Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1504 results about "Chloroplatinic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chloroplatinic acid or hexachloroplatinic acid is an inorganic compound with the formula [H₃O]₂[PtCl₆](H₂O)ₓ (0≤x≤6). A red solid, it is an important commercial source of platinum, usually as an aqueous solution. Although often written in shorthand as H₂PtCl₆, it is the hydronium (H₃O⁺) salt of the hexachloroplatinate anion (PtCl²⁻₆).. Hexachloroplatinic acid is highly hygroscopic.

Method for producing multicrystalline silicon substrate for solar cells

InactiveUS20050101153A1Promote oxidationHigh dissolution rateFinal product manufactureSemiconductor/solid-state device manufacturingMetal particleSolar cell

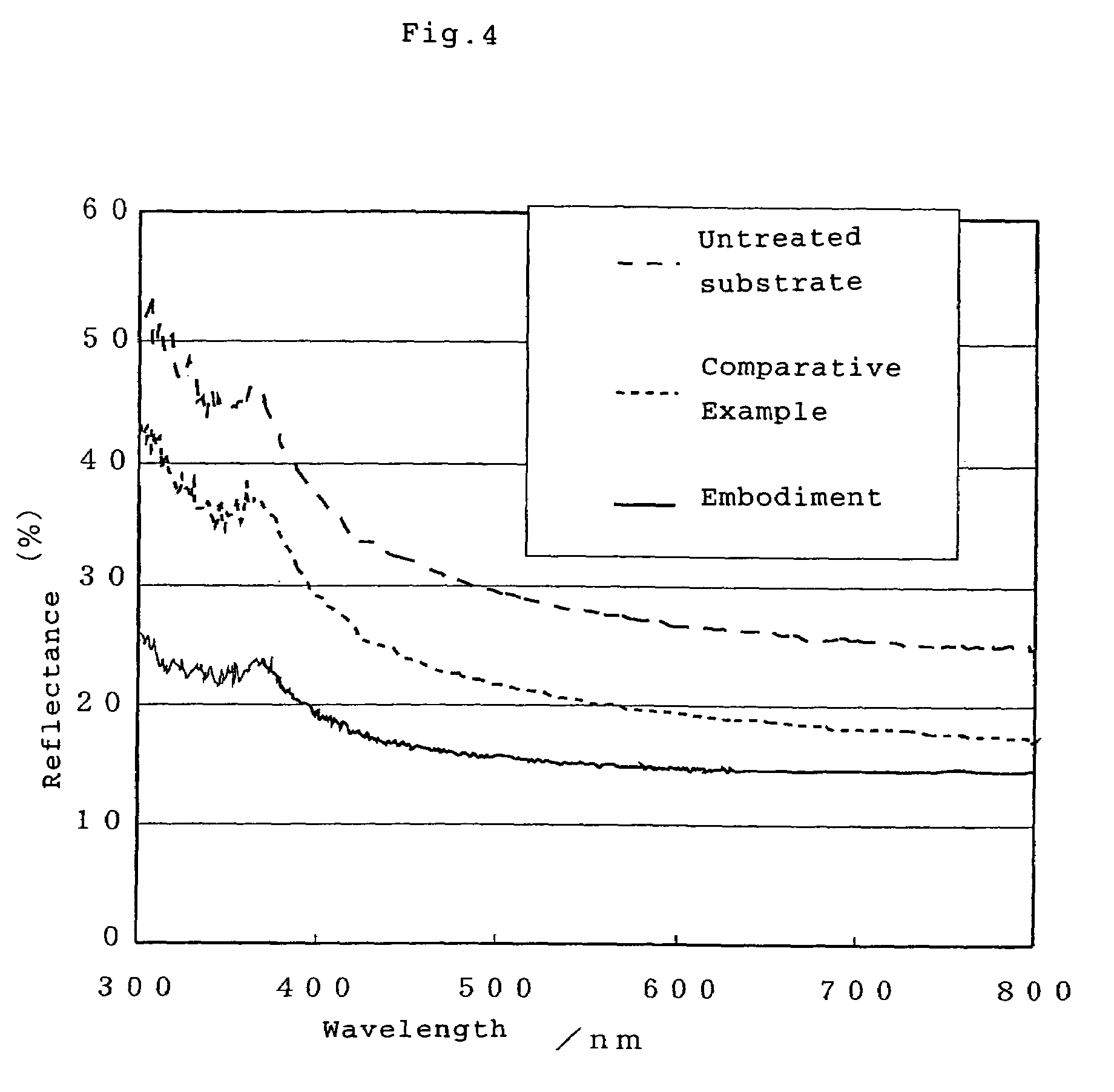

Disclosed is a method for producing a multicrystalline silicon substrate for solar cells comprising: a metal deposition step for depositing such metal particles as platinum and silver on the surface of the substrate by electroless-plating chloroplatinic acid or silver perchlorate; a boring step for subjecting the substrate surface to etching in a solution containing at least one of hydrofluoric acid and hydrogen peroxide; and a step for removing a stain layer by immersing the substrate into an alkaline solution. A multicrystalline silicon substrate having a lower reflectance is provided at a lower cost.

Owner:KANSAI TLO KK

Method for preparing catalyst for preparing synthesis gas by reforming methane and carbon dioxide

InactiveCN101637726ALow costHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel saltCerium

The invention relates to a method for preparing a catalyst for preparing synthesis gas by reforming methane and carbon dioxide, which comprises the following steps: soaking a carrier into a mixed solution of cerium(III) nitrate and lanthanum nitrate, and drying and roasting the soaked carrier for 2 to 10 hours to obtain a modified carrier (A); soaking the (A) into a soluble nickel salt solution orsoaking the (A) into a chloroplatinic acid solution, and drying and roasting the soaked carrier to obtain (B) or (C); soaking the (B) into the chloroplatinic acid solution or soaking the (C) into thesoluble nickel salt solution, and drying and roasting the soaked carrier to obtain a catalyst precursor, or soaking the modified carrier into a mixed solution of the soluble nickel salt solution andthe chloroplatinic acid, and drying and roasting the soaked carrier to obtain a catalyst precursor; and reducing the precursor in hydrogen and nitrogen mixed gas to obtain the catalyst. The catalyst has the advantages of low cost, good catalytic activity under the reaction condition of large space velocity, high selectivity for H2 and CO, and good sintering resistance and carbon deposition resistance.

Owner:PETROCHINA CO LTD

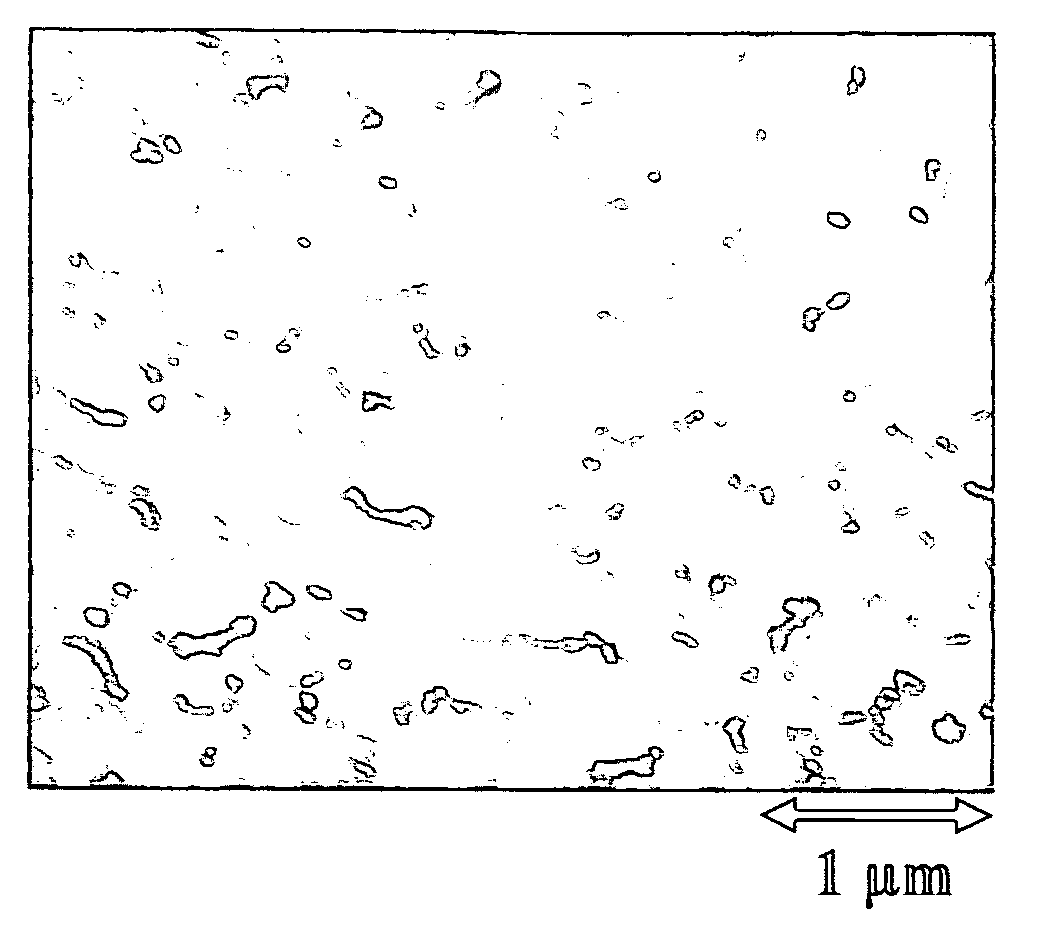

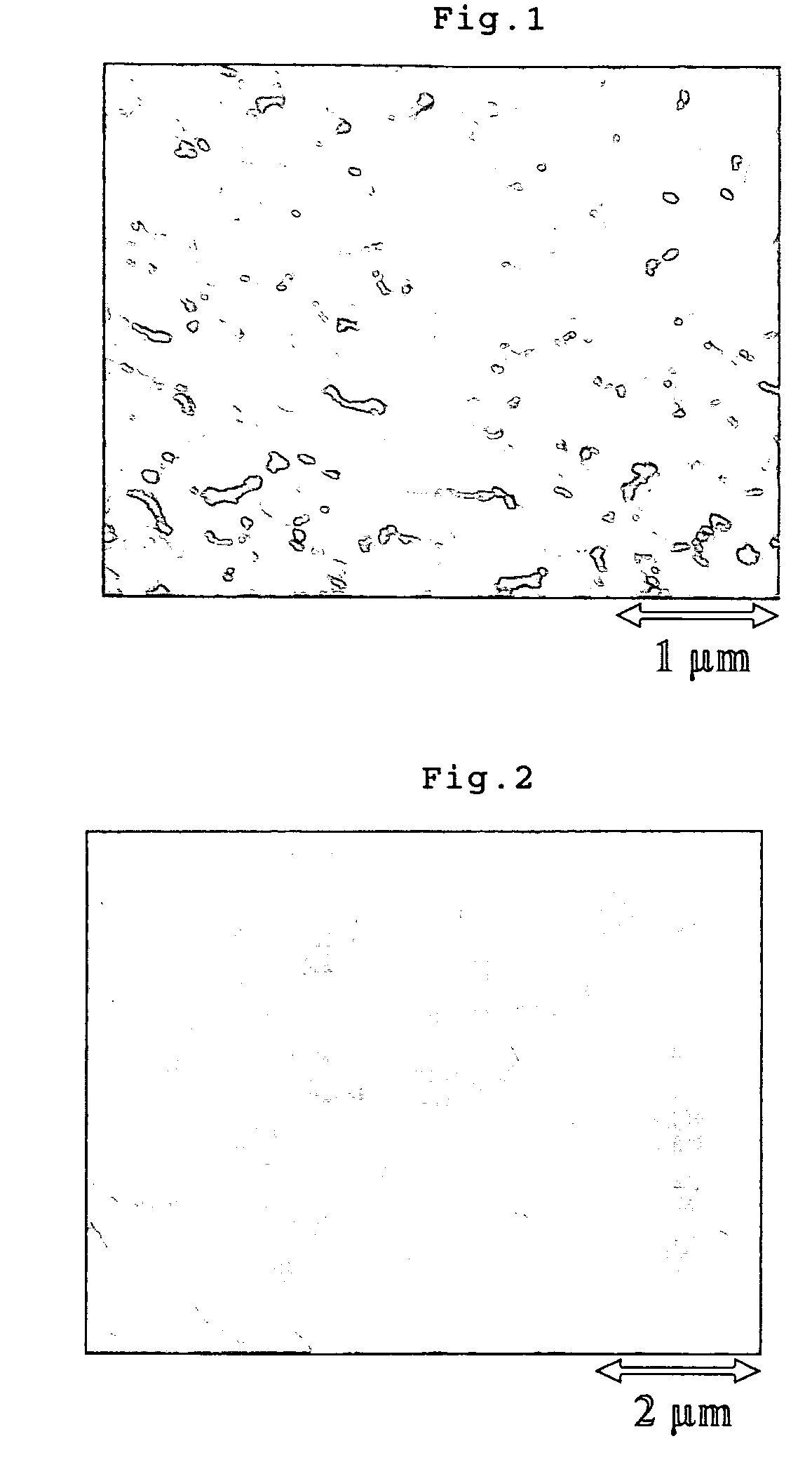

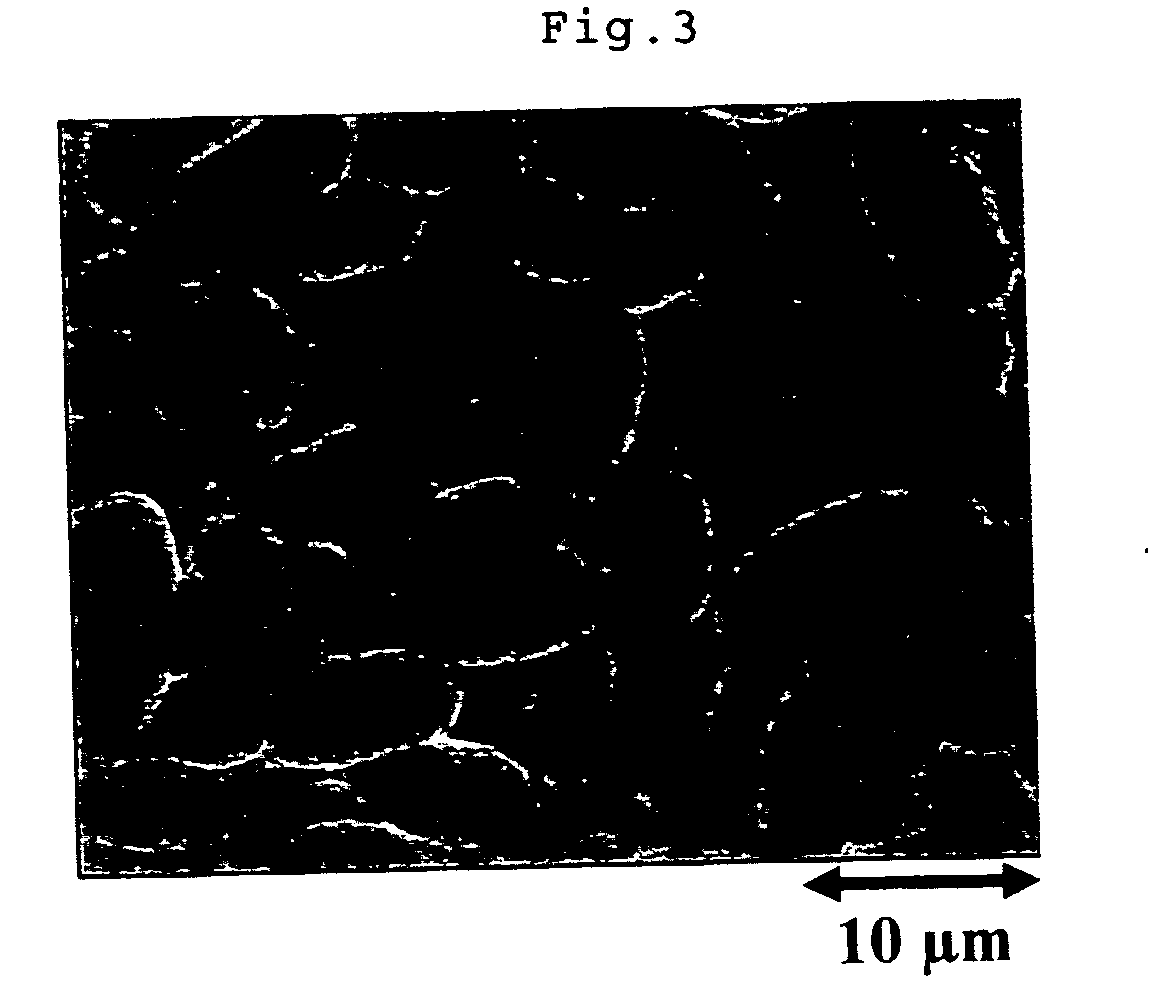

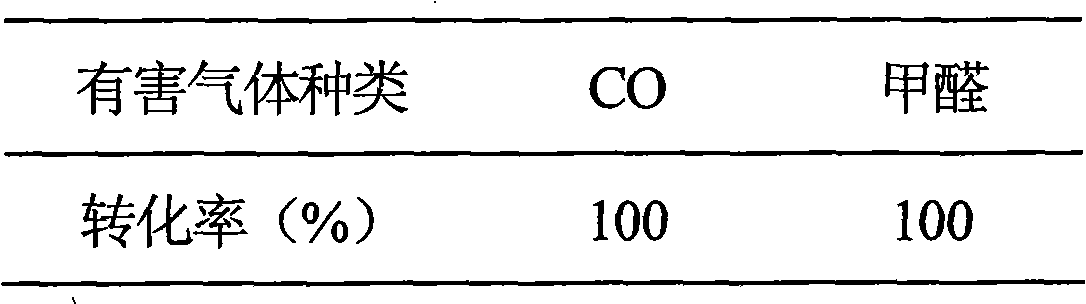

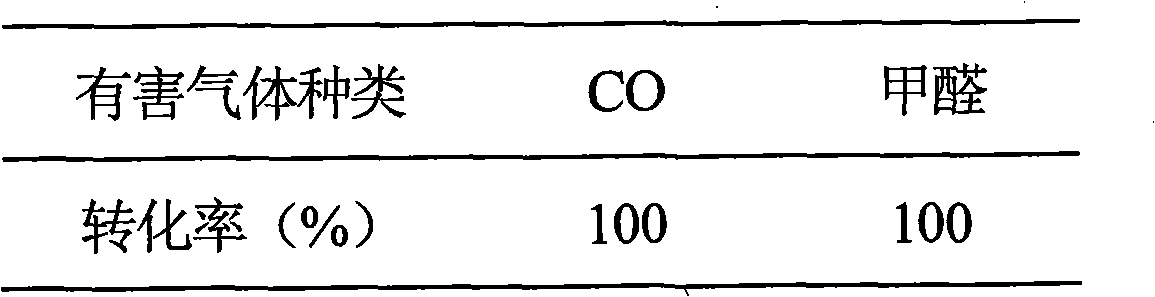

Monolithic catalyst used for oxidizing CO and methanal under ordinary temperature and preparation method thereof

