Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1567 results about "Heat curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

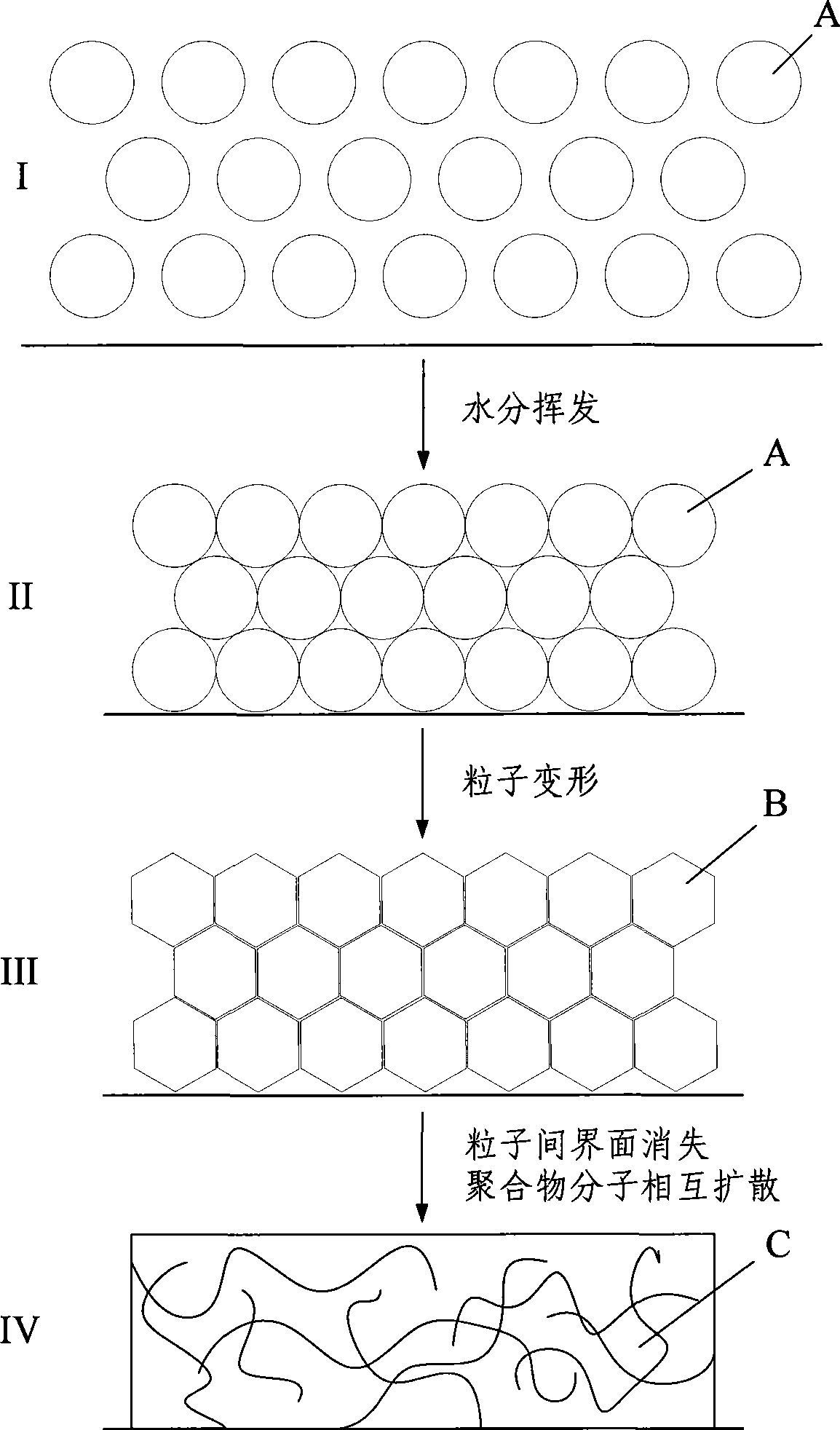

Heat curing refers to an industrial practice of using high temperature resins, chemicals, rods or other fluids to harden a polymer by facilitating the cross-linking of polymer chains. It is primarily performed on adhesives and coating materials that are exposed to harsh environmental conditions...

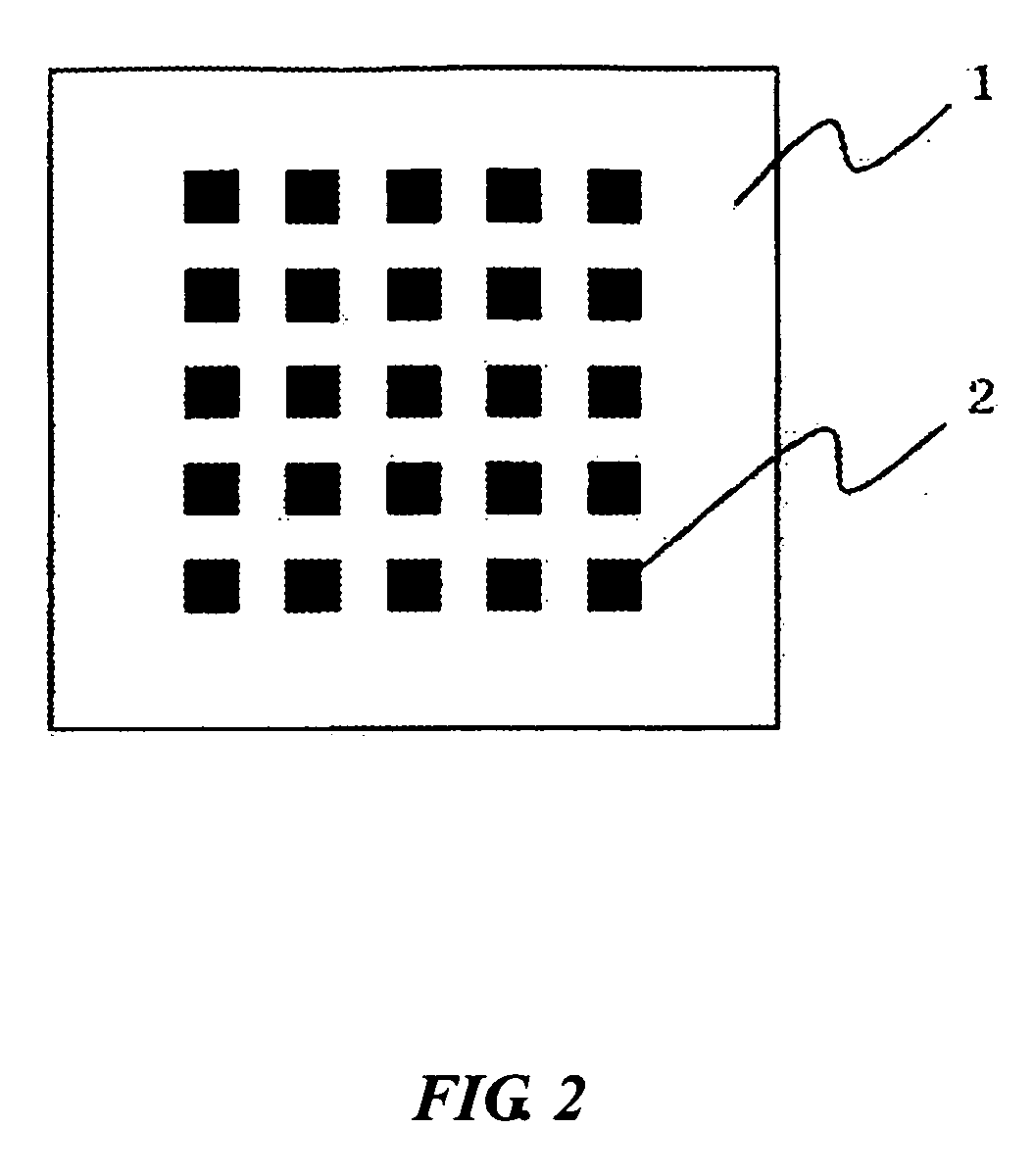

Conductive adhesive agent and process for manufacturing article using the conductive adhesive agent

ActiveUS20060038304A1Fully curedUniform thicknessSemiconductor/solid-state device detailsConductive materialPolymer scienceFluid viscosity

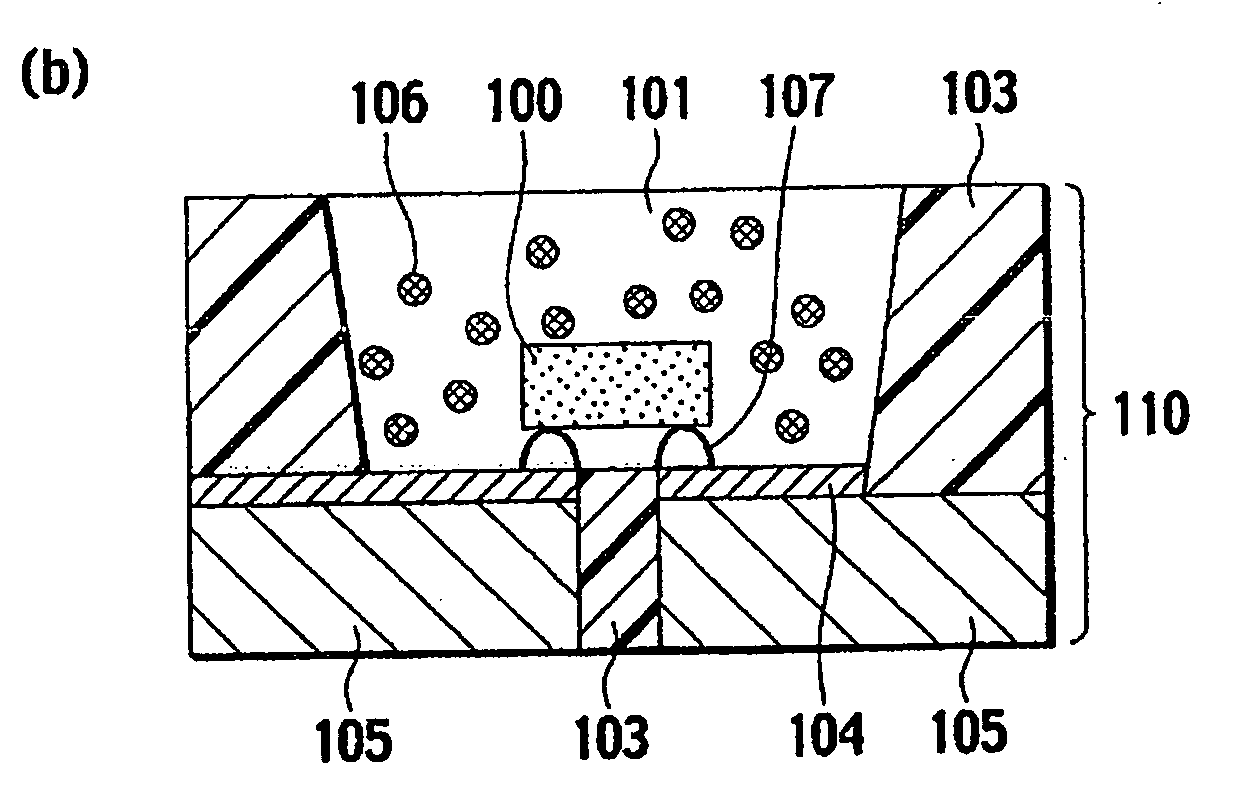

The present invention provides a conductive adhesive agent capable of being diluted with a solvent to give good coating workability and allowing formation of a conductive joint excellent in both thermal conductivity and electrical conductivity by inhibiting a gas generated when a binder resin is heat-cured after attachment of a part. The conductive adhesive agent according to the present invention is a conductive adhesive agent wherein, based on 100 parts by weight of silver powder having an average particle diameter of micrometers, which is used for a conductive medium, e.g. as a main component, 1 to 10 parts by weight of silver fine particles having an average particle diameter of nanometers is used in combination therewith and 5 to 15 parts by weight of thermosetting resin as a binder resin component and 10 parts or less by weight of solvent for adjustment of a fluid viscosity are blended therein as essential components, and by selection of such a blending ratio, generation of a gas component during heating and curing of the thermosetting resin to prevent formation of voids, and at the same time, fabrication of a conductive joint excellent in thermal conductivity and electrical conductivity is achieved.

Owner:HARIMA CHEM INC +1

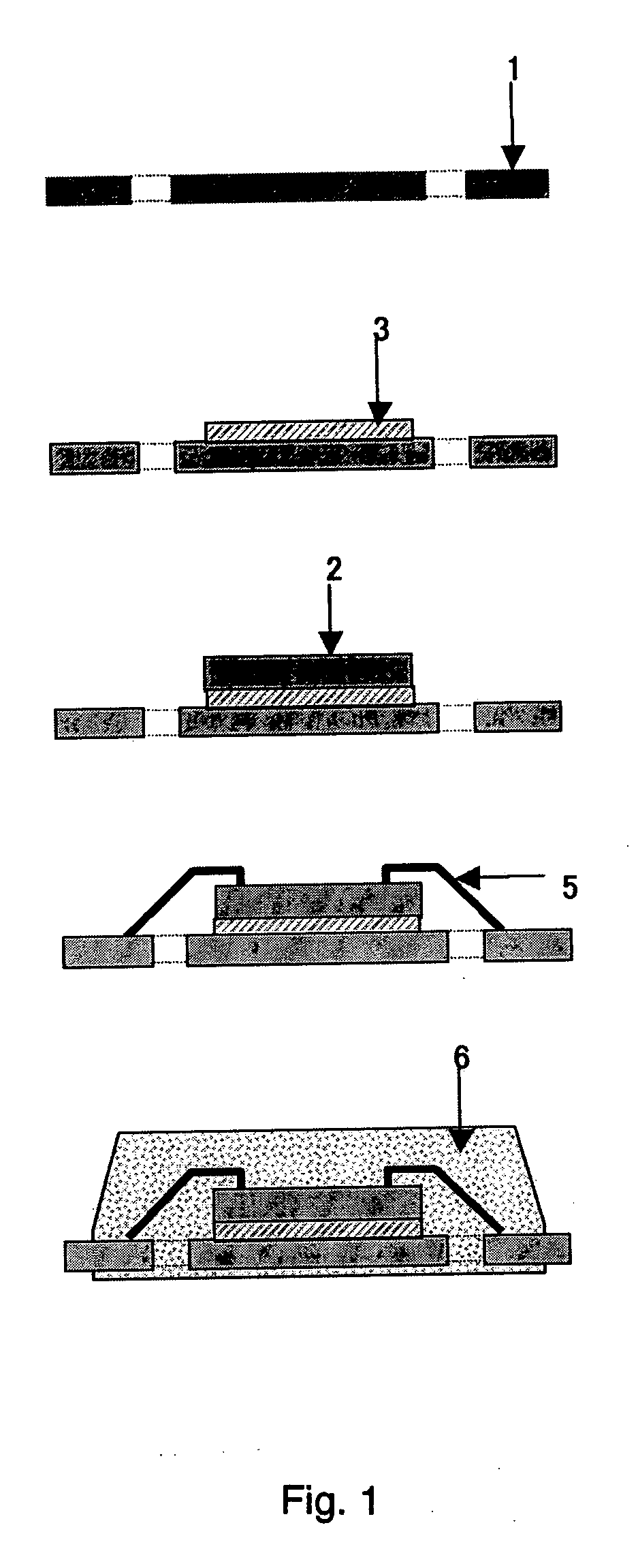

Composition for pressure sensitive adhesive film, pressure sensitive adhesive film, and dicing die bonding film including the same

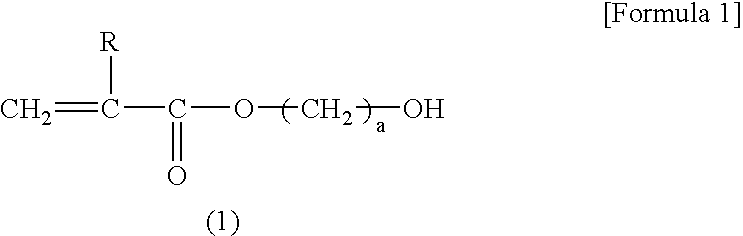

A composition, including a polymer binder resin A, a UV-curing acrylate B, a heat curing agent C, and a photopolymerization initiator D. The composition includes about 20 to about 150 parts by weight of the UV-curing acrylate B per 100 parts by weight of the polymer binder resin A, and the UV-curing acrylate B is a solid or near-solid at room temperature and has a viscosity of about 10,000 cps or more at 40° C.

Owner:CHEIL IND INC

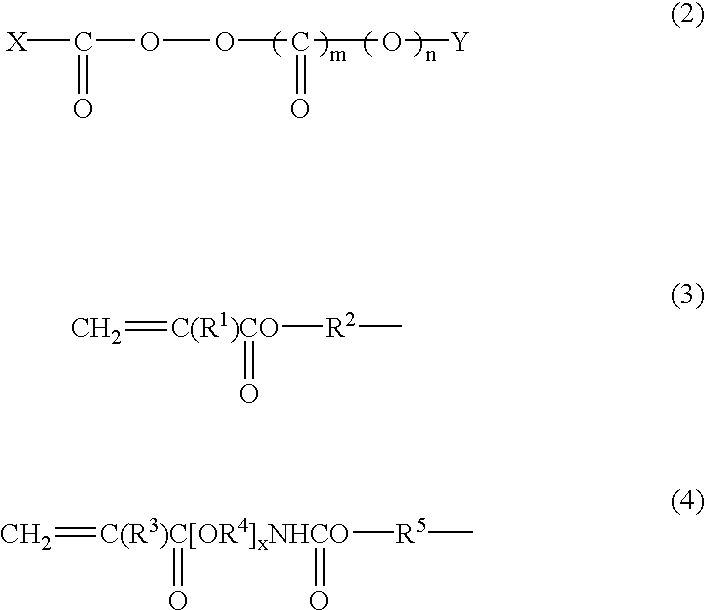

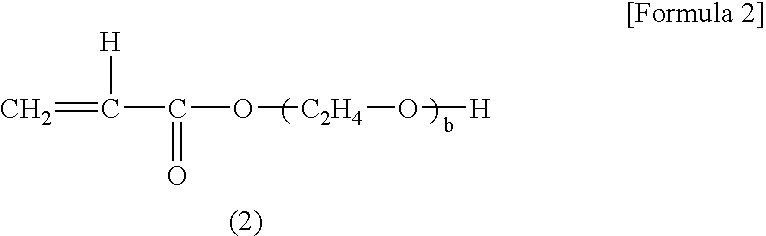

Thermopolymerizable composition for battery use

InactiveUS6562513B1Good storage stabilityHigh strengthCell electrodesFinal product manufactureMeth-Carbonate ester

The present invention provides (1) a thermopolymerizable composition containing a thermopolymerizable compound having (meth)acrylate having a moiety consisting of oxyalkylene, fluorocarbon, oxyfluorocarbon and / or carbonate group within the molecule, an electrolyte salt, an organic polymerization initiator having no benzene ring, and a polymerization retarder having vinyl group within the molecule, (2) a solid electrolyte obtained by heat-curing the composition, (3) a primary battery, a secondary battery and an electric double-layer capacitor each using the solid electrolyte, and processes for manufacturing the same.

Owner:SHOWA DENKO KK

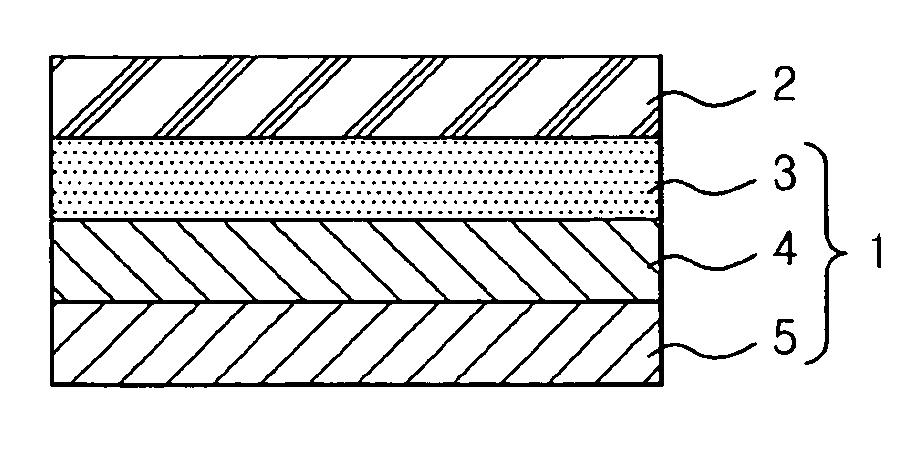

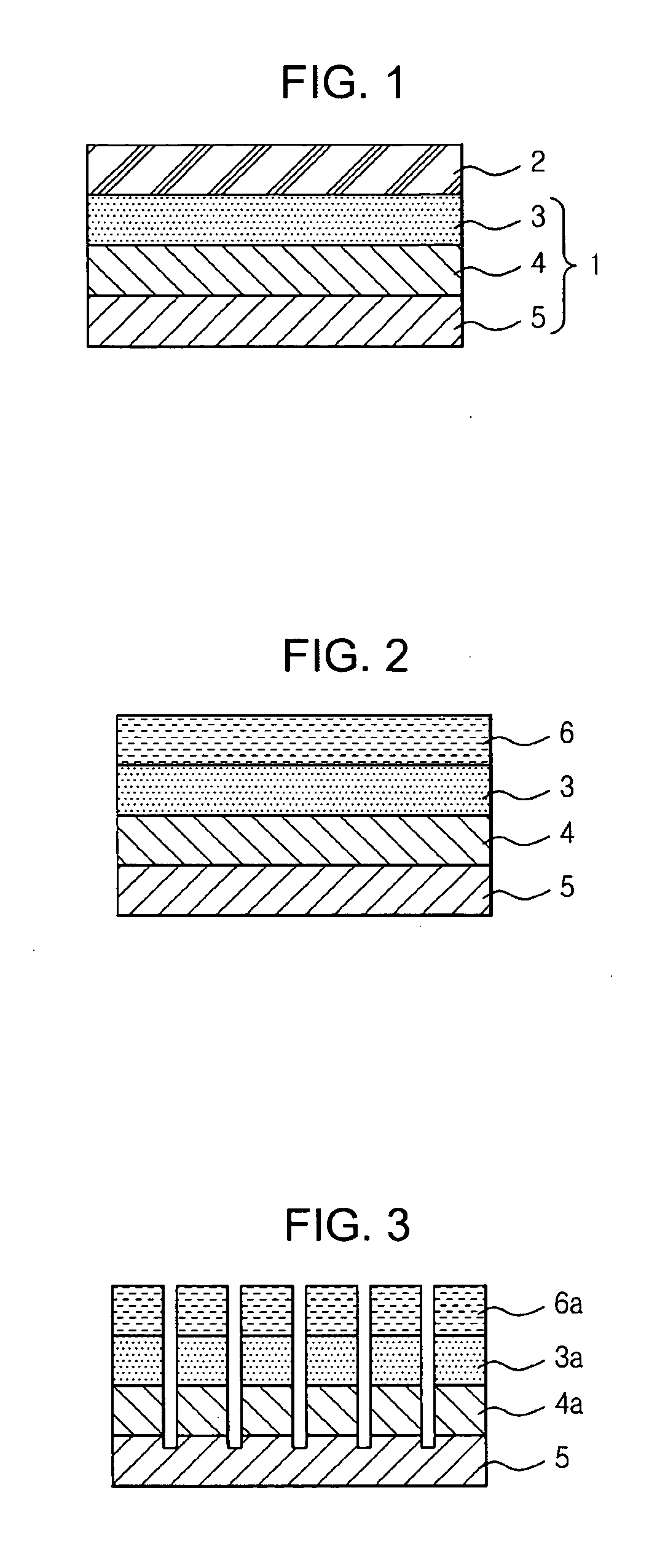

Thermosetting resin composition for light reflection, method for manufacturing the resin composition and optical semiconductor element mounting substrate and optical semiconductor device using the resin composition

ActiveUS20100140638A1Increase resistanceExcellent wire bondabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialTransfer molding

This invention provides a heat curable resin composition for light reflection, which, after curing, can realize high reflectance in a range of visible light to near ultraviolet light, has excellent heat deterioration resistance and tablet moldability, and is less likely to cause burrs during transfer molding, and a process for producing the resin composition, and an optical semiconductor element mounting substrate and an optical semiconductor device using the resin composition. The heat curable resin composition for light reflection comprises a heat curable component and a white pigment and is characterized in that the length of burrs caused upon transfer molding under conditions of molding temperature 100° C. to 200° C., molding pressure not more than 20 MPa, and molding time 60 to 120 sec is not more than 5 mm and the light reflectance after heat curing at a wavelength of 350 nm to 800 nm is not less than 80%. The resin composition can be used for constructing the optical semiconductor element mounting substrate and the optical semiconductor device.

