A method to prepare the phase-change material wrapped by microcapsule

A technology of phase change materials and microcapsules, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., and can solve the problem that it is difficult to meet the needs of full-band camouflage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

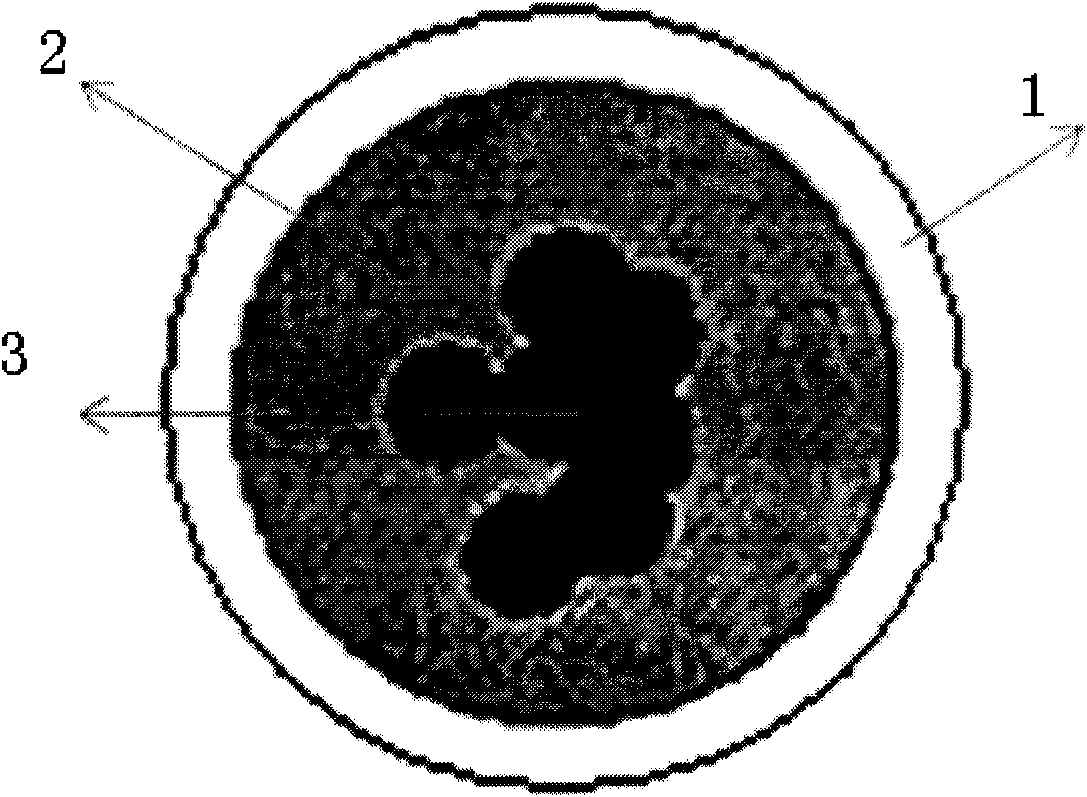

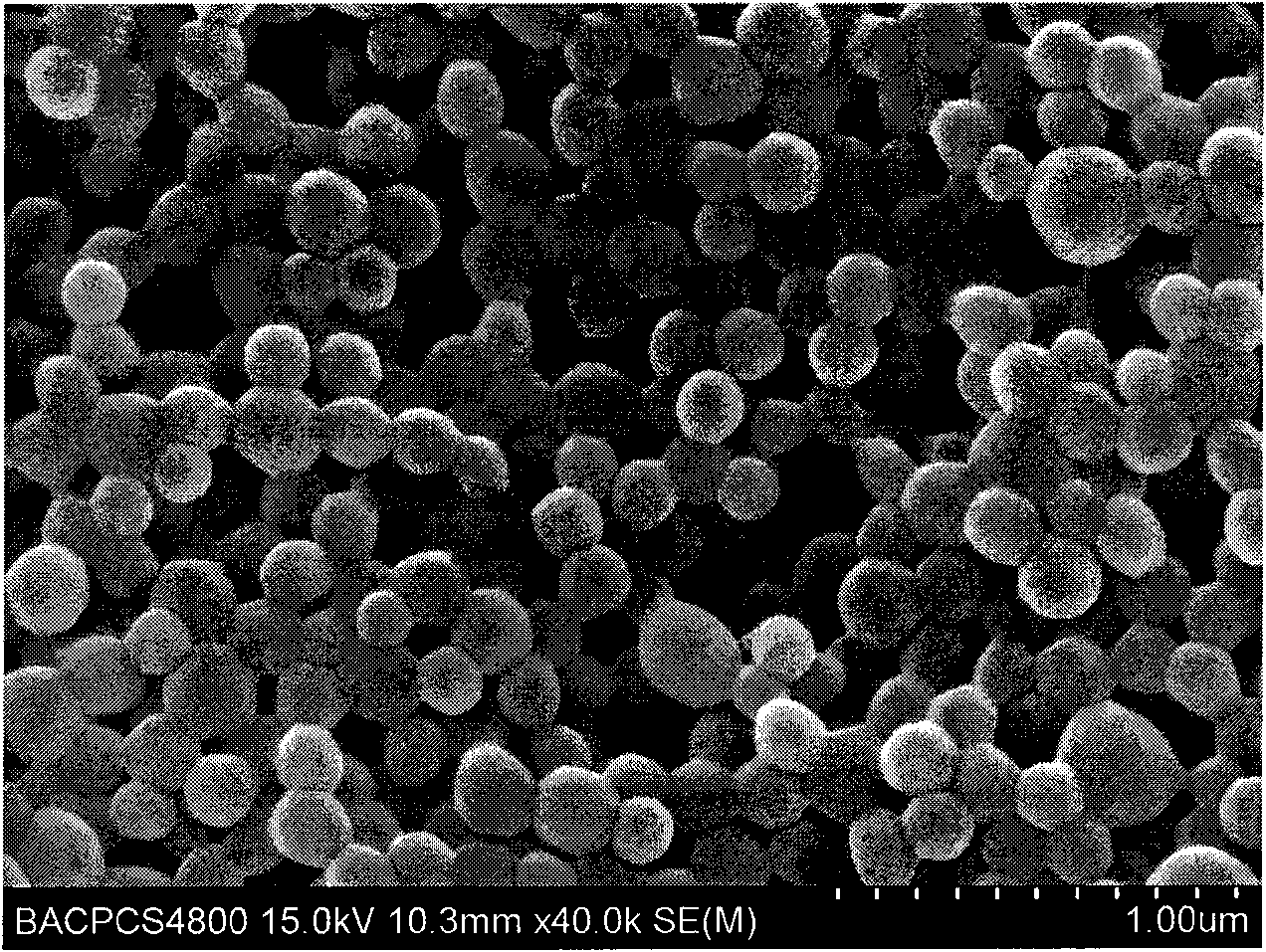

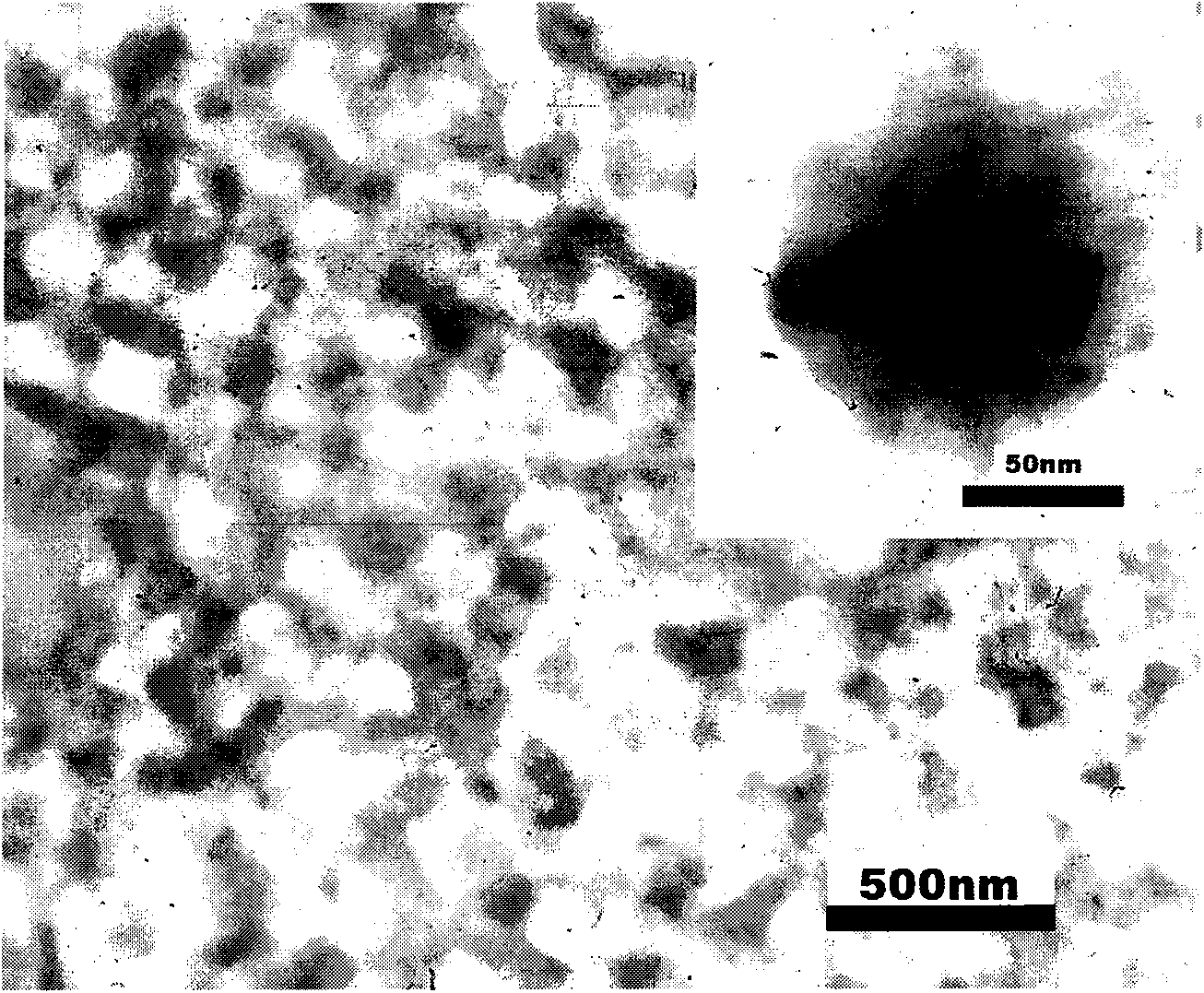

Method used

Image

Examples

Embodiment approach 1

[0030] Concrete steps of a preparation method of a microcapsule-coated phase-change material:

[0031] Step 1, weigh 5g of paraffin, 15g of methyl methacrylate; 0.1g of ethylene glycol dimethacrylate, 0.2g of methacrylic acid, 0.2g of sodium lauryl sulfate, 0.3g of potassium persulfate, ferrite 0.6g, 80g deionized water;

[0032] Step 2, adding sodium lauryl sulfate to deionized water and heating to 50°C;

[0033] Step 3, adding ferrite and heated and melted paraffin to the solution in step 3;

[0034] Step 4, using an ultrasonic cell pulverizer, after ultrasonic emulsification for 5 minutes, adding methyl methacrylate, ethylene glycol dimethacrylate and methacrylic acid;