ActiveCN102114428ASimple preparation processGood repeatabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrateRoom temperature

The invention provides monolithic catalysts used for oxidizing CO and methanal under ordinary temperature and the preparation method thereof, which belong to the field of environmental engineering. The monolithic catalyst comprises a carrier, a coating, Pt, Pd and addition agent. The preparation method comprises the steps as follows: the carrier is immersed in mixed solution comprising precursor solution of an auxiliary coating and main coating collosol, and then is blown, dried and calcined; then the carrier is immersed in mixed solution comprising chloroplatinic acid solution, chloropalladite acid solution and nitrate solution of the addition agent for more than 4 hours by adopting an isovolumetric immersion method; and finally, reducing agent is added into mixed solution in which the carrier is immersed under the temperature ranging from 45 to 90 DEG C, and then the carrier is taken out, washed through water and dried so as to obtain target products. The monolithic catalyst used for oxidizing CO and methanal under ordinary temperature and the preparation method thereof have the advantages of simple technology, low cost and the like, are easy to control the operation conditions, and are also easy to produce on a large scale. By adopting the Nanometer Pt and Pd catalyst, CO and methanal can be eliminated under the room temperature, thereby having high antitoxic performance, high moisture resistance and stable property.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

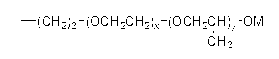

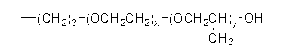

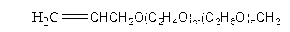

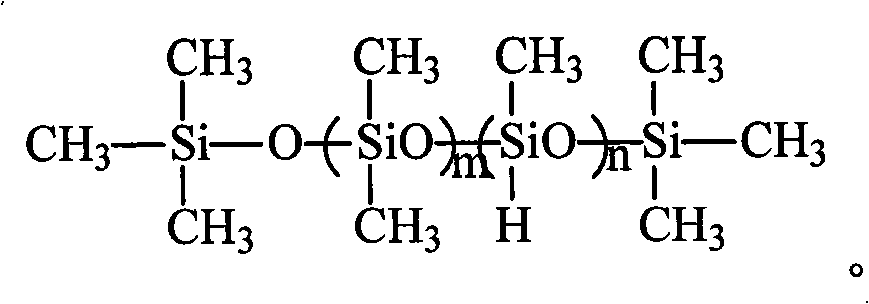

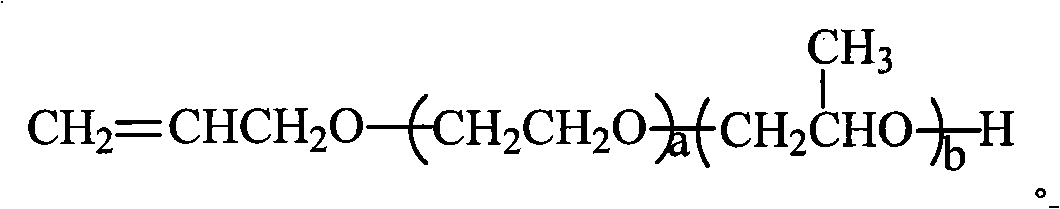

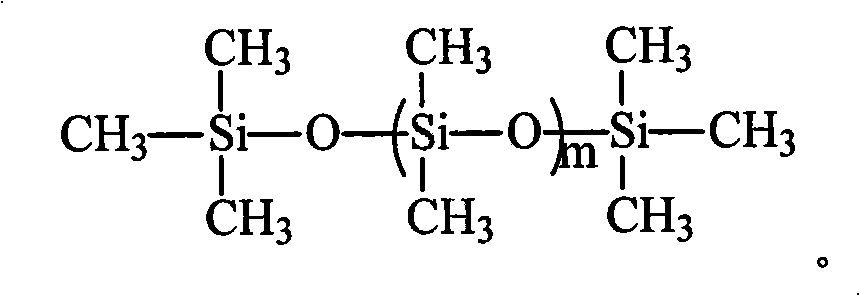

Preparation method of polyether modified polysiloxane foam stabilizer

The invention discloses a preparation method of a polyether modified polysiloxane foam stabilizer and relates to a preparation method of a foam stabilizer for flexible polyurethane foam. The polyether modified polysiloxane foam stabilizer is generated through reaction between allyl epoxyethane and methyloxirane methyl ethers with different molecular weights and silicone oil with low hydrogen content under the conditions that methylbenzene as a solvent and chloroplatinic acid as a catalyst. Through controlling the degree of polymerization of a hydrophilic polyether chain segment and a hydrophobic polysiloxane chain segment of polyether modified polysiloxane, the foam stabilizer has precise hydrophilic-lipophilic balance property, better emulsifying property and a favorable foam stabilizing effect, so that a flexible polyurethane foam mixture has enough stability in a coring stage, a form hole growing stage, a punching stage and an early-stage crosslinking stage, and foam collapse cannot be caused.