Owner:RESONAC CORP

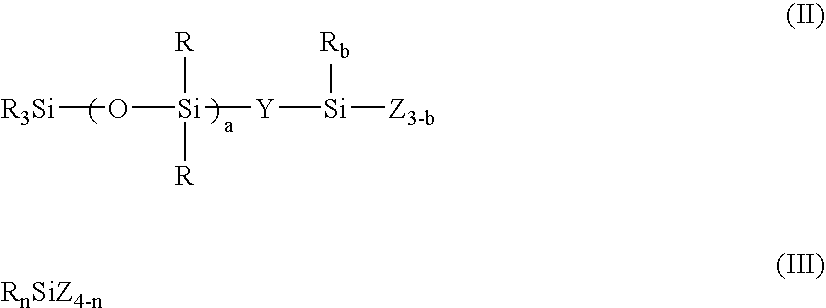

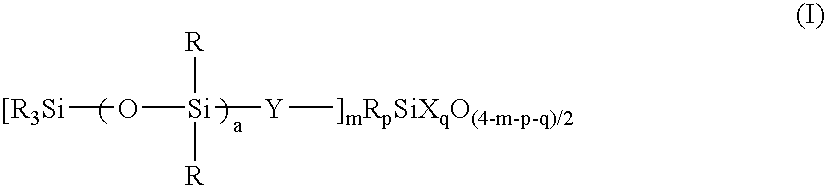

Antifouling coating compositions and coated articles

InactiveUS20050227092A1Antifouling/underwater paintsLighting and heating apparatusPolymer scienceSilylene

An antifouling coating composition is provided comprising an organosilicon compound having a one end-blocked diorganopolysiloxane group and a condensation-curable silyl group in a common molecule, and optionally a heat-curable compound. The composition is applied and cured to a substrate to form a coat which has an improved surface protective function and durable water repellent and antifouling properties.

Owner:SHIN ETSU CHEM IND CO LTD

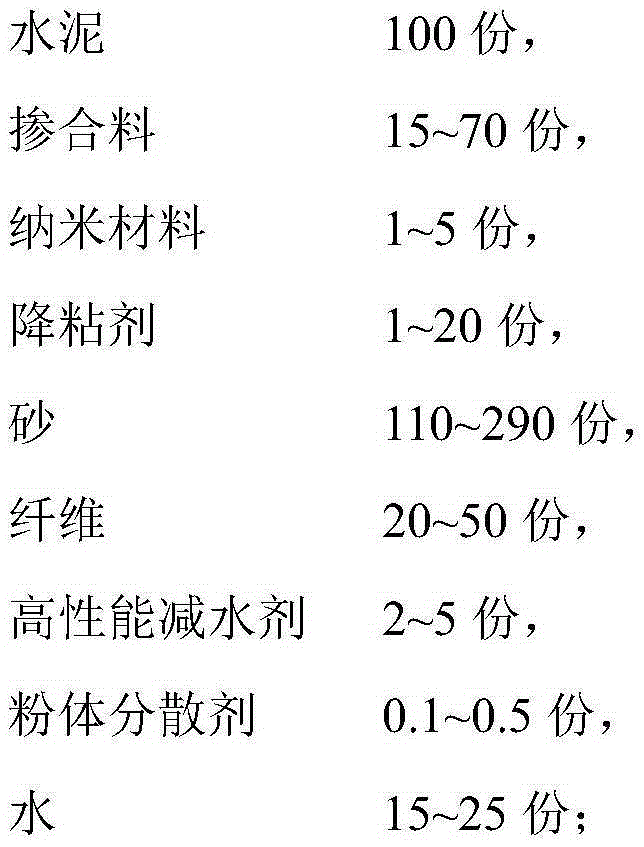

Ultra-high performance concrete with compressive strength of 300MPa or more and preparation method

The present invention discloses an ultra-high performance concrete with compressive strength of 300MPa or more and a preparation method, and the ultra-high performance concrete comprises the following components in parts by mass: 100 parts of cement, 15 to 70 parts of an admixture, 1 to 5 parts of a nanomaterial, 1 to 20 parts of a viscosity reducer, 110 to 290 parts of sand, 20-50 parts of fibers, 2 to 5 parts of a superplasticizer, 0.1 to 0.5 part of a powder dispersing agent and 15 to 25 parts of water. The ultra-high performance concrete has ultrahigh mechanical properties, the compressive strength after heat curing at 85 DEG C-90 DEG C in standard atmospheric pressure environment can be 300MPa or more, the flexural strength is greater than 55MPa, and the ultra-high performance concrete has excellent working performance and ultrahigh durability.

