Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174 results about "Nepheline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nepheline, also called nephelite (from Greek: νεφέλη, "cloud"), is a feldspathoid: a silica-undersaturated aluminosilicate, Na₃KAl₄Si₄O₁₆, that occurs in intrusive and volcanic rocks with low silica, and in their associated pegmatites.

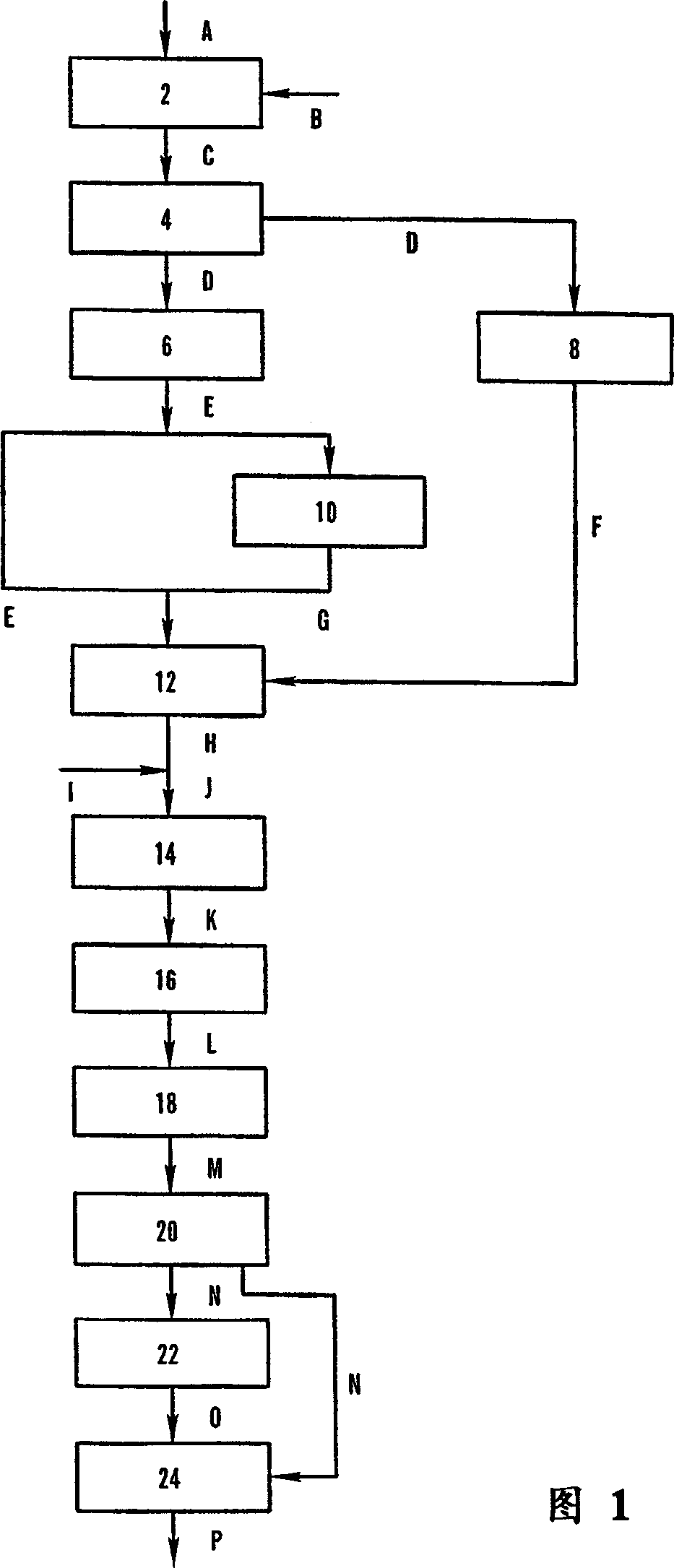

Method for comprehensive utilization of aluminum-containing material

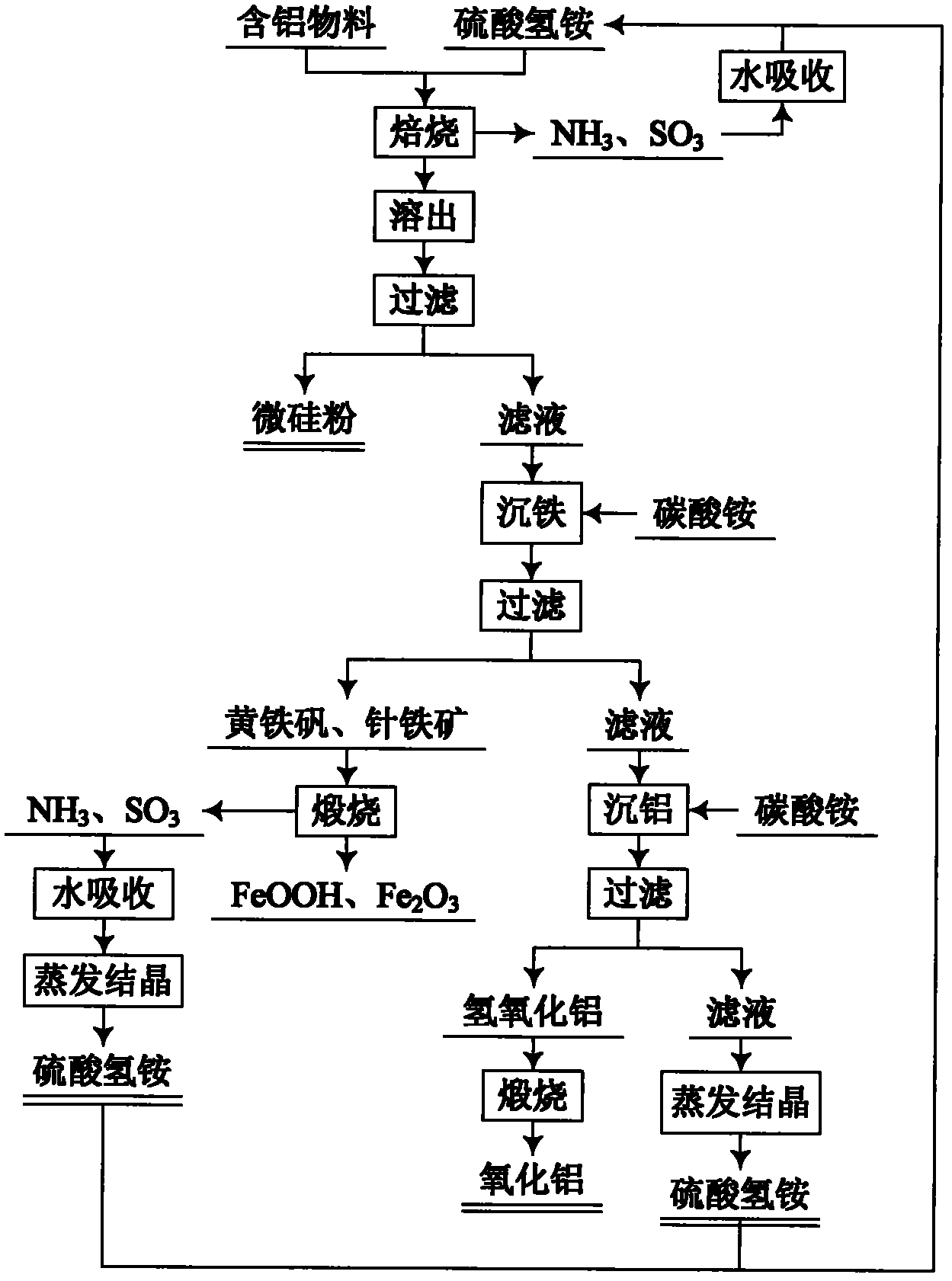

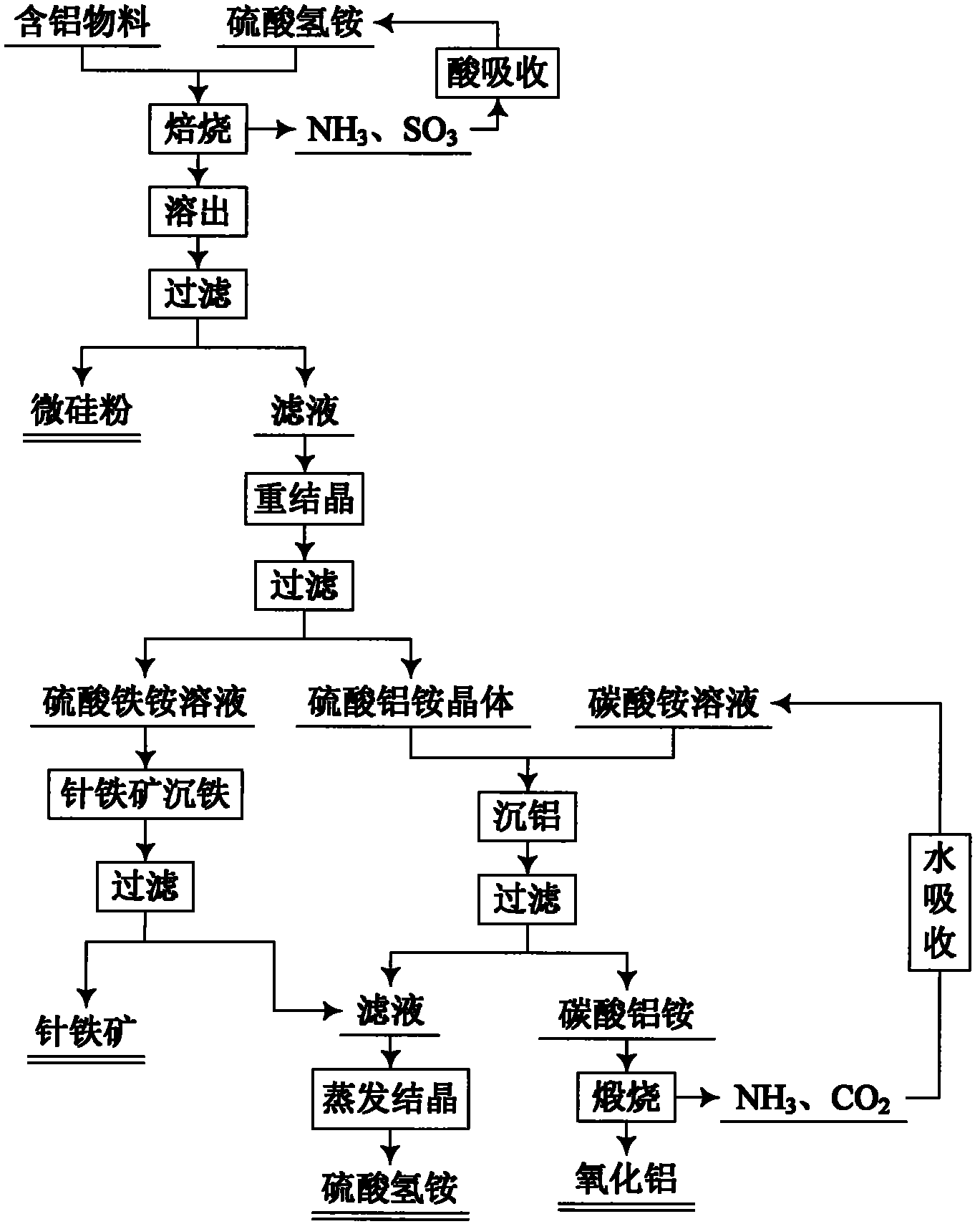

The invention relates to a method for preparing aluminum oxide and other products by aluminum-containing materials of bauxite, alunite, nepheline, fly ash, kaolin, coal gangue and clay. The method comprises the following steps: (1) crushing and grinding an aluminum-containing material, carrying out mixing and baking for the treated aluminum-containing material and ammonium bisulfate; (2) carryingout dissolution and filtering for the baked clinker to obtain a crude ammonium aluminum sulfate solution and aluminum extracting residue; (3) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration more than 1 g / L by adopting a jarosite method, then carrying out an iron precipitating treatment by a goethite method, carrying out an aluminum precipitating treatment for the resulting solution, carrying out calcination for the resulting aluminium hydroxide to prepare aluminum oxide; (4) carrying out an iron precipitating treatment for the ammonium aluminum sulfate solution with the concentration less than 1 g / L by adopting the goethite method, and carrying out an aluminum precipitating treatment to prepare aluminum oxide, or adopting a recrystallization method to carry out purification, adopting a reaction of the ammonium aluminum sulfate crystal and a ammonium carbonate solution to precipitate the aluminum to obtain ammonium aluminumcarbonate, carrying out calcination for the ammonium aluminum carbonate, and adopting a Bayer method to treat the calcined ammonium aluminum carbonate to prepare sandy aluminum oxide; (5) washing anddrying the aluminum extracting residue, wherein the dried aluminum extracting residue is adopted as the silicon dioxide product.

Owner:NORTHEASTERN UNIV

Wet water high anti-skid ink-jet ceramic tile with sunken glaze effect and preparation method of tile

The invention provides a wet water high anti-skid ink-jet ceramic tile with a sunken glaze effect and a preparation method of the tile. The preparation method includes sequentially applying anti-skidsurface glaze, decorative patterns, bright effect glaze and anti-skid protective glaze on a blank body, and then firing, wherein the mineral composition of the composition of the anti-skid surface glaze comprises 40-50% of potassium feldspar, 0-10% of albite, 7-10% of kaolin, 8-12% of quartz, 8-11% of calcined alumina, 0-5% of nepheline, 2-4% of zinc oxide, 7-10% of zirconium silicate and 6-10% ofbarium carbonate; and the mineral composition of the composition of the anti-skid protective glaze comprises 48-58% of potassium feldspar, 0-10% of albite, 10-20% of kaolin, 0-5% of quartz, 0-4% of nepheline, 2-5% of calcined alumina, 10-15% of barium carbonate and 5-8% of zinc oxide. The anti-skid ceramic tile can be used as a decorative material with a good decorative effect, excellent pollution resistance and anti-skid performance, and can be applied to the field of home decoration.