Owner:扬州晨化新材料股份有限公司

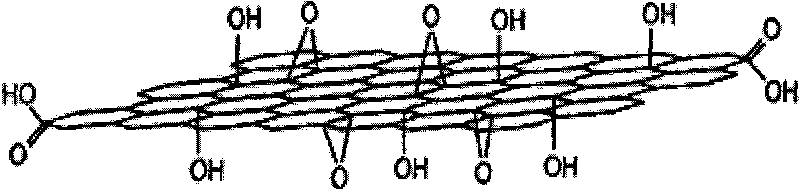

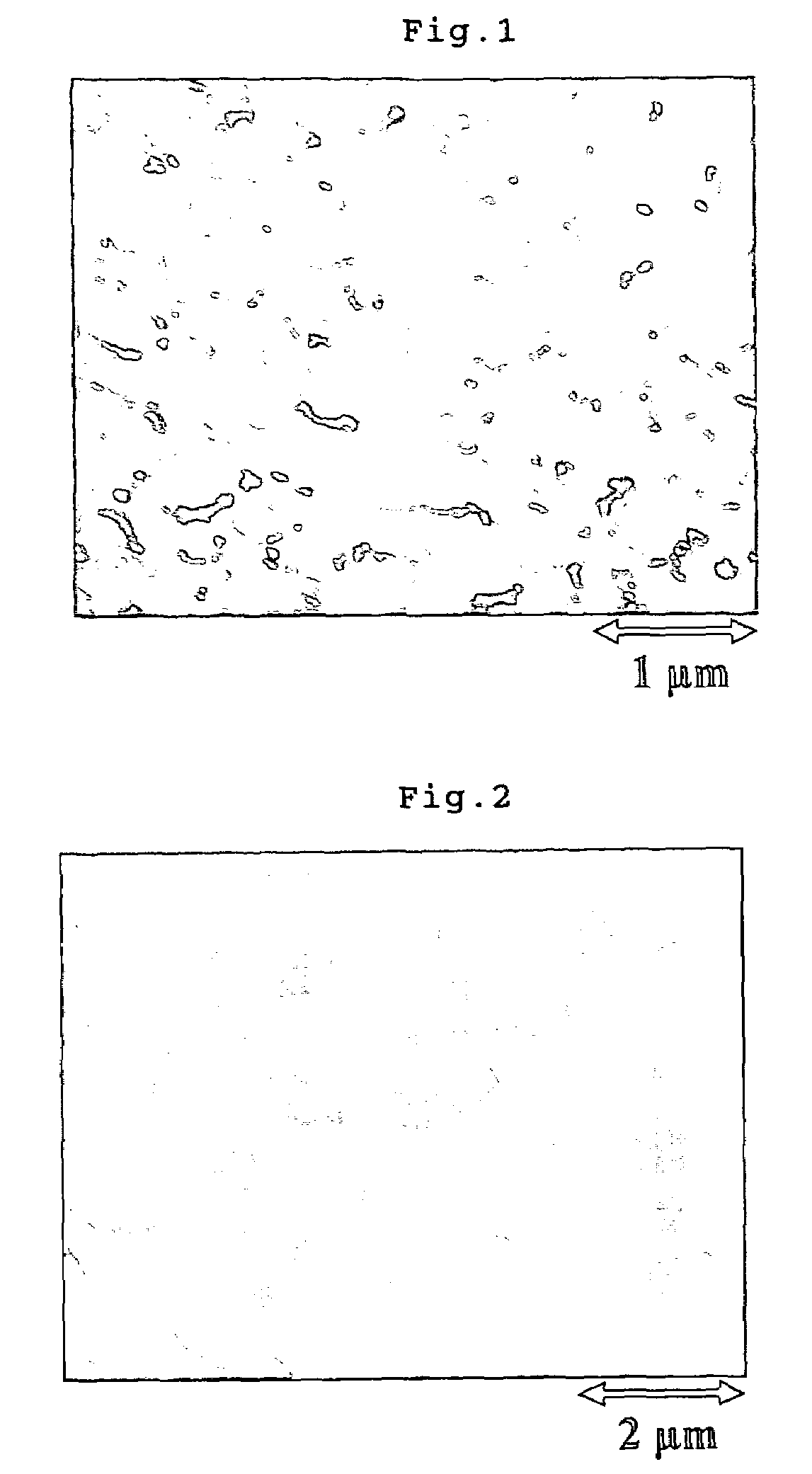

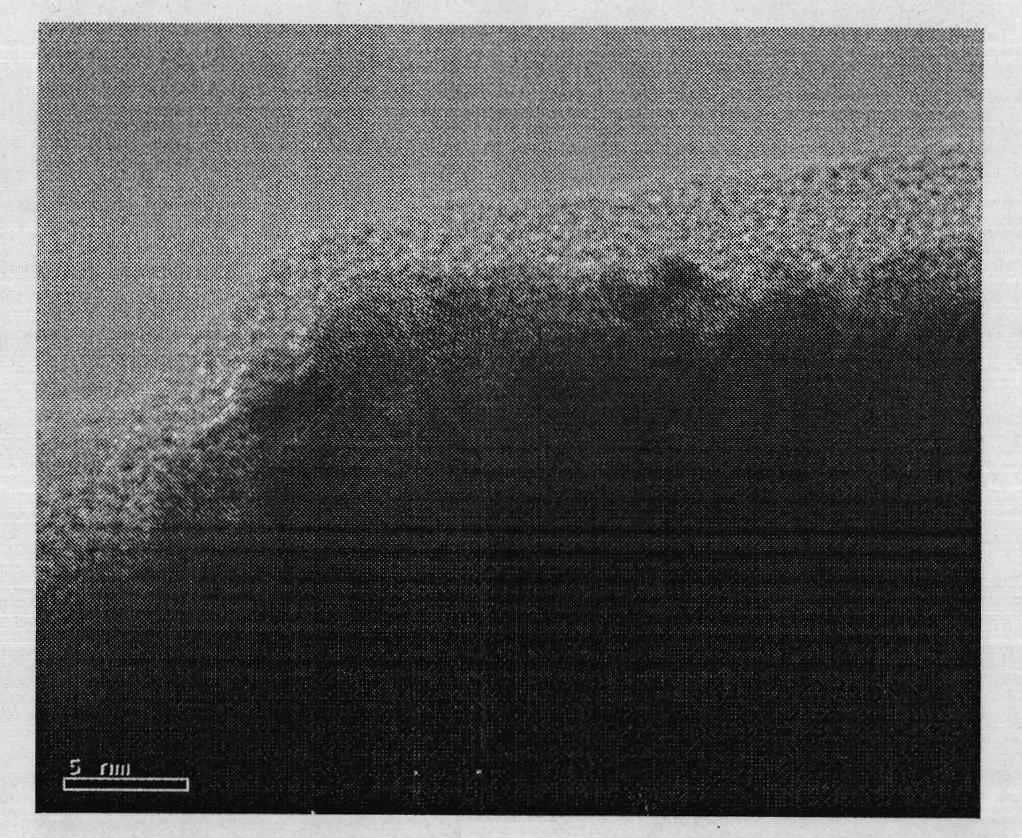

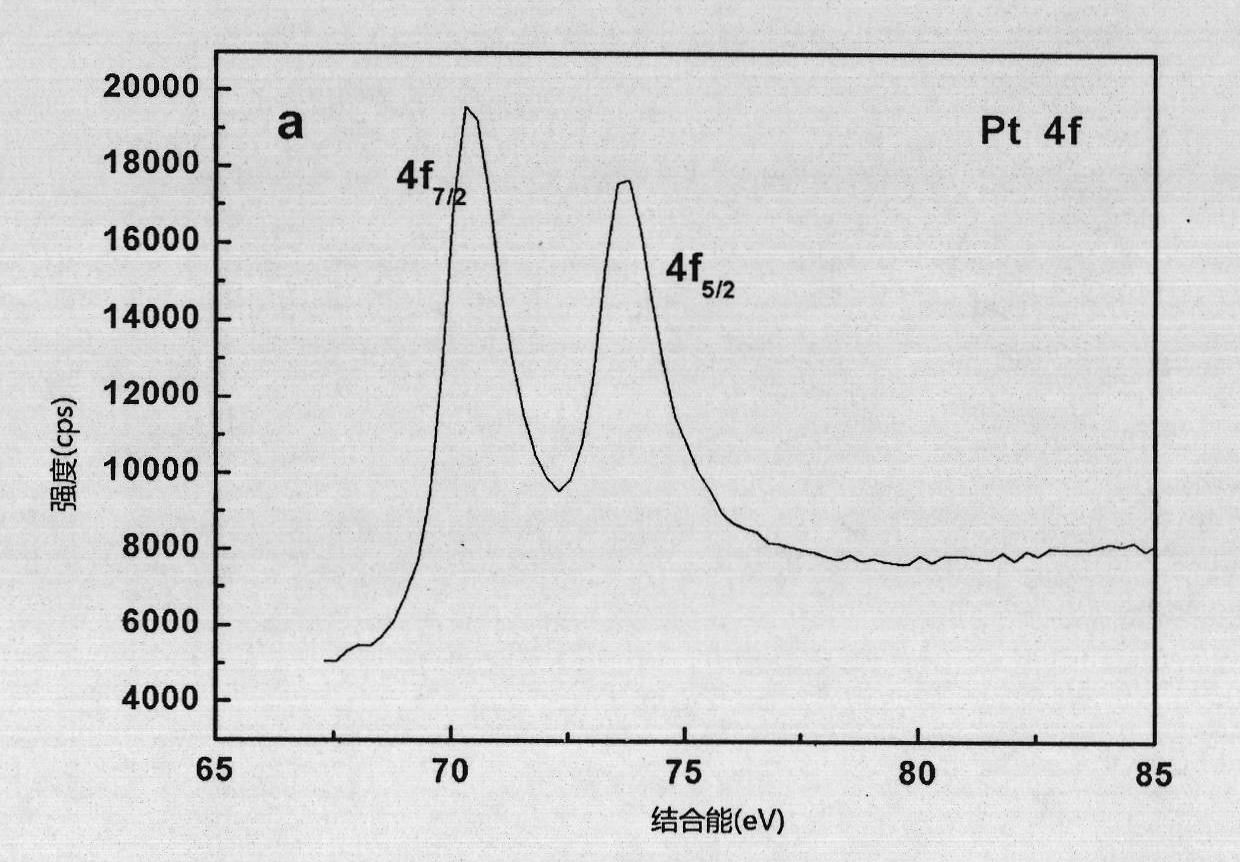

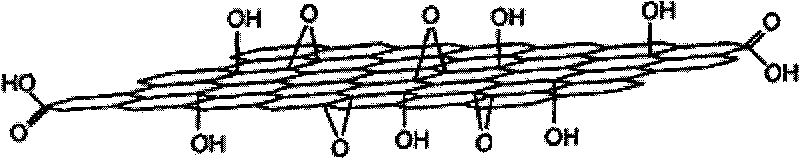

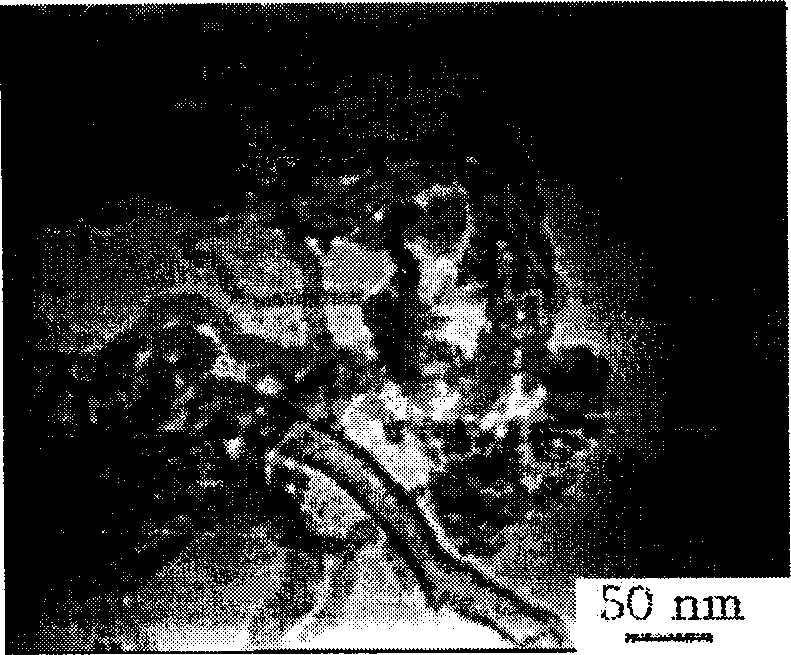

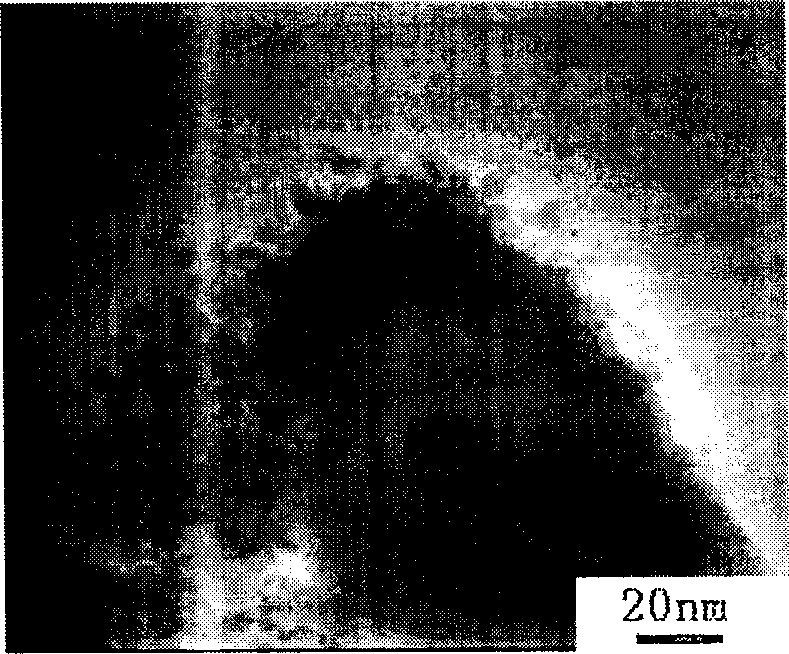

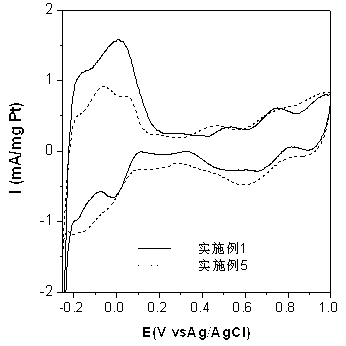

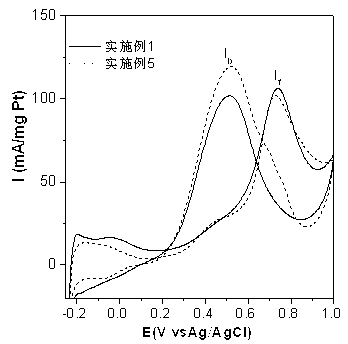

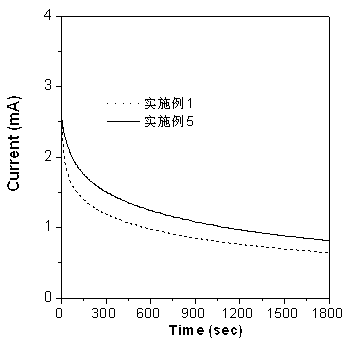

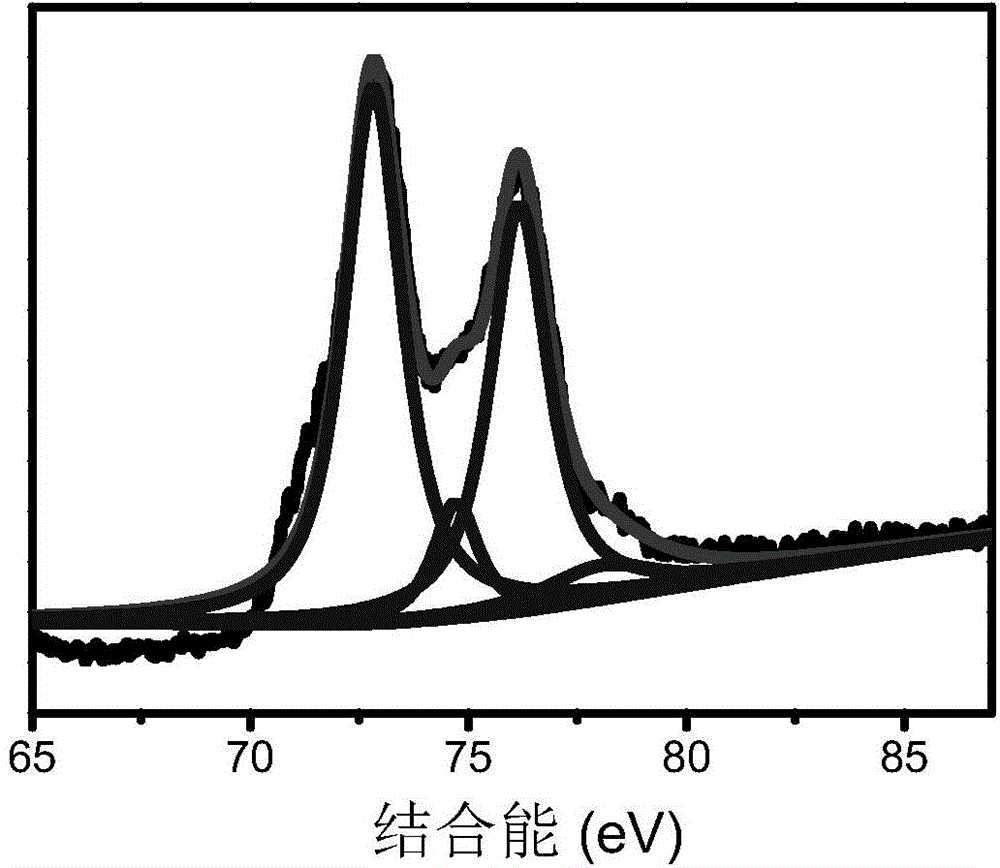

Platinum/graphene nano electro-catalyst and preparation method thereof

InactiveCN101745384AReductiveGood dispersionCell electrodesCatalyst activation/preparationSodium acetatePt element

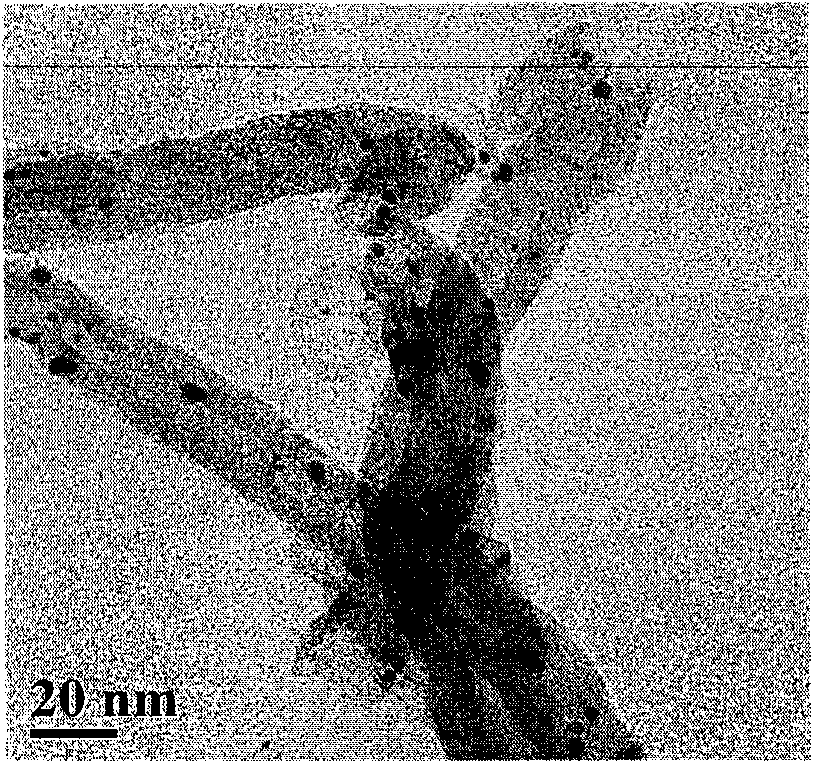

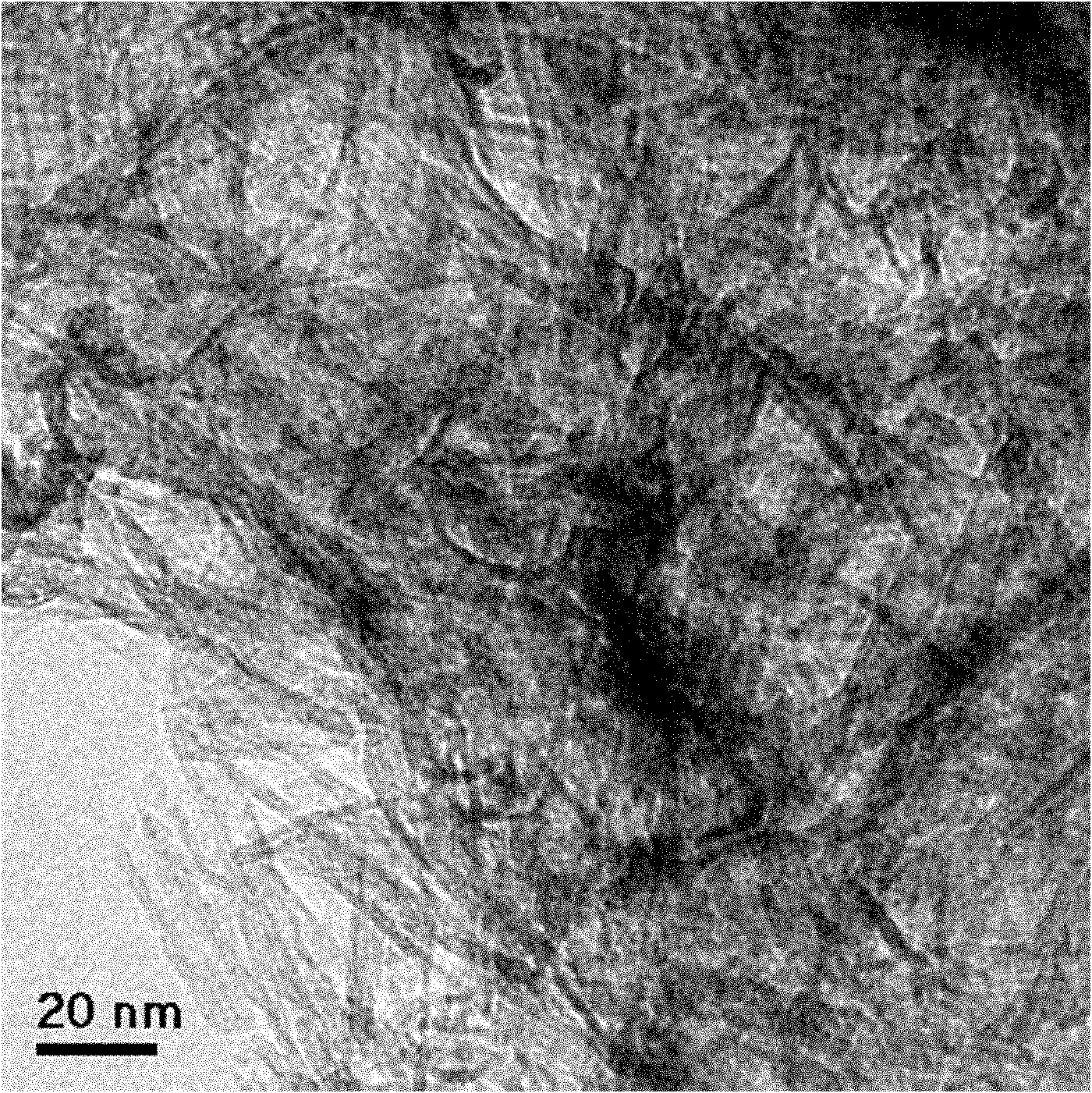

The invention discloses a platinum / graphene nano electro-catalyst. The platinum / graphene nano electro-catalyst uses graphene as a carrier and uses platinum as an active component, wherein the mass fraction of the platinum in the catalyst is 10 to 40 percent. A preparation method comprises the following steps: 1) ultrasonically dispersing an oxidized graphite nano sheet into liquid polyalcohol, then adding chloroplatinic acid solution and sodium acetate solution into the liquid polyalcohol, and fully mixing the solution uniformly, wherein the content of the oxidized graphite nano sheet in the mixture is between 0.48 and 1.3 g / L, the concentration of the chloroplatinic acid is between 0.0005 and 0.005 mol / L and the concentration of the sodium acetate is between 0.007 and 0.013 mol / L; and 2) transferring the mixture to a microwave hydrothermal reaction kettle, heating the mixture by microwave to react for 5 to 10 minutes, and then filtering, washing and drying the reaction product to obtain the platinum / graphene nano electro-catalyst. The preparation method of the invention has the advantages of energy conservation, quickness, simple process and the like. The particle diameters of the platinum nano particles in the prepared platinum / graphene nano electro-catalyst are uniform. The catalyst has good electro-catalysis performance, and has wide application in a fuel cell.

Owner:ZHEJIANG UNIV

Heat curing in-situ forming high-conductivity silicon rubber composition and application thereof

The invention relates to a heat curing in-situ forming high-conductivity silicon rubber composition and application thereof. The composition is composed of the following components: (1) 60-90 parts by weight of mixture of ethylene end-blocked polyorganosiloxane in the same or different viscosities; (2) 10-35 parts by weight of silicone oil containing hydrogen; (3) 1-25 parts by weight of one or multiple R<6>cSiX4-c or partial hydrolytic condensation product thereof; (4) 100-500 parts by weight of metal base conductive filler with the average particle size of 10-150 Mum; (5) 0.01-10 parts by weight of organic metal compound or chelate which contains chloroplatinic acid or contains platinum or palladium and is used as metal base catalyst of heat curing; (6) 1-30 parts by weight of reinforcing filler or functional filler. The invention is applied to the shielding case part of RF equipment requiring electromagnetic shielding and sealed environment. The invention reduces material consumption, simplifies production technology and improves production efficiency and cost performance of product.

Owner:SHANGHAI RELAND PHOTOVOLTAIC MATERIAL

Method for producing multicrystalline silicon substrate for solar cells

InactiveUS7135414B2Promote oxidationHigh dissolution rateFinal product manufactureSemiconductor/solid-state device manufacturingMetal particleSolar cell

Disclosed is a method for producing a multicrystalline silicon substrate for solar cells comprising: a metal deposition step for depositing such metal particles as platinum and silver on the surface of the substrate by electroless-plating chloroplatinic acid or silver perchlorate; a boring step for subjecting the substrate surface to etching in a solution containing at least one of hydrofluoric acid and hydrogen peroxide; and a step for removing a stain layer by immersing the substrate into an alkaline solution. A multicrystalline silicon substrate having a lower reflectance is provided at a lower cost.

Owner:KANSAI TLO KK

Platinum/carbon nanotube catalyst and preparation method and application thereof

InactiveCN102039121AMild conditionsEasy to manufactureOrganic reductionMaterial nanotechnologyCarbon nanotubeRoom temperature

The invention relates to a platinum / carbon nanotube catalyst suitable for multiphase asymmetric hydrogenation reaction. Platinum is loaded on a carbon nanotube carrier. A preparation method comprises the following steps of: heating a purified carbon nanotube in nitric acid, washing, filtering, washing by using water until the pH value of filtrate is neutral, drying to obtain the carbon nanotube carrier, soaking in aqueous solution of chloroplatinic acid, and performing ultrasonic treatment at room temperature; and stirring and impregnating a mixture of the carbon nanotube and the aqueous solution of chloroplatinic acid, raising the temperature to 110 DEG C from room temperature, drying at the temperature of 110 DEG C, grinding into fine powder, reducing by using aqueous solution of sodiumformate with heating, filtering, washing by using deionized water and drying. The invention also provides the preparation method of the catalyst and application of the catalyst to the multiphase asymmetric hydrogenation reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing noble metal modified one-dimensional titanium dioxide Hg-removing catalyst

ActiveCN101961651ASimple processEasy to masterOther chemical processesDispersed particle separationCatalytic oxidationRutile

The invention discloses a method for preparing a noble metal modified one-dimensional titanium dioxide Hg-removing catalyst. The method comprises the following steps of: by taking a titanium dioxide nanotube as an active main body and a noble metal salt or a nonmetal modifier as a modifier, heating in water, roasting, optically reducing, drying and grinding to prepare the noble metal elementary substance modified titanium dioxide nanotube photocatalyst. The nano titanium dioxide is in a rutile type, an anatase type or a mixed type of rutile and anatase; the noble metal salt is one or mixture of a plurality of silver nitrate, palladium chloride, palladium nitrate, chloroplatinic acid or chloroauric acid; and a photo-reduction sacrifice agent is one or mixture of a plurality of methanol, ethanol, ethylene glycol, propanol, isopropanol or propylene glycol. The invention is simple in process, easy to master and not easy to inactivate; and the prepared titanium dioxide nanotube and the noble metal elementary substance modified titanium dioxide nanotube photocatalyst can efficiently catalyze and oxidize Hg elementary substances in flue gas.