Owner:JIANGSU SOBUTE NEW MATERIALS

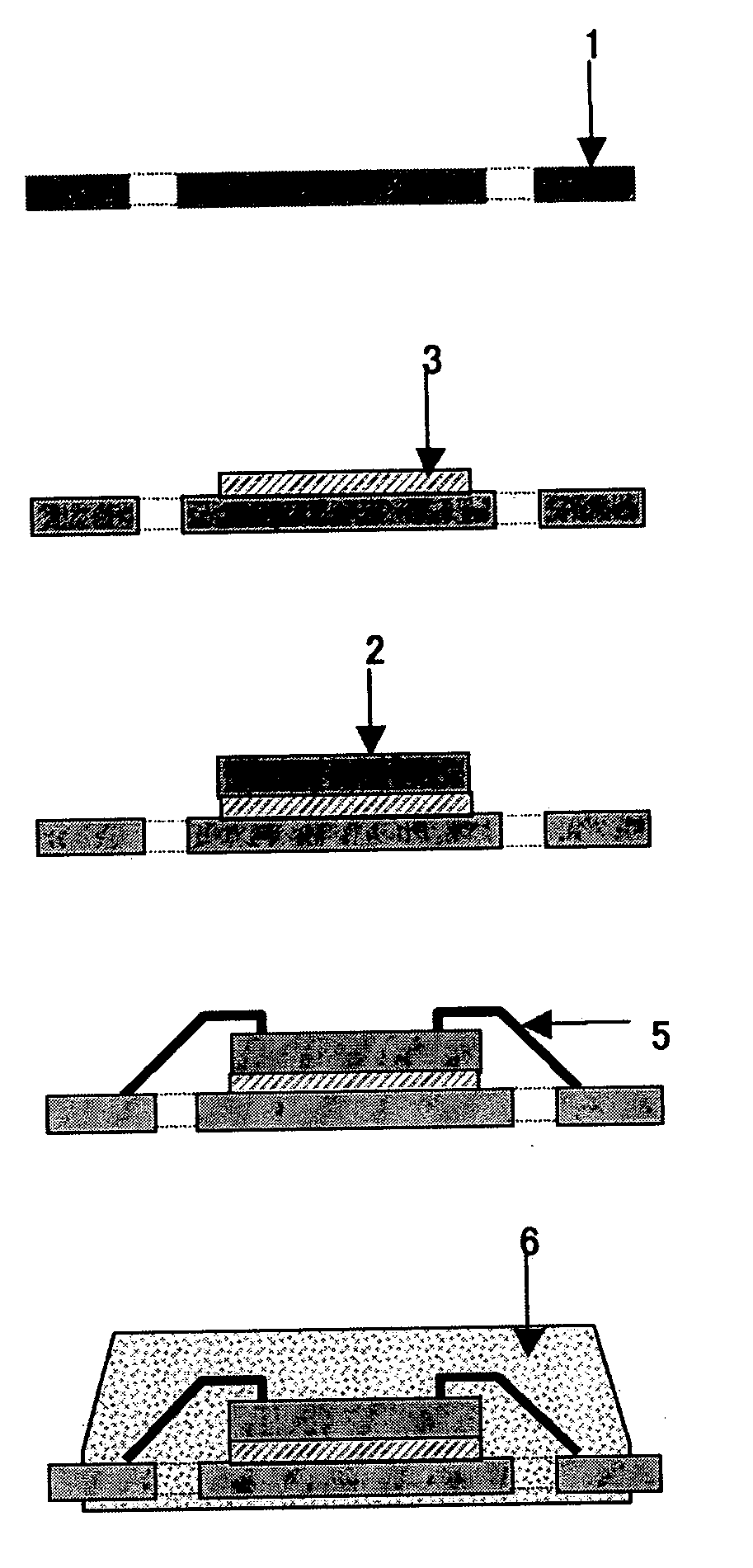

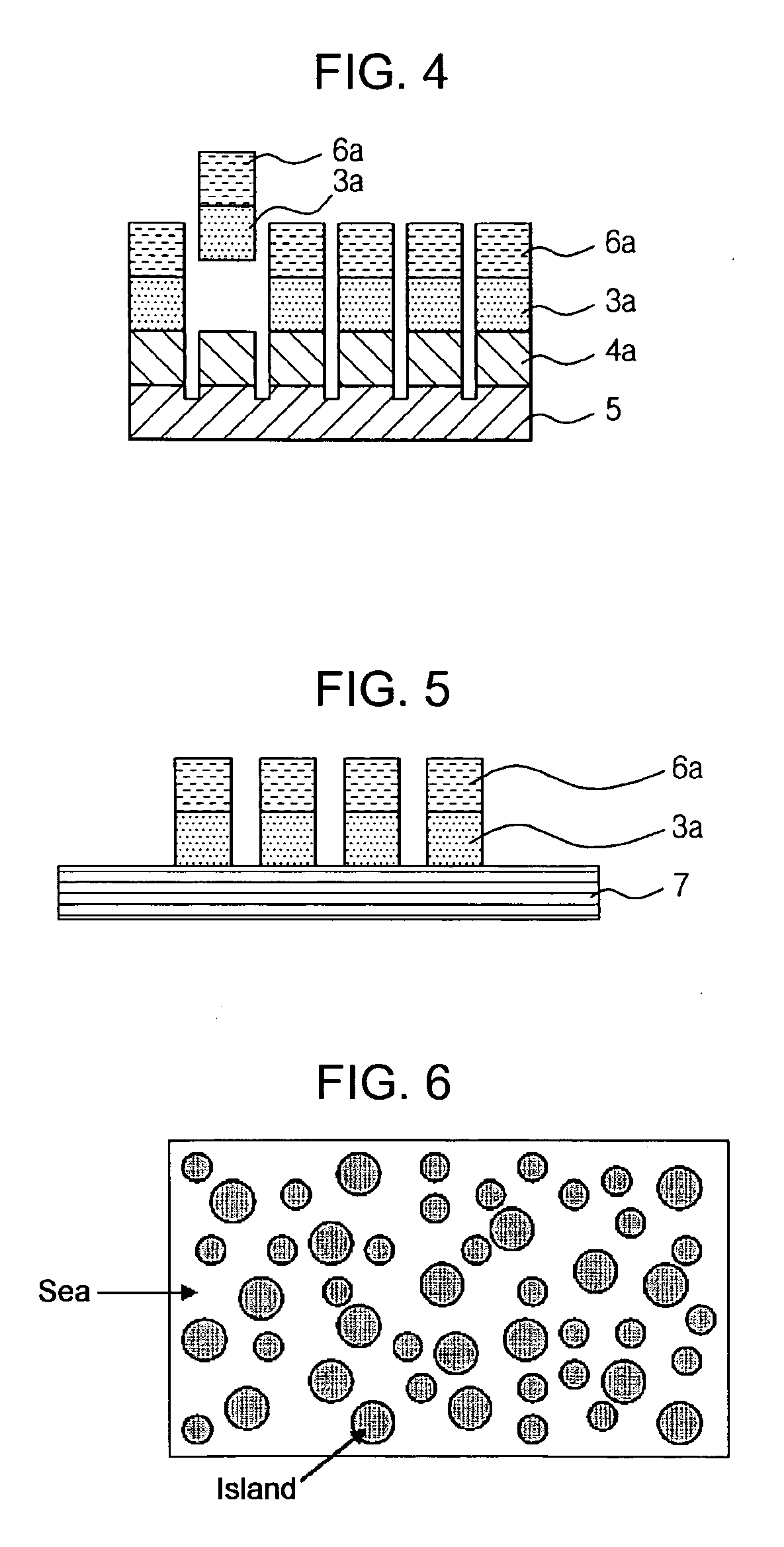

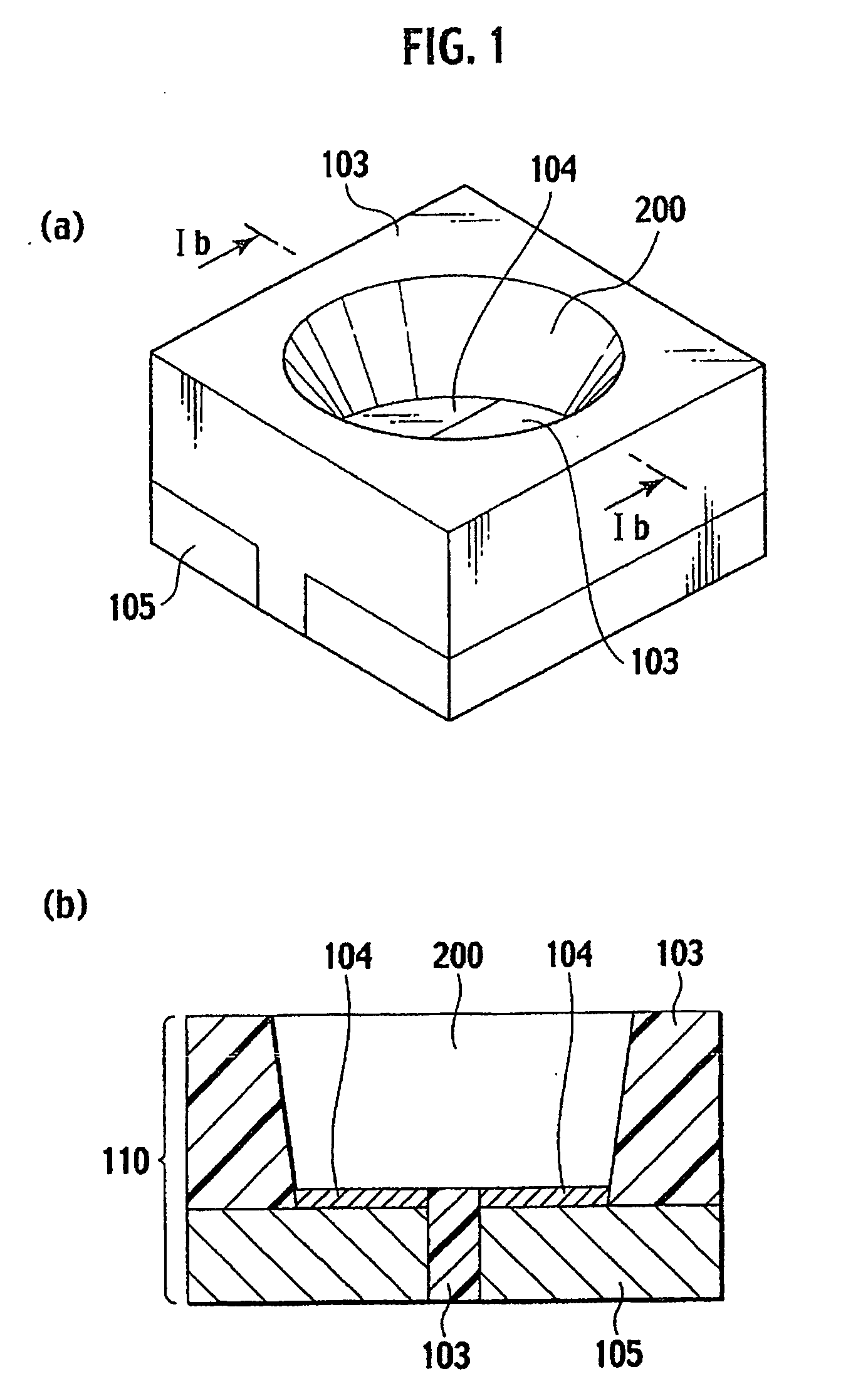

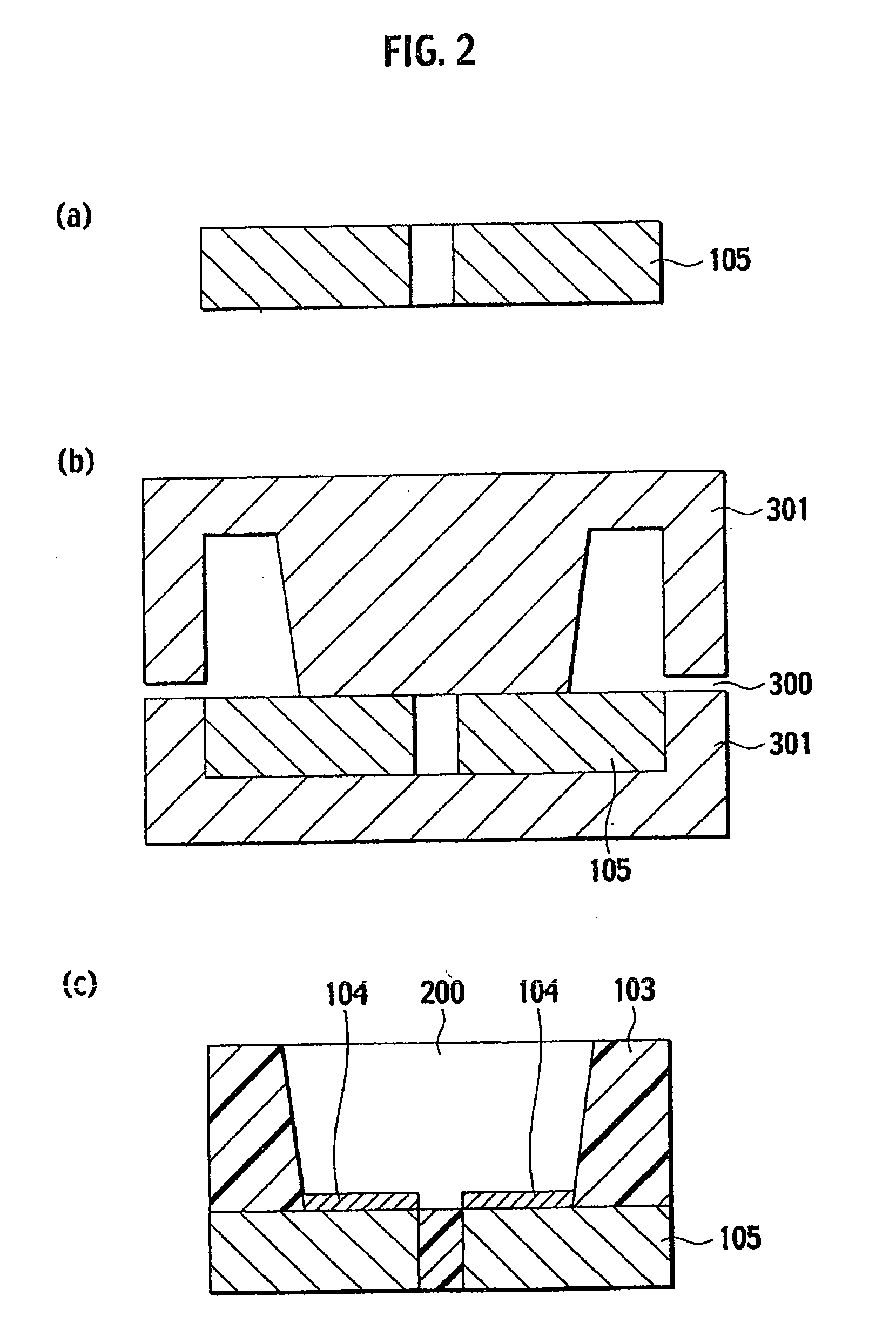

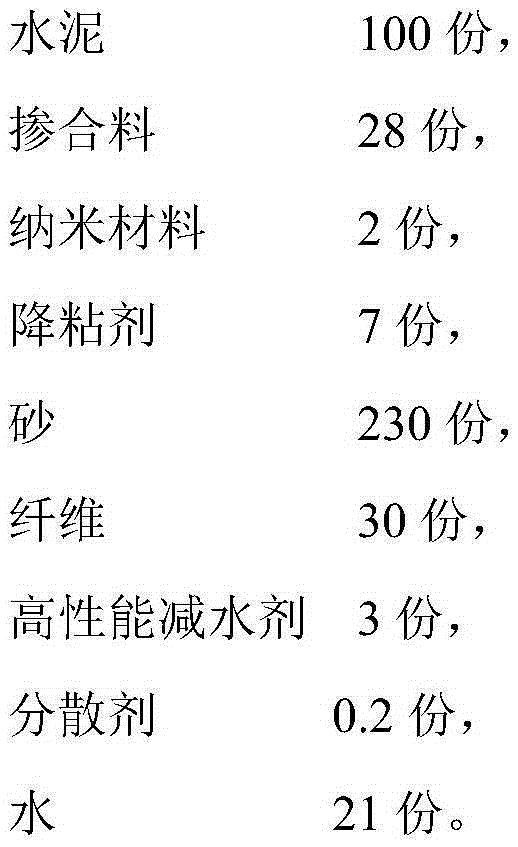

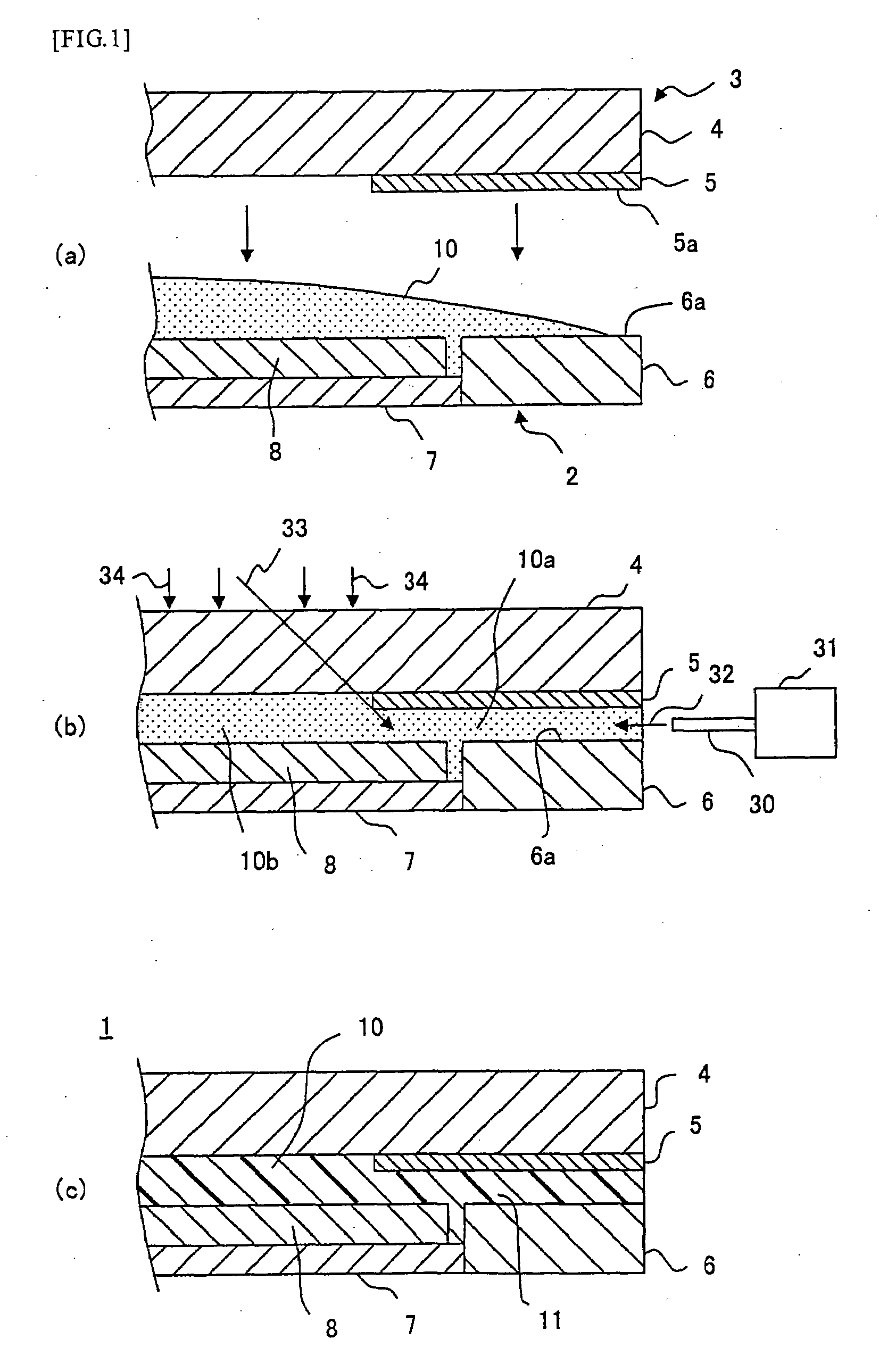

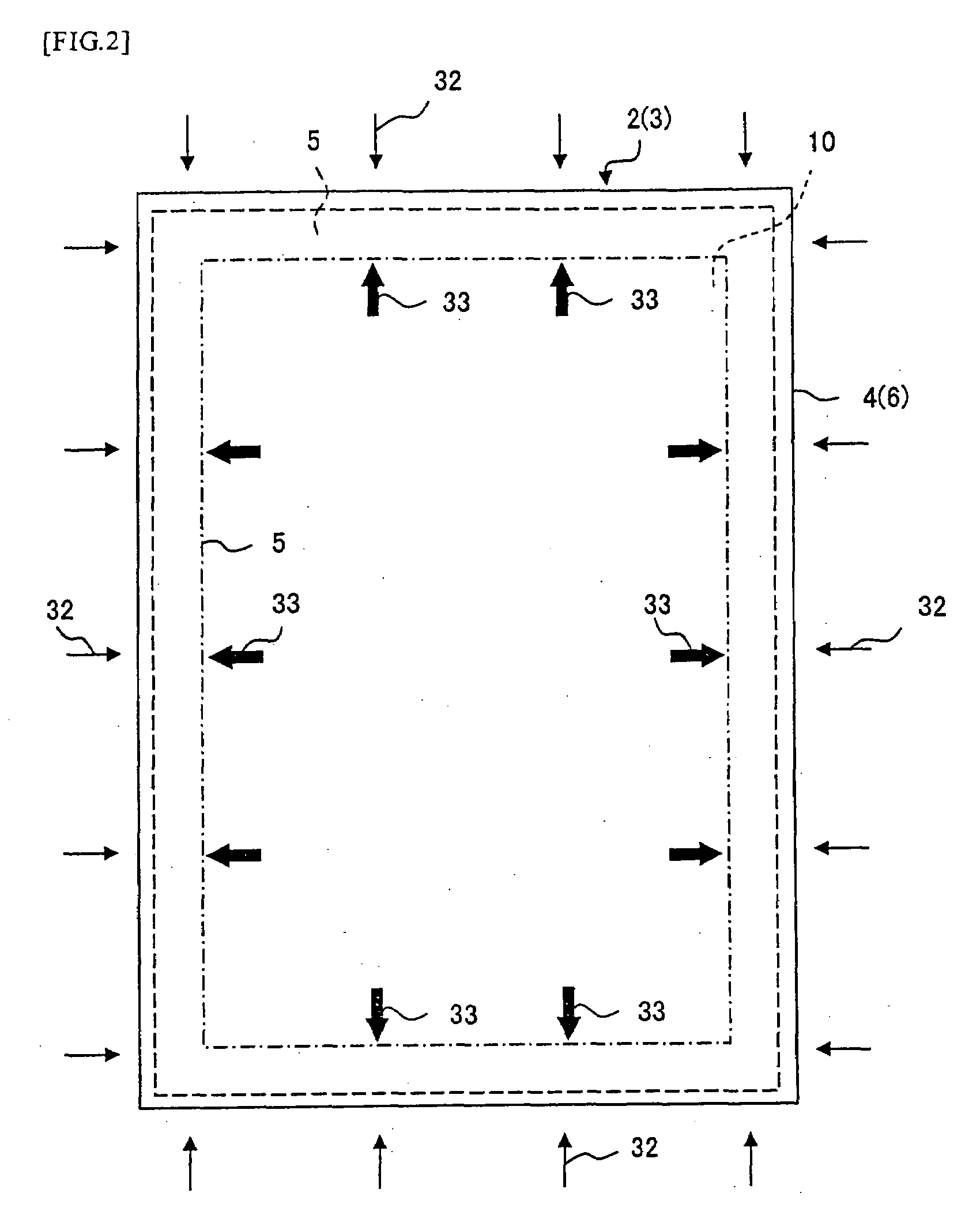

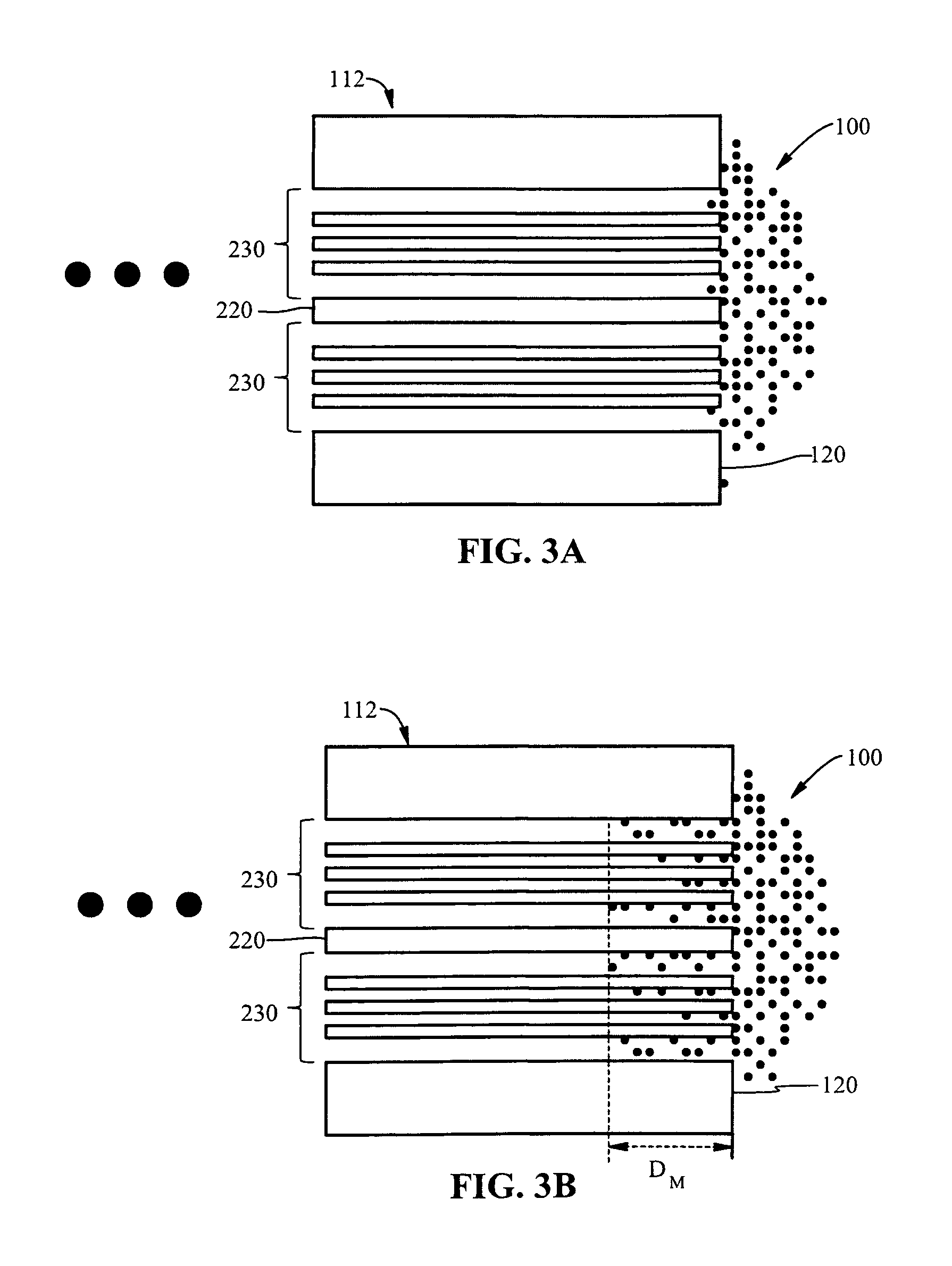

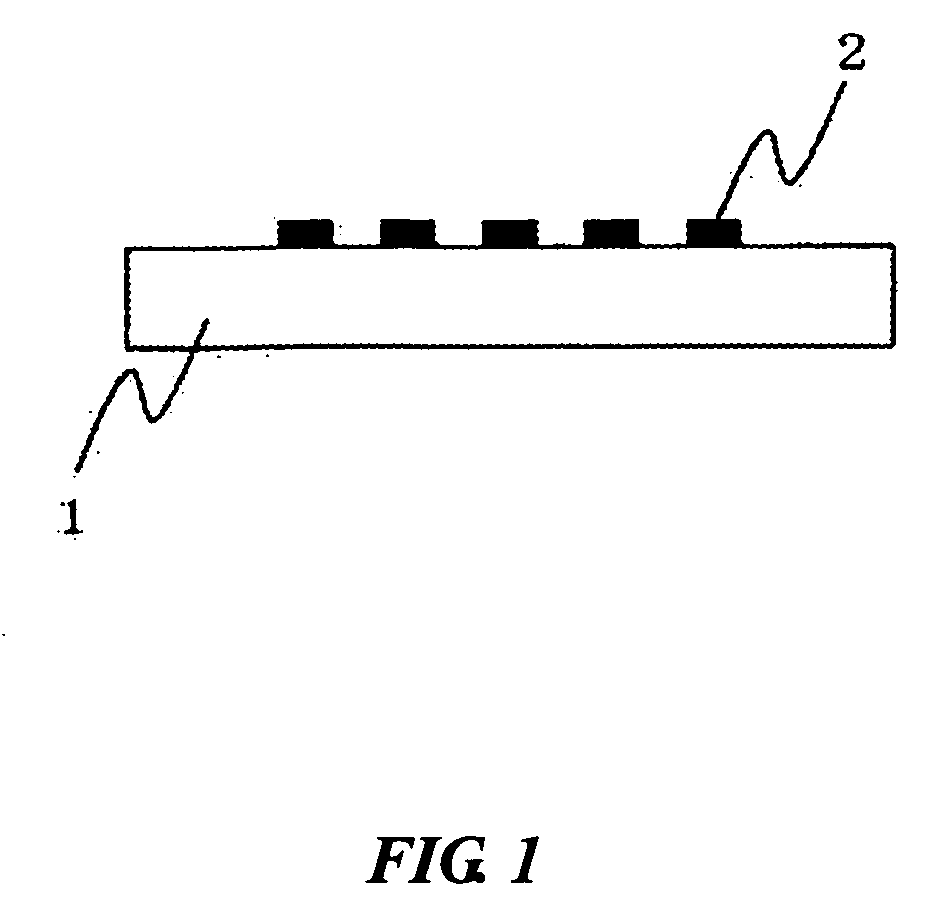

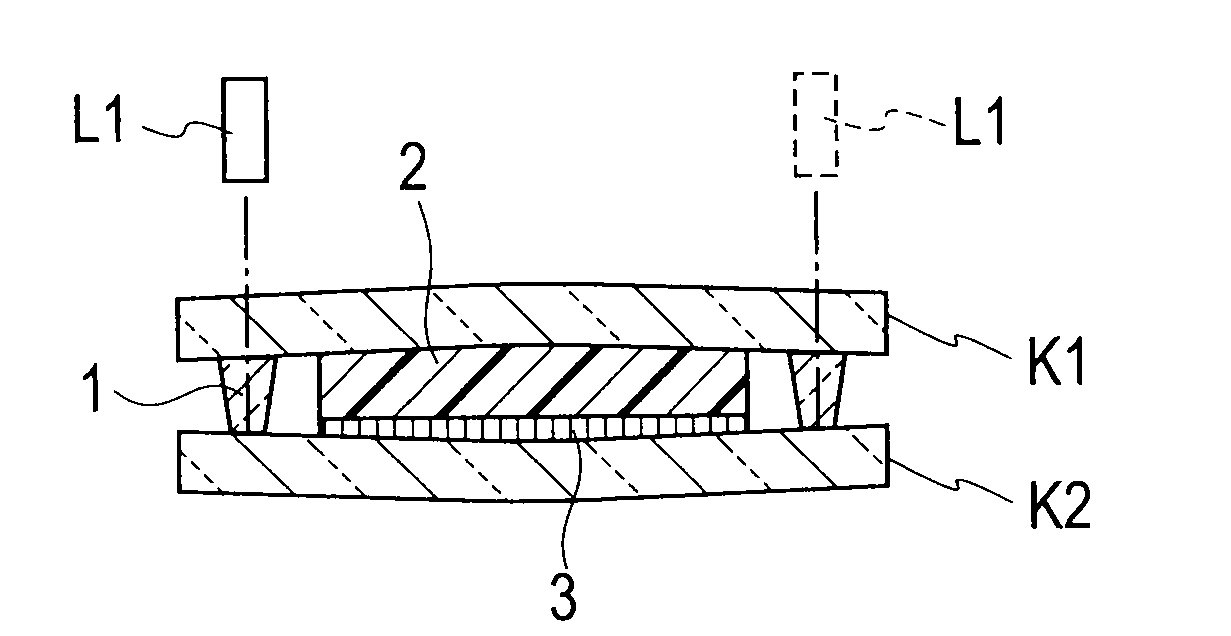

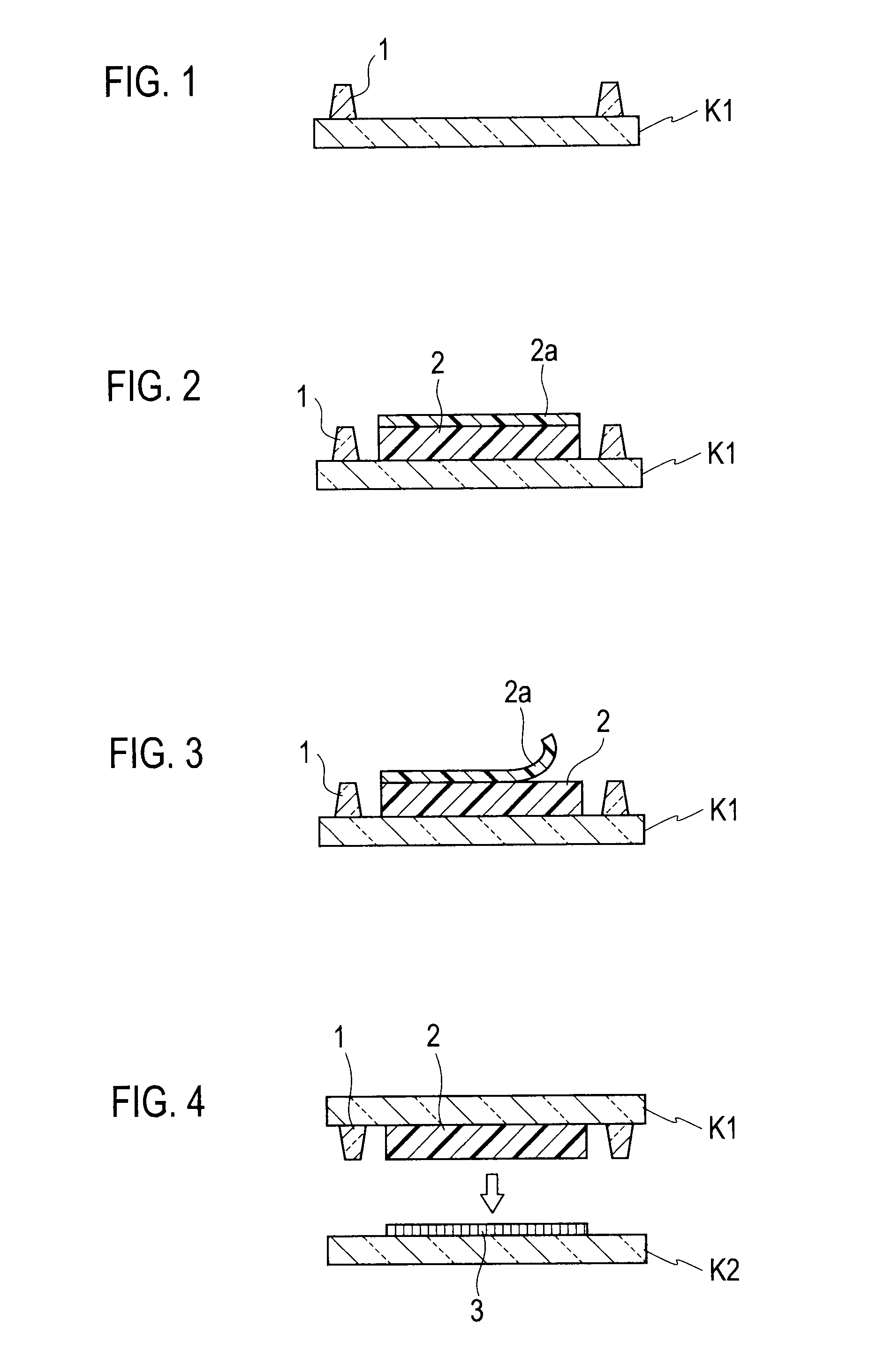

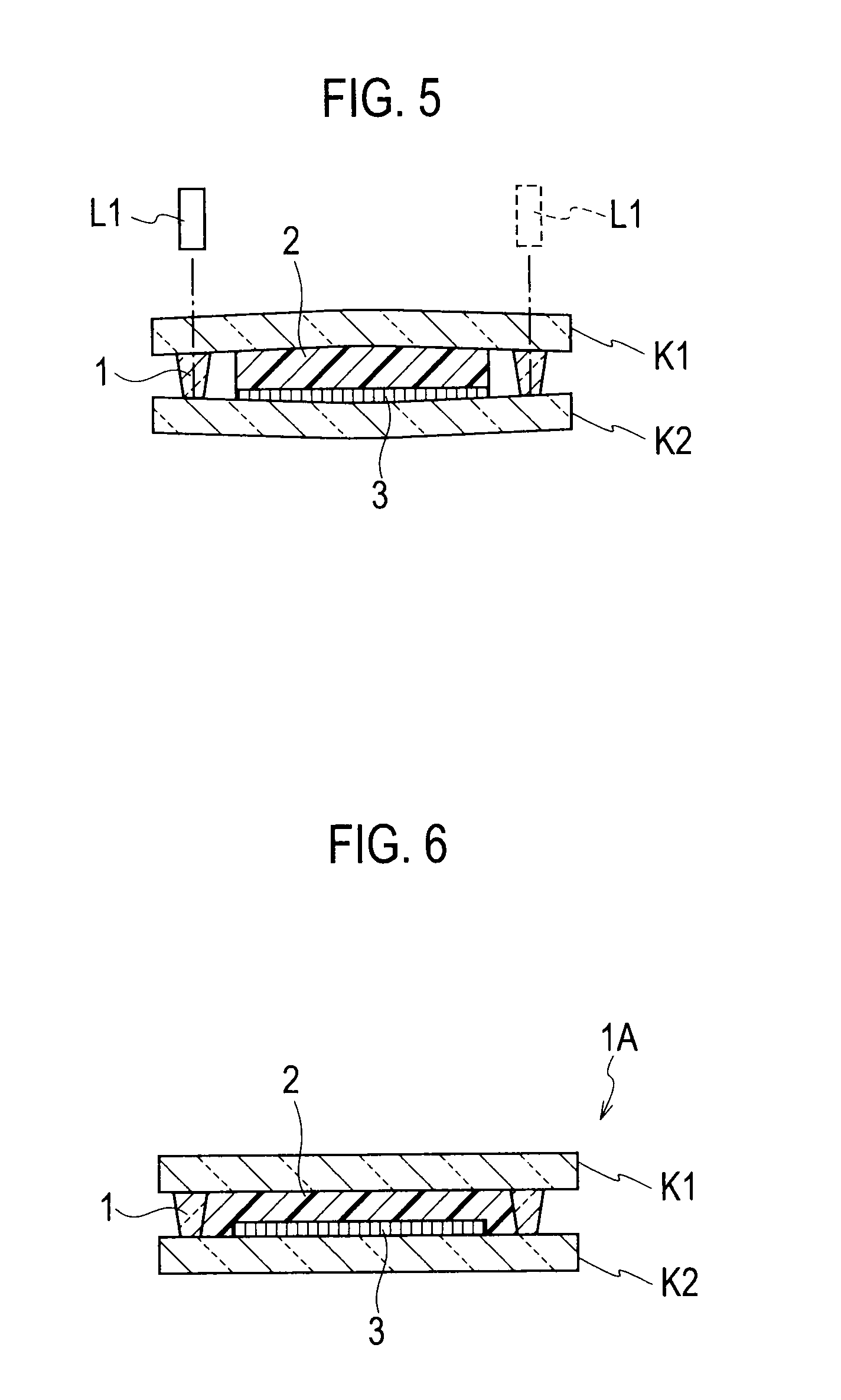

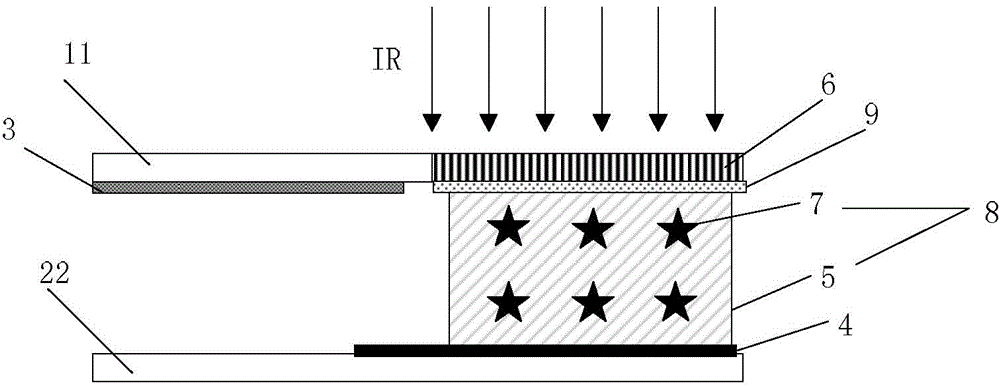

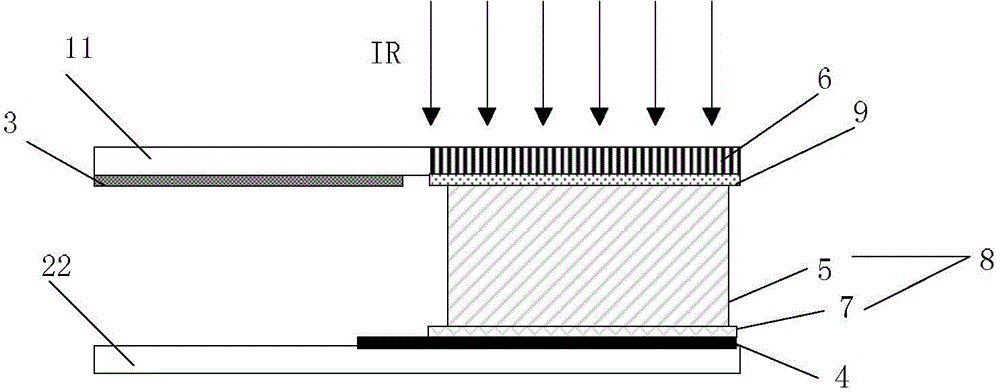

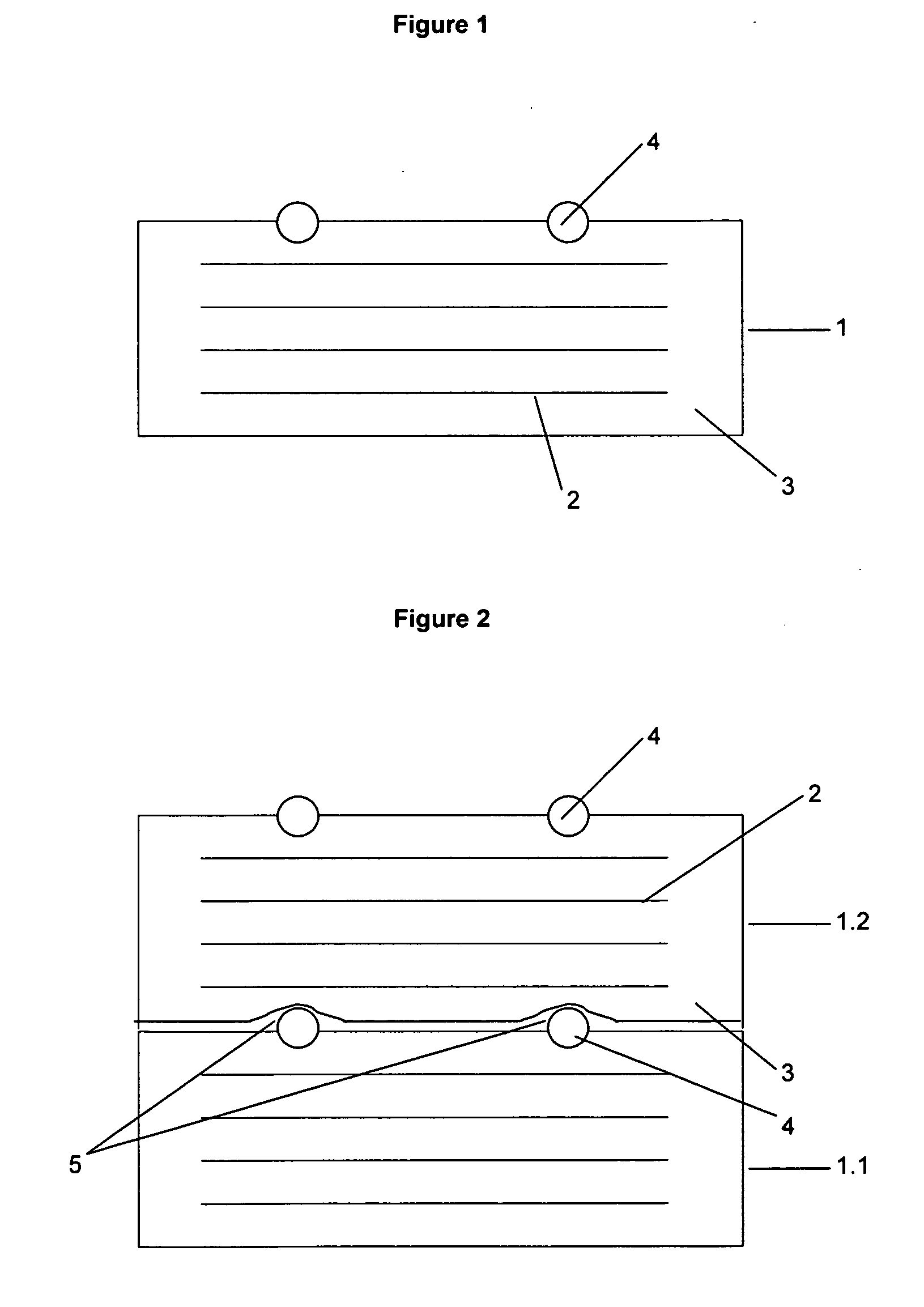

Image display device and its manufacturing method

ActiveUS20090186552A1Improve reliabilityImage display is highTube/lamp screens manufactureAdhesivesLiquid-crystal displayDisplay device

It is possible to manufacture a highly reliable image display device capable of proceeding with resin cure even in the case where a protective panel is provided with a light shielding portion.A liquid crystal display unit 2 having a liquid crystal display panel 8 and a light transmissive protective panel 3 having a light shielding portion 5 are disposed face to face, a resin composition 10 is interposed between the liquid crystal display unit and the protective panel, and the resin composition is cured into a cured resin layer 11. As the resin composition 10, a light-heat-curing resin