Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Allyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Allyl methacrylate contains chromophores that absorb at wavelengths >290 nm and therefore may be susceptible to direct photolysis by sunlight. If released to soil, allyl methacrylate is expected to have high mobility based upon an estimated Koc of 110.

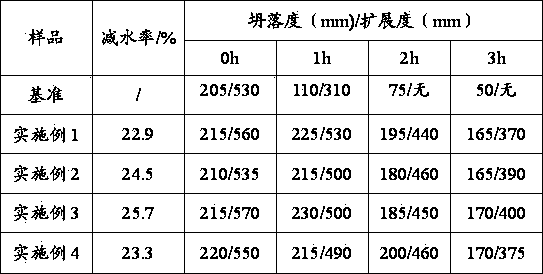

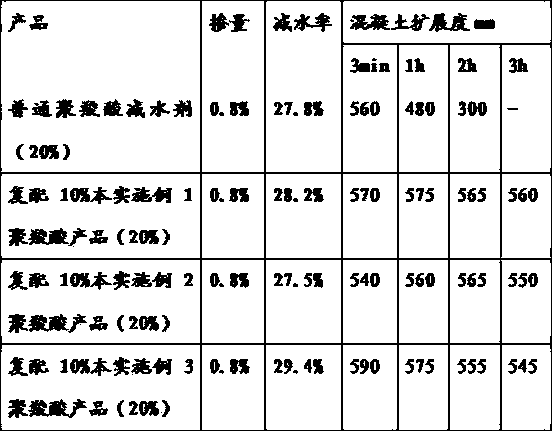

Preparation method for high-slump-retention polycarboxylate water reducer

InactiveCN103450411AIncreased steric hindranceSolve problems such as difficult pumpingMeth-Ptru catalyst

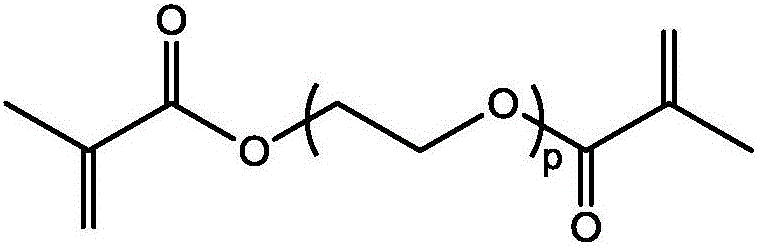

The invention discloses a preparation method for a high-slump-retention polycarboxylate water reducer. The preparation method comprises the following steps of: esterifying methoxylpolyethylene glycol monomethyl ethers with different molecular weights with methacrylic acid and a mixed polymerization inhibitor for a period of time under the action of a catalyst and at a certain temperature, then adding allyl alcohol in one time, further esterifying in the same conditions to obtain an esterified macromonomer MP containing crosslinking monomer allyl methacrylate; then performing aqueous solution polymerization on the MP, unsaturated sulfonate, (meth)acrylate unsaturated monomers and a chain transfer agent in a low-temperature condition and within a redox initiation system; and finally adding caustic soda liquid to neutralize, so as to obtain the polycarboxylate water reducer with a certain concentration. The high-slump-retention polycarboxylate water reducer prepared by the preparation method disclosed by the invention is a high-performance water reducer which is prepared at a low temperature by virtue of a molecular structure design, as well as is high in slump retention, excellent in dispersing performance, good in adaptability, simple in process, pollution-free, low in energy consumption, and easy to realize industrialized production.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Betaine type zwitterionic polymer antifogging coating and preparation method thereof

The invention discloses a betaine type zwitterionic polymer antifogging coating and a preparation method thereof. The coating is prepared from components as follows: 77%-100% of a random copolymer p (BMAm-co-FMAn-co-AMAr) and 0-23% of polyethylene glycol dimethacrylate; the coating is prepared from a betaine type zwitterionic polymer with a crosslinking point and polyethylene glycol dimethacrylate as a cross-linking agent through ultraviolet curing and film-forming, and is a random copolymer formed by betaine type acrylate monomers, fluorinated acrylate and allyl methacrylate through free radical polymerization. Hydrophilic betaine type zwitterionic components are subjected to hydration with water to realize the antifogging effect; with introduction of an appropriate quantity of hydrophobic components, water vapor can be effectively isolated, and interaction of a hydrophobic part and water is not influenced; the crosslinking point is provided by allyl methacrylate, so that stability of the coating is improved; the coating has good transparency and antifogging performance, and light transmittance of the coating in a visible light wavelength range reaches 80% or higher.

Owner:TIANJIN UNIV

Method for preparing antifouling material with surface of spherically raised microstructure

InactiveCN101691466ALower surfacePrevent adhesionAntifouling/underwater paintsPaints with biocidesAcrylonitrileHydrosilylation

The invention belongs to the technical field of antifouling material processing and relates to a method for preparing an antifouling material with surface of spherically raised microstructure which is formed by direct film forming. The antifouling material prevents marine growth from adhering to the surfaces of the ship and marine structures under marine environment. The method is characterized by first utilizing hydrogen-containing silicone oil and allyl methacrylate for hydrosilylation to synthesize a silicone component containing polymerizable double bonds, carrying out free radical copolymerization on the silicone component and acrylonitrile and acrylate monomers to form acrylate resin mixed liquor hinged with silicone gel particles, mixing the mixed liquor with resins and then coating films, thus obtaining the antifouling material. The mixed resin material has the characteristic of low surface energy. The characteristic of spherically raised microstructure is formed, thus improving the hydrophobic property of the antifouling material, so that the antifouling material prevents marine organisms from being contaminated. With the hydrophobic property being improved, the antifouling material reduces the possibility of organism adhesion, has no devastating impacts on the environment and has good application prospect, reduced surface energy, strong capability of preventing adhesion of diatom, simple and easily controlled preparation process and low cost.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