Owner:ZHEJIANG UNIV

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

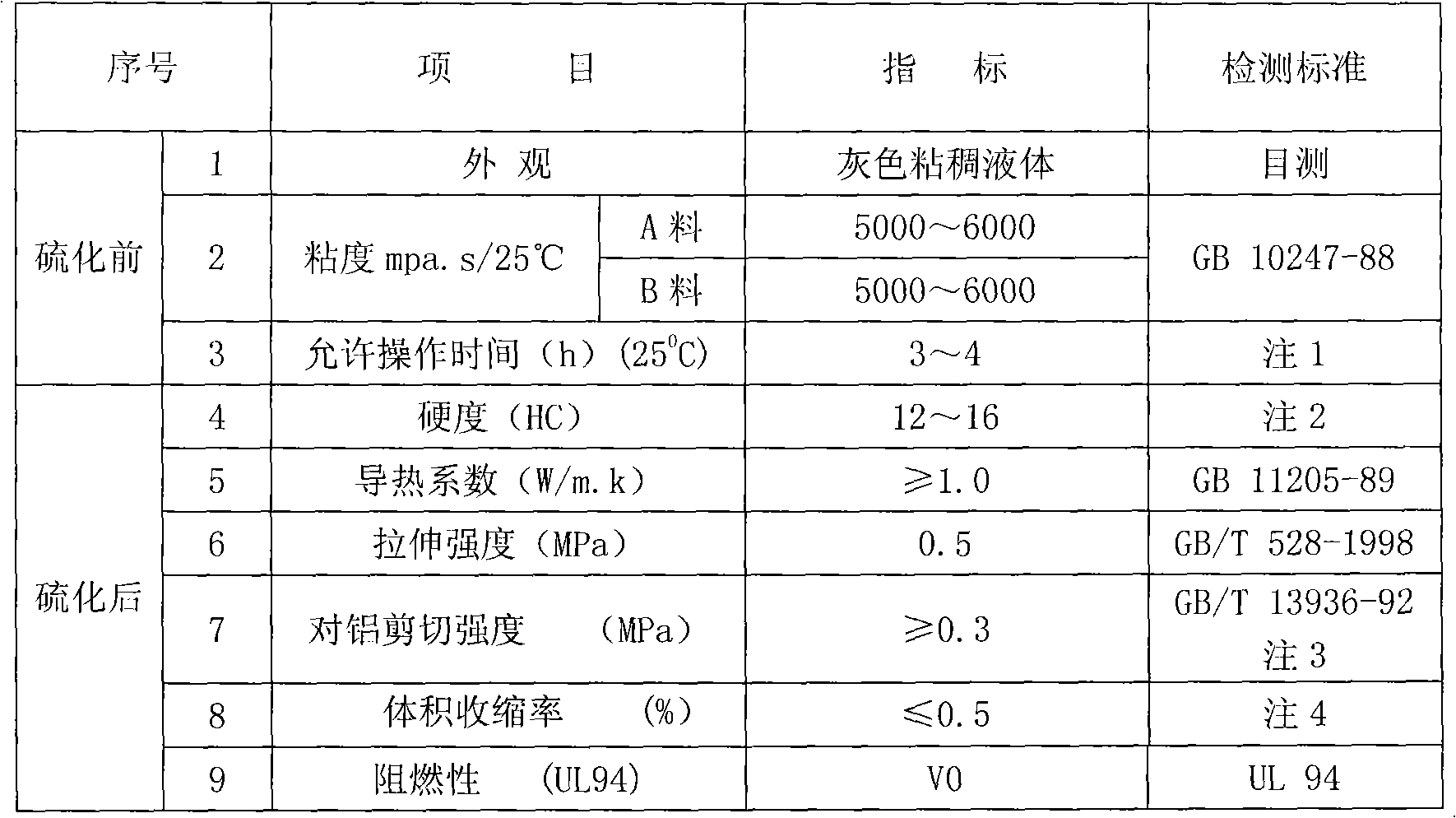

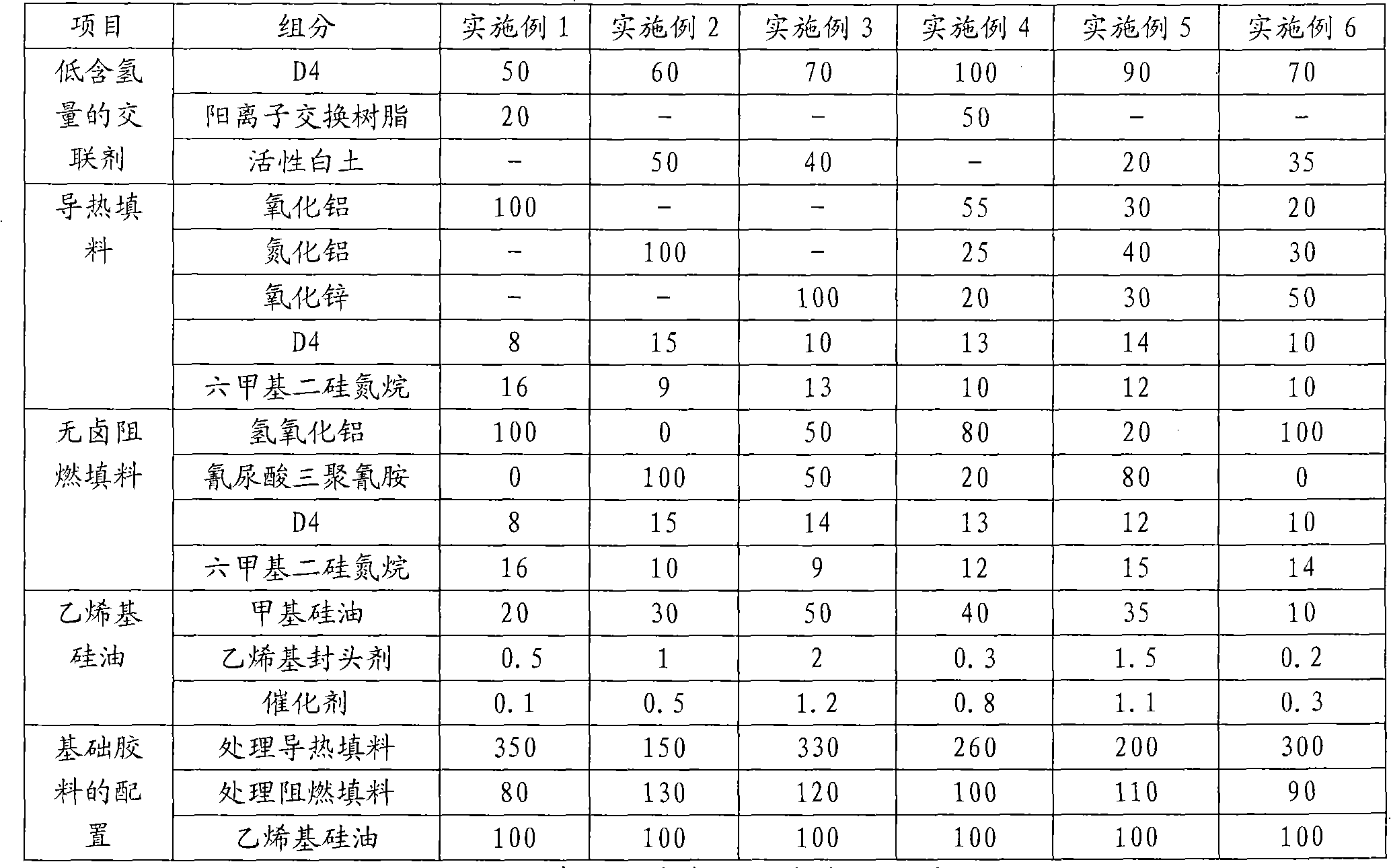

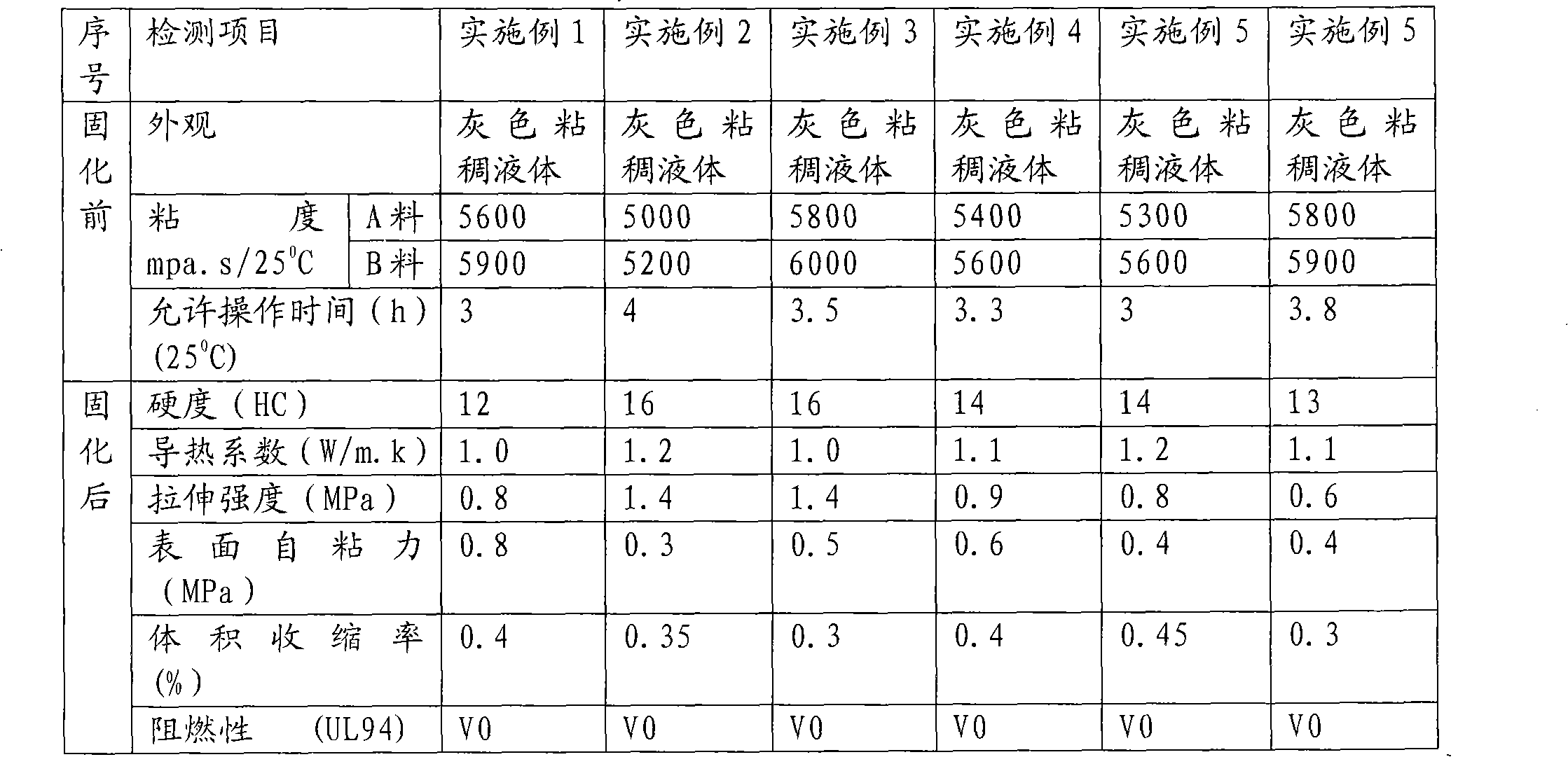

Double-component addition self-adhesive silicon rubber

The invention relates to a silicon rubber used for insulation protection of electronic products, in particular to a double-component addition self-adhesive silicon rubber. The double-component addition self-adhesive silicon rubber of the invention comprises material A and material B, and the mass ratio of the material A to the material B is 1:1, wherein material A is composed of 100 parts of basicrubber and 2-2.8 parts of cross linking agent containing low content of hydrogen; and material B is composed of 100 parts of basic rubber and 0.12 to 0.18 part of chloroplatinic acid complex. In theinvention, the raw material ratio of material A and material B of the silicon rubber is strictly controlled, each material is treated by a special process, therefore, the silicon rubber of the invention has good mobility, flame resistance, thermal conductivity and flexibility simultaneously, and have a certain degree of self-adhesion property. To the silicon rubber of the invention, the thermal conductivity is not less than 1.0w / m.k, the flame resistance is up to UL94V0 grade, the hardness is 12 to 16HC, and the shrinkage rate is less than 0.5%.

Owner:CHENGDU TALY TECH CO LTD

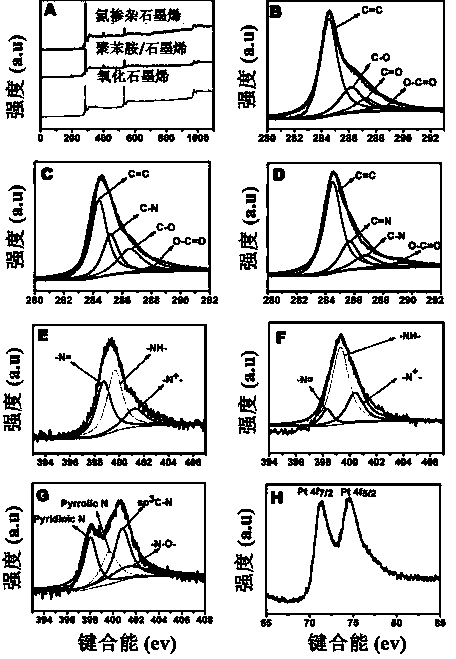

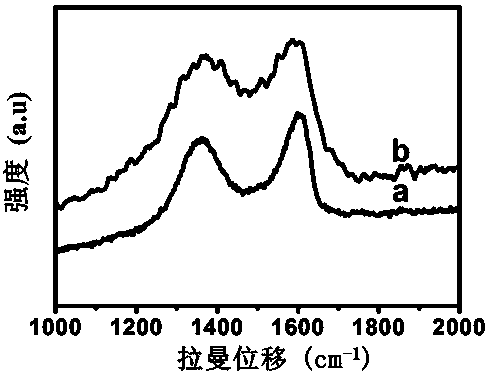

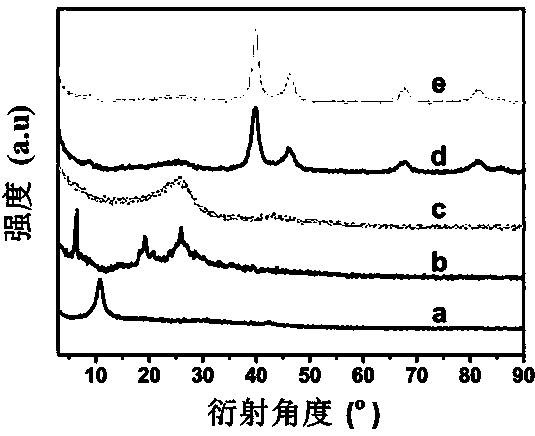

Preparation method of nitrogen-doped graphene loaded platinum nano-particle catalyst

InactiveCN103372428AAvoid uneven loadAvoid reunionMetal/metal-oxides/metal-hydroxide catalystsDoped graphenePtru catalyst

The invention discloses a preparation method of a nitrogen-doped graphene loaded platinum nano-particle catalyst. The preparation method comprises the following steps of: firstly, preparing graphene oxide (GO); secondly, preparing polyaniline / graphene oxide (PANI / GO) through a liquid-liquid interface polymerization method; thirdly, drying the PANI / GO, transferring the dried PANI / GO into a tubular furnace, and performing high-temperature treatment for 2 hours at 800 DEG C to prepare NGs (nitrogen-doped graphenes); and finally, ultrasonically dispersing the NGs into an aqueous solution, uniformly mixing the NGs with chloroplatinic acid according to a certain mass ratio, slowly adding sodium borohydride (NaBH4) into the mixed solution, and performing magnetic stirring for 8 hours to prepare the NGs loaded platinum nano-particle catalyst (Pt / NGs) which takes the NGs as a catalyst carrier to uniformly load platinum nano-particles to the surfaces of the NGs without any chemical modification. The nitrogen atoms which are doped into molecular structures of GNs not only provide a large amount of active sites for PtNPs loading, but also enhance the interaction between the PtNPs and an NGs carrier and improve the catalytic stability and catalytic activity of a nano composite material.

Owner:NANCHANG UNIV

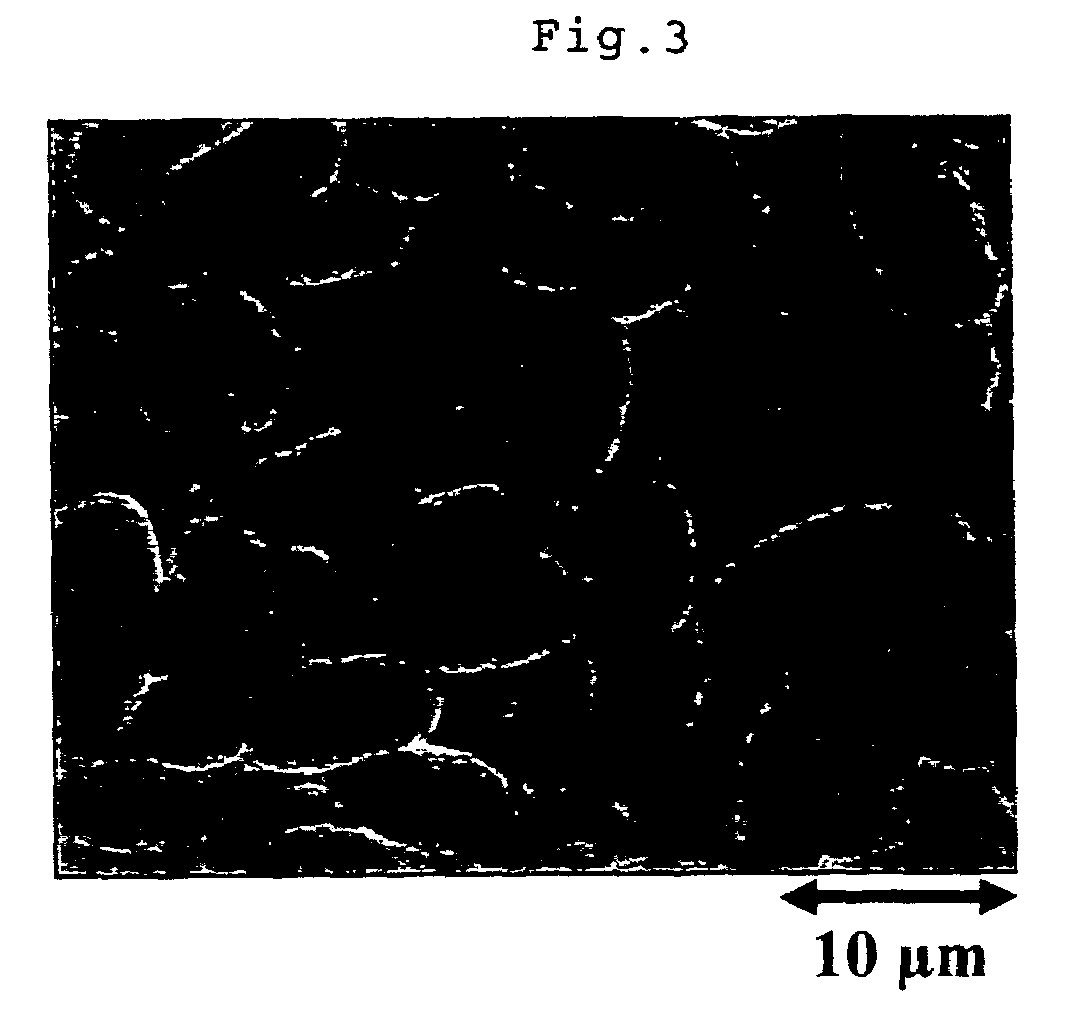

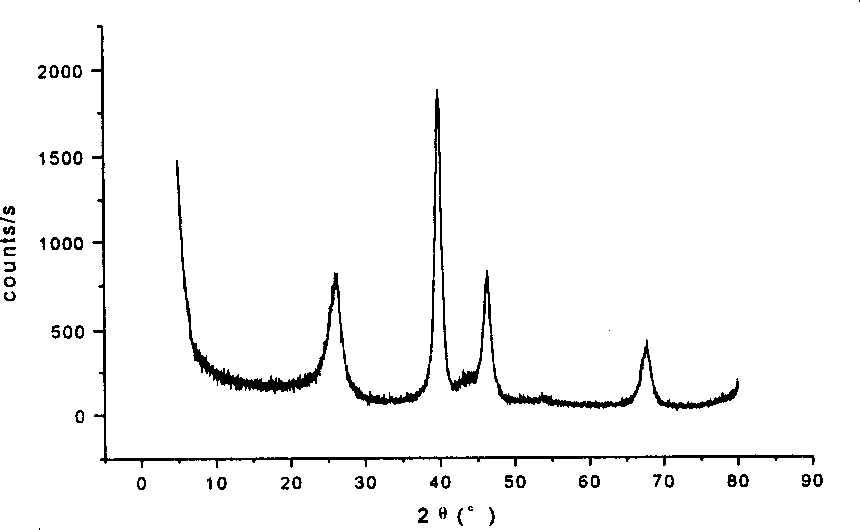

PtRu/graphene nano electro-catalyst and preparation method thereof

InactiveCN101740786AReductiveGood dispersionCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSodium acetrizoateSodium acetate

The invention discloses a preparation method of PtRu / graphene nano electro-catalyst, comprising the following steps of: ultrasonically dispersing oxidized nano graphite sheets into liquid polylol; then adding a chloroplatinic acid solution and a sodium acetate solution, sufficiently mixing, wherein the content of the oxidized nano graphite sheets contained in a mixture is 0.3-1.1 g / L, the concentration of chloroplatinic acid is 0.0004-0.002 mol / L, the concentration of ruthenium chloride is 0.0004-0.0013 mol / L, and the concentration of sodium acetate is 0.005-0.027 mol / L; transferring the mixture to a microwave hydro-thermal reaction kettle for microwave hydro-thermal reaction for 5-10 minutes; and filtering, washing and drying to obtain the PtRu / graphene nano electro-catalyst, wherein the mass fraction of a PtRu alloy contained in the PtRu / graphene nano electro-catalyst is 20-40 percent, the mass fraction of graphene is 80-60 percent, the atomic ratio of the PtRu alloy is Pt:Ru=1:2-1.5:1, and the liquid polylol is propanetriol or glycol. The preparation method has energy saving, fastness, simple process, and the like; and in addition, the prepared PtRu / graphene nano electro-catalyst has good electrocatalysis property for the oxidation of methanol and ethanol and is widely used as anode catalysts of direct methanol fuel cells.