composition and containing a photopolymerization initiator and organic peroxide of thermal polymerization initiator is used. In curing the resin composition 10, cure by light (ultraviolet rays) irradiation is performed until a cure ratio of the resin composition becomes 30% or more and thereafter thermal cure is performed.

Owner:DEXERIALS CORP

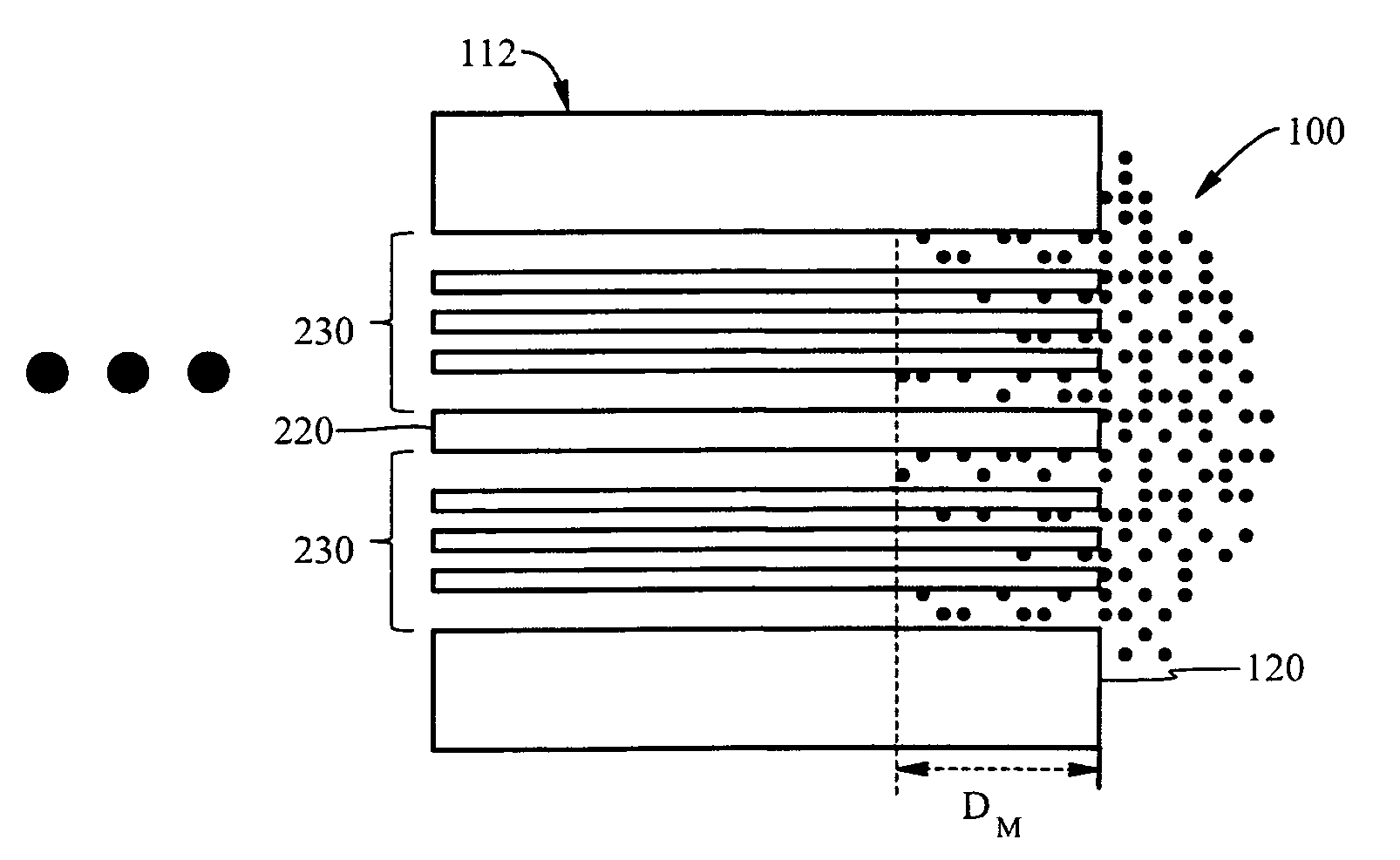

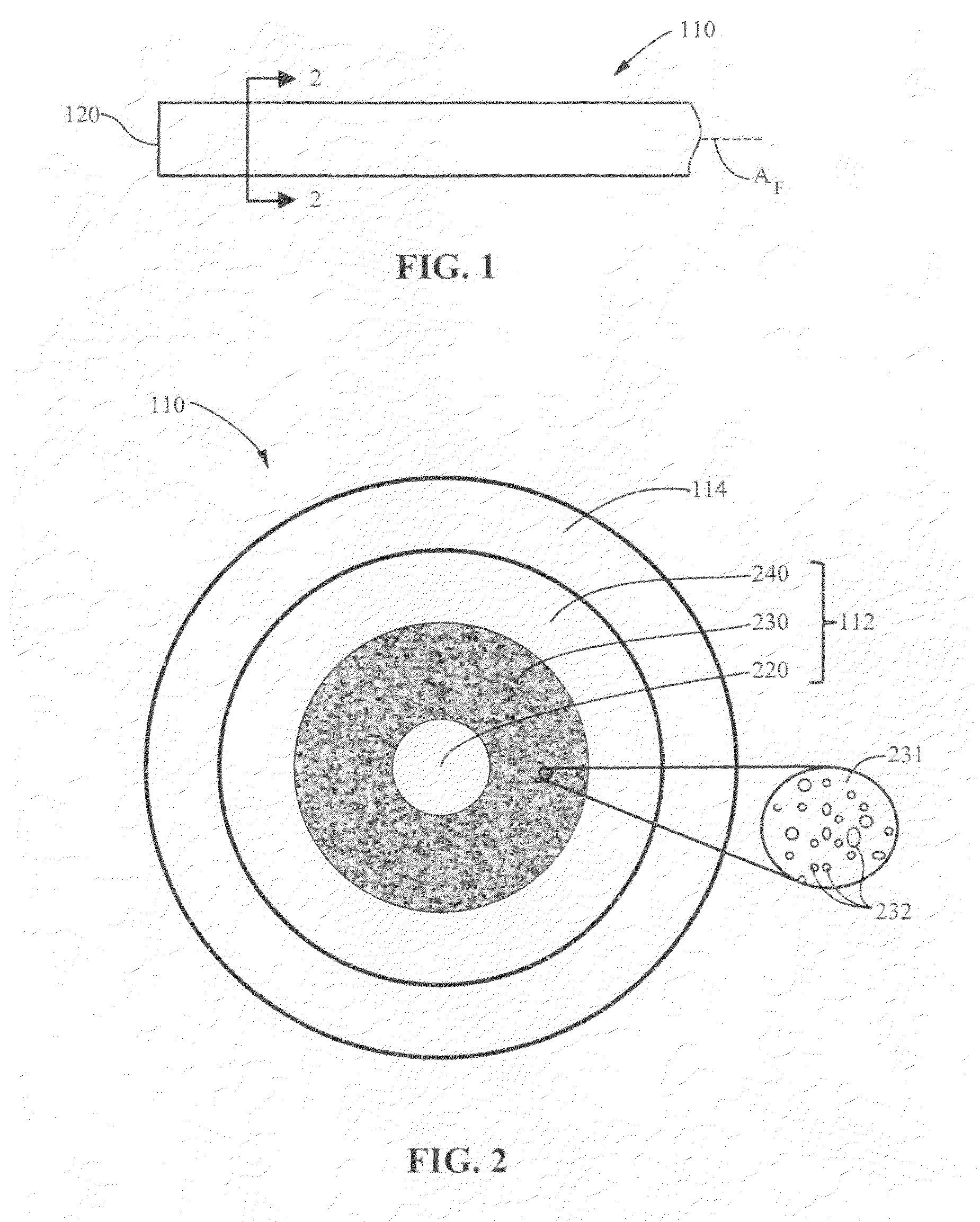

Index-matching gel for nano-engineered optical fibers and mechanical splice assemblies and connectors using same

An index-matching gel for use with nano-engineered optical fibers is disclosed. The index-matching gel is cross-linked, which prevents the gel from wicking into the voids and down the nano-engineered optical fiber to a depth where the fiber performance and / or device performance is compromised. The formulation comprises a non-reactive constituent A, two reactive constituents B and C, and a catalyst D. The gel is pre-cured and forms a cross-linked internal network that results in a single-component gel that does not require meter mixing of an additional constituent or heat curing. The gel is suitable for use in the mechanical splicing of optical fibers when at least one of the optical fibers is a nano-engineered optical fiber. The gel is also suitable for use in fiber optic connectors wherein at least one of the optical fibers constituting the connection is a nano-engineered optical fiber.