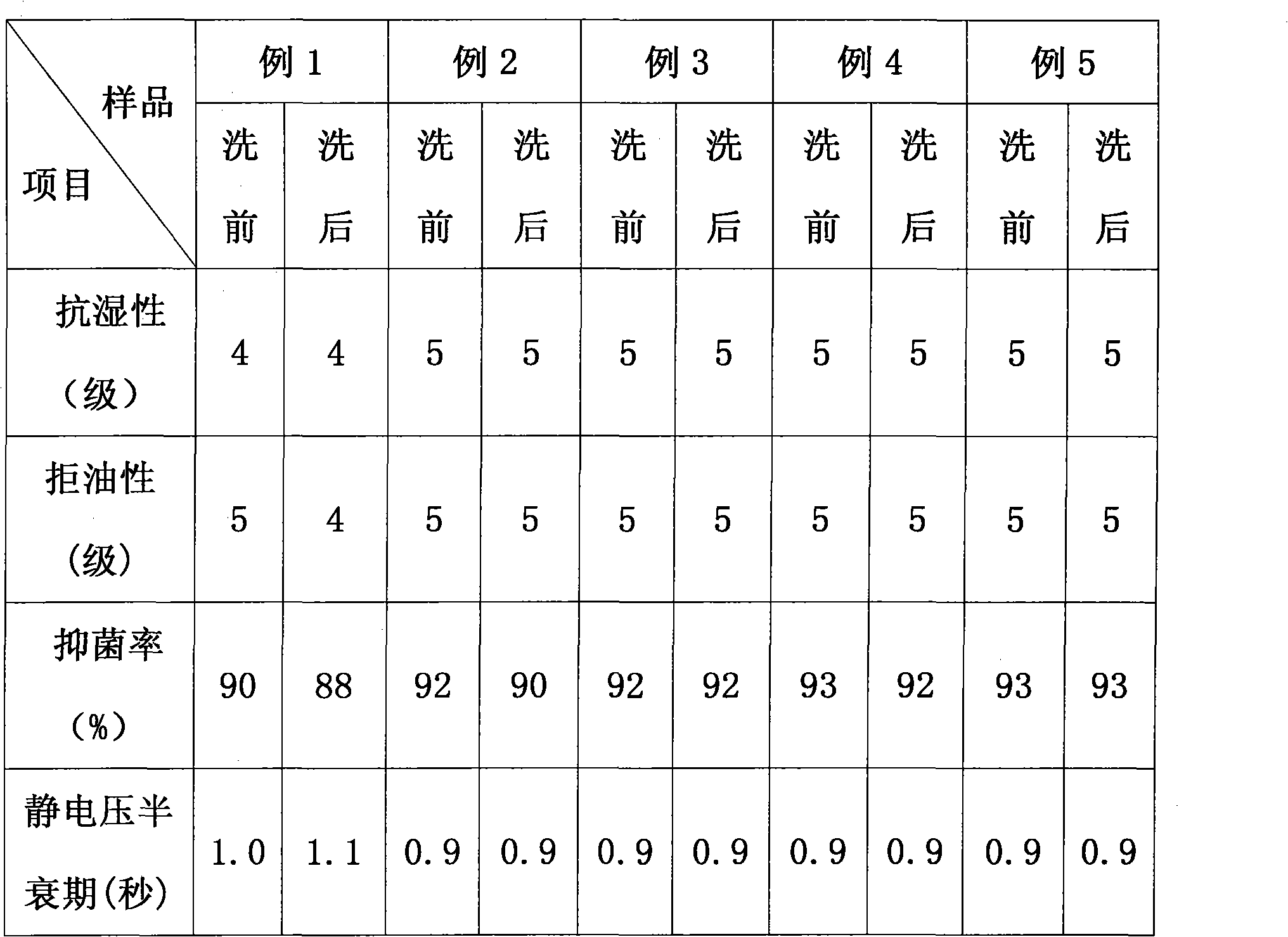

Durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and preparation method

ActiveCN102108638AImprove washing resistanceGood film fastnessFibre treatmentGlycidyl methacrylateAdhesive

The invention provides a durable, waterproof, oil-proof, antistatic and antibacterial functional coating adhesive and a preparation method. The coating adhesive is prepared from methyl acrylate, n-butyl acrylate, glycidyl methacrylate, allyl methacrylate, 2,2,2-trifluoroethyl methacrylate, acryloyloxyethyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether XL90, hexadecyl trimethyl ammonium chloride, 2,2-azobis(2-methylpropionamidine)hydrochloride, deionized water and an associative polyurethane levelling and rheological agent WT-203 through the processes of emulsification, initiated polymerization and thickening.

Owner:DANDONG UNIK TEXTILE

High-solid content pure acrylate elastic emulsion

A high-solid content pure acrylate elastic emulsion used for preparing coatings for the outer walls of buildings is prepared by adopting a core-shell emulsion polymerization method. The formula of theelastic emulsion consist of the following components: 4-13% of methyl methacrylate, 7-24% of butyl acrylate, 7.5-15% of acrylonitrile, 1-5% of allyl methacrylate, 6-17% of shell monomer: methyl methacrylate, 12-24% of butyl acrylate, 7.5-15% of acrylonitrile, 1-3% of methacrylic acid, 1-5% of emulsifier, 1-3% of persulfate and 35% of water. Compared with the prior art, the prepared coatings for the outer walls have the advantages of strong water resistance and contamination resistance, good elasticity, less cracked shape of coating films, saved painting manpower and the like.

Owner:佛山市顺德区巴德富实业有限公司

Silver ink with good metal printing effect and printing process using silver ink

ActiveCN104403407AGood metal effectImprove surface smoothnessInksOther printing apparatusCardboardSilver ink

The invention provides silver ink with a good metal printing effect and a printing process using the silver ink. The printing process comprises the steps that first, a coated surface of a white cardboard with a single side coated is coated with water-soluble varnish or UV (ultraviolet) varnish, images and texts are printed with well mixed gravure silver ink in a gravure manner, and finally, a layer of water-soluble varnish or UV varnish is printed on an image and text area with the gravure silver ink. The gravure silver ink is formed by blending the following materials in percentage by weight: 60-68% of silver powder, 24-30% of n-propyl acetate, 1-3% of methyl methacylate, 1-3% of butyl acrylate, 1-2% of methacrylic acid, 1-2% of N-hydroxymethyl acrylamide, 0.5-1% of allyl methacrylate, 0.5-1% of isooctyl thioglycolate, 0.2-0.5% of alkylphenol ethoxylates sodium sulfate, 1-2% of water-resistant agents and 0.1-0.5% of drying agents. By means of the silver ink and the printing process, a metal ink layer has a refraction effect, the metal effect is more obvious and an optimal metal effect is achieved.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

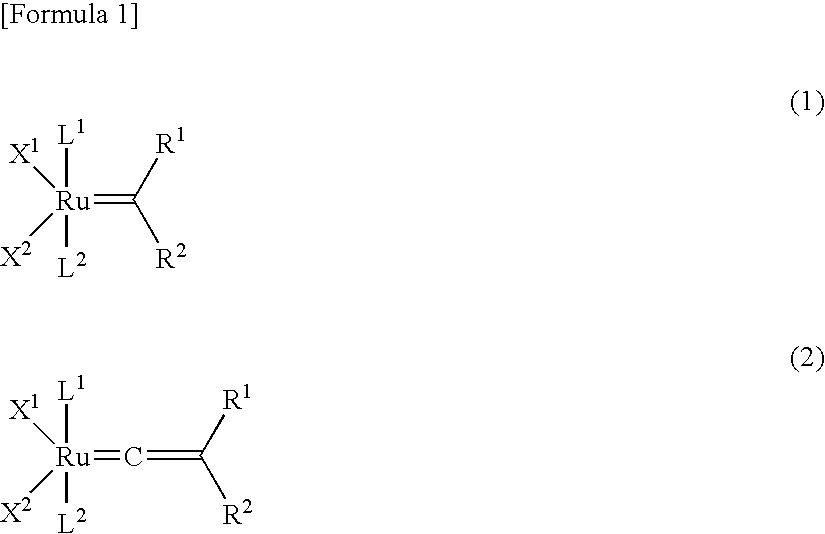

Polymerizable composition

InactiveUS20100144924A1Excellent characteristic in electric insulation and heat resistance and dielectric propertyImprove balanceSynthetic resin layered productsPrinted circuit aspectsBulk polymerizationEmulsion polymerization