Owner:MONALISA GRP CO LTD

Copper-red transmutation glaze, copper-red transmutation glaze ceramic product prepared from same and preparation method

The invention relates to a copper-red transmutation glaze, a copper-red transmutation glaze ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramics. The copper-red transmutation glaze comprises components in parts by weight as follows: a glaze type basic material including 34-35 parts of nepheline syenite, 20-22 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of zinc oxide, 1-2 parts of magnesium carbonate, 26-27 parts of kaolin and 9.5-10.5 parts of nano silicon oxide, and a chromogenic reagent including 1.8-2.5 parts of lithium carbonate, 2-4 parts of bone ash and 2-4 parts of copper carbonate. The ceramic product prepared from the copper-red transmutation glaze through firing has brighter red color, the glaze color is uniformly distributed, and the yield is high.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

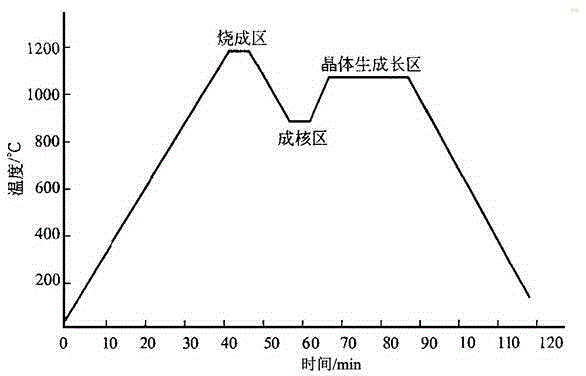

Black micro-crystalline glass plate made of gold ore tailings and manufacturing method thereof

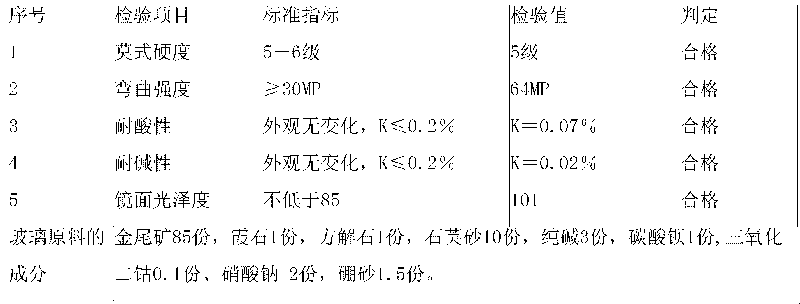

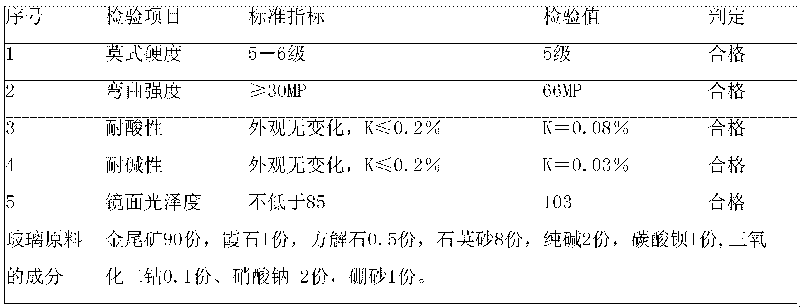

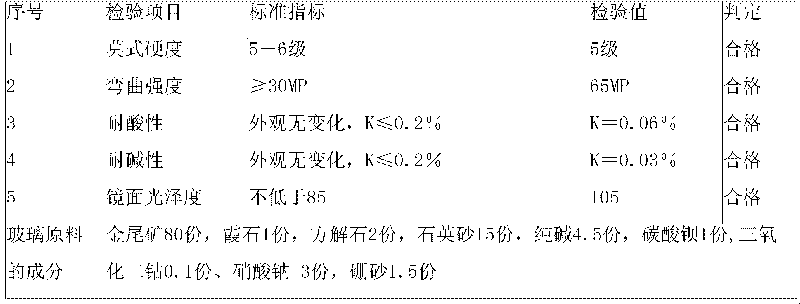

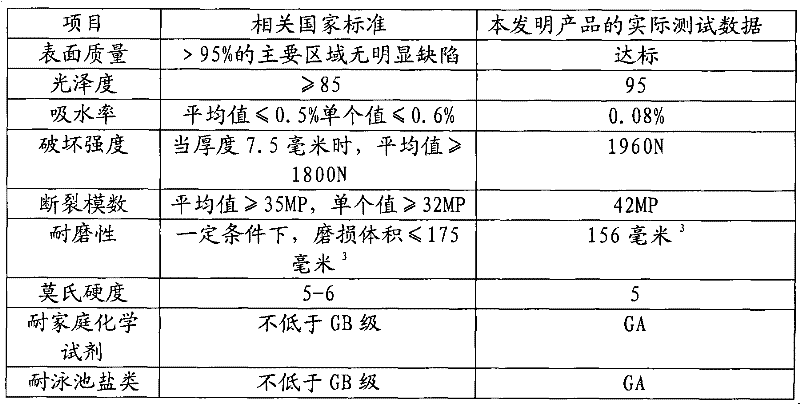

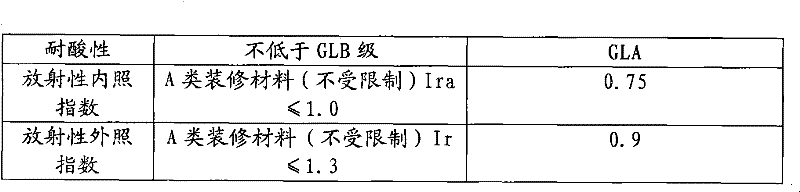

The invention discloses a black micro-crystalline glass plate made of gold ore tailings, which is prepared from the following raw materials in part by mass: gold ore tailings 60-90, quartz sand 8-20, calcite 0.5-2, nepheline 1-2, sodium carbonate 2-5, borax 1-2, barium carbonate 1-8, sodium nitrate 2-6 and cobalt oxide 0.1-0.5. A manufacturing method comprises: crushing and screening the gold ore tailings, the quartz sand, the calcite and the nepheline; removing cyanides from the gold ore tailings by an iron exchange method; weighing the raw materials in proportion and preparing a mixed material; melting the mixed material at 1,250 to 1,350 DEG C to form vitreous humour; allowing molten vitreous humour directly to flow into water to be quenched by water into glass grains; flatly spreading the glass grains in a refractory mould for crystallization; and grinding and cutting an obtained black crystalline glass sample. Compared with the traditional black crystalline glass, the product has more higher quality, and has the advantages of high Mohs' hardness, high bending strength, high chemical stability and pure color.

Owner:君达环保科技(宝鸡)有限公司

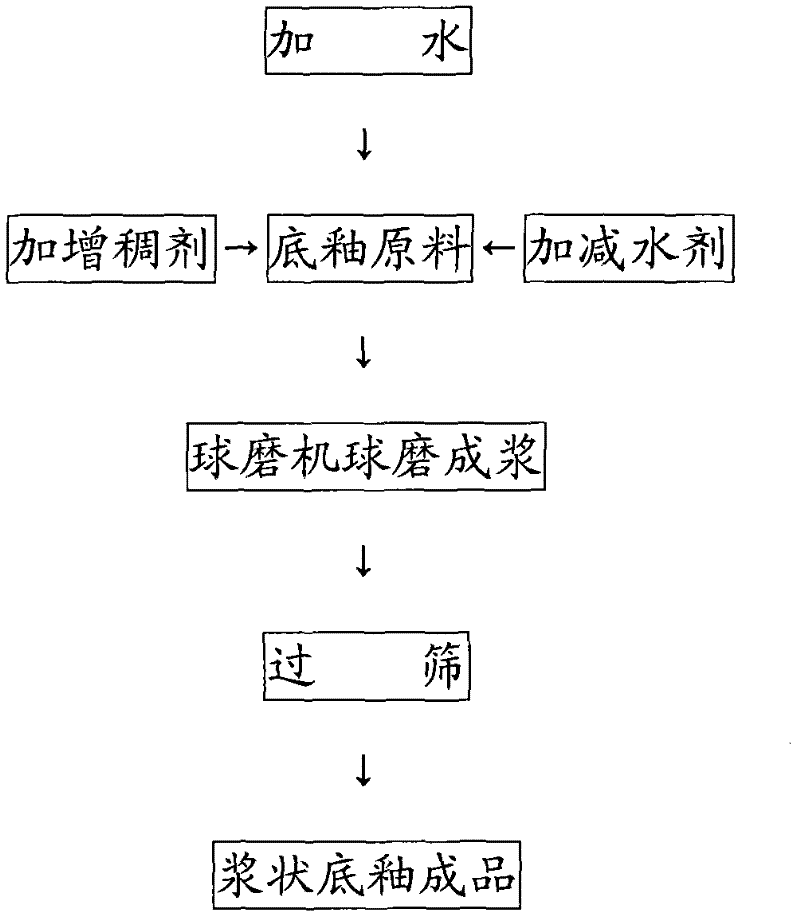

Method for producing base coat being matched with blank and having excellent glazing effect

The invention provides a method for producing a base coat being matched with a blank and having an excellent glazing effect and relates to the technical field of building materials. Materials are selected within a preset component scope of the base coat and the technology is standardized. The method comprises the following steps: mixing roasted kaolin, quartz, potash feldspar, soda feldspar, calcite, steatite, dolomite, zinc oxide, zircon powder and nepheline, which are less than 100 meshes and are 2-30kg, thereby obtaining the raw materials of the base coat; adding thickening agents, water reducing agents and a right amount of water into the raw materials of the base coat, wherein the thickening agents and the water reducing agents are both 0.3-0.5% of the raw materials of the base coat; and putting into a ball mill, thereby milling into a slurry base coat end product, wherein the end product comprises the following chemical components: 40-60% of SiO2, 15-25% of Al2O3, 5-15% of CaO, 0-8% of MgO, 2-10% of K2O+Na2O, 0-8% of ZnO, 3-12% of ZrO3, 0-2% of thickening agents and water reducing agents, and the fineness is 0.4-0.5% of ten-thousand hole screening. The method is used for producing the base coat. The base coat is matched with the blank and is excellent in glazing effect.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