Owner:CORNING OPTICAL COMM LLC

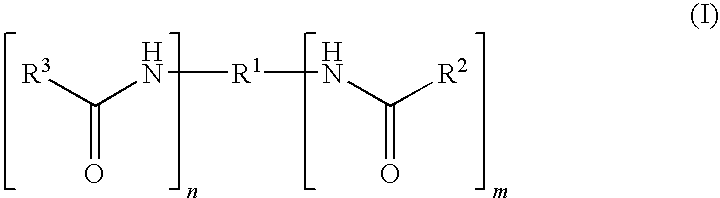

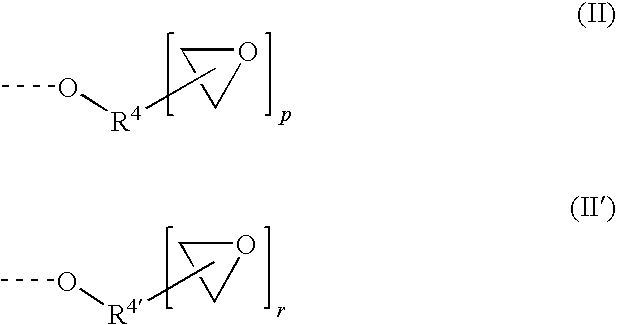

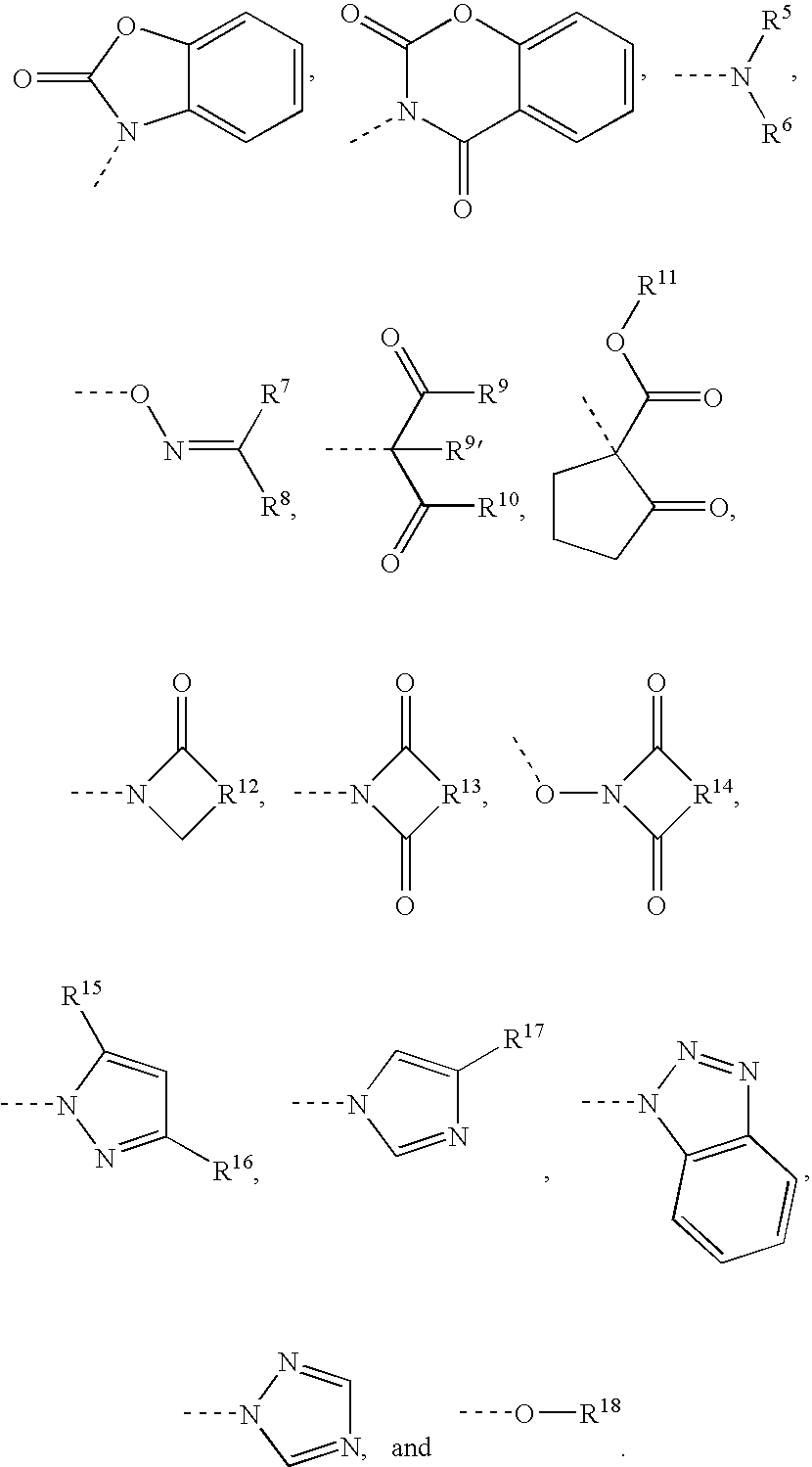

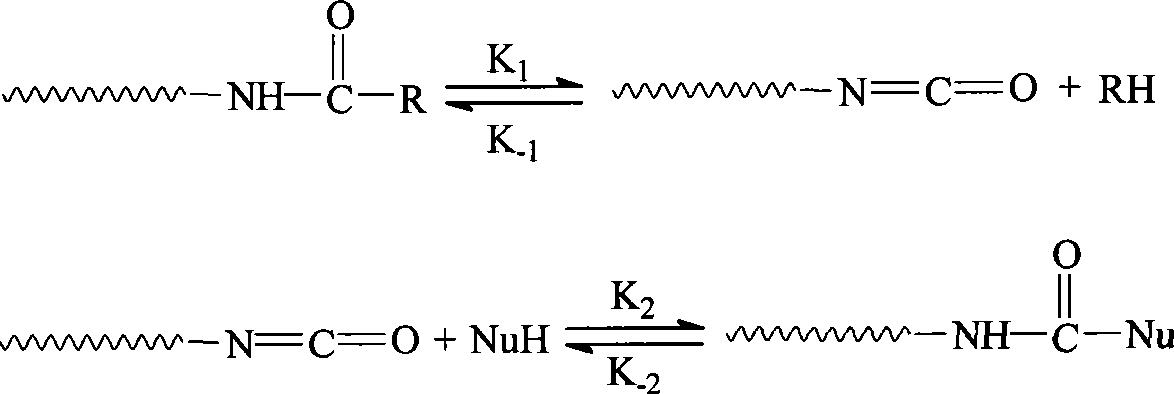

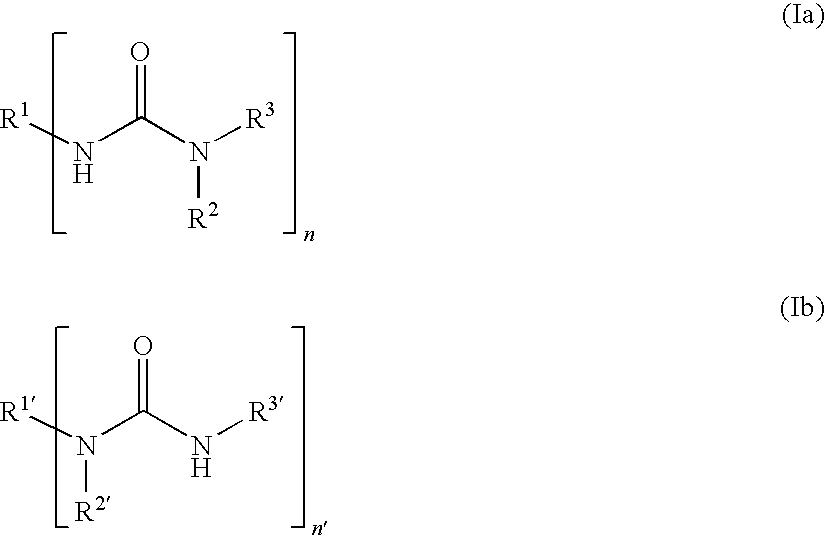

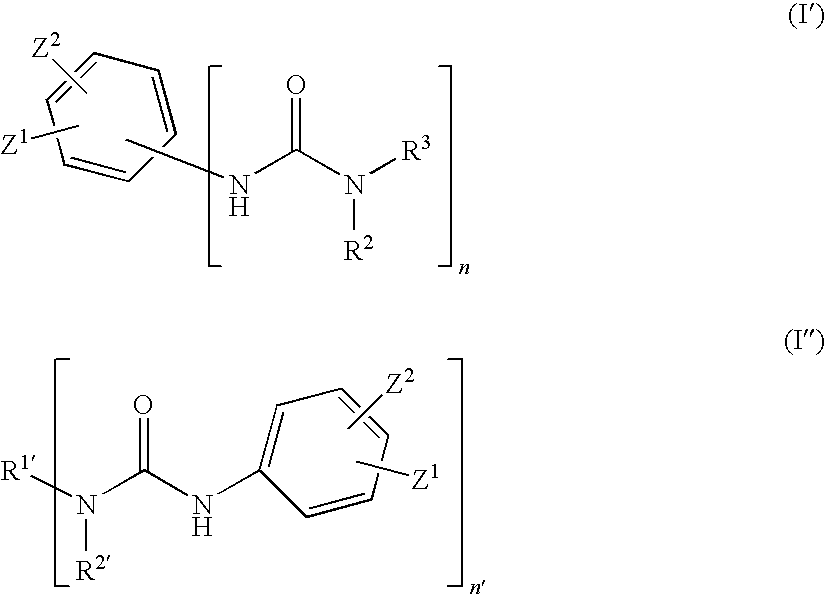

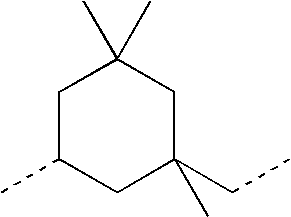

Capped polyurethane prepolymers and heat-curable epoxy resin compositions

InactiveUS20090264558A1Improve impact resistanceLamination ancillary operationsLaminationEpoxyPrepolymer

The invention relates to differently blocked polyurethane polymers of formula, to their use as impact resistance modifiers, to heat-curable epoxy resin compositions containing said impact resistance modifiers and to methods for the production of said compositions. The invention also relates to bonding methods using said compositions and to articles produced by said methods.

Owner:SIKA TECH AG

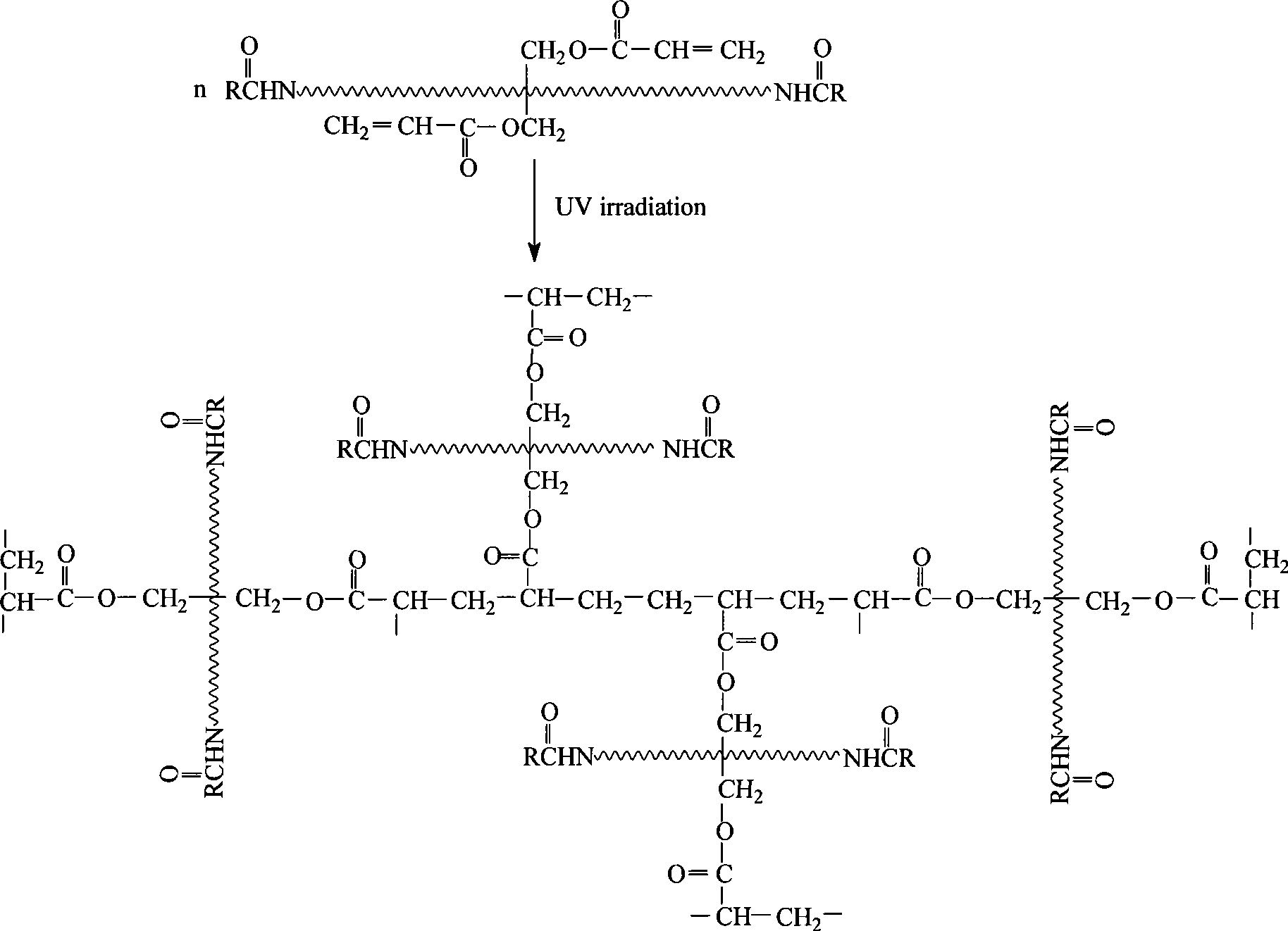

Sealed UV curable aqueous polyurethane resin and preparation method thereof

InactiveCN101381446AGood storage stabilityHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSide chainAdhesive

The invention discloses closed type ultraviolet light solidifying waterborne polyurethane resin and a method for preparing the same. The polyurethane resin and the method are characterized in that the double bond of acrylic ester is introduced to the side chain of the polyurethane by utilizing a chain extender mode, and an end NCO group is sealed and protected by a sealer; and the side chain of a molecular chain of the obtained product has the double bond of an acrylic ester group, wherein the double bond is capable of ultraviolet light solidifying, and the end of a molecular main chain of the product has an unsealable sealer group. The polyurethane resin has the advantages of good storage stability and high hardness after solidification, and further improves the solidifying degree and the adhesive force of a solidifying film and is applied to the coating of workpiece shadow areas, thicker coatings and three-dimensional parts which are hard to penetrate by ultraviolet light. Because the resin coating film is subjected to triple solidification of natural drying solidification, ultraviolet solidification and unsealing-hot solidification, the resin coating film has the advantages of high solidifying degree, high hardness and high adhesive force of base materials. The product of the invention is obviously environmental friendly, and can be widely applied in fields of thick coatings of various base materials and an adhesive.

Owner:UNIV OF SCI & TECH OF CHINA +1

Hard polyimide foaming structural material and preparation method thereof

The invention discloses a hard polyimide foaming structural material and a preparation method thereof. The method comprises the following steps of: mixing aromatic dianhydride and / or aromatic acid ester, high molecular alcohol, low molecular alcohol, a catalyst and a surfactant according to a ratio into a polar solvent and reacting to form polyimide foam precursor solution; reacting the precursor solution with isocyanate in a die; pressurizing and foaming to form a polyimide foam intermediate; and performing microwave radiation or / and performing heat curing by using an oven to obtain the hard polyimide foaming structural material. The preparation process route is short and the process is simple; the storage stability of the foam precursor solution is high; and the prepared hard polyimide foaming structural material has uniform aperture, hard quality, high strength, low density and high temperature resistance, is non-toxic and environmentally-friendly in the foaming process and easy to industrialize, and can be applied in the fields of electron, carrier rockets, aviation, ships, railway locomotives and the like.

Owner:BEIJING RADIATION APPL RES CENT

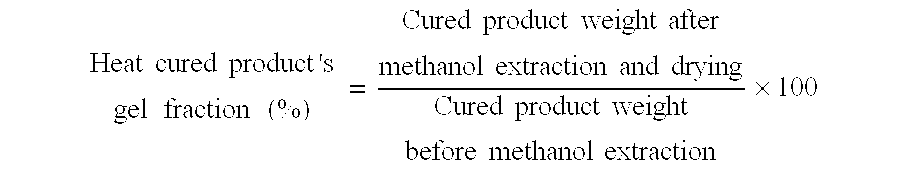

Heat curable thermosetting luminescent resins

InactiveUS6905634B2Improve luminous performanceImprove propertiesLuminescent paintsElectroluminescent light sourcesSodium BentoniteAlkaline earth metal

Luminescent polymers are prepared from thermosetting unsaturated polyesters, suspending fillers and phosphorescent pigments and utilized to make gel coated articles and molded, cast and fiberglass reinforced plastic (FRP) articles. The luminescent polymers show bright and long-lasting photoluminescent afterglow, strong thermostimulation of afterglow by heat and electroluminescent properties. The preferred thermosetting unsaturated polyester resins are prepared by condensing mixtures of ethylenically unsaturated and aromatic dicarboxylic acids and anhydrides with dihydric alcohols and a polymerizable vinylidene monomer. Preferred suspending fillers and thixotropic modifiers include silica, microspheres, glass fibers and other short fibers, nepheline syenite, feldspar, mica, pumice, magnesium sulfate, calcium carbonate, bentonite and the various clays and thixotropic modifiers and mixtures thereof. Preferred phosphorescent pigments include alkaline earth aluminate phosphors, zinc sulfide phosphors and mixtures of these phosphors.

Owner:BURNELL JONES PETER

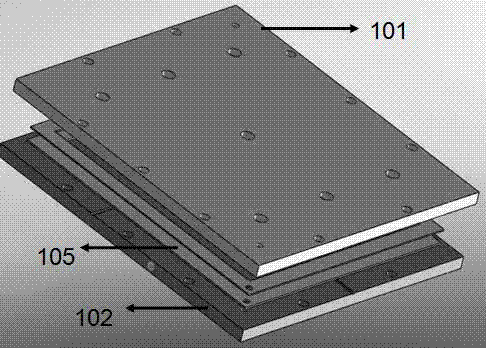

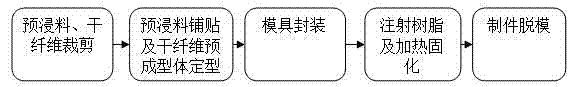

Prepreg/resin transfer molding co-curing process method for composite materials

The invention discloses a prepreg / resin transfer molding co-curing process method for composite materials. The method comprises the following steps: step 1, tailoring prepregs and dry fibers; step 2, spreading the prepregs and sizing dry fiber preforms; step 3, packaging a mould; step 4, injecting resin and carrying out heat curing; and step 5, demolding a product. The method combines a prepreg process with a resin transfer molding process in the mould. According to the structure features and performance requirements of the product, a composite material blank is formed by the prepregs and the dry fibers, then the resin is injected to impregnate the dry fibers, and finally the composite material product is thermally cured. The co-curing of the prepreg part and the liquid forming part is realized, and therefore, the purpose of efficient low-cost manufacture of the composite material structure is achieved. The method can significantly improve the forming efficiency of the composite material structure, reduce the manufacture cost, improve the quality of products and increase the weight loss benefit and is of great significance to the efficient low-cost manufacture of the composite material structure.

Owner:SHANGHAI AIRCRAFT MFG +1

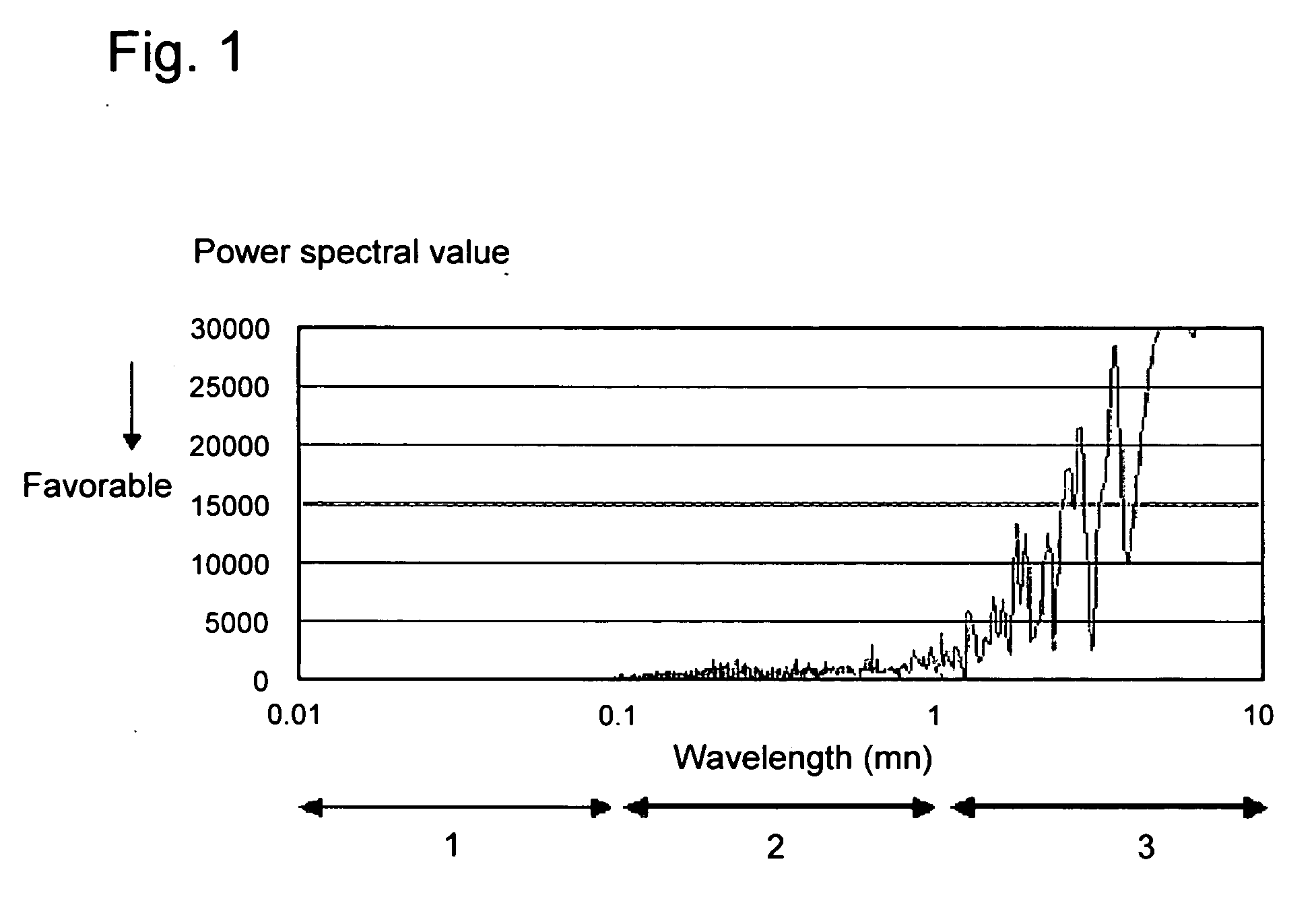

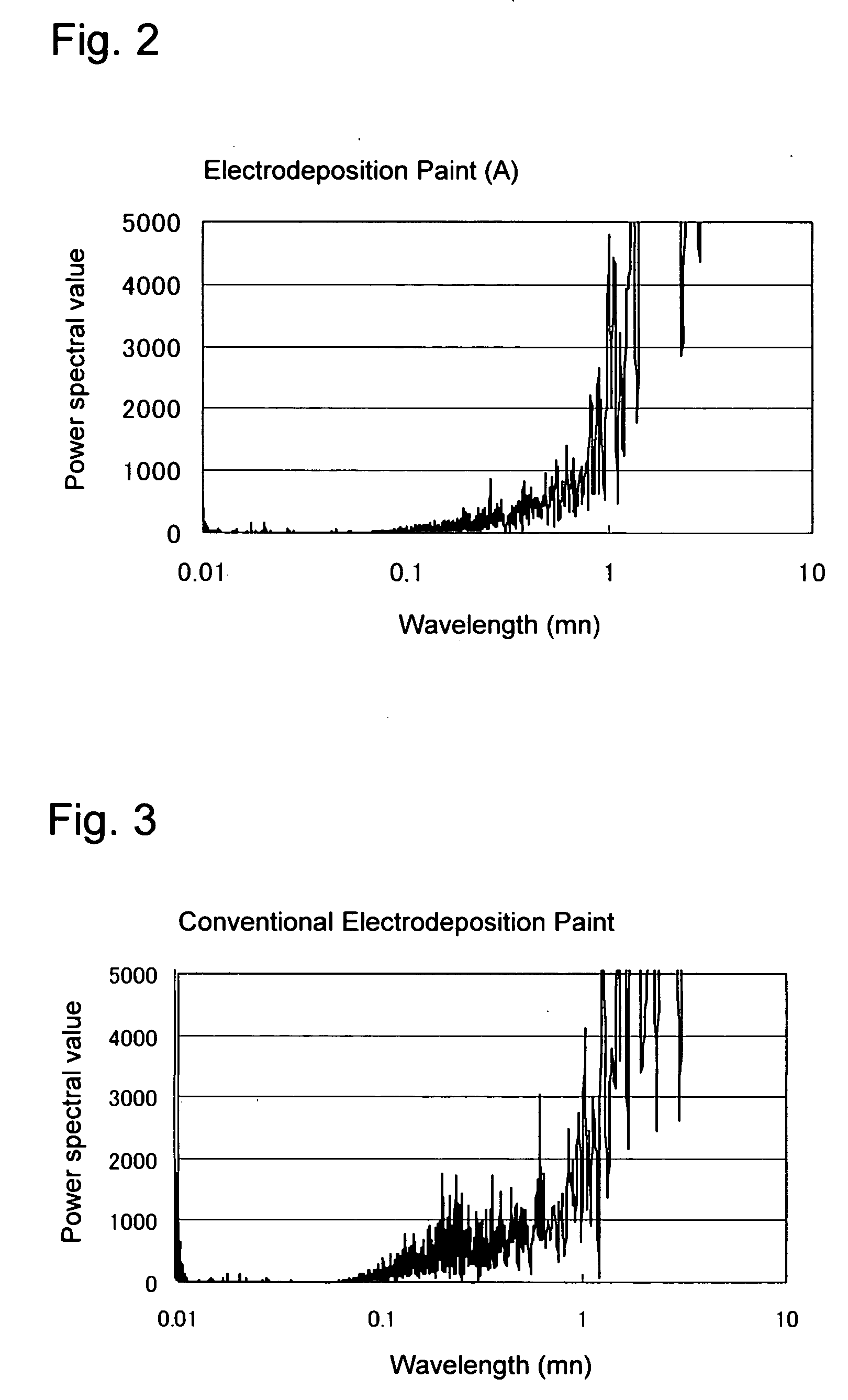

Method of forming multi-layered coating film

InactiveUS20070023288A1Reduce generationSmall weightLiquid surface applicatorsElectrolysis componentsLacquerCorrosion

This invention provides a method for forming multi-layered coating film excelling in appearance, corrosion resistance and chipping resistance, which comprises applying a first coloring paint (B), second coloring paint (C) and clear paint (D) onto cured coating film of a specific electrodeposition paint (A) of low weight loss under heating, wet-on-wet by the order stated; and heat-curing the three-layered coating film simultaneously.