A polymerizable composition is obtained by mixing a metathesis polymerization catalyst including benzylidene(1,3-dimethyl-4-imidazolidin-2-ylidene)(tricyclohexylphosphine)ruthenium dichloride, a cycloolefin monomer such as 2-norbornene or tetracyclo[6.2.1.13,6.02,7]dodec-4-ene, a chain transfer agent such as allyl methacrylate, and hollow particles such as Shirasu balloons. A crosslinkable resin composite is obtained by coating or impregnating the polymerizable composition onto or into a support medium, and carrying out bulk polymerization of the polymerizable composition. A crosslinked resin composite is obtained by crosslinking the crosslinkable resin composite.

Owner:ZEON CORP

Synthesis of methacrylate allyl propyl ester

InactiveCN1410412ANo gel phenomenonEasy to operateOrganic compound preparationCarboxylic acid esters preparationHydroquinone CompoundP-Toluenesulfonic acid

A process for synthesizing allyl methylacrylate includes such steps as under the existance of catalyst (p-toluenesulfonic acid) and polymerization inhibitor (hydroquinone), reaction between methylacrylic acid and allyl alcohol under the reflux condition while continuously removing the generated water, fractionating to recover the excessive allyl alcohol, and pressure-reduction distilling for purifying the product. Its advantages are high output rate (90-92%), high purity (98-99%), and no pollution.

Owner:湖北武大有机硅新材料股份有限公司

Method for preparing methyl acryloyl o-propyl dimethylchlorosilane

InactiveCN101157700AHigh selectivityEasy to recycleGroup 4/14 element organic compoundsSolventPolymerization

The invention discloses a preparation method of dimethoxymethylsilyl propyl methacrylate. The method takes the allyl methacrylate as the raw materials, the hydroquinone is taken as the polymerization inhibitor, the reaction is carried out with the dimethylchlorosilane with the presence of the catalyst, and the target product can be obtained by vacuum distillation. The purity of the product can achieve more than 98.5 percent (GC) and the yield is 85 to 90 percent. Compared with the prior art, the invention overcomes the shortcomings of cumbersome preparation of the catalysts, poor selectivity of the reaction and more by-products in the prior art; furthermore, the reaction process of the invention has mild conditions and no reaction solvent, the invention adopts the SiO2 load-type chloroplatinic acid as the catalyst, the selectivity of the catalyst is high, the catalyst is easy to reclaim, so the invention is in line with the requirements of green chemistry and is applicable to the industrialization scale production.

Owner:SHANGHAI CHEM REAGENT RES INST

Method for preparing 3-(methacryloxy)propyltrimethoxysilane

ActiveCN101121724AHigh catalytic efficiencyLow costGroup 4/14 element organic compoundsSilanesDissolution

The invention discloses a preparation method of the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The steps are: first the platinum chloride acid, isopropanol and the compound A are used as the raw materials; the platinum chloride acid is added into the isopropyl alcohol; after the dissolution, the compound A is added and then to be heated; secondly, the polymerization-preventing reagent phenothiazine and ZJ-701 are added into the tri-methoxy silane to dissolve the raw material X; thirdly, the polymerization-preventing reagent N, N'-drophenyl-p-phenylenediamine are added in the methacrylate allylic ester to dissolve the raw material Y; fourthly, the polymerization-preventing reagent ZJ-701 and ZJ-101 are added in the reaction materials after the reaction between the raw materials and the catalysts to dissolve to get the 3-(methacryloyl oxygen) propyl tri-methoxy silane. The invention is of the simple preparation, the high efficiency, the little consumption, the strong selectivity, and the high collection rate of the products; the polymerization-preventing effects of the polymerization-preventing technology are good; the polymerization-preventing reagents are not easy to be gelated; the consumption is little; the polymerization-preventing reagents are easily separated from the products; the products are easy to be decolorized, good in quality, and have no harm to the catalyst.

Owner:湖北武大有机硅新材料股份有限公司

Washable oiliness coating adhesive and preparation method

The invention relates to a washable oiliness coating adhesive. The washable oiliness coating adhesive comprises the following raw materials by weight percent: 25 to 30 percent of methyl methacrylate, 76 to 86 percent of n-butyl acrylate, 3 to 6 percent of 2-ethylhexyl acrylate, 2 to 4 percent of allyl methacrylate, 1 to 3 percent of vinyl trimethoxy silane, 0.3 to 0.6 percent of sodium dodecyl benzene sulfonate, 3 to 6 percent of fatty alcohol-polyoxyethylene ether XL90, 0.15 to 0.5 percent of sodium hydrogen sulfite, 0.25 to 0.6 percent of ammonium persulfate, 8 to 12 percent of refined castor oil, 180 to 220 percent of deionized water and 3.5 to 4 percent of associated polyurethane leveling rheological agent WT-203; and the raw materials are emulsified, polymerized and thickened to obtain the washable oiliness coating adhesive. The washable oiliness coasting adhesive is used for the after-treatment of textiles, the characteristics of oiliness and firmness can be realized, and a durable washable oiliness effect can be realized.