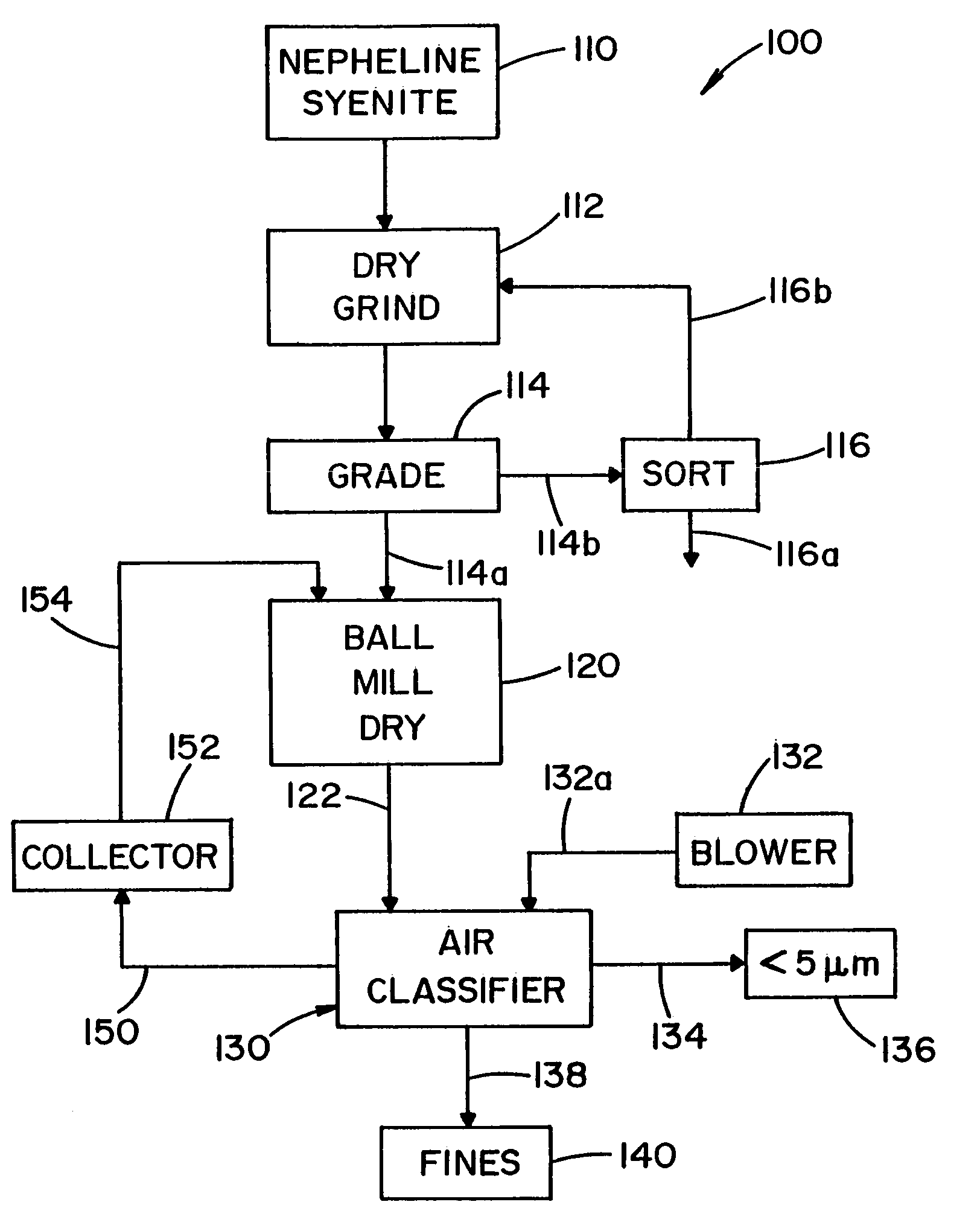

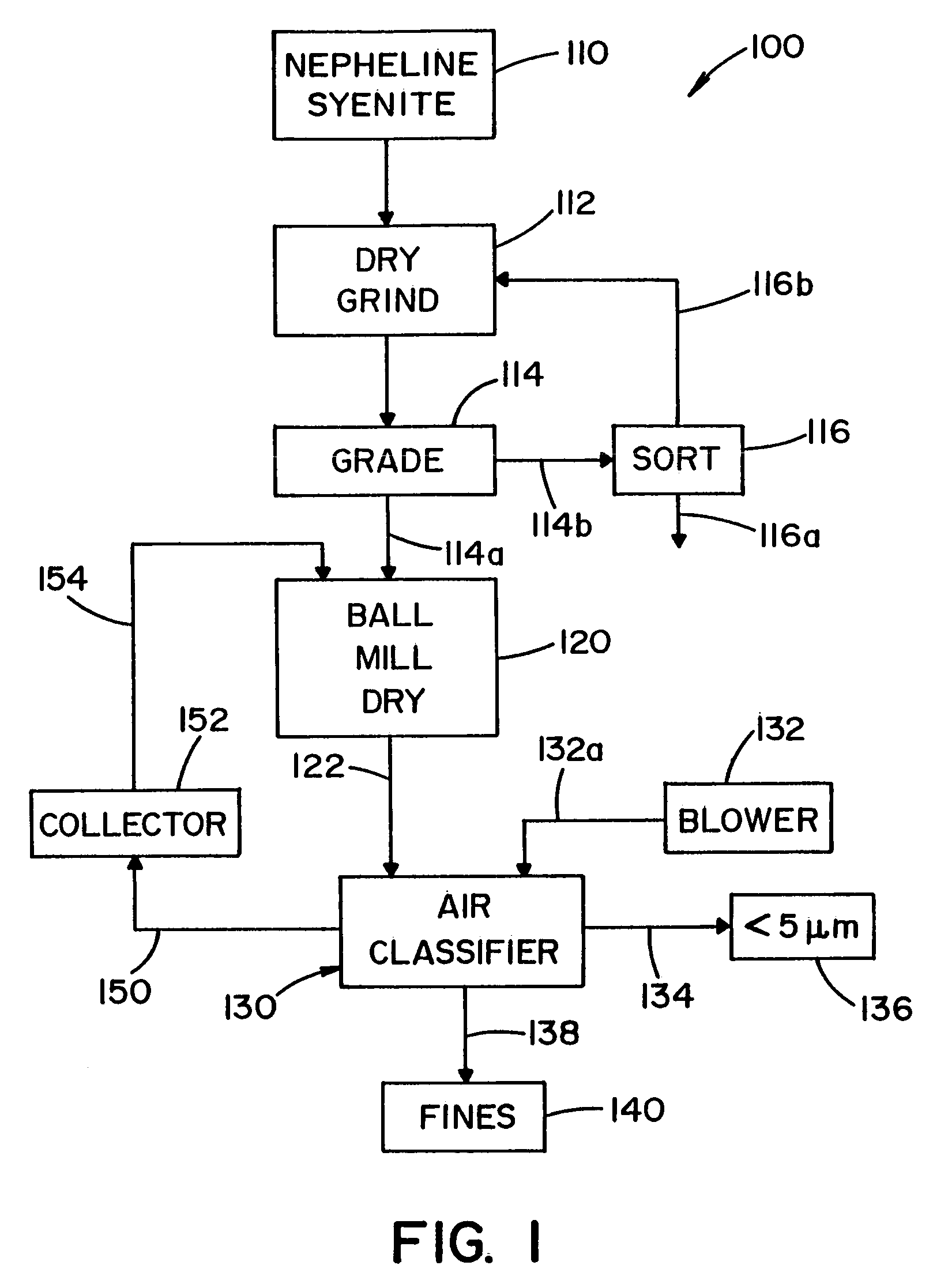

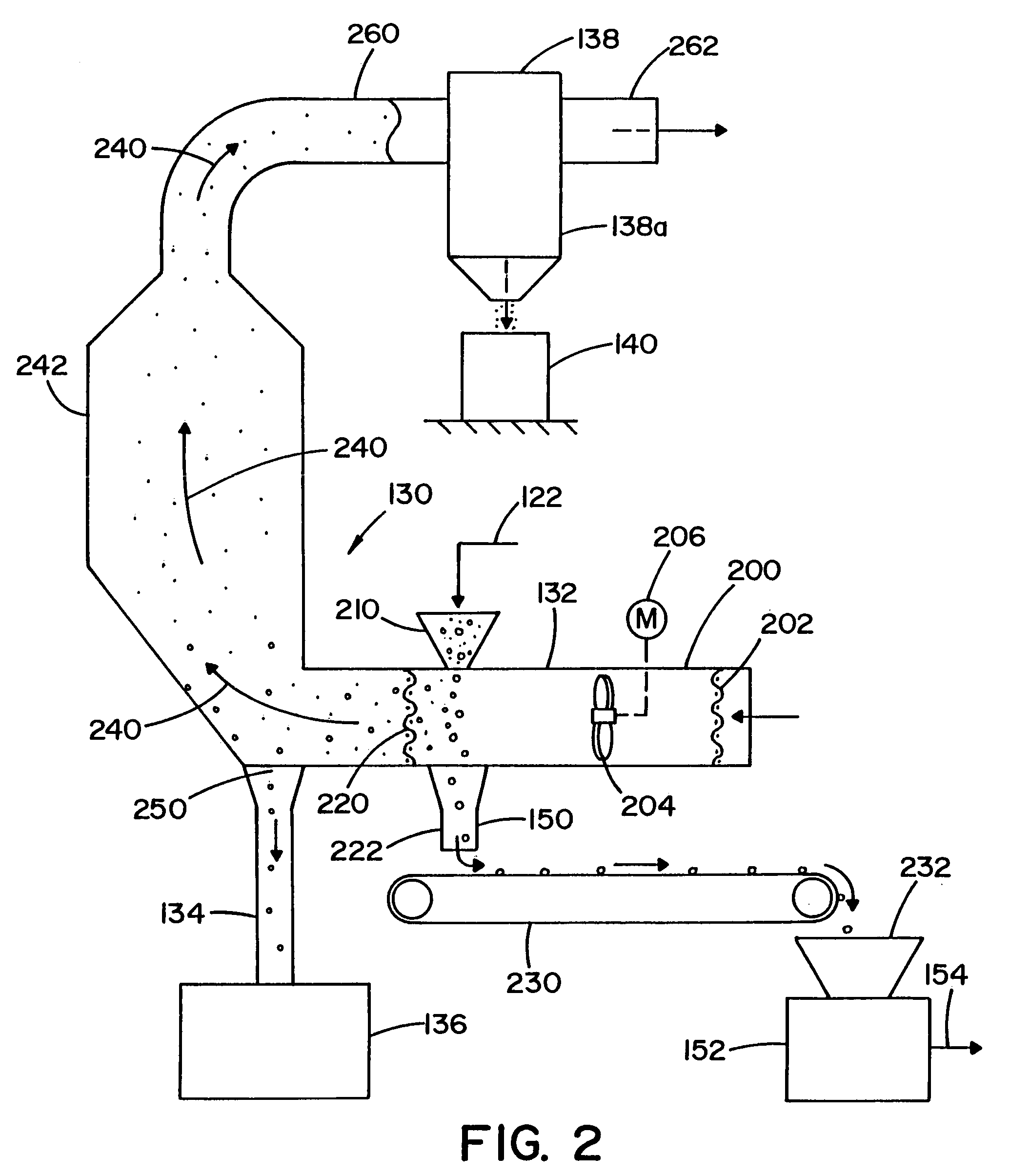

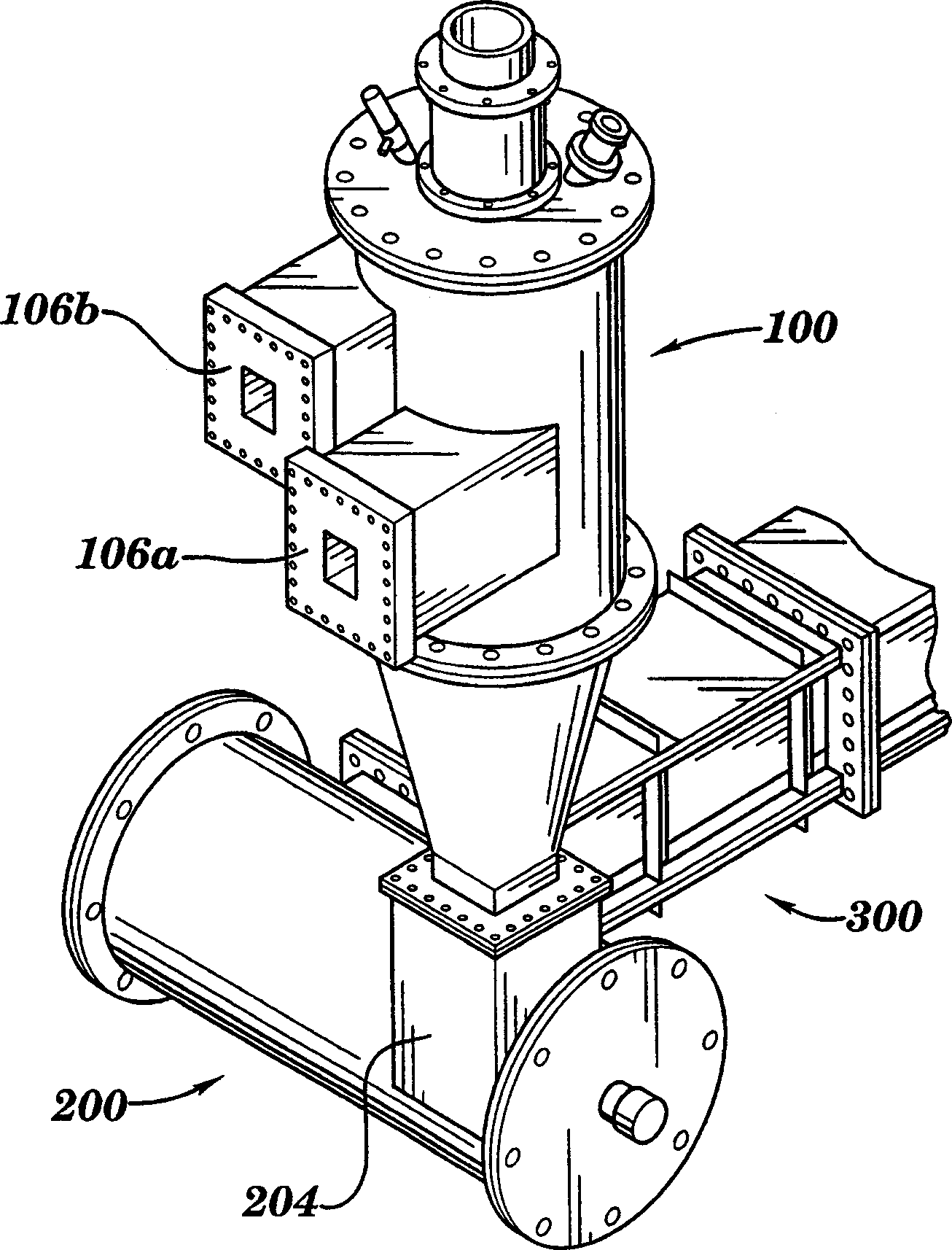

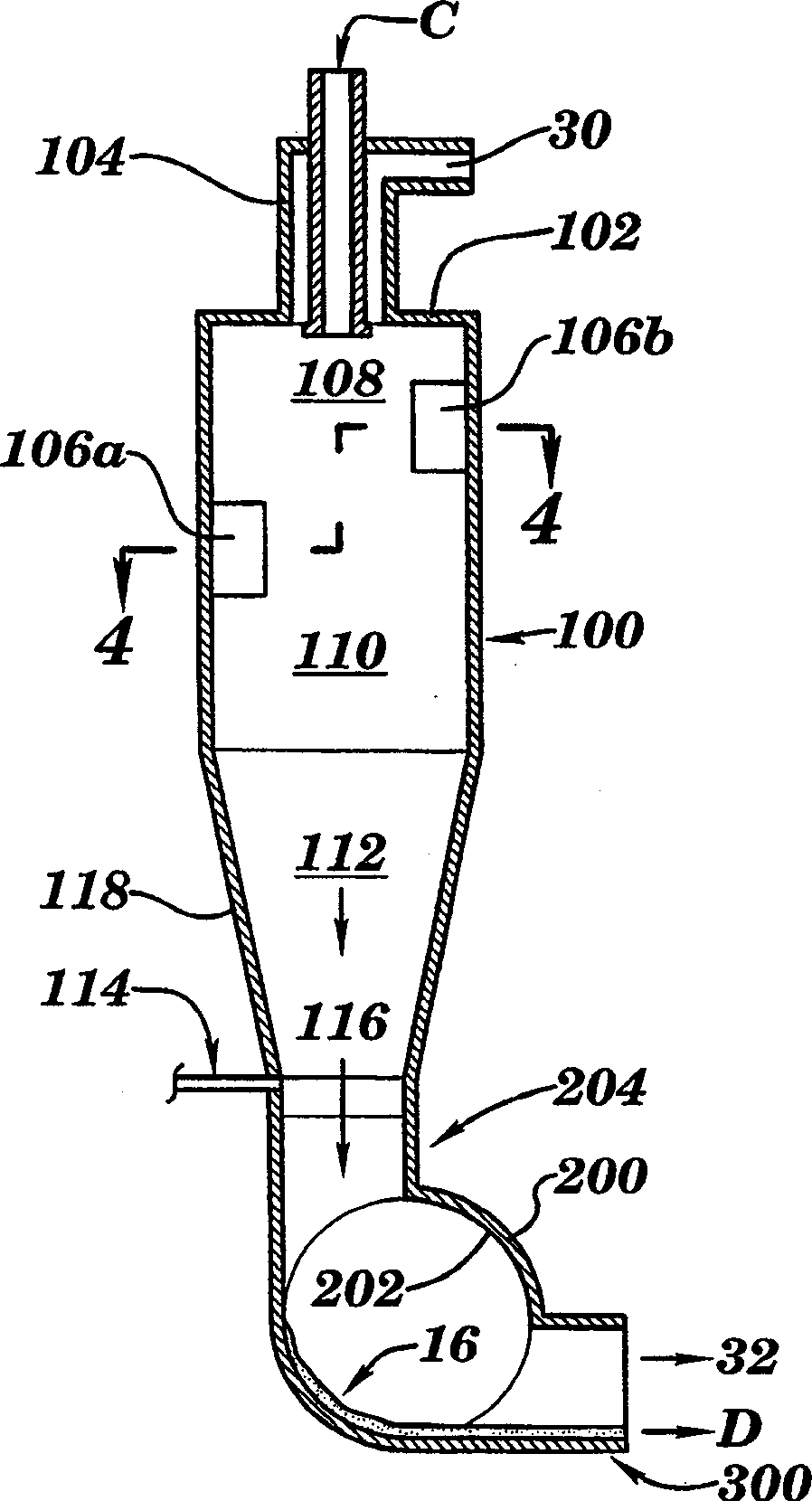

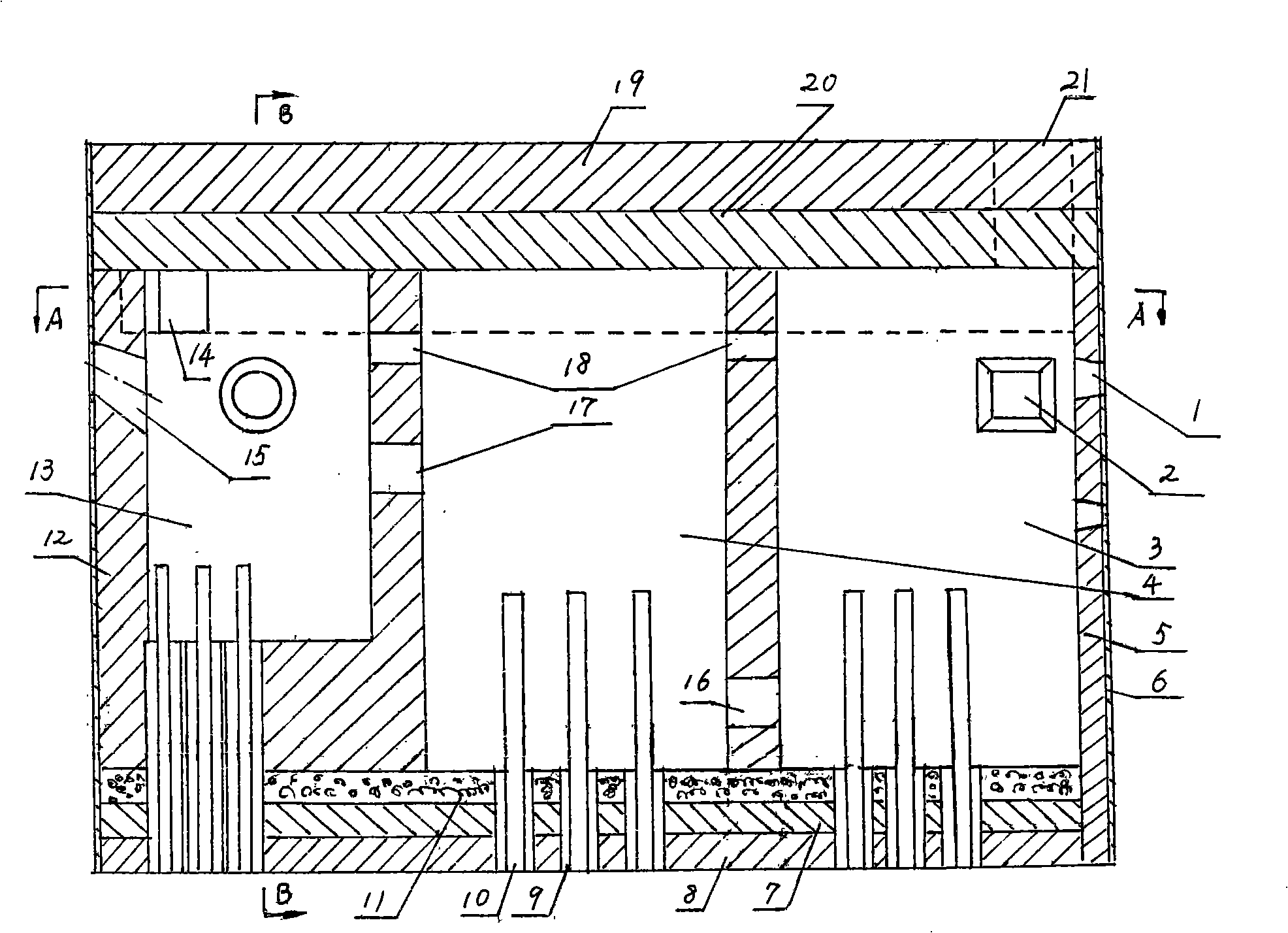

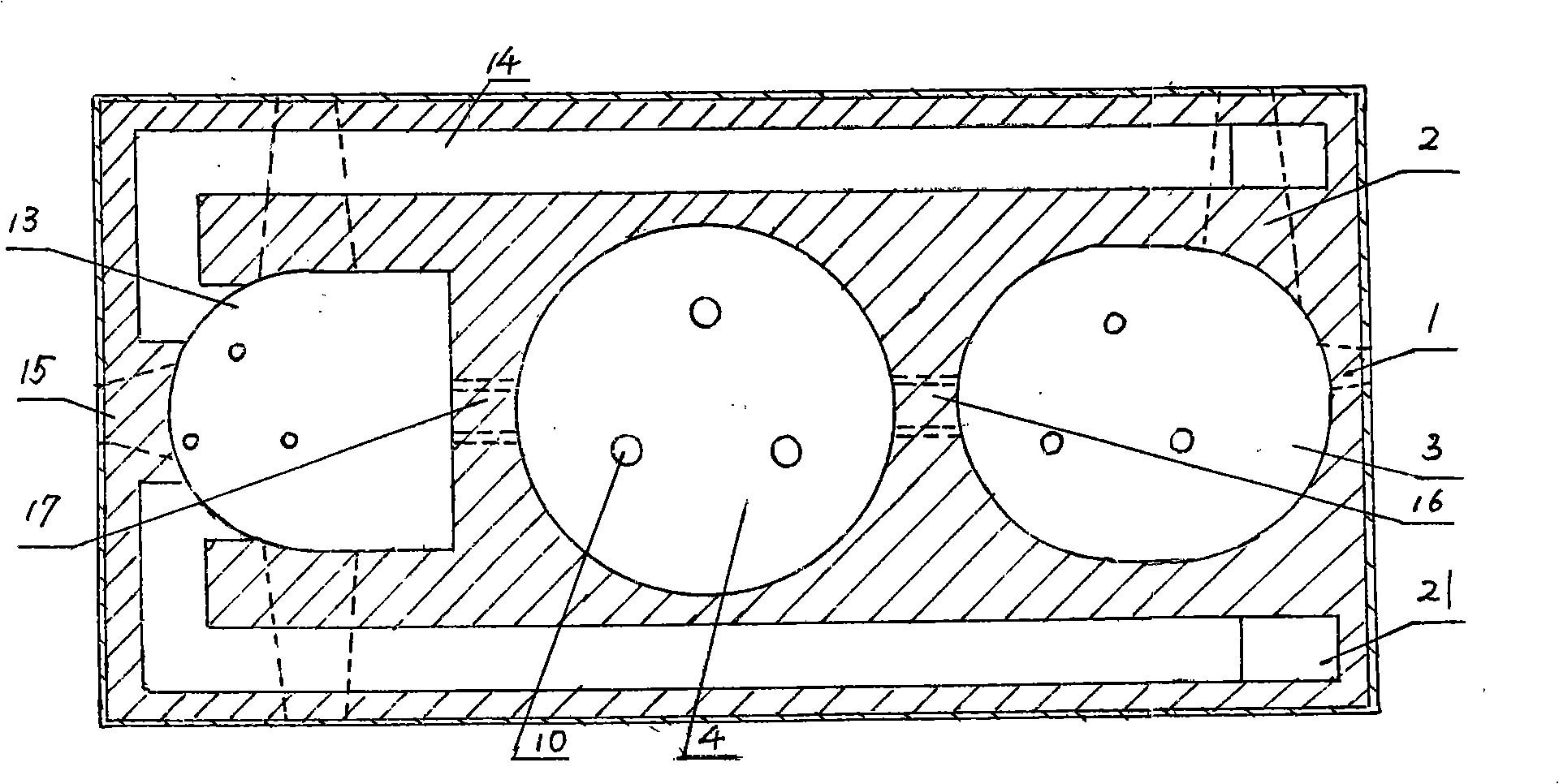

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

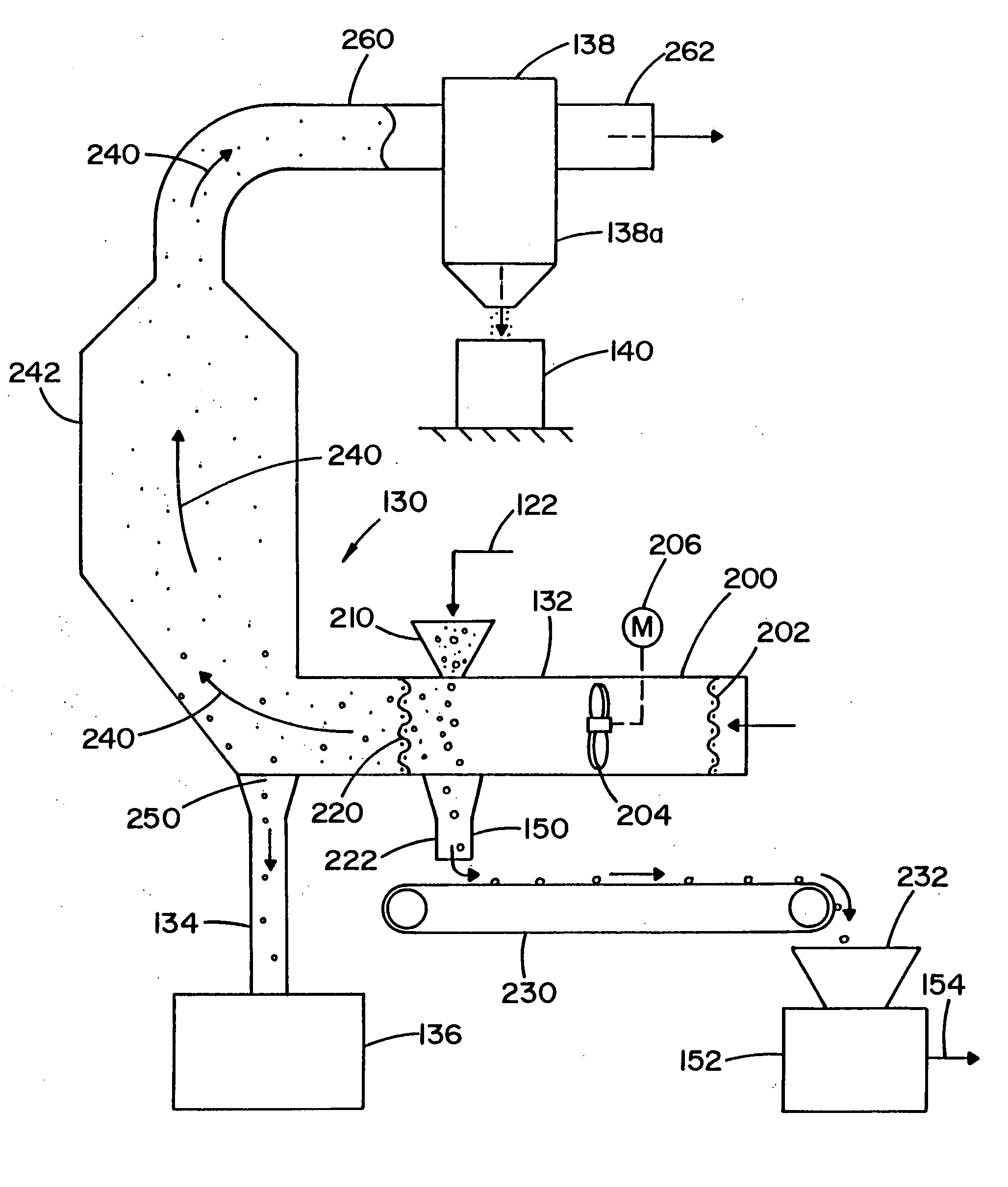

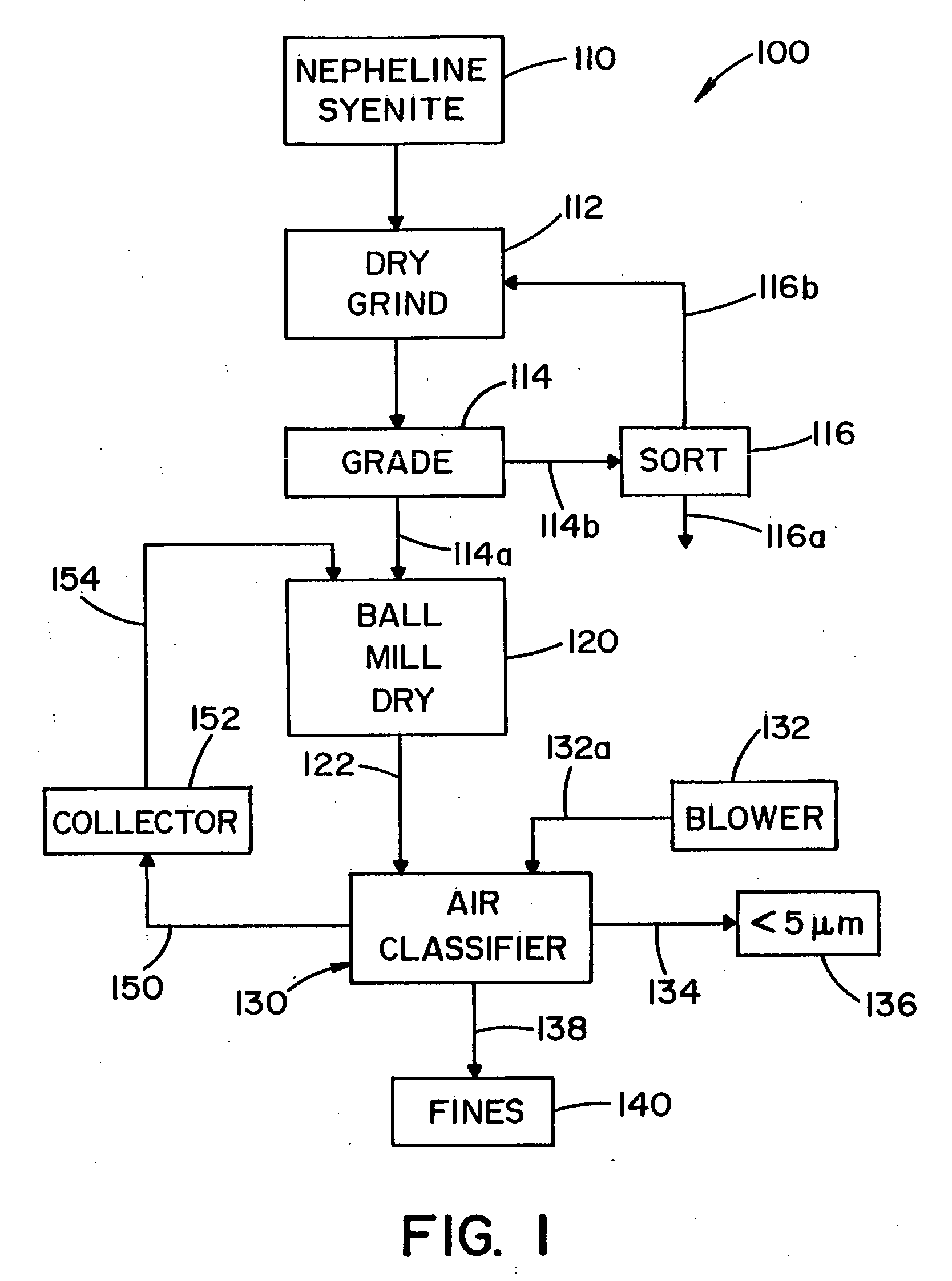

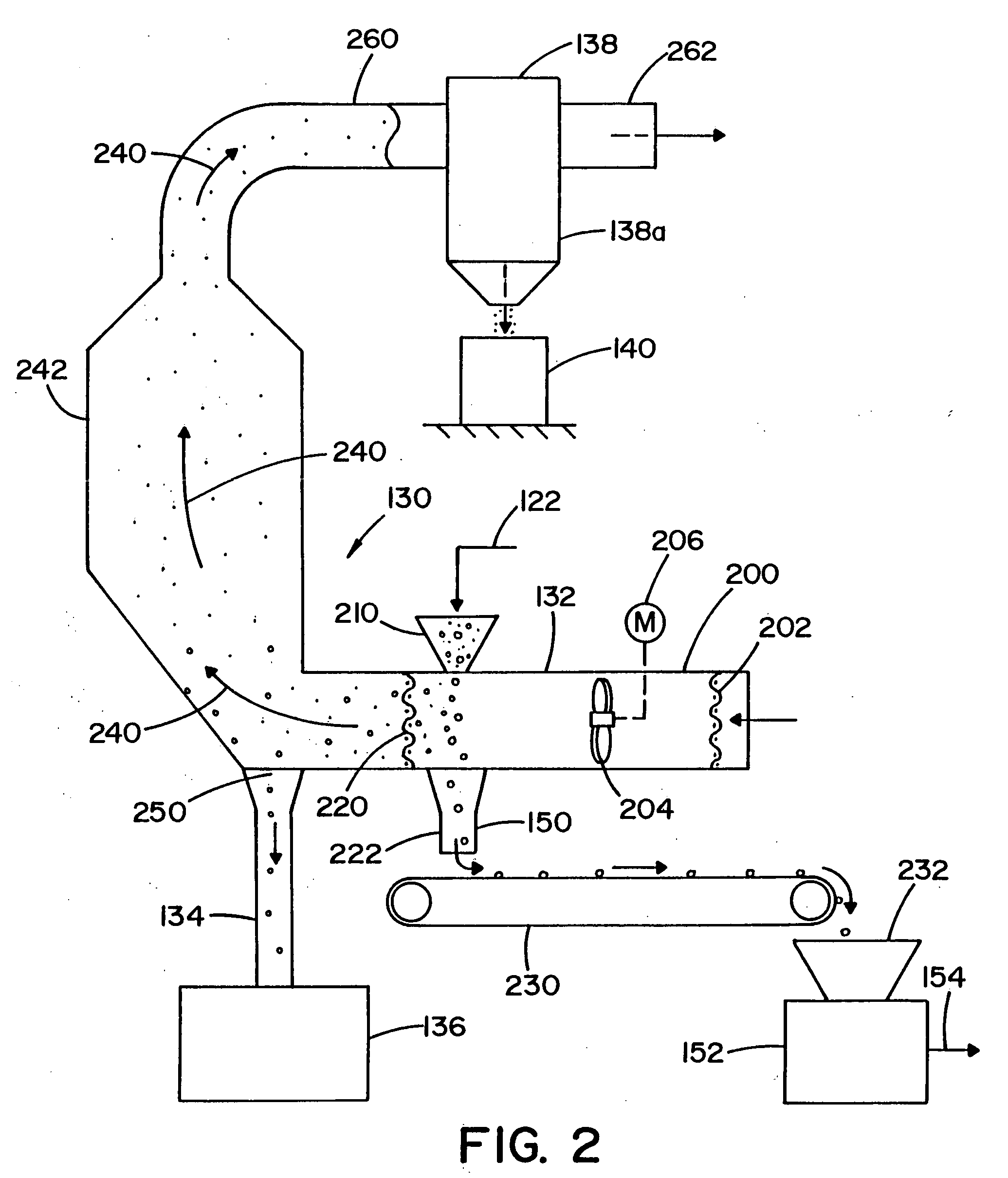

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

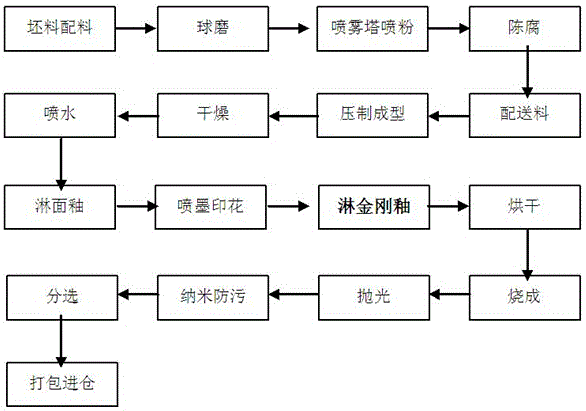

Wear-resistant antifouling glazed brick glaze and preparation method thereof

The invention discloses a wear-resistant antifouling glazed brick glaze and a preparation method thereof. The wear-resistant antifouling glazed brick glaze comprises raw glaze powder, No.1 frit powderand No.2 frit powder, wherein the raw glaze powder comprises the following raw materials in percentage by weight: 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 1-5% of wollastonite, 8-15% of nepheline, 5-10% of zinc oxide, 0-5% of calcite and 6-12% of strontium carbonate, wherein the No.1 frit powder is prepared from kaolin, calcined talc and fluorite, and the No.2 frit powder is prepared from zinc oxide, strontium carbonate and borax. The wear-resistant antifouling glazed brick glaze contains a large number of cordierite microcrystals, and the cordierite microcrystals have the characteristics of transparency, high hardness and the like, so that the wear resistance and the antiskid effect of a glaze layer can be enhanced, and thecontradiction between the transparency and the wear resistance of the glaze layer can be solved.

