorbent resin

InactiveCN106732447AHigh mechanical strengthExtended service lifeOther chemical processesWater contaminantsAcrylonitrileSolvent

The invention relates to macroporous adsorbent resin for treating phenol-containing industrial wastewater and a preparation method of the macroporous adsorbent resin and belongs to the technical field of the macroporous adsorbent resin. The macroporous adsorbent resin is characterized in that according to physical and chemical properties of a phenol compound, polymer molecular design is adopted, and styrene is selected as a main copolymer monomer; divinyl benzene is used as a main crosslinking agent and matched with glycol dimethacrylate with certain polarity to serve as a second crosslinking agent; moreover, acrylonitrile is used as a fourth monomer, so that the mechanical strength of macroporous resin is enhanced and the service life of the macroporous resin is prolonged; on the basis, a good solvent and a poor solvent are selected to be matched to serve as a pore forming system; the macroporous adsorbent resin which has better adsorption selectivity and higher adsorbing capacity to phenol, and is easy to dilute and long in service life is synthetized by applying a suspension polymerization process in one step; the adsorbing capacity of the macroporous adsorbent resin to the phenol can reach 50 to 60mg / g, and the service cycle is 100 or above.

Owner:华莉君

Cyclodextrin binder and preparation method thereof

InactiveCN105131846AIncrease stickinessImprove heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCyclodextrinPolymethyl methacrylate

The invention discloses cyclodextrin binder and a preparation method thereof. The cyclodextrin binder includes cyclodextrin, glycerin, polymethyl methacrylate, sodium dodecyl benzene sulfonate, glycol dimethacrylate and rosin. The cyclodextrin binder has excellent binding performance, and meanwhile has excellent heat resisting performance.

Owner:ANHUI EMINENT BUILDING MATERIALS TECH

Anti-seismic vegetable fiber cement composite strip plate and producing method thereof

InactiveCN104909655AImprove corrosion resistanceImprove water resistanceSolid waste managementAcoustic absorptionThermal insulation

The present invention discloses an anti-seismic vegetable fiber cement composite strip plate which is prepared from the following raw materials by weight: 30-35 parts of vegetable fiber, 20-25 parts of Portland cement, 40-46 parts of fly ash, 10-20 parts of silica fume, 10-13 parts of diatomite, 7-9 parts of nano calcium carbonate, 3-5 parts of algae carbon fiber, 0.2-0.4 part of potassium bisulfate, 0.3-0.5 part of aluminum nitride, 14-18 parts of water-soluble phenolic resin, 6-10 parts of glycol dimethacrylate, 4-6 parts of methylsilicone oil, 0.1-0.2 part of polyvinylpyrrolidone, and proper amount of water; the obtained anti-seismic vegetable fiber cement composite strip plate has the advantages of anti-seismic, acoustic absorption thermal insulation, compressive strength, fracture resistance, strong density, good permeability and the like, and is suitable for large-scale construction of the anti-seismic energy-saving houses.

Owner:HEFEI RUIHE DECORATION ENG

Plastic track material for stadiums

InactiveCN105860293AThe preparation process is simpleGood rebound rateBuilding insulationsPolyvinyl chlorideDiethylenetriamine

The invention relates to a plastic track material for stadiums. The plastic track material is prepared from triethylene-glycol dimethacrylate, dodecyl benzyl ammonium chloride, sodium dehydroacetate, barium stearate, ethylene-propylene-diene monomer rubber, zinc oxide powder, petroleum asphalt, carboxymethyl cellulose sodium, polyurethane, antimonous oxide powder, chlorfluazuron, abamectin, diethylenetriamine, isobutyltriethoxysilane, cocoanut fatty acid diethanolamide, bentonite powder, chitosan, sodium lauryl sulfate, barium sulfate, silica sol, aluminium hydroxide powder and polyvinyl chloride. The plastic track material for the stadiums is simple in preparation process. Moreover, the plastic track material has advantages of high resilience, tensile strength and breaking elongation and excellent abrasion resistance and antibacterial performance.