Owner:LIAONING FIXED STAR FINE CHEM

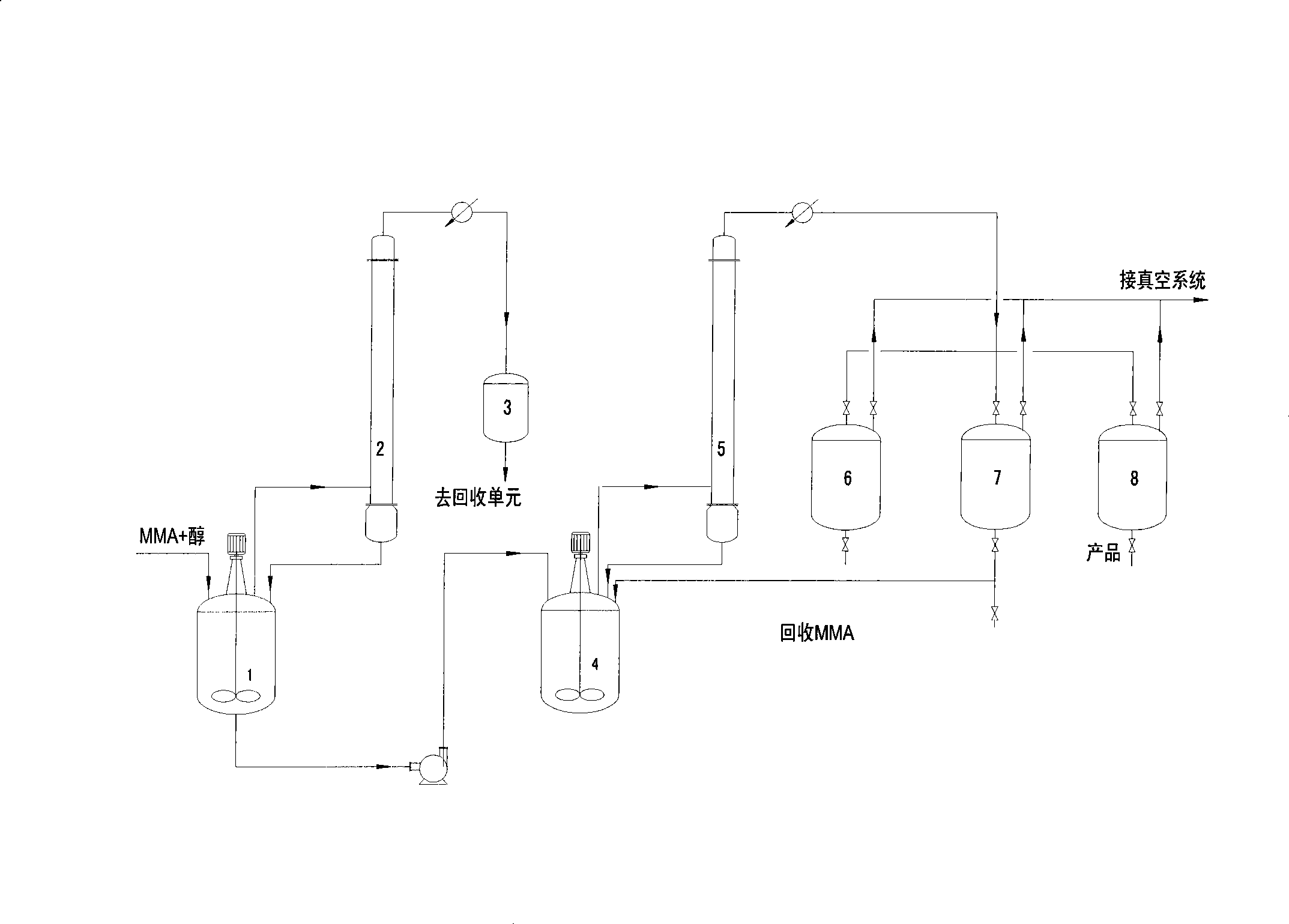

Preparation of allyl methacrylate

InactiveCN101486648AHigh activityReduce use costPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsAllyl methacrylatePressure reduction

The invention relates to a preparation method of allyl methacrylate. Methyl methacrylate and allyl alcohol are taken as raw materials; in the presence of a catalyst and a polymerization inhibitor, the reactive distillation transesterification technology is adopted for reaction, thus obtaining a reaction product containing allyl methacrylate; the reaction product is distilled under the condition of pressure reduction; after extra methyl methacrylate is removed, the catalyst and the polymerization inhibitor are removed so as to obtain the allyl methacrylate. The preparation method adopts a novel recyclable catalytic system, thereby reducing the cost of the catalyst; the novel combined polymerization inhibitor is adopted, thereby lowering the cost of the polymerization inhibitor; and the reactive distillation technology is adopted and the produced methanol is removed in time, thereby quickening the reaction pace to produce the product and improving the efficiency of a reactor.

Owner:上海和创化学股份有限公司

Polymerizable composition

InactiveUS7964685B2Excellent characteristic in electric insulation and heat resistance and dielectric propertyImprove balancePrinted circuit aspectsSynthetic resin layered productsBulk polymerizationPolymerization catalysts

A polymerizable composition is obtained by mixing a metathesis polymerization catalyst including benzylidene(1,3-dimethyl-4-imidazolidin-2-ylidene)(tricyclohexylphosphine)ruthenium dichloride, a cycloolefin monomer such as 2-norbornene or tetracyclo[6.2.1.13,6.02,7]dodec-4-ene, a chain transfer agent such as allyl methacrylate, and hollow particles such as Shirasu balloons. A crosslinkable resin composite is obtained by coating or impregnating the polymerizable composition onto or into a support medium, and carrying out bulk polymerization of the polymerizable composition. A crosslinked resin composite is obtained by crosslinking the crosslinkable resin composite.

Owner:ZEON CORP

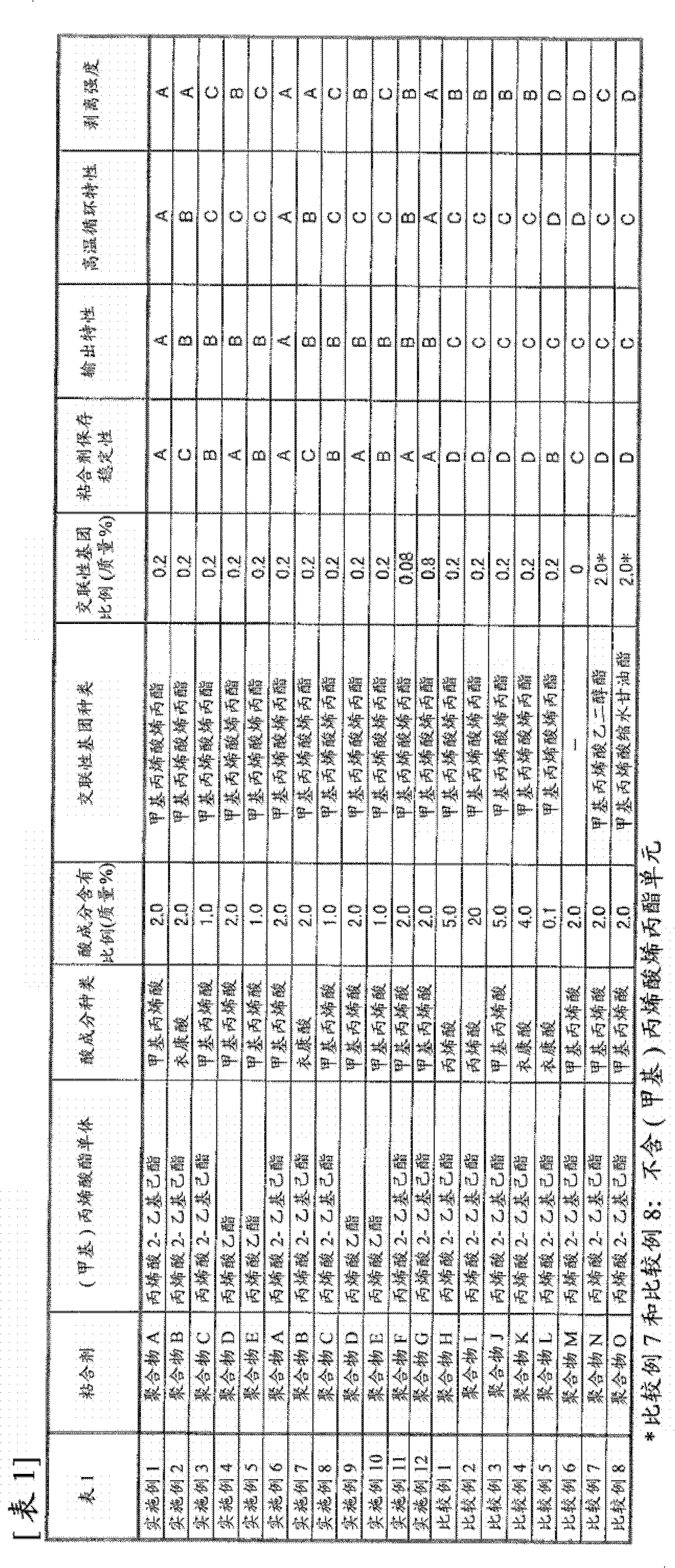

Positive electrode for secondary batteries, and secondary battery

ActiveCN102473918AExcellent cycle characteristicsImprove output characteristicsNon-aqueous electrolyte accumulatorsCell electrodesManganeseEngineering

