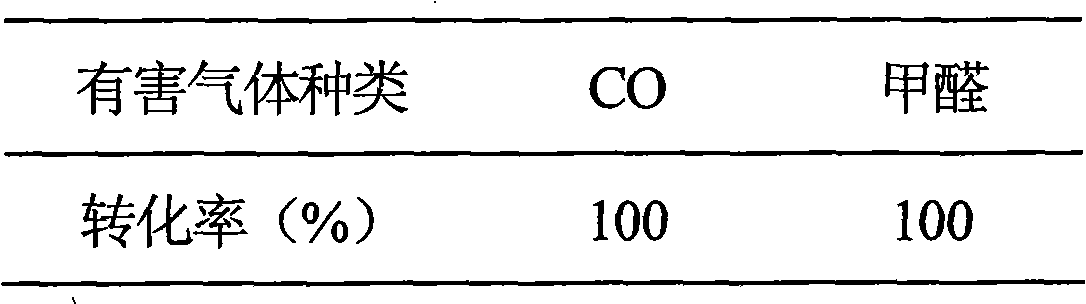

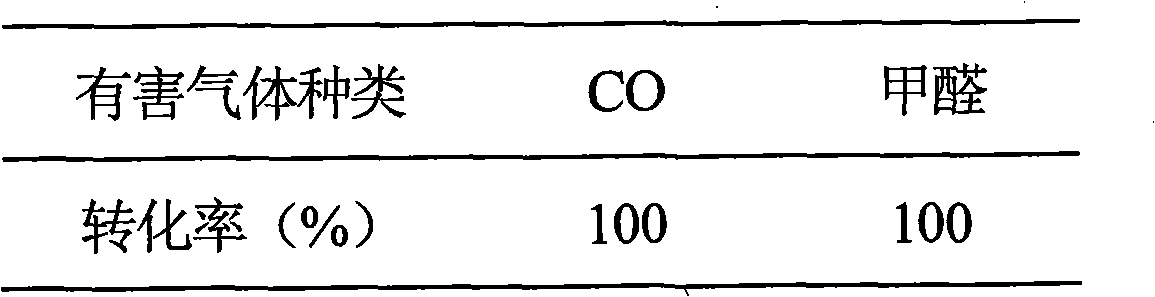

Monolithic catalyst used for oxidizing CO and methanal under ordinary temperature and preparation method thereof

An integral catalyst, room temperature oxidation technology, applied in the field of environmental engineering, can solve the problems of high operating cost of non-precious metal catalysts, expensive precious metal catalysts, poor catalyst strength, etc., and achieves easy control of operating conditions, low cost and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Dissolve 0.06gPd in 2ml of aqua regia to prepare H 2 PdCl 4 、H 2 PdCl 6 solution, evaporated to dryness and diluted with distilled water to 1.0ml; take 0.01g Pt dissolved in 2ml of aqua regia to obtain H 2 PtCl 4 、H 2 PtCl 6 solution, evaporated to dryness and diluted with distilled water to 1.0ml.

[0042] 2. Soak the cordierite honeycomb in 2% dilute hydrochloric acid and boil for 2 hours, then wash it with distilled water until neutral, dry it, and calcinate it at 400°C for 3 hours;

[0043] 3. Add 40ml of manganese nitrate solution with a concentration of 0.05g / ml dropwise into the alumina sol and stir evenly, take 20g of cordierite honeycomb treated with dilute acid and soak in the above mixture for 2 minutes, after purging, drying, Calcined at 400° C. for 3 hours and then ready for use, the loading of the coating was 3%.

[0044] 4. The 1.0ml chloroplatinic acid solution prepared in the first step, the 1.0ml chloropalladium acid solution and the 0.2ml...

Embodiment 2

[0049] 1. Dissolve 0.12g Pd in 6ml of aqua regia to obtain H 2 PdCl 4 、H 2 PdCl 6 solution, evaporated to dryness and diluted with distilled water to 1.0ml; take 0.05gPt dissolved in 4ml of aqua regia to obtain H 2 PtCl 4 、H 2 PtCl 6 solution, evaporated to dryness and diluted with distilled water to 1.0ml.

[0050] 2. Soak cordierite honeycomb in 6% dilute nitric acid and boil for 3 hours, then wash with distilled water until neutral, dry, and calcinate at 450°C for 4 hours;

[0051] 3. Add 40ml ferric nitrate solution with a concentration of 5g / ml dropwise into the alumina coating slurry and stir evenly, then take 20g cordierite honeycomb treated with dilute acid and soak in the above mixed solution for 3 minutes, after purging and drying , Calcined at 450° C. for 3 hours and then ready for use, the loading of the coating is 8%.

[0052] 4. After mixing 1.0ml of chloroplatinic acid solution and 1.0ml of chloropalladium acid solution prepared in the first step, soak...

Embodiment 3

[0062] 1. Dissolve 0.6gPd in 5ml of aqua regia to prepare H 2 PdCl 4 、H 2 PdCl 6 solution, evaporated to dryness and diluted with distilled water to 0.9ml; take 0.3gPt dissolved in 10ml of aqua regia to obtain H 2 PtCl 4 、H 2 PtCl 6 The solution was evaporated to dryness and diluted with distilled water to 0.8ml.

[0063] 2. Soak the cordierite honeycomb in 12% dilute nitric acid and boil for 3 hours, then wash it with distilled water until neutral, dry it, and calcinate it at 550°C for 4 hours;

[0064] 3. Add 40ml of cerium nitrate solution with a concentration of 13g / ml dropwise into the alumina sol and stir evenly, take 20g of cordierite honeycomb treated with dilute acid and soak in the above mixture for 4 minutes, after purging, drying, Calcined at 550° C. for 3 hours and then ready for use, the loading of the coating was 20%.

[0065] 4. After mixing 0.8ml of chloroplatinic acid solution and 0.9ml of chloropalladium acid solution prepared in the first step, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com