Owner:KANSAI PAINT CO LTD

Heat-curing epoxy resin composition containing non-aromatic ureas as accelerator

InactiveUS20100273005A1Good storage stabilityFast curingSynthetic resin layered productsLaminationEpoxyAdhesive

The present invention relates to heat-curing epoxy resin compositions, which are characterized by high impact strength, good storage stability, and a low curing temperature. The epoxy resin compositions are suitable for use as a construction shell adhesive and for producing structural foams. They can already be cured in so-called bottom-baking conditions. Furthermore, it has been found that the use of an accelerator of the formula (Ia) or (Ib) results in an increase of the impact strength of heat-curing epoxy resin compositions.

Owner:SIKA TECH AG

Silicone coating compositions and coated articles

InactiveUS20050244659A1Eliminate coat crackingImprove balanceLayered productsCoatingsCrack resistanceArame

A silicone coating composition comprising (A) a silicone resin resulting from (co)hydrolytic condensation of an alkoxysilane or a partial hydrolytic condensate thereof, (B) an aromatic-free compound for curing the silicone resin, and (C) a solvent remains stable during shelf storage. It is applied and heat cured to a plastic substrate to form a protective coat having a high hardness, mar resistance, adhesion, toughness and crack resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Heat curable resin composition having a low elastic modulus, heat curable film using same, and cured products

InactiveUS20060079609A1Outstanding featuresLow elastic modulusSemiconductor/solid-state device detailsSolid-state devicesEpoxyHeat resistance

A heat curable resin composition having a low elastic modulus comprising (A) an epoxy resin, (B) crosslinked fine particles, and (C) a curing agent, which when cured with heat, produces a cured product having a elastic modulus of less than 1 GPa is provided. A cured product excelling in characteristics such as stress relaxation property (low stress properties), electric insulation properties, heat shock resistance, and heat resistance can be produced from the heat curable resin.

Owner:JSR CORPORATIOON

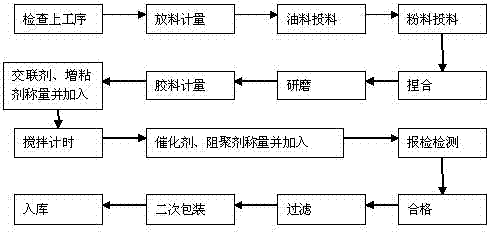

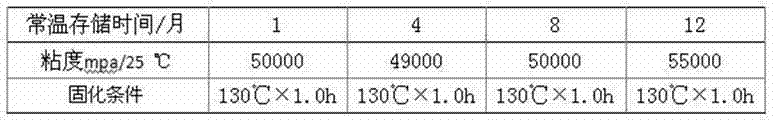

Single-component heat-curing liquid silicone rubber and preparation method thereof

The invention belongs to the field of liquid silicone rubber, and particularly relates to single-component heat-curing liquid silicone rubber and a preparation method thereof. Ethenyl polysiloxane is used as base rubber, hydrogen polysiloxane is used as a cross-linking agent, a complex of transition metal platinum is used as a catalyst, an alkynol mixture is used as an efficient polymerization inhibitor, aluminum oxide and aluminium nitride are used as heat conductive fillers, a silane coupling agent is used as a tackifier, aluminium hydroxide is used as a fire retardant, and fumed silica is used as a reinforcing agent. As a process is strictly controlled, and a process route that raw materials are treated and dried in advance, and mixed at room temperature to prepare the rubber is adopted, the low-viscosity single-component heat-curing silicone rubber is prepared. The fire retardant single-component heat-curing liquid silicone rubber can be stored for a long term at normal temperature, is low in viscosity, single in component, good in heat conductivity and temperature tolerance, and good in adhesion with a base material.

Owner:CHENGDU TALY TECH CO LTD

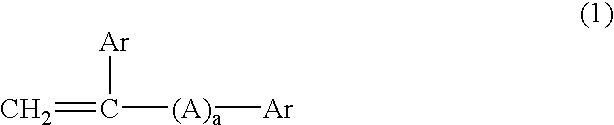

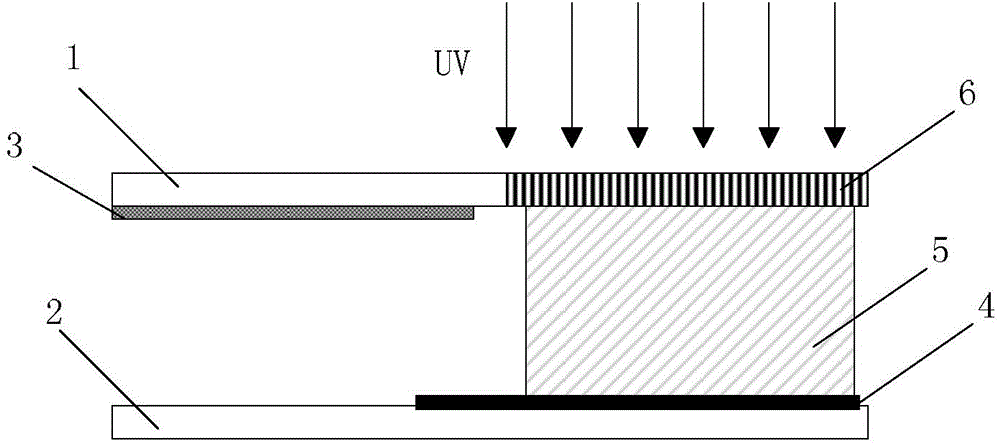

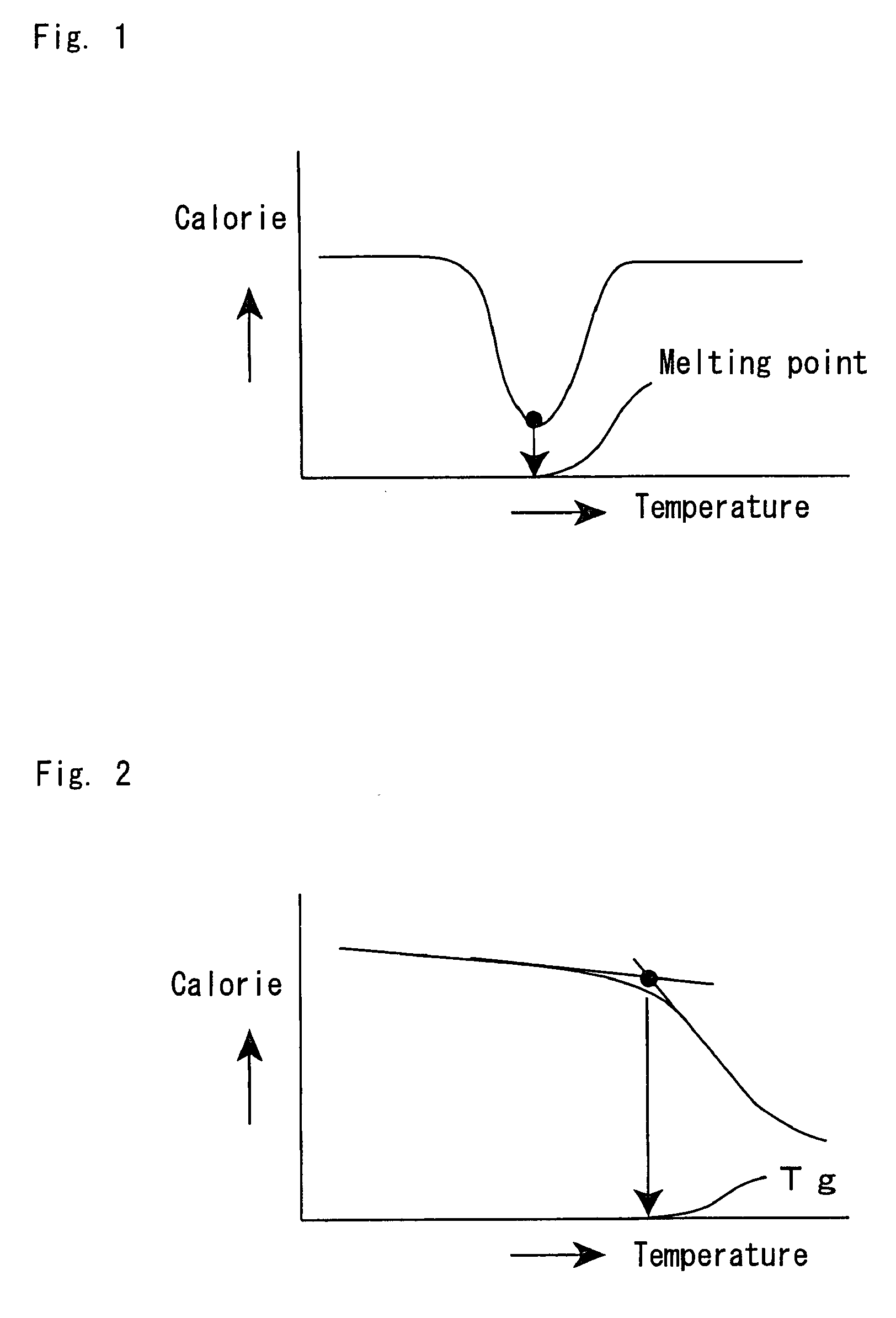

Sealing composition for liquid crystal displays and process for production of liquid crystal display panels

ActiveUS20060009579A1Improve curing effectImprove bond reliabilityLamination ancillary operationsLaminationMethacrylateLiquid crystalline

A liquid crystal sealing agent composition that is a one-component light and heat-curable resin composition containing: (1) a solid epoxy resin having a ring and ball method softening temperature of 40° C. or above; (2) an acrylate monomer and / or a methacrylate monomer, or an oligomer thereof; (3) a thermoplastic polymer having a ring and ball method softening temperature of 50 to 120° C., the thermoplastic polymer being obtained by copolymerizing an acrylate monomer and / or a methacrylate monomer with a monomer copolymerizable therewith; (4) a light-activated radical polymerization initiator; and (5) a latent epoxy curing agent. The light and heat curable liquid crystal sealing agent composition is employable in one drop fill, is excellent in properties of a cured product particularly after first-stage light curing, achieves stable cell gap after cell gap formation, permits prevention of contamination of the liquid crystal in second-stage heat curing, is excellent in curing properties in shaded area, and shows superior bonding reliability.

Owner:MITSUI CHEM INC

Heat curing in-situ forming high-conductivity silicon rubber composition and application thereof

The invention relates to a heat curing in-situ forming high-conductivity silicon rubber composition and application thereof. The composition is composed of the following components: (1) 60-90 parts by weight of mixture of ethylene end-blocked polyorganosiloxane in the same or different viscosities; (2) 10-35 parts by weight of silicone oil containing hydrogen; (3) 1-25 parts by weight of one or multiple R<6>cSiX4-c or partial hydrolytic condensation product thereof; (4) 100-500 parts by weight of metal base conductive filler with the average particle size of 10-150 Mum; (5) 0.01-10 parts by weight of organic metal compound or chelate which contains chloroplatinic acid or contains platinum or palladium and is used as metal base catalyst of heat curing; (6) 1-30 parts by weight of reinforcing filler or functional filler. The invention is applied to the shielding case part of RF equipment requiring electromagnetic shielding and sealed environment. The invention reduces material consumption, simplifies production technology and improves production efficiency and cost performance of product.

Owner:SHANGHAI RELAND PHOTOVOLTAIC MATERIAL

Fluoroelastomer bonding compositions suitable for high-temperature applications

InactiveUS20120100379A1Suitable for useNon-macromolecular adhesive additivesLamination ancillary operationsSolventAmmonia

Bonding compositions are provided herein for bonding a curable fluoroelastomer composition, and preferably a perfluoroelastomer composition, to a substrate during a heat curing process. The compositions include (a) a compound selected from the group consisting of aluminum acrylates, silicon acrylates, ammonia acrylates, and combinations thereof, (b) an adhesive compound; and (c) a solvent. Methods of bonding fluoro- and perfluoroelastomers to a substrate surface are also including herein which utilize the bonding compositions.