Disclosed is a positive electrode for secondary batteries, which can achieve high output properties, cycle properties and safety performance. The positive electrode for secondary batteries is characterized by comprising a current collector and an electrode active material layer which is laminated on the current collector and comprises a positive electrode active material comprising manganese and a binder, wherein the binder comprises a constituent unit derived from a (meth) acrylic acid ester monomer, a constituent unit derived from an vinyl monomer having an acid component, a constituent unit derived from an a,ss-unsaturated nitrile monomer, and a constituent unit derived from a monomer having a crosslinkable group, the content of the constituent unit derived from a vinyl monomer having an acid component in the binder is 1.0 to 3.0 mass%, and a constituent unit derived from allyl acrylate or a constituent unit derived from allyl methacrylate is contained as the constituent unit derived from a monomer having a crosslinkable group.

Owner:ZEON CORP

Functional red microsphere and preparation thereof

InactiveCN101353395AExtended service lifeHigh color fastnessNon-linear opticsGlycidyl methacrylateAllyl methacrylate

The invention relates to a functional red microsphere which is characterized in that the functional red microsphere includes a cue ball and a shell coated on the cue ball; the cue ball is formed by the polymerization of the monomers selected as follows: divinylbenzene, allyl raethacrylate or glycidyl methacrylate; the dosage of the monomers is 6 portions by weight; perylene is used as a copolymer crosslinking agent and the dosage thereof is 0.05 to 0.4 portions by weight; the shell is the homopolymer of the glycidyl methacrylate; the surface of the shell is processed by acid quaternary ammonium salt. The materials of the reaction related in the invention are easier to be obtained; the product of the invention is not only easy to be treated cleanly, but also does not dissolve in a higher organic solvent. The diameter of the microsphere can achieve 10Mum; and the functional red microsphere can be used as electrophoresis.

Owner:BEIJING JIAOTONG UNIV

Ink-jet printing coating adhesive for fabrics and preparation method

InactiveCN101613940AImprove washing fastnessImprove adsorption capacityFibre treatmentDyeing processGlycidyl methacrylatePolymer science

The invention discloses an ink-jet printing coating adhesive for fabrics and a preparation method. The preparation method comprises the following steps: using methyl methacrylate, n-butyl methacrylate, glycidyl methacrylate, allyl methacrylate, chlorinated methacrylic acid trimethyl ammonia ethyl ester, fatty alcohol-polyoxyethylene ether XL90, cetyltrimetheylammonium bromide, 2,2-azobis (2-methyl propionamidine) hydrochloride, deionized water, nanometer SiO2 and associative polyurethane leveling rheological agent WT-203 as raw materials; and forming the coating adhesive through four-step processes of emulsification, induced polymerization, nanometer SiO2 dispersion and thickening complex. The invention has simple and convenient production method, and is applied to the coatings on various natural fibers and synthetic fiber fabrics with good firmness, the printing color is not dissolved in water, and the line profile is clear without diffusion.

Owner:LIAONING FIXED STAR FINE CHEM

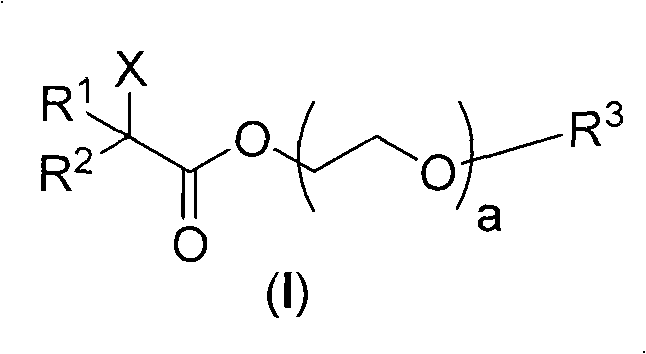

Method for preparing crosslinkable segmented copolymer by utilizing active free radical soap-free emulsion polymerization and prepared compound thereof

The invention discloses an active free radical soap-free emulsion polymerization reaction, a prepared crosslinkable segmented copolymer thereof and application of the copolymer. The copolymer is prepared through the following steps: under the protection of nitrogen gas or argon gas, mixing an allyl methacrylate monomer, other monomers, a compound with a structural formula (I), a catalyst and a ligand according to a certain mol ratio, stirring, reacting at the temperature of 40 to 80 DEG C for 5 to 20 hours, and purifying to obtain the copolymer. Other monomers are selected from one or more in an acrylic compound, a methacrylic compound and a styrene compound; the catalyst is selected from one of the chloride or the bromide of copper, iron, nickel or ruthenium; and the ligand is selected from one of 2, 2'-dipyridyl, 4, 4'- di(5-nonyl)dipyridyl, N, N, N', N'-tetramethylethylenediamine, pentamethyldiethylenetriamine, hexamethyltriethylenetetramine or methenamine. The invention also discloses the application of the compound with the structural formula (I) as an emulsifier and an initiator.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Tackifier, preparation method of tackifier and silicone rubber composition

ActiveCN106496565AImprove adhesionImprove stabilityMacromolecular adhesive additivesGlycidyl methacrylatePolymer science

The invention provides a tackifier with a structure shown as a formula (I), wherein R1 is selected from methyl, ethyl or phenyl; R2 is hydrogen; R3 is selected from cyclopentenyl, cyclohexenyl, 3-cyclohexene ethyl, 4-cyclohexene ethyl, 5-bicycloheptenyl, 4-cyclooctenyl, 4-cyclooctenyl ethyl, 1,5-bicyclooctenyl or norbornylene ethyl; R4 is selected from methyl methacrylate, allyl methacrylate or glycidyl methacrylate; each of a, b and c is more than or equal to 1; a+b+c is more than or equal to 20 and less than or equal to 70. The tackifier disclosed by the invention is capable of obviously improving the bonding effect between silicone rubber and hard bonding resin base materials.