Owner:BEIHUA UNIV

Wear-resistant paint used for metal components, and preparation method of wear-resistant paint

The invention provides wear-resistant paint used for metal components, and a preparation method of the wear-resistant paint. The wear-resistant paint contains the following ingredients in parts by weight: 5-16 parts of cellulose acetate, 15-31 parts of epoxy phenolic resin, 5-12 parts of trimethylolpropane triacrylate, 1-3.6 parts of chlorinated polyethylene, 0.5-1.3 parts of tetraethyl orthosilicate, 2-5 parts of glycol dimethacrylate, 20-35 parts of diethylenetriamine, 12-25 parts of ethylenediamine, 0.3-0.6 parts of antiager, and 0.1-0.3 parts of benzophenone. The paint provided by the invention has good wear resistance, scratch resistance and gloss, and also has good ageing resistance, so as to well protect metal components.

Owner:深圳市越丹科技有限公司

Organic-inorganic coating for ceramic antenna cover moisture resistance and preparation method thereof

InactiveCN109321012ADoes not affect the dielectric constantDoes not affect mechanicsPolyether coatingsSolventTemperature resistance

The invention discloses an organic-inorganic coating for ceramic antenna cover moisture resistance and a preparation method thereof. The coating is prepared from the following components in percentageby mass: 20-60% of vinyl polydimethylsiloxane, 2-30% of vinyl octahedral oligomeric silsesquiloxane, 2-6% of oligoethylene glycol dimethacrylate, 0.01-1% of a photoinitiator, and the balance of solvent. The prepared moisture-proof coating is good in moisture resistance effect, is not liable to carbonize, is good in coating film-forming property, is low in dielectric coefficient, is good in high temperature resistance, and can realize moisture resistance, high temperature resistance and wave-transmitting property of an antenna cover in the aerospace field of an antenna cover; and the inventionpreparation method is simple and convenient in preparation process, isadopts easily available in materials, is simple in preparation method, and is controllable in reaction condition.