Owner:ZHEJIANG UNIV

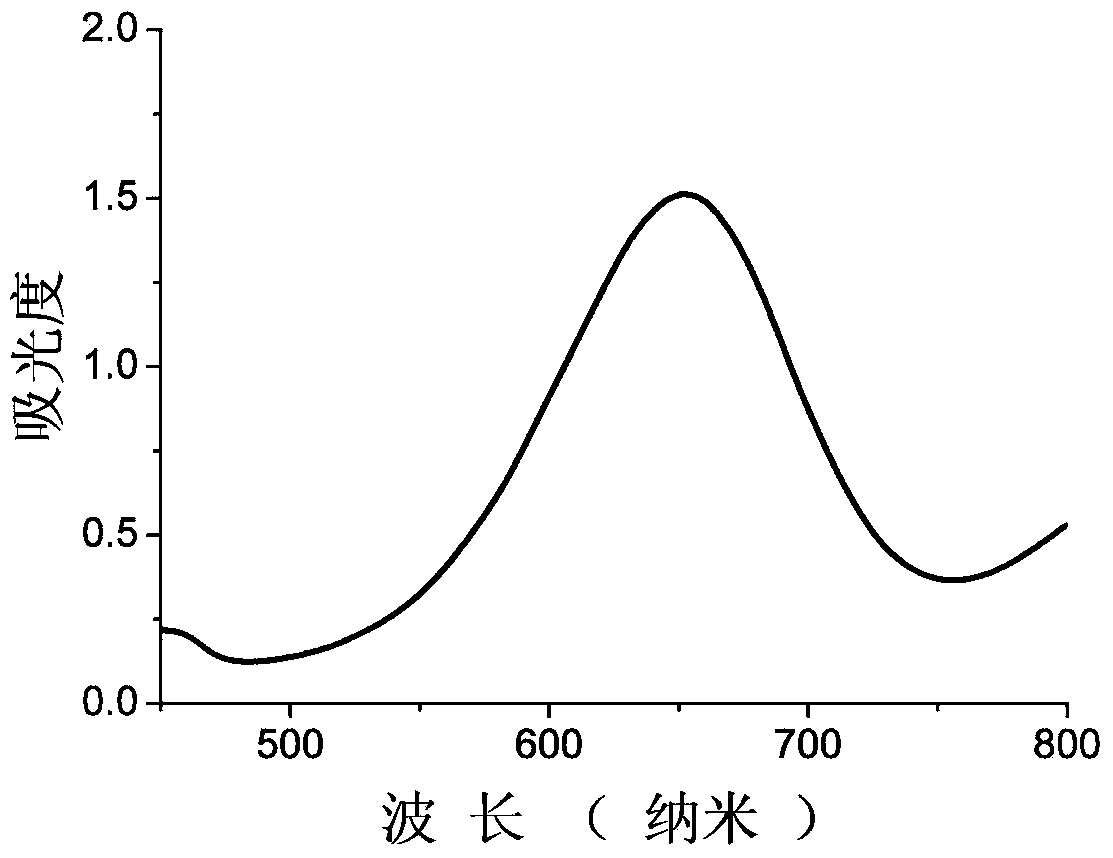

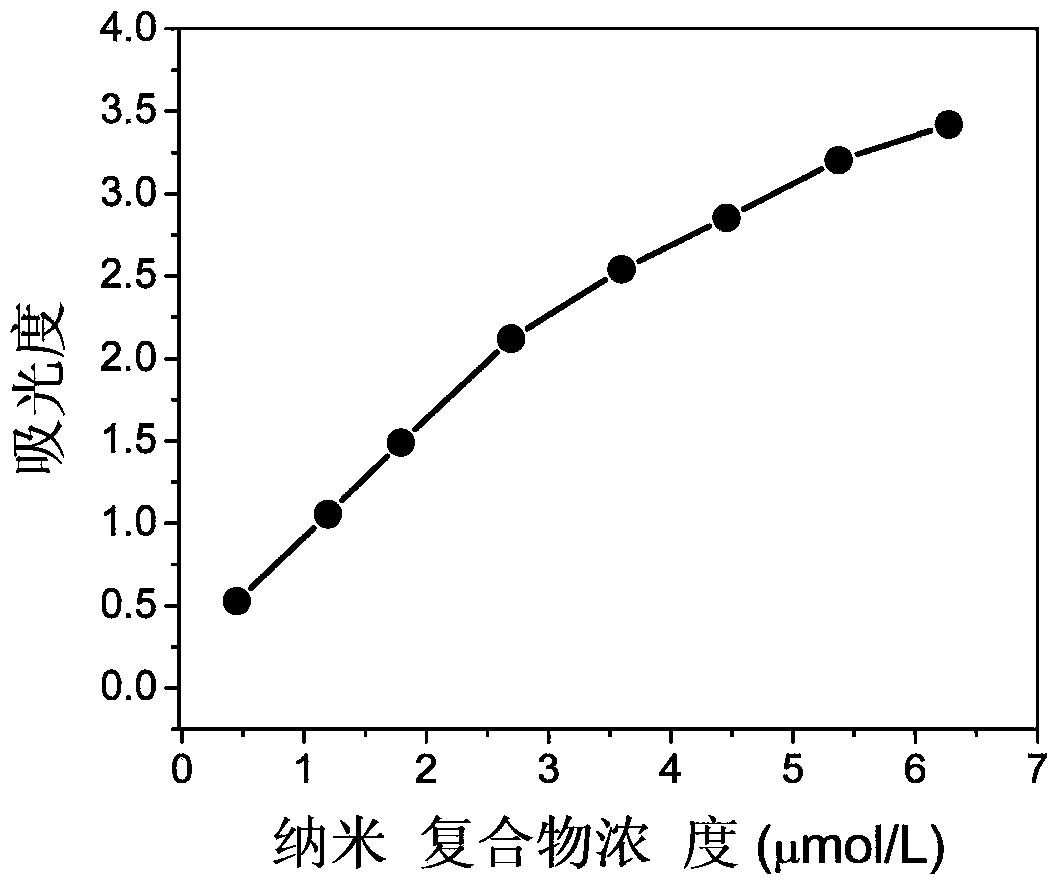

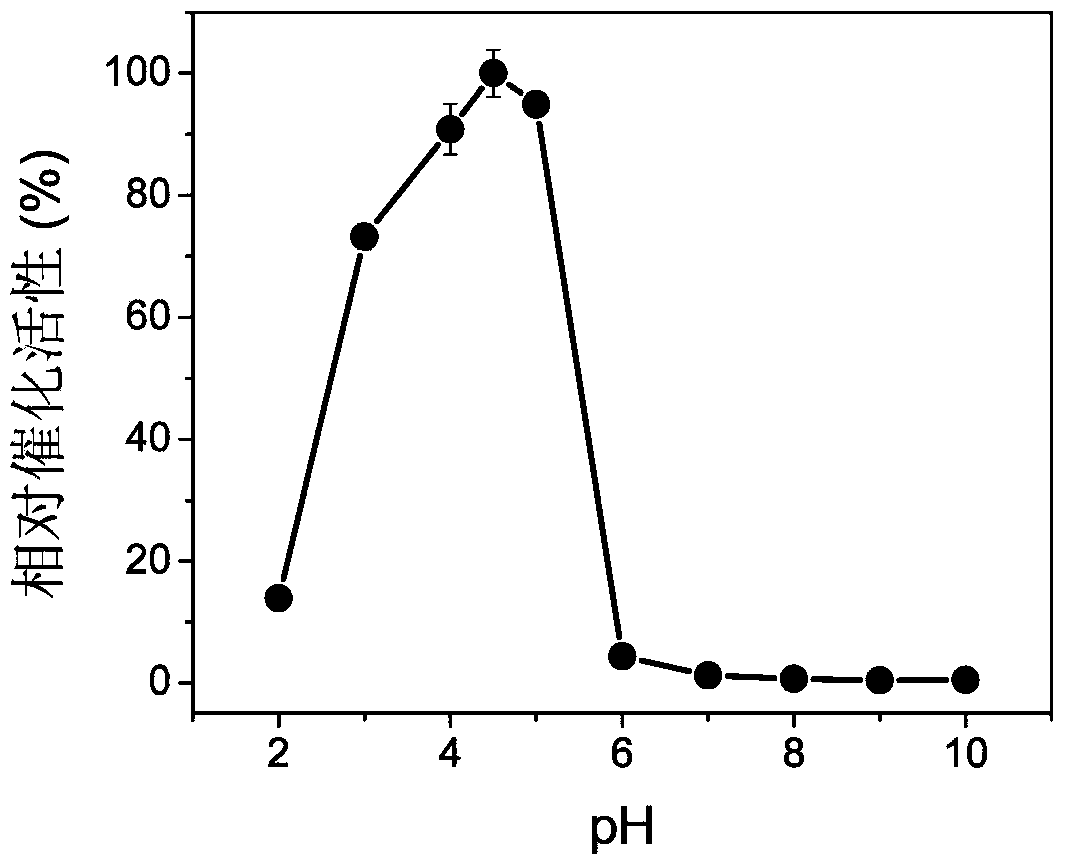

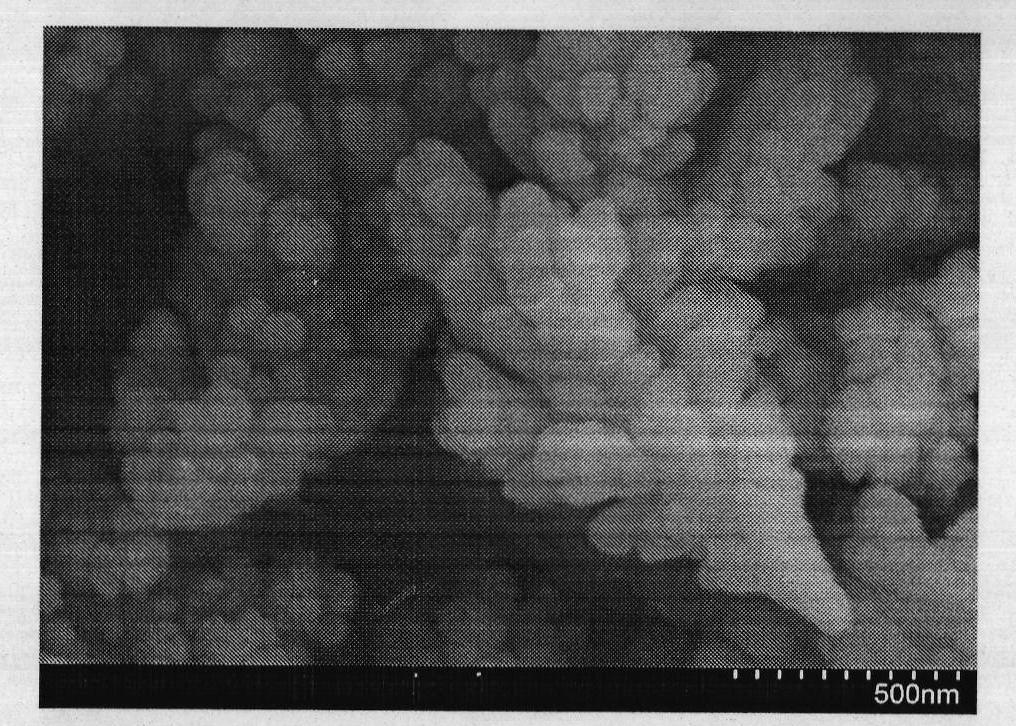

Bovine serum albumin-platinum composite nanomaterial mimetic peroxidase

InactiveCN103433484ANo significant change in catalytic activityImprove stabilitySerum albuminPeroxidaseUltrafiltration

The invention discloses bovine serum albumin-platinum composite nanomaterial mimetic peroxidase as well as a preparation method thereof and application. Bovine serum albumin is used as a template, and the bovine serum albumin-platinum composite nanomaterial mimetic peroxidase is prepared through biomineralization. Bovine serum albumin-platinum composite nanomaterials are prepared through the following method that chloroplatinic acid aqueous solutions are added to bovine serum albumin aqueous solutions and are mixed, sodium hydroxide aqueous solutions are added to obtain mixed solutions, and water bath heating is carried out; ultrafiltration is carried out on the solutions, then the solutions are washed, and bovine serum albumin-platinum composite nanomaterial aqueous solutions are obtained. The bovine serum albumin-platinum composite nanomaterials have excellent peroxidase activity, and can catalyze hydrogen peroxide oxidation 3, 3', 5, 5'-tetramethyl benzidine hydrochloride to be in color development. Meanwhile, the mimetic peroxidase resists acid and base, high temperature and high salinity, and has excellent short-term indoor temperature stability and long-term indoor temperature stability.

Owner:FUJIAN MEDICAL UNIV

Three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode as well as preparation and application thereof

ActiveCN101975807AElectrode area is smallHigh sensitivityMaterial electrochemical variablesGlucose sensorsPhosphate

The invention relates to a three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode as well as preparation and application thereof. The electrode consists of a three-dimensional Pt-Pb nano floricome array on a stainless steel acupuncture needle substrate, wherein three-dimensional Pt-Pb nano floricomes exist on the surface of the electrode in a good crystallization form, and the diameter of the single nano floricome is 50-80nm. The preparation method comprises the following steps of: polishing a stainless steel acupuncture needle on deerskin; after the stainless steel acupuncture needle is repeatedly washed through secondary distilled water and processed through ultrasound, putting the stainless steel acupuncture needle in a PBS (Phosphate Buffer Solution) of whichthe pH is 7.0 to scan and activate for 10 circles through cyclic voltammetry; putting the stainless steel acupuncture needle into a hydrochloric acid electrolyte of 0.5mol / L, which consists of chloroplatinic acid and lead acetate by a ratio of 1:1; and preparing an electrode sample through an ultrasonic oscillation electro-deposition method. The three-dimensional Pt-Pb nano floricome type enzyme-free glucose sensor electrode has good electro-catalysis activity, wide linear response range and high sensitivity and selectivity.

Owner:苏州盛泽科技创业园发展有限公司

Pt-CeO2/graphene electro-catalyst and preparation method thereof

InactiveCN101733094AReductiveGood dispersionCell electrodesCatalyst activation/preparationSodium acetateCerium

The invention discloses a Pt-CeO2 / graphene electro-catalyst which uses graphene as a carrier, platinum as an active component and CeO2 as an auxiliary component, wherein the mass fraction of the platinum contained in the Pt-CeO2 / graphene electro-catalyst is 20 percent; and the mole ratio of the platinum and cerium is 1:1-2.5:1. A preparation method of the Pt-CeO2 / graphene electro-catalyst comprises the following steps of: ultrasonically dispersing oxidized nano graphite sheets into glycol; then adding a chloroplatinic acid solution, an aqueous ammonium ceric nitrate solution and an aqueous sodium acetate solution, and sufficiently mixing; transferring a mixture to a microwave hydro-thermal reaction kettle; and after microwave hydro-thermal reaction, filtering, washing and drying to obtain the Pt-CeO2 / graphene electro-catalyst. The preparation method has energy saving, fastness, simple process, and the like; and in addition, the prepared Pt-CeO2 / graphene electro-catalyst has high electrocatalysis activity for the electrochemical oxidation of methanol and is widely used for direct methanol fuel cells.

Owner:ZHEJIANG UNIV

Method for preparing solvent-free polyether grafting organosilico/diamide compound emulsion defoamer

InactiveCN101637708AHarm reductionGood value for moneyTransportation and packagingMixingSolvent freeSolvent

The invention discloses a method for preparing a solvent-free polyether grafting organosilico / diamide compound emulsion defoamer. Under the action of chloroplatinic acid-isopropanol catalyst, hydrogen-containing silicone oil, allyl polyether and the like are used as raw materials to prepare serial polyether graft-modification organosilico surfactant in a solvent-free and dark condition; simultaneously, diamide and dimethyl silicon oil are used for reaction so as to obtain diamide silicon paste; and the serial compound emulsion defoamer is obtained by modifying the emulsification caused by theorganosilico to the silicon paste. In the preparation process no organic solvent needs to be added so that harm to operators and the environment can be reduced; in addition, the compound emulsion defoamer has the advantages of a plurality of defoaming components of the polyether, the organosilico and the diamide, not only can realize instant defoaming but also can inhibit foams for a long time, therefore the compound emulsion defoamer has high cost performance.

Owner:SHAANXI UNIV OF SCI & TECH

Three-dimensional nitrogen-doped graphene platinoid-loaded composite electro-catalyst and preparation method thereof

InactiveCN104353480ARaw materials are easy to getHigh yieldPhysical/chemical process catalystsCell electrodesNickel saltDoped graphene

The invention discloses a three-dimensional nitrogen-doped graphene platinoid-loaded composite electro-catalyst. A preparation method comprises the following steps of ultrasonically dispersing graphene oxide sheet in an aqueous solution, adding urea and soluble nickel salt for full and uniform mixing, transferring the mixture into a hydrothermal reaction kettle for reaction, performing freeze-drying to obtain three-dimensional nitrogen-doped graphene, dissolving the three-dimensional nitrogen-doped graphene in ethylene glycol, sequentially adding chloroplatinic acid, copper chloride dehydrate and glutamic acid, and performing microwave reaction to obtain the catalyst. The method has the characteristics of that energy is saved, the speed is high, and the operation is simple; the raw materials are easy to obtain, the yield is high, the capability of platinum in the direct electro-catalytic oxidation of methanol under an acidic condition can be remarkably improved, peak current is 3 to 4 times than that of a commercial carbon black platinum-loaded electro-catalyst and a commercial carbon black platinum-ruthenium-loaded electro-catalyst, and the prepared catalyst is widely applied to a methanol fuel cell.

Owner:GUANGXI NORMAL UNIV

Method for prepn. of electrode catalyst contg. platinum carried on carbon nanometer tube

InactiveCN1418726AGood dispersionHigh activityCell electrodesCatalyst activation/preparationPorosityIn situ chemical reduction

The present invention relates to a preparation method of Pt / CNT electrode catalyst carried by carbon nano tube. It is characterized by that the carbon nano tube can be used as carrier, a light-catalyzed in-situ chemical reduction precipitation method is utilized, and the ethylalcohol (or formaldehyde) can be used as reduction agent, and the chloroplatinic acid can be reduced and deposited on the activated carbon nano tube so as to obtain the invented Pt / CNTs catalyst with high activity for proton, exchange membrane fuel cell direct methyl alcohol fuel cell. As compared with existent electrodecatalyst said invention features large specific surface area, high porosity, good dispersion property and low platinum use level.

