Method for preparing noble metal modified one-dimensional titanium dioxide Hg-removing catalyst

A technology of titanium dioxide and precious metals, which is applied in the field of noble metal single substance modified one-dimensional structure TiO2 photocatalyst and its preparation, which can solve the problems of not having one-dimensional structure, and achieve the effect of simple process, easy mastery and high-efficiency catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

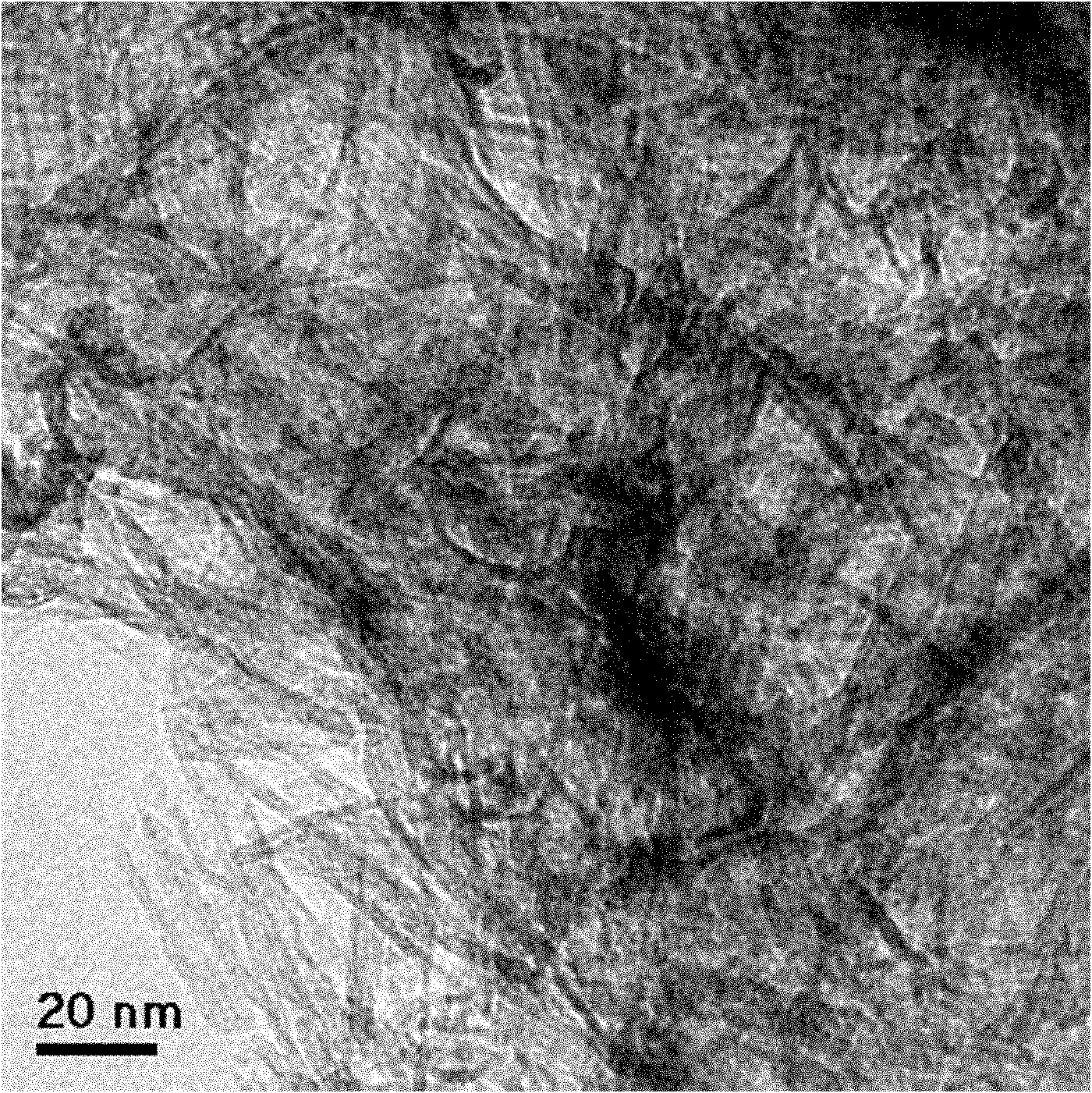

[0020] Raw material molar ratio is nano TiO 2 :NaOH:AgNO 3 : methanol = 1: 1: 0.001: 200, add nano-TiO to 0.5mol / L NaOH solution 2 , stirred for 2 hours, heated at 80°C for 48 hours, washed with 0.05mol / L hydrochloric acid until pH ≤ 2, then washed with deionized water until pH = 7, dried at 80°C, ground into a solid sample, and then dried at 400 Calcined at ℃ for 3h to prepare titanium dioxide nanotubes, see figure 1 .

[0021] The above titanium dioxide nanotubes, AgNO 3 and methanol to form a suspension, and ultrasonically disperse for 10 minutes. Under a helium atmosphere, 125w high-pressure mercury lamp was irradiated with ultraviolet rays for 11 hours, dried at 80° C., and ground to obtain Ag-doped titanium nanotubes. Load it on the mesoporous molecular sieve as a catalyst to photocatalytically oxidize 100ppb of Hg in industrial waste gas or boiler flue gas 0 , using a cold atomic fluorescence spectrometer enriched with gold mesh to detect Hg in the flue gas at the...

Embodiment 2

[0023] Raw material molar ratio is nano TiO 2 : NaOH: PdCl: Propanol = 1: 1: 0.01: 10, add nano-TiO to 10mol / L NaOH solution 2 , stirred for 2 hours, heated at 180°C for 12 hours, washed with 1mol / L hydrochloric acid until pH ≤ 2, then washed with deionized water until pH = 7, dried at 100°C, ground into a solid sample, and then dried at 500°C The titanium dioxide nanotubes were obtained by calcining for 2 hours.

[0024] The above-mentioned titanium dioxide nanotubes, PdCl and propanol were formulated into a suspension, and dispersed by ultrasonic for 15 minutes. Under a helium atmosphere, 200W high-pressure mercury lamp was irradiated with ultraviolet light for 18h, dried at 100°C, and ground to obtain Ag-doped titanium nanotubes. Load it on a glass plate as a catalyst to photocatalytically oxidize 100ppb of Hg in industrial waste gas or boiler flue gas 0 , using a cold atomic fluorescence spectrometer enriched with gold mesh to detect Hg in the flue gas at the import and...

Embodiment 3

[0026] Raw material molar ratio is nano TiO 2 :NaOH:H 2 PtCl 6: propylene glycol = 1: 9: 0.05: 50, add nanometer TiO in the NaOH solution of 12mol / L 2 , stirred for 5 hours, heated at 160°C for 12 hours, washed with 8mol / L hydrochloric acid until pH ≤ 2, then washed with deionized water until pH = 7, dried at 60°C, ground into a solid sample, and then heated at 300°C Calcined at lower temperature for 4h to prepare titanium dioxide nanotubes.

[0027] The above titanium dioxide nanotubes, H 2 PtCl 6 and propylene glycol to make a suspension, and ultrasonically disperse for 10 minutes. Under an argon atmosphere, 300W high-pressure mercury lamp ultraviolet light was irradiated for 12h, dried at 60°C, and ground to obtain Pt-doped titanium nanotubes. Load it on glass fiber as a catalyst to photocatalytically oxidize 100ppb of Hg in industrial waste gas or boiler flue gas 0 , using a cold atomic fluorescence spectrometer enriched with gold mesh to detect Hg in the flue gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com