Owner:湖北三江航天江北机械工程有限公司

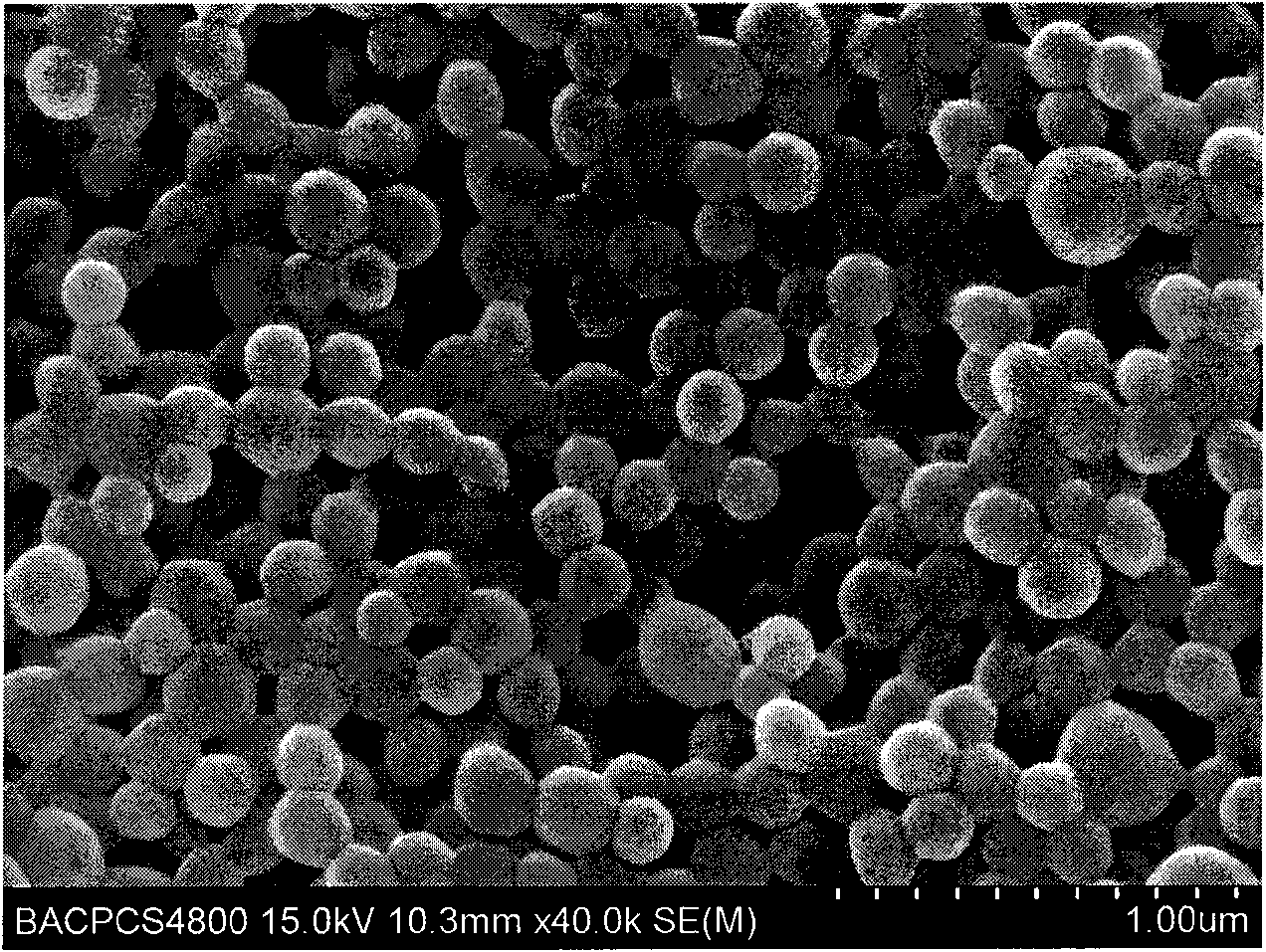

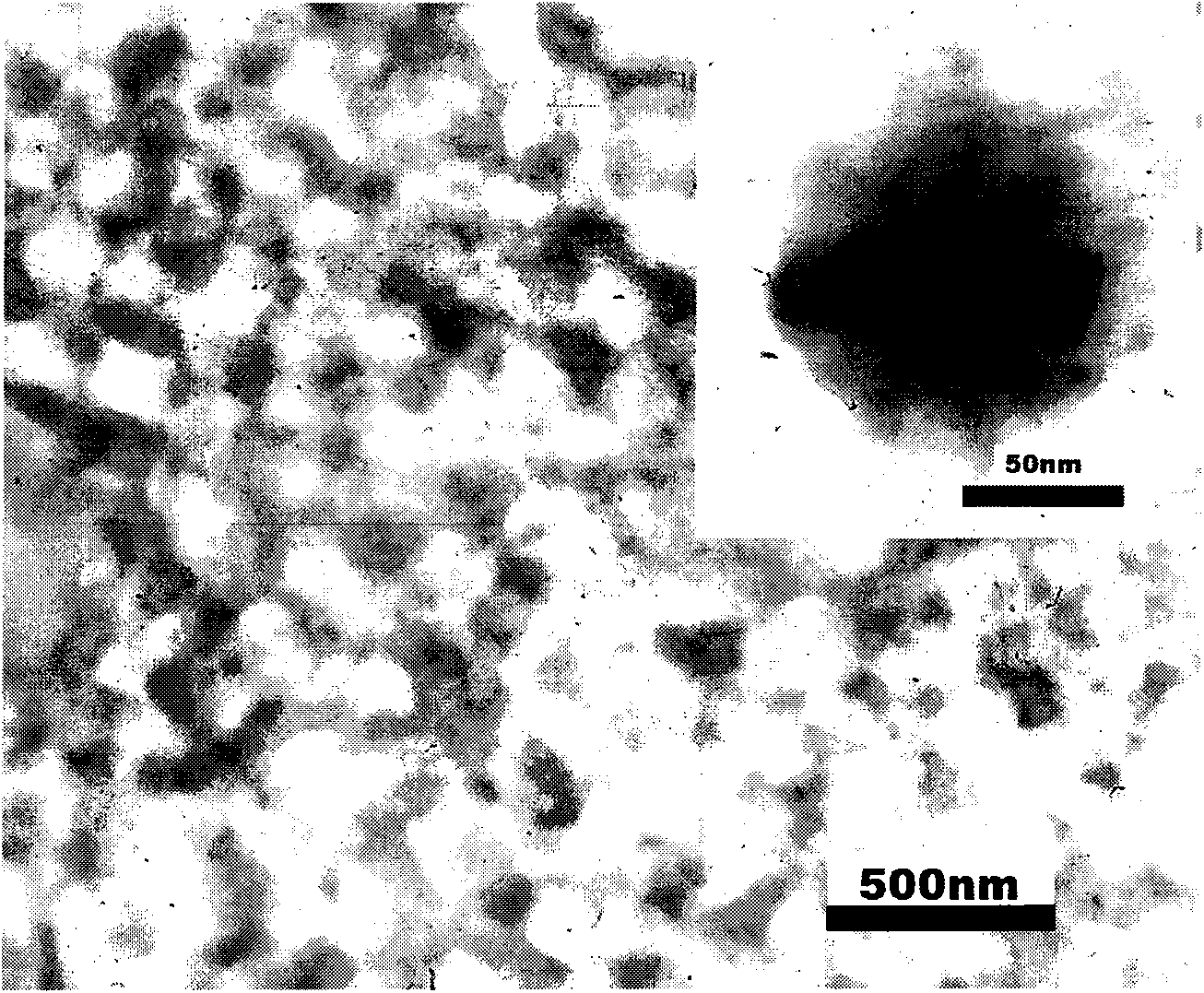

Polymeric microsphere and preparation method thereof

ActiveCN105175624ASolve the problem that the functional reaction cannot be carried out further to bring a certain functional groupXylylenePolymer science

The invention relates to a polymeric microsphere and a preparation method thereof, belonging to the technical field of high polymer materials. The polymeric microsphere comprises the following raw materials in parts by weight: oil phases: 10-20 parts of ethylene glycol dimethacrylate, 15-25 parts of pentaerythritol triacrylate, 50-60 parts of hydroxyethyl methylacrylate, 20-30 parts of butyl acrylate, 5-9 parts of styrene, 60-70 parts of xylene, 40-50 parts of isooctane and 2-8 parts of azodiisobutyronitrile; water phases: 3-10 parts of polyvinyl alcohol, 15-25 parts of gelatin, 50-60 parts of NaCl and 1000-2000 parts of deionized water. According to the preparation method, the polymeric microsphere which has hydroxyl groups and can be equipped with certain functional groups through further functional reaction is prepared by virtue of a suspension polymerization method by taking ethylene glycol dimethacrylate and pentaerythritol triacrylate as a mixing cross-linking agent and hydroxyethyl methylacrylate, butyl acrylate and styrene as copolymer monomers.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Super-macroporous adsorbent resin and preparation method thereof

InactiveCN104059187ALarge apertureGuaranteed mechanical strengthOther chemical processesPolymer sciencePolyvinyl alcohol

The invention relates to a super-macroporous adsorbent resin and a preparation method thereof, belonging to the field of high polymer materials. The super-macroporous adsorbent resin is prepared from the following raw materials in parts by weight: 50-70 parts of divinylbenzene, 5-10 parts of styrene, 10-20 parts of