Owner:BEIJING JIAOTONG UNIV +1

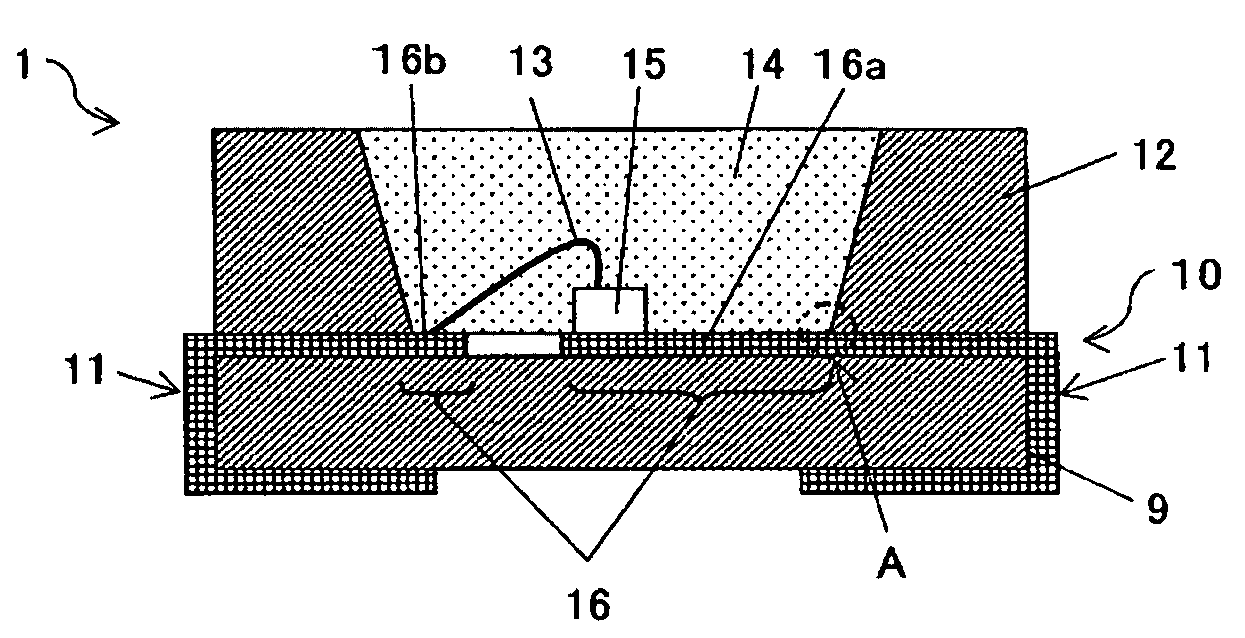

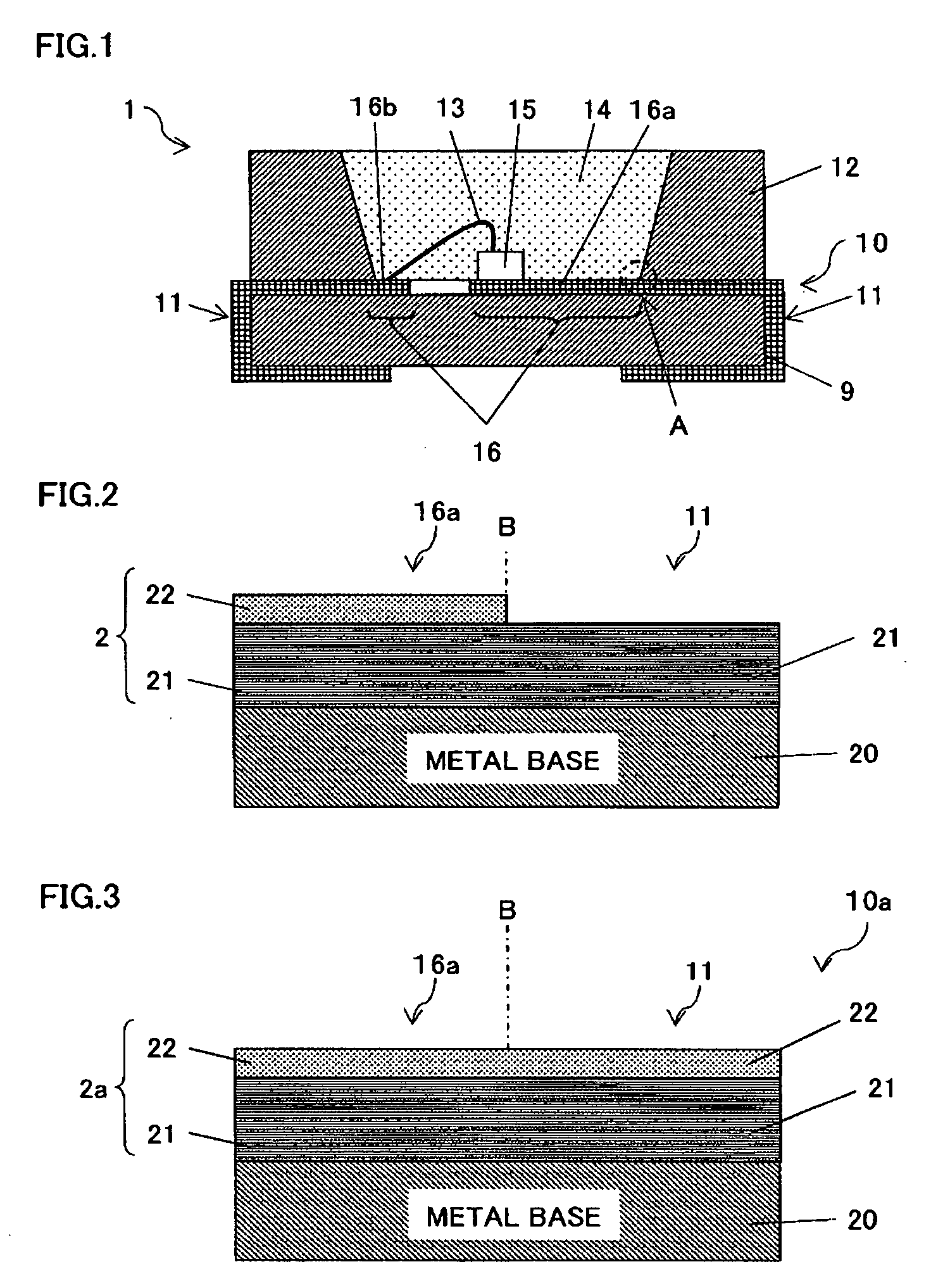

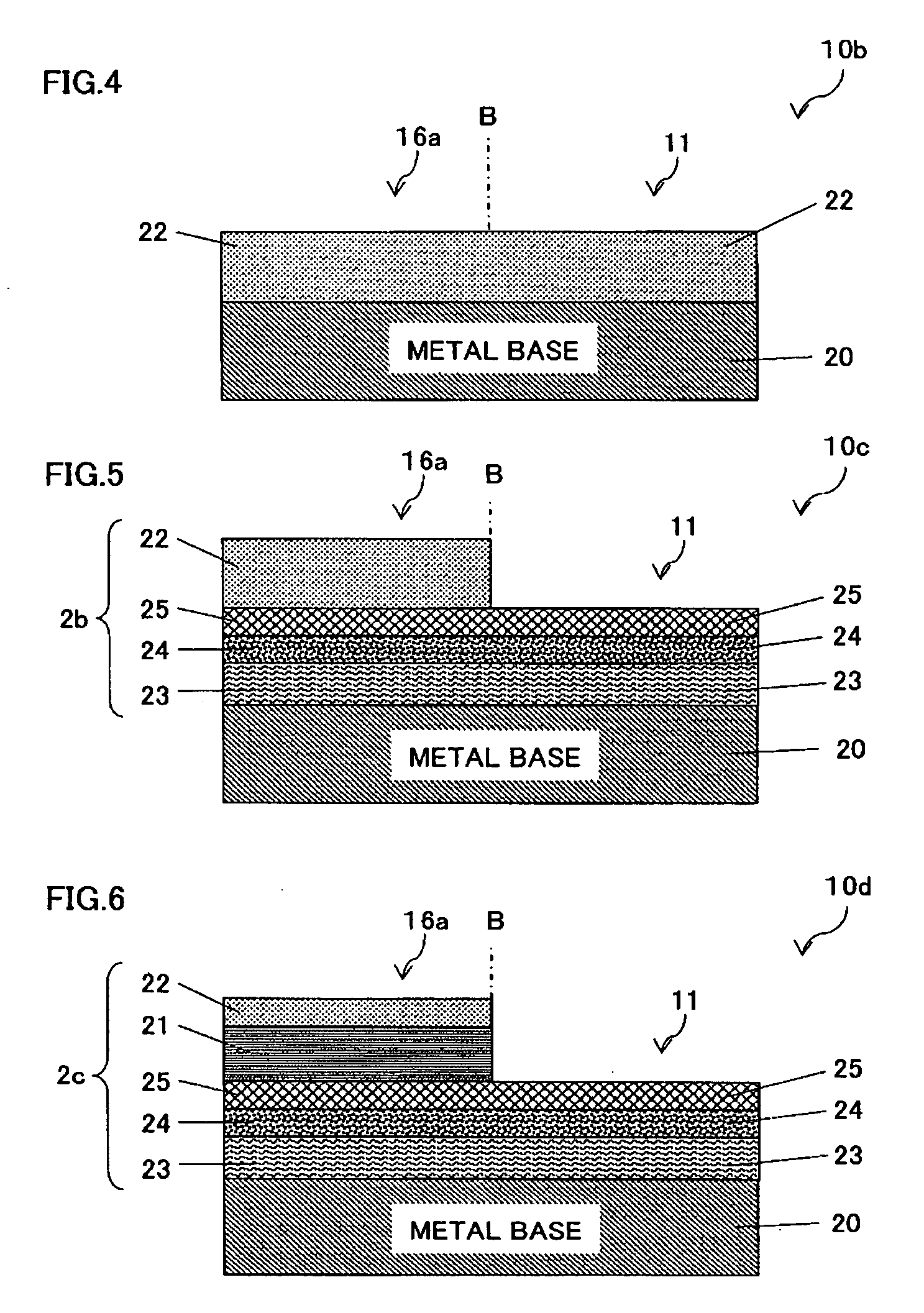

Lead frame for an optical semiconductor device, optical semiconductor device using the same, and manufacturing method for these

InactiveUS20080083973A1Increase brightnessReduce reflectionLine/current collector detailsSemiconductor/solid-state device detailsEngineeringLead frame

There is provided a lead frame for an optical semiconductor device, an optical semiconductor device using such lead frame, and a manufacturing method for these, where the optical semiconductor device exhibits favorable brightness over a long period of time by preventing discoloration and degeneration of a plating layer provide on the lead frame and a resulting reduction in a reflection coefficient for light emitted from a light emitting element, even when using silicone resin as a sealing resin. An Ag—Au alloy plating layer 22 is formed on the surface of a pure Ag plating layer 21 on a lead frame 10 sealed chloroplatinic acid-containing silicon resin, so as to prevent direct contact between the layer 21 and the silicone resin. This suppresses the formation of AgCl due to a reaction with a hardening catalyst of the silicon resin, thereby preventing the Ag plating layer from turning a blackish-brown color.

Owner:PANASONIC CORP

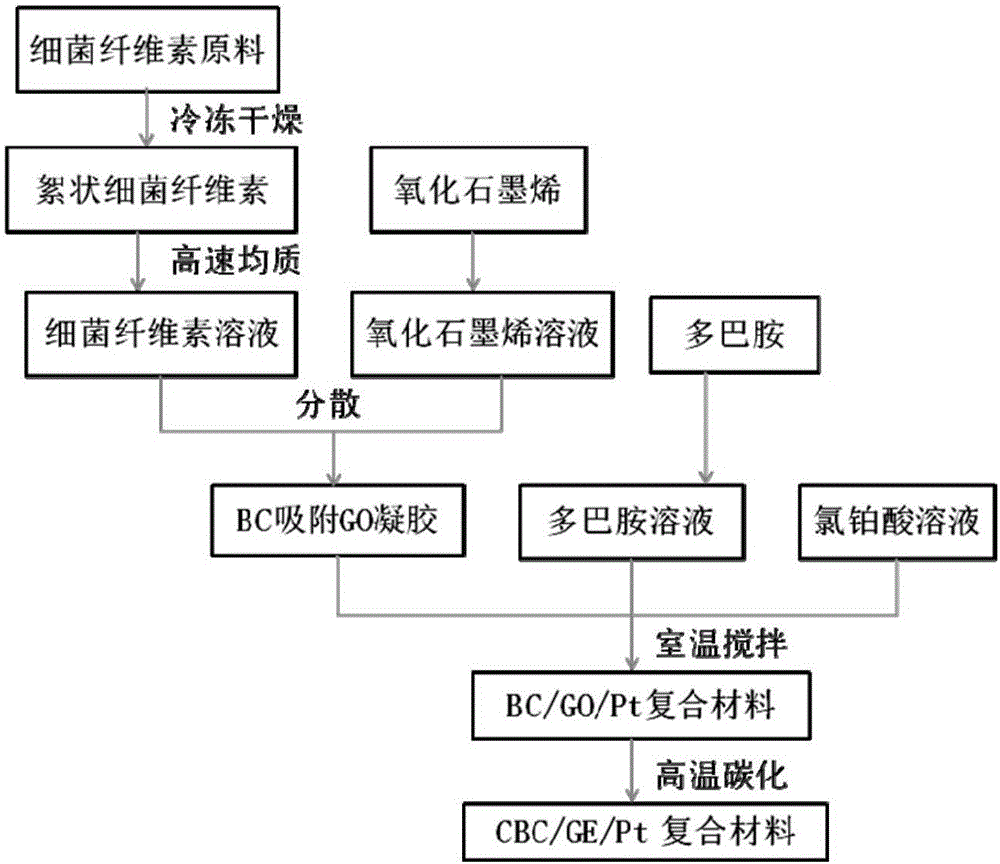

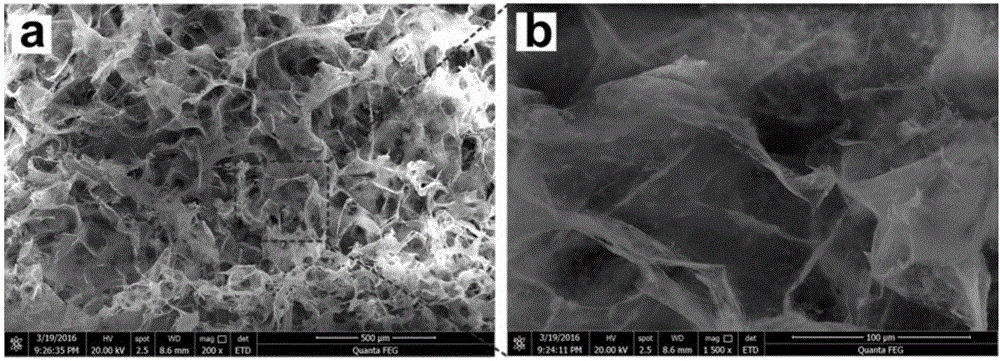

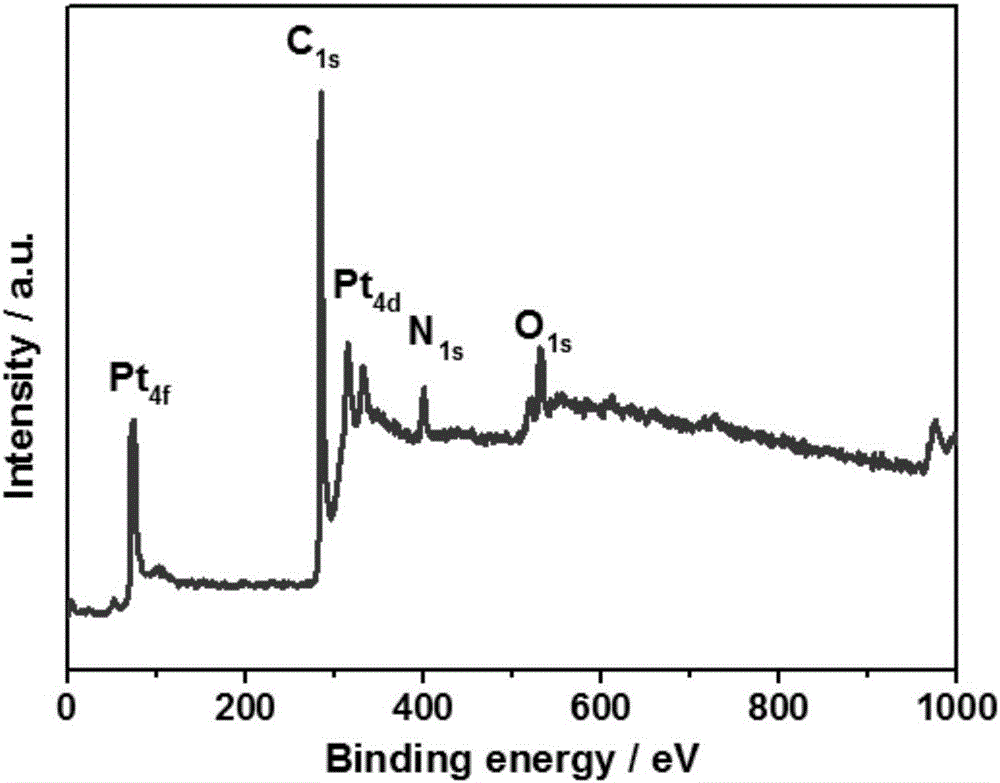

Nitrogen doping carbonized bacterial cellulose/graphene/platinum composite nanomaterial and preparation method thereof

ActiveCN106410223AAvoid stackingImprove catalytic performanceMaterial nanotechnologyCell electrodesCross-linkCarbonization

The present invention discloses a preparation method of a nitrogen doping carbonized bacterial cellulose / graphene / platinum composite nanomaterial. The material is prepared according to the following steps of pre-treating flocculent bacterial cellulose generated in fermentation of acetobacter xylophilus, then refrigering and drying the flocculent bacterial cellulose so as to obtain flocculent bacterial cellulose; homogenizing at high speed so as to obtain a uniform solution, mixing the uniform solution with graphene oxide, and dispersing the mixture uniformly through ultrasonic; and adding a dopamine solution, stirring and mixing by using a machine, adding chloroplatinic acid finally, and carbonizing at high temperature so as to obtain the nitrogen doping carbonized bacterial cellulose / graphene / platinum composite nanomaterial. The composite nanomaterial prepared by the method uses a one-step method to carbonize, and the reaction process is easy. Under the action of the dopamine, the flocculent bacterial cellulose and the graphene oxide are bonded, so as to form a three-dimensional networked cross-linked skeleton structure. In carbonization, nitrogen doping and platinum reduction are realized, and the conductive nanometer composite system that has small and uniformly distributed particles is prepared. The nanomaterial prepared by the method can be applied to application fields such as fuel batteries and super capacitors.

Owner:NANJING UNIV OF SCI & TECH

Carbon-containing metal catalyst, preparation method and application thereof

InactiveCN103227334AConducive to loadHigh catalytic activityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsHigh resistanceHigh current density

Owner:上海氢尚新能源科技有限公司

Platinum nano-material with activity of four mimic enzymes and preparation method thereof

InactiveCN104308139AEasy to manufactureSmall particle sizeMaterial nanotechnologyDismutasePeroxidase

The invention discloses a platinum nano-material with the activity of four mimic enzymes and a preparation method thereof. The preparation method comprises the following steps: using citrate ions as a modifier, reducing chloroplatinic acid by utilizing sodium borohydride, and preparing the platinum nano-material modified by citric acid. The platinum nano-material is simply and quickly prepared, the particle size is small, and the dispersibility and stability of a water solution are high. The obtained platinum nano-material has the activity of four mimic enzymes at the same time, and comprises peroxidase, oxidase, catalase and superoxide dismutase. The activity of the four mimic enzymes of the platinum nano-material can be adjusted and controlled through the concentration of the citrate ions used in the preparation process.