Owner:东莞市贝特利新材料有限公司

High-ductility modified hard asphalt and preparation method thereof

InactiveCN106977965AImprove ductilityImprove high temperature stabilityBuilding insulationsPolymer scienceAlkylphenol

The invention discloses high-ductility modified hard asphalt, which is prepared from the following raw materials in parts by weight: 130 to 140 parts of petroleum asphalt, 10 to 14 parts of methyl silicone rubber powder, 18 to 22 parts of methyl vinyl silicone rubber powder, 11 to 15 parts of modified kaolin, 5 to 9 parts of barium metaborate, 12 to 15 parts of sulfated castor oil, 5 to 8 parts of trimellitic anhydride, 2 to 5 parts of alkylphenol ethoxylate, 3 to 6 parts of allyl methacrylate and 4 to 8 parts of sodium thioglycollate. The invention also discloses a preparation method of the high-ductility modified hard asphalt. The prepared modified hard asphalt has high ductility, and has good high-temperature stability and low-temperature anti-cracking performance; important market values and social values are realized.

Owner:詹澍

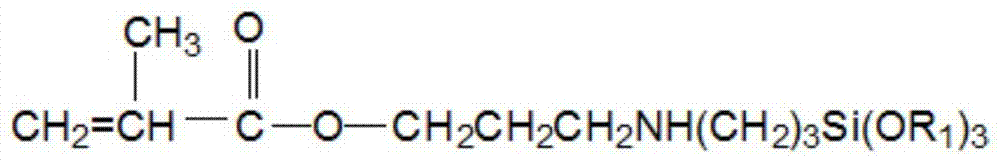

Aminosilyl acrylate and preparation method thereof

ActiveCN105440068AOvercome roughnessOvercome great resistanceGroup 4/14 element organic compoundsGlass fiberOrganic synthesis

The invention discloses aminosilyl acrylate and a preparation method thereof, and belongs to the technical field of organic synthesis. Needed aminosilyl acrylate is obtained by stirring amino silane and allyl methacrylate at a temperature of 50-100 DEG C for 3-6 h at presence of a catalyst. Aminosilyl acrylate is a product with a composite function group structure, and contains both acyloxy and amino which mutually coexist. When being applied to a glass fiber impregnating compound, aminosilyl acrylate possesses the strength improved by 20% compared with a silane product separately employing acyloxy and amino, and is obviously improved in strength compared with a singly-employed product containing one group.