glycol bis-methacrylate, 5-10 parts of polystyrene, 50-80 parts of diethyl phthalate, 30-50 parts of 200# gasoline, 1-2 parts of diphenyl acyl peroxide, 150-200 parts of deionized water and 1-2 parts of polyvinyl alcohol. The polystyrene and diethyl phthalate used as the pore-forming agent component for preparing the super-macroporous adsorbent resin increase the pore size of the resin and widen the application range of the resin. The second crosslinking agent increases the pore size of the resin, ensures the mechanical strength of the resin and provides the service life of the resin.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Modified highly-oil-absorbing resin and preparation method thereof

InactiveCN106496431ALarge oil absorptionHigh porosityOther chemical processesPorosityPolymer science

The invention relates to a modified highly-oil-absorbing resin and a preparation method thereof, belonging to the technical field of oil-absorbing resin. The modified highly-oil-absorbing resin comprises a water phase and an oil phase and is prepared by using a suspension polymerization process. During selection of a formula, glycol dimethacrylate and divinyl benzene are used as a composite cross-linking agent; dibenzoyl peroxide (BPO) is used as an initiator; polymerization monomers are composed of methyl methacrylate, octadecyl acrylate, dodecanol acrylate and other components of a traditional oil-absorbing resin, and in addition, butadiene rubber with good lipophilicity is added into a polymerization system to improve the oil absorption amount of the oil-absorbing resin; and gasoline No. 200 is added as a pore forming agent to improve porosity of the resin and accelerate the oil-absorbing rate of the resin. The highly-oil-absorbing resin prepared under the condition of such a formula has toluene and xylene adsorption quantities of 25 to 35 g / g and 20 to 25 g / g respectively, and has good application prospects.