[0035] Step 5, after ultrasonic emulsification for 5 minutes, move the obtained mixture solution into a four-neck flask with mechanical stirring, condenser, argon inlet and feed port;

[0036] Step 6: After passing argon gas to remove oxygen for 0.5 hours, heat in a water bath to 70° C., add potassium pe...

Embodiment approach 2

[0041] Concrete steps of a preparation method of a microcapsule-coated phase-change material:

[0042] Step 1, weigh 5g of paraffin, 15g of methyl methacrylate; 0.1g of ethylene glycol dimethacrylate, 0.2g of methacrylic acid, 0.2g of sodium lauryl sulfate, 0.3g of potassium persulfate, ferrite 0.2g, 80g deionized water;

[0043] Step 2, adding sodium lauryl sulfate into deionized water and heating to 50°C;

[0044] Step 3, adding the ferrite and the ferrite to the solution in step 3 after heating and melting;

[0045] Step 4, using an ultrasonic cleaner, ultrasonic emulsification for 15 minutes, adding methyl methacrylate, ethylene glycol dimethacrylate and methacrylic acid;

[0046] Step 5, after ultrasonic emulsification for 10 minutes, move the obtained mixture solution into a four-neck flask with mechanical stirring, condenser, nitrogen inlet and feeding port;

[0047] Step 6: After passing nitrogen gas to remove oxygen for 0.5 hours, heat in a water bath to 70°C, add ...

Embodiment approach 3

[0050] Concrete steps of a preparation method of a microcapsule-coated phase-change material:

[0051] Step 1, weigh 5g of paraffin, 15g of methyl methacrylate; 0.1g of ethylene glycol dimethacrylate, 0.2g of methacrylic acid, 0.2g of sodium lauryl sulfate, 0.3g of potassium persulfate, ferrite 3g, 80g deionized water;

[0052] Step 2, adding sodium lauryl sulfate into deionized water and heating to 50°C;

[0053] Step 3, adding ferrite and heated and melted paraffin to the solution in step 3;

[0054] Step 4, using ultrasonic cell pulverizer, ultrasonic emulsification for 5 minutes, adding methyl methacrylate, ethylene glycol dimethacrylate and methacrylic acid;

[0055] Step 5, after ultrasonic emulsification for 5 minutes, move the obtained mixture solution into a four-neck flask with mechanical stirring, condenser, argon inlet and feed port;

[0056] Step 6: After passing argon gas to remove oxygen for 0.5 hours, heat in a water bath to 70° C., add potassium persulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com