Owner:佛山市东鹏陶瓷发展有限公司

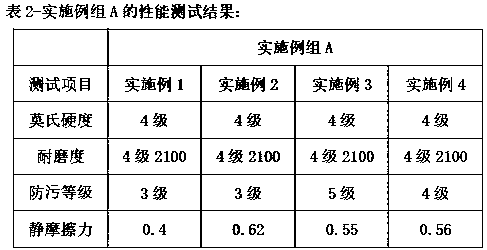

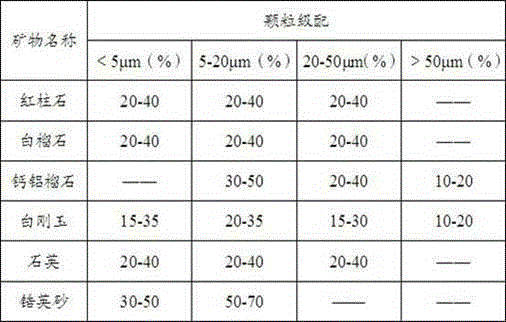

Wear resistant and high-hardness diamond glaze, preparation method and application

The invention discloses a wear resistant and high-hardness diamond glaze, a preparation method and application. The wear resistant and high-hardness diamond glaze is prepared from the following raw materials according to mass percent: 5 to 15% of kaolin, 5 to 10% of andalusite, 5 to 10% of orthoclase, 5 to 12% of leucite, 1 to 3% of essonite, 10 to 18% of nepheline, 5 to 15% of spodumene, 2 to 8% of wollastonite, 3 to 7% of quartz, 5 to 10% of zircon sand, 5 to 10% of white corundum, 1 to 3% of dolomite, 1 to 3% of calcined white talc, 0.1 to 0.5% of zinc oxide and 0.5 to 3% of additive. According to the wear resistant and high-hardness diamond glaze, the preparation method and the application, the selection of mineral raw materials of the glaze is optimized, firstly, the wear resistant and high-hardness mineral raw materials such as the andalusite (the hardness is 6.9 to 7.4), the white corundum (the hardness is 9.0), the leucite (the hardness is 5.5 to 6) and the essonite (the hardness is 7 to 7.5) are selected, the grain fineness and addition of the wear resistant and high-hardness mineral raw materials are controlled through reasonable grain composition, and by adopting the subsequent preparation process and application process, the wear resistance and hardness of the diamond glaze are greatly increased.

Owner:FOSHAN ZHONGCHENG SILICATE TECH CO LTD

Modified tourmaline powder for ceramic glaze, anion ceramic glaze and preparation method

The invention relates to modified tourmaline powder for ceramic glaze, anion ceramic glaze and a preparation method, belonging to the technical field of ceramics. The anion ceramic glaze comprises the following raw materials in parts by mass: 20-30 parts of nepheline syenite, 5-8 parts of kaolin, 6.8-9.5 parts of muscovite, 6.2-7.8 parts of modified tourmaline powder, 3-6 parts of zinc oxide, 8-12 parts of light calcium carbonate, 4.6-5.7 parts of aluminum oxide, 1-4 parts of magnesium oxide, 2.5-4.8 parts of potassium oxide and 0.1-0.3 part of rubidium oxide. According to the invention, through the modification of tourmaline powder, the anion release amount of the tourmaline powder is effectively increased, and the surface polarity of the modified tourmaline is relatively low; and due to the stable dispersing performance of the tourmaline powder, the agglomeration phenomenon is avoided in the preparation of glaze slurry, and the ceramic products get a good anion function.

Owner:FUJIAN WILL CERAMIC CO LTD

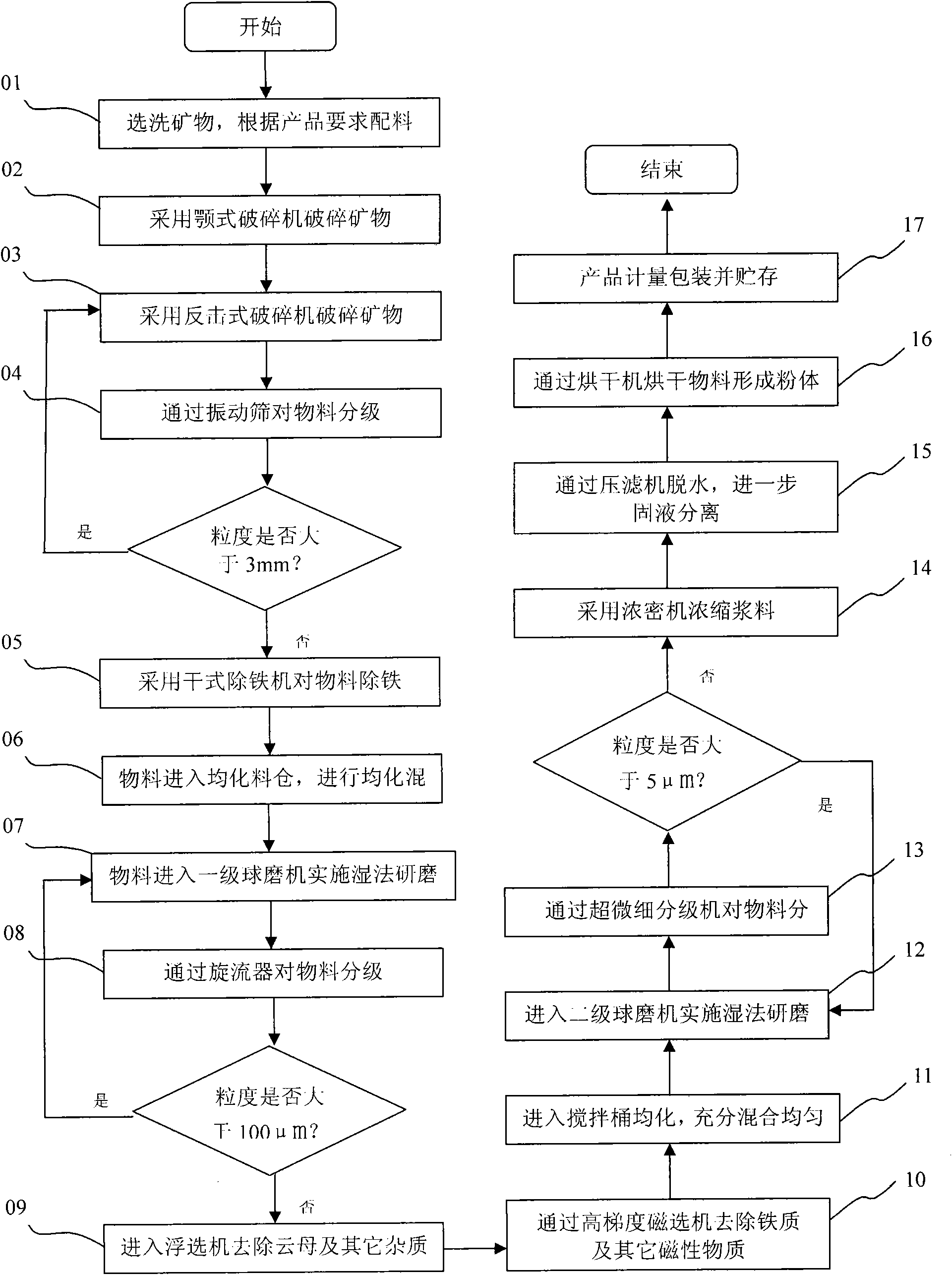

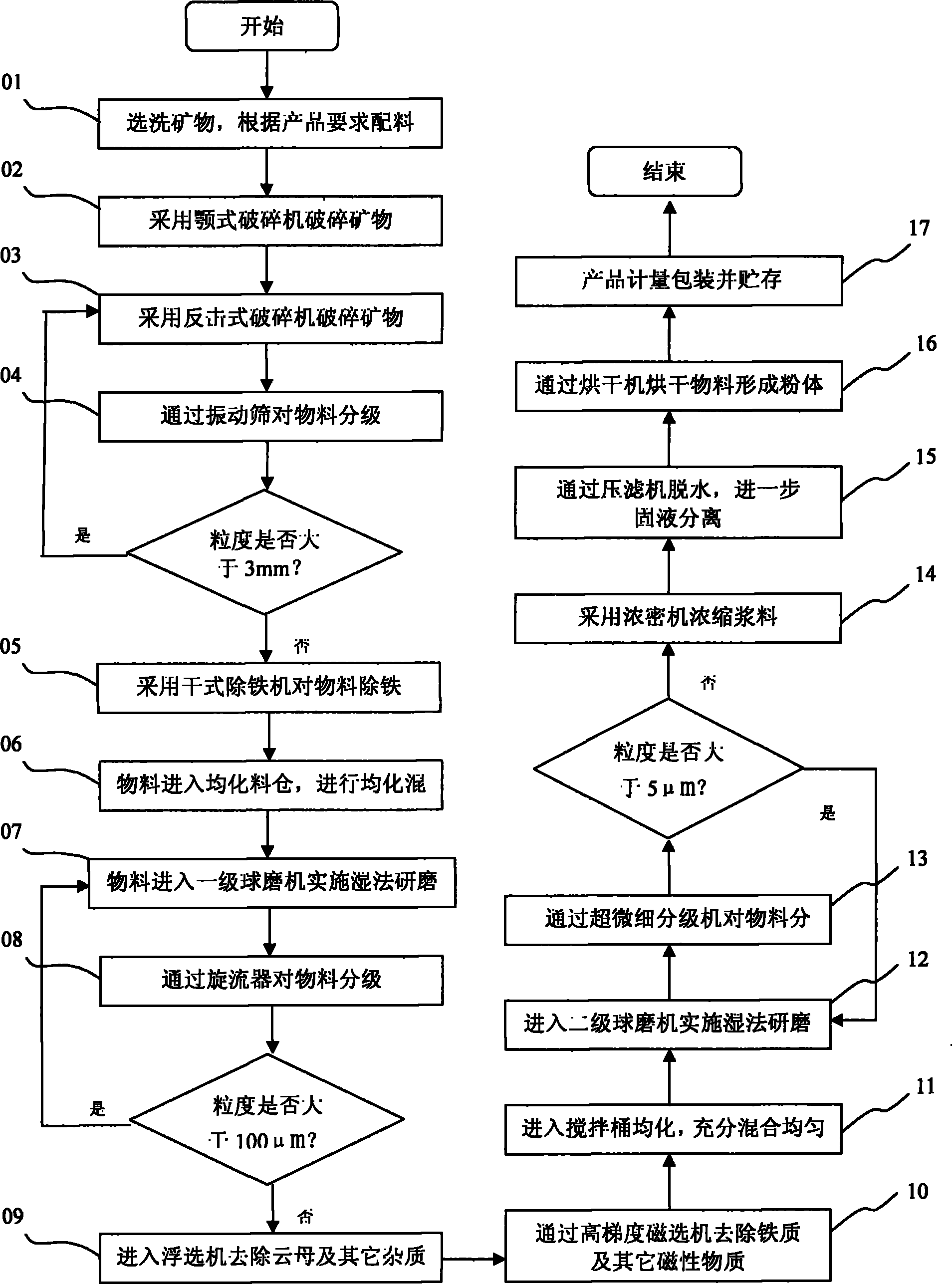

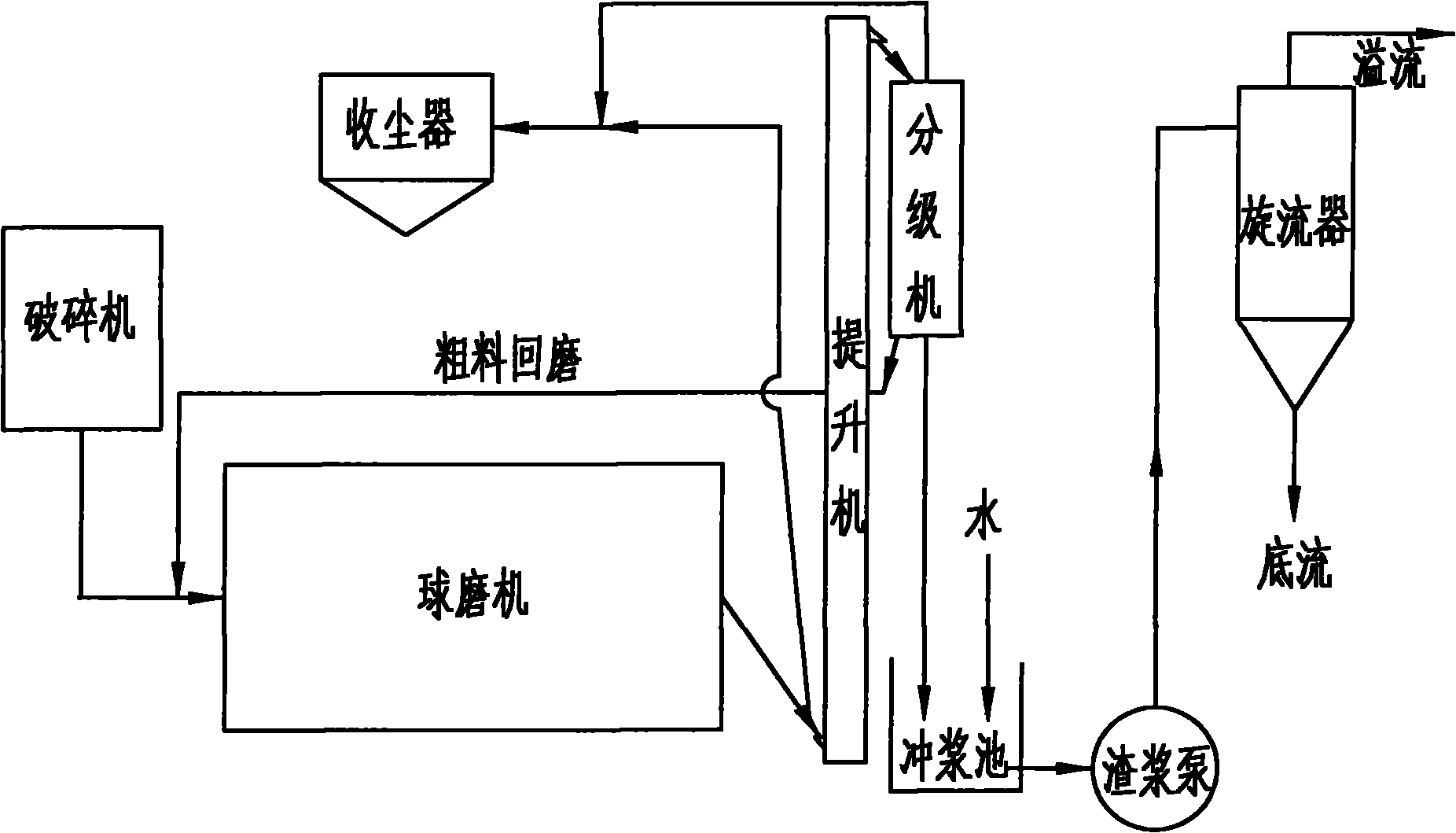

Method for preparing nepheline syenite powder

InactiveCN101912811AMeeting Structural Ceramic RequirementsUniform changeFlotationWet separationClosed loopEngineering

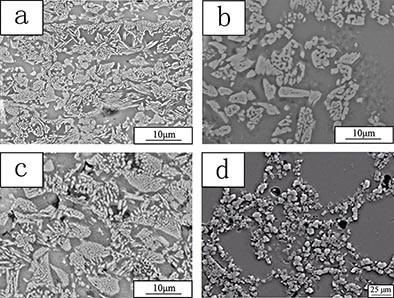

The invention relates to a method for preparing nepheline syenite powder. The method comprises the following steps of: elutriating and washing raw materials; smashing ores; performing graded screening; performing ball milling and fine crushing; removing impurities and filtering; and dewatering and drying, wherein the impurity-removing and filtering step comprises a flotation procedure for removing mica in the nepheline syenite. A two-stage closed-loop wet grinding process, a flotation process and a magnetic separation and impurity removing process are adopted by the method, so that impuritiessuch as the mica and the like can be removed basically and a contradiction between purification and super small product particle size is solved. Material smashing and grinding are performed by using a closed-loop system, so that power consumption is lowered to the maximum extent and the reasonable distribution of the product particle size is ensured simultaneously. A new high-purity nepheline syenite material which hardly contains any mica impurity and is prepared by the method has TiO2 content of lower than 0.01 percent and Fe2O3 content of lower than 0.10 percent and meets the requirements of functional ceramics and structural ceramics.