Owner:BLUESTAR CHENGDU NEW MATERIALS

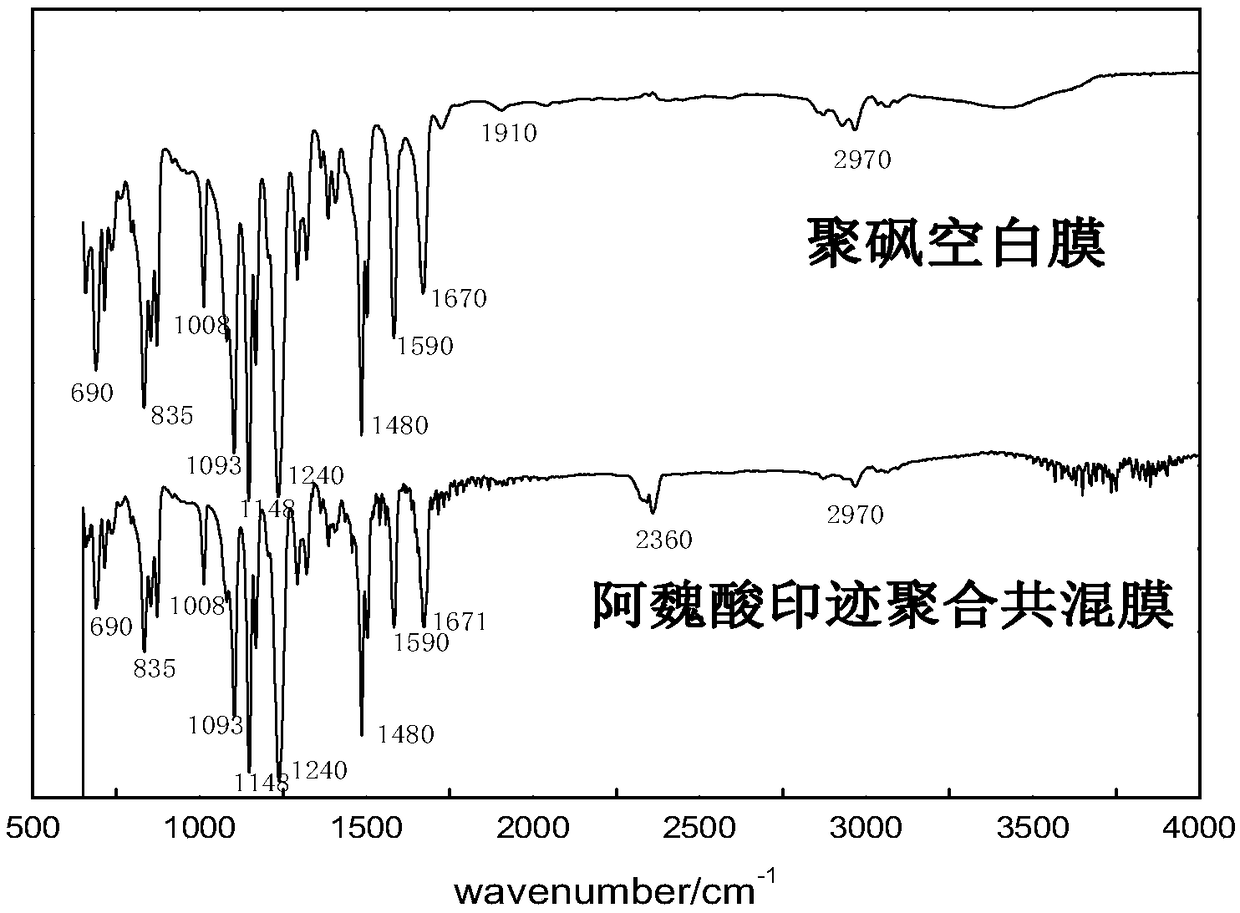

Preparation method of ferulic acid molecularly imprinted blend membrane material

InactiveCN109400804ASpecific selectivityExcellent binding affinityOther chemical processesWater bathsMicrosphere