Owner:GREENE TWEED TECH

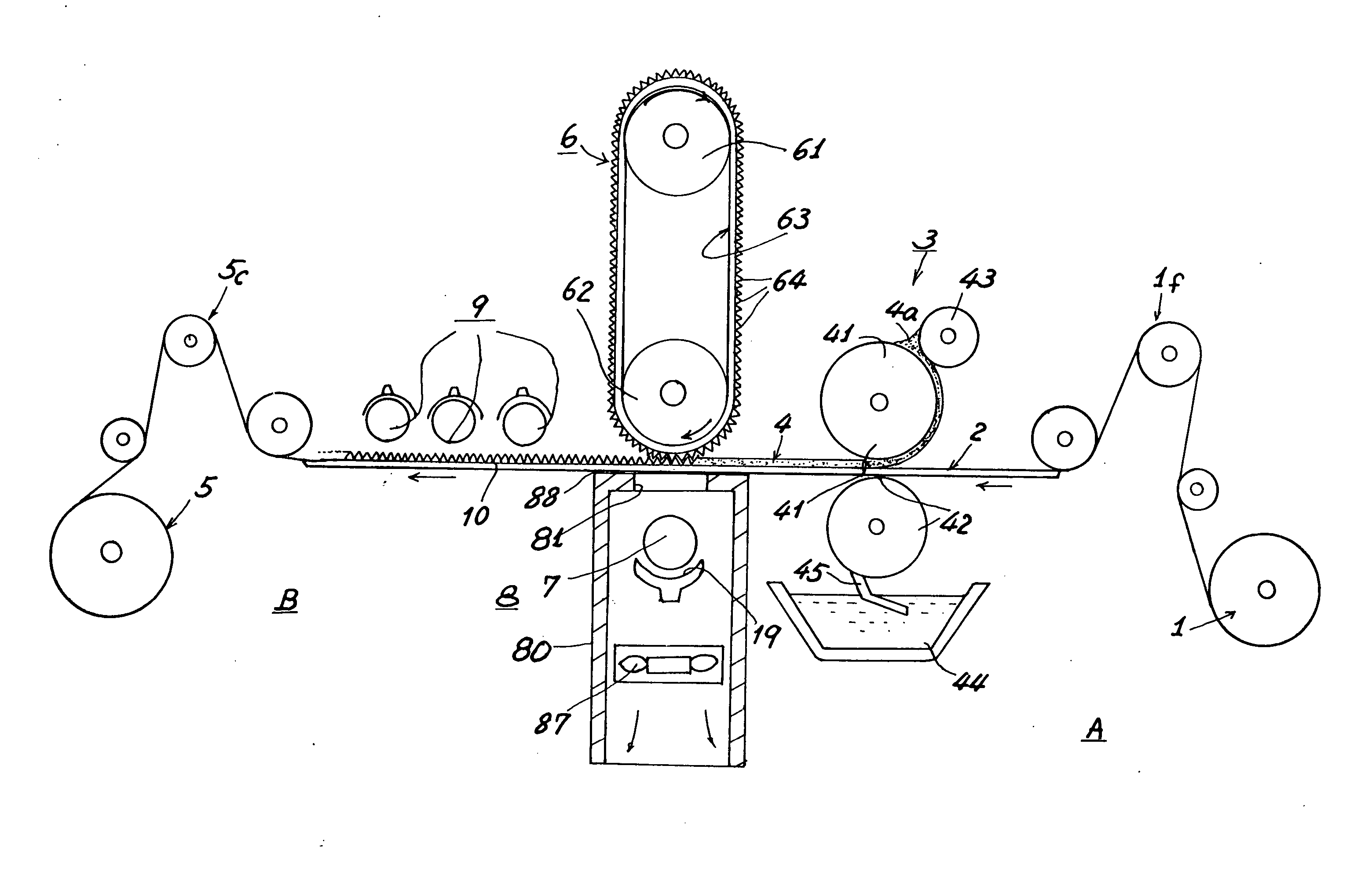

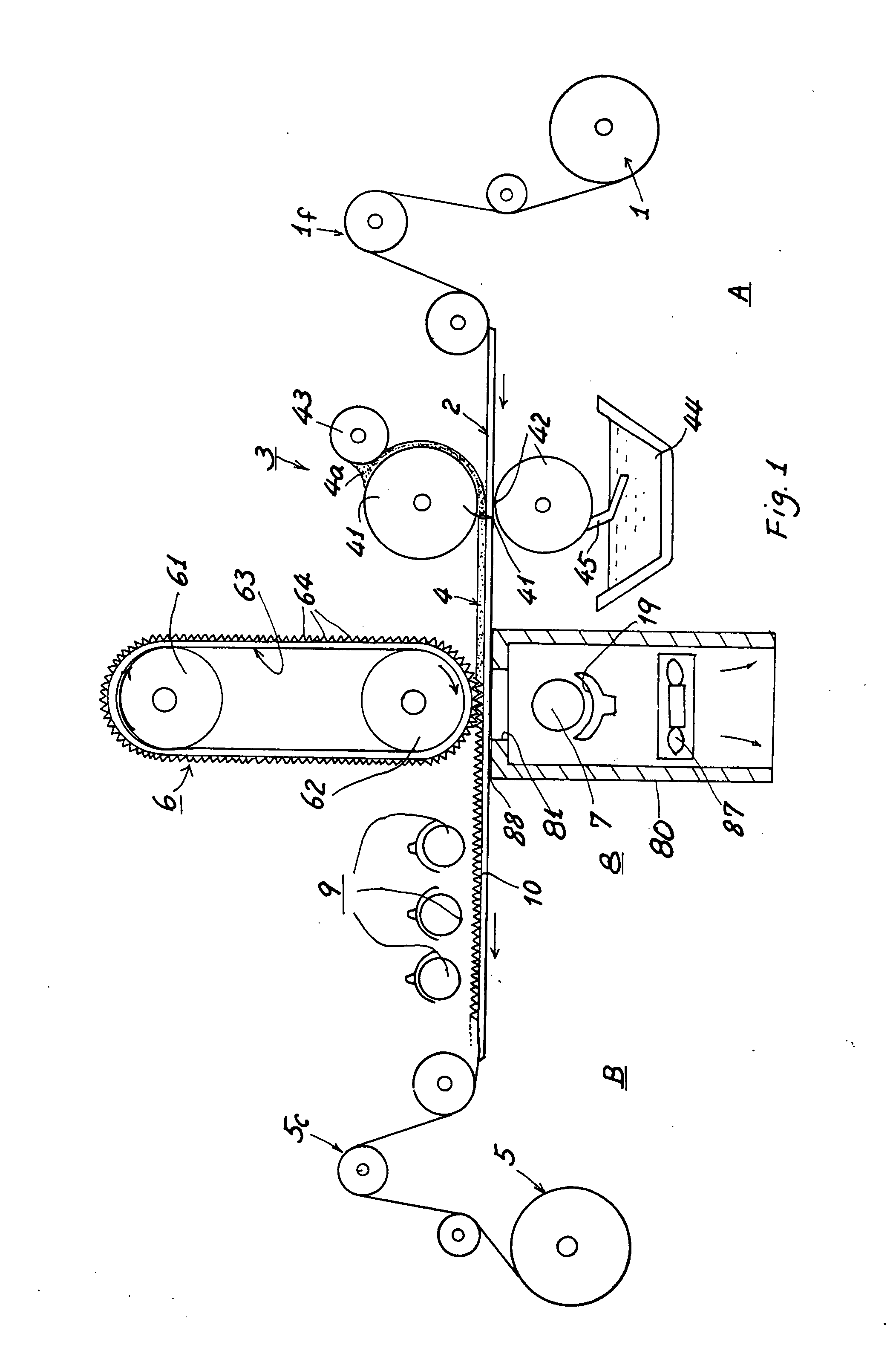

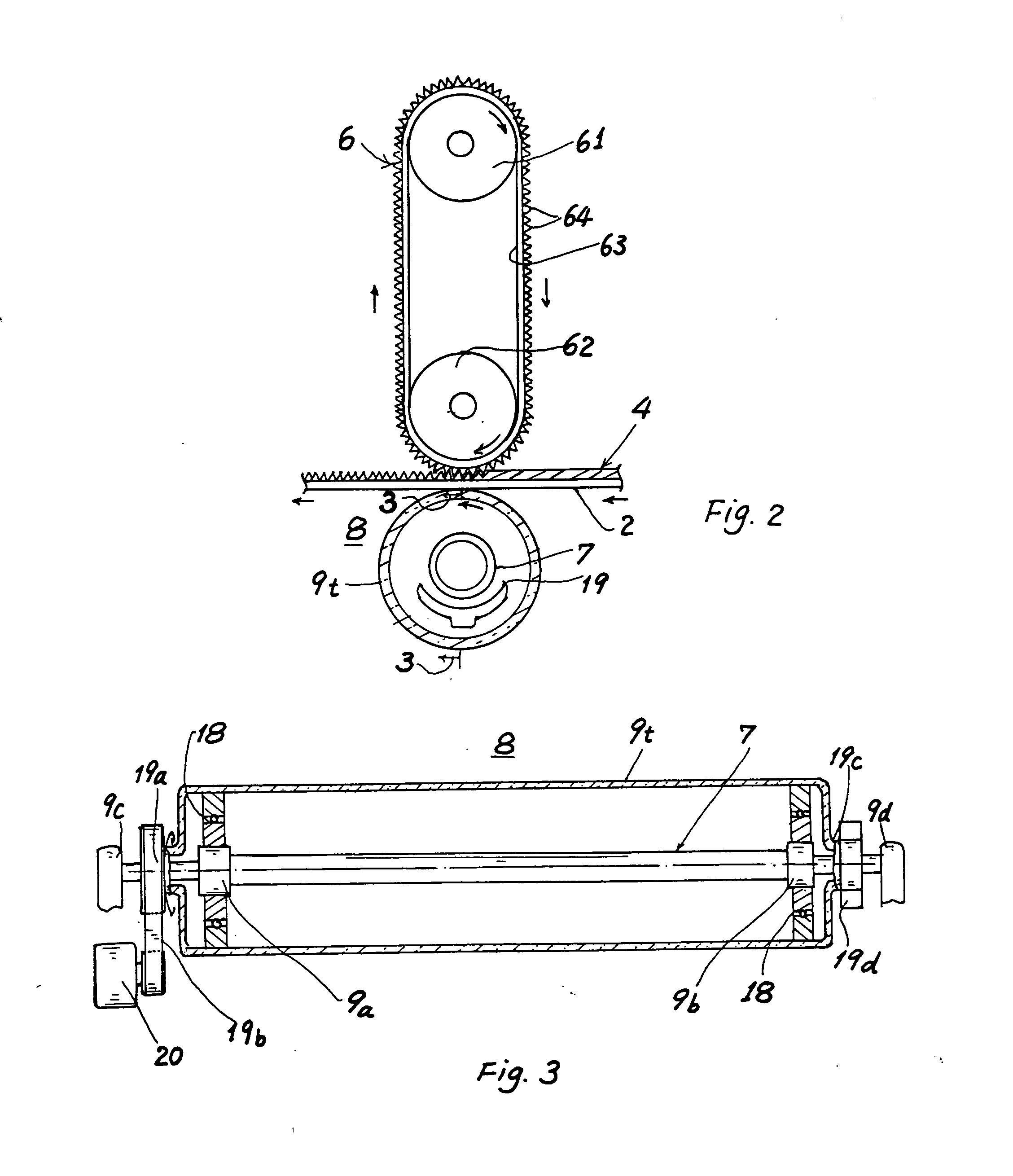

Method for forming structured film as molded by tape die

InactiveUS20070204953A1Lamination ancillary operationsDiffusing elementsComposite materialHeat curing

A method for forming structured or micro-structured film comprising the steps of: A. Coating a photocuring or heat-curing adhesive resin layer on a substrate layer; B. Molding or forming or imprinting a structured or micro-structured pattern including prismatic array on the adhesive resin layer by a tape die having the structured pattern preformed on the tape die; and C. Curing the photocuring or heat-curing adhesive resin layer on the substrate layer to obtain a layered film having a structured pattern surface. The structured pattern is formed on the tape, rather than on the rotary die or die roller, to prevent from sticking of the adhesive resin on the roller to prolong the service life of the production equipment and also to ensure a reliable film product quality.

Owner:LIN CHING BIN

Method of manufacturing flat-panel display device, apparatus for manufacturing flat-panel display device, and flat-panel display device

InactiveUS20100075563A1Improve product reliabilitySimple manufacturing processTube/lamp screens manufactureSolid-state devicesAir atmosphereDisplay device

Disclosed is a method of manufacturing a flat-panel display device, includes: laminating a thermosetting resin film on a sealing substrate; stacking the sealing substrate having the thermosetting resin film laminated thereon, and an element substrate having a light-emitting element together under a vacuum atmosphere with the thermosetting resin film and the light-emitting element facing inwardly, and with a frame-shaped sealing material around the thermosetting resin film interposed between the two substrates; joining the sealing substrate and the element substrate together under a vacuum atmosphere by the sealing material situated between the sealing substrate and the element substrate stacked together; and heat-curing the thermosetting resin film situated between the sealing substrate and the element substrate stacked together, under an air atmosphere.

Owner:KK TOSHIBA

Display panel and display device

The invention provides a display panel and a display device. The display panel comprises a first base board and a second base board which are arranged oppositely and a sealing frame glue structure used for bonding the first base board with the second base board, wherein the sealing frame glue structure comprises sealing frame glue and a converting unit, and the converting unit is used for converting infrared light irradiated when the sealing frame glue is cured into ultraviolet light. According to the display panel, through the arrangement of the converting unit in the sealing frame glue structure, light curing and heat curing are achieved through single-step technology, and problems that when the ultraviolet light curing and the heat curing are separately performed on the sealing frame glue, since the pre-curing is incomplete, the sealing frame glue is prone to making contact with liquid crystals, and the pollution and the impalement of the liquid crystals occur are avoided.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

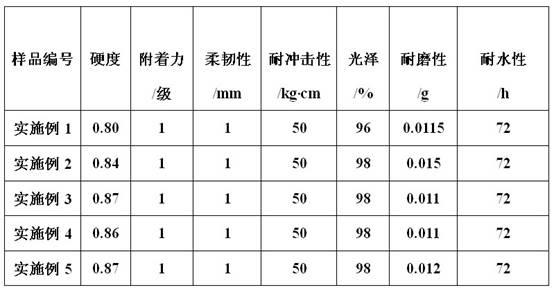

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

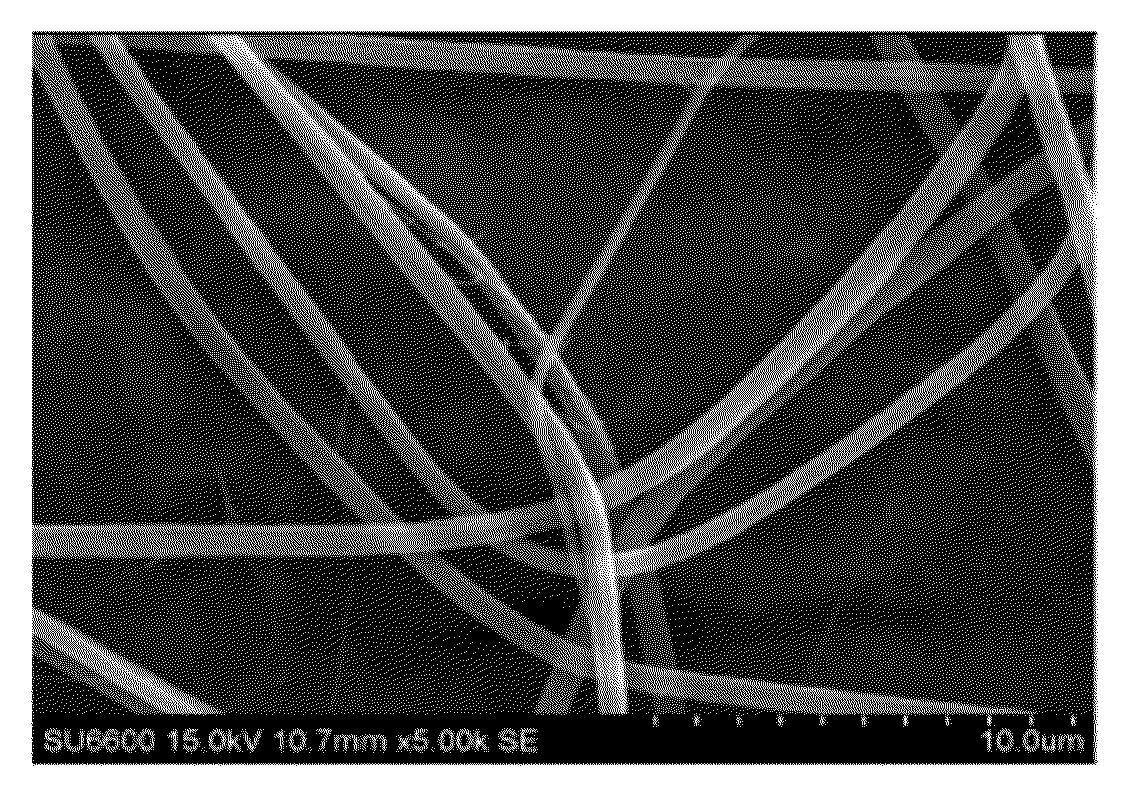

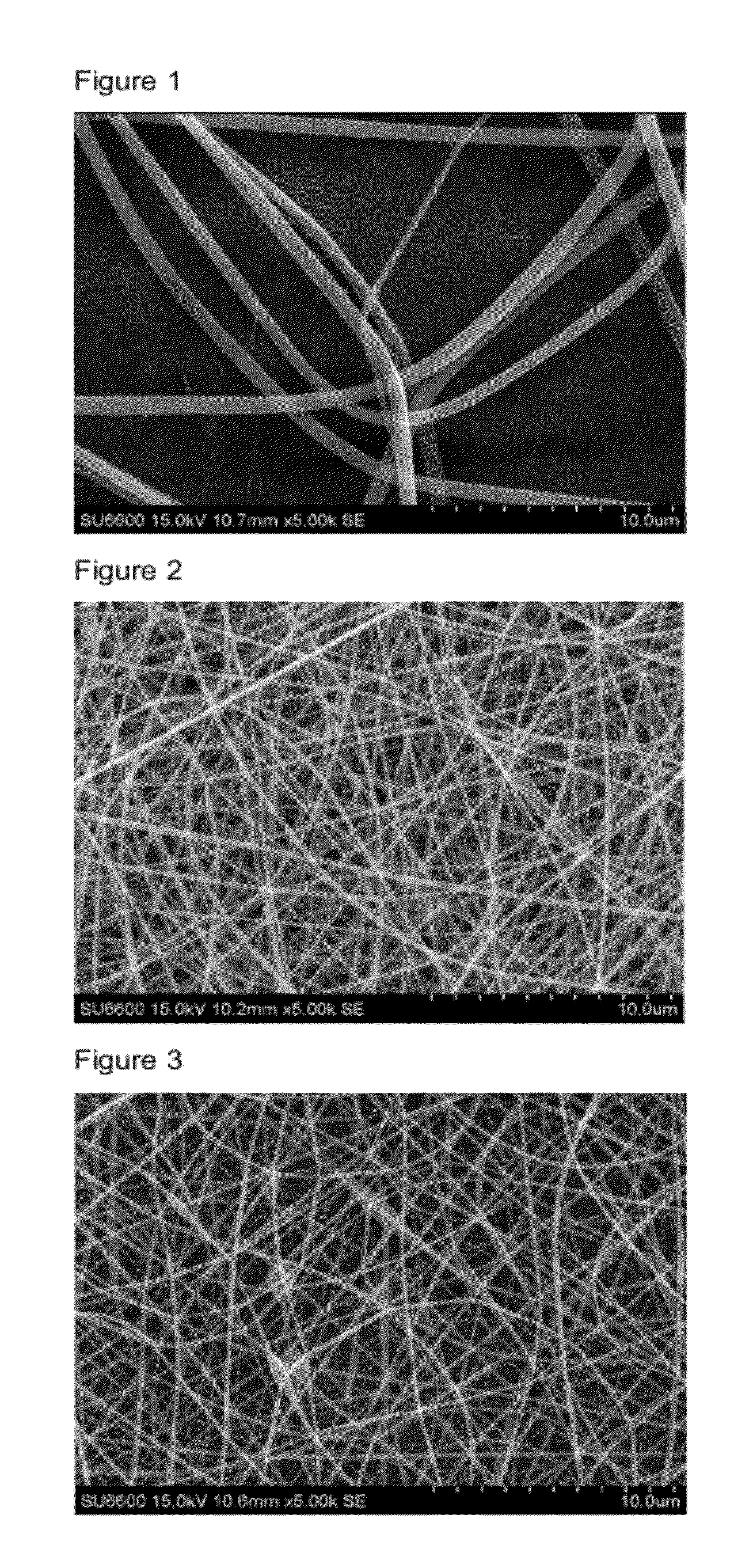

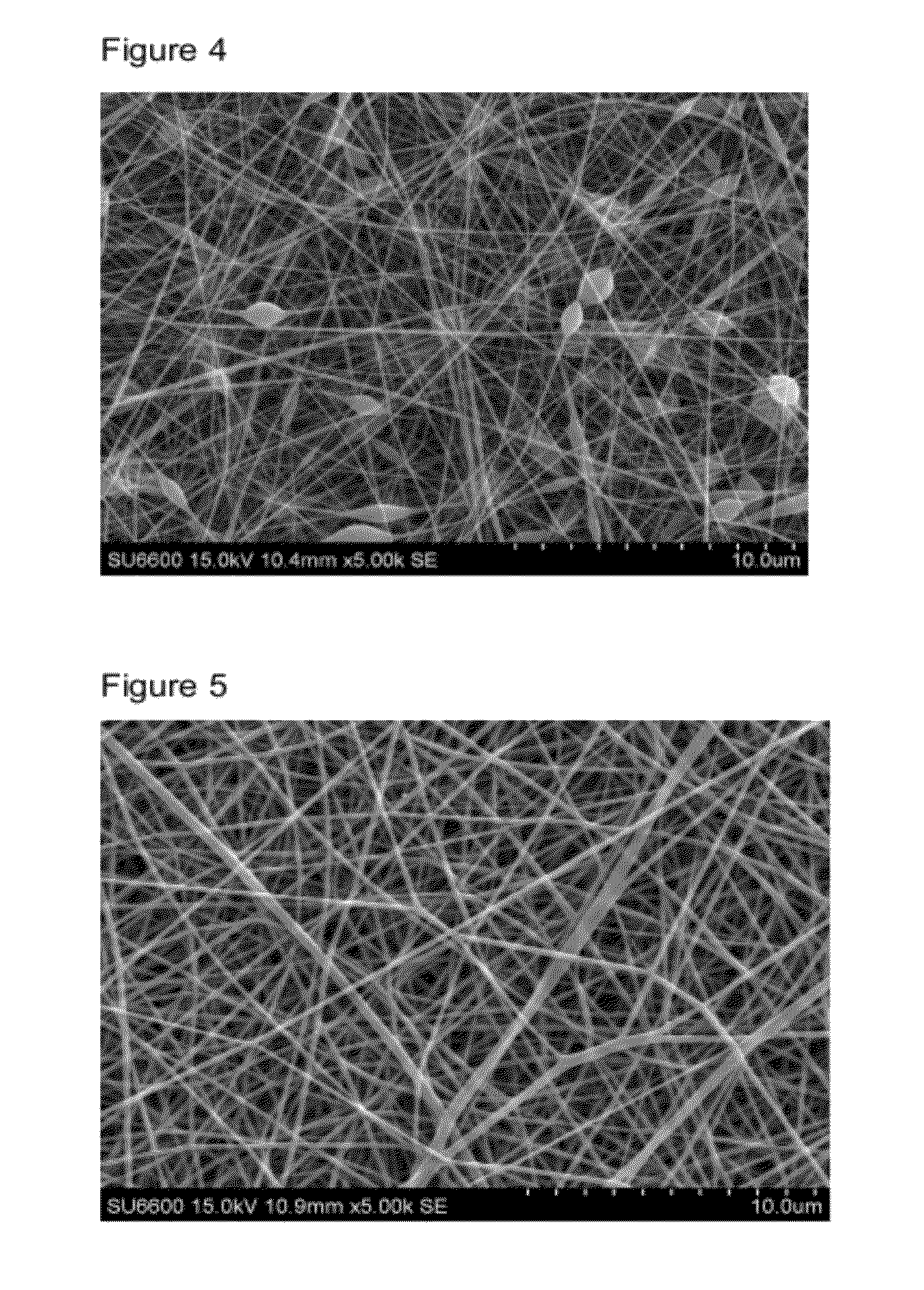

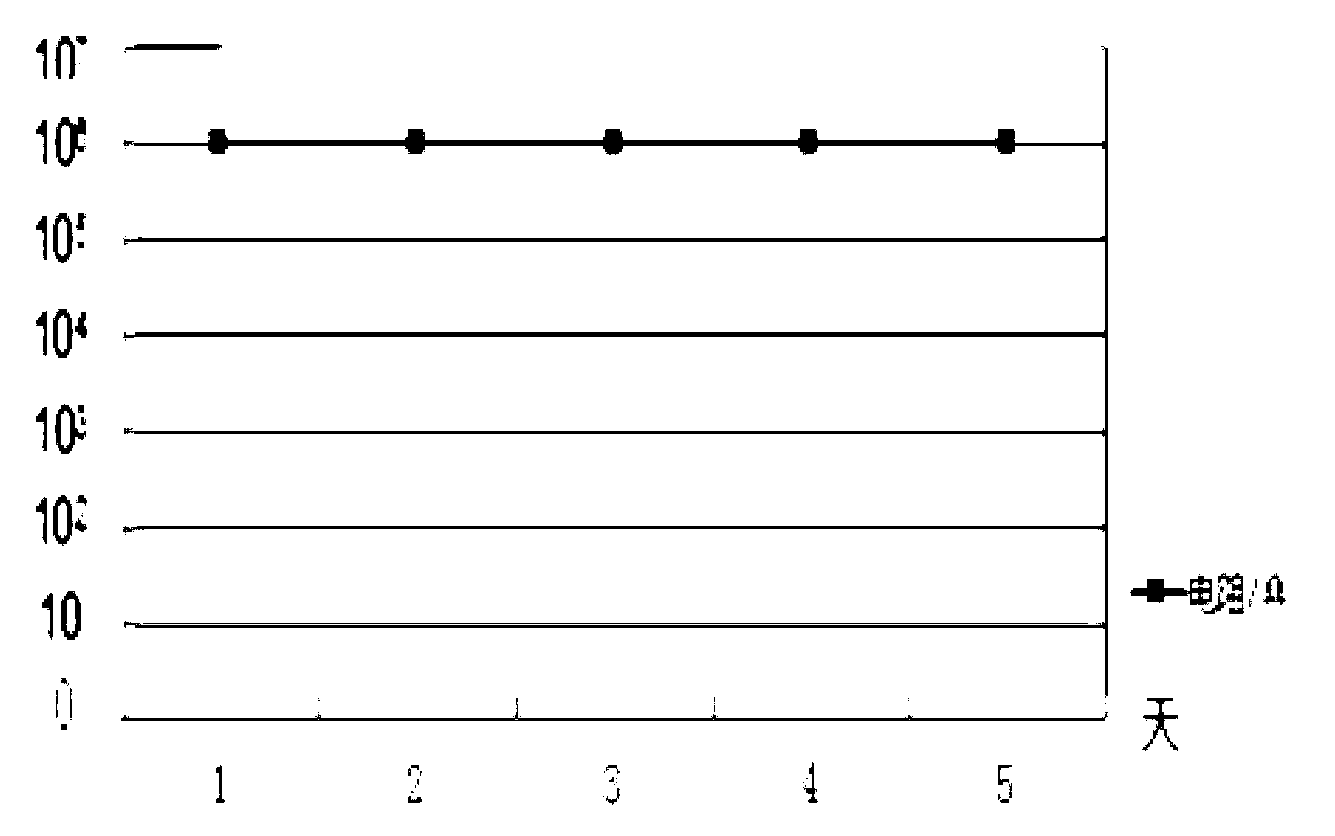

Fiber Comprising Heat Curable Polyamide Resin Composition, Nonwoven Fabric And Producing Method Thereof

InactiveUS20120178332A1Increase resistanceHigh strengthMaterial nanotechnologyElectric discharge heatingEpoxyPolyamide

The present invention relates to a fiber comprising a heat curable polyamide resin composition containing both a) a phenolic hydroxy group-containing polyamide and b) an epoxy resin having two or more epoxy groups in one molecule, a nanofiber comprising said resin composition obtained by electrospinning method, a nonwoven fabric obtained by applying heat treatment to a laminate of said nanofiber, a method for producing said nanofiber by electrospinning method and a heat curable polyamide resin composition for fiber. A nonwoven fabric can be obtained only by subjecting a deposit of the nanofiber obtained by electrospinning method to heat treatment, nanofibers in the obtained nonwoven fabric are bonded to each other by heat-curing, and the nonwoven fabric has such characteristics that its mechanical strength, heat resistance and chemical resistance are excellent and that it has a high strength.