Owner:广东奥胜新材料有限公司

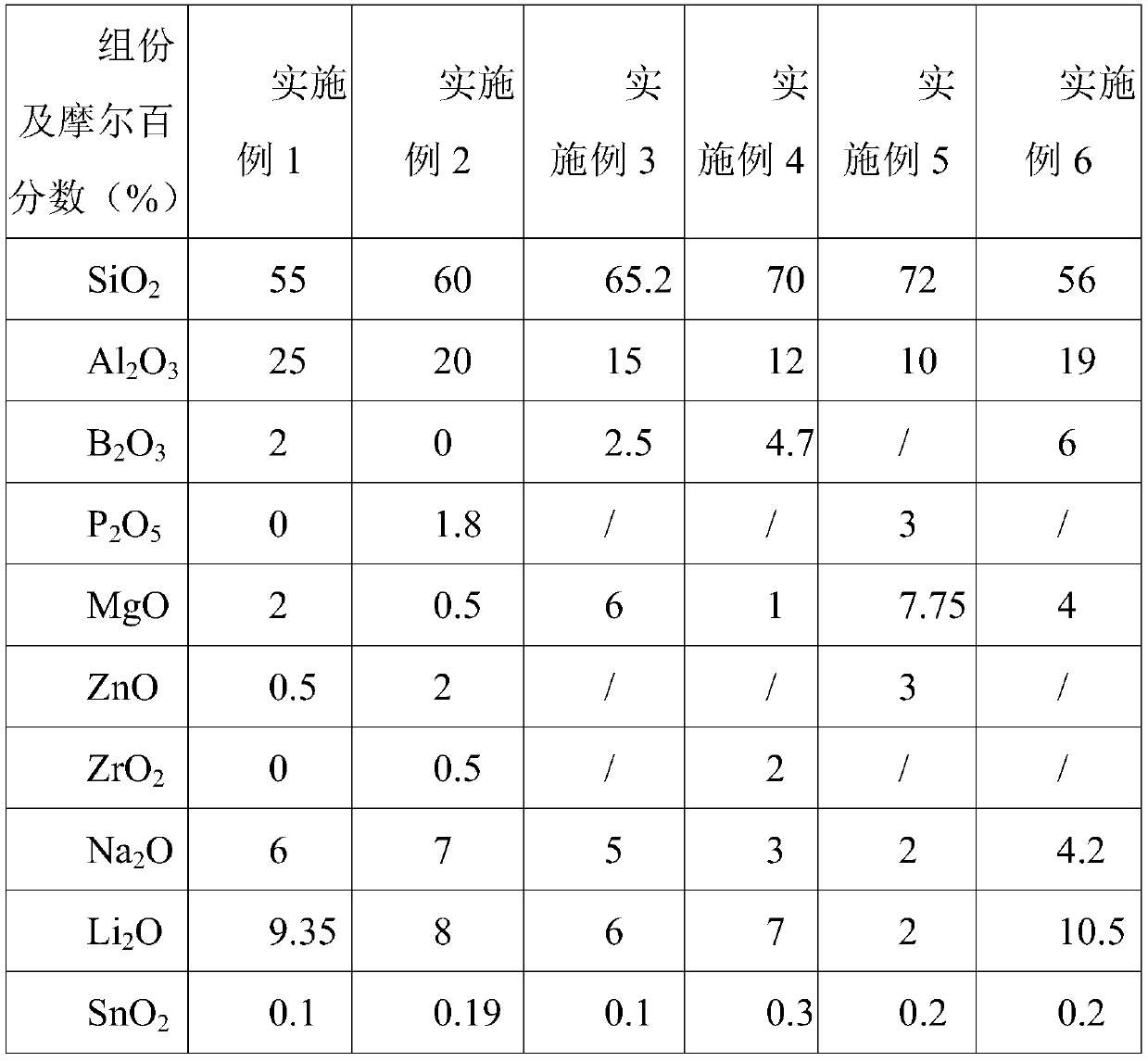

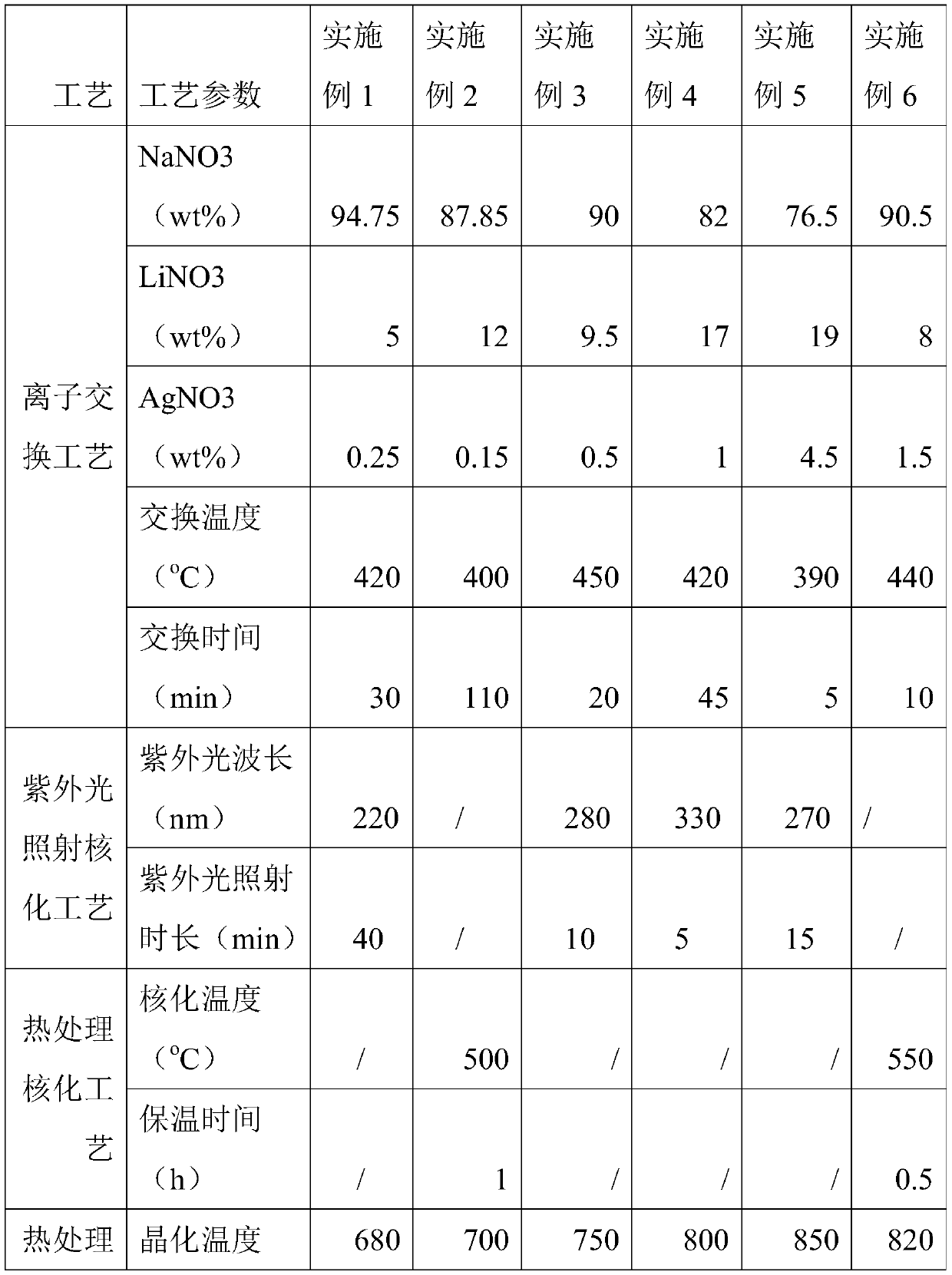

Glass ceramic containing micro nano crystals and preparation method of glass ceramic

The invention discloses glass ceramic containing micro nano crystals and a preparation method of the glass ceramic. The micro nano crystals are formed in a glass substrate by post-processing, the average crystal size of the micro nano crystals is less than or equal to 100 nm, the crystal phase includes at least one selected from a beta-quartz solid solution, nepheline and a nepheline solid solution, the glass ceramic has a Vickers hardness higher than 600 kgf / mm<2>, the post-processing refers to introducing a crystal nucleus element into the glass substrate by ion exchange and promoting growthof the micro nano crystals by the crystal nucleus through external energy, and the glass substrate can form a surface compressive stress depth of more than 80 [mu]m after the ion exchange. The glassceramic provided by the invention has the Vickers hardness improved by 10% or more than that of the glass substrate, and can obtain higher strength by chemical strengthening treatment; the preparationmethod of the glass ceramic can realize continuous production, and the preparation method has high universality; and the glass ceramic has an antibacterial function, an expanded application range andwider applicability.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD +1

Brilliant iron rust glaze, brilliant iron rust glaze ceramic product prepared from same and preparation method

The invention relates to a brilliant iron rust glaze, a brilliant iron rust glaze ceramic product prepared from the same and a preparation method, and belongs to the technical field of ceramics. The brilliant iron rust glaze comprises components in parts by mass as follows: 40-50 parts of nepheline-syenite, 10-20 parts of quartz, 2-8 parts of calcium carbonate, 18-22 parts of low-temperature frits, 2-6 parts of zinc oxide. 8-13 parts of calcium borate, 18-23 parts of manganese oxide and 1-4 parts of copper oxide, wherein the low-temperature frits comprise components in parts by mass as follows: 44-47 parts of borax, 28-32 parts of quartz, 18-22 parts of potash feldspar and 2-7 parts of kaolin. The brilliant iron rust glaze can imitate the iron rust appearance, so that the ceramic product can show the iron rust appearance on the surface and has brilliant silver bright points with three-dimensional sense; besides, with the adoption of the method, control is facilitated in a sintering process, energy saving is facilitated, and the yield of sintered products is higher.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Method of processing nepheline syenite powder to produce an ultra-fine grain size product

The method of converting nepheline syenite particulate feedstock with a grain size profile to an ultra-fine grain finish product for subsequent commercial use, the ultra-fine grain final product has a maximum grain size of less than about 6 microns. The method comprising: providing a dry feedstock with a controlled maximum particle size greater than about 20 microns; grinding the feedstock in a dry state by passing the feedstock vertically downward through a continuous, high-speed stirred ball mill whereby the feedstock is ground into an intermediate powder having a drastically reduced grain size profile than the grain size profile of the feedstock; and passing the intermediate powder from the mill through an air classifier using a rapidly moving high speed air stream moving along a given path to convey the ultra-fine grain product along the path and from the classifier and to allow coarse particulate material including particles larger than the ultra-fine product to be separated and then expelled from the classifier.

Owner:COVIA HLDG CORP

Manufacture of ceramic tiles from industrial waste

The present inveniton relates to a process of forming ceramic tiles having the appearance of tiles produced from clays. The process includes melting a material to form a glass melt, treating the glass melt to produce a solid glass product, grinding the solid glass product to produce glass particles having a particle size of less than 200 microns, mixing the glass particles with a first additive to form a glass power mixture having a composition of 55 to 99 wt.% glass particles and 45-1 wt.% first additive, forming the glass powder mixture into tiles by dry pressing, where the tiles have a primary crystalline phase selected from the group consisting of nepheline, diopside, anorthite, wollastonite, melilite, merwinite, spinel, akermanite, gehlenite, crystalline phases based on iron substitutions in the crystalline phase, and mitures thereof. The process includes a devitrifying step where the solid glass product is devitrified prior tothe grinding step or the glass particles in the tile are devitrified after the forming step.

Owner:沃特克有限公司 +1

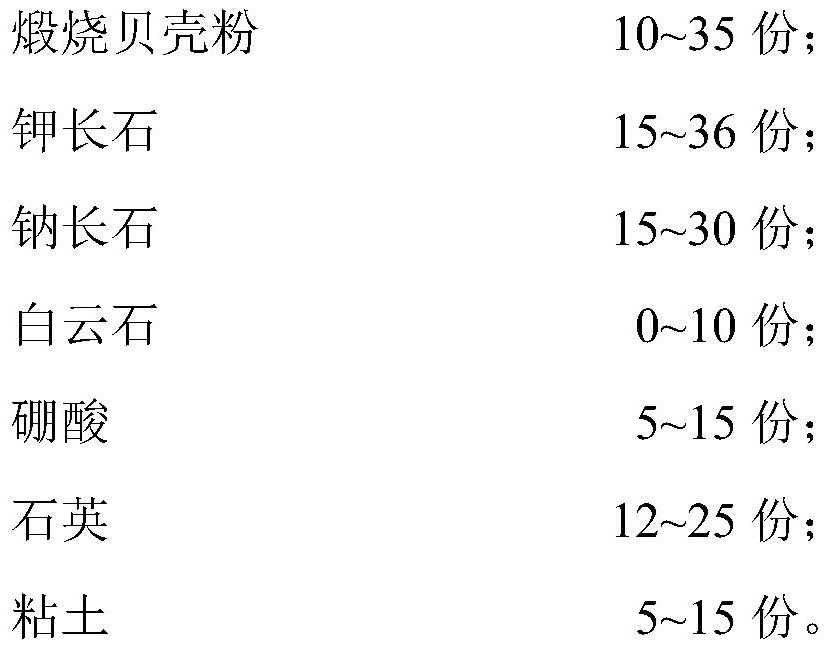

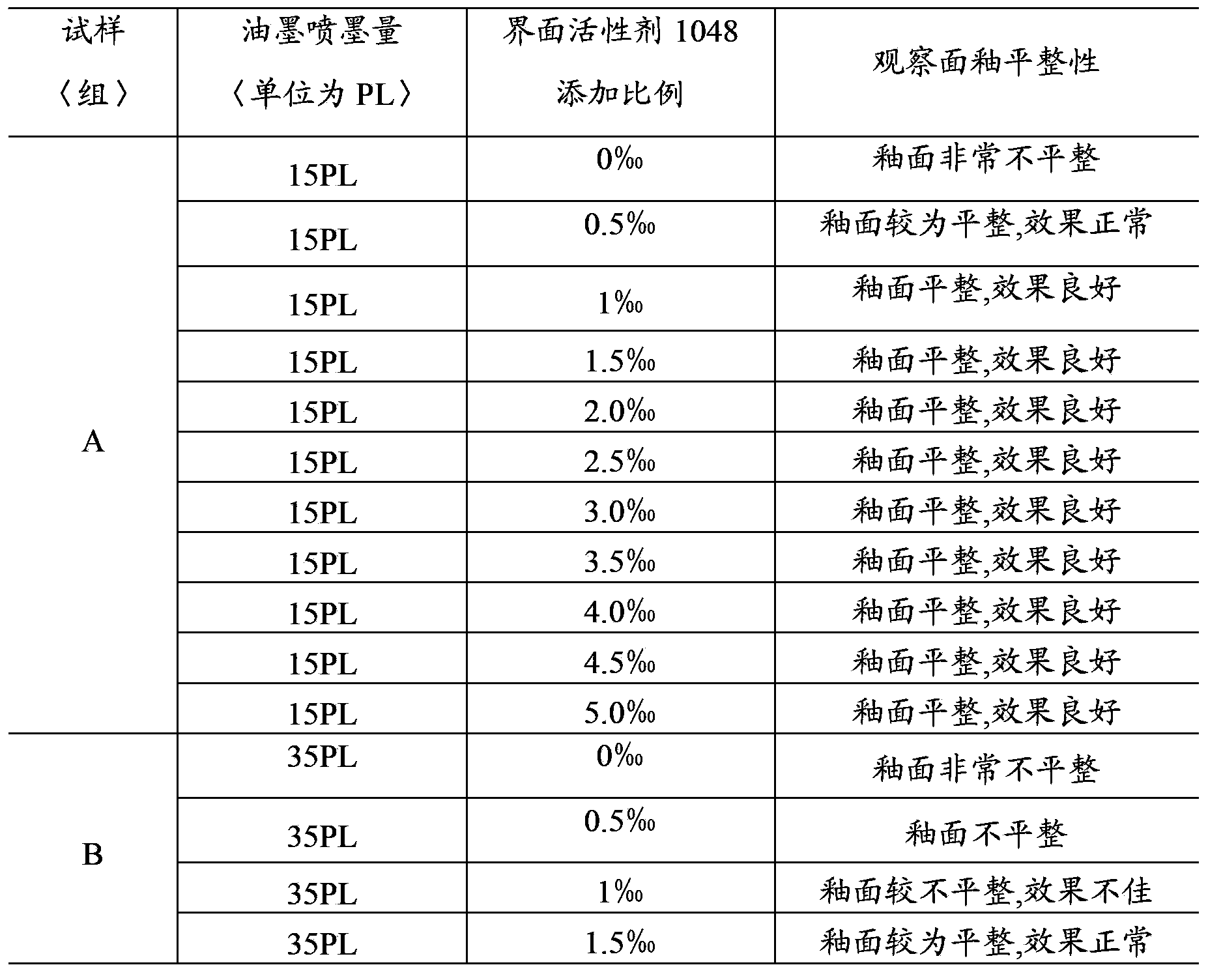

Silk- and satin-texture ceramic glaze, preparation method and ceramic rock plate using silk- and satin-texture ceramic glaze

ActiveCN111943723AExcellent overall performance of the glazeReduce manufacturing costFritPotassium feldspar

The invention discloses a silk- and satin-texture ceramic glaze which comprises the following components in parts by weight: 10-35 parts of calcined shell powder, 15-36 parts of potassium feldspar, 15-30 parts of albite, 0-10 parts of dolomite, 5-15 parts of boric acid, 12-25 parts of quartz and 5-15 parts of clay. According to the ceramic glaze disclosed by the invention, CaO is introduced by taking the calcined shell powder containing a large amount of nepheline crystal forms as a raw material, so that the ceramic glaze has the decorative effects of silk-like luster and texture and the advantage of excellent comprehensive performance of a glaze surface after sintering molding on the premise that a frit glaze raw material with a narrow sintering range is not required to be added; meanwhile, the production cost is low, the firing range is wide, and the glaze is particularly suitable for surface decoration of ceramic rock plates. The invention further discloses a ceramic rock plate withthe silk and satin texture on the surface, and the problems that an existing ceramic rock plate product is poor in surface decoration effect, and an existing ceramic brick with the silk glaze effectis narrow in firing range and high in production cost are solved.