The invention discloses a preparation method of a ferulic acid molecularly imprinted blend membrane material. The preparation method comprises the following operation steps: (1) dissolving a mixture of ferulic acid and acrylamide into acetonitrile, fully stirring, and putting in a refrigerator for standing; (2) adding azodiisobutyronitrile and the ferulic acid after taking out a solution, adding glycol dimethacrylate, introducing nitrogen, and heating in a water bath pot at a constant temperature of 50 to 60 DEG C, thus obtaining ferulic acid molecularly imprinted microspheres; (3) carrying out suction filtration on the polymer microspheres, and repeatedly washing by using a mixed solution of methanol and acetic acid until no ferulic acid is detected; (4) preparing a mixture of polysulfoneand the ferulic acid molecularly imprinted polymer microspheres, adding N,N-dimethyl formamide, stirring and heating at the constant temperature of 50 to 80 DEG C until the polysulfone is completelydissolving, putting and heating a completely dissolved casting solution in a vacuum drying machine at the constant temperature of 50 to 80 DEG C, and taking out and naturally air-drying a concentratedsolution with poorer fluidity, thus obtaining a ferulic acid molecularly imprinted blend membrane. The ferulic acid molecularly imprinted blend membrane prepared by the invention is high in specificsurface activity and good in comprehensive performance.

Owner:LONGYAN UNIV

Long-lasting concrete curing compound

A long-lasting concrete curing compound comprises the following raw materials by weight: 7 to 10 parts of ammonium thiosulfate, 6 to 8 parts of ethylene-propylene-diene monomer rubber, 2 to 7 parts of fatty ester, 5 to 8 parts of sodium carbonate, 7 to 10 parts of sodium dodecyl-benzene sulfonate, 4 to 8 parts of sodium gluconate, 4 to 7 parts of periodate lignin, 7 to 11 parts of tributyl citrate, 6 to 13 parts of ethyl acrylate, 4 to 10 parts of azodiisobutyronitrile, 3 to 8 parts of benzyl alcohol, 8 to 11 parts of glycol dimethacrylate, and 4 to 8 parts of gypsum powder. The long-lasting concrete curing compound has the advantages that the action time is long; the water retention effect is high; the service life of concrete can be prolonged.

Owner:QINGDAO XIANGJIA INTPROP SERVICE CO LTD

Preparation method of composite modified rubber asphalt with excellent anti-stripping performance

InactiveCN107815129AGood high and low temperature performanceImprove temperature sensitivityBuilding insulationsPolymer scienceSulfur

The invention discloses a preparation method of composite modified rubber asphalt with excellent anti-stripping performance. The preparation method comprises the following steps: stirring 15-25 partsby weight of tire rubber powder and 65-75 parts by weight of pavement petroleum asphalt at the temperature of 190-220 DEG C, then adding 2-4 parts by weight of hydroxypropyl acrylate, 2-4 parts by weight of glycol dimethacrylate and 0.3 part by weight of elemental sulfur as a crosslinking agent, firstly shearing by adopting a high-speed shearing machine at the temperature of 190-210 DEG C, so thata composite modified asphalt mixture is obtained, maintaining lingering warmth, standing for 30 minutes and carrying out development infiltration, adding 1-2 parts by weight of diisopropyl phthalate,and then stirring at a constant speed by adopting a stirring machine at the temperature of 180-200 DEG C, so that the composite modified rubber asphalt is prepared. The preparation method disclosed by the invention has the advantages that the obtained modified rubber asphalt can keep good high temperature performance, and anti-stripping performance and adhesion of common rubber asphalt are improved.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Polyacrylonitrile material and preparation method thereof

The invention discloses a polyacrylonitrile material and a preparation method thereof. The polyacrylonitrile material is prepared from components in parts by weight as follows: 79-86 parts of polyacrylonitrile, 20-25 parts of inorganic filler, 15-25 parts of polyamide fiber, 7-9 parts of maleic anhydride grafted polypropylene, 5-11 parts of triethylene-glycol dimethacrylate, 3-7 parts of epoxypropane butyl ether, 2-6 parts of 1,8-diazabicyclo(5,4,0)-undec-7-ene, 2-3 parts of montan wax acid ethylene diester, 0.5-2 parts of dibutyltin dilaurate, 0.5-1 part of barium metaborate and 0.02-1.5 parts of tung oil anhydride. The invention further provides a preparation method of the polyacrylonitrile material.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com