Owner:FUJIAN MEDICAL UNIV

Pt nanparticle-supported MnO2 catalyst, its preparation method and application thereof

ActiveCN102728356AFully catalytic degradationReduce energy consumptionMetal/metal-oxides/metal-hydroxide catalystsPollutionAscorbic acid

The invention relates to a high-dispersibility Pt nanoparticle supported MnO2 catalyst, its preparation method and an application thereof. According to the preparation method, under the condition of an aqueous solution, sodium citrate, PVP, ascorbic acid and chloroplatinic acid are used as raw materials to synthesize Pt nanoparticles, which are used as an active component to be loaded on an MnO2 carrier, so as to obtain the catalyst which is formed by the MnO2 carrier and the Pt nanoparticles loaded on the surface of the carrier. The loading of the Pt nanoparticles accounts for 0.1-10% of the weight of the catalyst. The catalyst can be used for catalytic degradation of indoor pollutants (such as formaldehyde) and used for preparation of electrode materials for cells, magnetic materials, fuel cells and the like. The catalyst can be used for complete catalytic degradation of formaldehyde at low temperatures, and has advantages of high efficiency, low energy consumption, simple operation, mild reaction condition and secondary pollution eradication.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

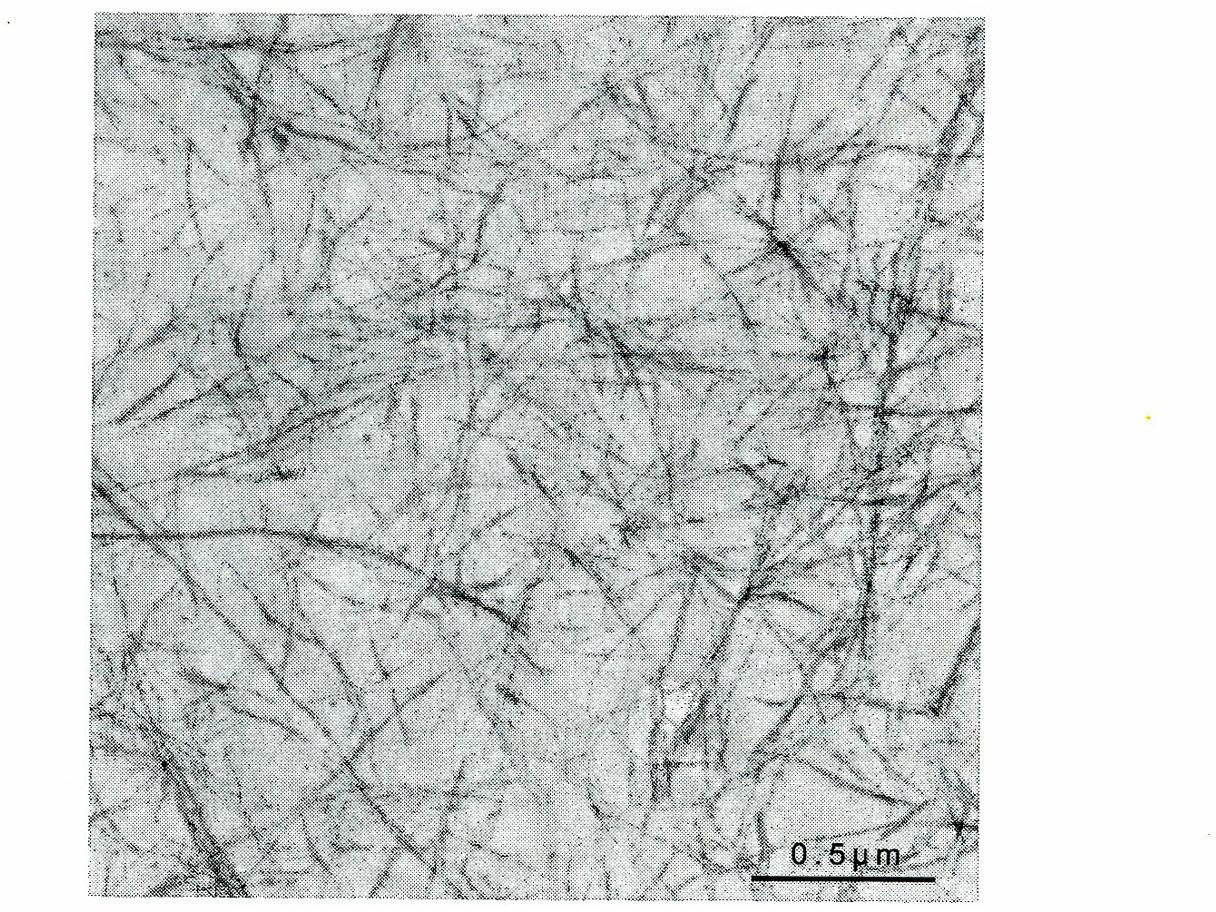

Preparation method of ultrafine platinum nano-wire

The invention relates to a preparation method of an ultrafine platinum nano-wire. The method mainly comprises that an insulin fiber suspension is obtained by dissolving bovine insulin powders into a hydrochloric acid solution with the concentration of 10-25 mM to prepare an insulin hydrochloric acid solution, blending the insulin hydrochloric acid solution with vortexes, and heating the blended insulin hydrochloric acid solution for 5-20 h in a constant-temperature metal bath at the temperature of 65-70 DEG C; and that the ultrafine platinum nano-wire is obtained by adding a chloroplatinic acid solution into the above insulin fiber suspension, fully blending the mixture, incubating the mixture for 10-20 h in a shaking table at the temperature of 4-10 DEG C and with the rotating speed of 50-100 r / min, dropwise adding a sodium borohydride reductant solution with a concentration of 5-10 mM into the mixture, and vibrating the mixture for 8-24 h in a shaking table at the temperature of 4-10 DEG C and with the rotating speed of 50-100 r / min to make the mixture fully reacted. The method of the invention has the advantages of a simple process, mild reaction conditions, and good repeatability, and is environment protective and highly efficient. With the method, appearance of the platinum nano-wire has no obvious changes while output of the nano-wire increases substantially. Thus, the nano-wire is provided with higher aspect ratio and simpler regulation and control method of output, thereby being easier to realize large-scale production.

Owner:YANSHAN UNIV

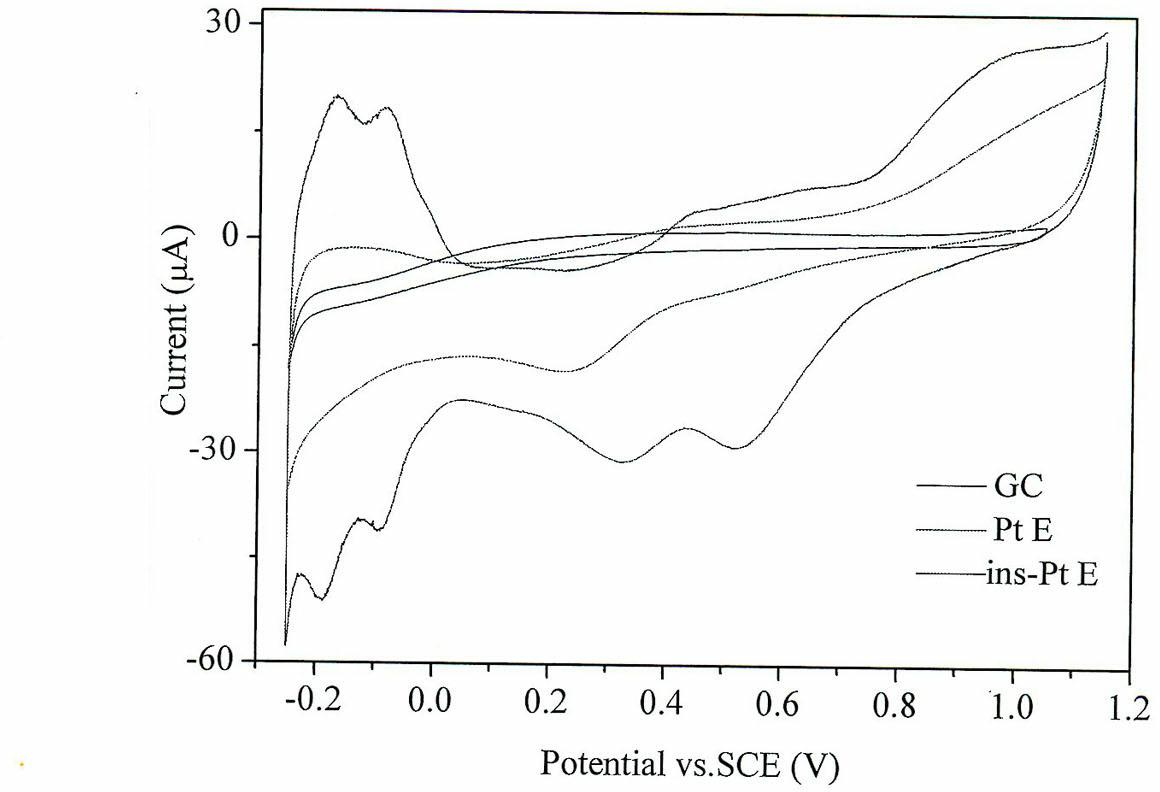

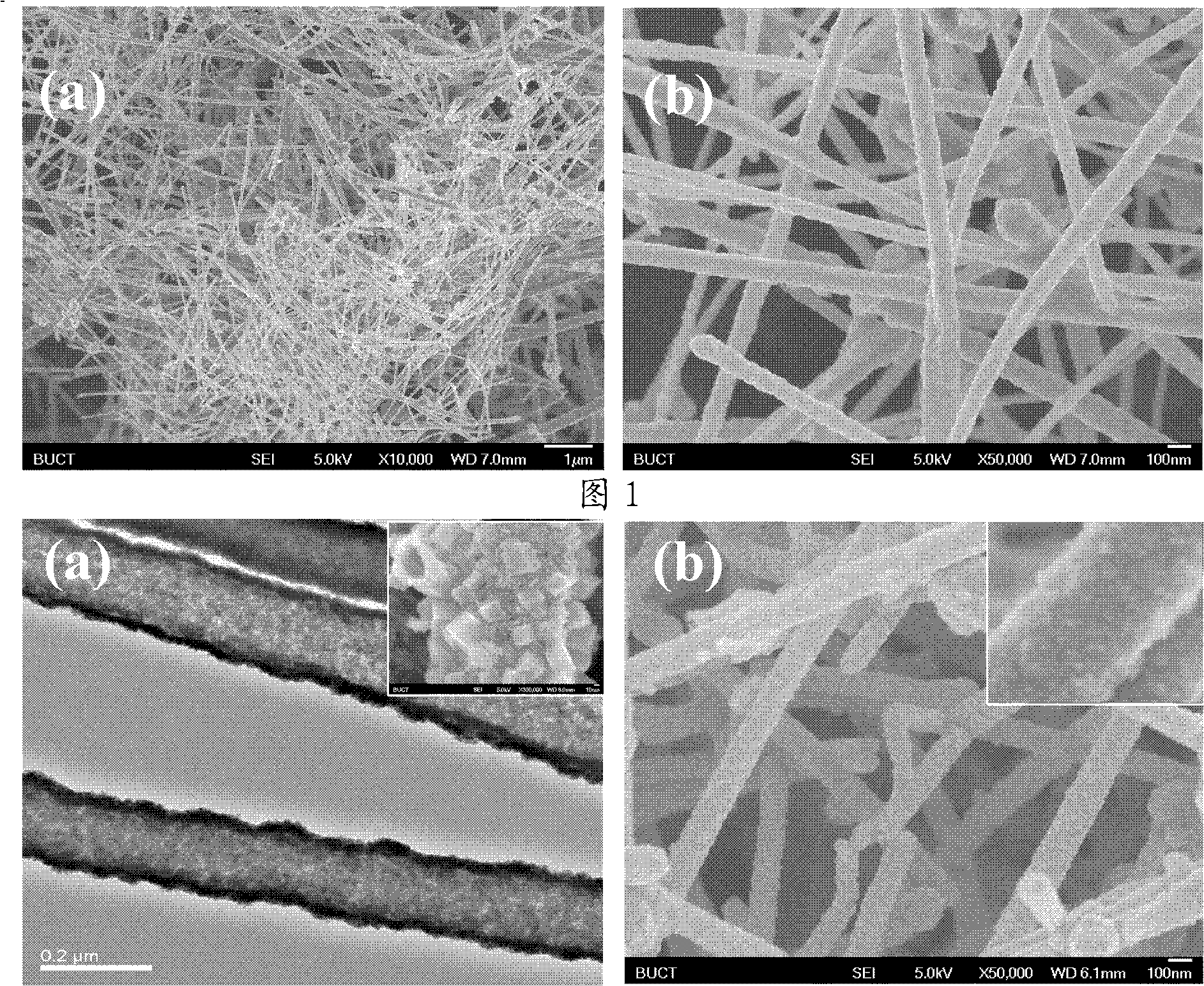

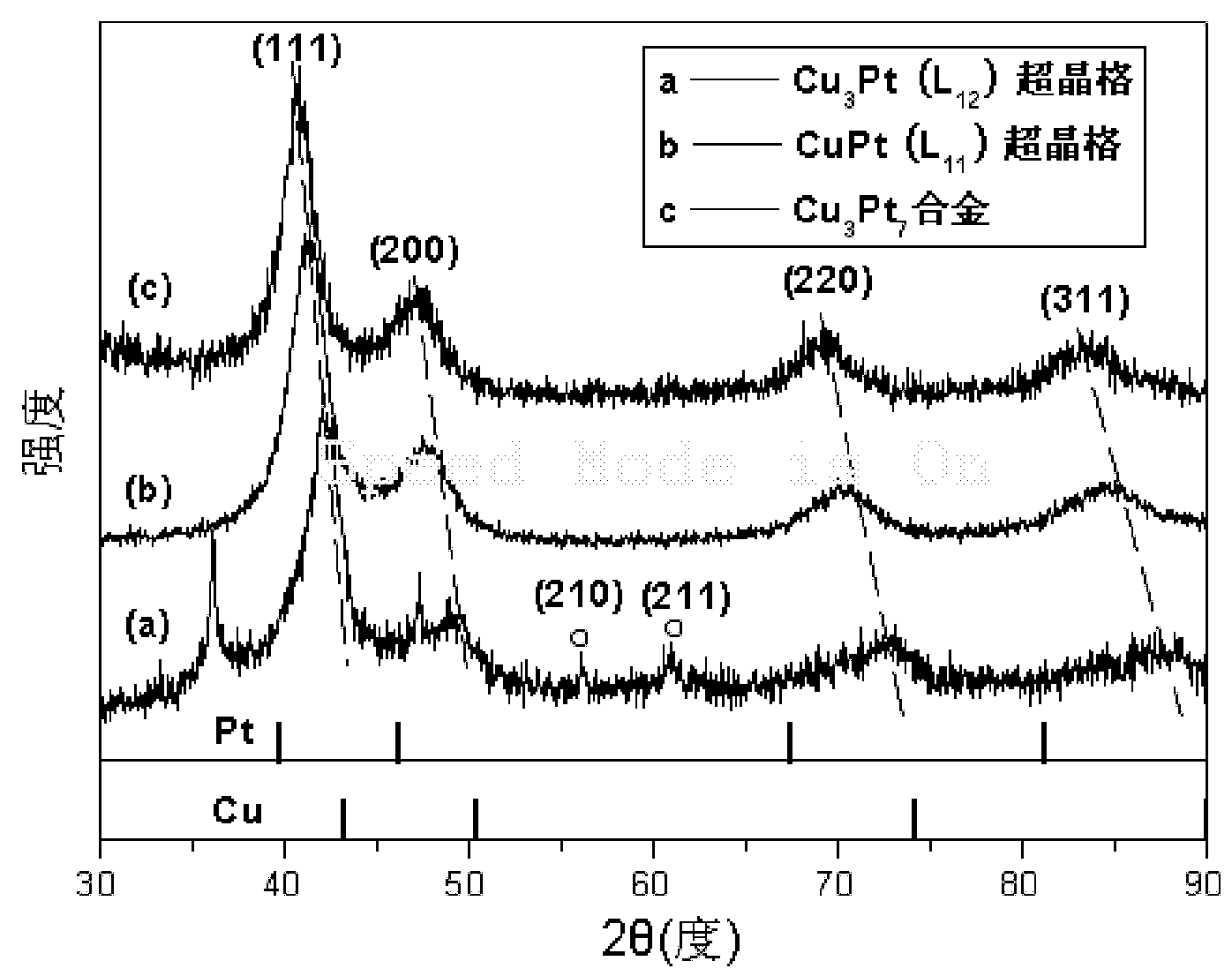

A kind of copper-platinum superlattice alloy nanotube and preparation method thereof

ActiveCN102277622AImprove conversion rateImprove responseMaterial nanotechnologyPolycrystalline material growthEthylenediamineCopper nitrate

The invention provides a copper-platinum superlattice alloy nano-tube and a preparation method thereof, and belongs to the technical field of alloy nano-tube preparation. The preparation method comprises the following steps: firstly, a sodium hydroxide solution is used as a pH regulating agent, anhydrous ethylenediamine is used as a morphological controlling agent, and a hydrazine hydrate solution is used as a reducing agent to reduce a copper nitrate solution to prepare a copper nano-wire; the copper nano-wire is treated with hydrochloric acid and water respectively and dried, and is dispersed in deionized water, in which nitrogen is introduced to remove oxygen; and a chloroplatinic acid solution is added to ensure the molar ratio of chloroplatinic acid to copper is 1:5 or 1:3, reaction is carried out for 20 to 60 minutes, and then filtering, cleaning and drying are carried out. The prepared copper-platinum superlattice alloy nano-tube has a hollow nano-tube structure with the lengthof between 3 and 5 mu m and an outer diameter of between 80 and 150 nm, and the alloy tube wall consists of alloy cubic particles with the particle diameter less than 20 nanometers. The preparation method has the advantages of simple condition, quick reaction and high product conversion rate.