Owner:GBXF SILICONES CO LTD

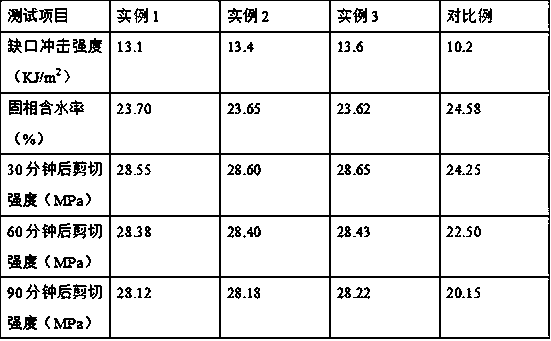

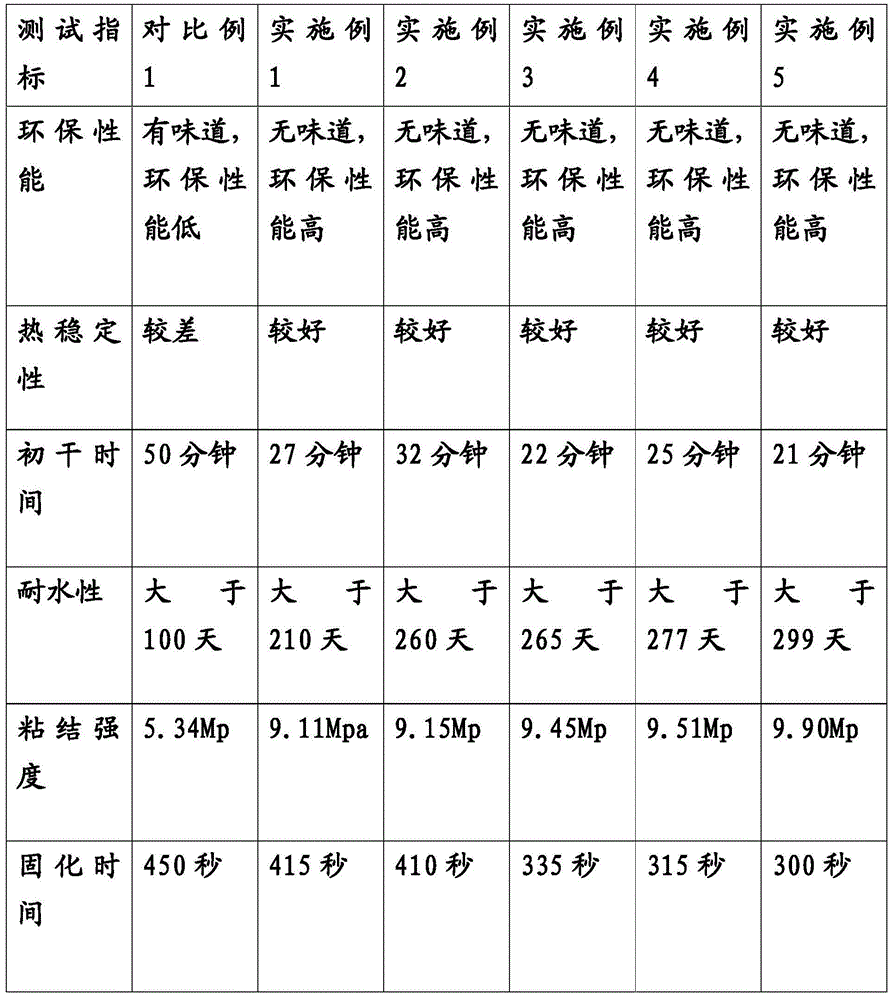

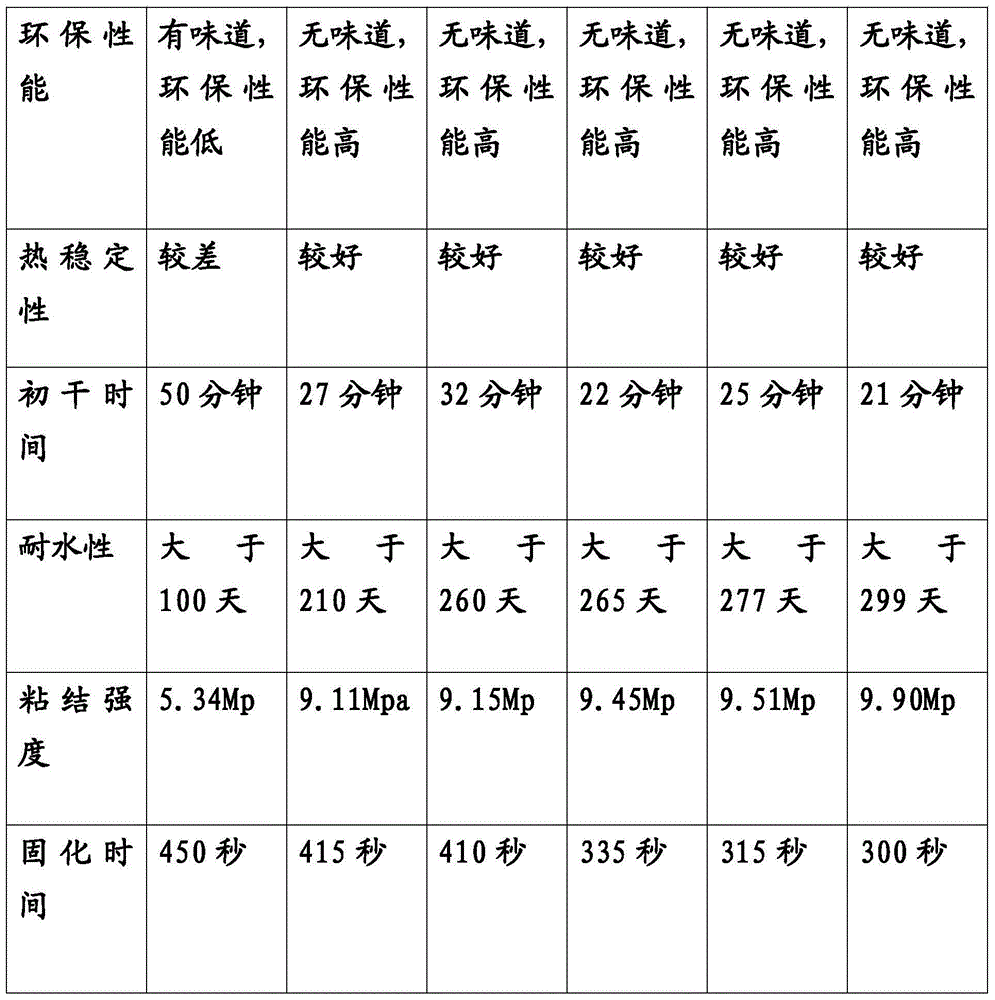

Water-resistant white latex

InactiveCN104629633AMeet the strict requirements of qualityImprove environmental performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonateToluene diisocyanate

The invention provides a water-resistant white latex which is composed of the following components in parts by weight: 700-1050 parts of polyvinyl acetate, 300-350 parts of vinyl acetate, 120-145 parts of polyvinyl alcohol, 60-100 parts of dibutyl phthalate, 20-40 parts of diethylene glycol dibenzoate, 10-15 parts of octanol, 30-45 parts of isopropanol, 10-25 parts of allyl methacrylate, 5-10 parts of glycol bis methacrylate, 3-7 parts of toluene diisocyanate, 35-50 parts of sodium bicarbonate, 1400-1500 parts of water, 40-50 parts of emulsifier 5-9 parts of composite initiator, 20-32 parts of hydroxymethyl acrylamide, 10-15 parts of waxy corn starch and 2-7 parts of sodium hypochlorite. The water-resistant white latex does not need formaldehyde or any other solvent, and has the advantages of environment friendliness, high heat stability, short primary drying time, excellent water resistance, excellent binding strength, excellent curing time, excellent comprehensive properties and the like.

Owner:海安县紫石涂料有限公司

Preparation method of high-impact-resistant waterproof type epoxy resin toughening agent

The invention discloses a preparation method of a high-impact-resistant waterproof type epoxy resin toughening agent, and belongs to the technical field of preparation of toughening agents. The methoddisclosed by the invention is characterized in that butyl acrylate, 1,4-butanediol diacrylate, allyl methacrylate, distilled water, sodium dodecyl benzene sulfonate and potassium persulfate are subjected to heating reaction to prepare a home-made seed emulsion, and the home-made seed emulsion is mixed with butyl acrylate, methyl methacrylate, a cross-linking agent, an emulsifying agent, an initiating agent and a grafting agent together to prepare a core layer emulsion and a shell layer emulsion; divinyl benzene is an oil-soluble initiating agent and mainly swells in emulsion particles, and only a small amount of divinyl benzene is dissolved in a water phase, thereby improving the impact-resistance strength of the toughening agent; and nano silicon dioxide is added to a polyacrylate emulsion with better water resistance and physical and mechanical properties to enable the polymer to have high water absorbing capacity, and resin can be cured in a humid environment or even underwater andcan keep good water resistance, thereby improving the water resistance of the toughening agent.

Owner:常州市万昌化工有限公司

Butylbenzene modified zero-ammonia acrylic acid waterproof mortar emulsion and preparation method thereof, and waterproof mortar

The invention discloses a butylbenzene modified zero-ammonia acrylic acid waterproof mortar emulsion and a preparation method thereof, and waterproof mortar. The waterproof mortar emulsion comprises 100 parts of deionized water, 25-35 parts of styrene, 50-60 parts of butyl acrylate, 1-5 parts of hydroxyethyl acrylate, 1-3 parts of hydroxyethyl methacrylate, 0.5-3 parts of methacrylic acid, 0.1-0.5part of allyl methacrylate, 0.1-0.5 part of a silane coupling agent, 55-65 parts of a styrene-butadiene emulsion, 1-10 parts of an emulsifier, 0.1-1 part of an initiator and 0.1-2 parts of sodium hydroxide. The waterproof mortar emulsion has excellent bonding strength and flexural and compressive strength, is ammonia-free and low-odor, and has good flexibility; and the preparation method is simple in process, high in controllability, low in equipment requirements and low in cost.

Owner:GUANGDONG YINYANG ENVIRONMENT FRIENDLY NEW MATERIALS CO LTD

Strong white latex

ActiveCN104673146AImprove thermal stabilityExcellent dry timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonateWaxy corn

The invention provides strong white latex. The strong white latex comprises the following components in parts by weight: 900 parts of polyvinyl acetate, 330 parts of vinyl acetate, 130 parts of polyvinyl alcohol, 85 parts of dibutyl phthalate, 30 parts diethylene glycol dibenzoate, 13 parts of octanol, 37 parts of isopropanol, 19 parts of allyl methacrylate, 8 parts of glycol dimethacrylate, 5 parts of toluene diisocynate, 41 parts of sodium bicarbonate, 1460 parts of water, 46 parts of an emulsifying agent, 8 parts of an initiator, 27 parts of hydroxymethyl acrylamide, 13 parts of waxy corn starch and 5 parts of sodium hypochlorite. The environmental-friendly performance of the strong white latex is fundamentally improved; meanwhile, the strong white latex has excellent representation on indexes of thermal stability, initial drying time, water resistance, bonding strength and curing time and has excellent overall performance.