Owner:FOSHAN OCEANO CERAMICS

Wear-resistant glaze for glazed bricks, and preparation method thereof

The invention discloses a wear-resistant glaze for glazed bricks, and a preparation method thereof. The wear-resistant glaze is prepared from raw glaze powder, No.1 frit powder and No.2 frit powder, wherein the raw glaze powder comprises, by weight, 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 8-15% of nepheline, 5-10% of zinc oxide, 3-6% of barium sulfate and 6-12% of strontium carbonate. The raw materials of the No.1 frit powder comprise zircon sand and barium sulfate, and raw materials of the No.2 frit powder comprise kaolin, calcined talc, fluorite and barium sulfate. The glaze disclosed by the invention contains barium sulfate, so that the color development condition can be improved, the problem of color difference of red and yellow ceramic ink-jet inks during firing of a product is avoided, and the transparency of the wear-resistant glaze is improved under the condition that the hardness and the wear resistance are notinfluenced.

Owner:佛山市东鹏陶瓷发展有限公司 +1

Novel printing glaze material and production method thereof

The invention provides a novel printing glaze material and a production method thereof. The novel printing glaze material consistent with standards is produced by putting the following components into a ball mill for grinding, wherein the components are as follows in percentage by weight: 32% to 42% of albite, 8% to 12% of nepheline orthoclase, 3% to 5% of wollastonite, 3% to 5% of kaolin, 1.5% to 2.5% of ball clay, 3% to 5% of quartz, 3% to 5% of aluminium oxide, 5% to 8% of corundum, 7% to 9% of calcium carbonate, 4% to 7% of zinc oxide, 1% to 2% of talc, 3% to 5% of dolomite, 1% to 2% of barium carbonate, 4% to 8% of clinker, and 6% to 15% of zirconium silicate. The produced novel printing glaze material has the advantages that color development of the ink is better, a problem of color system variation does not exist, the definition of ink figures and the flatness of glaze surfaces can be guaranteed, and a defect of printing ink gloss variation is overcome through controlling a molten softening point.

Owner:CARLOBBIA GLAZE KUNSHAN

Green transmutation sagging ceramic product and manufacturing process thereof

The invention discloses a green transmutation sagging ceramic product and a manufacturing process thereof, and belongs to the field of ceramic manufacturing processes. A formula of a ceramic is prepared from the following materials in parts by weight: 70-85 parts of nepheline, 8-12 parts of dolomite, 6-10 parts of kaolin, 9-13 parts of quartz, 5-10 parts of mica, 1-5 parts of bentonite, 13-16 parts of titanium dioxide, 3-7 parts of zinc oxide, 12-18 parts of calcium oxide, 2-6 parts of copper oxide and 2-5 parts of waste ceramic material. The manufacturing process comprises the following steps: material treatment, material allocation, green body firing, ground glaze preparation, overglaze preparation, ground color glaze firing and green glaze firing. According to the manufacturing process, the adopted raw materials can effectively lower the firing temperature of the ceramic, thus improving the production efficiency and improving the performance, including strength and the like, of the prepared ceramic; and a manufacturing method is beneficial to ensuring the purity of metal elements and reducing energy consumption, clear classification and easy operation are achieved, and the service life of a sintered utensil is prolonged.

Owner:福建省德化县宝艺陶瓷有限公司

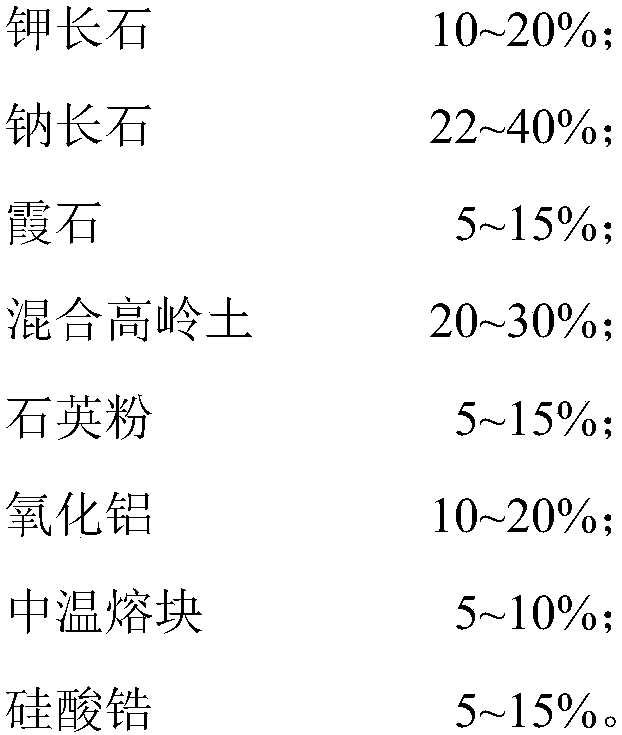

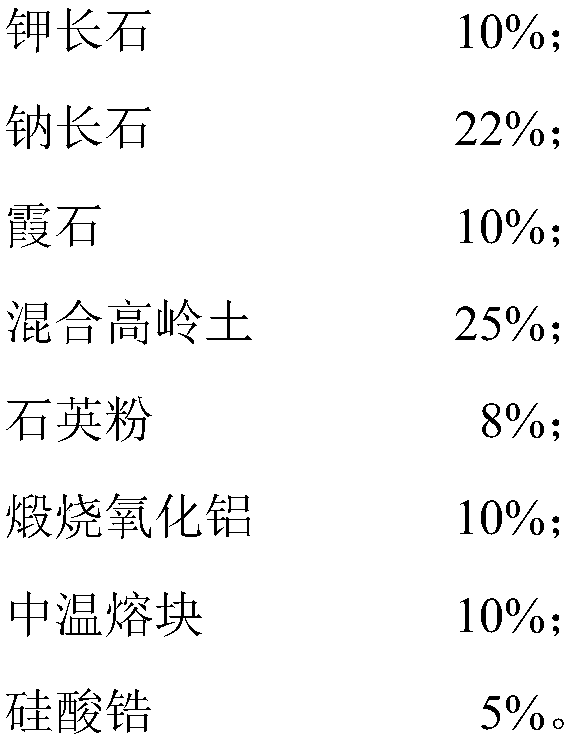

Ceramic large board ground glaze and preparation method thereof

The invention discloses ceramic large board ground glaze. The ceramic large board ground glaze is prepared from the following raw materials in percentage by weight: 10 to 20 percent of potassium feldspar, 22 to 40 percent of sodium feldspar, 5 to 15 percent of nepheline, 20 to 30 percent of mixed kaolin, 5 to 15 percent of quartz powder, 10 to 20 percent of aluminum oxide, 5 to 10 percent of middle-temperature frit and 5 to 15 percent of zirconium silicate. According to the ceramic large board ground glaze disclosed by the invention, the ground glaze has excellent performance through adjustingraw material components and ratios thereof, and can be suitable for glaze spraying technological operation in a production process; meanwhile, after high-temperature firing is carried out, a glaze surface has no defects of needle holes, concave glaze, air bubbles and the like, so that the color, luster and lines have the advantage that a natural large rock plate is smooth and natural and the ground glaze also has a noble and elegant appearance of ceramic tiles; a ceramic large board has good pollution resistance and chemical corrosion resistance. The invention further discloses a preparationmethod of the ground glaze; the preparation method has the advantages of simple technology, strong controllable technological parameters and high production efficiency, and is suitable for large-scaleindustrial production.

Owner:广东金牌陶瓷有限公司

Matte antifouling glaze, glaze preparing method, matte antifouling ceramic tile and preparing method of ceramic block

The invention discloses matte antifouling glaze. The matte antifouling glaze is prepared from glaze A and glaze B; calcined talc, nepheline and alpha-spodumene are used as raw materials of the glaze Ato adjust the firing temperature of the glaze, and the glaze generates a liquid phase locally at 950-1050 DEG C; and the glaze B is formed by using barium carbonate, calcite and zirconia to adjust aglass phase. Correspondingly, the invention further discloses a glaze preparing method of the matte antifouling glaze, a matte antifouling ceramic tile and a preparing method of the ceramic block. Inthe firing process of the glaze, when the temperature reaches 950-1050 DEG C, bubbles are generated during discharging of carbonate substances, organic matter and the like in the glaze, at the moment,the liquid phase enters bubble gaps to fill the bubble gaps, thus when the glaze is sintered at 1192-1205 DEG C, the glaze is denser, the number of air holes is minimum, and the glaze surface has a great antifouling effect.

Owner:FOSHAN DONGPENG CERAMIC +2

Copper red reduction transmutation glaze, copper red reduction transmutation glaze ceramic product and preparation method thereof

The invention relates to copper red reduction transmutation glaze, a copper red reduction transmutation glaze ceramic product and a preparation method thereof, which belong to the technical field of ceramics. The copper red reduction transmutation glaze comprises the following components in parts by weight: 34 to 36 parts of nepheline syenite, 19 to 23 parts of light calcium carbonate, 2 to 5 parts of barium carbonate, 2 to 4 parts of zinc oxide, 1 to 2 parts of magnesium carbonate, 9 to 11 parts of kaolin, 14 to 18 parts of waste ceramic biscuit treatment material, 8.5 to 11 parts of quartz, 2 to 4 parts of bone ash, 1 to 4 parts of lithium carbonate and 2 to 5 parts of copper oxide. The copper red reduction transmutation glaze is uniformly in glaze surface color, has double color generation effect of being green in red and black in red and has strong classical atmosphere; and moreover, when a ceramic product is sintered according to the method, the rate of finished product is relatively high, and the method is suitable for ceramics for daily use and decorative ceramics.

Owner:FUJIAN QUANZHOU DESHENG GROUP

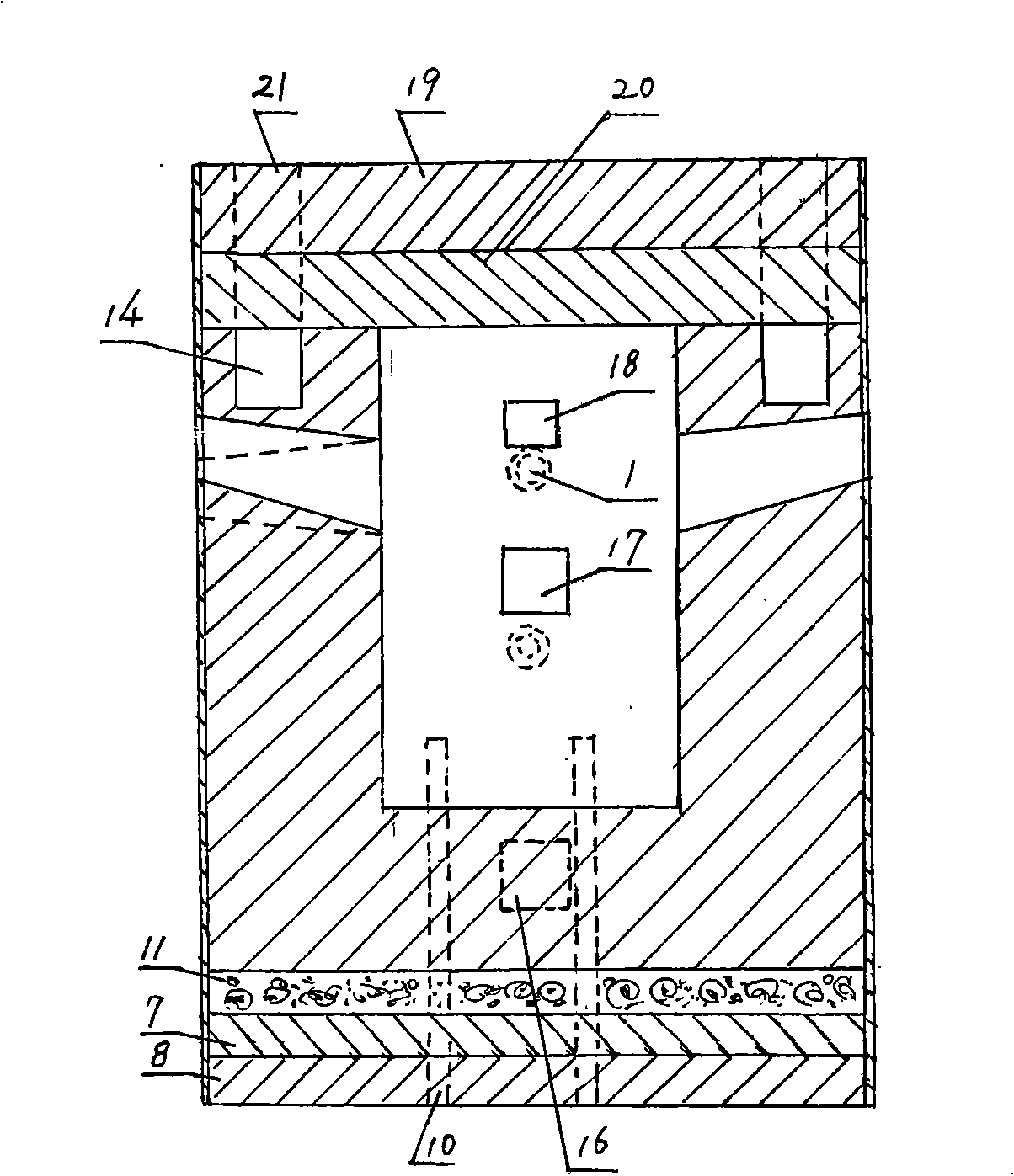

Process and apparatus for processing municipal sewage sludge by using nepheline nucleated glass

InactiveCN101302044AAchieve combustion heat releaseSave diversion pipeline construction costsSludge treatment by oxidationByproduct vaporizationParaffin waxWater quality

The method relates to a sewage water and sludge treatment technology, in particular to a process and equipment for treating municipal sewage water and sludge by utilizing a nepheline nucleated glass technology. The invention solves the problems that the prior incinerator has secondary pollution and upflowing black smoke, etc. in the process of treating the municipal sludge. The process comprises the following steps that: nepheline nucleated glass raw material is used to absorb and filter the sewage water, then sludge water is rapidly separated; upper-layer water is disinfected by steam, volatilizes odor and is further filtered to drinking water; underlayer slurry is mixed with diesel oil and olefin to be used as fuel of a liquation furnace; and residue falls on a hearth and is mixed with the added nepheline nucleated glass raw material to fuse superior nepheline nucleated glass particles, which can be used to produce nepheline nucleated glass and metal mixed powder metallurgical products, mechanical members and building materials. The equipment has a high energy formula of combining a superhigh temperature and bottom inserting-type three-phase electrode liquation furnace and nepheline and realizes the separation of hydrogen and oxygen in the water and the heat release of hydrogen combustion. The process and the equipment have no requirement on the water quality of incoming water, achieve the recovery of purified water and the emission of air without odor and realize the added value utilization of the residua.

