Method for recycling platinum from indissolvable silicon-aluminum-based platinum-containing waste catalyst

A waste catalyst, silicon-alumina-based technology, applied in the direction of process efficiency improvement, etc., can solve the problems of low enrichment of precious metals, seldom used, low recovery rate, etc., achieve good prospects for market implementation, break through technical bottlenecks, and simple process reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

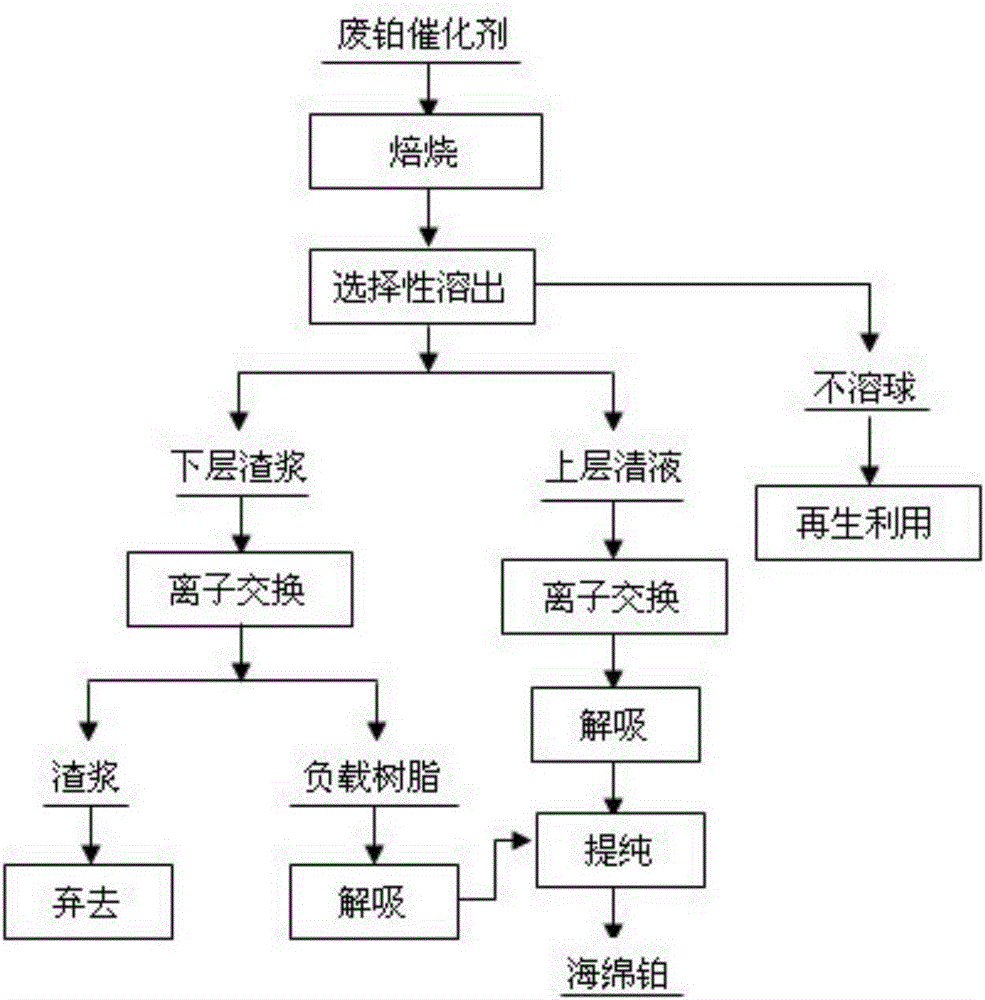

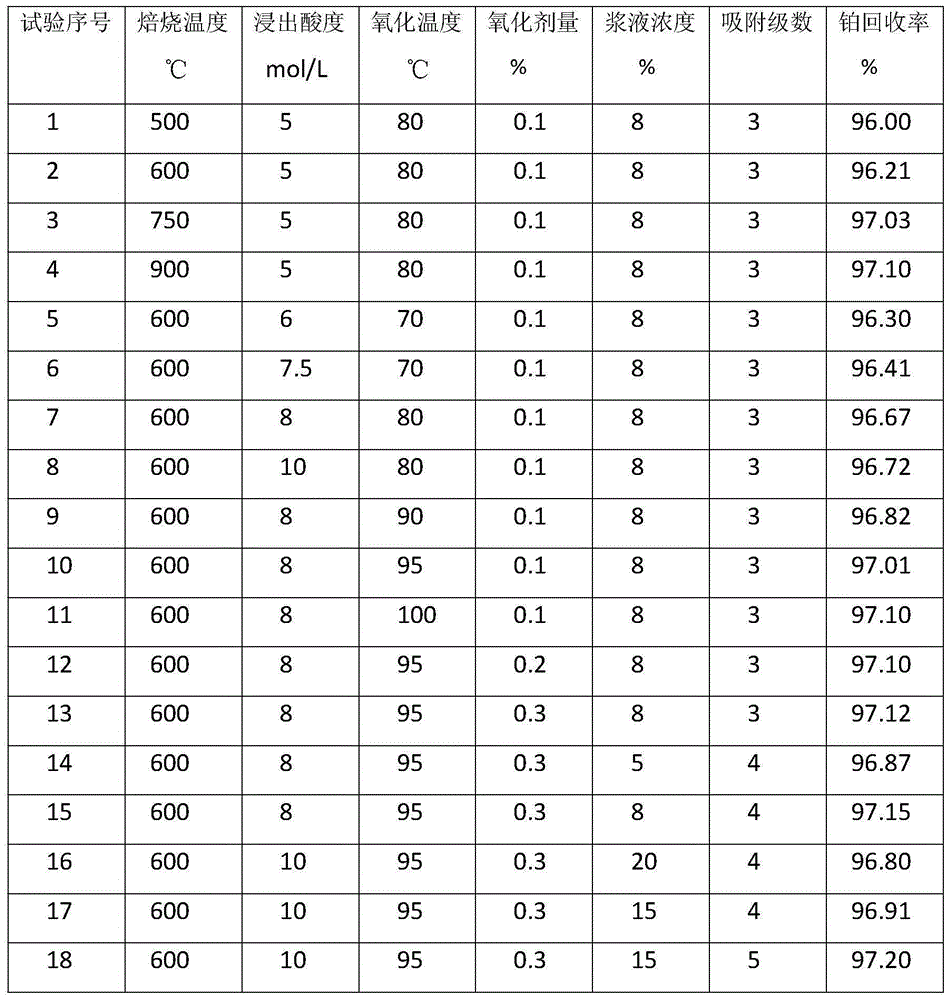

[0035] The NDC-10 waste platinum catalyst produced by a plant of Sinopec Jinling Petrochemical Company has a platinum content of 0.131%, a Si content of 14%, and an Al content of 27.4%. The catalyst has high silicon-aluminum content, low platinum content, and the matrix components are insoluble in acid and alkali. The experimental research is carried out according to the principle process flow chart shown in the attached drawing. Take 1000g of the waste material and roast it in a muffle furnace, the roasting temperature is 500-900°C, the roasting time is 4-8h, and then the precious metal is selectively oxidized and leached in a 5-10mol / L hydrochloric acid medium, and the oxidation temperature is 70-100°C ℃, the reaction time is 3-4h, the oxidizing agent is sodium nitrate, and the added amount is 0.1-0.3% of the amount of the spent catalyst after roasting. After natural sedimentation of the leachate, two-stage resin combined adsorption enrichment is adopted. The resin used is p...

Embodiment 2

[0040] A certain type of spent platinum catalyst produced by the UOP company in the United States has a platinum content of 0.154%, a Si content of 17.81%, an Al content of 23.41%, a tin content of 0.12%, and a density of 0.76g / cm 3 , particle diameter 1.2-1.3mm. The catalyst has high silicon-aluminum content, low platinum content, and the matrix components are insoluble in acid and alkali. The experimental research is carried out according to the principle process flow chart shown in the attached drawing.

[0041] Roasting process: It is completed in an electric rotary kiln with a processing capacity of 1t / d, the roasting temperature is 600°C, and the time is 6h.

[0042] Leaching process: using 1M3 The electric heating glass-lined reactor is leached, the acidity of hydrochloric acid medium is 6mol / L, the oxidation leaching temperature is 85°C, and the time is 4h. The oxidant is industrial hydrogen peroxide, and the addition amount is 0.15% of the feed amount.

[0043] Direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com