Owner:江苏中丽新材料有限公司

Preparation method of white latex

InactiveCN104628960AImprove thermal stabilityExcellent dry timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonateOctanol

The invention provides a preparation method of white latex. The method comprises the following steps: taking water and vinol, mixing and increasing the temperature; taking an emulgator, adding the emulgator and residual water to the solution under the condition of stirring, then slowly adding vinyl acetate and an initiator, increasing the temperature and preserving heat; cooling; after that adding residual vinyl acetate and residual initiator; adding the emulgator and polyvinyl acetate; adding sodium bicarbonate, dibutyl phthalate, diethylene glycol dibenzoate, octanol and isopropanol; adding residual emulgator, allyl methacrylate, glycol dimethacrylate, toluene diisocynate, N-hydroxymethyl acrylamide, waxy maize starch and sodium hypochlorite to obtain the white latex. The content of vinyl acetate in the white latex prepared by the preparation method is greatly reduced, the environmental protection property of a product is improved fundamentally, and the white latex is superior in combination property.

Owner:江苏中丽新材料有限公司

Binder used for 3D printing materials

InactiveCN109251455AGood adhesionAccelerates the infiltration processAdditive manufacturing apparatusPolyvinyl alcoholPotassium carbonate

The invention discloses a binder used for 3D printing materials. The binder is composed of a component A and a component B at a mass ratio of 2-3:1; the component A comprises, by mass, 50 to 60 partsof acrylic emulsion, 30 to 40 parts of polyvinyl alcohol, 10 to 13 parts of polyvinyl acetate emulsion, 8 to 15 parts of non-ionic polyacrylamide, 20 to 40 parts of soybean protein glue, 2 to 3 partsof sodium hypochlorite, 7 to 12 parts of sodium dodecyl benzene sulfonate, 15 to 20 parts of inorganic gel, 5 to 8 parts of hydroxypropyl methyl cellulose ether, 3 to 6 parts of a stabilizing agent, and 3 to 5 parts of a thickening agent; and the component B comprises, by mass, 35 to 45 parts of polylactic acid, 15 to 20 parts of aerosil, 30 to 40 parts of wax maize starch, 10 to 15 parts of ethylene glycol diacetate, 20 to 35 parts of alumina sol, 8 to 13 parts of allyl methacrylate, 15 to 22 parts of absolute ethyl alcohol, 5 to 8 parts of anhydrous potassium carbonate, 15 to 25 parts of anhydrous magnesium sulfate, 2 to 4 parts of glycol, 5 to 9 parts of nanometer manganous oxide, 3 to 5 parts of a composite initiator, 3 to 6 parts of a curing agent, and 6 to 11 parts of an activator.

Owner:江苏天泽教育咨询有限公司

Metal cross-linked acrylate emulsion and preparation method thereof

The invention discloses a metal cross-linked acrylate emulsion and a preparation method thereof, and belongs to the field of building coatings. The metal cross-linked acrylate emulsion is prepared from the following raw materials in parts by weight: 30 to 54 parts of methyl methacrylate, 15 to 35 parts of 2-ethylhexyl acrylate, 5 to 13 parts of styrene, 2 to 10 parts of methacrylic acid, 10 to 30 parts of zinc ammonia solution, 2 to 10 parts of a functional monomer, 2 to 6 parts of an emulsifying agent, 0.1 to 0.5 part of persulfate, 0.1 to 0.5 part of an oxidant, 0.1 to 0.5 part of a reducing agent, and 125 to 150 parts of water. The zinc ammonia solution contains 10 to 30 mass percent of zinc oxide; the functional monomer is at least one of vinyl trimethoxy silane, gamma-methacryloxy propyl trimethoxyl silane and allyl methacrylate; the emulsifying agent is sodium alkyl diphenyl ether disulfonate. The metal cross-linked acrylate emulsion disclosed by the invention has excellent rubbing property and after-tackiness resistance.

Owner:成都巴德富科技有限公司

Super-strong slump retaining agent and processing method thereof

ActiveCN103724560AImprovement of the amount of change over timeSatisfy mixing transportationPotassium persulfateHigh intensity

The invention discloses a super-strong slump retaining agent. The super-strong slump retaining agent is composed of following raw materials: a, isopentenol polyoxyethylene ether, b, acrylic acid or methylacrylic acid or a mixture thereof, c, ethyl acrylate or propyl acrylate or a mixture thereof, d, allyl methacrylate, e, ammonium persulfate or potassium persulfate, and f, sodium methallyl sulfonate, wherein the mol ratio of the raw materials is as follows: a:b:c:d:f=1:(1.5-2.5):(1.5-2):(0.05-0.15):(0.3-0.6); the use amount of the e accounts for 0.5%-1.0% of the total weight of a, b and c. According to the slump retaining agent, the initial water-reducing rate is not influenced and the time-dependent change amount of the concrete slump degree is obviously improved; the loss of the slump degree can be not generated in three hours; the requirements of concrete agitating and transporting, pumping, pouring technical processes, and the high-strength requirements can be completely met; the super-strong slump retaining agent has good workability.

Owner:大连市铭源全科技开发有限公司

Acrylate resin solution for water latex paint and its preparation method

InactiveCN102786854AHigh hardnessImprove water resistanceEmulsion paintsEthyl acrylateButylcellosolve

The invention relates to an acrylate resin solution for a water latex paint and its preparation method. The invention is characterized in that the acrylate resin solution for the water latex paint mainly comprises butyl cellosolve, allyl methacrylate, ethyl acrylate, methyl methacrylate, acrylic acid, methacrylic acid-2-ethylhexonate, azo-diformaldehyde pentanenitrile, tert-dodecyl mercaptan, etc. A coating prepared from the acrylate resin solution for the water latex paint has the characteristics of high glossiness, an excellent surface state, good water resistance, yellowing resistance, etc.

Owner:ZHANGJIAGANG TIANYUAN PAINTING & COATING APPL

Preparation method of composition with skin tightening effect

ActiveCN104323976AGood effectImprove coexistenceCosmetic preparationsToilet preparationsFreeze-dryingMethacrylate methyl

The invention relates to a preparation method of a composition with skin tightening effect. The preparation method comprises the following steps of A: weighing a klamath blue-green algae extractive, a chlamydomonas nivalis extractive, ethanol, a wild soybean seed extractive, a methyl methacrylate / ethylene glycol dmethylacrglate cross-linked polymer or a allyl methacrylate cross-linked polymer, uniformly mixing, and then heating to obtain a-phase liquid; B: weighing a cell enabling compound, an undaria pinnatifida extractive, trehalose and deionized water, and uniformly stirring to obtain b-phase liquid; C: mixing the a-phase liquid and the b-phase liquid to obtain a mixed solution c; D: weighing a padina pavonica thallus extractive and the mixed solution c, uniformly mixing and stirring to obtain a mixed solution d; and E: loading the mixed solution d into a freeze-drying glass bottle, carrying out freeze-drying to obtain freeze-dried powder, sealing in a vacuum environment to obtain the freeze-dried powder of the composition with the skin tightening effect. The composition prepared through the method disclosed by the invention has the advantages of obvious effect, good coexistence among active matters, stable quality and long retention period.

Owner:PROYA COSMETICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com