Owner:NIPPON KAYAKU CO LTD

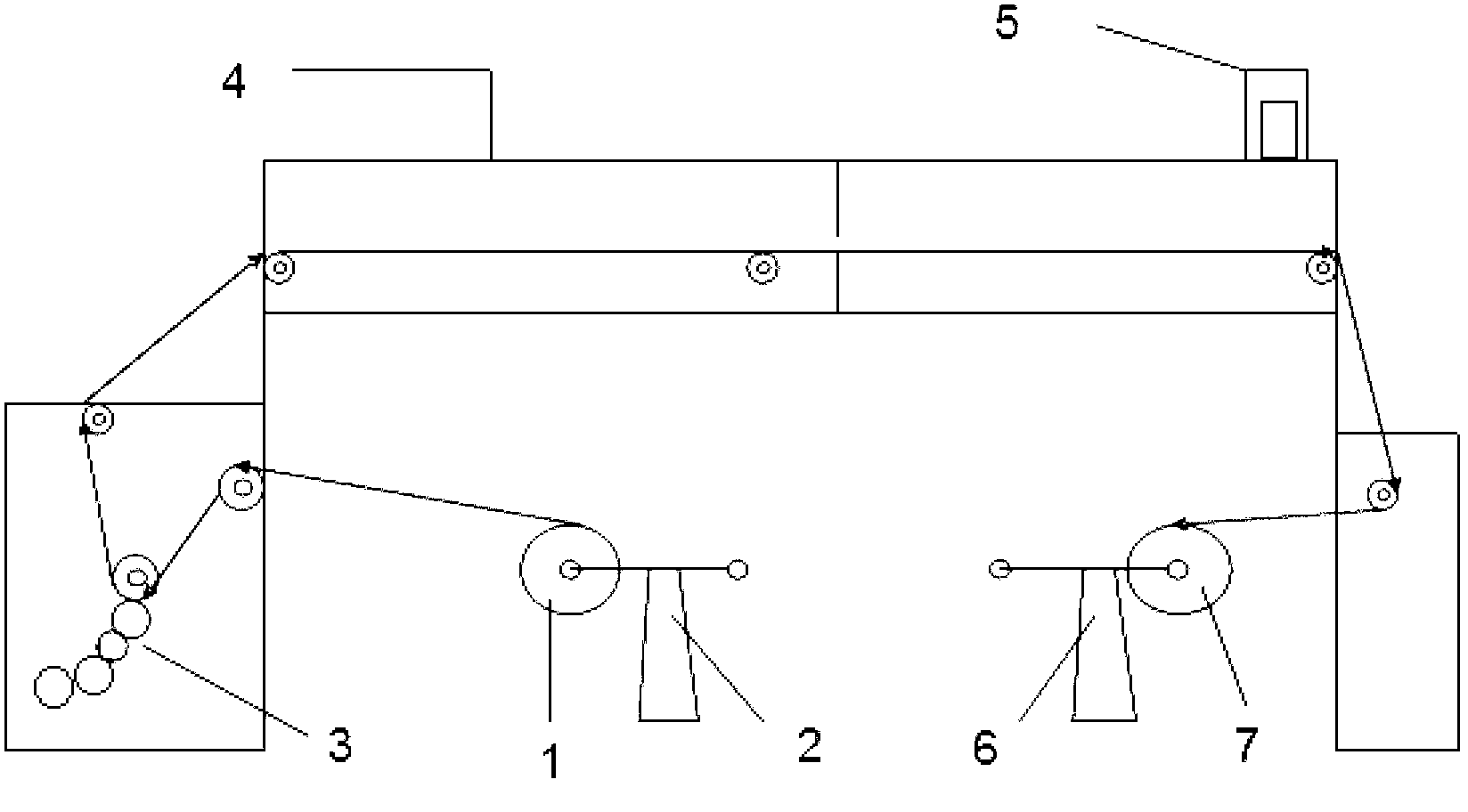

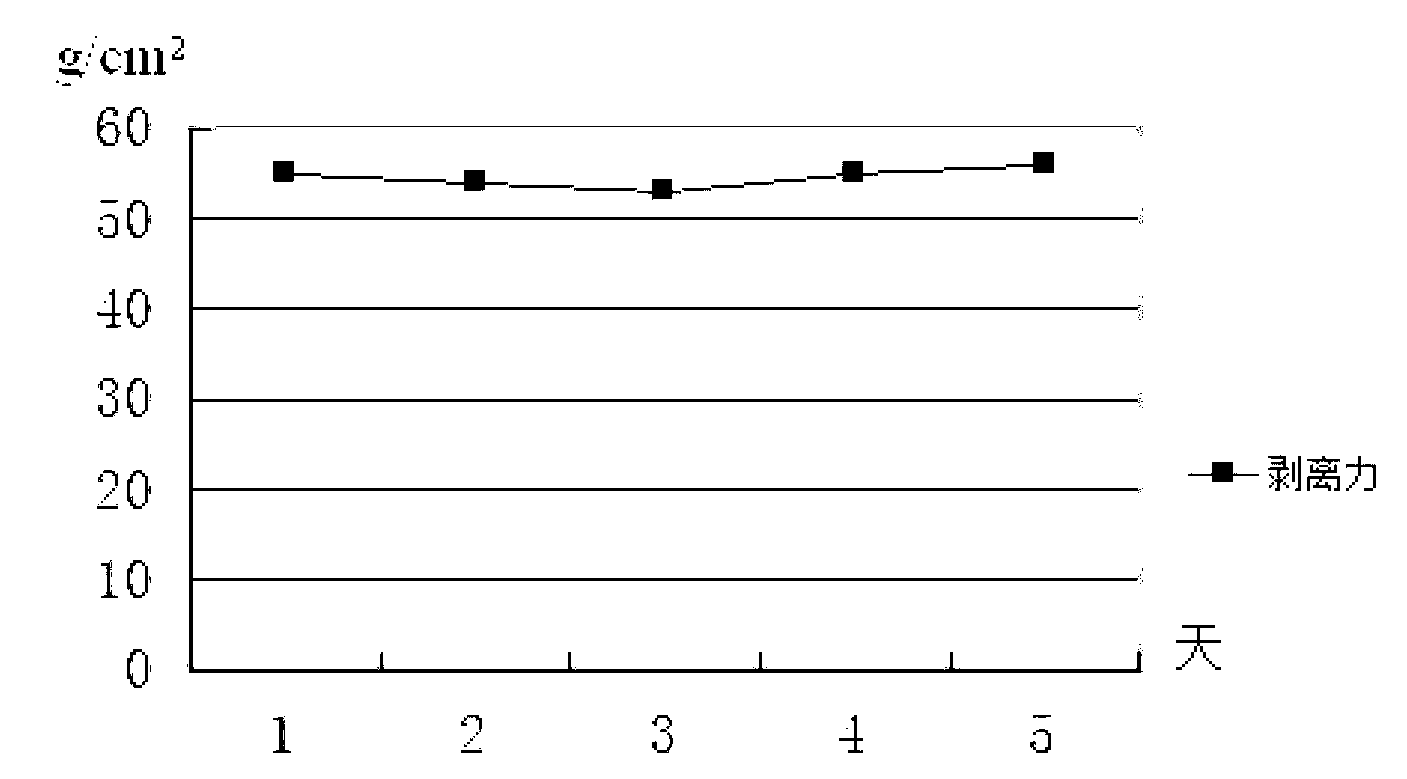

Anti-static release liner as well as preparation method and equipment thereof

ActiveCN102794960AReduce transferStable characteristicsSynthetic resin layered productsLaminationHydrogenPlatinum complex

The invention relates to an anti-static release liner, comprising a base membrane and a functional layer, wherein the functional layer is prepared from the following components in parts by weight: 0.5-1 part of conducting polymer resin, 1-2 parts of hydrogen-containing silicon oil, 5-10 parts of vinyl organic silicon resin, 0.05-0.2 part of platinum complex catalyst and 0.05-0.2 part of photoinitiator. The anti-static release liner disclosed by the invention has stable characteristics, double curing, namely heat curing and photo curing, is adopted, curing is thorough, chemical and physical properties are stable, stripping resistance and anti-static capacity are stable, an adhesive force is good, and less silicon is transferred. The invention has the advantages of a simple process, high production efficiency, low cost and less waste in production.

Owner:苏州市星辰科技有限公司

Two-component epoxy adhesive composition

ActiveUS20060205897A1High viscosityLate build-up of the wash-off resistanceThin material handlingEpoxy resin adhesivesElastomerPolymer science

The present invention relates to a two-component epoxy adhesive composition comprising a) a first component comprising a first epoxy resin and a second epoxy resin, the second epoxy resin being flexibilized by an elastomer, and b) a second component comprising at least one amine compound with one or more primary and / or secondary amino groups, said amine compound having a molecular weight of less than 450 g / mol. The ratio of the total number of amino groups of the amine compound to the total number of epoxy groups of the epoxy resins is 0.01:1 to 0.5:1. The mixing of the two components a) and b) results in a wash-off resistant composition. Said wash-off resistant composition results upon heat-curing in a crash-stable structural adhesive.

Owner:DOW GLOBAL TECH LLC

Method for forming bright coating film

InactiveUS20090041943A1Increase brightnessReduce processing stepsPretreated surfacesCoatingsWater basedEpoxy

A method for forming a bright coating film includes: (1) applying a water-based primer coating material composition to a substrate to form a water-based primer coating film; (2) applying a water-based bright coating material (i) to the water-based primer coating film to form a first base coating film; (3) applying a water-based bright coating material (ii) to the first base coating film to form a second base coating film; (4) applying a high-solid clear coating material to the second base coating film to form a clear coating film; and (5) heat-curing the water-based primer coating film, the first base coating film, the second base coating film, and the clear coating film simultaneously to form a cured coating film, wherein the water-based primer coating material composition includes a water-based non-chlorinated polyolefin resin (A), a water-based polyurethane resin (B), a water-based epoxy resin (C), and an internally crosslinked acrylic particle emulsion (D), and an emulsifier.

Owner:HONDA MOTOR CO LTD +1

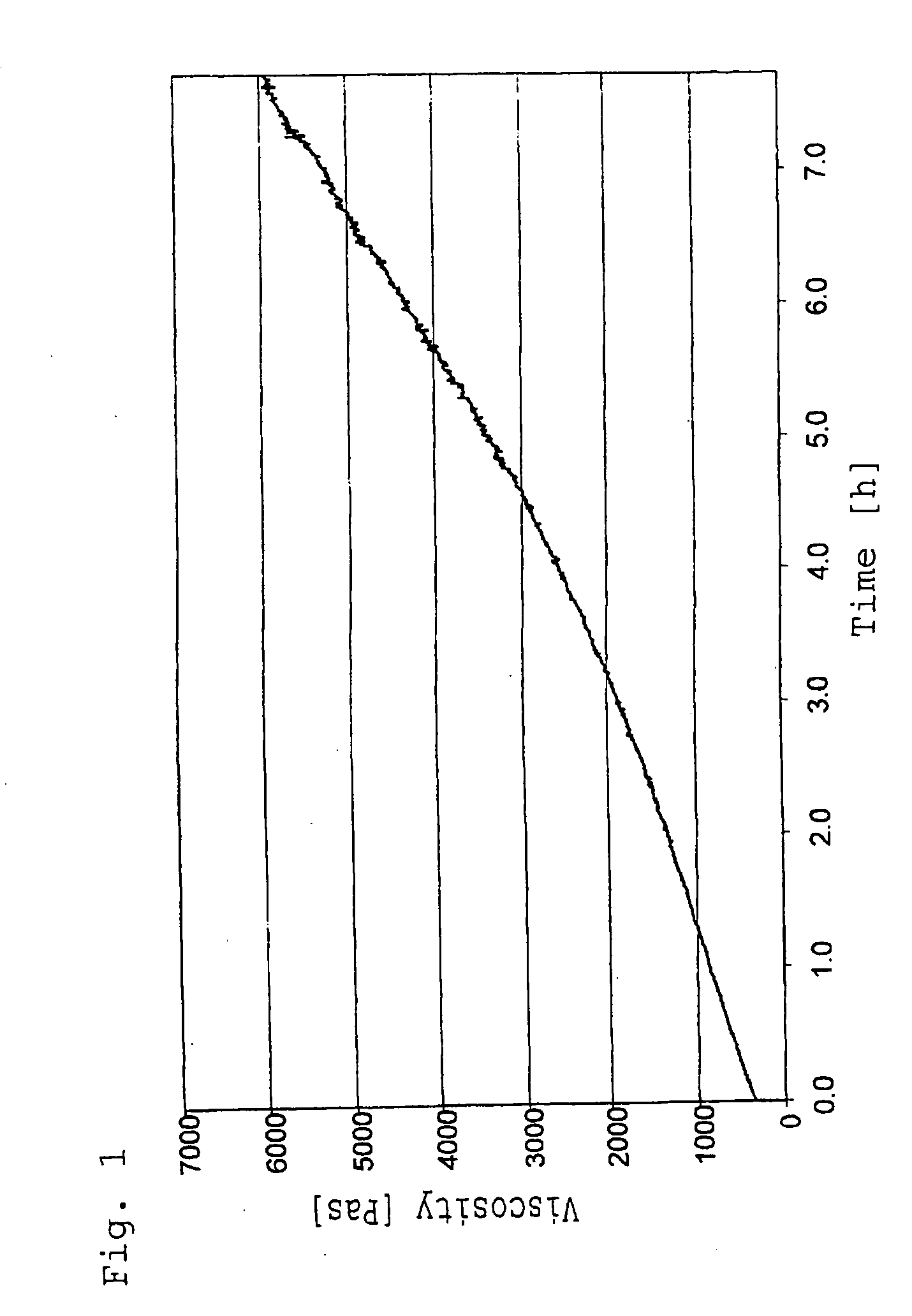

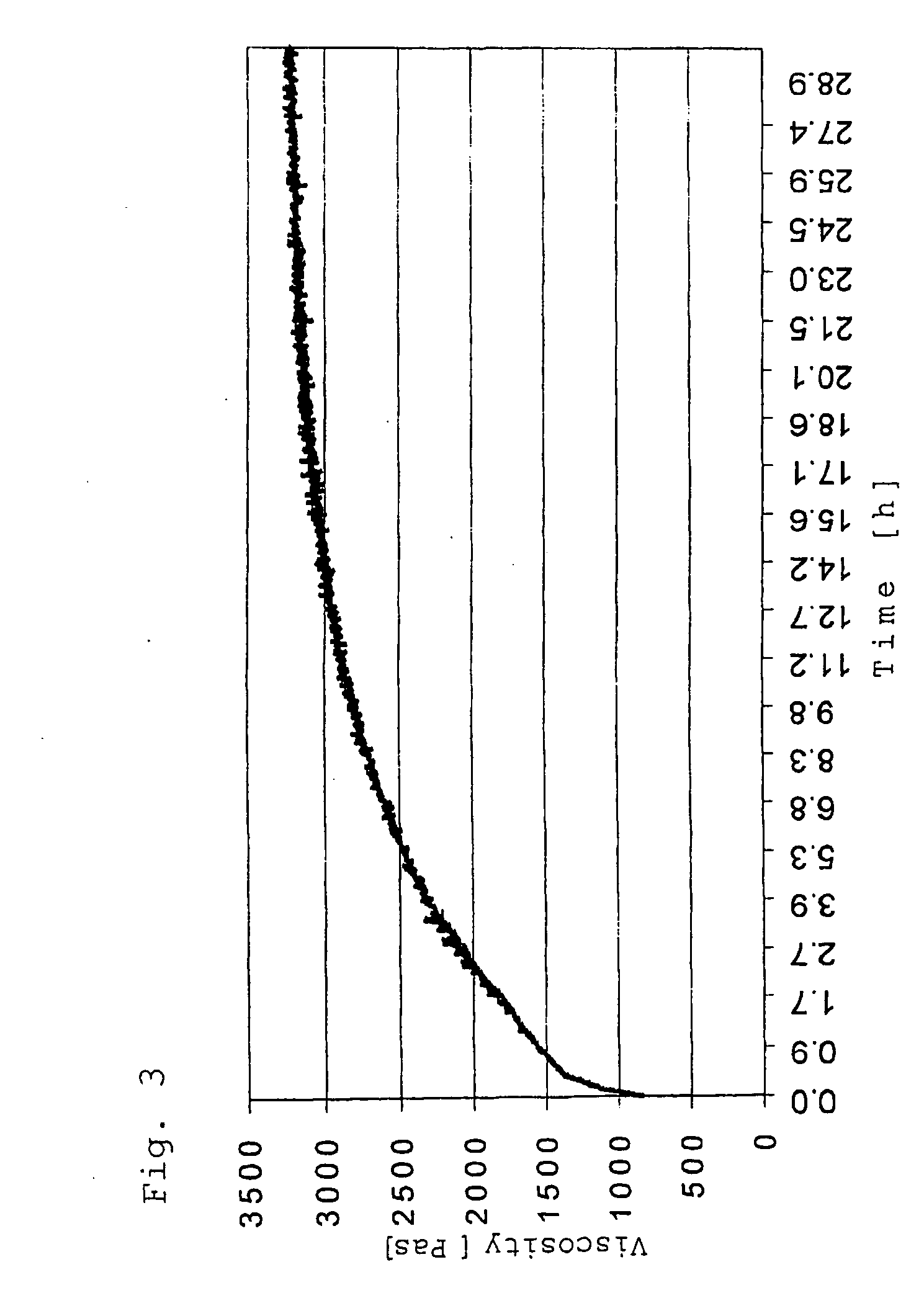

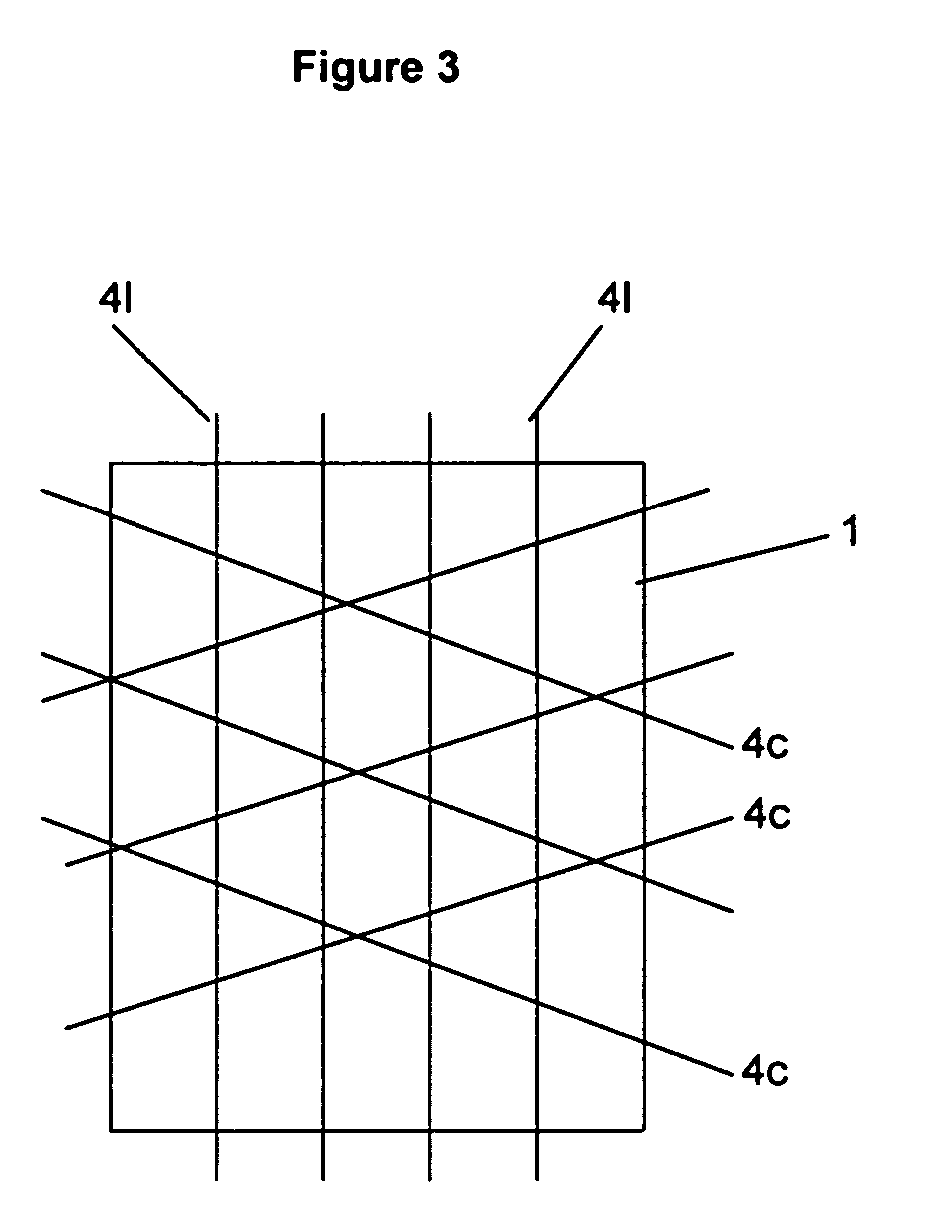

Prepregs for use in building lay-ups of composite materials and processes for their preparation

InactiveUS20050255766A1Reduction in laminate void levelImprove mechanical propertiesSynthetic resin layered productsLaminationPorosityViscosity

The invention concerns a process for making a scrim-reinforced prepreg for use in building low-porosity lay-ups, characterized in that a conventional prepreg is formed of a fibrous reinforcement and a heat-curable resin, the prepreg having suitable viscosity and sufficient tackiness to hold a scrim which is adhered to the prepreg by applying light pressure, so that the scrim is impressed onto the prepreg to such a degree, that less than half of the circumference of the scrim strands becomes coated by the prepreg-resin.

Owner:HEXCEL HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com