Owner:BEIJING UNIV OF CHEM TECH

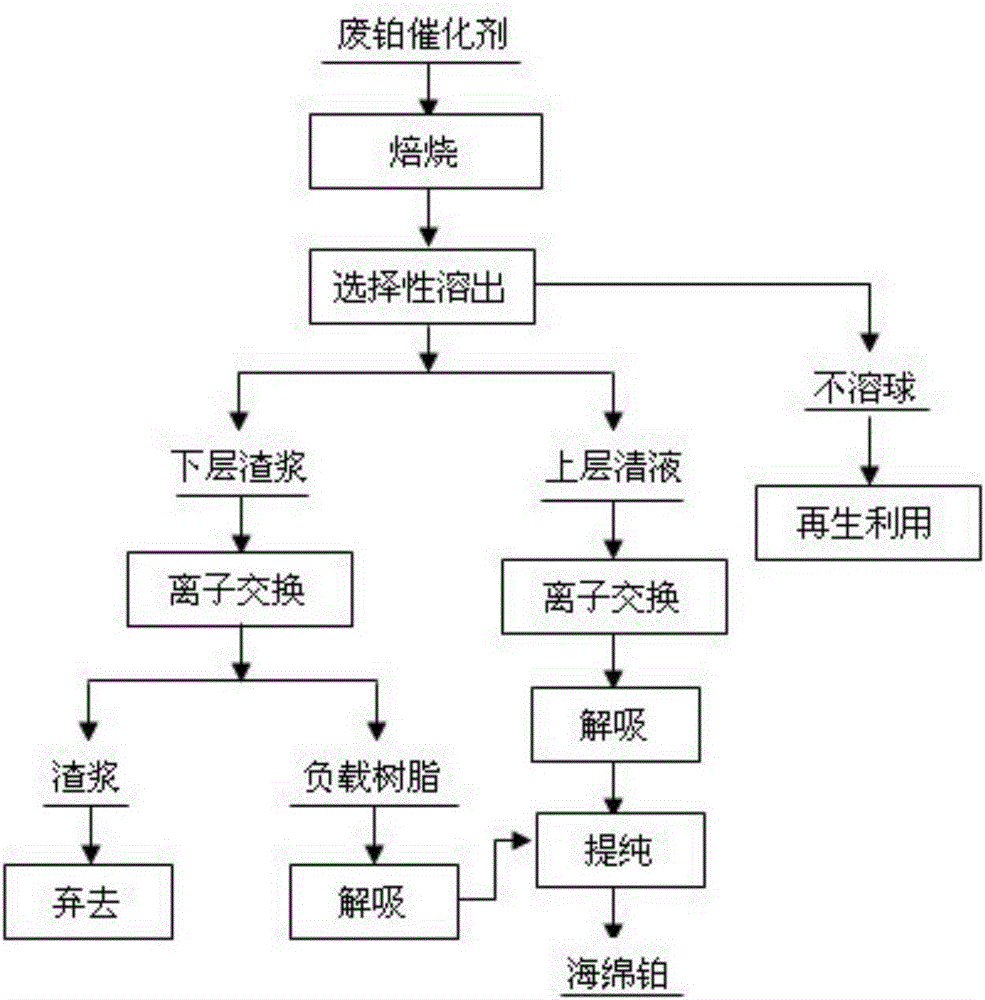

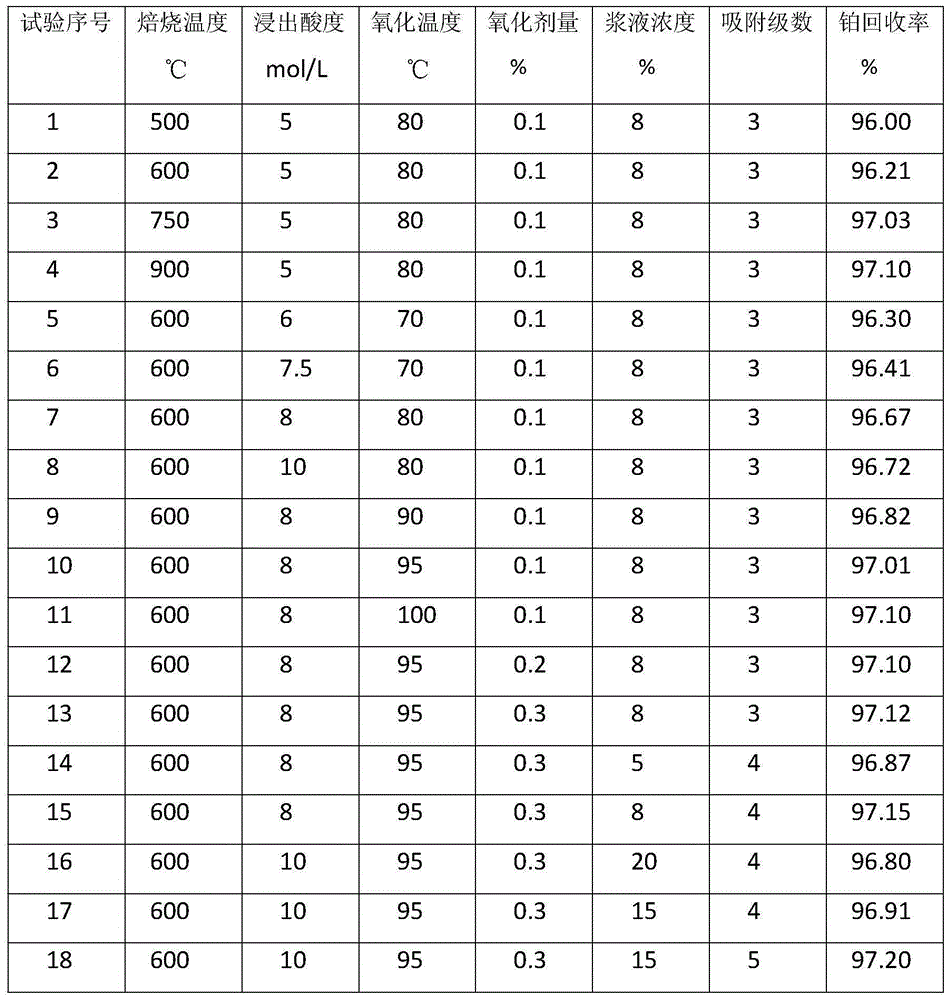

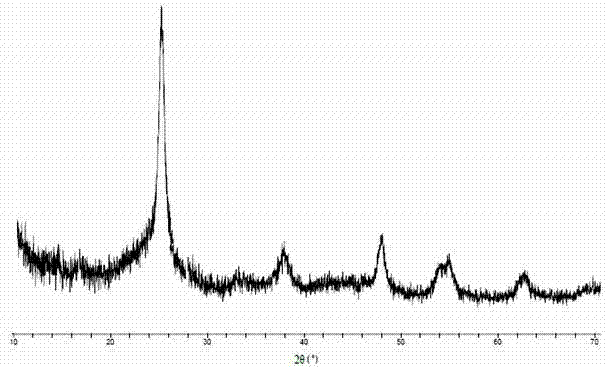

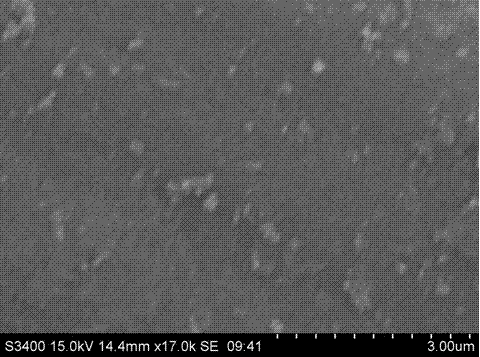

Method for recycling platinum from indissolvable silicon-aluminum-based platinum-containing waste catalyst

InactiveCN106480313AHigh recovery rateBreak through the technical bottleneck of the recycling processProcess efficiency improvementHigh concentrationSlag

The invention discloses a method for recycling platinum from an indissolvable silicon-aluminum-based platinum-containing waste catalyst. The precious metal selective oxidation leaching-resin slurry process adsorption technology is adopted for recycling platinum from the high-silicon and high-aluminum platinum-containing waste catalyst. The specific technology sequentially comprises the steps that the medium-temperature roasting is conducted in the platinum-containing waste catalyst for removing coil, deposited carbon and other organic matter; a high-concentration hydrochloric acid medium with the acidity not lower than 5 mol / L is adopted for selective oxidizing leaching of platinum, the platinum leaching rate can reach 99% or above, and the residual platinum in non-dissolved slag is smaller than or equal to 15 g / t; the resin slurry method is adopted for direct adsorption or the slurry method and fixed bed joint adsorption technology is adopted for enriching platinum in a leaching agent, and the platinum content in the tail slurry or the tail liquid is smaller than 1mg / L; the high-concentration platinum solution obtained after resin spraying is subjected to refinement purification, the chloroplatinic acid solution is directly prepared or the ammonium chloride repeated deposition method, the hydrazine hydrate reduction method and other methods are adopted for roasting, a sponge platinum product is obtained, the platinum recovery rate is larger than or equal to 96%, the purity of the sponge platinum is larger than or equal to 99.95%, and the content of other impurities meets the national related standard requirement.

Owner:XUZHOU GUOMAO VALUABLE & RARE METAL COMPREHENSIVE UTILIZATION INST

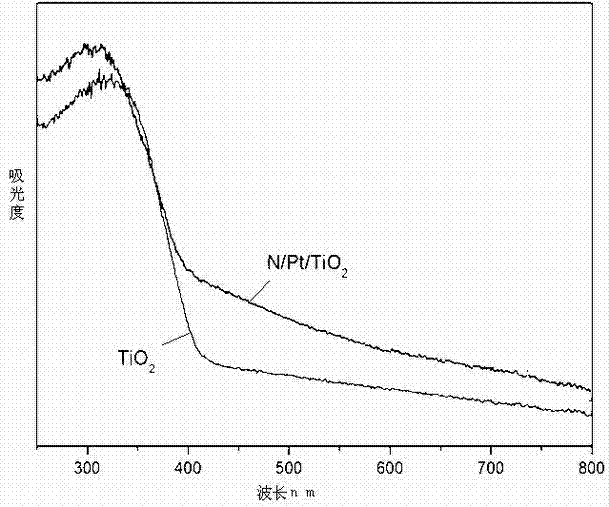

Method for preparing platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst

InactiveCN102211033APromote degradationHigh photocatalytic degradation ratePhysical/chemical process catalystsWater/sewage treatment by irradiationPolyethylene glycolHydrolysis

The invention discloses a method for preparing a platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst, which comprises the following steps of: adding tetrabutyl titanate into absolute ethanol, stirring for a period of time, slowing dripping into distilled water, adding acetylacetone and polyethylene glycol, regulating a pH value, and strongly stirring for complete hydrolysis to obtain a clear and transparent sol; adding urea with stirring, reacting, adding treated active carbon, continuously stirring, and performing ultrasonic dispersion, standing, filtration, washing, drying and roasting to obtain a nitrogen-doped active carbon supported TiO2 photocatalyst; immersing the nitrogen-doped active carbon supported TiO2 photocatalyst in a chloroplatinic acid solution, adding sodium borohydride for reduction, and drying to obtain a platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst. The invention solves the problem that a titanium dioxide catalyst in a suspension system is difficult to recover, the photocatalytic efficiency of the platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst on a liquid phase dye is further improved, and the platinum and nitrogen codoped active carbon supported titanium dioxide photocatalyst has stronger response under the condition of visible light.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

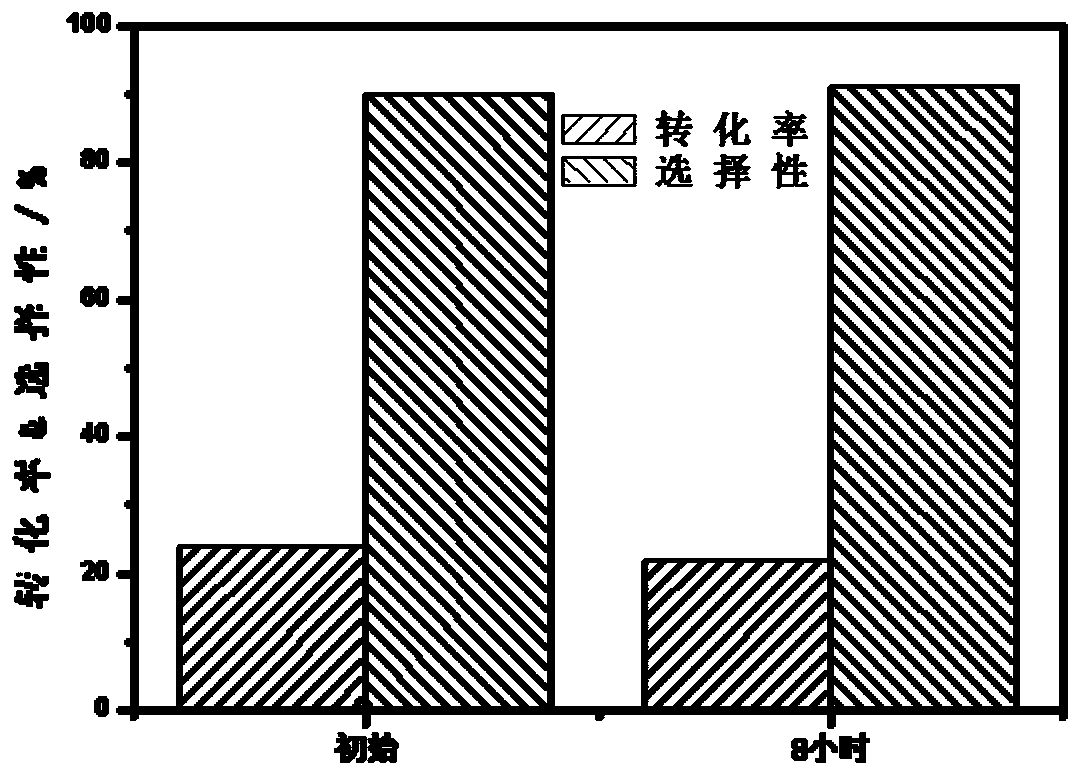

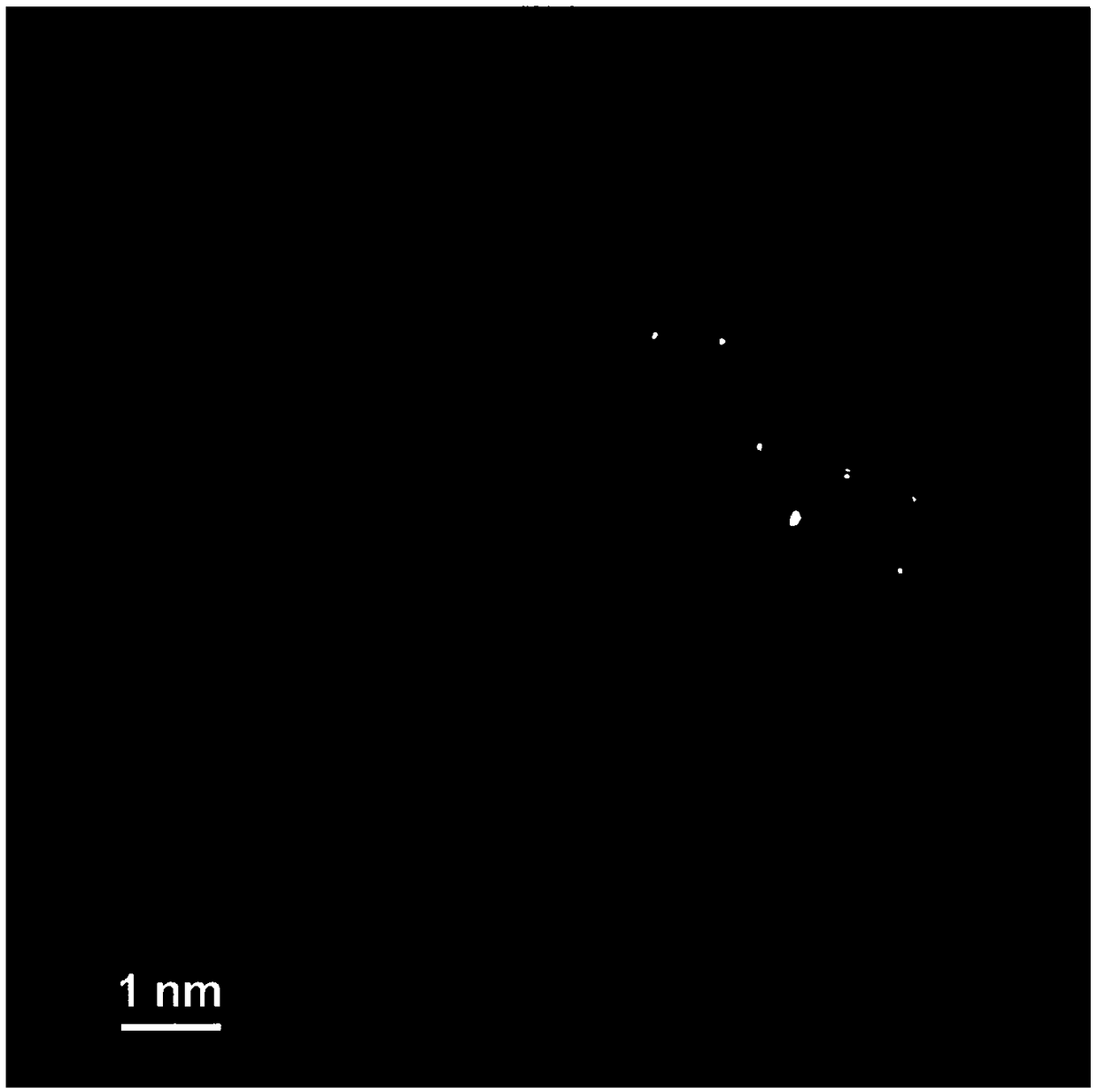

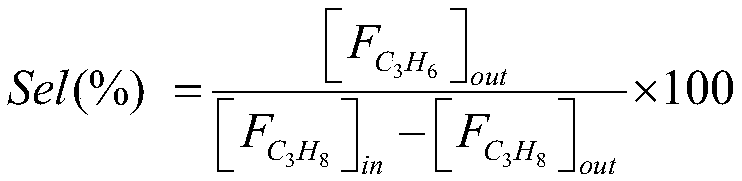

Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

ActiveCN108620092AHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention discloses an aluminum oxide loaded PtCu monatomic alloy catalyst and a preparation method and application thereof. The catalyst takes Al2O3 as a carrier, takes Cu as an auxiliary, and loads a small amount of active components Pt; the mass percent of Pt is 0.025%-0.15%, and the mass percent of Cu is 5%-20%; and during preparation, a co-impregnation method is used, the Al2O3 carrier isimpregnated in an aqueous solution of chloroplatinic acid and copper nitrate, the PtCu / Al2O3 catalyst is obtained after drying and roasting and high-temperature reduction, and the catalyst has high activity and high stability, and is low in price and low in toxicity. The catalyst is suitable for reaction for producing olefin by dehydrogenation through low alkane, and is particularly suitable forreaction for producing propylene by dehydrogenation through propane in a hydrogenation atmosphere, the dehydrogenation activity is quite high under the condition of high temperature, the selectivity of the propylene can reach 90% or above, the stability is good, the use amount of Pt is small, the utilization rate is high, and compared with an industrial Pt series catalyst, the aluminum oxide loaded PtCu monatomic alloy catalyst is cheaper.

Owner:TIANJIN UNIV

Method for preparing alcohol permselective silicon rubber composite membrane

The invention relates to a method for preparing an alcohol permselective silicon rubber composite membrane, comprising the following steps of: firstly preparing a PVDF (polyvinylidene fluoride) porous base membrane, dissolving PVDF in an organic solvent to prepare a PVDF solution, stirring to be uniform, filtering, defoaming, wiping a membrane on a polyester non-woven fabric, carrying out a gel bath with water, obtaining a non-woven fabric supported PVDF porous base membrane by adopting an immersion sedimentation phase inversion method, and drying in the air after solution exchange is complete; then preparing a silicon rubber membrane solution, namely mixing liquid silicon rubber containing vinyl, silicon oil containing hydrogen, MQ silicon resins, a chloroplatinic acid solution, nano silicon dioxide and a solvent, stirring to be uniform, filtering and defoaming; and finally preparing the silicon rubber composite membrane, namely coating the membrane solution on the PVDF porous supported base membrane, and carrying out deep crosslinking to obtain an addition-type silicon rubber composite membrane. The composite membrane provided by the invention breaks through the optimal separating property of the traditional pure silicon rubber membrane, has an excellent pervaporation alcohol permselective effect and also has a large-scale industrial application prospect.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com