Owner:赵凤宇

Zirconium-free ultra-white overglaze and preparation method thereof

The invention discloses a zirconium-free ultra-white overglaze, relates to the technical field of ceramic tiles, and solves the problem of high cost of ultra-white overglaze in the prior art. The technical key points of the ultra-white overglaze are as follows: the ultra-white overglaze comprises the following raw materials in parts by mass: 20-45 parts of Quartz, 0-10 parts of calcined talc, 4-10parts of water-washed kaolin, 5-15 parts of calcined kaolin, 0-25 parts of potassium feldspar, 10-25 parts of albite, 5-35 parts of lithium porcelain stone, 5-20 parts of nepheline, 0-3 parts of dolomite, 0-20 parts of alumina, 0-5 parts of titanium dioxide frit and 0-2 parts of zinc oxide. According to the invention, zirconium compounds are removed from the glaze, and other raw materials are added, so that the whiteness of the overglaze is ensured; and compared with the traditional glaze, the overglaze has lower cost and lower radiation..

Owner:佛山市玉矶材料科技有限公司

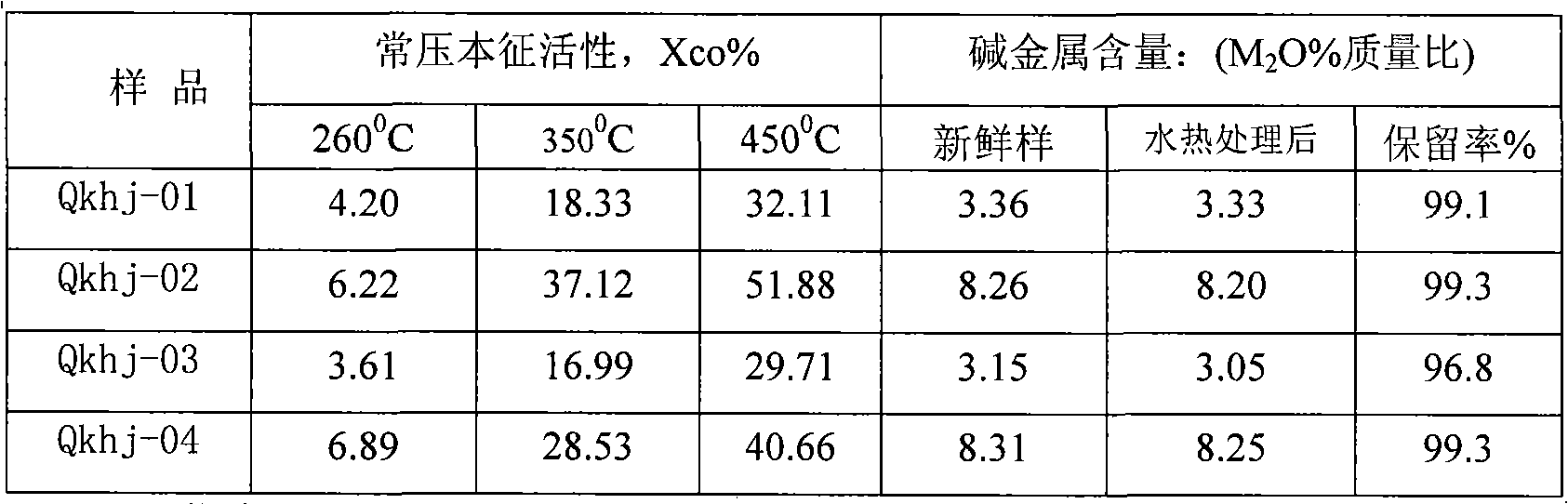

High voltage sulphur resistant translation catalyst of CO and preparation method thereof

ActiveCN101318137AHigh retention rateActivity hasMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideHigh pressure

The invention discloses a carbon monoxide high pressure sulfur-tolerant shift catalyst, comprising a catalyst active component, an alkali metal activated assistant and a carrier, which is characterized in that the alkali metal activated assistant is an alkali metal mineralizer. The alkali metal mineralizer is an albite, a potash feldspar, a sodium nepheline or / and a kalsilite, wherein, the sodium nepheline or / and a kalsilite is preferable. An alkali metal oxide accounts for 0.1 to 15 percent of the total weight of the catalyst. The invention also provides the preparation method of the catalyst. The operation technology is simple and the catalyst can be prepared by kneading, extruding and calcining. The prepared catalyst has low light-off temperature. Under the conditions of high pressure, high temperature and high water-gas ratio, the alkali metal has little drain rate or even no drain and has high strength and strength stability.

Owner:青岛联信催化材料有限公司

Reduced metal transmutation glaze, ceramic product prepared from same and preparation method

The invention relates to a reduced metal transmutation glaze, a ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramic. The reduced metal transmutation glaze comprises components in parts by mass as follows: 30-40 parts of nepheline-syenite, 4-7 parts of kyanite, 8-12 parts of barium carbonate, 22-27 parts of a frit, 14-17 parts of quartz, 7-12 parts of kaolin, 2-7 parts of calcium carbonate, 2-4 parts of cerium oxide, 28-32 parts of manganese oxide, 3-4 parts of copper oxide and 1-2 parts of nickel oxide, wherein the frit comprises components in parts by mass as follows: 48-52 parts of borax, 23-27 parts of quartz, 3-7 parts of kaolin, 13-17 parts of calcium carbonate and 3-7 parts of potassium carbonate. The reduced metal transmutation glaze ceramic product has reddish brown ground coat on the surface, gold spots flush with the glaze surface are formed on the glaze coat, and the color of the glaze is pure, bright and dazzling.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Glaze for achieving silk glazed surface effect on tile surface, preparation method and tile

InactiveCN109250914ASimple methodLow equipment requirementsCovering/liningsClaywaresNephelineSolvent

The invention discloses a glaze for achieving a silk glazed surface effect on a tile surface, a preparation method and the tile. The glaze is prepared from the following raw material components by weight: mineral material, limestone, 1-2 parts of dolomite, wollastonite, barium carbonate, calcined talcum powder, feldspar, nepheline, magnesium oxide, barium oxide, aluminum oxide, silicon dioxide anda solvent. The preparation method of the glaze comprises the following steps: adding the raw materials into a mixer according to the number of parts, adding water with the mass of 0.3 to 0.6 time ofthe total mass of the raw materials, mixing and grinding, until the fineness of glaze slip is 600 to 900 meshes, thus obtaining the glaze. The glaze prepared by the method has a soft, fine and smoothhand feeling and has good wear resistance, and the tile surface can have the silk glazed surface effect after the glaze is applied to the tile.

Owner:GUANGDONG SANSHUI TANDH GLAZE CO LTD

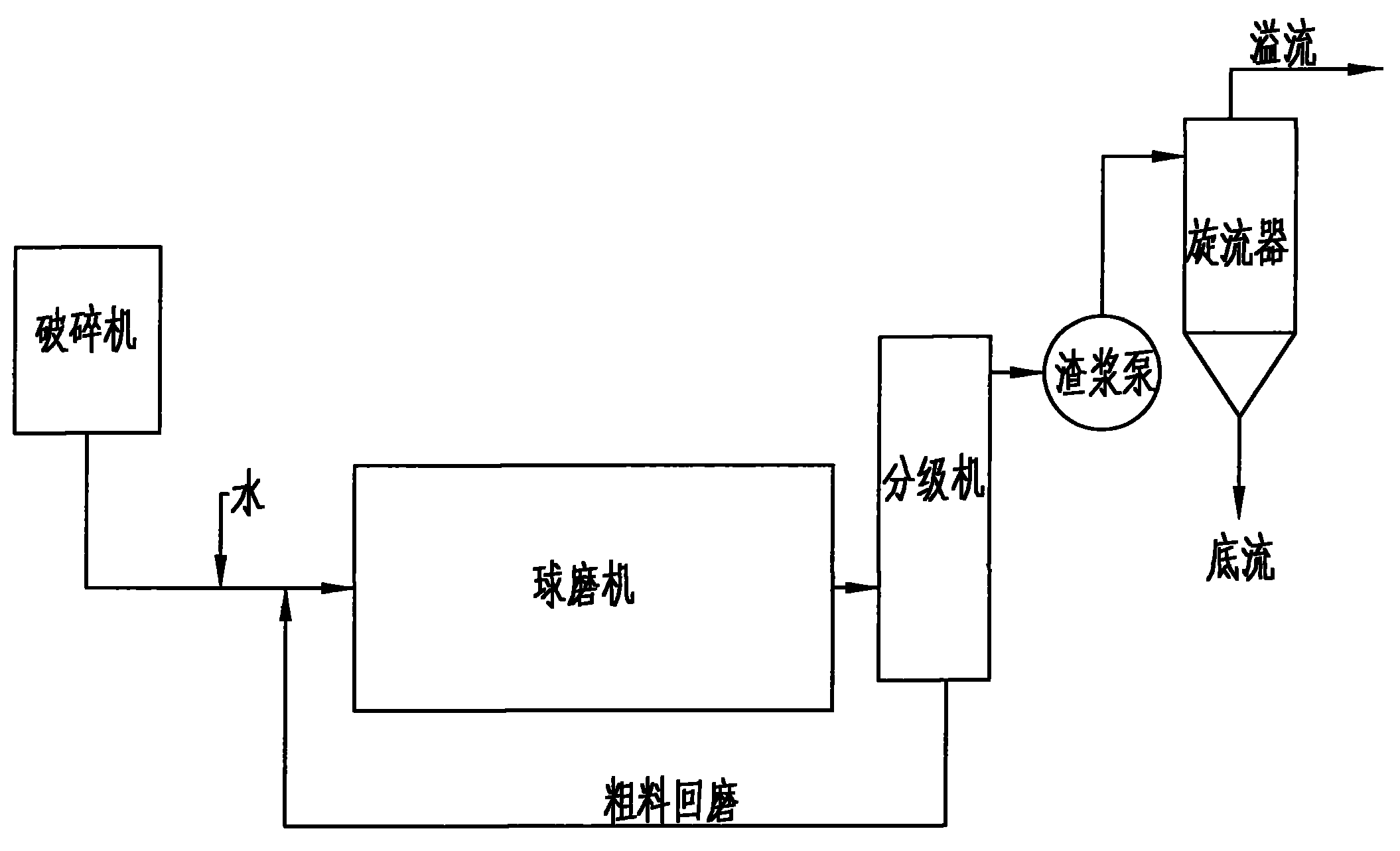

Method for removing micas in nephelite by using cyclone

The invention discloses a method for removing micas in nephelite by using a cyclone, which comprises the following steps of: (1) preprocessing a nephelite raw ore into an ore pulp consisting of nephelite powder, mica powder and water; (2) pumping the ore pulp into the cyclone by using a slurry pump; and (3) under the action of the centrifugal force of vortex, throwing spherical nephelite particles to a side wall of the cyclone to ensure that the spherical nephelite particles lose energy and are settled down, and then serve as underflows to flow out from the bottom of the cyclone, wherein the fluid resistance endured by sheet mica particles is greater than that of the spherical nephelite particles to ensure that the sheet mica particles cannot be thrown to the side wall of the cyclone to lose energy and be settled down; the fluid resistance endured by the sheet mica particles during settling down is greater than that of the spherical nephelite particles to ensure that the settling speed is slow; and the sheet mica particles are suspended in solid-phase two-phase flow to serve as an overflow which flows out from the top part of the cyclone under the pressure of a slurry pump. A product processed by the process method has a higher yield compared with the nephelite raw ore, and the mica content in the product is low.

Owner:广东奥胜新材料有限公司

Low-temperature cracked glaze, ceramic product prepared from same and preparation method of ceramic product

The invention relates to a low-temperature cracked glaze, a ceramic product prepared from the same and a preparation method of the ceramic product, belonging to the technical field of ceramics. The low-temperature cracked glaze comprises the following components in parts by mass: 390-410 parts of nepheline syenite, 48-52 parts of quartz, 48-52 parts of heavy calcium carbonate, 780-820 parts of first glaze frits, 19-21 parts of light calcium carbonate, 19-21 parts of second glaze frits and 76-84 parts of copper carbonate. The cracked glaze can be sintered at relatively low temperature through meticulously blending a glaze material of the low-temperature cracked glaze, so that energy sources are effectively saved; the ceramic product prepared from the low-temperature cracked glaze by using the method disclosed by the invention is not only high in finished product rate up to higher than 95, but also integrated and attractive in glaze surface and remarkable in crack effect; the ceramic product sintered by using the glaze material disclosed by the invention is deep green in glaze surface and uniform and meticulous in crack so as to have favorable application and market prospects.

Owner:FUJIAN PROVINCE DEHUA ZHENNAN CERAMIC CO LTD

High-strength rock plate and preparation method thereof

ActiveCN113248242AImprove flexural strengthHigh rate of straight crystal whiskersPolycrystalline material growthAfter-treatment detailsApatiteAluminium hydroxide

The invention discloses a high-strength rock plate and a preparation method thereof, and belongs to the technical field of rock plates. The high-strength rock plate is prepared from the following raw materials in parts by weight: 22 to 30 parts of albite, 15 to 20 parts of kaolin, 10 to 16 parts of nepheline powder, 6 to 12 parts of wollastonite, 5 to 9 parts of clay, 4 to 8 parts of hydroxyapatite, 3 to 6 parts of modified hollow glass beads, 2 to 6 parts of modified silicon carbide whiskers, 2 to 6 parts of aluminum oxide, 1 to 3 parts of strontium carbonate, 0.8 to 2 parts of calcium hydrophosphate, 0.8 to 2 parts of aluminum hydroxide, 1 to 2 parts of corundum powder, 0.6 to 1.5 parts of zinc oxide and 0.5 to 1 part of lanthanum carbonate. The rock plate disclosed by the invention has good breaking strength, and the modified silicon carbide whisker capable of remarkably improving the breaking strength is obtained by synthesizing and sintering in a solution by taking silicon dioxide and fly ash as silicon sources and crushed lignite as a carbon source.

Owner:GUANGDONG OVERLAND CERAMICS CO LTD

Black silver drop reduced transmutation glaze, black silver drop reduced transmutation glaze ceramic product prepared using same and preparation method

The invention relates to black silver drop reduced transmutation glaze, a black silver drop reduced transmutation glaze ceramic product prepared using the same and a preparation method and belongs to the technical field of ceramic. The black silver drop reduced transmutation glaze comprises, by mass, 33-36 parts of nepheline syenite, 18-22 parts of light calcium carbonate, 4-6 parts of barium carbonate, 2-4 parts of zinc oxide, 1-3 parts of magnesium carbonate, 9-12 pats of kaolin, 14-18 parts of waste ceramic biscuit treating material, 8-12 parts of quartz, 2-6 parts of bone ash, 2-8 parts of manganese oxide and 2-7 parts of copper oxide. The black silver drop reduced transmutation glaze is simple and easy in implementing of glazing mode, and production efficiency can be improved effectively; the black silver drop reduced transmutation glaze ceramic product prepared has pitch-black glaze surface and is modest luxury, and silver drops are adopted for decorating, so that the product is more noble and elegant; the product is calcined according to the method, finished product rate of the ceramic product can be up to higher than 92%, and the black silver drop reduced transmutation glaze is suitable for being used to produce ceramic for daily use and decorating ceramic.

Owner:FUJIAN QUANZHOU DESHENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com